Sony BVP-E30, BVP-E30P, BVP-E30WS, BVP-E30WSP Maintenance Manual

COLOR VIDEO CAMERA

BVP-E30

BVP-E30P

BVP-E30WS

BVP-E30WSP

MAINTENANCE MANUAL

Volume 1 1st Edition

Serial No. 100001 and Higher: BVP-E30

Serial No. 400001 and Higher: BVP-E30P

Serial No. 100001 and Higher: BVP-E30WS

Serial No. 400001 and Higher: BVP-E30WSP

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle War tungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

For the customers in the Netherlands

Voor de klanten in Nederland

Dit apparaat bevat een MnO

back-up.

Raadpleeg uw leverancier over de verwijdering van de

batterij op het moment dat u het apparaat bij einde

levensduur afdankt.

Gooi de batterij niet weg. maar lever hem in als KCA.

Bij dit produkt zijn batterijen geleverd.

Wanneer deze leeg zijn, moet u ze niet

weggooien maar inleveren als KCA.

2-Li batterij voor memory

Für Kunden in Deutschland

Entsorgungshinweis: Bitte werfen Sie nur entladene

Batterien in die Sammelboxen beim Handel oder den

Kommunen. Entladen sind Batterien in der Regel dann,

wenn das Gerät abschaltet und signalisiert “Batterie

leer” oder nach längerer Gebrauchsdauer der Batterien

“nicht mehr einwandfrei funktioniert”. Um

sicherzugehen, kleben Sie die Batteriepole z.B. mit

einem Klebestreifen ab oder geben Sie die Batterien

einzeln in einen Plastikbeutel.

BVP-E30/E30P M-V1

CAUTION

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch

der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ. Entsorgung

gebrauchter Batterien nach Angaben des

Herstellers.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du même

type ou d’un type équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées conformément

aux instructions du fabricant.

ADVARSEL

Lithiumbatteri - Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten.

Brukt batteri returneres

apparatleverandøren.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ

som rekommenderas av apparattillver karen.

Kassera använt batteri enligt gällande

föreskrifter.

VAROITUS

Paristo voi räjähtää jos se on virheellisesti

asennettu.

Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

BVP-E30/E30P M-V1

1 (P)

For the customers in Japan

For the customers in the U.S.A. and Canada

RECYCLING NICKEL-CADMIUM

BATTERIES

Nickel Cadmium batteries are

recyclable. You can help preserve our

environment by returning your unwanted

batteries to your nearest point for

collection, recycling or proper disposal.

Note: In some areas the disposal of

nickel cadmium batteries in household or business trash

may be prohibited.

RBRC (Rechargeable Battery Recycling Corporation)

advises you about spent battery collection by the

following phone number.

Call toll free number: 1-800-822-8837

(United States and Canada only)

Caution: Do not handle damaged or leaking nickelcadmium batteries.

For the customers in Japan

For the customers in the U.S.A. and Canada

RECYCLING LITHIUM-ION BATTERIES

Lithium-Ion batteries are recyclable.

You can help preserve our environment

by returning your used rechargeable

batteries to the collection and recycling

location nearest you.

For more information regarding recycling of rechargeable batteries, call toll free

1-800-822-8837, or visit http://www.rbrc.org/

Caution: Do not handle damaged or leaking Lithium-Ion

batteries.

2 (P)

BVP-E30/E30P M-V1

Table of Contents

Manual Structure

Purpose of this manual ........................................................................................ 5 (E)

Related manuals................................................................................................... 5 (E)

Contents ............................................................................................................... 6 (E)

1. Service Overview

1-1. Note on Service.....................................................................................1-1 (E)

1-1-1. Confirming the ROM Version .............................................1-1 (E)

1-1-2. Compatibility of File Data ...................................................1-1 (E)

1-1-3. Error Messages Displayed when Memory Stick is Used .....1-1 (E)

1-1-4. Note on PA-272/273/274 Boards .........................................1-1 (E)

1-1-5. Description on Backup Battery ............................................1-2 (E)

1-1-6. Description on CCD Block Number ....................................1-2 (E)

1-1-7. Notes on Spare Parts ............................................................1-2 (E)

1-1-8. Unleaded Solder...................................................................1-2 (E)

1-2. Connector Input/Output Signals............................................................1-3 (E)

1-3. Connection Connector...........................................................................1-7 (E)

1-4. Function of Internal Switches ...............................................................1-7 (E)

1-5. Remove and Installation of Exterior Parts ............................................1-9 (E)

1-6. Location of Printed Wiring Boards.......................................................1-9 (E)

1-7. Circuit Description..............................................................................1-10 (E)

1-7-1. CCD Block (PA-272/273/274 Boards, TG-229 Board,

and NR-72 Board) ..............................................................1-10 (E)

1-7-2. Video Signal System (VA-226 Board, DPR-261 Board,

and IF-969 Board) ..............................................................1-11 (E)

1-7-3. System Control (AT-148 Board)........................................1-12 (E)

1-7-4. Power Supply Block (DC-DC Converter)

(RE-201 Board) ..................................................................1-13 (E)

1-8. Diagnosis.............................................................................................1-14 (E)

1-9. Contents of the EEPROM and FRAM Data .......................................1-15 (E)

1-10. Adjustment and Setting Items After Replacement of Board...............1-16 (E)

1-10-1. CCD Unit ...........................................................................1-16 (E)

1-10-2. TG-229 Board ....................................................................1-16 (E)

1-10-3. NR-72 Board ......................................................................1-16 (E)

1-10-4. VA-226 Board ....................................................................1-16 (E)

1-10-5. DPR-261 Board ..................................................................1-16 (E)

1-10-6. AT-148 Board ....................................................................1-16 (E)

1-11. Upgrading the Software ......................................................................1-17 (E)

1-11-1. Upgrading MAIN Program ................................................1-17 (E)

1-11-2. Upgrading BOOT Program ................................................1-17 (E)

1-12. Setting Scene File Number..................................................................1-18 (E)

1-13. Removing and Reinstalling the Flexible Card Wires..........................1-19 (E)

BVP-E30/E30P M-V1

1 (E)

1-14. How to Extend the Circuit Board........................................................ 1-20 (E)

1-14-1. Extending the DPR-261 Board...........................................1-20 (E)

1-14-2. Extending the DC-DC Converter .......................................1-20 (E)

1-14-3. Extending the CCD Block..................................................1-21 (E)

1-15. Inspection and Maintenance................................................................1-22 (E)

1-15-1. Recommended Replacement Parts .....................................1-22 (E)

1-15-2. Cares after Using under Special Environment ...................1-24 (E)

1-15-3. Fixtures...............................................................................1-25 (E)

2. Replacement of Main Parts

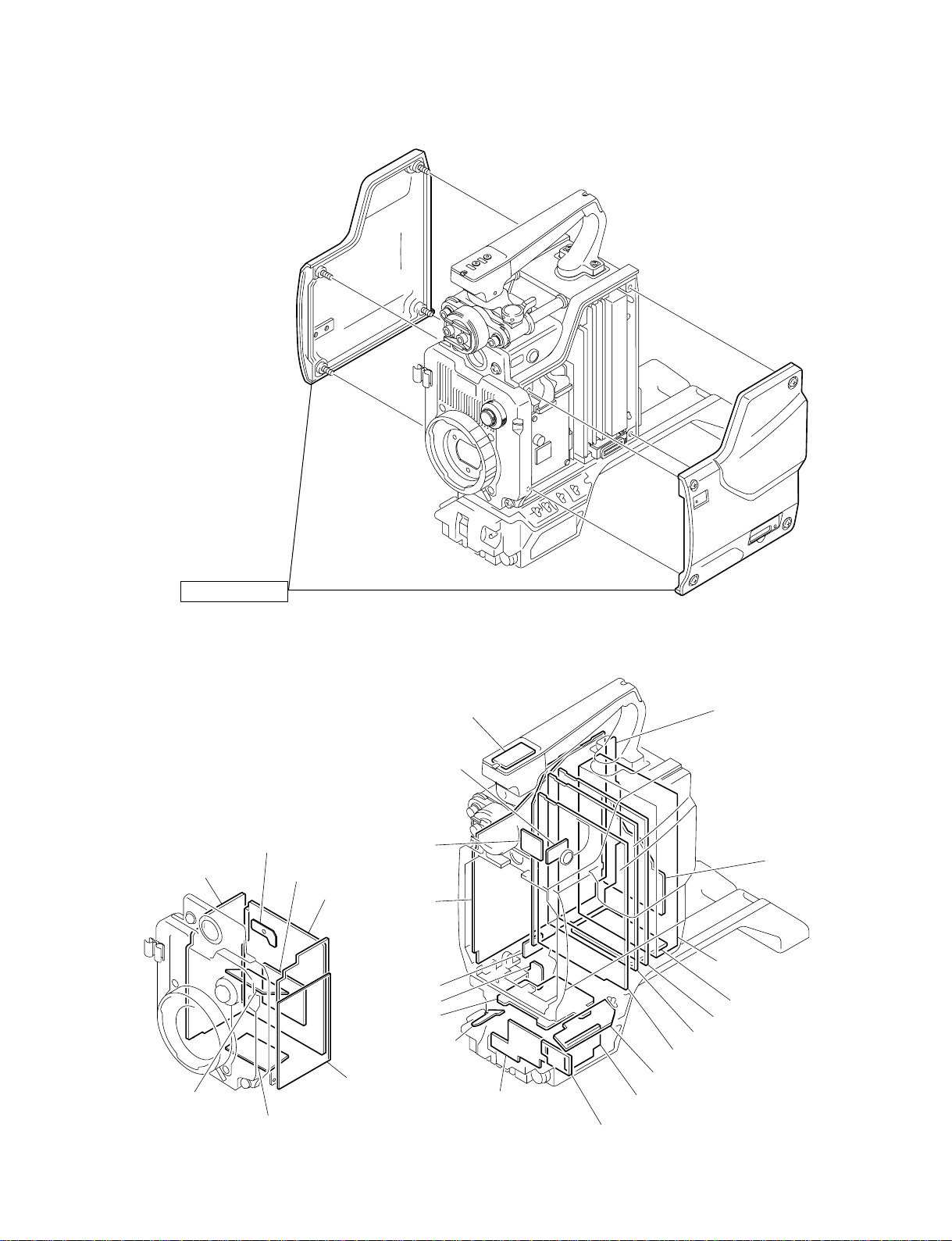

2-1. Replacing the CCD Block and Component Parts .................................2-1 (E)

2-1-1. Replacing the CCD Unit ......................................................2-1 (E)

2-1-2. Positioning Adjustment for Filter Knob...............................2-3 (E)

2-1-3. Replacing the Boards Inside the CCD Unit .........................2-4 (E)

2-1-4. Adjusting Filter Position After Replacing the

DR-536 Board ......................................................................2-6 (E)

2-2. Replacing the VF Connector.................................................................2-7 (E)

2-3. Replacing the Illuminated ASSIGNABLE Switch ...............................2-7 (E)

2-4. Replacing the RET/INCOM Switch......................................................2-9 (E)

2-5. Removing the V Shoe Bracket..............................................................2-9 (E)

2-6. Replacing the MENU SELECT Knob/MENU Switch/

DISPLAY Switch................................................................................ 2-10 (E)

2-7. Replacing the LENS Connector..........................................................2-11 (E)

2-8. Replacing the TEST OUT Connector .................................................2-11 (E)

2-9. Replacing the Side Switch Panel Block..............................................2-12 (E)

2-10. Replacing the Front Switch Panel Block ............................................2-12 (E)

2-11. Replacing the MIC Connector ............................................................2-13 (E)

2-12. Replacing the DC-DC Converter ........................................................ 2-13 (E)

2-13. Replacing the MB-953 Board .............................................................2-14 (E)

2-14. Replacing the CN-2204 Board ............................................................2-15 (E)

