Sony CFDS-47-L Service manual

CFD-S45L/S47L

MICROFILM

SERVICE MANUAL

Ver 1.1 2000. 04

With SUPPLEMENT-1

(9-924-966-81)

Photo: CFD-S47L

CD

Section

TC

Section

AEP Model

UK Model

Model Name Using Similar Mechanism NEW

CD Loading Mechanism Type FLM-S47-149

CD Mechanism Type KSM-213CCP

Optical Pick-up Name KSS-213C

Model Name Using Similar Mechanism CFD-V10

Tape Transport Mechanism Type MF-V10-117

CD player section

System

Compact disc digital audio system

Laser diode properties

Material: GaAlAs

Wave length: 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a distance of

about 200 mm from the objective lens surface on

the optical pick-up block with 7 mm aperture.)

Spindle speed

200 r/min (rpm) to 500 r/min (rpm) (CLV)

Number of channels

2

Frequency response

20 - 20,000 Hz +1/–2 dB

Wow and flutter

Below measurable limit

Radio section

Frequency range

FM 87.6 - 107 MHz

MW 531 - 1,602 kHz

LW 153 - 279 kHz

IF

FM: 10.7 MHz

MW/LW: 450 kHz

Aerials

FM: Telescopic aerial

MW/LW: Built-in ferrite bar aerial

SPECIFICATIONS

Cassette-corder section

Recording system

4-track 2 channel stereo

Fast winding time

Approx. 150 sec. with Sony cassette C-60

Frequency response

TYPE I (normal): 80 - 10,000 Hz

General

Speaker

Full range: 8 cm (3 1/4 in.) dia.,

6 ohms, cone type (2)

Outputs

Headphones jack (stereo minijack)

For 16 - 68 ohms impedance headphones

Maximum power output

4.5 W + 4.5 W

Power requirements

For CD radio cassette-corder:

230 V AC, 50 Hz

9 V DC, 6 R20 (size D) batteries

For memory back-up:

6 V DC, 4 R6 (size AA) batteries

For remote control (CFD-S47L only):

3 V DC, 2 R6 (size AA) batteries

Power consumption

AC 25 W

– Continued on next page –

CD RADIO CASSETTE-CORDER

– 1 –

Battery life

For CD radio cassette-corder:

FM recording

Sony R20P: approx. 3.5 h

Sony alkaline LR20: approx. 10 h

Tape playback

Sony R20P: approx. 1.5 h

Sony alkaline LR20: approx. 5 h

CD playback

Sony R20P: approx. 1 h

Sony alkaline LR20: approx. 4 h

Dimensions

Approx. 420 × 177 × 281 mm (w/h/d)

(16 5/8 × 7 × 11 1/8 inches) (incl. projecting parts)

Mass

Approx. 5.1 kg (11 lb. 4 oz.) (incl. batteries)

Supplied accessories

AC power cord (1)

Remote control (RMT-CS47A) (1)

(CFD-S47L only)

Design and specifications are subject to change without

notice.

This Compact Disc player is

classified as a CLASS 1

LASER product.

The CLASS 1 LASER

PRODUCT label is located

on the bottom exterior.

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair , pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

P ART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

TABLE OF CONTENTS

1. GENERAL

Playing a CD ........................................................................... 4

Listening to the radio...............................................................4

Playing a tape ..........................................................................5

Recording on a tape ................................................................. 5

2. DISASSEMBLY

2-1. Cabinet (Front) Assy ........................................................... 6

2-2. Power Board ........................................................................6

2-3. Cabinet (Upper) Assy.......................................................... 7

2-4. CD Mechanism Block ......................................................... 7

2-5. Tuner Board.........................................................................8

2-6. SW (L) Board, SW (R) Board............................................. 8

2-7. Main Board ......................................................................... 9

2-8. SW (Top) Board, Record/Playback Switch Board,

Headphone Board ................................................................ 9

2-9. Cassette Mechanism Block ............................................... 10

2-10. Chuck Plate Assy .............................................................. 10

2-11. Tray ................................................................................... 11

2-12. Loading Board................................................................... 11

2-13. CD Board .......................................................................... 12

2-14. CD Mechanism Block ....................................................... 12

3. MECHANICAL ADJUSTMENTS............................... 13

4. ELECTRICAL ADJUSTMENTS

Tape Section .......................................................................... 13

Tuner Section.........................................................................14

CD Section ............................................................................ 15

5. DIAGRAMS

5-1. IC Pin Description............................................................. 16

5-2. Circuit Boards Location .................................................... 18

5-3. Block Diagram – CD Section –......................................... 19

5-4. Block Diagram – Main Section – ......................................21

5-5. Printed Wiring Board – Tuner Section – ........................... 24

5-6. Schematic Diagram – Tuner Section –.............................. 25

5-7. Printed Wiring Boards – CD Section – ............................. 27

5-8. Schematic Diagram – CD Section –.................................. 29

5-9. Printed Wiring Boards – Main Section – .......................... 32

5-10. Schematic Diagram – Main Section (1/2) – ......................35

5-11. Schematic Diagram – Main Section (2/2) – ......................38

6. EXPLODED VIEWS

6-1. Cabinet (Front) Section ..................................................... 44

6-2. Cabinet (Upper) Section.................................................... 45

6-3. CD Chassis Section ........................................................... 46

6-4. Tape Mechanism Deck Section-1......................................47

6-5. Tape Mechanism Deck Section-2......................................48

6-6. Optical Pick-up Section .................................................... 49

