Page 1

C9000 Series

Color LED Page Printer

Service Manual

ODA

05-18-200 Based on Rev.2

41388601TH Rev.2A 1 / 157

Page 2

Document Revision History

3 05-18-2001 ODA Revisions ODA Training

Rev.No. Date

No.

Corrected items

Page Description of change

Person in

charge

1 2000-12-05 ISSUE EM3 Murakami

2 2000-12-13 8 Correction of errors in K Yamazaki

the parts list

41388601TH Rev.2A 2 /

Page 3

PREFACE

This maintenance manual provides procedures and techniques for the troubleshooting, maintenance, and

repair of C9000.

This manual is written for maintenance personnel, but it should always be accompanied with the C9000

User’s Manual for procedures for handling and operating C9000. For repairing each component of C9000,

see the Troubleshooting manual.

[Notices]

The contents of this manual are subject to change without prior notice.

Although reasonable efforts have been taken in the preparation of this manual to assure its accuracy, this

manual may still contain some errors and omissions. OKI will not be liable for any damage caused or

alleged to be caused, by the customer or any other person using this maintenance manual to repair,

modify, or alter C9000 in any manner.

[Warning]

Many parts of C9000 are very sensitive and can be easily damaged by improper servicing. We strongly

suggest that C9000 be serviced by OKI’s authorized technical service engineers.

41388601TH Rev.2 3 /

Page 4

CONTENTS

1. SPECIFICATIONS ............................................................................................ 7

1.1 Basic System Configuration............................................................................................. 7

1.2 Printer Engine Specifications ........................................................................................... 8

1.3 Option Configuration ........................................................................................................ 9

1.4 Specifications................................................................................................................. 10

2. OPERATION DESCRIPTION ......................................................................... 12

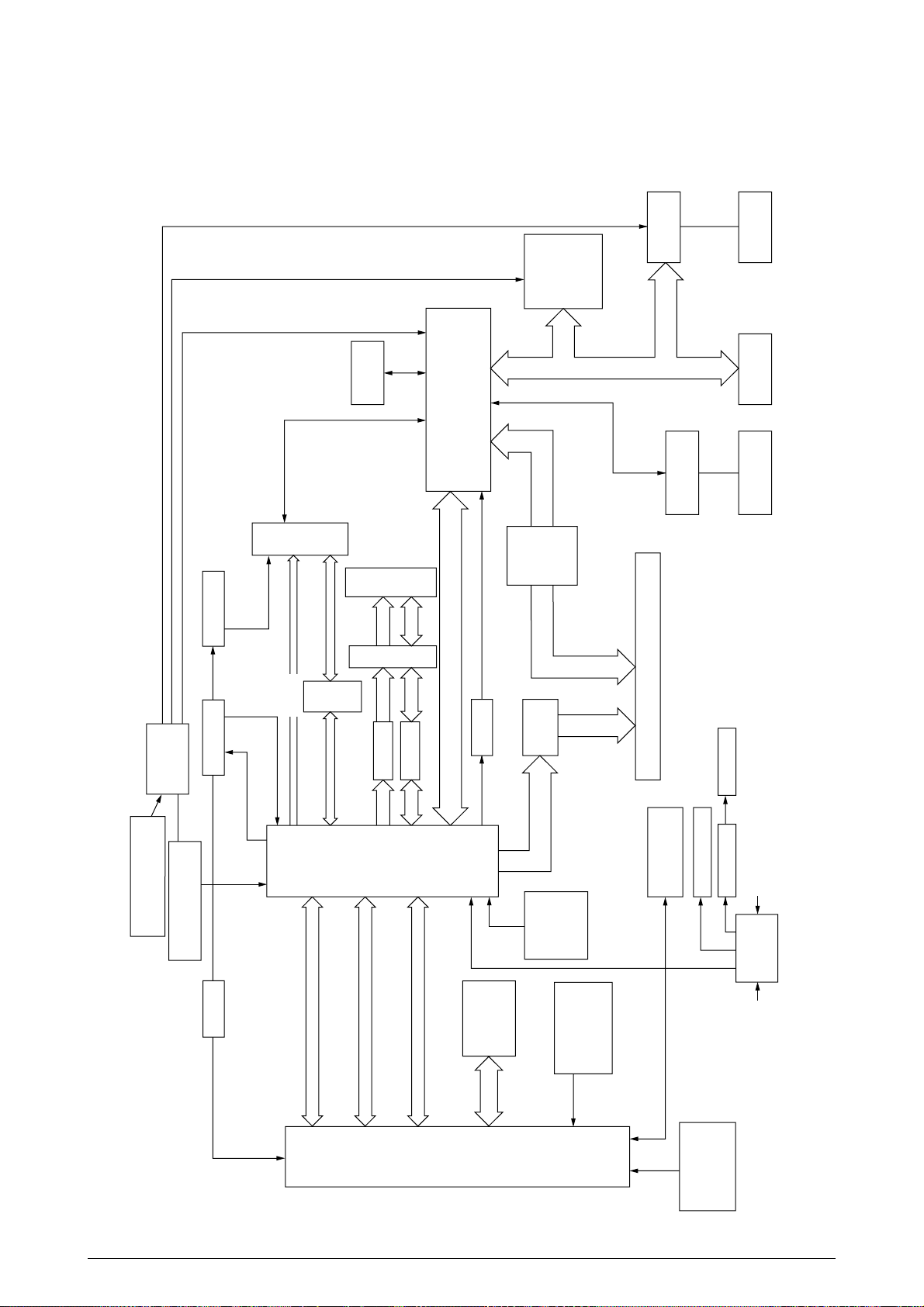

2.1 Main Control Board (CRM-PWB) ................................................................................... 13

2.2 Engine Control Board (K73 PWB).................................................................................. 15

2.3 Power Units.................................................................................................................... 16

2.4 Mechanical Processes ................................................................................................... 17

2.4.1 Electrophotographic process............................................................................ 18

2.4.2 Paper running process ..................................................................................... 22

2.5 Sensor............................................................................................................................ 31

2.5.1 Paper related sensors ...................................................................................... 31

2.5.2 Other sensors................................................................................................... 32

2.6 Color Misalignment Correction....................................................................................... 33

2.7 Transfer Control Responds to Environmental Changes

(Room Temperatures and Relative Humidities)............................................................. 33

2.8 Paper Jam Detection ..................................................................................................... 34

2.9 Cover Opening............................................................................................................... 35

2.10 Toner Low Detection...................................................................................................... 36

2.11 Paper Size Detection ..................................................................................................... 37

2.12 Operation at Power-on................................................................................................... 38

2.12.1 Self-diagnostic test........................................................................................... 38

2.13 Color Misalignment Detection ........................................................................................ 39

2.14 Version Read of Periodically Replaced Units ................................................................ 40

2.15 Life Counter for Replaceable Units ................................................................................ 40

2.16 Toner Consumption Detection ....................................................................................... 40

3. PARTS REPLACEMENT................................................................................41

3.1 Precautions in Replacing Parts...................................................................................... 41

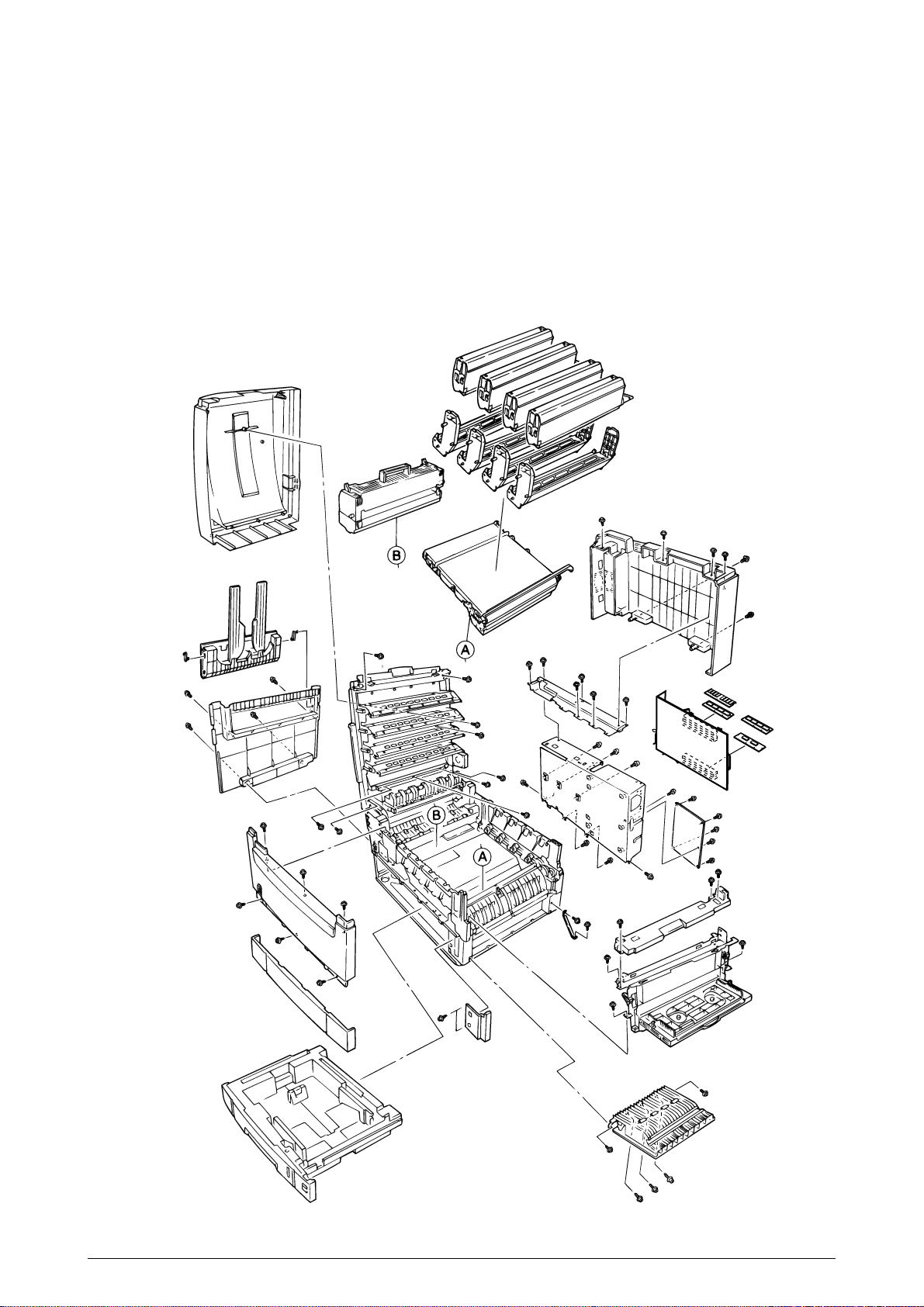

3.2 Parts Layout................................................................................................................... 43

3.3 Replacing Parts..............................................................................................................50

3.3.1 Top cover.......................................................................................................... 51

3.3.2 LED Assy/ LED Assy spring ............................................................................. 52

3.3.3 Top cover unit................................................................................................... 53

3.3.4 Control panel Assy/ Control panel bezel/ LED control PWB/ Toner sensor/

Stack full sensor/ Control panel tape harness/ Eject roller............................... 54

3.3.5 Top cover handle/ Tope cover latch/ Top cover latch spring............................ 55

3.3.6 Eject guide Assy ............................................................................................... 56

3.3.7 Cassette Assy/ Blind cover/ Side cover R Assy ............................................... 57

3.3.8 Feed rollers....................................................................................................... 58

3.3.9 Left side cover .................................................................................................. 59

3.3.10 Face-up tray ..................................................................................................... 60

3.3.11 Front cover ....................................................................................................... 61

3.3.12 Rear cover........................................................................................................ 62

3.3.13 Multipurpose tray Assy/ Multipurpose tray cover Assy/ Links/

Multipurpose tray top cover/ Multipurpose tray drive gear................................ 63

3.3.14 Drum contact Assys.......................................................................................... 64

3.3.15 Registration roller Assy (A)/ Registration drive gear (A)................................... 65

41388601TH Rev.2 4 /

Page 5

3.3.16 Registration roller Assy (B)............................................................................... 66

3.3.17 Registration clutch, Registration motor Assy.................................................... 67

3.3.18 Cooling fan ....................................................................................................... 68

3.3.19 Color registration sensor Assy.......................................................................... 69

3.3.20 Duplex guide Assy............................................................................................ 70

3.3.21 Electrical chassis/ Electrical chassis cooling fan.............................................. 71

3.3.22 Printer engine controller PWB .......................................................................... 72

3.3.23 Printer unit chassis........................................................................................... 73

3.3.24 Entrance cassette sensor actuator................................................................... 74

3.3.25 Entrance sensor PWB ...................................................................................... 75

3.3.26 Entrance MT sensor actuator and Entrance belt sensor actuator.................... 76

3.3.27 Main motor fan/ Fuser eject roller..................................................................... 77

3.3.28 Eject sensor Assy............................................................................................. 78

3.3.29 Fuser latching handle (L).................................................................................. 79

3.3.30 Belt motor Assy ................................................................................................ 80

3.3.31 Fuser latching handle (R)................................................................................. 81

3.3.32 Main motor Assy............................................................................................... 82

3.3.33 Contact Assy/ Side plate Assy.......................................................................... 83

3.3.34 Low voltage power supply ................................................................................ 84

3.3.35 High voltage power supply ............................................................................... 85

3.3.36 Main feed Assy................................................................................................. 86

3.3.37 Fuser unit.......................................................................................................... 87

3.3.38 Belt unit............................................................................................................. 88

3.3.39 Duplex unit........................................................................................................ 89

3.3.40 CU Assy............................................................................................................ 90

4. Adjustment .................................................................................................... 92

4.1 Maintenance Menu and Its Functions ............................................................................ 92

4.2 Short Plug Settings ........................................................................................................ 93

4.3 Printing Singly Using Controller-Equipped Printer ......................................................... 93

4.4 Adjustment after Part Replacement ............................................................................... 94

4.5 Color Balance Adjustment ............................................................................................. 95

4.6 EEPROM Replacement after CRM Board and K73 Board Replacement ...................... 97

5. Regular Maintenance ....................................................................................98

5.1 Parts to be Replaced Regularly ..................................................................................... 98

5.2 Cleaning......................................................................................................................... 98

5.3 Cleaning of LED Lens Array .......................................................................................... 98

5.4 Cleaning of Pick-up Roller ............................................................................................. 98

6. TROUBLESHOOTING PROCEDURES .........................................................99

6.1 Tips for Troubleshooting ................................................................................................ 99

6.2 Check Points before Correcting Image Problems.......................................................... 99

6.3 Tips for Correcting Image Problems .............................................................................. 99

6.4 Preparation for Troubleshooting .................................................................................. 100

6.5 Troubleshooting Flow................................................................................................... 100

6.5.1 LCD Message List .......................................................................................... 101

6.5.2 LCD message troubleshooting ....................................................................... 106

6.5.3 Image troubleshooting.................................................................................... 117

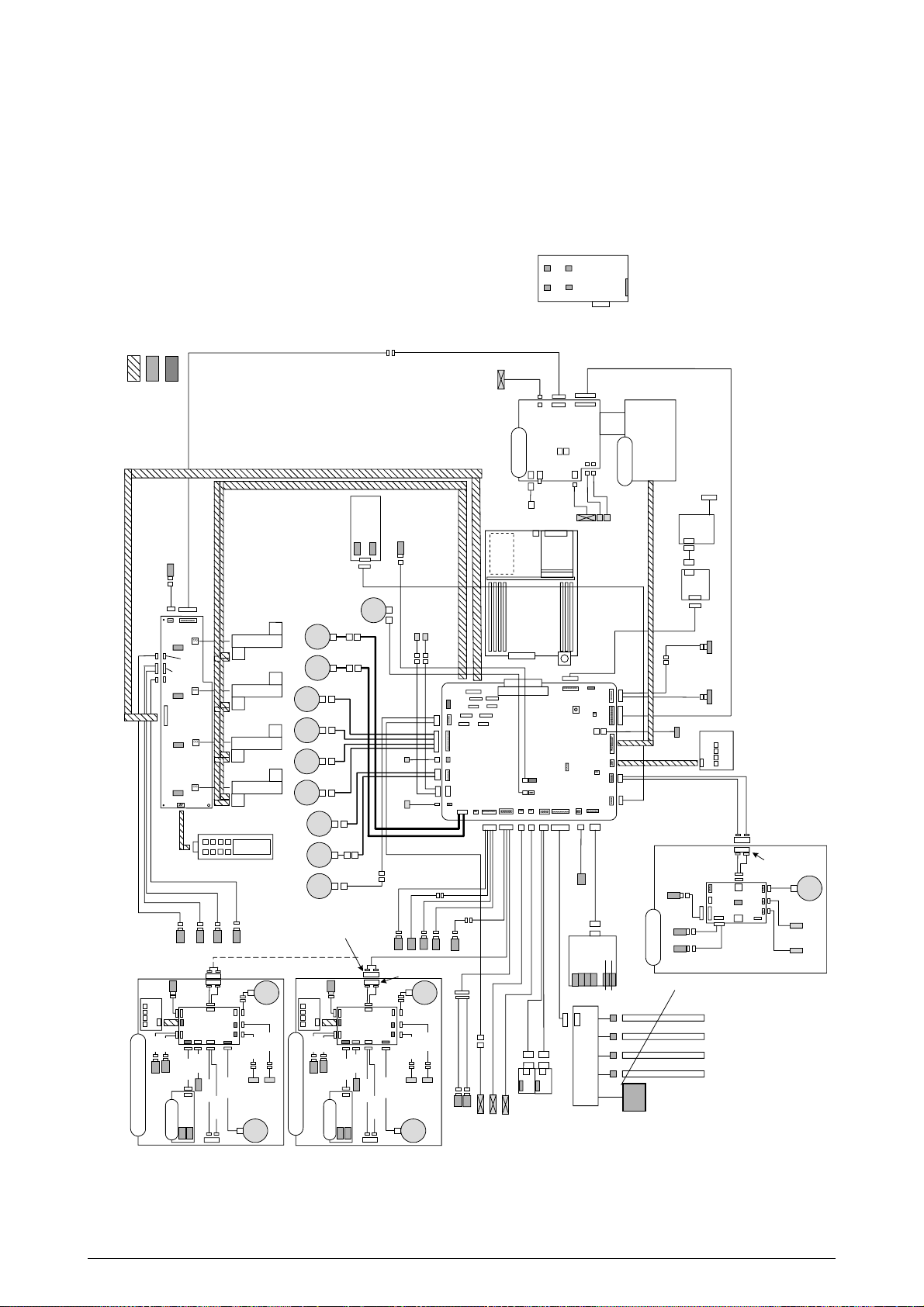

7. WIRING DIAGRAM...................................................................................... 129

7.1 Resistance Check ........................................................................................................ 129

