Page 1

CVX-V18NS/V18NSP

SERVICE MANUAL

Ver 1.0 1999. 04

NTSC model: CVX-V18NS

PAL model : CVX-V18NSP

Printed wiring boards and schematic diagrams are not mentioned

because mounted boards are replaced to repair this model.

US Model

Canadian Model

CVX-18NS

AEP Model

CVX-V18NSP

SPECIFICATIONS

MICROFILM

COLOR VIDEO CAMERA

Page 2

SER VICE NOTE

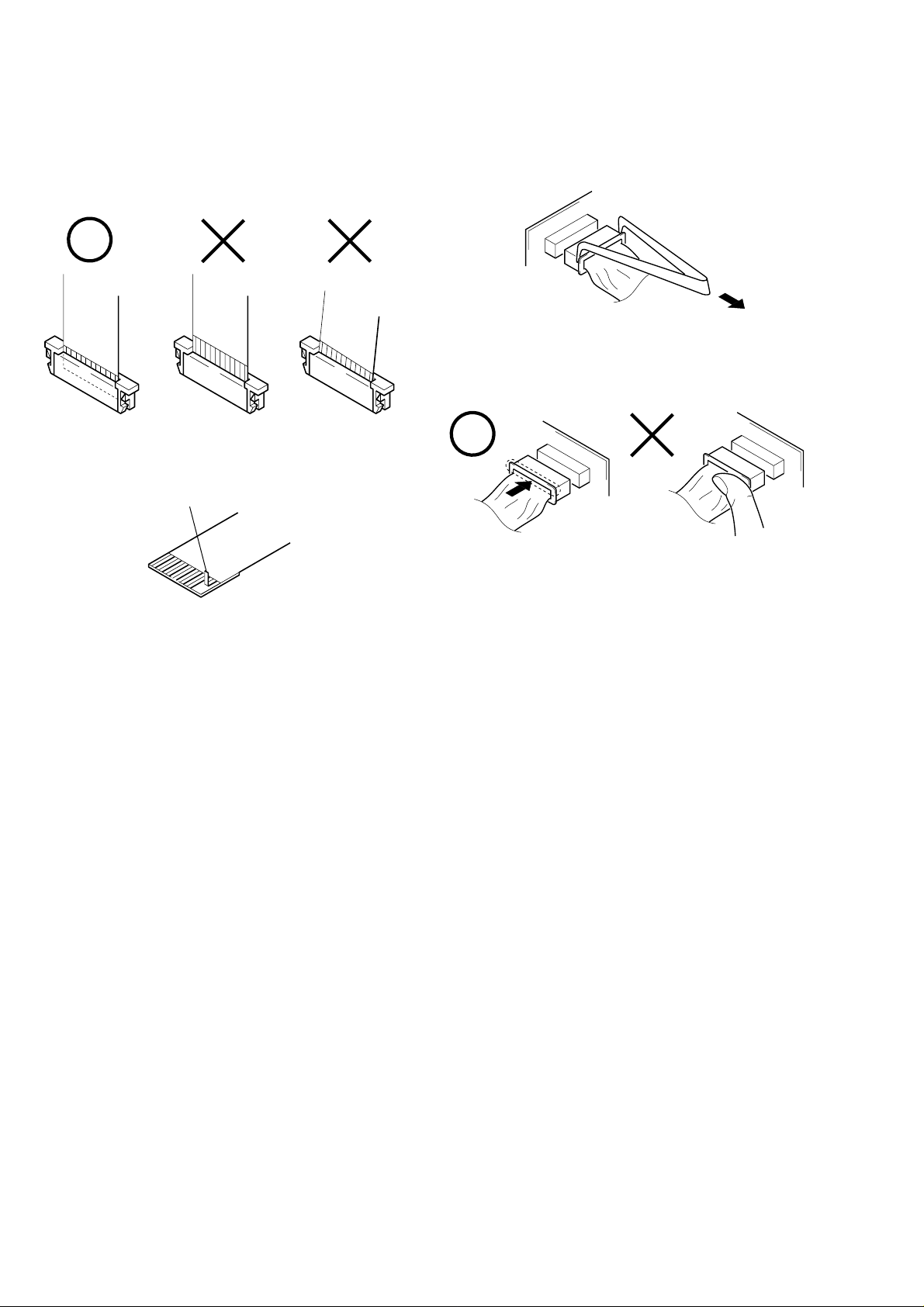

• NOTE FOR REPAIR

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there are some

pieces of gilt left inside)

When remove a connector, don’t pull at wire of connector.

Be in danger of the snapping of a wire.

When installing a connector, don’t press down at wire of connector.

Be in danger of the snapping of a wire.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

4. Look for parts which, though functioning, show obvious signs

of deterioration. Point them out to the customer and recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C

during repairing.

• Do not touch the soldering iron on the same conductor of

the circuit board (within 3 times).

• Be careful not to apply force on the conductor when sol-

dering or unsoldering.

– 2 –

Page 3

TABLE OF CONTENTS

Section Title Page Section Title Page

SERVICE NOTE...................................................................... 2

1. GENERAL

Features ........................................................................ 1-1

Identifying the Parts ...................................................... 1-1

Connections .................................................................. 1-1

Resetting the Data and Time ........................................ 1-3

Recording ...................................................................... 1-3

Using Various Features................................................. 1-5

2. DISASSEMBLY

2-1. Cabinet (Upper) Block Ass’y ......................................... 2-2

2-2. Cabinet (Rear) Block Ass’y ........................................... 2-2

2-3. VW-1 Board, Battery Terminal Board............................ 2-2

2-4. DT-106/VA-108 Board ................................................... 2-2

2-5. CN-116 Board ............................................................... 2-3

2-6. Cabinet (F/B) Ass’y ....................................................... 2-3

2-7. Cabinet (R) Ass’y .......................................................... 2-3

2-8. IF-73 Board ................................................................... 2-3

2-9. Cabinet (L) Ass’y ........................................................... 2-4

2-10. Motor (IR Use)............................................................... 2-4

2-11. Connection Cord ........................................................... 2-4

2-12. IR-34/35 Board .............................................................. 2-4

2-13. SE-93 Board .................................................................. 2-5

2-14. VC-211 Board................................................................ 2-5

2-15. Lens Device................................................................... 2-5

2-16. Focus/Zoom Stepping Motor......................................... 2-5

2-17. Circuit Boards Location ................................................. 2-6

3. BLOCK DIAGRAMS

3. D Page Table ................................................................. 5-7

4. E Page Table ................................................................. 5-7

5. F Page Table.................................................................. 5-7

5-3. Electrical Adjustments ................................................... 5-8

1. Y Out Level Adjustment................................................. 5-8

2. C Out Level Adjustment ................................................ 5-8

3. 28 MHz origin Oscillation Adjustment ........................... 5-9

5-4. Camera System Adjustment ......................................... 5-10

1. Lens T ype Adjustment................................................... 5-10

2. G-CAM Flip Adjustment................................................. 5-10

3. G-CAM Version Adjustment .......................................... 5-11

4. HALL Adjustment........................................................... 5-12

5. Flange Back Adjustment

(Using the Mini-pattern Box) ......................................... 5-13

6. Flange Back Adjustment

(Using the Flange Back Adjustment Chart and

the Subject More than 500 m away) ............................. 5-14

6-1. Flange Back Adjustment (1).......................................... 5-14

6-2. Flange Back Adjustment (2).......................................... 5-14

7. Flange Back Check ....................................................... 5-15

8. Picture Frame Setting ................................................... 5-16

9. Color Reproduction Adjustment .................................... 5-17

10. IRIS IN/OUT Adjustment ............................................... 5-18

11. Auto White Balance Standard Data Input..................... 5-19

12. Auto White Balance Adjustment ................................... 5-19

13. White Balance Check .................................................... 5-20

6. REPAIR PARTS LIST

6-1. Exploded Views ............................................................. 6-1

6-1-1. Main Unit Section ..................................................... 6-1

6-1-2. Camera Head Section-1 .......................................... 6-2

6-1-3. Camera Head Section-2 .......................................... 6-3

6-2. Electrical Parts List........................................................ 6-4

3-1. Overall Block Diagram................................................... 3-1

3-2. Camera Block Diagram ................................................. 3-5

3-3. Camera Control (1/2) Block Diagram ........................... 3-9

3-4. Camera Control (2/2) Block Diagram ........................... 3-11

3-5. Video Out, Audio Block Diagram .................................. 3-13

3-6. Power (MAIN UNIT) Block Diagram ............................. 3-15

3-7. Power (CAMERA) Block Diagram ................................ 3-17

4. SCHEMATIC DIAGRAMS

4-1. Frame (1/2) Schematic Diagram................................... 4-1

4-2. Frame (2/2) Schematic Diagram................................... 4-3

5. ADJUSTMENTS

5-1. Preparations Before Adjustment ................................... 5-1

5-1-1. List of Service Tools ................................................. 5-1

5-1-2. Preparations ............................................................. 5-2

5-1-3. Precautions .............................................................. 5-3

1. Setting the Switch ......................................................... 5-3

2. Order of Adjustments .................................................... 5-3

3. Subjects......................................................................... 5-3

5-1-4. Adjusting Remote Commander................................ 5-4

1. Used Adjusting Remote Commander ........................... 5-4

2. Precautions Upon Using the Adjusting Remote

Commander................................................................... 5-4

5-1-5. Data Processing ....................................................... 5-5

5-1-6. Adjusting Items when Replacing a Board or

5-2. Initialization of D, E, F Page Data ................................. 5-6

Main Parts ................................................................ 5-5

1. Initializing D, E, F Page Data........................................ 5-6

2. Modification of D, E, F Page Data ................................ 5-6

– 3 –

Page 4

SECTION 1

GENERAL

CVX-V18NS/V18NSP

This section is extracted from CVXV18NS/V18NSP instruction manual.

1-1

Page 5

1-2

Page 6

1-3

Page 7

1-4

Page 8

1-5

Page 9

1-6

Page 10

1-7

1-7 E

Page 11

DISASSEMBLY

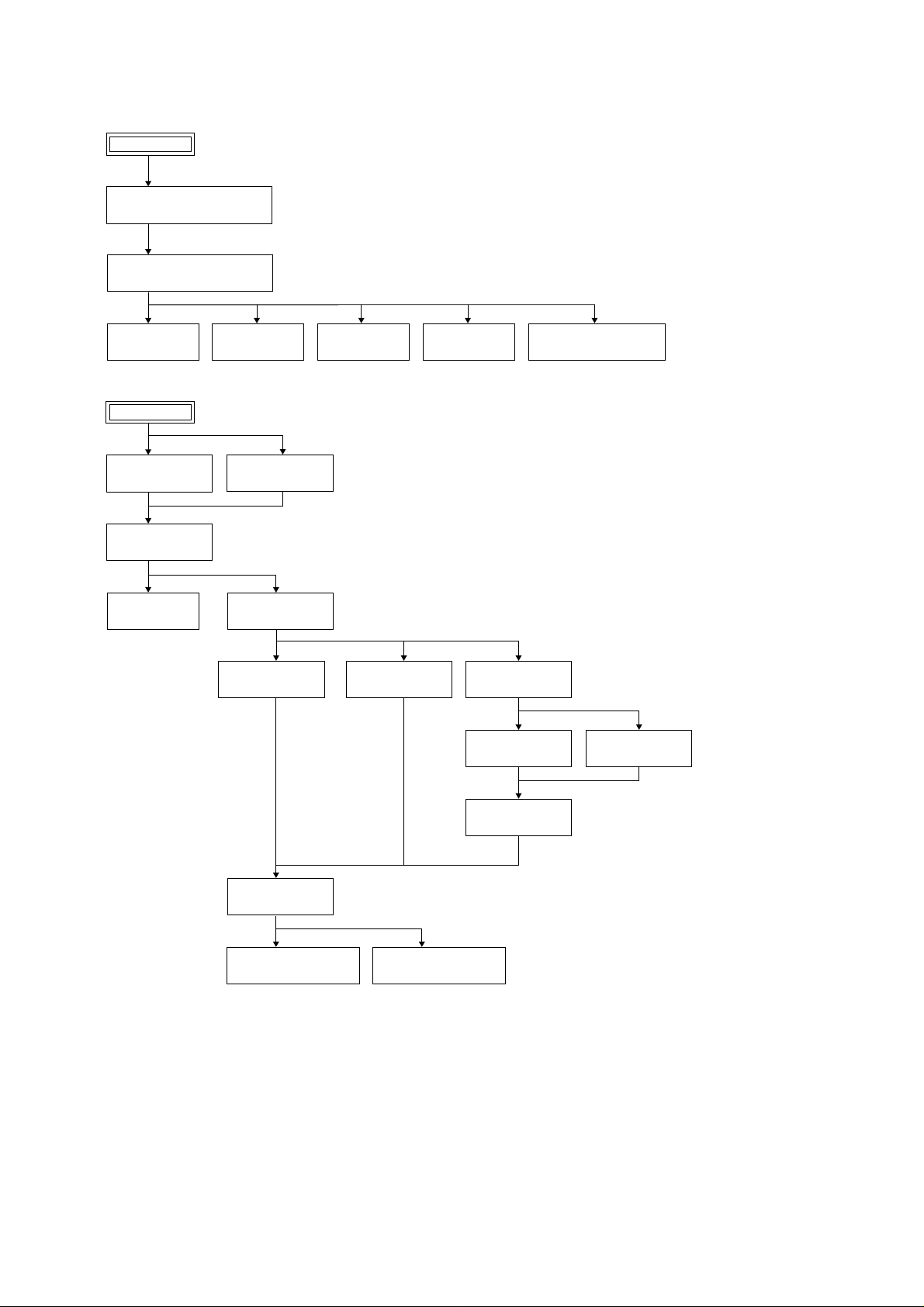

• This set can be disassembled in the order shown below.