7. ELECTRICAL PARTS LIST......................................... 50

– 3 –

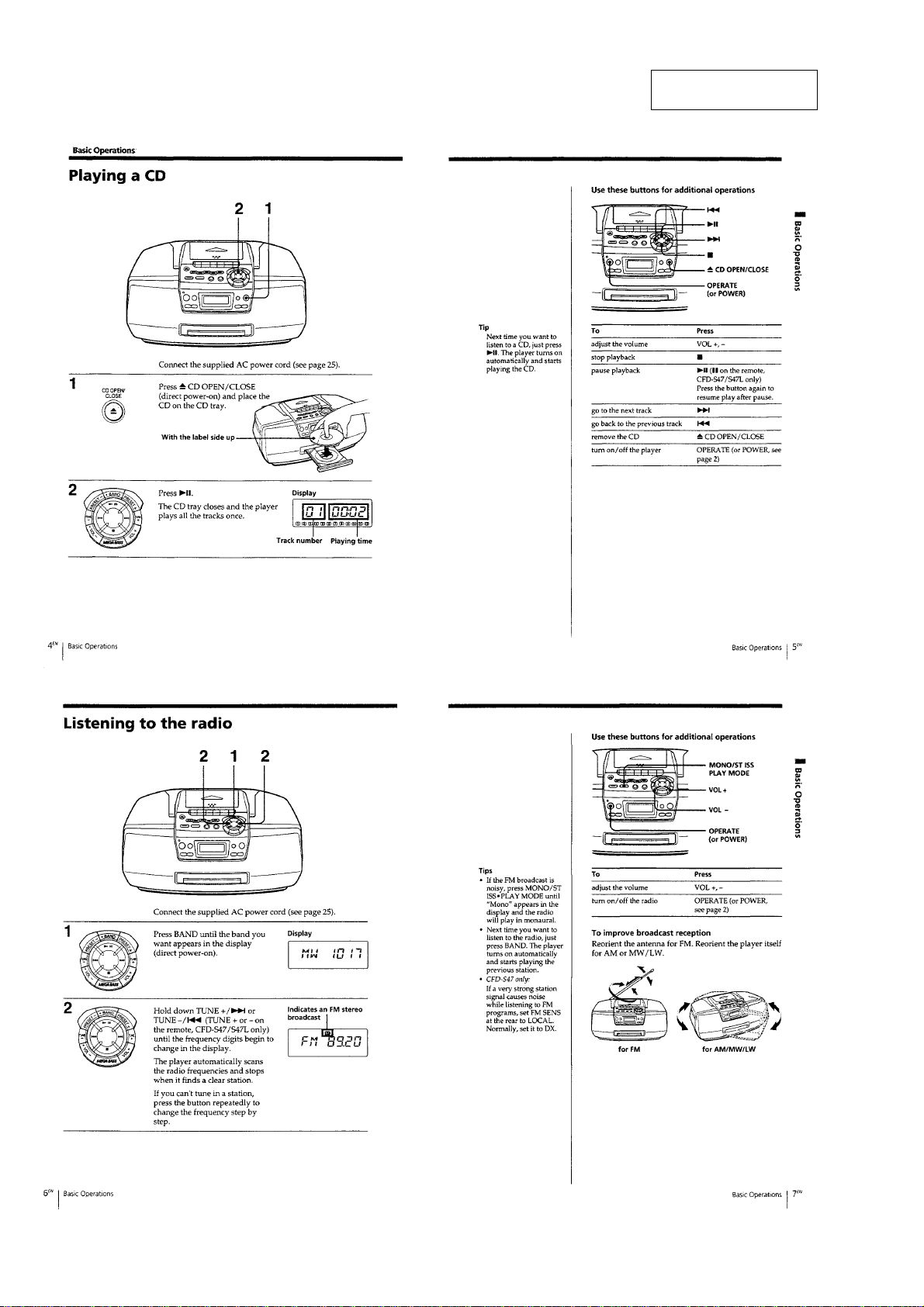

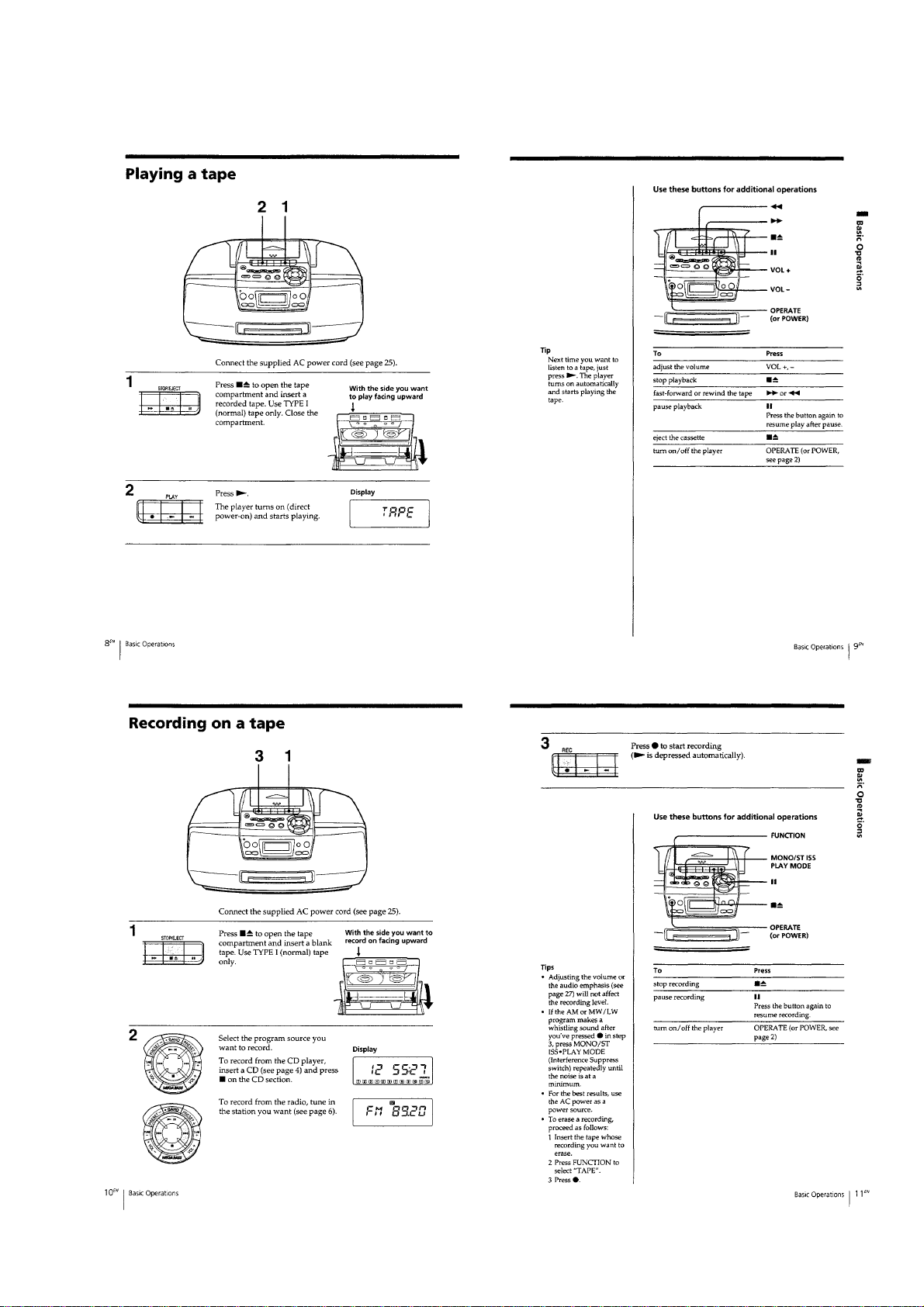

SECTION 1

GENERAL

This section is extracted

from instruction manual.

