Sony CDL1100 Service Manual

SERVICE MANUAL

For Technical Service

SUPPLEMENT-2

File this supplement with the service manual.

SUBJECT :1. ADDITION CDL1100-40 SERIES

CDL1100

(ENG-99001)

The 40 series has been added to the CDL1100. Use this manual together with the service manual already distributed (SUPPLEMENT-1).

MODEL IDENTIFICATION

— SPECIFICATION LABEL —

SONY MODEL NO CDL1100-

CD-ROM LIBRARY

-2 : 20 series

-4 : 40 series

1

OUTLINE AND SPECIFICATIONS OF THE CDL110040 SERIES

The CDL1100-40 series is a CD-ROM library system with two 24X

(MAX) speed drives. It incorporates the compact feature of the

CDL1100-20 series.

The main specifications are as follows.

SPECIFICATIONS

CDL1100-40 series (* indicates the differences from the CDL110020 series.)

Capacity

Number of drives 2

Number of slots 100

Total capacity 65GB

Library Performance

Disc Exchange Time Typ.12.2sec. (average)

Drive Performance

*Sustained Transfer Rate 1800-3600KB (P-CAV)

*Access Time Typ.90ms (average)

Interface

Robotics SCSI-2 single ended

Drives SCSI-2 single ended

Analog Audio Output Stereo mini jack

Async RS-232C

Readable Format

CD-DA

CD-ROM (Mode 1 and Mode 2)

CD-ROM XA (Mode 2 Form 1 and Mode 2 Form 2)

CD-I Ready

CD-Bridge

CD-EXTRA

Video CD

Photo CD (Single and multiple session)

Physical Size

Dimentions (WxHxD) 215x430x435 (mm)

