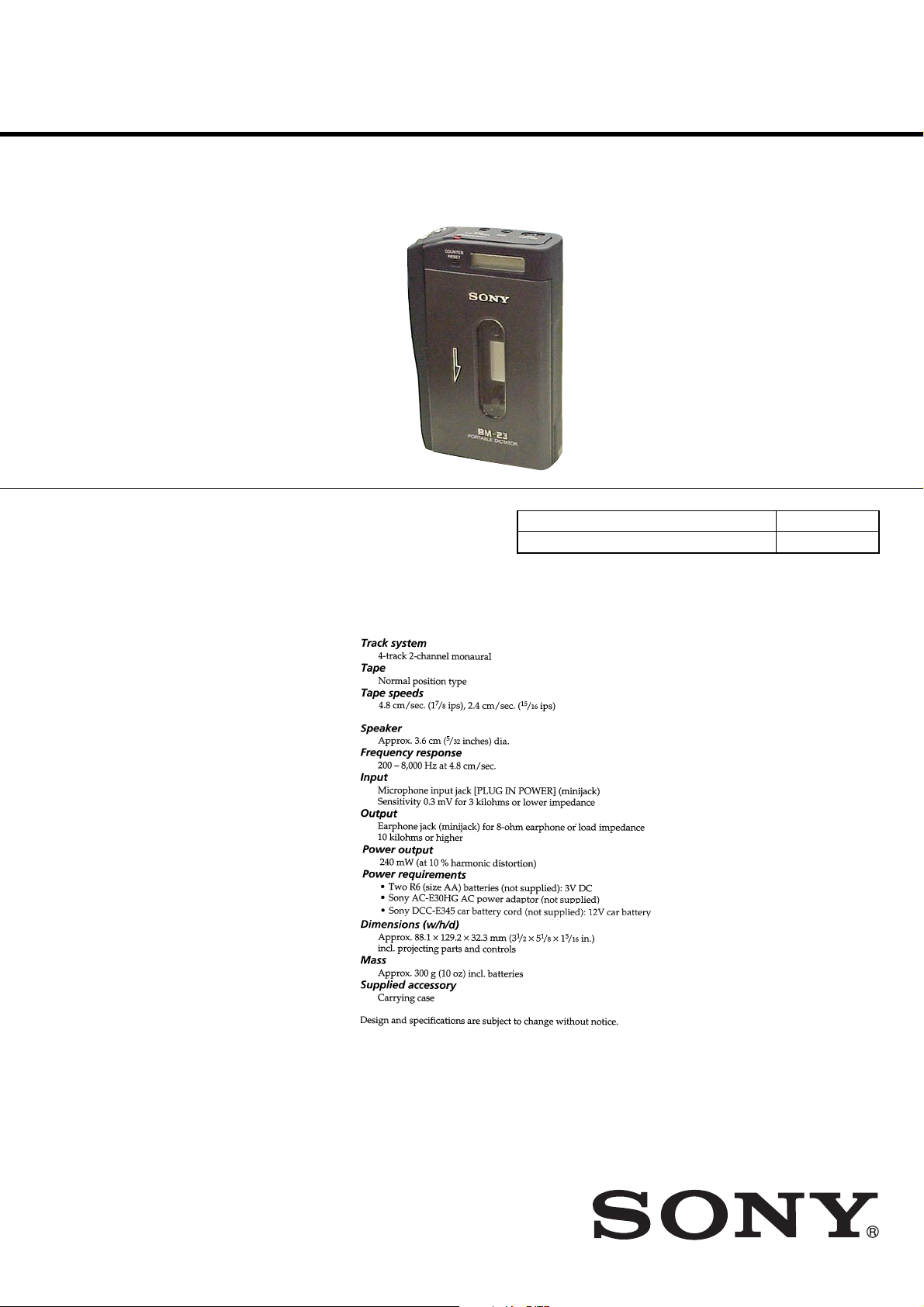

Sony BM-23 Mk2 Service manual

BM-23MK2

SERVICE MANUAL

Ver. 1.0 2005.08

SPECIFICATIONS

US Model

Model Name Using Similar Mechanism NEW

Tape T ransport Mechanism T ype MB-23MK2-101

9-879-836-01

2005H1678-1

© 2005.08

PORTABLE DICTATOR

Sony Corporation

Personal Audio Group

Published by Sony Engineering Corporation

BM-23MK2

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

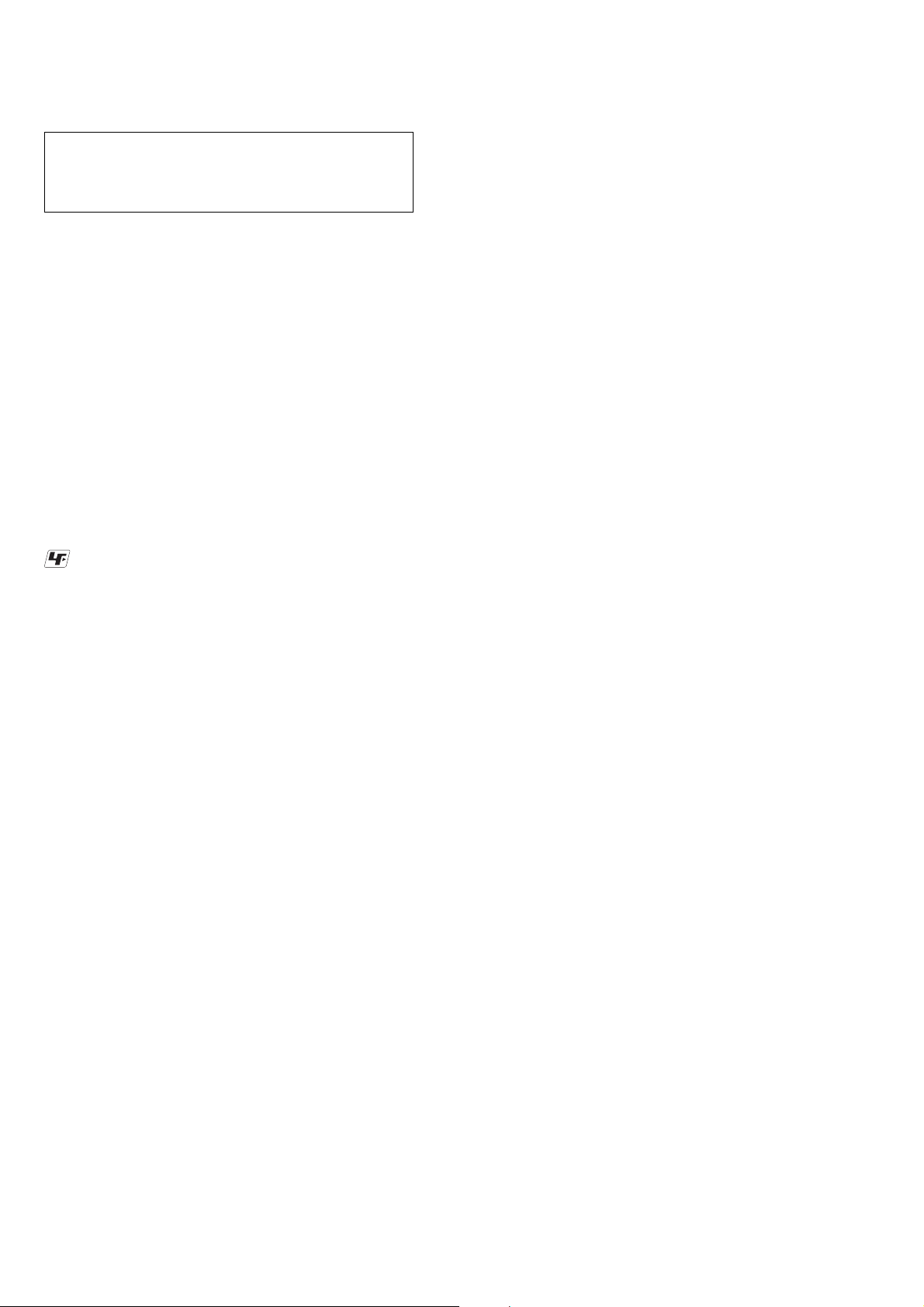

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of soldering iron around 270˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 4

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 5

3-2. Cabinet (Rear) Block Assembly ...................................... 6

3-3. Control Panel Block Assembly........................................ 7

3-4. AUDIO Board.................................................................. 8

3-5. Mechanism Deck (MB-23MK2-101) .............................. 9

3-6. Holder Panel Assembly ................................................... 9

4. MECHANICAL ADJUSTMENTS......................... 10

5. ELECTRICAL ADJUSTMENTS .......................... 10

6. DIAGRAMS

6-1. Block Diagram – AUDIO Section – ................................ 13

6-2. Printed Wiring Boards ..................................................... 14

6-3. Schematic Diagram – AUDIO Board (1/4) – .................. 15

6-4. Schematic Diagram – AUDIO Board (2/4) – .................. 16

6-5. Schematic Diagram – AUDIO Board (3/4) – .................. 17

6-6. Schematic Diagram – AUDIO Board (4/4) – .................. 18

6-7. Schematic Diagram – LCD Board –............................... 19

7. EXPLODED VIEWS

7-1. Cabinet Section................................................................ 22

7-2. Chassis Section ................................................................ 23

7-3. Mechanism Deck Section-1 (MB-23MK2-101).............. 24

7-4. Mechanism Deck Section-2 (MB-23MK2-101).............. 25

8. ELECTRICAL PARTS LIST .................................. 26

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

BM-23MK2

2

SECTION 1

SERVICING NOTES

This unit use PH501 (photo coupler) to detect reel rotation.

As PH501 is mounted on the AUDIO board, reel rotation will not be detected if the AUDIO board has been removed.

When performing mechanism deck operation and voltage checks whit the A UDIO board removed, perform them using the follo wing method.

Method:

Connect TP32 of the AUDIO board and GND with a jumper wire.

