Sony CPD-4403 Service manual

CPD-4403

SERVICE MANUAL

SPECIFICATIONS

AEP Model

Chassis No. SCC-L30N-A

(OEM STD)

Chassis No. SCC-L30Q-A

(ELSA, FORMAC)

F99

CHASSIS

TRINITRON

®

COLOR COMPUTER DISPLAY

CPD-4403

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps,

and mounting hardware have been replaced. Be absolutely

certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer and

recommend their replacement.

6. Check the line cords for cracks and abrasion. Recommend

the replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specified values.

Make sure your instruments are accurate; be suspicious of

your HV meter if sets always have low HV.

8. Check the antenna terminals, metal trim, “metallized”

knobs, screws, and all other exposed metal parts for AC

Leakage. Check leakage as described below.

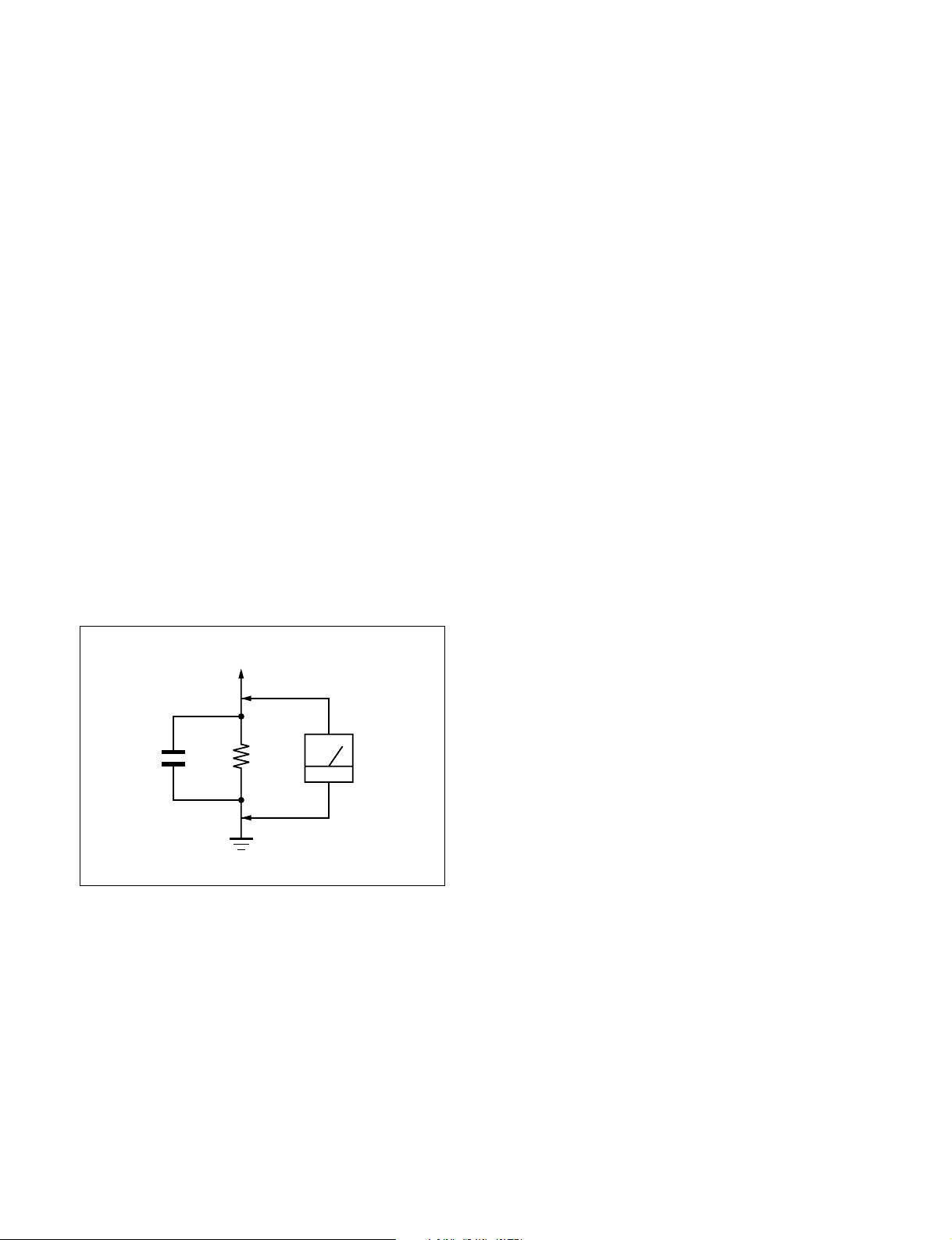

To Exposed Metal

Parts on Set

0.15 µF

1.5 k

Ω

AC

Voltmeter

(0.75 V)

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having a return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to

use these instruments.

2. A battery-operated AC milliammeter. The Data Precision

245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are

examples of a passive VOMs that are suitable. Nearly all

battery operated digital multimeters that have a 2 V AC

range are suitable. (See Fig. A)

WARNING!!

NEVER TURN ON THE POWER IN A CONDITION IN

WHICH THE DEGAUSS COIL HAS BEEN REMOVED.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

¡ ON THE SCHEMATIC DIAGRAMS, EXPLODED

VIEWS AND IN THE PARTS LIST ARE CRITICAL FOR

SAFE OPERATION. REPLACE THESE COMPONENTS

WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE CRITICAL FOR SAFE OPERATION