7.2 Parts Layout on Boards ............................................................................................... 134

8. Parts List...................................................................................................... 138

41388601TH Rev.2 5 /

Page 6

Job

offset

M

M

M

M

M

M

M

LED Head

Junction Board

Pulse Motors

Engine Controller

Low-Voltage

Power Unit

Fuser Unit

High-Voltage

Power Unit

2nd/3rd T r ay/

Large-Capacity

Tray

Duplex Unit

Belt Unit

<Sensors, Switches and Thermistors>

Paper carrier sensors

Paper size detection

Fuser temperature detection

Ambient temperature and humidity detection

Toner remaining detection

Color registration sensor

ID, belt and fuser checks

C-ID

Unit

M-ID

Unit

Y-ID

Unit

K-ID

Unit

C ID

M

Heater

M ID

Y ID

K ID

Belt

MT/

Registration

Hopping

Geared

motor

DC motor

Operator Panel

Centronics

USB

IDE

HDD

DC

FAN

Ethernet

ROM DIMM × 3

SDRAM DIMM

× 4

Controller

Block

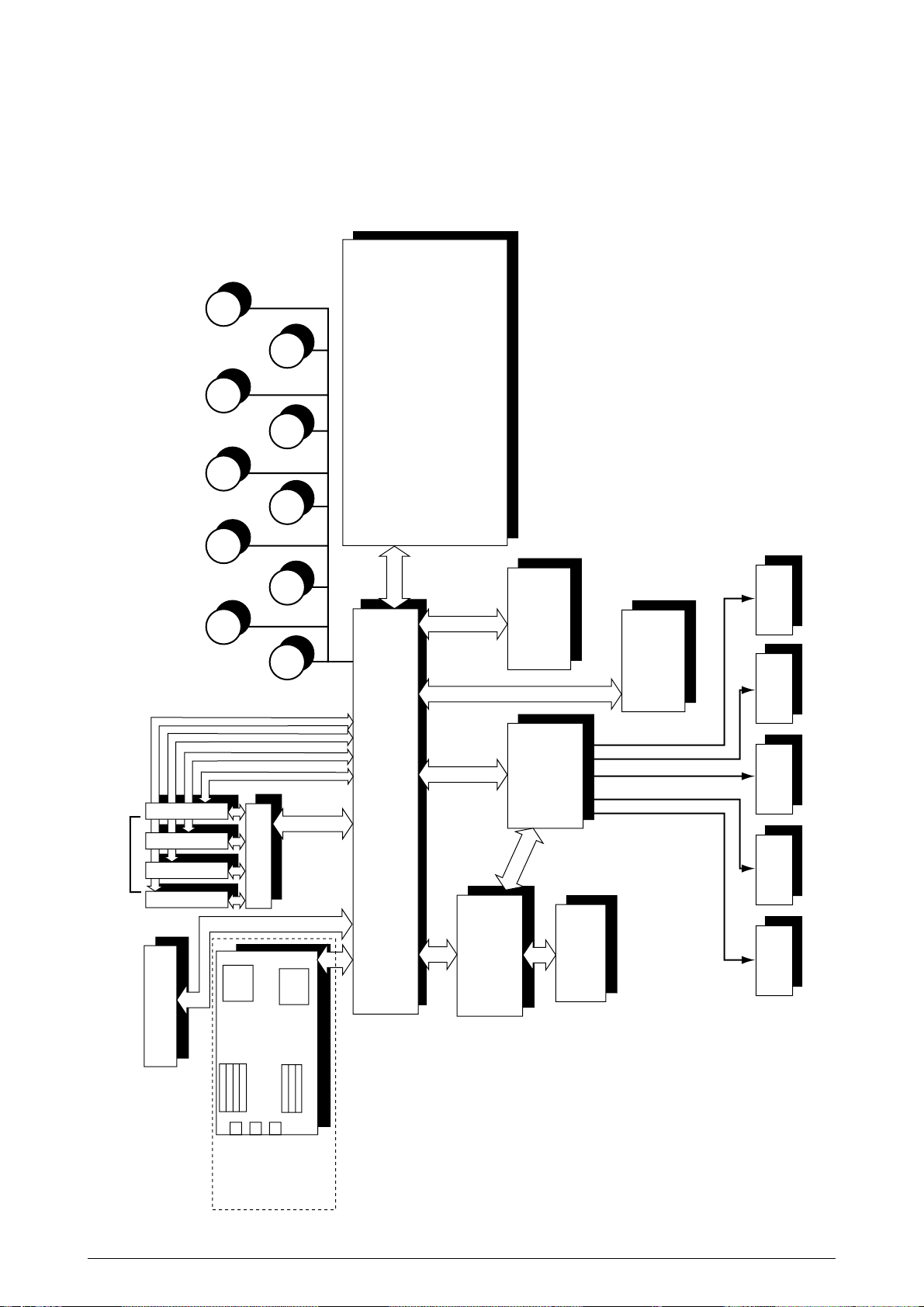

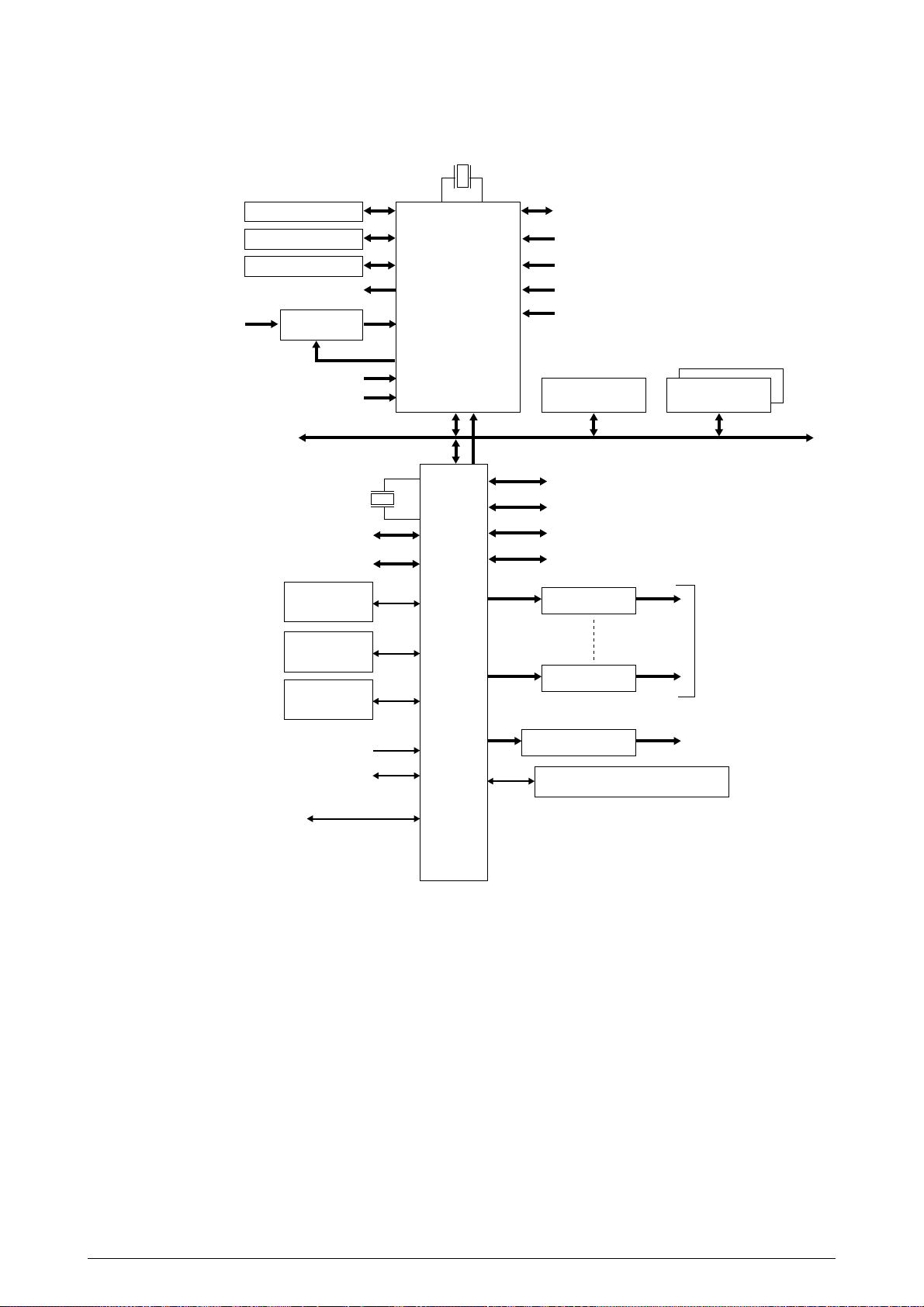

1. SPECIFICATIONS

1.1 Basic System Configuration

The basic system configuration of C9000 is illustrated in Figure 1.1.

Figure 1.1

41388601TH Rev.2 6 /

Page 7

1.2 Printer Engine Specifications

The inside of the printer is composed of the followings:

• Electrophotographic Processor

• Paper Paths

• Controller Block (CU and PU)

• Operator Panel

• Power Units (High-Voltage Unit and Low-Voltage Unit)

Figure 1-2 shows the printer configuration.

Figure 1.2

41388601TH Rev.2 7 /

Page 8

1.3 Option Configuration

The followings are available as options on C9000.

(1) 2nd Tray/ 3rd Tray

(2) Duplex Unit

(3) Large-Capacity Tray

(4) Expansion Memory 64/128/256MB

(5) Internal Hard Disk

(6) Ethernet Board

41388601TH Rev. 2 8 /

Page 9

1.4 Specifications

(1) Dimensions Height: 18.11 in. Width: 26.22 in. Length: 24.65 in.

(2) Weight 158.7 lbs.

(3) Paper Type: Ordinary paper and transparencies (Recommended: ML OHP01)

(4) Print Speed Color: 21 pages per minute (Transparency: 5 pages per minute)

(5) Resolution 600 × 600 DPI / 600 x 1200 DPI (C9200 series) & 1200 x 1200 DPI (C9400 series)

(6) Power Input 100VAC ±10%

(7) Power Consumption Peak: 1400W Normal Operation: 550W (5% duty)

Size: Postal card, Legal 13" or 14", Executive, A4, A5, B5, A6, A3 A3-Nobi, B4

(Only the 1st tray and the front feeder support A6 and postal card

sizes.)

Weight: 1st tray 55 kg to 90 kg (64 to 105g/m

2

)

Front feeder 55 kg to 140 kg (64 to 163g/ m2)

Monochrome: 26 pages per minute (Transparency: 15 pages per minute)

Postal Card, Label, Thick Paper: 10 pages per minute

Idle: 150W Power Saving Mode: 50W

(8) Frequency 50Hz or 60Hz ± 2%

(9) Noise Operating: 54 dB (without Second tray)

Standby: 45 dB

Power Saving: 43 dB

(10) Consumable Life Toner Cartridge: 15,000 pages (5% duty)

(in each of Y, M, C and K)

Image Drum: 39,000 pages (5% duty, Continuous printing)

(in each of Y, M, C and K)

(11) Parts Replaced Periodically Fuser Unit Assy: Every 80,000 pages

Belt Cassette Assy: Equivalent of 80,000 pages (3P/J)

Transfer Belt cartridge: 60,000 prints

41388601TH Rev.2 9 /

Page 10

(12) Temperatures and Relative Humidities

Temperature

Temperature (ºF) RemarkTemperature (ºC)

Operating 50 to 89.6 10 to 32

Non-Operating 32 to 109.4 0 to 43 Power-off

Storage (Max. One Year) -14 to 109.4 -10 to 43 With drum and toner

Transport (Max. One Month) -20 to 122 -29 to 50 With drum and without toner

Transport (Max. One Month) -20 to 122 -29 to 50 With drum and toner

17 to 27ºC (Temperatures to

assure full color print quality)

Humidity

Relative Humidity (%) Max. Wet-Bulb Temperature (ºC) Remark

Operating 20 to 80 25 50 to 70%

(Humidities to assure full color print quality)

Non-Operating 10 to 90 26.8 Power-off

Storage 10 to 90 35

Transport 10 to 90 40

(13 Printer Life 1,000,000 pages (on a A4 basis) or five years

41388601TH Rev.2 10 /

Page 11

Stacker Open

Microswitch

SUMI Card

Sensor/Microswitch

New C9000 Connector

Backup Roller

Thermistor

L-Side Color Registration Adjustment

AOUT3

R-Side Color Registration Adjustment

AOUT2

Eject Sensor Heater

Shutter Clutch

SHUTTER

Regist

Clutch

R

SNS

PO

WER

C

UIFPSIZE

HV

OLT

JO

DEN

FS

ENS

TR

1OP

P5

P6

R

EG

BEL

THETDUPLEX

K73 Main Board

CP

UFL

PAR

TTEMP

SHU

TTER

DCLFC

OVER

DU

COV

PE

NDF

O

HP1

FF

POS

PA

PWID

M7L Board

M7R Board

F

AN1

F

AN2

FF/

Registration

Motor

CO

VOPN

Right Side Cover

Open Microswitch

Upper Cover

Open Microswitch

(+38V cut)

S

W1

Y71 Head

Relay Board

TNRK

TNRY

STUCK POWER

PANEL

MPOW2

CPOW2

YPOW2

KPOW2

TNRM

TNRC

Stacker Full Sensor

Geared

Motor

Loading Clutch

Pickup Clutch

Carrier Sensor

Paper Width Sensor

Offset

Motor

Hopping

Motor

Offset Zero Sensor

C73

I/F Board

Finisher

A73 Retard Sensor Board

Lifter Sensor

Loading Sensor

Belt

Fuse

I DPOSK

I DPOSY

I DPOSM

I DPOSC

N71 Board

(charge elimination relay)

IDC

IDM

IDY

ID

D2 Green

D2 Yellow

K

NBLT

4 x P73 Boards

AC

Input

AC

Input

Fan 3 (off-the-shelf)

Fan 2 (power eject)

Fan 1 (PU)

works as stepper

PEND

PNEND

Offset PE Sensor

Offset Sensor

STDUCOV

JO

BOFF

OPTN

KPOW

K12 00

Y12 00

M120 0

MPOW

YPOW

ID

R

CL

HO

PFF

FR

PUCL

C1200

CPOW

F

ACE

K

L

E

D

H

E

A

D

L

E

D

H

E

A

D

L

E

D

H

E

A

D

L

E

D

H

E

A

D

Y

M

C

F

EED

PAPSIZ3-0

aVR

Paper Width

Sensing Board

HOP

LIFT

MAIL

HOP(I

NSNS1)

H

UM

T

EMP

R71

Board

PAPIN(

INSNS2)

PSWR(

WRSNS)

TN

RFUL

GE

ARED

K IDU

Motor

JOB

OFFS

JOB

OFFPE

connected to next tray

(no tray in lowest section)

connected to trays of up to 5th,

including 2nd tray

(does not exist in the lowest)

2nd T ray/3rd Tray

Large-Capacity T ray

Geared

Motor

Loading

Carrier Clutch

(does not exist

in the lowest)

Loading Clutch

V73 Board

Paper End

Paper Near

End

Cover Opem SW

Carrier Sensor

Paper Width

Sensing Board

T9 Blue

T3 White

T4 Red

T5 Red

T8 Red

T2 Blue

T6

Yellow

Lifter Sensor

Loading Sensor

Retard Sensor

Board A73

T2 White

T1 Blue

T1 White

T7 White

T11

(does not exist

in the lowest)

DUP-In Sensor

DUP Middle Sensor

DUP Front Sensor

DUP

DUP Front Clutch DUP Rear Clutch

D3 Blue

V73 Board

Duplex

D1 Blue

D1 White

Belt

Motor

P1 Yellow

P1 White

P2

P2 Yellow

P3 White

P2 Blue

P2 Red

P4

P4 Red

P4 Yellow

P4 Blue/

White

P6 Brown

P7 Blue

P7 Gray

P7

P8

P7 Gray

attached to

sensor

P9

P9 Black

P10P10

P10 Brown

P11

P11 Blue

P11 White

P21P21

P22

P12P12

P12 Yellow

P13

P13 Red

P14

P14 Yellow

P14 Red

P15 Red

P16 Browm

P17 Red

attached to motor

P16

P5 Red

P18 Black

P19

P18

P17

P20

P18 Yellow

P18 Red

P18 Blue

attached

to clutch

P19 White

P1

P19 Red

P20 White

P20 Yellow

P24 to P31

P23

Y1 White

Y2 Blue

Y1 White

S1 Gray

Heater Unit

Heat Roller

Thermistor

Sensor

Fuse

TH

ERM1

TH

ERM2

NFULH

RTMP

LB

RTMP

C

N8

C

N9

C

N2

C

N1

High-Voltage

Power Supply

C

N5

CN4-

2,6-2

CN4-

1,6-1

AC

SW

S1

Low-Voltage

Power Supply

attached to fan

attached to fan

*1

attached to fan

attached to fan

attached to fan

Heat

Motor

FD

WPAP

Jam Sensor

P2 White

P4 Green

Fan 0 (power-on)

