Page 1

CDX-1000RF

SERVICE MANUAL

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

13 watts per channel minimum continuous average power into

4 ohms, 4 channels driven from 20 Hz to 20 kHz with no more

than 1% total harmonic distortion.

US Model

Model Name Using Similar Mechanism CDX-2500R

CD Drive Mechanism Type MG-363X-121

Optical Pick-up Name KSS-521A

Other Specifications

CD player section

System Compact disc digital audio

system

Signal-to-noise ratio 90 dB

Frequency response 10 – 20,000 Hz

Wow and flutter Below measurable limit

Laser Diode Properties

Material GaAs+GaAlAs

Wavelength 785 – 815 nm (Typ. 800 nm)

Emission Duration Continuous

Laser output power Less than 0.5 mW*

* This output is the value measured at a distance

of 0.7 mm from the objective lens surface on the

Optical Pick-up Block.

General

Outputs Line outputs

Power requirements 12 V DC car battery

(negative ground)

Current drain 2A (at disc loading)

Dimensions Approx. 178 × 50 × 173 mm

(7 1/8 × 2 × 6 7/8 in.)

(w/h/d)

Mounting dimensions Approx. 182 × 53 × 159 mm

(7 1/4 × 2 1/8 × 6 3/8 in.)

(w/h/d)

Mass Approx. 1.1 kg (2 lb. 7 oz.)

Supplied accessories Parts for installation and

connections (1 set)

Design and specifications are subject to change without

notice.

COMPACT DISC PLAYER

1

Page 2

SERVICE NOTE

TABLE OF CONTENTS

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

NOTES ON PICK-UP FLEXIBLE BOARD

The pick-up flexible board in this set is secured to the optical pickup with an adhesive tape. Once the tape is removed, an adhering

force becomes weak, and it cannot be reused.

Therefore, if the optical pick-up is replaced, replace also the pickup flexible board with a new one.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

P ART NUMBERS APPEAR AS SHOWN IN THIS MANU AL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

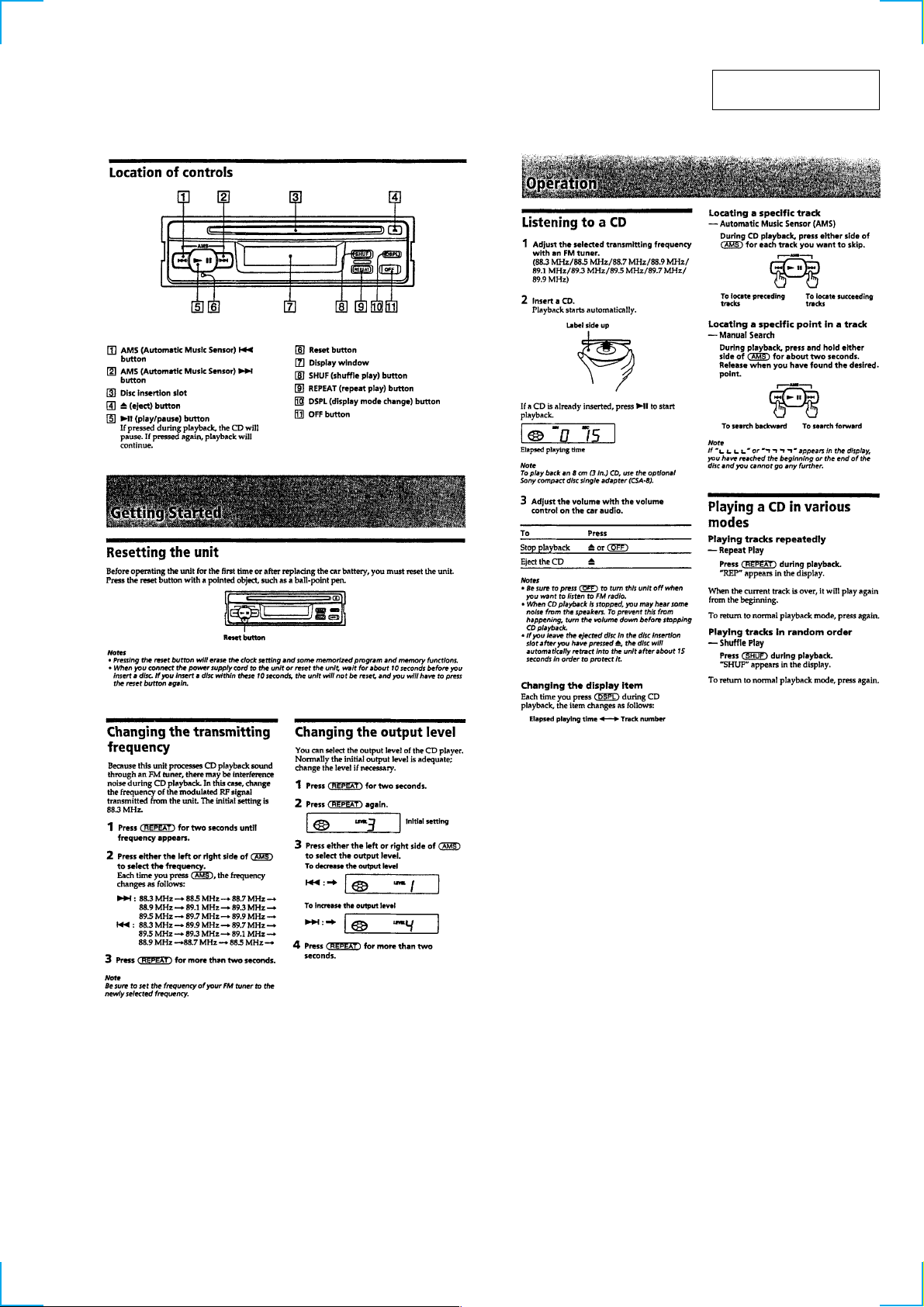

1. GENERAL

Location of controls................................................................. 3

Getting Started......................................................................... 3

Operation ................................................................................. 3

Connections ............................................................................. 4

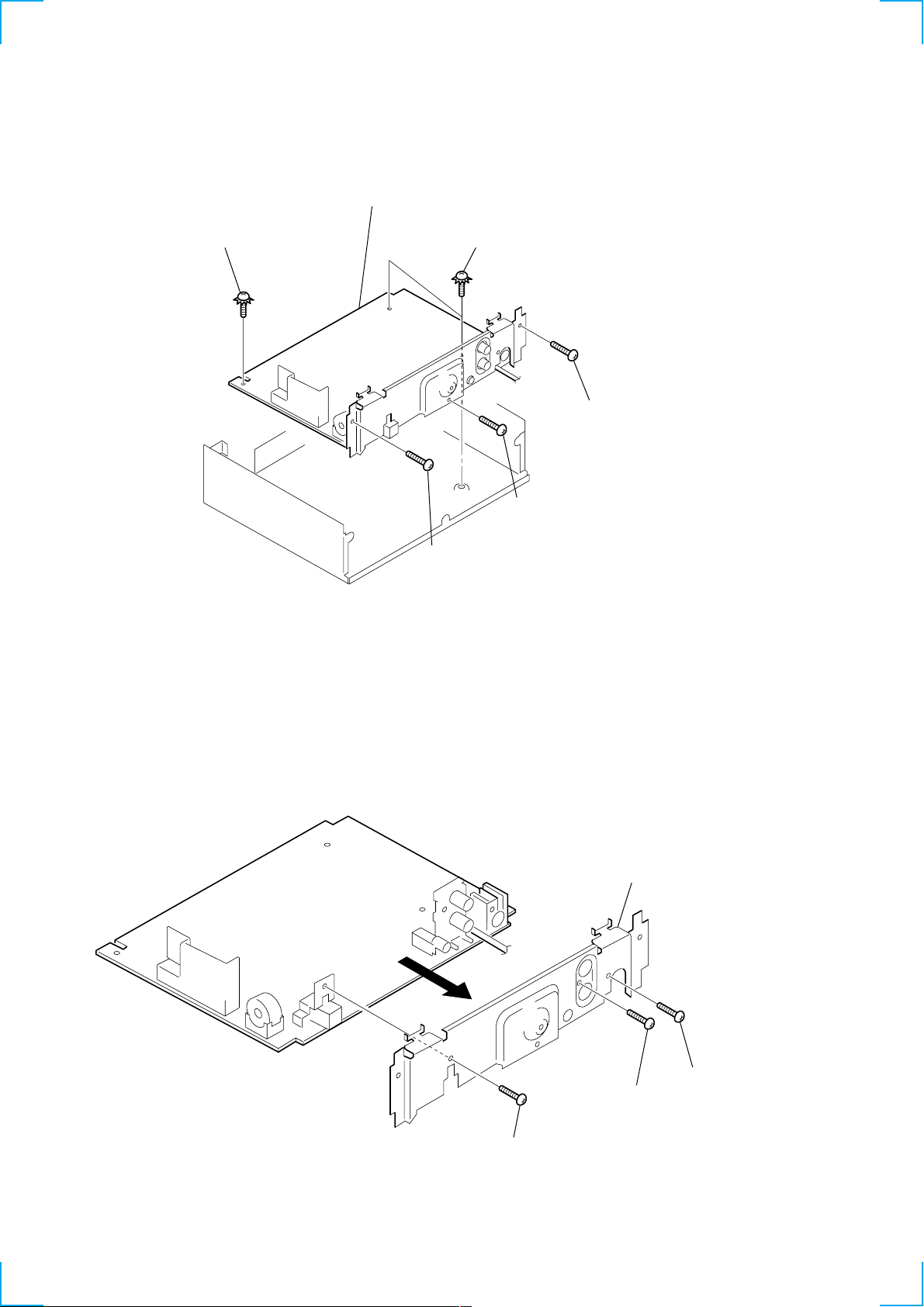

2. DISASSEMBLY

2-1. Panel Assy, Front ................................................................. 5

2-2. CD Mechanism Block ......................................................... 5

2-3. Main Board ......................................................................... 6

2-4. Chassis (Rear) .....................................................................6

2-5. Chassis (T) Sub Assy .......................................................... 7

2-6. Lever Assy ........................................................................... 7

2-7. Servo Board......................................................................... 8

2-8. Roller Assy.......................................................................... 8

2-9. Chassis (OP) (O/S) Assy ..................................................... 9

2-10. Optical Pick-up Block ......................................................... 9

3. ELECTRICAL ADJUSTMENTS

CD Section ............................................................................10

4. DIAGRAMS

4-1. IC Pin Description............................................................. 11

4-2. Block Diagram –CD Section (1/2)– .................................. 12

4-3. Block Diagram –CD Section (2/2)– .................................. 13

4-4. Block Diagram –Display, Power Supply Section– ............ 14

4-5. Circuit Boards Location .................................................... 15

4-6. Printed Wiring Boards –CD Mechanism Section–............ 16

4-7. Schematic Diagram –CD Mechanism Section– ................ 17

4-8. Printed Wiring Board –Main Section– ..............................18

4-9. Schematic Diagram –Main Section (1/2)– ........................ 19

4-10. Schematic Diagram –Main Section (2/2)– ........................ 20

4-11. Schematic Diagram –Display Section–............................. 21

4-12. Printed Wiring Board –Display Section– ..........................22

5. EXPLODED VIEWS

5-1. Chassis Section ................................................................. 26

5-2. Front Panel Section ........................................................... 27

5-3. CD Mechanism Section (1) ............................................... 28

5-4. CD Mechanism Section (2) ............................................... 29

5-5. CD Mechanism Section (3) ............................................... 30

6. ELECTRICAL PARTS LIST ........................................ 31

2

Page 3

SECTION 1

GENERAL

This section is extracted

from instruction manual.

