SONY PFM-42B2, PFM-42B2E, BKM-B10, BKM-B12, BKM-B13 Service Manual

...

SERVICE MANUAL

MODEL

.............. ......... ....................

DEST. CHASSIS NO. MODEL DEST. CHASSIS NO.

PFM-42B2 US/CND/E

PFM-42B2E AEP

.............. ......... ....................

BKM-B10 AEP

RM-42B US/CND/AEP/E

1 32

4 5 6

7 8 9

0

PFM-42B2 Flat Panel Monitor

PFM-42B2E Flat Panel Monitor

BKM-B10 Video Input Adaptor (AEP only) (SEPARATE VOLUME)

BKM-B12 Component Input Adaptor (SEPARATE VOLUME)

BKM-B13 Video Input & Control S Adaptor (SEPARATE VOLUME)

RM-42B Remote Commander

FLAT PANEL MONITOR

! W ARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

WARNING!!

AN INSULATED TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECEIVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY A

DIAGRAMS, EXPLODED VIEWS AND IN THE PARTS LIST ARE

CRITICAL TO SAFE OPERATION. REPLACE THESE COMPONENTS WITH SONY P AR TS WHOSE P AR T NUMBERS APPEAR

AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

!!

! MARK ON THE SCHEMATIC

!!

ATTENTION!!

AFIN D’ÉVITER TOUT RISQUE D’ÉLECTROCUTION

PROVENANT D’UN CHÂSSIS SOUS TENSION, UN

TRANSFORMATEUR D’ISOLEMENT DOIT ETRE UTILISÉ LORS

DE TOUT DÉPANNAGE.

LE CHÂSSIS DE CE RÉCEPTEUR EST DIRECTEMENT

RACCORDÉ Á L’ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS Á LA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE MAPQUE

LES SCHÉMAS DE PRINCIPE, LES VUES EXPLOSÉES ET LES

LISTES DE PIECES SONT D’UNE IMPORTANCE CRITIQUE

POUR LA SÉCURITÉ DU FONCTIONNEMENT. NE LES

REMPLACER QUE PAR DES COMPOSANTS SONY DONT LE

NUMÉRO DE PIÈCE EST INDIQUÉ DANS LE PRÉSENT

MANUEL OU DANS DES SUPPLÉMENTS PUBLIÉS P AR SONY .

!!

! SUR

!!

PFM-42B2/42B2E

For the customers in the Netherlands

Voor de klanten in Nederland

Dit apparaat bevat een CR2025 batterij voor memory

back-up.

Raadpleeg uw leverancier over de verwijdering van de

batterij op het moment dat u het apparaat bij einde

levensduur afdankt.

Gooi de batterij niet weg. maar lever hem in als KCA.

Bij dit product zijn batterijen geleverd.

Wanneer deze leeg zijn, moet u ze niet

weggooien maar inleveren als KCA.

For the customers in the Netherlands

Voor de klanten in Nederland

Bij dit product zijn batterijen geleverd.

Wanneer deze leeg zijn, moet u ze niet

weggooien maar inleveren als KCA.

Für Kunden in Deutschland

Entsorgungshinweis: Bitte werfen Sie nur entladene

Batterien in die Sammelboxen beim Handel oder den

Kommunen. Entladen sind Batterien in der Regel dann,

wenn das Gerät abschaltet und signalisiert “Batterie

leer” oder nach längerer Gebrauchsdauer der Batterien

“nicht mehr einwandfrei funktioniert”. Um

sicherzugehen, kleben Sie die Batteriepole z.B. mit

einem Klebestreifen ab oder geben Sie die Batterien

einzeln in einen Plastikbeutel.

PFM-42B2/42B2E

1 (P)

CAUTION

ADVARSEL

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch

der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ. Entsorgung

gebrauchter Batterien nach Angaben des

Herstellers.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du même

type ou d’un type équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées conformément

aux instructions du fabricant.

Lithiumbatteri - Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten.

Brukt batteri returneres

apparatleverandøren.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ

som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande

föreskrifter.

VAROITUS

Paristo voi räjähtää jos se on virheellisesti

asennettu.

Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

2 (P)

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

PFM-42B2/42B2E

Table of Contents

1. Service Informations

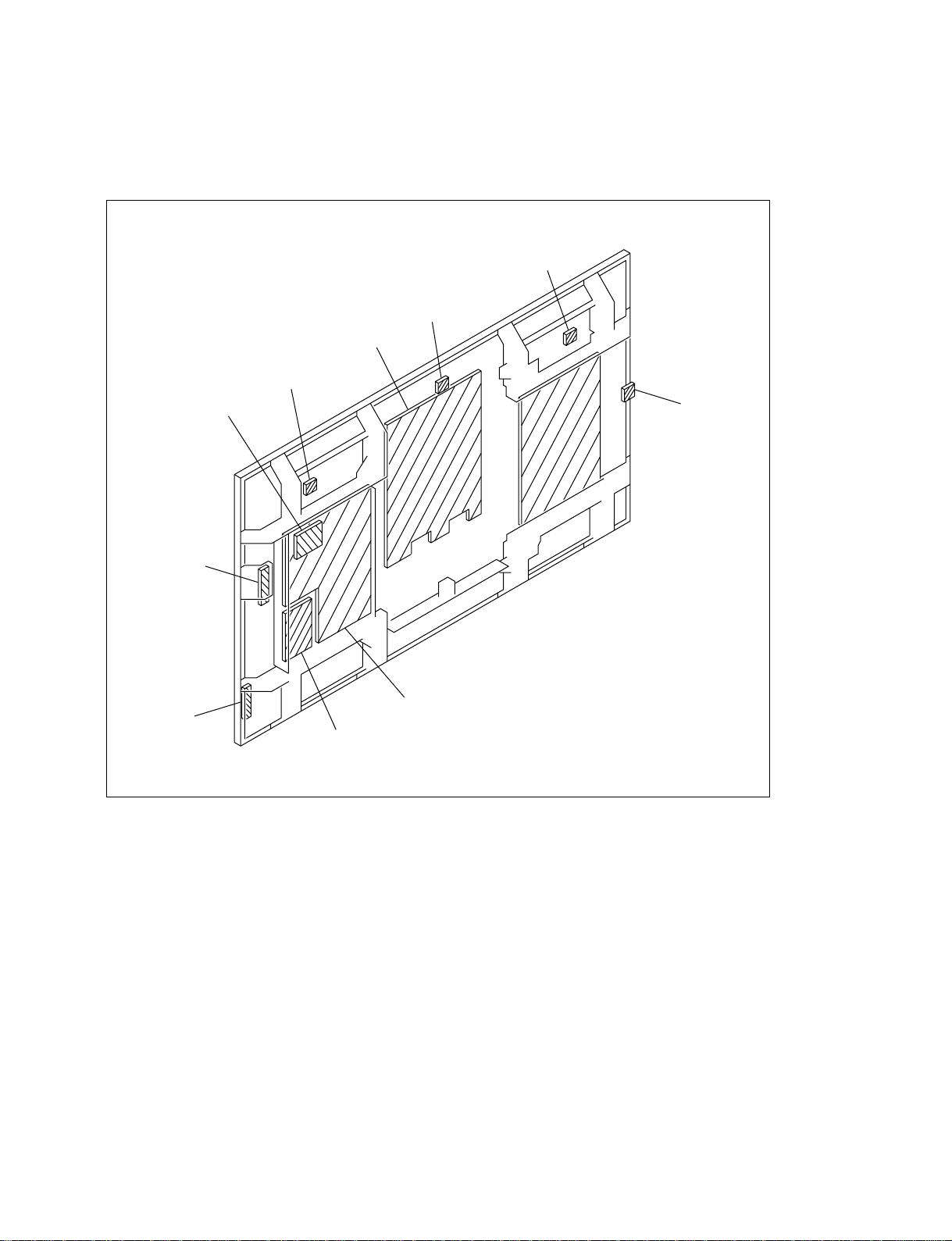

1-1. Board Layout............................................................................................... 1-1