Main Unit

Cabinet (Upper) Block Ass’y

(Page 2-2)

Cabinet (Rear) Block Ass’y

(Page 2-2)

CVX-V18NS/V18NSP

SECTION 2

CN-116 Board

(Page 2-3)

Camera Head

Cabinet (F) Ass’y

(Page 2-3)

Cabinet (R) Ass’y

(Page 2-3)

IF-73 Board

(Page 2-3)

DT-106 Board

(Page 2-2)

Cabinet (B) Ass’y

(Page 2-3)

Cabinet (L) Ass’y

(Page 2-4)

Motor (IR Use)

(Page 2-4)

VA-108 Board

(Page 2-2)

IR-34 Board

(Page 2-4)

VW-1 Board

(Page 2-2)

Connection Code

(Page 2-4)

IR-35 Board

(Page 2-4)

Battery Terminal Board

(Page 2-2)

SE-93 Board

(Page 2-5)

Lens Device

(Page 2-5)

Focus Stepping Motor

(Page 2-5)

VC-211 Board

(Page 2-5)

Zoom Stepping Motor

(Page 2-5)

2-1

Page 12

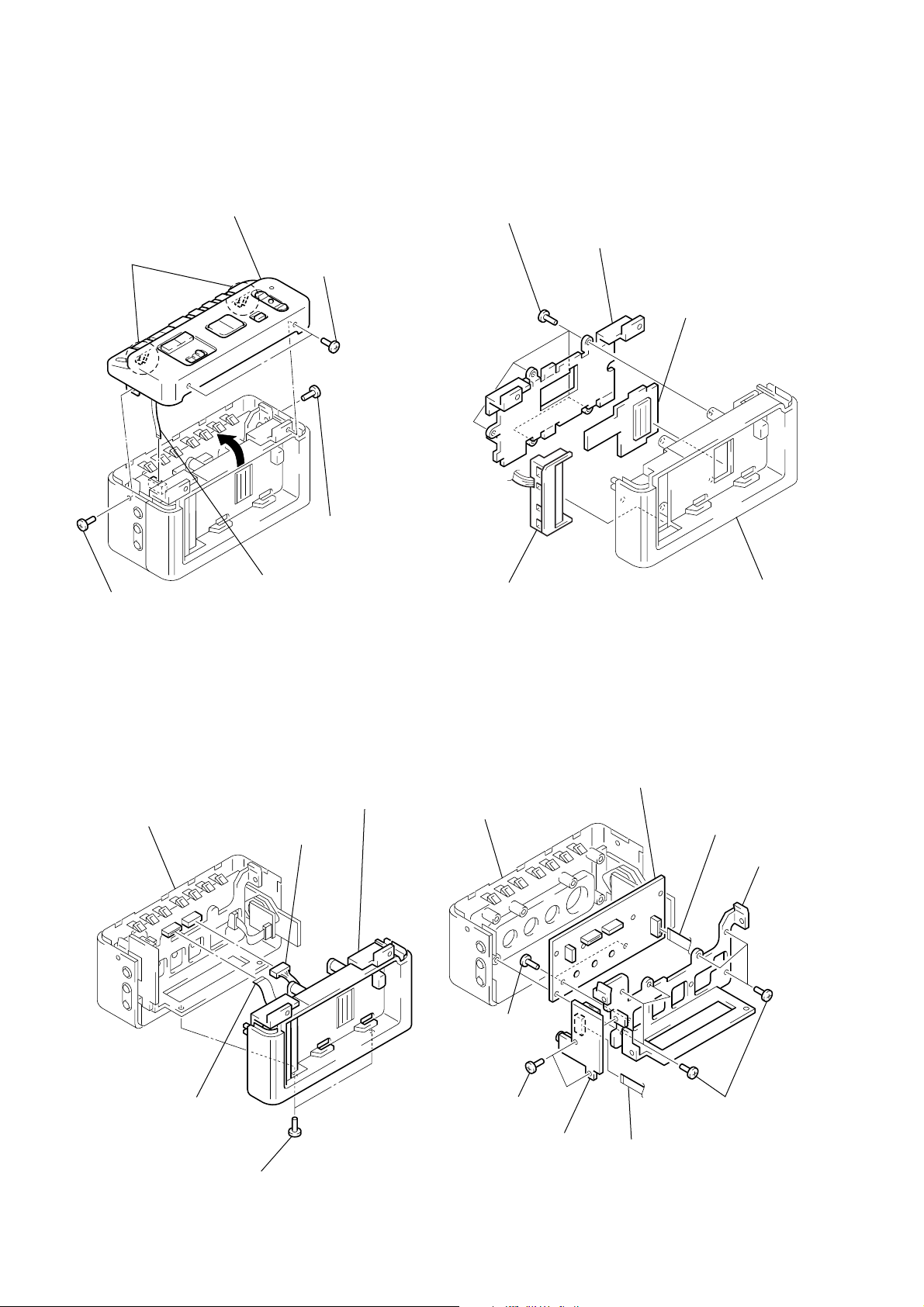

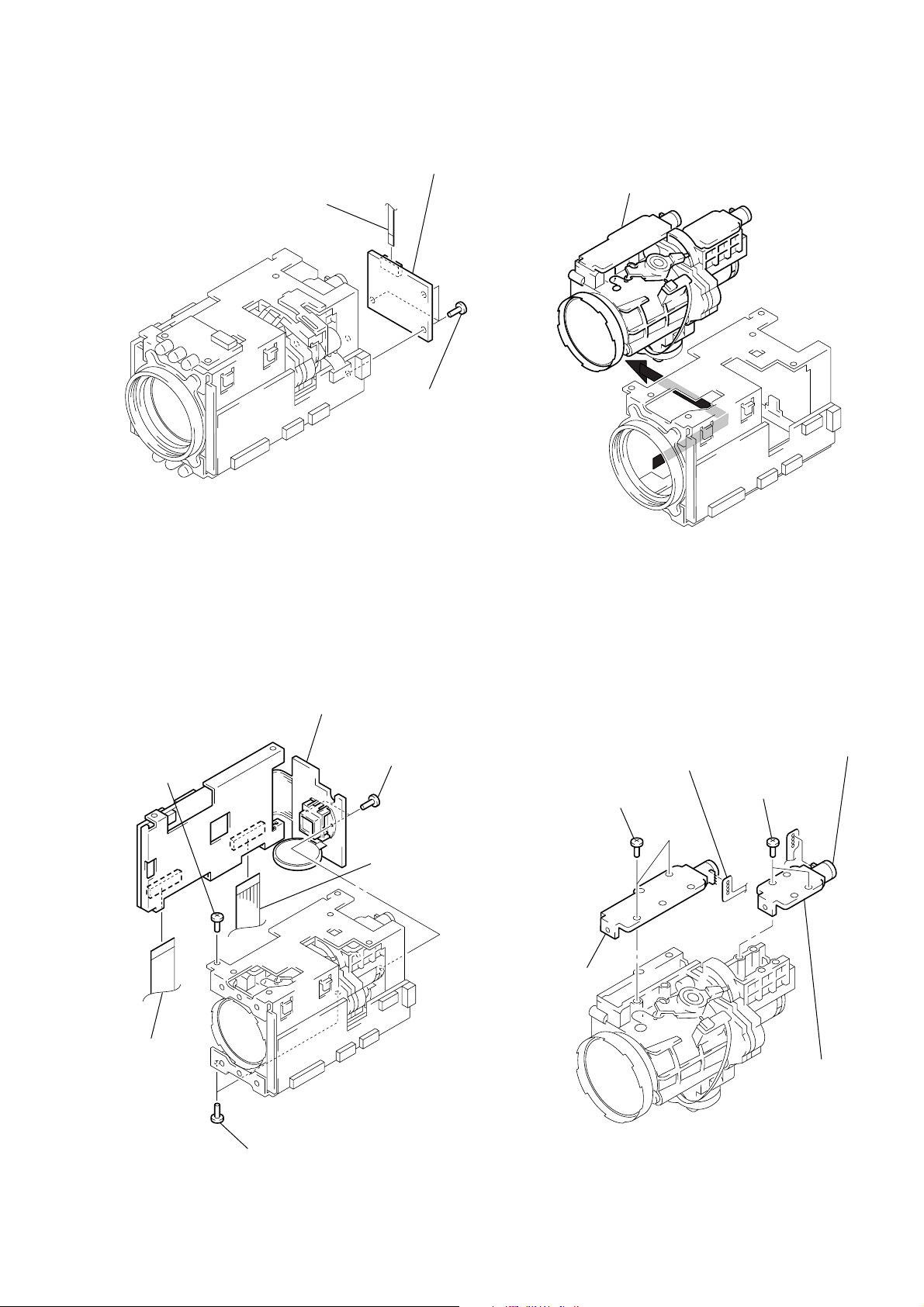

Note: Follow the disassembly procedure in the numerical order given.

2-1. CABINET (UPPER) BLOCK ASS’Y 2-3. VW-1 BOARD, BATTERY TERMINAL

BOARD

5 Cabinet (upper) block ass’y

4 Two claws

1 Screw

(M2)

3 Two screws

(M2)

2 Screw

(M2)

6 Flat cable (FFC-272)

(CN997)

1 Five screws

2 Terminal board retainer

4 Battery terminal board

3 VW-1 board

VW-1

Cabinet (back) ass’y

2-2. CABINET (REAR) BLOCK ASS’Y

4 Cabinet (rear) block ass’y

Cabinet (front) block ass’y

VA-108 board

1 Flat cable (FFC-275)

(CN882)

3 Two screws

2 Connector

(CN881)

CN-116

(M2)

2-4. DT-106/VA-108 BOARD

8 VA-108 board

Cabinet (front) ass’y

VA-108 board

7 Two screws

(M2)

5 Two screws

(M2)

6 DT-106 board

DT-106

4 Flat cable (FFC-273)

(CN996)

1 Flat cable (FFC-274)

(CN883)

3 Main frame

2 Six screws

2-2

Page 13

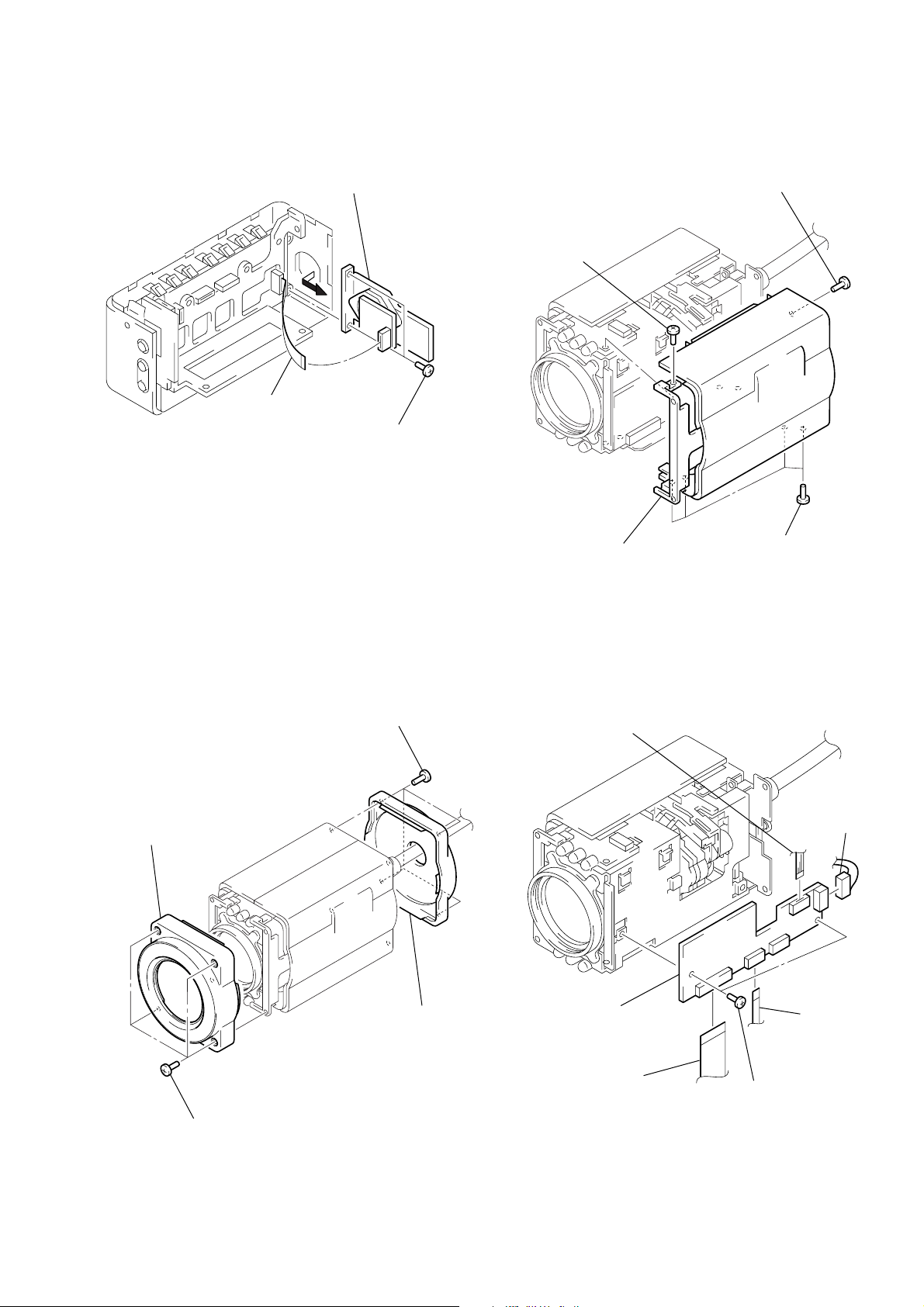

2-5. CN-116 BOARD 2-7. CABINET (R) ASS’Y

3 Four screws

(M2)

