Page 1

CDX-V5800

SERVICE MANUAL

Ver. 1.4 2006. 05

• The tuner and CD sections have no adjustments.

SPECIFICATIONS

E Model

Chinese Model

Model Name Using Similar Mechanism NEW

CD Drive Mechanism Type MG-611MK-186//K

Optical Pick-up Name KSS1000E

CD player section

Signal-to-noise ratio 90 dB

Frequency response 10 – 20,000 Hz

Wow and flutter Below measurable limit

Signal format system PAL/NTSC

Tuner section

FM

Tuning range FM tuning interval:

50 kHz/200 kHz

switchable

87.5 – 108.0 MHz

(at 50 kHz step)

87.5 – 107.9 MHz

(at 200 kHz step)

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Usable sensitivity 9 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 67 dB (stereo),

69 dB (mono)

Harmonic distortion at 1 kHz

0.5% (stereo),

0.3% (mono)

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

AM

Tuning range AM tuning interval:

9 kHz/10 kHz switchable

531 – 1,602 kHz

(at 9 kHz step)

530 – 1,710 kHz

(at 10 kHz step)

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity 30 µV

Power amplifier section

Outputs Speaker outputs

(sure seal connectors)

Speaker impedance 4 – 8 ohms

Maximum power output 52 W × 4 (at 4 ohms)

General

Outputs Audio output terminals (front, rear/sub switchable)

Video output terminal

Power aerial relay control terminal

Power amplifier control terminal

Inputs Telephone ATT control terminal

AUX IN terminal

Parking break control terminal

Tone controls Low:

±10 dB at 60 Hz (XPLOD)

Mid:

±10 dB at 1 kHz (XPLOD)

High:

±10 dB at 10 kHz (XPLOD)

Power requirements 12 V DC car battery

(negative earth)

Dimensions Approx. 178 × 50 × 177 mm (w/h/d)

Mounting dimensions Approx. 182 × 53 × 161 mm (w/h/d)

Mass Approx. 1.2 kg

Supplied accessories Parts for installation and connections (1 set)

Front panel case (1)

Card remote commander RM-X138

Design and specifications are subject to change without

notice.

9-879-047-05

2006E04-1

© 2006. 05

FM/AM MULTI MEDIA PLAYER

Sony Corporation

eVehicle Division

Published by Sony Techno Create Corporation

1

Page 2

CDX-V5800

Ver. 1.3

SERVICE NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

Notes on Chip Component Replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

If the optical pick-up block is defective, please replace the whole

optical pick-up block.

Never turn the semi-fixed resistor located at the side of optical

pick-up block.

optical pick-up

semi-fixed resistor

TEST DISCS

This set can playback CD-R and CD-ROM discs. The following

test discs should be used to check the capability:

CD-R test disc TCD-R082LMT (Part No. J-2502-063-1)

CD-RW test disc TCD-W082L (Part No. J-2502-063-2)

E model

This label is located on the bottom of the chassis.

Chinese model

SAFETY-RELATED COMPONENT W ARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

Page 3

CDX-V5800

Notes on CD-Rs (recordable CDs)/CD-RWs (rewritable

CDs)

This unit can play the following discs:

Type of discs Label on the disc

Audio CD

MP3 files

• Some CD-Rs/CD-RWs (depending on the equipment used for

its recording or the condition of the disc) may not play on this

unit.

• You cannot play a CD-R/CD-RW that is not finalized∗.

• You can play MP3 files recorded on CD-ROMs, CD-Rs, and

CD-RWs.

• A CD-R/CD-RW to which a session can be added can be played.

z

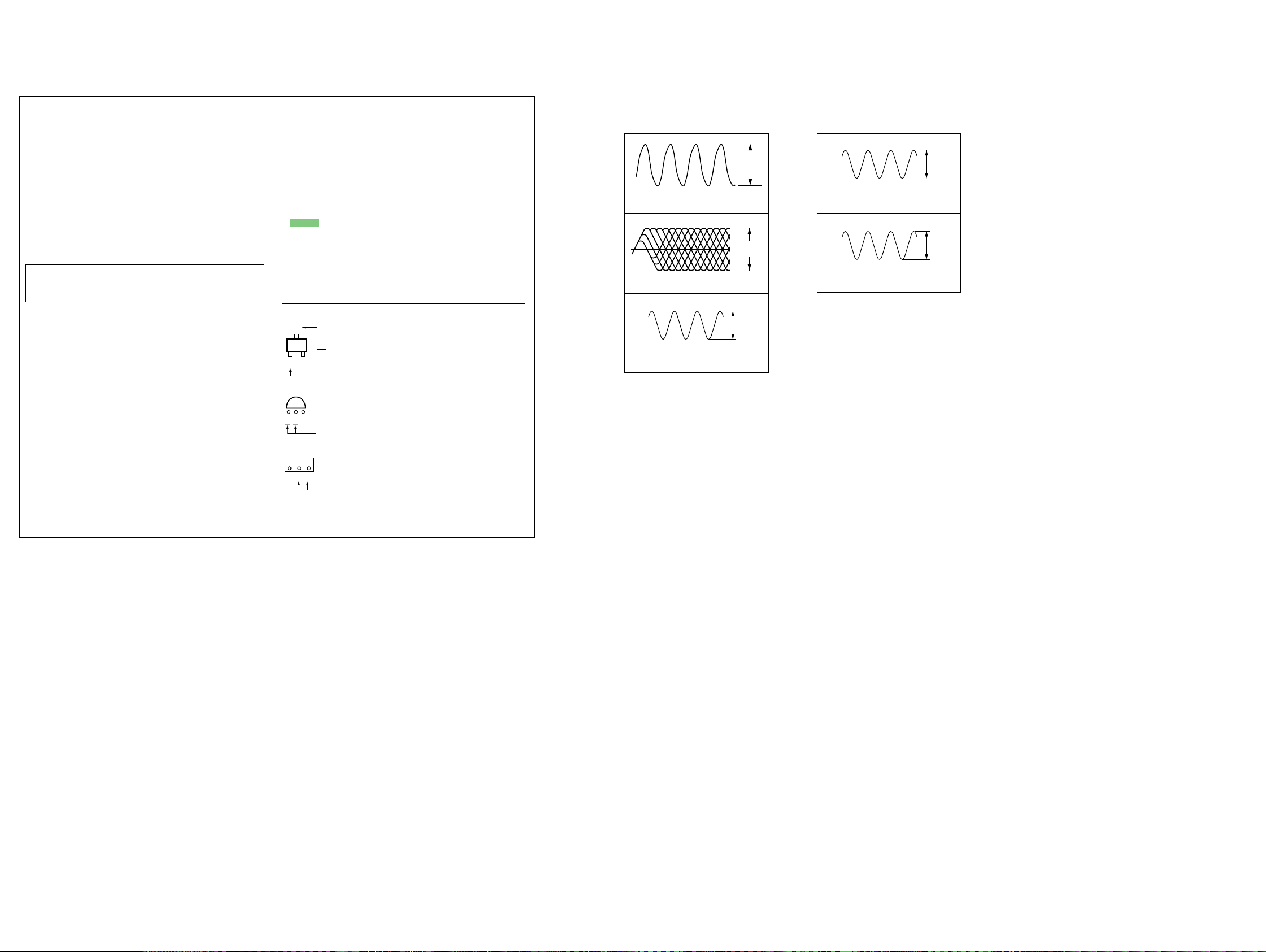

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the lead

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

∗ A process necessary for a recorded CD-R/CD-RW disc to be

played on the audio CD player.

Notes on Video CDs

This unit can play the following discs:

Type of discs Label on the disc

Video CD

VCD

A compact disc that contains moving pictures.

The picture data uses the MPEG 1 format (Video CD), worldwide

standards of digital compression technology.

Video CDs also contain compact audio data.

Sounds outside the range of human hearing are compressed while

the sounds we can hear are not compressed.

3

Page 4

CDX-V5800

TABLE OF CONTENTS

1. GENERAL

Location of Controls................................................................ 5

Connections ............................................................................. 5

2. DISASSEMBLY

2-1. Sub Panel Assy (CD)........................................................... 8

2-2. CD Mechanism Block ......................................................... 8

2-3. Main Board ......................................................................... 9

2-4. Chassis (T) Sub Assy .......................................................... 9

2-5. Roller Arm Assy................................................................10

2-6. Chassis (OP) Assy.............................................................10

2-7. Optical Pick-up ................................................................. 11

2-8. SL Motor Assy (M902) .....................................................11

2-9. LE Motor Assy (M903)..................................................... 12

2-10. Servo Board....................................................................... 12

3. DIAGRAMS

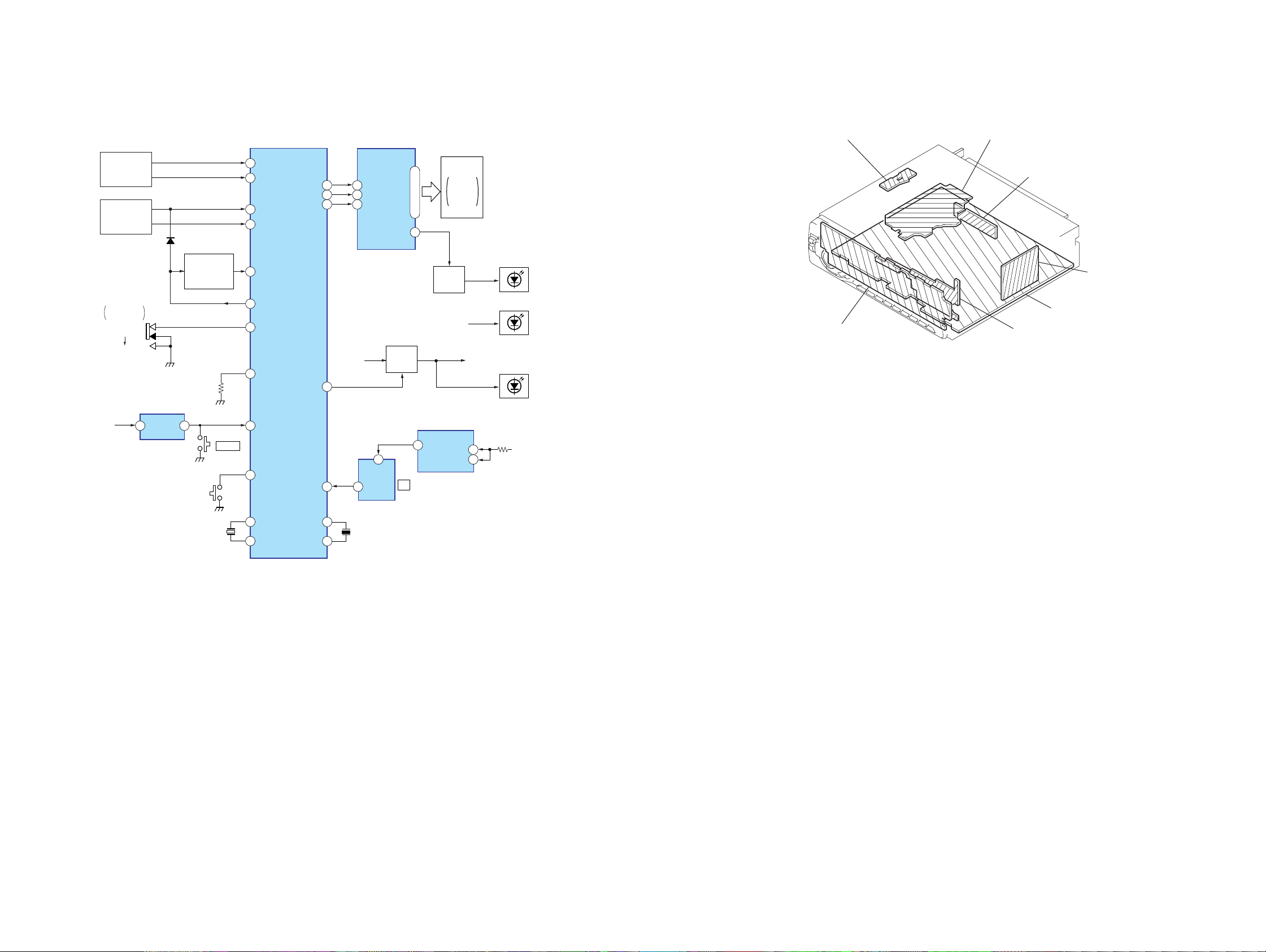

3-1. Block Diagram –CD Section–........................................... 13

3-2. Block Diagram –Main Section–........................................14

3-3. Block Diagram –Display Section–....................................15

3-4. Circuit Boards Location .................................................... 15

3-5. Note for Printed Wiring Boards and

Schematic Diagrams ..........................................................16

3-6. Waveforms......................................................................... 16

3-7. Printed Wiring Boards –CD Mechanism Section–............ 17

3-8. Schematic Diagram –CD Mechanism Section (1/2)– ....... 18

3-9. Schematic Diagram –CD Mechanism Section (2/2)– ....... 19

3-10. Printed Wiring Boards –Main Section– ............................ 20

3-11. Schematic Diagram –Main Section (1/3)– ........................21

3-12. Schematic Diagram –Main Section (2/3)– ........................22

3-13. Schematic Diagram –Main Section (3/3)– ........................23

3-14. Printed Wiring Board –Display Section– .......................... 24

3-15. Printed Wiring Board –Relay Section– ............................. 25

3-16. Schematic Diagram –Display Section–............................. 26

3-17. IC Block Diagrams............................................................ 27

4. EXPLODED VIEWS

4-1. Main Section ..................................................................... 34

4-2. Front Panel Section ........................................................... 35

