Sony CDPEX-77 Service manual

CDP-EX77

SERVICE MANUAL

CDP-EX77 is the CD player section

in MHC-EX66, DHC-EX77MD/MD77

SPECIFICATIONS

AEP Model

UK Model

E Model

Model Name Using Similar Mechanism HCD-MD5

CD Mechanism Type

Base Unit Name BU-5BD19

Optical Pick-up Name KSS-213B/K-N

CDM38A-5BD19

System Compact disc and digital audio system

Laser Semiconductor laser (λ = 780 nm)

Laser output Max. 44.6 µW*

Frequency response 2 Hz to 20 kHz (± 0.5 dB)

CD OPTICAL DIGITAL OUT

(Square optical connector jack, rear panel)

Dimensions (w/h/d) incl. projecting parts and

controls: Approx. 280 × 122.5 × 347 mm

Mass Approx. 3.7 kg

Design and specifications are subject to change without notice.

Emission duration: continuous

* This output is the value measured at a distance of

200 mm from the objective lens surface on the Optical Pick-up Block with 7 mm aperture.

MICROFILM

COMPACT DISC PLAYER

TABLE OF CONTENTS

1. SERVICING NOTES

1-1. Power Supply During Servicing ...................................... 3

1-2. Fluorescent Indicator Tube/Key Check Mode ................. 3

2. GENERAL ................................................................... 4

3. DISASSEMBLY.......................................................... 9

4. ELECTRICAL ADJUSTMENTS ......................... 14

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

5. DIAGRAMS ................................................................ 16

5-1. Printed Wiring Board – BD Section – ............................. 17

5-2. Schematic Diagram – BD Section – ................................ 19

5-3. Schematic Diagram

– MAIN/PANEL/MOTOR Section – .............................. 23

5-4. Printed Wiring Boards

– MAIN/PANEL/MOTOR Section – .............................. 27

5-5. IC Pin Function Description ............................................ 34

6. EXPLODED VIEWS ................................................ 36

7. ELECTRICAL PARTS LIST................................ 41

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and

check that the S curve waveforms is output three times.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of

procedures other than those specified herein may

result in hazardous radiation exposure.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL

OR IN SUPPLEMENTS PUBLISHED BY SONY.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

