Page 1

CONSOLIDATED STORAGE MANAGEMENT SYSTEM

CSM-200BF/200BS

CSM-100BF/100BS

CSM-60BF/60BS

CSM-200D

CSM-200C

電気製品は、安全のための注意事項を守らないと、

火災や人身事故になることがあります。

万一、異常が起きた場合は

このオペレーションマニュアルの「安全のために」に記載された指示に

従って電源を切ってください。

このオペレーションマニュアルには、事故を防ぐための重要な注意

•

事項と製品の取り扱いかたを示してあります。このオペレーション

マニュアルをよくお読みのうえ、製品を安全にお使いください。お

読みになったあとは、いつでも見られるところに必ず保管してくだ

さい。

本システムをあやまって設置すると、火災・感電やその他の事故に

•

より、けがをしたり周辺の物品に損害を与えたりすることがありま

す。危険を避けるため、設置はサービストレーニングを受けた技術

者にご依頼ください。

本システムを設置する技術者へ

設置のしかたは、

い。

OPERATION MANUAL

インストレーションマニュアルをご覧くださ

CSM

[Japanese/English]

1st Edition (Revised 1)

Page 2

日本語

安全のために

本機は安全に十分に配慮して設計されています。しかし、電気製品はまちがった

使いかたをすると、火災や感電などにより死亡や大けがなど人身事故につながる

ことが あり、危 険 で す 。

事故を防ぐために次のことを 必 ず お 守りください。

安全のための注意事項を守る

2(J)〜4(J)ページの注意事項をよくお読みください。

定期点検を実施する

長期間安全に使用していただくために、当社が指定している定期点検をかならず

実施してください 。定 期 点検を実 施しな いと、感電や火災の原因になります。点

検の内容、費用については、ソニーのサービス担当者、または 営 業担当者にご相

談ください 。

故障したら使用を中止する

ソニーのサービス担当者または営業担当者にご連絡ください。

万一、異常が起きたら

警告表示の意味

このオペレーションマニュアル

および製品では、次のような表

示をしています。表示の内容を

よく理解してから本文をお読み

ください。

この表示の注意事項を守らない

と、火災や感電などにより死亡

や大けがなど人身事故につなが

ることがあります。

この表示の注意事項を守らない

と、感電やその他の事故により

けがをしたり周辺の物品に損害

を与えたりすることがありま

す。

煙が出たら

•

異常な音、におい

•

がしたら

内部に水、異物が

•

1 電源を切る。

c

2 ソニーのサービス担当者または営業担当者

に修理を依頼する。

入ったら

炎が出たら

すぐに電 源を 切り、消火 する。

c

緊急時に電源を遮断するには

ロボット用とドライブ用のすべての電源コードを抜 い てください。

注意を促す記号

行為を禁止する記号

行為を指示する記号

Page 3

目次

警告 ...................................................................................................................

注意 ...................................................................................................................

概要 .........................................................................................................................

システムの概要 .............................................................................................................. 5(J)

PetaSiteS200シリーズ商品構成 ................................................................................... 5(J)

PetaSiteS200シリーズの特長 ....................................................................................... 6(J)

拡張例 .............................................................................................................................. 7(J)

関連製品 .......................................................................................................................... 8(J)

システムの性能を保持するために ............................................................................

各部の名称と働き ..................................................................................................

前面および側面 ............................................................................................................ 10(J)

ディスプレイパネル .................................................................................................... 12(J)

IN/OUTポート ............................................................................................................. 13(J)

PetaSiteコントロールユニット(PCU)..................................................................... 13(J)

準備 .......................................................................................................................

設置について ................................................................................................................ 14(J)

接続例 ............................................................................................................................ 14(J)

PCUのEthernetI/Fポートについて .......................................................................... 14(J)

設定 ................................................................................................................................ 15(J)

操作 .......................................................................................................................

始動手順 ........................................................................................................................ 19(J)

停止手順 ........................................................................................................................ 19(J)

カートリッジの挿入と取り出し ................................................................................ 20(J)

メニュー操作 ................................................................................................................ 21(J)

PCUの再起動 ................................................................................................................ 22(J)

DZC-PSC2の操作について.......................................................................................... 23(J)

プリインストールPetaServe/PetaBackについて .................................................... 23(J)

PetaAppLinuxについて ............................................................................................... 24(J)

GPL/LGPLについて .................................................................................................... 24(J)

各機材の初期設定値 .................................................................................................... 24(J)

仕様 .......................................................................................................................

S-AITの仕様 .................................................................................................................. 28(J)

バーコードラベルの仕様 ............................................................................................ 28(J)

2(J)

4(J)

5(J)

9(J)

10(J)

14(J)

19(J)

27(J)

日

本

語

1 (J)

Page 4

下記の注意を守らないと、

火災や感電により死亡や大けがにつながることがあります。

外装を外さない、改造しない

外装を外したり、改造したりすると、感電や大けがまたは死亡の原因となります。

内部の調整や設定および点検を行う必要がある場合は、必ずサービストレーニン

グを受けた技術 者にご依頼ください。

内部に水や異物を入れない

水や異物が入ると火災や感電の原因となります。

万一、水や異物が入ったときは 、すぐ に 電 源を 切り、ソニーのサービス担当者ま

たは営業担当者にご相談ください。

電源コードを傷つけない

電源コードを 傷つけると、火災や感電の原因となります。

• 電源コードを 加工し たり、傷つけたりしない。

• 重いものをのせたり、引 っ張ったりしない。

• 熱器具に近づけたり、加熱したりしない。

万一、電源コードが 傷んだら、ソニーのサービス担当者に交換をご依頼ください 。

油煙、湯気、湿気、ほこりの多い場所では設置•使用しない

上記のような場所で設置・使用すると、火災や感電の原因となります。

表示された電源電圧で使用する

機器に表示されたものと異なる電源電圧で使用すると、火災や感電の原因となり

ます。

電源工事は有資格者が行う

電源への接続については、電気工事士の資格が必要ですので、ソニーのサービ

ス担当 者または営業担当者にご相談ください 。

2 (J)

Page 5

安定した場所に設置する

ぐらつ いた台の上や傾いたところなどに設置すると、製品が転倒して死亡や大け

がの原因となることがあります。

耐震工事をする

耐震工事をしないと、地震が発生したときにコンソールが 倒れ たり、動いたりして、

死亡や大けがの原因となります。

また、コンソール の 設置状況、床面の強度を充分にお確かめください。

詳しくは、ソニーのサービス担当者または営業担当者にご相談ください。

規定の床面強度を確保する

コンソー ルを 設置 する床の荷重強度が規定に満たない場合、床が破損してコン

ソール が 転倒し、死亡や大けがの原因となります。詳しくは、ソニーのサービス担

当者または営業担当者にご相談ください。

ポ−ト部分に異物を入れない

I/O

システムの動作中にI/Oポート部 の隙 間から異物を入れると、トランスファー に 衝 突

して故障の原因となることがあります。

3 (J)

Page 6

下記の注意を守らないと、

けがをしたり周辺の物品に損害を与えることがあります。

通風孔をふさがない

コンソー ル前面、後面および下部の通風孔をふさぐと内部に熱がこもり、火災の

原因となることがあります。

4 (J)

Page 7

概要

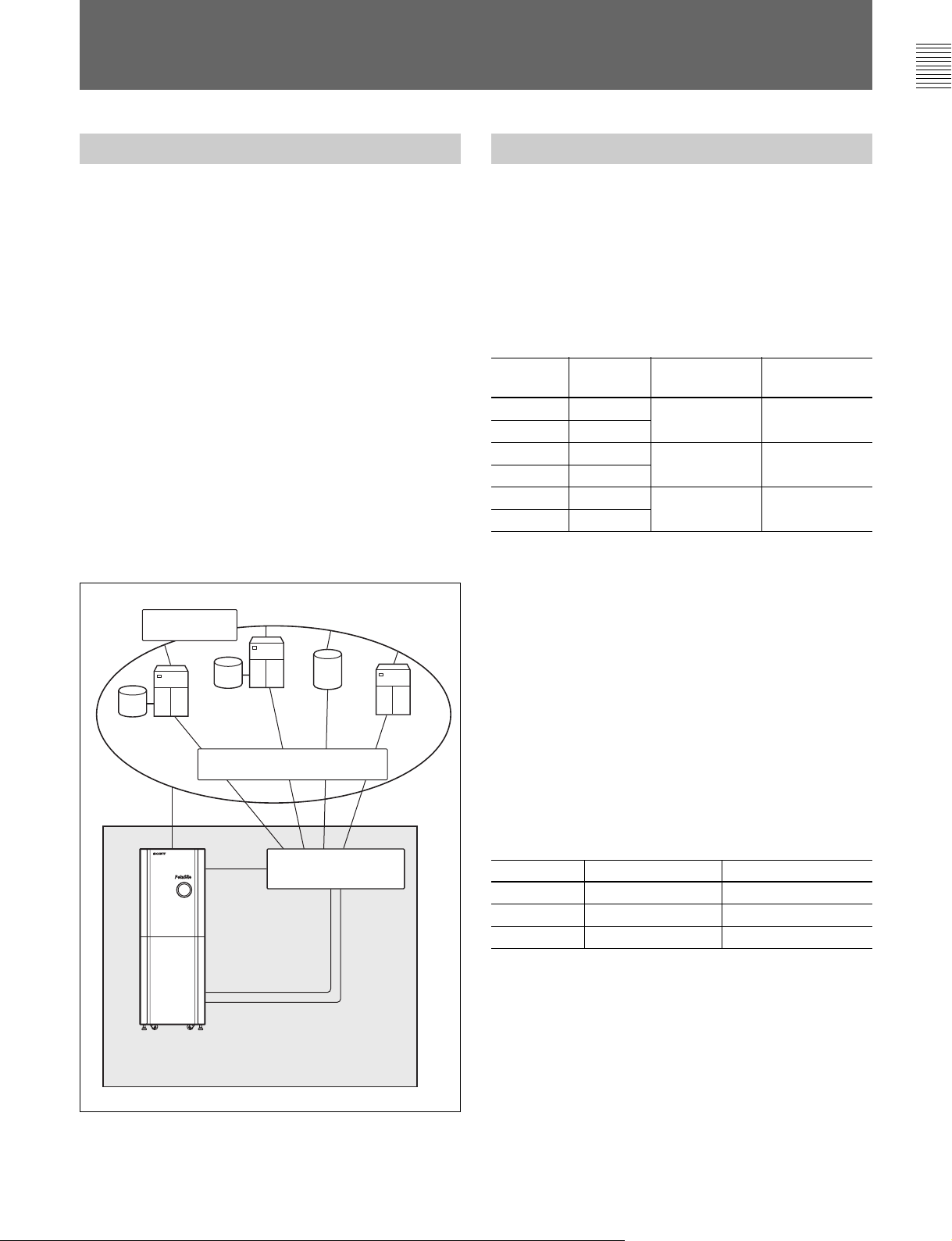

システムの概要

ConsolidatedStorageManagement(以下CSM)システムは、大

容量のデータ処理とバックアップや階層型ストレージ管理を、高速

で確実に実行するシステムです。

必要なソフトウェアとハードウェアを 一体化することにより、信頼性

の高いストレージソリューションシステムを構築します。

CSMシステムは、テープライブラリーPetaSite S200シリーズ、

PetaSiteコントロールソフトウェア DZC-PSC2、PetaSiteコントロール

ユニット(PCU)、ア プリケーションソフトウェア PetaBackまたは

PetaServe、ファイバ ー チ ャネ ル ス イッチ(オプション)で構成され ま

す。

PetaSiteS200シリーズは、SuperAITフォーマットのカートリッジ を 管

理し、大量のデータを高速で保管/検索/記録/再生するテープラ

イブラリー シ ス テ ム で 、ベーシックストレージシステムにPetaSiteコン

トロールソフトウェア DZC-PSC2 およびPetaSiteコントロールユニッ

トをビ ルトインした パッケ ージシステムです。

Ethernet

PetaSite S200

シリーズ商品構成

ベーシックストレージシステム

CSM-200BF/200BS/100BF/100BS/60BF/60BS

ベーシックストレージシステムには、FC対応のS-AITドライブを搭載

したモデルとSCSI対応のS-AITドライブを搭載したモデルがあり、

それぞれカートリッジ 収納巻数の異なる3タイプが用意されていま

す。ドライブはそれぞれ 12 台まで搭載可能です。

ベーシックストレージシステム商品構成

モデル名 搭載 カートリッジ データ容量

ドライブ 収納数

CSM-200BF FC

CSM-200BS SCSI

CSM-100BF FC

CSM-100BS SCSI

CSM-60BF FC

CSM-60BS SCSI

さらに、別売りの 冗 長ライブラリー 専用電源CSMA-PSLと冗長ドライ

ブ専用電源CSMA-PSD、冗長ドライブIFボードキットCSMA-DIFを

使用すれば、信頼性の高いシステムを容易に構築することが可能

になります。

最大216 巻 最大108TB

最大108 巻 最大54TB

最大60 巻 最大30TB

アプリケー

ションサーバー

データサーバー

Storage Area Network

PetaSite S200

(PetaSite

ハブ、ターミナルサーバー内蔵)

シリーズ

コントロールユニット、

サーバー

NAS

アプリケーション

クライアント

ファイバーチャネル

スイッチ

CSM

拡張コンソール

CSM-200D/200C

ドライブとカートリッジ が 搭 載できるドライブコンソールCSM-200Dと

カートリッジ のみが搭載できるカートリッジ コンソール CSM-200Cがあ

りま す 。

別売りの拡張ベルトキットお よ び拡張ケーブルキットを組み合わせる

ことに よって、1台のベーシックストレージシステムに対し最大 7 台ま

で増設することができます。

増設台数

1 CSMA-BLTS 不要

2〜3 CSMA-BLTS CSMA-CBLS

4〜7 CSMA-BLTL CSMA-CBLL

拡張ベルトキット

拡張ケーブルキット

5(J)