*Weight 14.0Kg

Power Requirements

Line Voltage 120V/230V

Line Frequency 50Hz/60Hz

Power Consumption

*0.33A 120V

*0.17A 230V

T emperature

Operating 5 to 35degC

Relative Humidity

Operating 30 to 80%

2

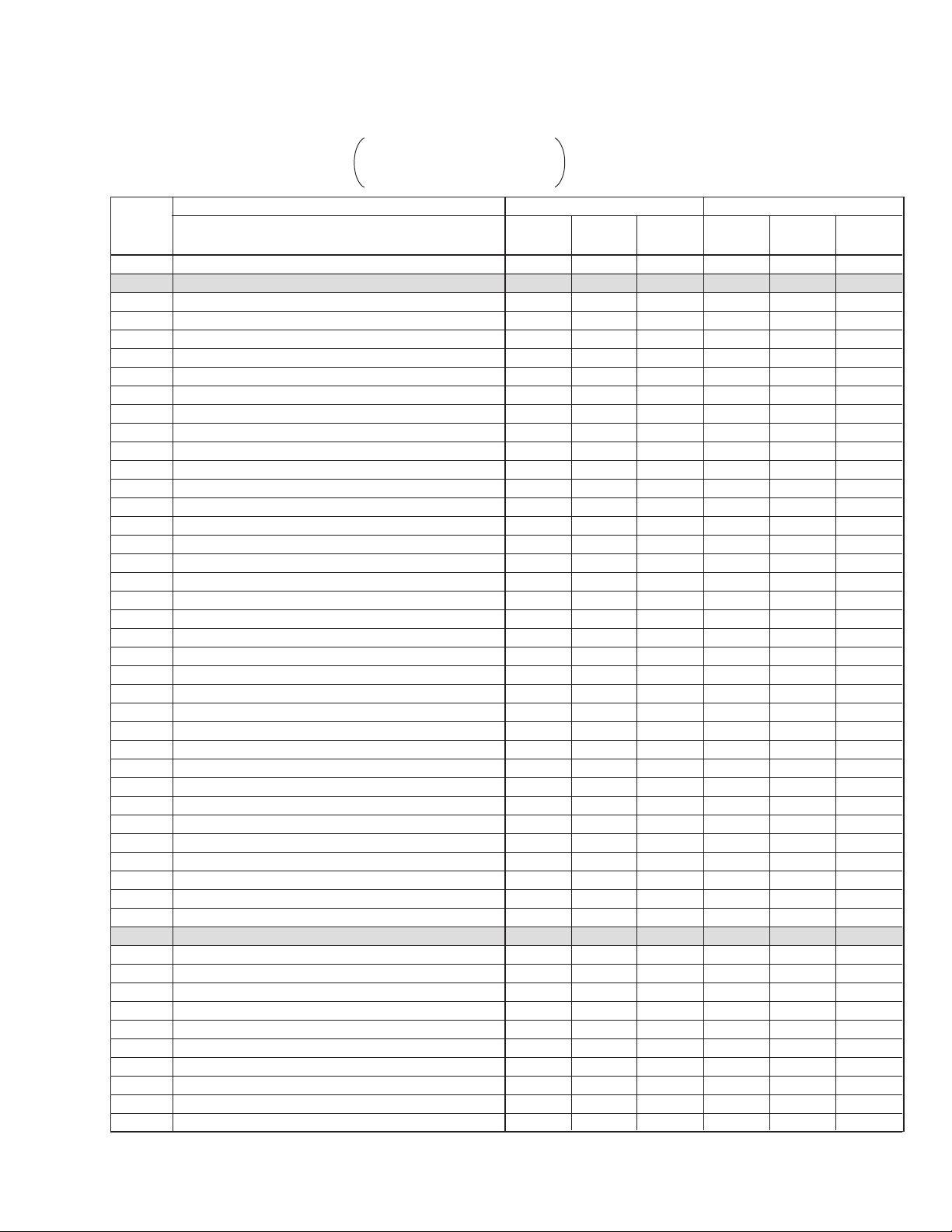

TABLE OF CONTENTS

List of For Primary Service Contents G: Need not refer

Page No: Added, Refer to on page

—: Not applicable

MODEL CDL1100-20 Series CDL1100-40 Series

Section ORIGI- SUPPLE- SUPPLE- ORIGI- SUPPLE- SUPPLE-

List of T ec hnical Service Tools — — 3 — — 3

6 CDM-47/57

6-1 GENERAL 6-1 2 — 6-1 2 —

6-2 T ools and Measuring Instr uments 6-3 — — G —6

6-2-1 Tools and Special Tools List 6-3 — — G —6

6-2-1-1 General T ools 6-3 — — G —6

6-2-1-2 Special T ools 6-3 — — G —6

6-2-1-3 Test Disc 6-3 — — G —6

6-2-1-4 Measuring Equipments G 2—GG 6

6-2-1-5 Software 6-3 — — G —6

6-2-1-6 Expendable and Chemical Supplies 6-3 — — G —6

6-2-2 Setting Single-Operation of CDM-47/57 Mechanism Block 6-4 — — G —7

6-2-3 System Configuration 6-6 — — G —9

6-2-3-1 Set up PS/VS System 6-6 — — G —9

6-2-3-2 System Configuration 6-6 — — G —9

6-3 Trouble Shooting 6-8 — — G —11

6-3-1 Before Trouble Shooting 6-8 — — G —11

6-3-2 Flowchart for Trouble Shooting 6-8 — — G —11

6-3-3 Procedure of ATP Test 6-9 — — G —12

6-3-3-1 Pre-setting 6-9 — — G —12

6-3-3-2 Test Procedure 6-10 — — G —13

6-3-4 Drive Function Check 6-12 — — G —15

6-3-4-1 Pre-setting for T est Mode Operation 6-12 — — G —15

6-3-4-2 Flowchart 6-13 — — G —16

6-3-4-3 Test Command List 6-16 — — G —19

6-3-4-4 Spindle Motor 6-16 — — G —19

6-3-4-5 Sled Gear Train 6-16 — — G —19

6-3-4-6 2-Axis Actuator 6-16 — — G —19

6-3-4-7 Focusing (Focus Bias) 6-16 — — G —19

6-3-4-8 Laser Power 6-16 — — G —19

6-3-4-9 Chucking Mechanism 6-17 — — G —20

6-3-4-10 Sled Motor 6-17 — — G —20

6-3-4-11 Spindle Motor Drive 6-17 —————

6-3-4-12 E-F Balance 6-18 — — G —21

6-3-4-13 RF Level 6-18 — — G —21

6-3-5 Down Load Program 6-20 — — G —23

7 DIAGRAMS

7-1 Circuit Boards Location 7-1 9 — GG25

7-2 IC Pin Function 7-2 — — 7-2 — 26 to 30

7-3 Block Diagrams 7-21 9 — 7-21 9 31, 32

7-4 Frame Schematic Diagram 7-29 9 — 7-29 9 33

7-5 Printed Wir ing Board/Schematic Diagram 7-33 — — 7-33 — 34

Main Section 7-33 10 to 15 — 7-33 10 to 15 —

Power Supply Section 7-40 16 to 20 — 7-40 16 to 20 —

Carrier,Mail Box Section 7-46 21,22 — 7-46 21,22 —

Panel Section 7-52 — — 7-52 — —

CD-ROM Drive Section 7-55 — — G — 34 to 41

EDITION

NAL MENT -1 MENT -2 NAL MENT-1 MENT-2

Continued next page

3

MODEL CDL1100-20 Series CDL1100-40 Series

Section ORIGI- SUPPLE- SUPPLE- ORIGI- SUPPLE- SUPPLE-

7-6 IC Block Diagrams 7-67 — — 7-67 — —

Main Section 7-67 — — 7-67 — —

Power Supply Section 7-69 — — 7-69 — —

CD-ROM Drive Section 7-70 — — G — 42 to 45

8 EXPLODED VIEWS

8-1 Case Section 8-1 G — GG46

8-2 Front Panel Assy Section 8-2 3 — 8-2 3 —

8-3 Chassis Section G 4—G 4—

8-4 Back Panel Section G 23 — G 23 —

8-5 Carrier Assy Section1 8-5 — — 8-5 — —

8-6 Carrier Assy Section2 G 5—G 5—

8-7 Carrier Assy Section3 8-7 — — 8-7 — —

8-8 Disc Case Assy Section 8-8 6 — 8-8 6 —

8-9 Mail Box Assy Section G 7—G 7—

8-10 CDM-47/57 Section 8-10 3 — GG47

8-11 BU Houlder Section 8-11 — G —48

9 ELECTRICAL PARTS LIST

EDITION

NAL MENT -1 MENT -2 NAL MENT-1 MENT-2

9-1

2,3,8,24,

25

—

9-1

2,3,8,

24,25

49 to 52

4

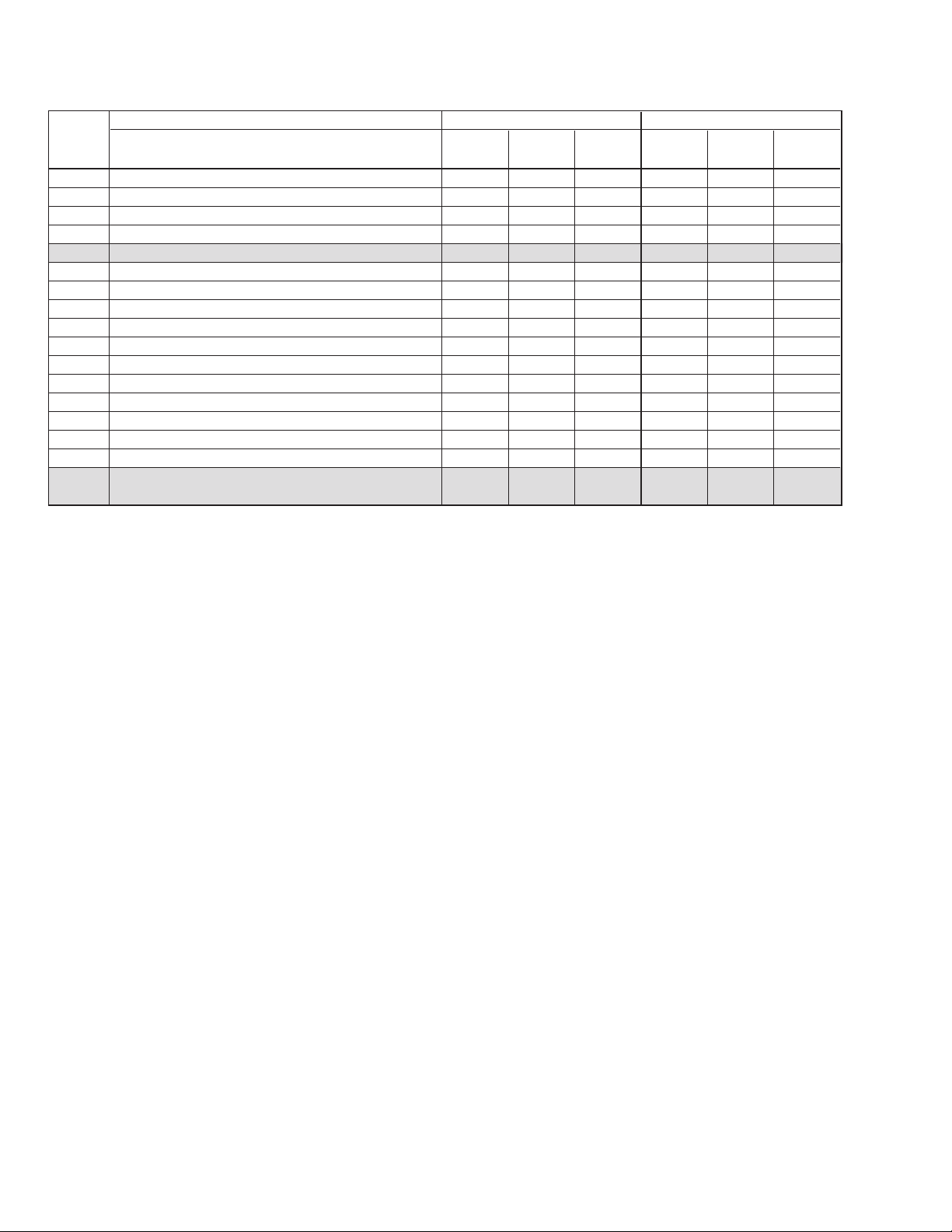

List of Technical Service Tools

Name

Test software-ATP415 system disc (OR-D019)

Test software-ATP625 disc (CDM-001)

Test disc YEDS-18

Test disc TGRS-21

Test disc YEHS-4

DC power supply (Can be substituted with CDL1100)

SCSI 50P Flat Cable

AU-CNBoard

CDL1100 (CDM-47) CONTROLLER

Parts No.