Face-Down Solenoid

Eject Solenoid

Removed-Edge Side

Removed-

Edge Side

P33 White

P33 Blue

Temperature Sensor

P33 Green

Fan 0 (power eject)

DUP_PAP

T6

Blue

White

connected to next tray

(no tray in lowest section)

Geared

Motor

Loading

Carrier Clutch

Loading Clutch

V73 Board

Paper End

Paper Near

End

Cover Opem SW

Carrier Sensor

Paper Width

Sensing Board

T9 Blue

T3 White

T4 Red

T5 Red

T8 Red

T2 Blue

T6

Yellow

Lifter Sensor

Loading Sensor

Retard Sensor

Board A73

T2 White

T10 Red

T1 Blue

T1 White

T7 White

T11

*1

T6

Blue

White

Black

Removed-

Edge Side

White

Black

DUP Rear Sensor

Y6

Y5

Y3

Y4

P24 to P31

Y IDU

Motor

M IDU

Motor

C IDU

Motor

Motor

P17 Yellow

S2

Black

Black

Black

Y4 Green

Y3 Yellow

Y3 Red

Y5 Blown

X71 Board

P24

P28

P25

P29

P26

P30

P27

P31

Operator

Panel

C Charge Elimination Lamp Fuse

M Charge Elimination Lamp Fuse

Y Charge Elimination Lamp Fuse

K Charge Elimination Lamp Fuse

P27

ACSW

Assy

FAN

RAM

CRM Board

ROM

HDD

LAN

USB

CENTRO

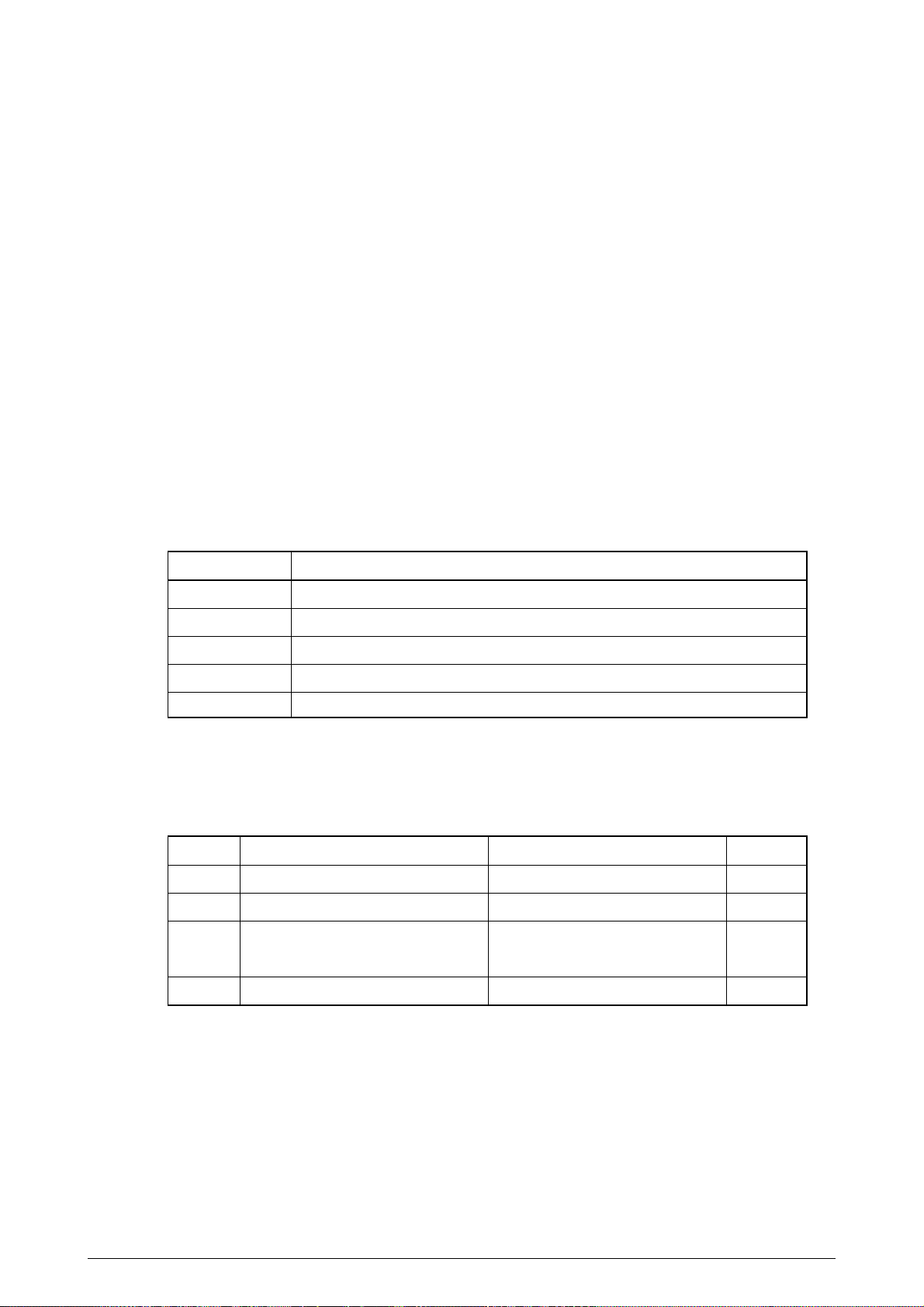

2. OPERATION DESCRIPTION

C9000, a tandem color electrophotographic page printer, adopts technologies such as 4992-LED

array, OPC, dry single-component non-magnetic developing, roller transfer and heat-compression

fusing. The printing method is black writing by shedding light on print areas.

Figure 2-1 provides the block diagram of this device.

Figure 2.1

41388601TH Rev.2 11 /

Page 12

2.1 Main Control Board (CRM-PWB)

PPC

750

L2

Cache

Delay

Delay

Buf

16244

Buf

16244

IF Bus

EEPROM

A

D

Cont

Y, M, C and K Video Data

PU-CU I/F,

Operator Panel

A/D,Cont

A/D, Cont(SUB Bus)

14.31818MHz

Crystal Resonator

CY2292

CY2308

FET SW

162212

FLASH ROM

FLASH DIMM

×3

SDRAM DIMM

·4

IMI1530

Fluctuation Circuit

Internal-CLK-

Setting

Resistance

Reset

DS1834

to C2 and

3.3V ICs

to 5V ICs

PU Board Connector, 200 Pins

Inverter

RESET-P

2.0V

Regulator

2.5V

Regulator

C1 LSI

MHM

2030-002

C2 LSI

MHM2031-002

CDC516

80MHz

LVC244

LVC161284

Centro USB

L60851

PCI Bus

LAN Board

IDE

HDD

LVC245

80MHz

80MHz

3.3V5V

40MHz

48MHz

33MHz

33MHz

·2

SPD

80MHz

×2

80MHz

×16

A,Cont

A,Cont A,Cont A,Cont

DDD

Figure 2-2 provides the block diagram of the main control board (CRM-PWB).

Figure 2.2

41388601TH Rev.2 12 /

Page 13

(1) CPU

The CPU is 64-bit bus RISC processor PowerPC750, which receives an input of 80MHz

(=BUS CLK) and operates at 400MHz, four-times the input.

(2) Secondary Cache SRAM

SRAM is included as a secondary cache of the CPU on the board.

(3) ROM

The ROM is inserted into the three 168-pin DIMM slots. The slot A is for a program ROM

and the slot B is for the Japanese Kanji font. The slot C is not assigned.

(4) RAM

The RAM is inserted into the four 168-pin DIMM slots. The DIMMs must be fitted in

descending order of the type No. labeled on each of them into the slots 1, 3, 2 and 4.

SDRAM DIMM Specifications:

Speed: PC100 or more

Capacity: 64/128/256MB

Configuration: Without parity and ECC. Requires the SPD information. Number of

chips contained = 8 or 16.

(5) EEPROM

The EEPROM (16Kb), an 8-pin DIP package, is inserted into the IC socket supplying the 3.3V

power. Settings for controlling the controller block are stored in the memory.

(6) Flash ROM

A 2-megabyte flash ROM is surface-mounted on the CRM board. The flash ROM, composed

of four chips of 256 kilo x 16 bits, can store fonts and macros.

(7) Memory Control LSI (CI)

A 696-pin BGA package ASIC made by NEC, which is equipped with a cooling heat sink and

mainly controls the CPU I/F, memory, video data compression and decompression, and PUvideo I/F.

(8) Interface Control LSI (C2)

A BGA package ASIC made by Toshiba, which controls the PU command I/F, operator panel

I/F, IDE I/F, Centronics I/F, USB I/F, PCI I/F, EEPROM and SPD (SDRAM DIMM) I/F.

(9) IDE HDD

An IDE connector is surface-mounted on the board to which an IDE HDD, assembled using

molds for the purpose, is connected. The IDE HDD is used for storing font data, spooling

edited video data temporarily and registering form data.

(10) PCI Bus Option

Two PCI I/F slots are provided for option board use. The bus, which uses an Oki Data original

connector, can accept an Ethernet board.

(11) Host Interface

Standard: Centronics two-way parallel I/F (IEEE-1284-compliant)

USB (USB1.1-compliant)

Additional Board: (connected to PCI BUS)

Ethernet Board

41388601TH Rev.2 13 /

Page 14

2.2 Engine Control Board (K73 PWB)

28MHz

Control Panel

Duplex

Cassette 2/3

Analog output

(Color registration sensor adjustment)

Analog input

(Temperature change)

Analog Input

Switch

Analog input (OHP)

Analog input (Various densities)

CPU BUS

32bit Video I/F

Heater control

Fuse Cut Driver

EEPROM

Toner and ID sensors ID check

D/A

48MHz

CU I/F

CPU

MSM66Q577

A/D CON

LSI

(VIDEO MEM

Containing

4Mbit DRAM)

Fan control

Cover front/upper open

Stacker full

Test switch

(Power supply cooling)

8Mbit(1MByte)

Motor interruption

UART interruption

K Head I/F

Y Head I/F

M Head I/F

C Head I/F

Motor Driver

Motor Driver

DC Motor Driver

High-Voltage Power Supply

Serial Interface (2 channels)

FLASH

256Kbit(32KByte)

SRAM

9x Pulse Motors

DC Motor

(Geared Motor)

×

2

Paper Feed System Sensors

(Paper Feed, Paper Registration and Eject Sensors)

MT Sensor (Stage position and paper empty)

Cassette 1 Sensor (Paper empty and near empty)

Shutter, clutch, belt and fuser checks

Cassette size

Figure 2.3

The engine control block (PU) is controlled by the engine control board (K73 PWB) which consists

of a CPU (MSM66Q577), general LSI chip, flash ROM, EEPROM, pulse motor drivers, and video

memory (see Figure 2.3).

(1) CPU

This, a 16-bit CPU with an AD converter (OKI MIM66Q577), controls the entire system.

(2) General LSI

This LSI (MG63P011-001LA), which is contained in the printer engine control block,

incorporates 4 megabits of video memory and has functions such as engine-controller

interfacing, LED interfacing, motor control, sensor input, video memory control, main scan

color misalignment correction, skew correction and high-voltage power supply control.

41388601TH Rev.2 14 /

Page 15

(3) Flash ROM

8 megabits of flash ROM (MBM29F800TA-70) which stores PU programs.

(4) EEPROM

4 kilobits of EEPROM (NM93C66N-NW) which is mounted on the board with an IC socket and

stores correction values.

(5) Pulse Motor Driver

The pulse motor driver (A2918, A2919, A3955) drives nine pulse motors to revolve the EP

and carry media.

(6) SRAM

This SRAM (62256LFP-7LL) is used as working memory of the CPU.

2.3 Power Units

There is a low-voltage power unit, which consists of an AC filter circuit, low-voltage power circuit

and heater driver circuit, and a high-voltage power unit which supplies a high-voltage power circuit.

(1) Low-Voltage Power Unit

This circuit generates the following voltages:

Output voltage Use for

+3.3 V Logic circuit power supply

+3.8V Logic circuit power supply

+5 V Motor and drive voltage for high-voltage power supply

+32 V OP Amp, High-voltage power supply

+12 V LED head

(2) High-Voltage Power Unit

This circuit generates the following 34V or more voltages, which are required for electrophotographic process, according to control sequences from the control board.

Output Voltage Use for Remarks

CH -900 to -1400±50V Voltage to charging roller

DB Y, M, C: -10 to -400V/+300V Voltage to developing roller

K: -10 to -400V/+300V

SB Y, M, C: -100 to -700/0V Voltage to toner supplying roller

TR 0 to 7KV Voltage to transfer roller Variable

41388601TH Rev.2 15 /

Page 16

2.4 Mechanical Processes

Paper Eject Roller

Paper Ejection

(Face down)

Power Supply

Charging Roller

Cleaning Blade

Paper Path

Selection

Heat Roller

Ejection

Roller

Fusing

Backup Roller

Control Signals

LED Head

Developing Roller

Power Supply

Toner Cartridge

Transfer Roller

Registration

Roller 1

Paper loading

Hopping Roller

Power

Supply

Registration

Roller 2

Paper Ejection Fusing Cleaning Transfer

Paper carriage Paper advance

Paper traveling

OPC drum revolution

Transfer

Charging

Expose

Development

Cleaning

Paper Eject Sensor

Paper Feed Sensor 1

Paper Ejection

(Face up)

Paper Feed Sensor 2

Multipurpose

Tray

Paper Cassette

Paper

registration

Paper

registration

(MT, 1ST, 2ND)

Write Sensor

x 4

K

YMC

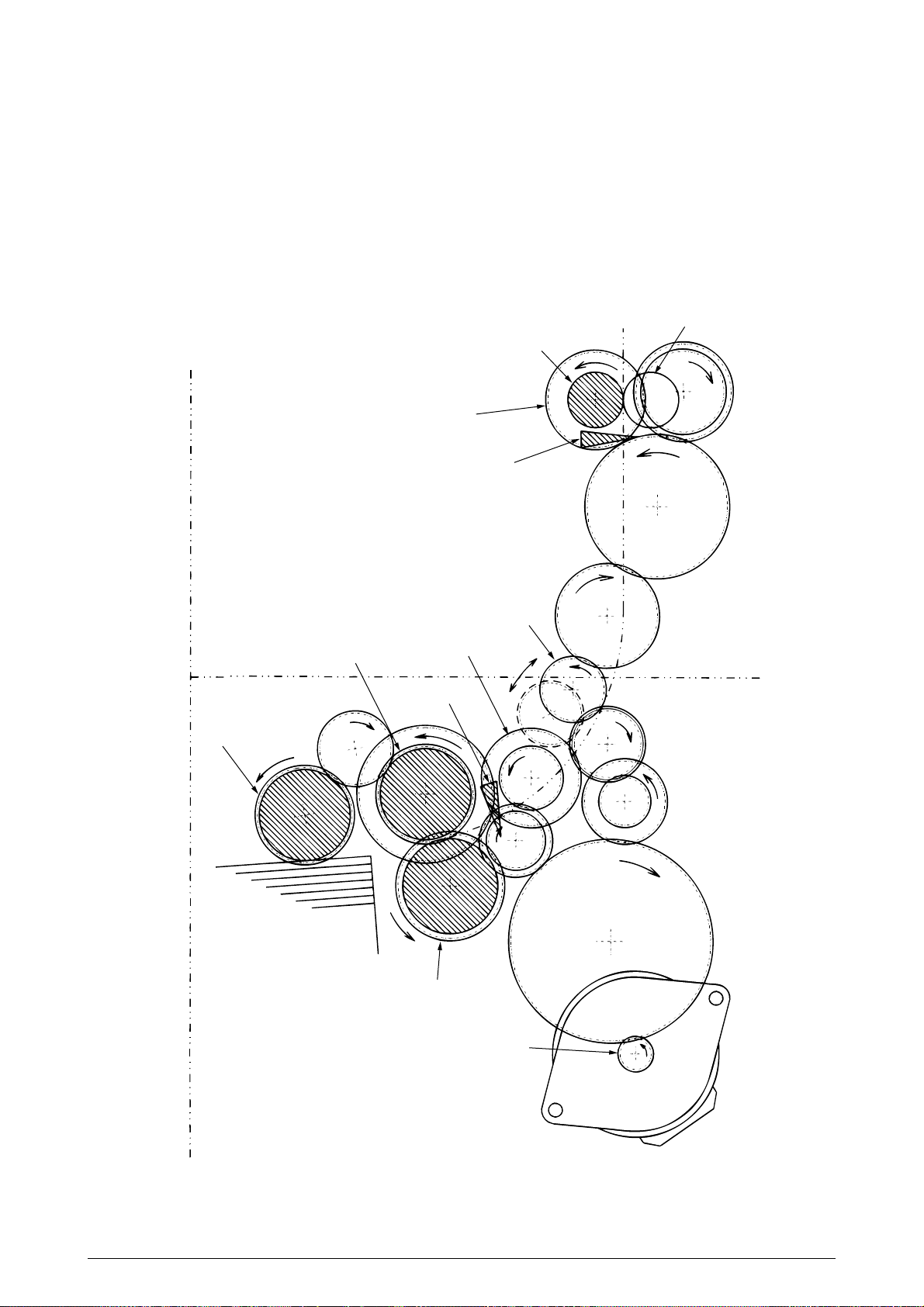

Figure 2.4 shows the mechanical processes of the printer.

