Sony CDXL-480-N Service manual

CDX-L480N

SERVICE MANUAL

Ver 1.0 2003. 07

• The tuner and CD sections have no adjustments.

Thai Model

Model Name Using Similar Mechanism CDX-L480X

CD Drive Mechanism Type MG-393XC-121//Q

Optical Pick-up Name KSS-721A

9-961-055-01

2003G04-1

© 2003. 07

FM/AM COMPACT DISC PLAYER

Sony Corporation

e Vehicle Company

Published by Sony Engineering Corporation

1

CDX-L480N

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

TEST DISCS

This set can playback CD-R and CD-ROM discs. The following

test discs should be used to check the capability:

CD-R test disc TCD-R082LMT (Part No. J-2502-063-1)

CD-RW test disc TCD-W082L (Part No. J-2502-063-2)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

z

MAIN BOARD

CNP301

J-2502-011-1

SERVO BOARD

CN1

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the lead

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

CDX-L480N

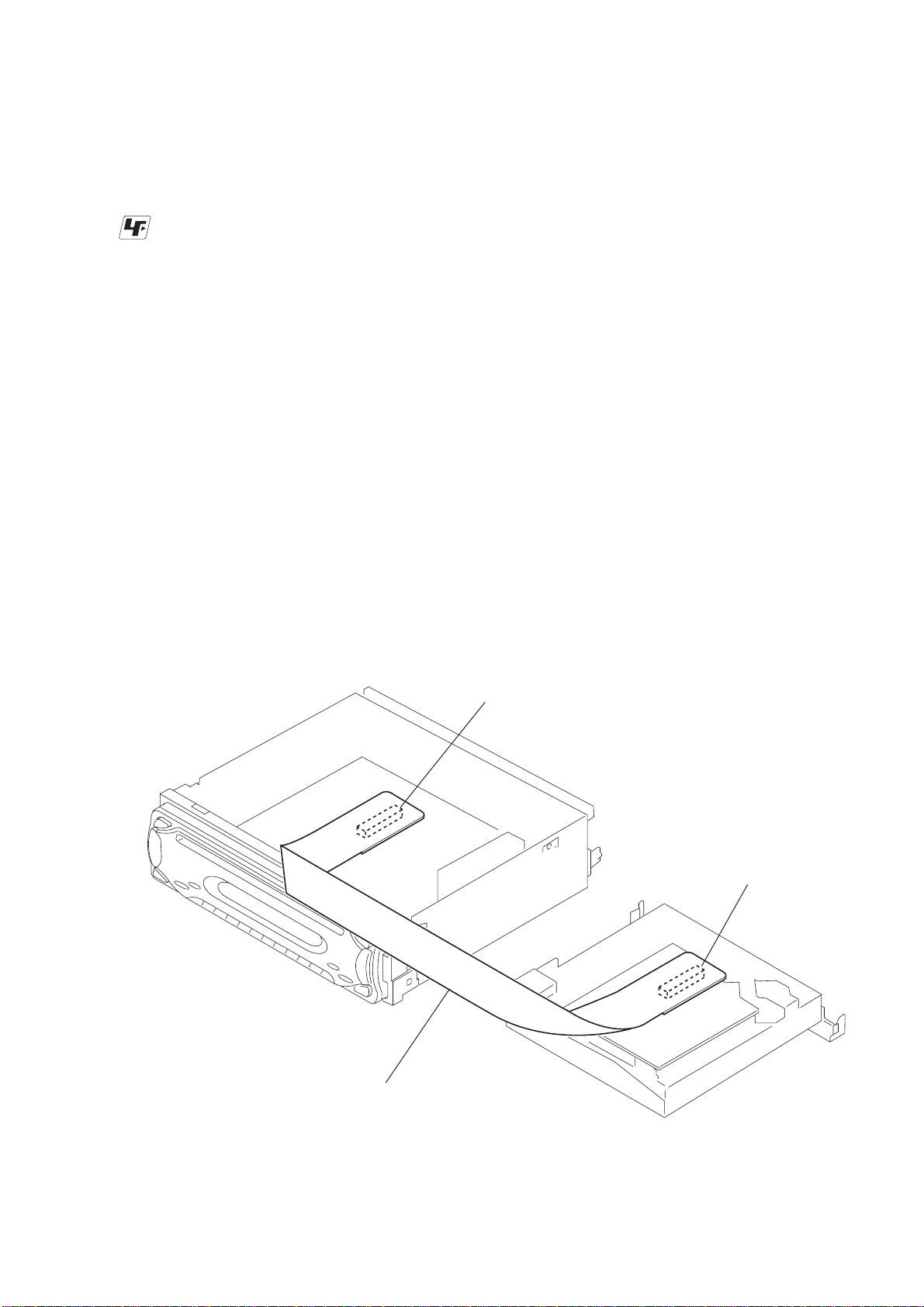

EXTENSION CABLE AND SERVICE POSITION

When repairing or servicing this set, connect the jig (extension cable)

as shown below.

• Connect the MAIN board (CNP301) and the SER V O board (CN1)

with the extension cable (Part No. J-2502-011-1).