8-980-308-19

J-2501-173-A

3-702-101-01

J-2501-110-A

3-702-548-01

1-413-362-12

J-902-900-0A

A-8080-815-A

J-2501-141-A

CDL1100-20

Series

g

G

g

g

g

g

g

g

g

CDL1100-40

Series

G

g

g

g

G

g

g

g

g

5

6-2. TOOLS AND MEASURING INSTRUMENTS

6-2-1. GENERAL AND SPECIAL TOOLS LIST

The tools and measuring instruments for performing maintenance on

the CDM-47 are listed below.

6-2-1-1. General Tools

SONY Parts No.

⊕Driver 2mm (7-700-749-01)

⊕Driver 2.6mm (7-700-749-03)

T w eezers (7-700-753-02)

Round Nose Plier (7-700-757-01)

Cutter (7-700-758-02)

Soldering Iron (20W)

Desoldering Metal Braid (Solder Wick)

Multi Meter (DRM)

6-2-1-2. Special Tools

IBM PS/VP System

PS/VP and the monitor (640kbyte RAM, 3.5" FDD, HDD, V ideo

RAM-CGA or Higher, DOS Ver. 6.2 or later)

Adaptec SCSI board AHA-1520B or AHA-2940

DC Power Supply (1-413-362-12)

(If no power supply unit is available:Supply power from the

CDL1100 unit.)

Power cord (1-559-370-11)

SCSI 50P Flat Cable (J-902-900-0A)

AU-CN Board (A-8080-815-A)

BLER Counter For TC940X (J-907-564-0A)

CDL1100 (CDM-47) CONTROLLER (J-2501-141-A)

Active Speaker

6-2-1-3. T est Disc

SONY Test Disc (YEDS-18) (3-702-101-01)

SONY Test Disc (TGRS-21) (J-2501-110-A)

6-2-1-4. Measuring Equipments

Oscilloscope Dual Trace 20MHz (probe x10)

DC Volt Meter (min. 10mA)

6-2-1-5. Software

ATP625 Disc (CDM-001) (J-2501-173-A)

6-2-1-6. Expendable and Chemical Supplies

Cotton Swab (200 pieces) (7-740-900-65)

Lens Cleaning Liquid (J-250-100-0A)

Molykote Grease (EM-30L) (4-918-645-01)

Hanarl (SFL-9) (7-400-000-00)

6

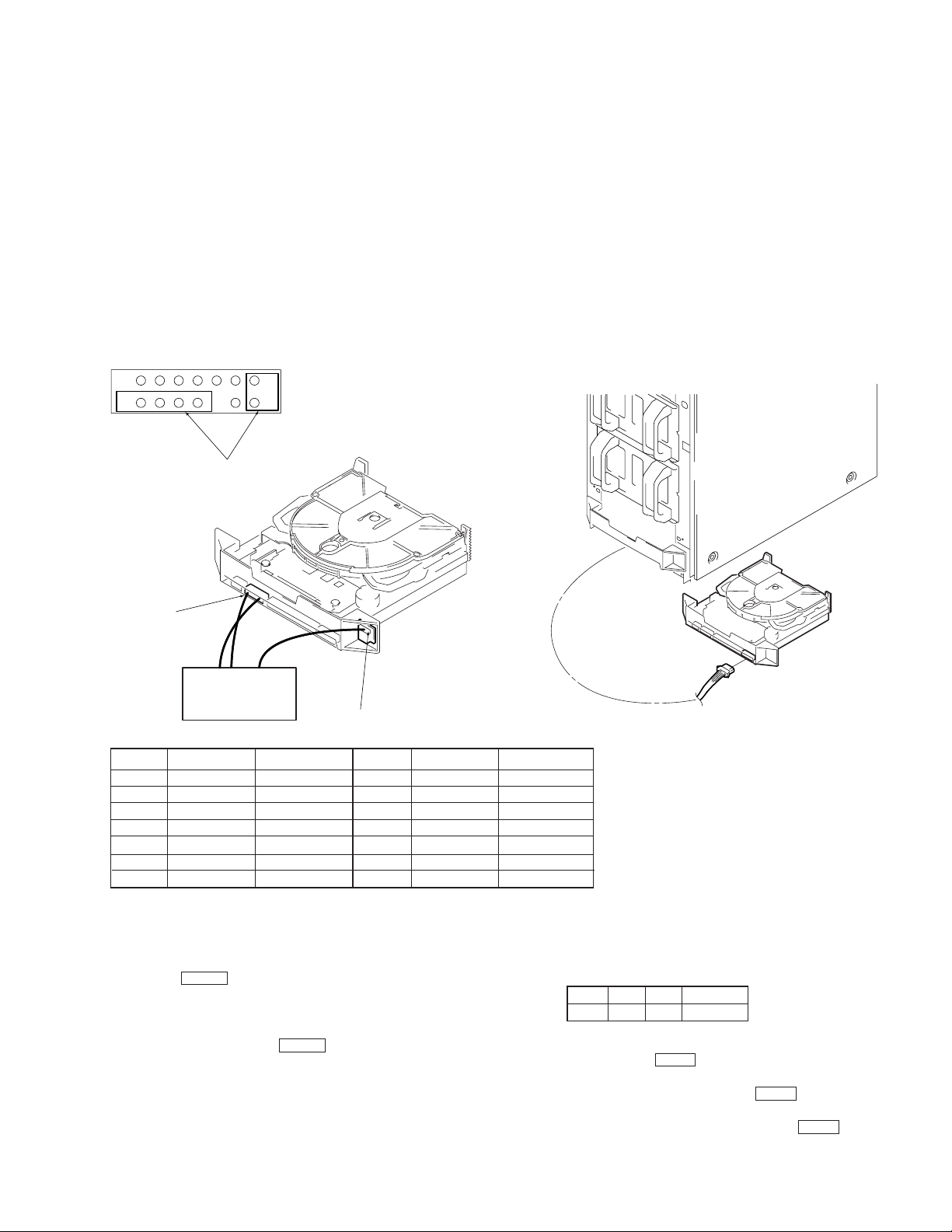

6-2-2. Setting Single-Operation of CDM-47 Mechanism

Block

Jig :

CDL-1100 (CDM-47) controller : J-2501-141-A

Power supply unit : 1-413-362-12 (If no power supply units available : Supply power from the CDL1100 unit)