ARE IDENTIFIED IN THIS MANUAL. FOLLOW THESE

PROCEDURES WHENEVER CRITICAL COMPONENTS

ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

– 2 –

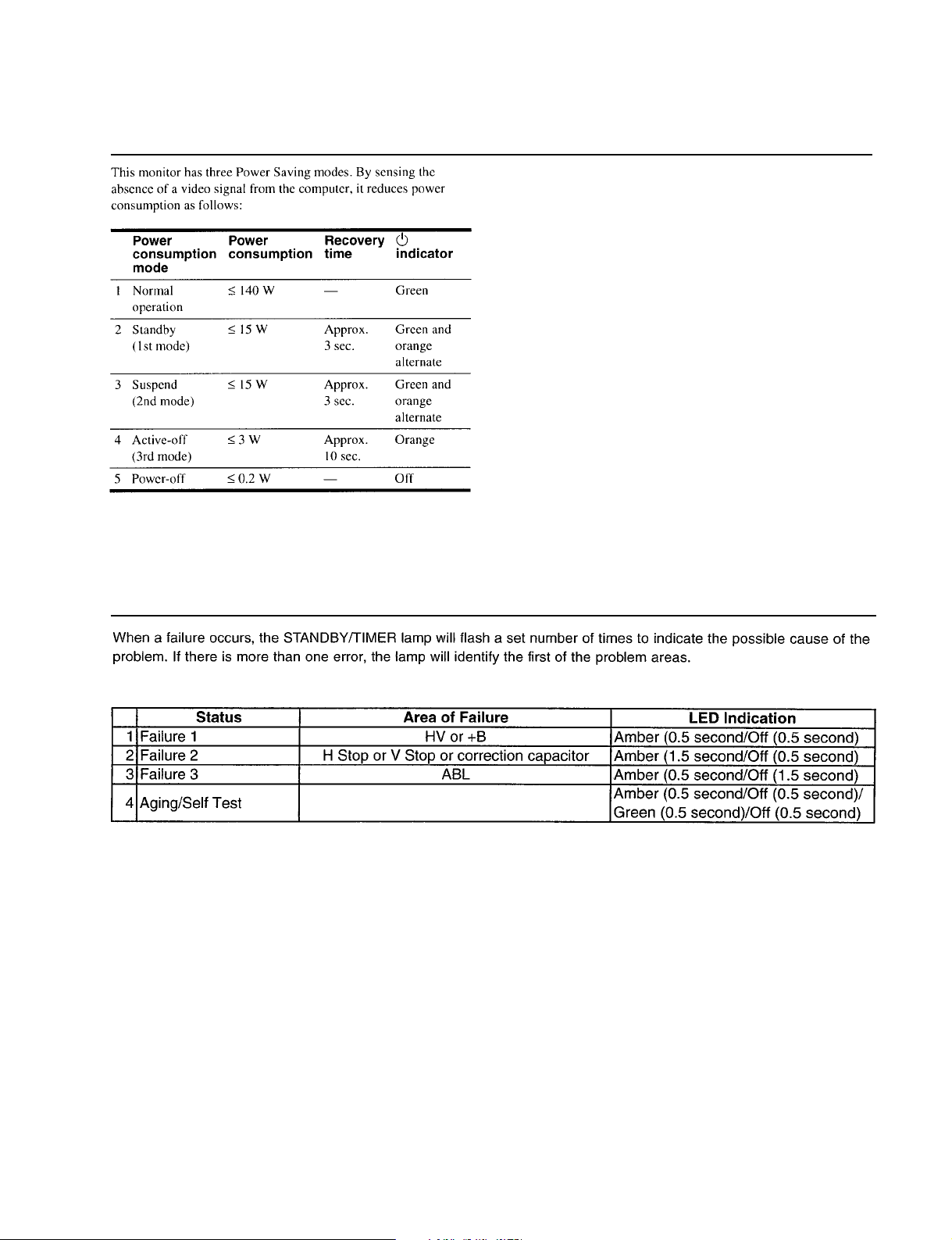

POWER SAVING FUNCTION

CPD-4403

DIAGNOSIS

– 3 –

CPD-4403

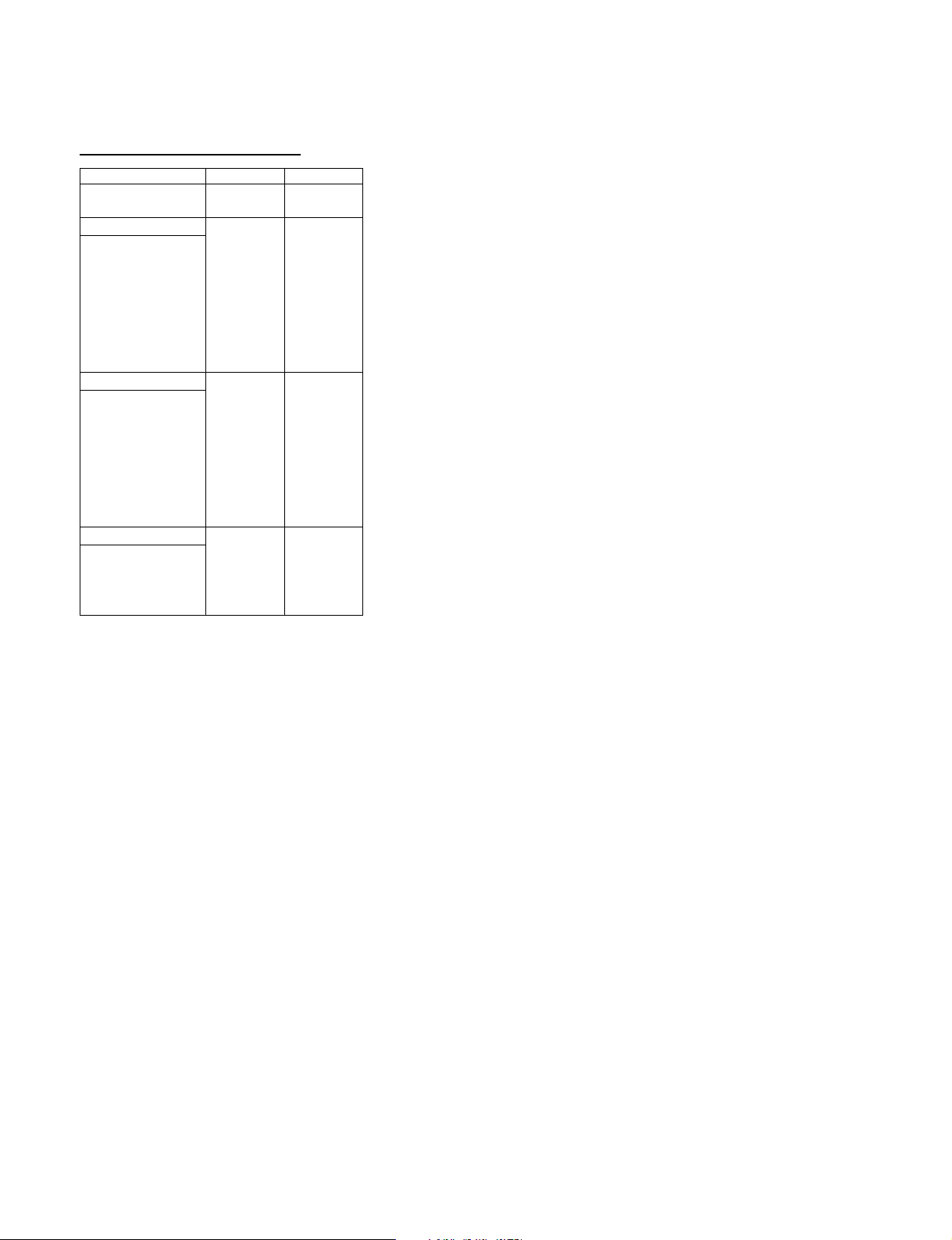

TIMING SPECIFICATION

MODE AT PRODUCTION MODE 1 MODE 2

RESOLUTION 738 X 414 1600 X 1200

CLOCK 28.322 MHz 202.500 MHz

HORIZONTAL

H-FREQ 31.469 kHz 93.750 kHz

usec usec

H. TOTAL 31.777 10.667

H. BLK 5.720 2.765

H. FP 0.318 0.316

H. SYNC 3.813 0.948

H. BP 1.589 1.501

H. ACTIV 26.057 7.901

– VERTICAL –

V. FREQ(HZ) 70.087 Hz 75.000 Hz

lines lines

V. TOTAL 449 1250

V. BLK 35 50

V. FP 5 1

V. SYNC 2 3

V. BP 28 46

V. ACTIV 414 1200

– SYNC –

INT(G) NO NO

EXT(H/V)/POLARITY YES N/P YES P/P

EXT(CS) /POLARITY NO NO

INT/NON INT NON INT NON INT

99.10.26 VER.

– 4 –

TABLE OF CONTENTS

Section Title Page

1. GENERAL ................................................................. 1-1

2. DISASSEMBLY

2-1. Cabinet Removal ................................................ 2-1

2-2. Shield (EMI, Video),

Side Cover (L and R) Removal.......................... 2-1

2-3. A Board Removal ............................................... 2-2

2-4. Rear Shield Complete Assy,

D Board Removal ............................................... 2-2

2-5. Service Position .................................................. 2-3

2-6. H Board Removal ............................................... 2-3

2-7. Picture Tube Removal........................................ 2-4

2-8. Harness Location ................................................ 2-5

3. SAFETY RELATED ADJUSTMENT............. 3-1

CPD-4403

4. ADJUSTMENTS ..................................................... 4-1

5. DIAGRAMS

5-1. Block Diagrams .................................................. 5-1

5-2. Frame Schematic Diagram ................................. 5-5

5-3. Circuit Boards Location ..................................... 5-6

5-4. Schematic Diagrams and Printed Wiring

Boards ................................................................. 5-7

(1) Schematic Diagram of A Board......................... 5-9

(2) Schematic Diagrams of D (a,b,c) Board.... 5-11

(3) Schematic Diagrams of N, H Boards................. 5-19

5-5. Semiconductors .................................................. 5-21

6. EXPLODED VIEWS

6-1. Chassis ................................................................ 6-1

6-2. Picture Tube........................................................ 6-2

6-3. Packing Materials ............................................... 6-3

7. ELECTRICAL PARTS LIST ............................ 7-1

– 5 –

1-1

The operating instructions mentioned here are partial abstracts

from the Operating Instruction Manual. The page numbers of

the Operating Instruction Manual remain as in the manual.