4-3. CD Mechanism Section (1) ...............................................36

4-4. CD Mechanism Section (2) ...............................................37

4-5. CD Mechanism Section (3) ...............................................38

4-6. CD Mechanism Section (4) ...............................................39

5. ELECTRICAL PARTS LIST ........................................ 40

4

Page 5

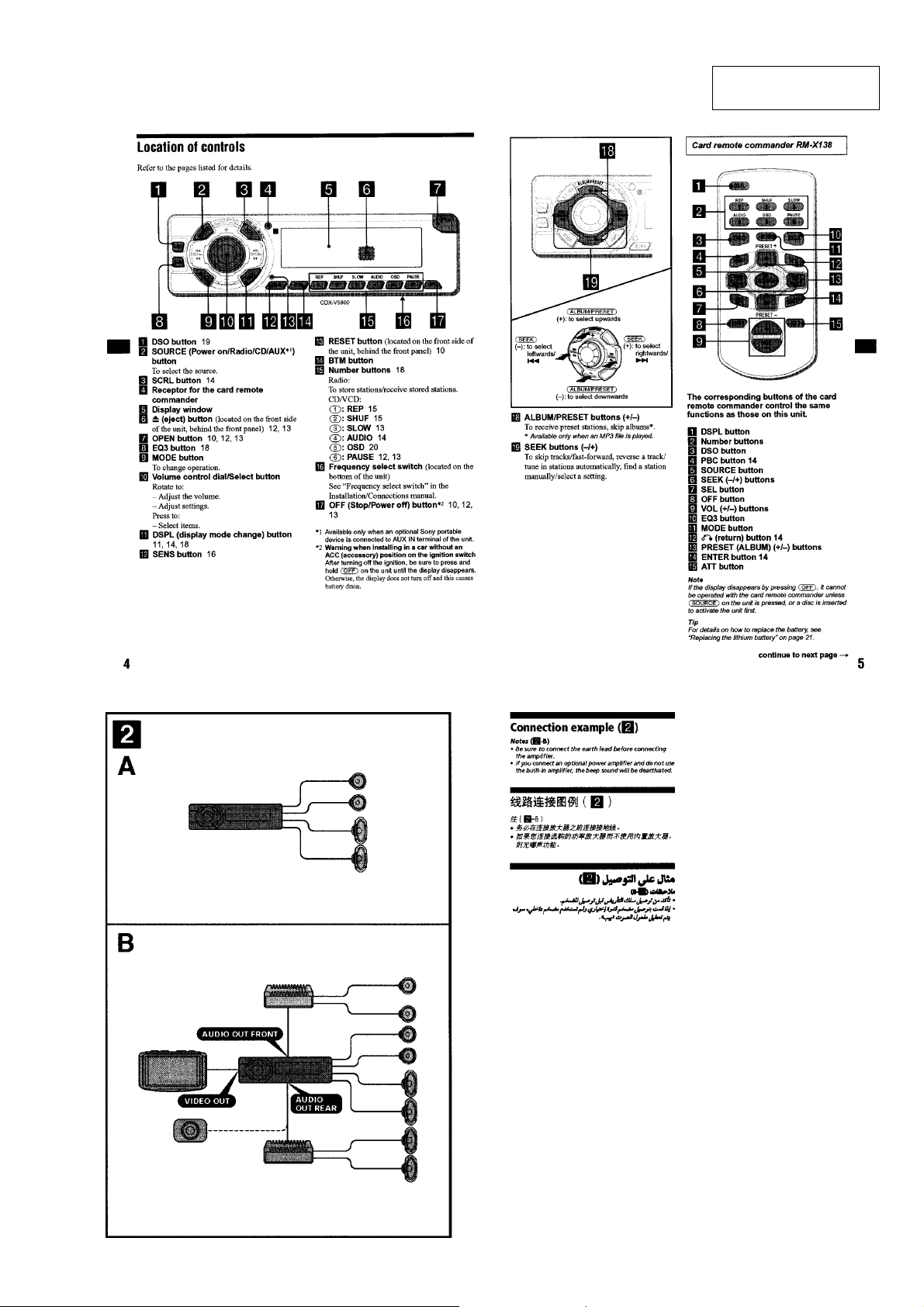

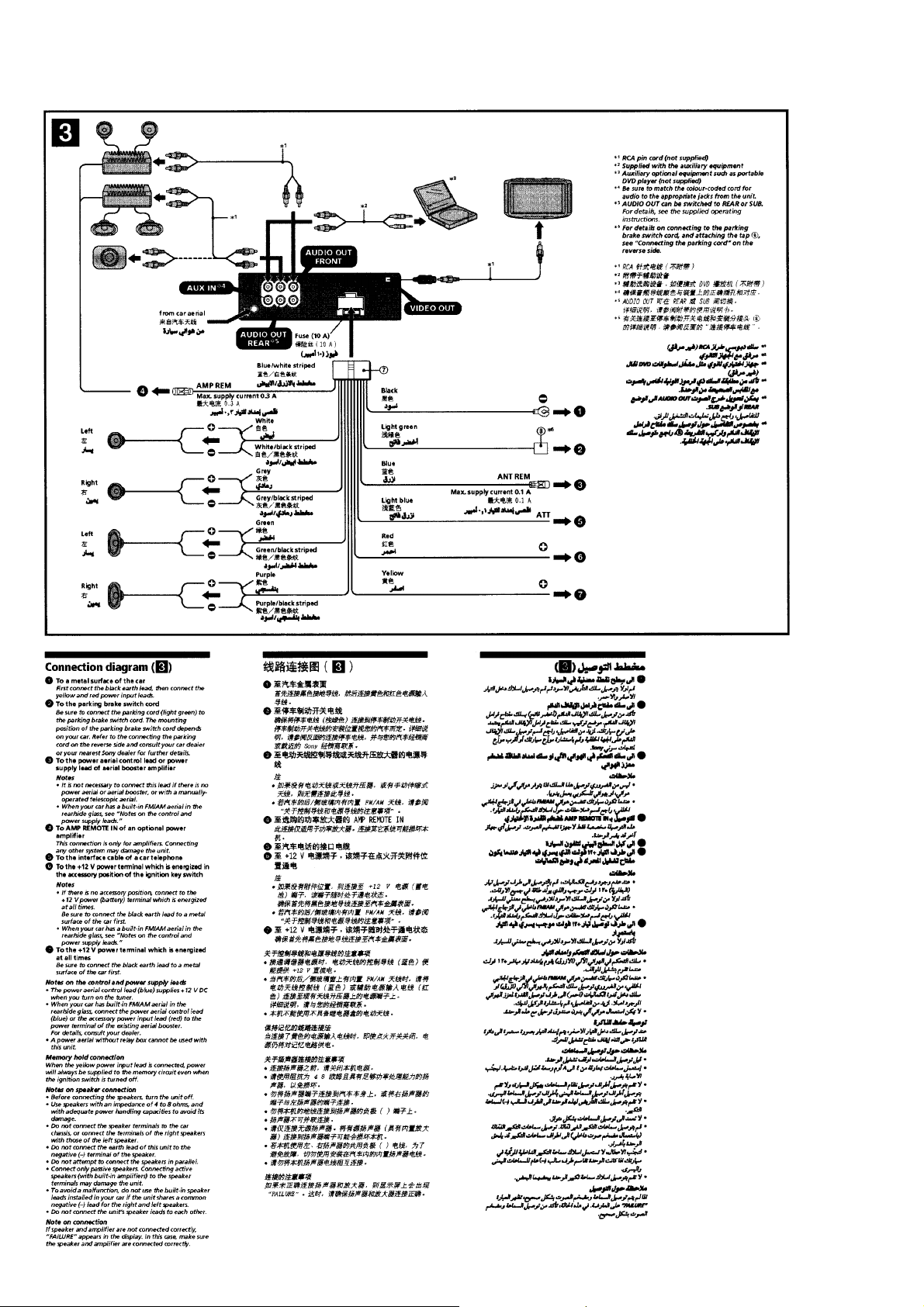

SECTION 1

GENERAL

CDX-V5800

This section is extracted

from instruction manual.

CONNECTIONS

5

Page 6

CDX-V5800

6

Page 7

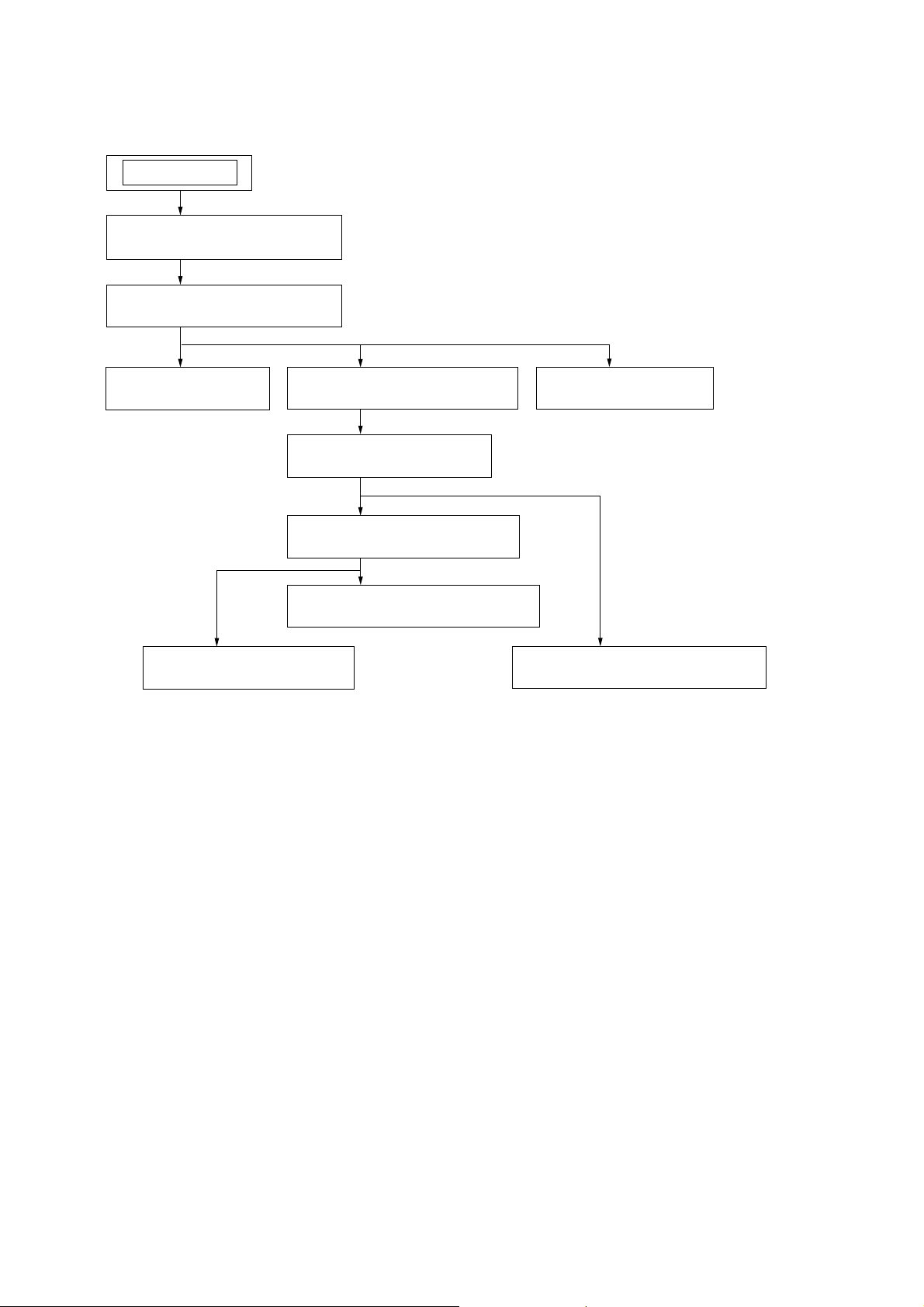

SECTION 2

DISASSEMBLY

Note : This set can be disassemble according to the following sequence.

SET

2-1. SUB PANEL ASSY (CD)

(Page 8)

2-2. CD MECHANISM BLOCK

(Page 8)

CDX-V5800

2-3. MAIN BOARD

(Page 9)

2-7. OPTICAL PICK-UP

(Page 11)

2-4. CHASSIS (T) SUB ASSY

(Page 9)

2-5. ROLLER ARM ASSY

(Page 10)

2-6. CHASSIS (OP) ASSY

(Page 10)

2-8. SL MOTOR ASSY (M902)

(Page 11)

2-10. SERVO BOARD

(Page 12)

2-9. LE MOTOR ASSY (M903)

(Page 12)

7

Page 8

CDX-V5800

s

)

Note : Follow the disassembly procedure in the numerical order given.

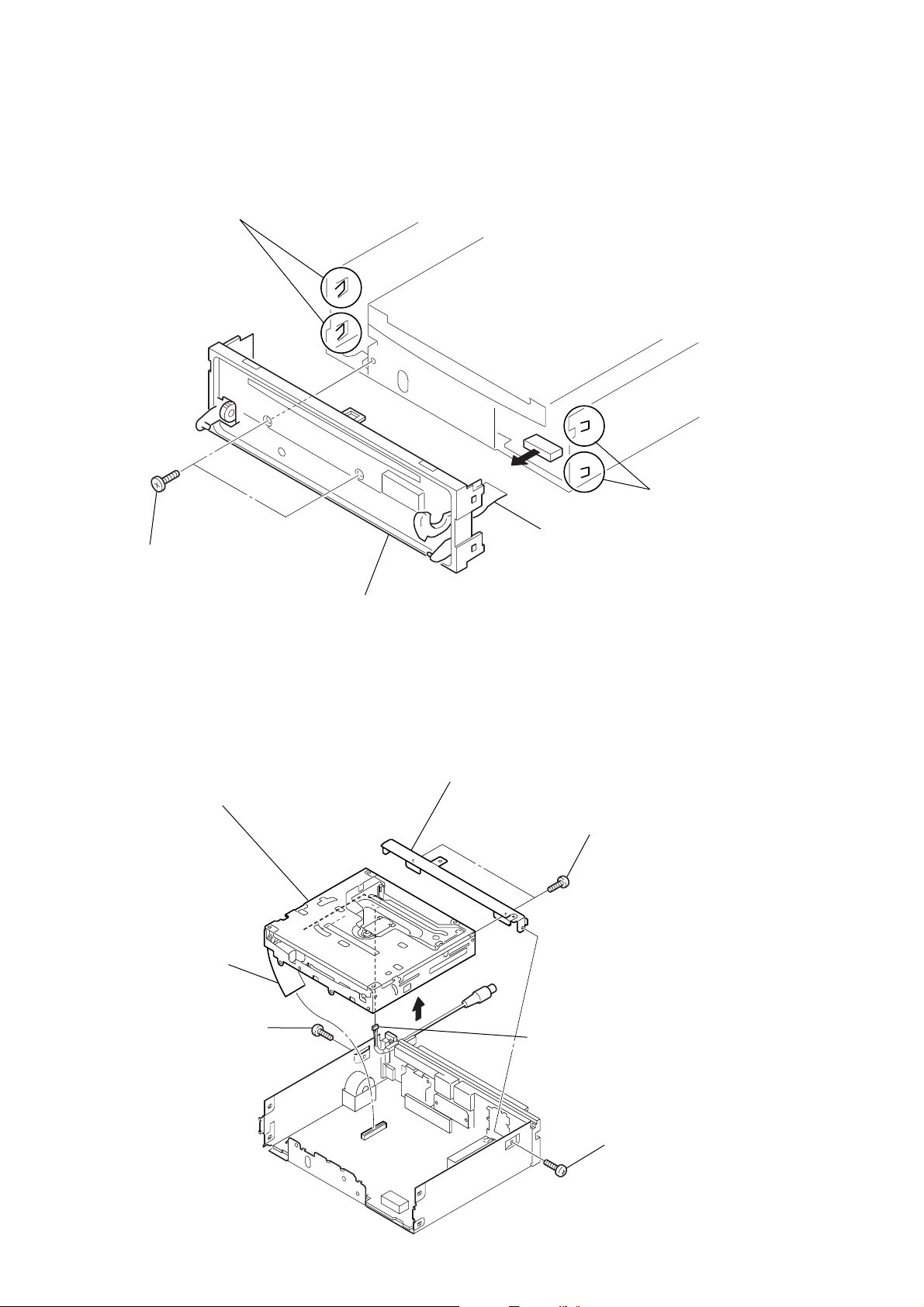

2-1. SUB PANEL ASSY (CD)

3

two claws

4

2

two claw

1

two

screws

(+PTT 2.6

x

6)

2-2. CD MECHANISM BLOCK

6

CD mechanism block

5

CN751

5

sub panel assy (CD)

8

bracket (CD)

CNP802

7

two

screws

(+PTT 2.6

x

6)

3

2

screw

(+PTT 2.6

x

6)

4

CN401

1

screw

(+PTT 2.6

x

6

8

Page 9

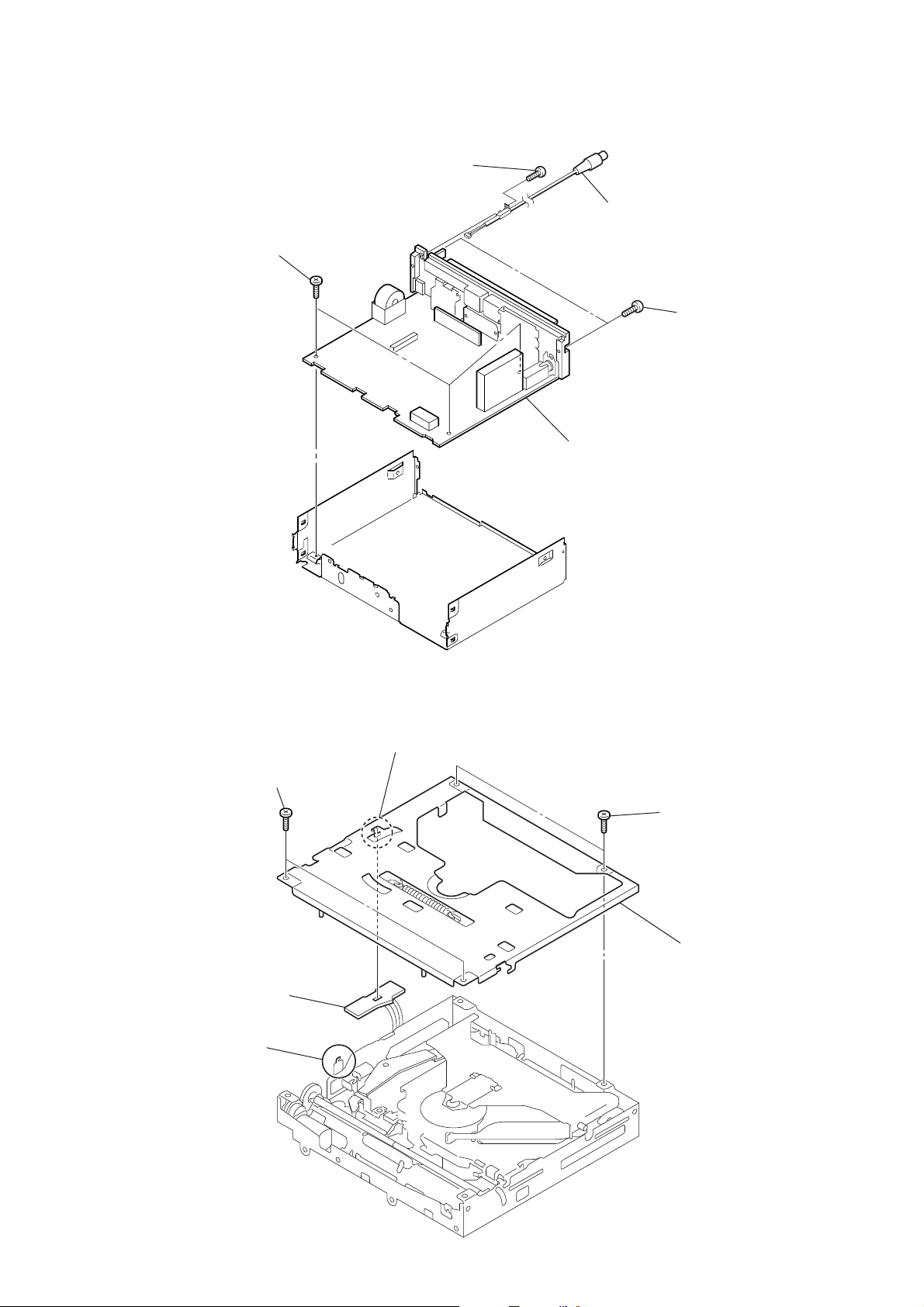

2-3. MAIN BOARD

)