41388601TH Rev.2 16 /

Figure 2.4

Page 17

2.4.1 Electrophotographic process

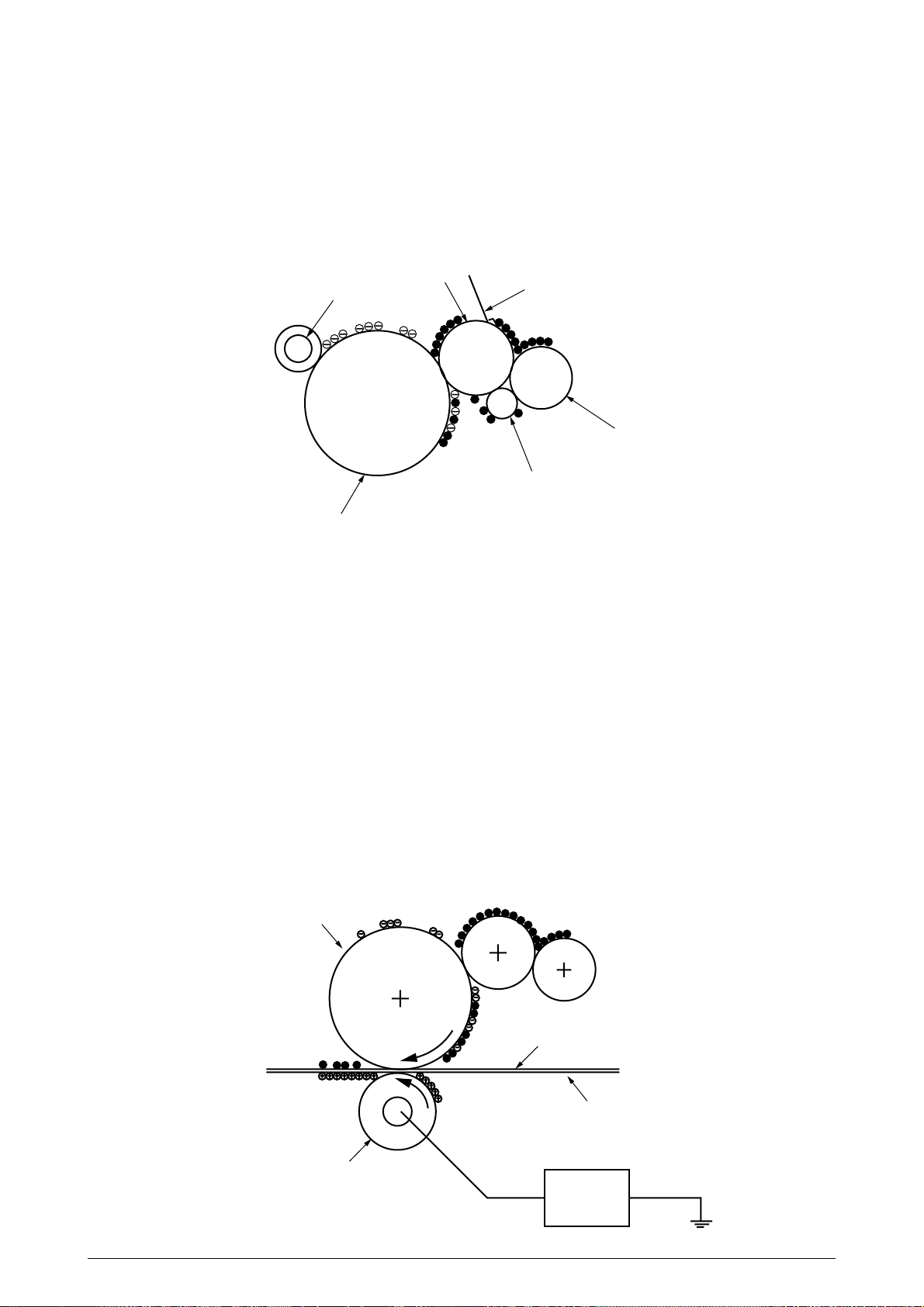

(1) Electrophotographic process

The following is the outline of electrophotographic process:

1 Charging

DC voltage is applied to the charging roller and the surface of the OPC drum is negatively

and evenly charged.

2 Exposure

The LED head, under image signals, emits light to the negatively charged surface of the

OPC drum. The radiated portions of the drum surface attenuate in negative charge

according to the intensity of the light and, based on the surface potentials, a latent

electrostatic image is formed on the drum surface.

3 Development

Negatively charged toner contacts the OPC drum and, by electrostatic force, adheres to

the latent electrostatic image to form a clear image on the drum surface.

4 Transfer

Paper is placed on the surface of the OPC drum, and positively, or opposite to the polarity

of the toner, charged by the transfer roller on its back to transfer the toner image to the

paper.

5 Cleaning

The cleaning blade removes residual toner from the OPC drum after the transfer.

6 Fusing

The toner image on the paper is fused into place through the application of heat and

pressure to it.

41388601TH Rev.2 17 /

Page 18

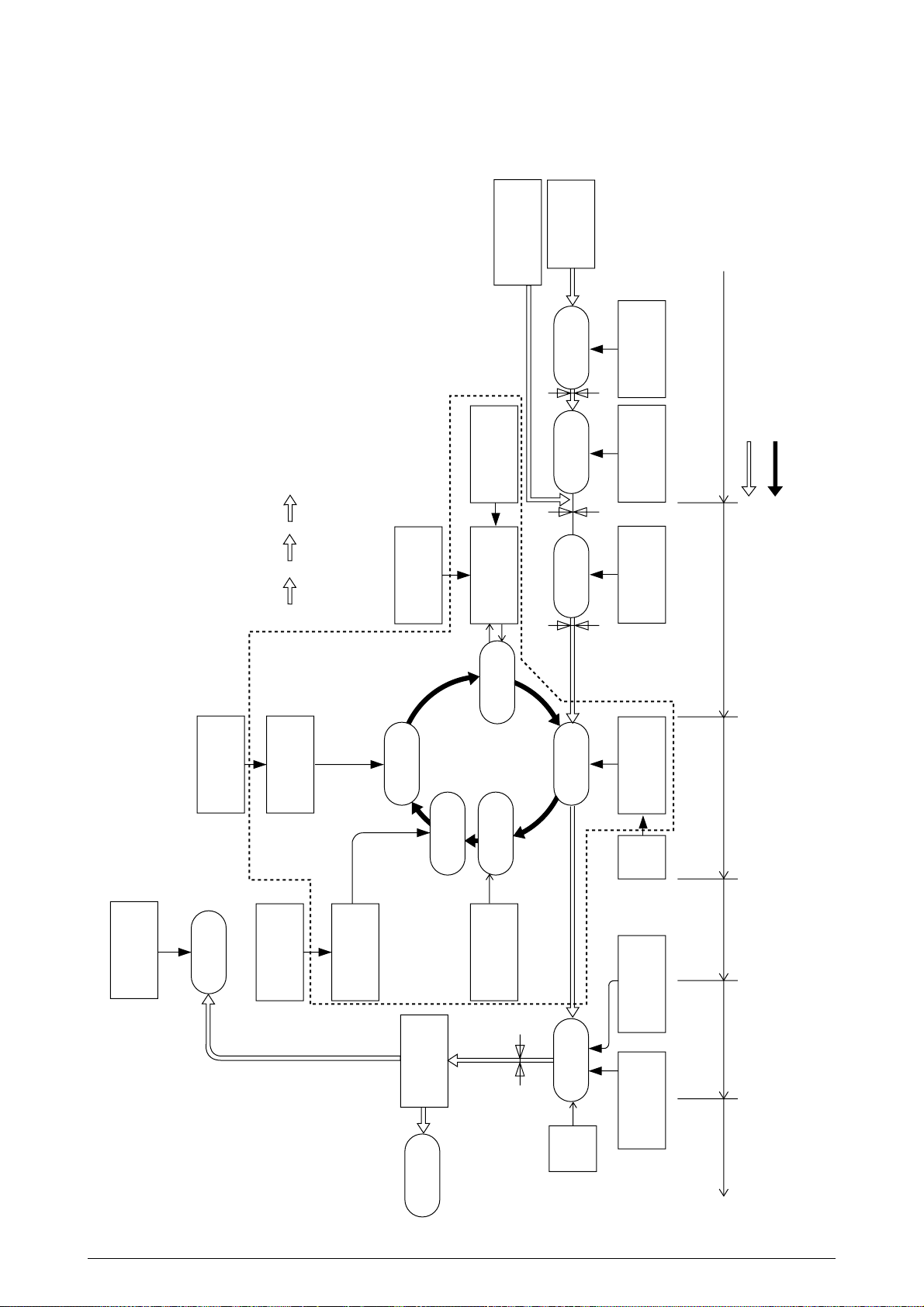

(2) Charging

Negative DC voltage is applied to the charging roller contacting the surface of the OPC drum.

Power

Unit

Charging roller

OPC drum

(3) Exposure

The negatively charged surface of the OPC drum is radiated with light from the LED head.

The negative charge of the radiated portions of the drum surface attenuates in response to

the intensity of the light and a latent electrostatic image responsive to the potentials of the

surface is formed on the drum surface.

LED head

Power

Unit

Charging roller

OPC drum

Paper

LED head

OPC drum

41388601TH Rev.2 18 /

Page 19

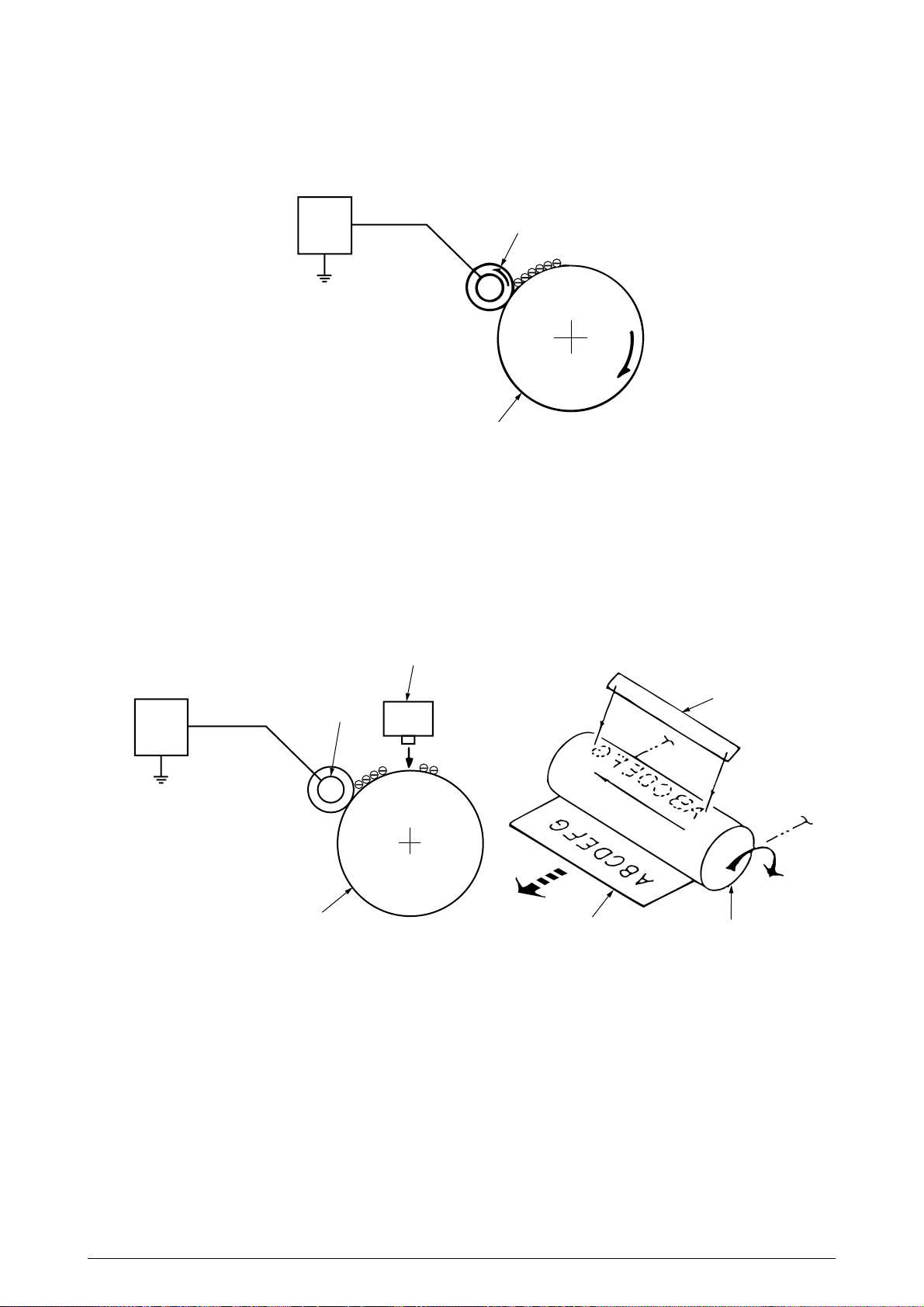

(4) Developing

By the adhesion of toner to the latent electrostatic image on the drum surface, the image is

changed to a toner image. The developing is processed at the contact part between the OPC

drum and the developing roller.

1 The sponge roller causes toner to adhere to the developing roller. The toner becomes

negatively charged.

Developing roller

Charging roller

OPC drum

Developing blade

Sponge roller

Developing roller

2 The developing blade removes excess toner from the developing roller and a thin layer

of remaining toner is formed on the developing roller.

3 The toner is drawn by the latent electrostatic image at the contact portion between the

OPC drum and the developing roller.

The latent electrostatic image on the drum surface is made visible with the toner.

(5) Transferring

The transfer roller, which is made of conductive sponge, presses paper against the surface

of the OPC drum and brings the paper into intimate contact with the drum surface.

The paper is placed on the drum surface and positively (opposite to the charge of the toner)

charged by the transfer roller on its back.

Applying positive high voltage from the power supply to the transfer roller moves the positive

charge induced by the transfer roller to the paper surface at the contact portion between the

transfer roller and the paper, the paper surface drawing the negatively charged toner from the

drum surface.

OPC drum

Paper

Carrier belt

Transfer roller

Power unit

41388601TH Rev.2 19 /

Page 20

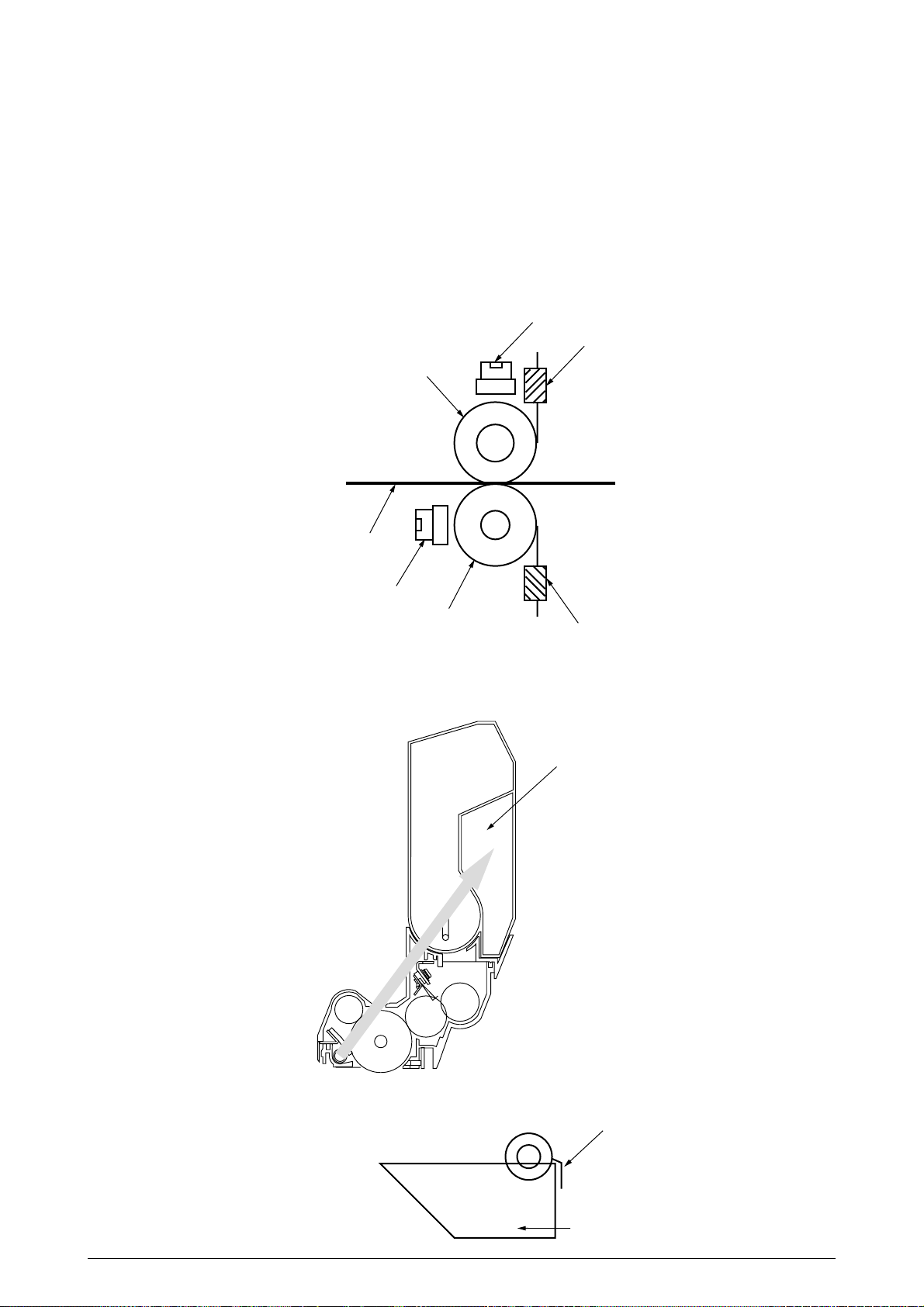

(6) Fusing

When passed between the heat roller and the backup roller, the toner image transferred to

the paper is fused into place by the application of heat and pressure to it.