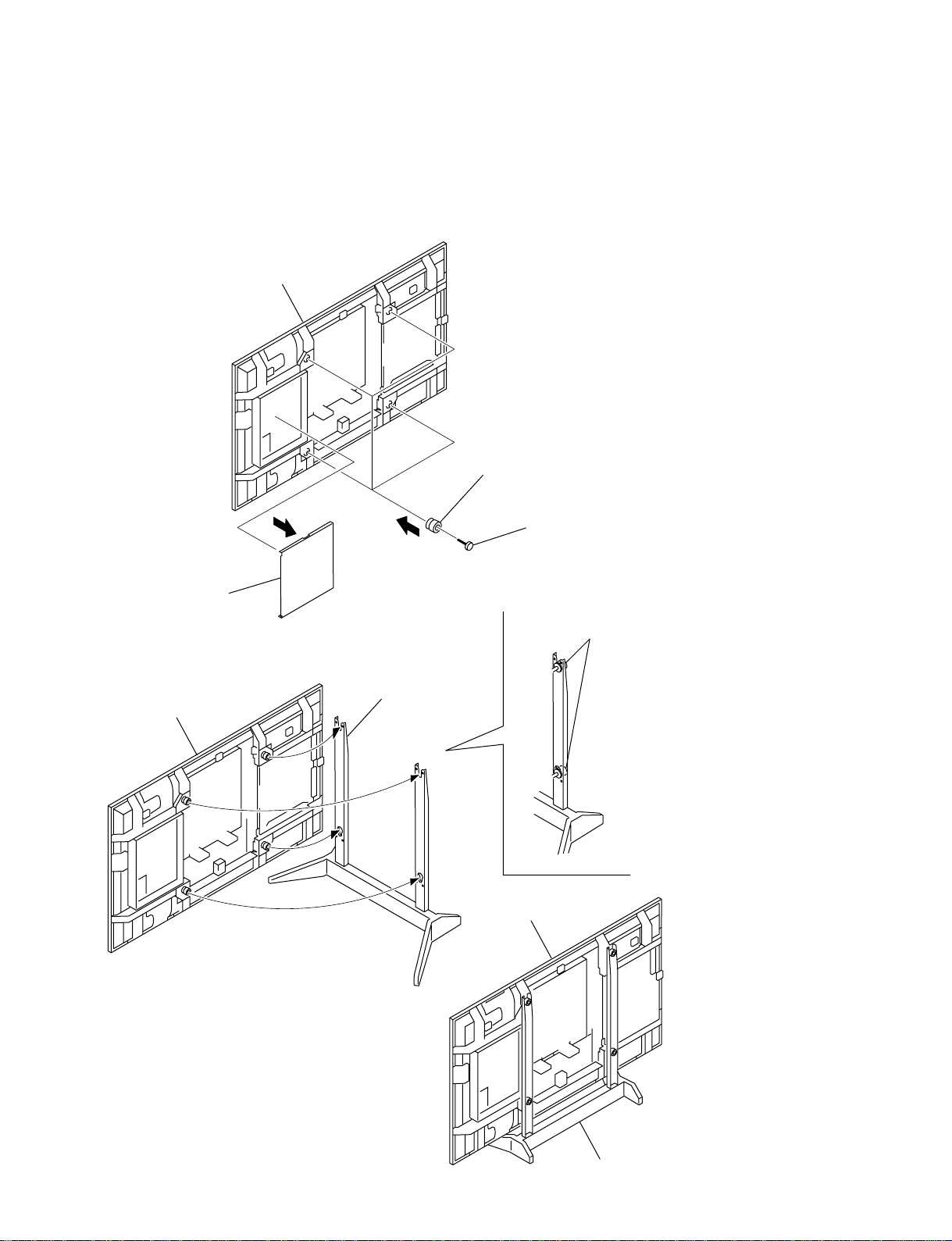

1-2. Disassembly ................................................................................................1-2