4 Cabinet (R) ass’y

2 Screw

(M2)

1 Screw

(M2)

3 CN-116 board

CN-116

1 Flat cable (FFC-274)

(CN990)

2 Two screws

2-6. CABINT (F/B) ASS’Y

2 Cabinet (F) ass’y

1 Four screws

(M2)

3 Four screws

(M2)

4 Cabinet (B) ass’y

2-8. IF-73 BOARD

1 Flexible board

(CN1801)

6 IF-73 board

4 Flat cable

(FFC-262)

(CN1802)

2 Connector

(CN1803)

IF-73 board

3 Flat cable

(FFC-280)

(CN1805)

5 Two screws

(M2)

2-3

Page 14

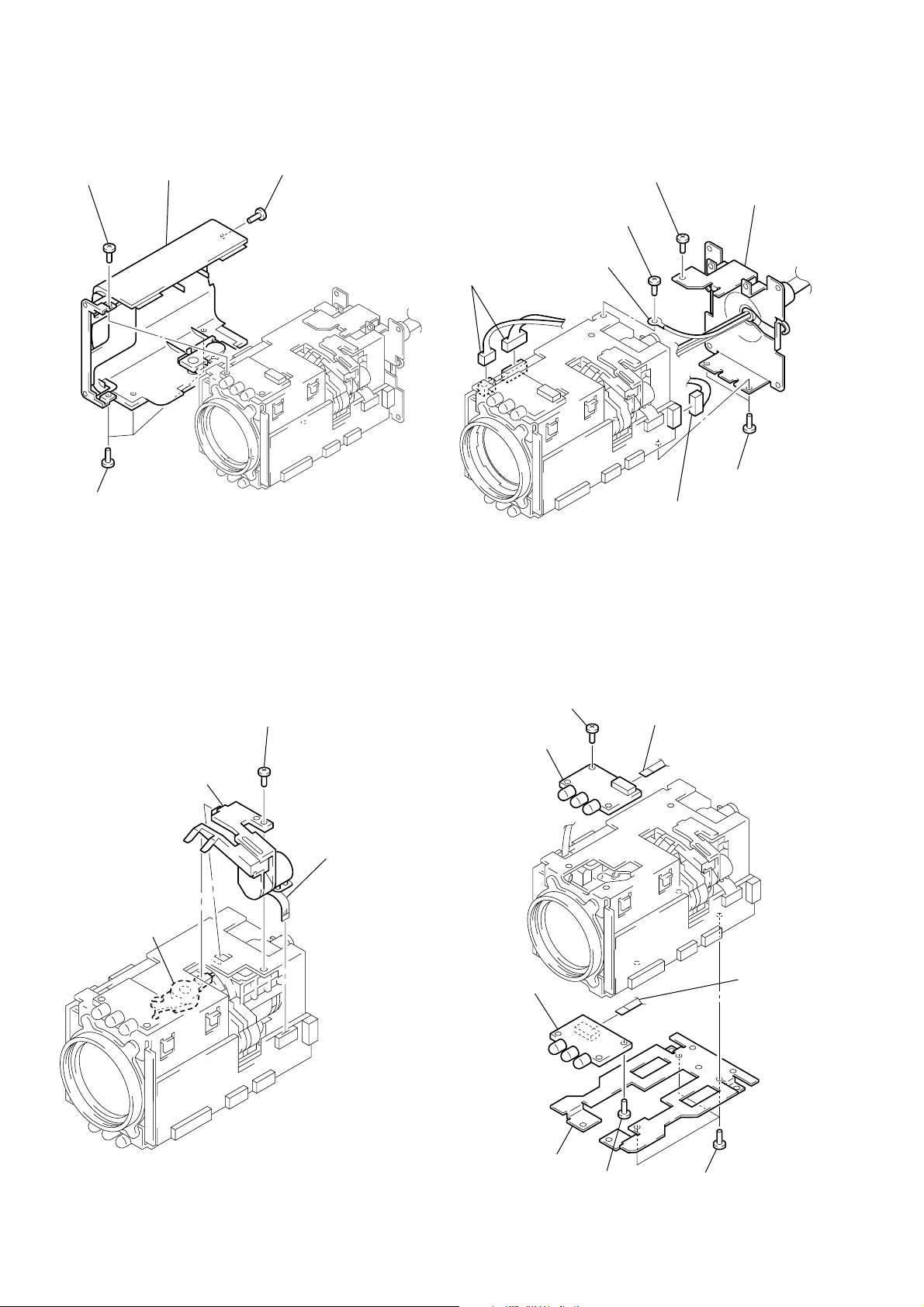

2-11. CONNECTION CORD2-9. CABINET (L) ASS’Y

1 Screw

(M2)

3 Three screws

4 Cabinet (L) ass’y

(M2)

IR-34

2 Screw

(M2)

IF-73 board

2 Two connectors

(CN301, 501)

IR-34

4 Lug

IF-73 board

6 Screw

3 Screw

(M2)

(M2)

1 Connector

(CN1803)

7 Connection cord

(BB bracket)

5 Two screws

(M2)

2-10. MOTOR (IR USE)

3 Motor (IR use)

Note: When installing

motor (IR use),

connect lever of

motor with IR lever.

IR lever

IR-34

IF-73 board

2 Screw

(M2)

1 Flexible board

(CN1801)

2-12. IR-34/35 BOARD

2 Screw

(M2)

3 IR-34 board

8 IR-35 board

1 Flat cable (FFC-264)

IR-34

IR-35

(CN090)

IF-73 board

6 Flat cable

(FFC-280)

(CN1090)

2-4

5 Tripod frame

7 Screw

(M2)

4 Three screws

(M2)

Page 15

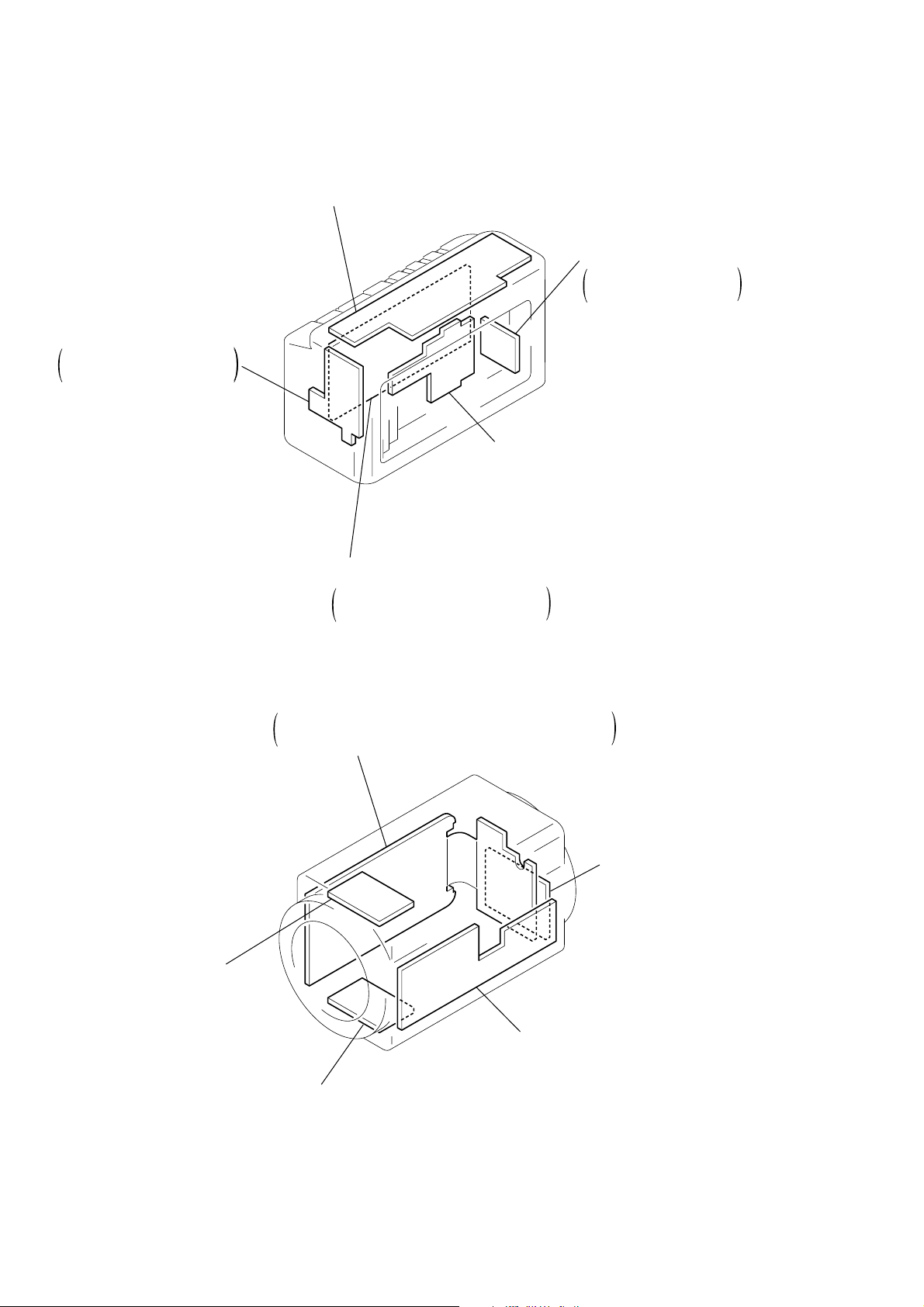

2-13. SE-93 BOARD 2-15. LENS DEVICE

6 Zoom stepping

motor

3 Focus stepping

motor

4 Two screws

(M1.7 × 3.5)

1 Break solders of

the flexible board

2 Two screws

(M1.7 × 3.5)

5 Break solders of

the flexible board

1 Flat cable (FFC-219)

(CN050)

IR-34

IF-73 board

3 SE-93 board

SE-93

2 Three screws

(M2)

1 Remove the lens device in the

direction of the arrow.

IF-73 board

2-14. VC-211 BOARD

2 Flat cable

4 Screw

(M2)

(CN703)

2-16. FOCUS/ZOOM STEPPING MOTOR

6 VC-211 board

5 Two screws

(B1.7 × 6)

VC-211

1 Flexible board

(CN401)

IF-73 board

3 Two screws

(M2)

Note: Flexible board of lens device is not supplied.

Please be careful not break the flexible board

when you change the motor unit.

2-5

Page 16

2-17. CIRCUIT BOARDS LOCATION

SW-328

(CONTROL SWITCH)

DT-106

MIC IN,

CONTROL SWITCH

CN-116

CAMERA CABLE

CONNECTOR

VW-1

(VIDEO WALKMAN CONNECTOR)

IR-34

(IR LIGHT)

VA-108

VIDEO/AUDIO OUTPUT,

CONTROL SWITCH

VC-211

CCD IMAGER, CAMERA Y/C PROCESS,

CAMERA CONTROL, MODE CONTROL

SE-93

(STEADY SHOT SENSOR)

IR-35

(IR LIGHT)

2-6

2-6 E

IF-73

(IR MOTOR DRIVE)

Page 17

3-1. OVERALL BLOCK DIAGRAM

CVX-V18NS/V18NSP

SECTION 3

BLOCK DIAGRAMS

IC401

IR-34 BOARD

IR-35 BOARD

D1090,1091,1092

M903

ZOOM

MOTOR

ZOOM

SENSOR

ZOOM

MOTOR

DRIVE

SE-93 BOARD

SE050

PITCH

SENSOR

SE051

YAW

SENSOR

D090,091,092

ZOOM LENS UNIT

ZOOM

LENS

M902

FOCUS

MOTOR

FOCUS

SENSOR

FOCUS

MOTOR

DRIVE

IC050

SENSOR

AMP

IR ON

IR ON

METER

IRIS

DRIVE

IRIS

HALL

SENSOR

HALL

AMP

IC402

M901

IR

MOTOR

MM M

VC-211 BOARD

IC001

CCD

IMAGER

CCD OUT

ZM RST SENS

HALL AD

IRIS COM

IRIS PWM

DIR0 A,B DIRI A,B

IF-73 BOARD

IC1801

IR MOTOR

DRIVE

V1-V4,VSHT

H1,H2,RG

IC102

S/H

AGC

FC RST SENS

IC1803

KEY SWITCH

CONTROL

A/D

CONV.

IC1802

IR MOTOR

PREDRIVER

KEY AD

IC101

TIMING

GENERATOR

10

IC203

ADJUST

VOLTAGE

CAMERA Y/C PROCESS

ZOOM/FOCUS

MOTOR CONTROL

8X2

DIGITAL

EFFECT

VC SO, VC SI, VC SCK

IC301

IC201

CHARACTER

GENERATOR

D/A

CONV.

IC202

2.0V

3.2V

15V

–7.0V

4.9V

EEPROM

Y OUT

C OUT

IC601

IC501

D/D

CONV.

IC302

75Ω

DRIVER

OSD SCK, OSD SO

IC602

CAMERA

CONTROL

UNREG

HI SO

HI SI

HI SCK

KEY AD

XRESET

INITIAL RESET

BACK UP VCC

IC703

D/D

CONV.