1

(+BTT)

three screws

4

screw

(+PTT 2.6

x

CDX-V5800

6)

5

connector

2

two

screws

3

MAIN board

(+PTT 2.6

x

8

2-4. CHASSIS (T) SUB ASSY

2

two

screws

(+P 1.7

5

SENSOR board

3

claw

x

2.2)

4

claw

1

two

screws

x

(+P 1.7

6

2.2)

chassis (T) sub assy

9

Page 10

CDX-V5800

)

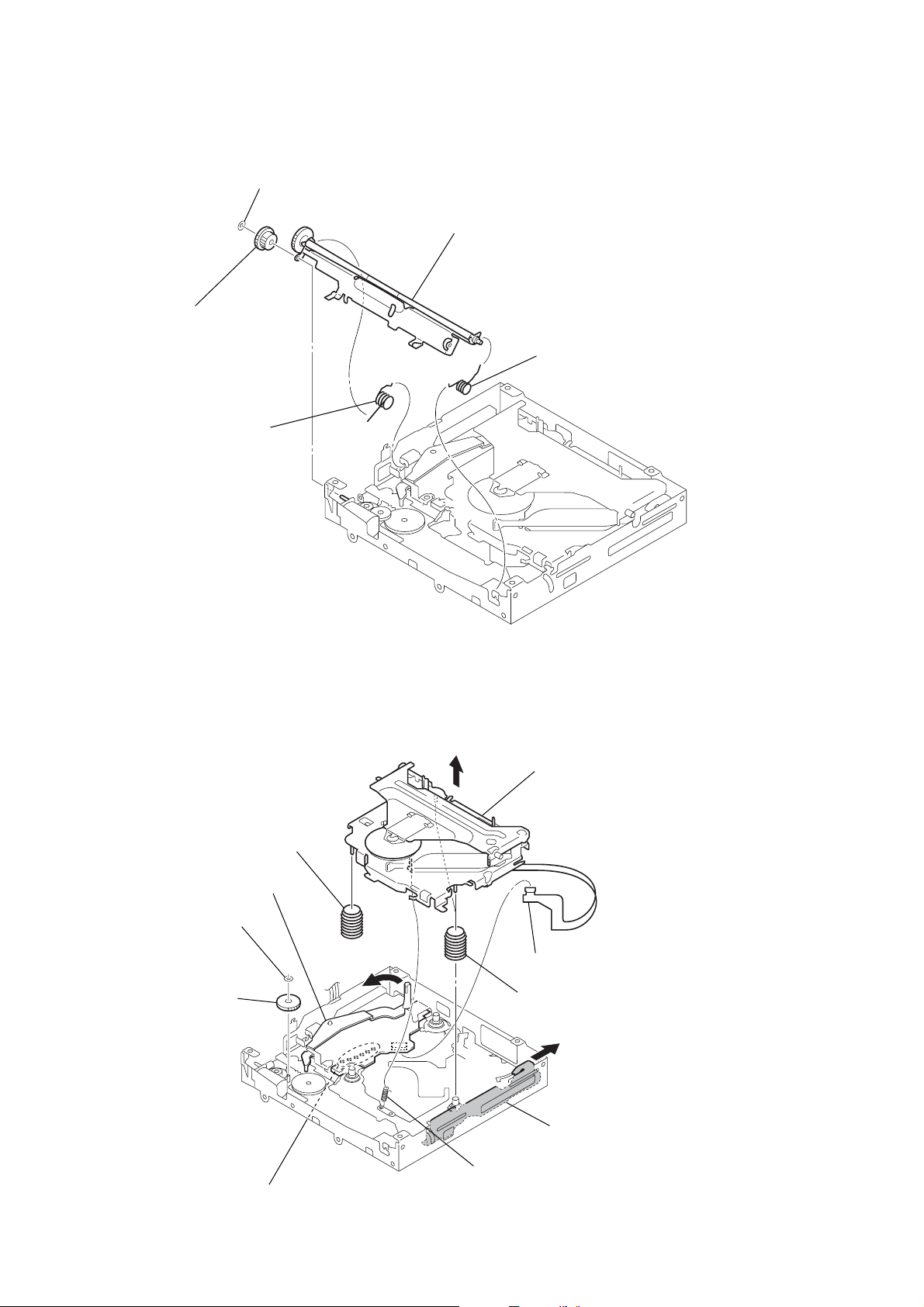

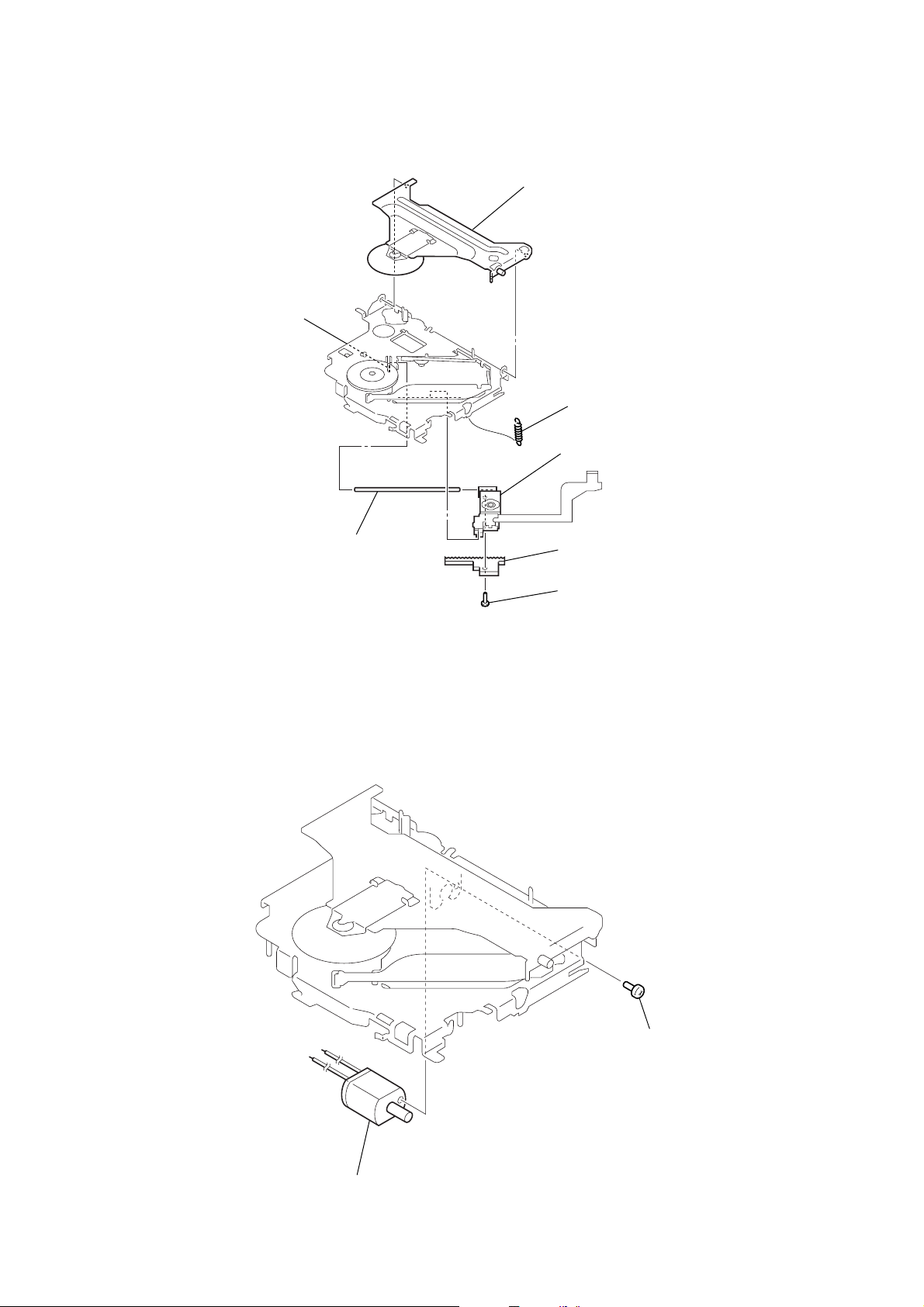

2-5. ROLLER ARM ASSY

4

worm wheel (RA)

1

spring (RAL)

3

washer (1.1 – 2.5)

5

roller arm assy

2

spring (RAR)

2-6. CHASSIS (OP) ASSY

0

compression spring (damper)

4

washer

5

gear (LE1)

lever (D)

6

8

qa

chassis (OP) assy

1

CN500

9

two compression springs (damper

7

slider (R)

10

2

Remove the six solderings.

3

tension coil spring (KF)

Page 11

2-7. OPTICAL PICK-UP

5

claw

2

chucking arm sub assy

1

tension coil spring (CHKG)

7

optical pick-up

CDX-V5800

2-8. SL MOTOR ASSY (M902)

6

main shaft

4

rack (SL)

3

screw

(+B 1.4

x

5)

2

SL motor assy (M902)

1

screw

(+P 1.4

x

1.8)

11

Page 12

CDX-V5800

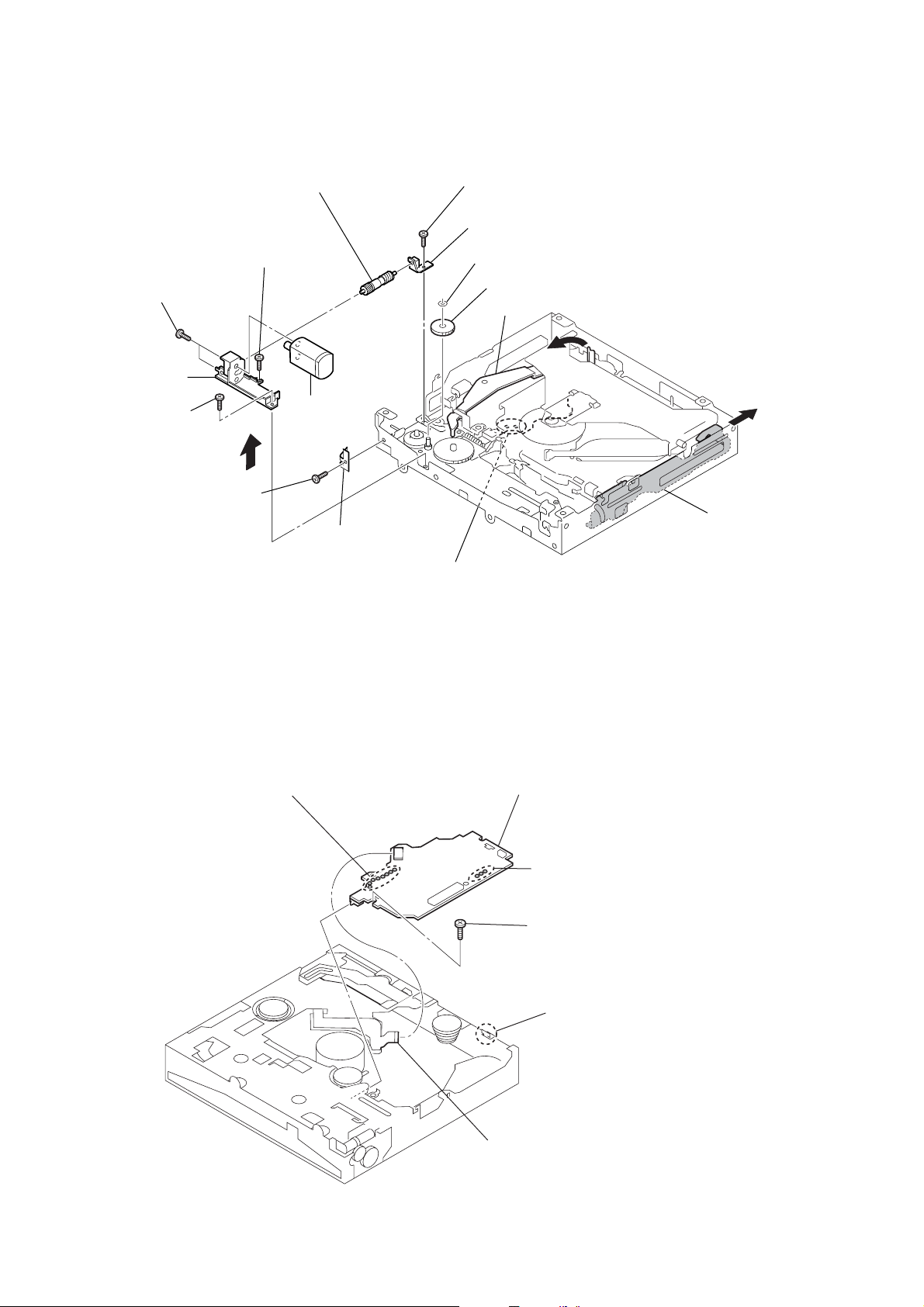

2-9. LE MOTOR ASSY (M903)

qf

two toothed lock

(+M 1.4

bracket (LEM)

qs

screw

(+M 1.7

x

)

screws

2.5)

6

screw

(+P 1.7

x

qd

2.2)

qa

screw

(+M 1.7

qg

(M903)

0

woam (LEB) assy

x

2.5)

LE motor assy

7

leaf spring (LE)

8

screw

(+M 1.7

9

bearing (LEB)

2

washer

gear (LE1)

3

lever (D)

x

2.5)

4

5

slider (R)

2-10. SERVO BOARD

1

Remove the eight solderings.

1

Remove the soldering.