2-15. Replacing the Memory Stick Case (CN-2206 Board).........................2-16 (E)

2 (E)

3. Setup Menu

3-1. Setup Menu ...........................................................................................3-1 (E)

3-2. TOP Menu.............................................................................................3-3 (E)

3-3. OPERATION Menu..............................................................................3-4 (E)

3-4. PAINT Menu.......................................................................................3-13 (E)

3-5. MAINTENANCE Menu .....................................................................3-26 (E)

3-6. FILE Menu..........................................................................................3-35 (E)

3-7. DIAGNOSIS Menu.............................................................................3-40 (E)

3-8. SERVICE Menu..................................................................................3-40 (E)

BVP-E30/E30P M-V1

4. File System

4-1. File Structure.........................................................................................4-1 (E)

4-2. Operator File .........................................................................................4-2 (E)

4-3. Preset Operator File...............................................................................4-3 (E)

4-4. Scene File..............................................................................................4-4 (E)

4-5. Reference File .......................................................................................4-6 (E)

4-6. Lens File................................................................................................4-8 (E)

4-7. OHB File .............................................................................................4-10 (E)

4-8. File Items.............................................................................................4-12 (E)

5. Electrical Alignment

5-1. Preparation ............................................................................................5-1 (E)

5-1-1. Equipment Required............................................................. 5-1 (E)

5-1-2. Notes on Adjustment............................................................5-2 (E)

5-1-3. Connection ...........................................................................5-2 (E)

5-1-4. Initial Settings ......................................................................5-3 (E)

5-1-5. Presetting Compensation Data .............................................5-4 (E)

5-1-6. SERVICE Menu...................................................................5-4 (E)

5-1-7. Maintaining the Grayscale Chart .........................................5-5 (E)

5-2. VA-226 Board Adjustment ...................................................................5-7 (E)

5-2-1. Black Balance Adjustment...................................................5-7 (E)

5-2-2. Flare Offset Adjustment.......................................................5-7 (E)

5-2-3. Offset Adjustment ................................................................5-8 (E)

5-3. PA-272/273/274 Boards Adjustment ....................................................5-9 (E)

5-3-1. PA Gain Adjustment ............................................................5-9 (E)

5-4. DPR-261 Board Adjustment ...............................................................5-10 (E)

5-4-1. Video Level Adjustment (1)...............................................5-10 (E)

5-4-2. Video Level Adjustment (2)...............................................5-11 (E)

5-4-3. TEST OUT Level Adjustment ...........................................5-12 (E)

5-4-4. SC Frequency Adjustment .................................................5-13 (E)

5-5. RPN Pixel Concealment......................................................................5-14 (E)

5-6. RPN Compensation Adjustment .........................................................5-15 (E)

5-7. White Vertical Line Compensation.....................................................5-16 (E)

5-8. V-SUB Voltage Adjustment ...............................................................5-17 (E)

5-9. V-REG Voltage Adjustment ...............................................................5-18 (E)

BVP-E30/E30P M-V1

3 (E)

Purpose of this manual

Related manuals

Manual Structure

This manual is the maintenance manual volume 1 of Color Video Camera BVP-E30/

E30P/E30WS/E30WSP.

This manual is intended for use by trained system and service engineers, and is

provided information that is premised parts levels service for this unit.

Besides this maintenance manual volume 1, the following manuals are available.

..

. Operation Manual (Supplied with this unit)

..

This manual is necessary for the use and the operation of this unit.

Part No.: 3-854-245-XX

..

. CD-ROM Manual (Supplied with this unit)

..

This manual contains the operation manual of BVP-E30/E30WS, the operation

manual of each peripheral equipment included in BVP-E30 series, and the maintenance manual of partial equipment (camera adaptor and the like).

Part No.: 3-854-379-XX

..

. Maintenance Manual Volume 2 (Available on request)

..

This manual is provided information that is premised the parts level service

(exploded views, block diagrams, board layouts, schematic diagrams, detailed

parts lists and the like.) for this unit.

If this manual is required, please contact to your local Sony Sales Office/Service

Center.

Part No.: 9-968-050-XX

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in Communication B&P Company equipment.

Semiconductors that cannot be searched for on this CD-ROM are listed in the

maintenance manual for the corresponding unit. The maintenance manual contains

a complete list of all semiconductors and their ID Nos., and thus should be used

together with the CD-ROM.

Part number: 9-968-546-XX

BVP-E30/E30P M-V1

5 (E)

Contents

The following is a summary of the sections of this manual.

Section 1 Service Overview

Describes the location of major parts, on-board, switches, tools, fixtures, adjustments/setup after board replace, etc.

Section 2 Parts Replacement

Describes the replacement procedure of circuit board, CCD unit, connectors,

switches and others.

Section 3 Setup Menu

Describes the setup menu, etc.

Section 4 File System

Describes the file structure, etc.

Section 5 Electrical Alignment

Describes electrical adjustment necessary for maintenance of the unit or replacement

of parts.

6 (E)

BVP-E30/E30P M-V1

Section 1

Service Overview

1-1. Note on Service

1-1-1. Confirming the ROM Version

When connecting any of the peripheral equipment in the

following list to this unit, be sure to check that the version

of ROM of each peripheral device to be connected.

If ROM version is lower than the specified below, be sure

to perform ROM replacement.

Model Ref No. ROM version

MSU-700A IC5, IC6/CPU-293 board Ver. 1.20 and

higher

MSU-750 IC5, IC6/CPU-286 board Ver. 1.20 and

higher

CCU-700A IC1004/AT-88 board Ver. 2.90 and

higher

CCU-550A IC133/AT-111 board Ver. 3.00 and

higher

CNU-700 IC4, IC5/AT-89 or Ver. 3.30 and

AT-89A board higher

CNU-500 IC4, IC5/AT-100 board Ver. 2.90 and

higher

RCP-720 Series IC10/MPU-79 board Ver. 2.80 and

RCP-730 Series higher

RCP-740 Series

RM-B750 Series Ver. 1.01 and

higher

RCP-750 Series Ver. 1.01 and

higher

RM-B150 IC4/CPU-266 board Ver. 1.20 and

higher

1-1-3. Error Messages Displayed when

Memory Stick is Used

Describes the error messages displayed when the data is

stored or read using a memory stick in the table below.

Error message Description

NO MEMORY STICK No memory stick is inserted.

FORMAT ERROR The memory stick is not formatted.

OTHER MODEL’S FILE The memory stick contains data

cannot be read by this unit.

FILE NOT FOUND No data is stored in the memory

stick.

FILE ERROR Circuit or memory stick fault and/or

the data in the memory stick fault.

1-1-4. Note on PA-272/273/274 Boards

The PA-272/273/274 boards cannot be replaced as the

mounted board level. If the component part mounted on

the board cannot be replaced, replace with the whole CCD

unit.

1-1-2. Compatibility of File Data

The file data does not have compatibility with other

cameras.

When using the file data stored in the memory stick or the

IC memory card (for MSU), make sure that the file data for

BVP-E10 series or BVP-E30 series are stored.

(For details on the file system, refer to Section 4.)

BVP-E30/E30P M-V1

1-1 (E)

1-1-5. Description on Backup Battery

1-1-7. Notes on Spare Parts

w

The lithium battery is critical part to safe operation.

Replace the component with Sony part whose part number

appears in the manual published by Sony.

If the component is replaced by any part other than the

specified ones, this may cause a fire or electric shock.

c

When replacing the lithium battery, ensure that the battery

is installed with + and _ poles connected to the correct

terminals. An inconnect connection may cause an explosion or leakage of fluid result in physical damage in the

surrounding materials.

A lithium battery on the AT-148 board is used to back up

the date data to be stored in the memory stick. Reset the

date data using the DATE/TIME page (Refer to Section

3-5) in the MAINTENANCE menu after replacing the

dead battery.

Replacement part : BT1 (AT-148 board)

Description : CR-2032

(Lithium battery)

Parts number : ! 1-528-174-31

Recommended replacement period : Every 7 years

m

. When replacing the AT-148 board, it is recommended to

replacing the battery at the same time.

. Resetting the date data is required even when the battery

is disconnected from the battery holder.

1. Safety Related Components Warning

w

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

Parts list has the present standardized repair parts.

3. Stock of Parts

Parts marked with “o” at SP (Supply Code) column of

the spare parts list may not be stocked.

Therefore, the delivery date will be delayed.

4. Harness

The harness with which the part number is not described is not registered as the service parts. Replace

with the component part described in the lists.

1-1-8. Unleaded Solder

Boards requiring use of unleaded solder are printed with a

lead free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come

printed with the lead free mark due to their particular size.)

: LEAD FREE MARK

1-1-6. Description on CCD Block Number

Every CCD unit has its own ID number called CCD block

number. It shows the CCD block type and serial number of

the CCD block.

The CCD block number label is put in the CCD unit.

As for the replacement procedures of CCD block, refer to

Section 2-1-1. “Replacing the CCD Block”.

AKA xxxxx

Serial number for CCD block

CCD block type

1-2 (E)

m

. Be sure to use the unleaded solder for the printed circuit

board printed with the lead free mark.

. The unleaded solder melts at a temperature about 40 dC

higher than the ordinary solder, therefore, it is recommended to use the soldering iron having a temperature

regulator.

. The ordinary soldering iron can be used but the iron tip

has to be applied to the solder joint for a slightly longer

time. The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful.