3

CDX-L480N

TABLE OF CONTENTS

1. DISASSEMBLY

1-1. Sub Panel Assy.................................................................... 5

1-2. CD Mechanism Block ......................................................... 6

1-3. Main Board ......................................................................... 6

1-4. Heat Sink .............................................................................7

1-5. Chassis (T.U) Assy .............................................................. 7

1-6. Disc in Board ...................................................................... 8

1-7. Servo Board......................................................................... 8

1-8. Shaft Roller Assy ................................................................ 9

1-9. Floating Block Assy ............................................................9

1-10. Optical Pick-up Block ....................................................... 10

2. DIAGRAMS

2-1. IC Pin Description.............................................................11

2-2. Block Diagram –CD Section–........................................... 12

2-3. Block Diagram –Tuner Section–....................................... 13

2-4. Block Diagram –Display Section–....................................14

2-5. Circuit Boards Location .................................................... 15

2-6. Printed Wiring Boards –CD Mechanism Section–............ 16

2-7. Schematic Diagram –CD Mechanism Section– ................18

2-8. Printed Wiring Board –Main Section– .............................. 19

2-9. Schematic Diagram –Main Section (1/2)– ........................20

2-10. Schematic Diagram –Main Section (2/2)– ........................21

2-11. Printed Wiring Board –Key Section– ................................22

2-12. Schematic Diagram –Key Section–................................... 23

2-13. IC Block Diagrams............................................................ 24

3. EXPLODED VIEWS

3-1. Chassis Section ................................................................. 27

3-2. Front Panel Section ........................................................... 28

3-3. CD Mechanism Section (1) ...............................................29

3-4. CD Mechanism Section (2) ...............................................30

3-5. CD Mechanism Section (3) ...............................................31

4. ELECTRICAL PARTS LIST ........................................ 32

4

SECTION 1

DISASSEMBLY

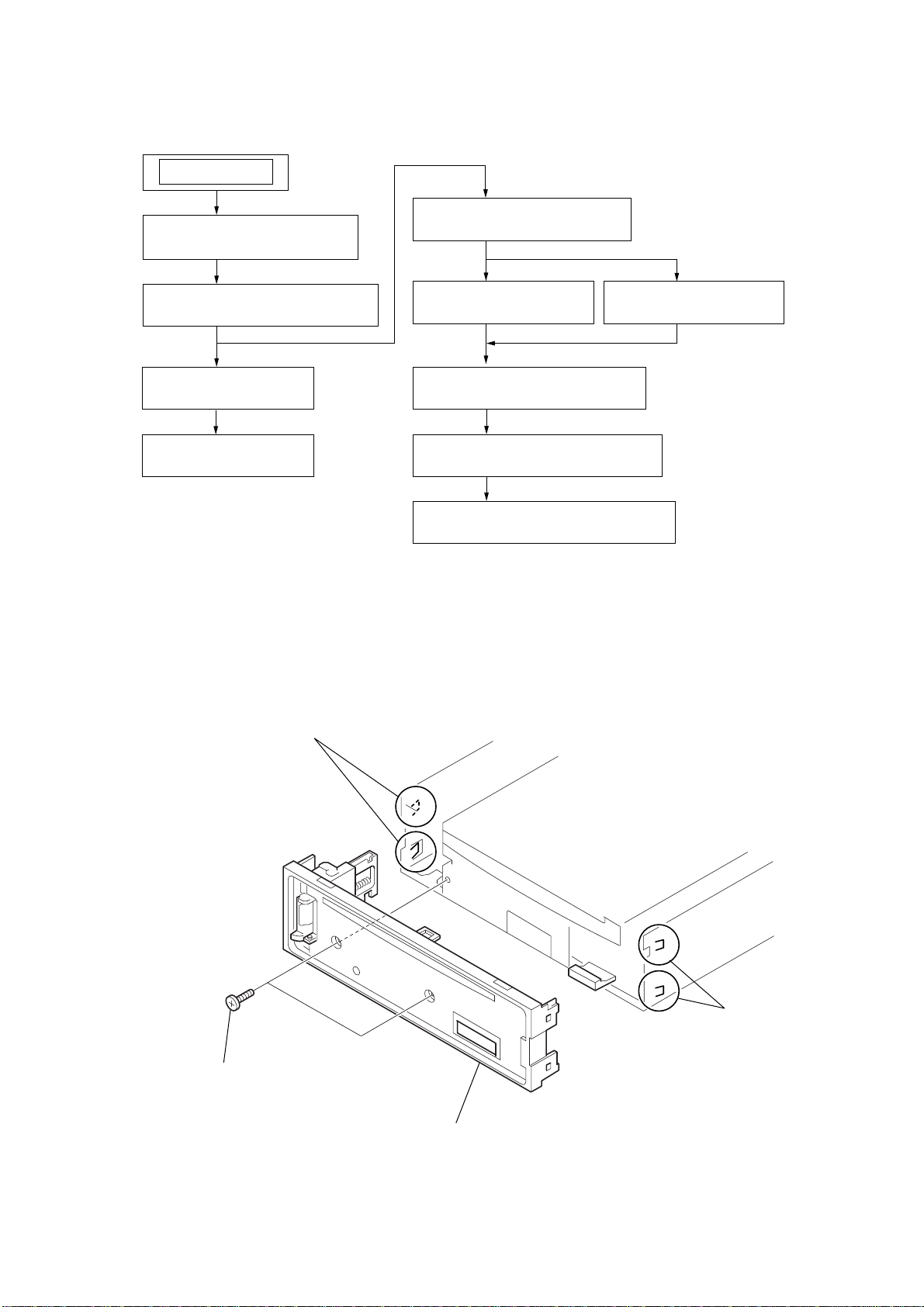

Note : This set can be disassemble according to the following sequence.