SECTION 1

GENERAL

1-2

1-3

1-4

1-5

SECTION 2

DISASSEMBLY

CPD-4403

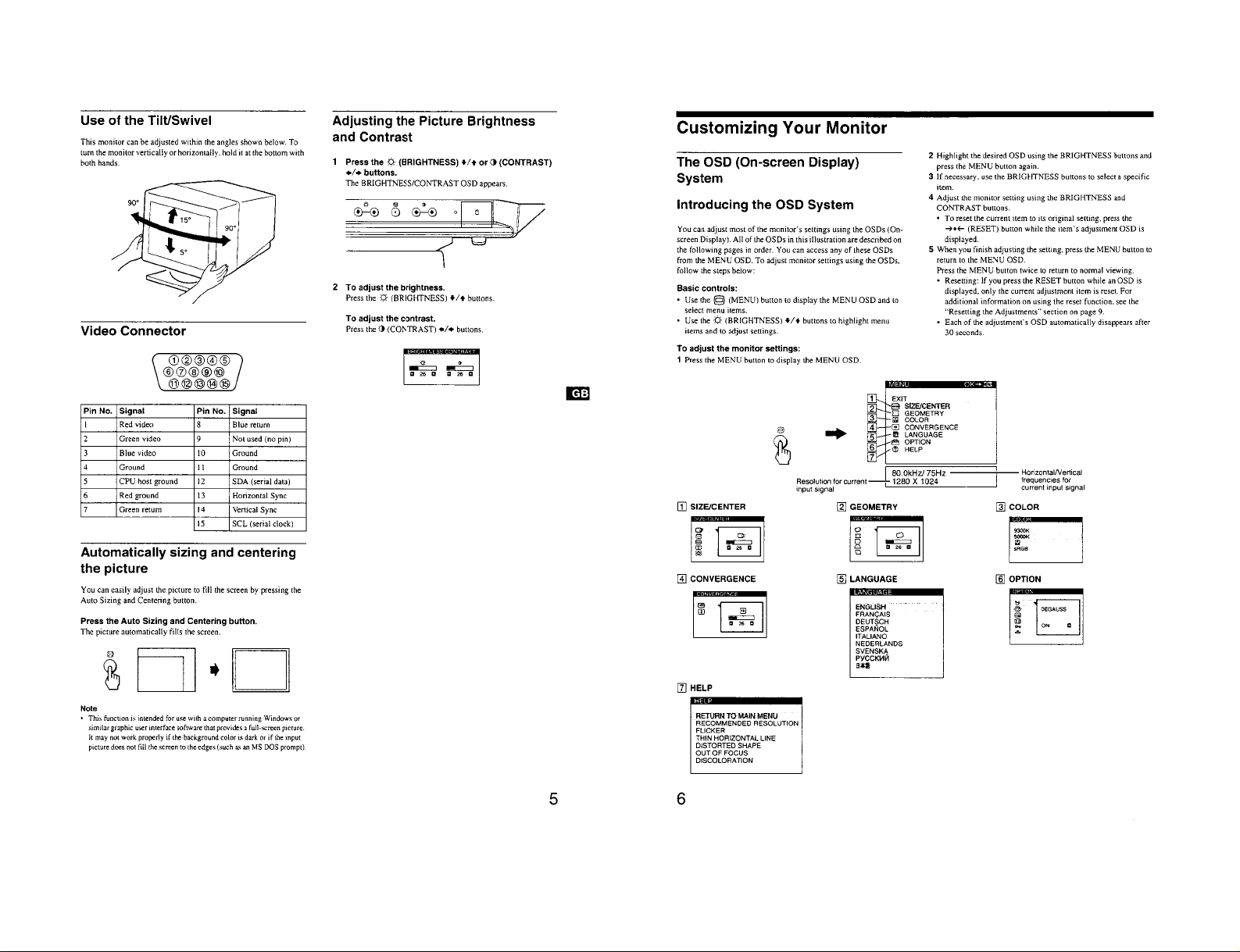

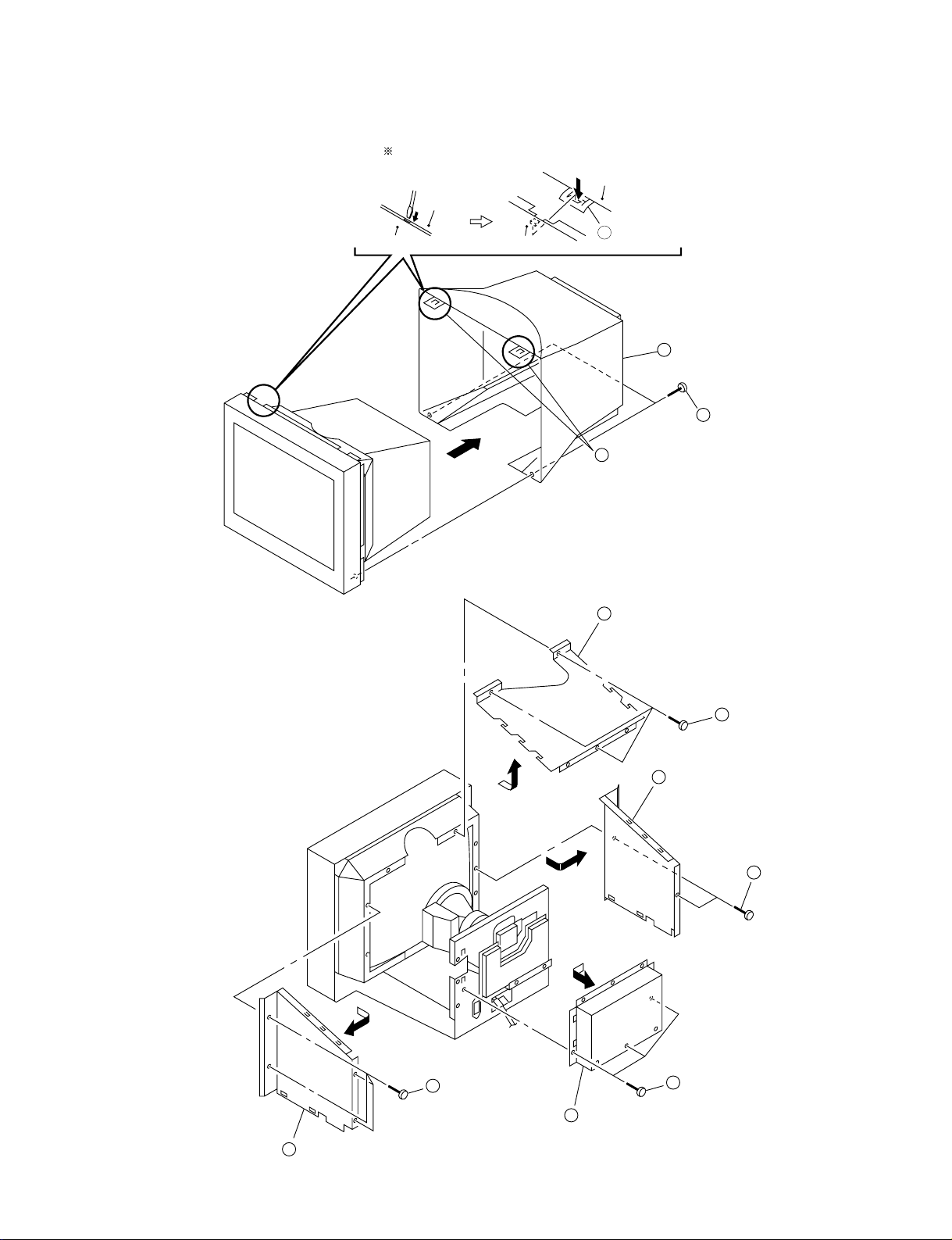

2-1. CABINET REMOVAL

Push in the tip of a screwdriver about

5mm to unlock the two claws.

Cabinet

Bezel assembly

Bezel assembly

Cabinet

1

Two claws

1

Two claws

3

Cabinet

2

Two screws

(+BVTP 4 x 16)

2-2. SHIELD (EMI, VIDEO),

SIDE COVER (L and R) REMOVAL

2

EMI shield (Upper)

4

Side cover (L)

1

Three screws

(+BVTT 4 x 8)

3

Two screws

(+BVTT 4 x 8)

6

Side cover (R)

5

Four screws

(+BVTT 4 x 8)

2-1

8

Video shield

7

Three screws

(+BVTT 4 x 8)

