CDX-M610

SERVICE MANUAL

Ver 1.0 2001. 01

• The tuner and CD sections have no adjustments.

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

23 watts per channel minimum continuous average power into

4 ohms, 4 channels driven from 20 Hz to 20 kHz with no more

than 5% total harmonic distortion.

Other Specifications

CD player section

System Compact disc digital audio

system

Signal-to-noise ratio 90 dB

Frequency response 10 – 20,000 Hz

Wow and flutter Below measurable limit

Laser Diode Properties

Material GaAlAs

Wavelength 780 nm

Emission Duration Continuous

Laser output power Less than 44.6 µW*

* This output is the value measured at a distance

of 200 mm from the objective lens surface on the

Optical Pick-up Block.

Tuner section

FM

Tuning range 87.5 – 107.9 MHz

Antenna terminal External antenna connector

Intermediate frequency 10.7 MHz/450 kHz

Usable sensitivity 8 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 66 dB (stereo),

72 dB (mono)

Harmonic distortion at 1 kHz

0.6% (stereo),

0.3% (mono)

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

AM

Tuning range 530 – 1,710 kHz

Antenna terminal External antenna connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity 30 µV

US Model

Model Name Using Similar Mechanism CDX-M610

CD Drive Mechanism Type MG-383Z-121//K

Optical Pick-up Name KSS-720A

Power amplifier section

Outputs Speaker outputs

Speaker impedance 4 – 8 ohms

Maximum power output 52 W × 4 (at 4 ohms)

General

Outputs Audio outputs (3)

Inputs Telephone A TT control

Power requirements 12 V DC car battery

Dimensions Approx. 178 × 50 × 182 mm

Mounting dimensions Approx. 182 × 53 × 163 mm

Mass Approx. 1.5 kg (3 lb. 5 oz.)

Supplied accessories Card remote commander

Design and specifications are subject to change without

notice.

Power antenna relay

control lead

Power amplifier control

lead

lead

Illumination control lead

Treble ± 10 dB at 100 Hz

(negative ground)

1/8 × 2 × 7 1/4 in.)

(7

(w/h/d)

1/4 × 2 1/8 × 6 1/2 in.)

(7

(w/h/d)

RM-X93

Parts for installation and

connections (1 set)

FM/AM COMPACT DISC PLAYER

9-870-261-11

2001A0400-1

© 2001. 1

Sony Corporation

Audio Entertainment Group

General Engineering Dept.

1

CDX-M610

k

SERVICE NOTES

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

If the optical pick-up block is defective, please replace the whole

optical pick-up block.

