Sony CDPEX-100 Service manual

CDP-EX100

SERVICE MANUAL

This set is the CD player section in

MHC-EX50/EX70AV/EX100AV.

SPECIFICATIONS

AEP Model

UK Model

E Model

Model Name Using Similar Mechanism CDP-EX10

CD Mechanism Type CDM28-5BD19

Base Unit Name BU-5BD19

MICROFILM

COMPACT DISC PLAYER

– 1 –

The laser component in this product

is capable of emitting radiation

exceeding the limit for Class 1.

TABLE OF CONTENTS

1. SERVICE NOTE .................................................................. 3

The following caution label is located inside of the unit.

This appliance is classified

as a CLASS 1 LASER

product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

2. GENERAL ............................................................................. 4

3. DISASSEMBLY

3-1. Loading Panel.......................................................................... 4

3-2. MD Block................................................................................ 5

3-3. Holder (BU) Assy.................................................................... 5

4. ELECTRICAL ADJUSTMENTS .................................... 6

5. DIAGRAMS

5-1. IC Pin Function ....................................................................... 8

5-2. Circuit Boards Location ........................................................ 10

5-3. Printed Wiring Board – BD Section –................................... 11

5-4. Schematic Diagram – BD Section –...................................... 13

5-5. Printed Wiring Boards – Main Section – .............................. 16

5-6. Schematic Diagram – Main Section –................................... 19

6. EXPLODED VIEWS

6-1. Chassis Section...................................................................... 26

6-2. Front Panel Section ............................................................... 27

6-3. CD Mechanism Section......................................................... 28

6-4. Base Unit Section .................................................................. 29

7. ELECTRICAL PARTS LIST .......................................... 30

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK OR

BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objectiv e lens in the optical pick-up

block. Therefore, when checking the laser diode emission, observe

from more than 30 cm away from the objective lens.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE

P AR TS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

SECTION 1

SERVICE NOTE

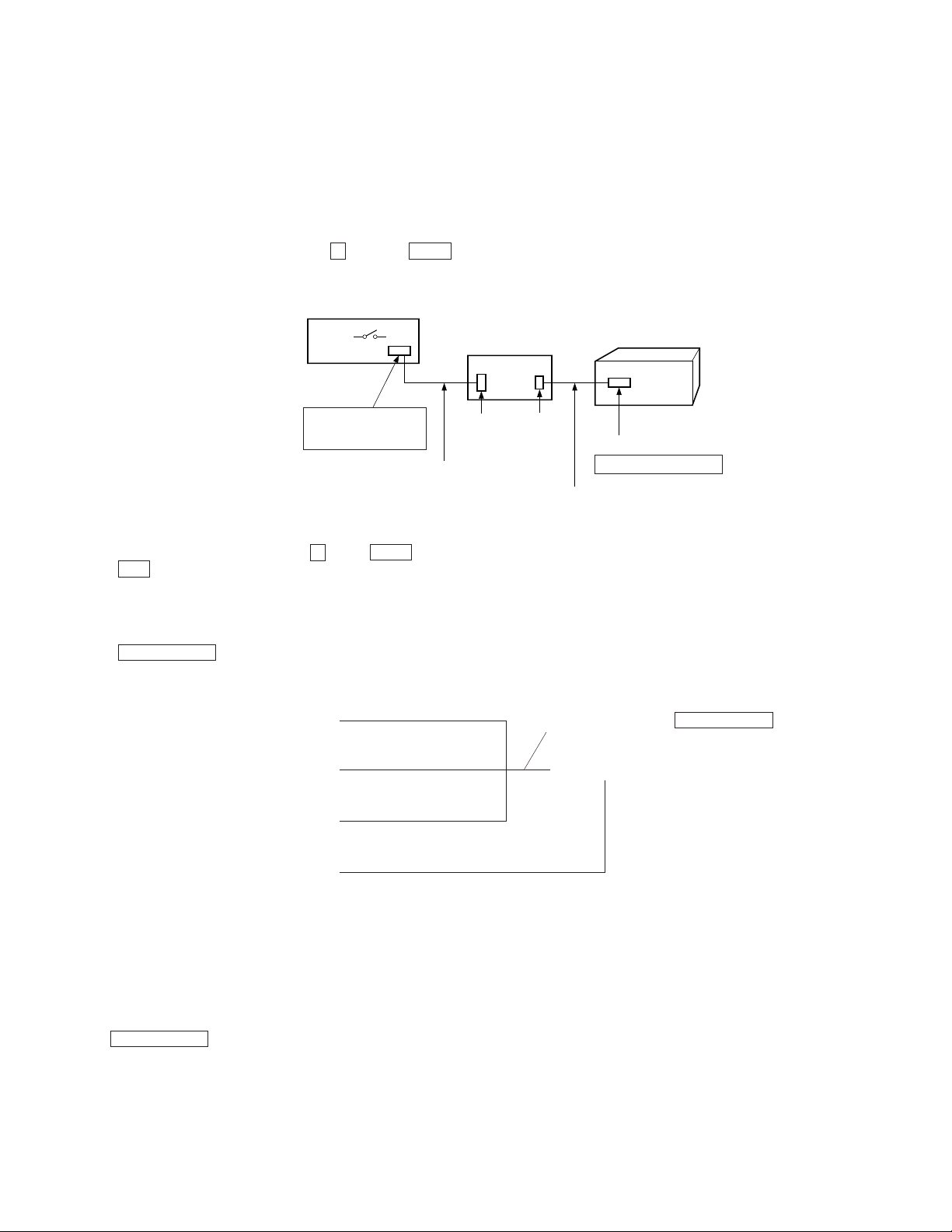

• How to operate with a single unit

Normally this set does not operate with a single unit.

When you must be mending, connect to other unit.

If the SYSTEM POWER switch of the amplifire is set to ON, the

power supply of the set is turned on.

In case of other unit is nothing, the service box (PFJ-1) and

exclusive jig (J-2501-078-A) are necessary to operate the set with

a single unit.

In case of above mentioned, press the p button and TIME button

at the same time, to enter the power on.

SERVICE BOX (PFJ-1)

POWER SW

JIG

(J-2501-078-A)

SET

FH-E939, 838, 737

CDP/TC

CORD WITH CONNECTOR 17P

(attached to PFJ-1)

• FL tube/ KEY check mode

After to enter the power on, when p button, TIME button and

) button are pressed at the same time, you will be check FL

tube.

Whenever press the above mentioned three buttons at the same

time, change to check mode of FL tube.

Under check mode of FL tube when any pressing button or turn

= AMS + button, change to KEY check mode.

To finish KEY check mode, press the above mentioned three

buttons at the same time.

All FL tube indicator light on

nn n

(Press three buttons at the same time)

A segment pattern mode 1

(Press three buttons at the same time)

A segment pattern mode 2

(Press three buttons at the same time)

Finish the test mode

9

CN904

17P

CN902

7P

CORD WITH CONNECTOR 7P

(attached to set)

CN301 7P

SYSTEM CONTROL

Any pressing button or turn = AMS + button.

(

(

KEY check mode

(Press three buttons at the same time)

Note 1)

All FL tube light on mode is kept when three buttons which is

pressed to enter all FL tube light on mode, release at the same time.

If you will be release failure them, it is moved to KEY check mode

after all FL tube light on mode.

Note 2)

Under KEY check mode, every time and button pressed or

= AMS + button turned on, figure on “ KEY= ” of FL tube

is increased.