6

SERVO board

2

4

toothed lock

(M 1.7)

5

Remove the three solderings.

screw

claw

12

3

CN500

Page 13

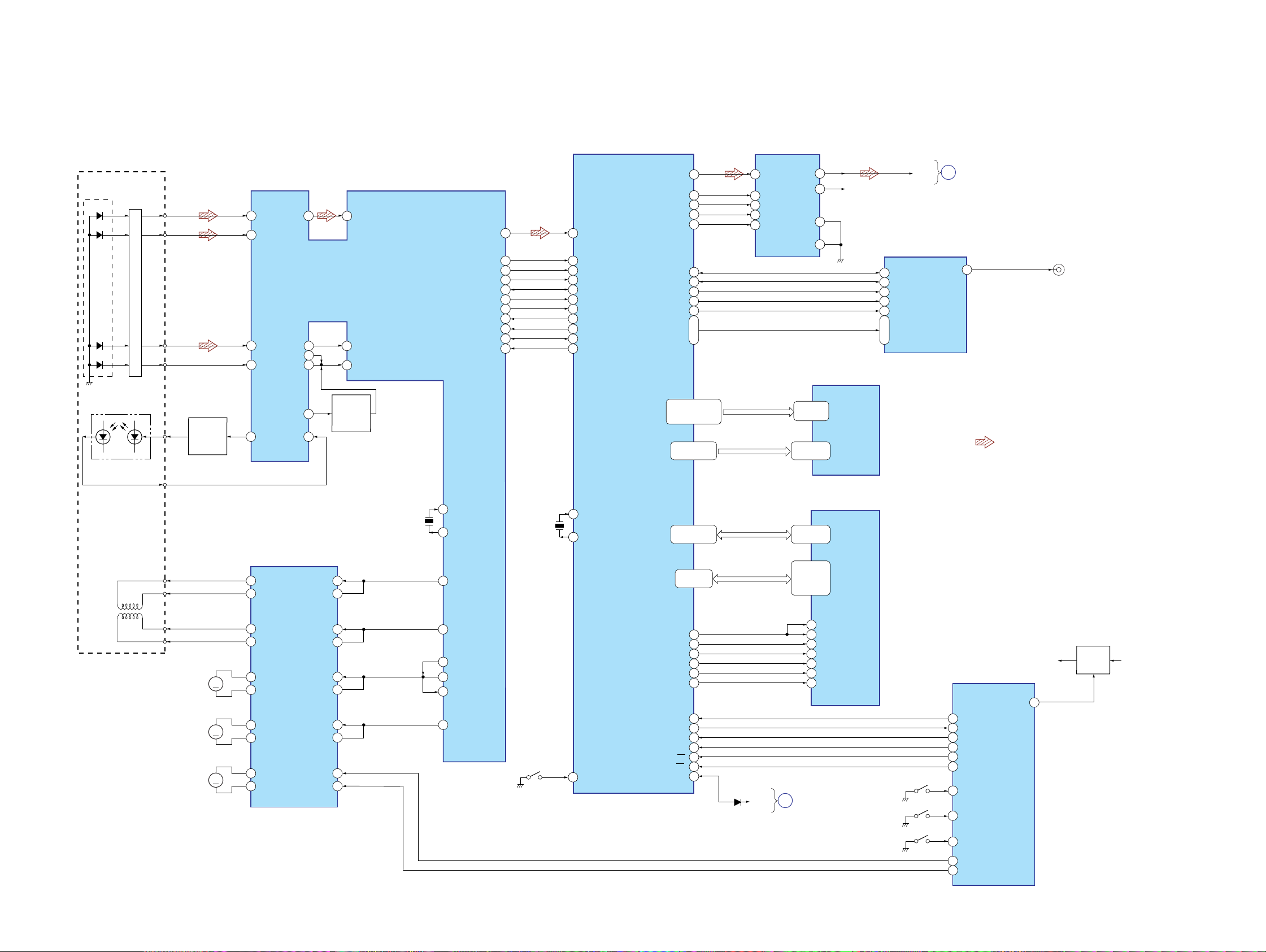

3-1. BLOCK DIAGRAM — CD SECTION —

CDX-V5800

SECTION 3

DIAGRAMS

DETECTOR

PD1

PD2

E

F

LASER DIODE

I-V AMP

PD LD

PD1

PD2

2

1

3

14

12

DIGITAL

MODULATOR

DIN

LRCK

BCKIN

SCKI

DEEMP

IC700

LOUT

ROUT

MUTE

FORMAT

45•25–18•

8–1•48•17

29•31•33•35

•38•30•42–44

9

6

10

13

16M SDROM

A18

DQ0

DQ7

IC200

A0

I

I

R-CH

28

29

15

14

90

17

I

24

VIDEO SIGNAL

PROCESSOR

VSYNC

HSYNC

CLK

MODEB

SLEEP

P0

I

P7

CD-L

IC400

MAIN

A

SECTION

(Page 14)

32

CVBS/Y

• R-ch is omitted due to same as L-ch.

• Siganal Path

: CD PLAY

CN401

(VIDEO OUT)

DIGITAL SIGNAL PROCESSOR

IC100

77

AU DATA

78

AU LRCK

79

AU BCK

76

ROMA0

I

ROMA18

ROMD0

I

ROMD7

CLK27 OUT

AU XCK

103

DEEMP

56

VSYNC

55

HSYNC

69

70

PLA NTSC

54

V RST

64

YC0

I

57

YC7

29–32•34•38•40•42

•41•39•33•35•44•

43•45–49

27•25•23•21•22

•24•26•28

I

ROMA0-ROMA18

ROMD0-ROMD7

2

BD

3

E

F

LD

AUTOMATIC

POWER

CONTROL

Q501

5

E

6

F

13

LD

FEO

TZCRFM

TEO

LON

52

RF AMP,

DIGITAL SERVO,

IC500

9

46

48

24

12

PD

EQ0

AC

RFI

51

FEN

8

TEN

49

LASER ON

CONTROL

SWITCH

Q502

DOUTA

LRCK

WFCK

DCK

EFLAG

SUBSYQ

BUSY

RESETX

R/W

DIN/OUT

MCK

35

36

34

37

38

31

30

29

28

27

26

96

97

50

98

102

81

80

82

83

84

85

CD DATA

CD LRCK

BATTLOW

CD BCLK

CD XCK

SUBSYQ

BUSY

XRESET

R/W

DI/DO

MCK

PICK-UP BLOCK

2-AXIS DEVICE

(FOCUS)

(TRACKING)

OPTICAL

MONOUT

FCS+

FCS–

TRK+

TRK–

M902

(SLED)

M901

(SPINDLE)

M903

(LOADING)

16M SDROM

XI

X541

16.934MHz

FOCUS/TRACKING COIL DRIVE,

SLED/SPINDLE/LOADING

MOTOR DRIVE

IC600

16

VO4(–)

15

VO4(+)

VO3(–)

17

VO3+)

18

14

M

M

M

VO1(–)

13

VO1(+)

VO2(–)

12

VO2(+)

11

10

VOL+

9

VOL–

IN1(–)

OUT1

IN2(–)

OUT2

IN3(–)

OUT3

IN4(–)

OUT4

FWD

REV

3

4

6

7

23

22

26

25

1

28

42

43

20

22

17

18

19

21

XO

SD OUT

CLV OUT

JUMP0

TDOUT

SDIN

FD OUT

X401

27MHz

S901

(LIMIT)

65

CLKIN

DA0

17–20•16–12

66

CLKIO

LIMIT

92

DA10

DD0

DD15

I

•111•110

116–123•6–2

I

•126–124

DQMO

114

9 15

WE B

10 16

CAS B

11 17

RASO BT

112 19

BAO

127 35

RAMCLK

SI

91

SO

93

SCK

99

RESET B

88

SP

89

MP

113

MUTE

RAMA0-RAMA10

RAMD0-RAMD15

MUTE

D701

21–24•

27–32•20

2•3•5•6•8•

9•11•12•39•

40•42•43•45

•46•48•49

MAIN

B

SECTION

(Page 14)

IC300

A0

I

A10

DQ0

I

DQ15

14

LDON

36

UDQM

WE

CAS

RAS

BA

CLK

SW1

(DOWN)

SW2

(SELF)

SW3

(DISC IN)

SYSTEM CONTROL

CD SO

1990

CD SI

18

CD SCK

20

CD RESET

98

SP

54

MP

90

CD DSW

95

CD SELFSW

55

CD INSW

92

CD LOAD

93

EJECT

94

IC801 (1/3)

BU+3.3V U COM+3.3V

CD ON

87

BU+3.3V

REG

Q701,703

CDX-V5800

13 13

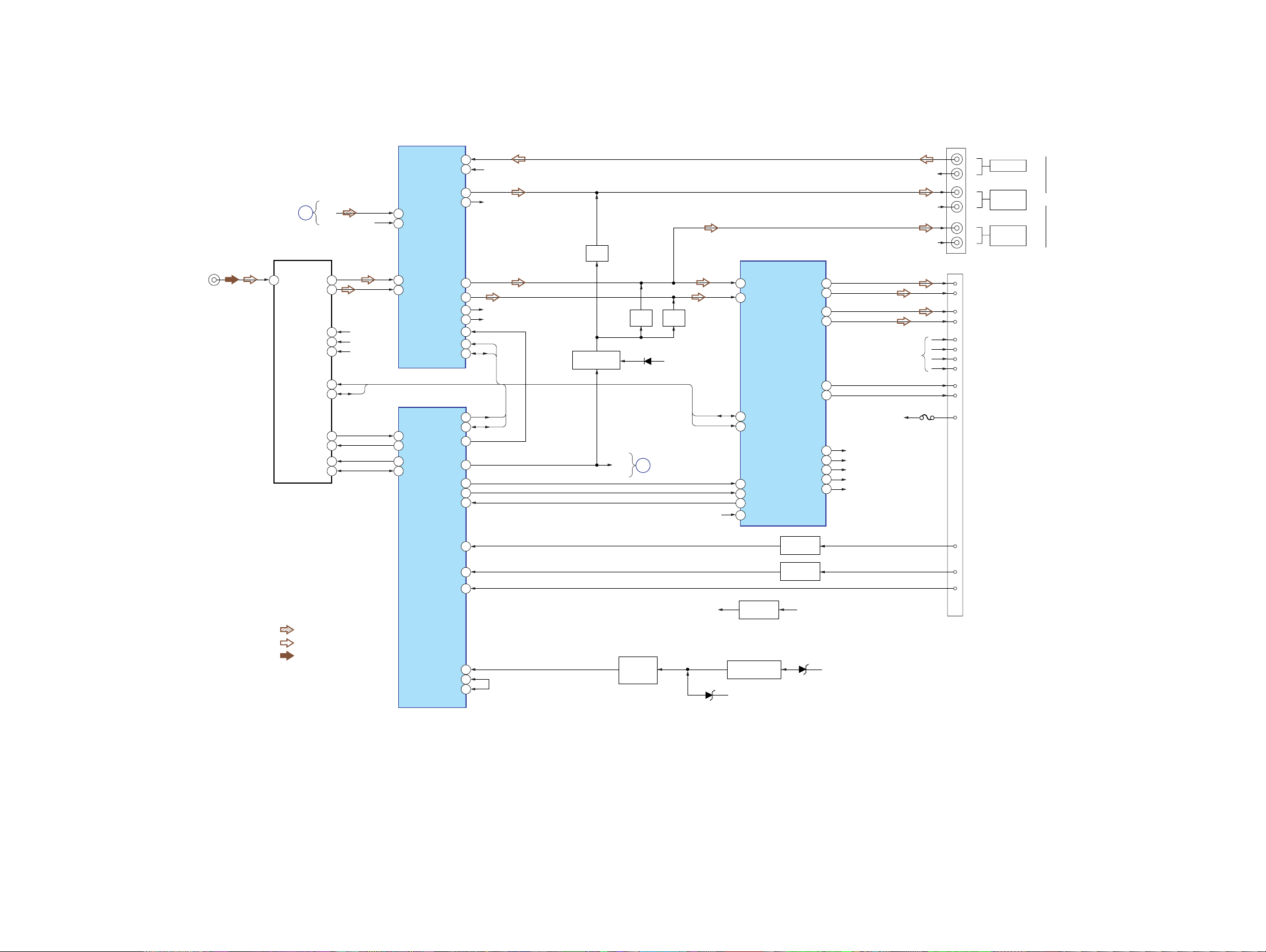

Page 14

CDX-V5800

3-2. BLOCK DIAGRAM — MAIN SECTION —

ELECTRONIC VOLUME

PJ601

(ANTENNA)

CD

SECTION

(Page 13)

(TUNER UNIT)

1

ANT

TUX601

E2P VDD

S-METER

TU MUTE

E2P SCL

E2P SDA

A

VCC

TU VDD

TU-SCL

TU-SDA

CD-L

L

R

10

11

15

13

14

16

17

4

3

6

7

R-CH

AU+8V

TU+5V

U COM+3.3V

SCL

SDA

9

8

7

6

45

15

25

24

IC401

OUTS1

OUTS2

C2

C1

B2

B1

VSM

TU ATT

EEP SCK

EEP SIO

OUTF2

OUTR2

OUTF1

OUTR1

MUTE

SYSTEM CONTROL

IC801 (2/3)

IIC SCK

IIC SIO

VOL ATT

LINE ATT

AP2

AP1

SCL

SDA

BEEP

STB

DIAG

5

3

17

18

23

22

25

24

29

30

31

33

34

6

1

5

31

56

R-CH

R-CH

R-CH (FRONT)

R-CH (REAR)

SCL

SDA

SCL

SDA

MUTE

Q407

MUTE CONTROL

Q400,401

MUTE

MUTE

Q405

D400

B

MUTE

Q404

BATT

CD

SECTION

SDA

SCL

(Page 13)

BATT

12

11

2

4

16

22

25

35

POWER AMP

IN RR(FL)

IN RF(RL)

SDA

SCL

ACGND

STB

DIAG

VP

IC100

RF+

RF-

SW1

SW2

REG1

REG2

REG3

REG4

REG5

LF+

LF-

29

27

30

37

31

33

34

5

3

9

7

AU+8V

U-COM+3.3V

SERVO+3.3V

MECHA+6V

DISP+B

BATT

R-CH

R-CH

R-CH

R-CH

F901

CNP901

1

9

2

10

4

12

3

11

5

6

16

L

R

L

R

L

R

FL+

FL-

RL+

RL-

FR+

FRRR+

RR-

AMP-REM

ANT-REM

BATT

AUX IN

REAR

AUDIO OUT

FRONT

AUDIO OUT

PJ401

• R-CH is omitted due to same as L-CH.

• Signal Path

: CD PLAY

: FM

: AM

ACC IN

TEL ATT

PAK BK

BU IN

UNI SI

UNI SO

7

ACC

13

ATT

15

TEST

Q601

ACC CHECK

Q900

TEL ATT

Q901

AU+8V

D912

BATT

64

63

67

TU+5V

53

58

59

BACK-UP

DETECT

Q906,907

D915

TU+5V REG

BATTERY CHECK

Q902

BATT

CDX-V5800

1414

Page 15

CDX-V5800

3-3. BLOCK DIAGRAM — DISPLAY SECTION —

SYSTEM CONTROL

IC801 (3/3)

U COM+3.3V

ROTARY

ENCODER

RE901(1/2)

KEY MATRIX

S901-919,931,

RE901(2/2)

S800

FREQUENCY

SELECTOR

9K

10K

D801

KEY

ACKNOWLEDGE

SWITCH

Q800

RESET

IC802

OUT

2

IN

1

S801

(NOSE DET)

S802

RESET

21

22

38

39

47

75

46

46

77

69

RE0

RE1

KEYIN0

KEYIN1

KEY ACK

XKEY ON

DST SEL

DST SEL

RESET

NOSE SW

LCD SO

LCD SCK

LCD CE

DOOR IND

SIRCS

28

29

27

BATT

73

REMOTE CONTROL

SIGNAL RECEIVER

65

78

77

76

IC951

2

DI

CL

CLK

CE

CE

OUT

LCD DRIVER

IC901

SEG10

SEG21

SEG23

SEG66

DIMMER

DIMMER

SUB +B

SWITCH

Q801,802

1

VCC

3-4. CIRCUIT BOARDS LOCATION

SENSOR board

3

DIMMER

CONTROL

+3.3V REG

IC905

V OUT

Q501

DISP+B

LCD901

LIQUID

CRYSTAL

DISPLAY

PANEL

VDD

CE

LED902,905

LCD

BACK LIGHT

()

LED907-918,

921-924,927-929

SUB+B

LED930,931

2

4

DISP+B

DISPLAY board

8

|

I

19

•

21

|

I

64

1

IR

SERVO board

SPEAKER board

tuner unit

(TUX601)

MAIN board

RELAY board

X801

32.768kHz

X1A

79

X0A

80

82

X0

X1

83

X800

3.68MHz

CDX-V5800

15 15

Page 16

CDX-V5800

Ver. 1.4

3-6. WA VEFORMS3-5. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed

in each block.)

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• C : panel designation.

Note: The components identified by mark 0 or dotted line

• A : B+ Line.

•Voltages and waveforms are dc with respect to ground

• CD mechanism section (1/2, 2/2)

no mark : CD PLAY

• Main (1/3), (2/3), (3/3) and Display sections

no mark : FM

: internal component.

with mark 0 are critical for safety.

Replace only with part number specified.

under no-signal (detuned) conditions.

(): AM

<>: CD PLAY

4

W or less unless otherwise

∗ : Impossible to measure

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : CD PLAY

F : FM

f : AM

For printed wiring boards.

Note:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

a

•

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

: Through hole.