CD test disc (YEDS-18) : 3-702-101-01

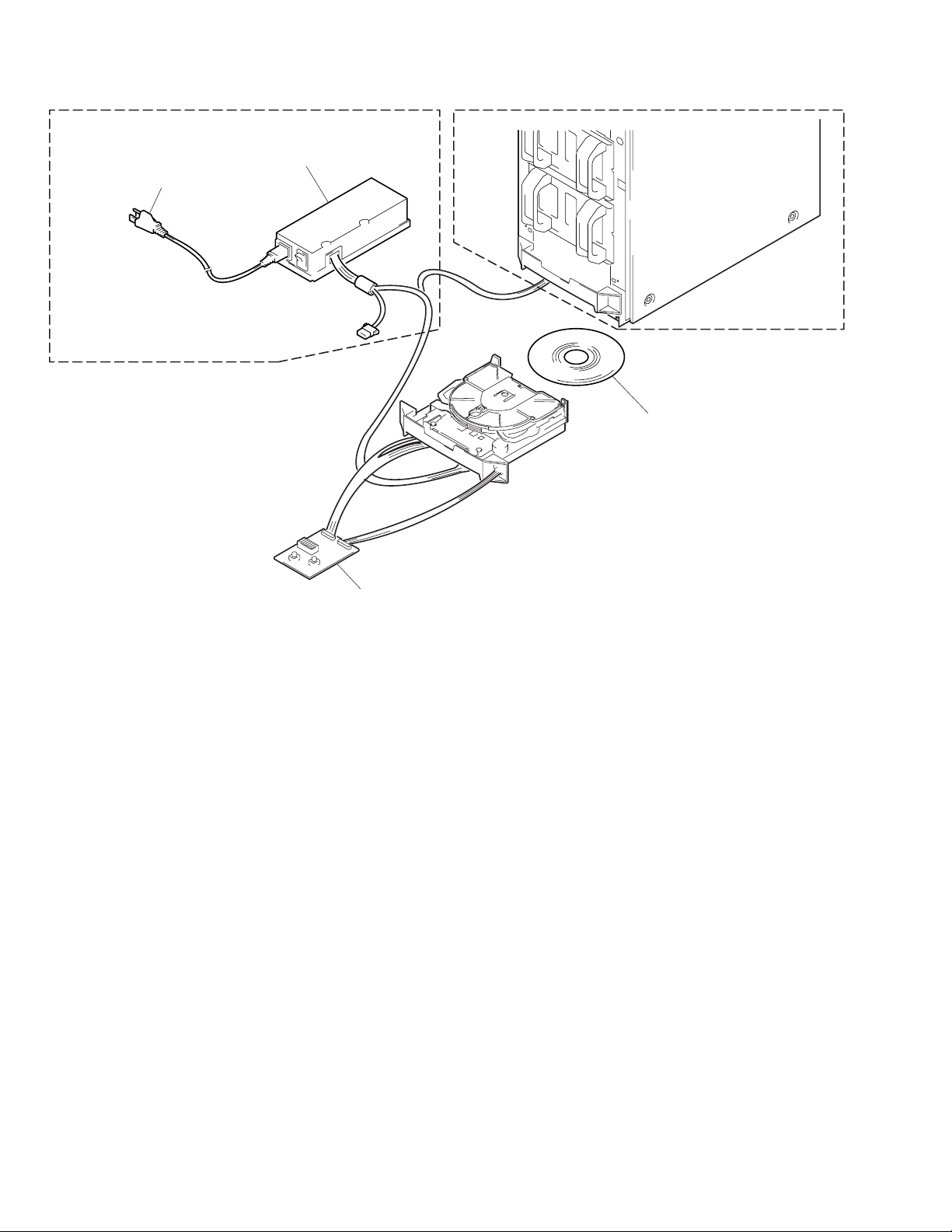

Connection Method :

If no power supply unit is available : Supply power from the CDL1100

unit.

Connect the unit (CNJ202, CN56:MA-C30 board) and controller.

CNJ202 enlargement

7

8

Connect this part to the

controller

CNJ202

(MA-C30 board)

Controller

Pin No.

1

2

3

4

5

6

7

Signal Name

Ground

Ground

Ground

Ground

Ground

Ground

Ground

1

14

CN56 (CN board)

Jig Wire Color

White

—

—

—

—

—

—

Pin No.

8

9

10

11

12

13

14

CDM-47

Signal Name

Parity

ID0

ID1

ID2

NC

P/A

TEST

Supplying power from the CDL1100 unit

CDL1100

CDM-47

CNJ201

Jig Wire Color

Brown

Black

Yellow

Blue

—

—

Red

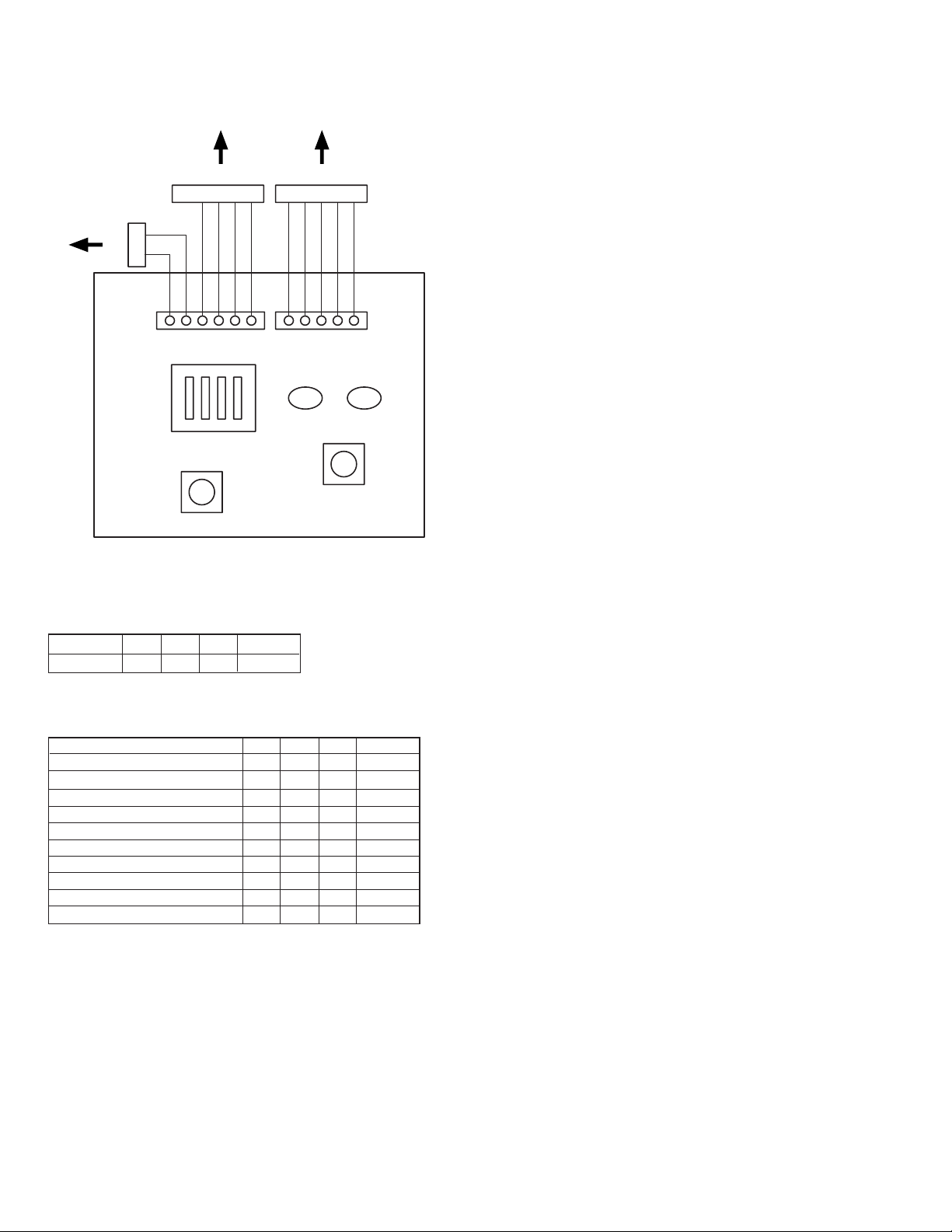

[Disc Chucking/Unchucking Method]

1. Connect the controller.

2. Load a disc directly into the drive with your hand.

3. Press the EJECT button of the controller. The LEDs will go off

in the order of red and green.