SET

1-5. CHASSIS (T.U) ASSY

1-1. SUB PANEL ASSY

(Page 5)

(Page 7)

CDX-L480N

1-2. CD MECHANISM BLOCK

(Page 6)

1-3. MAIN BOARD

(Page 6)

1-4. HEAT SINK

(Page 7)

1-6. DISC IN BOARD

(Page 8)

1-8. SHAFT ROLLER ASSY

(Page 9)

1-9. FLOATING BLOCK ASSY

(Page 9)

1-10. OPTICAL PICK-UP BLOCK

(Page 10)

Note : Follow the disassembly procedure in the numerical order given.

1-1. SUB PANEL ASSY

3

claws

1-7. SERVO BOARD

(Page 8)

1

two screws

(PTT 2.6x6)

4

sub panel assy

2

claws

5

CDX-L480N

)

)

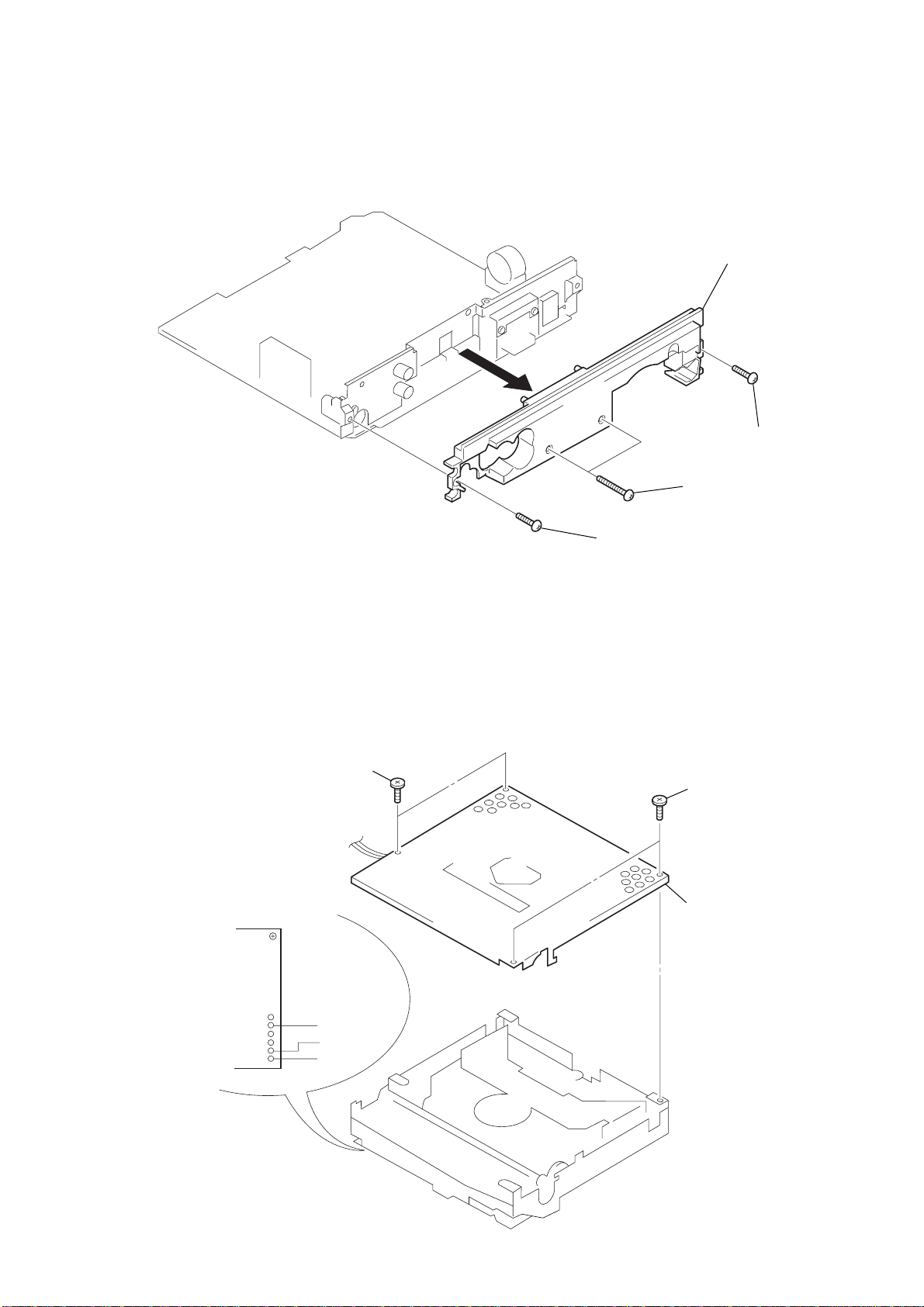

1-2. CD MECHANISM BLOCK

5

CD mechanism block

2

screw

(PTT 2.6x6)

7

bracket (CD)