BVP-E30/E30P M-V1

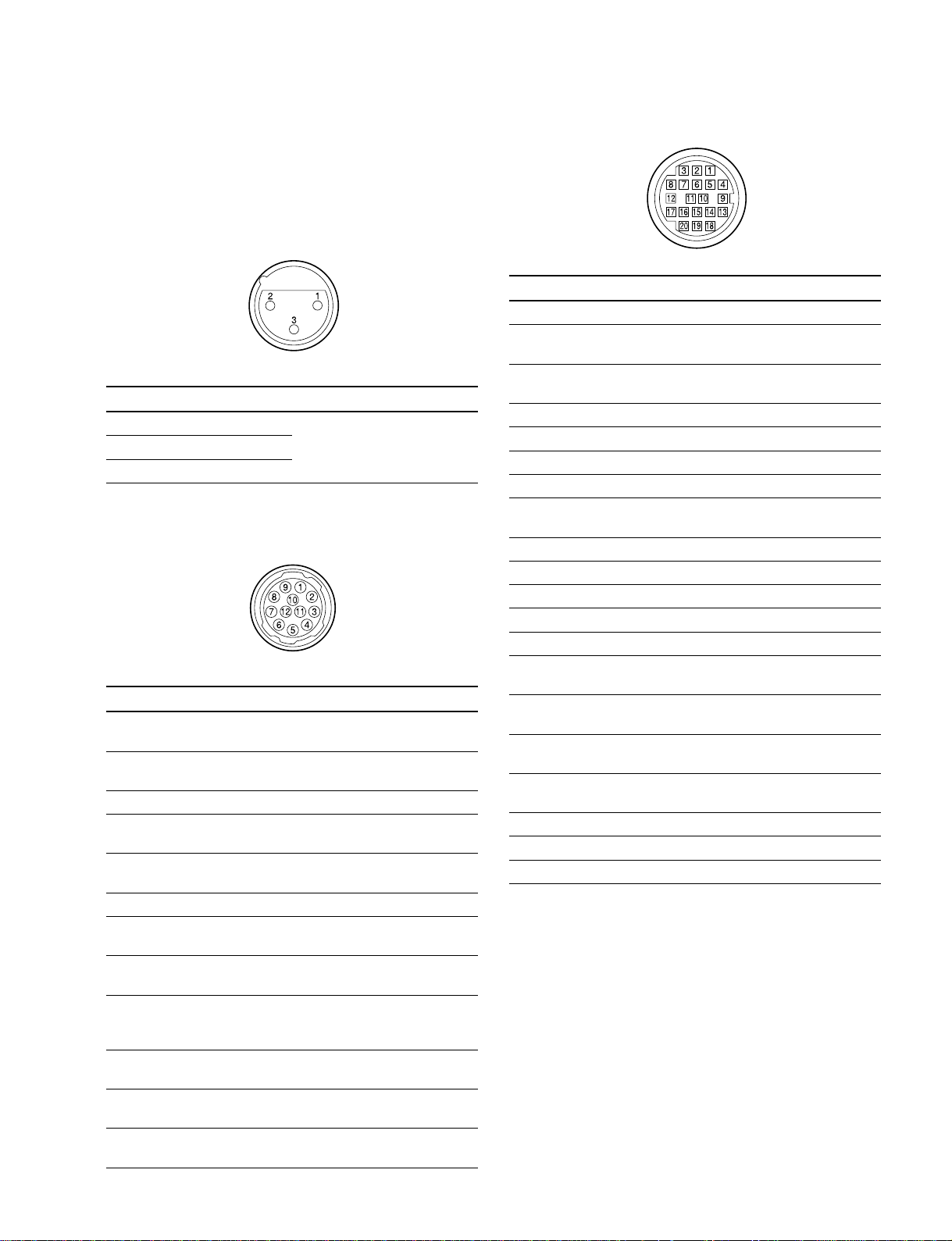

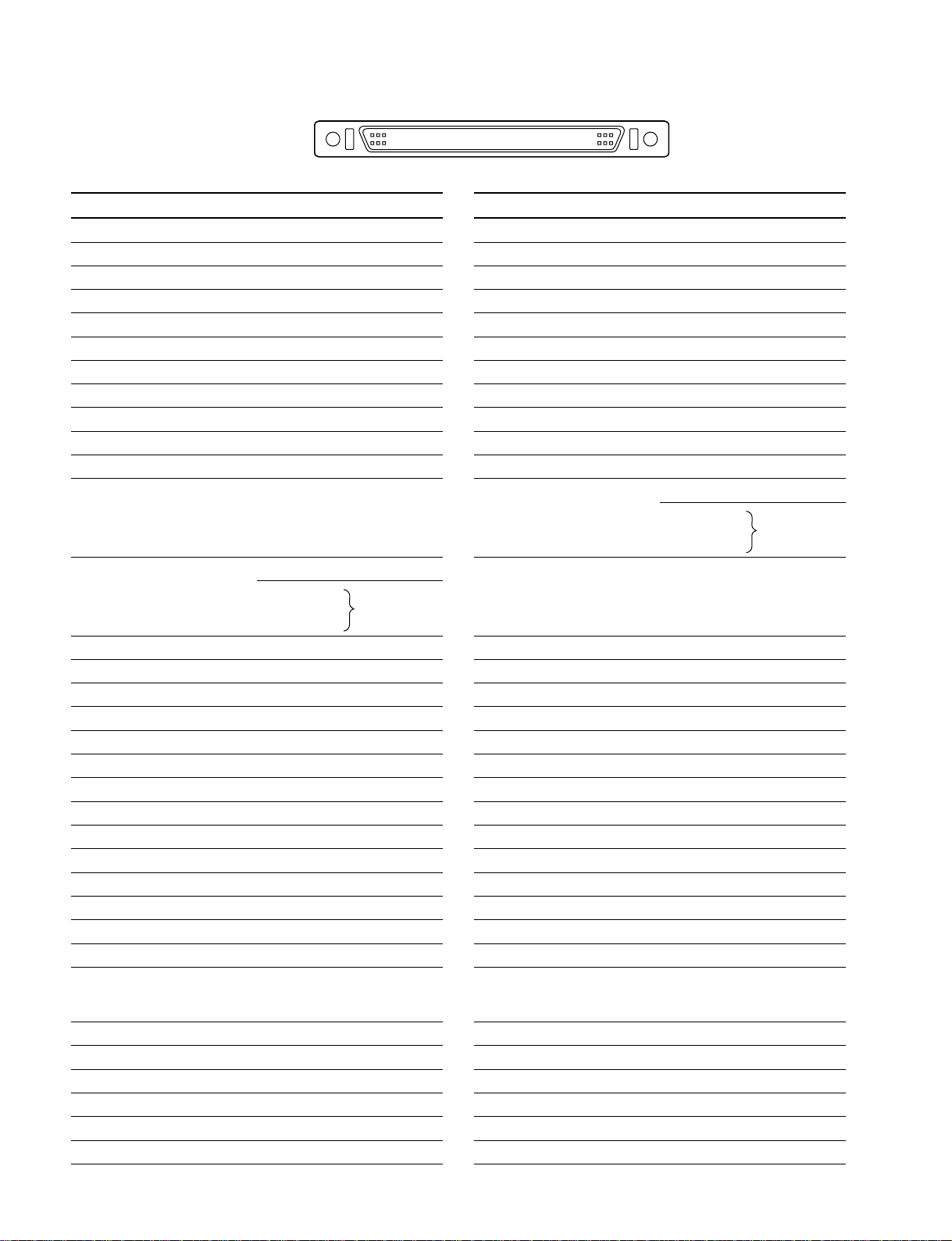

1-2. Connector Input/Output Signals

TEST OUT

BNC 75 Z 1.0 V p-p

VF (20P FEMALE)

MIC IN (3P FEMALE)

(EXTERNAL VIEW)

No. SIGNAL SPECIFICATIONS

1 MIC IN (G) _60 dBu High impedance

2 MIC IN (X)

3 MIC IN (Y)

balanced

(0 dBu = 0.775 Vrms)

LENS (12P FEMALE)

(EXTERNAL VIEW)

No. SIGNAL SPECIFICATIONS

1 RET VIDEO ENABLE IN ENABLE: 0 V

2 RET 2 ENABLE IN ENABLE: 0 V

3 GND GND for UNREG

4 AUTO +5 V OUT AUTO: +5 V

5 IRIS CONT OUT +3.4 V (F16) to

6 UNREG OUT +10.5 V to +17 V

7 IRIS POSITION IN +3.4 V (F16) to

8 AUTO/MANU OUT AUTO IRIS: 0 V

9 EXTENDER ON/OFF IN EX 2 ON: 0 V

10 ZOOM POSITION IN WIDE: +2 V

11 SER DATA OUT H: +5V

12 SER DATA IN H: +5V

BVP-E30/E30P M-V1

DISABLE: +5 V or OPEN

DISABLE: +5 V or OPEN

MANU: 0 V or OPEN

+6.2 V (F2.8)

+6.2 V (F2.8)

MANUAL IRIS: +5 V

EX 0.8 ON: +1.8 V

OFF: +4.8 V

TELE: +7 V

L: 0V

L: 0V

(EXTERNAL VIEW)

No. SIGNAL SPECIFICATIONS

1 NC No connection

2 ABNORMAL IND OUT L: Indicator lights

3 16:9 MODE OUT H: NORMAL (4:3)

4 NC No connection

5 COMP/VBS SW IN/OUT *

6 CCIR/EIA OUT H: CCIR, L: EIA

7 NC No connection

8 G TALLY OUT H: Indicator lights

9 NC No connection

10 Y (X) OUT 1 V p-p, VF: Zi = 1 kZ

11 ZEBRA ON IN H: OFF, L: ON

12 VF VIDEO OUT (X) 1.0 V p-p, VF: Zi = 1 kZ

13 NC No connection

14 B-Y (X) OUT 700 mV p-p, VF: Zi = 1 kZ,

15 R-Y (X) OUT 700 mV p-p, VF: Zi = 1 kZ,

16 BATT IND OUT H: Indicator lights

17 TALLY IND OUT H: Indicator lights

18 +9.3 V (VF) OUT REG +9.3 V

19 GND GND

20 UNREG OUT +10.5 V to +17 V

OPEN: Indicator goes out

L: WIDE (16:9)

Note1

L: Indicator goes out

75 % color-bars

75 % color-bars

L: Indicator goes out

L: Indicator goes out

Note1: Specification of COMP/VBS SW Signal

When powering on, the microcomputer of the camera identifies a

viewfinder in use by detecting the voltage at pin 5.

H: Color VF, L: B/W VF

. In use of B/W VF

Voltage control of pin 5 is disabled during operation.

Switching between the return video signal and monochrome signal for the viewfinder is done by the camera

and selected signal is output at pin 12 to the viewfinder.

. In use of Color VF

By controlling the voltage at pin 5 during operation,

switching between the decoded return video signal and

the camera component signal is done in the viewfinder.

H: Camera, L: Return video

1-3 (E)

ANALOG CA (68P FEMALE)

34

68

*: In connection with CCU, **: In connection with VTR

No. SIGNAL SPECIFICATIONS

1 UNREG GND GND for UNREG

2 UNREG GND GND for UNREG

3 VF UNREG GND GND for VF UNREG

4 LENS UNREG GND GND for LENS UNREG

5 UNREG IN 10.5 V to 17 V

6 UNREG IN 10.5 V to 17 V

7 VF UNREG IN 10.5 V to 17 V

8 LENS UNREG IN 10.5 V to 17 V

9 NC No connection

10 NC No connection

11 VBS OUT (G) GND for VBS VIDEO

12 Y OUT (X) VS 1.0 V p-p, Zo = 75 Z

13 B-Y OUT (X) 700 mV p-p, with sample 350 mV*

756 mV p-p (J)

700 mV p-p (UC) **

525 mV p-p (CE)

14 NC No connection

15 NC No connection

16 VBS GENLOCK IN (X) 1.0 V p-p ±6 dB

17 RET VIDEO IN (G) GND for RET VIDEO

18

MONITOR VIDEO OUT (X)

19 BATTERY ALARM IN Zi = 300 Z *

20 NC No connection

21

AUDIO CH1 CONT OUT

22 MIC 1 OUT (Y) Zo < 600 Z, _60 dBu balanced

23 NC No connection

24 SKIN TONE GATE OUT 1.0 V p-p

25 TAPE REM IN *

26 VTR SYNC OUT +

27 RET EN OUT

28 PB REF IN PB; +4.5 V,

29 H CONT IN 0 V to 5 V, Analog

30 ANALOG GND

31 DIGITAL HD OUT 3.3 V p-p for Digital

32 COM CONT IN 5 V p-p

33 IIC CLOCK OUT (CA) 5 V p-p

34 NC No connection

VS 1.0 V p-p, Zo = 75 Z

Note 2

0 V (0 dB) to 7 V (_50 dB or less)

Note 4

5.0 V p-p Negative pulse, Zo < 100 Z

ENABLE; 0 V, DISABLE; +5 V or OPEN

CAM; 0 V or OPEN

1-4 (E)

1

(EXTERNAL VIEW)

35

No. SIGNAL SPECIFICATIONS

35 UNREG GND GND for UNREG

36 UNREG GND GND for UNREG

37 VF UNREG GND GND for VF UNREG

38 LENS UNREG GND GND for LENS UNREG

39 UNREG IN 10.5 V to 17 V

40 UNREG IN 10.5 V to 17 V

41 VF UNREG IN 10.5 V to 17 V

42 LENS UNREG IN 10.5 V to 17 V

43 NC No connection

44 NC No connection

45 VBS OUT (X) 1.0 V p-p ±10 %, Zo = 75 Z

46 R-Y OUT (X) 700 mV p-p, with sync 350 mV*

756 mV p-p (J)

700 mV p-p (UC) **

525 mV p-p (CE)

47 Y/R-Y/B-Y GND GND for Y/R-Y/B-Y

48 NC No connection

49 NC No connection

50 VBS GENLOCK IN (G) GND for GENLOCK/H CONT IN

51 RET VIDEO IN (X) 1.0 V p-p, Zi = 1 kZ

52

MONITOR VIDEO OUT (G)