Page 8

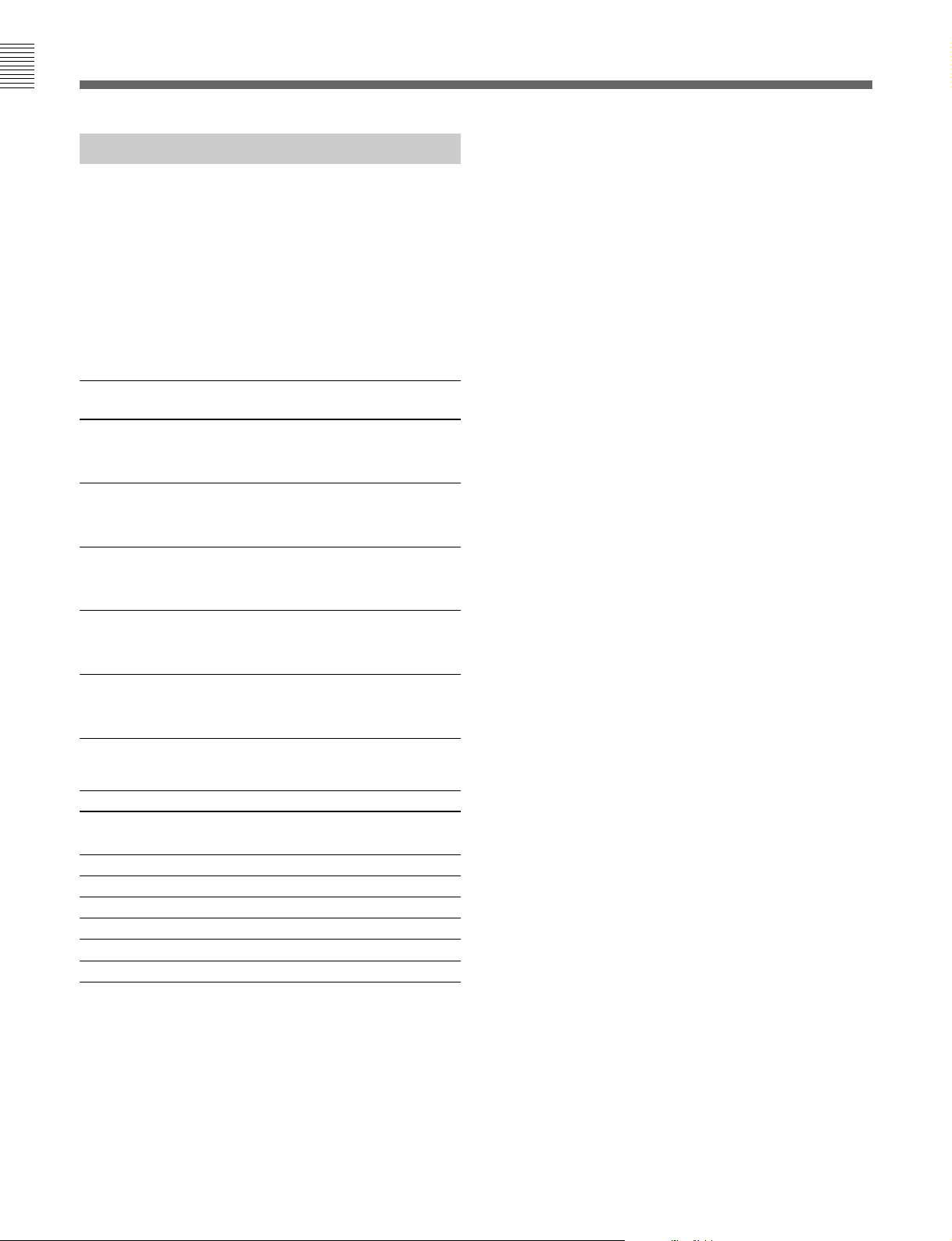

概要

PetaSite S200

シリーズの特長

ヘテロジニアス環境を実現するSANソリューションに おける高 速ス

トレージサブシステムで、次のような特長を備えています。

大量データの保管を実現

ベーシックストレージシステムに拡張コンソールを組 合 わ せることに

よって、最大 96ドライブ構成で 1.49PB のデータを保管することが

できます。

それぞれ 1 台ごとの 最 大データ収納量は次のとおりです。

機種名 ドライブ カートリッジ 容量

搭載台数 収納数

CSM-200BF/200BS 4 216 108

8 204 102

12 192 96

CSM-100BF/100BS 4 108 54

8 108 54

12 108 54

CSM-60BF/60BS 4 60 30

86030

12 60 30

CSM-200C − 396 198

− 396 198

− 396 198

CSM-200D 4 348 174

8 336 168

12 324 162

ベーシックストレージシステム

拡張ユニット

CSM-200C

最大カートリッジ数 最大容量

CSM-200BF/200BS

を組み合わせた場合

(TB)

に

(TB)

CSM-200BF/200BS+

CSM-200C× 1 612 306

CSM-200C× 2 1008 504

CSM-200C× 3 1404 702

CSM-200C× 4 1800 900

CSM-200C× 5 2196 1098

CSM-200C× 6 2592 1296

CSM-200C× 7 2988 1494

バーコードによるカートリッジの管理

バーコードリー ダーユニットを内蔵し、カートリッジ に 貼り付けたバー

コードによりカートリッジ を 管 理し ます 。

容易なロボット制御

ロボット制 御 インターフェースは、SCSIおよびAPIに対応していま

す。

自己診断機能

ロボットの 自己診断のみならず、搭載しているカートリッジ の ステ ー

タスを、見やすいGUI(グラフィカル ユーザーインターフェース)で

表示します。

環境による高速データ転送

SAN

FC(FibreChannel:ファイバ ー チ ャネ ル )直結テープドライブを採

用し、高 速の デ ータ転 送を可能にしました。

の転送スピードと大容量

S-AIT

ドライブ1台当たり30MB/s(非圧縮時)

テープ 1巻当たり500GB(非圧縮時)

の負荷軽減とライブラリーシェアリングによる低コスト

LAN

LANフリーバックアップ、NDMPに対応しています。

リモートメンテナンス機能

SNMP対応

Java対応リモート監 視ソフトウェア

PC

サーバー

(PetaSite Control Unit)

内蔵

テープライブラリーを制 御、監視するPetaSiteControlUnit(PCU)

を内蔵しています。

PCUは、PetaServe や PetaBackのバックアップサーバーとしても

動作します。

6(J)

Page 9

拡張例

ベーシックシステムに拡 張コンソール 7 台まで増設し、容量を増やすことができます。

CSM-200BF/200BS

ご注意

CSM-100BF/BS、CSM-60BF/BSに拡張コンソールを接続するこ

とは できません。拡張コンソールを接続するときは、オプションの

アップ グレードキットを使用して、CSM-200BF/BSにアップグレード

してください。

CSM-200D/CSM-200C

7(J)

Page 10

概要

関連製品

CSMA-DR130F Storage Management System

Drive Unit (FC)

ホットスワップ 対 応 ライブラリー 専用のFCドライブユニットで す( ア

タッチメント込み)。

CSMA-DR100S Storage Management System

Drive Unit (SCSI)

ホットスワップ 対 応 ライブラリー 専用のSCSIドライブユニットで す(ア

タッチメント込み)。

CSMA-CBLL Extension Kit (CL)

拡張コンソール4〜7 台連結用の拡張ケーブルキットで す 。

CSMA-CBLS Extension Kit (CS)

拡張コンソール2〜3 台連結用の拡張ケーブルキットで す 。

CSMA-BLTL Extension Kit(BL

拡張コンソール4〜7 台連結用の拡張ベルトキットで す 。

)

CSMU-100B Upgrade Kit CSM-60BF/BS to

CSM-100BF/BS

CSM-60BF/BSを CSM-100BF/BS にアップグレードするキットで

す。

CSMU-200B Upgrade Kit CSM-100BF/BS to

CSM-200BF/BS

CSM-100BF/BSをCSM-200BF/BSにアップグレードするキットで

す。

DMSA-CPJ Power Cord

PetaSiteS200シリーズおよびPetaSiteコントロールユニット(PCU)

用の電源コードです(AC100V用)。

DMSA-CPE Power Cord

PetaSiteS200シリーズおよびPetaSiteコントロールユニット(PCU)

用の電源コードです(AC120V用)。

CSMA-BLTS Extension Kit(BS

拡張コンソール1〜3 台連結用の拡張ベルトキットで す 。

CSMA-PSL Redundant Power Unit (Library)

ホットスワップ 可 能 な 冗 長ライブラリー 専用電源ユニットで す。

)

CSMA-PSD Redundant Power Unit (Drive)

ホットスワップ 可 能 な 冗 長ドライブ専用電源ユニットで す。

CSMA-DIF Redundant Drive Control Unit

冗長ドライブ専用のインターフェースボードキットで す。

DMSP-KBE1/DMSP-KBJ1 PC Keyboard

DMSP-KMS1 PC Mouse

PetaSite S200シリーズに内蔵の PetaSite コントロ ー ルユニット

(PCU)用のキーボードとマ ウスで す。

8(J)

Page 11

システムの性能を保持するために

万一の故障を防ぎ、高い性能を維持するために、装置、メディアの

取り扱いの際には以下の点にご注意ください 。

装置の取り扱い

振動、衝撃を与えないでください。本システムは精密に作られてい

ますので、振動や衝撃が故障の原因になることがあります。

• 各装置の通風孔をふさがないでください。

• 性能を維持するために、システム内の各装置の定期点検を必ず

受けてください 。

メディアの取り扱い

• 磁気の強いものに近づけないでください。

• カートリッジ 内部のテープに手を触れないでください。

使用・保管場所について

システムの各装置、メディアともに次 のような場 所での使用、保管は

絶対に避けてください。

• 湿気の多いところ

• 温度の高いところ

• 直射日光があたるところ

• ほこりの 多いところ

• 激し い振動のあるところ

• 温度変化の激しいところ

• 水平でないところ

輸送について

本システムを輸送する場合は、PetaSiteコントロール ユニットを取り

外し、輸 送 用 金 具を取り付 けて 、 必 ず専 用の 梱 包 材 を 使 用 の 上、

輸送してください。

PetaSiteコントロー ルユニットの 取り外しは、サービストレーニングを

受けた技術者にご依頼ください。

PetaSite

コントロールユニットの取り付けにつ

いて

PetaSiteコントロールユニットの 取り付けは、サービストレーニング

を受けた技術者にご依頼ください。

クリーニングについて

外装部は、ぬるま湯または薄い中性洗剤で湿らせた布でふき、そ

の後からぶきしてください。

シンナー、アルコールなどの溶剤は使用しないでください。塗装部

分を傷 めるおそれがあります。

また、S-AITドライブのクリー ニ ン グ方法に関しては、S-AITドライブ

の取扱説明書をご覧ください 。

9(J)

Page 12

各部の名称と働き

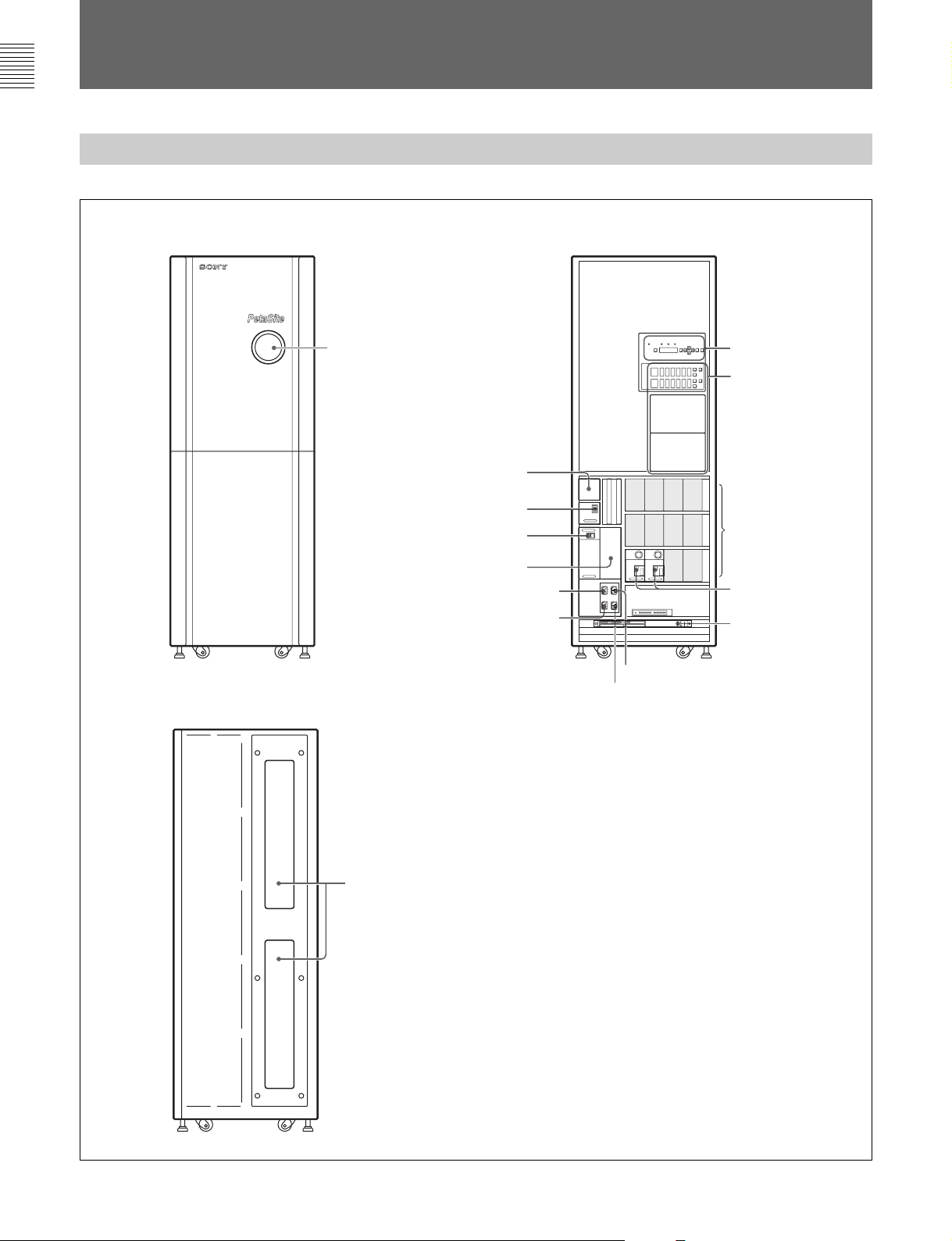

前面および側面

CSM-200BF/200BS/100BF/100BS/60BF/60BS

前面 正面内部

右側面

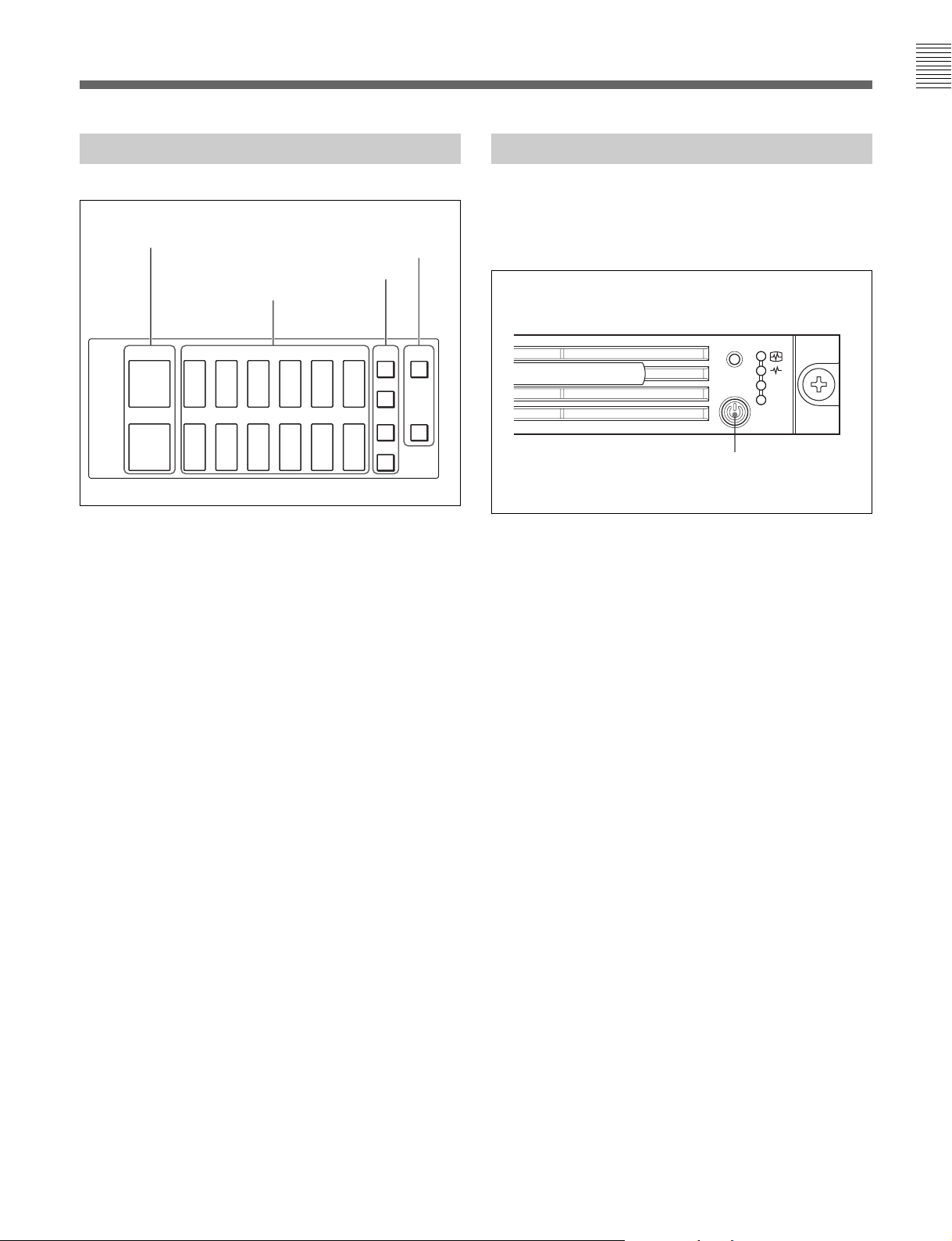

ディスプレイパネル

確認窓

オプションリダンダント電源用

スロット(ドライブ用)