C

Q

These are omitted

EB

E

CB

These are omitted

C

BE

These are omitted

— Servo Board —

(MODE: CD PLAY)

1

16.9344MHz

IC500 rd (XO)

2

ts

(EQO)

IC500

3

27MHz

IC100

(CLKIN)

yg

1.8Vp-p

0.8V to

1.3Vp-p

1.5Vp-p

— Main Board —

1

32.768kHz

IC801 ul (X1A)

2

3.68MHz

IC801

id

1.6Vp-p

3Vp-p

(X1)

CDX-V5800

1616

Page 17

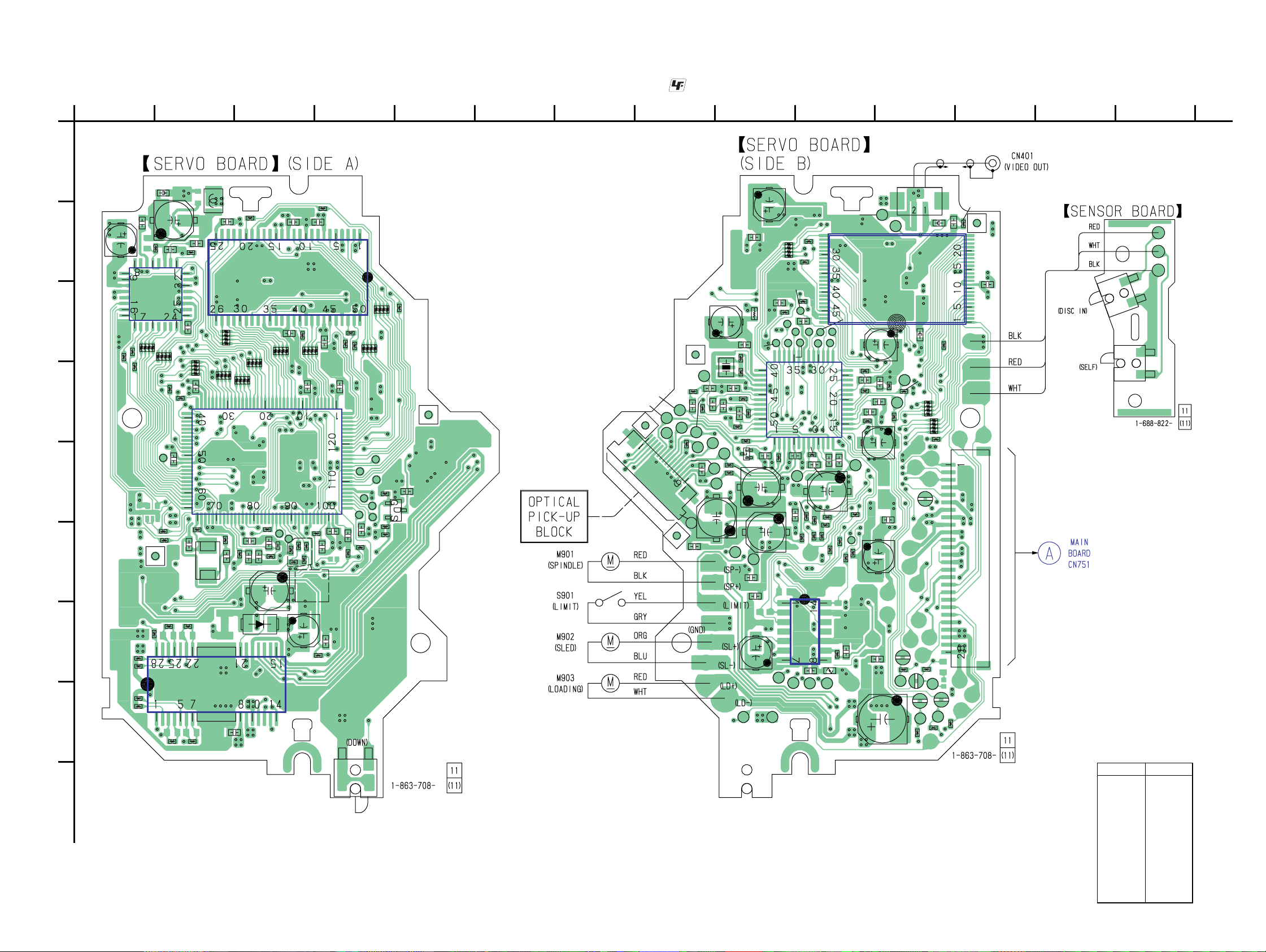

3-7. PRINTED WIRING BOARDS — CD MECHANISM SECTION — • Refer to page 15 for Circuit Boards Location. : Uses unleaded solder.

CDX-V5800

A

B

C

D

E

F

G

H

1

FB504

C404

C201

R402

IC400

RB111

R107

R108

R106

TP131

R161

R162

FMA4

R627

R626

R623

R606

R605

23456789101112 13 14 15

L401

TP55

TP53

RB108

RB109

TP24

R104

TP601

C405

R105

BP3

TP4

R403

FMB6

C202

SW3

TP56

SW2

TP6

CN1

(Page 20)

TP1

TP2

R600

• Semiconductor

Location

C402

RB110

R102

R624

R601

C401

R103

C132

R401

C407

R621

R603

C403

R404

C133

X401

RB107

RB106

C131

IC600

C605

C305

RB103

R405

C406

RB105

IC100

R163

R109

RB104

R178

C164

C163

C161

D101

C162

R164

C102

IC300

C312

RB102

TP188

C304

C112

TP189

C166

RB101

R629

R167

C303

R101

R180

R166

C708

R709

R111

R168

R169

C313

C181

C180

C709

R113

TP181

C182

R114

R112

C111

TP186

TP184

TP183

C183

R175

SW1

RB112

RB113

TP185

R181

TP187

R507

TP182

R509

R508

R110

Q501

FMA3

TP559

FMB3

TP542

TP558

CN500

C546

TP557

TP551

FMB4

FMB5

TP541

R546

R551

C551

TP560

C508

TP58

C545

TP556

R547

TP555

C531

X541

C542

TP554

TP553

TP552

C501

TP62

C541

C543

R503

TP504

TP63

TP64

TP57

TP61

TP59

R545

TP51

C540

R504

Q502

TP60

C302

R541

R543

C544

C509

C705

TP564

FB501

TP530

R542

R544

R502

C518

C506

C519

R311

TP528

TP531

C502

TP503

TP561

TP52

C301

C311

TP529

TP527

RB301

TP523

IC500

C507

R501

R176

C165

C707

R631

R630

R312

R505

TP19

R506

IC700

TP563

C521

TP526

TP501

R172

C503

C517

R708

TP524

C505

R170

R171

R177

R173

TP562

TP402

TP521

R704

R707

TP525

TP522

R513

C516

R515

C512

R511

C504

R703

R702

R701

TP10

TP11

C513

R165

C706

TP401

C514

C515

TP502

TP519

TP12

C510

IC200

C511

C160

TP20

TP18

R622

TP622

C600

TP513

R514

R512

C103

BP4

TP512

TP15

TP14

TP13

BP1

CN401

FB503

TP22

TP17

TP16

TP3

BP2

R516

TP21

BP7

TP9

R625

TP621

R604

TP23

TP8

R602

TP5

FB502

TP603

Ref. No. Location

D101 G-3

I

CDX-V5800

IC100 E-3

IC200 B-11

IC300 B-3

IC400 C-2

IC500 D-10

IC600 G-2

IC700 G-10

Q501 E-5

Q502 E-9

17 17

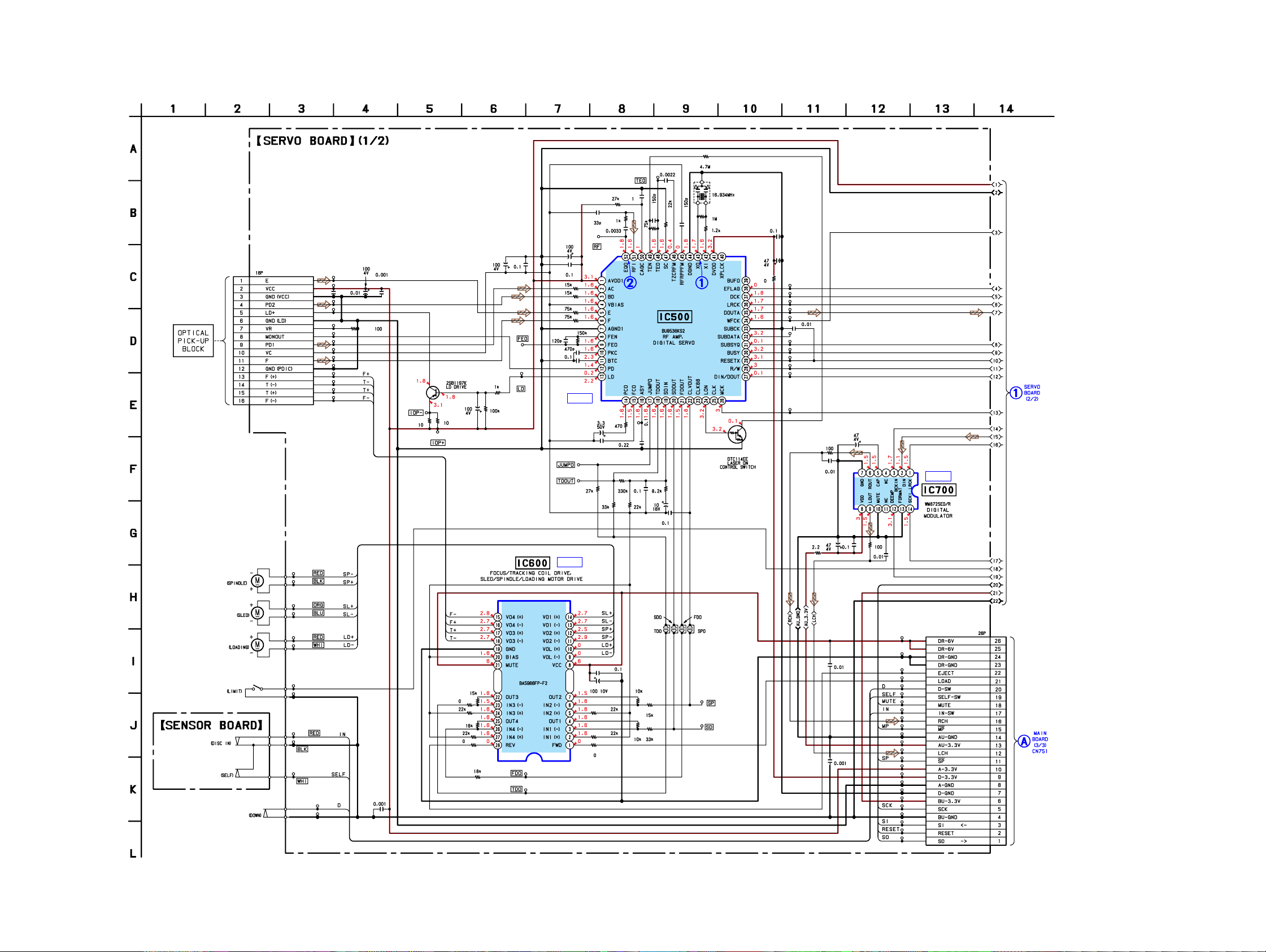

Page 18

CDX-V5800

Ver. 1.4

• Refer to page 16 for Waveforms.

3-8. SCHEMATIC DIAGRAM — CD MECHANISM SECTION (1/2) — • Refer to page 27 for IC Block Diagrams. • Refer to page 29 for IC Pin Description of IC500.

CN500

TP551

TP552

C551

TP555

TP556

TP557

TP558

TP559

TP560

TP561

TP562

TP563

TP564

TP553

TP554

C501

R551

C508

TP504

R509

TP503

R508

Q501

C506

C517

R506

R507

C507

TP501

TP502

R501

R502

R503

R504

C503

C504

C505

C518

C502

R505

IC B/D

TP512

TP513

R512

C545

TP542

C511

R516

C512

C546

R545

R546

R511

R515

C544

TP541

C515

R514

TP511

R544

C513

C514

R513

IC500

R547

X541

C541

R542

R541

Q502

C531

FB501

C540

C521

TP531

TP530

TP529

TP528

TP527

TP526

TP525

TP524

TP523

TP522

TP521

TP519

(Page 19)

C705

R709

C709

543

R

C542

543

C

IC B/D

IC700

C516

SW3

SW2

M901

S901

M902

M903

SW1

TP63

TP64

TP61

TP62

TP59

TP60

TP57

TP58

TP55

TP56

TP53

TP51

TP52

C509

R622

R623

R626

R627

R624

R621

R625

IC600

TP621

TP622

IC B/D

R600

C600

R606

R605

C605

R603

R604

R602R601

C708

R708

C707

R707

C706

BP3

BP4

BP2

BP1

TP603

TP601

C510

C519

TP1

TP2

TP3

TP4

TP5

TP6

TP24

TP7

TP8

TP9

TP10

TP11

TP12

TP13

TP14

TP15

TP16

TP17

TP18

TP19

TP20

TP21

TP22

TP23

CN1

(Page 23)

CDX-V5800

1818

Page 19

• Refer to page 16 for Waveform.

3-9. SCHEMATIC DIAGRAM — CD MECHANISM SECTION (2/2) — • Refer to page 28 for IC Block Diagram. • Refer to page 31 for IC Pin Description of IC400.

L401

IC B/D

C404

R402

RB110

TP131

C132

R105

R104

R103

RB109

RB108

IC400

BP7

R108

R107

R106

RB111

C401

C402

R403

C405

FB503

FB504

TP401

TP402

CN401

CDX-V5800

CN401

(Page

18)

C102

C103

D101

R165

R163

C406

C164

C407

R167

R161

R162

R169

R629

X401

R171

R405

R173

C166C163C161

R164

R175

R701

R703

R702

R704

R178

R166

R168

R170

R172

R177

R180

R404

C160

TP188TP189

C180

C162

R176

C165

C131

R102

RB107

C133

FB502

RB106

C201

C202

RB105

RB104

IC100

C182C181

TP181

C183

TP182

TP183

TP185

TP184

R109

R110

R111

TP186

TP187

RB112

R181

RB113

R112

R113

R114

RB103

RB102

R101

C111

C112

RB101

IC200

R630

R631

C403

R401

RB301

C302

C303

C305

C304

C301

IC300

C311

C313

C312

R312

R311

CDX-V5800

19 19

Page 20

CDX-V5800

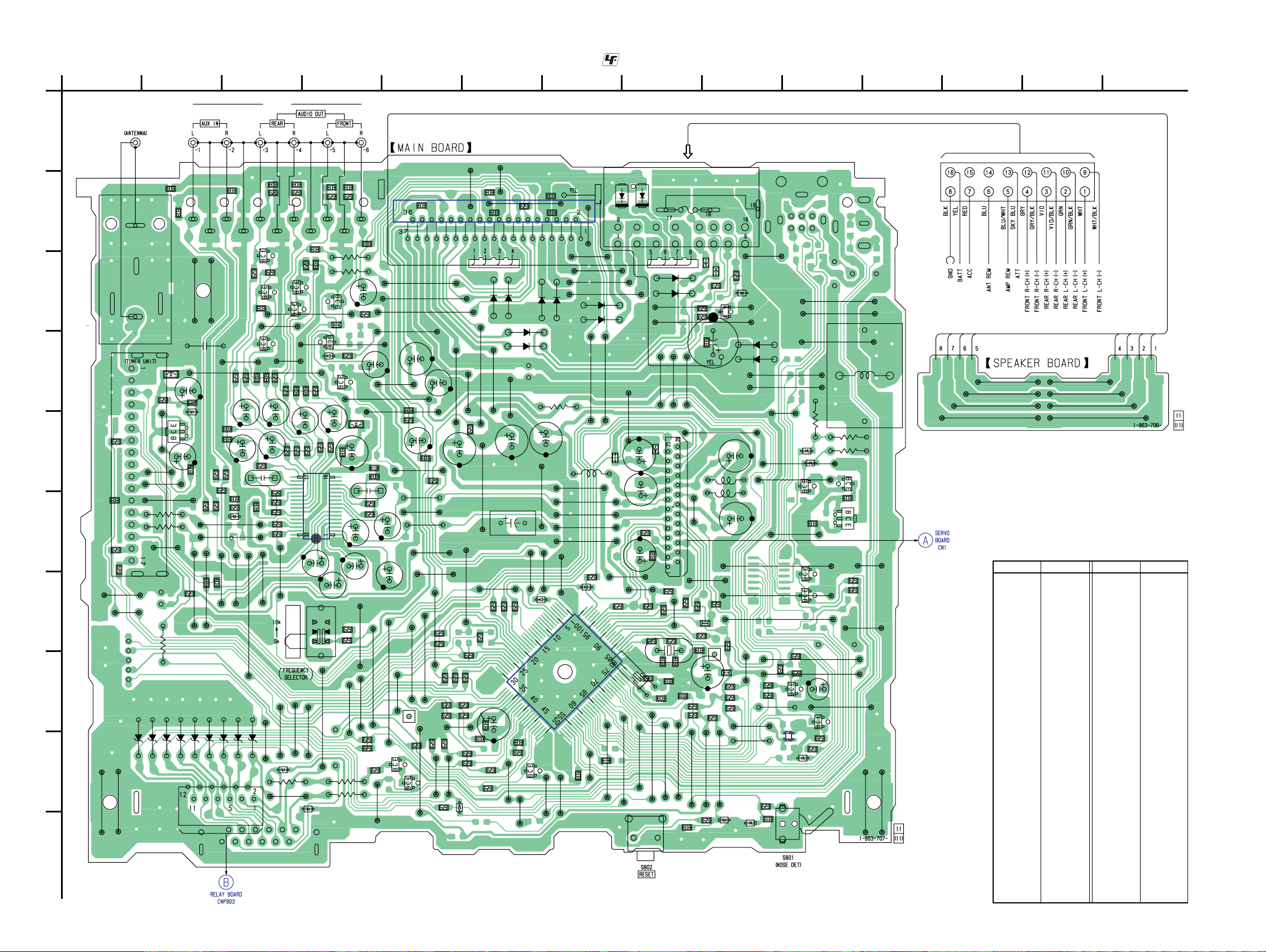

3-10. PRINTED WIRING BOARDS — MAIN SECTION — • Refer to page 15 for Circuit Boards Location. : Uses unleaded solder.