– 3 –

SECTION 2

GENERAL

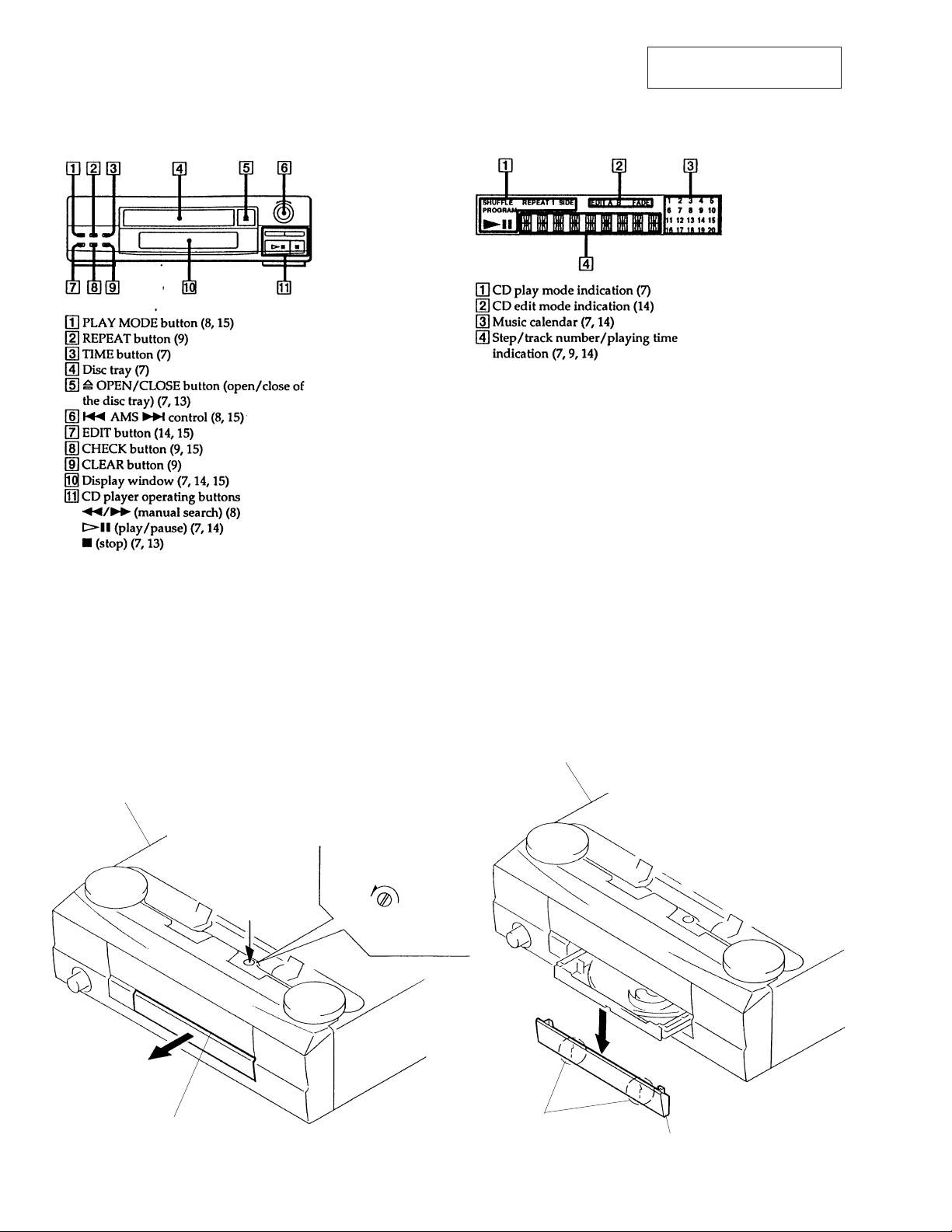

Front Panel Display Window

This section is extracted from

instruction manual.