IC702

MODE

CONTROL

Y OUT

C OUT

BACK UP

VCC

IC701

KEY AD

CAMERA CABLE

CN-116 BOARD

Y OUT

C OUT

KEY AD KEY AD

SW-328 BOARD

INFINITY

MANU

AUTO

NIGHTSHOT

FAR

NEAR

POWER

T

ZOOM

W

FOCUS

DT-106 BOARD

MIC

PLUG IN

POWER

DISPLAY

DATE

TIME

Y OUT

C OUT

VA-108 BOARD

EXPOSURE

SHUTTER

TITLE

MENU

+

–

EXEC

IC841

AUDIO

AMP

AUDIO

5V

CAMERA

5V

IC821

Y/C MIX

75Ω

DRIVER

IC842

ALC AMP

IC843

D/D

CONV.

IC881

D/D

CONV.

UNREG

Q882

S-Y, S-C

AUDIO L, R

SWITCH

Y OUT

C OUT

VIDEO

AUDIO L

AUDIO R

VOLTAGE

S-TERMINAL

IC882

WATCH

VW-1 BOARD

VIDEO WALKMAN

CONNECTOR

IC883

VOLTAGE

WATCH

BATT(+)

BATT(–)

BATTERY

TERMINAL

05

3-1 3-2 3-3

Page 18

CVX-V18NS/V18NSP

3-2. CAMERA BLOCK DIAGRAM

VC-211 BOARD (1/3)

TO VIDEO OUT, AUDIO BLOCK

CN-116 BOARD CN991

(SEE PAGE 3-13)

IC001

CCD IMAGER

CCD OUT

VDD (+15V)

S_C OUT

S_Y OUT

SHT

IC102

S/H. AGC. A/D CONVERTER

PBL K

19

XSHP

(IC201)

X101

NTSC:28.6363

PAL:28.375

XCS TG

CK CONT

6dB

6dB

4.9V

21

XSHD

22

CLPDM

23

26

27

34

36

CAM DD ON

MUTE

S/H

S/H

CLP

CENTER

BIAS

WEN

FRQ

(IC301)

TO CAMERA CONTROL BLOCK(2/2)

CLAMP

MUTE

13

AMP

GCA

PB

35 30 29 4241

(SEE PAGE 3-12)

XVC SCK

VC SO

24

22

AGC

LINE

PB

S/H BLK

S/H

CAM

LINE

FLIP

AGC CONT 2

AGC CONT 1

Q302

B P F

DRV

REF SLOW ADCLK

44 16

(IC301)

L.P.F

FL301

Q301

A/D

CONVERTER

Q201

BUFFER

12

17

33

D9

43

I

11

D0

10

10

I

2

20

CLPOB

MCK

TO CAMERA

CONTROL BLOCK(1/2)

(SEE PAGE 3-9)

Q202

BUFFER

3.2V

(IC101)

XSG 1

XV 1

PB LK

VGAT

FSC

EN0

DIR0B

DIR0A

DIR1A

DIR1B

EN1

IRIS COM

FC RST

ZM RST

CL

MCK

ID

163

I

172

159

161

148

138

68

140

142

145

146

141

143

144

43

47

49

75

66

127

128

129

130

131

132

133

135

136

37

3

6

33

26

23

AD IN 10

I

AD IN 1

CLP1

ADCK

CCD CLKL

VCK

MCK

XSG 1

XV 1

ID

PB LK

VGAT

AHD

AVD

AMPO

OSCI

OSCO

BCK

OFSC

EN0

DIR0B

DIR0A

DIR1A

DIR1B

EN1

IRIS COM

FC RST

ZM RST

C IN

C OUT

Y OUT

IO Y

IO U

IO V

ENCODER

D/A CONY

7

V1

4

V2

3

2

V3

1

V4

RG

12

H2

14

H1

13

11

VL

10

8

Q001

BUFFER

V1

V2

V3

V4

RG

H2

H1

–7V

VSHT

15V

CN301

2

4

CCD OUT

–7V

15V

IC101

TIMING GENERATOR

10

3.2V

15V

–7V

H2

H1

RG

CLAMP

VDD1

13

VDD2

19

VDD3

20

VDD4

43

VDD6

24

XV HT

26

V1

25

V2

28

V3

31

V4

27

VH

29

VL

30

VM

22

H2

21

H1

18

RG

IC302

14 16

9

CLPDM

XSHP

XSHD

XRS

PB LK

XSG1

XV1

VGAT

WEN

CCDCKH

VCK

CLK 510

CK

OSCO

OSCI

DSGAT

AHD

AVD

SSK

SSI

SEN

RST

VSK

VSI

VEN

CKINH

6dB

6dB

1

15

16

17

2

32

48

ID

41

36

47

11

12

9

7

5

4

42

44

45

37

38

39

40

33

34

35

46

18

PB L K

XSG1

ID

XV1

V GAT

MCK

CL

XCS SYSTEM

XRST SYSTEM

26

31

10 27 30

FOCUS/ZOOM MOTOR CONTROL

CAM

SG

FOCUS/

ZOOM

MOTOR

CONTROL

A/D

D/A

D/A

YUV

XSCKSOSI

82 83 84 85 86

IC201

CAMERA Y/C PROCESS.

CAMERA

Y/C

PROCESS.

XCS

XRST

D/A

D/A

A/D

A/DAFT

MEM FLDI

DSD L ON

DSD R ON

DSD P ON

XSG V RST

ATF SAMPLE

MDCHA FLD

MECHA HD

MECHA VD

REC Y RF

REC C RF

Y RF IN

DOP IN

ATF IN

YMO1

YMO8

CMO1

CMO4

VI HDO

VI VDO

VI FLDO

YMI1

YMI4

CMI1

CMI4

MEM HDI

MEM VDI

CGCK

COLOR4

COLOR3

COLOR2

COLOR1

JOG VD

1/2 SWP

SWP DIR

SYS V

CK CONT

OSD SO

VIHDO

CL

XRST SYSTEM

XCS SYSTEM

SYS V

CL

CAM DD ON

TO CAMERA

CONTROL BLOCK (2/2)

(SEE PAGE 3-12)

15V

–7V

TBC VD

XTBC V RST

MEM VD

Q513

Q507,Q509,Q510,Q511

REG

IC301

D/A CONVERTER

HALL OFFSET

11

VCC

10

VDD

UNREG

2V

3.2V

4.9V

FB-3

FB-2

HALL GAIN

HALL REF

AGC CONT2

AGC CONT1

2

3

6

FRQ (X101)

18

7

FLIP

13

12

SI

17

16

SCK

15

DA STB

FRQ

FLIP

AGC CONT2

AGC CONT1

T501,Q501,D504

FB-4

FB-5

Q503,D502

REG

Q504,D503

REG

Q502,D501

REG

REG

(IC102)

OUT5

OUT4

OUT3

OUT2

IC501

64

57

DC/DC

CONTROL

56

50

TBC VD

XTBC V RESET

MEM VD

HALL GAIN

HALL OFFSET

HALL REF

SYS V

XCS SYSTEM

XRST SYSTEM

XCS TG

XVC SCK

VC SO

VC SI

MECHA VD

MECHA HD

MECHA FLD

XSG V RST

CK CONT

DA STB

SL SHUTTER WEWEN

CN501

UNREG

1

FB-5

14

FB-4

18

FB-2

38

FB-3

34

CONTROL BLOCK(1/2)

TO VIDEO OUT, AUDIO BLOCK

CN-116 BOARD CN991

(SEE PAGE 3-13)

TO CAMERA

(SEE PAGE 3-9, 10)

16

13

40

63

38

118

116

113

111

108

106

103

101

91

93

96

98

125

123

121

117

115

112

110

107

105

102

100

90

92

95

97

124

122

120

155

158

157

153

156

152

151

150

70

71

72

73

74

75

76

80

81

87

8

4

8

4

CONTROL BLOCK(2/2)

IC203

MEMORY

71

IY1

I

I

78

IY8

IC1

3

I

I

IC4

6

65

IHD

66

IVD

67

IFLD

30

OY1

I

I

23

OY8

15

DC1

I

I

12

DC4

16

OHD

17

OVD

15

OFLD

IC202

CHARACTER

GENERATOR

20

XHSYNC

19

XYSYNC

8

OSC

11

BLKC

13

BLKB

14

VC3

15

BLKA

16

VC2

17

VC1

18

VC0

TO CAMERA

(SEE PAGE 3-12)

RCK

WCK

TBC VD

VRSTL

SYSV

XRST

XCS

XSCK

CLK

XCS

DATA

XPCL

CL

50

MCK

52

36

54

55

53

45

46

SI

44

SO

43

XOSD SCK

1

XCS OSD

2

3

XSYS RST

4

XSYS RST

OSD SO

XCS OSD

XOSD SCK

XCS SYSTEM XRST SYSTEM

05

3-5 3-6 3-7 3-8

Page 19

3-3. CAMERA CONTROL (1/2) BLOCK DIAGRAM

CVX-V18NS/V18NSP

SE-93 BOARD

SE050

1

2

4

SE051

1

2

4

05

SENSOR AMP

4

8

16

12

IRIS

METER

M

H

ZOOM LENS

UNIT

ZOOM

SENSOR

FOCUS

SENSOR

M903

ZOOM

MOTOR

M

M902

FOCUS

MOTOR

M

IC050

20

2

19

18

3

6

4

5

TEMP COM

TEMP OUT

DRIVE (+)

DRIVE (–)

CONT (–)

CONT (+)

BIAS (+)

HALL (–)

HALL (+)

BIAS (–)

GND

SENSE VCC

ZM RST

FC RST

ZM XA

ZM A

ZM XB

ZM B

FC A

FC XA

FC B

FC XB

VC-211 BOARD (2/3)

CN601CN050

3.2V

3

PITCH AD

6

VST C RESET

4

YAW AD

5

22

23

20

18

21

19

17

12

10

11

16

13

15

14

8

7

5

6

1

4

2

3

9

CN401

Q552

DRIVE

Q553

ZM RST SENS

LENS RST LED

FC RST SENS

PLA/GLASS

3.2V

3.2V

22

20

10

26

24

IC402

IRIS DRIVE

–

8

+

IC402

HALL BIAS CONTROL

+

1

–

+

14

–

IC402

HALL GAIN CONTROL

IC401

B3

ZOOM

A3

8

MOTOR

B4

DRIVE

A4

A1

5

FOCUS

B1

MOTOR

A2

7

DRIVE

B2

VM2

VM1 VM33VC

4

(1/4)

(1/4)

(1/4)

IC602

CAMERA CONTROL

VDD3.2V

25

64

VDD

100

AVDD

AVRH

101

120

VDD

1

1

6

XTAL

2

EXTAL

7

XSYS RST

XCS VC

77

HI SO

76

HI SI

75

HI SCK

74

SYS V

108

43

LENS FILTER ON SW

LENS RST LED

22

VST C CHAGE

85

23

ZM RST SENS

YAW AD

98

PITCH AD

97

70

IRIS PWM

LENS TEMP AD

86

93

HALL AD

FC RST SENS

24

94

PLA/GLASS

XCS SYSTEM

19

80

VC SI

79

VC SO

78

XVC SCK

XTBC V RESET

107

XRST SYSTEM

119

16

XCS IO

MECHA VD

118

113

TBC VD

112

MECHA HD

MECHA FLD

111

MEM VDI

114

CK CONT

18

XSG V RST

45

XCS TG

84

DA STB

21

XCS EEPROM

27

XWE EEPROM

26

SL SHUTTER WE

51

9

PDR CS

VC SO

XVC SCK

XRST SYSTEM

MEM VDI

TO CAMERA

CONTROL

BLOCK(2/2)

(SEE PAGE

3-12)

X401

20MHz

XSYS RST

VC SI

VC SO

SYS V

TBC VD

DA STB

XCS TG

XCS VC

HI SO

HI SI

HI SCK

SYS V

VST C RESET

MEM VDI

XCS

DO

4

DI

3

RST

XSCK

2

VCC 3.2V

8

IC601

EEPROM

TO CAMERA

CONTROL BLOCK(2/2)

(SEE PAGE 3-12)

LENS TEMP AD

9

10

3

2

EN4

EN3

EN2

EN1

HALL GAIN

HALL OFFSET

HALL REF

19

18

IN4

17

16

IN3

15

14

IN2

13

12

IN

12

13

1123

3.2V

4.9V

5

6

LPF

IC402

HALL ANP

+

–

IRIS PWM

LENS FILTER ON SW

(1/4)

HALL AD

7

HALL GAIN

HALL OFFSET

HALL REF

ZM RST

FC RST

IRIS COM

EN1

DIR1B

DIR1A

EN0

DIR0B

DIR0A

TO CAMERA BLOCK

(SEE PAGE 3-6, 8)

TO CAMERA BLOCK

(SEE PAGE 3-8)

XVC SCK

XCS SYSTEM

XTBC-V RESET

XRST SYSTEM

MECHA VD

MECHA HD

MECHA FLD

CK CONT

XSG V RST

MEM VDI

SL SHUTTER WE

3-9 3-10

Page 20

CVX-V18NS/V18NSP

3-4. CAMERA CONTROL (2/2) BLOCK DIAGRAM

IF-73 BOARD VC-211 BOARD (3/3)

E3.2V

CN1803

CAMERA BLOCK

CN-116 BOARD

CN991

(SEE PAGE 3-13)