– 4 –

– 5 –

SECTION 2

DISASSEMBLY

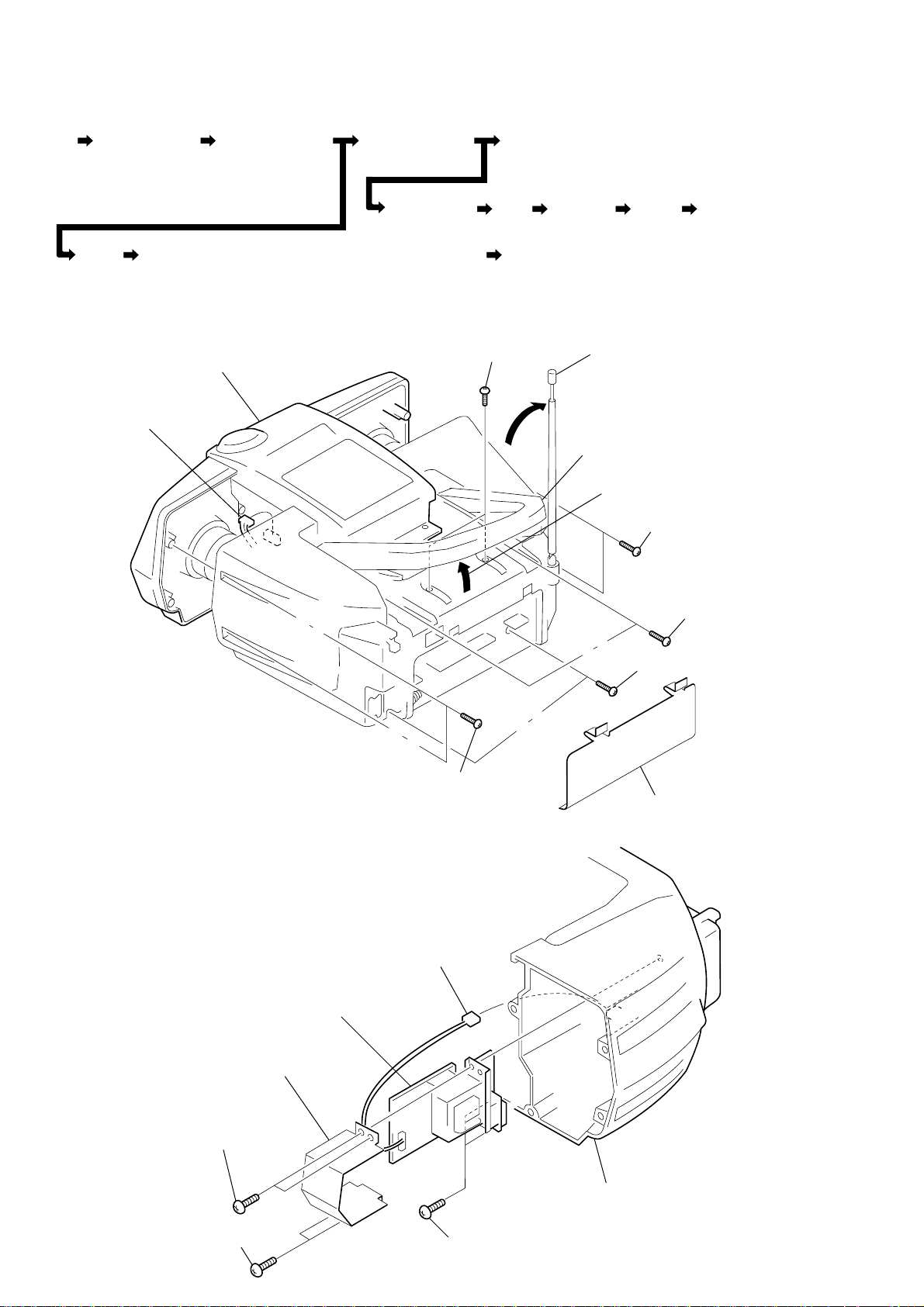

• The equipment can be removed using the following procedure.

Set Cabinet (front)

assy

Cabinet (upper)

assy

CD mechanism

block

SW (L) board,

SW (R) board

Chuck plate

assy

Main

board

Note : Follow the disassembly procedure in the numerical order given.

SW (TOP) board, Record/Playback switch board,

Headphone board

2-1. CABINET (FRONT) ASSY

0 cabinet (front) assy

9 CNP302

Tray Loading

board

Cassette mechanism

block

3 P 3x14

1 telescopic antenna

handle

CD

board

2 Pull the handle up

approx. 30˚.

5 P 3x14

CD mechanism

block

7 P 3x14

2-2. POWER BOARD

8 P 3x14

6 P 3x14

4 battery case lid

1 CNP901

6 POWER board

5 shield plate (transformer)