1 電源スイッチ(ドライブ用)

2 電源スイッチ(ロボット用)

オプションリダンダント電源用

スロット(ロボット用)

インレット(ロボットリダンダント用)

AC

インレット(ロボット用)

AC

POWER READYBUSYERROR

INITIAL

MENU

123456

789101112

ESC/

CLR

ENTER

3 ディスプレイパネル

OPEN

OPEN

4

IN/OUT

オプションドライブ用

スロット

標準ドライブ

5

PetaSite

コントロール

ユニット

インレット(ドライブリダンダント用)

AC

インレット(ドライブ用)

AC

ポート

10(J)

6トランスファー確認窓

Page 13

1 電源スイッチ(ドライブ用)

ドライブ部の電源をON/OFFします。

電源を入れるときはI 側(入)にしま す。

O

電源を切るときは

側(切)にします。

5

PetaSite

ドライブおよびロボットを制御・監視するシステムです。

◆詳しくは「PetaSiteコントロ ー ル ユ ニ ット(PCU)」(13(J)ページ)をご覧く

ださい。

コントロールユニット

ご注意

•リダンダント電 源使用時に電源を切るときは、両方の電源スイッチ

を切ってください。

• 電源を切った直後に電源を入れるときは、5秒以上間隔を開けて

ください。

2 電源スイッチ(ロボット用)

ロボット部 の電源を ON/OFFします。

電源を入れるときはI 側(入)にしま す。

O

電源を切るときは

電源が切れると、ディスプレイパネルのインジケーターが すべ て消

えます 。

ご注意

•リダンダント電 源使用時に電源を切るときは、両方の電源スイッチ

を切ってください。

• 電源を切った直後に電源を入れるときは、ディスプレイパネ ル の

インジケーターが 消えるまで 待って から入 れてください。

側(切)にします。

6 トランスファー確認窓

トラン スファーの 移動状態/ 停止位置が確認できます。

この機器には、電源供給口(ACインレット)が4系統あります。電源

を完全に遮断するには、すべての電源コードを 抜 い てください。

3 ディスプレイパネル

本システムの運用状態、ステータス等を表示します。また、システ

ムの初期化や、メニュー操 作 による構成の確認、アワーズメーター

の確認などを行います。

◆詳しくは「 ディスプレイパネル」(12(J)ページ)をご 覧ください。

4

IN/OUT

カートリッジ の 出し 入 れ をしま す。ポートに は 6 巻 ま で カ ートリッジを 収

納できるマガジンを2 個搭載できます。

カートリッジの向きに注意して確実に投入してください。

◆詳しくは「 IN/OUTポート」(13(J)ページ)をご 覧ください。

ポート

11(J)

Page 14

各部の名称と働き

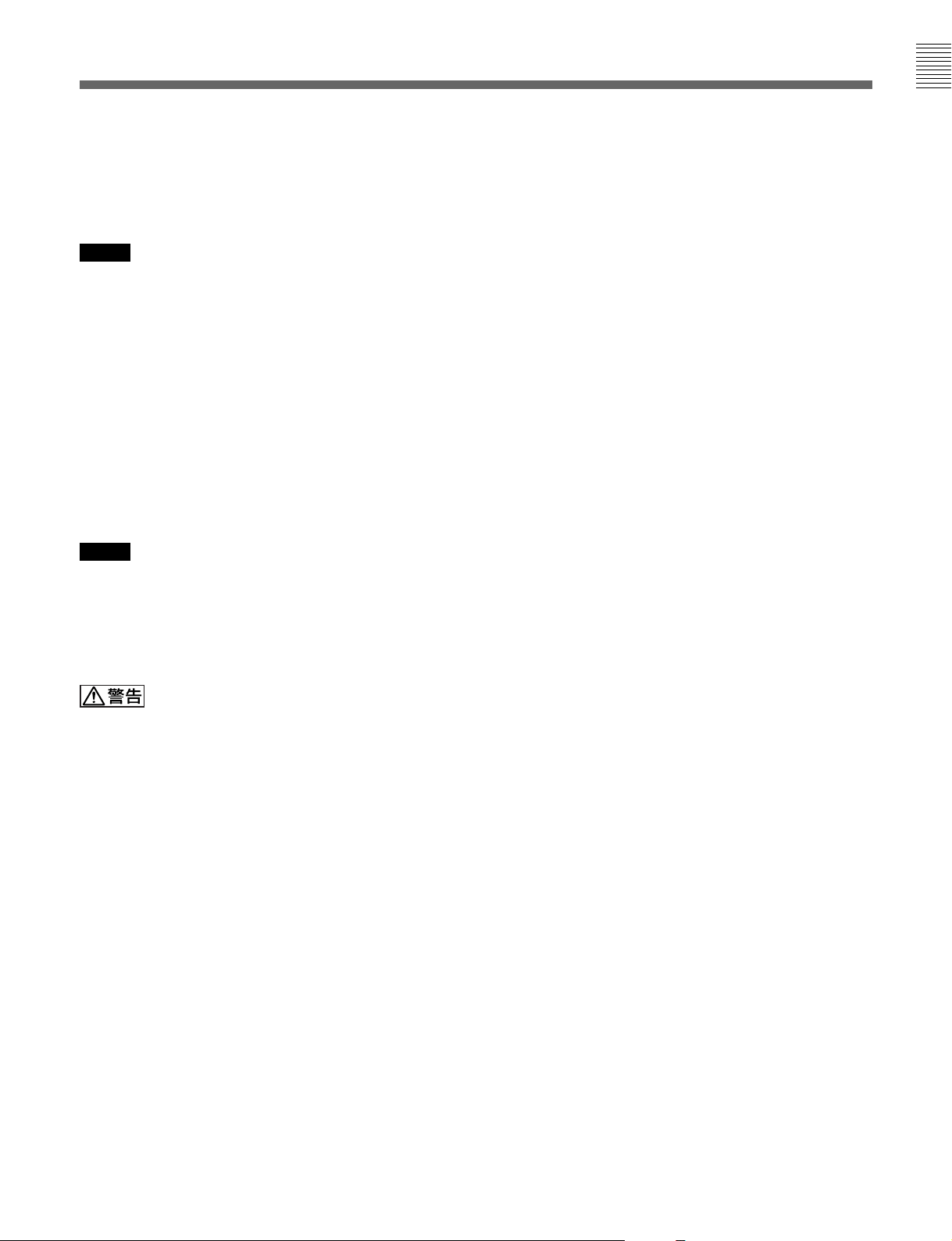

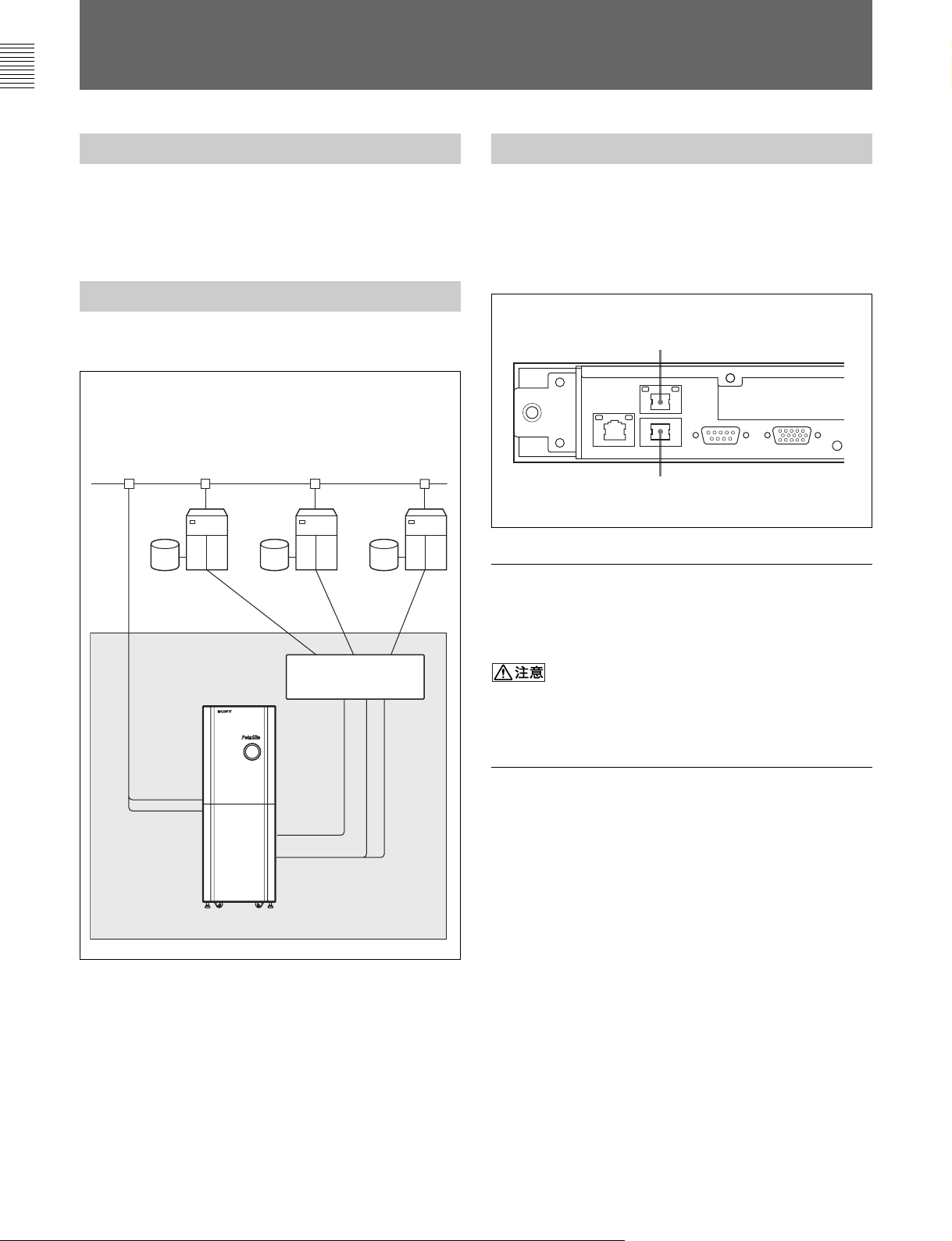

ディスプレイパネル

1

INITIAL

POWER READY BUSY ERROR

INITIAL

ボタン

2

READY

3

BUSY

5 表示部

6

MENU

7 矢印ボタン

8

ENTER

9

ESC/CLR

ボタン

インジケーター

4

ボタン

インジケーター

ERROR

MENU ENTER

インジケーター

F

f

ボタン

5 表示部

操作状態や、メニュー操作の項目を表示します。

6

(メニュー)ボタン

MENU

このボタンを押 すと、表示部にメニュー項目が表示されます。表示

部が消灯している場合は、表示が点灯します。この場 合はもう一 度

押してください。

◆詳しくは「 メニ ュー操作」(21(J)ページ)をご覧ください。

7 矢印ボタン

ESC/

CLR

gG

メニュー 操作時に、点灯しているボタンを押すと、次のメニュー項

目または数値が表示されます。

8

ENTER

(エンター)ボタン

メニュー 操作で、設定した内容を確定するときに押します。

9

ESC/CLR

(エスケープ/クリア)ボタン

メニュー 操作時に押すと、ひとつ前の状態に戻ります。

1

INITIAL

(イニシャル)ボタン

表示部にInitialRequestまたはFullInitialRequestが表示

され て いるとき、このボタンを押してシステムを初 期化します。ボタ

ンを 5 秒以上押し続けると初期化の動作を開始します。初期化中

はBUSYインジケ ーターが 点灯します。

本システムは、電源投入後は必ず初期化が必要です。

SetUpメニューのAutoInitialを有効にすると、電源投入後に自動

で初期化の動作を行います。

2

READY

(レディ)インジケーター

本システムが運用可能な状態のとき点灯します。

3

(ビジー)インジケーター

BUSY

本システムが動作中のとき点灯します。

初期化中も点灯します。

4

ERROR

(エラー)インジケーター

本システムに エラーが発生すると点灯します。

表示部の表示に従い以下の対応をしてください。

Initial Request

または

Full Initial Request

が表示されてい

る場合

INITIALボタンを押してシステムを初期化し直してください。

Power off Request

が表示されている場合

いったん電源を切ってから、再投入してください。

以上を実施しても復帰しない場合は、ソニーのサービス担当者に

連絡してください。

12(J)