3

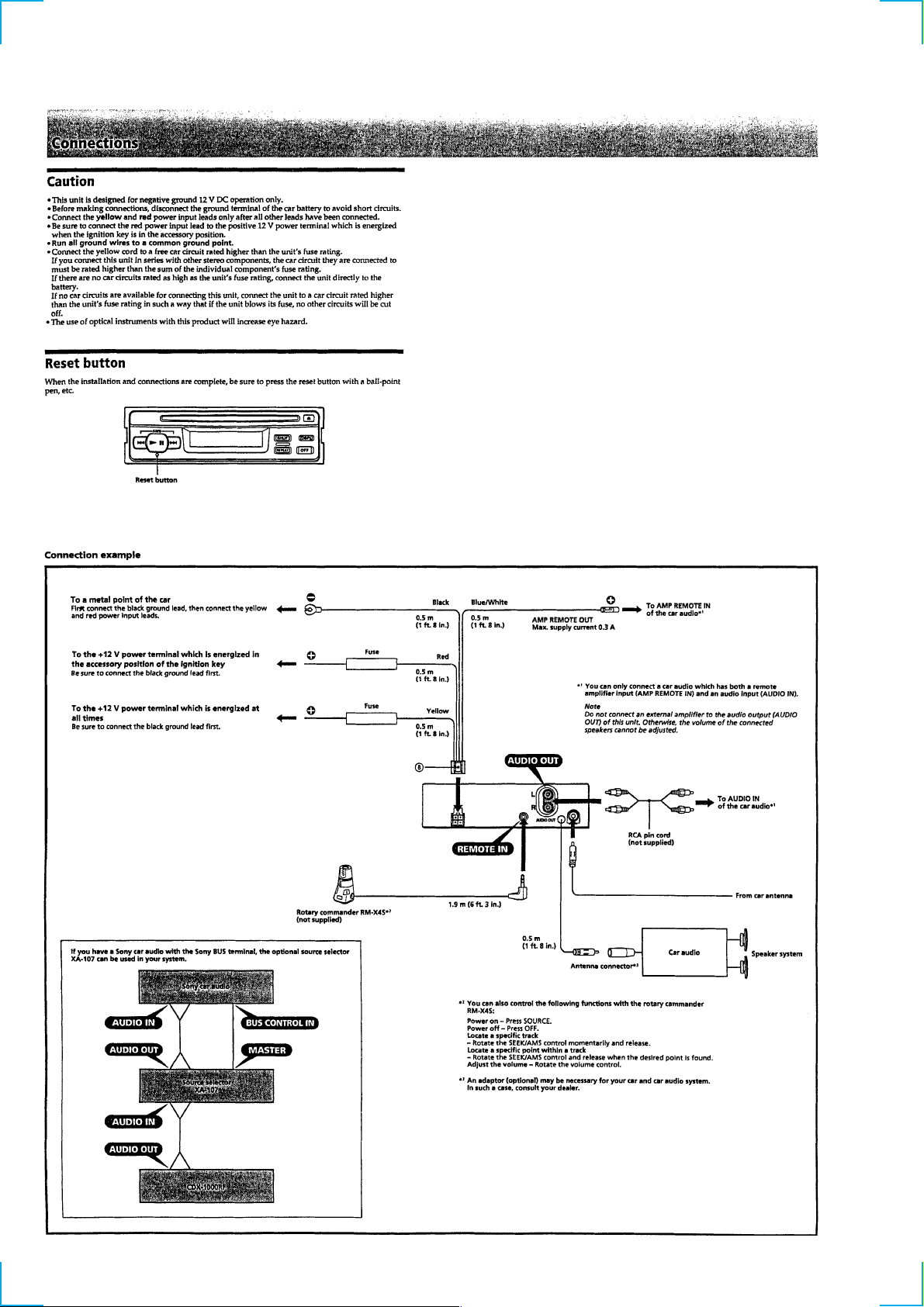

Page 4

4

Page 5

6

SECTION 2

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

2-1. PANEL ASSY, FRONT

3 claw

2 claws

1 claws

2-2. CD MECHANISM BLOCK

5 CD mechanism block

5 panel assy, front

2 PTT 2.6x6

8 bracket (M/D)

4 CNP801

7 PTT 2.6x6

3 PTT 2.6x6

6 PTT 2.6x

1 PTT 2.6x6

4 CNP701

5

Page 6

6

6

2-3. MAIN BOARD

6 MAIN board

2-4. CHASSIS (REAR)

5 ground point screw

(PTT 2.6x6)

4 ground point screws

(PTT 2.6x6)

3 PTT 2.6x

2 PTT 2.6x6

1 PTT 2.6x6

4 chassis (rear)

3 PTT 2.6x

2 PTT 2.6x6

1 PTT 2.6x6

6

Page 7

2-5. CHASSIS (T) SUB ASSY

4 P 2x3

3 P 2x3

1 Unsolder the

lead wires.

2-6. LEVER ASSY

5 chassis (T) sub assy

2 P 2x3

red

white

black

4 claws

5 guide (disc)

6 lever (R) assy

3 tension spring (LR)

7 lever (L) assy

1 PS 2x4

2 DISC IN SW board

7

Page 8

2-7. SERVO BOARD

8 PS 2x4

7 PS 2x4

3 Removal the solders.

1 CN3

5 P 2x3

6 loading motor assy

2 CN2

9 SERVO board

4 Removal the solders.

2-8. ROLLER ASSY

• When installing, take note of the positions

arm (roller) and washers. (Fig. 1)

4 PS 2x3

5 LOAD SW board

washer

ring (roller), retaining

arm

3 roller assy

2 arm (roller)

spacer, insulating

arm

Fig. 1

1 tension spring (RA)

8

Page 9

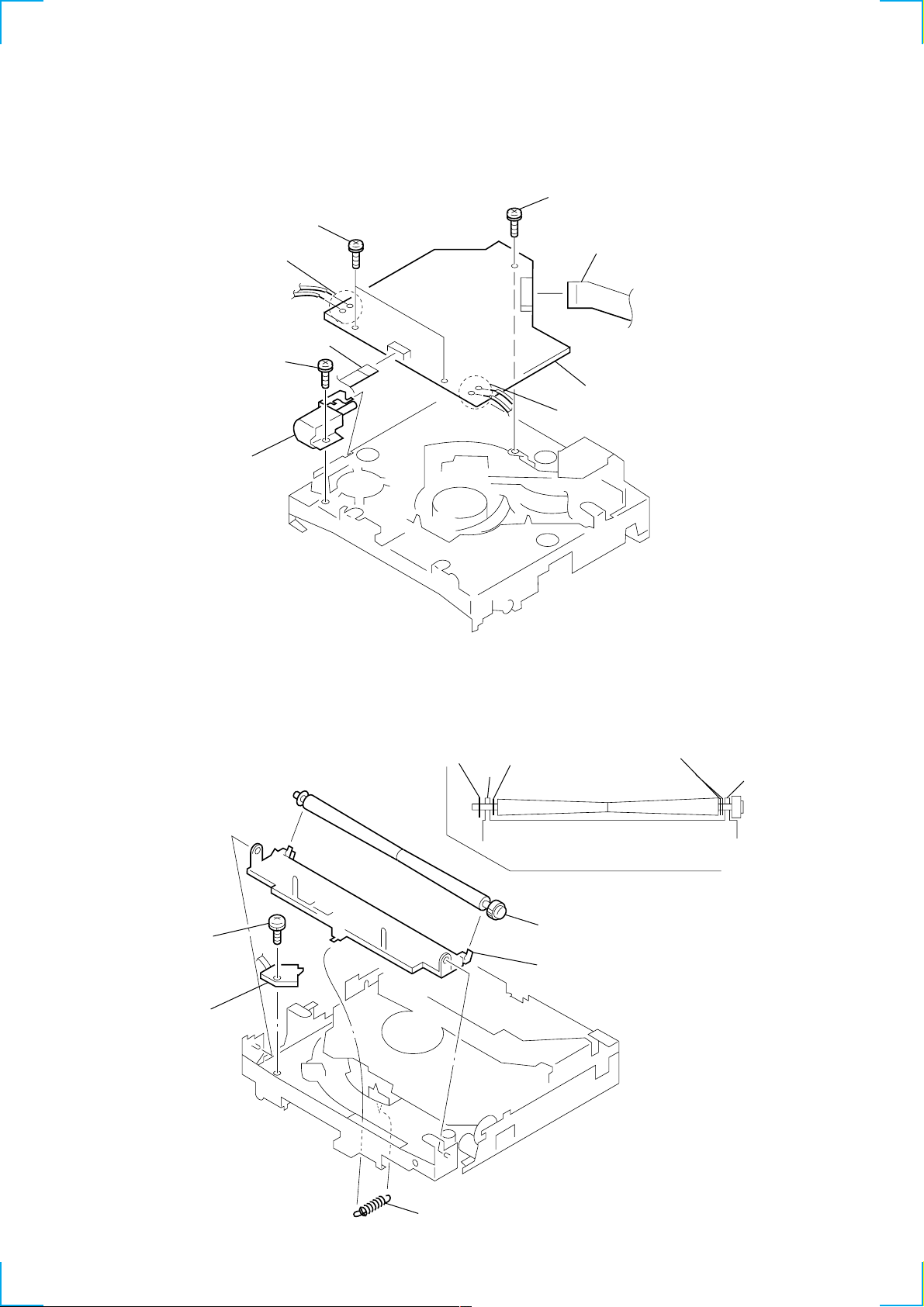

2-9. CHASSIS (OP) (O/S) ASSY

8 compression spring (FL)

1 tension spring (KF1)

7 chassis (OP) (O/S) assy

9 compression spring (FL)

2 tension spring (KR1)

5 Fit lever (D) in the

direction of the arrow.

6 Turn loading ring in the

direction of the arrow.

4 damper (T)

2-10. OPTICAL PICK-UP BLOCK

1 P 2x3

2 sled motor assy

3 damper (T)

3 optical pick-up block

9

Page 10

SECTION 3

ELECTRICAL ADJUSTMENTS

CD SECTION

Note:

1. CD Block basically constructed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indica ted.

3. Use the oscilloscope with more than 10 MΩ impedance.

4. Clean an objective lens by an applicator with neutral detergent

when the signal level is low than specif ied value with the f ollowing

checks.

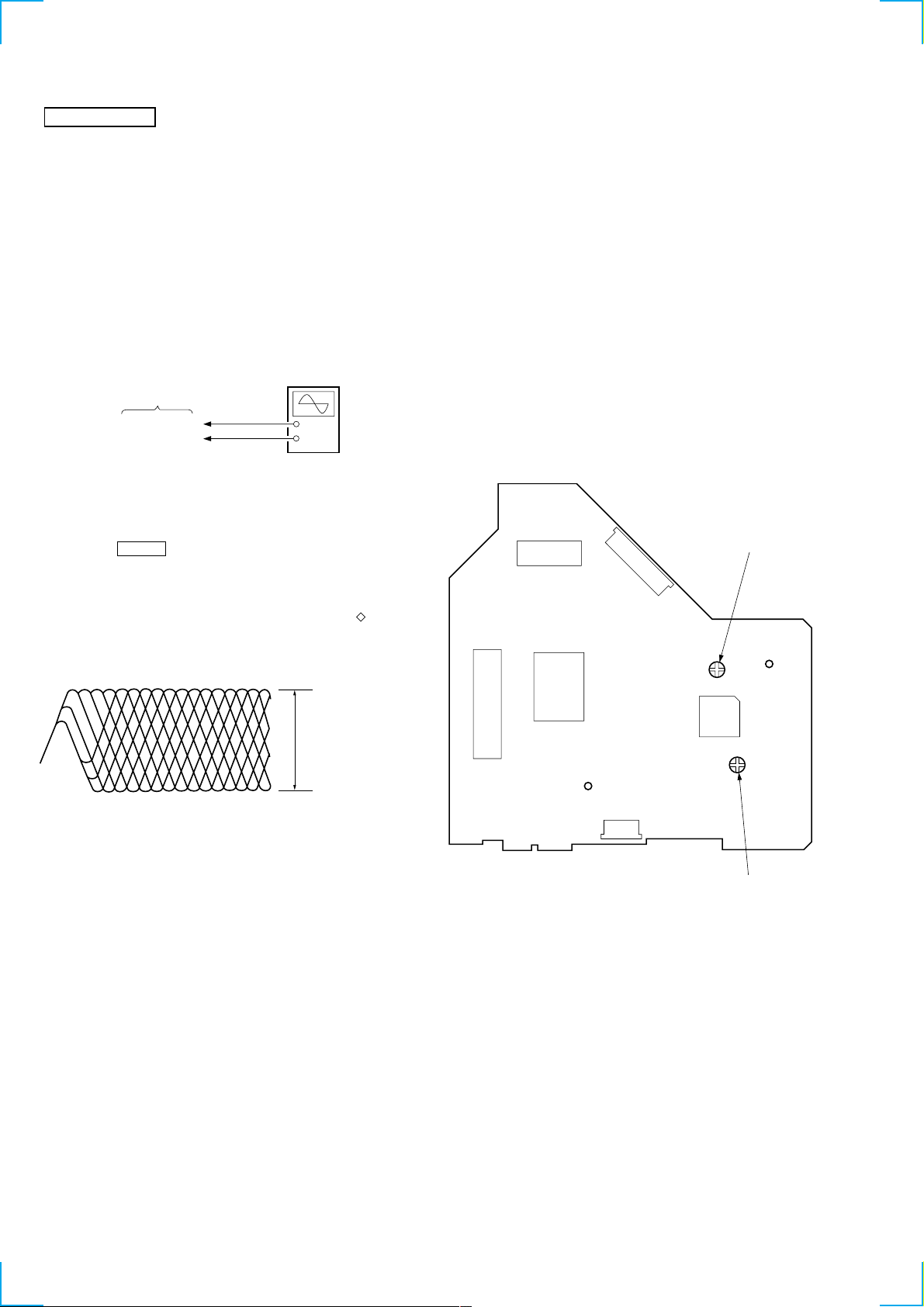

Focus Bias Adjustment

Setting: This adjustment is performed with the set placed

horizontally.

oscilloscope

SERVO board

TP (RF)

TP (RF. GND)

Procedure:

1. Connect an oscilloscope between TP (RF) and TP (RF. GND)

on the SERVO board.