When both LEDs go off, it means that both discs have been

chucked.

4. To eject the disc, press the EJECT button again.

5. The LEDs light up in the order of green and red. When both LEDs

light up, it means that the discs have been unchucked.

NOTE :

If the LEDs remain lit or off even when chucking/unchucking is performed, S51 (red:UNCHUCK), S52 (green:CHUCK) of the CDM47 LDSW board may be improperly connected.

[Single-Operation of CDM-47]

1. Chuck the disc beforehand.

2. Set the COMMAND SW of the controller to the test mode.

ID2LID1HID0LPARITY

L

3. While pressing the TEST button of the controller, turn on the

power of the CDL1100 or power supply unit.

4. After about 1 second later, release the TEST button.

5. This sets the test mode. To enter the other mode, refer to the following table, set the dip switch, and press the TEST button.

7

to CNJ202 to CN56

to CNJ202

White

Red

H

L

COMMAND SW (SW1)

TEST (SW2)

ID2

Blue

ID1

ID0

Yellow

Black

PARITY

Setting of Single-Operation Mode

Mode

Test Mode

ID2

L

ID1

ID0LPARITY

H

Brown

White

UNCHUCK

(RED)

D1

EJECT (SW3)

L

Gray

Gray

Gray

Gray

CHUCK

(GREEN)

D2

Command list of Single-Operation Mode

ID2

Mode

Initialize

x1 speed

x4 speed

x8 speed

x12 –x24(Partial CAV) speed

Tracking servo OFF

Tracking servo ON

PlayAudio (23’47”)

PlayAudio (5’00”)

PlayAudio (55’00”)

ID1

L

L

L

L

L

H

L

H

H

L

L

L

L

L

H

H

H

L

H

H

ID0

L

H

L

H

L

H

L

L

H

H

PARITY

L

L

L

L

L

H

H

L

L

L

8

6-2-3. SYSTEM CONFIGURATION

Setting of SW and Configuration file.

6-2-3-1. Set up PS/VP System

a. Install the ANSI.SYS (Device = ANSI. SYS) and ASPI 2 DOS.SYS

in Config. SYS.

(Refer to Instruction Manual for more detail)

b. Set the jumpers on the Adaptec SCSI Interface board as follows.

(Refer to Instruction Manual for Adaptec SCSI board AHA-1520B

or 2940 in detail)

6-2-3-2. System Configuration

PS/VP System

SCSI Interface board

Adaptec AHA-1520B or 2940

AHA-1520B (for ISA BUS)…

All of DIP SW (1 to 4) are OFF.…

AHA-2940 (for PCI BUS)…

No Jumper and SW setting on the board.

Use default parameter for SSI Select configuration utility.

It is not necessary to install the device driver when using on the

windows ’95.

It is necessary to install the device driver a t first line of config. sys

when using on DOS.

c. Install the SCSI Interface board in the PS/VP System.

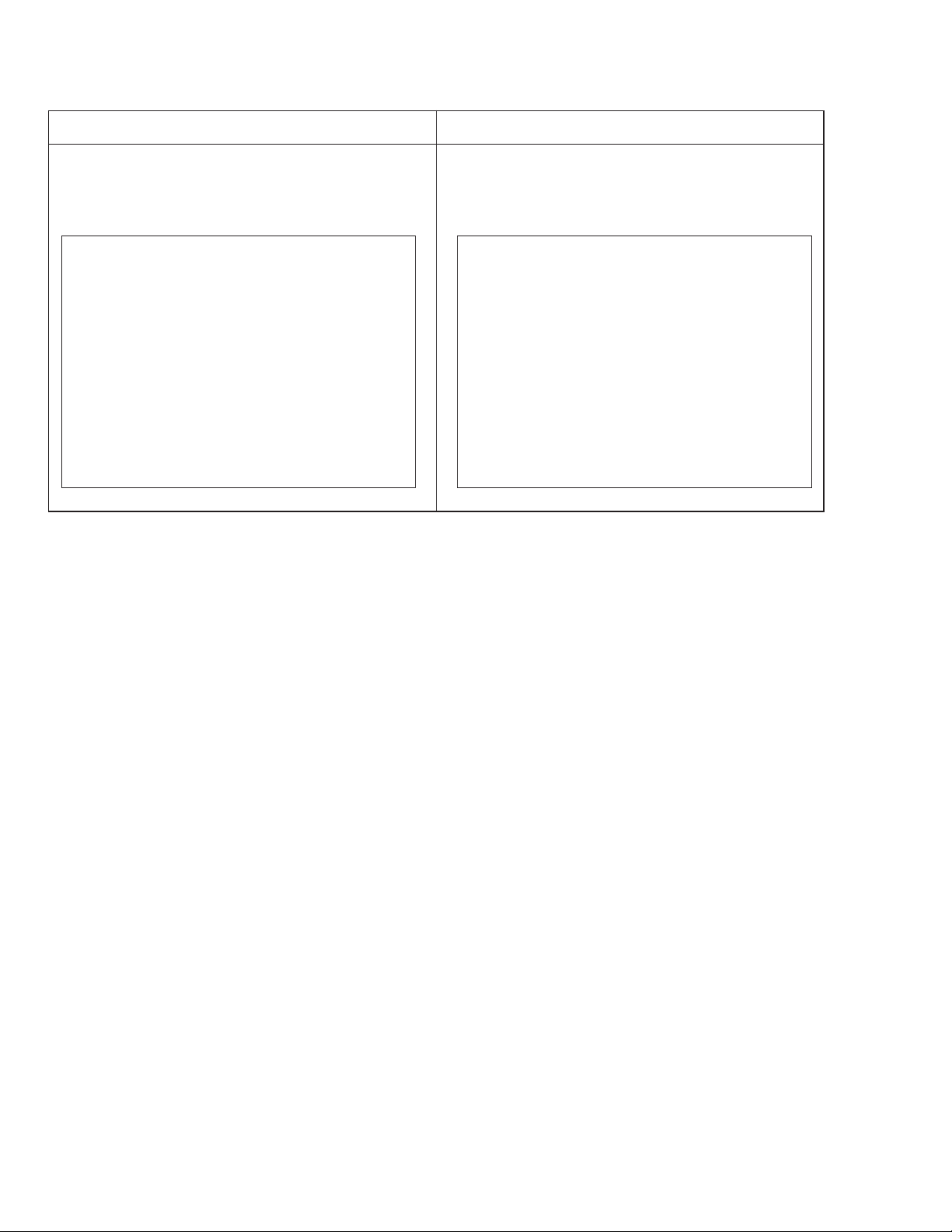

RCC-015H

ATP625 Disc

Firmware Program Disc

Power Code

SONY T est Disc

(TGRS-21) (for ATP)

Power Supply

AU-CN Mount

(ATAPI)

CDL1100 (CDM-47)

Controller

ATP/DOWNLOAD System

Terminator

Active Speaker

9

Power Cord

Power Supply

SONY T est Disc

(YEDS-18)

CDL1100 (CDM-47)

Controller

Function check

10

6-3. TROUBLE SHOOTING

This section describes trouble shooting methods.