CPD-4403

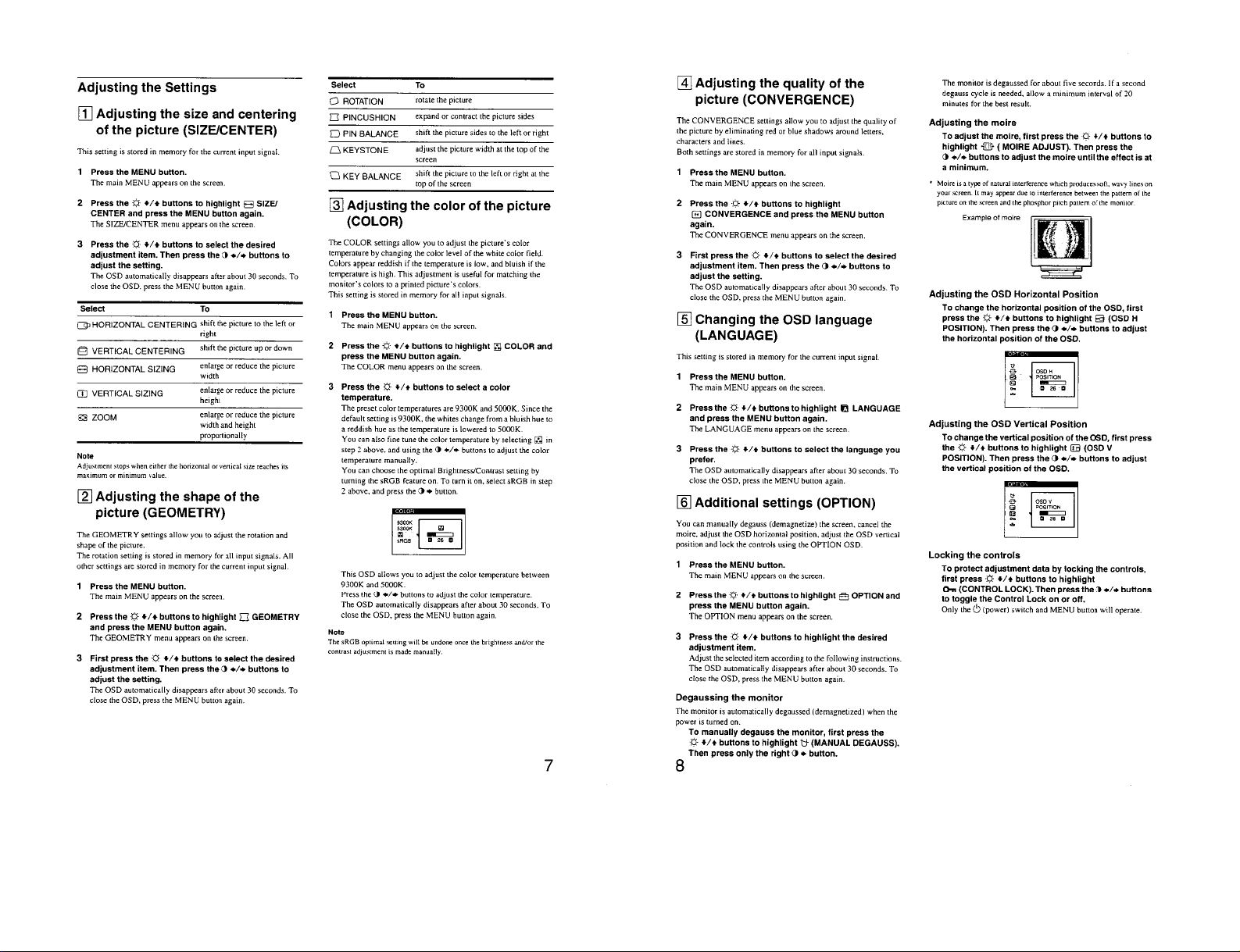

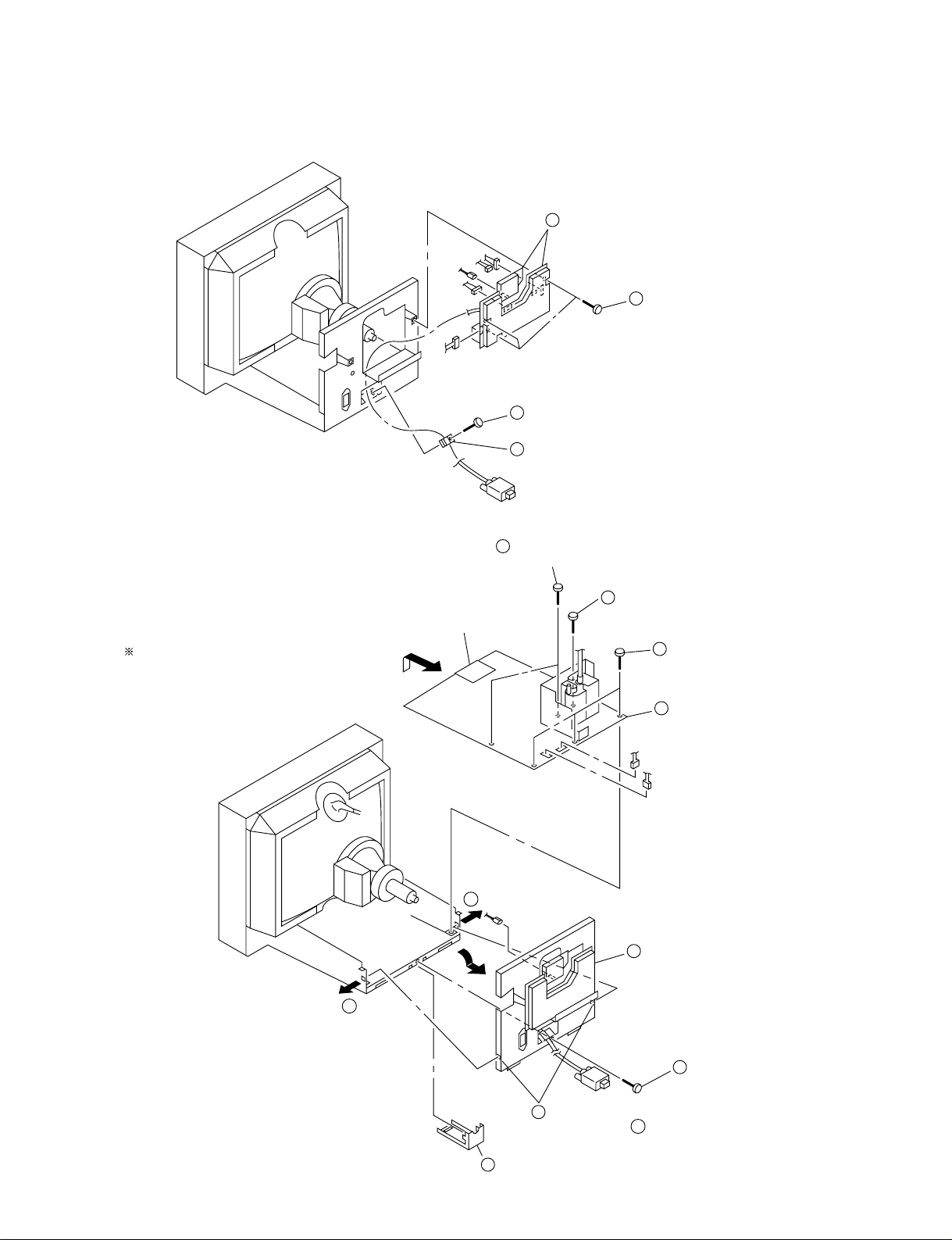

2-3. A BOARD REMOVAL

CN303

CN309

CN306

CN311

CN305

4

A board

1

Screw

(+BVTT 4 x 8)

2

Cable stopper

3

Three screws

(+BVTT 3 x 8)

2-4. REAR SHIELD COMPLETE ASSY,

D BOARD REMOVAL

Refering to 2-3, disconnect five connectors

(CN303, CN305, CN306, CN309 and CN311).

N board

A

7

Two screws

(+BVTP 3 x 8)

CN303

6

Screw

(+P 3.5 x 20)

5

Three screws

(+BVTT 3 x 8)

8

D board

CN601

CN600

4

Rear shield

complete assembly

A

2

Screw

(+BVTT 4 x 8)

3

Widening the chassis toward

the direction A , disengage

two claws.