SECTION 3

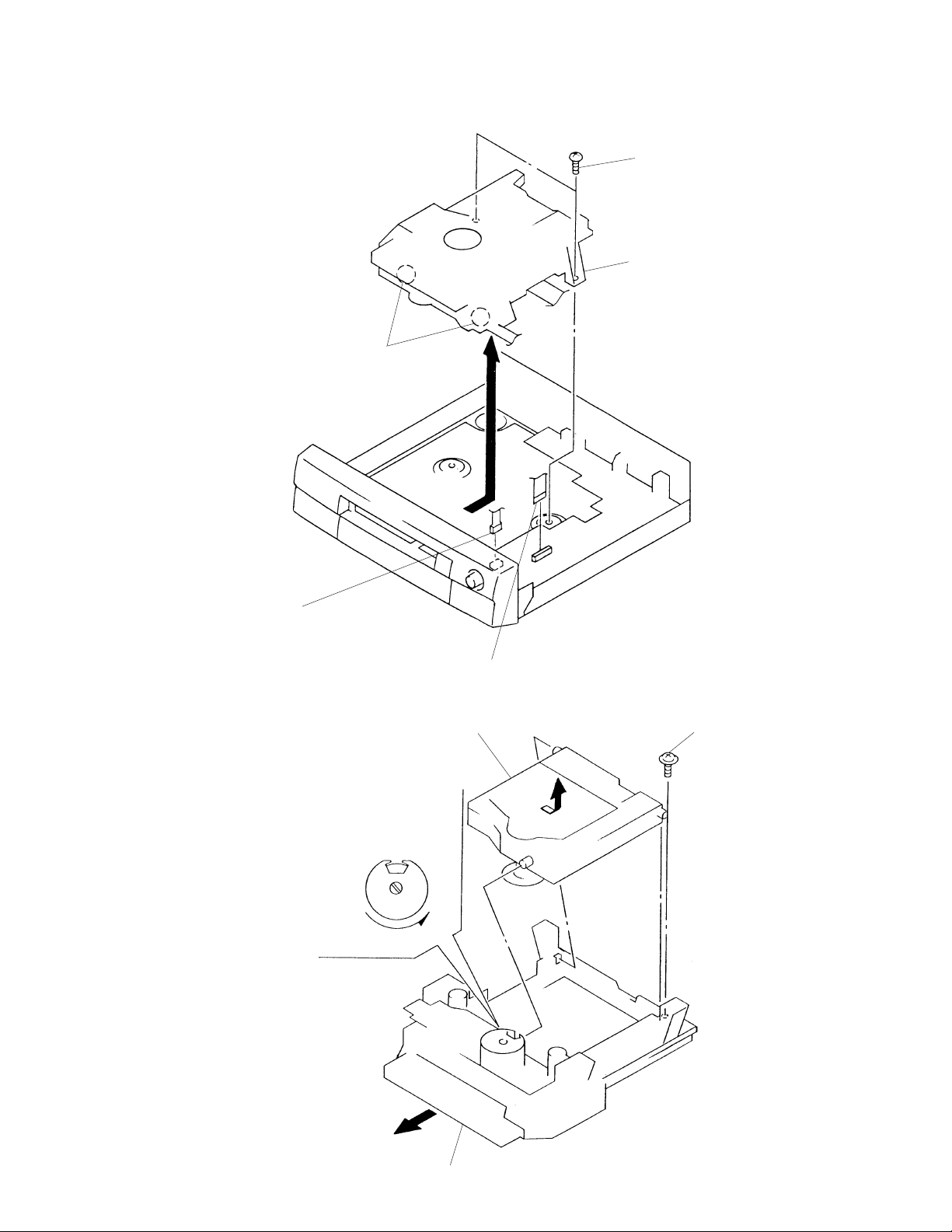

DISASSEMBLY

Note : Follo w the disassembly procedure in the numerical order giv en.

3-1. LOADING PANEL

bottom of chassis

1

Turn the cam in the

direction of arrow.

bottom of chassis

2

Pull out the disc table.

– 4 –

3

claws

4

Remove the loading panel

in the direction of arrow.

3-2. MD BLOCK

4

claws

3

BVTP 3×8

5

MD block

(CDM28-5BD19)

1

CN202

3-3. HOLDER (BU) ASSY

1

Turn the cam in the direction of arrow.

4

holder (BU) assy

(BU-5BD19)

2

CN201

3

yoke bracket

2

Pull out disc table.

– 5 –

SECTION 4

ELECTRICAL ADJUSTMENTS

Note :

1. Basically designed to operate without adjustment. Therefore, check

each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the objective lens by an applicator with neutral detergent

when the signal level is low than specif ied value with the following

checks.