– 2 –

SECTION 1

b

SERVICING NOTES

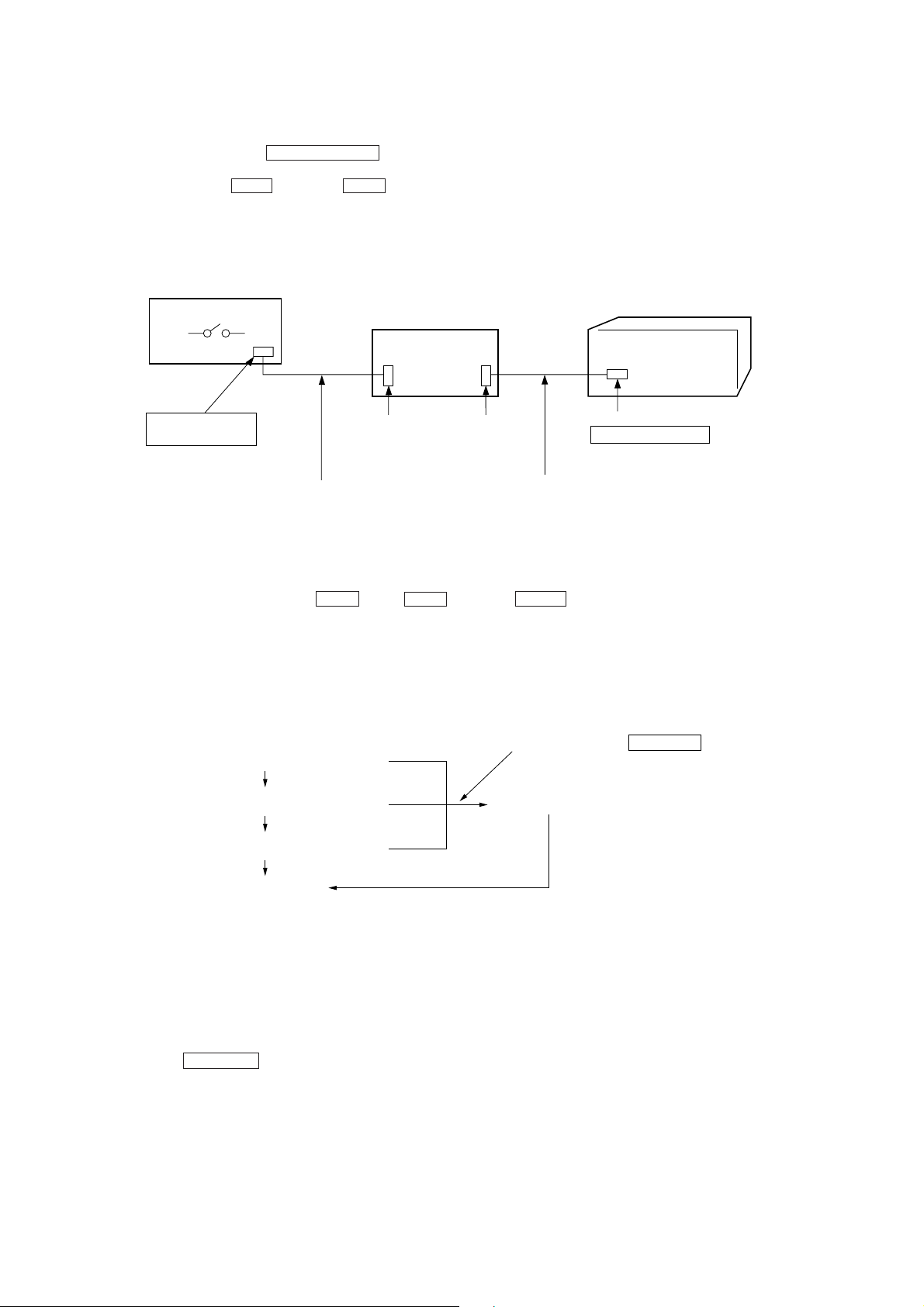

1-1. Power Supply During Servicing

This unit is not able to operate on its own because it does not have its own power supply. During servicing, connect to other units.

Power is supplied when the SYSTEM POWER button of the amplifier (TA-EX66/EX77) is turned ON.

If the other units are not available, use a service box (PFJ-1) and jig (J-2501-078-A).

In this case, press the STOP button and TIME button simultaneously to turn on the power.

[Connection Diagram]

SERVICE BOX (PFJ-1)

POWER SW

FH-E939, 838, 937

CDP/TC

CORD WITH CONNECTOR 17 P

(Provided with PFJ-1)

JIG

(J-2501-078-A)

CN904

17P

CN902

7P

CORD WITH CONNECTOR 7 P

(Provided with unit)

CN101 7P

SYSTEM CONTROL

UNIT (CDP-EX77)