2. Connect the power supply.

3. Push the RESET button (S900) on the MAIN board.

4. Insert the disc (YEDS-18) and playback.

5. Adjust RV1 so that the oscilloscope w aveform is clear and check

RF signal level is correct or not.

Note: Clear RF signal waveform means that the sharp “ ” can be

clearly distinguished at the center of the waveform.

+

–

Focus Gain Adjustment (Coarse adjustment)

This adjustment is not required unless the following parts are re placed:

• Optical pick-up

• RV4

Procedure:

1. Set RV4 to the standard position. (mechanical center)

2. Check whether operation noise (while noise type) caused by

the 2-axis device (lens section of the optical pick-up) is

abnormally loud.

If the operation noise is too loud, turn RV4 slightly counterclockwise.

• If the gain is too low:

Focus does not function and no music is selected.

• If the gain is too high:

Noise caused by scratches and dust is heard and the operation

becomes unstable.

Adjustment Location: servo board

Adjustment Location: servo board (component side)

FOCUS GAIN ADJ

IC3

CN2

RV4

RF signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 nS

level: 1.0 – 1.5 Vp-p

• When observing the ey e pattern, set the oscilloscope to AC range

and raise the vertical sensitivity so that it may be easily seen.

Adjustment Location: servo board

CN1

IC1

TP

(RF. GND)

IC2

TP

(RF)

CN3

RV1

FOCUS BIAS ADJ

10

Page 11

SECTION 4

DIAGRAMS

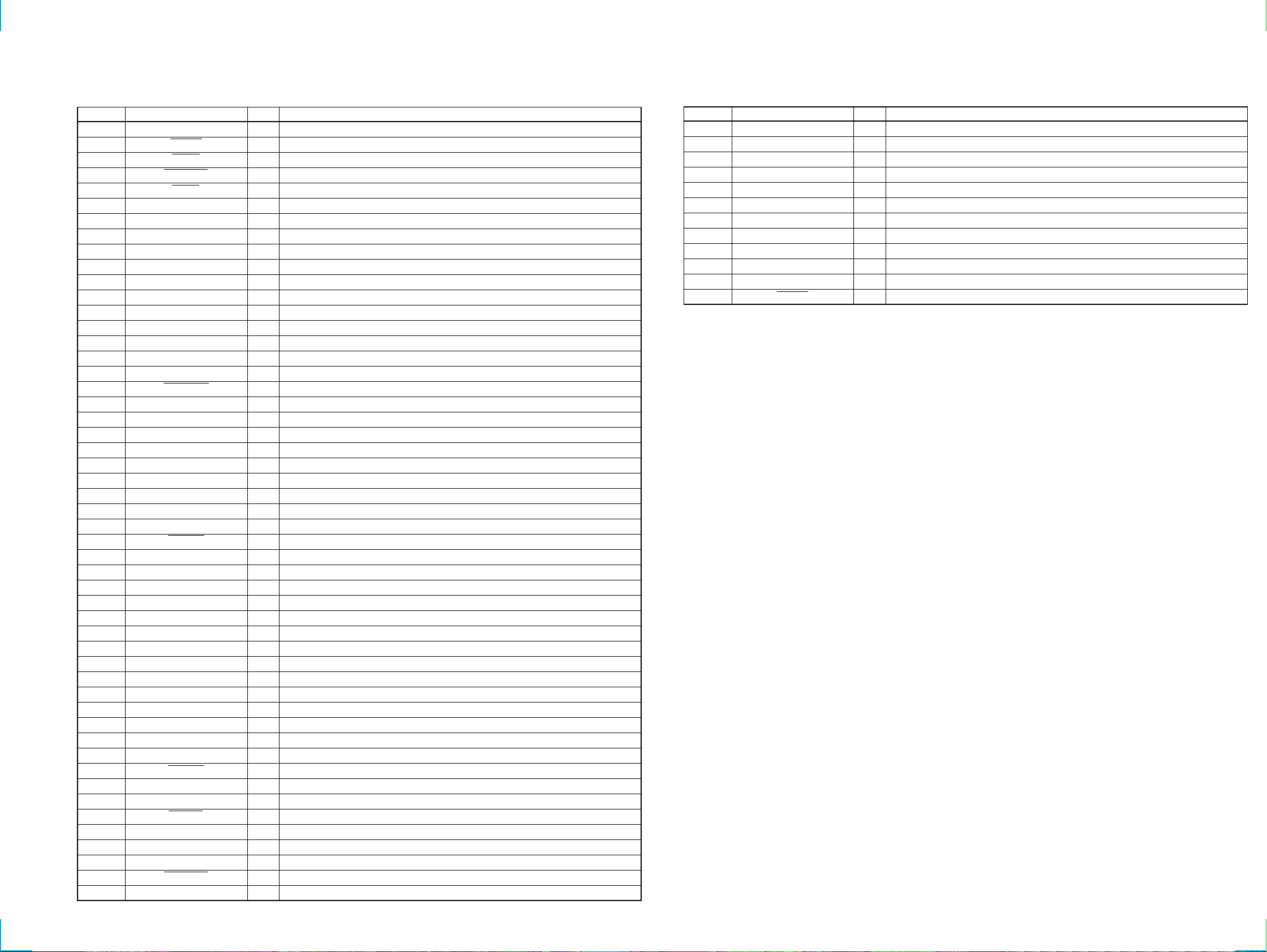

4-1. IC PIN DESCRIPTION

• IC801 µPD17705GC-547-3B9 (SYSTEM CONTROL)

Pin No. Pin Name I/O Pin Description

1 NC — Not used. (Connect to ground in this set.)

2 IN_SW I Disc insertion detection input L: IN_SW

3 D_SW I DOWN switch detection input L: D_SW

4 SELF_SW I Disc self store detection input L: SELF_SW

5 L_SW I Sled limit switch detection input L: L_SW

6 LM_EJ O Loading motor control output (Eject direction)

7 LM_LD O Loading motor control output (Loading direction)

8 RY_ON O Relay control output

9, 10 NC — Not used. (Open)

11 BAND_SW I BAND select input 0: US

12 – 20 NC — Not used. (Open)

21 GND3 — Ground

22 NC — Not used. (Open)

23 ADKI2 I A/D key input 2

24 ADKI1 I A/D key input 1

25 ROTCOM I Rotary commander shift key input

26 NC — Not used. (Open)

27 TEST_SW I Test mode initial setting detection input L: TEST_SW

28, 29 NC — Not used. (Open)

30 VDD2 — Power supply pin (+5 V)

31 FMIN I PLL local oscillator frequency input

32 NC — Not used. (Open)

33 GND2 — Ground

34 NC — Not used. (Open)

35 EO1 O PLL error 1 output

36 TEST0 — Connect to GND line.

37 – 40 NC — Not used. (Open)

41 ACC_IN I Accessory power detection input L: ACC_IN

42 SCOR I SCOR signal detection input

43 MUTE O Mute control output

44 LEVEL D O Level control output

45 NC — Not used. (Open)

46 PH2 I Connect to +5 V line.

47 LEVEL 1 O Volume control output

48, 49 NC O Not used. (Open)

50 EMPH_O O Emphasis control output

51 PW_ON O System power control output

52 LM_ON O Loading motor power control output

53 CD_ON O CD power control output

54 ILLON O Illumination power control output

55 – 57 NC — Not used. (Open)

58 LCD_CE O LCD chip enable output

59 EZ_SEL I Rotary commander shift key input L: EZ_SEL

60 SENS I CD SENS signal detection input

61 FOK I Focus OK signal detection input

62 LD_ON O Laser ON/OFF control output L: LD_ON

63, 64 NC — Not used. (Open)

65 LCD_CLK O LCD serial clock output

66 LCD_DAT O LCD serial data output

67 LCD_INH O LCD inhibition output L: LCD_INH

68 SQCK0 O Sub Q read clock output

Pin No. Pin Name I/O Pin Description

69 CD_RST O Reset output to CD signal processor IC.

70 SQ_SI I Sub Q data input

71 CD_SO0 O CD signal serial data output

72 CD_LAT O CD signal processing data latch output

73 CD_CK0 O CD signal processing serial clock output

74 NC — Not used. (Open)

75 GND1 — Ground

76 XOUT O ceramic oscillator output (4.5 MHz)

77 XIN I ceramic oscillator input (4.5 MHz)

78 BU_IN I Backup power detection input

79 VDD1 — Power supply pin (+5 V)

80 RESET I Reset input L: RESET

11 11

Page 12

CDX-1000RF

4-2. BLOCK DIAGRAM — CD SECTION (1/2) —

OPTICAL PICK-UP

KSS-521A

I-V

AMP

PD

LD

TRACKING

FOCUS

M902

(SLED)

LD POWER

CONTROL

Q1, 2

M

RF AMP, SERVO CONTROL

PD1 RF

35 31

PD2

36

E

39

F

38

FEO

1

FEI

2

RV4

FOCUS

GAIN

PD

34

LD

33

FOCUS/TRACKING COIL DRIVE,

CH2+

16

CH2–

15

CH1+

18

CH1–

17

CH3+

13

CH3–

14

IC2

FE BIAS

MOTOR DRIVE

IC3

LEVEL

SHIFT

LEVEL

SHIFT

LEVEL

SHIFT

RF 0

CLK

19

XLT

20

DATA

21

SENS

24

FOK

25

C. OUT

23

37

RV1

FOCUS

BIAS

XRST

22 50

SL O

16

FE O

6

TA O

13

CH2 IN

22

CH1 IN

19

CH3 IN

24

DIGITAL SIGNAL PROCESSOR

14

59

57

56

54

1

55

3

CLKO

XLTO

DATO

SEIN

FOK

CNIN

XRST

MDP

IC1

PCMD

BCK

LRCK

XTAI

SENS

SQSO

SQCK

DATA

XLAT

CLOK

SCOR

D/A CONVERTER

IC701

CD

DIN

21

22

20

34

X701

16.9344MHz

49

46

47

51

52

53

43

5

BCKIN

6

LRCIN

4

CLKO

19

XTI

1

XTO

20

RSTB

15

VOUTL

VOUTR

MC/DM1

SW3

(LIMIT)

SW1

(DISC IN)

SW4

(DOWN)

SW2

(SELF)

12

9

17

CD L-CH

CD R-CH

SYSTEM CONTROL

IC801 (1/3)

50

EMPH_O

69

CD_RST

60

SENS

70

SQ_SI

68

SQCK0

71

CD_SO0

72

CD_LAT

73

CD_CK0

42

SCOR

5

L_SW

2

IN_SW

3

D_SW

4

SELF_SW

SECTION

A

(Page 13)

(2/2)

CTL2

3

5

6

7

CH4 IN

FWD

REV

61

62

6

7

FOK

LD_ON

LM_EJ

LM_LD

M901

(SPINDLE)

M903

(LOADING)

04

CH4+

M

M

CH5+

12

10

LEVEL

SHIFT

LEVEL

SHIFT

• Signal path

: CD

• R-ch : same as L-ch.