AUDIO BOARD (SIDE B)

TP3

PH501

IC503

3

BM-23MK2

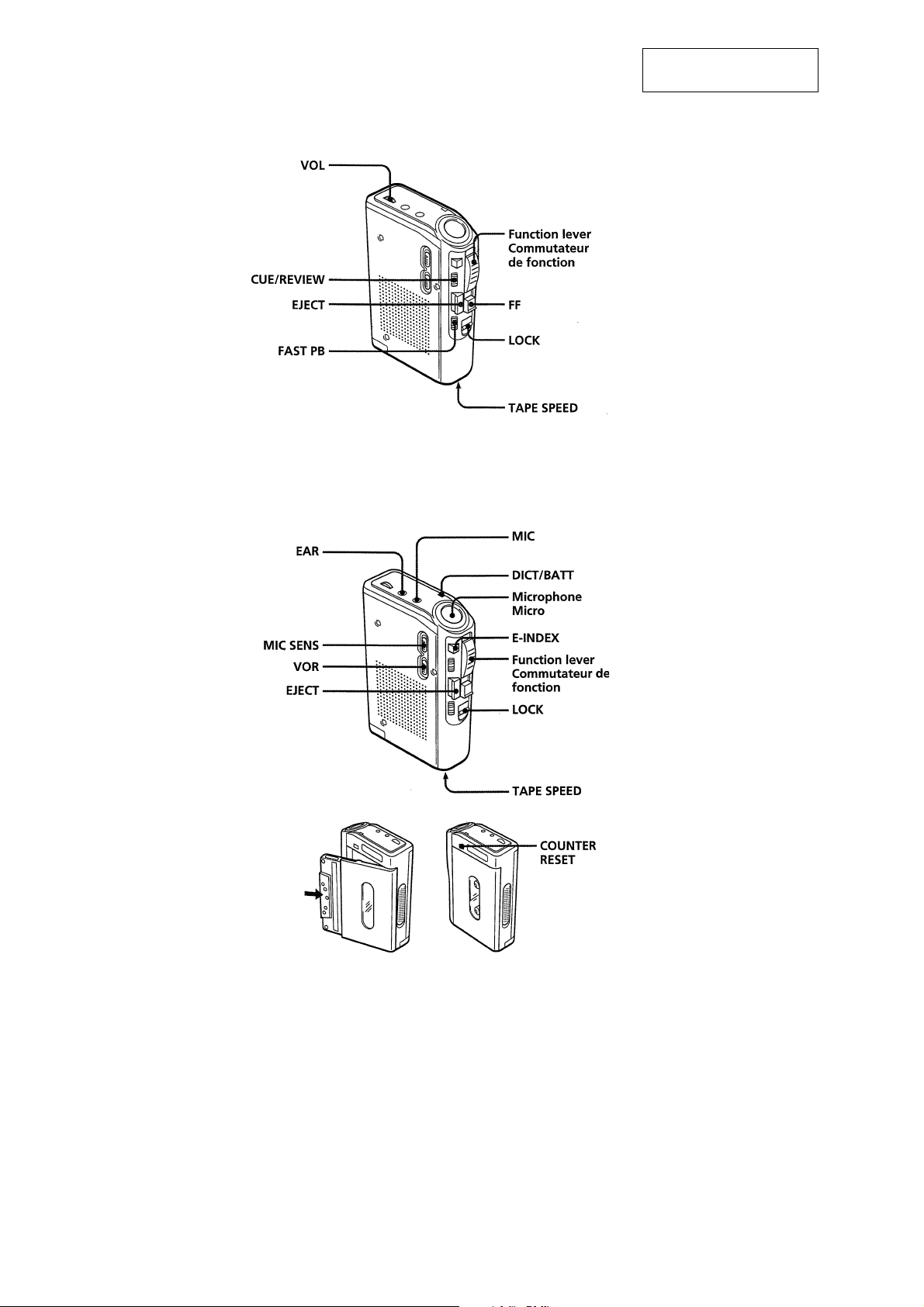

SECTION 2

GENERAL

This section is extracted

from instruction manual.