Section 6-3-2. shows the flowchart of the processing routine of the

unit. Section 6-3-3. describes the ATP procedures. These sections

define the detective parts under operating conditions.

6-3-1. BEFORE TROUBLE SHOOTING

The following procedures are recommended to verify if the drive is

really faulty or not:

a. Poor connection with the host system

(esp. GND-related connection, frame GND, etc.)

b. Incorrect operational procedure.

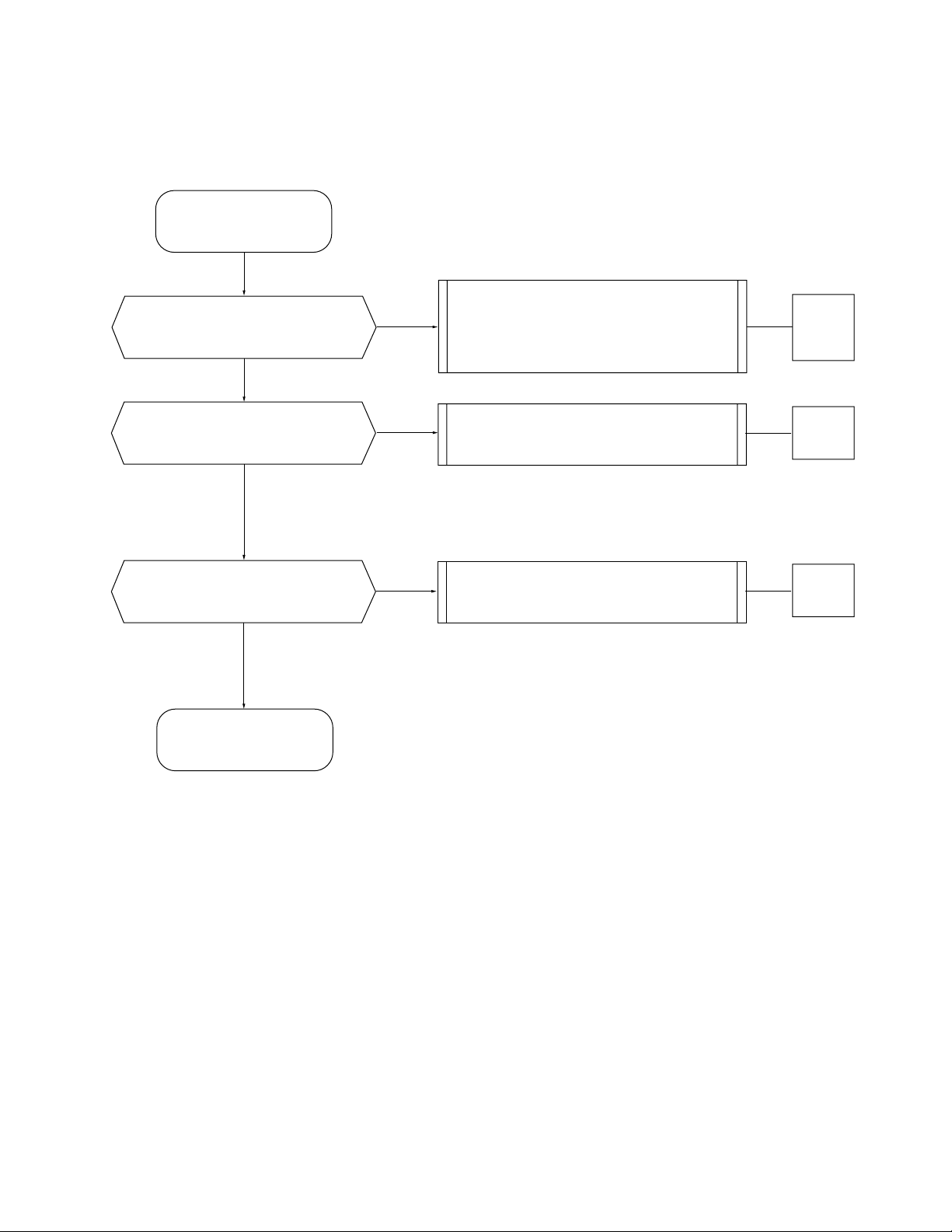

6-3-2. FLOWCHART FOR TROUBLE SHOOTING

START

c. Program error of host system

d. No Interface Cable Terminator at the end of Data Bus

e. Wrong Drive Number selection

f. Wrong supply voltage

g. Environmental conditions (where electrical noise easily jumps into

signal)

h. Influence of strong magnetic field.

(Refer to section 6-3-3.)

ATP

Pass

END

Fail

Optical Pick-up Cleaning

Perform drive

function check

(Refer to section 6-3-4.)

Fail

Part Replacement

Pass

11

6-3-3. PROCEDURE OF ATP TEST

6-3-3-1. Pre-setting

a. Connect the test drive to the PS/VP System. (Refer to 6-2-3-1.)

b. Set the Jumpers on the Adaptec SCSI board. (Refer to 6-2-3-1.)

c. Connect the test drive to the CDL1100 (CDM-47) CONTROL-

LER and set the COMMAND SW as below.

ID2HID1LID0LPARITY

L

d. Connect the test drive to the DC power supply.

e. Turn on the power of PS/VP System.

f. After loading the system, “C >” is displayed on the screen. Then,

insert A TP625 Disc.

Sony SCSI CD-ROM Failure Verification Test Ver. 1.00.02 [MAR. -04-1997]

[ID:7]=ASW-1210 V 3.60 ADAPTEC AHA-1520ADAPTEC AHA-1520

ATP625.CFG X-XXX-XX-XX

00: Inquiry Check

01: TEST UNIT READY

02: TOC Read

03: Incremental Read

04: Random Seek &Read

05: Spin Up/Down (X1)

06: Spin Up/Down (X4)

07: Spin Up/Down (MAX)

08: Full seek Read (X1)

09: 1/3 seek Read (X1)

10: Full seek Read (X4)

11: 1/3 seek Read (X4)

12: Full seek Read (MAX)

13: 1/3 seek Read (MAX)

14: Play Audio (De-TRCK)

15: Play Audio (E-Volume)

16: Play Audio (Play Mode)

17: Play Audio (X’Talk L->R)

18: Play Audio (X’Talk R->L)

19: Sub Code Read

g. Change the directory in the drive A. (“A >” is displayed on the

screen.)

h. Type A T P 6 2 5 and hit Enter key. (After loading the test

program, Display 6-3-3-1. (a) shows up.)

Drive Status Column

Hit any key to start or Esc to exit.

?

12

Display 6-3-3-1. (a)

6-3-3-2. T est Procedure

TEST item

To execute ATP test of the drive.

1. Insert the test disc (TGRS-21) into the CDM-47 drive unit. and

hit any key to start ATP test.

Note:

When some errors occurred during the test, “ A bort R etry I

gnore” message will be displayed i=on the drive status column, at

that time hit A key to exit and then check which part is broken in

accordance with 3-4.