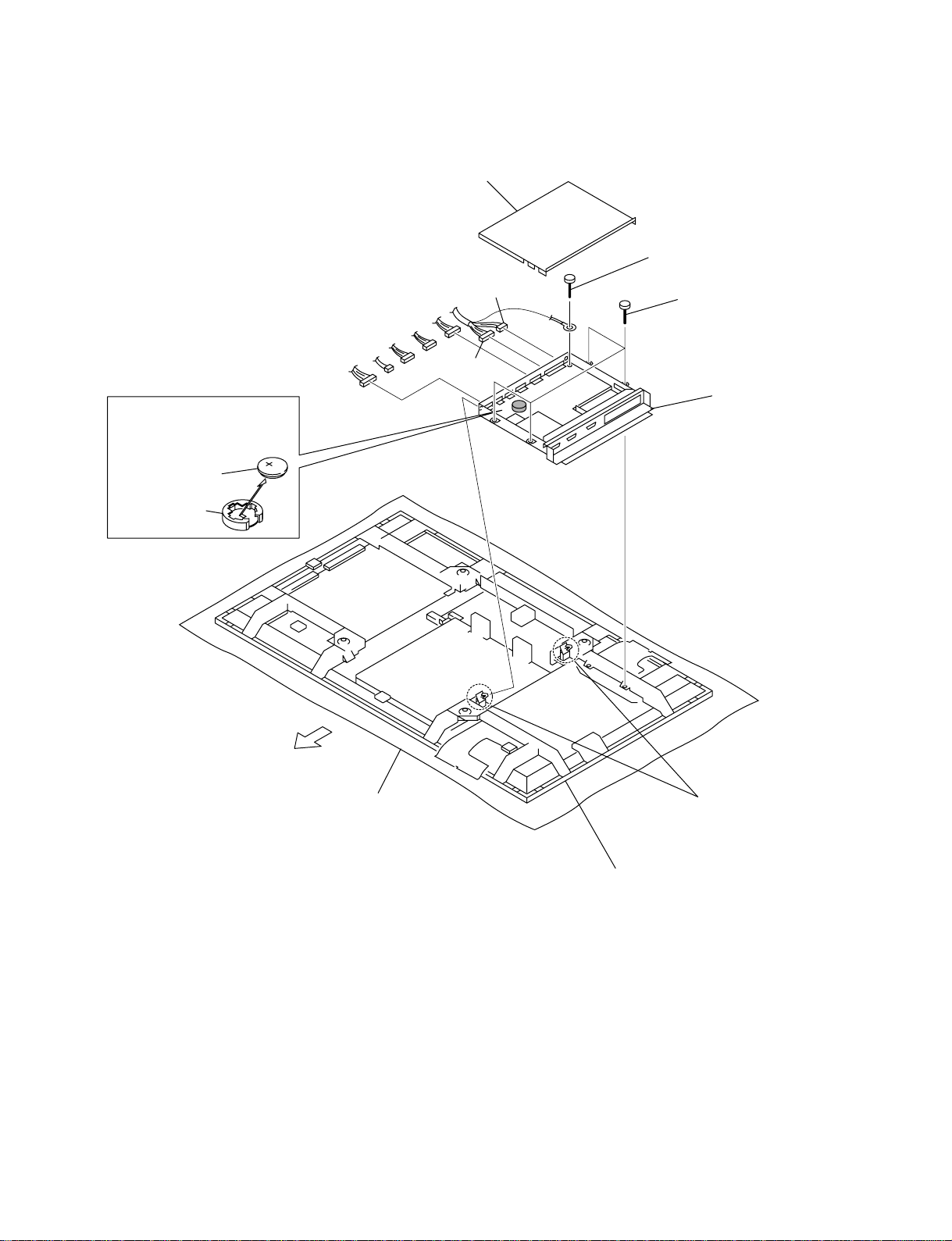

1-2-1. QA Board Removal....................................................................1-2