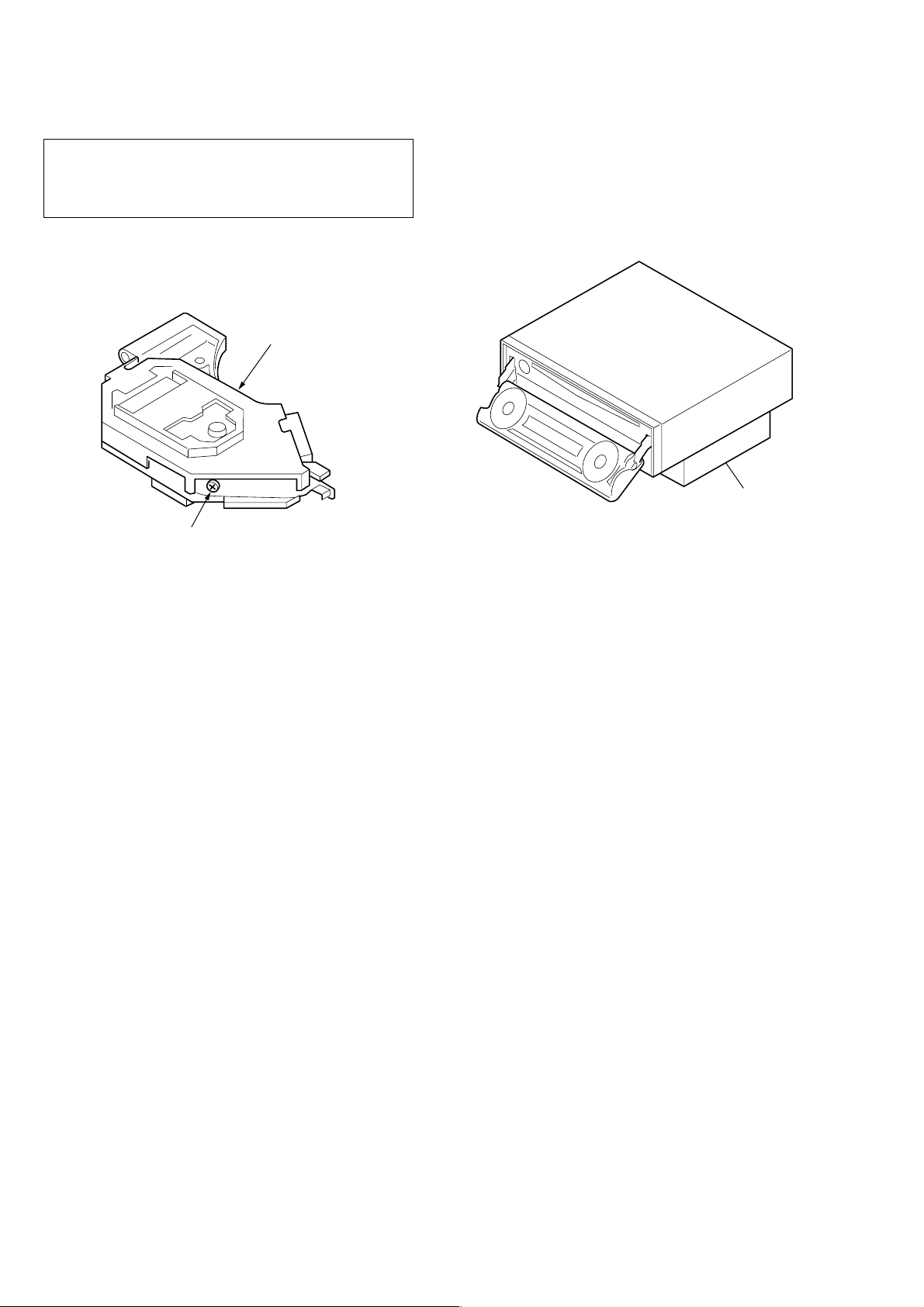

Never turn the semi-fixed resistor located at the side of optical

pick-up block.

optical pick-up bloc

semi-fixed resistor

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

NOTE FOR THE OPENING OF THE FRONT PANEL

In this set, the front panel is lowered to below the bottom face when

it is opened.

When servicing the set, place it on a stand having a height of about

2 cm.

stand

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P AR TS WHOSE

P ART NUMBERS APPEAR AS SHO WN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

TABLE OF CONTENTS

CDX-M610

1. GENERAL

Location of controls................................................................. 4

Getting Started......................................................................... 4

Setting the clock ...................................................................... 5

CD Player CD/MD Unit .......................................................... 5

Radio ....................................................................................... 6

Other Functions ....................................................................... 7

TV/Video.................................................................................8

Connections ........................................................................... 10

2. DISASSEMBLY

2-1. Front Panel Assy (Normal) ...............................................13

2-2. Front Panel Assy (Inoperative) .........................................14

2-3. CD Mechanism Block, Front Panel Assy.......................... 14

2-4. Sub Panel (CD) Sub Assy ................................................. 15

2-5. Motor Block Assy, Cam (R) Assy ..................................... 15

2-6. Main Board ....................................................................... 16

2-7. Heat Sink ...........................................................................16

2-8. Chassis (T) Sub Assy ........................................................17

2-9. Lever Section .................................................................... 17

2-10. Servo Board....................................................................... 18

2-11. Shaft Roller Assy ............................................................... 18

2-12. Floating Block Assy ..........................................................19

2-13. Optical Pick-up Block ....................................................... 19

3. PHASE ALIGNMENT

3-1. Arm (A-L) Assy, Arm (B-L) Assy ..................................... 20

3-2. Cam (L) ............................................................................. 20

3-3. Motor Block ......................................................................21

3-4. Alignment between Arm (A-L) Assy

and Arm (B-L) Assy .......................................................... 21

3-5. Arm (A-R) Assy, Arm (B-R) Assy ....................................22

3-6. Cam (R) .............................................................................22

4. DIAGRAMS

4-1. IC Pin Descriptions ........................................................... 23

4-2. Block Diagram –CD Section–........................................... 32

4-3. Block Diagram –Tuner Section–....................................... 33

4-4. Block Diagram –Display Section–.................................... 34

4-5. Circuit Boards Location .................................................... 35

4-6. Printed Wiring Boards –CD Mechanism Section–............ 36

4-7. Schematic Diagram –CD Mechanism Section (1/2)– ....... 38

4-8. Schematic Diagram –CD Mechanism Section (2/2)– ....... 38

4-9. Printed Wiring Boards –Main Section– ............................ 40

4-10. Schematic Diagram –Main Section (1/4)–........................42

4-11. Schematic Diagram –Main Section (2/4)–........................43

4-12. Schematic Diagram –Main Section (3/4)–........................44

4-13. Schematic Diagram –Main Section (4/4)–........................45

4-14. Printed Wiring Board –Sub Section– ................................ 46

4-15. Schematic Diagram –Sub Section– ...................................47

4-16. Printed Wiring Board –Display Section– .......................... 48

4-17. Schematic Diagram –Display Section–............................. 49

5. EXPLODED VIEWS

5-1. Chassis Section ................................................................. 52

5-2. Main Board Section .......................................................... 53

5-3. Front panel Section ........................................................... 54

5-4. CD Mechanism Section (1) ...............................................55

5-5. CD Mechanism Section (2) ...............................................56

5-6. CD Mechanism Section (3) ...............................................57

6. ELECTRICAL PARTS LIST ........................................ 58

3

CDX-M610

SECTION 1

GENERAL

This section is extracted

from instruction manual.