4 BVTP 3x10

3 BVTP 3x10

cabinet (rear) assy

2 BVTP 3x10

– 6 –

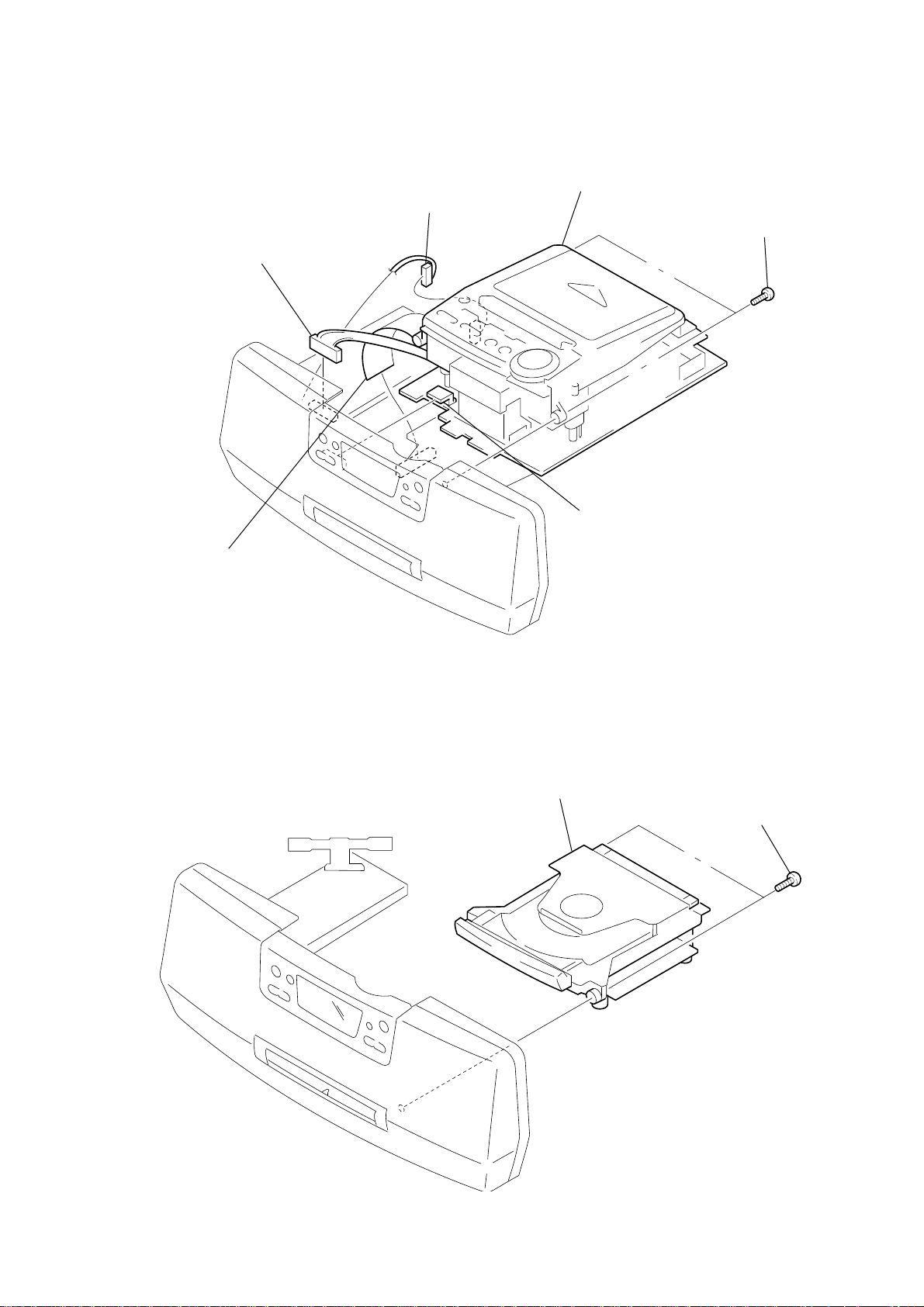

2-3. CABINET (UPPER) ASSY

0

1 CNP1

3 CNP702

6 cabinet (upper) assy

2 CNP307

4 BVTP 3x1

5 CNP601

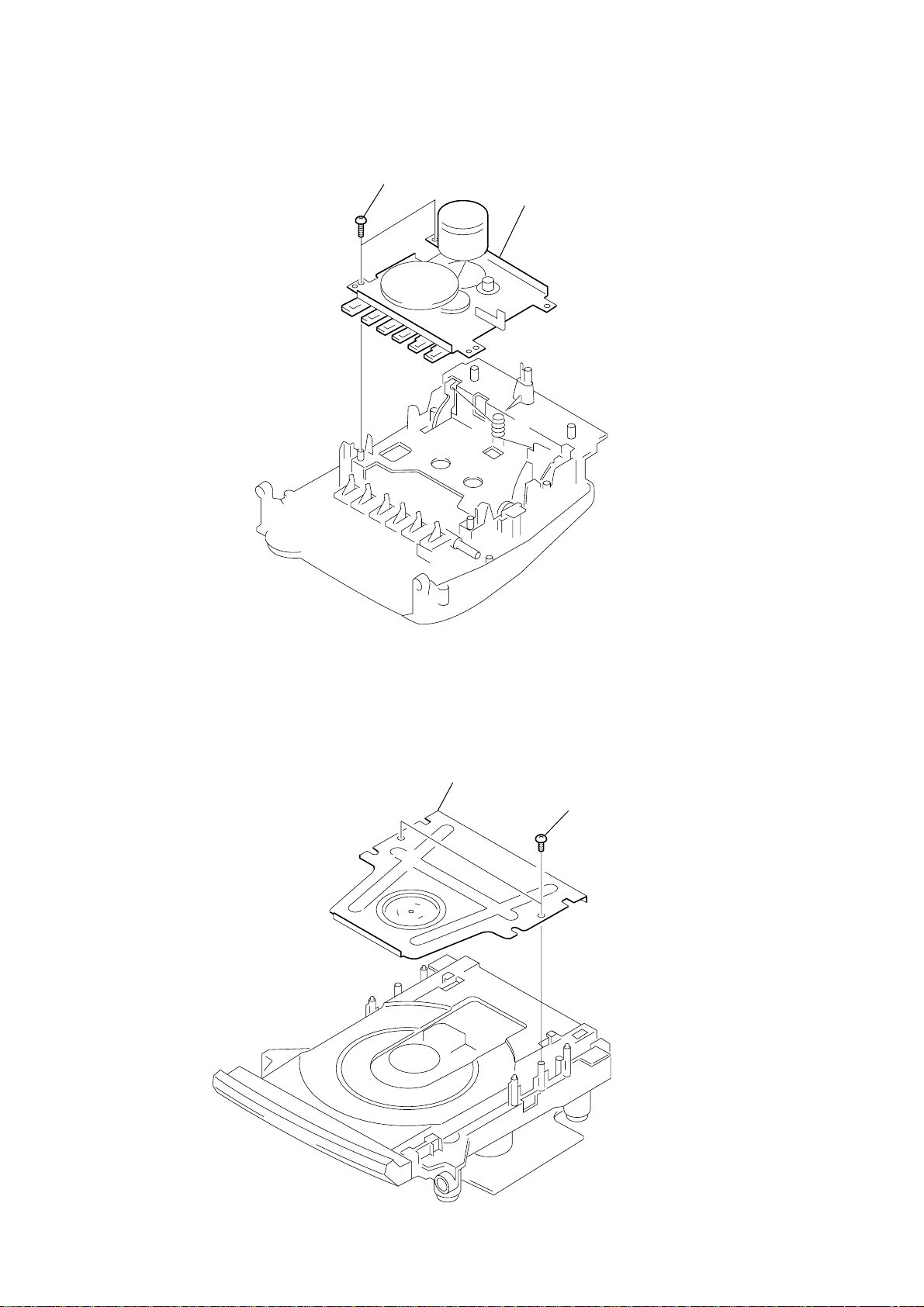

2-4. CD MECHANISM BLOCK

2 CD mechanism block

1 BVTP 3x10

– 7 –

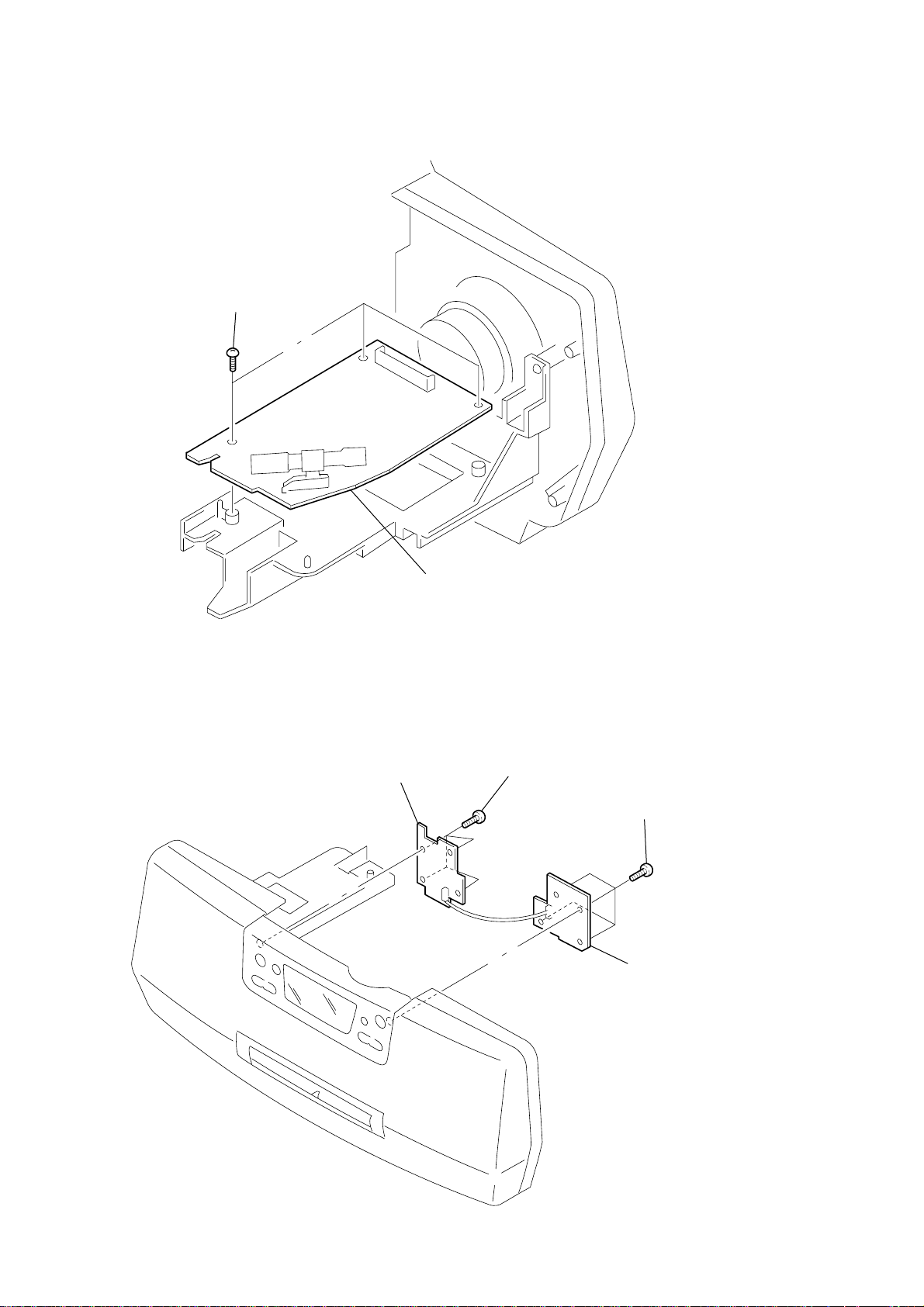

2-5. TUNER BOARD

8

1 BVTP 3x8

2-6. SW (L) BOARD, SW (R) BOARD

2 TUNER board

2 SW (L) board

1 BVTP 2.6x8

3 BVTP 2.6x

4 SW (R) board

– 8 –

2-7. MAIN BOARD

6

5

4 CNP503

6 BVTP 3x10

7 BVTP 3x10

8 BVTP 3x10

9 MAIN board

1 CNP30

2 CNP301

3 CNP30

5 CNP303

2-8. SW (TOP) BOARD, RECORD/PLAYBACK SWITCH BOARD, HEADPHONE BOARD

2 chassis (PWB)