M901

IR

M

MOTOR

KEY AD3

KEY AD4

KEY AD5

2A

-2A

-2B

2B

1

2

3

4

CN1801

3

4

5

6

KEY AD3

KEY AD4

KEY AD5

KEY AD6

22

10

20

MOTOR DRIVER

2A

8

2A

2B

2B

IC1801

VM

IN3

EN3

IN4

EN4

4

11

23

VC

3

16

17

18

19

30

31

32

33

4.9V

3.2V

IC1803

VISCA CONTROL

KEY AD3

KEY AD4

KEY AD5

KEY AD6

IC1802

MOTOR PRE DRIVER

15

DIR2A

17

EN2

16

DIR2B

WAKE UP

VDD

VD IN

CS

SCK

SIN

CKIN

X CLR

VCC

RESET

SCK

TITLE

DOWN

MENU

20

1

3

4

5

8

9

SI

SO

CS

UP

5

6

8

29

47

1

9

10

11

18

39

25

28

27

26

3.2V

E3.2V E3.2V

IC804

REGULATOR

VOUT VIN

1 3

UNREG

3.2V

4.9V

XVISCA RESET

SCK2

SO2

SI2

CS2

XWAKE UP

MEM VD

PDR CS

XVC SCK

VC SO

XRST SYSTEM

CL

30

20

19

13

18

17

16

15

14

24 7

8

7

11

12

10

9

CN703CN1802

1

11

12

18

13

14

15

16

17

23

24

20

19

21

22

UNREG

3.2V

4.9V

XVISCA RESET

SCK2

SO2

SI2

CS2

XWAKE UP

KEY AD3

CL

MEM VD

PDR CS

XVC SCK

VC SO

XRST

SYSTEM

X701

20MHz

X702

32.768kHz

TO CAMERA BLOCK

(SEE PAGE 3-7)

TO CAMERA

CONTROL

BLOCK(1/2)

(SEE PAGE

3-10)

20MHz OUT

40

20MHz IN

41

32kHz IN

52

32kHz OUT

53

5

RESET

50

SCK2

SO2

49

48

SI2

CS2

47

WAKE UP

21

96

KEY AD3

IC702

MODE CONTROL

ACV SENSE

XSYS RST

XOSD SCK

CAM DD ON

VTR DD ON

LANC OUT

VDD

XRESET

BATT IN

XCS VC

HI SI

HI SO

XHI SCK

SYS V

XCS OSD

OSD SO

LANC IN

IC701

INITIAL RESET

V OUT

6

5

RESET

4

CS

BACKUP VCC

V BAT

XSYS RST

XCS VC

HI SI

HI SO

XHI SCK

SYS V

XSYS RST

XCS OSD

OSD SO

XOSD SCK

CAM DD ON

CAM DD ON

VTR DD ON

3.2V

UNREG

V IN

7

3

CN704 LANC

D704

2 3

BT701

TO CAMERA

CONTROL BLOCK(1/2)

(SEE PAGE 3-10)

TO CAMERA BLOCK

(SEE PAGE 3-6, 7)

TO POWER(CAMERA) BLOCK

(SEE PAGE 3-17)

1

3.2V

UNREG

2

3

4

LANC OUT

LANC IN

TO LANC JIG

V OUT

IC703

REGULATOR

D701

UNREG

V IN

42

51

75

76

77

86

87

38

61

91

9

22

33

34

35

64

44

45

46

28

29

2

1

IR-34 BOARD

4.9V

CN502

1

1

2

2

3

3

D091

IR-35 BOARD

D1091

D1092

Q1091

05

D1090

Q1090

CN1090

D090 D092

43

CN1805

1

1

2

2

3

3

4

4

4.9V

4.9V

IR_ON

1

20

4.9V

2

29

IR ON

4

4

CN090

Q090

Q091

3-11 3-12

Page 21

3-5. VIDEO OUT, AUDIO BLOCK DIAGRAM

CVX-V18NS/V18NSP

TO CAMERA BLOCK

VC-211 BOARD CN501

(SEE PAGE 3-8)

TO CAMERA BLOCK

VC-211 BOARD CN301

(SEE PAGE 3-5)

TO CAMER CONTRL BLOCK (2/2)

IF-73 BOARD CN1805

(SEE PAGE 3-11)

UNREG

S-Y_OUT

S-C_OUT

KEY_AD3

KEY_AD4

KEY_AD5

CN-116 BOARD

CN991

1

4

6

7

8

10

CN990 CN883

UNREG

14

UNREG

13

S-Y_OUT

10

S-C_OUT

8

KEY_AD3

6

KEY_AD4

5

KEY_AD5

4

VA-108 BOARD

1

2

S-Y_IN

5

S-C_IN

7

9

10

11

UNREG

KEY_AD5

KEY_AD4

18

16

MENU

IC821

Y/C MIX VIDEO AMP

6dB

6dB

1211

TITLE

+

EXPOSURE

CN884

KEY_AD3

KEY_AD4

J821

43

J823

1

2

1

S VIDEO

2

VIDEO

DT-106 BORAD (2/2)

CN996

KEY_AD3 KEY_AD3

10

KEY_AD4

9

DATE

TIME

DISPLAY

CN997

KEY_AD4

4

5

SW-328 BOARD

CN941

KEY_AD3

3

W

KEY_AD4

2

NIGHTSHOT

T

NEAR

ON

OFF

FAR

FOCUS

INFINITY

MANU

AUTO

9

14

6dB6dB

6

SHUTTER

–

EXEC

MIC

PLUG IN

POWER

DT-106 BOARD (1/2)

J995

MIC_R

MIC_L

05

CN996 CN884

3

2

8

9

R

AUDIO

L

VW-1 BOARD

CN901

CAM_Y

6

CAM_C

8

AUDIO_L

10

AUDIO_R

11

CN902

CAM_Y

CAM_C

AUDIO L

AUDIO R

3

20

VIDEO WALKMAN

CONNECTOR

6

5

Q821

BUFFER

Q822

BUFFER

AMP

AMP

IC842

ALC AMP

LEVEL

DETECT

7

1

IC841

AMP

BUFFER

5

3

BUFFER

7 9

1 13

CN882

CAM_Y

CAM_C

AUDIO_L

AUDIO_R

11

9

7

6

J823

3-13 3-14

Page 22

CVX-V18NS/V18NSP

3-6. POWER (MAIN UNIT) BLOCK DIAGRAM

VIDEO WALKMAN

CONNECTOR

BATTERY

TERMINAL

VW-1 BOARD

18

19

2

4

9

10

12

13

7

VA-108 BOARD

CN881

BATT (+)

1

2

BATT SW (-)

3

BATT (-)

4

5

CN901CN902

CN882

UNREG

16

1

UNREG

15

2

UNREG GND

14

3

UNREG GND

13

4

GND

12

5

GND

10

7

GND

5

12

16

9

GND

1

GND

8

F881

1.25A

Q841

BUFFER

5.5V DETECT

2

VDD OUT

4.7V DETECT

2

VDD

IC883

IC884

OUT

IC841

MIC AMP

1

1

Q882

SWITCH

Q881

SWITCH

8 5

IC842

ALC

VCCVCC

Q884

SWITCH

IC881

VOLTAGE REGURATOR

IC843

VOUT

VOUT

1

1

3

VIN

VOLTAGE REGURATOR

3

VIN

Q883

SWITCH

Q821

BUFFER

Q822

BUFFER

IC821

Y/C MIX VIDEO AMP

VCC2

10

27

VCC1

30

VCC3

CN883

UNREG

UNREG

GND

GND

Y_GND

C_GND

GND

GND

CN884

BATT LED

POWER(1)

POWER(2)

GND

AU_GND

1

2

3

4

6

8

13

14

3

4

5

5V

6

7

10

CN-116 BOARD

CN990

UNREG

14

UNREG

13

GND

12

GND

11

Y_GND

9

C_GND

7

GND

2

GND

1

CN996

BATT LED

8

POWER(1)

7

POWER(2)

6

5V

5

GND

4

AU_GND

1

D995

BATT

LED

CN995

POWER(1)

POWER(2)

GND

CN991

TO POWER (CAMERA)

POWER(1)

POWER(2)

5V

GND

UNREG

GND

Y_GND

C_GND

GND

VC-211 BOARD CN501

(SEE PAGE 3-17)

TO POWER (CAMERA)

VC-211 BOARD CN301

(SEE PAGE 3-17)

TO POWER (CAMERA)

IF-73 BOARD CN1803

(SEE PAGE 3-20)

S948

POWER

ON

OFF

D941

POWER

LED

1

2

3

5

9

CN941

1

2

5V

3

6

6

5

4

1

DT-106 BOARD

AU_GND

05

SW-328 BOARD

3-15 3-16

Page 23

3-7. POWER (CAMERA) BLOCK DIAGRAM

CVX-V18NS/V18NSP

TO POWER (MAIN UNIT)

CN-116 BOARD CN991

(SEE PAGE 3-16)

TO POWER (MAIN UNIT)

CN-116 BOARD CN991

(SEE PAGE 3-16)

UNREG

GND

Y_GND

C_GND

VC-211 BOARD

CN501

UNREG

1

2

CN301

3

5

CN704

UNREG

2

4.9V

4.9V

4.9V

4.9V

4.9V

1

1

11

12

30

1

2

3

TO LANC JIG

IF-73 BOARD

CN1802CN703

UNREG

30

3.2V

20

4.9V

19

4.9V

1

F.B.

3

IC1804

3.2V REG

V IN

20

V OUT

IC1802

PRE DRIVER

VCC

1

PULL UP

RESISTANCE

F.B.

IC1803

VISCA COM

8

VCC

29

AVCC

47

VCC

NS MOTOR DRIVER

3

4

11

23

IC1801

VCC

VM1

VM3

VM2

CN1803

CN1805

4.9V

4.9V

4.9V

33

5

1

2

3

GND

SE-93 BOARD

CN050

3.2V3.2V

TO POWER (MAIN UNIT)

CN-116 BOARD CN991

(SEE PAGE 3-16)

IR-35 BOARD

CN1090

4.9V

1

4.9V

2

4.9V

3

IR-34 BOARD

CN090

4.9V

1

4.9V

2

4.9V

3

PITCH SENSOR

Q1090

SWITCH

Q090

SWITCH

SE050

Q1091

SWITCH

Q091

SWITCH

IC050

SENSOR AMP

20

VCC

SE051

YAW SENSOR

11

3.2V

IC701

Q513

7

3

Q508

RESET

VIN

VOUT

VBAT

6

2V

3.2V

–7V

+15V

CAM_DD_ON

4.9V

VTR_DD_ON

SW_UNREG

2V

IC703

REGURATOR

VIN

2

VOUT

3.2V

2

6

4

5

3

D504

D704

Q507,Q509

Q510,Q511

–7.0V REG

EMERGENCY

BT701

DETECT

D701

L501

CHOKE

IC501

DD CONV

Q503

VREF

SWITCHING

Q504

SWITCHING

Q501

SWITCHING

Q502

SWITCHING

D502

CHOKE

D503

SWITCHING

3

1

L503

CHOKE

L504

Q506

T501

28

VCC

22

CT

FB-5

FB-4

COMP

FB-3

FB-2

STC BY

VREF

64

14

57

60

18

63

51

43

13

56

34

50

38

29

30

27

21

RT

OUTPUT-5

OUTPUT-4

MOSGATE-4

OUTPUTVCC-56

OUTPUTVCC-24

OUTPUTVCC-13

OUTPUT-3

OUTPUT-2

STD BY3

42

51

77

86

87

28

29

IC702

HI-COM

VDD

VDD

AVDD

VDD

VDD

CAM_DD ON

VTR_DD_ON

TIMING GENERATOR

S/H AGC A/D

IC101

VDD1

VDD2

VDD3

VDD4

VDD6

29

VL

VH

27

IC001

CCD IMAGER

11

VL

8

VDD

IC102

DRVDD

DVDD

ACVCC

ADVDD

10

13

19

20

43

3.2V

IC202

CHARACTER GENERATOR

12

17

33

43

F.B.

3.2V

3.2V

2V

IC401

ZOOM/FOCUS DRIVE

VM1

3

VCC

VM3

VM2

IC402

IRIS DRIVE

F.B.

4

11

23

ZOOM/FOCUS MOTOR CONTROL

58

77

94

114

137

147

162

4.9V

Q401

SENSOR

POWER SUPPLY

IC203

MEMORY

VDD DRAM

VDD LOGIC

VDD LOGIC

VDD LOGIC

VDD LOGIC

IC201

CAMERA Y/C PROCESS

DVDD1

DVDD2

DVDD3

DVDD4

DVDD5

DVDD6

DVDD7

VDD IO

ADVD2

VDD IO

ADVD3

ADVD4

AVDD

AVDD

AVDD

AVDD

AVDD

AVDD

AVDD

AVDD

AVDD

PLL_VDD

EVR_VDD

AVDD

IO_VDD1

IO_VDD2

IO_VDD3

IO_VDD4

10

19

20

29

30

41

42

50

52

175

176

67

104

119

154

3.2V

F.B.

5

VDD

IC301

D/A CONVERTER

10

VDD

11

VCC

Q301

BUFFER

Q302

BUFFER

IC302

Y/C MIX VIDEO AMP

10

VCC2

27

VCC1

30

VCC3

F.B.

Q201

BUFFER

Q202

BUFFER

F.B.