53 VTR START/STOP OUT Zo < 10 kZ

54 NC No connection

55 MIC 1 OUT (G) GND for CAM MIC

56 MIC 1 OUT (X) Zo < 600 Z, _60 dBu balanced

57 NC No connection

58 NC No connection

59 AUDIO LEVEL IN Zi > 1 kZ (_15 dBu at 0 VU)

60 NC No connection

61 NC No connection

62 REC TALLY IN ON; +5 V,

63 VTR SAVE OUT

64 GND

65 NC No connection

66 COM DATA OUT 5 V p-p

67 IIC DATA IN/OUT (CA) 5 V p-p, 4700 Z, Pull up

68 NC No connection

GND for MONITOR VIDEO

OFF; +2.5 V or 0 V,

Zi > 20 kZ *

SAVE; +4.5 V, STANDBY; 0 V, Zo < 10 kZ

Note 3

(0 dBu = 0.775 Vrms)

BVP-E30/E30P M-V1

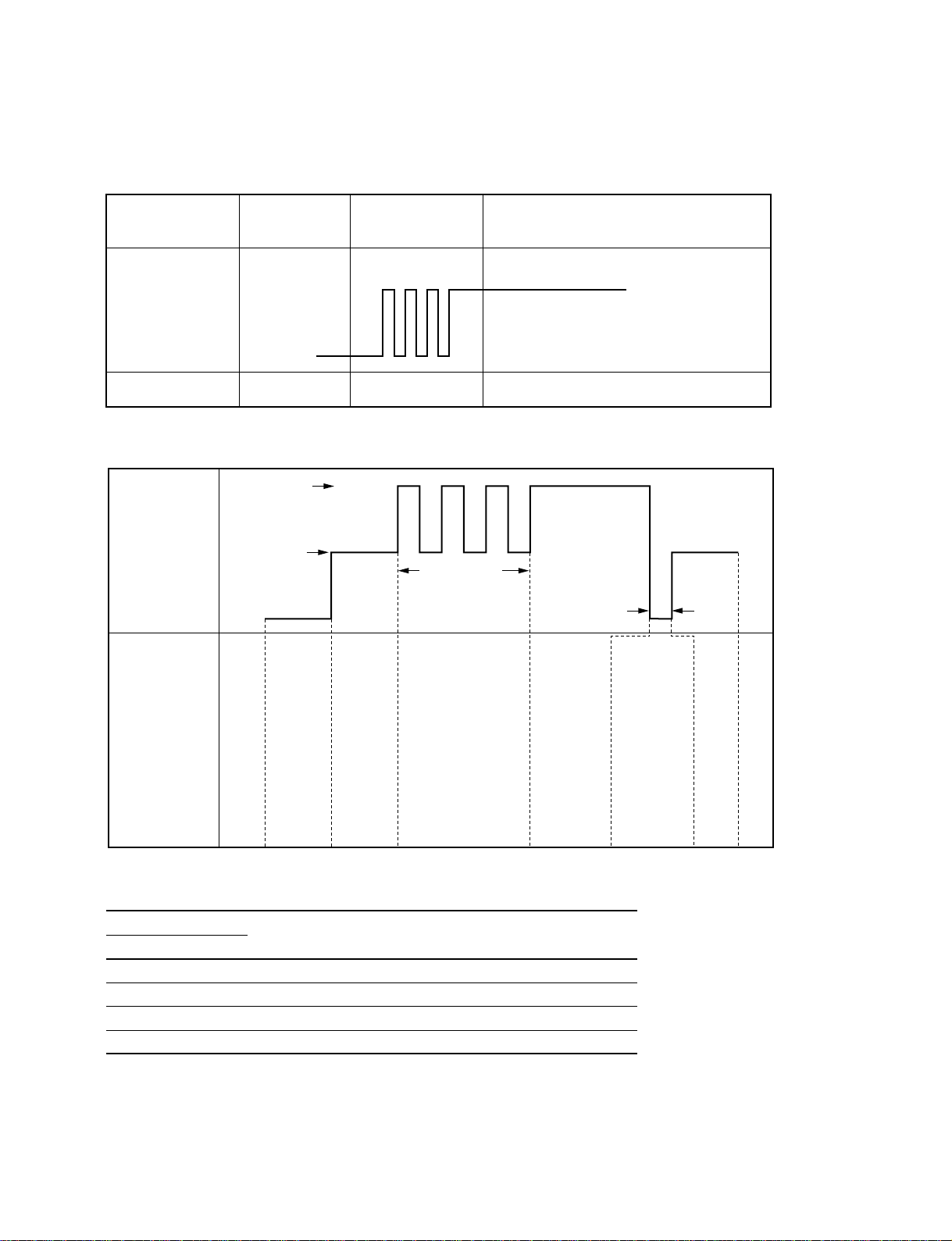

Note 2 : Specifications of BATT ALARM Signal

VTR has a battery voltage detection and waring signal generation circuits and it sends the signal shown

below to the camera.

Battery Terminal

Voltage

(VTR internal battery)

Input Signal at

Pin 19

LED on Viewfinder

12.0—11.1 V dc 11.1—10.8 V dc

1.0 ±0.2 Hz

duty 50 ±10 %

0 V

Stays out Blinks at 1 Hz Lights up

Note 3 : Specifications of REC TALLY Signal

+1

5.0

Input Signal at

Pin 62

VTR Action

_0.5 V dc

2.5 ±0.5 V dc

0 ±0.3 V dc

Power

OFF

Power ONWhen VTR changes

10.8 V dc—

REC TALLY

signal

1.0 ±0.2 Hz

duty 50 ±10 %

from POWER SAVE

to REC START mode,

or when the servo is

lost

REC RESET signal

10—100 msec

When VTR

changes from

STANDBY to

REC START

mode, or in

REC mode

At the end of

tape or When

VTR is put

into STOP

mode by itself

(REC RESET

signal does

not appear

when VTR is

put into STOP

mode by

operating the

camera)

2—3 V dc

across 300 Z

STOP

mode

Note 4 : Specifications of TAPE REM Signal

Tape Remaining (VTR) Input Signal at Pin 25 Remark

TAPE1 TAPE2

+5 V +5 V +3.4 V

+5 V 0 V +3.1 V G TALLY lamp lights at +3.1 V

0 V +5 V +2.2 V

0 V 0 V 0 V

BVP-E30/E30P M-V1

1-5 (E)

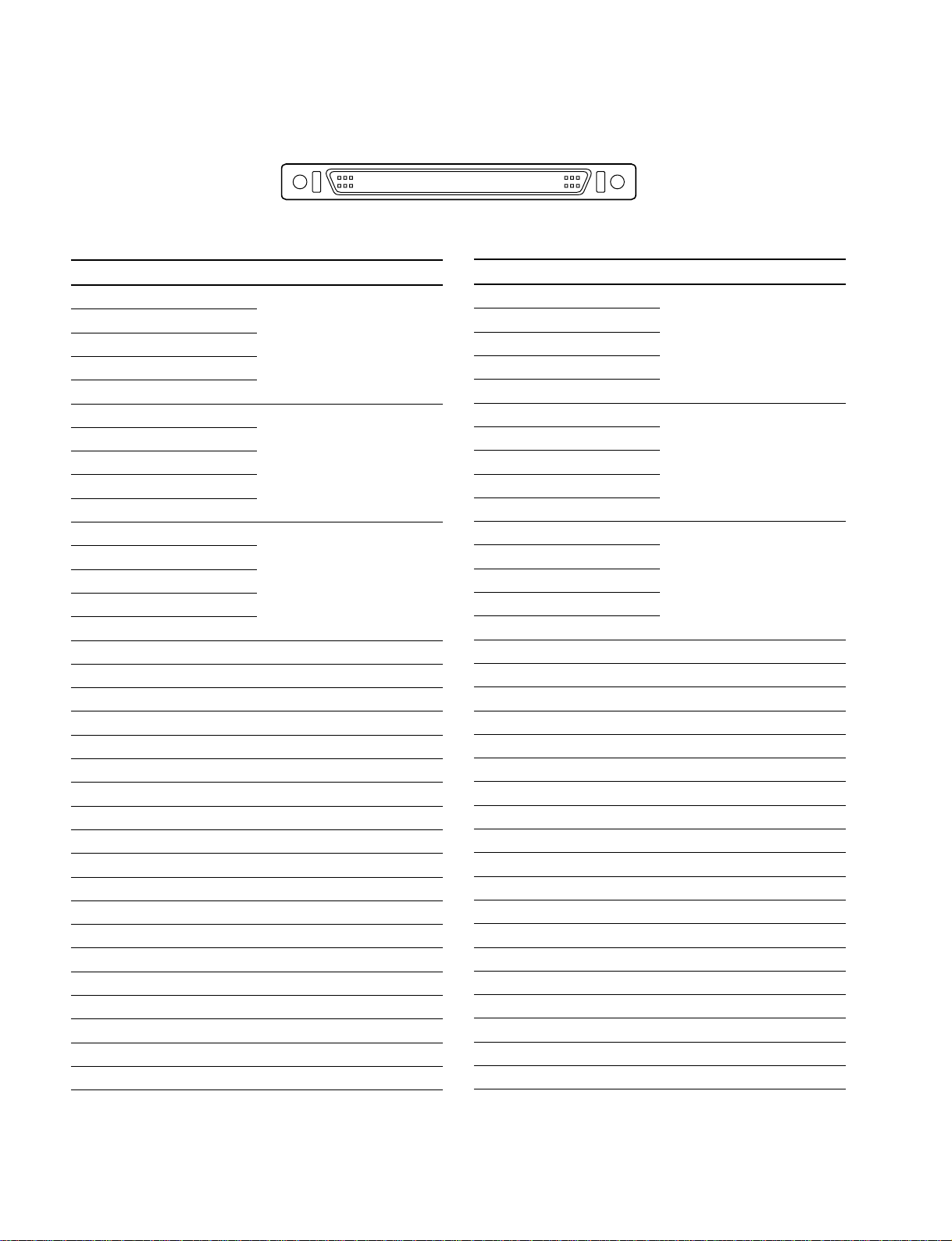

DIGITAL CA (68P FEMALE)

34

68

No. SIGNAL SPECIFICATIONS

1 G (L) OUT

2 G (2) OUT

3 G (4) OUT 2.5 V p-p

4 G (6) OUT

5 G (8) OUT

6 R (L) OUT

7 R (2) OUT

8 R (4) OUT 2.5 V p-p

9 R (6) OUT

10 R (8) OUT

11 B (L) OUT

12 B (2) OUT

13 B (4) OUT 2.5 V p-p

14 B (6) OUT

15 B (8) OUT

16 DIGITAL GND GND for DIGITAL

17

DIGITAL BLANKING OUT

3.3 V p-p

18 DIGITAL SYNC OUT 3.3 V p-p

19 NC No connection

20 NC No connection

21 NC No connection

22 NC No connection

23 NC No connection

24 NC No connection

25 NC No connection

26 NC No connection

27 NC No connection

28 NC No connection

29 NC No connection

30 NC No connection

31 NC No connection

32 NC No connection

33 (Reserve)

34 18 MHz OUT (G) GND for 18 MHz

1

35

(EXTERNAL VIEW)

No. SIGNAL SPECIFICATIONS

35 G (1) OUT

36 G (3) OUT

37 G (5) OUT 2.5 V p-p

38 G (7) OUT

39 G (M) OUT

40 R (1) OUT

41 R (3) OUT

42 R (5) OUT 2.5 V p-p

43 R (7) OUT

44 R (M) OUT

45 B (1) OUT

46 B (3) OUT

47 B (5) OUT 2.5 V p-p

48 B (7) OUT

49 B (M) OUT

50 DIGITAL GND GND for DIGITAL

51 DIGITAL SAMPLE OUT 3.3 V p-p

52 DIGITAL VD OUT 3.3 V p-p

53 DIGITAL CF OUT 3.3 V p-p

54 NC No connection

55 NC No connection

56 NC No connection

57 NC No connection

58 NC No connection

59 NC No connection

60 NC No connection

61 (Reserve)

62 NC No connection

63 NC No connection

64 NC No connection

65 NC No connection

66 NC No connection

67 (Reserve)

68 18 MHz OUT (X) 3.3 V p-p

1-6 (E)

BVP-E30/E30P M-V1

1-3. Connection Connector

Connection made with the connector panels during installation or service, should be made with the

connector specified in the following list, or equivalent parts.