!™ HEADPHONE board

1 BVTP 3x10

4 BVTP 2.6x8

3 BVTP 2.6x8

5 SW (TOP) board

0 BVTP 2.6x8

!¡ H/P SUB board

6 BVTP 3x10

7 RECORD/PLAYBACK

SWITCH board

8 BVTP 3x10

9 chassis (REC)

– 9 –

2-9. CASSETTE MECHANISM BLOCK

k

1 BVTP 3x10

2 cassette mechanism bloc

2-10. CHUCK PLATE ASSY

2 chuck plate assy

1 P 2.6x8

– 10 –

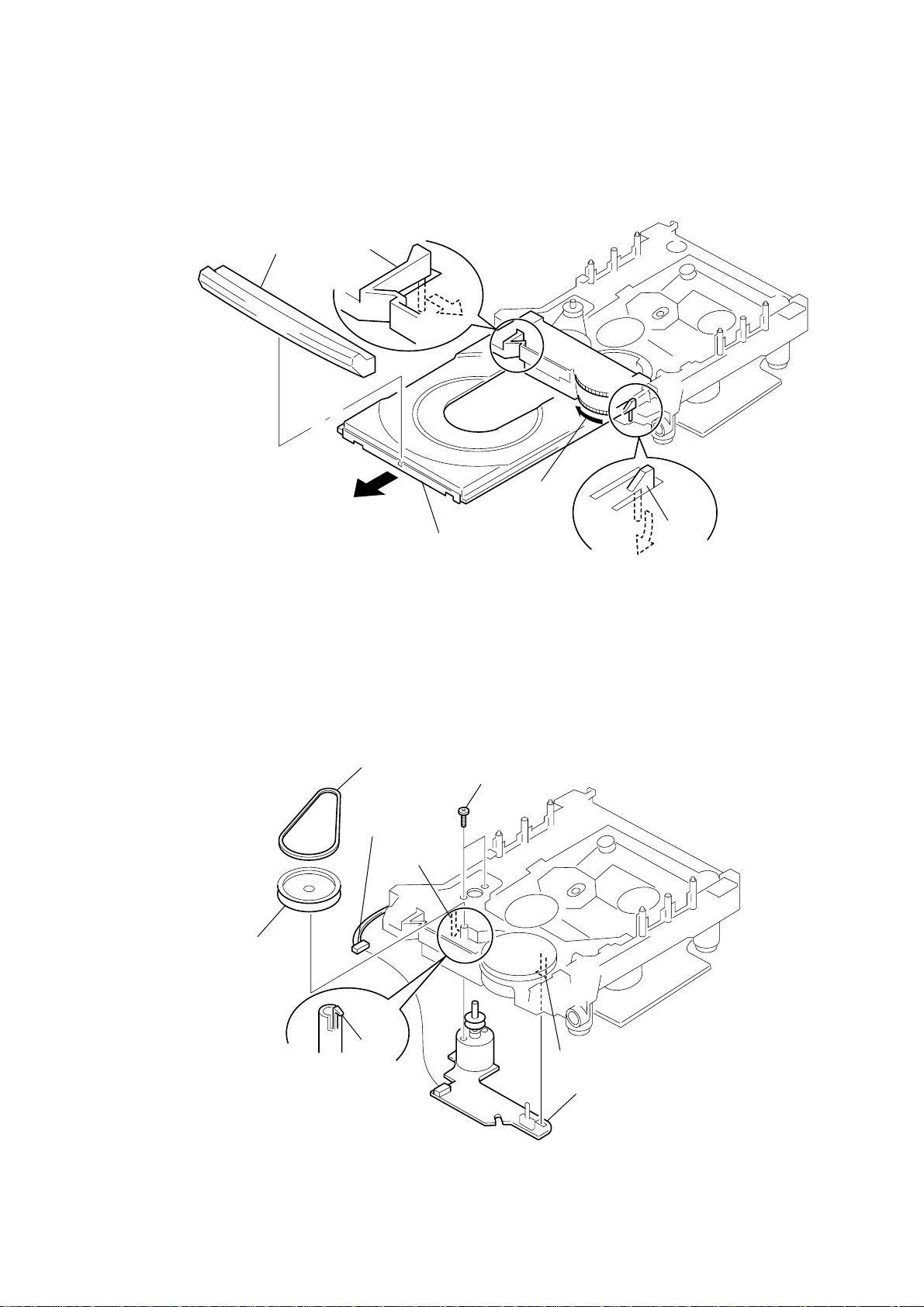

2-11. TRAY

6 lid (CD)