Page 15

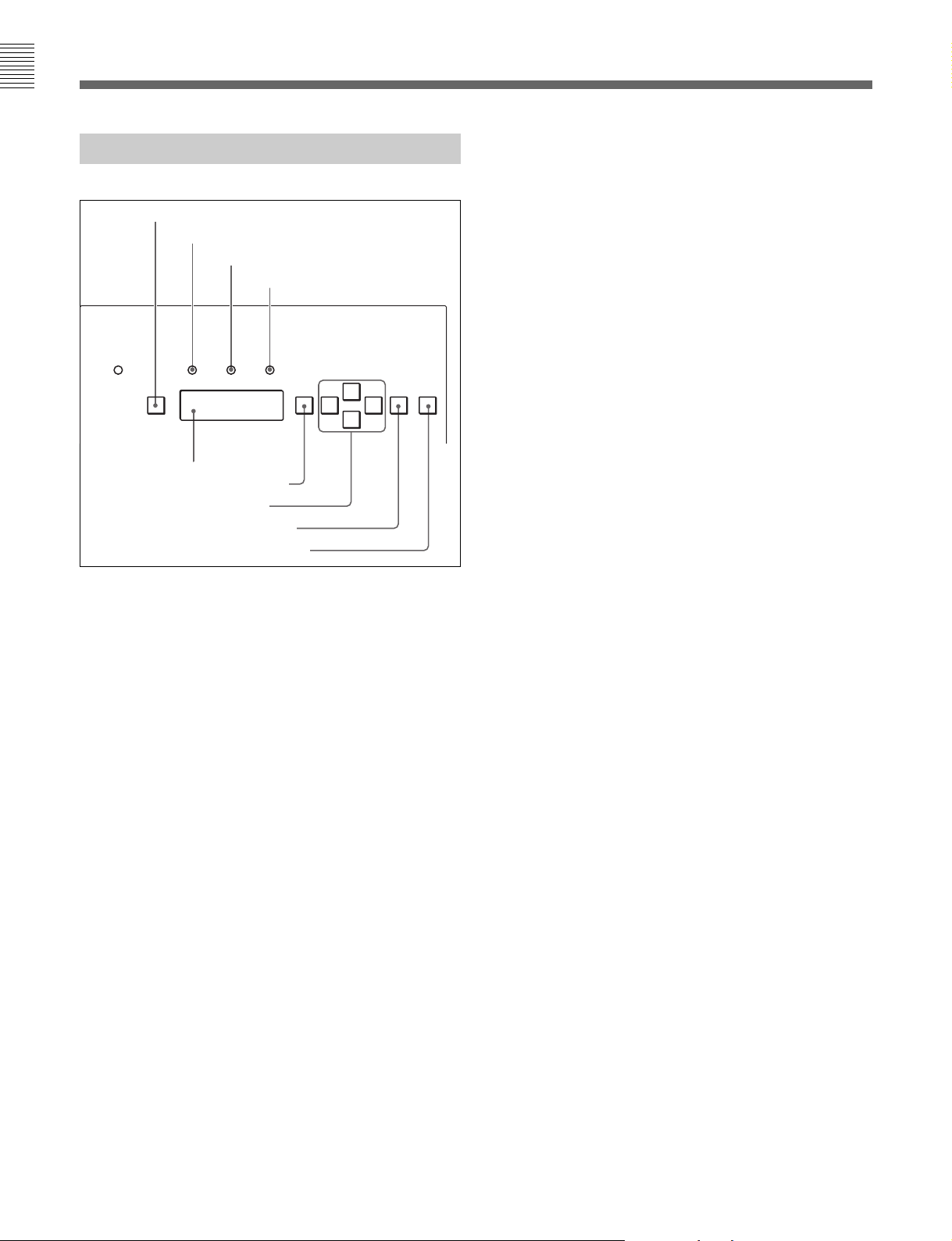

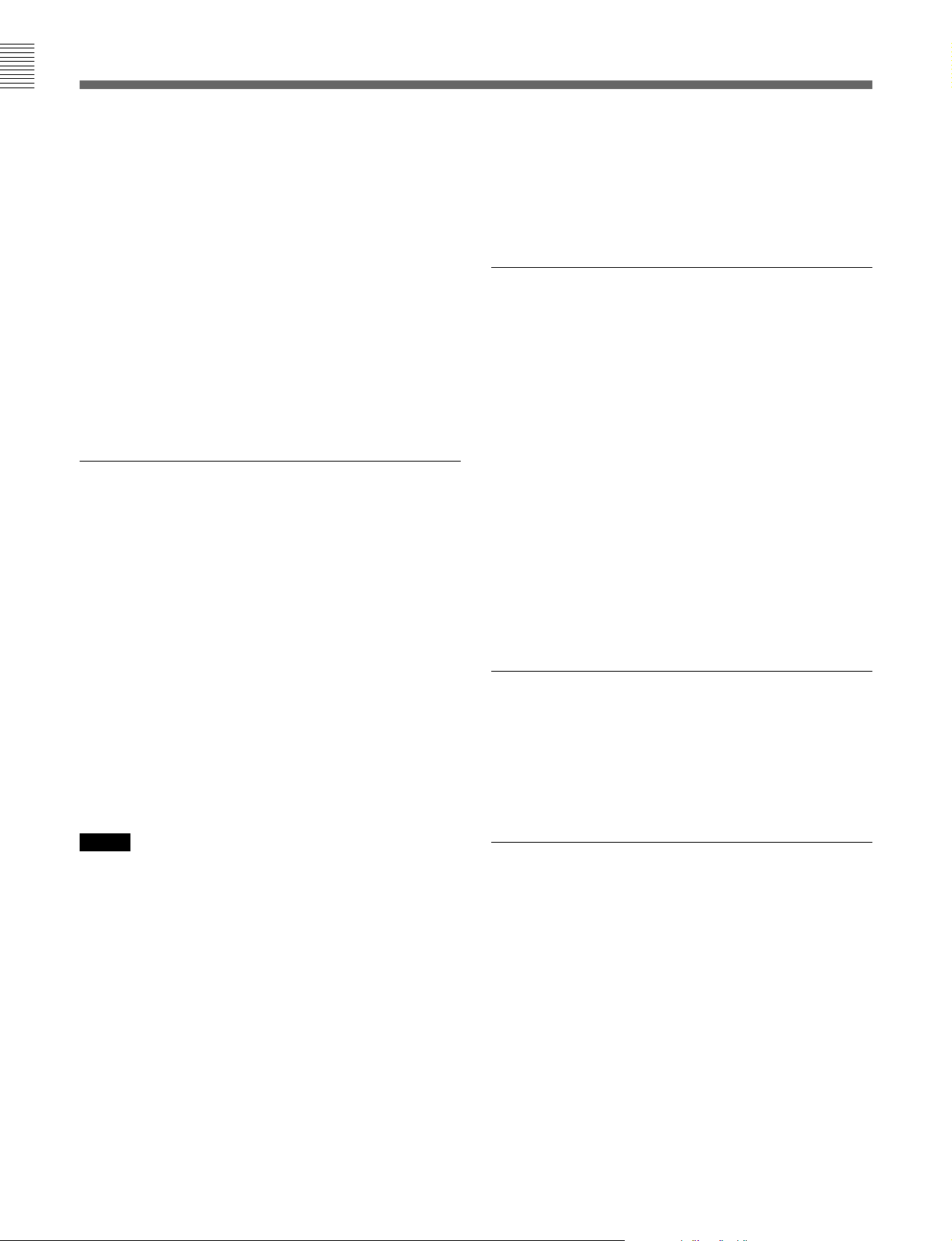

IN/OUT

1

NO MAGAZINE

ポート

インジケーター

2

IN /OUT

4

OPEN

3

ファンクションボタン

表示

ボタン

PetaSite

コントロールユニット(

PCU

)

ドライブおよびロボットを制御・監視するシステムです。

PetaServeやPetaBackのアプリケーションサーバーとしても動作し

ます。

123456

NO

MAGAZINE

NO

MAGAZINE

1

NO MAGAZINE

IN

OUTINOUTINOUTINOUTINOUTINOUT

7891011 12

IN

OUTINOUTINOUTINOUTINOUTINOUT

(ノーマガジン)インジケーター

マガジンが入っていないときに赤く点灯します。

2

IN/OUT

表示

各カートリッジ スロットの 状態を 表 示します 。

のみ点灯: カートリッジ が 投 入され たことを示します。

IN

のみ点灯: 使用済みのカートリッジ が 排 出され たことを 示し

OUT

ます。

同時点灯:

カートリッジ の バ ーコードを読 むと IN とOUTが点灯し

ます。使用モードによっては、点灯する前にカートリッジ を 取り

込むこともあります。

同時点滅:

カートリッジ に バーコードラベ ルが貼られていない場合、

あるい はなんらか の 理由で読めない場合にINとOUTが点滅

します。

OPEN

OPEN

POWER

POWER

スイッチ

PCUの電源をON/OFFします。

UID

スイッチ

NIC

1

NIC

2

3 ファンクションボタン

ソフトウェア で 機 能を 設定します。

4

(オープン)ボタン

OPEN

カートリッジ を出し 入 れ するときに 、このボタンを押して 扉を開きま

す。

扉が開いている間、ボタンは点灯します。

動作状態によって、扉が開くまでに時間がかかる場合があります。

エラーが発生するとボタンは点滅します。

13(J)

Page 16

準備

設置について

各機器の設定や配線、および環境設定はCSMシステムおよび

PetaSiteシリーズのサービストレーニングを受けた 技 術者にご依頼

ください。

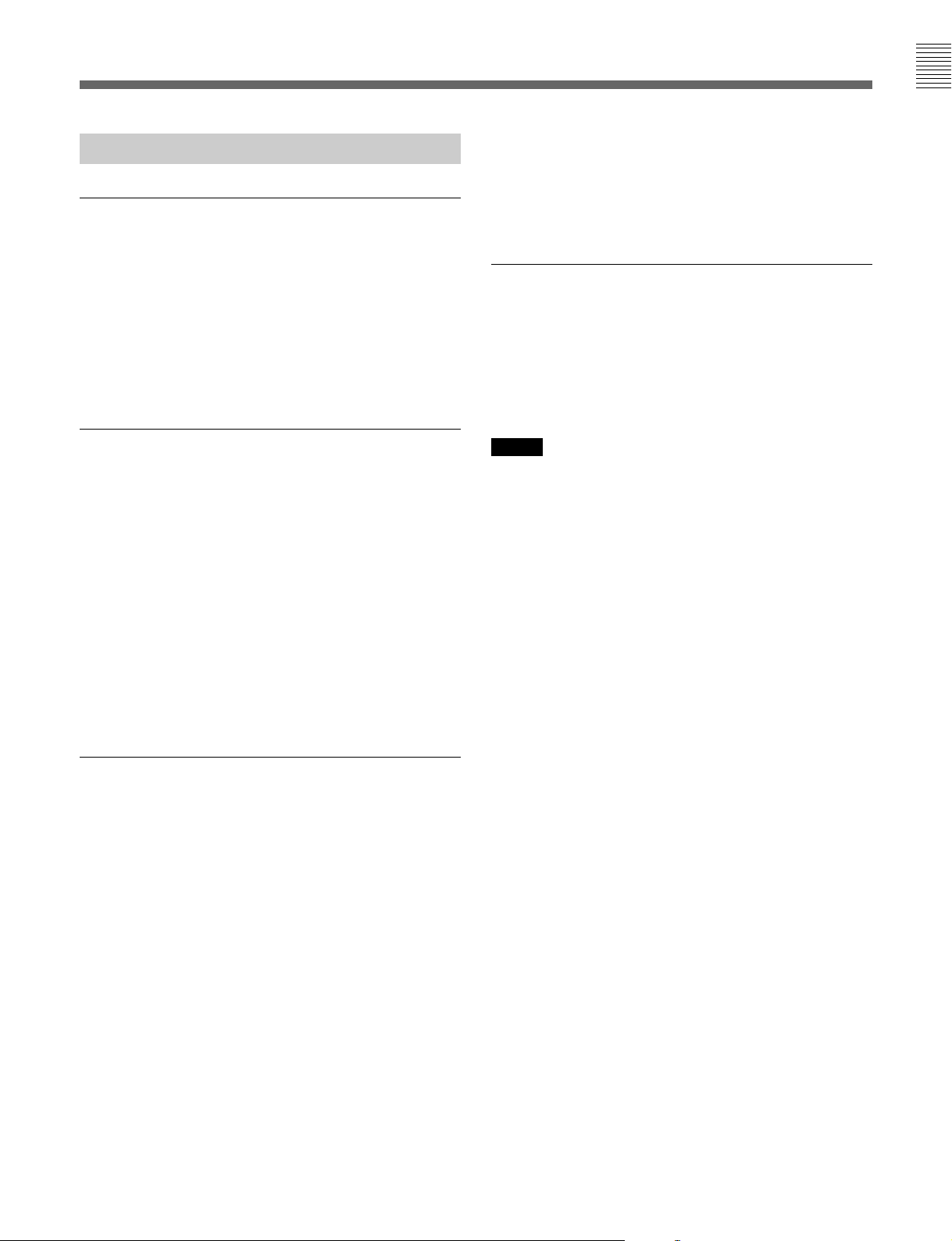

接続例

2TB のデータを8 時間でフルバックアップするシステム例です。

アプリ

ケーション

サーバー

SUN Solaris

500GB

ネットワーク

アプリ

ケーション

サーバー

HP-UX

500GB

サーバー

NAS

NetApp

ラー

1TB

ファイ

PCUのEthernet I/F

PetaSiteコントロールユニット(PCU)は EthernetI/Fポートを2個

持っています。1つはPetaSiteシステム制御用のローカルネットワー

ク用、もう1 つは PetaSiteシステム以外のネットワーク用 の ポ ートで

す。

PCU

外部ネットワーク用

PetaSite

PetaSite

システム制御用

Ethernet I/F

システムのネットワーク用ポート

ポートについて

リアパネル

Ethernet I/F

ポート

ポート

PetaSite

シリーズ

S200

(

PetaSite

コントロール

ユニット内蔵)

ファイバーチャネル

スイッチ

用

CSM

PetaServe/PetaBack

ソフトウェア

PetaSiteシステム制御用のネットワークには 、本システム用 の機 材

以外は接続しないでください。

安全のため、LANポートに は 過 電圧が加わるおそれのないネット

ワークに接 続してください。

PetaSite

こちらのポートは ネットワーク管 理 者よりIPアドレ スを 取 得し 、設定し

ます。

◆設定方法については、「PCUのホスト名 /IPアドレ スの 設定」(15(J)ペー

ジ)をご 覧ください。

システム以外のネットワーク用ポート

14(J)