Note:

If each test result satisfies the specification, the word of “Pass” or

value of the test result will be displayed on the judgement column.

a. Inquity check test will be executed.

b. “Returned Data OK ? (Y/N) = >?” message will be displayed

on the drive status column, then check the inquiry data and

hit Y key.

c. When “Place CD-ROM TEST DISC (TGRS-2D)...” is dis-

played, press the EJECT button of the CDL1100 (CDM-47)

controller, and chuck the disc. If the disc has already been

chucked, the display will not be shown, and the unit will pro-

ceed onto the next step.

d. TOC Read test will be executed.

e. Incremental Read Test will be executed.

f. Random Seek & Read test will be executed.

g. Spin Up, Spin Down test (normal) will be executed.

h. Spin Up, Spin Down test (quadruple) will be executed.

i. Spin Up, Spin Down test (Max) will be executed.

j. Full seek test (normal) will be executed.

k. 1/3 seek test (normal) will be executed.

l. Full seek test (quadruple) will be executed.

m. 1/3 seek test (quadruple) will be executed.

n. Full seek test (Max) will be executed.

o. 1/3 seek test (Max) will be executed.

2. After Seek test completion, Play Audio (DeTRCK) test will be

executed.

a. “Hit any key when ready” message will be displayed on the

drive status column, then hit any key.

b. Play Audio (E-Volume) test will be executed.

c. “Any key when Okay or Esc when NG” message will be dis-

played on the drive status column, then hit any key.

d. Play Audio (Play Mode) test will be executed.

e. “Space bar when ready, ESC to abort” message will be dis-

played on drive status column, then hit space bar.

f. Play Audio (X’Talk LnR) test will be executed.

g. “ Any k ey when Okay or Esc when NG” message will be dis-

played on drive status column, then hit any key.

h. Play Audio (X’Talk RnL) test will be executed.

i. “ Any k ey when Okay or Esc when NG” message will be dis-

played on drive status column, then hit any key.

3. After Audio test completion, Sub Code Read test will be executed.

Check point

The music (both left and right channel) can be heard from the active speaker.

The music (both left and right channel) will be faded-out slowly.

(After several minutes, the drive is set to mute mode.)

The music (both left and right channel) can be heard from the active speaker. And the play mode can be changed by pushing some

key.

(Refer to Drive Status Column)

The sound (only left channel) can be heard for 3 sec. from the active speaker.

The sound (only lright channel) can be heard for 3 sec. from the

active speaker.

13

TEST item

Check point

Note:

If all of test items are completed, words of OK will be displayed on

the screen.If not, NG will be displayed.

Sony SCSI CD-ROM Failure Verification Test Ver. 1.00.00 [Nov. -22-1996]

[ID:7]=ASW-1210 V 3.60 ADAPTEC AHA-1520ADAPTEC AHA-1520

ATP625.CFG

00: Inquiry check [ Pass ] [ ID:3 ]=SONY CD-ROM CDU625 X.Xx

01: TEST UNIT READY [ Pass ] READY

02: TOC read [ Pass ]

03: Incremental Read [ Pass ]

04: Random Seek & Read

05: Spin Up/Down (X1) [ Pass ] Spin Up : XXXX [ms] Spin Down : XXX [ms]

06: Spin Up/Down (X4) [ Pass ] Spin Up : XXXX [ms] Spin Down : XXX [ms]

07: Spin Up/Down (Max) [ Pass ] Spin Up : XXXX [ms] Spin Down : XXXX [ms]

08: Full seek Read (X1) [ Pass ] Max : XXXX [ms] Ave : XXXX [ms]

09: 1/3 seek Read (X1) [ Pass ] Max : XXXX [ms] Ave : XXXX [ms]

10: Full seek Read (X4) [ Pass ] Max : XXXX [ms] Ave : XXXX [ms]

11: 1/3 seek Read (X4) [ Pass ] Max : XXXX [ms] Ave : XXXX [ms]

12: Full seek Read (Max) [ Pass ] Max : XXXX [ms] Ave : XXXX [ms]

13: 1/3 seek Read (Max) [ Pass ] Max : XXXX [ms] Ave : XXXX [ms]

14: Play Audio (DeTRCK) [ Pass ]

15: Play Audio (E-Volume) [ Pass ]

16: Play Audio (Play Mode) [ Pass ]

17: Play Audio (X’Talk L->R) [ Pass ]

18: Play Audio (X’Talk R->L) [ Pass ]

19: Sub Code Read [ Pass ]

Remove the DISC Hit any key when ready

OK

The disc will automatically be unchucked.

Sony SCSI CD-ROM Failure Verification Test Ver. 1.00.00 [Nov. -22-1996]

[ID:7]=ASW-1210 V 3.60 ADAPTEC AHA-1520ADAPTEC AHA-1520

ATP625.CFG

0: Inquiry check [ Pass ] [ ID:3 ]=SONY CD-ROM CDU625 X.Xx

1: TEST UNIT READY [ Pass ] READY

2: TOC read [ Pass ]

3: Incremental Read [ Pass ]

4: Random Seek & Read

5: Spin Up/Down (X1) [ Pass ] Spin Up : XXXX [ms] Spin Down : XXX [ms]

6: Spin Up/Down (X4) [ Pass ] Spin Up : XXXX [ms] Spin Down : XXX [ms]

7: Spin Up/Down (Max) [ Pass ] Spin Up : XXXX [ms] Spin Down : XXXX [ms]

8: Full seek Read (X1) [ Pass ] Max : XXXX [ms] Ave : XXXX [ms]

9: 1/3 seek Read (X1) [ Pass ] Max : XXXX [ms] Ave : XXXX [ms]

10: Full seek Read (X4) [ Pass ] Max : XXXX [ms] Ave : XXXX [ms]

11: 1/3 seek Read (X4) [ Pass ] Max : XXXX [ms] Ave : XXXX [ms]

12: Full seek Read (Max) [ Pass ] Max : XXXX [ms] Ave : XXXX [ms]

13: 1/3 seek Read (Max) [ Pass ] Max : XXXX [ms] Ave : XXXX [ms]

14: Play Audio (DeTRCK) [ Pass ]

15: Play Audio (E-Volume) [ Pass ]

16: Play Audio (Play Mode) [ Pass ]

17: Play Audio (X’Talk L->R) [ Pass ]

18: Play Audio (X’Talk R->L) [ Pass ]

19: Sub Code Read [ Pass ]

Remove the DISC Hit any key when ready

NG

14

6-3-4. DRIVE FUNCTION CHECK

6-3-4-1. Pre-Setting for Test Mode Operation

Since CDM-47 models is adjustment-free drive, there is no potentiometer fo electrical adjustment in the MA-C30 Mounted Board. Therefore BU or MA Mounted Board can be swapped over without any

manual adjustment so that you will easily find defective components

(if the trouble depends on BU or MA Mounted Board). (Refer to 6-34-2.)

Note: All of adjustment items, will be automatically performed after

power-on by the function of CD DSP IC.

The page 6-15 shows the sequence of execution items in Po werOn Reset Actions. It will help you finding any defective point

on the drive to know the specified processing sequence of the

auto adjustment items and drive’s action in the Power-On Reset Actions.