2 claw

1

4

3 claw

5 tray

2-12. LOADING BOARD

3 pulley

1 belt

4 connector

2 claw

5 B 2x3

6 claw

7 claw

8 LOADING board

– 11 –

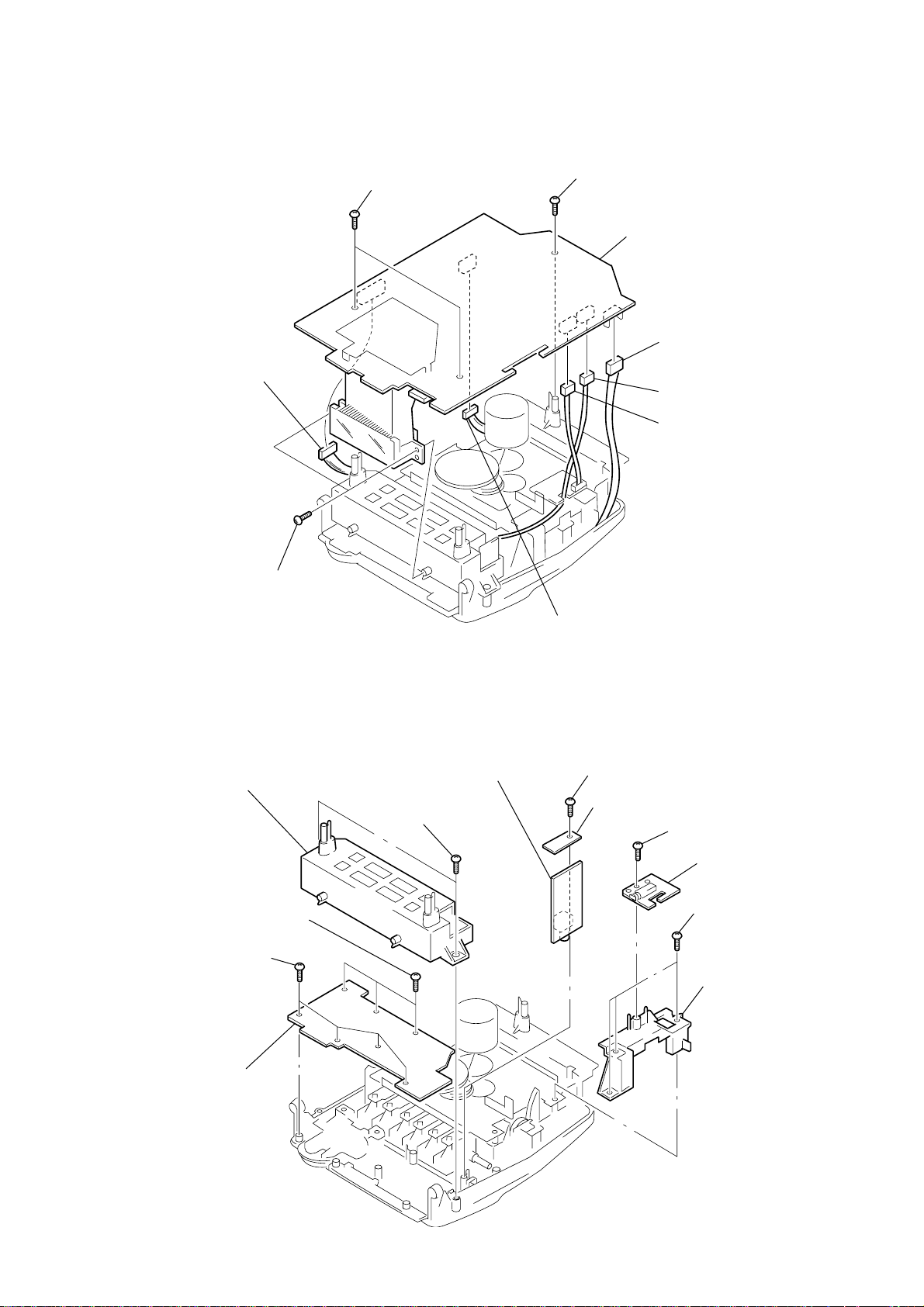

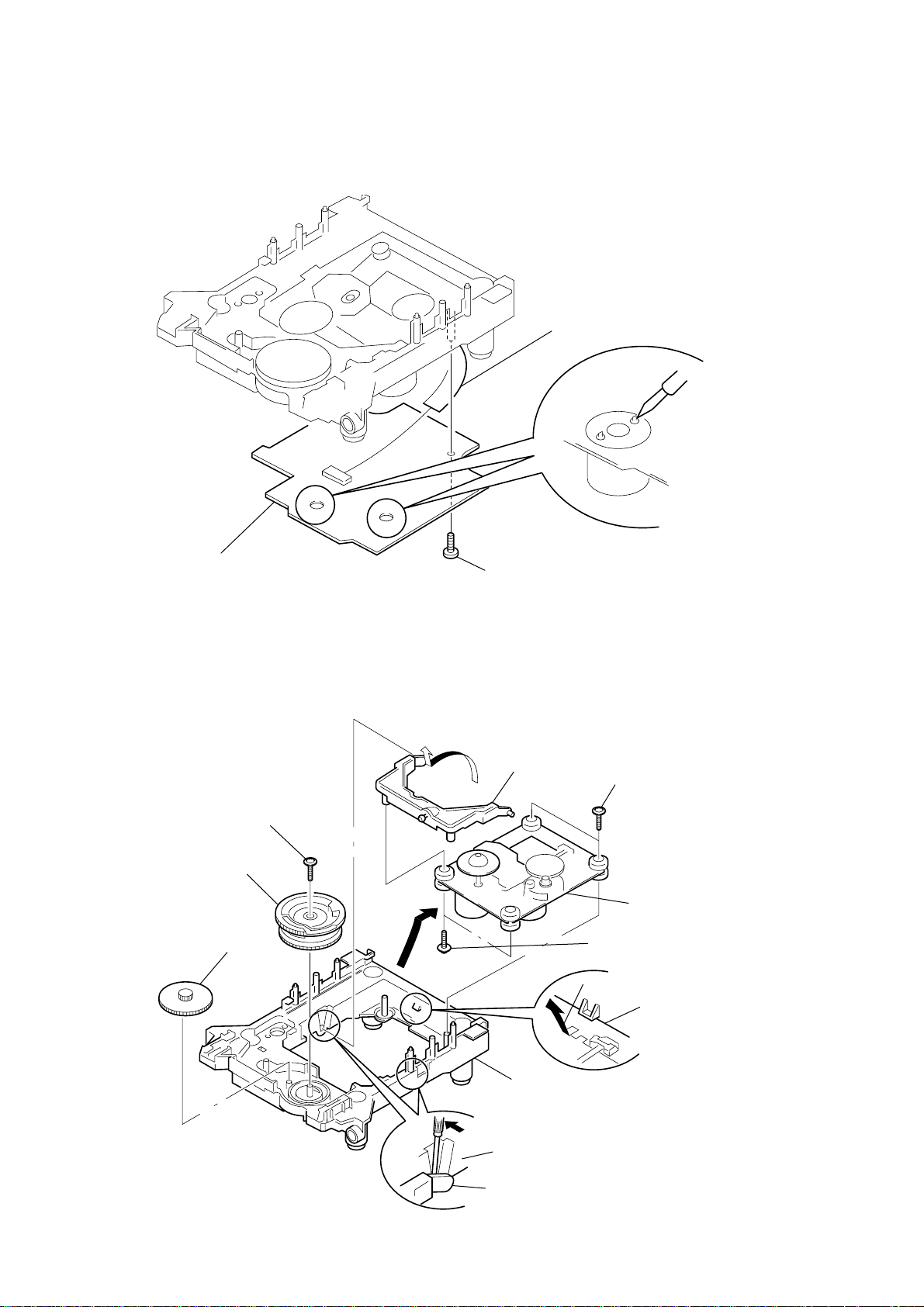

2-13. CD BOARD

k

3 CNP701

1 Removal the

four solders.

4 CD board

2 P 2x6

2-14. CD MECHANISM BLOCK

2 drive gear

3 gear

1 PWH 2.6x10

7

9

0 arm

chassis

4 PWH 2.6x10

!¡ CD mechanism bloc

8 PWH 2.6x10

5

CD mechanism block

– 12 –

6

chassis

arm

phones jack

set

32 Ω

test tape

WS-48A

(3 kHz, 0 dB)

digital frequency

counter

SECTION 3

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback head pinch roller

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagne-

tizer. (Do not bring the head magnetizer close to the erase head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