The Teflon coated heat roller is heated by the built-in heat roller of 800W/backup roller of

500W (halogen lamp). The fusing temperature is controlled by the sum of the temperature

detected by the thermistor moving over the surface of the heat roller and the temperature

detected by the thermistor moving over the surface of the backup roller. A thermostat, which

is provided for safety, becomes open by a heat roller temperature rise of not less than fixed

degrees and cuts off voltage supply to the heater. The backup roller is being pressed against

the heater by the pressure springs on both sides.

Thermostat

Thermistor

Heat roller

Paper

Thermostat

Backup roller

Thermistor

(7) Cleaning

Non-fused, residual toner on the OPC drum is scraped with the cleaning blade and collected

in the waste toner area of the toner cartridge.

Waste toner area

(8) Cleaning

Residual toner on the transfer belt is scraped with the cleaning blade and collected in the

waste toner box of the transfer belt unit.

41388601TH Rev.2 20 /

Cleaning blade

Waste toner box

Page 21

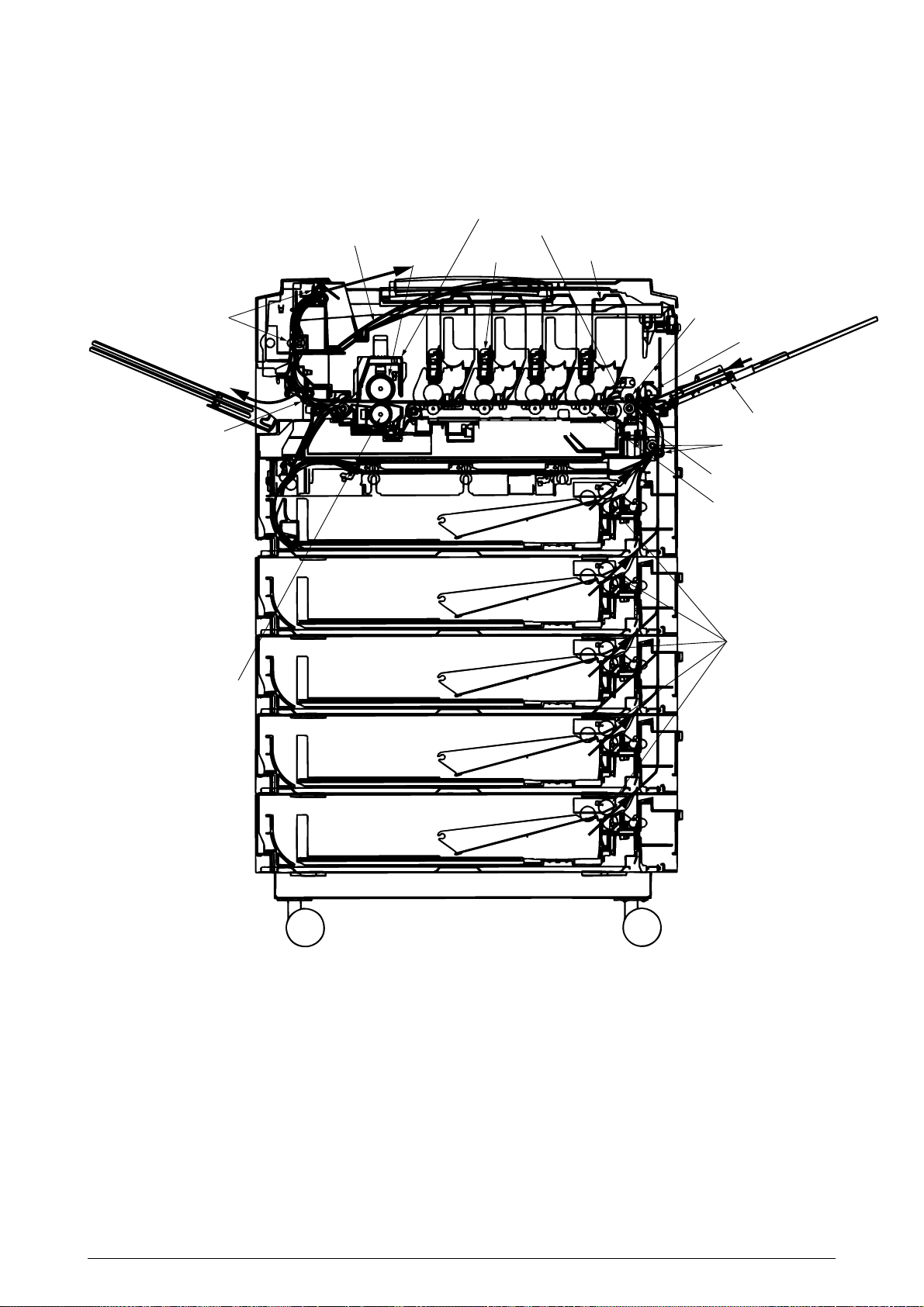

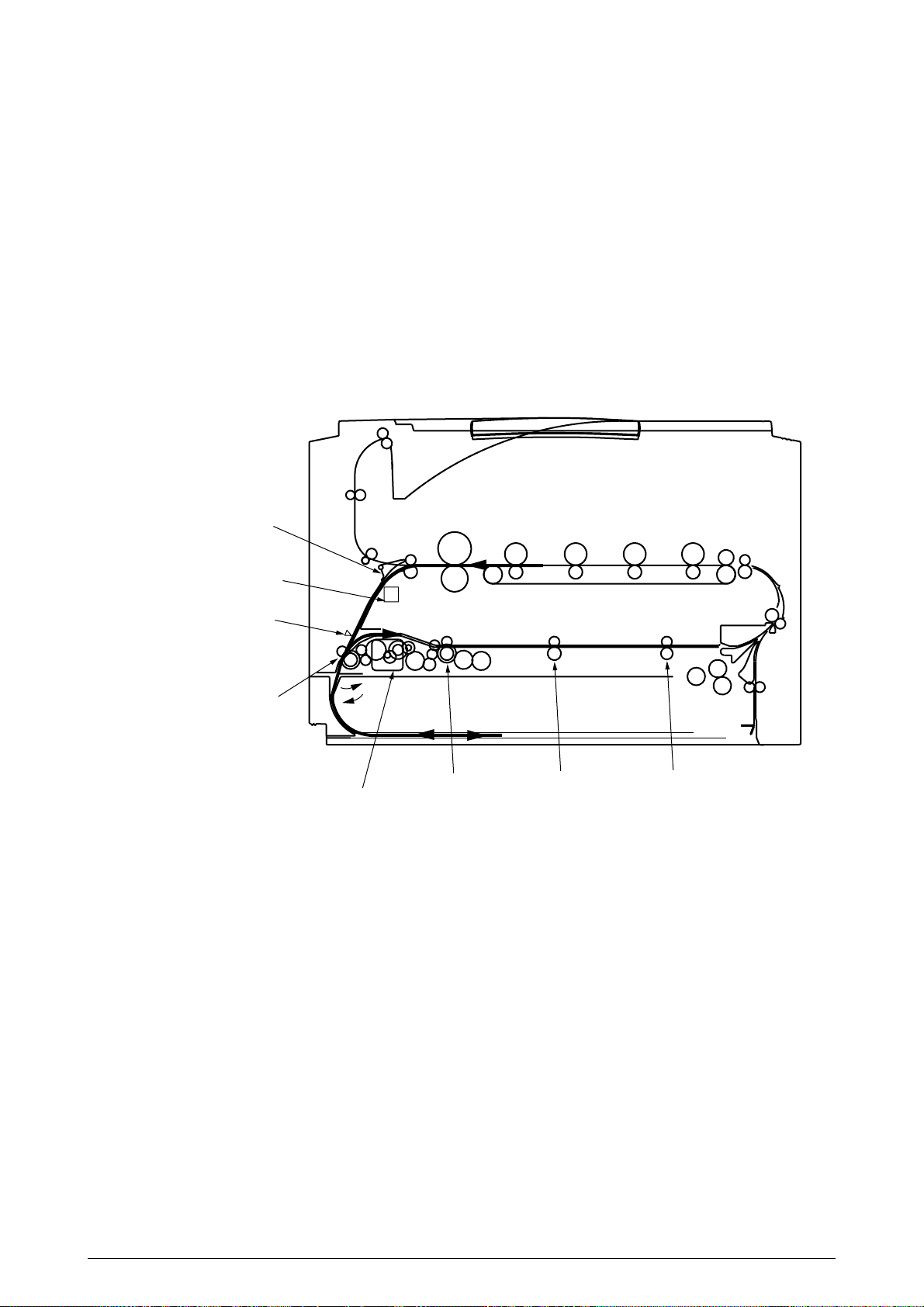

2.4.2 Paper running process

Figure 2.5 shows how paper moves in the C9000.

Face-down stacker

Heat roller

Fuser

Registration roller Assy (B)

4 x LED heads

4 x LED Units

Eject roller

Eject roller

Backup roller

Low-voltage power supply

Cassette 1

Cassette 2

Cassette 3

Cassette 4

Belt unit

High-voltage power supply

Registration roller Assy (B)

Hopping roller

Multipurpose tray

Registration roller Assy (A)

Cleaning blade

Transfer roller

Feed roller

Cassette 5

Figure 2.5 Paper Route

41388601TH Rev.2 21 /

Page 22

(1) Paper Loading from 1st Tray

1. The paper loading motor runs (CCW), the paper loading clutch is engaged and, until the

entrance cassette sensor is turned on, paper is advanced (the on/off operations of the

paper loading clutch control the pickup roller).

2. After the paper turns the entrance cassette sensor on, the paper is forwarded a further

fixed length and touches the registration roller Assy (A) (this corrects paper skew).

3. The electromagnetic clutch is engaged and the paper is carried onto the carrier belt.

Pickup roller

Registration roller Assy (B)

Entrance belt sensor

Feed roller

Electromagnetic clutch

Registration motor

Entrance sensor

Electromagnetic clutch

Entrance cassette sensor

Registration roller Assy (A)

Loading sensor

Paper

Retard roller

Loading motor

Figure 2.6

41388601TH Rev.2 22 /

Page 23

(2) Paper Loading from Option Tray

1. The paper loading motor runs (CW), the paper loading clutch is engaged and, until the

carrier sensor on a tray which sits atop a loading tray is turned on, paper is advanced.

2. After the paper turns the carrier sensor on, the paper is forwarded a further fixed length

and touches the carrier roller (this corrects paper skew).

3. The carrier clutch is thrown in and the paper is fed into the main body.

Pinch roller

Carrier roller

Carrier clutch

Carrier sensor

Upper tray

Optional paper loading tray

Pickup roller

Feed roller

Planet gear

Paper loading clutch

Paper loading sensor

Retard roller

Paper loading motor

Figure 2.7

41388601TH Rev.2 23 /

Page 24

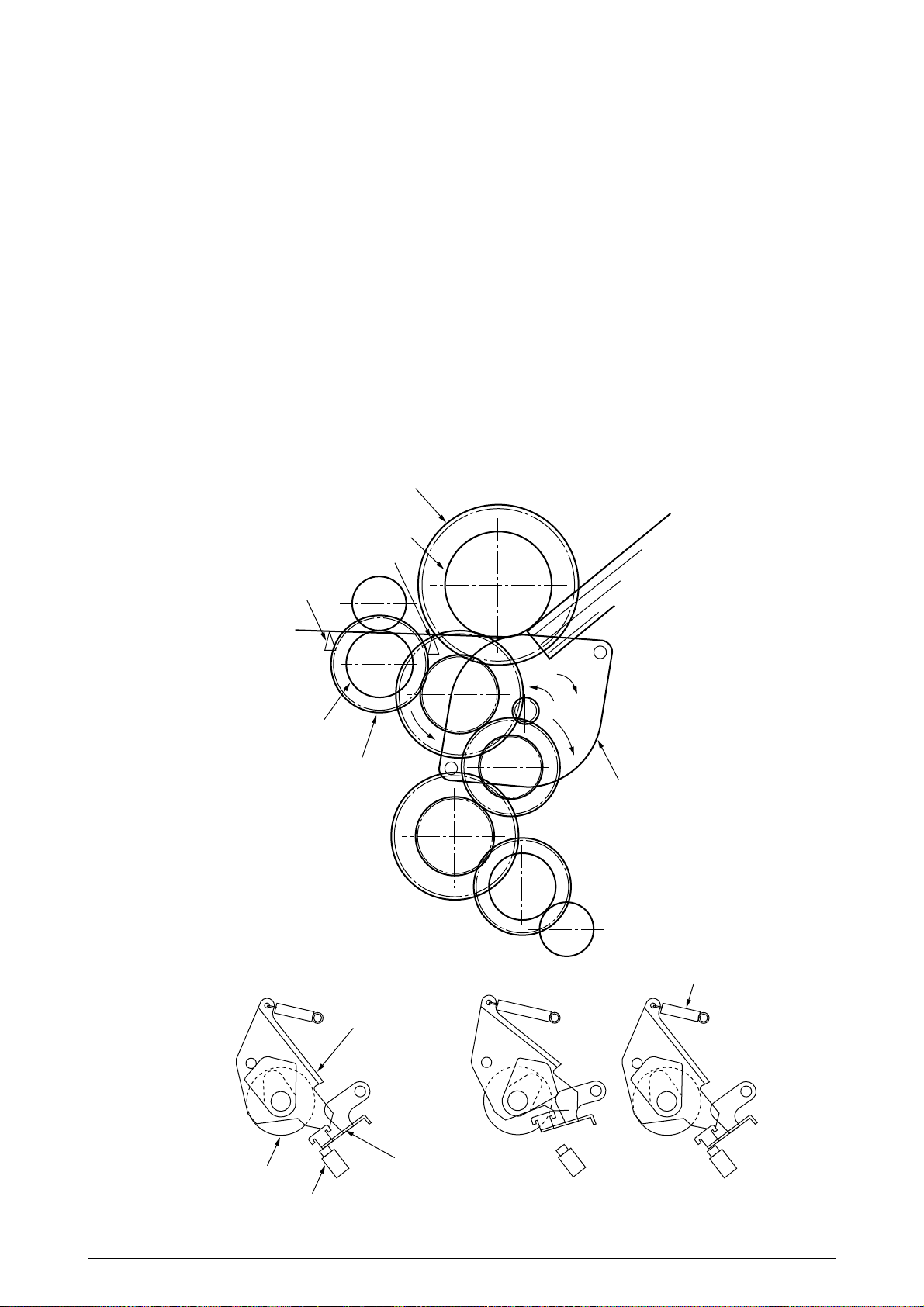

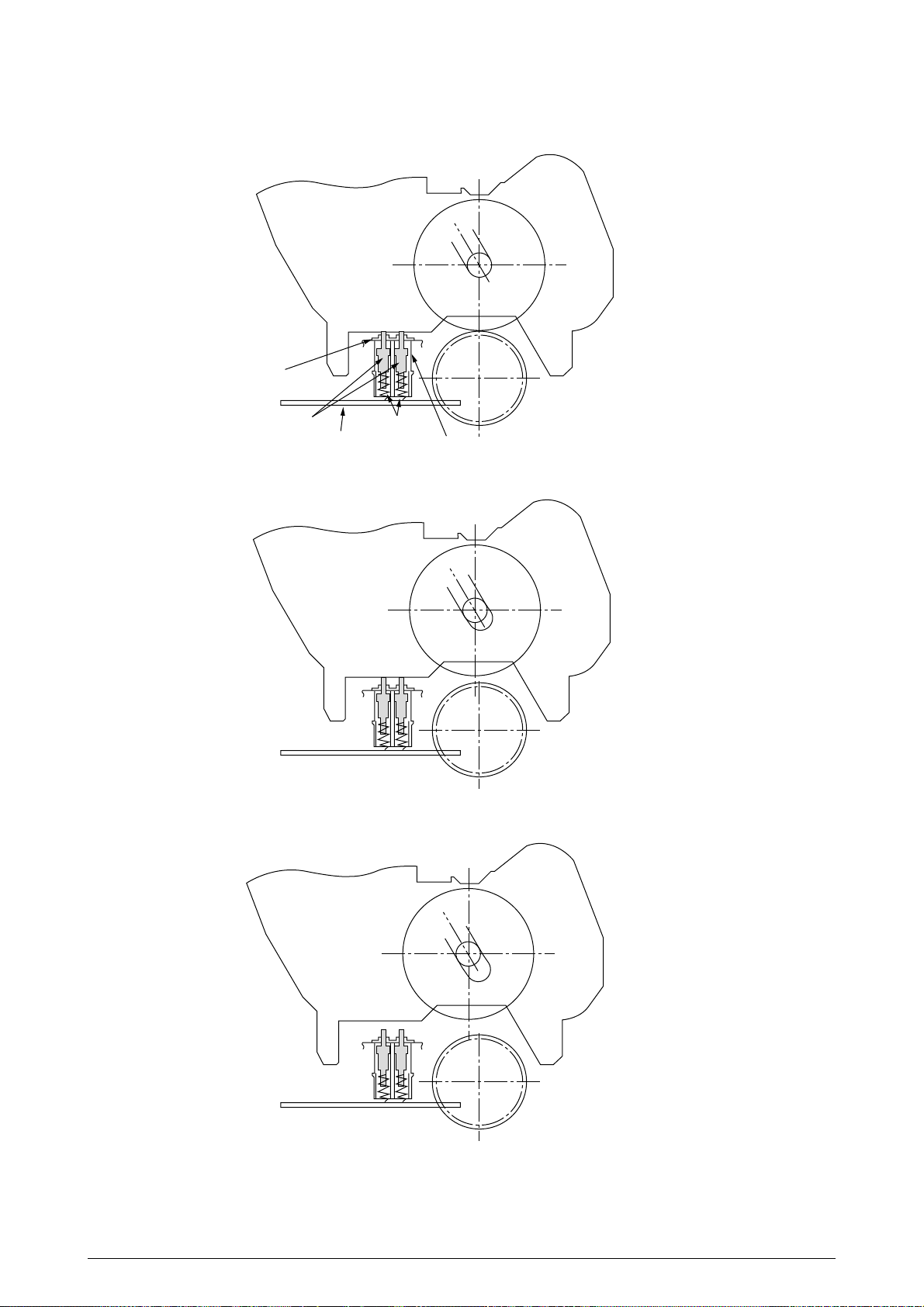

(3) Paper Loading from Multipurpose Tray (MT)

1. The release lever usually pushes down the hopping plate to a position to turn the micro

SW on (Figure 2.8-a).