4

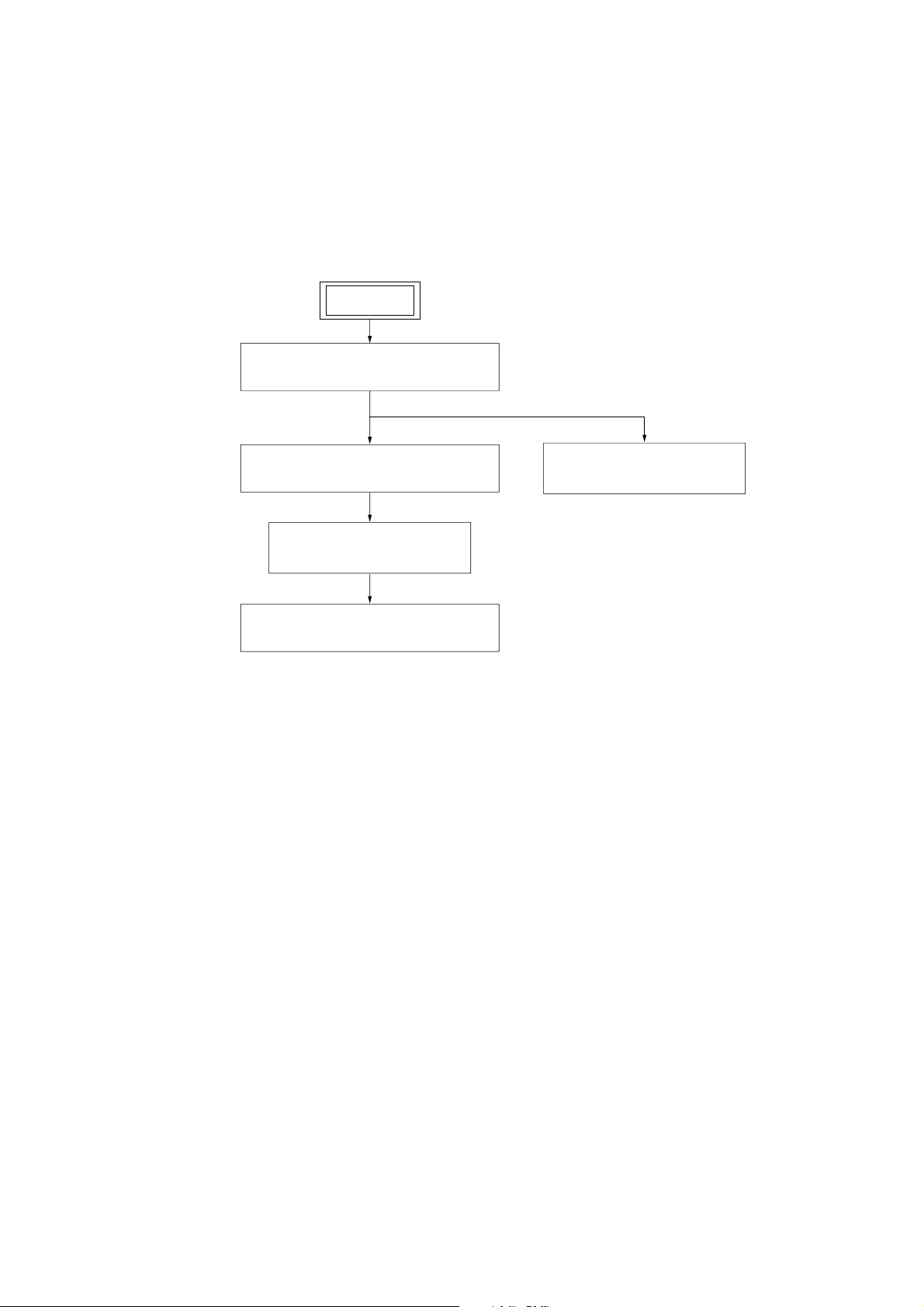

3-1. DISASSEMBLY FLOW

•This set can be disassembled in the order shown below.

SET

BM-23MK2

SECTION 3

DISASSEMBLY

3-2. CABINET (REAR) BLOCK ASSEMBLY

(Page 6)

3-3. CONTROL PANEL BLOCK ASSEMBLY

(Page 7)

3-4. AUDIO BOARD

(Page 8)

3-5. MECHANISM DECK (MB-23MK2-101)

(Page 9)

3-6. HOLDER PANEL ASSEMBLY

(Page 9)