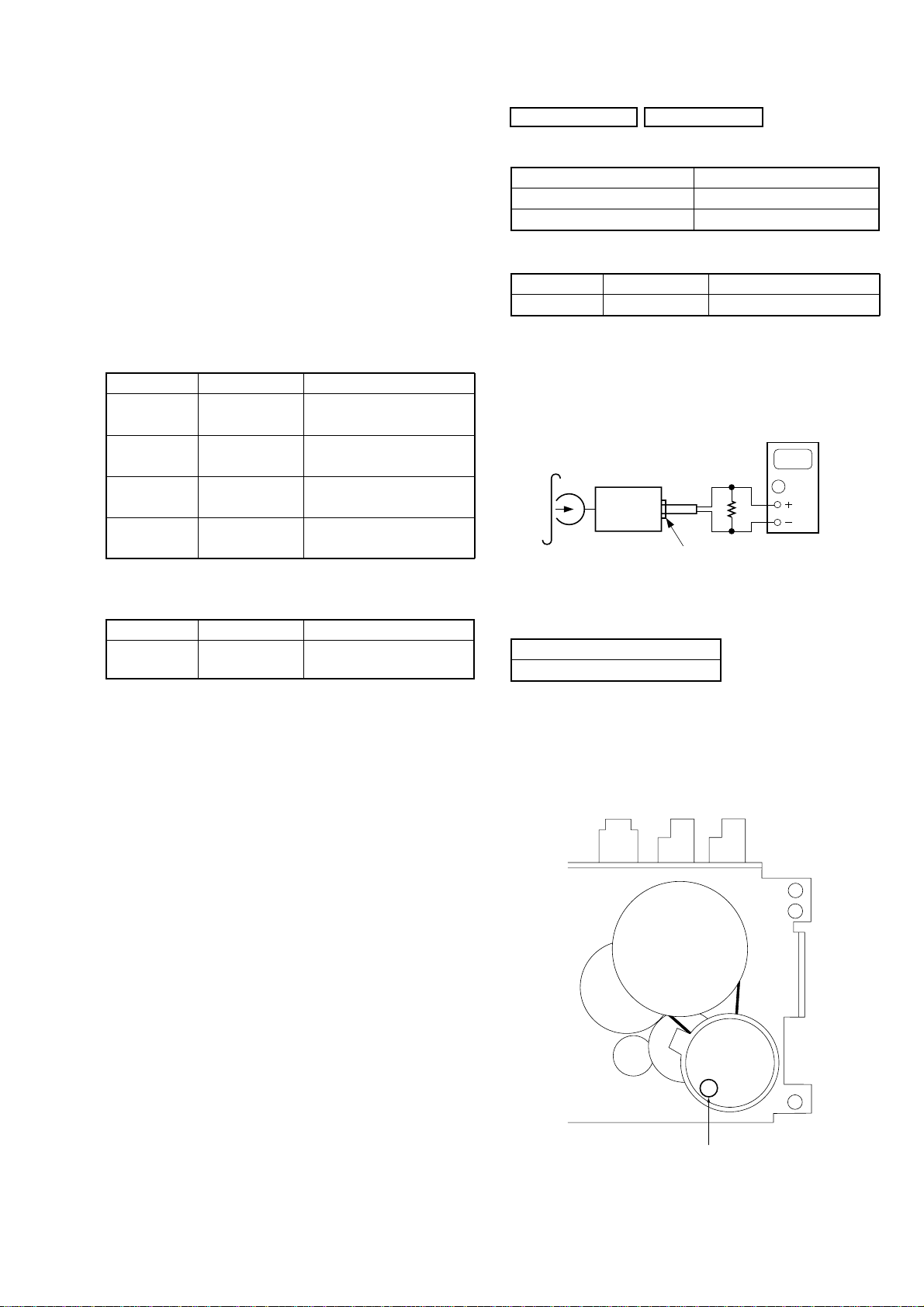

Torque Measurement

Mode Torque meter Meter reading

FWD CQ-102C

FWD

Back Tension (0.021 – 0.076 oz • inch)

FF CQ-201B

REW CQ-201B

CQ-102C

30 – 70 g • cm

(0.42 – 0.97 oz • inch)

1.5 – 5.5 g • cm

more than 60 g • cm

(more than 0.83 oz • inch)

more than 60 g • cm

(more than 0.83 oz • inch)

TAPE SECTION 0 dB = 0.775 V

• Standard Output Level

Output terminal HP OUT

load impedance 32 Ω

output signal level 0.25 V (–10 dB)

• Test Tape

Type Signal Used for

WS-48A 3 kHz, 0 dB tape speed adjustment

Tape Speed Adjustment

Procedure:

Mode: playback

Tape T ension Measurement

Mode Tension meter Meter Reading

FWD CQ-403A

more than 100 g

(more than 3.53 oz)

Adjust so that the value on the frequency counter is 3 kHz.

Specification Value:

Digital frequency counter

2,985 to 3,015 Hz

Adjust so that the frequency at the beginning and that at the end of

tape winding are between 2,955 to 3,045 Hz.

Adjustment Location:

Tape speed adjustment

control inside motor

– 13 –

)

TUNER SECTION 0 dB = 1 µV

• FM Section

Setting:

BAND switch: FM

FM RF signal

generator

TP (FM ANT)

0.01 µF

set

75 kHz frequency

deviation by 1 kHz signal

output level : as low as possible

• MW/LW Section

Setting:

BAND switch: MW or LW

AM RF signal

generator

30% amplitude

modulation by

400 Hz signal

• Connecting Level Meter (FM, MW and LW)

Put the lead-wire

antenna close to

the supplied MW/LW

loop antenna.

level meter

(range: 0.5–5 V ac

32 Ω

FM FREQUENCY COVERAGE

ADJUSTMENT

Frequency Display 87.5 MHz 108 MHz

Reading on Digital voltmeter 1.25 ± 0.3 V 5.2 ± 0.1V

Adjustment Part <confirmation> L2

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L1 CT1

87.5 MHz 108 MHz

MW FREQUENCY COVERAGE

ADJUSTMENT

Frequency Display 531 kHz 1,611 kHz

Reading on Digital voltmeter 0.8

– 0.4 V – 0.4 V

+ 0.5 V

5.2

+ 0.5V

Adjustment Part <confirmation> <confirmation>

MW TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L3 CT3

621 kHz 1,404 kHz

LW FREQUENCY COVERAGE

ADJUSTMENT

Frequency Display 153 kHz 279 kHz

Reading on Digital voltmeter 0.6

+ 0.4 V

– 0.3 V

5.5 ± 0.1V

Adjustment Part <confirmation> L4

set

phones jack

• Connecting Digital Voltmeter (FM, MW and LW)

digital

voltmeter

100 kΩ

TP (VT)

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

LW TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L3 CT5

162 kHz 261 kHz

Adjustment Location: See page 15.