6

two screws

(PTT 2.6x4

1-3. MAIN BOARD

4

two screws

(PTT 2.6x6)

(ground point)

5

MAIN board

3

4

CNP301

3

screw

(PTT 2.6x6)

(ground point)

1

screw

(PTT 2.6x6)

1

two screws

(PTT 2.6x6

2

two screws

(PTT 2.6x6)

6

1-4. HEAT SINK

)

4

5

heat sink

3

(PTT 2.6x8

2

two screws

(PTT 2.6x12)

CDX-L480N

screw

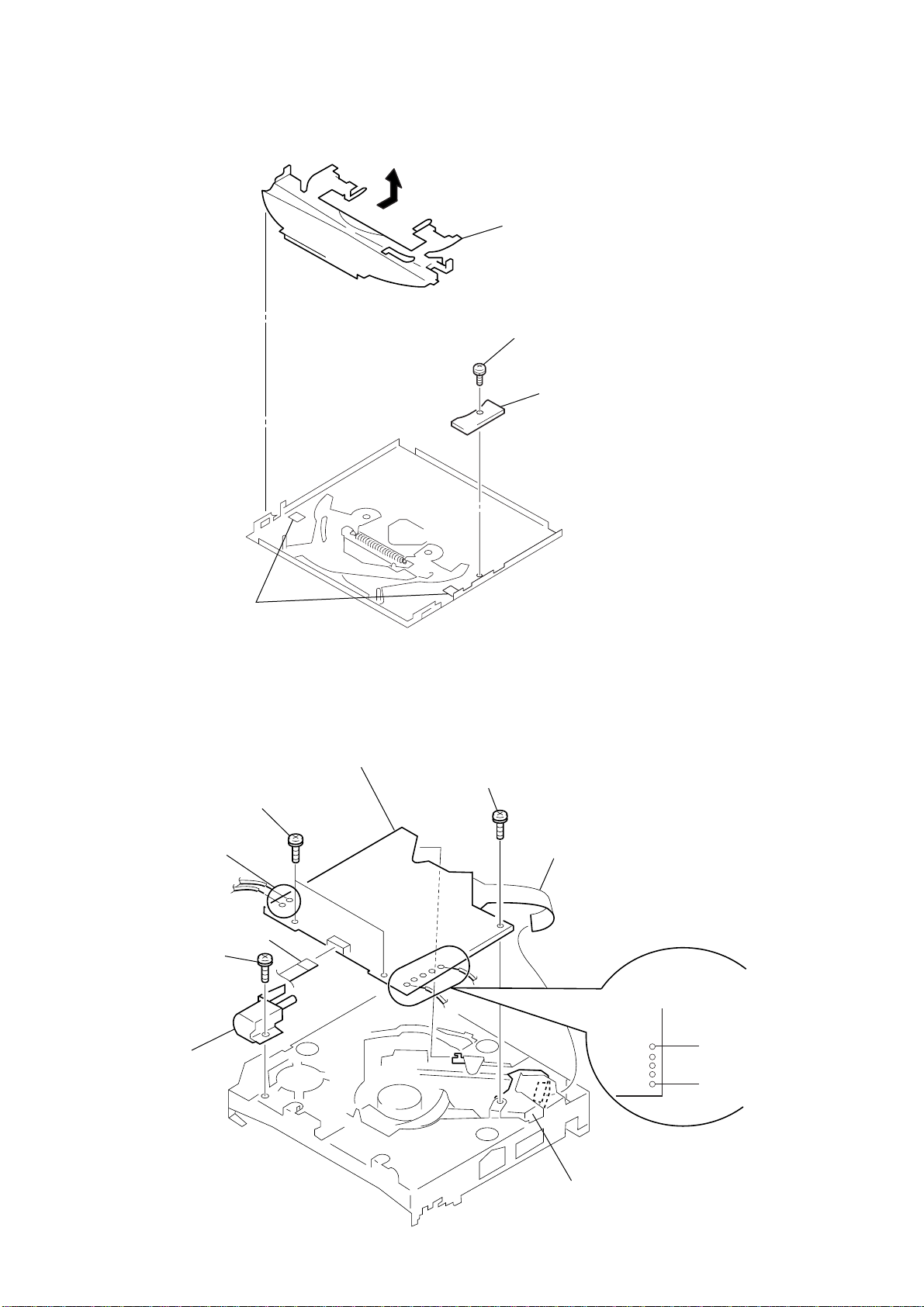

1-5. CHASSIS (T.U) ASSY

1

Unsolder the

lead wires.

2

two screws

(P 2x3)

1

screw

(PTT 2.6x8)

3

two screws

(P 2x3)

4

chassis (T.U) assy

black

red

white

7

CDX-L480N

1-6. DISC IN BOARD

4

guide (disc)

1

screw

(PS 2x3)

2

DISC IN board

1-7. SERVO BOARD

2

Removal the solders.