Connector Name Connection Connectors

TEST OUT (BNC) 1-569-370-12 Plug, BNC

MIC IN (3P FEMALE) 1-508-084-00 XLR, 3P Male or ITT Cannon XLR-3-12C equivalent

1-4. Function of Internal Switches

Ref. No. Designation Description Factory setting

S1 MIC +48 V MIC POWER +48 V ON/OFF switch ON

1

2

3

Set to OFF when using the microphone of the internal

batteries type.

ON OFF

S1

4

5

6

7

8

9

10

11

12

13

14

G

F E D

C

BA

MB-953 board (B side)

BVP-E30/E30P M-V1

1-7 (E)

NR-72 Board

Ref. No. Designation Description Factory setting

S101-1 SINGLE/DUAL Set corresponding to the filter disk type of BVP-E30P: S

the camera to be used. BVP-E30: D

S: Single filter BVP-E30WS: D

D: Dual filters BVP-E30WSP: D

S101-2 _ NC _

TG-229 Board

Ref. No. Designation Description Factory setting

S1-1 4:3/16:9 Set corresponding to the camera to be used. BVP-E30/E30P: 4:3

BVP-E30WS/E30WSP: 16:9

S1-2 PAL/NTSC Set corresponding to the camera to be used. BVP-E30/E30WS: NTSC

123456

S

D

1 2

S101

H

G

BVP-E30P/E30WSP: PAL

1

2

NR-72 board (B side)

F

16:9

PAL

4:3

D

1 2

S1

NTSC

C

B

E

D

C

B

A

3

4

5

6

7

8

A

TG-229 board (B side)

1-8 (E)

BVP-E30/E30P M-V1

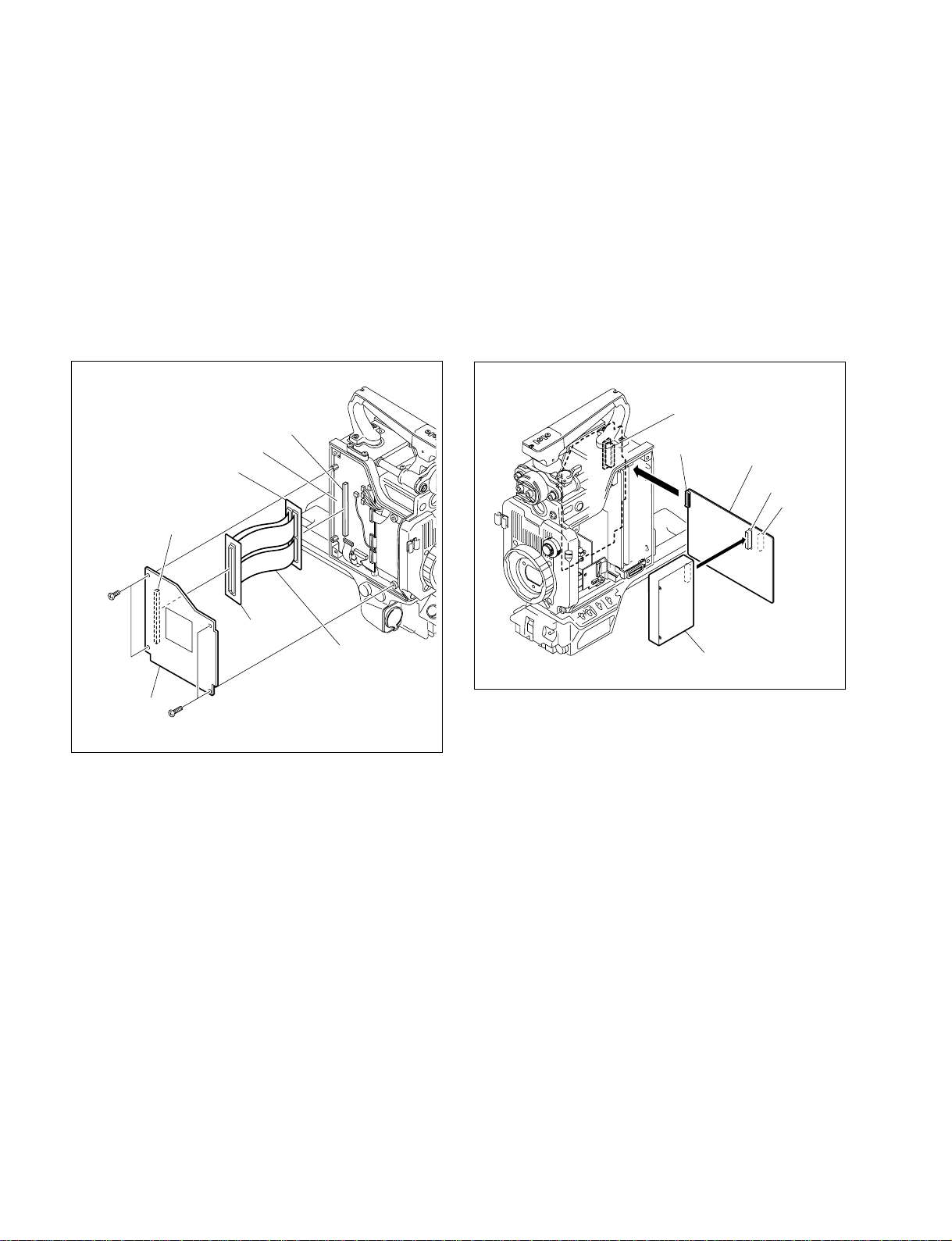

1-5. Remove and Installation of Exterior Parts

Loosen 4 screws.

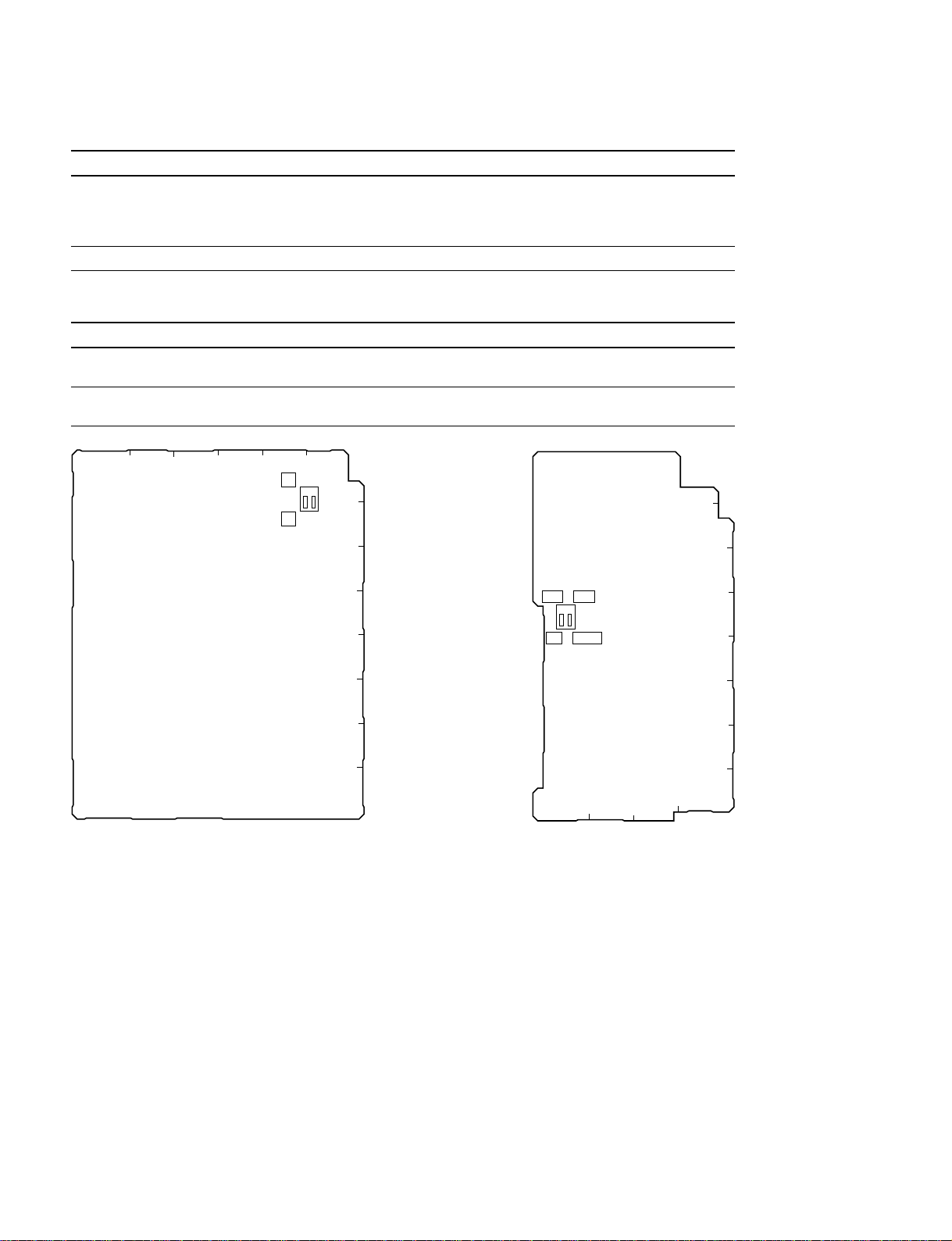

1-6. Location of Printed Wiring Boards

SW-1075

SW-1071

TG-229

PA-272

SE-767

(BVP-E30P only)

PA-273

NR-72

PA-274

CN-2209

DPR-261

CN-2210

CN-2208

CN-2205

CN-2207

DR-536

(BVP-E30/E30WS/

E30WSP only)

SW-1068

MB-953

CN-2204

DC-DC CONVERTER

(RE-201 board)

CN-2206

AT-148

IF-969

VA-226

SW-1067

SW-1069

SW-1070

BVP-E30/E30P M-V1

1-9 (E)

1-7. Circuit Description

1-7-1. CCD Block (PA-272/273/274 Boards,

TG-229 Board, and NR-72 Board)

PA-272/273/274 Boards

The PA boards contains the CCD bias circuit, horizontal

register drive circuit (H1, H2, LH1 driver), CDS (Correlated Double Sampling) circuit which extracts video signals

from the CCD and eliminates noise, and preamp circuit

which adjusts sensitivity.

IC9 of PA-273 board detects temperature around the CCD

block with a temperature sensor, and sends the detected

signal to the AT-148 board.

Various CCD drive conditions, adjustment data (V-sub

voltage, RG voltage, black/white shading, etc.) are written

in IC8 (EEPROM) of PA-272 board.

TG-229 Board

The TG-229 board contains the CCD drive pulse generation circuit and its drive circuit.

The 18 MHz clock generated from the voltage control

generation circuit (X1) is sent to the DPR-261 board to

generate the AHD, AVD pulse synchronized with the

video output signal.

The TG IC (IC1) generates the CCD drive pulse synchronized with this AHD, AVD pulse and the sample and hold

pulse for the CDS circuit of the PA boards.

These pulses are passed through the following drive circuit

and are sent to each PA board.

. V clock: Passed through IC201 to IC206 drivers ICs

. RG pulse: Passed through IC309 and then the bias

potential specific to each. CCD is added to the

output of IC309.