2. The running of the motor in the (a) direction drives the MT feed roller, causing the cam to

turn. The cam pushes the release lever and the hopping plate picks up paper sent out by

the MT feed roller (Figure 2.8-b), where the registration roller Assy (B) does not move as

its one-way clutch gear (1) idles.

3. After the front edge of the paper turns the entrance sensor on, the paper is forwarded a

fixed length. The paper stops when its front edge reaches the registration roller Assy (B).

4. Concurrently, the cam pushes down the hopping plate. The release lever that has been

placed in its original position by the spring locks the hopping plate (Figure 2.8-c).

5. After the completion of the paper feed operation, the registration motor runs in the direction

of the arrow (b) to drive the registration roller Assy (B), where the one-way clutch gear does

not allow the MT feed roller to move.

Oneway clutch gear (2)

MT feed roller

Entrance sensor

Entrance belt sensor

Paper

Registration roller Assy(B)

Oneway clutch gear (1)

Relerse lever

Figure 2.8

b

a

Registration motor

Spring

Feed roller

Micro SW

Figure 2.8-a Figure 2.8-b Figure 2.8-c

41388601TH Rev.2 24 /

Hopper plate

Page 25

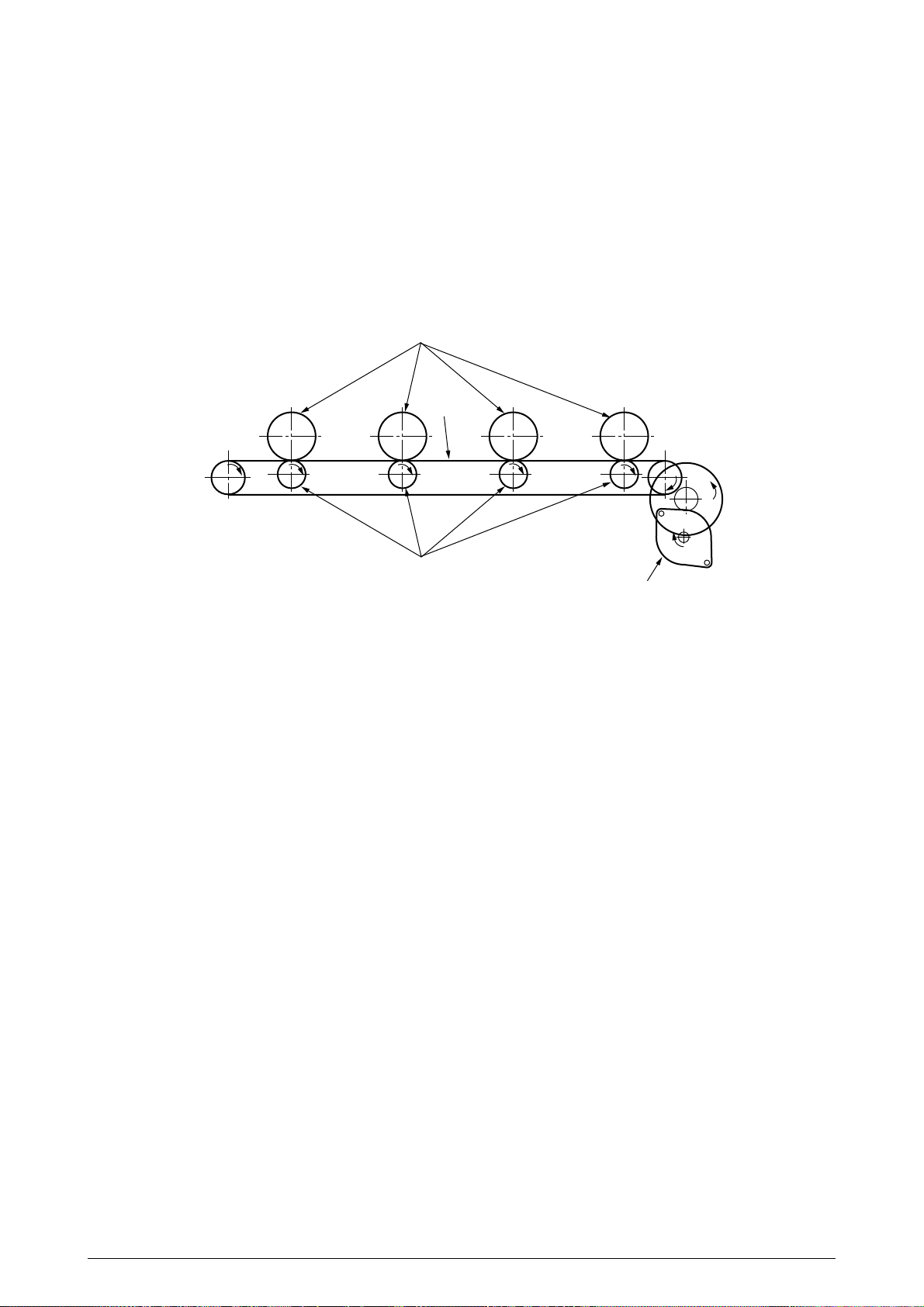

(4) Carrier Belt

1. The running of the carrier belt motor in the direction of the arrow (a) drives the carrier belt.

The belt unit sits with one carrier roller immediately below each color’s drum, and the

carrier belt between them. By the application of a fixed voltage, the carrier belt and carrier

roller feed paper on the carrier belt into the fuser unit, transferring a toner image from

each color’s drum.

Drum

Carrier belt

KYMC

Carrier (transfer) roller

Carrier (transfer) belt motor

Figure 2.9

41388601TH Rev.2 25 /

Page 26

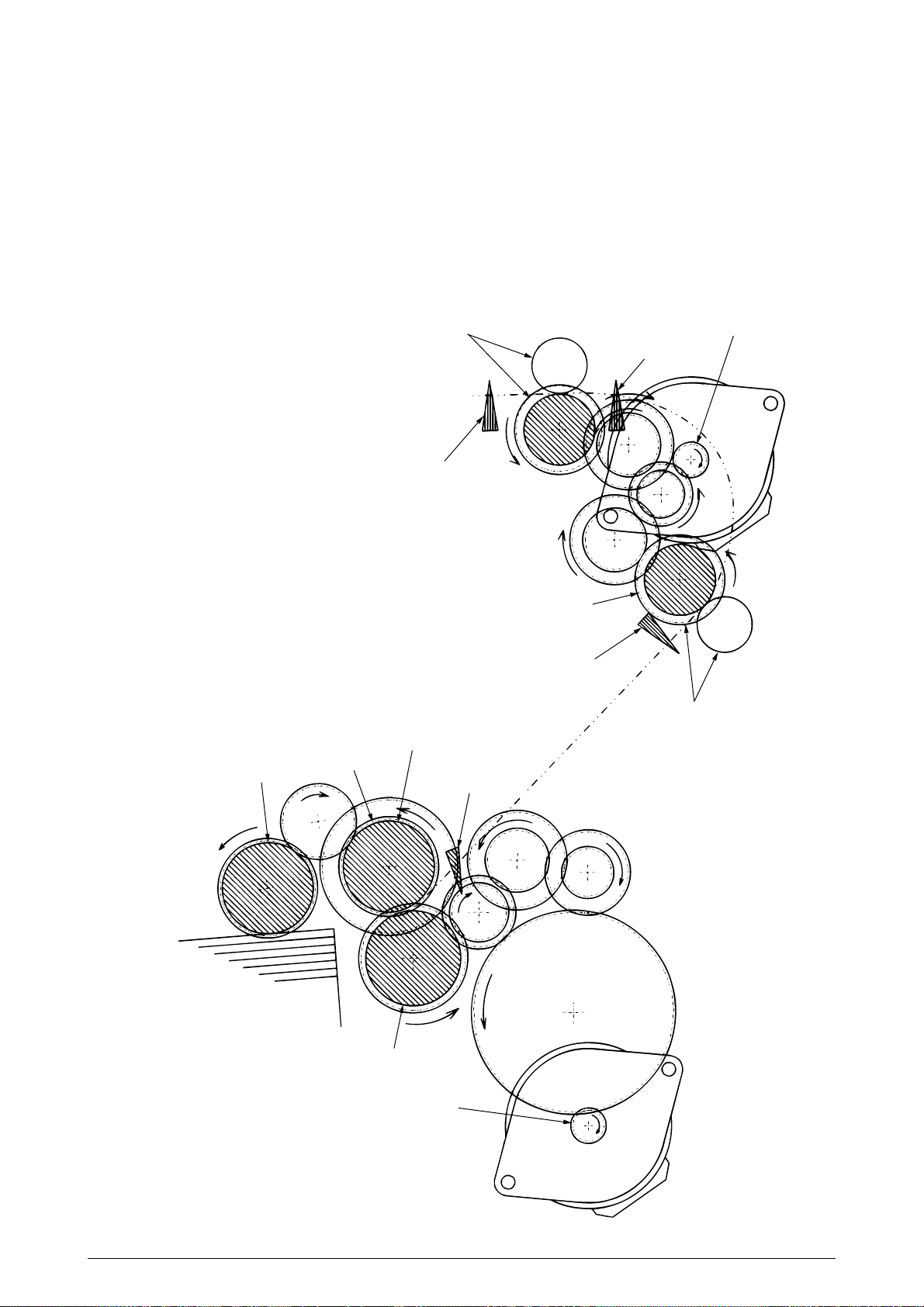

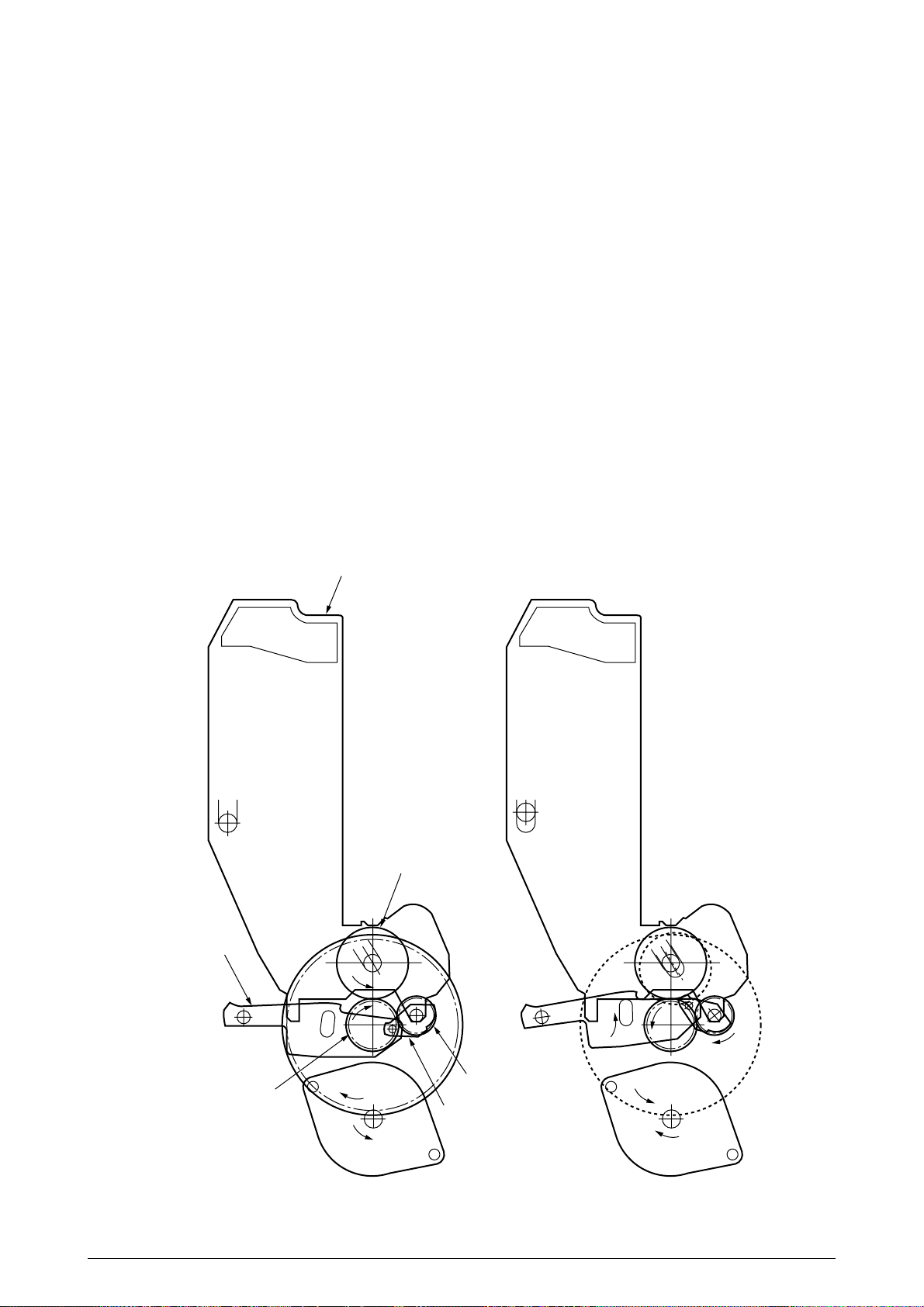

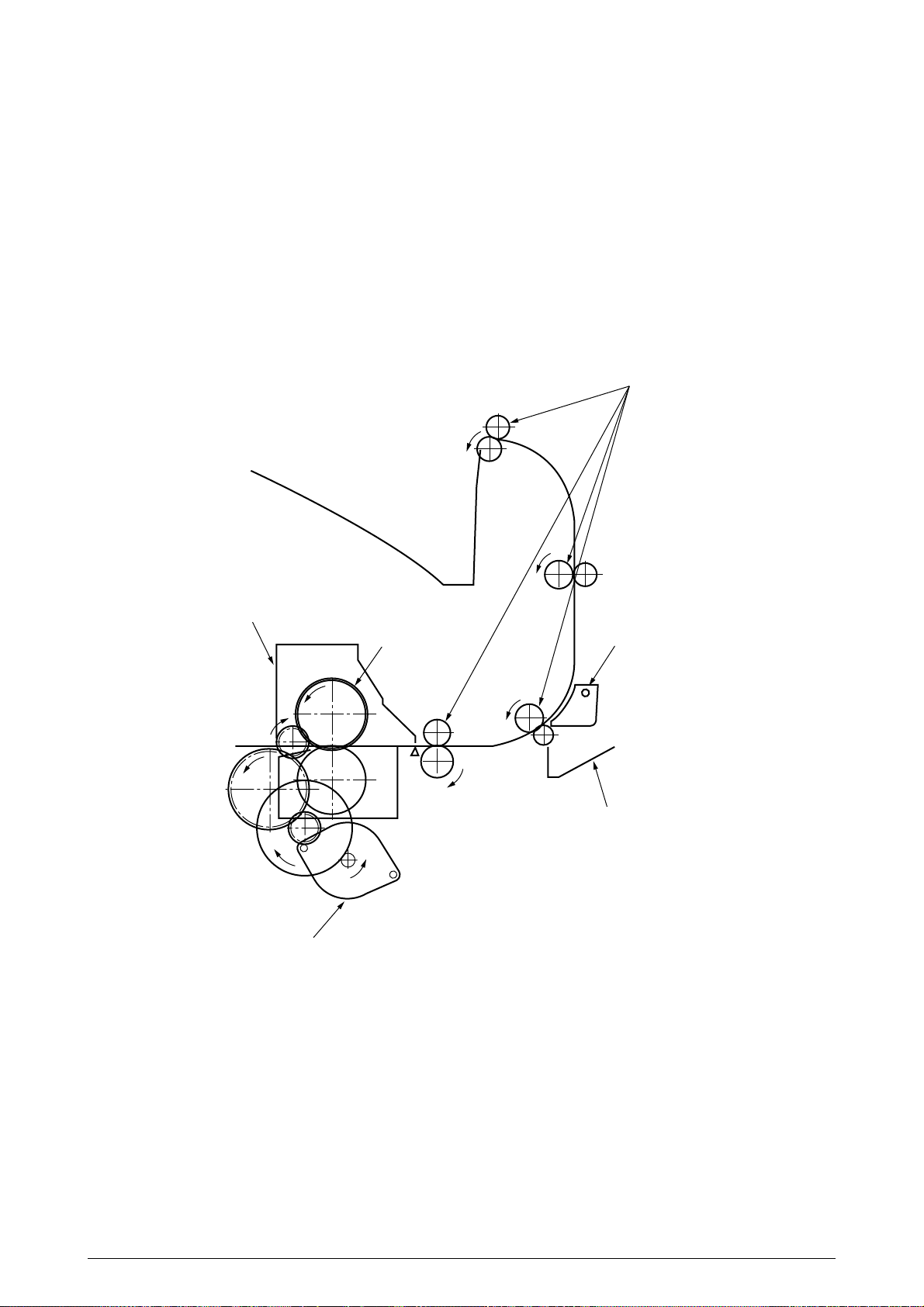

(5) Driving and Up-and-Down Movements of I/D Unit

1. The I/D unit driving and up-and-down movements are effected by a single-pulse motor.

The running of the main motor in the direction of the arrow (a) turns the lever 1 to the left.