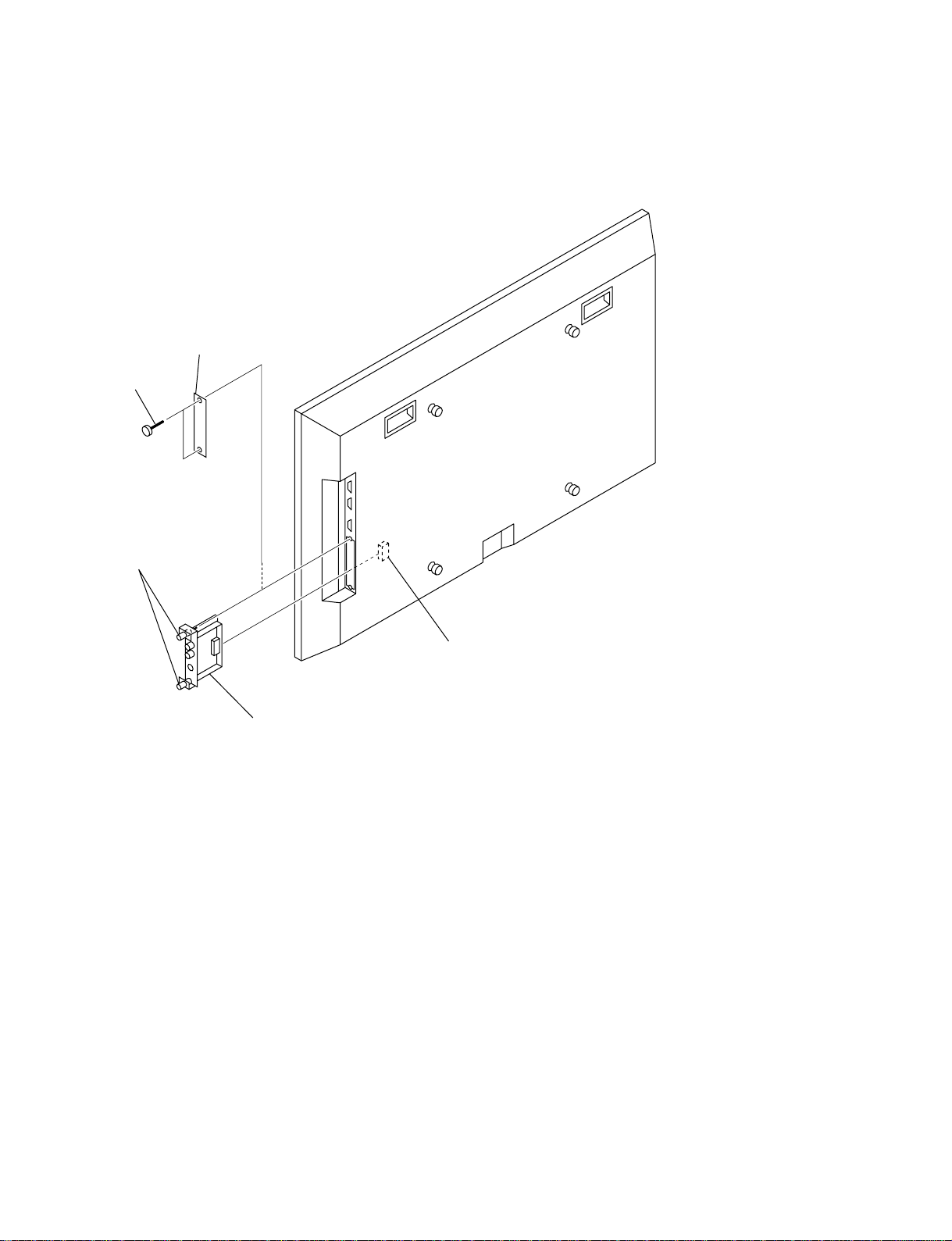

1-2-2. Rear Cover Assy Removal .........................................................1-3

1-2-3. Bezel Assy and YA, YB Boards Removal .................................1-4

1-2-4. B Block Assy Removal ..............................................................1-5