12 12

Page 13

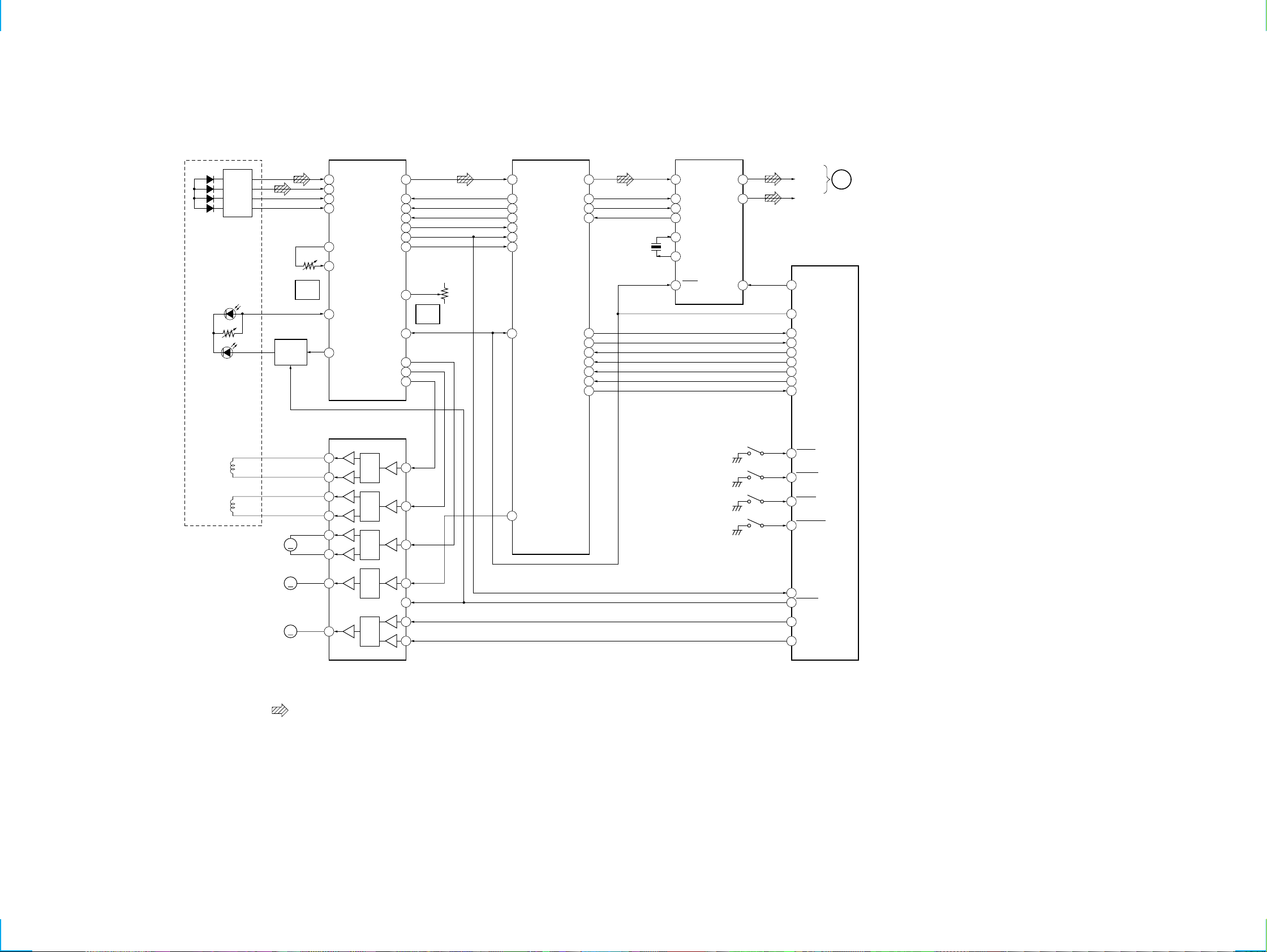

4-3. BLOCK DIAGRAM — CD SECTION (2/2) —

(Page 12)

CD

SECTION

(1/2)

A

CD L-CH

ELECTRONIC VOLUME

IC401

2 1

L/R

VOLUME

CONTROL

Q30

L/R

LEVEL

CONTROL

Q29

MUTE

Q401

CD R-CH

-1

L

-2

R

PJ401

AUDIO OUT

VOLUME

CONTROL

Q22

CDX-1000RF

L101

2 10

LEVEL

CONTROL

MPX OUT

BALANCE

BALANCE

Q23

13

15

17

TRANSMITTER

L/R BALANCE

RV1

4.5MHz

XOUT

BUFFER

X801

Q1

MPX

IC1

L IN

18

PMUTE

Q45

MUTE

CONTROL

Q403,404

47 44 43 76 77

LEVEL 1

LEVEL D

MUTE

CD R-CH

X1

38kHz

1

R IN

OSC

6

OSC

8

SYSTEM CONTROL

IC801(2/3)

XIN

D2

DEVIATION

RV10

TUNER +5V

D1

BUFFER

AMP

Q81,82

35 31

EO1

RF AMP

Q2,3

L1

RF

RF OSC

Q21

FMIN

L2

RF OSC

BATT

RELAY

SWITCH

Q15

RELAY

CONTROL

Q16

8

D919

RY_ON

RY1

• Signal path

: CD

: FM

: AM

CNJ601

(ANTENNA IN)

CN601

(ANTENNA OUT)

• R-ch : same as L-ch.

04

13 13

Page 14

CDX-1000RF

4-4. BLOCK DIAGRAM — DISPLAY, POWER SUPPLY SECTION —

SYSTEM CONTROL

IC801 (3/3)

LCD DRIVER

IC851

LIQUID CRYSTAL

DISPLAY PANEL

LCD851

CD +5V

MD +8V

CD

+5V REG

Q904

D905

D906

BACK-UP

CHECK

Q908,911,912

CD POWER

CONTROL

Q906,918

MD

+8V REG

Q901

S881

(RESET)

MD POWER

CONTROL

Q902,914

RESET LCD_DAT

80 66

BU_IN

78

PH2

46

CD_ON

53

LM_ON

52

LCD_CLK

LCD_CE

LCD_INH INH

ILLON

ADKI1

DATA

62

65

58

67

54

24

S861-864

CLK

61

CE

60

57

LCD DRIVER

POWER

CONTROL

Q913,915

COM1

COM2

S6-S26

S28-S30

U-COM +5V

64

63

6

I

23

•

25

I

27

•

29

I

31

LCD

+B REG

Q917

24

U-COM +5V

Q910

17

16

26

I

18

•

15

I

1

PL851

D861-868

ADKI2

23

S851-854

AMP REM

+B REG

Q921

TUNER +5V

04

TUNER

+5V REG

Q907

AMP REM

POWER

CONTROL

Q922

TUNER

POWER

CONTROL

Q903,905

51

PW_ON

ACC-IN

ROTCOM

EZ_SEL

ACC

41

25

59

CHECK

Q909

D913

(REMOTE IN)

J801

CNP901

4

2

1

BATTBATT

ACC

AMP REM

14 14

Page 15

4-5. CIRCUIT BOARDS LOCATION

LOAD SW board

DISC IN SW board

DISPLAY board

SUB board

SERVO board

LIMIT SW board

MAIN board

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is

printed in each block.)

for schematic diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• % : indicates tolerance.

• C : panel designation.

Note: The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

• U : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 14.4V and fed with regulated dc power

supply from ACC and BATT cords.

• Voltages are tak en with a V OM (Input impedance 10 MΩ).

Voltage var iations may be noted due to normal production tolerances.

• Wavefor ms are taken with a oscilloscope.

Voltage var iations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : FM

f : AM

J : CD

for printed wiring boards:

• X : parts extracted from the component side.

• b : Pattern from the side which enables seeing.

4

W or less unless otherwise

• Waveforms (MODE:PLAY)

1

0V

Approx. 620mVp-p

1

(FEO)

IC2

2

1.2Vp-p

ea

(RFO)

IC2

3

0V

Approx. 200mVp-p

rs

(TEO)

IC2

4

2.6Vp-p

7.6µsec

3

(MDP)

IC1

5

5.8Vp-p

22.7µsec

IC1

(LRCK)

w;

6

7

IC1

IC1

474nsec

(BCK)

ws

16.89MHz

(XTAI)

ef

5.7Vp-p

3.2Vp-p

15 15

Page 16

CDX-1000RF

4-6. PRINTED WIRING BOARDS — CD MECHANISM SECTION — • Refer to page 15 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

IC1 D-2

IC2 E-5

IC3 B-2

Q1 F-5

Q2 F-6

(Page 18)

16 16

Page 17

4-7. SCHEMATIC DIAGRAM — CD MECHANISM SECTION — • Refer to page 15 for Waveforms.

• Refer to page 23 for IC Block Diagrams.

CDX-1000RF

Note:

• Voltage and waveforms are dc with respect to ground

under no-signal conditions.

no mark : CD PLAY

: Impossible to measure

∗

(Page

19)

17 17

Page 18

CDX-1000RF

• Semiconductor

Location

Ref. No. Location

D1 F-13

D2 F-11

D401 A-7

D402 A-8

D901 F-1

D902 D-1

D903 H-1

D904 I-1

D905 J-2

D906 D-2

D907 C-2

D908 B-4

D912 K-3

D913 C-4

D919 D-12

4-8. PRINTED WIRING BOARD — MAIN SECTION — • Refer to page 15 for Circuit Boards Location.

IC1 E-11

IC401 C-8

IC701 F-4

IC801 I-8

Q1 E-12

Q2 G-13

Q3 F-13

Q15 E-12

Q16 D-11

Q21 G-13

Q22 G-11

Q23 G-11

Q27 C-9

Q28 C-9

Q29 A-9

Q30 A-9

Q45 E-8

Q65 E-8

Q81 F-9

Q82 F-9

Q401 C-10

Q402 C-10

Q403 B-7

Q404 A-8

Q901 G-1

Q902 F-2

Q903 C-3

Q904 H-2

Q905 C-3

Q906 G-2

Q907 E-1

Q908 D-3

Q909 C-5

Q910 J-1

Q911 J-3

Q912 J-2

Q913 I-2

Q914 F-2

Q915 J-2

Q917 K-2

Q918 G-2

Q921 B-5

Q922 C-6

(Page 22)

(Page 16)

18 18

Page 19

4-9. SCHEMATIC DIAGRAM — MAIN SECTION (1/2) — • Refer to page 21 for Waveforms.

• Refer to page 25 for IC Block Diagrams.

8

10

(Page 17)

9

CDX-1000RF

11

(Page 20)

12

(Page 21)

19 19

Note:

• Voltage is dc with respect to

ground under no-signal

condition.

no mark : CD PLAY

Page 20

CDX-1000RF

4-10. SCHEMATIC DIAGRAM — MAIN SECTION (2/2) — • Refer to page 21 for Waveforms.

• Refer to page 25 for IC Block Diagrams.

(Page 19)

13

20 20

Note:

• Voltage is dc with respect to ground under no-signal

condition.

no mark : CD PLAY

Page 21

• Waveforms (MODE:PLAY)

8

5.1Vp-p

22.7µsec

IC701

(LRCIN)

4

CDX-1000RF

4-11. SCHEMATIC DIAGRAM — DISPLAY SECTION —

9

q;

qa

qs

qd

IC701

16.9344MHz

IC701

IC701

IC801

474nsec

(BCKIN)

6

(XTO)

w;

16.89MHz

(CLKO)

ql

4.5MHz

(XOUT)

uh

(Page 19)

5.1Vp-p

4.7Vp-p

4Vp-p

2.7Vp-p

IC1

22.7µsec

(OSC)

8

4.1Vp-p

Note:

• Voltage is dc with respect to ground under no-signal

condition.

no mark : CD PLAY

21 21

Page 22

CDX-1000RF

4-12. PRINTED WIRING BOARD — DISPLAY SECTION — • Refer to page 15 for Circuit Boards Location.