5. Adjust the focus bias adjustment when optical block is replaced.

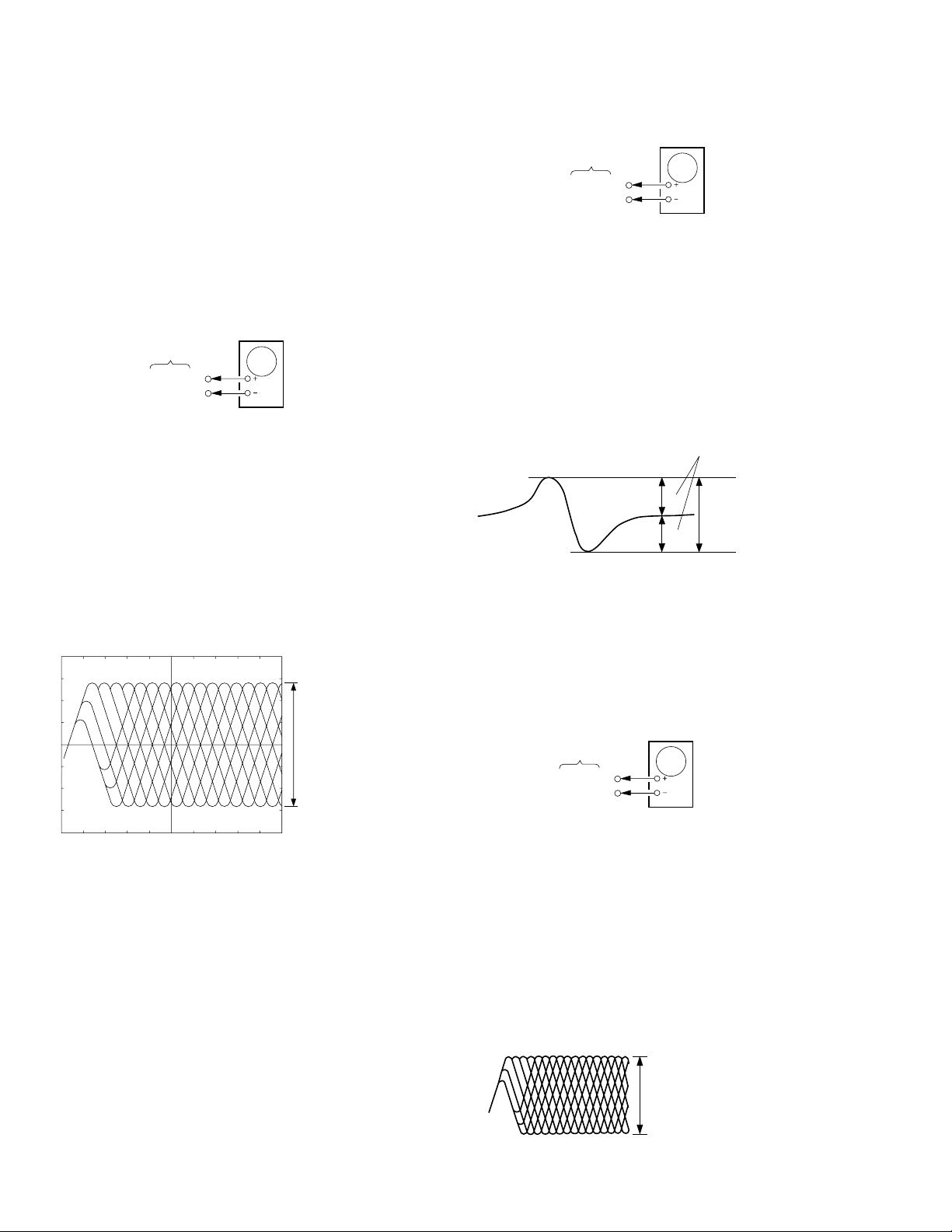

Focus Bias Adjustment

oscilloscope

(DC range)

BD board

TP (RF)

VC

Procedure:

1. Connect oscilloscope to test point TP (RF). (GND terminal : VC)

2. Turn Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Adjust RV101 so that the waveform is clear.

(Clear RF signal waveform means that the shape “ ≈ ” can be

clearly distinguished at the center of the waveform.)

5. After adjustment, check the RF signal level.

S Curve Check

oscilloscope

BD board

TP (FEO)

TP (FOK)

Procedure:

1. Connect oscilloscope to test point TP(FEO).

2. Connect between test point TP(FOK)and GND by lead wire.

3. Turn Power switch on.

4. Put disc (YEDS-18) in and turnd Power switch on again and

actuate the focus search. (In case of using SER VICE BO X actuate

the focus search when disc table is moving in and out.)

5. Check the oscillosope waveform (S-curve) is symmetrical between

A and B. And conf irm peak to peak level within 2.4±0.7 Vp-p.

S-curve waveform

symmetry

A

within 2.4±0.7 Vp-p

B

• RF signal

VOLT/DIV : 200 mV

TIME/DIV : 500 nS

level

1.3±0.3 Vp-p

6. After check, remove the lead wire connected in step 2.

Note : • Try to measure several times to make sure than the ratio of

A:B or B:A is more than 10:7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

RF Level Check

oscilloscope

BD board

TP (RF)

TP (VC)

Procedure:

1. Connect oscilloscope to test point TP (RF) on BD board.

2. Turn Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that oscilloscope waveform is clear and check RF signal

level is correct or not.

Note :