3.2V

2V

3.2V

3.2V

3.2V

3.2V

EEPROM

8

IC601

VCC

3.2V

4.9V

25

64

100

120

IC602

CAMERA MICOM

VDD

VDD

AVDD

VDD

8

19

32

37

38

64

7

31

51

68

9

UNREG

3.2V

CN502

CN601

3.2V

05

3-17 3-18 3-19

4

VCC

CN401

IRIS DRIVE+

8

ZOOM

LENS UNIT

3-20 E

Page 24

SECTION 4

SCHEMATIC DIAGRAMS

4-1. FRAME (1/2) SCHEMATIC DIAGRAM

1 2 3 4 5 6 7 8 9 10 11 12

CVX-V18NS/V18NSP

D

A

B

C

E

F

M901

IR

MOTOR

8765432

CN1801 8P

2B

NC

NC

–2B

IF-73 BOARD

–2A

CONNECTION

CORD

1

CN501 2P

UNREG

2

UNREG_GND

12345

CN301 6P

S_GND

S_C_OUT

Y_GND

S_Y _OUT

6

GND

VIDEO_OUT

VC-211 BOARD

CN401 23P

TEMP

TEMP

ZM

GND

FC_RST

SENSE

PLA/GLASS

FC_A

FC_B

FC_XB

FC_XA

ZM_A

ZM_B

ZM_XB

ZM_XA

DRIVE(+)

DRIVE(–)

CONT(+)

CONT(–)

HALL(–)

BIAS(–)

HALL(+)

BIAS(+)

CN601 6P

GND

GND

3.2V

VST_C_RESET

YAW_AD

PITCH_AD

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

FFC-219

1

2

3

4

5

6

LENS UNIT

CN050 6P

GND

GND

3.2V

VST_C_RESET

YAW_AD

PITCH_AD

1

2A

NC

NC

12345

CN1803 5P

KEY_AD3

KEY_AD4

KEY_AD5

KEY_AD6

GND

UNREG

GND

GND

KEY_AD6

KEY_AD5

KEY_AD4

KEY_AD3

KEY_AD2

KEY_AD1

KEY_AD0

3.2V

4.9V

SCK2

SO2

SI2

CS2

XWAKE_UP

XVISCA_RESET

VC_SO/EN2

XVC_SCK/DIR_2B

CL/DIR_2A

XRST_TANUKI

MEMVD

PDR_CS

O_ZOOM

D_ZOOM

N.C.

N.C.

IR_ON

D4.9V

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

FFC-262

CN703 30PCN1802 30P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

UNREG

GND

GND

KEY_AD6

KEY_AD5

KEY_AD4

KEY_AD3

KEY_AD2

KEY_AD1

KEY_AD0

3.2V

4.9V

SCK2

SO2

SI2

CS2

XWAKE_UP

XVISCA_RESET

VC_SO/EN

XVC_SCK/DIR_0B

CL/DIR_0A

XRST_TANUKI

MEMVD

PDR_CS

O_ZOOM

D_ZOOM

N.C.

N.C.

IR_ON

D4.9V

CN-116 BOARD

CN991

(SEE PAGE 4-4)

ZOOM

SE-93 BOARD

G

H

GND

GND

GND

IR_ON

7654321

7654321

CN1090 7P CN1805 7P

GND

GND

GND

IR_ON

4.9V

4.9V

4.9V

4.9V

GND

7654321

7654321

CN090 7P CN502 7P

GND

GND

FFC-264FFC-280

GND

GND

GND

IR_ON

IR_ON

4.9V

4.9V

4.9V

4.9V

4.9V

4.9V

GND

GND

CN704 6P

65432

LANC_IN

TO

LANC JIG

3.2V

UNREG

LANC_OUT

1

4.9V

4.9V

I

IR-35 BOARD IR-34 BOARD

J

05

FRAME (1/2)

4-1 4-2

Page 25

CVX-V18NS/V18NSP

4-2. FRAME (2/2) SCHEMATIC DIAGRAM

1 2 3 4 5 6 7 8 9 10 11

VIDEO WALKMAN CONNECTOR

D

G

A

POWER

ON

OFF

B

NIGHTSHOT

OFF

ON

123456789

CN902 20P

Y_OUT

AUDIO_L_IN

(VIDEO_OUT)

AUDIO_R_IN

VIDEO_IN_GND

(VIDEO_OUT_GND)

1011121314151617181920

ID1

IO_GND

ADI_GND

LANC_GND

ADI_GND

LANC_SIG

AUDIO_IN_GND

VW-1 BOARD

ID2

(AUDIO_L_OUT)

(AUDIO_R_OUT)

(AUDIO_OUT_GND)

C_OUT

ADI_UNREG

ADI_UNREG

SW-328 BOARD

ID1

T

C

ZOOM

W

FAR

NEAR

FOCUS

INFINITY

MANU

AUTO

5V

GND

KEY_AD4

KEY_AD3

12345

POWER(2)

POWER(1)

6

UNREG

CN901 16PCN882 16P

123456789

16151413121110

UNREG

UNREG

UNREG_GND

UNREG

UNREG_GND

GND

CAM_Y

UNREG_GND

FFC-275

GND

CAM_Y

UNREG_GND

GND

GND

CAM_C

AUDIO_L

10111213141516

987654321

GND

GND

CAM_C

AUDIO_L

FFC-272

E

65432

CN997 6P CN941 6P

BATT

F

MIC

PLUG IN

POWER

DISPLAY

DATE

TIME

DT-106 BOARD

GND

KEY_AD4

5V

KEY_AD3

1

POWER(2)

POWER(1)

CN996 10P

KEY_AD3

KEY_AD4

BATT_LED

POWER(1)

POWER(2)

5V

GND

MIC_R

MIC_L

AU_GND

10

9

8

7

6

5

4

3

2

1

FFC-273

1

2

3

4

5

6

7

8

9

10

CN884 10P

KEY_AD3

KEY_AD4

BATT_LED

POWER(1)

POWER(2)

5V

GND

MIC_R

MIC_L

AU_GND

EXPOSURE

SHUTTER

TITLE

MENU

EXEC

VA-108 BOARD

S VIDEO

OUT PUT

+

–

AUDIO_R

AUDIO_R

VIDEO

L

R

GND

GND

ID1

AUDIO

ID2

ID2

LANC

LANC

GND

GND

CN883 14P

UNREG

UNREG

GND

GND

S_Y_IN

Y_GND

S_C_IN

C_GND

KEY_AD3

KEY_AD4

KEY_AD5

KEY_AD6

GND

GND

CN881 5P

BATT_(+)

BATT_SW(+)

BATT_SW(–)

BATT_(–)

BATT_SIG

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

2

3

4

5

FFC-274

CN-116 BOARD

CN990 14P

9

8

7

6

5

4

3

2

1

TERMINAL

UNREG

UNREG

GND

GND

S_Y_IN

Y_GND

S_C_IN

C_GND

KEY_AD3

KEY_AD4

KEY_AD5

KEY_AD6

GND

GND

BATTERY

14

13

12

11

10

CN991 12P

UNREG

UNREG_GND

Y_GND

S-Y_OUT

C_GND

S_C_OUT

KEY_AD3

KEY_AD4

GND

KEY_AD5

KEY_AD6

NC

1

2

3

4

5

6

7

8

9

10

11

12

TO

CONNECTION CORD

(SEE PAGE 4-2)

FRAME (2/2)

H

05

4-3 4-4 E

Page 26

CVX-V18NS/V18NSP

SECTION 5

ADJUSTMENTS

NTSC model : CVX-V18NS

PAL model : CVX-V18NSP

5-1. PREPARATIONS BEFORE ADJUSTMENT

5-1-1. List of Service Tools

• Oscilloscope • Regulated power supply • Vectorscope • Frequency counter

• Color monitor • Digital voltmeter

Ref. No.

Filter for color temperature correction (C14)

J-1

ND filter 1.0

J-2

ND filter 0.3

Pattern box PTB-450

J-3

Color chart for pattern box

J-4

Adjusting remote commander

J-5

(RM-95 upgraded). Note

Clear chart for pattern box

J-6

CPC jig

J-7

Siemens star

J-8

Mini pattern box

J-9

Note: If the microprocessor IC in the adjusting remote commander is not the new microprocessor (UPD7503G-C56-12), the pages

cannot be switched.

In this case, replace with the new microprocessor (8-759-148-35).

J-1 J-2

Name

J-3

Parts Code

J-6080-058-A

J-6080-808-A

J-6080-818-A

J-6082-200-A

J-6020-250-A

J-6082-053-B

J-6080-621-A

J-649-193-0A

J-6080-875-A

J-6082-353-B

Usage

Auto white balance adjustment/check

White balance adjustment/check

White balance check

White balance check

Flange back check

Flange back Adjustment

J-4 J-5

J-6

J-7

J-8 J-9

Fig. 5-1-1

5-1

Page 27

5-1-2. Preparations

l

Note 1: For details of how remove the cabinet and boards, refer

to “2. DISASSEMBLY”.

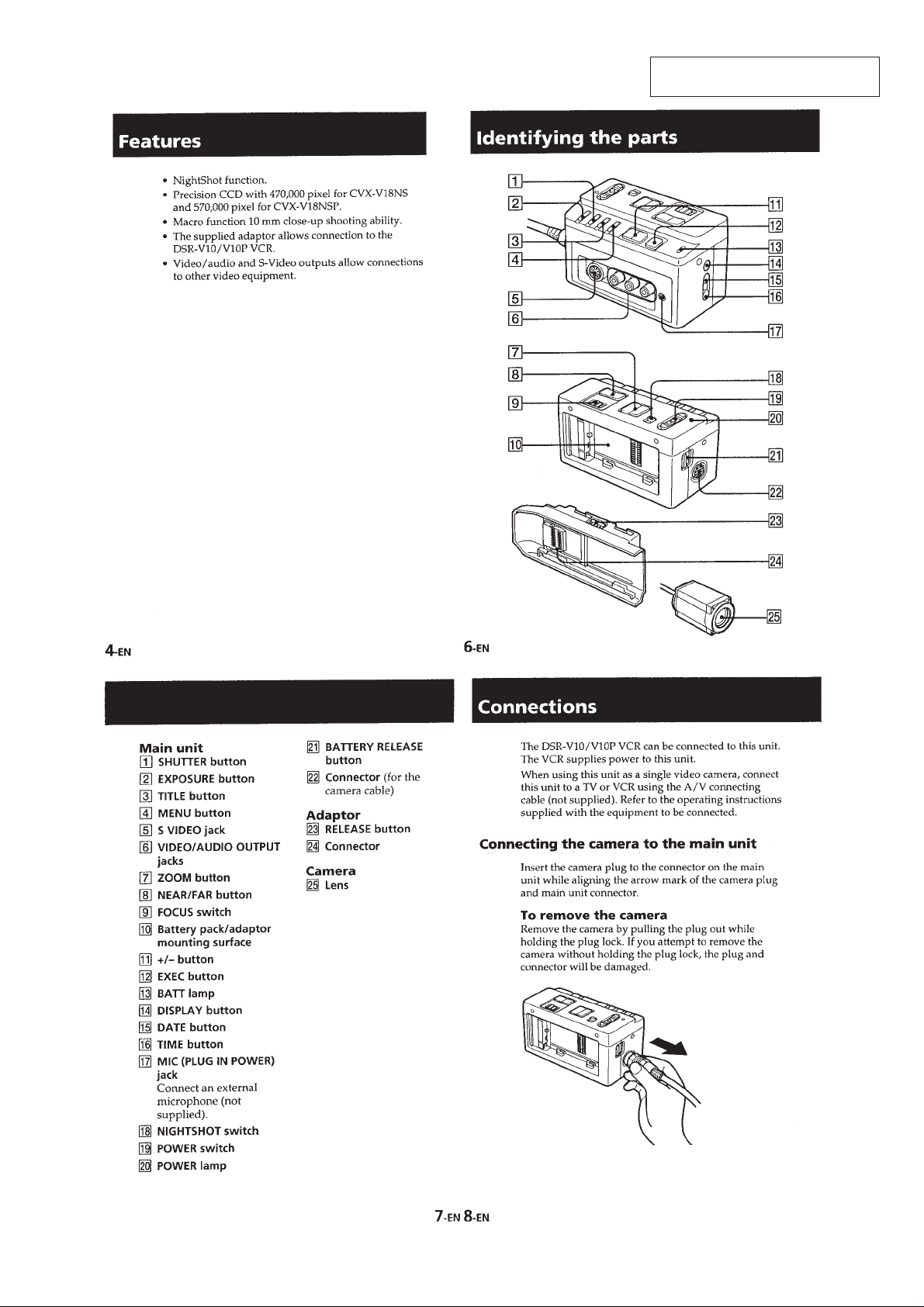

1) Connect the equipment for adjustments according to Fig. 5-1-3.

2) Connect the adjusting remote commander to the CN704 on

the VC-211 board via CPC jig (J-649-193-0A).

Pattern box

L

Front side of the lens

L = About 40 cm

Fig. 5-1-2

Regulated power supply

(7.2

±

0.1 Vdc)

Main unit

CN704

Video/Audio

output terminal

Camera

VC-211

board

CPC jig

(J-649-193-0A)

Audio (L)

Audio (R)

Video

Adjusting remote comander

(J-6082-053-B)

color minitor vectorscope

Ω

75

termina

Fig. 5-1-3

5-2

Page 28

5-1-3. Precautions

1. Setting the Switch

Unless otherwise specified, set the switches as follows and perform adjustments.

1. POWER switch (Main unit) ................................ON

2. NIGHT SHOT switch (Main unit) ...................... OFF

3. FOCUS switch (Main unit) .................................AUTO

2. Order of Adjustments

Basically carry out adjustments in the order given.