4

(P 2x3)

5

loading motor assy

3

screw

claws

6

(PTT 2x4)

1

CN3

two screws

8

SERVO board

7

screw

(PTT 2x4)

9

PICK-UP FLEXIBLE board

3

Unsolder the

lead wires.

black

yellow

optical pick-up block

8

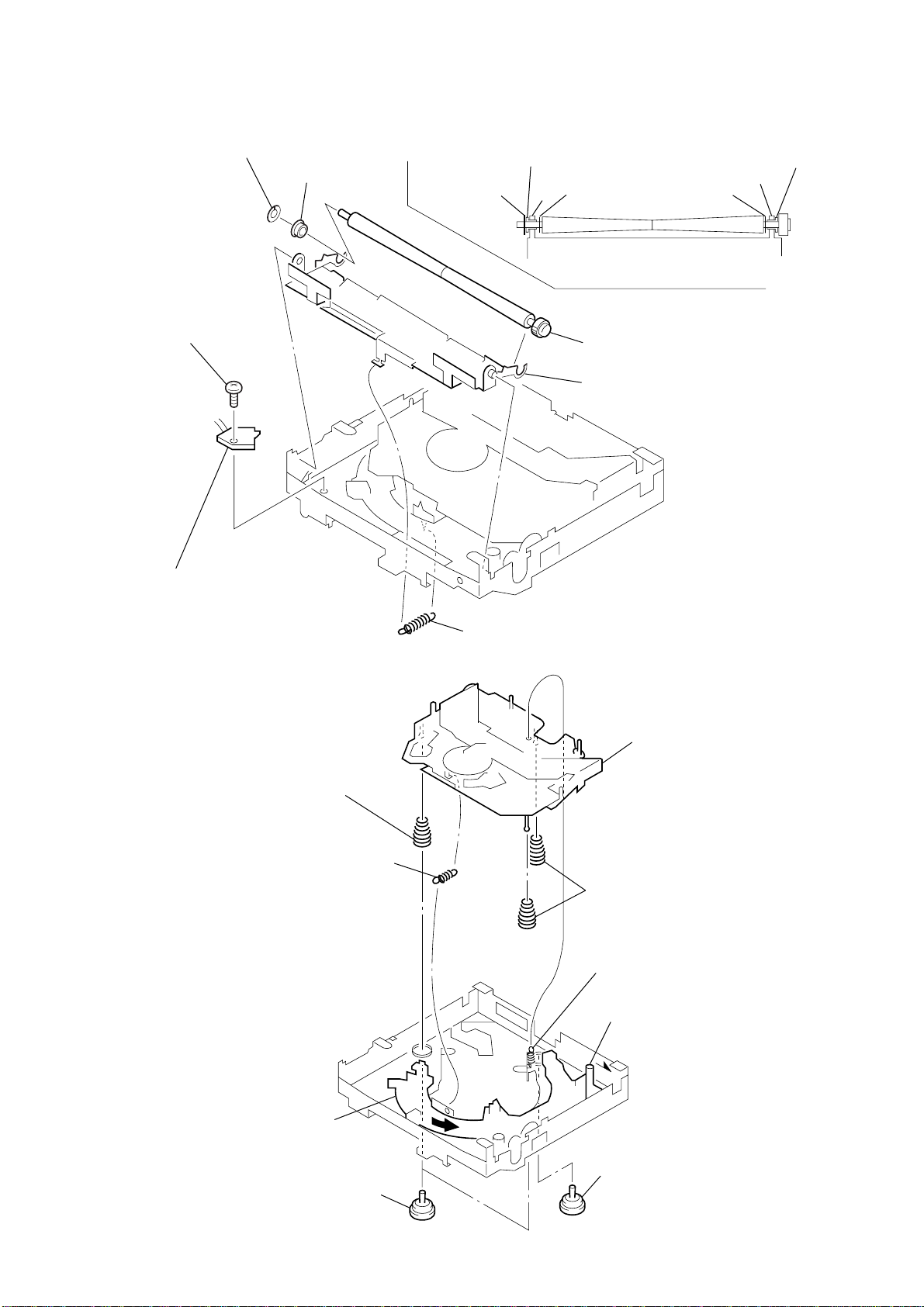

1-8. SHAFT ROLLER ASSY

• When installing, take note of the positions

arm (roller) and washers. (Fig. 1)

3

retaining ring (roller)

4

bearing (roller)

6

screw

(PTT 2x4)

bearing (roller)

retaining ring (roller)

washer (RA)

arm

Fig. 1

5

shaft roller assy

2

arm (roller T)

washer (RA)

CDX-L480N

bearing (roller)

arm

7

LOAD board

1-9. FLOATING BLOCK ASSY

8

compression spring (FL)

1

tension spring (KF1)

1

tension spring (RA3)

7

floating block assy

9

compression spring (FL)

2

tension spring (KR1)

5

Fit lever (D) in the

direction of the arrow.

6

Turn loading ring in the

direction of the arrow.