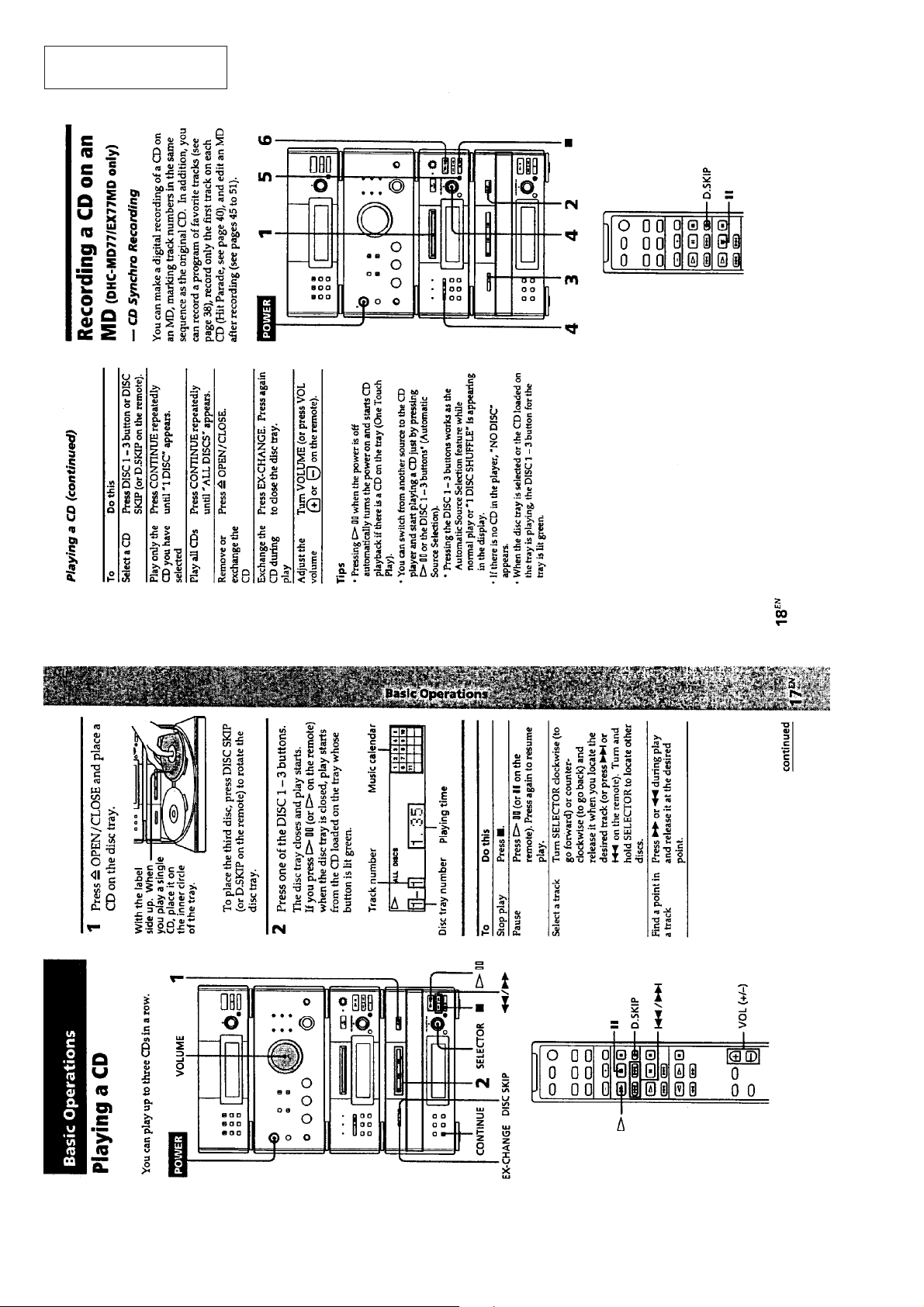

1-2. Fluorescent Indicator Tube/Key Check Mode

After turning on the power , press the STOP button, TIME button, and DISC 1 button simultaneously to perform the Fluorescent indicator tube check.

The steps of the Fluorescent Indicator Tube check mode will proceed onto the next one by the above multiple pressing.

During the Fluorescent Indicator Tube check mode, press any button or rotate the selector knob to set the key check mode.

To end the mode, press the above three buttons simultaneously.

Fluorescent Indicator Tube all lit mode

Multiple pressing

Segment pattern 1 mode

Multiple pressing

Segment pattern 2 mode

Multiple pressing

End of test mode

Press any key or roted the SELECTOR kno

Key check mode

Multiple pressing

Note 1) When the three buttons pressed to enter the Fluorescent Indicator T ube all lit mode are released together , the Fluorescent Indica-

tor Tube all lit mode will remain on. When released separately, the key check mode will be set soon after the Fluorescent

Indicator Tube all lit mode.

In “multiple pressing”, if the three buttons are pressed and released together, the next mode will be set. If not, the key check

mode will be set.

Note 2) In the key check mode, each time the button is pressed, the “KEY=” number on the Fluorescent indicator tube increases. When

the SELECTOR knob is rotated, the “KEY=” number on the Fluorescent indicator tube increases in the + direction and decreases in the – direction.

– 3 –

This section is extracted

from instruction manual.