4

CDX-M610

5

CDX-M610

6

CDX-M610

7

CDX-M610

8

CDX-M610

9

CDX-M610

10

CDX-M610

11

CDX-M610

12

SECTION 2

DISASSEMBLY

Note : This set can be disassemble according to the following sequence.

CDX-M610

Front Panel Assy (Normal)

CD Mechanism Block, Front Panel Assy

Front Panel Assy (Inoperative)

Sub Panel (CD) Sub Assy Motor Block Assy, Cam (R) Assy

Chassis (T) Sub Assy

Lever Section

Servo Board

Shaft Roller Assy Floating Block Assy

Optical Pick-up Block

Note : Follow the disassembly procedure in the numerical order given.

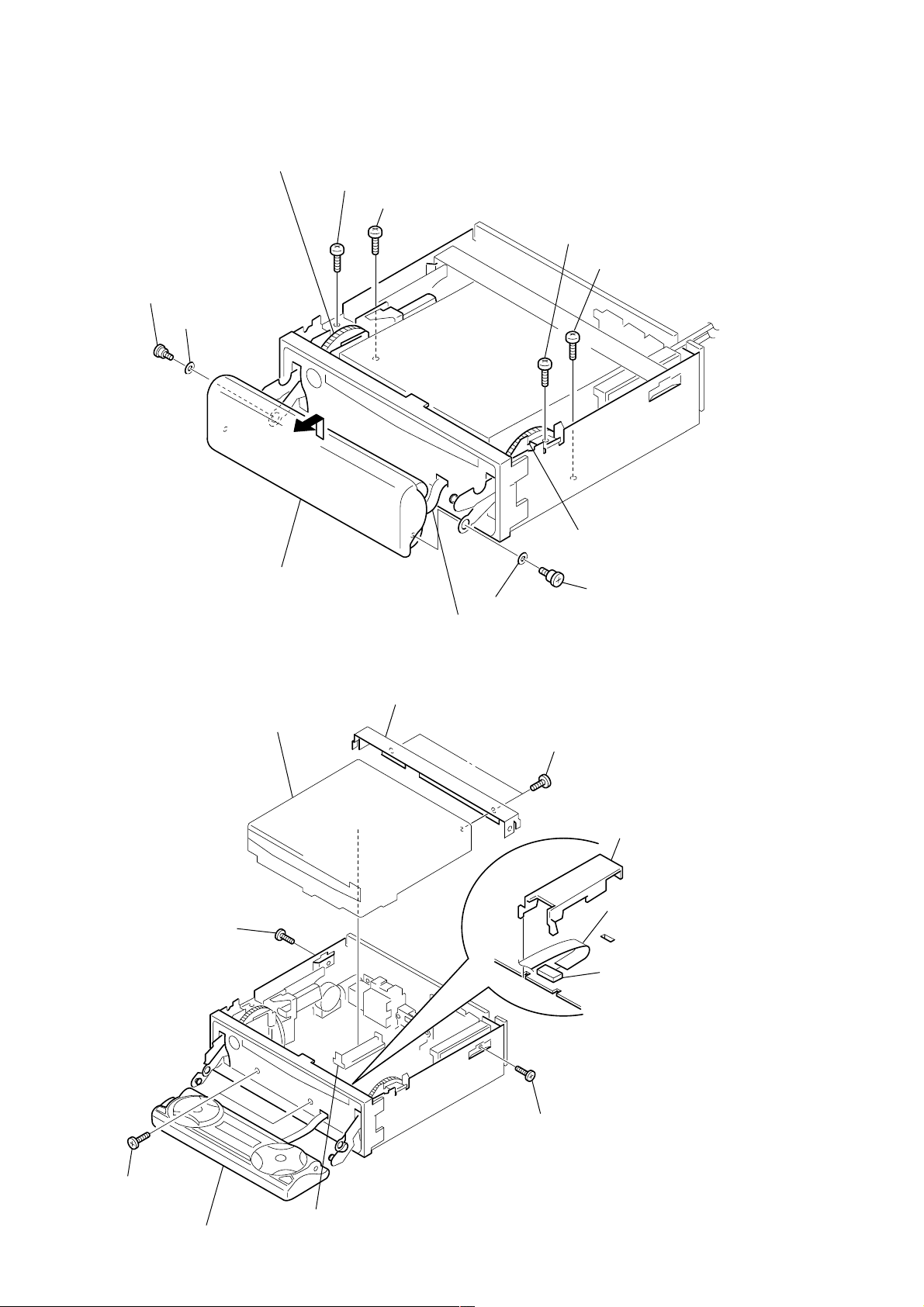

2-1. FRONT PANEL ASSY (NORMAL)

Main Board

Heat Sink

4 screw (panel)

5 spacer (arm)

6 front panel assy

(Take care not to

pull the flexible

board excessively.)