. V-sub voltage:

Enters IC310 DC amplifier to be adjusted for

the specified voltage.

. Shutter pulse:

Passes through the drive circuit consisting of

Q201 to Q204.

. SHP/SHD/H1/H2/LH1:

Passes through IC312, IC313, and IC307

AND gate ICs.

NR-72 Board

The NR-72 board contains a power stabilization circuit to

stabilize various power supply voltages to be supplied to

the CCD block, black/white shading correction signal

generation circuit, and optical filter interface circuits.

. The power stabilization circuit stabilizes the following

power supply voltages to be supplied to the CCD block.

+15.0 V +30.0 V +6.0 V +5.3 V +3.3 V +2.5 V

+1.8 V +1.1 V _10.0V _8.0 V _4.5 V

. The black/white shading correction signal and TEST

SAW signal are generated in IC104, and are sent to the

VA-226 board to mix with the video signal.

. This board has two optical filter interface circuits, one is

for the two-filters type with a servomotor used in the

BVP-E30/E30WS/E30WSP, the other is for one filter

type without a servomotor used in the BVP-E30P.

The switch S101 switches these circuits.

1-10 (E)

BVP-E30/E30P M-V1

1-7-2. Video Signal System (VA-226 Board,

DPR-261 Board, and IF-969 Board)

VA-226 Board

The VA-226 circuit amplifies the R, G, B video signals

output from the PA boards, performs various correction,

and then sends them to the DPR-261 board. As the R, G,

and B circuits are basically the same, Rch is explained as

an example below.

The video signal output from the PA board is passed

through the trap filter (FL101), and input to the first

amplifier stage composed of Q102 to Q108. In this amplifier, black shading correction, 5600K switching (Rch and

Bch only) and clamping are performed.

The clamped signal is switched between 0 dB/6 dB/12 dB/

18 dB by the amplifier composed of Q110 to Q117 and

blanking cleaning is performed by IC102. Clamping is also

performed in this amplifier.

After this, the change of 0 dB/3 dB/6 dB/12 dB and flare

correction are performed in the amplifier composed of

Q125 to Q131 and Q133 to Q135, and the signals are

output to the DPR-261 board.

In addition, switching of the video signal and TEST SAW

signal is also performed.

DPR-261 Board

The DPR-261 board is mainly composed of the A/D block

which converts analog RGB signals input from the VA226 board to digital, camera DSP (digital signal processor)

block which performs various signal processing, and D/A

block which converts digital signals processed by the

camera DSP block to analog.

In the A/D block, after analog RGB signals input from the

VA-226 board are clamped, they are passed through the

pre-filters (FL101, FL102, and FL103), and converted to

14-bit digital signals by the A/D converter (IC102, IC202,

and IC302).

The A/D-converted digital signals are input to the camera

DSP LSI (IC1).

IC1 performs detection of average values and peak values

of video signals required for automatic operations of the

camera such as auto black balance, auto white balance,

auto iris, etc., processings white balance, white shading

correction, matrix, detail, and gamma, and digital encoding

for VBS signals. 25 PsF/29.94 PsF conversion functions

and slow shutter are also realized using the SDRAM

(IC801). These processed signals are output from IC1 as

various digital video signals.

Of the digital video signals output from IC1, only the Y/RY/B-Y signals for the digital CA are passed through the

buffers (IC1001 to IC1005) and then output at the DPR261 board as the digital signals. The other digital signals

are converted to analog signal.

In the D/A block, the Y/R-Y/B-Y signal is D/A-converted

by IC501, the VBS/SC by IC502, the Y/R-Y/B-Y signal

for VF by IC503, and the TEST signal by IC800.

The DPR-261 board, also control PLL and H-Phase/SCPhase at genlock and generates various timing pulses such

as HD/VD/SYNC.

BVP-E30/E30P M-V1

1-11 (E)

IF-969 Board

The IF-969 board is composed of the driver block which

switches and outputs the analog signals D/A converted by

the DPR-261 board and RET signal sent when CCU is

connected to each block, and the I/O block inputs/outputs

the control signals from/to the lens, VF and the camera

adaptor.

The VBS signal which is D/A-converted by the DPR-261

board is input to the IF-969 board and branched into two.

One is sent to the camera adaptor as VBS output by 75 Z

output driver after passed through the video driver IC

(IC105). The other is switched by the analog switch IC

(IC104) and output at the TEST OUT terminal.

This unit has the two systems to output the TEST signal.

One system outputs the TEST signal as a MONITOR OUT

to the camera adapter after being switched by IC104

analog switch.

The other outputs that at the TEST OUT terminal by the

75 Z output driver after passing through IC105 driver IC.

At this terminal, VBS, TEST or RET signals which is

selected by IC104 analog switch is output. According to

another switch setting, character signal can be added to the

above output signal.

The RET signal sent when CCU is connected and the

GENLOCK input signal from the camera adaptor are

switched by the analog switch circuit (Q101 to Q107) and

the RET signal is separated to two pathes. The one is

output at the TEST OUT terminal via the analog switch IC

(IC104) after switching between the RET signal and the

TEST signal is done by the analog switch circuit (Q126,

Q115 to Q117, IC2). The other is output to VF VIDEO

OUT after switching between the RET signal and the VFVIDEO signal is done by the analog switch circuit (Q4 to

Q6).

To synchronize the GENLOCK input of the camera

adaptor with the external input video signal, the IF-969

board is provided with the floating amplifier circuit and

sync separation circuit to send the external sync signals

EXT-SC and EXT-SYNC to the DPR-261 board.

When a color VF is connected, the signals VF-Y, VF R-Y,

VF B-Y input from the DPR-261 board are mixed with the

cursor, marker signal and character signal generated in the

character generator IC (IC5) and then output as a COLOR

VF signal.

When a white/black VF is connected, the VF-Y signal

input from the DPR-261 board are mixed with the cursor,

marker and character signals in the different block to the

COLOR VF signal and then output to VF VIDEO OUT as

a monochrome VF signal.

The I/O block controls the switching input signal from the

switches of the camera, input/output signals from/to the

camera adaptor and lens, and output signal to VF using the

I/O expander (IC307) which communicates with the AT148 board.

1-7-3. System Control (AT-148 Board)

AT-148 Board

The AT-148 board is provided with a CPU (IC11) which

performs system control.

It is operated by the program written in the ROM (IC231

and IC232). The program can be upgraded using a memory

stick via the controller IC222.

The AT-148 board is also provided with a general memory

SRAM (IC216 and IC217) and FRAM (IC220 and IC221)

for recording system setting conditions, etc.

The external 8-bit bus (IC205, IC206, IC207, and IC208)

controls the I/O expander (IC307) of the IF-969 board and

the digital signal processor LSI (IC1). It also controls IC1

of the TG-229 board, IC104 of the NR-72 board, D/A

converter of the VA-226 board (IC702 and IC704), D/A

converter of the DPR-261 board, and switch input (IC1001

and IC1002) of the CN-2205 board by serial communication.

The A/D converter of the CPU reads the IRIS, ZOOM, and

EXTENDER signals from the lens, and controls the lens

via the channel B of the communication IC (IC224).

In additional the CPU performs temperature control using

the temperature sensor signal of channel G sent from the

CCD block (PA-273 board), position control from the filter

block, tape remainder control, and audio volume control.

It is also provided with the serial I/O which communicates

with the CCU using the 700 protocol (channel A of IC224)

and the calendar function (IC3).

1-12 (E)

BVP-E30/E30P M-V1

1-7-4. Power Supply Block (DC-DC

Converter) (RE-201 Board)

RE-201 Board

. The RE-201 board is a DC-DC converter which outputs

11 types of voltages altogether.

. PWM Clock Signal

The PWM POWER CONTROL (IC8) generates and

supplies the master clock (triangular wave of 90 ±10

kHz) for all controller ICs (IC2, IC3, IC7, and IC8) .

. Input Voltage Monitoring Circuit

The RE-201 board has an input voltage monitoring

circuit (IC4). If the voltage is within the appropriate

range, it supplies power to each controller IC (IC2, IC3,

IC7, and IC8) and REF voltage IC (IC1).

The power supply circuit starts up when the input power

voltage is within the range of +10.0 V to +18.8 V. Once

it has started up, the circuit keeps operating until the

input power voltage decreases below the lower limit

(+9.4 V).

. Voltage Control Circuit

The eight output voltages out of the 11 voltages are

stabilized with direct feedback control by the PWM

POWER CONTROL (IC2, IC3, IC7, and IC8). Each

control IC can independently control two voltages each.

+1.4 V, +2.5 V, +5.3 V, +3.3 V, +6.6 V, and +9.3 V

are output from the step-down chopper circuit while

_5 V is output from the polarity reversed chopper

circuit. The sync rectification circuit is adopted for all

except +9.3V to obtain high efficiency.

_10.5 V is output from the flyback regulator using the

transformer T1. The three voltages +16.0 V, +32.0 V,

and +46.0 V are also output by the T1 coil, however

they are not directly stabilized.

For +1.4 V, accurate voltage is required.

Therefore, it detects the voltage in the DPR-261 board to

absorb voltage drop during transmission.

. Protection Circuit for Shorting of Output Circuit

Each output is connected with a diode or transistor. In

normal operations, they are reverse-biased so that they

are turned OFF.

However if any single output is shorted, or if there is no

output due to some defect, the diode and transistor of the

corresponding block are turned ON and IC9 sends a

L_SHUTDOWN signal. The master clock is stopped by

this signal, and the outputs of all voltages stop.

. Output Overvoltage Protection Circuit

An overvoltage detection circuit is equipped only for the

+1.4 V output.

When the +1.4 V output exceeds +2.0 V under abnormal conditions, the outputs of all voltages are stopped by

the L_SHUTDOWN signal like the output short-circuit

protection circuit.

BVP-E30/E30P M-V1

1-13 (E)