Page 17

設定

4 新しい パスワード(変更したいパスワード)を2回聞かれるの

で、それぞれプロンプトに 続 けて新しいパスワードを 入力する。

DZC-PSC2

PCUに は PetaSiteコントロー ルソフトウェア DZC-PSC2が

工場出荷時に導入され、動作に必要な初期値は設定されています

が、使用環境に合わせて設定を変更する必要があります。

◆設定変更などの操作方法については、DZC-PSC2のオンラインヘルプを

ご覧ください。

オンラインヘルプは、DZC-PSC2のMMTウィンドウ の[Help]ボタンをク

リックす ると参 照 す ることが で きま す。

DZC-PSC2

次の手順で起動します。

の初期設定について

の起動

1 PCUの電源を入れる。

2 ログイン画面で、Usernameにsonypsc、Passwordにpsc2002

(初期パスワード)を入力する。

3 デスクトップにあるPetaAppのアイコンをクリックする。

これで、次のログインのときに新しいパスワードが有効になります。

のホスト名

PCU

PCUには、ホスト名/IPアドレスを 鍵に 設 定され てい るファイル がい

くつ か ありま す 。CSMシステムの導入時にホスト名 /IPアドレスを 設

定して、これらのファイルに設定を反映させる必要があります。下記

の手順でホスト名 /IPアドレスを 設 定し てください。上記ファイルに

設定が反映されます。

ご注意

CSMシステムでは運用開始後は基本的にホスト名 /IPアドレスの

変更はできません。やむをえず変更の必要が生じた場合は、ソ

ニーのサポートセンターまでご 連絡ください。

アドレスの設定

/IP

1 Usernameにrootと入力してログインし 、ターミナ ル画面を1つ

起動しておく。

2 デスクトップ の PetaAppアイコンを クリックする。

工場出荷時の初期パスワードを変 更した い場合は、DZC-PSC2 の

オンラインヘルプをご覧ください 。

でのログインについて

root

管理者用のアカウントrootでログインするには、ログイン画面で

Usernameに root、Passwordにsony2002(初期パスワード)を入

力します。

パスワードを変更するには

パスワードを変更したい場合は、次の手順で操作します。

1 パスワードを変 更したいユーザー名でログインする。

2 ターミナ ル画面を開き、passwdと入力し、Enter キーを押す。

3 今までのパスワードを聞 かれるので、プロンプトに 続 けてパス

ワードを 入力する。

3 Utilityアイコンを クリックし て、ユーティリティ画 面 を 起動する。

4 ユーティリティ画 面右上の Modeリストボックスで

Administratorを選択する。

5 Passwordに sony(初期パスワード)を入力する。

6 ユーティリティ画面のNetworkタブをクリックして選択する。

7 注意書きをよく読み、画面下のNetwork Configuratorを

クリックし、NetworkConfiguratorを起動する。

8 Names画面で HostName欄に新しいホスト名 、Domain 欄に

新しいドメイン名を入力する。

9 Hosts画面で新しいホスト名、IPアドレスと運 用 に必要なホスト

名、IPアドレスの関係を追加する。

10Interface画面でeth1側のIPアドレスを 新しい I P アドレスに 変

更する。

15(J)

Page 18

準備

11NetworkConfigurator画面下の[SAVE]ボタンをクリックし、

設定事項を保存する。

12[Cancel]ボタンをクリックして、PetaAppユーティリティ画 面 を

終了する。

13コマンドラインから下記のコマンドを入 力し 、Enterキーを押し

て実行する。

# /osm/bin/app_sethostname

14手順 1 で開いておいたターミナ ル画面で/sbin/init6を入力

し、Enterキーを押してPCUを再起動する。

のタイムゾーンの設定変更

PCU

1 Usernameに rootと入力してログインし 、ターミナ ル画面を起

動する。

2 以下のコマンドを 入 力し て、TimezoneConfiguratorを起動す

る。

dateのオプションは MMDDhhmmYY(MMは月、DDは日、hhは

時、mmは分、YYは年)となります。

◆詳しくは、date--helpまたはmandateと入力してオンラインマニュアル

を参照してください 。

の設定を変更して、画面が表示されなく

PCU

なったら

1 [Ctrl]+[Alt]+[F6]を同時に押す。

テキストベ ースのログイン画面が 表示されます 。

2 rootでログインする。

3 以下のコマンドを 入 力して、Xserverを設定しなおす。

# /usr/bin/redhat-config-xfree86 --noui --reconfig

4 以下のコマンドを 入力してPCUを再起動する。

# /sbin/init 6

# /usr/sbin/timeconfig

#:rootでのコマンドプロンプト

3 設定したいタイムゾーンにフォーカスを合わ せ、[OK]ボタンを

クリックする。

• 入力項目の移動はTABキーを使います。

• 設定項目の移動は上下の矢印キーを使います。

ご注意

一番上の入力項目([]ハードウェアクロックをGMTに合わせて設

定する/[]HardwareclocksettoGMT)のチェックボックスの

空欄を、スペースキーを押して[*]にし てください。ここに チ ェック

([*])を入れないと、PCU の時刻の設定が変わってしまう場合が

あります 。

時間を合わせるには

rootユーザーでdateコマンドを 使 用します。最初にタイムゾーンを

設定してから、以下のように入力します。

2002年1月23

# /bin/date 0123045602

日午前4:56に設定するには:

表示周波数外の設定になってしまったら

モニター画面にメッセージ OutofRangeなどが表示され、表示周

波数外の設定になってしまった場合も、前項「PCUの設定を変更

して、画面が表示されなくなったら」と同様の手順で、PCUを再起

動してください。

DZC-PSC2

のリモートメンテナンスツールの

インストール

他のコンピューターからサー バ ーの状 態を監視し たり、メンテナンス

を行なうために、リモ ートメンテナンスツールをインストー ルします。

リモートメンテナンスツールをインストールするには、CSMシステムの

場合は、PetaAppClientInstallKitディスクの PetaAppGUI/ 以下

のインストー ル キットを 使 用します。DZC-PSC2単体の場合には、

DZC-PSC2の InstallKit ディスクの Remote/ 以下のインストー ル

キットを使用します。

リモ ートメンテナンスツールを使用するには、サーバーのDZC-PSC2

への設定も必要です。

◆詳しくは、DZC-PSC2 のオンラインヘルプを参照してください。

#:rootでのコマンドプロンプト

16(J)

Page 19

ご注意

•リモ ートメン テナン スツー ルを 実行するには、Java Run Time

Environment(JRE 1.4.1)が必要です。InstallKitディスクの

toolsの下にRedHatLinux7.1/8.0 用、Solaris用、Windows 用

のJREが入っていますのでインストー ルし て 使 用し てください。

◆詳しい情報は、以下のURLを参照してください。

http://java.sun.com/products/plugin/1.3/docs/ja/

quickstart.html

•リモ ートメン テ ナン スツ ー ルのオンラインヘルプを利用するには、

ウェブブラウザーが必要です。以下のウェブブラウザーにおける

動作が確認されています。

Netscape7.01(6.xは未確認)

InternetExplorer5.5以上

Mozilla1.1.2以上

InternetExplorer では、オンラインヘルプ の表示が乱れる場合

がありま す。そのような場合には、画面を再度読み込み直してく

ださい。

リモートメンテナンスツールをインストールするには

Windows

Windows/の下のSetup.exeを起動します。

の場合:

NPX_PLUGIN_PATH="{JRE

sparc/ns4"

export NPX_PLUGIN_PATH

ご注意

RedHatLinux の場合には、NPXPLUGINPATHの sparc

の部分は i386になります。

のインストー ル 先

}/plugin/

2 オンラインヘルプの起動ファイル {DZC-PSC2 のインストー ル

先}/bin/webhelpで、環境変数BROWSERとXAPPLRESDIR

を以下のように設定する。

setenv BROWSER {Netscape

setenv XAPPLRESDIR {Netscapeのdefault

例: setenv XAPPLRESDIR /usr/openwin/lib/locale/

ja/app-defaults

ご注意

webhelpの初期設定で、BROWSERは RedHatLinux7.1/

8.0のデフォルトに 設 定されて います ので、以下の行の頭に#

を入れてコメントア ウトしてください。

#setenv BROWSER /usr/bin/netscape

のインストー ル 先

}/netscape

設定ファイル

}

UNIX(Solaris 2.6/7/8

場合:

Unix/の下のpainstallを実行します。

Solarisで使用する場合には、インストール後に環境変数を設定しま

す。RedHatLinux7.1/8.0 の場合には、rpmパッケージでインス

トー ル されるデフォルトの 設 定とな って いるの で 、設定は不要です。

ただし、Netscape や JREをデフォルトと違う場所に移動した場合

は、Solaris の設定を参考にして環境変数を設定してください 。

Solaris

の環境で使用する場合の環境変数を設定するには

および

Red Hat Linux 7.1/8.0

)の

1 シェルの設定ファイル で、環境変数 JAVABINと NPX

PLUGINPATHを以下のように設定する。

の場合: .cshrc に以下の行を追加する。

csh

setenv JAVABIN {JRE

setenv NPX_PLUGIN_PATH {JRE

plugin/sparc/ns4

の場合:以下のように環境変数の設定を行なう。

sh

J

AVABIN="{JRE

export JAVABIN

のインストー ル 先

のインストー ル 先

}/bin/java

のインストー ル 先

}/bin/java"

}/

リモートメンテナンスツールを起動するには

リモ ートメンテナンスツールの3つのGUI(PetaAppMonitorGUI、

BetaBackGUI、Monitoring&MaintenanceTerminalGUI)は、

まず PetaAppMonitorGUIを起動し、次にこのGUIから残りの2つ

のGUIを起動します。

Windows

PetaApp Monitor GUI

Monitoring & Maintenance Terminal GUI

PetaBack GUI

の場合:

の起動:[スタート]ボタンの[プログ

ラム]の中の[PetaAppController]から、[PetaAppMonitor]

を選択し て PetaAppMonitorGUIを起動します。

の起動:

PetaAppMonitorGUIで[PetaSite]ボタンをクリックします。

Monitoring&MaintenanceTerminalGUIが起動します。

の起動:PetaBackGUIはウェブブラウザーから

URLアドレ スを指 定し て起 動し ます 。

PetaAppMonitorGUIで[PetaBack]ボタンをクリックすると、

ウェブブラウザ ーが起動します。サーバー(PCU)では、自動

的にPetaBackGUIのURLアドレ スで ウェブ ブラウザ ーが起動

します。リモ ートの 場 合 は URLアドレスの指 定が 必要です。

PCUで PetaBackGUIを起動したときのURLアドレスを 入 力

してください。

17(J)

Page 20

準備

の場合:

UNIX

PetaApp Monitor GUI

の起動:以下のコマンドを 入力します。

% {DZC-PSC2

%:コマンドプロンプト

PetaAppMonitorGUIが起動します。

Monitoring & Maintenance Terminal GUI

PetaAppMonitorGUIで[PetaSite]ボタンをクリックします。

Monitoring&MaintenanceTerminalGUIが起動します。

PetaBack GUI

URLアドレスを 指 定し て起 動します 。

PetaAppMonitorGUIで[PetaBack]ボタンをクリックすると、

ウェブブラウザ ーが起動します。サーバー(PCU)では、自動

的にPetaBackGUIのURLアドレ スで ウェブ ブラウザ ーが起動

します。リモ ートの 場 合 は URLアドレスの指 定が必要です。

PCUで PetaBackGUIを起動したときのURLアドレスを 入 力

してください。

のインストー ル 先

の起動:PetaBackGUIはウェブブラウザーから

}/bin/petaapp

の起動:

18(J)

Page 21

操作

始動手順

始動させる手 順 は 、次 の通りで す。

1 CSM-200BF/200BS/100BF/100BS/60BF/60BSのドライブ

用電源スイッチとロボット用電源スイッチを、両方ともI側(入)

にする。

2 オプションでファイバ ー チ ャネ ル スイッチがシステムに組み込ま

れているときは 、そ の電 源 を O N に する。

(ファイバ ーチ ャネル スイッチ が 動 作可能な状態になるまで

約3分間かかります。)

3 PCUの電源をONにする。

4 Usernameに sonypscを入力し、ログインする。

5 デスクトップ の PetaAppアイコンをクリックし て、PetaAppを起

動する。

停止手順

1 すべてのアプリケーションを停 止する。

2 すべてのドライブにカートリッジ が 入 っ て いないことを確認する。

3 PCUを次の手順で終了する。

)Usernameにrootを入力してログインする。

1

)ターミナ ル画面で次のように入力する。

2

# /sbin/init 0

または

# /sbin/poweroff

#:rootでのコマンドプロンプト

各プロセスの停止状況が表示されます。

)最後に以下の表示が出たら前 面の 電 源ボタンを 押 して電

3

源を切る。

Halting system....

Stopping all md devices.

Power down

4 オプションでファイバ ー チ ャネ ル スイッチがシステムに組み込ま

れているときは 、そ の電源を切る。

5 ドライブ用電源スイッチを

6 ロボット用電源スイッチを

O

側(切)にする。

O

側(切)にする。

19(J)

Page 22

操作

カートリッジの挿入と取り出し

カートリッジの挿入と取り出しの手順は、次のとおりです。

1 IN/OUTポートの OPEN ボタンを押す。

扉が開きます。

2 マガジンを引き出 す 。

ご注意

カートリッジ に 衝 撃 を与えないように、ゆっくりとマガジンを引き

出してください。

マガジンを引き出した後、カートリッジ を出し 入 れする側を下に

向けないようにご注意ください。下に向けた状態で衝撃が加え

られると、カートリッジ が落下する可能性があります。

3 マガジンにカートリッジを 出し 入れする。

入れるときは、カートリッジ の バ ーコードが 見える向きで、SONY

などの 文字印刷面を下図に示す向きにして入れます。

バーコード

SA1 500

GB

4 マガジンを元どおり装 着する。

ご注意

カートリッジ に 衝 撃を 与えないように、ゆっくりとマガジンを押し

込んでください 。

5 扉を閉 める。

ご注意

カートリッジ に 衝 撃を 与えないように、ゆっくりと扉を閉めてくだ

さい。

20(J)

Page 23

メニュー操作

Set Up

項目を設定をするには

ディスプレイパネルの MENUボタンを押すと、表示部に次のメ

ニュー項目が 1 つ表示されます。

Hours Meter

Console:電源投入時の合計時間

I/O1(×1000):上 の IN/OUTポート扉 の開 いた回数(×1000回)

I/O2(×1000):下 の IN/OUTポート扉 の開 いた回数(×1000回)

Access(×1000):トラン スファーの 移動回数(×1000 回)

X:トラン スファーのX軸(横方向)の移動距離(km)

Y:トラン スファーのY軸(縦方向)の移動距離(km)

Z:キャリア のZ軸(奥行き方向)の移動距離(km)

R:キャリア のR軸(回転方向)の移動回数(×1000 回)

Program Version

ファー ムウ ェア の バ ージョンを表 示します。ファームウェアは CCC、

SV1、RCX、RCY、RCR、RCZ の6 種類あります。

Set Up

SerialNo.(シリアルナンバーの表示)

Date(日付の表示)

Time(時間の表示)

LCDContrast(表示部のコントラストの 調整)

AutoInitial(自動初期化の設定)

Configuration

コンソールの構成を英数字で表示します。

B:CSM-200BF/200BS

1:CSM-100BF/100BS

6:CSM-60BF/60BS

D:CSM-200D

C:CSM-200C

SetUpメニューの各項目は、必要に応じて次の手順で設定しま

す。

1 MENUボタンを押して、表示部にメニューを表示させる。

2 矢印ボタンを押して、SetUpの設定したい項目を表示させる。

3 矢印ボタンを押して、設定したい数値を表示させる。

4 ENTERボタンを押す。

手順3 で設定した値が確定します。

手順2〜 4を必要なだけ繰り返します。

メニュー表示を1つ前の状態に戻すには

ESC/CLRボタンを押します。

メニューから抜けるには

ディスプレイパネル に、HoursMeter、ProgramVersion、

SetUpまたはConfigurationが表示され ているときに、ESC/

CLRボタンを押します。

表示する項目を選択するには

表示項目は、矢印ボタンを押し て 選択します。矢印ボタンが点灯し

ている場合は、さらに 表示する項目があります。点灯しているボタ

ンを押し てください。

21(J)

Page 24

操作

の再起動

PCU

1 Usernameに rootと入力してログインする。

2 ターミナ ル画面で次のように入力する。

# /sbin/init 6

#:rootでのコマンドプロンプト

各プロセスの停止状況が表示され、その後再起動します。

の電源がONのとき途中で停止してしまっ

PCU

た場合の再起動

PCUの電源を正しい手順で切らなかった場合や停電が発生した

場合などは、PCUの電源をONにしても、次のような表示が出て、

起動が途中で停止することがあります。

*** An error occurred during the file system check.

*** Dropping you to a shell; the system will reboot

*** when you leave the shell.

Give root password for maintenance

(or type Control-D for normal startup):

4(Repairfilesystem)2#と表示されたら、init6と入力し、Enter

キーを押して再起動する。

(Repair filesystem) 2# init 6

修復が完了していれば、正常に起動します。

再起動中に起動が停止した場合

再起動中に起動が停止した場合、次の表示が出ます。

/export/home:UNEXPECTED INCONSISTENCY; RUN fsck

MANUALLY.