3 spacer (arm)

flexible board

stand

2 screw (panel)

13

CDX-M610

2-2. FRONT PANEL ASSY (INOPERATIVE)

0 Lift the motor block assy

slightly to make a play.

3 screw (panel)

4 spacer (arm)

qa

7 PTT 2.6x6

8 PTT 2.6x6

5 PTT 2.6x6

6 PTT 2.6x6

qs front panel assy

(Take care not to pull the

flexible board excessively.)

2-3. CD MECHANISM BLOCK, FR ONT PANEL ASSY

7 bracket (CD)

5 CD mechanism block

3 PTT 2.6x4

9 Lift the cam (R) assy

slightly to make a play.

1 screw (panel)

2 spacer (arm)

flexible board

6 PTT 2.6x6

8 cover (flexible)

0 flexible board

9 CNP802

14

Note: When installing

the flexible board,

make the board slack

as illustrated.

2 PTT 2.6x4

1 PTT 2.6x6

4 CNP701

qs front panel assy

2-4. SUB PANEL (CD) SUB ASSY

h

4 claw

3 PTT 2.6x6

CDX-M610

1 CNP805

6 sub panel (CD) sub assy

2-5. MOTOR BLOCK ASSY, CAM (R) ASSY

Note : Install the motor block assy and cam (R) assy in this roder.

For phase alignment between cams (L) and (R), see page 20 and 22.

4 PTT 2.6x6

5 motor block assy

1 PTT 2.6x6

2 cam (R) assy

5 claw

2 PTT 2.6 x6

Note: Install the cam (R) assy wit

the cam fully rotated in the

direction of the arrow A.