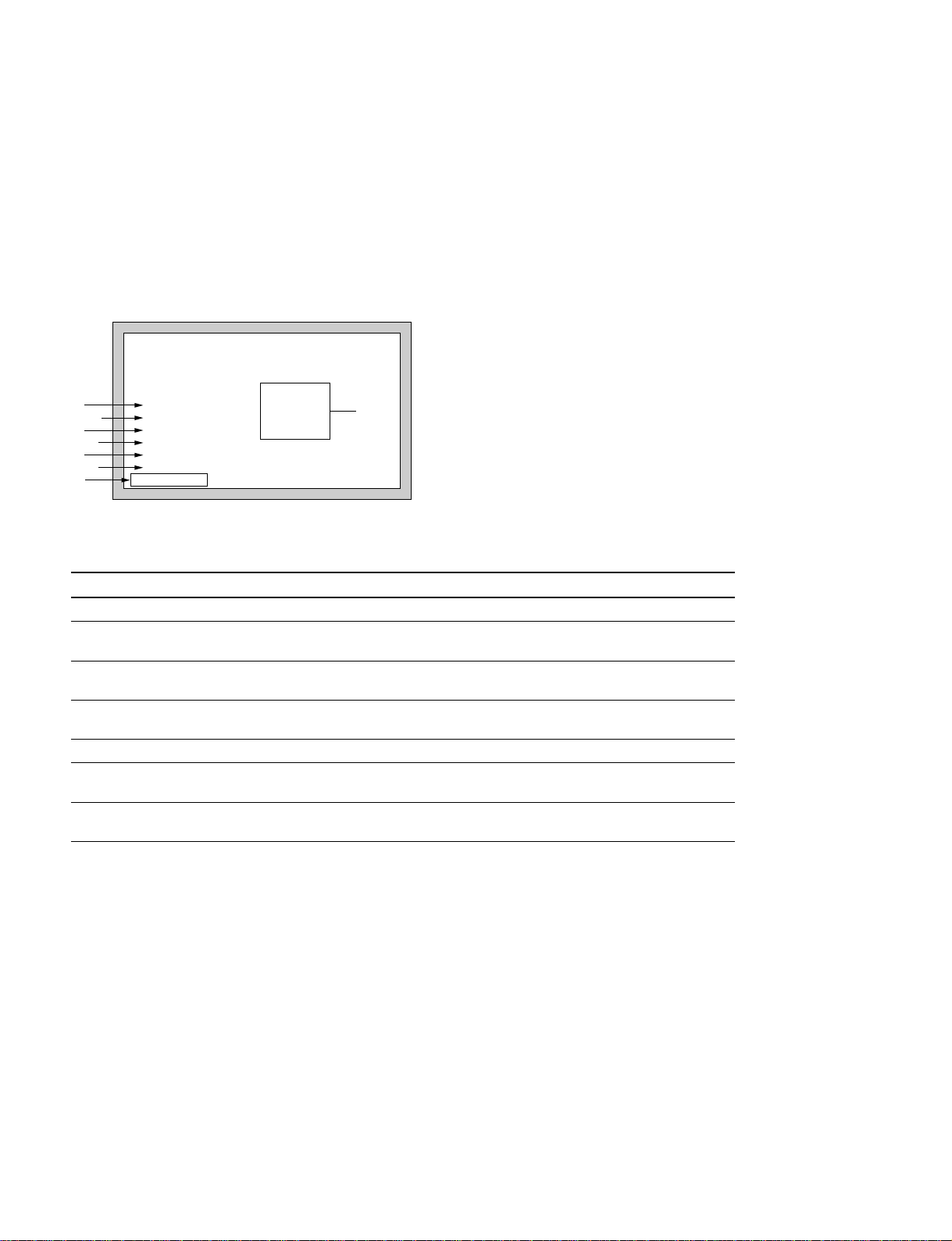

1-8. Diagnosis

The unit is provided with the diagnosis function which can be used for the self-diagnosis of each plug-in

board and the OHB, and is displayed in the OPERATION menu.

Operation

Display the “DIAGNOSIS” page of the OPERATION menu referring to Section 3-1.

Display

<DIAGNOSIS>

ROM:V1.00

CAMERA:UC CA-570

1

3

4

5

6

7

Description on display

OHB:-- MD:- VA :-- AU:--

2

DPR:-- TR:- IF :- AT :- HUR:99999H

CCU :--

8

Marks Board/Block Criteria for judging

1 OHB (CCD UNIT) Communication error with IC8/PA-272 board

2 VA-226 Communication error with IC701 or defect of sub-regulator circuit operation inside the

3 DPR-261 Communication error with IC507 or defect of sub-regulator circuit operation inside the

4 IF-969 Communication error with IC307 or defect of sub-regulator circuit operation inside the

5 AT-148 Low capacity of BT1

6 HUR Indicates the power-on time of the camera. (The display stops in 99999 when the

7 CCU/RM

* When neither CCU nor RM is connected, “RM: NC” is displays.

*

board.

board.

board.

power-on time exceeds 99999H.)

The serial data is correctly received from the CCU or RM connected to the unit.

(“__” is displayed during a normal operation.)

About mark 8 CA, is as described below according to the type of CA connected to the camera.

Refer to the maintenance manual supplied with the camera adaptor.

CA-570 CA-550

MD:-- MD:- AU:-- AU:- TR:-- TR:--

CA-530 CA-950

VSE:-- DA :- DVP:-- IF :- DC :-- AU :- SDI:- DPR:- TX :--

1-14 (E)

BVP-E30/E30P M-V1

1-9. Contents of the EEPROM and FRAM Data

The data that is stored in the EEPROM and FRAM on the respective boards, is shown below.

n

Part numbers of the following ICs are shown in Vol. 2 Section “1. Spare Parts” of the separate Maintenance Manual are the ICs before saving the data contents.

Board Ref. No. EEPROM/ Contents of the saved data Adjustment/setup upon

AT-148 IC220 FRAM Reference file setting data Refer to Section 1-10-7.

DPR-261 IC507 EEPROM Factory adjustment data of Refer to Section 1-10-6.

PA-272 IC8 EEPROM Factory adjustment data of *1

VA-226 IC701 EEPROM Factory adjustment data of Refer to Section 1-10-5.

*1: IC8 on the PA-272 board cannot be replaced because the data cannot be re-set.

When IC needs to be replaced due to defective IC, contact your local Sony Sales Office/Service Center.

(address) FRAM replacement of EEPROM/FRAM

(A-2/A side) Scene file setting data

IC221 Lens file setting data

(A-3/A side) Operator file setting data

VF menu setting data

(F-10/A side) DPR-261 board

(except SC Frequency data)

(B-1/B side) CCD block

SC Frequency data

(D-12/A side) VA-226 board

BVP-E30/E30P M-V1

1-15 (E)

1-10. Adjustment and Setting Items After

Replacement of Board

When replacing the following boards, perform the adjustments or settings referring to Section 5 “Electrical Alignment”

If no adjustment item is listed, no adjustment is required.

Board Referring section

CCD unit 1-10-1. CCD Unit

TG-229 board 1-10-2. TG-229 Board

NR-72 board 1-10-3. NR-72 Board

VA-226 board 1-10-4. VA-226 Board

DPR-261 board 1-10-5. DPR-261 Board

AT-148 board 1-10-6. AT-148 Board

1-10-1. CCD Unit

1-10-4. VA-226 Board

The EEPROM (IC701) is mounted on the VA-226 board.

Perform the following adjustments, when this IC is

replaced, too.

Adjustment Items After Board or EEPROM is

Replaced

5-2-1. Black Balance Adjustment

5-2-2. Offset Adjustment

5-2-3. Flare Offset Adjustment

1-10-5. DPR-261 Board

The EEPROM (IC507) is mounted on the DPR-261 board.

Perform the following adjustments, when this IC is

replaced, too.

Adjustment and Setting Items After CCD Unit is

Replaced

5-3-1. PA Gain Adjustment

5-4-3. SC Frequency Adjustment

4-7. OHB file (Adjustment and Saving the OHB file)

1-10-2. TG-229 Board

Setting Items After Board is Replaced

Referring to Section 1-4, set the internal switches.

1-10-3. NR-72 Board

Setting Items After Board is Replaced

Referring to Section 1-4, set the internal switch.

Adjustment Items After Board or EEPROM is

Replaced

5-4-1. Video Level Adjustment

5-4-2. TEST OUT Level Adjustment

1-10-6. AT-148 Board

The unique setting data that is set by user is written into

IC220 and IC221 on the AT-148 board.

Therefore, when these ICs were replaced with new ICs in

replacing the board or IC itself, the data set by user is lost,

and is returned to their factory-setting values.

Perform the following settings, when these ICs are replaced, too.

Setting Items After Board or FRAM is Replaced

. Reset the reference file, operator file and scene file.

(Refer to Section 4.)

. Replace lithium battery on the AT-148 board with a new

one, and reset date. (Refer to Sections 1-1-5 and 3-5.)

1-16 (E)

BVP-E30/E30P M-V1

1-11. Upgrading the Software

The version of the MAIN program and BOOT program can

be upgraded using the memory stick. According to necessary, follow the procedures shown below.

m

. The upgrading program must have already been saved in

a memory stick before.

. Refer to Section 5-1-6 to display of the SERVICE menu.

. Refer to Section 3-1 for the basic operations of the setup

menu.

1-11-1. Upgrading MAIN Program

When the Setup Menu is Used for Version

Upgrading

1. Insert the memory stick in which the upgrading

program is already saved.

2. Display the FIRM UPDATE page of the SERVICE

menu, and execute the MAIN PROGRAM.

3. The upgrading status is displayed on the viewfinder

screen.

4. When the version upgrade is completed, the message

“Complete” will be displayed.

n

When the tally switch on the camera adaptor is set to

ON, the tally lamp will blink during being upgrading,

and then light up when upgrading is completed.

5. Restart the unit, and confirm the version indication

using DIAGNOSIS menu.

Upgrading by Powering ON the Unit

1. Insert the memory stick in which the upgrading

program is already saved.

2. Turn on the power while pressing the VTR START

switch and MENU SELECT knob on the camera front

simultaneously.

3. The upgrading status is displayed on the viewfinder

screen.

4. When the version upgrade is completed, the message

“Complete” will be displayed.

n

When the tally switch on the camera adaptor is set to

ON, the tally lamp will blink during being upgrading,

and then light up when upgrading is completed.

5. Restart the unit, and confirm the version indication

using DIAGNOSIS menu.

1-11-2. Upgrading BOOT Program

BOOT program is a software renewing the firmware using

the memory stick. Do not operate this program except

upgrading the program.

1. Insert the memory stick in which the upgrading

program is already saved.

2. Display the FIRM UPDATE page of the SERVICE

menu, and execute the BOOT PROGRAM.

3. When the version upgrade is completed, the message

“Complete” will be displayed.

n

When the tally switch on the camera adaptor is set to

ON, the tally lamp will blink during being upgrading,

and then light up when upgrading is completed.

BVP-E30/E30P M-V1

1-17 (E)

1-12. Setting Scene File Number

The number of scene files that can be registered can be

changed (to 5 or 32) using the SERVICE menu of this unit.

The number of scene files can be stored in the internal

memory of this unit, memory stick, and IC memory card

(when MSU is used).

However, pay attention to the following when changing the

number of scene files again after it is changed.

When the number of scene files is switched from

5 to 32:

Indefinite data is registered in the values of scene files 6 to

32. Be sure to register new data again before using the

scene files.

When the number of scene files is switched from

32 to 5:

The data registered in scene files 6 to 32 is deleted. The

deleted data cannot be restored.

m

. This setting corresponds only to MSU-700A/750 and

RCP-730 series.

. Each scene file have no compatibility among the camer-

as if their scene file number differs.

How to change

Change the scene file number using the SETUP page in the

SERVICE menu.

Refer to Section 5-1-6 to display of the SERVICE menu.

Menu setting:

MENU: SERVICE

PAGE: SETUP

ITEM: SCENE FILE TYPE → 5 or 32

1-18 (E)