A

B

C

D

E

F

G

H

J

1

PJ601

TUX601

R606

C612

JW

JW

JW

47

48

R608

R607

I

JW4

JW3

234567891011 12 13 14

PJ401

C818

R854

JW19

D903

R847

C816

FB702

C709

R836

R853

JW18

CNP901

D916

D917

R932

JW103

CN751

C820

C817

R873

R814

JW17

C815

F901

JW102

R709

JW142

JW16

R931

JW101

C822

C812

C992

L702

JW49

JW

R703

JR12

JW15

R437

FB901

R920

L701

82

R837

R860

JW92

C825

JW14

D808

FB902

C922

C704

C705

JW

R810

FMB3

JR5

R901

JW13

JW

D918

JW

JW

R835

R848

R844

84

R913

99

100

85

R925

JW

R845

D803

JW

D914

JW

JW11

12

D920

D919

JW

R903

R863

R855

C814

98

94

JW

JW

R852

97

JW

96

JW

95

JW

L900

93

88

JW

R917

R702

R928

R912

Q703

JW

Q701

JW

R824

R825

81

86

(Page 17)

D915

78

D912

77

Q902

R701

79

JW

Q907

Q906

83

JW

206

JW

205

JW

202

JW

201

JW

• Semiconductor Location

Ref. No. Location

D301 F-3

D400 D-4

D600 E-2

D701 G-7

D702 G-6

JW

JW

JW

207

204

203

JW

D801 I-6

R904

Q900

R902

JW

C908

JW

80

8

JW

9

D803 J-9

D808 J-9

D811 I-3

D812 I-3

D813 I-3

D814 I-2

D815 I-2

D816 I-2

IC802

S801

D901

R905

R907

Q901

JW2

JW1

D817 I-2

D821 I-2

D822 I-2

D823 J-4

D824 I-3

D901 I-10

D902 B-7

D903 B-8

D904 C-6

D905 C-6

D906 C-7

D907 C-7

D908 C-8

D909 C-8

D912 E-10

D914 C-9

D915 E-10

D916 C-8

R615

JW

JW

R604

R603

150

D821

JW61

60

59

L602

Q601

JW

D822

C617

C619

JR10

R815

D817

C618

58

C443

D815

JW6

C616

JW

C620

D600

C614

JW50

C409

D816

130

C450

C451

R468

R430

145

JW

144

JW

JW51

CNP802

JW5

R425

C408

D814

C439

JW

R415

R426

C303

R428

JW52

D813

Q407

R441

R420

Q404

C444

Q403

134

C420

R414

C423

C426

C453

R436

C415

R302

D301

JW53

JW54

D811

D812

(Page 25)

C436

R440

C418

R412

JW55

R443

JW

JW

R416

C452

JW136

D824

Q405

Q406

128

131

C421

C425

R413

R408

R409

R411

JW56

S800

JW43

JW

C440

JW

R435

R870

44

R419

C422

R404

JW42

D823

C435

R442

JW127

121

D400

R417

R406

C412

C424

R405

IC401

C454

JW41

C438

Q402

JR6

JW39

C434

R421

R431

Q401

Q400

R407

C406

R808

R800

R871

R833

R429

R424

C428

C416

R418

C407

R402

R403

C413

C433

R432

JW46

R864

R865

C437

L400

C417

R872

C106

C430

C400

C411

JW34

JW45

JW28

JW

JW

R447

JW40

Q802

122

120

C410

JW37

JW

C446

C414

FM

R809

Q801

123

C101

C447

JW87

B4

C113

JW

JW

JW

JW

C441

JW

R400

JW

R401

JW36

126

125

124

151

66

63

JW

R832

R834

JW27

C107

67

JW

R861

JW38

R806

R817

IC100

R448

62

JW35

R862

R821

JW30

R819

JW

R805

R823

R818

31

C823

R804

JW29

C991

JW118

C111

JW64

R801

D801

C993

JW113

JW117

R927

R830

R828

R822

C821

R850

R849

JW

JW116

JW141

JW

R839

C813

JW112

111

D904

JW115

C810

65

R840

R427

D905

D922

JW114

C809

R841

C807

R826

Q800

JW26

D921

JW68

D702

JW138

C994

R101

JW140

JW69

D907

JW25

C990

D906

C109

JW

JW

JW

JW

JW

JW

143

JW70

IC801

C706

JW24

JW

L700

72

76

74

73

D701

109

107

JW

R843

JW22

JW110

106

R916

108

JW

JW105

L703

R705

D902

JW104

C707

75

JW

JW20

D908

D909

JW91

JW

X800

X801

C711

C701

R708

10

R846

R936

JW139

S802

200

Ref. No. Location

D917 C-8

D918 C-9

D919 D-9

D920 D-9

D921 D-6

D922 C-6

IC100 B-5

IC401 F-4

IC801 H-7

IC802 I-10

Q400 D-4

Q401 D-4

Q402 C-4

Q403 D-3

Q404 C-3

Q405 C-3

Q406 C-3

Q407 C-3

Q601 E-2

Q701 F-10

Q703 E-10

Q800 I-6

Q801 I-5

Q802 I-5

Q900 H-10

Q901 H-10

Q902 E-10

Q906 G-10

Q907 F-10

CDX-V5800

2020

Page 21

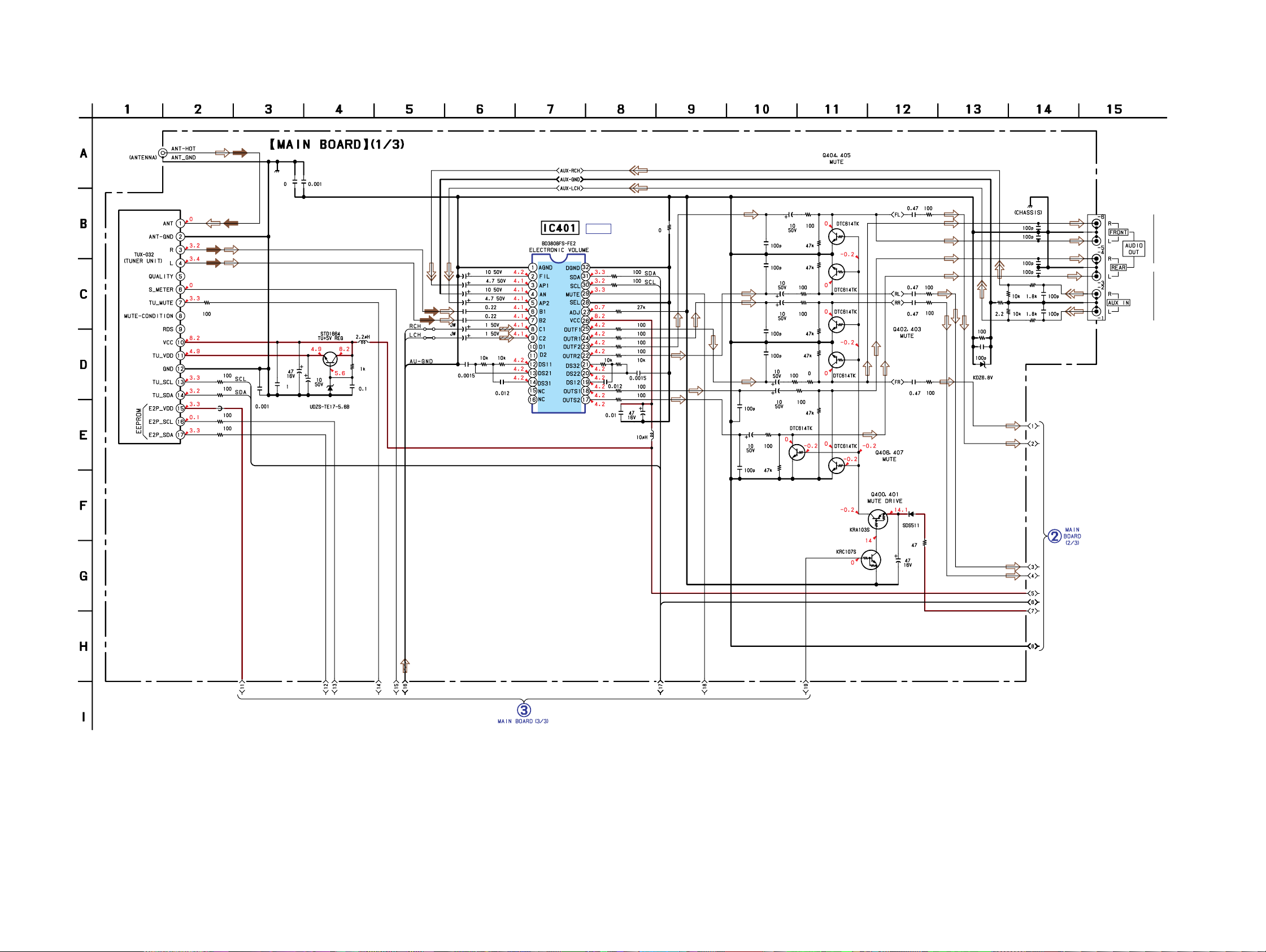

3-11. SCHEMATIC DIAGRAM — MAIN SECTION (1/3) — • Refer to page 28 for IC Block Diagram.

PJ601

C616

C617

TUX601

R606

R604

R603

R608

R607

JR10

C612

C614

C618

C619

Q601

D600

L602

R615

C620

R401

R400

C407

C414

C413

C454

C412

C409

C408

C411

C410

R403R402

C406

IC401

IC B/D

R408

C416

C415

R412

R411

R409

R407

R406

R405

R404

R413

R435

R436

C417

C418

L400

C400

C450

C453

C424

C421

C420

C426

C425

C423

C422 R418

C428

R417

C452

R441

R415

R414

R440

Q407

R416

R421

R420

R419

JR6

R442

Q405

Q404

Q403

Q402

Q406

C440 R431

C444 R432

R429

C438

C437 R427

R302

C303

D301

C433

C434

C435

C436

CDX-V5800

PJ401

R426R425

C439

R430R428R468

C443

(Page 23)

R443C451

C430

D400

R424

(Page 22)

Q401

Q400

CDX-V5800

21 21

Page 22

CDX-V5800

3-12. SCHEMATIC DIAGRAM — MAIN SECTION (2/3) —

C113

C101

C107

C993

IC100

D921

D922

D904

D903

D902

D905

D906

D907

D908

D909

D917

D916

CNP901

(Page 21)

C441

R448

C106

R447

C446

C447

C991

FB901

R920

FB902

R931

R932

R913

C990C994

D914

D918

L900

Q900

R902

R903

C908

R904

C111

C109

R905

Q901

R101

R907

D901

C922

C992

D920

D919

F901

CDX-V5800

(Page 23)

C706

R825

Q906

R912 R917 R928

R824

Q907

D912

D915

Q902

2222

Page 23

• Refer to page 16 for Waveforms.

3-13. SCHEMATIC DIAGRAM — MAIN SECTION (3/3) — • Refer to page 32 for IC Pin Description of IC801.

CDX-V5800

Ver. 1.1

(Page 18)

(Page 26)

CN751

CNP802

C705

C701

C709

L702

C711

R708

R709

R703

C704

L703

R843

C707

L700

L701

FB702

D701

Q703

R702

Q701

R870

R833

R701

R871 R872

(Page 21)

C807 R826

R815

S800

Q802

R800

C813

R805

R806

R865

R864

R809R808

R814

R834

R818

R832

R801

R804

R850

C821

Q800

R819

R849

R821

R823

R822

D801

R927

R835

R828

C810

R830

R916

R862

R861

R839

R863

C809

R840

R841

IC801

R817

R852

(Page 22)

D702

R705

JR12

TP11

R837

C825

C822

C820

R936

R853

C818

X800

R854

X801

R848

R844

R901R925

R873

C816

C812

C817

R845

R860

IC802

R846

R847

R836

R810

JR5

CDX-V5800

D824

D822

D821

D817

D815

D816

D814

D813

D812

D811

D823

Q801

23 23

R855

C814 C815

D803 D808

R437

S802S801

Page 24

CDX-V5800

3-14. PRINTED WIRING BOARD — DISPLAY SECTION — • Refer to page 15 for Circuit Boards Location. : Uses unleaded solder.

A

B

C

D

1

LED907

234567891011 12 13 14

S903

S919

S904

LED927

S905

R990

R972

S918

S906

R989

LED923

LED908

LED929

S902

LED909

LED924

S908

LED910

LED928

LED921

S907

S909

IC951

S917

LED902

LED922

S916

LED915

S915

LED916

LCD901

S914

LED917

S913

LED918

S912

LED911

S911

LED912

S910

S901

LED913

LED905

LED914

E

F

G

H

R978

R908

R906

R905

• Semiconductor Location

Ref. No. Location

D902 G-11

D903 H-11

D904 H-11

D905 G-7

D906 G-11

D951 G-7

IC901 G-9

IC905 G-6

R994

R907

R992

R988

Ref. No. Location

IC951 A-6

LED902 B-6

LED905 B-14

LED907 B-2

LED908 A-3

LED909 B-4

LED910 B-5

LED911 D-11

R909

RE901

R904

R903

Ref. No. Location

LED912 D-12

LED913 D-12

LED914 D-13

LED915 D-7

LED916 D-8

LED917 D-9

LED918 D-10

LED921 D-5

LED922 D-6

R902

R980

R918

R919

R982

R910

R991

R971

Ref. No. Location

LED923 D-3

LED924 C-4

LED927 C-2

LED928 C-5

LED929 C-3

Q501 G-7

C951

R952

R924

R917

R977

IC905

R947

R925

R916

R976

Q501

R926

C958

R940

R941

R951

D951

D905

R961

R954

R958

R960

R955

R959

C954

C956

R953

R956

R915 R914

R985

C957

C955

C953

R957

C952

FMB6

IC901

R912R986

R913

FMB5

D902

D906

R927

D903

R974

R928

D904

CN901

(Page 25)

R983

R975

R901

R984

R911

R922

R973

CDX-V5800

2424

Page 25

3-15. PRINTED WIRING BOARD — RELAY SECTION — • Refer to page 15 for Circuit Boards Location. : Uses unleaded solder.