4

damper (T)

3

damper (T)

9

CDX-L480N

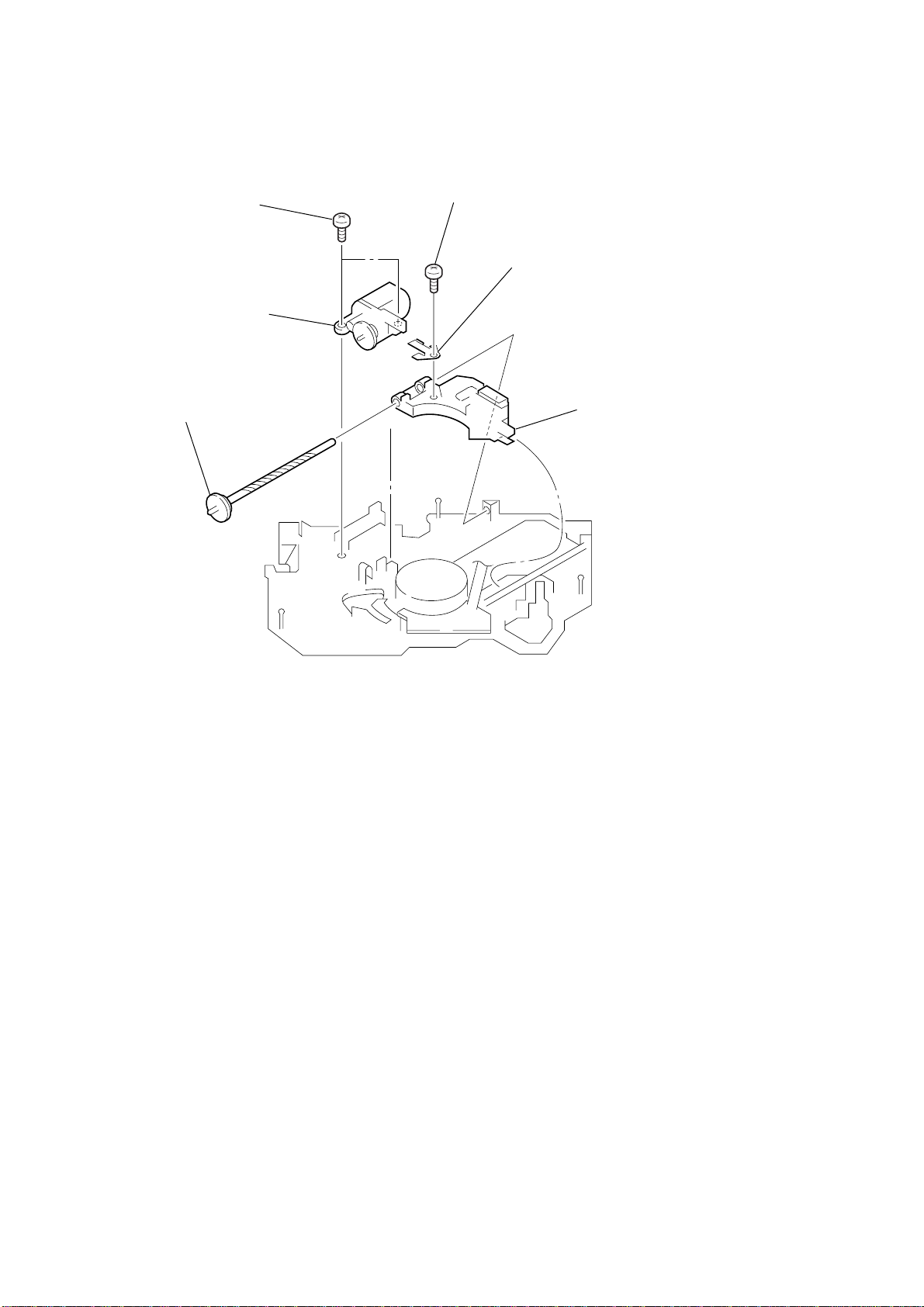

1-10. OPTICAL PICK-UP BLOCK

1

two screws

(P 2x3)

2

sled motor assy

6

shaft (feed) assy

4

screw

(P 2x3)

5

leaf spring (feed)

3

optical pick-up block

10

SECTION 2

DIAGRAMS

2-1. IC PIN DESCRIPTION

• IC501 MN101C49KSG (SYSTEM CONTROL)