Clear RF signal waveform means that the shape “ ≈ ” can be clearly

distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500nS

– 6 –

level : 1.3±0.3 Vp-p

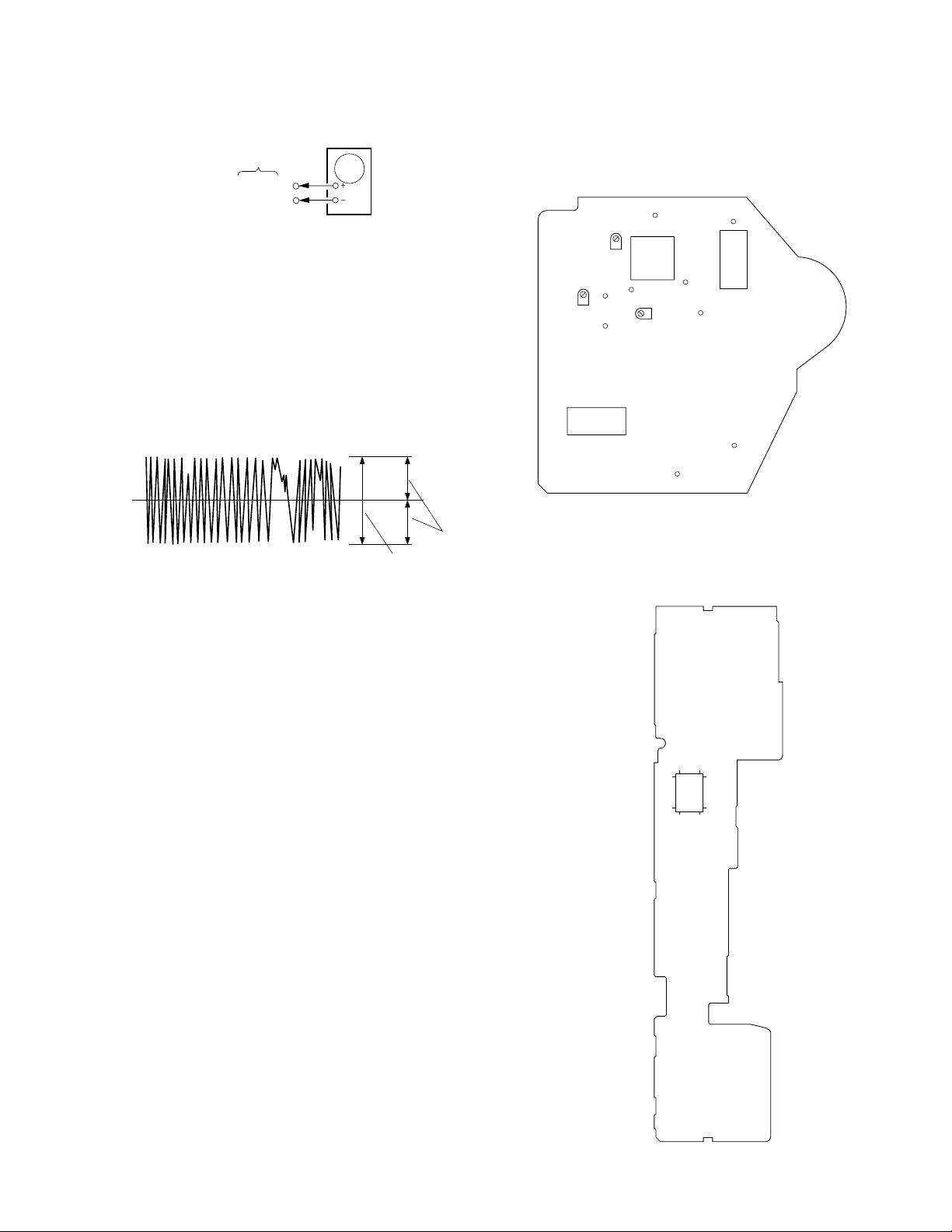

E-F Balance Check

oscilloscope

BD board

TP (TEO)

TP (VC)

Procedure:

1. Connect oscilloscpe to test point TP (TEO).

2. Turn Power switch on.

3. Connect pin @¢ of IC60I on the P ANEL board to GND with a lead

wire.

4. Put disc (YEDS-18) in and playback.

5. Push TIME button.

6. Confirm that the oscilloscope waveform is symmetrical on the top

and bottom in relation to 0Vdc, and check this level.

Adjustment Location :

[BD BOARD] (Conductor Side)

RF

RV101

IC101

RV103

TEO

VC

RV102

FEO

TEI

FEI

FOK

IC102

Traverse waveform

0V

symmetry

level : 300±100 mVp-p

7.Remove the lead wire connected in step 3.

Focus/Tracking Gain Adjustment (RV102, 103)

This gain has a margin, so even if it is slightly off.

There is no problem.

Therefore, do not perform this adjustment.

Please note that it should be fixed to mechanical center position when

you moved and do not know original position.

IC104

GND

PCK

[PANEL BOARD] (Conductor Side)

40

25

65

IC601

24

1

80

41

64

– 7 –

Loading...

Loading...