(Page 18)

• Semiconductor

Location

Ref. No. Location

D851 C-5

D861 A-1

D862 B-1

D863 C-1

D864 B-3

D865 B-11

D866 B-12

D867 B-13

D868 C-3

IC851 C-7

22 22

Page 23

• IC Block Diagrams

IC1 CXD2507AQ (SERVO Board)

FOK

MON

MDP

MDS

LOCK

TEST

FILO

FILI

PCO

VSS

AVSS

CLTV

AVDD

BIAS

ASYI

ASYO

ASYE

WDCK

XLON

SPOC

SPOD

63

62

64

1

2

3

4

5

6

7

8

9

10

11

12

13

RF

14

15

16

17

18

19

SERVO AUTO

SEQUENCER

CPU

INTERFACE

14

DIGITAL

PLL

ASYMMETRY

CORRECTOR

5

20 21 22 23 24 25 26 27 293031 3228

LRCK

PCMD

BCLK

16K

RAM

GTOP

CLKO

SPOB

SPOA

58596061

5

SUB CODE

PROCESSOR

EFM

DEMODULATOR

3

ERROR

CORRECTOR

GFS

VDD

XUGF

XPCK

VDD

XLTO

RFCK

DATO

CNIN

5455

5657

4

D/A

INTERFACE

3

C2PO

XROF

SEIN

53

6

MNT3

CLOK

52

MNT1

XLAT

DIGITAL

CLV

DIGITAL

OUT

CLOCK

GENERATOR

51

DATA

50

XRST

49

SENS

48

MUTE

47

SQCK

SQSO

46

45

EXCK

44

SBSO

43

SCOR

42

VSS

41

WFCK

40

EMPH

39

DOUT

C4M

38

37

FSTT

36

XTSL

35

XTAO

34

XTAI

MNTO

33

IC3 BA6796FP-T1

OP IN –

OP IN +

VREF

CH3

28

1

OPOUT

26

27

THERMAL

CTL1 CTL2 FWD REV

23 4

CH4

CH4-IN

CTL1

SHUT

DOWN

5

2425

CTL2

CH3-IN

LEVEL

SHIFT

LOGIC

CH2

23

78

6

FWD

REV

22

CH2-IN

LEVEL

SHIFT

V/I

TRAY

21

VCC

LEVEL

SHIFT

9

VCC

GND

DRIVE

BUFFER

10

CH1

CH5 –

1920

CH1-IN

DRIVE

BUFFER

DRIVE

BUFFER

11

CH1 +

LEVEL

SHIFT

COM

CH1 –

DRIVE

BUFFER

DRIVE

BUFFER

12 13

CH4 +

161718

DRIVE

BUFFER

DRIVE

BUFFER

CH2 +

CH3 +

15

DRIVE

BUFFER

DRIVE

BUFFER

14

CH2 –

CH3 –

23

Page 24

IC2 CXA1782BQ

FE BIAS

PHD 2

36 35 34

37

F

38

E

39

PHD 1

RF IV AMP1

APC

RF IV AMP2

F IV AMP

PHD

33

FE AMP

LD

RF M

32

LEVEL S

FOK

RF O

31

TTL

IIL

FZC COMP

RF I

30 29 28 27 26 25

MIRR

IIL DATA REGISTER

TOG1-3

FS1-4 TG1-2 TM1-7 PS1-4

BAL1-3

CP

CB

DFCT

INPUT SHIFT REGISTER

ADDRESS DECODER

OUTPUT DECODER

CC1

TTL

TTL

FOK

CC2

IIL

24

SENS

23

C.OUT

22

XRST

21

DATA

20

IIL

XLT

19

CLK

VCC

18

VEE

TED

LPFI

TEI

ATSC

TZC

TDFCT

BAL2

BAL 3

TOG1

TOG2

WINDOW COMP

E IV AMP

TOG3

ATSC

TE AMP

HPF COMP

TZC COMP

DFCT

TM1

DFCT

FS4

2

1

FEI

FEO

FDFCT

43

FGD

LPF COMP

TG1

FCS PHASE

COMPENSATION

5

6

FLB

FE O

FS1

FS2

FE M

TRACKING

PHASE

COMPENSATION

TM6

TM5

TM4

TM3

TM7

TG2

987

TGU

SRCH

ISET

TM2

12

TA M

17

SL O

16

SL M

15

SL P

14

13

TA O

ISET

F SET

11

10

TG2

FSET

EI

40

BAL1

41

42

43

44

45

46

47

VC

48

24

Page 25

IC1 BA1405F-E2 (MAIN Board)

L IN

18 17 16 15 14 13 12 11 10

L

AMP

R

AMP

1 2 3 4 5 6 7 8 9

R IN

IC401 BA4558F

1

OUT1

2

–IN1

+IN1

3

1CH

BALANCE

AMP BIAS

2CH

BALANCENCVCC

MPX

NC

GND

8

VCC

OUT2

7

–IN2

6

MPX OUTNCPILOT OUT

BUFFER

BUFFER 1/2

OSC 38kHz

NC

OSC

NC

OSC

OSC BIAS

NC

VEE

4

IC701 PCM1717E-S

1

XTI

2

DGND

3

VDD

4

LRCIN

5

DIN

BCKIN

6

7

ZERO

LOWPASS FILTER

D/CR

8

9

VOUTR

10

AGND

INPUT

INTERFACE

DIGITAL

FILTER

NOISE SHAPER

5LEVE DAC

CMOS

AMP

5

CLK

CONTROL

LOWPASS FILTER

+IN2

MODE

CONT

ROL

5LEVEL DAC

CMOS

AMP

20

19

18

17

16

15

14

13

12

11

XTO

CLKO

ML/MUTE

MC/DM1

MD/DM0

RSTB

MODE

D/CL

VOUTL

AVCC

25

Page 26

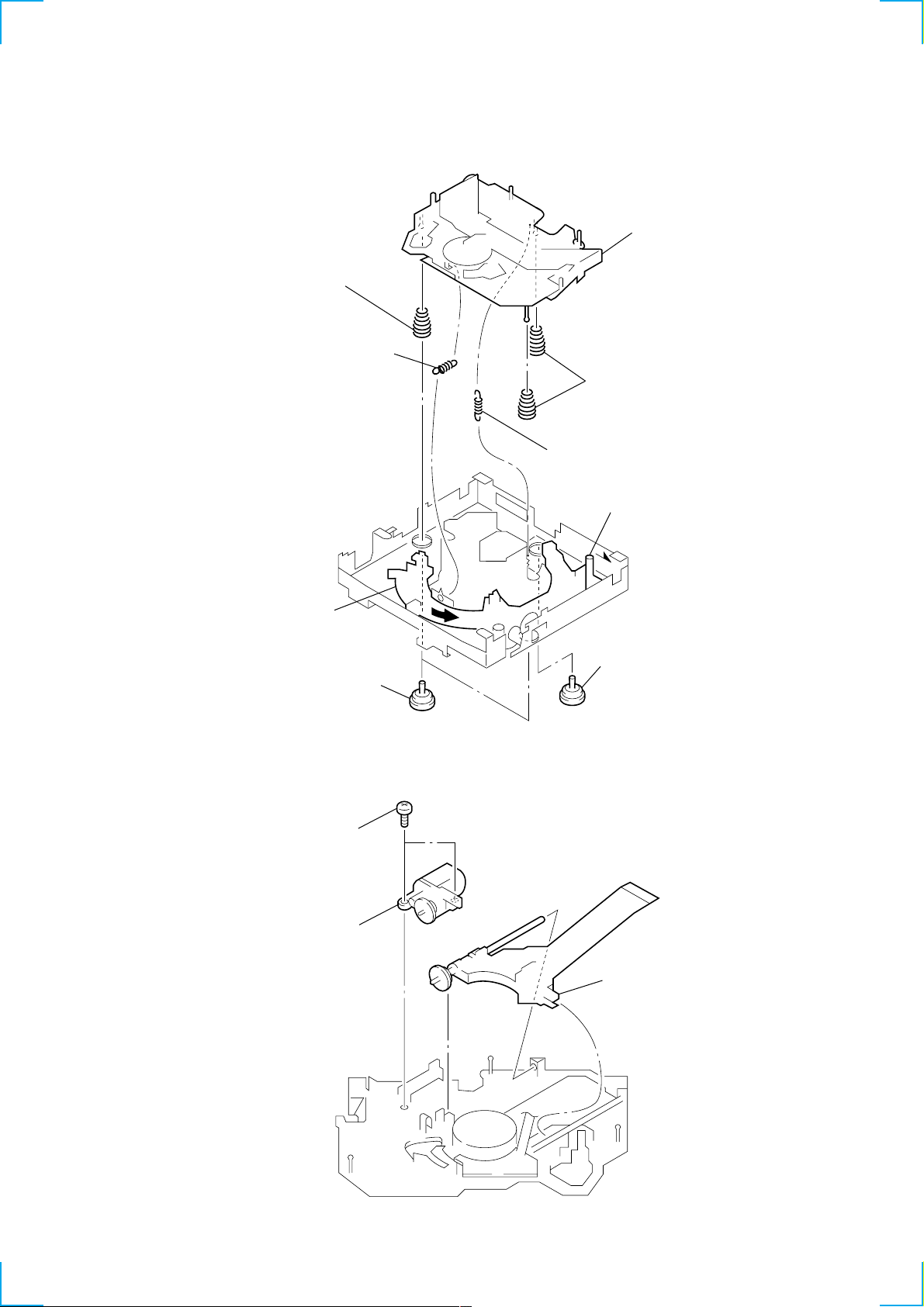

NOTE:

• The mechanical parts with no reference

number in the exploded views are not supplied.

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

5-1. CHASSIS SECTION

2

SECTION 5

EXPLODED VIEWS

• Color Indication of Appearance Parts

Example :

KNOB, BALANCE (WHITE) ... (RED)

• Accessories and packing materials and

hardware (# mark) list are given in

the last of this parts list.

F901

5

F902

R

Parts Color Cabinet’s Color

R

#1

4

3

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

#1

#1

#1

#1

MG-363X-121

#1

#1

CN601

#1

#1

7

#1

#1

10

#1

8

9

6

7

Ref. No. Part No. Description Remark

* 1 3-030-876-01 CHASSIS (MAIN)

* 2 3-030-925-41 COVER

* 3 3-024-285-01 CUSHION (RUBBER)

* 4 3-030-927-01 BRACKET (M/D)

5 1-792-738-11 CORD (WITH CONNECTOR) (POWER)

(INCLUDING F901,902)

* 6 A-3294-932-A MAIN BOARD, COMPLETE

26

1

Ref. No. Part No. Description Remark

7 3-922-535-11 SCREW (+BTT)

* 8 3-045-807-01 BRACKET (CONNECTOR)

* 9 3-043-192-01 CHASSIS (REAR)

* 10 3-030-850-01 HEAT SINK (REG)

CN601 1-792-841-11 CORD (WITH CONNECTOR) (ANTENNA OUT)

F901 1-532-798-11 FUSE (BLADE TYPE) (AUTO FUSE) (1A)

F902 1-532-731-11 FUSE (BLADE TYPE) (AUTO FUSE) (3A)

Page 27

5-2. FRONT PANEL SECTION

53

#2

55

57

58

LCD851

56

51

52

51 3-043-188-01 BUTTON (PLAY)

52 X-3378-481-1 PANEL ASSY, FRONT

53 3-043-190-01 BUTTON (AMS)

54 3-043-189-01 BUTTON (EJECT)

* 55 A-3294-933-A DISPLAY BOARD, COMPLETE

54

Ref. No. Part No. Description RemarkRef. No. Part No. Description Remark

* 56 3-043-193-01 PLATE (LCD), GROUND

* 57 3-043-196-01 SHEET (D)

* 58 X-3378-707-1 HOLDER (LCD) ASSY

LCD851 1-803-904-21 DISPLAY PANEL, LIQUID CRYSTAL

27

Page 28

5-3. CD MECHANISM SECTION (1)

(MG-363X-121)

102

104

111

112

103

#4

107

#4

#4

101

C

#3

108

109

110

105

106

114

115

111

112

113

C

M903

#5

#3

116

#3

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 101 1-659-836-11 DISC IN SW BOARD

* 102 A-3291-816-B CHASSIS (T) SUB ASSY

103 3-931-909-01 SPRING (LR), TENSION

104 X-3371-501-5 LEVER (L) ASSY

105 3-338-737-01 SCREW (2X3), +PS

* 106 1-659-837-11 LOAD SW BOARD

107 X-3371-502-4 LEVER (R) ASSY

108 A-3301-203-A ROLLER ASSY

109 3-931-908-01 GUIDE (DISC)

110 3-017-301-01 ARM (ROLLER)

111 3-936-756-01 ROLLER (D)

112 3-321-393-01 WASHER, STOPPER

* 113 3-939-139-01 SPACER

114 3-931-916-01 SPRING (RA), TENSION

* 115 A-3309-227-A SERVO BOARD, COMPLETE

* 116 3-007-530-01 BRACKET (MOTOR)

M903 A-3291-676-A MOTOR SUB ASSY, LOADING (LOADING)

#4

28

Page 29

5-4. CD MECHANISM SECTION (2)

(MG-363X-121)

155

#5

154

157

158

162

166

163

D

160

166

165

164

151

156

157

153

161

D

159

152

152

152

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

151 3-931-893-01 ARM, CHUCKING

152 3-931-897-01 DAMPER (T)

153 3-931-879-02 LEVER (D)

* 154 3-913-404-11 RETAINER (DISC)

155 3-931-894-01 BRACKET (CP)

156 3-931-895-01 SPRING (CH), TENSION

157 3-931-898-01 SPRING (FL), COMPRESSION

158 3-032-483-02 SPRING (KF1), TENSION

159 A-3277-802-C CHASSIS (M) COMPLETE ASSY

160 3-931-883-01 SPRING (TR), TENSION

161 3-931-881-01 LEVER (LOCK)

162 3-931-882-02 GEAR (MDL)

163 3-007-537-11 WHEEL (U), WORM

164 3-032-484-01 SPRING (KR1), TENSION

165 3-014-727-01 WHEEL (LW), WORM

166 3-018-272-01 WASHER

29

Page 30

5-5. CD MECHANISM SECTION (3)

(MG-363X-121)

#6

M901

207

201

202

#5

M902

208

203

205

#7

206

209

210

#4

204

213

211

212

#4

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 201 X-3374-022-1 CHASSIS (OP) (O/S) ASSY

202 3-931-829-01 SPRING (SL), PLATE

203 X-3371-504-1 BASE (DRIVING) ASSY

204 3-931-832-01 GEAR (SL MIDWAY)

* 205 1-659-835-12 LIMIT SW BOARD

209 3-909-607-01 SCREW

0 210 8-820-010-06 PICK-UP, OPTICAL KSS-521A/K1RP

211 3-931-834-01 SPRING (FEED), PLATE

212 1-659-881-11 PICK-UP FLEXIBLE BOARD

213 A-3291-669-A SHAFT (FEED) ASSY

206 3-338-737-01 SCREW (2X3), +PS

207 1-659-880-11 MOTOR FLEXIBLE BOARD

* 208 1-659-834-11 SUB BOARD

30

M901 X-3371-664-2 MOTOR ASSY (SPINDLE)

M902 A-3291-674-A MOTOR ASSY, SLED (SLED)

Page 31

SECTION 6

ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in

the parts list may be different from the

parts specified in the diagrams or the

components used on the set.