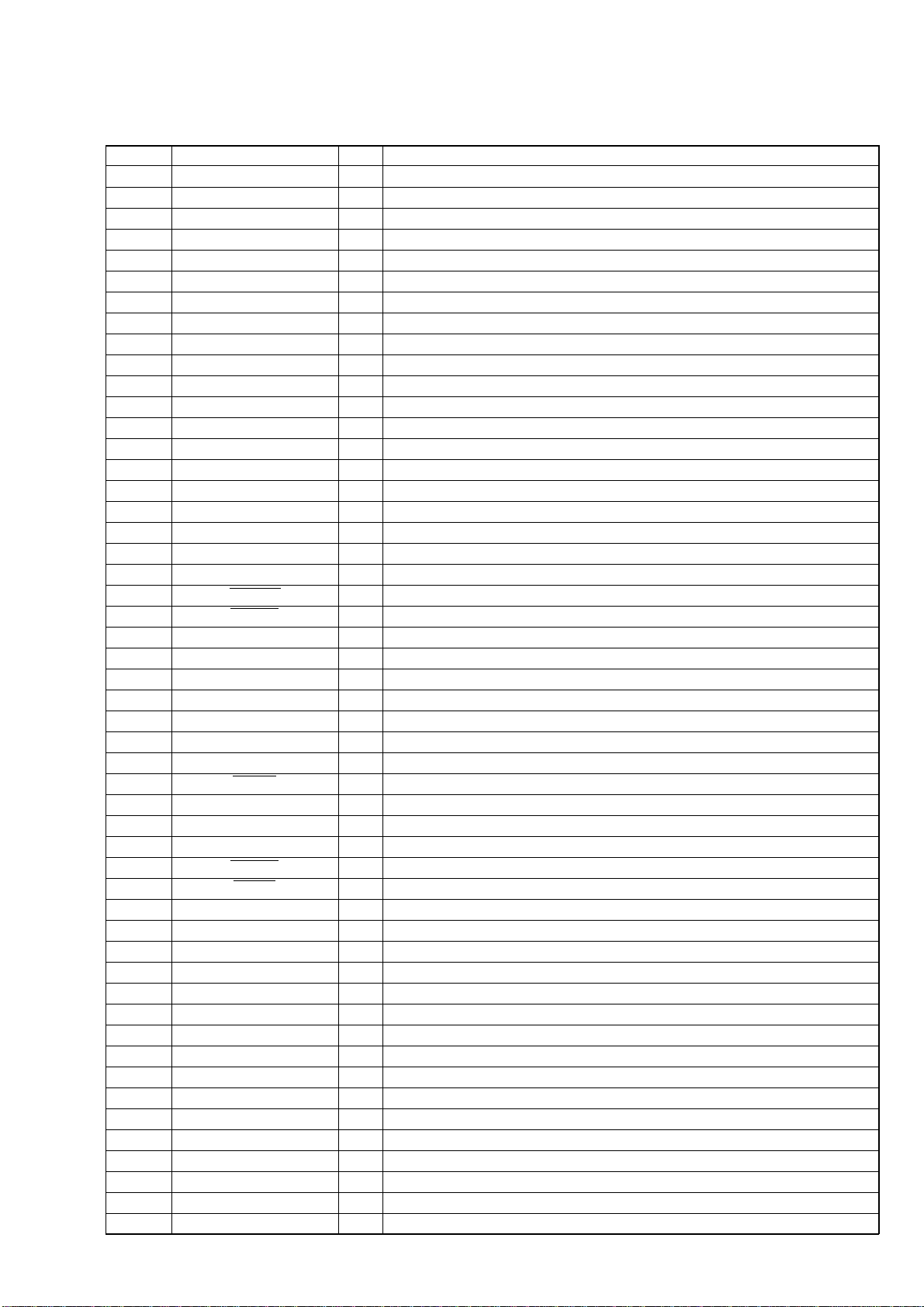

Pin No. Pin Name I/O Pin Description

1VREF– — A/D converter power supply (–) pin

2 VSM I S-meter voltage detection input

3QUALITY I Noise detection input

4, 5 KEYIN1, 0 I Key input 1, 0

6 RCIN0 I Rotary commander key input

7 to 9 NIL I Not used. (Fixed at L in this set)

10 VREF+ — A/D converter power supply (+) pin (+5 V)

11 VDD — Power supply pin (+5 V)

12 OSCOUT O Main clock output (18.432 MHz)

13 OSCIN I Main clock input (18.432 MHz)

14 VSS — Ground

15 XIN I Sub clock input (32.768 kHz)

16 XOUT O Sub clock output (32.768 kHz)

17 MMOD I Not used. (Fixed at L in this set)

18 LCDSO O Serial data output for LCD driver IC.

19 LCDCE O Chip enable output for LCD driver IC.

20 LCDCKO O Serial clock output for LCD driver IC.

21 CD_TSO O Serial data output for CD servo IC.

22 CD_TSI I Serial data input from CD servo IC.

23 CD_TCKO O Serial clock output for CD servo IC.

24 SYSRST O Not used. (Fixed at H in this set)

25 BUSON O Not used. (Fixed at H in this set)

26 KEYACK I Key acknowledge detection input

27 DAVN I RDS data block synchronization detection input

28 BUIN I Backup power supply input

29 SIRCS I SIRCS input

30 TU_ATTIN I Tuner attenuator control input

31 CD_PACK I CD text pack synchronization signal input from CD servo IC.

32 NC (VCC) — Power supply pin (+5 V)

33 RESET I Microcomputer reset input

34 NOSE-SW I Not used. (Fixed at H in this set)

35 BEEP O Beep output

36 NC O Not used. (Open)

37 TESTIN I Test mode detection input

38 ACCIN I Accessory power supply detection input

39 NC O Not used. (Open)

40 TELATT I Telephone attenuator detection input

41 NC (VCC) I Not used. (Fixed at H in this set)

42 UNISO O Not used. (Open)

43 UNISI I Not used. (Fixed at L in this set)

44 UNICKO O Not used. (Fixed at L in this set)

45 I2C_SIO I/O I2C BUS serial data input/output

46 NC O Not used. (Open)

47 I2C_CKO O I2C BUS serial clock output

48, 49 NC O Not used. (Open)