1

Cable cover

2-2

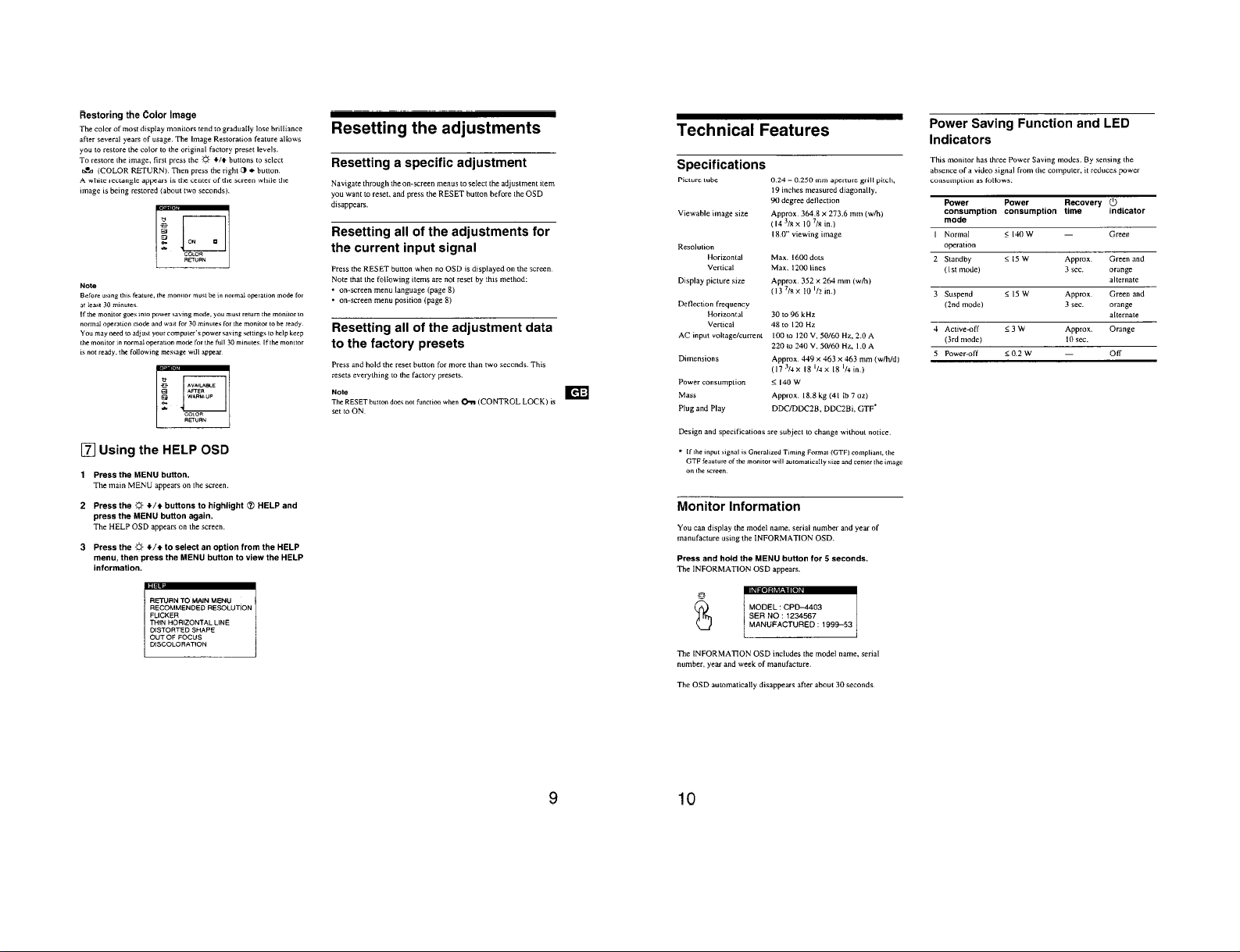

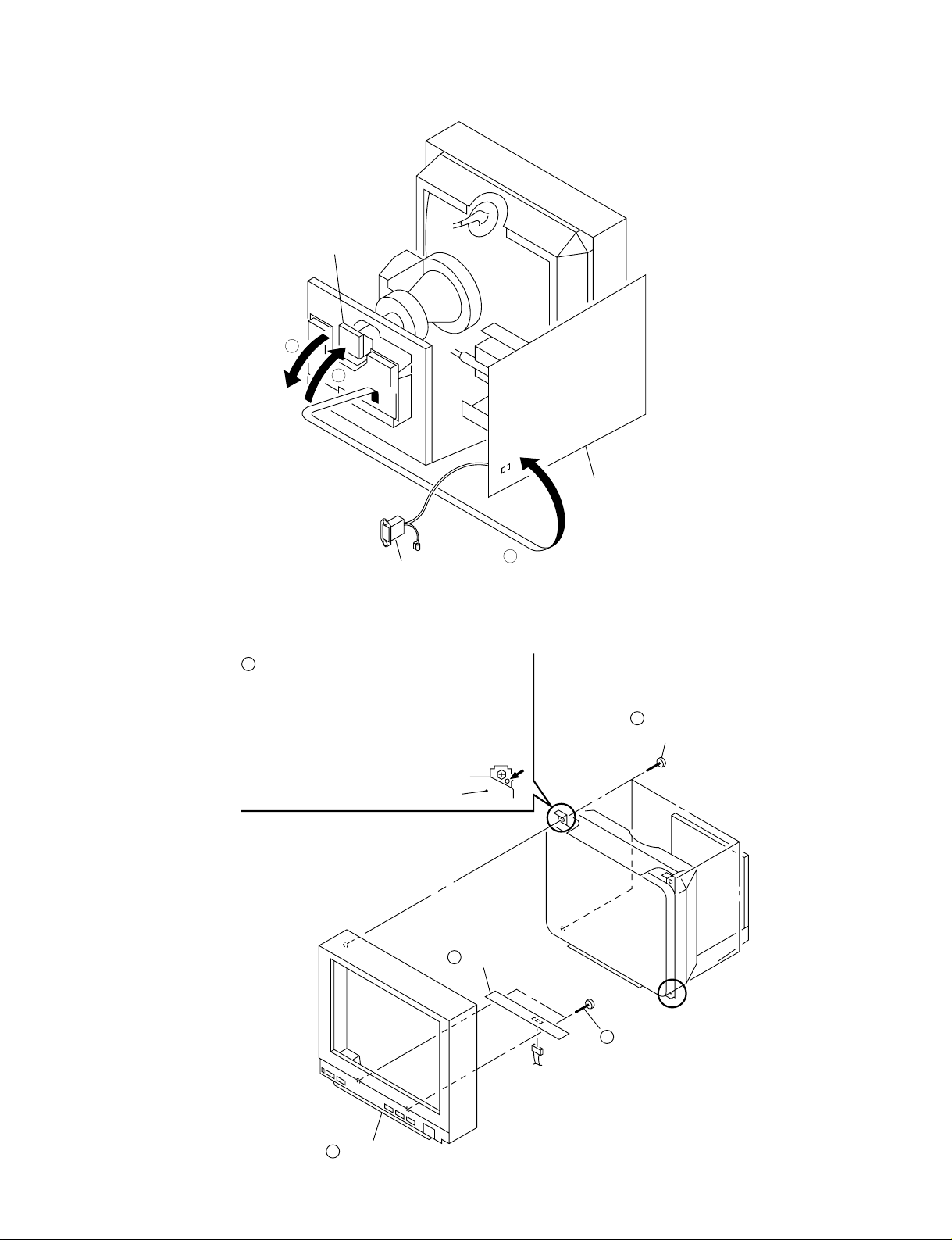

2-5. SERVICE POSITION

1

CPD-4403

A board

3

D board

2-6. H BOARD REMOVAL

1

Before removing the bezel assembly,

secure the picture tube shield at the

positions shown with the arrow (diagonal

two places) to prevent the picture tube

from falling. (Use the screws +BVTT4x8

that fix shield.)

AC inlet

Picture tube shield

5

H board

2

2

Four screws

(Tapping screw(5))

3

Bezel assembly

2-3

CN801

4

Two screws

(+ BVTP 3 x 8)