SECTION 2

GENERAL

– 4 –

– 5 –

– 6 –

– 7 –

– 8 –

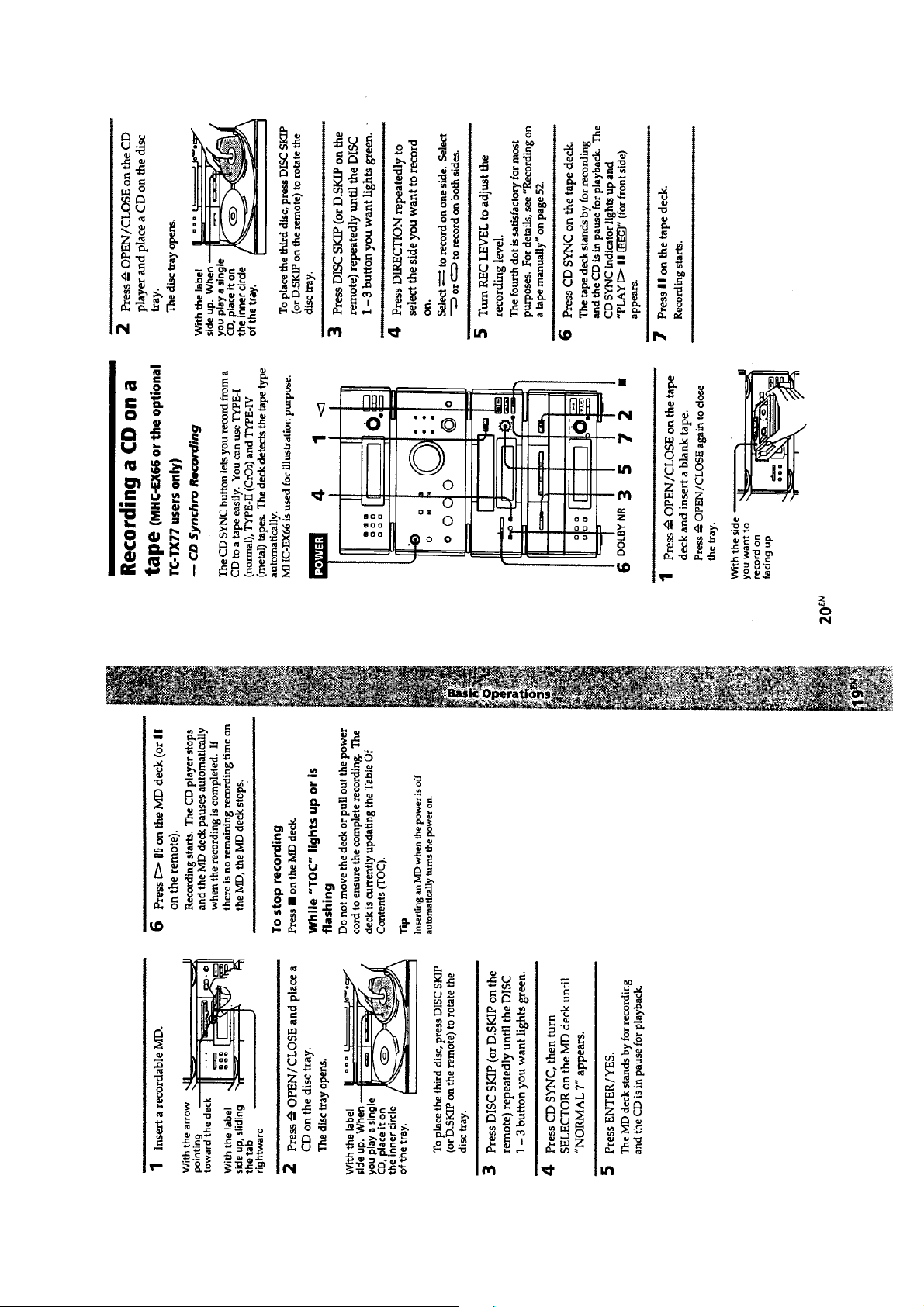

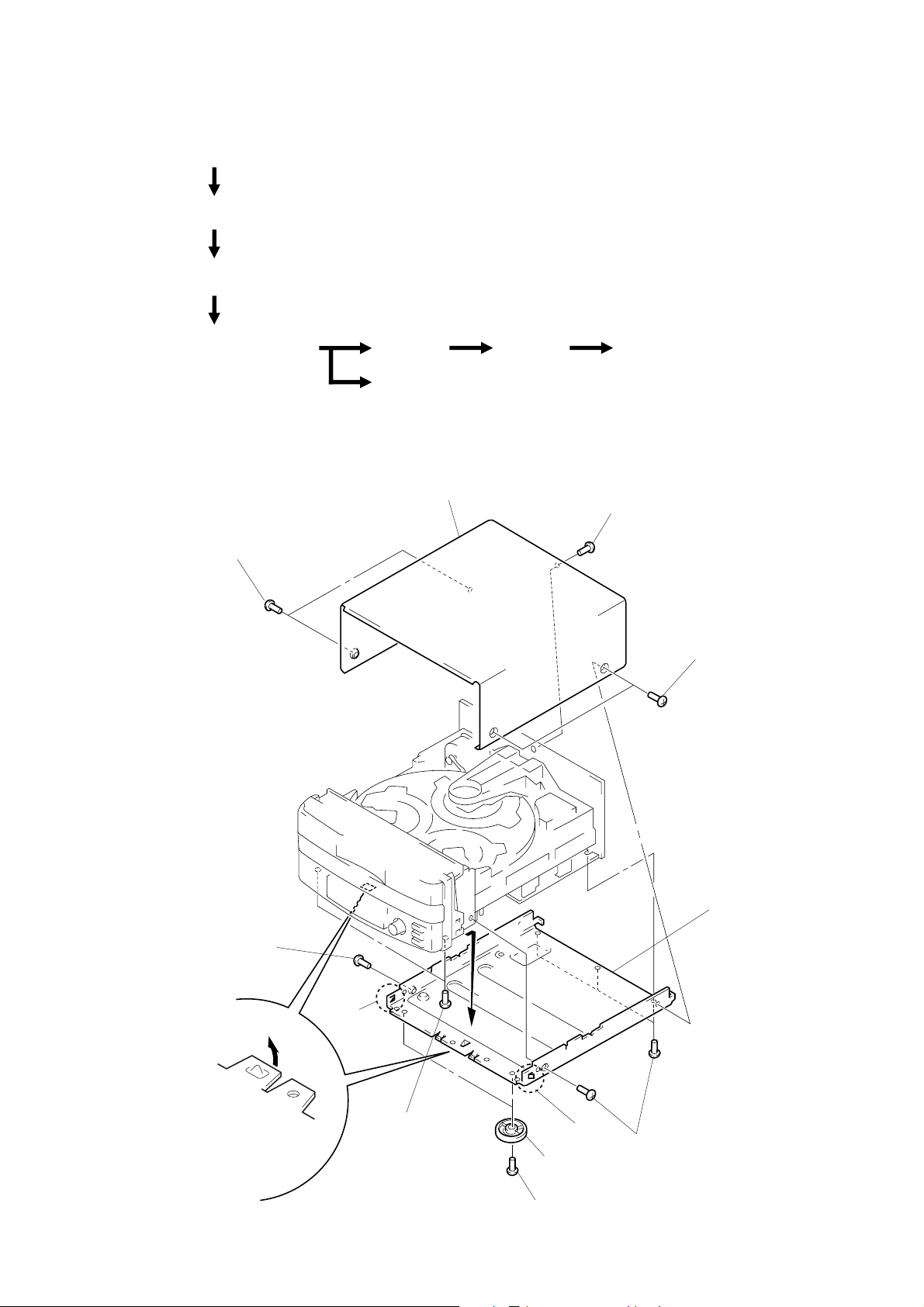

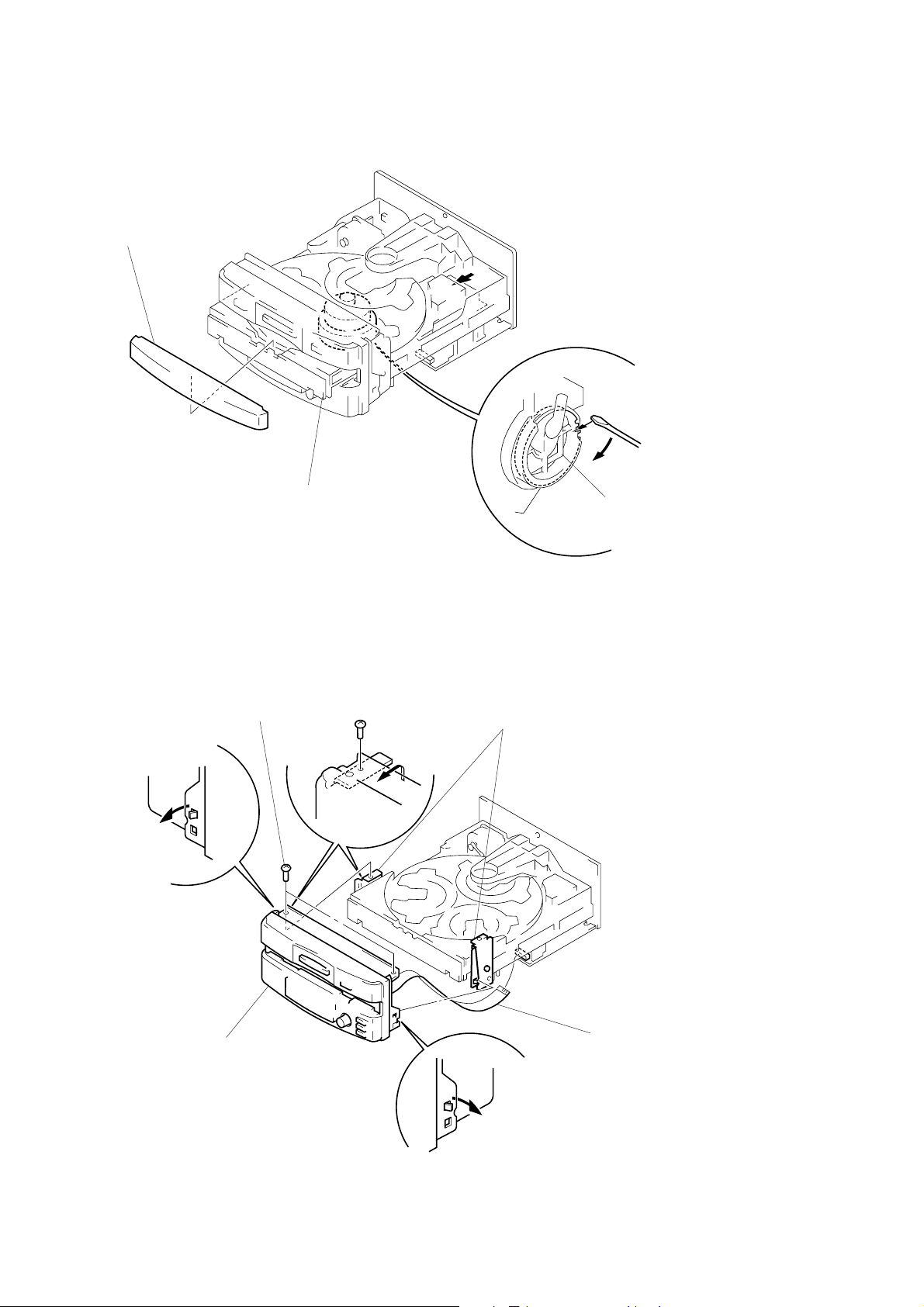

• This set can be disassembled in the order shown below.

CASE, CHASSIS

(Page 9)

LOADING PANEL

(Page 10)

FRONT PANEL SECTION

(Page 10)

SECTION 3

DISASSEMBLY

MAIN BOARD,

CD MECHANISM DECK

(Page 11)

Note: Follow the disassembly procedure in the numerical order given.

BASE UNIT

(Page 11)

TRAY SECTION

(Page 12)

CASE, CHASSIS

3

case

2

two screws

(case 3 TP2)

BD BOARD

(Page 13)

OPTICAL PICK-UP,

SLED MOTOR

(Page 13)

1

screw

(BVTT3

×

8)

2

two screws

(case 3 TP2)

6

screw

(BV3

×

7

10)

claw

7

claw

6

screw

(BV3

×

10)

– 9 –

5

4

two screws

(BV3

7

claw

two legs (F)

×

10)

6

four screws

(BV3

×

8

10)

chassis

LOADING PANEL

3

loading panel

2

Pull the tray (slide).

1

Rotate the BU cam ass’y

to direction of the arrow

A

BU cam ass’y

A

.