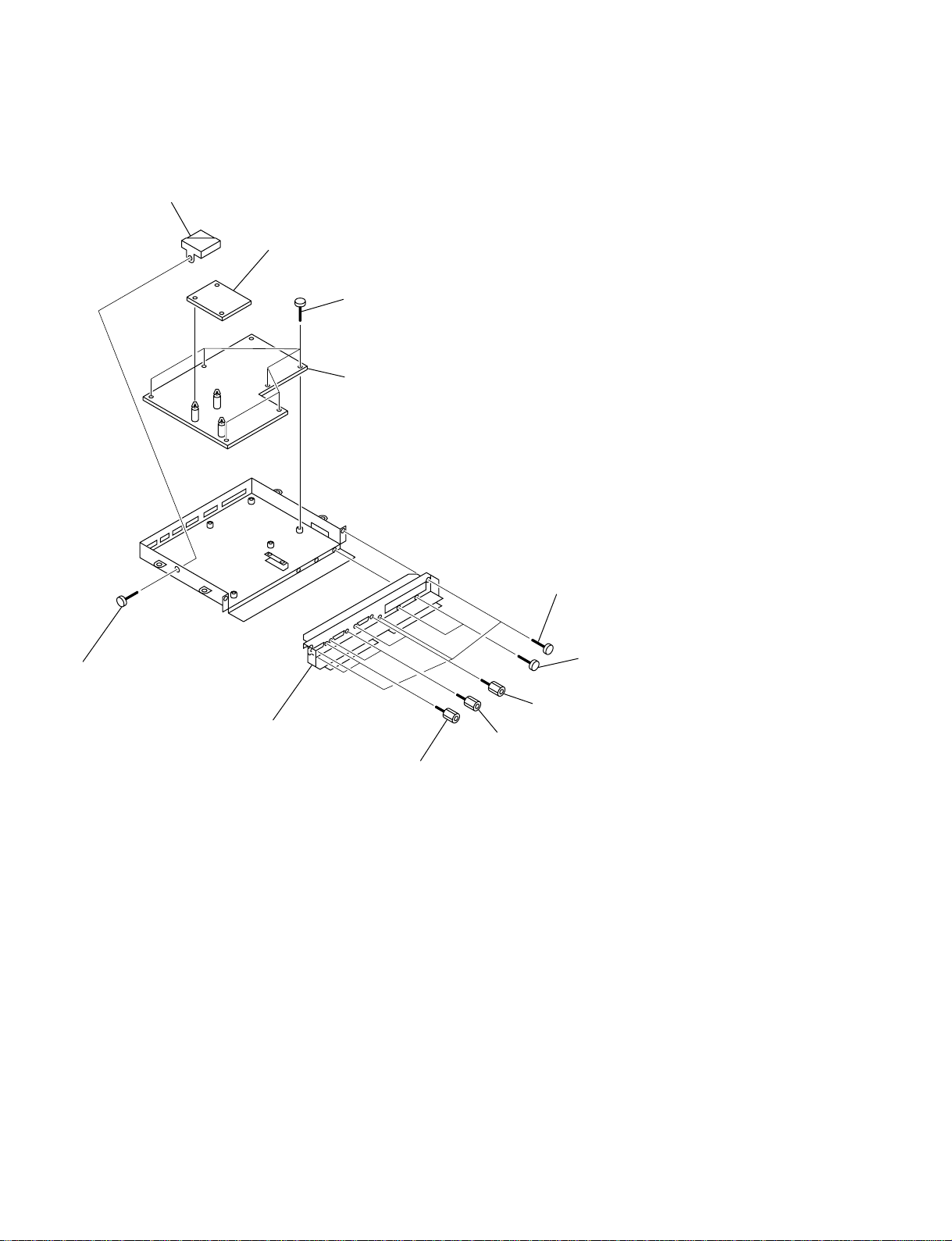

1-2-5. B and B1 Boards Removal .........................................................1-6