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• RESISTORS

All resistors are in ohms.

METAL:Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F:nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 1-659-836-11 DISC IN SW BOARD

****************

< SWITCH >

SW1 1-572-288-21 SWITCH, PUSH (DISC IN)

SW2 1-572-288-21 SWITCH, PUSH (SELF)

*************************************************************

* A-3294-933-A DISPLAY BOARD, COMPLETE

************************

X-3378-707-1 HOLDER (LCD) ASSY

* 3-043-193-01 PLATE (LCD), GROUND

* 3-043-196-01 SHEET (D)

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

• SEMICONDUCTORS

In each case, u : µ, for example:

uA.. : µA.. uPA.. : µPA..

uPB.. : µPB.. uPC.. : µPC.. uPD.. : µPD..

• CAPACITORS

uF : µF

• COILS

uH : µH

LCD851 1-803-904-21 DISPLAY PANEL, LIQUID CRYSTAL

PL851 1-517-973-11 LAMP, PILOT

R851 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R852 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R853 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R861 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R862 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

DISC IN SW DISPLAY

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

When indicating parts by reference

number, please include the board.

< LIQUID CRYSTAL DISPLAY >

< PILOT LAMP >

< RESISTOR >

< CAPACITOR >

C851 1-163-137-00 CERAMIC CHIP 680PF 5% 50V

C852 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C853 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

< CONNECTOR >

CN801 1-783-268-11 CABLE, FLAT

< DIODE >

D851 8-719-976-99 DIODE UDZ-TE-17-5.1B

D861 8-719-052-61 LED SLR-342PGT31 (Z)

D862 8-719-052-61 LED SLR-342PGT31 (DSPL)

D863 8-719-052-61 LED SLR-342PGT31 (OFF)

D864 8-719-052-61 LED SLR-342PGT31 (SHUF)

D865 8-719-052-61 LED SLR-342PGT31 (> (AMS))

D866 8-719-052-61 LED SLR-342PGT31 (B X)

D867 8-719-052-61 LED SLR-342PGT31 (. (AMS))

D868 8-719-052-61 LED SLR-342PGT31 (REPEAT)

< IC >

IC851 8-759-369-90 IC LC75822ED

< JUMPER RESISTOR >

R863 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R881 1-216-090-00 METAL CHIP 51K 5% 1/10W

R882 1-216-194-00 METAL CHIP 680 5% 1/8W

R884 1-216-178-00 RES-CHIP 150 5% 1/8W

R885 1-216-178-00 RES-CHIP 150 5% 1/8W

R889 1-216-043-11 RES-CHIP 560 5% 1/10W

R890 1-216-043-11 RES-CHIP 560 5% 1/10W

R891 1-216-043-11 RES-CHIP 560 5% 1/10W

R892 1-216-043-11 RES-CHIP 560 5% 1/10W

R893 1-216-043-11 RES-CHIP 560 5% 1/10W

R894 1-216-043-11 RES-CHIP 560 5% 1/10W

R895 1-216-043-11 RES-CHIP 560 5% 1/10W

R896 1-216-043-11 RES-CHIP 560 5% 1/10W

R897 1-216-043-11 RES-CHIP 560 5% 1/10W

R898 1-216-043-11 RES-CHIP 560 5% 1/10W

R899 1-216-043-11 RES-CHIP 560 5% 1/10W

R900 1-216-043-11 RES-CHIP 560 5% 1/10W

< SWITCH >

S851 1-572-704-31 SWITCH, KEY BOARD (Z)

S852 1-572-704-31 SWITCH, KEY BOARD (SHUF)

S853 1-572-704-31 SWITCH, KEY BOARD (DSPL)

S854 1-572-704-31 SWITCH, KEY BOARD (OFF)

S861 1-572-704-31 SWITCH, KEY BOARD (REPEAT)

JR805 1-216-296-00 SHORT 0

JR810 1-216-296-00 SHORT 0

JR811 1-216-296-00 SHORT 0

JR813 1-216-296-00 SHORT 0

JR814 1-216-296-00 SHORT 0

JR817 1-216-296-00 SHORT 0

JR818 1-216-296-00 SHORT 0

JR819 1-216-296-00 SHORT 0

S862 1-572-704-31 SWITCH, KEY BOARD (B X)

S863 1-572-704-31 SWITCH, KEY BOARD (> (AMS))

S864 1-572-704-31 SWITCH, KEY BOARD (. (AMS))

S881 1-572-704-31 SWITCH, KEY BOARD (RESET)

*************************************************************

31

Page 32

LIMIT SW

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 1-659-835-12 LIMIT SW BOARD

***************

< SWITCH >

SW3 1-572-688-11 SWITCH, PUSH (1 KEY) (LIMIT)

*************************************************************

* 1-659-837-11 LOAD SW BOARD

***************

< SWITCH >

SW4 1-572-288-21 SWITCH, PUSH (DOWN)

*************************************************************

* A-3294-932-A MAIN BOARD, COMPLETE

*********************

* 3-030-850-01 HEAT SINK (REG)

* 3-043-192-01 CHASSIS (REAR)

* 3-045-807-01 BRACKET (CONNECTOR)

7-685-792-09 SCREW +PTT 2.6X6 (S)

MAINLOAD SW

C66 1-126-160-11 ELECT 1uF 20% 50V

C67 1-164-346-11 CERAMIC CHIP 1uF 16V

C69 1-164-346-11 CERAMIC CHIP 1uF 16V

C84 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C85 1-124-233-11 ELECT 10uF 20% 16V

C86 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C87 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C101 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C107 1-124-259-11 ELECT 4.7uF 20% 16V

C108 1-124-259-11 ELECT 4.7uF 20% 16V

C201 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C207 1-124-259-11 ELECT 4.7uF 20% 16V

C208 1-124-259-11 ELECT 4.7uF 20% 16V

C209 1-124-472-11 ELECT 470uF 20% 10V

C401 1-124-584-00 ELECT 100uF 20% 10V

C402 1-164-346-11 CERAMIC CHIP 1uF 16V

C701 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C702 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C703 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C704 1-124-233-11 ELECT 10uF 20% 16V

< CAPACITOR >

C1 1-124-259-11 ELECT 4.7uF 20% 16V

C2 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C3 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C4 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C5 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C6 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C7 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C8 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C9 1-163-229-11 CERAMIC CHIP 12PF 5% 50V

C10 1-124-234-00 ELECT 22uF 20% 16V

C11 1-163-091-00 CERAMIC CHIP 8PF 50V

C12 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C13 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C14 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C15 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C20 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C21 1-163-231-11 CERAMIC CHIP 15PF 5% 50V

C24 1-124-584-00 ELECT 100uF 20% 10V

C30 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C41 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C42 1-124-257-00 ELECT 2.2uF 20% 50V

C43 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C44 1-124-229-00 ELECT 33uF 20% 10V

C45 1-164-346-11 CERAMIC CHIP 1uF 16V

C46 1-126-160-11 ELECT 1uF 20% 50V

C47 1-164-346-11 CERAMIC CHIP 1uF 16V

C48 1-164-346-11 CERAMIC CHIP 1uF 16V

C61 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C62 1-124-257-00 ELECT 2.2uF 20% 50V

C63 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C65 1-164-346-11 CERAMIC CHIP 1uF 16V

C705 1-124-589-11 ELECT 47uF 20% 16V

C708 1-124-233-11 ELECT 10uF 20% 16V

C709 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C712 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C713 1-163-239-11 CERAMIC CHIP 33PF 5% 50V

C714 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C804 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C807 1-163-233-11 CERAMIC CHIP 18PF 5% 50V

C808 1-163-234-11 CERAMIC CHIP 20PF 5% 50V

C809 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C812 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C813 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C814 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C831 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C901 1-124-257-00 ELECT 2.2uF 20% 50V

C902 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C903 1-124-257-00 ELECT 2.2uF 20% 50V

C904 1-110-654-11 DOUBLE LAYERS 0.047F 5.5V

C905 1-124-259-11 ELECT 4.7uF 20% 16V

C907 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C908 1-124-233-11 ELECT 10uF 20% 16V

C909 1-126-768-11 ELECT 2200uF 20% 16V

C911 1-124-259-11 ELECT 4.7uF 20% 16V

C912 1-124-584-00 ELECT 100uF 20% 10V

C914 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C915 1-124-259-11 ELECT 4.7uF 20% 16V

C916 1-124-584-00 ELECT 100uF 20% 10V

< CONNECTOR >

CN601 1-792-841-11 CORD (WITH CONNECTOR) (ANTENNA OUT)

CNP701 1-764-617-12 PIN, CONNECTOR (PC BOARD) 30P

CNP801 1-563-614-31 CONNECTOR, FLEXIBLE 11P

* CNP901 1-691-785-11 PIN, CONNECTOR (PC BOARD) 4P

32

Page 33

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

< JACK >

CNJ600 1-793-598-11 JACK (ANTENNA IN)

< DIODE >

D1 8-719-058-78 DIODE HVU202A3TRF

D2 8-719-991-33 DIODE 1SS133T-77

D401 8-719-991-33 DIODE 1SS133T-77

D402 8-719-109-71 DIODE MTZJ-T-77-3.9A

D901 8-719-929-15 DIODE MTZJ-T-77-9.1B

D902 8-719-109-89 DIODE MTZJ-T-77-5.6B

D903 8-719-109-89 DIODE MTZJ-T-77-5.6B

D904 8-719-109-89 DIODE MTZJ-T-77-5.6C

D905 8-719-109-93 DIODE MTZJ-T-77-6.2B

D906 8-719-923-91 DIODE MTZJ-T-77-16A

D907 8-719-049-38 DIODE 1N5404TU

D908 8-719-200-82 DIODE 11ES2-TA1B

D912 8-719-921-80 DIODE MTZJ-T-77-11B

D913 8-719-991-33 DIODE 1SS133T-77

D919 8-719-991-33 DIODE 1SS133T-77

< IC >

IC1 8-759-393-50 IC A1405F-E2

IC401 8-759-909-71 IC BA4558F-T1

IC701 8-759-464-81 IC PCM1717E-ST2

IC801 8-759-675-96 IC uPD17705GC-547-3B9

< JACK >

J801 1-566-822-41 JACK (REMOTE IN)

L101 1-235-778-21 FILTER, LOW PASS

L201 1-235-778-21 FILTER, LOW PASS

L801 1-410-501-11 INDUCTOR 2.2uH

L901 1-416-539-11 INDUCTOR 370uH

< JACK >

PJ401 1-764-424-11 JACK, PIN 2P (AUDIO OUT)