BVP-E30/E30P M-V1

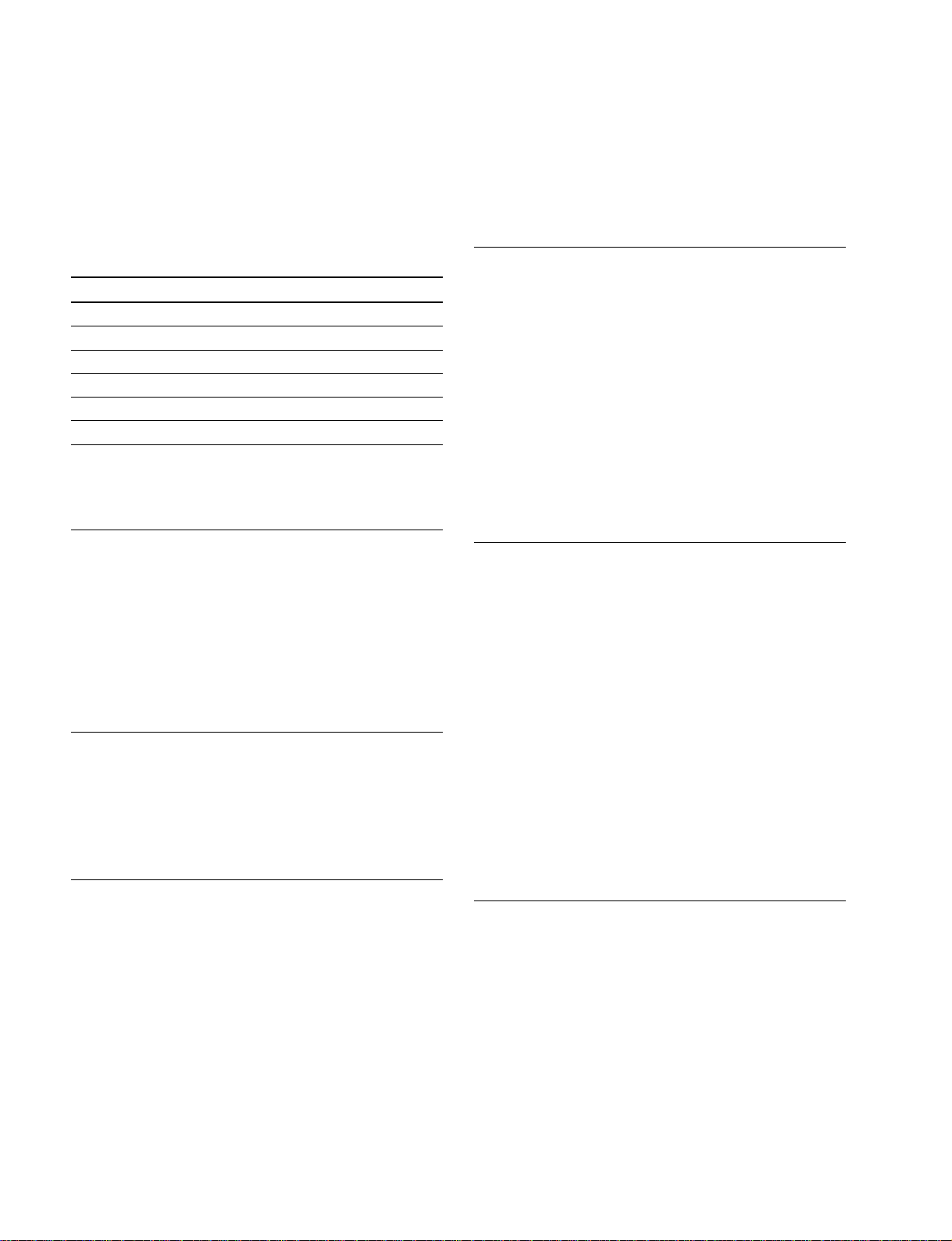

1-13. Removing and Reinstalling the

Flexible Card Wires

This unit uses two types of flexible card wire.

n

Life of flexible card wire will be significantly shortened if

it is folded. Be very careful not to fold the flexible card

wire.

Type-B

Removal

1. Open the connector latch in the direction of arrow A to

release the lock.

2. Remove the flexible card wire in the direction of arrow

B.

Type-A

Removal

1. Open the connector latch in the direction of arrow A to

release the lock.

2. Remove the flexible card wire in the direction of arrow

B.

Flexible card wire

B

A

Connector

Connector latch

Reinstallation

1. Hold the flexible card wire with its blue surface facing

to the front, and insert it in the direction of arrow A.

2. Close the connector latch in the direction of arrow B to

lock it.

Connector latch

Connector

A

Flexible card wire

B

Reinstallation

1. Hold the flexible card wire with its blue surface facing

upward, and insert it in the direction of arrow A.

2. Close the connector latch in the direction of arrow B to

lock it.

Connector latch

Connector

B

Blue surface

Flexible card wire

A

Connector

BVP-E30/E30P M-V1

A

B

Blue surface

Flexible card wire

Connector latch

1-19 (E)

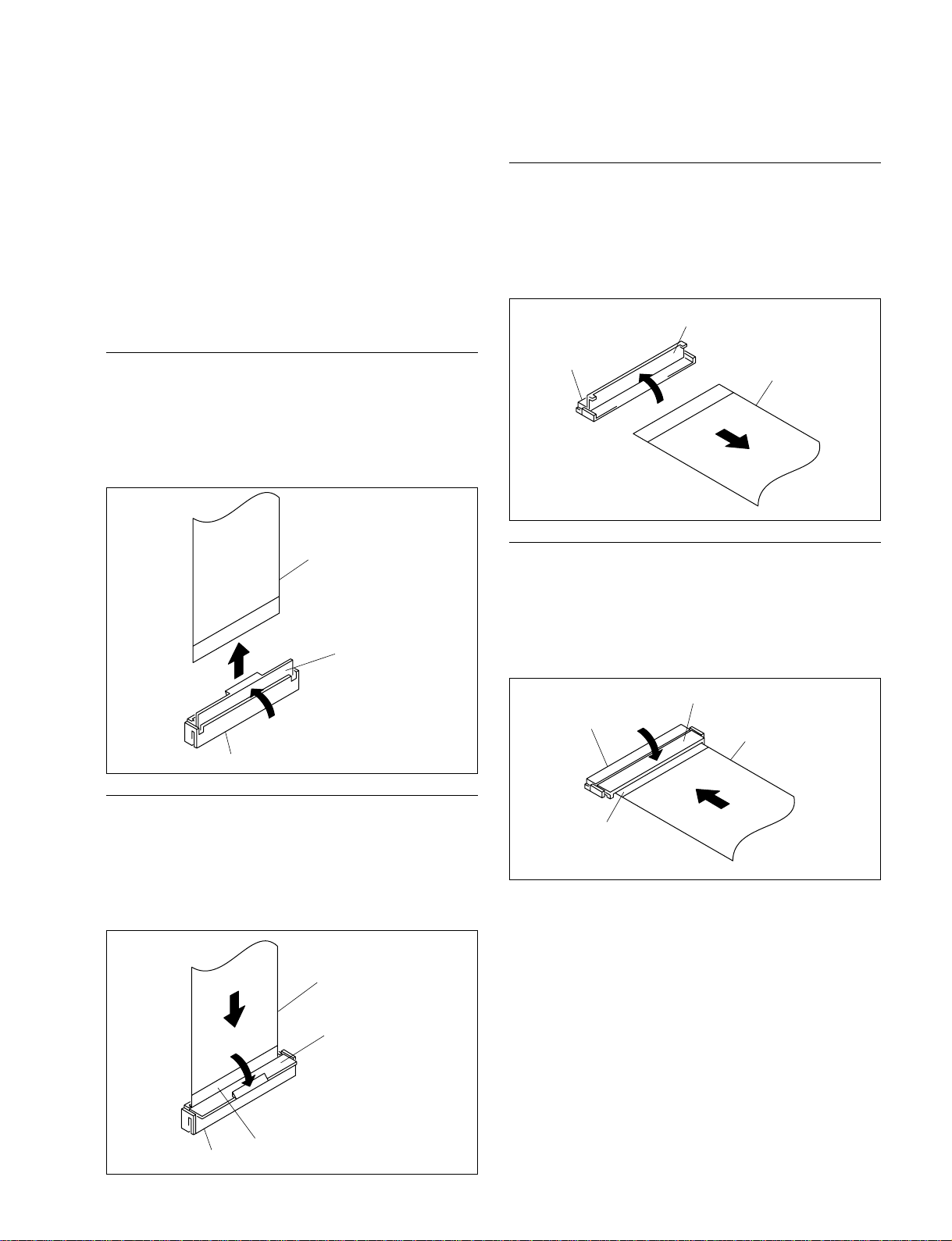

1-14. How to Extend the Circuit Board

1-14-2. Extending the DC-DC Converter

1-14-1. Extending the DPR-261 Board

Tool: DPR-261 board extension assembly

1. Remove the left side panel. (Refer to Section 1-5.)

2. Remove the four screws, and remove the DPR-261

board.

3. Extend the DPR-261 board as shown below using the

DPR-261 board extension assembly.

CN13

MB-953 board

EX-884 board side

CN1

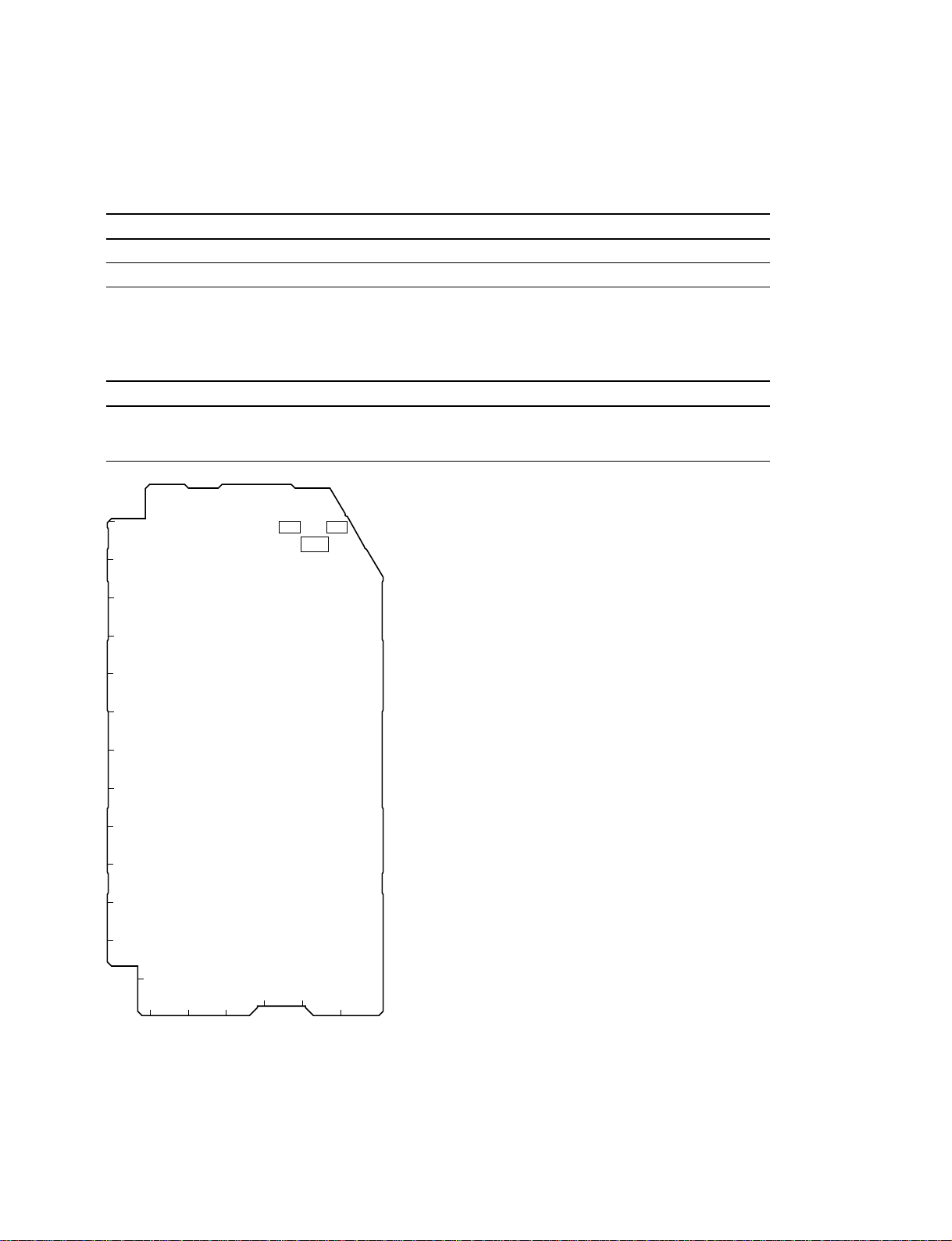

B2.6 x 5

Tool: EX-878 Board

1. Remove the right side panel. (Refer to Section 1-5.)

2. Remove the DC-DC converter (RE-201 board). (Refer

to Section 2-12.)

3. Connect the connector CN1 on the EX-878 board to

the connector CN10 on the MB-953 board.

4. Connect the DC-DC converter to the connector CN2 or

CN3 on the EX-878 board.

CN10/MB-953 board

CN1

EX-878 board

CN2

CN3

DPR-261

board

B2.6 x 5

EX-885

board side

DPR-261 board

extension assembly

DC-DC converter

1-20 (E)

BVP-E30/E30P M-V1

Loading...

Loading...