A

3 CNP902

15

CDX-M610

8

8

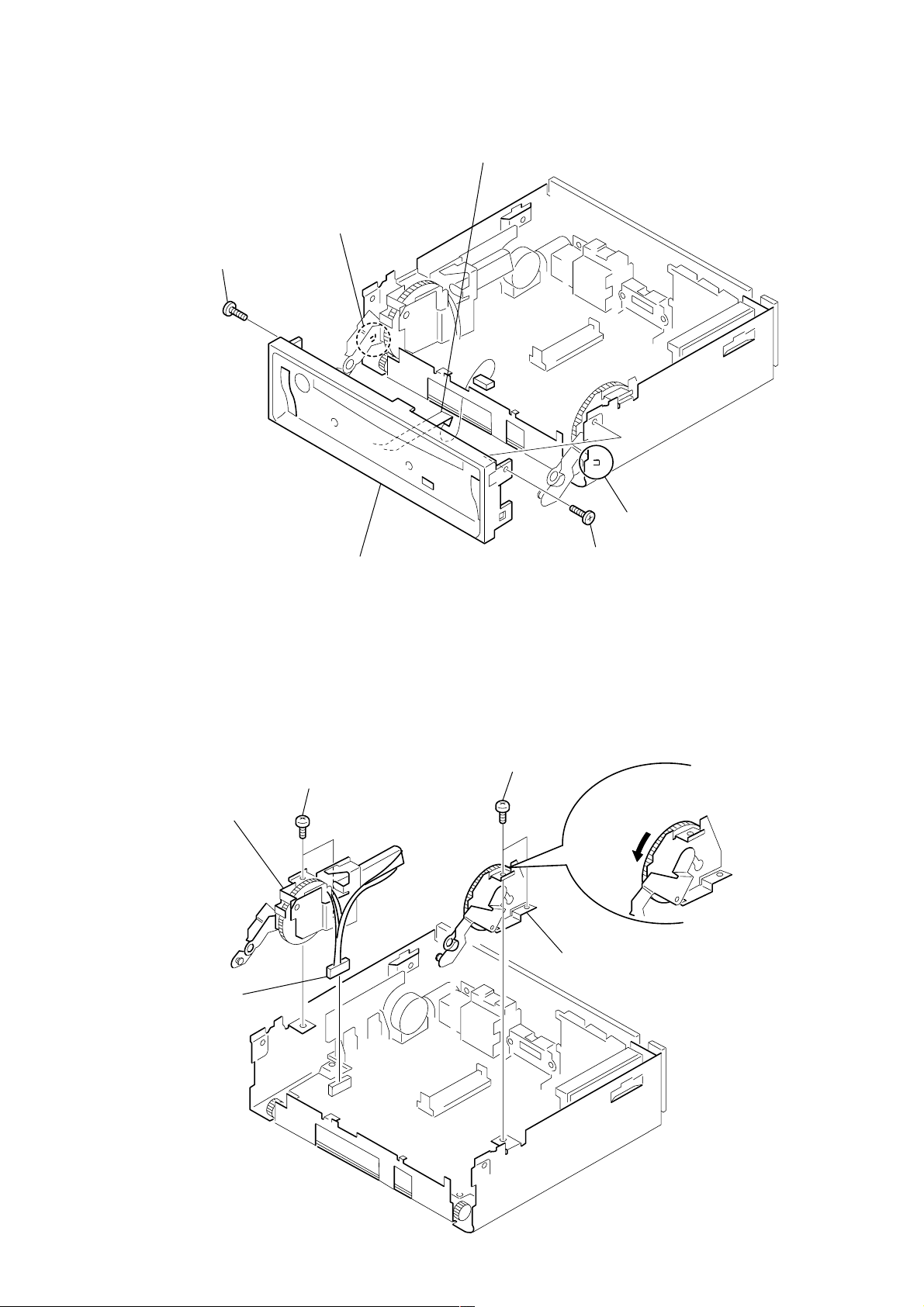

2-6. MAIN BOARD

6 MAIN board

5 PTT 2.6x6

ground point

4 PTT 2.6x6

ground point

3 PTT 2.6x

2 PTT 2.6x8

1 PTT 2.6x8

2-7. HEAT SINK

5 heat sink

4 PTT 2.6x

3 PTT 2.6x8

2 PTT 2.6x12

1 PTT 2.6x8

16

2-8. CHASSIS (T) SUB ASSY

CDX-M610

2 P 2x3

3 P 2x3

1 Unsolder the

lead wires.

2-9. LEVER SECTION

4 chassis (T) sub assy

black

red

white

4 claws

5 guide (disc)

6 lever (R)

3 tension spring (LR)

7 lever (L)