Color bar chart standard picture frame

H

Yellow

AB B

Cyan

Green

A=B

White

Magenta

Red

Blue

A

Enlargement

0

±

0.1msec

V

Fig. a (Video output terminal

output waveform)

Difference in level

B

A

Fig. 5-1-4

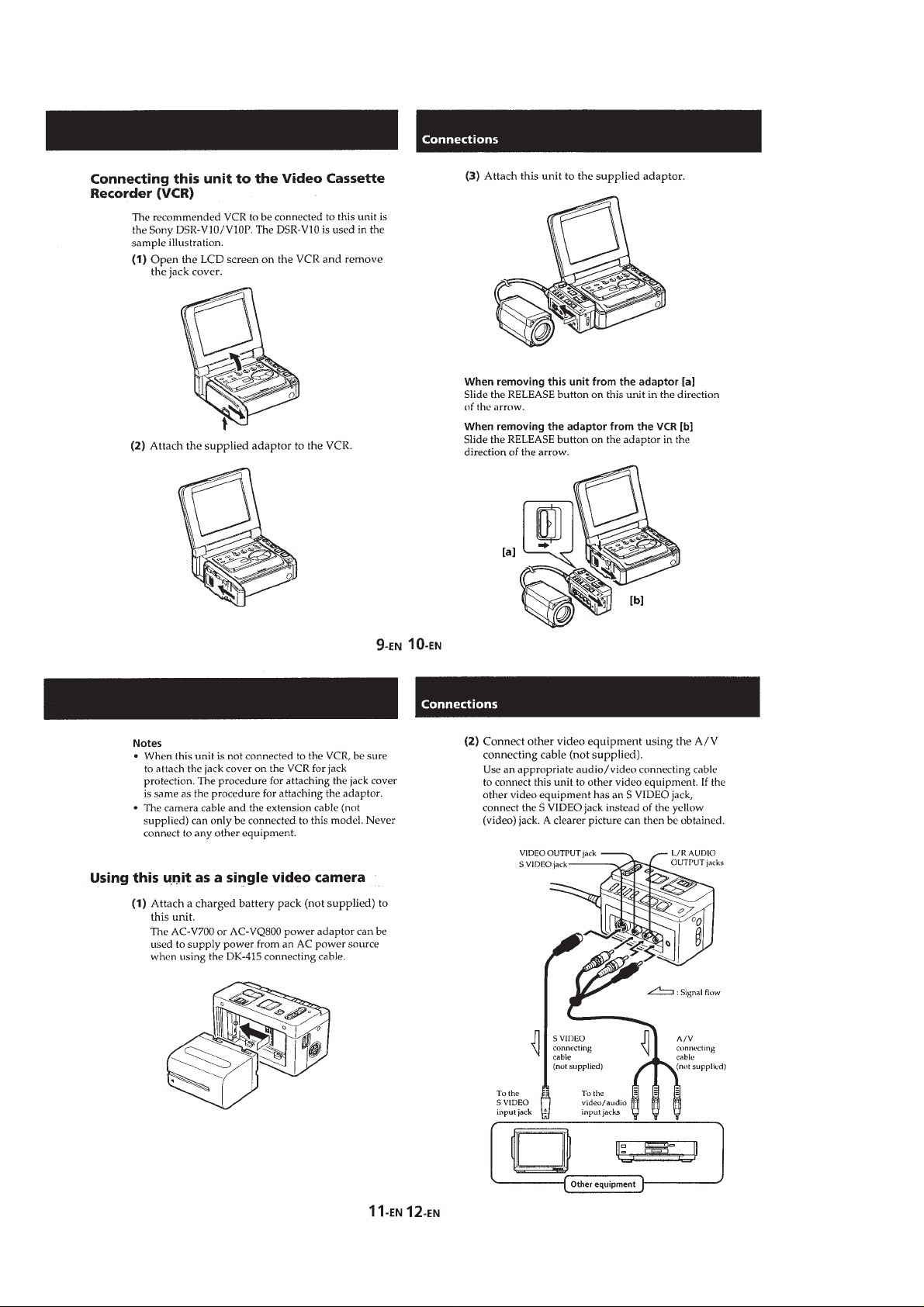

3. Subjects

1) Color bar chart (Standard picture frame).

When performing adjustments using the color bar chart, adjust the picture frame as shown in Fig. 5-1-4. (Standard picture frame)

2) Clear chart (Standard picture frame)

Remove the color bar chart from the pattern box and insert a

clear chart in its place. (Do not perform zoom operations during this time.)

3) Chart for flange back adjustment

Join together a piece of white A0 size paper (1189mm × 841

mm) and a piece of black paper to make the chart shown in

Fig. 5-1-5.

Note: Use a non-reflecting and non-glazing vellum paper. The

size must be A0 or larger and the joint between the white

and black paper must not have any undulations.

Electronic beam scanning frame

Red

Cyan

White

Green

Yellow

Blue

Magenta

CRT picture frame

Fig. b (TV monitor picture)

Direct the camera toward the subject and place the

subject with the distance (about 40 cm) from camera

until the specified picture frame fills the monitor display as shown in Fig. a and Fig. b.

White

Black

841mm

5-3

1189mm

Fig. 5-1-5

Page 29

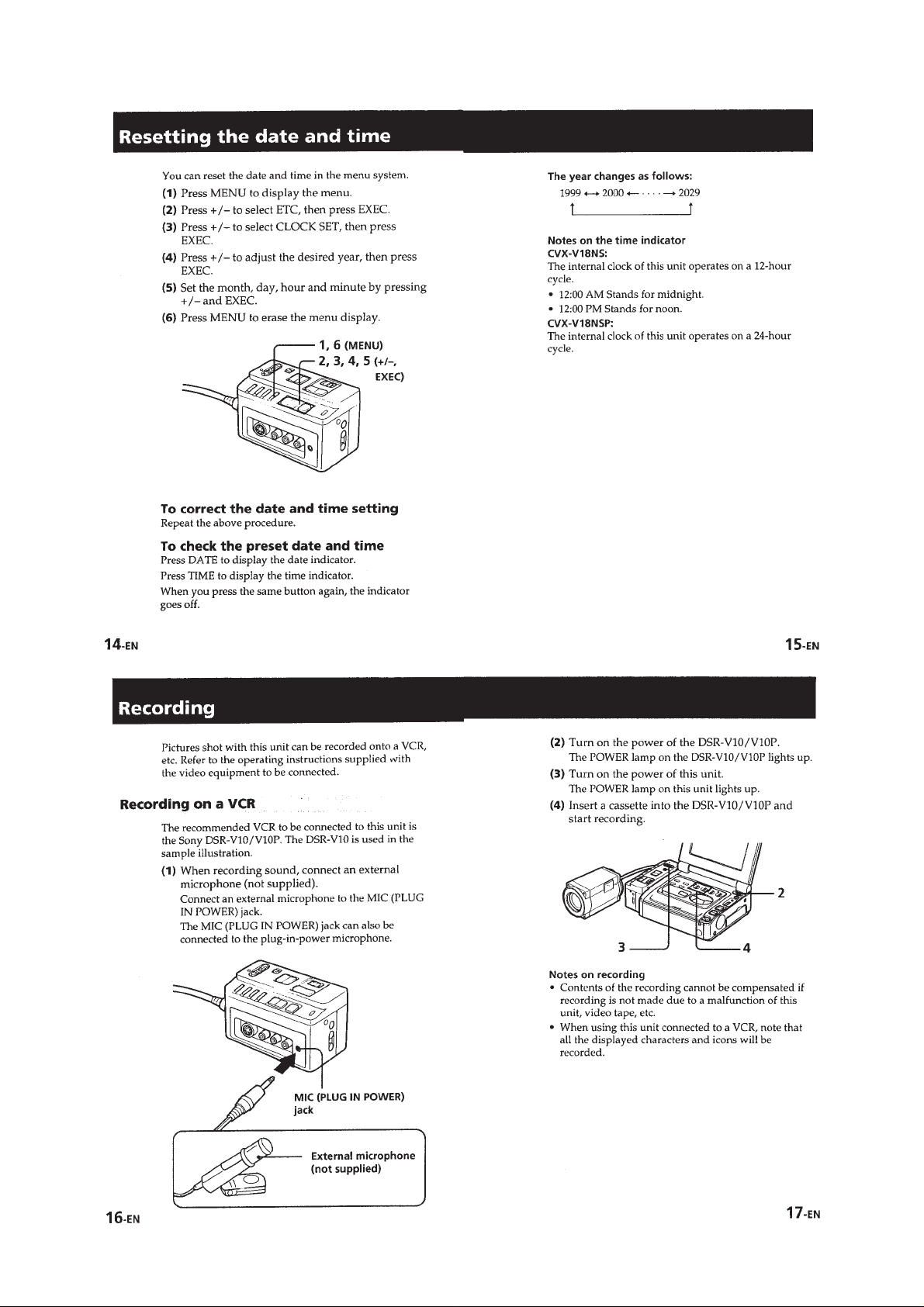

5-1-4. Adjusting Remote Commander

The adjusting remote commander is used for changing the calculation coefficient in signal processing, EVR data, etc. The adjusting remote commander performs bi-directional communication

with the unit using the remote commander signal line (LANC).

The resultant data of this bi-directional communication is written

in the non-volatile memory.

1. Used Adjusting Remote Commander

1) Connect the adjusting remote commander to the CN704 on

the VC-211 board via CPC jig (J-649-193-0A).

2) Adjust the HOLD switch of the adjusting remote commander

to “HOLD” (SERVICE position).

3) Turn on the power with the POWER switch of the unit.

If it has been properly connected, the LCD on the adjusting remote commander will display as shown in Fig. 5-1-6.

0 : 00 : 00

Page Data Address

• Changing the address

The address increases when the FF ()) button is pressed,

and decreases when the REW (0) button is pressed. There

are altogether 256 addresses, from 00 to FF.

• Changing the data (Data setting)

The data increases when the PLAY (() button is pressed,

and decreases when the STOP (p) button is pressed. There

are altogether 256 data, from 00 to FF.

• Writing the adjustment data

The PAUSE button must be pressed to write the adjustment

data in the nonvolatile memory. (The new adjustment data

will not be recorded in the nonvolatile memory if this step is

not performed)

2. Precautions Upon Using the Adjusting Remote

Commander

Mishandling of the adjusting remote commander may erase the

correct adjustment data at times. T o prev ent this, it is recommended

that all adjustment data be noted down before beginning adjustments and new adjustment data after each adjustment.

Fig. 5-1-6

4) Operate the adjusting remote commander as follows.

• Changing the page

The page increases when the EDIT SEARCH + button is

pressed, and decreases when the EDIT SEARCH – button is

pressed. There are altogether 16 pages, from 0 to F.

Hexadecimal

notation

LCD Display 0123456789AbcdEF

Decimal notation

conversion value

0123456789ABCDEF

01234567891011

12 13 14 15

Table 5-1-1

5-4

Page 30

5-1-5. Data Processing

The calculation of the DDS display and adjusting remote commander display data (hexadecimal notation) are required for obtaining the adjustment data of some adjustment items. In this case,

after converting the hexadecimal notation to decimal notation,

calculate and convert the result to hexadecimal notation, and use

it as the adjustment data. Table 5-1-2. indicates the hexadecimal

notation- the decimal notation, calculation table.

Hexadecimal nontation-Decimal notation

The lower digits of the 0 1 2 3 4 5 6 7 8 9 A B C D E F

hexadecimal notation

The upper digits of the (A)(b)(c)(d)(E)(F)

hexadecimal notation

0 0 1 2 3 4 5 6 7 8 9 101112131415

1 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

2 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47

3 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63

4 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79

5 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95

6 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111

7 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127

8 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143

9 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159

A (A) 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175

1→

B (b) 176 177 178 179 180 181 182 183 184 185 186 187 188 189 190 191

C (c) 192 193 194 195 196 197 198 199 200 201 202 203 204 205 206 207

D (d) 208 209 210 211 212 213 214 215 216 217 218 219 220 221 222 223

E (E) 224 225 226 227 228 229 230 231 232 233 234 235 236 237 238 239

F (F) 240 241 242 243 244 245 246 247 248 249 250 251 252 253 254 255

Note : ( ) indicate the adjusting remote control unit display.

2

↓

(Example) In the case that the adjusting remote control unit display are BD (bd).

As the upper digit of the hexadecimal notation is B (b), and the lower digit is D (d), the intersection “189” of the

1 and 2 in the above table is the decimal notation to be calculated.

Table 5-1-2

5-1-6. Adjusting Items when Replacing a Board or Main Parts

When replacing a board or main parts, adjust the items indicated by r in the following table.

Replaced parts

Adjustment

Lens device

VC-211 board VA-108 board IC001

(COMPLETE) (COMPLETE) (CCD BLOCK ASSY)

Y OUT level adj. rr

C OUT level adj. rr

28 MHz origin oscillation adj. r

Lens type adj. rr

HALL adj. rr

Flange back adj. rr r

Color reproduction adj. rr

IRIS IN/OUT adj. rr r

Auto white balance standard data input rr

Auto white balance adj. rr

5-5

Page 31

5-2. INITIALIZATION OF D, E, F PAGE DATA

1. Initializing D, E, F Page Data

Note 1: If “Initializing D, E, F Page Data” is performed, all data

of the D page, E page and F page will be initialized.

Note 2: If the D, E, F page data has been initialized, “Modifica-

tion of D, E, F page Data” and all adjustments need to be

performed again.

Adjustment Page D

Adjustment Address 00 to FF

Adjustment Page E

Adjustment Address 00 to FF

Adjustment Page F

Adjustment Address 10 to FF

Initializing Method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: 2, address: 00, set data: 55 (NTSC) or data: 51

(PAL), and press the PAUSE button of the adjusting remote

commander.

3) Select page: 2, address: 01, set data: 55 (NTSC) or data: 51

(PAL), and press the PAUSE button of the adjusting remote

commander.

4) Select page: 2, address: 02, and check that the data is “01”.

5) Select page: 3, address: 00, set data: 29, and press the PAUSE

button of the adjusting remote commander.

6) Select page: 3, address: 01, set data: 29, and press the PAUSE

button of the adjusting remote commander.

7) Select page: 0, address: 01, and set data: 00.