(i.e., without -a or -p options)

*** An error occurred during the file system check.

*** Dropping you to a shell; the system will reboot

*** when you leave the shell.

Give root password for maintenance

(or type Control-D for normal startup)

障害があると表示されたファイルシステムは、次の手順で修復して

ください。

1 UNEXPECTEDINCOSISTENCY;と表示された行の最初に

表示されているディレクトリ名 を控 えて おく(上記の表示例の場

合は、/export/home)。

次の手順で再起動してください 。

1 rootユーザーのパスワードを入力する。

rootユーザーの初期パスワードは sony2002です。

(Repairfilesystem)1#というプロンプトが表示されます。

2 fsck-Aと入力し、Enter キーを押す。

(Repair filesystem)1# fsck -A

このとき「Doyoureallywanttocontinue(y/n)?」と表示さ

れた場合は、yを入力する。

ファイル シ ステ ム の チェック処理が 起動し、チェック内 容 が 表

示され、最 後に XXXX<y>?(XXXXの部分にはFix、Clearなど

の文字列が入ります)と表 示されます。

3 (Repairfilesystem)2#と表示されるまで Enter キーを押す。

この行は以下のように表示される場合もあります(xは数字)。

/export/home:xxxx/xxxx files (x.x% non-contiguous),

xxxx/xxxx blocks [FAILED]

この場合も最初に 表 示されて いるディレクトリ名( /export/

home)を控えておいてください。

2 rootユーザーのパスワードを入力する。

(Repairfilesystem)1#のプロンプトが表示されます。

3 fsckに続けて手順1で控えておいたディレクトリ名 を 入力する。

(Repair filesystem)1# fsck /export/home

ファイル シ ステ ム の チェック処理が 起動し、チェック内 容 が 表

示され、最 後に XXXX<y>?(XXXXの部分にはFix、Clearなど

の文字列が入ります)と表 示されます。

22(J)

Page 25

4 (Repairfilesystem)2#と表示されるまでEnterキーを押す。

DZC-PSC2

の操作について

5 (Repairfilesystem)2#と表示されたら、init6と入力し、Enter

キーを押して再起動する。

(Repair filesystem)2# init 6

修復が完了していれば、正常に起動します。

正常に起動されず、上記の表示が出る場合は、手順 1〜5を繰り

返します。

UPS(Uninterrupted Power Supply

電源)について

UPSは、停電や電源トラブル発生時にデータの損傷を防ぐための

装置です。UPSを経由して電源を接続すると元電源からの電源供

給が途絶えた際、UPS内部の電池に切り換わり、PCUへの電源の

供給を続けることができます。

PCUのシリアルポートに UPSをケーブルで接続して、DZC-PSC2

の「システムのシャットダ ウ ンと UPSデバイスの使用に関する設定」

を行なうことに より、UPSの状態を監視して停電を検出すると自動

的にシャットダ ウン 処 理 を 実 行します 。

停電や電源トラブル 発生時のシステムの信頼性を向上させるため、

停電が多発するような地域へシステムを設置する場合には、UPSを

使用することを推奨します。

:無停電

PetaSiteコントロールソフトウェア DZC-PSC2の各機能の操作およ

び表示内容については、オンラインヘルプに表示されます。

オンラインヘルプは、DZC-PSC2のMMTウィンドウの[Help]ボタ

ンをクリックすると参照することができます。

のオンラインヘルプについて

MMT

MMT( Monitoring & Maintenance Terminal)は 、GUI

(GraphicalUserInterface)を使用し、本システムおよび搭載する

ドライブの状態の監視とメインテナンスを行います。

MMTは次の機能を持ってます。

•

PetaSiteおよび搭載ドライブのステータス表示

•

PetaSite内のカートリッジ についての情報表示

•

PetaSiteおよび搭載ドライブのファームウェアバ ージョン表示

•

ドライブの使用状況の監視

•

PSCおよびPetaSite、ドライブのログデータの収集および表示

•

PSCおよびPetaSiteについての各種設定

•

上記機能に対するオンラインヘルプ

プリインストール

PetaBack

について

PetaServe/

PCUにPetaServeおよびPetaBackがプリインストー ルさ れ て いま

す。

製造時に90 日のデモライセンスが インストー ル され て い ます の で 、

コンフィグレーションを行なうことに より、HSMおよびバックアップソ

フトウェアを試使用できます。

詳細については、PCU のPetaServeマニュアルのアイコンを クリッ

クして、READMEJ.TXT(日本語)または READMEE.TXT(英

語)を参照してください。

READMEを含むすべてのドキュメントは 、/osm/docディレクトリー

配下にインストー ル さ れ て い ま す 。

プリインストー ル PetaServe/PetaBackを使用する際のコンフィグ

レーションや、相互接続性に関わる環境などについては、ソニーの

営業担当者にご相談ください 。

実際の運用でPetaServe/PetaBackをご使用になる場合は、正式

なソフトウェアライセンスを購 入されることにより、継続して運用する

ことが で きます 。

23(J)

Page 26

操作

PetaApp Linux

PCUには、OSとして PetaApp Linuxを採用しています。この

PetaAppLinuxはRedHatLinux8.0ftp版をベースにしたソニー独

自のPetaApp Control Unit 専用の OS です。画面表示の中に

RedHat社に関連するものが表示されることがありますが、RedHat

社とは無関係です。RedHat社には問い合わせなどはしないようお

願いいたします。

GPL/LGPL

PetaAppLinuxは、GPL/LGPL適用ソフトウェアを 含 みます 。した

がって、PetaAppLinux内の該当ソフトウェアに つい てのソースコー

ドの入手、改変、再配布の権利があることをお知らせいたします。

PetaAppLinux で使用しているGPL/LGPL 適用ソースコードは、

下記のいずれかの方法で入手することができます。

• サーバーからのダウンロード

• CD-ROM の郵送

具体的な入手方法については、以下のURLにアクセスしてくださ

い。

について

について

各機材の初期設定値

工場出荷時の設定値は以下のとおりです。

PCU

Hostname/IP Address

初期アカウント/パスワード : root、sony2002

: petalocal.petadomain

(eth0)

10.0.0.100/255.255.255.0

: petahost.petadomain

(eth1)

192.168.20.3/255.255.255.0

: sonypsc、psc2002

CSM-200BF/200BS/100BF/100BS/60BF/

60BS

コントロールコンソール

IP Address

ドライブインターフェース

: 10.0.0.30(Basic)

http://www.sony.net/Products/Linux/

なお、ソースコードの中身についてのお問い合わせはご遠慮くださ

い。

本製品で提供しているソフトウェア DZC-PSC2およびFZC-PABS/

PABM/PABLは、開発上LGPL 適用ライブラリー であるglibcをダ

イナミックリンクという方 法 で 使用しています。したがって、LGPLの

規定により、これらのソフトウェア のソースコードは 提供しておりませ

ん。しかし、本ソフトウェアの 購入者に限り、購入者自身のための

修正、もしくはデバック目的によるオブジェクトコードの解 析は認め

られています。

IP Address

Port Number

: 10.0.0.40(Basic)

: 10.0.0.41(Redundant)

:10001(Basic/Redundant共通)

ファイバーチャネルスイッチ(ブロケード

SILKWORM 3800/3200

IP Address

初期アカウント/パスワード:admin、password

: 10.0.0.20(1 台目)

: 10.0.0.21(2 台目)

)(オプション)

24(J)

Page 27

DZC-PSC2/MMT

SetupのMail/RemoteMaintenanceを設定していなければ、初期

設定不要。

項目

Communication Port Condition

DMS TerminalServer 10.0.0.30,10001

DRV TerminalServer 10.0.0.40,10001

BinDivision 設定なし(ユーザーのシステム構成による設定が必要)

ReserveBin 設定なし

DriveCondition Drive1、Drive2 のみON(搭載するドライブのみチェック

ExecuteMode

BusNo. other のみ設定済み

UserID –

(以下、StandardSetupをPetaServeにして[Apply]をクリックすると自動設定) チェック有 =1 / 無 =0

AutoEntry 0

ThreadwithLoad 1

UnthreadatLoadError 1

UnthreadwithFastUnload 0

UnthreadwithHalfWayUnload 0

UnthreadwithEject 0

DriveAutoLoadMode 0

BCReadwithCassetteMove 0

EraseofNewTape 1

RecoverofDestroy 0

WaitforDriveUse 0

UseCassettewithoutBC 0

UPS チェック有 =1/ 無=0

UseUPS 0

Executemachineshutdown 1

AutoHeadCleaning

BinArea 設定なし

AutoRetension 設定なし

AutoTakeLog チェック有 =1/ 無=0

ErrorTakeLog 0

AutoTakeLog 0

CassettePrifix 初期設定のまま

Network 9000

DZC-PSC2/MMT

を入れることが 必 要 )

25(J)

Page 28

操作

CSMA-DR100S/CSMA-DR130F

項目

VendorID(0-99999999) 0 0

Vendorname(8characters) SONY SONY

VendorROMversion(4characters) 1.?? 1.??

Machinename(16characters) SDZ-100 SDZ-130

Interface(0:SCSI-WD/1:SCSI-WS/2:SCSI-UWD/3:SCSI-LVD/ 3 8

8:Fibrechannel/12:VRP)

Series(0:SAIT-1/1:SAIT-2/2:SAIT-3/3:SAIT-4) 0 0

Serialnumber ???????? ????????

SCSIID(0-15) 5 設定無し

LoopIDrequest(0:OFF/1:ON) 設定無し 1

LoopID(0-126) 設定無し 0

AutoThreadmode(0:OFF/1:ON)

WriteRetryCount(0-20) 0 0

ReadRetryCount(0-16) 0 0

FCportname ff.ff.ff.ff.ff.ff.ff.ff 50.80.04.60.12.10.??.??

FCnodename ff.ff.ff.ff.ff.ff.ff.ff 50.80.04.60.12.10.??.??

a)DZC-PSC2 の DrivePropertyダイアログボックスのSetupタブで、Standard

Setupリストボックスを Default に設定するとデフォルトで 選 択される設 定。

a)

CSMA-DR100S CSMA-DR130F

00

26(J)

Page 29

仕様

一般

電源 AC100V−240V、50/60Hz

消費電力

CSM-200BF/200BS/100BF/100BS/60BF/60BS

−

2.7A

6.5A

−

CSM-200C/200D 3.5A

外形寸法(幅/ 高さ/奥行き)

質量

CSM-200BF/200BS/100BF/100BS/60BF/60BS

CSM-200C/200D 300kg

発熱量 560kcal/h

1.5A

680× 1980× 950mm

350kg

性能/容量/その他

データ収納量 CSM-200BF/200BS:最大108TB

CSM-100BF/100BS:最大54TB

CSM-60BF/60BS:最大30TB

CSM-200C:最大198TB

CSM-200D:最大174TB

ドライブ搭載台数 12 台まで

環境条件

付属品

CSM-200BS/100BS/60BS

オペレーションマニュアル(1)

プラグホルダー(8)

ターミネ ーター(2)

バーコードラベ ルシ ート(14)

バーコードラベ ルシート(クリー ニ ング用)(2)

PetaAppLinuxリカバーCD-ROMdisk1、disk2(各 1)

PetaAppSoftwarePackageCD-ROMdisk1、disk2(各 1)

ライセンス証(1)(CSM-200BS/100BS のみ)

ディスプレイ延長 ケーブル(1)

キーボード/マウス延長ケーブ ル(各 1)

スパナ(1)

CSM-200BF/100BF/60BF

オペレーションマニュアル(1)

プラグホルダー(8)

バーコードラベ ルシ ート(14)

バーコードラベ ルシート(クリー ニ ング用)(2)

PetaAppLinuxリカバーCD-ROMdisk1、disk2(各 1)

PetaAppSoftwarePackageCD-ROMdisk1、disk2(各 1)

ライセンス証(1)(CSM-200BF/100BF のみ)

ディスプレイ延長 ケーブル(1)

キーボード/マウス延長ケーブ ル(各 1)

スパナ(1)

動作温度 +10℃〜+30℃

保存温度 − 20℃〜+60℃(カートリッジを 取り外し

ておくこと)

動作湿度 25%〜80%(結露しないこと)

バーコードリーダーの光学仕様

光源波長 赤色LED:630nm

受光素子 CCDリニアセンサー

スキャン速 度 5 0 0 スキャン / 秒

CSM-200D

プラグホルダー(4)

バーコードラベ ルシ ート(16)

スパナ(1)

CSM-200C

バーコードラベ ルシ ート(16)

スパナ(1)

27(J)

Page 30

仕様

別売りコンポーネント/アクセサリー

FCドライブユニット CSMA-DR130F

SCSIドライブユニット CSMA-DR100S

拡張ベルトキット CSMA-BLTS(拡張コンソール1〜 3

台連結用)

CSMA-BLTL(拡張コンソール4〜 7

台連結用)

拡張ケーブルキット CSMA-CBLS(拡張コンソール2 〜 3

台連結用)

CSMA-CBLL(拡張コンソール4〜7

台連結用)

電源ユニット CSMA-PSL(冗長ライブラリー 専用)

CSMA-PSD(冗長ドライブ専用)

冗長ドライブインターフェースボ ードキット

CSMA-DIF

アップ グレードキット CSMU-100B

CSMU-200B

キーボード DMSP-KBE1/DMSP-KBJ1

マウス DMSP-KMS1

電源コード DMSA-CPJ(AC100V)

DMSA-CPE(AC120V)

仕様および外観は、改良のため予告なく変更することがあります

が、ご了承ください。

本機は「高調波ガイドライン適合品」です。

注意

この装置は、情報処理装置等電波障害自主規制協議会

(VCCI)の基準に基づくクラ スA情報技術装置です。この装 置

を家庭環境で使用すると電波障害を引き起こすことがあります。

この場合には 使 用者が適切な対策を講ずるよう要求されること

があります。

S-AIT

構造 AME(蒸着)テープ

記録容量 500GB(非圧縮時)

転送速度 30MB/s(非圧縮)

の仕様

600m× 1/2シング ルリー ル

1.3TB(2.6:1圧縮時)

バーコードラベルの仕様

バーコードリー ダーユニットは CODE39に対応しています。付属の

バーコードラベルの仕様は以下のとおりです。

00007BS1

11.1 mm

ストップマージンスタートマージン

バーコードラベル

外形寸法 使用するカートリッジ のラ ベ ル フレーム

サイズに準拠

バーの幅細バー:0.432mm

太バー/ 細バー比 2.75:1

バーの長さ 11.1mm

ストップ / スタートマ ージン 8 mm

桁数 8桁(スタート/ ストップ コード含まず)

チェック デジットなし

ご注意

バーコードラベ ル はカートリッジ のラベル エリア内に貼り付けてくださ

い。また、はが れないように バーコードラベ ルをカートリッジ側に強

く押し 付 けてください。

28(J)

Page 31

WARNING

To prevent fire or shock hazard, do not expose the unit to

rain or moisture.