CDX-V5800

A

B

C

D

1

23456

(Page 24)

LED931

LED930

R931

C974

S931

C973

CNP902

(Page 20)

CNP903

E

F

CDX-V5800

25 25

Page 26

CDX-V5800

3-16. SCHEMATIC DIAGRAM — DISPLAY SECTION —

(Page 23)

R926R925

R928R927

LED902 LED905

R922R924

Q501

R947

R940

LED931

R931

CNP903

C973

R971 R983 R976 R977

LED910

LED912

LED911

R989 R974

R941

LED930

S931

R991 R973 R975 R980 R972

LED915

LED922

LED916 LED917

LED921

R985 R982 R994 R984 R986 R978 R990

CNP902

C974

LED914

LED929

LED913

CN901

LED918

LED924

LED923

RE901(1/2)

D906

LED927LED928

LED909

LED907LED908

R988

R992

IC951

R952

C954

C956

C955

R901

S901 S910

R902

R903

R904

R905

R906

R907

R911

R912

R913

R914

R915

R916

S919

S902

S903

S904

S905

S906

C951

R951

S911

S912

S913

S914

S915

S916

D951

C957

R954

R955

R956

R961

R958

R959

R960

C953

C958

D905

R957

IC905

C952

IC901

R953

LCD901

CDX-V5800

D902

D903

D904

RE901(2/2)

S908

S909

2626

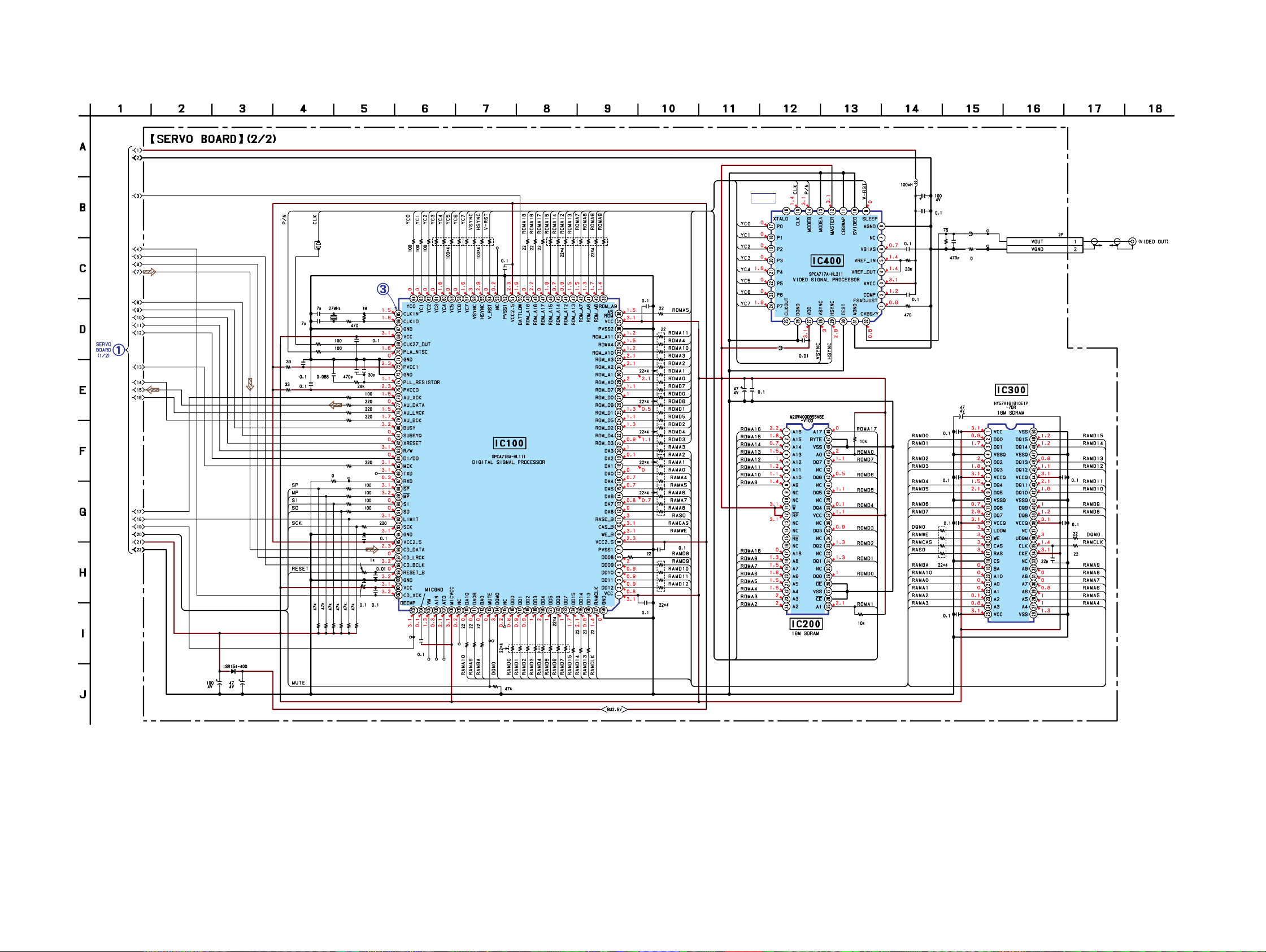

R908

R917

R909

R918

R910 R919

S917

S918

S907

Page 27

3-17. IC BLOCK DIAGRAMS

IC500 BU9536KS2 (SERVO Board)

EQO

RFI

CAGC

TEN

TEOSCTZCRFM

RFRPRFN

DIGITAL

SERVO

FILTER

DIGITAL SERVO

SIGNAL

PROCESSOR

AVDD

VBIAS

AGND

FEN

FEO

PKC

BTC

51 5052

49 48 47 46 45 44 43 42 41 40

1

AC

2

BD

3

4

E

5

F

6

7

8

9

10

11

PD

12

LD

13

RF SIGNAL GEN.

GEN.

SERVO SIGNAL

APC

PLL

DGNDXOXI

DIGITAL

SIGNAL

PROCESSOR

16K

SRAM

COMMAND

INTERFACE

DVDD

XPLCK

39

38

37

36

35

34

33

32

31

30

29

28

27

XBUFO

EFLAG

DCK

LRCK

DOUTA

WFCK

SUBCK

SUBDATA

SUBSYQ

BUSY

RESETX

R/W

DIO

CDX-V5800

IC600 BA5966FP-F2

REV

OPIN4(+)

OPIN4(–)

2728 26 25

+–

LOADING DRIVER

REV

OUT F

FWD

OUT R

14 15 16

PCO

OPOUT4

OPIN3(+)

24 23 22 21 20 19 18 17 16 15

OPIN3(–)

+–

–

+

+

–

17 18 19 20 21 22 26252423

FCO

ASY

JUMPO

OPOUT3

TDOUT

–

+

+

–

SDIN

FDOUT

SDOUT

MUTE

CLVOUT

MUTE

CLK88

LON

CLK

BIAS

MCK

GND

VO3(–)

+–

+–

+

–

LEVEL

SHIFT

LEVEL

SHIFT

–+

VO3(+)

VO4(–)

+–

–

LEVEL

SHIFT

LEVEL

SHIFT

–

VO4(+)

+–

+

+

FWD

+–+–

4 5 6 7 8 9 10 11 12 13 1421 3

OPIN1(–)

OPOUT1

OPIN1(+)

OPIN2(+)

OPIN2(–)

OPOUT2

VCC

VCC

VOL(–)

VOL(+)

+–

VO2(–)

+–

VO2(+)

+–

VO1(–)

+–

VO1(+)

27

Page 28

CDX-V5800

IC700 WM8725ED/R

(SERVO Board)

LRCIN

DIN

BCKIN

CAP

VOUTR

GND

1

2

3

NC

4

5

SIGMA-DELTA

MODULATOR

6

7

DIGITAL

SWICHED

CAPACITOR

DAC

SERIAL

INTERFACE

DIGITAL

FILTER

DIGITAL

SIGMA-DELTA

MODULATOR

SWICHED

CAPACITOR

DAC

IC401 BD3808FS-FE2 (MAIN Board)

DGND

SDA

SCL

MUTE

32 31 30 29 28 27 26 25 24 23 22

SEL

14

13

12

11

10

9

8

ADJ

SCKI

FORMAT

DEEMPH

NC

MUTE

VOUTL

VDD

VCC

OUTF1

OUTR1

OUTF2

FSADJUST

COMP

VAA

VREFOUT

VREFIN

VBIAS

AGND

OUTR2

IC400 SPCA717A-HL211

(SERVO Board)

CVBS/Y32AGND31TEST30HSYNC29VSYNC28VDD27DGND26CLKOUT

1

2

9

DAC

3

4

INTERNAL

5

VREF

6

DS12

VBI

GENERATOR

9

SLEEP

DS22

10

LUMA

DS32

7

8

21 20 19 18 17

11

CBSWP

12

MASTER

LATCH

1.3MHz

LPF

2X

UPSAMPLE

MOD.AND

MIXER

14

MODEA13MODEB

OUTS1

15

16

CLK

OUTS2

XTALO

25

DATA7

24

23

DATA6

DATA5

22

21

DATA4

20

DATA3

19

DATA2

18

DATA1

DATA0

17

2

I

C BUS

LOGIC

BASS

fo:60,70,80,100,120,140,160,200Hz

Q:0.5,0.75,1,1.25

MIDDLE

fo:500Hz,1kHz

Q:1

TABLE

fo:5,7.5,10,12.5kHz

VCO

VCC

FADER

(0~-58,

-∞dB)

EFFECT (0dB~

+20dB,2dB STEP)

TONE

PASS

(+23~-79dB,-∞dB

fc:40kHz fc:40kHz

(0~15dB,1dB STEP)

(4 STEREO INCLUDE 1 ISOLATION INPUT)

FADER

(0~-58,

-∞dB)

TONE

PASS

BASS,TREBLE, MIDDLE

(-15dB~+15dB,1dB STEP)

VOLUME

1dB STEP)

ANTI-ALIASING

FILTER

INPUT GAIN

MUTE

INPUT SELECTOR

FADER

(0~-58,

-∞dB)

EFFECT (0dB~

+20dB,2dB STEP)

BASS,TREBLE, MIDDLE

(-15dB~+15dB,1dB STEP)

VOLUME

(+23~-79dB,-∞dB

1dB STEP)

ANTI-ALIASING

FILTER

INPUT GAIN

(0~15dB,1dB STEP)

MUTE

FADER

(0~-58,

-∞dB)

2ND ORDER LPF

fc:OFF,80,120,160Hz

Q: 0.707

MIX

GAIN+ATT

(+10~-29,

-∞dB)

2ND ORDER

LPF

28

AGND

VCC/2

6 7 8 9 10 113 4 521

AP1

AN

FIL

AP2

B1

B2

C2

C1

D1

D2

12 14 1613 15

DS11

DS21

DS31

NC

NC

Page 29

• IC PIN DESCRIPTIONS

• IC500 BU9536KS2 (RF AMP, DIGITAL SERVO) (SERVO BOARD (1/2))

Pin No. Pin Name I/O Pin Description

1AVDD1 — Analog power supply pin (+3.3 V)

2ACIA+C voltage signal input from optical pick-up block

3BDIB+D voltage signal input from optical pick-up block

4 VBIAS O Bias level (VDD/2) signal output

5EIE voltage signal input from optical pick-up block

6FIF voltage signal input from optical pick-up block

7AGND1 — Analog ground pin

8 FEN I Focus error amplifier feedback signal input

9 FEO O Focus error signal output

10 PKC O RF signal peak detection capacitance connected pin

11 BTC O RF signal bottom detection capacitance connected pin

12 PD I APC photo detecter signal input

13 LD O APC laser drive signal output

14 PCO O PLL PCO signal output

15 FCO O PLL FCO-DAC signal output

16 ASY I Asymmetry revice and ccomparator slice capacitor install pin

17 JUMPO O Tracking jump pulse signal output

18 TDOUT O Tracking drive signal output

19 SDIN I Sled signal input

20 SDOUT O Sled drive signal output

21 FDOUT O Focus drive signal output

22 CLVOUT O CLV drive signal output

23 CLK88 O Clock signal output for driver IC Not used in this set. (Open)

24 LON O Laser on control signal output

25 CLK O Clock signal output Not used in this set. (Open)

26 MCK I Transfer clock signal input for sub Q and command

27 DIN/DOUT I/O Command signal input/status, sub-Q signal output

28 R/W I Read/write signal input for command

29 RESETX I System reset signal input “L”: reset

30 BUSY O Busy signal output

31 SUBSYQ O Sub cord synchronizing signal output

32 SUBDATA O Sub cord data signal output

33 SUBCK I Sub cord bit clock signal input Not used in this set. (Fixed at “L”.)

34 WFCK O Disc frame synchronizing signal output

35 DOUTA O Audio serial data signal output

36 LRCK O Audio LR signal output

37 DCK O Audio serial bit clock signal output

38 EFLAG I/O Error flag signal input/output

39 BUFO O X'tal 16.9344 MHz buffer signal output Not used in this set. (Open)

40 XPLCK I/O XPLCK signal input/output Not used in this set. (Open)

41 DVDD — Digital power supply pin (+3.3 V)

42 XI I X'tal 16.9344 MHz connect input

43 XO O X'tal 16.9344 MHz connect output

44 DGND — Digital ground pin

45 RFRPPFM O RFRP capacitor install pin or RF test monitor signal output

46 TZCRFM O TZC capacitor install pin or RF monitor signal output

47 SC I Scratch depth adjustment resistor connected pin

48 TEO O Tracking error signal output

CDX-V5800

29

Page 30

CDX-V5800

Pin No. Pin Name I/O Pin Description

49 TEN I Tracking error amplifier feedback signal input

50 CAGC I RFAGC capacitor install pin

51 RFI I RF signal input

52 EQO O RF equalizer signal output

30

Page 31

CDX-V5800

• IC400 SPCA717A-HL211 (VIDEO SIGNAL PROCESSOR) (SERVO BOARD (2/2))

Pin No. Pin Name I/O Pin Description

1 FSADJUST —

2 COMP —

3AVCC — Analog power supply pin (+3.3 V)

4 VREF OUT O

5 VREF IN I

6 VBIAS — DAC bias voltage Potential normally 0.7 V less than pin 2 (COMP).

7NC—Not used. (Open)

8AGND — Analog ground pin

9 SLEEP I pin is equal to reset pin. An external logic high pulse should input to the pin when

10 SVIDEO I

11 CBSWAP I

12 MASTER I

13 MODEA I Mode configuration pin Not used in this set. (Fixed at “L”.)

14 MODEB I Mode configuration pin

15 CLK I

16 XTALO O Crystal oscillator output Not used in this set. (Open)

17 to 24 P0 to P7 I

25 CLKOUT O Pixel clock signal output Not used in this set. (Open)

26 DGND — Digital ground pin

27 VDD — Digital power supply pin (+3.3 V)

28 VSYNC I/O

29 HSYNC I/O

30 TEST I Test pin These pins must be connected to digital ground.

31 AGND — Analog ground pin.

32 CVBSY O

Full-Scale adjust control pin The Full-Scale current of D/A converters can be

adjusted by connecting a resistor (RESET) between this pin and ground.

Compensation pin A0.1 µF ceramic capacitor must be used to bypass this pin to VAA.

The lead length must be kept as short as possible to avoid noise.

Voltage reference signal output It generates typical 1.2 V voltage reference and may

be used to drive pin 5 (VREF IN) directly.

Voltage reference signal input An external voltage reference must supply typical

1.235 V to this pin. A0.1 µF ceramic capacitor must be used to de-couple this input

to ground. The decoupling capacitor must be as closed as possible to minimize the

length of the load. The pin may be connected derectry to pin 4 (VREF OUT).

Power save mode A logic high on this pin puts the chip into power-down mode. This

power on.

Video signal selection pin A logic high selects Y output. A logic low selects

composite video output. Not used in this set. (Fixed at “L”.)

Cr and Cb pixel sequence configuration pin A logic high sw ap the Cr and Cb sequence.

Not used in this set. (Fixed at “L”.)

Master/Slave mode selection A logical high for master mode operation. A logical 0

for slave mode operation. Not used in this set. (+3.3 V)

27 MHz crystal oscillator input A crystal with 27 MHz clock frequency can be

connected between this pin and pin qh (XTALO).

YCrCb pixel inputs

They are latched on the rising edge of CLK.

Vertical sync input/output

VSYNC is latched/output following the rising edge of CLK.

Horizontal sync input/output

HSYNC is latched/output following the rising edge of CLK.

Composite/Luminance output. This is a high-impedance current source output. The

output format can be selected by the PAL pin. The CVBSY can drive a 37.5 Ω load.

31

Page 32

CDX-V5800

Ver. 1.1

• IC801 MB90477PF-G-185-BNDE1 (SYSTEM CONTROL) (MAIN BOARD (3/3))

Pin No. Pin Name I/O Pin Description

1 LINE ATT O Audio mute control signal output

2 to 4 NC — Not used in this set. (Open)

5 BEEP O Beep signal output to power amp IC

6VOL ATT O Electrical volume ATT control signal output

7 to 10 NC — Not used in this set. (Open)

11 VSS — Ground pin

12 to 14 NC — Not used in this set. (Open)

15 TU ATT O Tuner mute control signal output

16, 17 NC — Not used in this set. (Open)

18 CD SI I CD servo serial data signal input

19 CD SO O CD servo serial data signal output

20 CD SCK O CD servo serial clock signal output

21 RE 0 I Rotary encoder signal input 0

22 RE 1 I Rotary encoder signal input 1

23 VCC+3.3 — Power supply pin (+3.3 V)

24 EEP SIO I/O Serial data signal input/output for EEPROM communication

25 EEP SCK O Serial clock signal output for EEPROM communication

26 SHUT SW I

27 LCD CE O Chip enable signal output to LCD driver IC

28 LCD SO O Serial data signal output to LCD driver IC Flash: UART serial out

29 LCD SCK O Serial clock signal output to LCD driver IC

30 NC — Not used in this set. (Open)

31 STB O Standby signal output to power amp IC

32 AUX — Not used in this set. (Open)

33 IIC SCK O IIC bus serial clock signal output

34 IIC SIO I/O IIC bus serial data signal input/output

35 VCC+3.3 — Power supply pin (+3.3 V) (for A/D converter)

36 AVRH+3.3 — External reference power supply (+3.3 V) (for A/D converter)

37 AVSS — Ground pin (for A/D converter)

38, 39 KEY IN0, 1 I Key signal input

40 NC — Not used in this set. (Open)

41 NC — Not used in this set. (Fixed at “H”.)

42 VSS — Ground pin

43, 44 NC — Not used in this set. (Fixed at “L”.)