1 special screw

2 DISC IN SW board

17

CDX-M610

r

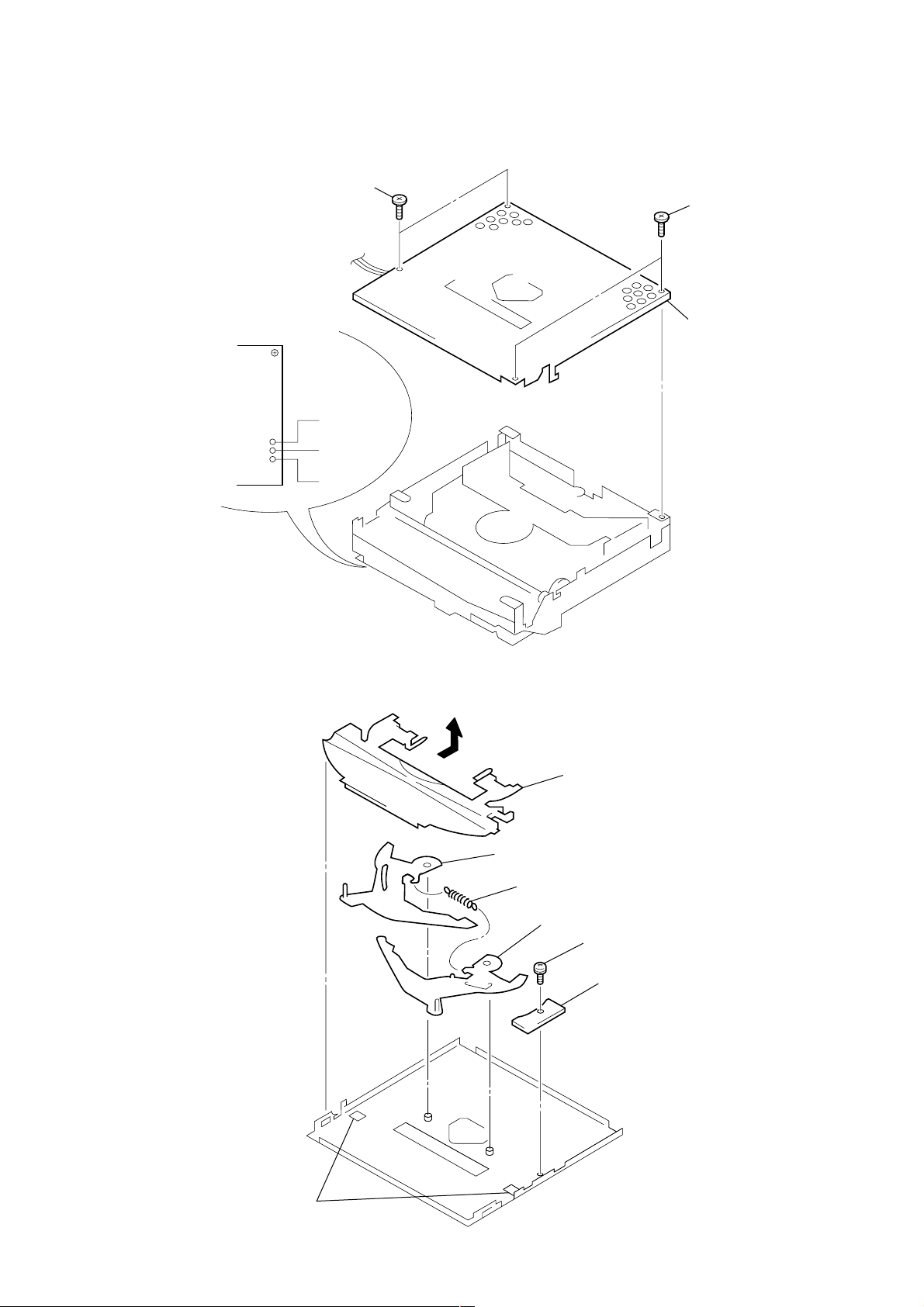

2-10. SERVO BOARD

7 special screws

6 special screws

3 Removal the solders.

4 P 2x3

5 loading motor assy

2-11. SHAFT R OLLER ASSY

• When installing, take note of the positions

arm (roller) and washers. (Fig. 1)

2 CN2

1 CN3

8 SERVO board

3 retaing ring (RA)

4 shaft retainer

shaft retainer

retaing ring (RA)

arm

washer

5 shaft roller assy

2 arm (roller)

Fig. 1

washer

arm

shaft retaine

18

1 tension spring (RA)

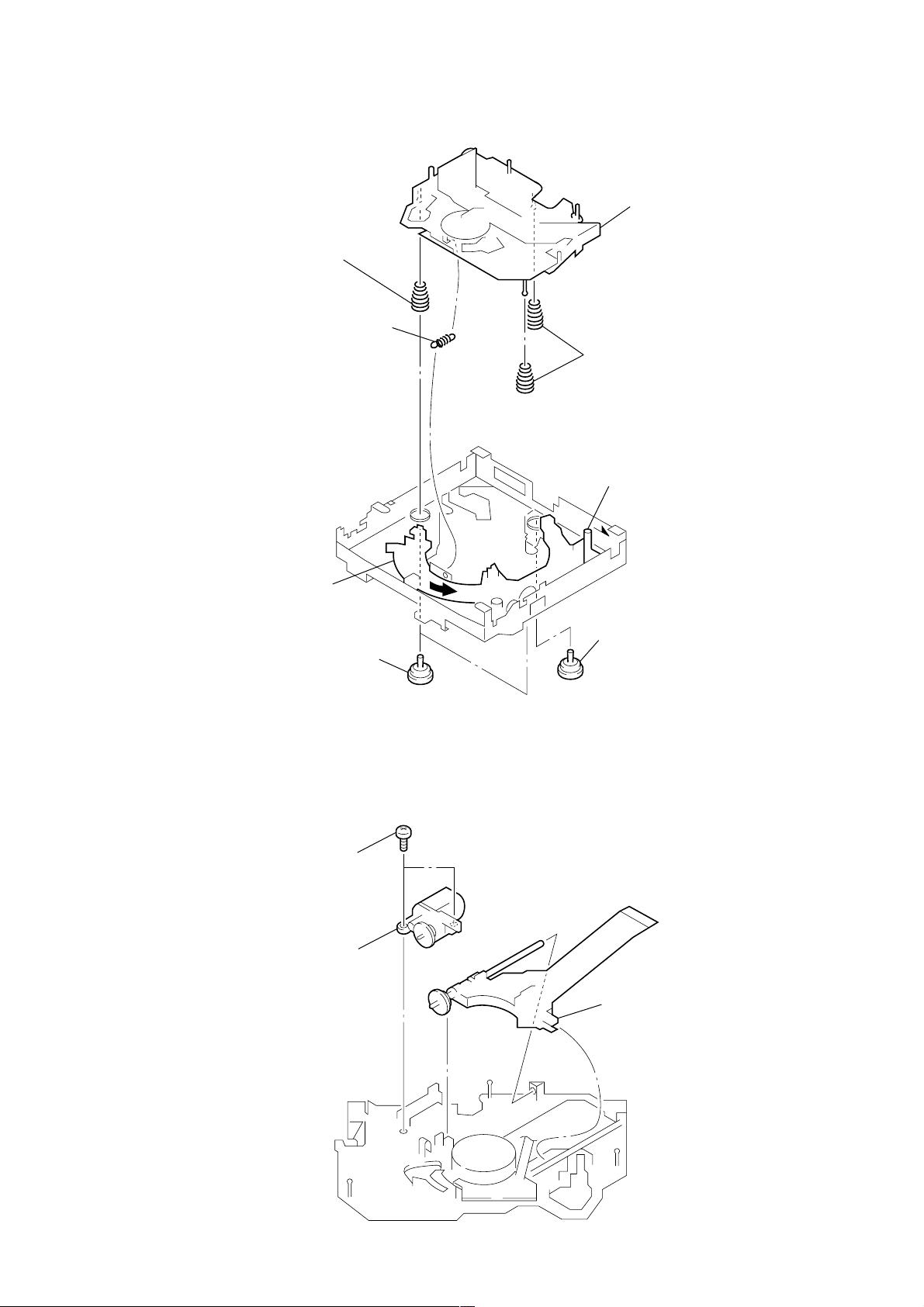

2-12. FLOATING BLOCK ASSY

7 compression spring (FL)

1 tension spring (KF1)

CDX-M610

6 floating block assy

8 compression spring (FL)

4 Fit lever (D) in the

direction of the arrow.