CPD-4403

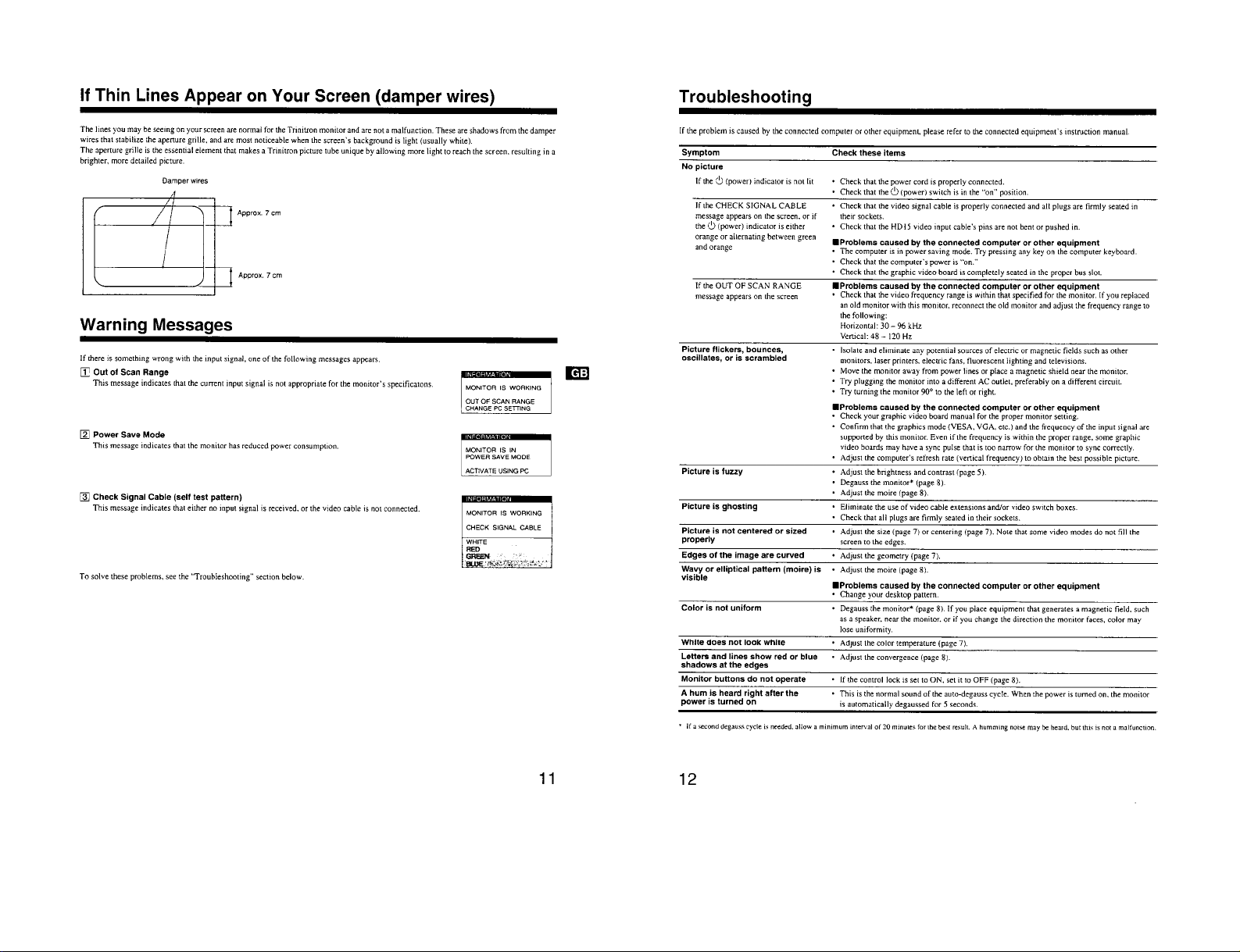

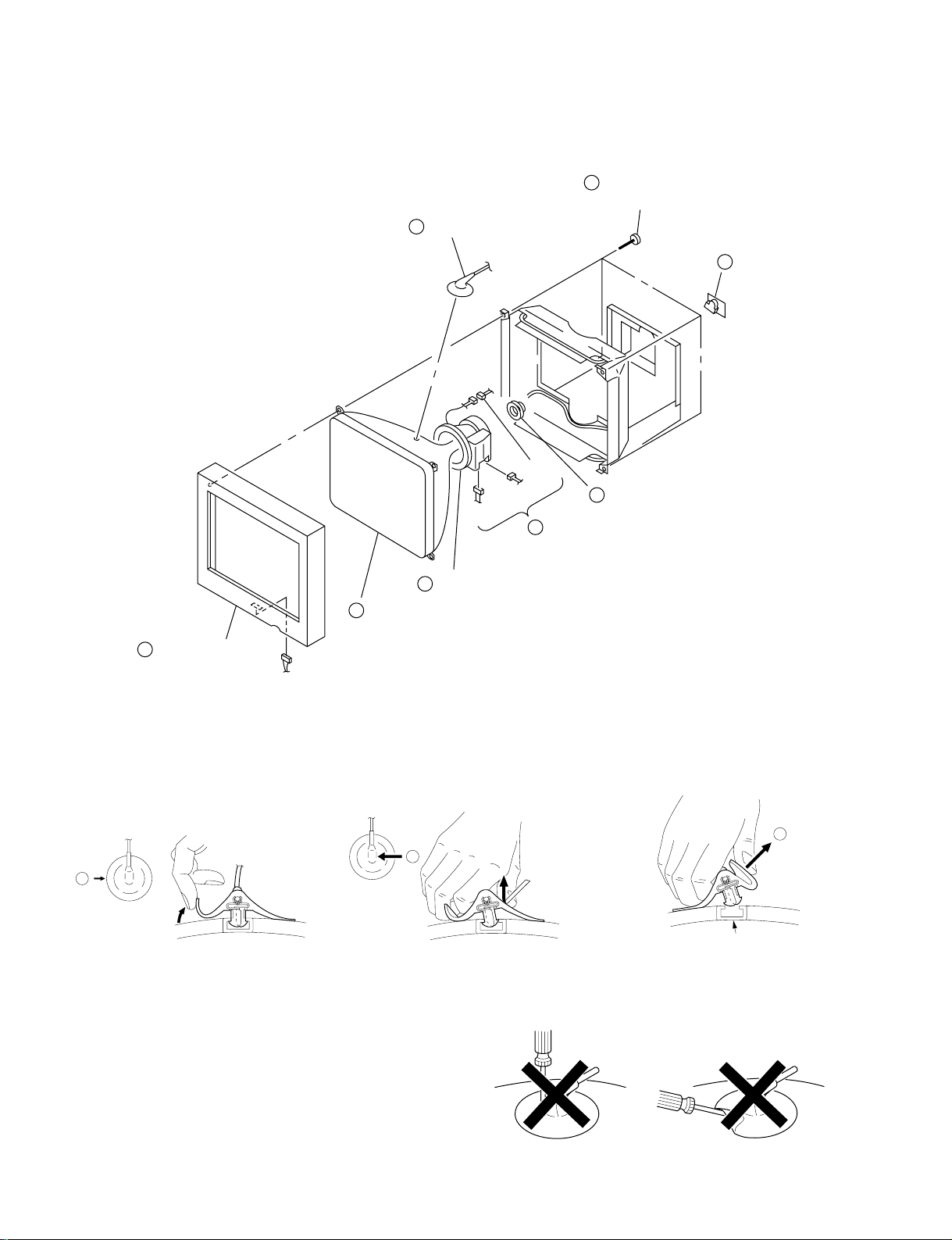

2-7. PICTURE TUBE REMOVAL

1

Anode cap

CN11

4

Four screws

(Tapping screw (5))

2pin

CN1

3

Three connectors

7

Neck assembly

2

A board

8

Deflection yoke

6

Picture tube

5

Bezel assembly

CN801

• REMOVAL OF ANODE-CAP

NOTE: Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield or carbon painted on the CRT, after

removing the anode.

• REMOVING PROCEDURES

c

b

a

Anode Button

1 Turn up one side of the rubber cap in

the direction indicated by the arrow a.

2 Using a thumb pull up the rubber cap

firmly in the direction indicated by the

arrow b.

• HOW TO HANDLE AN ANODE-CAP

1 Don’t scratch the surface of anode-caps with sharp shaped

material!

2 Don’t press the rubber hardly not to damage inside of anode-

caps!

A material fitting called as shatter-hook terminal is built in the

rubber.

3 Don’t turn the foot of rubber over hardly!

The shatter-hook terminal will stick out or damage the rubber.

3 When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling up it in the

direction of the arrow c.

2-4

Loading...

Loading...