5

BM-23MK2

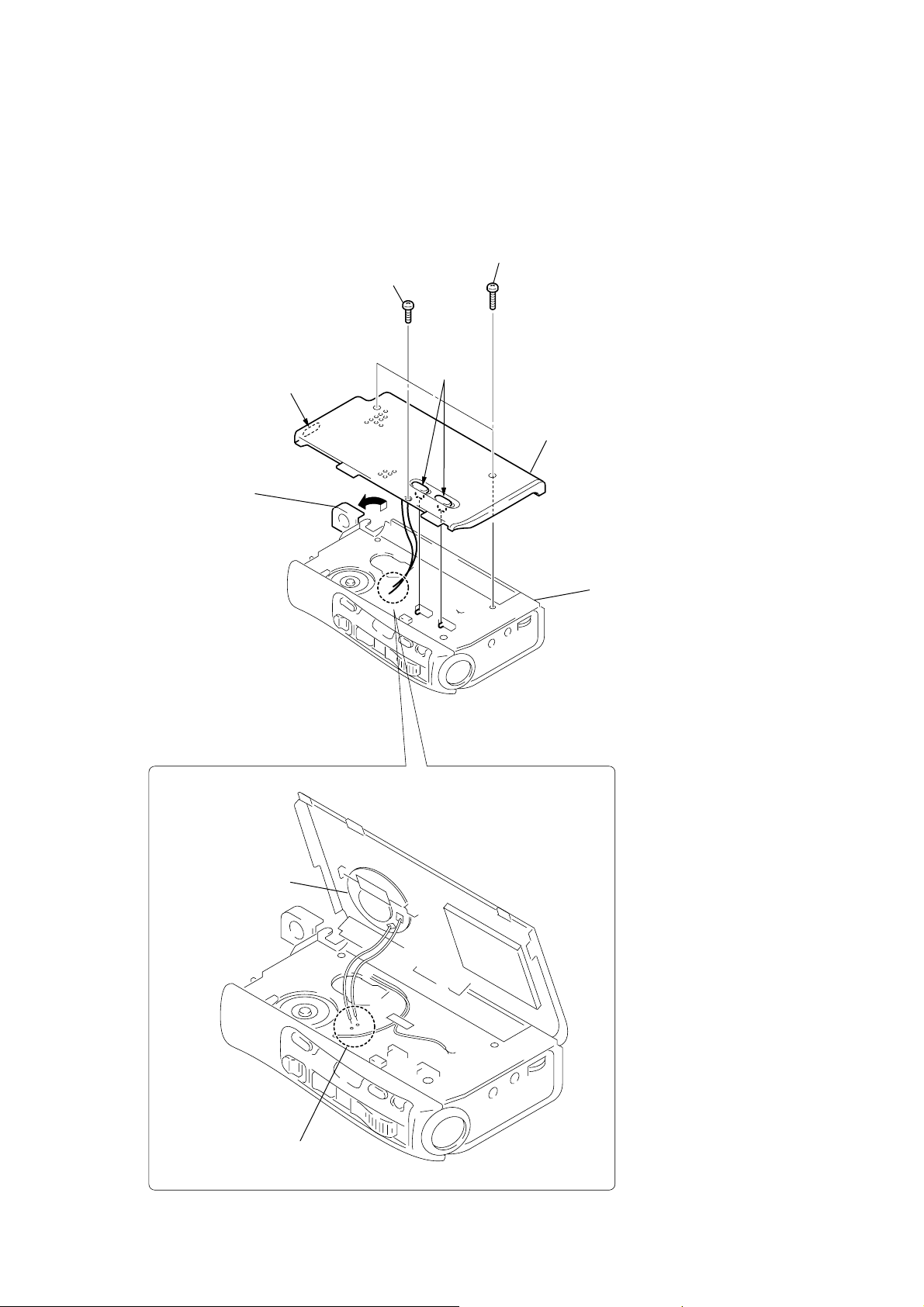

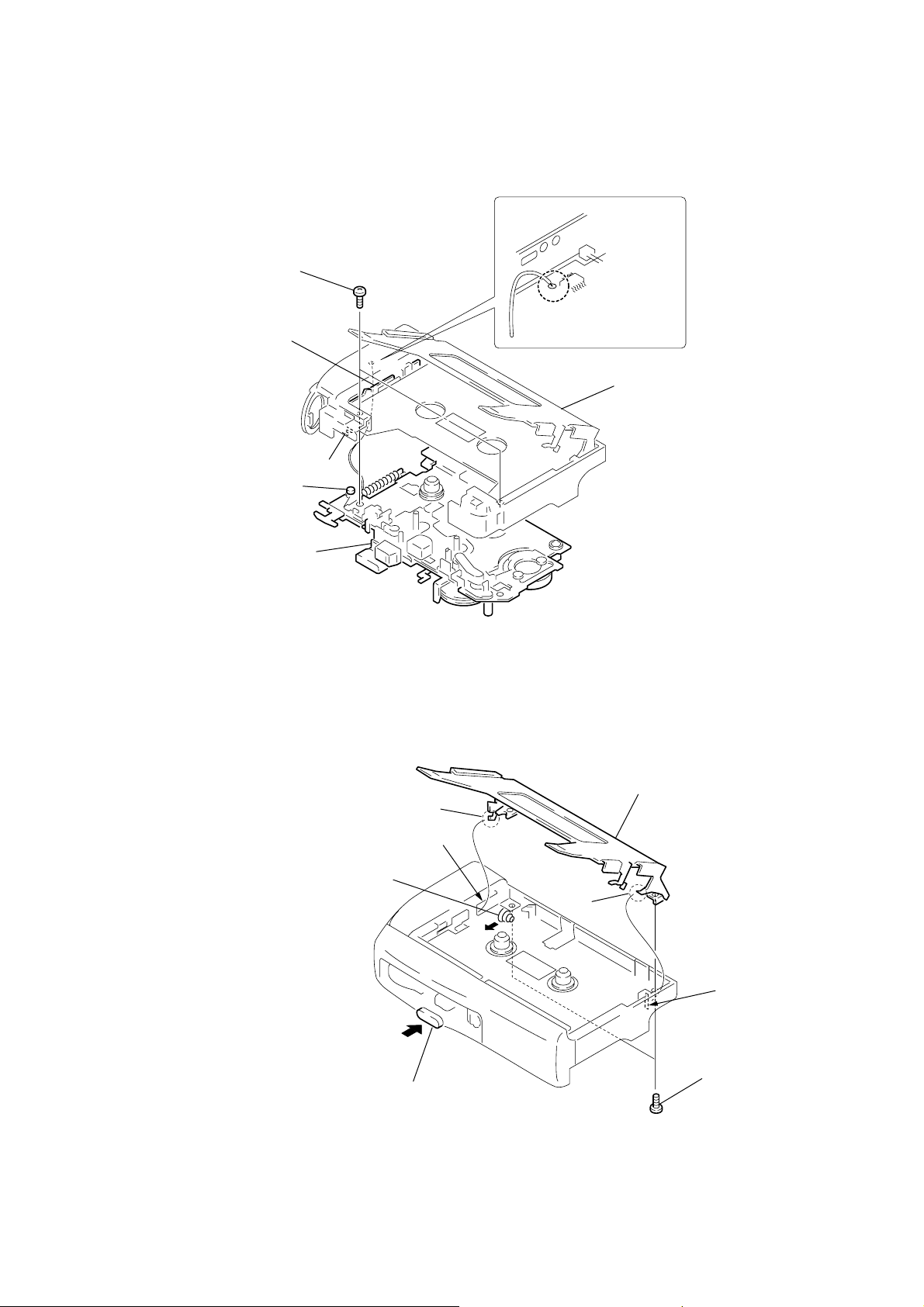

Note: Follow the disassembly procedure in the numerical order given.