Preparing

a. The following tools and measuring equipments are necessary for

performing this section.

DC Power Supply or CDL1100 unit

Oscilloscope

Sony Test Disc (YEDS-18) (3-702-101-01)

CDL1100 (CDM-47) CONTROLLER (J-2501-141-A)

b. Connect the test drive to the DC power supply or CDL1100 unit.

Note: This section is performed only specified following sections.

Note: This section describes usages of Test Mode Operation and sig-

nal checking on the CDM-47 drives with the CDL1100 (CDM-

47) CONTROLLER.

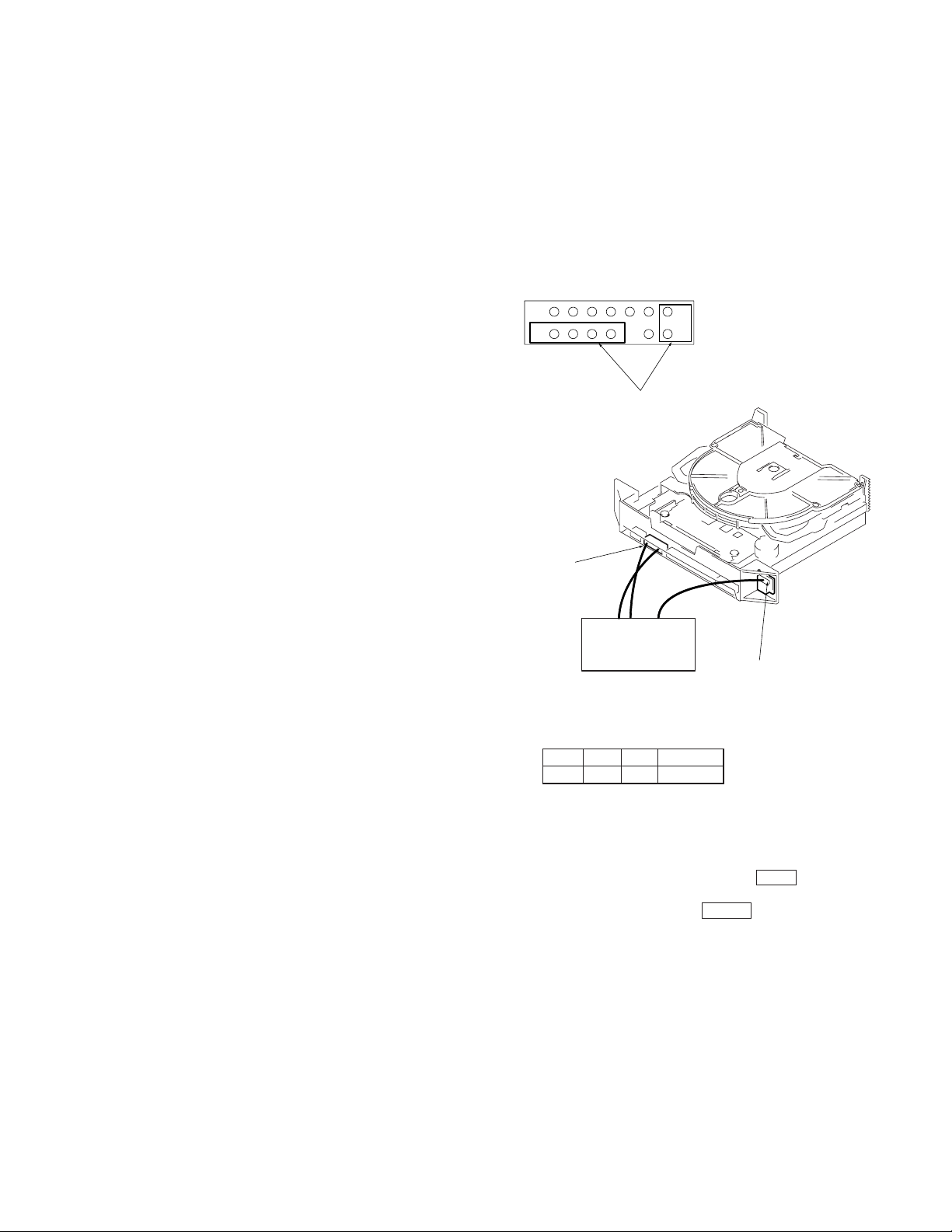

a. Connect CDM-47 to CDL1100 (CDM-47) CONTROLLER as

shown in following Fig. 3-4-1.

CNJ202 enlargement

7

8

Connect this part to the

controller

CNJ202

(MA-C30 board)

1

14

CDM-47

Controller

CN56 (CN board)

b. See the COMMAND SW ON CDL1100 (CDM-47) CONTROL-

LER as following table.

ID2LID1HID0LPARITY

L

c. While pressing the TEST button of the controller, turn on the

power of the CDL1100 or power supply unit.

d. After about 1 second later, release the TEST button.

Note: Even drive is Test Mode, EJECT button is activated.

15

6-3-4-2. Flowchart

Note: These flowchart is described assuming that IC failure causes any trouble.

Start

Mechanical or Electrical trouble ?

Electrical

Nothing in action in Power-On ?

Proceeding Adjustment Action

BU/Main PWB/HP PWB

dependent ?

(check by swapping BU or PWBs.)

Main PWB dependent

Power-On Reset actions Completes or

Failed/action NG ?

Completed

Mechanical

No action

BU dependent

HP PWB dependent

Failed /NG

Mechanical Checking/Repairing

IC303 (CPU) failure

IC305 (gate-array) failure

IC304 (Flash-ROM) failure

BU/OP checking/Replace BU

HP PWB checking

IC201 (CD DSP/servo IC) failure

IC101 (RF Amp IC) failure

Drive ICs failure

SCSI command execution

communication OK or NG ?

(check with any SCSI command)

OK

Read Operation

OK

End

Flowchart (1) Repairing/Trouble Shooting-General

NG

Access Time NG

Read Data Error

Refer to Flowchart (2)-Power-on Reset Actions

IC301 (CDROM/SCSI I/F IC) failure

IC304 (Flash-ROM) failure

IC201 (CD DSP/servo IC) failure

Motor Driver ICs failure

IC301 (CDROM/SCSI I/F IC) failure

IC302 (buffer RAM) failure

16

Power on Reset Action

Failed/Action NG

Retry for detailed checking

Trouble/Failed in Step (2)-(11)

(Spin-up/Focus-on)

OK/Passed

Trouble/Failed in Step (12)-(15)

(Auto Adjustment Functions)

OK/Passed

Trouble/Failed in Step (16)-(21)

(Read TOC/Set x8 speed)

OK/Passed

OK/Completed

(Try Read operation)

NG

NG

NG

Focus Search (Refer to 6-3-4-6.)

Spindle Motor Driver IC (Refer to 6-3-4-11.)

RF Signal (Refer to 6-3-4-13.)

Check Focus/Tracking Servo Error Signal

RF Signal (Refer to 6-3-4-13.)

RF Signal (Refer to 6-3-4-13.)

Spindle Motor Driver IC (Refer to 6-3-4-11.)

IC101

IC201

IC106

IC101

IC201

IC101

IC106

Flowchart (2) Repairing/Trouble Shooting-Power-on Reset Actions

17

Loading...

Loading...