– 14 –

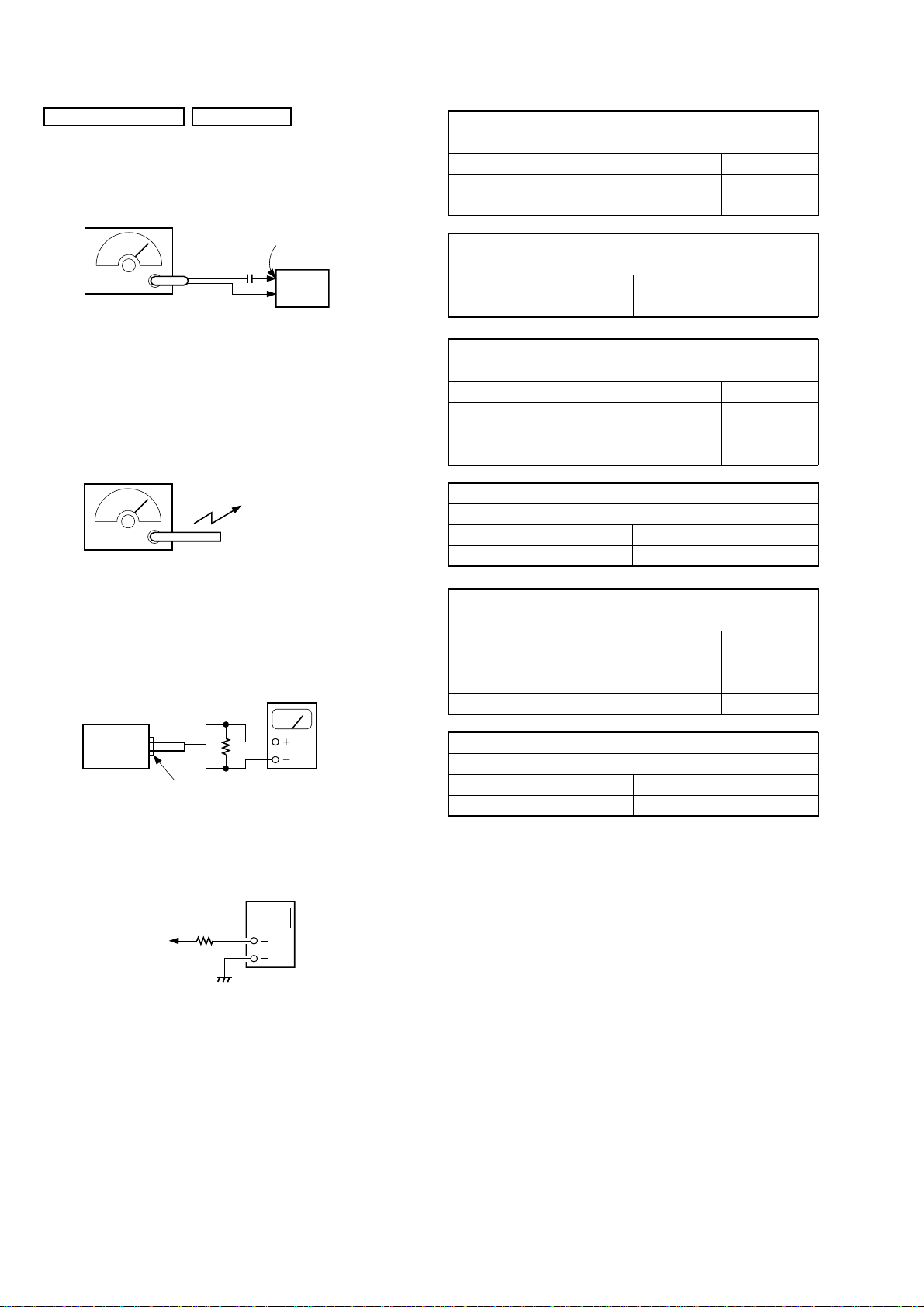

Adjustment Location:

T

– tuner board (component side) –

L3

CT5

LW

TRACKING

ADJUSTMEN

FM

L3

CT3

L4

LW

CT1

L1

L2

FM

MW

TRACKING

ADJUSTMENT

FREQUENCY

COVERAGE

ADJUSTMENT

TRACKING

ADJUSTMENT

FREQUENCY

COVERAGE

ADJUSTMENT

CD SECTION

CD section adjustments are done automatically in this set.

In case of operation check, confirm that focus bias.

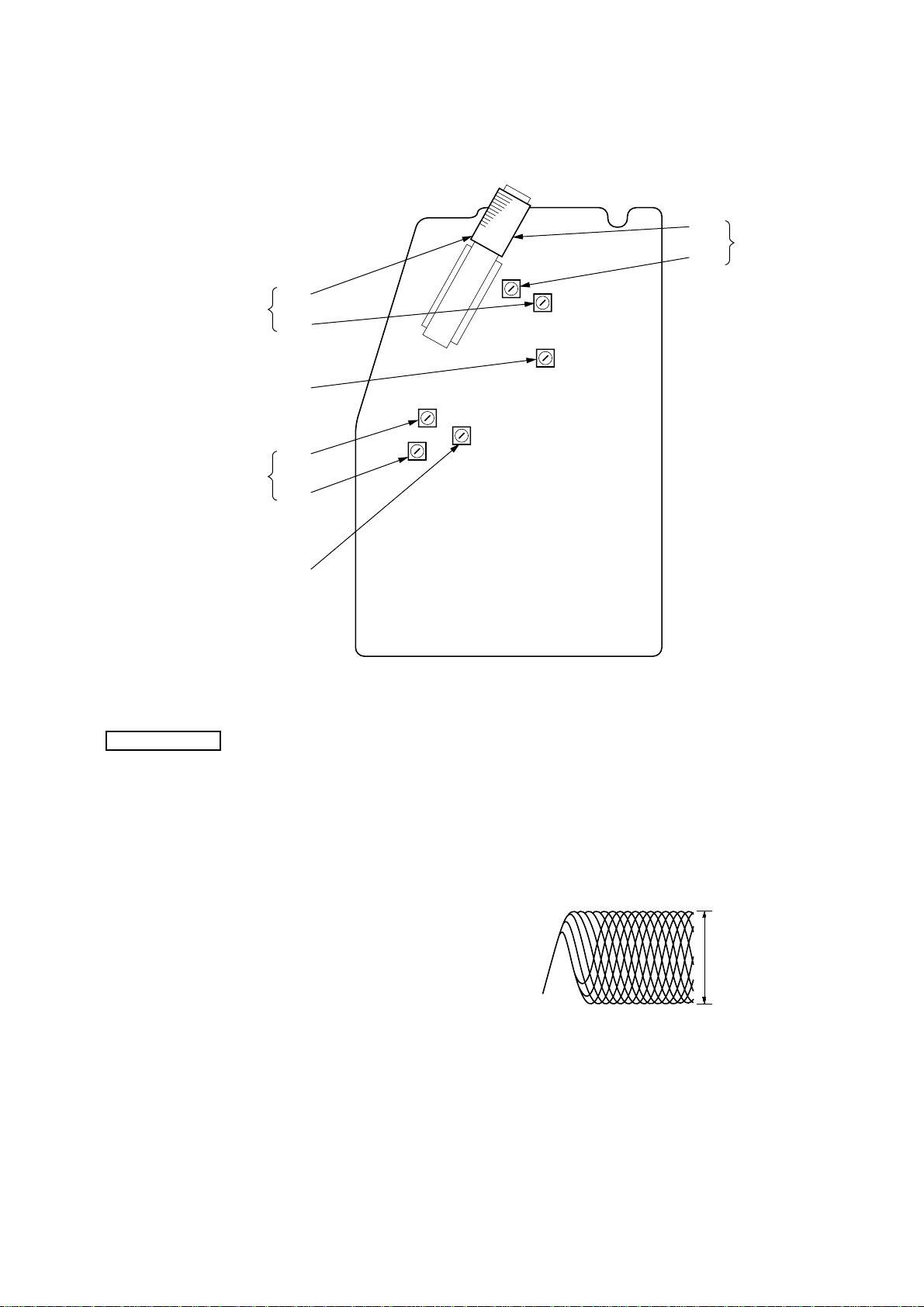

FOCUS BIAS CHECK

1. Connect the oscilloscope between IC701 pin #£ and GND on

CD board.

2. Insert the disc (YEDS-18). (Part No. : 3-702-101-01)

3. Press the ^ button.

4. Confirm that the oscilloscope waveform is as shown in the

figure below. (eye pattern)

A good eye pattern means that the diamond shape ( ) in the

center of the waveform can be clearly distinguished.

π

• RF signal reference waveform (eye pattern)

VOLT/DIV : 200 mV (10 : 1 probe in use)

TIME/DIV : 500 nS

RF level :

1.3 ± 0.5 Vp-p

When observing the eye pattern, set the oscilloscope for AC range

and raise vertical sensitivity.

– 15 –

Loading...

Loading...