3-2. CABINET (REAR) BLOCK ASSEMBLY

2

screw

(M 1.4

×

5.0)

3

two screws

(+BTP 1.7

×

10)

1

Open the battery case lid

in the direction of arrow.

A

A

5

cabinet (rear) block assembly

note : When attaching the cabinet (rear)

block assembly, adjust the position

of the three knobs indicated by

arrows

AUDIO board.

A

and the switch of the

AUDIO board

speaker

4

Remove soldering

two the four points.

6

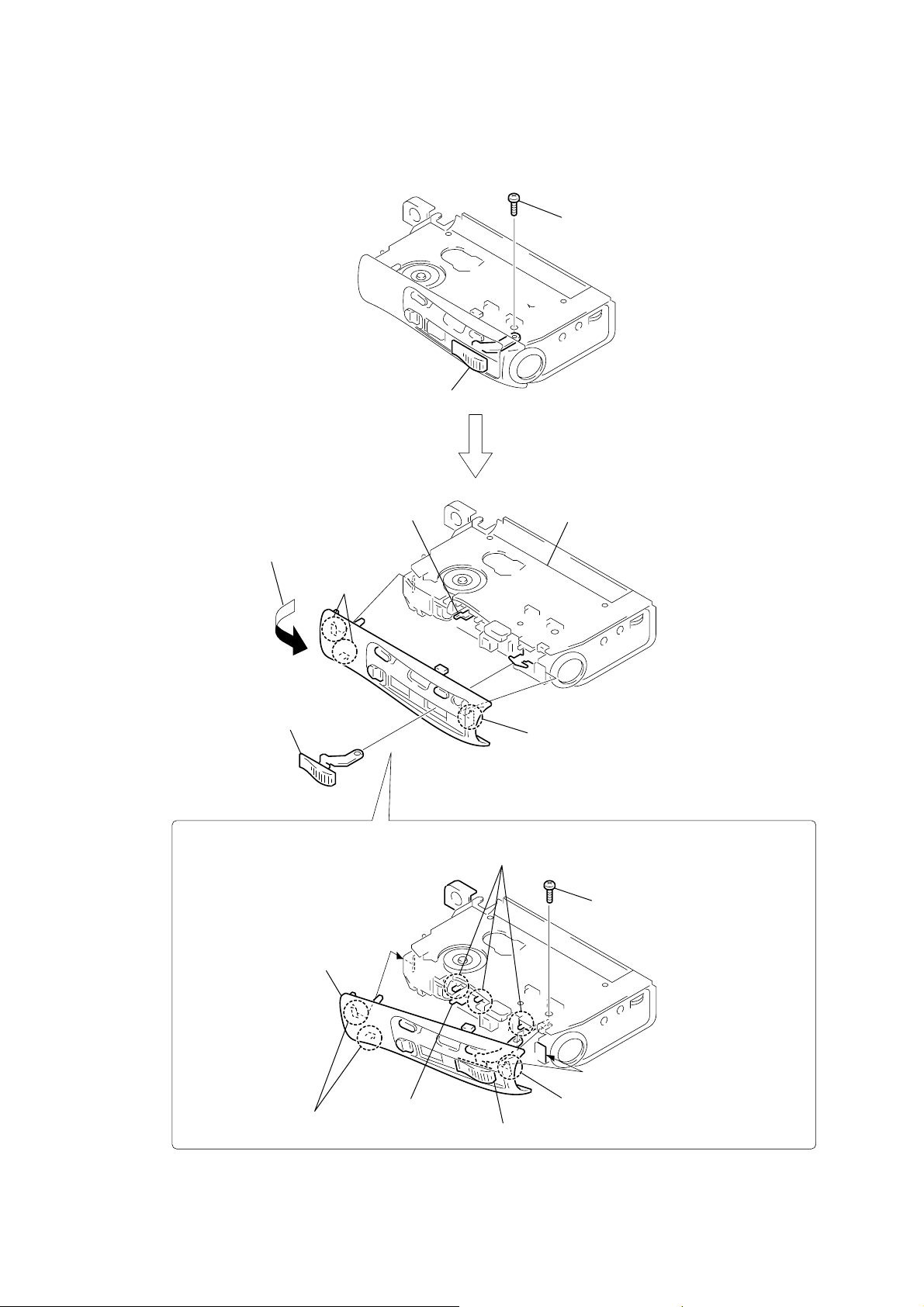

3-3. CONTROL PANEL BLOCK ASSEMBLY

control button assembly

1

screw (M1.4)

BM-23MK2

4

lever (lock)

6

Remove the control panel block

assembly in the direction of the arrow.

2

two claws

5

control button assembly

qd

control panel

block assembly

AUDIO board

3

claw

PRECAUTION DURING CONTROL PANEL BLOCK

ASSEMBLY INSTALLATION

8

To attach the control panel block

assembly , align the three switch positions as shown.

qs

screw (M1.4)

qa

two claws

9

lever (lock)

0

7

control button assembly

claw

7

BM-23MK2

)

3-4. AUDIO BOARD

3

Remove the soldering.

4

battery case

2

screw (1.7 × 2.5)

1

screw (M1.4 × 3)

6

harnesses

7

from the five points.