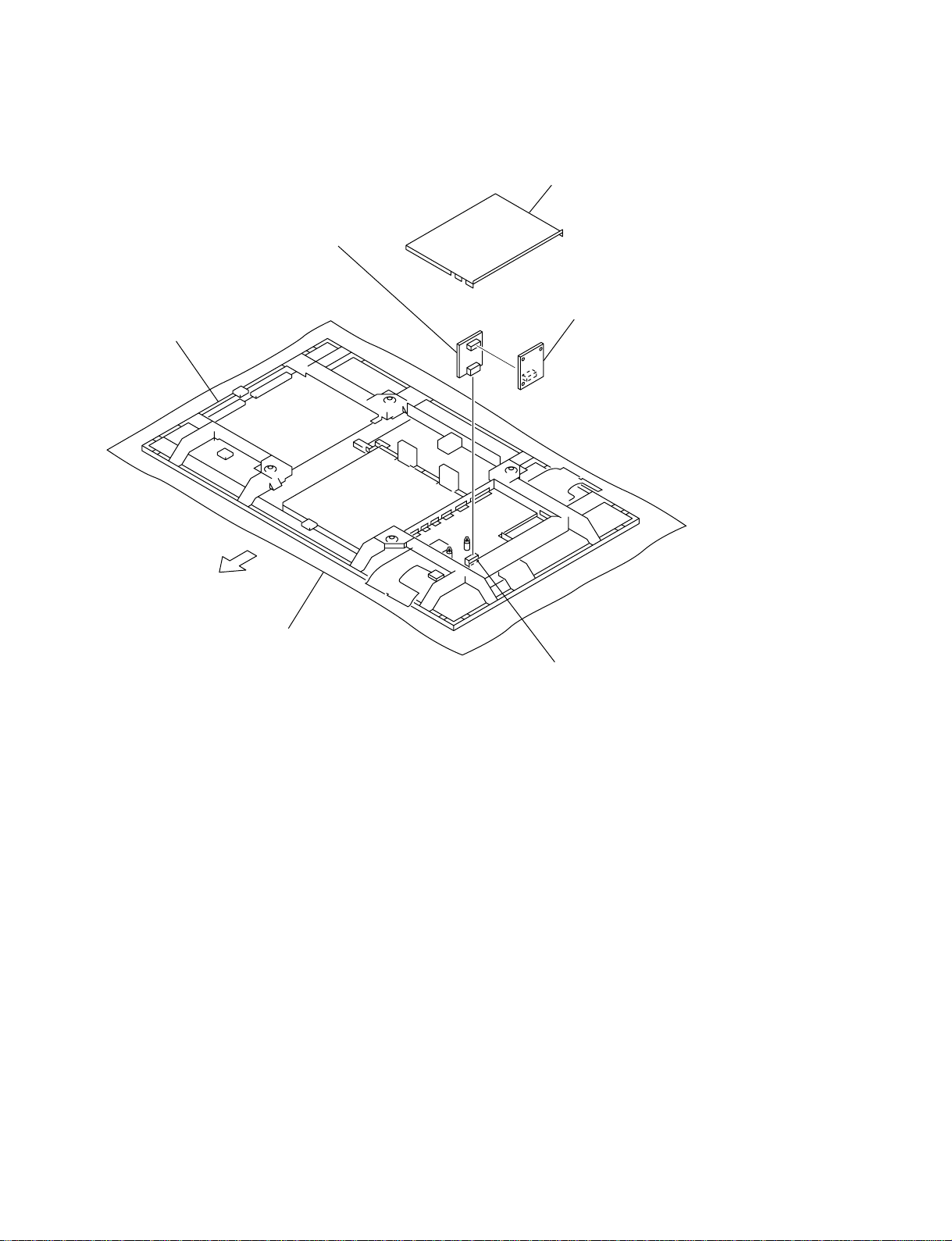

1-2-6. Extension Board Connection......................................................1-7