45 VSM I S meter voltage detect signal input

46 DST SEL I Destination select pin

47 KEY ACK I Key acknowledge detect signal input

48 NC — Not used in this set. (Open)

49, 50 MD0, 1 I Input for operation mode designation (Fixed at “H”.)

51 MD2 I Input for operation mode designation (Fixed at “L”.)

52 NC — Not used in this set. (Open)

53 BU IN I Back up power supply detect signal input

54 SP O SP mode select signal output

55 CD SELFSW I CD mechanism self load position detect switch signal input

56 DIAG I Condition input from power amp IC

57 NC — Not used in this set. (Open)

58 UNI SI I Serial data signal input

59 UNI SO O Serial data signal output

60 UNI SCK O Serial clock signal output Not used in this set. (Open)

61 BUS ON O Bus on signal output

62 SYS RST O System reset signal output

Shutter switch open/close detect signal input

“L”: Panel open, “H”: Panel close Not used in this set. (Open)

32

Page 33

CDX-V5800

Pin No. Pin Name I/O Pin Description

63 TEL ATT O TEL ATT signal output

64 ACC IN I Accessory power supply detect signal input

65 SIRCS I Remote control signal (infrared rays) input

66 NC — Not used in this set. (Fixed at “L”.)

67 PAK BK I Test mode detect signal input

68 FLASH W I

69 NOSE SW I Nose detect switch signal input

70, 71 NC — Not used in this set. (Open)

72 DOOR SW I

73 DOOR IND O Door indicator control signal output

74 NC — Not used in this set. (Fixed at “H”.)

75 XKEY ON O Key power supply control signal output Pin rj (KEY ACK) active: “L” output

76 NC — Not used in this set. (Open)

77 RESET I Reset signal input

78 NC — Not used in this set. (Open)

79 X1A — Oscillator connect pin (32.768 kHz)

80 X0A — Oscillator connect pin (32.768 kHz)

81 VSS — Ground pin

82 X0 — Oscillator connect pin (3.68 MHz)

83 X1 — Oscillator connect pin (3.68 MHz)

84 VCC+3.3 — Power supply pin (+3.3 V)

85, 86 NC — Not used in this set. (Open)

87 CD ON O CD power on/off control signal output

88 NC — Not used in this set. (Open)

89 TEST MODE I Test mode pin

90 MP O MP mode select signal output

91 NC — Not used in this set. (Open)

92 CD IN SW I CD mechanism IN-SW detect signal input

93 CD LOAD O CD mechanism loading motor control signal output

94 EJECT O CD mechanism eject motor control signal output

95 D SW I CD mechanism DSW detect signal input

96 LIMIT SW I CD mechanism IN-LIMIT SW signal input Not used in this set. (Open)

97 NC — Not used in this set. (Open)

98 CD XRST O CD servo reset signal output

99 NC — Not used in this set. (Open)

100 NC — Not used in this set. (Open)

Memory mode changeover signal input

Normally “H” input (single chip mode) “L” after reset: Flash write mode

Front panel open/close detect signal input

“L” input: Panel close, “H” input: Panel open

33

Page 34

CDX-V5800

NOTE:

• The mechanical parts with no reference

number in the exploded views are not supplied.

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

SECTION 4

EXPLODED VIEWS

• Color Indication of Appearance Parts

Example :

KNOB, BALANCE (WHITE) ... (RED)

RR

Parts Color Cabinet’s Color

• Accessories are given in the last of this

parts list.

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

4-1. MAIN SECTION

8

not supplied

MG-611MK-186//K

#1

A

#1

#1

13

A

B

10

F901

12

9

TUX601

6

not supplied

7

#1

11

not supplied

#2

5

4

#1

3

4

Ref. No. Part No. Description Remark

1 X-3384-273-1 LOCK ASSY

2 1-792-173-11 CABLE, FLAT (FFC) 12P

3 3-246-030-01 BUTTON (EJECT)

4 3-261-903-01 SCREW (+BTT M2X5)

5 X-3384-270-1 PANEL ASSY (CD), SUB

6 X-3384-271-2 GEAR ASSY

7 3-713-786-51 SCREW +P 2X3

* 8 3-246-006-31 COVER

9 3-922-535-11 SCREW (+BTT)

B

#1

1

2

Ref. No. Part No. Description Remark

10 1-792-194-41 CORD (WITH CONNECTOR) (POWER)

11 A-1066-866-A MAIN BOARD, COMPLETE

12 1-829-847-11 CABLE, FLAT (FFC) 26P

13 1-829-836-11 CORD, CONNECTION (VIDEO) (VIDEO OUT)

F901 1-532-877-11 FUSE (BLADE TYPE) (AUTO FUSE) 10A

TUX601 A-3220-961-A TUNER UNIT (TUX-032//Q)

#1 7-685-792-09 SCREW +PTT 2.6X6 (S)

#2 7-685-793-09 SCREW +PTT 2.6X8 (S)

not supplied

(RELAY board)

34

Page 35

4-2. FRONT PANEL SECTION

CDX-V5800

53

58

not

supplied

not

supplied

LCD901

not

supplied

54

not

supplied

55

#3

not supplied

(DISPLAY board)

not

supplied

57

#3

56

51

52

51 X-2022-327-1 KIT (SVX) ASSY, BUTTON

52 X-3384-637-1 KNOB VOL (SVX) ASSY

53 X-2022-326-1 PANEL ASSY (SVX), FRONT

54 1-780-097-11 CONDUCTIVE BOARD, CONNECTION

55 X-3384-501-2 PLATE SUB ASSY (N), LIGHT GUIDE

not supplied

Ref. No. Part No. Description RemarkRef. No. Part No. Description Remark

56 X-3384-284-1 PANEL ASSY (SVX), FRONT BACK

57 X-3378-390-3 CASE (PANEL) (for FRONT PANEL)

58 A-1065-505-A PANEL COMPLETE ASSY, FRONT

LCD901 1-805-455-11 DISPLAY PANEL, LIQUID CRYSTAL

#3 7-685-106-19 SCREW +P 2X10 TYPE2 NON-SLIT

35

Page 36

CDX-V5800

4-3. CD MECHANISM SECTION (1)

(MG-611MK-186//K)

not supplied

not supplied

102

not supplied

(SENSOR board)

not supplied

101

#4

103

104

106

105

108

107

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

101 A-3372-455-A CHASSIS (T) SUB ASSY

102 3-253-729-01 SPRING (LTR), TENSION COIL

103 3-253-746-14 SPRING (DAMPER), COMPRESSION

104 3-253-746-03 SPRING (DAMPER), COMPRESSION

105 3-253-695-01 SPRING (KF), TENSION COIL

106 3-253-748-01 DAMPER (S)

107 3-352-758-31 SCREW (M1.7), TOOTHED LOCK

108 A-1068-848-A SERVO BOARD, COMPLETE

#4 7-627-552-87 SCREW, PRECISION +P 1.7X2.2

36

Page 37

4-4. CD MECHANISM SECTION (2)

(MG-611MK-186//K)

154

(including M901)

CDX-V5800

155

156

157

#5

SW4

151

not supplied

M902

not supplied

not supplied

not supplied

158

153

not supplied

152

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

151 A-3337-637-A CHASSIS (OP) COMPLETE ASSY

152 3-316-938-91 SCREW (B1.4X5), TAPPING

0 153 8-820-207-02 OPTICAL PICK-UP (KSS1000E/K1RP)

154 A-3337-640-A CHASSIS (OP) SUB ASSY (including M901)

155 A-3337-641-A ARM SUB ASSY, CHUCKING

156 A-3337-639-A LEVER (SL) SUB ASSY

157 X-3383-454-3 LEVER (SL) ASSY

158 3-261-959-02 SPRING (SL), TORSION

M902 A-3337-638-A MOTOR ASSY, SL (SLED)

SW4 1-571-099-11 SWITCH (1 KEY) (LIMIT)

#5 7-627-850-77 SCREW, PRECISION +P 1.4X1.8

37

Page 38

CDX-V5800

4-5. CD MECHANISM SECTION (3)

(MG-611MK-186//K)

209

207

208

201

202

207

#4

M903

210

206

207

203

211

204

205

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

201 3-262-755-01 WASHER (1.1-2.5)

202 3-259-024-01 WHEEL (RA), WORM

203 A-3337-633-A ARM ASSY, ROLLER

204 3-259-455-02 SPRING (RAL)

205 3-253-713-01 SPRING (RAR)

206 3-259-469-01 SPRING (LE), LEAF

207 2-134-636-31 SCREW (M1.7X2.5)

208 3-259-467-01 BRACKET (LEM)

209 3-345-648-91 SCREW (M1.4), TOOTHED LOCK

210 A-3372-456-A WORM (LEB) ASSY

211 3-259-468-01 BEARING (LEB)

M903 A-3372-454-A MOTOR ASSY, LE (LOADING)

#4 7-627-552-87 SCREW, PRECISION +P 1.7X2.2

38

Page 39

4-6. CD MECHANISM SECTION (4)

(MG-611MK-186//K)

252

CDX-V5800

254

252

255

251

256

253

257

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

251 3-259-429-01 WHEEL (LE), WORM

252 3-344-223-01 WASHER

253 3-259-470-01 GEAR (LE1)

254 3-253-755-02 LEVER (D)

255 3-899-829-01 WASHER (SLIT)

256 3-259-032-01 GEAR (LE2)

257 A-3372-453-A CHASSIS (M) BLOCK ASSY

39

Page 40

CDX-V5800

SECTION 5

DISPLAY

NOTE:

• Due to standardization, replacements in

the parts list may be different from the

parts specified in the diagrams or the

components used on the set.

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• RESISTORS

All resistors are in ohms.

METAL:Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F:nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

DISPLAY BOARD

**************

1-780-097-11 CONDUCTIVE BOARD, CONNECTION

< CAPACITOR >

C951 1-135-834-11 CERAMIC CHIP 2.2uF 6.3V

C952 1-125-891-11 CERAMIC CHIP 0.47uF 10% 10V

C953 1-162-963-11 CERAMIC CHIP 680PF 10% 50V

C954 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C955 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C956 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C957 1-135-834-11 CERAMIC CHIP 2.2uF 6.3V

C958 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

ELECTRICAL PARTS LIST

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

• SEMICONDUCTORS

In each case, u : µ, for example:

uA.. : µA.. uPA.. : µPA..

uPB.. : µPB.. uPC.. : µPC.. uPD.. : µPD..

• CAPACITORS

uF : µF

• COILS

uH : µH

LED914 6-500-476-01 LED SML310BA1TT86 (OFF)

LED915 6-500-476-01 LED SML310BA1TT86 (BTM)

LED916 6-500-476-01 LED SML310BA1TT86 (1)

LED917 6-500-476-01 LED SML310BA1TT86 (2)

LED918 6-500-476-01 LED SML310BA1TT86 (3)

LED921 6-500-476-01 LED SML310BA1TT86 (DSPL)

LED922 6-500-476-01 LED SML310BA1TT86 (SENS)

LED923 6-500-476-01 LED SML310BA1TT86 (MODE)

LED924 6-500-476-01 LED SML310BA1TT86 (ALBUM/PRESET –)

LED927 6-500-476-01 LED SML310BA1TT86 (EQ3)

LED928 6-500-476-01 LED SML310BA1TT86 (RING ILLUMINATION)

LED929 6-500-476-01 LED SML310BA1TT86 (RING ILLUMINATION)

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

When indicating parts by reference

number, please include the board.

< TRANSISTOR >

< CONNECTOR >

CN901 1-817-158-11 PLUG, CONNECTOR 14P

< DIODE >

D902 8-719-978-33 DIODE DTZ-TT11-6.8B

D903 8-719-978-33 DIODE DTZ-TT11-6.8B

D904 8-719-978-33 DIODE DTZ-TT11-6.8B

D905 8-719-988-61 DIODE 1SS355TE-17

D906 8-719-978-33 DIODE DTZ-TT11-6.8B

D951 8-719-069-54 DIODE UDZSTE-175.1B

< IC >

IC901 8-759-826-21 IC LC75874W

IC905 6-705-374-01 IC MM3033DULE

IC951 6-600-384-01 IC KSM-401E (IR)

< LIQUID CRYSTAL DISPLAY >

LCD901 1-805-455-11 DISPLAY PANEL, LIQUID CRYSTAL

< DIODE >

LED902 6-500-459-01 LED NSCW505T-ARS (LCD BACK LIGHT)

LED905 6-500-459-01 LED NSCW505T-ARS (LCD BACK LIGHT)

LED907 6-500-476-01 LED SML310BA1TT86 (DSO)

LED908 6-500-476-01 LED SML310BA1TT86 (SOURCE)

LED909 6-500-476-01 LED SML310BA1TT86 (ALBUM/PRESET +)

LED910 6-500-476-01 LED SML310BA1TT86 (SCRL)

LED911 6-500-476-01 LED SML310BA1TT86 (4)

LED912 6-500-476-01 LED SML310BA1TT86 (5)

LED913 6-500-476-01 LED SML310BA1TT86 (6)

Q501 8-729-901-81 TRANSISTOR 2SC2412K-T-146-R

< RESISTOR >

R901 1-216-819-11 METAL CHIP 680 5% 1/10W

R902 1-216-819-11 METAL CHIP 680 5% 1/10W

R903 1-216-819-11 METAL CHIP 680 5% 1/10W

R904 1-216-821-11 METAL CHIP 1K 5% 1/10W

R905 1-216-823-11 METAL CHIP 1.5K 5% 1/10W

R906 1-216-823-11 METAL CHIP 1.5K 5% 1/10W

R907 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R908 1-216-827-11 METAL CHIP 3.3K 5% 1/10W

R909 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

R910 1-218-867-11 METAL CHIP 6.8K 0.5% 1/10W

R911 1-216-819-11 METAL CHIP 680 5% 1/10W

R912 1-216-819-11 METAL CHIP 680 5% 1/10W

R913 1-216-819-11 METAL CHIP 680 5% 1/10W

R914 1-216-821-11 METAL CHIP 1K 5% 1/10W

R915 1-216-823-11 METAL CHIP 1.5K 5% 1/10W

R916 1-216-823-11 METAL CHIP 1.5K 5% 1/10W

R917 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R918 1-216-827-11 METAL CHIP 3.3K 5% 1/10W

R919 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

R922 1-216-809-11 METAL CHIP 100 5% 1/10W

R924 1-216-809-11 METAL CHIP 100 5% 1/10W

R925 1-216-817-11 METAL CHIP 470 5% 1/10W

R926 1-216-817-11 METAL CHIP 470 5% 1/10W

R927 1-216-817-11 METAL CHIP 470 5% 1/10W

R928 1-216-817-11 METAL CHIP 470 5% 1/10W

R940 1-216-833-11 METAL CHIP 10K 5% 1/10W

R941 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

40

Page 41

CDX-V5800

DISPLAY

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

R947 1-216-814-11 METAL CHIP 270 5% 1/10W

R951 1-216-815-11 METAL CHIP 330 5% 1/10W

R952 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R953 1-216-821-11 METAL CHIP 1K 5% 1/10W

R954 1-216-821-11 METAL CHIP 1K 5% 1/10W

R955 1-216-821-11 METAL CHIP 1K 5% 1/10W

R956 1-216-821-11 METAL CHIP 1K 5% 1/10W

R957 1-218-731-11 METAL CHIP 43K 0.5% 1/10W

R958 1-216-821-11 METAL CHIP 1K 5% 1/10W

R959 1-216-821-11 METAL CHIP 1K 5% 1/10W

R960 1-216-821-11 METAL CHIP 1K 5% 1/10W

R961 1-216-845-11 METAL CHIP 100K 5% 1/10W

R971 1-216-809-11 METAL CHIP 100 5% 1/10W

R972 1-216-809-11 METAL CHIP 100 5% 1/10W

R973 1-216-809-11 METAL CHIP 100 5% 1/10W

R974 1-216-809-11 METAL CHIP 100 5% 1/10W

R975 1-216-809-11 METAL CHIP 100 5% 1/10W

R976 1-216-809-11 METAL CHIP 100 5% 1/10W

R977 1-216-809-11 METAL CHIP 100 5% 1/10W

R978 1-216-809-11 METAL CHIP 100 5% 1/10W

R980 1-216-809-11 METAL CHIP 100 5% 1/10W

R982 1-216-809-11 METAL CHIP 100 5% 1/10W

R983 1-216-809-11 METAL CHIP 100 5% 1/10W

R984 1-216-809-11 METAL CHIP 100 5% 1/10W