5 Turn loading ring in the

direction of the arrow.

3 damper (T)

2-13. OPTICAL PICK-UP BLOCK

1 P 2x3

2 sled motor assy

2 damper (T)

3 optical pick-up block

19

CDX-M610

)

y

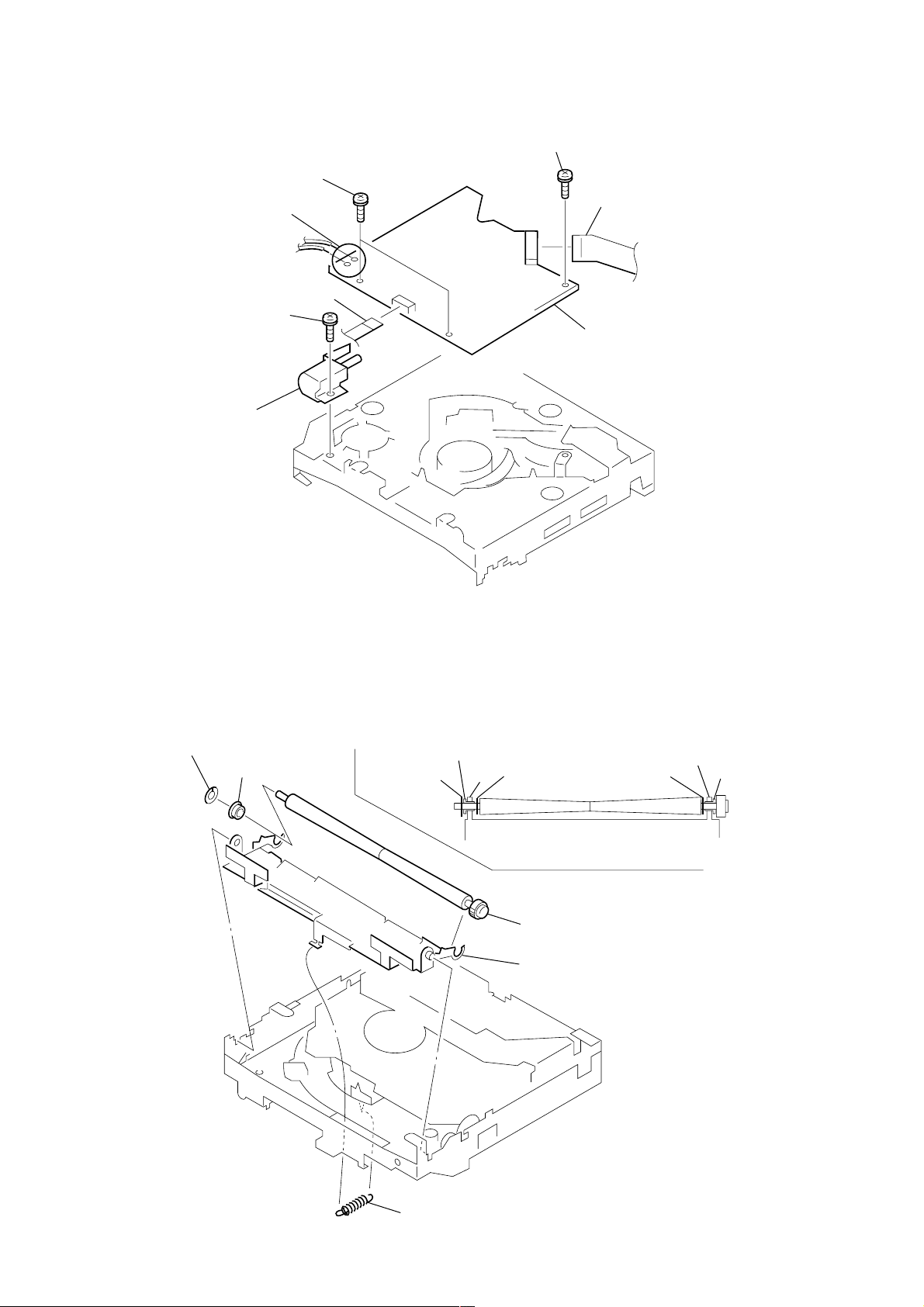

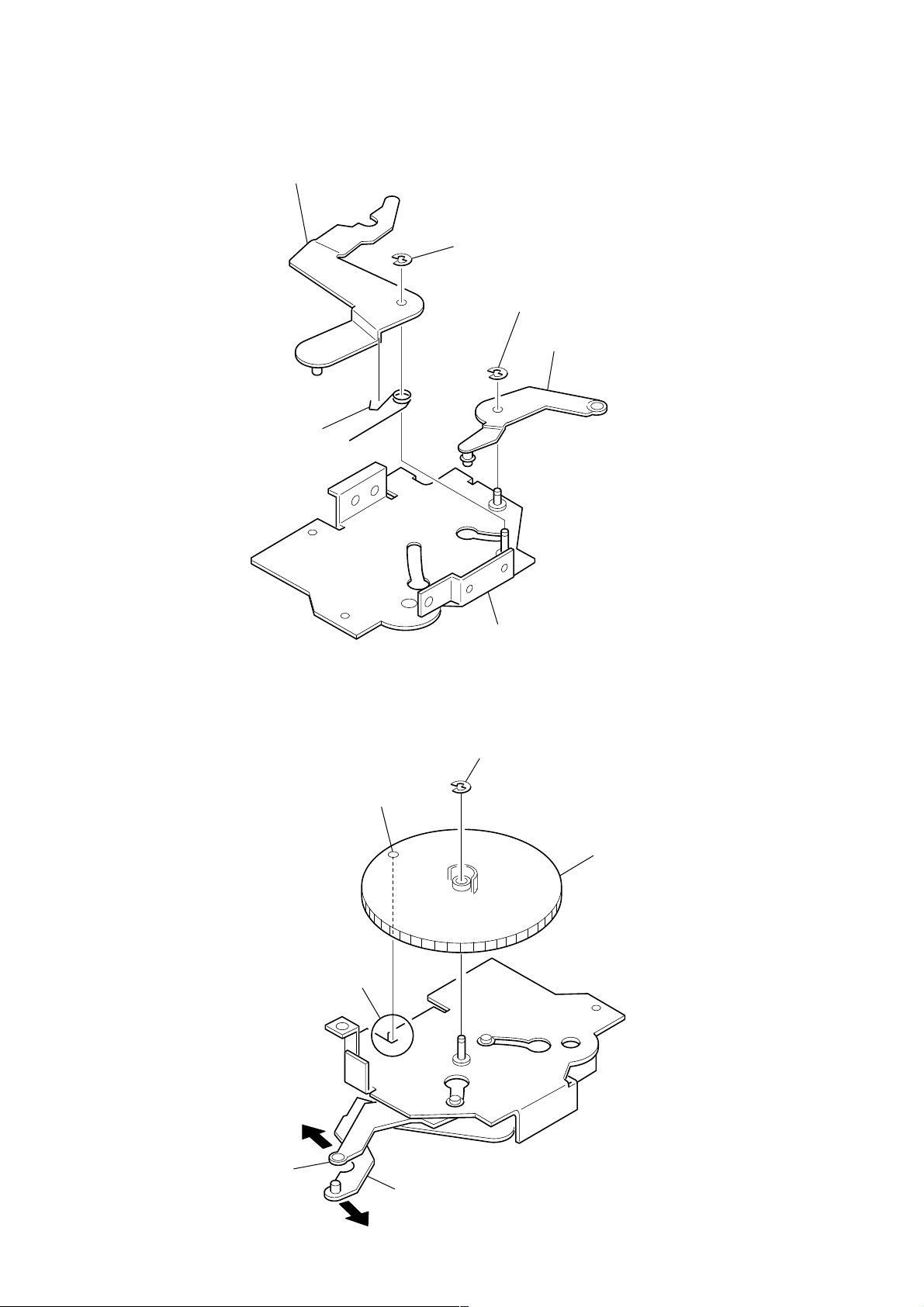

3-1. ARM (A-L) ASSY, ARM (B-L) ASSY

4 arm (A-L) assy

3 spring (arm L)

SECTION 3

PHASE ALIGNMENT

5 stop ring 1.5, type-E

2 stop ring 1.5, type-E

1 arm (B-L) ass

3-2. CAM (L)

1 Move the arm (B-L) assy in the direction of the

arrow A and the arm (A-L) assy in the direction of

the arrow B fully (full open state).

2 Align the hole on the cam (L) with part C and install

the cam.

4 Turn the cam (L) clockwise and counterclockwise to

verify that both the arms are operated.

bracket (L) assy

3 stop ring 1.5, type-E

hole

cam (L

C

20

A

arm (B-L) assy

arm (A-L) assy

B

3-3. MOTOR BLOCK

)

V

1 Turn the cam (L) and position the cam so that part A

does not touch the SWITCH board SW900.

SWITCH board

5 screw (+BTT)

SW900

4 PTT 2.6x6

CDX-M610

3 PTT 2.6x6

2 motor block

3-4. ALIGNMENT BETWEEN ARM (A-L) ASSY

AND ARM (B-L) ASSY

1 Input 9V DC to the motor terminal until the cam (L)

stops rotating.

Take care to avoid overload of the motor.

2 Verify that the arm (A-L) assy and arm (B-L) assy

are positioned as shown below (full open).

cam (L

A

motor

arm (B-L) assy

arm (A-L) assy

GND

DC 9

+B

21

Loading...

Loading...