8) Perform “Modification of D, E, F Page Data”.

2. Modification of D, E, F Page Data

If D, E, F PAGE data has been initialized, change the data of the

“Fixed data-2” address shown in the following tables by manual

input.

Modifying Method:

1) Before changing the data, select page: 0, address: 01, and set

data: 01.

2) New data for changing are not shown in the tables because

they are different in destination. When changing the data, copy

the data built in the same model.

Note: If copy the data built in the different model, the this unit

may not operate.

3) When changing the data, press the PAUSE button of the adjusting remote commander each time when setting new data

to write the data in the non-volatile memory.

4) Check that the data of adjustment addresses is the initial value.

If not, change the data to the initial value.

5) After changing the data, select page: 0, address: 01, and set

data: 00.

5-6

Page 32

3. D Page T able

Note 1: Fixed data-1: Initialized Data. (Refer to “1. Initializing

D, E, F Page Data”)

Fixed data-2: Modified Data. (Refer to “2. Modification

of D, E, F Page Data”)

5. F Page T able

Note 1: Fixed data-1: Initialized Data. (Refer to “1. Initializing

D, E, F Page Data”)

Fixed data-2: Modified Data. (Refer to “2. Modification

of D, E, F Page Data”)

Address Initial Remark

Value

NTSC PAL

00 to 12 Fixed data-1 (Initialized data)

13 Fixed data-2

14 to16 Fixed data-1 (Initialized data)

17 Fixed data-2

18 to FF Fixed data-1 (Initialized data)

4. E Page T able

Note 1: Fixed data-1: Initialized Data. (Refer to “1. Initializing

D, E, F Page Data”)

Fixed data-2: Modified Data. (Refer to “2. Modification

of D, E, F Page Data”)

Address Initial Remark

Value

NTSC PAL

00 to 09 Fixed data-1 (Initialized data)

0A 42 42 G-CAM version adjustment

0B 06 06

0C, 0D Fixed data-1 (Initialized data)

0E Fixed data-2

0F to 1D Fixed data-1 (Initialized data)

1E Fixed data-2

1F to 25 Fixed data-1 (Initialized data)

26 Fixed data-2

27 to 2A Fixed data-1 (Initialized data)

2B 11 11 Lens type adjustment

2C 83 83

2D FB FB

2E F5 F5

2F to 4E Fixed data-1 (Initialized data)

4F Fixed data-2

50 to E4 Fixed data-1 (Initialized data)

E5 Fixed data-2

E5 to FF Fixed data-1 (Initialized data)

Address Initial Remark

Value

NTSC PAL

10 to 1B Fixed data-1 (Initialized data)

1C Fixed data-2

1D

1E to 20 Fixed data-1 (Initialized data)

21 52 52 G-CAM flip adjustment

22 to 25 Fixed data-1 (Initialized data)

26 94 96 Lens type adjustment

27 to 2B Fixed data-1 (Initialized data)

2C A0 A0 28MHz origin oscillation adjustment

2D, 2E Fixed data-1 (Initialized data)

2F 80 80 HALL adjustment

30 80 80

31 Fixed data-2

32

33 Fixed data-1 (Initialized data)

34 1B 1B Color reproduction adjustment

35 Fixed data-1 (Initialized data)

36 42 42 Color reproduction adjustment

37 to 39 Fixed data-1 (Initialized data)

3A 89 89 Auto white balance adjustment

3B 59 59

3C 38 38 IRIS IN/OUT adjustment

3D 41 41

3E 25 25 Flange back adjustment

3F 00 00

40 19 19

41 00 00

42 35 35

43 to 48 Fixed data-1 (Initialized data)

49 6B 6B Y OUT level adjustment

4A Fixed data-1 (Initialized data)

4B 9A 9A C OUT level adjustment

4C to 6F Fixed data-1 (Initialized data)

70 3B 3B Auto white balance reference data input

71 FF FF

72 56 56

73 7D 7D

74, 75 Fixed data-1 (Initialized data)

76 1B 1B Flange back adjustment

77 54 54

78 25 25

79 80 80

7A 10 10

7B FF FF

7C to 82 Fixed data-1 (Initialized data)

83 Fixed data-2

84 to 8C Fixed data-1 (Initialized data)

8D 00 00 G-CAM version adjustment

8E 80 80

8F to EF Fixed data-1 (Initialized data)

F0 to F4 Fixed data-2

F5 FD FD Color reproduction adjustment

F6 F8 F6

F7 Fixed data-2

F8

F9 to FF Fixed data-1 (Initialized data)

5-7

Page 33

5-3. ELECTRICAL ADJUSTMENTS

1. Y OUT Level Adjustment

Set the Y signal output level

Subject Not required

Measurement Point VIDEO output terminal

(75 Ω terminated)

Measuring Instrument Oscilloscope

Adjustment Page F

Adjustment Address 49

Specified Value A = 286 ± 50 mV (NTSC)

A = 300 ± 50 mV (PAL)

Adjusting method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: F, address: 49, change the data and set the SYNC

level (A) to the specified value.

3) Press the PAUSE button of the adjusting remote commander.

Processing after Completing Adjustments:

1) Select page: 0, address: 01, and set data: 00.

2. C OUT Level Adjustment

Set the Chroma signal output level

Subject Not required

Measurement Point VIDEO output terminal

(75 Ω terminated)

Measuring Instrument Oscilloscope

Adjustment Page F

Adjustment Address 4B

Specified Value A = 286 ± 50 mV (NTSC)

A = 300 ± 50 mV (PAL)

Adjusting method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: F, address: 4B, change the data and set the burst

level (A) to the specified value.

3) Press the PAUSE button of the adjusting remote commander.

Processing after Completing Adjustments:

1) Select page: 0, address: 01, and set data: 00.

A

A

Fig. 5-3-2

Fig. 5-3-1

5-8

Page 34

3. 28 MHz Origin Oscillation Adjustment

Set the frequency of the clock for synchronization.

If deviated, the synchronization will be disrupted and the color

will become inconsistent.

Subject Not required

Measurement Point Pin @¡ of CN703 on VC-211

board

Measuring Instrument Frequency counter

Adjustment Page F

Adjustment Address 2C

Specified Value f = 14318181 ± 68 Hz (NTSC)

f = 14187500 ± 69 Hz (PAL)

Adjusting method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: F, address: 2C, change the data and set the clock

frequency (f) to the specified value.

3) Press the PAUSE button of the adjusting remote commander.

Processing after Completing Adjustments:

1) Select page: 0, address: 01, and set data: 00.

• PARTS LOCATION DIAGRAM FOR 28 MHz ORIGIN OSCILLATION ADJUSTMENT

VC-211 board

1

CN703

21

30

5-9

Page 35

5-4. CAMERA SYSTEM ADJUSTMENT

Before perform the camera system adjustments, check that the

specified value of

“Y OUT Level Adjustment”, “C OUT Level Adjustment” and

“28MHz Origin Oscillation Adjustment” of “ELECTRICAL ADJUSTMENTS” are satisfied.

1. Lens Type Adjustment

Judge whether the lens used in the set is a plastic or glass, then

enter the data according to the lens material.

Subject Not required

Measurement Point DDS displayed data of TV

Measuring Instrument monitor (Note 1)

Adjustment Address Page: E, Address: 2B to 2E

Page: F, Address: 26

Note 1: The right two digits of the displayed data at the right

bottom side of the TV monitor.

00 00XX

→ D1

Adjusting method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 11, and set data: 02, and press the

PAUSE button of the adjusting remote commander.

3) Select page: 0, address: 03, and set data: 19.

4) Select page: 2, address: 01, and set data: 65.

5) Read the DDS displayed data (Note 1), and take the lower tw o

digits as D1.

When D1 = 00 (glass lens)

Perform steps 6) onwards.

When D1 = 01 (plastic lens)

Perform steps “Processing after Completing Adjustments”.

6) Write data in page: E, address: 2B to 2E, and page: F , address:

26 as shown in the following table.

Page Address Data

E2B11

E2C83

E2DFB

E2EF5

F2696

2. G-CAM Flip Adjustment

Set the color reproduction conditions to optimum.

Subject Color bar chart standard picture

frame

Measurement Point DDS displayed data of TV

Measuring Instrument monitor (Note 1)

Adjustment Page F

Adjustment Address 21

Note 1: The right four digits of the displayed data at the right

bottom side of the TV monitor.

00 XXXX

→S

2

→S1

Adjusting method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 11, and set data: 02, and press the

PAUSE button of the adjusting remote commander.

3) Select page: 0, address: 03, and set data: 16.

4) Read the DDS displayed data (Note 1), and upper two digits

data is named S1, and lower two digits data is named S2.

When S1<S2

Perform steps 5) onwards.

>

When S1

S

2

=

Perform steps “Processing after Completing Adjustments”.

5) Select page: F, address: 21, and set data:

when the read data is “D2”, change to “52”, the read data is

“52”, change to “D2” (initial value is 52), and press the P A USE

button of the adjusting remote commander.

Processing after Completing Adjustments:

1) Select page: 0, address: 03, and set data: 00.

2) Select page: D, address: 11, and set data: 00, and press the

PAUSE button

of the adjusting remote commander.

3) Select page: 0, address: 01, and set data: 00.

Processing after Completing Adjustments:

1) Select page: 2, address: 01, and set data: 00.

2) Select page: 0, address: 03, and set data: 00.

3) Select page: D, address: 11, and set data: 00, and press the

PAUSE button of the adjusting remote commander.

4) Select page: 0, address: 01, and set data: 00.

5-10

Page 36

3. G-CAM Version Adjustment

Confirm the G-CAM version, and enter the data according

to the version.

Subject Not required

Measurement Point Displayed data of page: 2,

address: 04

Measuring Instrument on adjusting remote commander

Adjustment Address Page: E, Address: 0A, 0B

Page: F, Address: 8D, 8E

Adjusting method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: 2, address: 04, and read data is D

1.

When D1 = FF

Perform steps 3) onwards.

When D1 FF

Perform steps “Processing after Completing Adjustments”.

3) Write data in page: E, address: 0A, 0B, and page: F, address:

8D, 8E as shown in the following table.

Page Address Data

E0A72

E0B76

F8DD3

F8E00

Processing after Completing Adjustments:

1) Select page: 0, address: 01, and set data: 00.

5-11

Page 37

4. HALL Adjustment

For detecting the position of lens iris, adjust the HALL AMP gain

and offset.

Subject Not required

Measurement Point DDS displayed data of TV

Measuring Instrument monitor (Note 3)

Adjustment Page F

Adjustment Address 2F, 30

Specified Value 7E to 82 during IRIS OPEN

(Note 1)

13 to 17 during IRIS CLOSE

(Note 2)

Note 1: Select page: 2, address: 01, and set data: 01, and press

the PAUSE button of the adjusting remote commander.

Note 2: Select page: 2, address: 01, and set data: 03, and press

the PAUSE button of the adjusting remote commander.

Note 3: The right two digits of the displayed data at the right

bottom side of the TV monitor.

00 00

XX

→Object data

Adjusting method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: 0, address: 03, and set data: 03.

3) Select page: D, address: 11, and set data: 02, and press the

PAUSE button of the adjusting remote commander.

4) Select page: 2, address: 01, and set data: 03, and press the

PAUSE button of the adjusting remote commander.

5) Select page: F, address: 30, and set data: 80, and press the

PAUSE button of the adjusting remote commander.

6) Select page: F, address: 2F, and set data: 40, and press the

PAUSE button of the adjusting remote commander.

7) Read the DDS displayed data (Note 3), and this data is named

W2.

8) Select page: F, address: 2F, and set data: 30, and press the

PAUSE button of the adjusting remote commander.

9) Read the DDS displayed data (Note 3), and this data is named

W1.

10) Select page: 2, address: 01, and set data: 01, and press the

PAUSE button of the adjusting remote commander.

11) Read the DDS displayed data (Note 3), and this data is named

K1.

12) Select pa ge: F, address: 2F, and set data: 40, and press the

PAUSE button of the adjusting remote commander.

13) Read the DDS displayed data, and this data is named K2.

14) Convert W1, W2, K1, K2, to decimal notation, and obtain W1’,

W2’, K1’, K2’.

(Refer to table 5-1-2. “Hexadecimal notation - decimal notation conversion table”)

15) Calculate X1’ using the following equations. (decimal notation calculation)

A’= W2’+ K1’– W1’– K2’ .......................................Equation 1

B’= W1’– K1’ .........................................................Equation 2

X1’= [1712 + (48 × A’) – (16 × B’)] / A’ ..............Equation 3

16) Convert X1’ to hexadecimal notation, and obtain X1.

(Round off to one decimal place)

17) Select page: F, address: 2F, and set data: X1, and press the

PAUSE button of the adjusting remote commander.

18) Select page: 2, address: 01, and set data: 01, and press the

PAUSE button of the adjusting remote commander.

19) Select page: F, address: 30, change data and adjusting the DDS

displayed data to “80”.

20) Press the PAUSE button of the adjusting remote commander.

21) Select page: 2, address: 01, and set data: 03, and press the

PAUSE button of the adjusting remote commander.

22) Read the DDS displayed data, and this data is named K0.

If K0 lies within the “13” to “17” range, perform “Processing

after Completing adjustments”.

If K0 lies outside the range, perform the following adjustments.

23) Convert K0 to decimal notation, and obtain K0’

24) Calculate X2’ using the following equations (decimal notation

calculation).

C’ = K0’– B’– 21 ....................................................Equation 4

X2’ = [(107 – B’) × (X1’ – 48) + (48 × C’)] / C’ ...Equation 5

(X1’and B’ are values obtained from “Equation 2” and “Equation 3”)