0

screw (M1.4 × 3)

5

three cabinet

upper cushions

Remove soldering

8

Remove soldering

from the seven points.

qa

Remove the AUDIO board complete

in the direction of arrow.

9

flexible board

(CN101) (12core

8

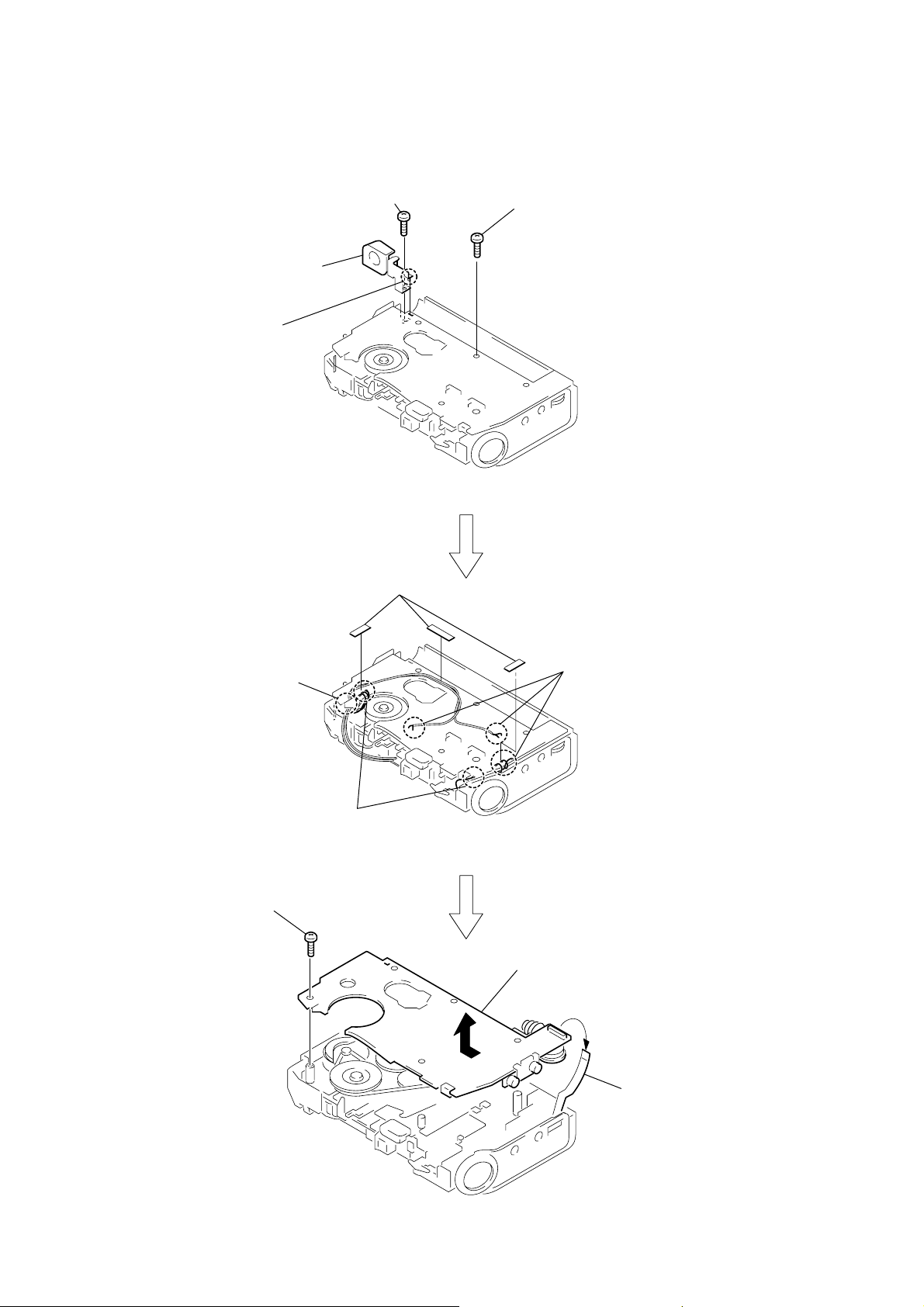

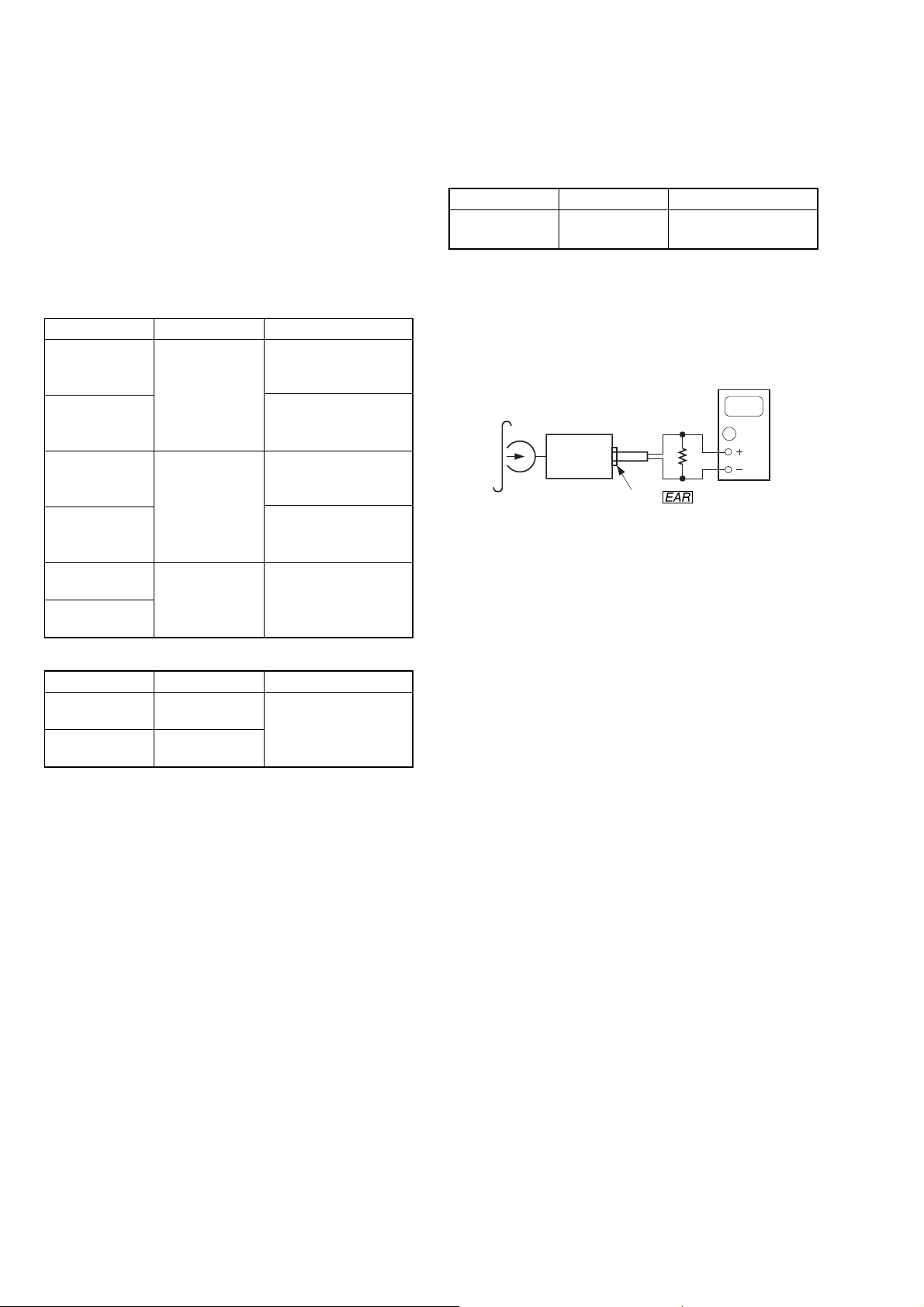

3-5. MECHANISM DECK (MB-23MK2-101)

t

3

two screws (M1.4 × 3.0)

lock plate assembly

A

shaft-A

1

Remove the soldering.

2

Set the holder panel

assembly to eject.

BM-23MK2

4

mechanism deck

(MB-23MK2-101)

3-6. HOLDER PANEL ASSEMBLY

2

Move the battery coil spring in the direction

of the arrow and secure it with the screw.

claw

A

note : When attaching the mechanism deck,

set the mechanism deck to stop and

adjust the position of shaft-A and par

A of the lock plate assembly.

4

holder panel assembly

claw

A

1

While pressing the button (eject), insert

the two claws of the holder panel assembly

into the holes indicated by arrows

A

.

3

two screws (M1.4 × 1.6)

9

BM-23MK2

SECTION 4

MECHANICAL ADJUSTMENTS

SECTION 5

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

playback head rubber belts

capstan idlers

pinch roller