To avoid electrical shock, do not open the cabinet. Refer

servicing to qualified personnel only.

THIS APPARATUS MUST BE EARTHED.

CAUTION

The mains plug on this equipment must be used to

disconnect mains power.

Please ensure that the socket outlet is installed near the

equipment and shall be easily accessible.

Use the power cord set approved by the appropriate testing

organization for the specific countries where this unit is to be

used

WARNING: THIS WARNING IS APPLICABLE FOR USA

ONLY.

If used in USA, use the UL LISTED power cord specified

below.

DO NOT USE ANY OTHER POWER CORD.

Plug Cap Parallel blade with ground pin

(NEMA 5-15P Configuration)

Cord Type SJT or SVT, three 16 or 18 AWG wires

Length Less than 2.5 m (8 ft. 3 in.)

Rating Minimum 10 A, 125 V

For the customers in Canada

This Class A digital apparatus complies with Canadian ICES-

003.

English

Caution for LAN port

For safety reason, do not connect the LAN port to any

network devices that might have excessive voltage.

AVERTISSEMENT

Afin d’éviter tout risque d’incendie ou d’électrocution, ne pas

exposer cet appareil à la pluie ou à l’humidité.

Afin d’écarter tout risque d’électrocution, garder le coffret

fermé. Ne confier l’entretien de l’appareil qu’à un personnel

qualifié.

CET APPAREIL DOIT ÊTRE RELIÉ À LA TERRE.

WARNUNG

Um Feuergefahr und die Gefahr eines elektrischen Schlages

zu vermeiden, darf das Gerät weder Regen noch

Feuchtigkeit ausgesetzt werden.

Um einen elektrischen Schlag zu vermeiden, darf das

Gehäuse nicht geöffnet werden. Überlassen Sie

Wartungsarbeiten stets nur qualifiziertem Fachpersonal.

DIESES GERÄT MUSS GEERDET WERDEN.

For the customers in the USA

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own

expense.

Pour les utilisateurs en Canada

Cet appareil numérique de la classe A est conforme à la

norme NMB-003 du Canada.

For the customers in Europe

WARNING

This is a Class A product. In a domestic environment, this

product may cause radio interference in which case the user

may be required to take adequate measures.

Pour les utilisateurs en Europe

AVERTISSMENT

Il s’agit d’un produit de Classe A. Dans un environnement

domestique, cet appareil peut provoquer des interférences

radio, dans ce cas l’utilisateur être amené à prendre des

measures appropriées.

Für Kunden in Europa

Warnung

Dies ist eine Einrichtung, welche die Funk-Entstörung nach

Klasse A besitzt.

Diese Einrichtung kann im Wohnbereich Funkstörungen

verursachen; in diesem Fall kann vom Betreiber verlangt

werden, angemessene Maßnahmen durchzuführen und

dafür aufzukommen.

Für Kunden in Deutschland

Diese Ausrüstung erfüllt die Europäischen EMCBestimmungen für die Verwendung in folgender / folgenden

Umgebung(en):

• Gewerbegebiete

• Leichtindustriegebiete

(Diese Ausrüstung erfüllt die Bestimmungen der Norm

EN55022, Klasse A.)

You are cautioned that any changes or modifications not

expressly approved in this manual could void your authority

to operate this equipment.

The device requires shielded interface cable to comply with

FCC emission limits.

Dieses Gerät ist nur für den Gebrauch in Gewerbe und

Leichtindustrie bestimmt.

1(E)

Page 32

LED Notice:

The LED of the barcode reader incorporated inside this

product complies with IEC 60825-1.

This product is classified as a CLASS 1 LED PRODUCT.

LED (barcode reader)

Wavelength 630–660 nm

For models with FC-conforming SAIT drives

Laser Notice:

The equipment contains tape drives using laser that

complies with IEC 60825-1.

The equipment is classified as a CLASS 1 LASER

PRODUCT.

CAUTION

The use of controls or adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

Do not look at the end of optical connector of the internal

tape driver with naked eyes or through optical equipment

while the power is supplied to this product. Otherwise, your

eyes may be injured

Caution to service personnel:

This equipment has four power supply connections. Power

to drive operation is supplied through appliance inlets

marked with DRIVE. Power to robot mechanism is supplied

through appliance inlets marked with ROBOT. All

connections need to be removed to completely de-energize

the equipment.

2(E)

Page 33

Table of Contents

Overview............................................................................................... 4(E)

Product Line-up of the PetaSite S200-Series ..................................4(E)

Features of the PetaSite S200-Series ...............................................5(E)

Extension Example..........................................................................6(E)

System Equipment........................................................................... 7(E)

Notes on Maintaining the Performance of

the System ..................................................................................... 8(E)

Locations and Functions of Parts....................................................... 9(E)

Front and Side ................................................................................. 9(E)

Display Panel................................................................................. 11(E)

IN/OUT Ports ................................................................................12(E)

PetaSite Control Unit (PCU) .........................................................12(E)

Preparations ....................................................................................... 13(E)

Installation .....................................................................................13(E)

Connection Example .....................................................................13(E)

Ethernet Interface Ports of the PCU ..............................................13(E)

Settings ..........................................................................................14(E)

Operations .......................................................................................... 18(E)

Starting Up .................................................................................... 18(E)

Ending ........................................................................................... 18(E)

Installing or Removing Cartridges ................................................19(E)

Menu Operation............................................................................. 20(E)

Restarting the PCU ........................................................................21(E)

Operations of the DZC-PSC2........................................................22(E)

Preinstalled PetaServe/PetaBack ...................................................22(E)

PetaApp Linux............................................................................... 23(E)

GPL/LGPL ....................................................................................23(E)

Initial Settings of Device ...............................................................23(E)

Specifications...................................................................................... 26(E)

Specifications of SAIT ..................................................................27(E)

Specifications of Barcode Reader .................................................27(E)

3(E)

Page 34

Overview

The Consolidated Storage Management (CSM) System

achieves rapid and accurate processing, backup, and

hierarchical

storage management of large amounts of

data.

The required software and hardware are configured

into one package to construct a storage solution system

of high reliability.

The CSM system is composed of PetaSite S200-series

tape libraries, DZC-PSC2 PetaSite control software,

PetaSite Control Unit (PCU) , PetaBack or PetaServe

backup application software, and fibre channel

switches.

The PetaSite S200-series is a tape library that controls

cartridges of the Super AIT format to store, check,

record, and reproduce large amounts of data at high

speed. It contains the PetaSite Control Unit and DZCPSC2 PetaSite control software in the Basic Storage

System models as a package.

Ethernet

Product Line-up of the PetaSite

S200-Series

CSM-200BF/200BS/100BF/100BS/60BF/60BS

Basic Storage System

There are models with FC-conforming SAIT drives

and models with SCSI-conforming SAIT drives. They

are further configured into three types according to the

number of cartridges to be stored. Up to 12 drives can

be mounted in any types.

Basic Storage System models

Model Mounted Number of Data

CSM-200BF FC

CSM-200BS SCSI

CSM-100BF FC

CSM-100BS SCSI

CSM-60BF FC

CSM-60BS SCSI

Using the optional CSMA-PSL power unit dedicated

for redundant libraries, CSMA-PSD power unit

dedicated for redundant drives, and CSMA-DIF

redundant drive IF board kit in combination, you can

easily establish a highly reliable system.

drive type cartridges capacity

Max. 216 Max. 108TB

Max. 108 Max. 54TB

Max. 60 Max. 30TB

Application

server

Data server

PetaSite S200-series (with

PetaSite Control Unit, Hub,

and terminal server built in)

NAS server

Storage Area Network

Fibre channel switch

Application client

CSM

CSM-200D/200C Extension Console

The CSM-200D is a drive console that can hold both

drives and cartridges, and the CSM-200C is a cartridge

console that can hold cartridges only.

Using one of the following combinations shown below

of optional extension belt kit and extension cable kit,

you can add up to 7 extension console units to one

Basic Storage System model.

Number of Extension belt kit Extension cable kit

extension

1 CSMA-BLTS Not necessary

2 or 3 CSMA-BLTS CSMA-CBLS

4 to 7 CSMA-BLTL CSMA-CBLL

4(E)

Page 35

Features of the PetaSite S200Series

The CSM System works in a heterogeneous

environment. Its SAN solution makes this high-speed

backup subsystem possible.

It features:

Cassette management using bar codes

The system includes a barcode reader to aid in

management of cartridges with barcode labels attached

to the cartridges.

Easy control

The system can be controlled via an SCSI or API

interface.

Huge storage capacity

Combining extension consoles with the Basic Storage

System, the system can store data of 1.49PB on 96

drives at maximum.

The maximum capacity of each single unit is:

Model Number Number Data

CSM-200BF/200BS 4 216 108

CSM-100BF/100BS 4 108 54

CSM-60BF/60BS 4 60 30

CSM-200C – 396 198

CSM-200D 4 348 174

When combining the CSM-200C expansion console(s)

with the CSM-200BF/200BS Basic Storage System

Model Max. number Max.

CSM-200BF/200BS+

CSM-200C×1 612 306

CSM-200C×2 1008 504

CSM-200C×3 1404 702

CSM-200C×4 1800 900

CSM-200C×5 2196 1098

CSM-200C×6 2592 1296

CSM-200C×7 2988 1494

of of capacity

drives cartridges

8 204 102

12 192 96

8 108 54

12 108 54

86030

12 60 30

– 396 198

– 396 198

8 336 168

12 324 162

of cartridges capacity

(TB)

(TB)

Self-diagnostic functions

The system can check the statuses of the cartridges

mounted in the system as well as the system itself, and

the results are displayed with the GUI (Graphical User

Interface).

High-speed data transmission in SAN

environments

Having the tape drive directly connected to the FC

(Fibre Channel) enables high-speed data transmission.

Transmission rate and large capacity of SAIT

30 MB/s for one drive (without data compression)

500 GB for one cartridge (without data compression)

Reducing load on the LAN and lowering cost

by sharing libraries

The system complies with LAN free backup and

NDMP.

Remote maintenance function

In compliance with SNMP

Remote monitoring software supporting Java

PC server (PetaSite Control Unit) built in

The built-in PetaSite Control Unit (PCU) manages and

monitors the tape library. The PCU also functions as a

backup server for PetaServe and PetaBack.

5(E)

Page 36

Overview

Extension Example

Data capacity can be increased by connecting up to

seven CSM-200D/200C Extension Consoles to the

CSM-200BF/200BS Basic Storage System.

CSM-200BF/200BS CSM-200D/200C

Note

The Extension Consoles cannot be connected to the

CSM-100BF/100BS/60BF/60BS. To connect one,

upgrade the CSM-100BF/100BS/60BF/60BS to the

CSM-200BF/200BS using the appropriate Upgrade Kit

(option).

6(E)

Page 37

System Equipment

CSMA-DR130F Storage Management System

Drive Unit (FC)

This is the hot-swapping FC drive unit (attachment

included) for dedicated use with libraries.

CSMA-DR100S Storage Management System

Drive Unit (SCSI)

This is the hot-swapping SCSI drive unit (attachment

included) for dedicated use with libraries.

CSMA-CBLL Extension Kit (CL)

This is the extension cable kit to connect 4 to 7

extension consoles.

CSMA-CBLS Extension Kit (CS)

This is the extension cable kit to connect 2 or 3

extension consoles.

CSMA-BLTL Extension Kit (BL)

This is the extension belt kit to connect 4 to 7

extension consoles.

CSMU-200B Upgrade Kit CSM-100BF/100BS to

CSM-200BF/200BS

This is the kit to upgrage the CSM-100BF/100BS to

the CSM-200BF/200BS.

DMSA-CPE Power Cord

This is the power cord for the PetaSite S200-series and

the PetaSite Control Unit (PCU) (AC 120 V).

CSMA-BLTS Extension Kit (BS)

This is the extension belt kit to connect 1 to 3

extension consoles.

CSMA-PSL Redundant Power Unit (Library)

This is the hot-swapping power unit for dedicated use

with redundant libraries.

CSMA-PSD Redundant Power Unit (Drive)

This is the hot-swapping power unit for dedicated use

with redundant drives.

CSMA-DIF Redundant Drive Control Unit

This is the interface board kit for redundant drives.

DMSP-KBE1/DMSP-KBJ1 PC Keyboard

DMSP-KMS1 PC Mouse

These are the keyboard and mouse for the PetaSite

Control Unit (PCU) built into the PetaSite S200-series.

CSMU-100B Upgrade Kit CSM-60BF/60BS to

CSM-100BF/100BS

This is the kit to upgrage the CSM-60BF/60BS to the

CSM-100BF/100BS.

7(E)

Page 38

Notes on Maintaining the Performance of

the System

Pay attention to the following points when handling

the system equipment and media, so as not to damage

them and to maintain top performance.

Handling the unit

Avoid vibration or shock, which may cause damage to

or malfunction of the system.

• Do not block the ventilation holes of each unit.

• Periodic maintenance of the system is recommended

in order to maintain top performance.

Handling the media

• Do not bring it close to a device with a strong

magnetic field.

• Do not touch the tape inside a cartridge.

Location

Do not use or keep the system equipment and media in

a place with any of the following conditions:

–High humidity

–High temperature

–Direct sunlight

–Dust

–Vibration

–Extreme temperature changes

–Not level

Mounting the PetaSite Control Unit

A specially trained technician must mount the PetaSite

Control Unit.

Cleaning

Clean the system equipment with a cloth lightly

moistened with warm water or a mild detergent

solution, then wipe with a dry cloth.

Do not use any type of solvent, such as thinner or

alcohol, which may damage the finish.

For the cleaning of the S-AIT drive, refer to the

operation manual for the drive.

Transportation

When you transport the system, be sure to remove the

PetaSite Control Unit and pack the system equipment

with the transporting brackets attached and using the

packing materials for them.

A specially trained technician must remove the

PetaSite Control Unit.