< TRANSISTOR >

Q1 8-729-034-51 TRANSISTOR KTC3875

Q2 8-729-052-33 TRANSISTOR KTC3879

Q3 8-729-052-33 TRANSISTOR KTC3879

Q15 8-729-034-50 TRANSISTOR KTA1504

Q16 8-729-034-49 TRANSISTOR KRC104S

Q21 8-729-052-33 TRANSISTOR KTC3879

Q22 8-729-038-74 TRANSISTOR KRC110S

Q23 8-729-038-74 TRANSISTOR KRC110S

Q27 8-729-038-74 TRANSISTOR KRC110S

Q28 8-729-038-74 TRANSISTOR KRC110S

Q29 8-729-038-74 TRANSISTOR KRC110S

Q30 8-729-038-74 TRANSISTOR KRC110S

Q45 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q65 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q81 8-729-034-51 TRANSISTOR KTC3875

Q82 8-729-034-51 TRANSISTOR KTC3875

Q401 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q402 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q403 8-729-038-68 TRANSISTOR KRC103S

Q404 8-729-038-55 TRANSISTOR KRA103S

< JUMPER RESISTOR >

JR5 1-216-295-00 SHORT 0

JR6 1-216-295-00 SHORT 0

JR7 1-216-295-00 SHORT 0

JR10 1-216-296-00 SHORT 0

JR11 1-216-296-00 SHORT 0

JR12 1-216-296-00 SHORT 0

JR14 1-216-296-00 SHORT 0

JR17 1-216-296-00 SHORT 0

JR19 1-216-296-00 SHORT 0

JR21 1-216-296-00 SHORT 0

JR23 1-216-295-00 SHORT 0

JR24 1-216-296-00 SHORT 0

JR28 1-216-295-00 SHORT 0

JR31 1-216-295-00 SHORT 0

JR32 1-216-295-00 SHORT 0

JR35 1-216-296-00 SHORT 0

JR46 1-216-296-00 SHORT 0

JR922 1-216-296-00 SHORT 0

< COIL >

L1 1-419-619-11 COIL, IFT

L2 1-419-620-11 COIL, AIR-CORE

Q901 8-729-019-00 TRANSISTOR 2SD2394-G

Q902 8-729-038-55 TRANSISTOR KRA103S

Q903 8-729-038-55 TRANSISTOR KRA103S

Q904 8-729-922-62 TRANSISTOR 2SD1760F5-TLQ

Q905 8-729-038-67 TRANSISTOR KRC102S

Q906 8-729-038-55 TRANSISTOR KRA103S

Q907 8-729-019-00 TRANSISTOR 2SD2394-G

Q908 8-729-038-67 TRANSISTOR KRC102S

Q909 8-729-034-51 TRANSISTOR KTC3875

Q910 8-729-052-35 TRANSISTOR STD1664

Q911 8-729-034-51 TRANSISTOR KTC3875

Q912 8-729-034-51 TRANSISTOR KTC3875

Q913 8-729-038-67 TRANSISTOR KRC102S

Q914 8-729-038-67 TRANSISTOR KRC102S

Q915 8-729-038-55 TRANSISTOR KRA103S

Q917 8-729-052-35 TRANSISTOR STD1664

Q918 8-729-038-67 TRANSISTOR KRC102S

Q921 8-729-922-47 TRANSISTOR 2SB1184-TLR

Q922 8-729-038-67 TRANSISTOR KRC102S

< RESISTOR >

R1 1-216-107-00 METAL CHIP 270K 5% 1/10W

R2 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R4 1-216-025-11 RES-CHIP 100 5% 1/10W

33

Page 34

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

R5 1-216-063-11 RES-CHIP 3.9K 5% 1/10W

R6 1-216-073-00 METAL CHIP 10K 5% 1/10W

R7 1-216-073-00 METAL CHIP 10K 5% 1/10W

R8 1-216-075-00 METAL CHIP 12K 5% 1/10W

R9 1-216-198-11 RES-CHIP 1K 5% 1/8W

R332 1-216-049-11 RES-CHIP 1K 5% 1/10W

R333 1-216-073-00 METAL CHIP 10K 5% 1/10W

R401 1-216-049-11 RES-CHIP 1K 5% 1/10W

R408 1-216-073-00 METAL CHIP 10K 5% 1/10W

R409 1-216-073-00 METAL CHIP 10K 5% 1/10W

R10 1-216-073-00 METAL CHIP 10K 5% 1/10W

R11 1-216-059-00 METAL CHIP 2.7K 5% 1/10W

R12 1-216-190-00 RES-CHIP 470 5% 1/8W

R13 1-216-097-11 RES-CHIP 100K 5% 1/10W

R14 1-216-037-00 METAL CHIP 330 5% 1/10W

R15 1-216-174-00 RES-CHIP 100 5% 1/8W

R16 1-216-037-00 METAL CHIP 330 5% 1/10W

R17 1-216-043-11 RES-CHIP 560 5% 1/10W

R18 1-216-049-11 RES-CHIP 1K 5% 1/10W

R19 1-216-025-11 RES-CHIP 100 5% 1/10W

R20 1-216-041-00 METAL CHIP 470 5% 1/10W

R21 1-216-073-00 METAL CHIP 10K 5% 1/10W

R22 1-216-049-11 RES-CHIP 1K 5% 1/10W

R23 1-216-073-00 METAL CHIP 10K 5% 1/10W

R41 1-216-049-11 RES-CHIP 1K 5% 1/10W

R42 1-216-073-00 METAL CHIP 10K 5% 1/10W

R43 1-216-689-11 METAL CHIP 39K 0.5% 1/10W

R45 1-216-073-00 METAL CHIP 10K 5% 1/10W

R46 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R61 1-216-049-11 RES-CHIP 1K 5% 1/10W

R62 1-216-073-00 METAL CHIP 10K 5% 1/10W

R63 1-216-689-11 METAL CHIP 39K 0.5% 1/10W

R65 1-216-073-00 METAL CHIP 10K 5% 1/10W

R66 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R81 1-216-081-00 METAL CHIP 22K 5% 1/10W

R701 1-216-025-11 RES-CHIP 100 5% 1/10W

R702 1-216-033-00 METAL CHIP 220 5% 1/10W

R703 1-216-033-00 METAL CHIP 220 5% 1/10W

R704 1-216-033-00 METAL CHIP 220 5% 1/10W

R706 1-216-037-00 METAL CHIP 330 5% 1/10W

R707 1-216-027-00 METAL CHIP 120 5% 1/10W

R708 1-249-393-11 CARBON 10 5% 1/4W

R801 1-216-073-00 METAL CHIP 10K 5% 1/10W

R802 1-216-105-11 RES-CHIP 220K 5% 1/10W

R804 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R806 1-216-049-11 RES-CHIP 1K 5% 1/10W

R807 1-216-049-11 RES-CHIP 1K 5% 1/10W

R810 1-216-105-11 RES-CHIP 220K 5% 1/10W

R812 1-216-073-00 METAL CHIP 10K 5% 1/10W

R813 1-216-073-00 METAL CHIP 10K 5% 1/10W

R814 1-216-049-11 RES-CHIP 1K 5% 1/10W

R815 1-216-049-11 RES-CHIP 1K 5% 1/10W

R817 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R818 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R820 1-216-073-00 METAL CHIP 10K 5% 1/10W

R824 1-216-105-11 RES-CHIP 220K 5% 1/10W

R825 1-216-105-11 RES-CHIP 220K 5% 1/10W

R826 1-216-105-11 RES-CHIP 220K 5% 1/10W

R828 1-216-254-00 RES-CHIP 220K 5% 1/8W

R830 1-216-254-00 RES-CHIP 220K 5% 1/8W

R82 1-216-049-11 RES-CHIP 1K 5% 1/10W

R83 1-216-045-00 METAL CHIP 680 5% 1/10W

R85 1-216-689-11 METAL CHIP 39K 0.5% 1/10W

R101 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R102 1-216-073-00 METAL CHIP 10K 5% 1/10W

R104 1-216-097-11 RES-CHIP 100K 5% 1/10W

R105 1-216-088-00 METAL CHIP 43K 5% 1/10W

R106 1-216-065-11 RES-CHIP 4.7K 5% 1/10W

R107 1-216-088-00 METAL CHIP 43K 5% 1/10W

R108 1-216-059-00 METAL CHIP 2.7K 5% 1/10W

R109 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R110 1-216-071-00 METAL CHIP 8.2K 5% 1/10W

R119 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R201 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R202 1-216-073-00 METAL CHIP 10K 5% 1/10W

R204 1-216-097-11 RES-CHIP 100K 5% 1/10W

R205 1-216-088-00 METAL CHIP 43K 5% 1/10W

R206 1-216-065-11 RES-CHIP 4.7K 5% 1/10W

R207 1-216-088-00 METAL CHIP 43K 5% 1/10W

R208 1-216-059-00 METAL CHIP 2.7K 5% 1/10W

R209 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R210 1-216-071-00 METAL CHIP 8.2K 5% 1/10W

R219 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R831 1-216-089-11 RES-CHIP 47K 5% 1/10W

R832 1-216-073-00 METAL CHIP 10K 5% 1/10W

R833 1-216-049-11 RES-CHIP 1K 5% 1/10W

R834 1-216-049-11 RES-CHIP 1K 5% 1/10W

R901 1-216-182-00 RES-CHIP 220 5% 1/8W

R902 1-216-182-00 RES-CHIP 220 5% 1/8W

R903 1-216-190-00 RES-CHIP 470 5% 1/8W

R904 1-249-395-11 CARBON 15 5% 1/4W

R905 1-216-077-11 RES-CHIP 15K 5% 1/10W

R907 1-216-081-00 METAL CHIP 22K 5% 1/10W

R908 1-216-105-11 RES-CHIP 220K 5% 1/10W

R909 1-216-105-11 RES-CHIP 220K 5% 1/10W

R910 1-216-079-00 METAL CHIP 18K 5% 1/10W

R912 1-216-079-00 METAL CHIP 18K 5% 1/10W

R913 1-216-081-00 METAL CHIP 22K 5% 1/10W

R914 1-249-413-11 CARBON 470 5% 1/4W

R916 1-216-065-11 RES-CHIP 4.7K 5% 1/10W

R918 1-216-065-11 RES-CHIP 4.7K 5% 1/10W

R919 1-216-105-11 RES-CHIP 220K 5% 1/10W

R920 1-216-025-11 RES-CHIP 100 5% 1/10W

R921 1-216-025-11 RES-CHIP 100 5% 1/10W

R922 1-216-049-11 RES-CHIP 1K 5% 1/10W

R923 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

34

Page 35

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

< VARIABLE RESISTOR >

RV10 1-241-761-11 RES, ADJ, CARBON 1K

RV11 1-238-019-11 RES, ADJ, CARBON 47K

< RELAY >

RY1 1-515-614-11 RELAY

C34 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C35 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C36 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C37 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C38 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C39 1-126-204-11 ELECT CHIP 47uF 20% 16V

C40 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

SERVO

< THERMISTOR >

TH801 1-809-148-11 THERMISTOR PTH8L07AR2R0M1B510

< VIBRATOR >

X1 1-567-093-00 VIBRATOR, CRYSTAL (38kHz)

X701 1-579-345-11 VIBRATOR, CERAMIC (16.9344MHz)

X801 1-760-223-11 VIBRATOR, CRYSTAL (4.5MHz)

*************************************************************

* A-3309-227-A SERVO BOARD, COMPLETE

**********************

< CAPACITOR >

C1 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C2 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C3 1-135-145-11 TANTALUM CHIP 0.47uF 10% 35V

C4 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C5 1-164-182-11 CERAMIC CHIP 0.0033uF 10% 50V

C6 1-163-011-11 CERAMIC CHIP 0.0015uF 10% 50V

C7 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C9 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C10 1-126-206-11 ELECT CHIP 100uF 20% 6.3V

C11 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C12 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C13 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C14 1-163-989-11 CERAMIC CHIP 0.033uF 10% 25V

C15 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C16 1-163-989-11 CERAMIC CHIP 0.033uF 10% 25V

C17 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C18 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C19 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C20 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C21 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C22 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C23 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C24 1-163-259-11 CERAMIC CHIP 220PF 5% 50V

C25 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C26 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C27 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C28 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C29 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C30 1-126-603-11 ELECT CHIP 4.7uF 20% 35V

C31 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C32 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C33 1-124-779-00 ELECT CHIP 10uF 20% 16V