Then, the lever 2 that was lifted by the lever 1 lowers to move down the I/D unit. After the

up-and-down sensor is turned on (Figure 2.10-c), the specified downward pulsing places

the I/D unit in its lowest position (or equivalently, printing position).

The drum gear engages with the driving gear and starts revolving to transfer an image on

the drum to running paper, where the one-way gear idles upon placement of the lever in

its lowest position.

2. With the running of the main motor in the direction of the arrow (b), the lever 1 pushes up

the I/D unit via the lever 2. After the up-and-down sensor is activated (Figure 2.10-d), the

lever 1 lifts the I/D unit to a specified level and stops to keep space to an extent between

the drum and the carrier belt (Figures 2.10-c and 2.10-e).

The drum gear is not engaged with the driving gear and does not revolve.

3. When the two pins of the up-and-down sensor are pushed up by the I/D unit, and touches

and electrically connected to the plate above the pins, the sensor recognizes the on state.

When the two pins are pushed down by the I/D unit, and separated and insulated from the

plate, the sensor recognizes the off state.

The installation of the I/D unit can also be verified by recognizing the off state of the upand-down sensor.

Lever 2

I/D unit

Drum

One-way gear

Driving gear

a

Figure 2.10-a Figure 2.10-b

41388601TH Rev.2 26 /

Lever 1

b

Page 27

Plate

Pin Spring

Board

Up-and-down Sensor

Figure 2.10-c

Figure 2.10-d

Figure 2.10-e

41388601TH Rev.2 27 /

Page 28

(6) Fuser Unit and Paper Ejection

1. A single-pulse motor drives the fuser unit and the eject rollers.

In response to the running of the heat motor in the direction of the arrow (a), the heat roller

turns. This roller fuses a toner image to paper by heat and pressure.

2. At the same time, the four eject rollers move to eject the paper.

3. The paper separator solenoid switches the path back and forth between the route to the

face-up stacker and the route to face-down stacker.

Eject rollers

Fuser unit

Fuser motor

Heat rollers

a

Paper separator

Face-up stacker

Figure 2.11

41388601TH Rev.2 28 /

Page 29

(7) Duplex Unit

1. When the duplex unit receives an instruction from the printer to print on both sides of a

sheet of paper, the solenoid opens the separator after the completion of one side printing

of a sheet of paper sent from the tray. The path is switched to that to the duplex unit.

At this time, as the roller (1) turns in the direction of the arrow “a,” the paper is retracted

on the rear of the cassette.

2. When fixed time has elapsed after the front edge of the paper passes through the duplexin sensor, the rollers reverse and the roller (1) turns in the direction of the arrow “b” to feed

the paper into the duplex unit. After that, the paper passes through the rollers (2), (3) and

(4), and ejected with the other side printed, and fed again into the printer.

Separator

Solenoid

Duplex-in sensor

Roller(1)

Motor

a

b

Roller(2)

Roller(3)

Roller(4)

Figure 2.12

41388601TH Rev.2 29 /

Page 30

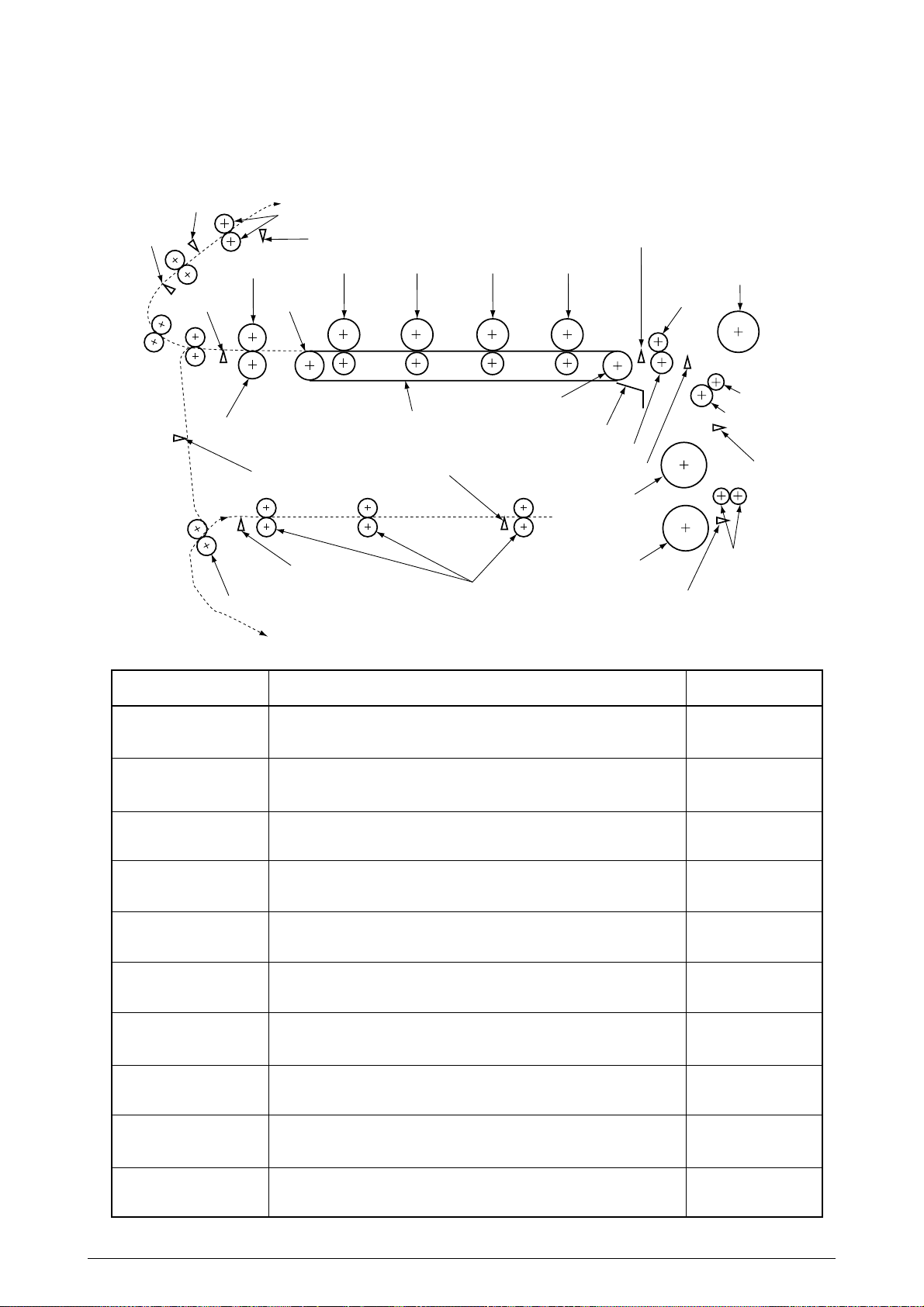

2.5 Sensor

r

2.5.1 Paper related sensors

Face-down paper eject sensor

Face-down sensor

Paper eject sensor

Backup roller

Duplex roller

Paper eject roller

Heat roller

Driving roller

Duplex-in sensor

Duplex rear sensor

Stacker full sensor

C drum

Carrier belt

Duplex front sensor

Duplex feed roller

Entrance belt sensor

K drumY drumM drum

Driving roller

Belt cleaning blade

Registration roller B

Entrance MT sensor

1st feed roller

2nd feed roller

MT feed roller

Pinch roller 2

Pinch roller 1

Registration roller A

Entrance cassette senso

Auxiliary roller

Carrier sensor

Sensor

Entrance MT Sensor

Entrance Cassette sensor

Entrance Belt sensor

Detects the beginning of incoming paper to determine the timing for

switching from hopping to carriage.

Detects the beginning of transferred paper and, based on the time taken

until the paper front edge reaches the sensor, determines the paper length.

Paper Eject sensor

Detects the beginning and end of paper to determine the paper ejection

timing.

Duplex-In sensor

Detects the beginning of paper which enters into the duplex unit to

determine the time taken until the reversed rollers turn in forward direction.

Duplex Rear sensor

Detects the beginning of paper after the turns in reverse direction, in the

duplex unit.

Duplex Front sensor

Detects the end of paper after the turns in reverse direction to determine

the paper ejection timing, in the duplex unit.

Stacker Full sensor

Face-Down Paper Eject

sensor

Face-Down Route sensor

Detects the face-down stacker full of paper.

Detects paper carriage to the paper eject roller to determine the timing for

job offset operation.

Detects the face-down carrier route jammed with paper when it has a

paper jam.

Function

Sensor status

ON

: Paper exists.

OFF

: Paper is empty.

ON

: Paper exists.

OFF

: Paper is empty.

ON

: Paper exists.

OFF

: Paper is empty.

ON

: Paper exists.

OFF

: Paper is empty.

ON

: Paper exists.

OFF

: Paper is empty.

ON

: Paper exists.

OFF

: Paper is empty.

ON

: Stacker is full.

OFF

: Stacker is empty.

ON

: Stacker is full.

OFF

: Stacker is empty.

ON

: Stacker is full.

OFF

: Stacker is empty.

Carrier sensor

41388601TH Rev.2 30 /

Detects paper carriage from the option tray.

ON

: Stacker is full.

OFF

: Stacker is empty.

Page 31

2.5.2 Other sensors

1 Paper Empty sensor

This sensor checks whether the paper cassette is empty.

2 Paper Near sensor

This sensor checks whether the paper cassette is near empty.

3 MPF Paper Empty sensor

This sensor checks whether the front feeder has paper.

4 MPF Hopping switch

This microswitch checks whether the front feeder table is in the up position or in the down

position.

5 Stacker Full sensor

This sensor checks whether the stacker is full.

6 Paper Size switch

This sensor detects the size of paper in the paper cassette.

7 EP Up/Down sensor (one for each of colors, Y, M, C and K)

This sensor checks whether the I/D unit is in the up position or in the down position.

8 Toner K, Y, M and C sensors

By measuring the time interval between regular opening movements of each sensor’s lever,

the sensor checks whether its toner cartridge is empty.

9 Temperature sensor

See Section 2.6 (Transfer Control Responds to Environmental Changes)

0 Humidity sensor

See Section 2.6 (Transfer Control Responds to Environmental Changes)

A OHP sensor

This sensor detects the presence or the absence of transparencies.

B Alignment sensor

When color misalignment has been corrected, this sensor reads the alignment pattern printed

at the right and left ends of the transfer belt (see Section 2.13).

41388601TH Rev.2 31 /

Page 32

2.6 Color Misalignment Correction

C9000 is equipped with multiple LED heads, which can result in color misalignment.

The mechanically induced color misalignment is automatically corrected as follows:

(1) Color alignment to be corrected

1 Color misalignment in X-axis direction (Positional error caused by LED head)

2 Color misalignment in slanting direction (Positional error caused by LED head)

3 Color misalignment in Y-axis direction (Positional error caused by I/D unit and LED head)

(2) Correcting

Printing the preset color misalignment detection pattern on the belt and, by a reflection

sensor, reading the printed pattern detects each color’s misalignment value to determine its

correction value. The correction value is used to change each color’s (Cyan, Magenta and

Yellow) writing timing in comparison with that of Black.

2.7 Transfer Control Responds to Environmental Changes (Room Temperatures and

Relative Humidities)

C9000 measures room temperature and relative humidity using a room temperature sensor and

humidity sensor, and calculates an optimum transfer voltage under its measurement environment

to perform real-time control on printing with the optimum voltage.

41388601TH Rev.2 32 /

Page 33

2.8 Paper Jam Detection

C9000 detects paper jams after power-on and during printing. When a paper jam occurs, the

printer immediately suspends the printing operation. Opening the cover to remove the jammed

paper and closing it resumes the printing.

LCD Error Code

400

372

390

5-395

4-394

3-393

2-392

1-391

370

383

371

382

381

380

490

5-495

4-494

3-493

2-492

1-491

Error

Paper Size Error

The entrance cassette sensor does not turn off within fixed time

after it turns on. Loading of plural sheets of paper is sensed.

Misfeed from Duplex Carrier Assembly

Misfeed from Multipurpose Tray (MT)

Paper could not be loaded from the duplex carrier assembly.

Paper could not be loaded from the MT (the entrance MT

sensor does not turn on within fixed time after the hopping).

Misfeed from Cassette 1, 2, 3, 4 or 5

Paper could not be loaded from the cassette 1, 2, 3, 4 or 5 (the

entrance cassette sensor does not turn on within fixed time after

the hopping).

Duplex Paper Jam in Reversing

The duplex rear sensor does not turn on during the paper

reversing operation of the duplex unit.

Duplex Unit Entrance Paper Jam

The duplex-in sensor does not turn on during the paper loading

in the duplex unit.

Duplex Unit Input Paper Jam

Paper Ejection Jam

The duplex front sensor does not turn on during the operation.

The paper eject sensor does not detect the end of paper within

fixed time after sensing the beginning of it. The paper eject

sensor does not turn off after it turns on.

Paper Carriage Jam

The paper eject sensor does not turn on while paper is running

on the belt.

Loading Jam

Paper does not reach the entrance belt sensor or the MT sensor

after the completion of the hopping.

MT Paper Empty

Cassette 1, 2, 3, 4 or 5 Paper Empty

Printing occurs with no paper in the MT.

The cassette 1, 2, 3, 4 or 5 has no paper.

Description

Duplex-in sensor

Duplex Rear Sensor

Paper Ejection

Paper eject sensor

Duplex Entry

Duplex rear sensor

Entrance belt sensor

Paper Carriage

Duplex Input

Duplex front sensor

Entrance MT sensor

Cassette

Cassette

Cassette

Cassette

Cassette

1

2

3

4

5

Paper Ejection

Misfeed from MT

Entrance cassette sensor

Multipurpose T ray

(MT)

Misfeed from Duplex Unit

Misfeed from Cassette 1

Misfeed from Cassette 2

Misfeed from Cassette 3

Misfeed from Cassette 4

Misfeed from Cassette 5

41388601TH Rev.2 33 /

Page 34

2.9 Cover Opening

When the top cover of the printer is open, the cover open microswitch turns opens to cut off the highvoltage power supply, and outputs which are not less than 32V. At the same time, the CPU receives

CVOPN signals indicating the status of the microswitch and performs cover open operations.

Detection

Circuit

CPU

66577

P10, 5

P7, 6

71K-PCB

Top cover microswitch

+32V

COVOPN (2P)

High-voltage power supply board

HVOLT (16P)

detect

circuit

High-voltage power supply unit

detect

circuit

+32V

FCOVER(3P)

Duplex (16P)

Front cover

microswitch

+32V

Duplex unit

V71-PCB

41388601TH Rev.2 34 /

Page 35

2.10 Toner Low Detection

• Structure

This device consists of the stirring gear which revolves at a constant speed, the stirring bar, and

the magnet on the stirring bar. The stirring bar turns in synchronization with the protrusion of

the stirring gear.

Stirring gear

Link

Stirring bar

• Detection

A toner low condition is detected by measuring the contact time between the sensor lever magnet

and the stirring bar.

Toner low sensor

Sensor lever A

Toner Full Condition

• The stirring bar turns in synchronization with the

stirring gear.

Sensor lever B

• Since the opposite side is in toner, the stirring bar

turns by the force of the stirring gear even when

the stirring magnet is placed in its highest position.

Toner cartridge

Stirring bar

Toner Low Condition

• The stirring bar reaches its highest position, then

Sensor lever A

Toner low sensor

falls to its lowest position under its own weight

because of the absence of toner resistance on the

opposite side. In this situation, bar-magnet contact time becomes long. By measuring the time,

a toner low condition can be detected.

41388601TH Rev.2 35 /

Sensor lever B

Toner cartridge

Stirring bar

Page 36

Toner Full Condition (At warming-up,A4 transverse:16ppm *1)

t1

TNRSNS

T=2.3

Toner Low Condition (At warming-up,A4 transverse:16ppm *1)

t1

t1

1.12

TNRSNS

T=2.3

t1 1.12

• When the toner low condition is detected 20 consecutive times, toner low is detected.

(The toner low message is displayed when about 1000 A4 sheets at 5% density have been printed

after toner low had been detected.)

The detection is not performed until toner low occurs after the detection of toner low.

• When the toner full condition is detected 10 consecutive times, toner low is removed.

• When the toner sensor remains unchanged for more than 15 cycles of 2.3 seconds, the toner

sensor alarm is activated.

• The toner sensor does not perform the detection while the drum motor is not running.

* 16ppm is the print speed at warm-up. T and t1 change in proportion to the print speed.

41388601TH Rev.2 36 /

Page 37

2.11 Paper Size Detection

Via the cam tied to the paper guide of the paper cassette, the four tab pieces are driven according

to the set position of the paper guide.