8(E)

Page 39

Locations and Functions of Parts

Front and Side

CSM-200BF/200BS/100BF/100BS/60BF/60BS

Front panel

Display panel check window

Slot for optional redundant

power unit (for DRIVE)

1 DRIVE power switch

2 ROBOT power switch

Slot for optional redundant

power unit (for ROBOT)

AC inlet (for ROBOT redundant)

AC inlet (for ROBOT)

Inside front

AC inlet (for DRIVE redundant)

AC inlet (for DRIVE)

POWER READYBUSYERROR

INITIAL

123456

789101112

ESC/

CLR

ENTER

MENU

3 Display panel

OPEN

OPEN

4 IN/OUT port

Slot for optional drives

Standard drives

5 PetaSite Control Unit

Right side panel

6 Transfer check window

9(E)

Page 40

Locations and Functions of Parts

1 DRIVE power switch

This is for turning the power to the drive block on and

off.

When turning on the power, set it to the I position

(ON).

To turn the power off, set it to the a position (OFF).

Notes

• When you also use the redundant power unit, set the

power switches to OFF on the both power units.

• When you turn the power on immediately after you

turn it off, wait for at least 5 seconds.

2 ROBOT power switch

This is for turning the power to the robot block on and

off.

When turning on the power, set it to the I position

(ON).

To turn the power off, set it to the a position (OFF).

When the power is turned off, all indicators on the

display panels go dark.

Notes

• When you also use the redundant power unit, set the

power switches to OFF on the both power units.

• When you turn the power on soon after you turn it off,

wait until the indicator on the display panel goes off.

5 PetaSite Control Unit

The unit controls and monitors the drives and robot

block.

For details, see “PetaSite Control Unit (PCU)” on page

12(E).

6 Transfer check window

The position of a transfer may be checked through this

window.

Warning

This system has four power-reception (AC inlet) lines.

In an emergency, be sure to disconnect all power cords

to completely shut off the power supply.

3 Display panel

The operating conditions, status, etc., of the system

appear here. Using this panel, initialization of the

system, and menu operation for checking the system

configuration and hour meters are also possible.

For details, see “Display Panel” on page 11(E).

4 IN/OUT ports

These ports are for loading and removing cartridges.

You can mount a magazine containing up to six

cartridges in a port.

Care must be taken to load the cartridges in the right

direction.

For details, see “IN/OUT Ports” on page 12(E).

10(E)

Page 41

Display Panel

1 INITIAL button

2 READY indicator

3 BUSY indicator

4 ERROR indicator

POWER READY BUSY ERROR

INITIAL

5 Display window

6 MENU button

7 Arrow buttons

8 ENTER button

9 ESC/CLR button

MENU ENTER

F

gG

f

1 INITIAL button

Holding this button pressed for more than five seconds

while “Initial Request” or “Full Initial Request” is

shown in the display window initializes the system.

While the system is being initialized, the BUSY

indicator is lit.

Each time the power is turned on, the system must be

initialized.

If Auto Initial on the Set Up menu is activated, the

system is automatically initialized after the power is

turned on.

ESC/

CLR

When “Initial Request” or “Full Initial Request”

appears:

Press the INITIAL button to reinitialize the

system.

When “Power off Request” appears:

Turn the power off and then on again.

If the problem persists after executing the above,

consult Sony service personnel.

5 Display window

The operating condition, menu items, or values are

displayed here.

6 MENU button

Pressing this button displays one of the menu items in

the display window. If the display window is closed

when you press the button, the window is turned

opened. Press the button again.

For details, see “Menu Operation” on page 20(E).

7 Arrow buttons

During menu operation, press one of the lit arrow

buttons, and one of the following menu items or values

will appear.

8 ENTER button

During menu operation, pressing this button registers

the set value.

9 ESC/CLR (escape/clear) button

Pressing this button restores the status of one step

before.

2 READY indicator

This indicator lights when the system is ready to be

operated.

3 BUSY indicator

This indicator remains lit while the system is

operating.

It is also lit during initialization.

4 ERROR indicator

This indicator lights if some trouble occurs in the

system.

Perform the following according to the message that

appears in the display window.

11(E)

Page 42

Locations and Functions of Parts

IN/OUT Ports

1 NO MAGAZINE indicators

2 IN/OUT indicators

123456

NO

MAGAZINE

NO

MAGAZINE

IN

OUTINOUTINOUTINOUTINOUTINOUT

7891011 1 2

IN

OUTINOUTINOUTINOUTINOUTINOUT

1 NO MAGAZINE indicators

Light in red if no magazines is loaded.

2 IN/OUT indicators

These indicators show the status of each cartridge slot.

IN indicator lit: A cartridge is loaded in the slot.

OUT indicator lit: A cartridge is being removed

from the drive.

IN and OUT indicators lit: The bar code on a

cartridge is being read. In some operating modes,

a cartridge may be pulled in before the indicators

are lit.

IN and OUT indicators blinking: No barcode label

is attached to the cartridge or the label cannot be

read.

4 OPEN buttons

3 Function buttons

OPEN

OPEN

PetaSite Control Unit (PCU)

The unit controls and monitors the drives and robot

block.

It also functions as the application server for PetaServe

and PetaBack.

UID

NIC

1

NIC

2

Power switch

Power switch

Turn the power of the unit on and off.

3 Function buttons

The functions of these buttons are set using software.

4 OPEN buttons

To load or remove a cartridge via the ports, press the

buttons to open the doors. When the buttons are

pressed, they light and remain lit until the ports are

closed.

Depending on the operating condition of the system,

some time may be required until the doors open.

When an error is generated, the lamps of the buttons

flash.

12(E)

Page 43

Preparations

Installation

A technician specially trained for CSM system and

PetaSite-series equipment must perform setting and

wiring the units, and making system environment

settings.

Connection Example

This is an example of the system to completely back

up 2 terabytes of data in eight hours.

Application

server

HP-UX

500 GB

NAS server

NetApp filer

1 TBNetwork

Application

server

SUN Solaris

500 GB

Ethernet Interface Ports of the

PCU

The PCU has two Ethernet interface ports: one for the

local network to control the PetaSite system, and

another for the network for the other system other than

PetaSite.

PCU Rear Panel

Ethernet interface port to control the PetaSite system

Ethernet interface port to control the other system

Port for the PetaSite system network

PetaSite S200

series (PetaSite

Control Unit

built-in)

Fibre Channel switch

PetaServe/PetaBack

software for CSM

Be sure to connect the units for this system only to the

network to be used to control the PetaSite system.

Caution

For your safety, connect the LAN port only to a

network with surge protection.

Port for the system other than PetaSite

For setting this port, ask the network administrator for

the IP address.

For settings, see “Setting the host name and IP address of

the PCU” on page 14(E).

13(E)

Page 44

Preparations

Settings

Initial settings of the DZC-PSC2

The DZC-PSC2 PetaSite Control Software has been

installed on the PCU, and the required initial settings

have been made at the factory. Depending on the

environment, the initial settings may be changed.

For changing the initial settings, refer to on-line help for

the DZC-PSC2. To refer to on-line help, click on the Help

button of the MMT window of the DZC-PSC2.

Starting the DZC-PSC2

Follow the procedures below to start the DZC-PSC2.

1 Turn the PCU on.

2 Type “sonypsc” in the Username box, and

“psc2002” (initial password) in the Password box

of the Login window.

3 Click on the PetaApp icon on the desktop.

Setting the host name and IP address of

the PCU

The PCU has several files keyed with the host name

and IP address. Before starting operation of the CSM

System, set the host name and IP address, and reflect

them in these files. Set the host name and IP address

following the procedure below, then the settings will

be reflected in the files.

Note

The host name and IP address can not be changed after

starting operation of the CSM System. If you need to

change them, contact to Sony support center.

1 Type “root” in the Username box to log in, and

open the Terminal window.

2 Click on the PetaApp icon on the desktop.

3 Click on the Utility icon to open the Utility

window.

4 Select “Administrator” from the Mode list box at

the right top on the Utility window.

If you wish to change the initial password, refer to online help for the DZC-PSC2.

Log in as a root user

To log in with the account root for the administrator,

type “root” in the Username box, and “sony2002”

(initial password) in the Password box.

To change the password

Proceed as follows.

1 Log in with the user name whose password is to be

changed.

2 Open the Terminal window, type “passwd,” and

press the Enter key.

3 Enter the original password at the prompt.

4 Enter the new password twice, at the prompts.

5 Type “sony” (initial password) in the Password

box.

6 Click on the Network tab of the Utility window.

7 Read the notice, then click on Network

Configurator at the bottom of the window to start

Network Configurator.

8 Type the new host name in the HostName column,

and the new domain name in the Domain column

in the Names window.

9 Add the host name and IP address relationships

required for operating the new host and the IP

address in the Hosts window.

10Change the IP address for eth1 to the new IP

address in the Interface window.

11Click on the SAVE button in the Network

Configurator window to retain the settings.

Then the new password will be effective upon the next

log-in.

14(E)

12Click on the Cancel button to close the PetaApp

utility window.

Page 45

13Enter the command shown below and press the

Enter key to execute the command.

# /osm/bin/app_sethostname

If no display appears after changing the

PCU settings

14Type “/sbin/init 6” in the Terminal window

opened in step 1 and press the Enter key to restart

the PCU.

Changing the time zone settings of the

PCU

1 Type “root” in the Username box to start the

terminal display.

2 Enter the command below to start Timezone

Configurator.

# /usr/sbin/timeconfig

where # is the command prompt for the root user.

3 Focus on the time zone to be set, and click on the

OK button.

• Use the TAB key to select the input item.

• Use the up and down arrow keys to select a

setting item.

Note

Check the check box ([ ] Hardware clock set to GMT)

at the top of the input items to change the blank to [*]

by pressing the space key. If the box is not

checked([*]), the time setting of the PCU may be

changed.

To set the time

Use the “date” command for the root user. Then enter

the time zone, and type as shown below.

To set January 23, 2002, 4:56 A.M.:

# /bin/date 0123045602

where # is the command prompt for the root user.

The date option is MMDDhhmmYY (MM: month,

DD: day, hh: hours, mm: minutes, YY: year).

For details, type “date --help” or “man date” to refer to the

on-line manual.

1 Press [Ctrl]+[Alt]+[F6] simultanously.

2 Log in as a root user.

3 Enter the command below to set the X server

again.

# /bin/usr/redhat-config-xfree86 --noui --reconfig

4 Enter the command below to restart the PCU.

# /sbin/init 6

If the display frequency range is exceeded

If a message such as “Out of Range” is displayed on

the monitor screen, indicating that the setting exceeds

the display frequency range, restart the PCU in the

same manner as mentioned in “If no display appears

after changing the PCU settings” above.

Installation of the remote maintenance

tool of the DZC-PSC2

For monitoring the status of the server from another

computer or for the maintenance, install the remote

maintenance tool of the DZC-PSC2.

To install the remote maintenance tool on the CSM

System, use the install kit under the PetaAppGUI/ on

the PetaApp Client Install Kit CD-ROM disk. If the

DZC-PSC2 is used alone, use the install kit under

Remote/ on the Install Kit CD-ROM disk of the DZCPSC2.

To use the remote maintenance tool, settings for the

DZC-PSC2 is required on the server.

For details, refer to the on-line help for the DZC-PSC2.

Notes

• To run the remote maintenance tool, Java Run Time

Environment (JRE 1.4.1) is required. Install the JRE

for Red Hat Linux 7.1/8.0, for Solaris, or for

Windows under tools of the Install Kit CD-ROM

disk.

For details, access to the URL below.

http://java.sun.com/products/plugin/1.3/docs/ja/

quick_start.html

15(E)

Page 46

Preparations

• To use the on-line help for the remote maintenance

tool, you need a Web browser. Operation with the

Web browsers shown below has been confirmed.

Netscape 7.01 (6.x has not been confirmed)

Internet Explorer 5.5 or higher

Mozilla 1.1.2 or higher

With Internet Explorer, display of the on-line help

may be unstable. In such a case, try refreshing the

display.

To install the remote maintenance tool

For Windows:

Run the Setup.exe under Windows/.

For UNIX (Solaris 2.6/7/8 or Red Hat Linux 7.1/8.0):

Execute the painstalll under Unix/.

For Solaris, set the environmental variables after

installation. For Red Hat Linux 7.1/8.0, setting is not

required, because the default settings installed with the

rpm package are used. However, if Netscape or JRE

has been moved to a position other than default, set the

environmental variables referring to the settings for

Solaris.

To set the environmental variables for

operation under a Solaris environment

2 Set the environmental variables BROWSER and

XAPPLRESDIR with the startup file of the on-line

help {folder where DZC-PSC2 has been installed}/

bin/webhelp as shown below.

setenv BROWSER {folder where Netscape has been

installed}/netscape

setenv XAPPLRESDIR {default setting file for

Netscape}

Example: setenv XAPPLRESDIR /usr/openwin/lib/

locale/ja/app-defaults

Note

In initial settings of webhelp, BROWSER has been

set as default of Red Hat Linux 7.1/8.0. Enter # at

the beginning of the line below to comment that

out.

#setenv BROWSER /usr/bin/netscape

To start the remote maintenance tool

To start three GUIs for the remote maintenance tool

(PetaApp Monitor GUI, PetaBack GUI, and

Monitoring & Maintenance Terminal GUI), first start

the PetaApp Monitor GUI, then start the rest from the

PetaApp Monitor GUI.

For windows:

1 Set the environmental variables JAVABIN and

NPX_PLUGIN_PATH in the setting file of the

shell as shown below.

For csh: Add the following to .cshrc.

setenv JAVABIN {folder where JRE has been

installed}/bin/java

setenv NPX_PLUGIN_PATH {folder where JRE has

been installed}/plugin/sparc/ns4

For sh: Set the environmental variables as shown

below.

JAVABIN= “{folder where JRE has been installed}/bin/

java”

export JAVABIN

NPX_PLUGIN_PATH= “{folder where JRE has been

installed}/plugin/sparc/ns4”

export NPX_PLUGIN_PATH

Note

For Red Hat Linux, enter “i386” instead of “sparc”

for NPX_PLUGIN_PATH.

To start the PetaApp Monitor GUI: Select Programs

from the Start menu, then select “PetaApp

Controller”, then “PetaApp Monitor” to start the

PetaApp Monitor GUI.

To start the Monitoring & Maintenance Terminal

GUI: Click on the PetaSite button of the PetaApp

Monitor GUI, and the Monitoring & Maintenance

Terminal GUI is activated.

To start the PetaBack GUI: Specify the URL address

of the Web browser.

Click on the PetaBack button of the PetaApp

Monitor GUI, and the Web browser is activated.

On the server PCU, the Web browser is

automatically activated with the PetaBack GUI’s

URL address. For remote operation, you need to

specify the URL address. Type the URL address

that is used to start the PetaBack GUI on the PCU.

16(E)

Page 47

For UNIX:

To start the PetaApp Monitor GUI: Enter the

command below.

%{folder where the DZC-PSC2 has been installed}/bin/

petaapp

where % is the command prompt.

The PetaApp Monitor GUI is activated.

To start the Monitoring & Maintenance Terminal

GUI: Click on the PetaSite button of the PetaApp

Monitor GUI, and the Monitoring & Maintenance

Terminal GUI is activated.

To start the PetaBack GUI: Specify the URL address

of the Web browser.

Click on the PetaBack button of the PetaApp

Monitor GUI, and the Web browser is activated.

On the server PCU, the Web browser is

automatically activated with the PetaBack GUI’s