2. Demagnetize the playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the rated power

supply voltage (3V) unless otherwise noted.

•Torque Measurement

Mode Torque Meter Meter Reading

2.06 – 3.72 mN•m

FWD 21 – 38 g•cm

CQ-102C

FWD

Back Tension

REV 21 – 38 g•cm

CQ-102RC

REV

Back Tension

FF

CQ-201B

REW

(0.30 – 0.52 oz•inch)

0.05 – 0.29 mN•m

0.5 – 3 g•cm

(0.01 – 0.04 oz•inch)

2.06 – 3.72 mN•m

(0.30 – 0.52 oz•inch)

0.05 – 0.29 mN•m

0.5 – 3 g•cm

(0.01 – 0.04 oz•inch)

more than 60 g•cm

(more than 0.84 oz•inch)

PRECAUTION

1. Power supply voltage : 3V

Test T ape

Type Signal Used for

WS-48A 3 kHz, 0 db Tape Speed Adjustment

Tape Speed 4.8cm/s Adjustment

Switch position

TAPE SPEED Switch : 4.8 cm

Procedure:

test

WS-48A

(3 kHz, 0 dB)

18

set

J102

1. Play back WS-48A (tape center portion) in FWD mode.

Adjust the R V601 so that the frequenc y counter reads 2,980±

30 Hz.

2. Play back WS-48A (tape center portion) in REV mode.

Confirm that the reading of frequency counter is within 2.5 %

from the reading in step 1.

frequency

counter

Ω

•Tape Pulling Force Measurement

Mode Torque Meter Meter Reading

FF CQ-403A

REW CQ-403R

(more than 1.42 oz)

more than 40 g

10

Loading...

Loading...