Upon installation of the paper cassette, the microswitch detects the condition of the tab pieces and

the paper size is recognized.

Without Cassette

A3-Nobi

Tabloid

A3

B4

Regal 14"

Regal 13"

A4 in Portrait Orientation

Letter in Portrait Orientation

Executive

B5 in Portrait Orientation

Letter in Landscape Orientation

A4 in Landscape Orientation

A5

B5 in Landscape Orientation

A6

PSZSW1

0

0

1

1

0

0

0

1

1

1

1

1

0

0

1

0

PSZSW2

0

0

0

0

0

1

1

1

1

1

1

0

0

1

0

1

PSZSW3

0

1

1

0

0

0

0

1

1

0

0

1

1

1

0

1

PSZSW4

0

1

1

1

1

1

0

0

1

1

0

0

0

0

0

1

41388601TH Rev.2 37 /

Page 38

2.12 Operation at Power-on

2.12.1 Self-diagnostic test

(1) Initial test

The following checks are automatically performed at power-on.

(a)ROM check

(b)RAM check

(c) EEPROM check

(d)Flash ROM check

(2) ROM check

The ROM is checked by calculating a HASH value.

(3) RAM check

(a)Checking is conducted by RAM type. Out-of-specification RAM is judged as an error.

(b)The order of mounted RAMs is checked. Out-of-standard RAM is judged as an error.

(c) The RAM in each slot is checked by read-after-write operation.

(4) EEPROM Check

Specific data stored at the fixed EEPROM address is checked.

(5) Flash ROM Check

The flash ROM format is checked. Unformatted ROM is formatted after the read-after-write

checking.

(6) Option Unit Check

Checking whether the option units (including a HDD, NIC, option trays and the duplex unit)

are equipped with the printer is performed.

41388601TH Rev.2 38 /

Page 39

2.13 Color Misalignment Detection

Reflection-type optical sensors (Z71-PCB) are mounted at the right and left ends of the belt,

respectively, in front of the toner scraping (cleaning) blade which is at the back of the belt unit. The

color misalignment detection pattern is printed on the belt at the right and left ends each and, by

reading the patterns by the reflection-type optical sensors, the misalignment amounts are

measured with respect to Black to determine correction values. Then, the misalignment in mainscanning, sub-scanning and slanting directions is corrected.

These operations are performed at power-on, at cover-close and every 400 pages.

CMYK

ID

CMYK

Transfer

belt

LED head

Belt running direction

Color alignment sensors L and R

Transfer Belt

Color alignment sensor R

Belt running direction

Color alignment sensor L

(Bottom View)

Cleaning blade

Cleaning blade

41388601TH Rev.2 39 /

Page 40

2.14 Version Read of Periodically Replaced Units

The condition (new or used) of the I/D, fuser unit and belt unit are determined by an internal fuse

within the units. When the unit is powered on or the upper cover is opened and closed, the

printer scans for consumables fuses. If a conducting fuse is found, that unit's counter is reset

and the fuse is opened. The life counters of the consumables are checked at each power on

and each closing of the upper cover. Once a fuse is opened the consumable is judged used.

2.15 Life Counter for Replaceable Units

Each life of the periodically replaced units - I/D, fuse unit and belt unit is counted as shown in the

following table:

Unit Name

I/D

Toner Cartridge

Belt Unit

Fuser Unit

The number of drum revolutions is counted in the unit of letter

paper length + paper interval in continuous printing.

End of Life: Time when a distance equivalent to pages of 26K is

printed (on 3P/J).

The number of dots printed is counted. The used amount is

determined based on the counter value (See Section 2.16).

End of Life: Time when a toner-low error occurs.

The number of turns revolutions is counted in the unit of letter

paper length + paper interval in continuous printing.

End of Life: Time when the counter value reaches 80K.

One is counted every time when one page is passed.

End of Life: Time when the counter value reaches 80K.

2.16 Toner Consumption Detection

The used toner amount is detected by counting the number of dots printed.

The counting starts after toner-low is released. The sum of the counted values is stored in

EEPROM. When toner-low is detected, the amount used is forcedly set to 7%.

When the equivalent of pages of 1K on A4 and 5% duty is reached after that, toner-empty is

detected.

Condition

Action

Warning (the unit can still be used).

Do not use the unit anymore.

Warning (the unit can still be used).

Warning (the unit can still be used).

41388601TH Rev.2 40 /

Page 41

3. PARTS REPLACEMENT

This section describes the procedure for replacing the parts, assemblies and units in the field. The

replacing procedure is given for detachment. To attach, use the reverse procedure.

3.1 Precautions in Replacing Parts

(1) Before replacing the parts, be sure to remove the AC cable and the interface cable.

(a) To remove the AC cable, always use the following procedure.

1 Flip the power switch of the printer off (to “O”).

2 Pull the AC inlet plug of the AC cable out of the AC receptable.

3 Remove the AC cable and the interface cable from the printer.

(b) To connect the printer again, always use the following procedure.

1 Connect the AC cable and the interface cable to the printer.

2 Insert the AC inlet plug into the AC receptacle.

3 Flip the power switch of the printer on (to “I”).

Disconnect

(2) Do not disassemble the printer so long as it operates properly.

(3) Minimize the disassembly. Do not detach parts other than those shown in the replacing

(4) For maintenance applications, use designated tools.

(5) Follow the order instructed to disassemble the printer. Incorrect order may damage the

(6) Small parts such as screws and collars tend to get lost, so temporarily replace them in

(7) When handling ICs and circuit boards such as microprocessors, ROMs and RAMs, do not

(8) Do not place the printed circuit boards directly on the printer or the floor.

Connect

procedure.

parts.

their original positions.

use gloves that are likely to have static.

41388601TH Rev.2 41 /

Page 42

[Maintenance Tools]

Table 3-1 lists tools necessary to replace the units.

Table 3-1 Maintenance Tools

No.

1

2

3

4

5

6

7 1

8

9

No. 1-100 Philips

screwdriver

No. 2-200 Philips

screwdriver, Magnetized

No. 3-100 screwdriver

No. 5-200 screwdriver

Digital multimeter

Pliers

Handy cleaner

LED Head cleaner

P/N 4PB4083-2248P001

High voltage probe

Q' ty Place of use RemarksService Tools

1

2~2.5 mm screws

1

3~5 mm screws

1

1

1

1

1

Cleans LED head

1

41388601TH Rev.2 42 /

Page 43

3.2 Parts Layout

Figure 3.1

41388601TH Rev.2 43 /

Page 44

[Top Cover Assy]

Figure 3.2

41388601TH Rev.2 44 /

Page 45

[Printer Unit-1/2]

Figure 3.3

41388601TH Rev.2 45 /

Page 46

[Printer Unit-2/2]

Figure 3.4

41388601TH Rev.2 46 /

Page 47

[Cassette Guide Assy (L), (R)]

Figure 3.5

41388601TH Rev.2 47 /

Page 48

41388601TH Rev.2 48 /

Page 49

[Duplex Unit]

D

C

B

A

D

C

E

B

E

A

Figure 3.6

41388601TH Rev.2 49 /

Page 50

3.3 Replacing Parts

This section describes how to replace the parts and assemblies illustrated below.

41531301 41515110

Print Engine Controller PWB (3.3.22)

41502304 × 4

LED Assy (3.3.2)

40737401

Power-Unit AC-DC Switching (115V) (3.3.34)

40737501

Power-Unit AC-DC Switching (230V) (3.3.34)

40737601

HV Power Supply (3.3.35)

41531402, 41531404

Fuser Unit (3.3.37)

41531502

Belt Unit (3.3.38)

41178202

Duplex Unit (3.3.39)

41480901

Printer NIP

41483001

Printer Unit

41481001

Unit-Lower-Frame (3.3.36)

41500101

Insurator

41483701

Main Cooling Fan Assy (3.3.18)

2381018P0001

HV Tape Harness

41484101

Electrical Chassis (3.3.21)

41483801

Main Motor Assy (3.3.32)

41483902

Belt Motor Assy (3.3.30)

41489001

Plate Assy-Side (3.3.33)

41493002

Multipurpose Tray (3.3.13)

41276502

Rear Cover (3.3.12)

41277402

Left Side Cover (3.3.9)

41481202

Right Side Cover (3.3.7)

41276402

Front Cover (3.3.11)

41277502

Face Up Tray (3.3.10)

41504401

Top Cover

41484402

Top cover (3.3.1)

40866212

Control panel Bezel (3.3.4)

41493002

Multipurpose Tray Assy (3.3.13)

41484902

Cassette Assy (3.3.7)

41277902

Cover-Blind (3.3.7)

41481701

Feed-Roller (3.3.8)

40863801

Plate-Side (3.3.21)

41483102

Printer Chassis (3.3.23)

41483202

Regist Roller Assy (A) (3.3.15)

41483301

Regist Roller Assy (B) (3.3.16)

41483401

Registration Motor Assy (3.3.17)

41187101

Registration Clutch (3.3.17)

41486601

Duplex Guide Assy (3.3.20)

41481301

Main Feed Assy (3.3.36)

41515801

PCE-Size Sence (3.3.36)

22011000P0140

IMSA-9714N-14A (3.3.36)

41490702

Electrical Chassis Cooling Fan

40841402

Fuser Latching Handle (R) (3.3.31)

41628301

Fuser Latching Handle Spring (3.3.31)

40850201

Contact Assy (3.3.33)

41045802 × 2

Link (3.3.13)

41486202

MT Tray Cover Assy (3.3.13)

41278002

MT Top Cover (3.3.13)

40325101

MT Drive Gear (3.3.13)

40841302

Fuser Latching Handle (L) (3.3.29)

41628301

Fuser Latching Handle Spring (3.3.29)

40841601

Entrance Sensor Actuator #1 (3.3.24)

41578501

Entrance Sensor Actuator #2 (3.3.26)

40841801

Entrance Sensor Actuator #3 (3.3.26)

41621801

Registration Shutter Solenoid Assy

41488801

Registration Shutter

41589401

Registration Shutter Spring

41641701

Fuser Driver Gear-A (3.3.27)

41095901

Fuser Exit Roller (3.3.27)

4PP4043-4489P001

Fuser Exit Roller Bushing (L) (3.3.27)

4PP4076-3949P001

Fuser Exit Roller Bushing (R) (3.3.27)

41189701 × 4

Drum Contact Assy (3.3.14)

41258301

Entrance Sensor PWB (3.3.25)

41491001

Color Registration Sensor Assy (3.3.19)

41073601

Exit Sensor Assy (3.3.28)

41483701

Main Motor FAN Assy (3.3.27)

40861001 × 8

LED Assy Spring (3.3.2)

41257902

LED Control PWB (Y71) (3.3.4)

41349801

Stack Full Sensor (3.3.4)

41349301 × 4

Eject Roller (3.3.4)

41484501

Control Panel Assy (3.3.4)

2381005P0015

Control Panel Tape Harness (3.3.4)

41514101

LED Harness K

41514102

LED Harness Y

41514103

LED Harness M

41514104

LED Harness C

41328402

Top Cover Handle (3.3.5)

41277602

Top Cover Latch (3.3.5)

40861401 × 2

Top Cover Latch Spring (3.3.5)

41484701

Eject Guide Assy (3.3.6)

41388601TH Rev.2 50 /

Page 51

3.3.1 Top cover

(1) Open the top cover Assy.

(2) Remove the nine screws 1 to detach the top cover 2.

2

1

1

1

41388601TH Rev.2 51 /

Page 52

3.3.2 LED Assy/ LED Assy spring

(1) Open the top cove 1.

(2) Remove the three cables, and unhook the LED Assy 2 at the two places to demount it (The

two springs 3 become detached together with the LED Assy 2).

(3) Detach the LED connector 4.

When assembling, attach the LED connector 4 to the LED head and insert the flat cable.

1

3

4

3

4

2

41388601TH Rev.2 52 /

Page 53

3.3.3 Top cover unit

(1) Remove the top cover (see section 3.3.1).

(2) Remove the rear cover (see section 3.3.12).

(3) Remove the front cover (see section 3.3.11).

(4) Remove the electrical chassis (see section 3.3.21).

(5) Unscrew the screws 1 and 2 to remove the limiters (F) 3 and (R) 4.

(6) Remove the inner shaft 5, then the top cover unit 8 (The inner springs 6 and 7 become

detached).

8

7

5

2

1

1

4

6

2

3

41388601TH Rev.2 53 /

Page 54

3.3.4 Control panel Assy/ Control panel bezel/ LED control PWB/ Toner sensor/ Stack full sensor/

Control panel tape harness/ Eject roller

(1) Detach the control panel bezel 1.

(2) Remove the screws 2 to demount the control panel 3.

(3) Detach the control panel tape harness 4.

(4) Remove the screws 6, unhook the connector 7 and demount the LED control PWB 8.

(5) Unscrew the screws 9 to remove the plate 0.

(6) Disengage the claw to demount the toner sensor A.

(7) Demount the stacker full sensor B.

(8) Unscrew the eject sensor bracket C, D.

1

2

6

2

7

3

9

C

D

4

8

B

A

9

0

41388601TH Rev.2 54 /

Page 55

3.3.5 Top cover handle/ Top cover latch/ Top cover latch spring

(1) Remove the two screws 1 to detach the top cover handle 2 and disengage the top cover

latch 3 (The two top cover latch springs 4 become detached).

1

1

4

3

2

4

41388601TH Rev.2 55 /

Page 56

3.3.6 Eject guide Assy

(1) Remove the seven screws 1 to detach the eject guide Assy 2.

1

2

1

1

1

41388601TH Rev.2 56 /

Page 57

3.3.7 Cassette Assy/ Blind cover/ Side cover R Assy

(1) Detach the cassette Assy 1.

(2) Disengage the blind cover 2 at the two places to detach it.

(3) Unscrew the two screws to remove the stopper 4.

(4) Disengage the claw on the left support of the side cover R to detach the side cover R.

2

1

5

4

5

5

3

5

41388601TH Rev.2 57 /

Page 58

3.3.8 Feed rollers

(1) Remove the cassette.

(2) Unlatch and demount the feed rollers 1.

1

1

1

41388601TH Rev.2 58 /

Page 59

3.3.9 Left side cover

(1) Remove the four screws 1 to detach the left side cover 2.

2

1

1

41388601TH Rev.2 59 /

Page 60

3.3.10 Face-up tray

(1) Open the face-up tray in the arrow direction and move the links 2 out of engagement (at two

places each of the links) to detach the face-up tray 1.

2

2

1

41388601TH Rev.2 60 /

Page 61

3.3.11 Front cover

(1) Open the top cover 1.

(2) Disengage the claws and remove the blind cover 2.

(3) Unscrew the six screws 4 to detach the front cover 3.

1

4

4

4

4

3

4

2

41388601TH Rev.2 61 /

Page 62

3.3.12 Rear cover

(1) Open the top cover 1,

(2) Remove the five screws 3 and 4 to detach the rear cover 2.

1

4

3

3

2

41388601TH Rev.2 62 /

Page 63

3.3.13 Multipurpose tray Assy/ Multipurpose tray cover Assy/ Links/ Multipurpose tray top cover/

Multipurpose tray drive gear

(1) Remove the rear cover (see section 3.3.12).

(2) Remove the front cover (see section 3.3.11).

(3) Unscrew the three screws 1 to detach the multipurpose tray top cover 2.

(4) Unscrew the two screws 3 and remove the connector to detach the multipurpose tray 4.

(5) Disengage 4 and 5 to detach the multipurpose tray cover Assy 5 (the links 7 become

detached).

(6) Unhook and detach the multipurpose tray drive gear 8.

1

6

3

1

5

Engagement

2

4

6

Engagement

8

3

8

5

41388601TH Rev.2 63 /

Page 64

3.3.14 Drum contact Assys

(1) Insert a flatblade screwdriver between the printer case and the drum contact Assy 1 to

demount the drum contact Assy.

1

41388601TH Rev.2 64 /

Page 65

3.3.15 Registration roller Assy (A)/ Registration drive gear (A)

(1) Remove the front cover (see section 3.3.11).

(2) Remove the rear cover (see section 3.3.12).

(3) Remove the multipurpose tray (see section 3.3.13).

(4) Unscrew the four screws 1 to demount the registration roller Assy (A) 2.

(5) Remove the E ring 3 to detach the registration gear (A) 4.

2

1

1

4

3

41388601TH Rev.2 65 /

Page 66

3.3.16 Registration roller Assy (B)

(1) Remove the cassette Assy.

(2) Remove the front cover (see section 3.3.11).

(3) Remove the rear cover (see section 3.3.12).

(4) Remove the electrical chassis (see section 3.3.21).

(5) Remove the registration clutch (see section 3.3.17).

(6) Remove the printer chassis (see section 3.3.23).

(7) Unscrew the four screws and pull out the registration Assy (B) 2 in the arrow direction.

1

2

1

1

41388601TH Rev.2 66 /

Page 67

3.3.17 Registration clutch, Registration motor Assy

(1) Remove the left side cover (see section 3.3.9).

(2) Remove the electrical chassis (see section 3.3.21).

(3) Remove the connector and the E ring 1, then screws 3 and 4, and then the earth plate 5.

(4) Remove the connector and unscrew the two screws 6 to demount the registration motor Assy

7.

7

6

3

2

5

4

6

1

41388601TH Rev.2 67 /

Page 68

3.3.18 Cooling fan

(1) Unhook the connector 1, and remove the screws 2 and the cooling fan 3.

1

3

air direction

2

41388601TH Rev.2 68 /

Page 69

3.3.19 Color registration sensor Assy

(1) Remove the two screws 1 and the three connectors to demount the color registration sensor

Assy 2.

(2) Remove the earth plate B 3.