FRONT PANEL SECTION

2

4

claw

5

front panel

section

two screws

(BV3

×

10)

3

two bosses

1

flat wire (29 core)

(CN305)

– 10 –

4

claw

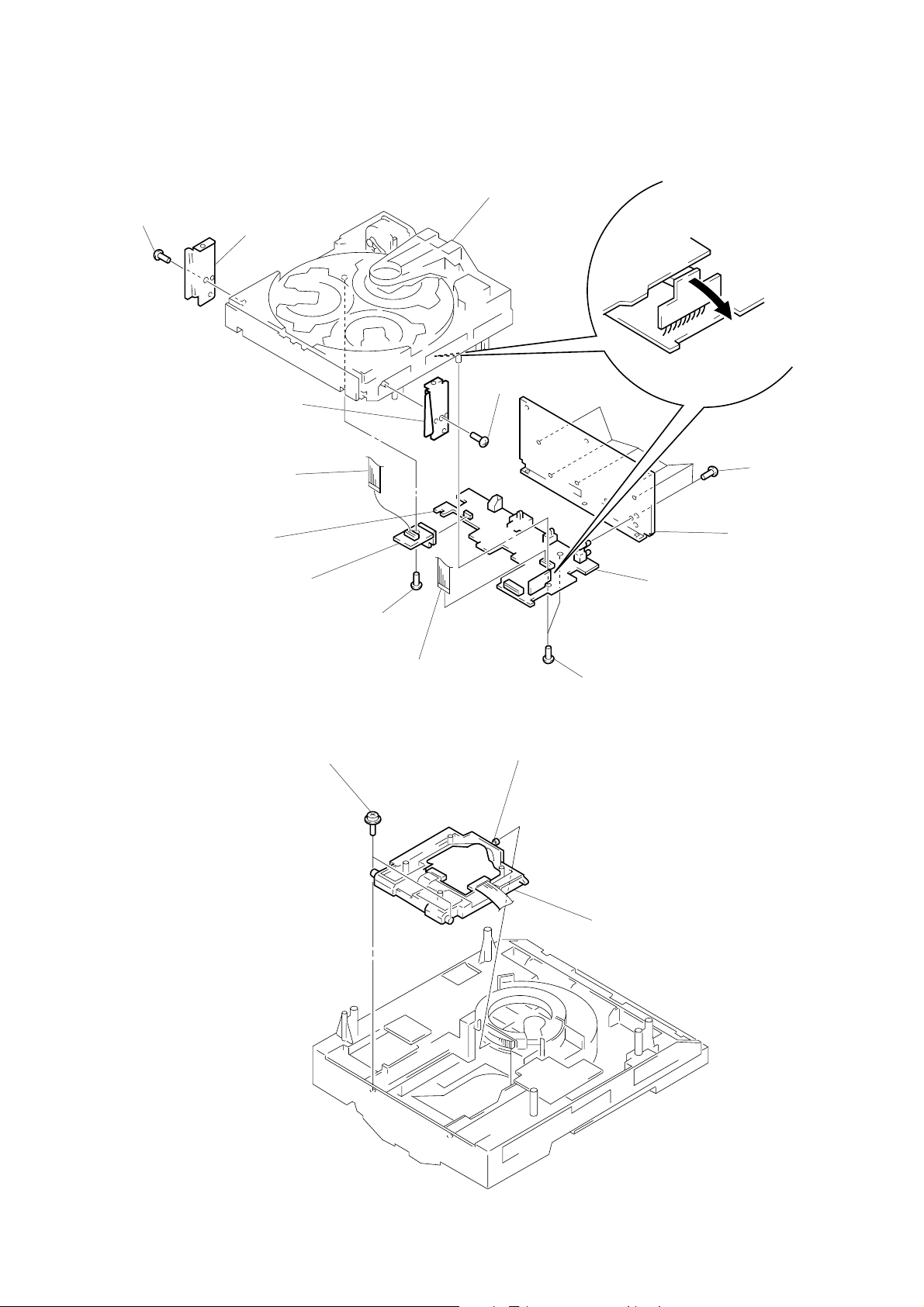

MAIN BOARD, CD MECHANISM DECK

!¡

screw

(BV3

×

10)

0

4

!™

bracket (L)

!™

bracket (R)

flat wire (8 core)

(CN702)

connector

(CN304)

9

relay

board

!£

CD mechanism deck

!¡

screw

(BV3

×

10)

6

main board

3

connector

(CN303)

2

1

Six screws

(BV3

back panel

×

10)

BASE UNIT

1

two yoke brackets

8

screws

(BV3

×

8)

7

flat wire (19 CORE)

(CN302)

2

boss

5

3

base unit

two screws

(BV3

×

8)

– 11 –

Loading...

Loading...