< CONNECTOR >

CN1 1-764-616-12 HOUSING, CONNECTOR (PC BOARD) 30P

CN2 1-565-728-51 CONNECTOR, FPC 17P

CN3 1-770-347-21 CONNECTOR, FPC 6P

< IC >

IC1 8-752-372-94 IC XD2507AQ

IC2 8-752-074-34 IC XA1782BQ

IC3 8-759-354-16 IC A6796FP-T1

< JUMPER RESISTOR >

JR1 1-216-296-00 SHORT 0

JR2 1-216-296-00 SHORT 0

JR3 1-216-296-00 SHORT 0

JR4 1-216-296-00 SHORT 0

JR5 1-216-296-00 SHORT 0

JR6 1-216-296-00 SHORT 0

JR7 1-216-296-00 SHORT 0

JR8 1-216-296-00 SHORT 0

JR9 1-216-296-00 SHORT 0

JR10 1-216-296-00 SHORT 0

JR11 1-216-296-00 SHORT 0

JR12 1-216-296-00 SHORT 0

JR13 1-216-296-00 SHORT 0

JR14 1-216-296-00 SHORT 0

JR15 1-216-296-00 SHORT 0

JR16 1-216-296-00 SHORT 0

JR17 1-216-296-00 SHORT 0

JR18 1-216-296-00 SHORT 0

JR19 1-216-296-00 SHORT 0

JR20 1-216-296-00 SHORT 0

JR21 1-216-296-00 SHORT 0

JR22 1-216-296-00 SHORT 0

JR23 1-216-296-00 SHORT 0

JR24 1-216-296-00 SHORT 0

JR25 1-216-296-00 SHORT 0

JR26 1-216-296-00 SHORT 0

JR27 1-216-296-00 SHORT 0

JR28 1-216-296-00 SHORT 0

JR29 1-216-296-00 SHORT 0

JR30 1-216-296-00 SHORT 0

JR31 1-216-296-00 SHORT 0

JR32 1-216-296-00 SHORT 0

JR33 1-216-296-00 SHORT 0

JR34 1-216-296-00 SHORT 0

35

Page 36

SERVO

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

JR35 1-216-296-00 SHORT 0

JR36 1-216-296-00 SHORT 0

JR37 1-216-296-00 SHORT 0

JR38 1-216-296-00 SHORT 0

JR39 1-216-296-00 SHORT 0

SUB

R36 1-216-097-11 RES-CHIP 100K 5% 1/10W

R37 1-216-117-00 METAL CHIP 680K 5% 1/10W

R38 1-216-109-00 METAL CHIP 330K 5% 1/10W

R39 1-216-101-00 METAL CHIP 150K 5% 1/10W

R40 1-216-114-00 RES-CHIP 510K 5% 1/10W

JR40 1-216-296-00 SHORT 0

JR41 1-216-296-00 SHORT 0

JR43 1-216-296-00 SHORT 0

JR44 1-216-296-00 SHORT 0

JR45 1-216-296-00 SHORT 0

JR46 1-216-296-00 SHORT 0

< COIL >

L1 1-412-058-11 INDUCTOR CHIP 10uH

L2 1-412-058-11 INDUCTOR CHIP 10uH

L3 1-412-058-11 INDUCTOR CHIP 10uH

< TRANSISTOR >

Q1 8-729-904-60 TRANSISTOR DTB113ZK-T-146

Q2 8-729-904-86 TRANSISTOR 2SB1197K-T-146-Q

< RESISTOR >

R1 1-216-073-00 METAL CHIP 10K 5% 1/10W

R2 1-216-097-11 RES-CHIP 100K 5% 1/10W

R3 1-216-121-11 RES-CHIP 1M 5% 1/10W

R4 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R5 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R6 1-216-073-00 METAL CHIP 10K 5% 1/10W

R7 1-216-009-11 RES-CHIP 22 5% 1/10W

R8 1-216-119-00 METAL CHIP 820K 5% 1/10W

R9 1-216-119-00 METAL CHIP 820K 5% 1/10W

R10 1-216-073-00 METAL CHIP 10K 5% 1/10W

R11 1-216-073-00 METAL CHIP 10K 5% 1/10W

R14 1-216-085-00 METAL CHIP 33K 5% 1/10W

R15 1-216-085-00 METAL CHIP 33K 5% 1/10W

R16 1-216-077-11 RES-CHIP 15K 5% 1/10W

R17 1-216-081-00 METAL CHIP 22K 5% 1/10W

R19 1-216-079-00 METAL CHIP 18K 5% 1/10W

R20 1-216-105-11 RES-CHIP 220K 5% 1/10W

R21 1-216-105-11 RES-CHIP 220K 5% 1/10W

R22 1-216-085-00 METAL CHIP 33K 5% 1/10W

R23 1-216-121-11 RES-CHIP 1M 5% 1/10W

R24 1-216-073-00 METAL CHIP 10K 5% 1/10W

R27 1-216-295-00 SHORT 0

R28 1-216-101-00 METAL CHIP 150K 5% 1/10W

R29 1-216-097-11 RES-CHIP 100K 5% 1/10W

R30 1-216-097-11 RES-CHIP 100K 5% 1/10W

R41 1-216-093-11 RES-CHIP 68K 5% 1/10W

R42 1-216-103-00 METAL CHIP 180K 5% 1/10W

R43 1-216-097-11 RES-CHIP 100K 5% 1/10W

R44 1-216-085-00 METAL CHIP 33K 5% 1/10W

R45 1-216-081-00 METAL CHIP 22K 5% 1/10W

R45 1-216-089-11 RES-CHIP 47K 5% 1/10W

R46 1-216-097-11 RES-CHIP 100K 5% 1/10W

R47 1-216-105-11 RES-CHIP 220K 5% 1/10W

R48 1-216-073-00 METAL CHIP 10K 5% 1/10W

R49 1-216-065-11 RES-CHIP 4.7K 5% 1/10W

R50 1-216-065-11 RES-CHIP 4.7K 5% 1/10W

R51 1-216-295-00 SHORT 0

< CERMET RESISTOR >

RV1 1-238-091-11 RES, ADJ, CERMET 22K

RV4 1-238-091-11 RES, ADJ, CERMET 22K

*************************************************************

* 1-659-834-11 SUB BOARD

**********

< CONNECTOR >

CN1 1-770-347-21 CONNECTOR, FPC 6P

*************************************************************

MISCELLANEOUS

***************

5 1-792-738-11 CORD (WITH CONNECTOR) (POWER)

207 1-659-880-11 MOTOR FLEXIBLE BOARD

0 210 8-820-010-06 PICK-UP, OPTICAL KSS-521A/K1RP

212 1-659-881-11 PICK-UP FLEXIBLE BOARD

F901 1-532-798-11 FUSE (BLADE TYPE) (AUTO FUSE) (1A)

F902 1-532-731-11 FUSE (BLADE TYPE) (AUTO FUSE) (3A)

M901 X-3371-664-2 MOTOR ASSY (SPINDLE)

M902 A-3291-674-A MOTOR ASSY, SLED (SLED)

M903 A-3291-676-A MOTOR SUB ASSY, LOADING (LOADING)

*************************************************************

ACCESSORIES & PACKING MATERIALS

********************************

3-045-044-11 MANUAL, INSTRUCTION (ENGLISH)

*************************************************************

R31 1-216-081-00 METAL CHIP 22K 5% 1/10W

R32 1-216-109-00 METAL CHIP 330K 5% 1/10W

R33 1-216-105-11 RES-CHIP 220K 5% 1/10W

R34 1-216-009-11 RES-CHIP 22 5% 1/10W

R35 1-216-065-11 RES-CHIP 4.7K 5% 1/10W

36

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Page 37

Ref. No. Part No. Description Remark

**************

HARDWARE LIST

**************

#1 7-685-792-09 SCREW +PTT 2.6X6 (S)

#2 7-685-105-19 SCREW +P 2X8 TYPE2 NON-SLIT

#3 7-628-253-00 SCREW +PS 2X4

#4 7-627-553-37 SCREW, PRECISION +P 2X3 TYPE3

#5 7-627-553-17 SCREW, PRECISION +P 2X2 TYPE3

#6 7-627-000-00 SCREW, PRECISION +P 1.7X2.2 TYPE3

#7 7-627-850-28 SCREW, PRECISION +P 1.4X3

*************************************************************

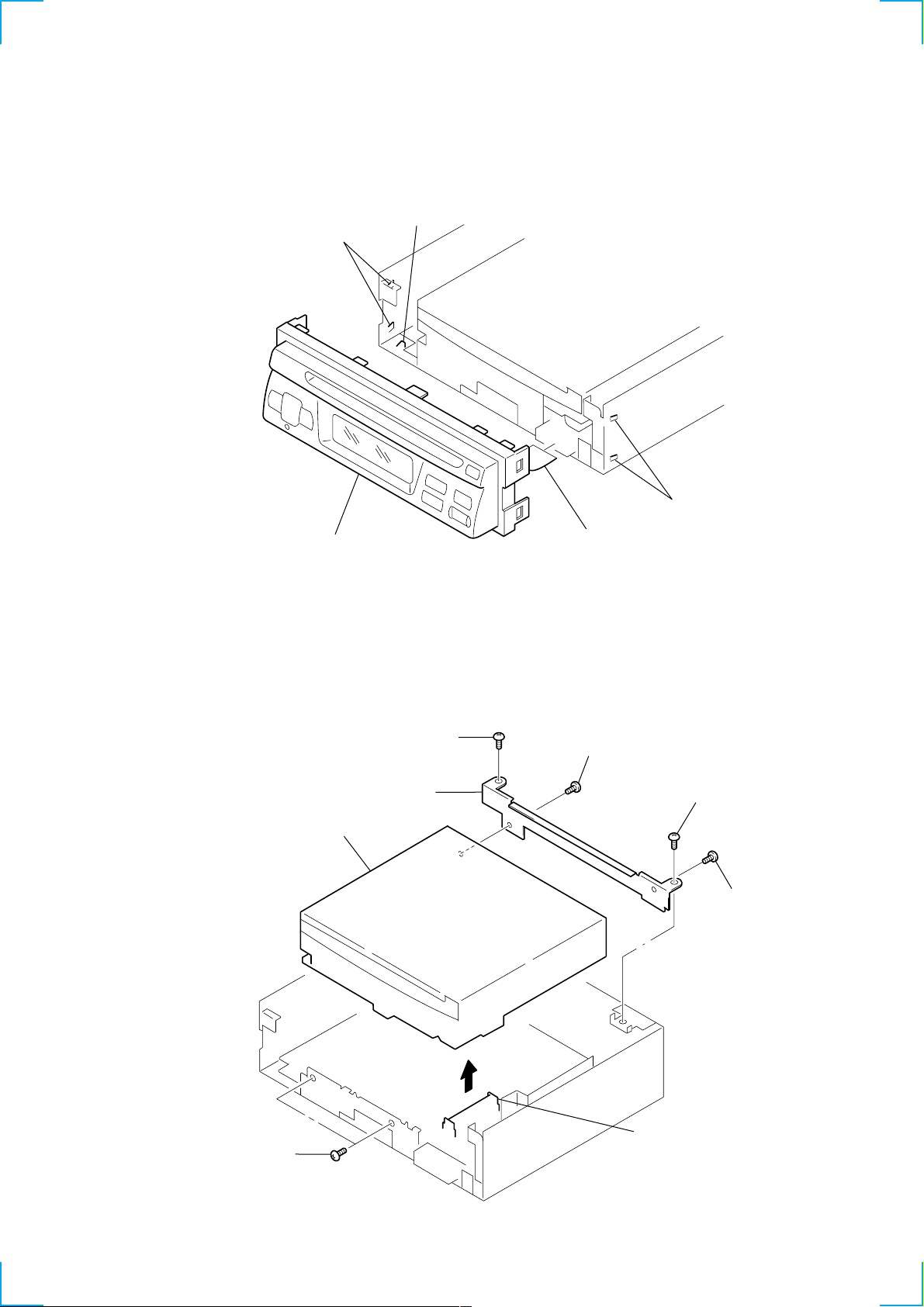

PARTS FOR INSTALLATION AND CONNECTIONS

***************************************

251 3-014-370-21 FRAME, FITTING

252 3-916-012-01 BRACKET (ND), FITTING ASSIST

253 7-682-160-01 SCREW +P 4X6

254 X-3368-725-1 SCREW ASSY, FITTING

255 X-3378-482-1 COLLAR ASSY

256 3-931-977-01 BRACKET

257 3-934-325-01 SCREW (+K 5X8 TP)

258 1-792-738-11 CORD (WITH CONNECTOR) (POWER)

* 259 3-035-161-01 BRACKET (RELEASE)

(INCLUDING F901,902)

251

255

252

256 257

258 259

254

253

37

Page 38

CDX-1000RF

9-870-139-11

38

Sony Corporation

Mobile Electronics Division Company

Printed in Japan ©2000. 3

2000C0416-1

Published by General Engineering Dept.

Loading...

Loading...