50 CD_SELFSW I CD mechanism deck Self switch detection input

51 TSTB O CD text parameter strobe output for CD servo IC.

52 RFOK I RFOK signal input from CD servo IC.

53 CD_RST O Reset signal output for CD servo IC.

54 A0 O Command/parameter discrimination signal output for CD servo IC.

55 STB O Data strobe signal output for CD servo IC.

CDX-L480N

11

CDX-L480N

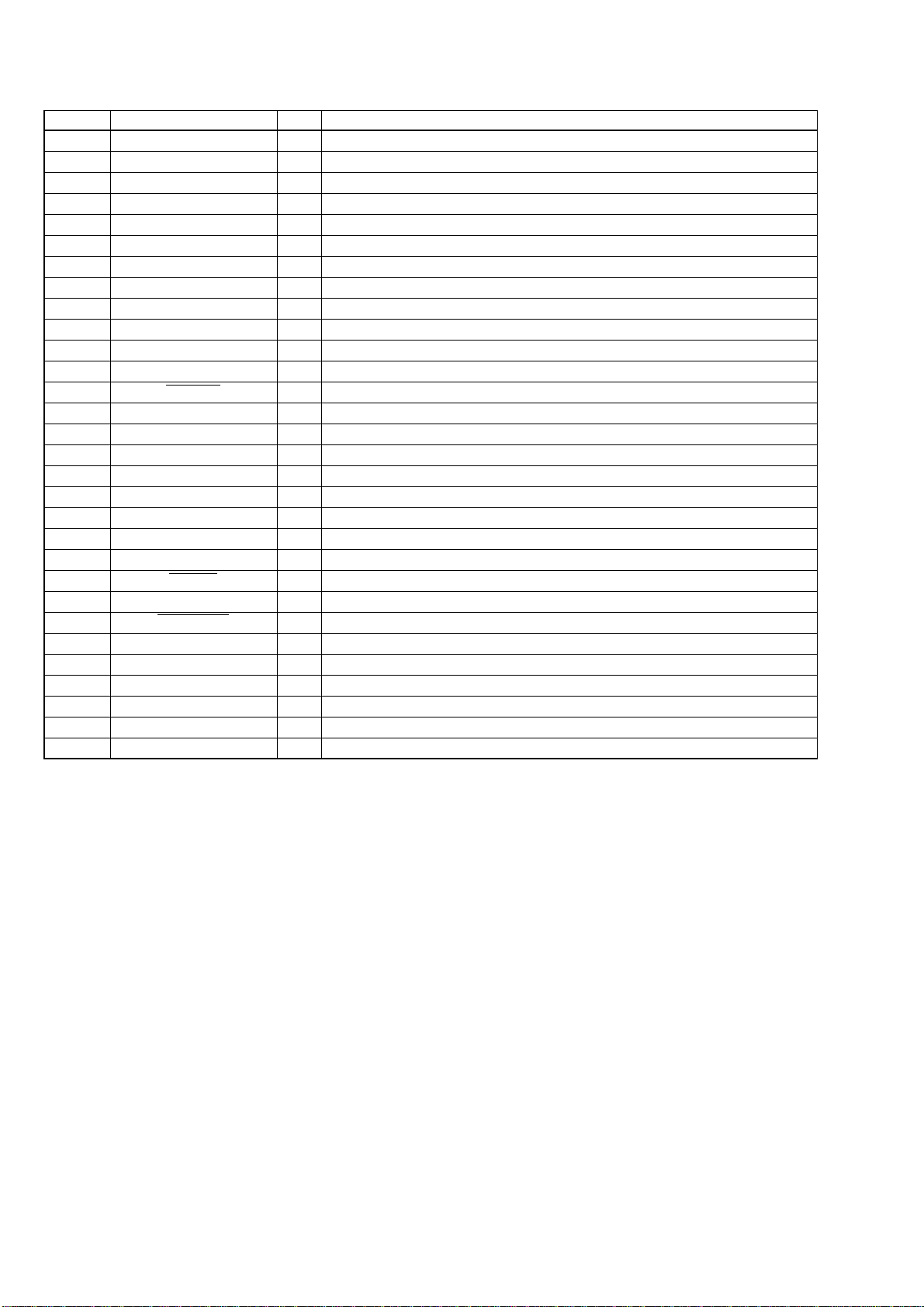

Pin No. Pin Name I/O Pin Description

56 X_EN O Not used. (Open)

57 LIMIT I CD mechanism deck Limit switch detection input

58 NCO O Not used. (Open)

59 D_SW I CD mechanism deck Down switch detection input

60 INSW I CD mechanism deck Disc in switch detection input

61 NC O Not used. (Open)

62 CD_LM_LO O CD mechanism deck loading motor control output (Loading direction)

63 CD_LM_EJ O CD mechanism deck loading motor control output (Eject direction)

64 to 66 NC O Not used. (Open)

67 ATT O System attenuator control output

68 DIAG I Mode input from power amp IC.

69 STB O Standby control output for power amp IC.

70 VOLATT O Electronic volume attenuator control output

71 to 74 NC O Not used. (Open)

75 DOOR-IND O Not used. (Open)

76 to 84 NC O Not used. (Open)

85 NS_MASK O Noise mask output

86 E2P_CKO O EEPROM serial clock output

87 E2P_SIO I/O EEPROM serial data input/output

88 TU-ATT O Tuner attenuator control output

89, 90 NC O Not used. (Open)

91 AD_ON O Key power supply control output

92, 93 NC O Not used. (Open)

94 PANEL_SW I Front panel OPEN/CLOSE detection input

95 DAVSS — D/A converter power supply (–) pin

96 COLSW I Not used. (Open)

97 FLASH_W I Flash microcomputer write detection input

98 RCIN1 I Rotary commander SHIFT key input

99 NC O Not used. (Open)

100 DAVDD — D/A converter power supply (+) pin (+5 V)

12

Loading...

Loading...