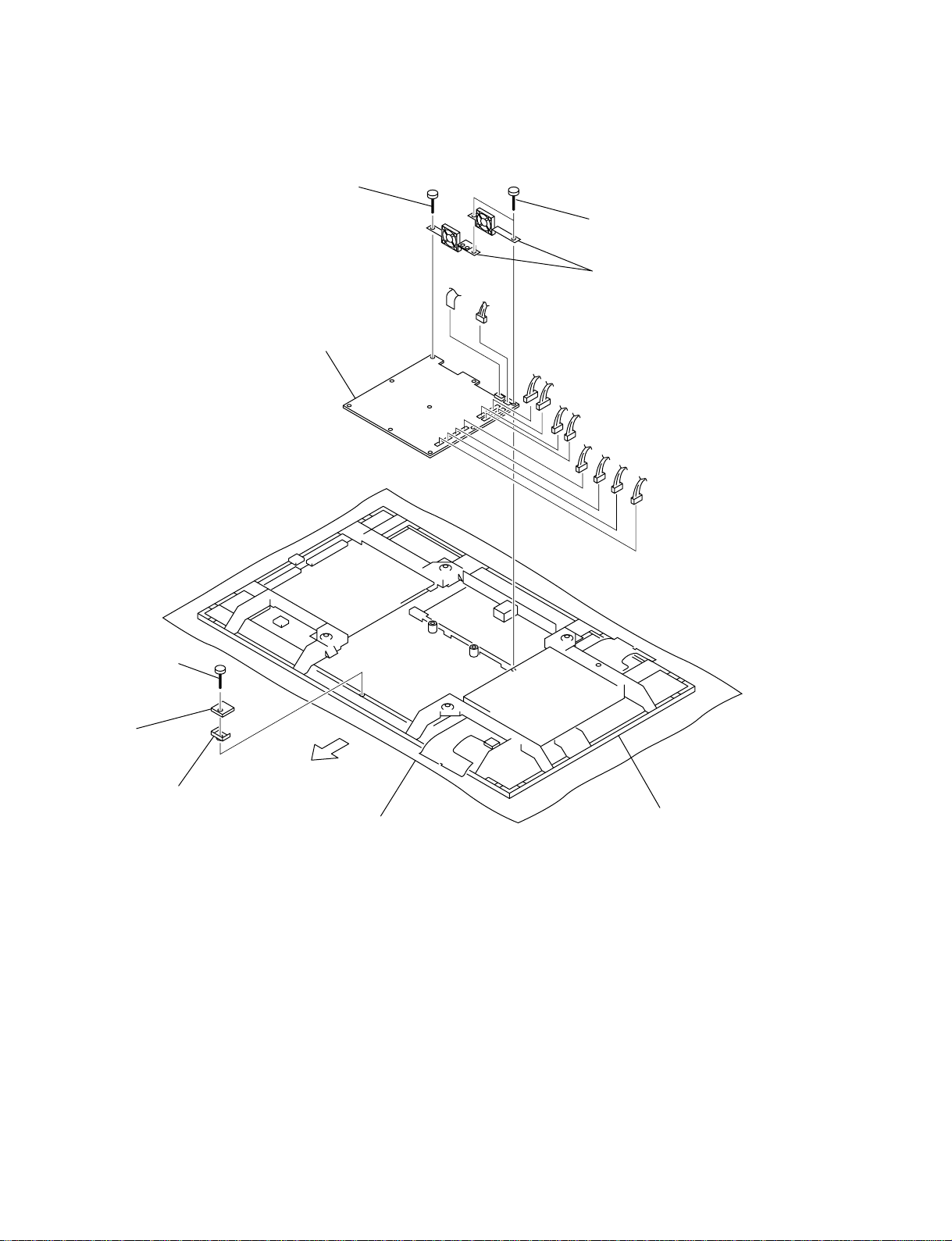

1-2-7. Switching Regulator (APS-179 board) Removal .......................1-8

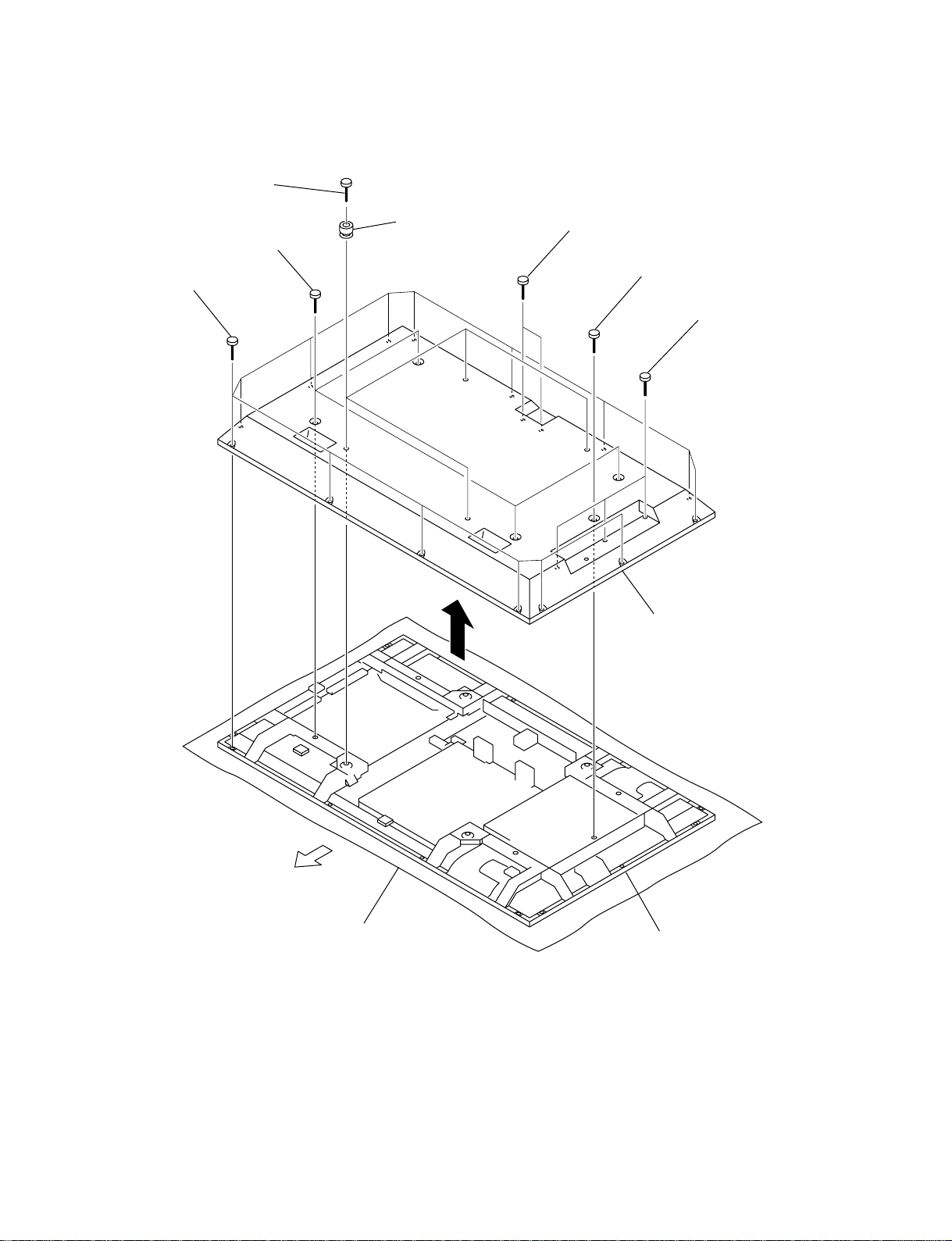

1-2-8. Plasma Display Panel Unit Removal (1/2).................................1-9

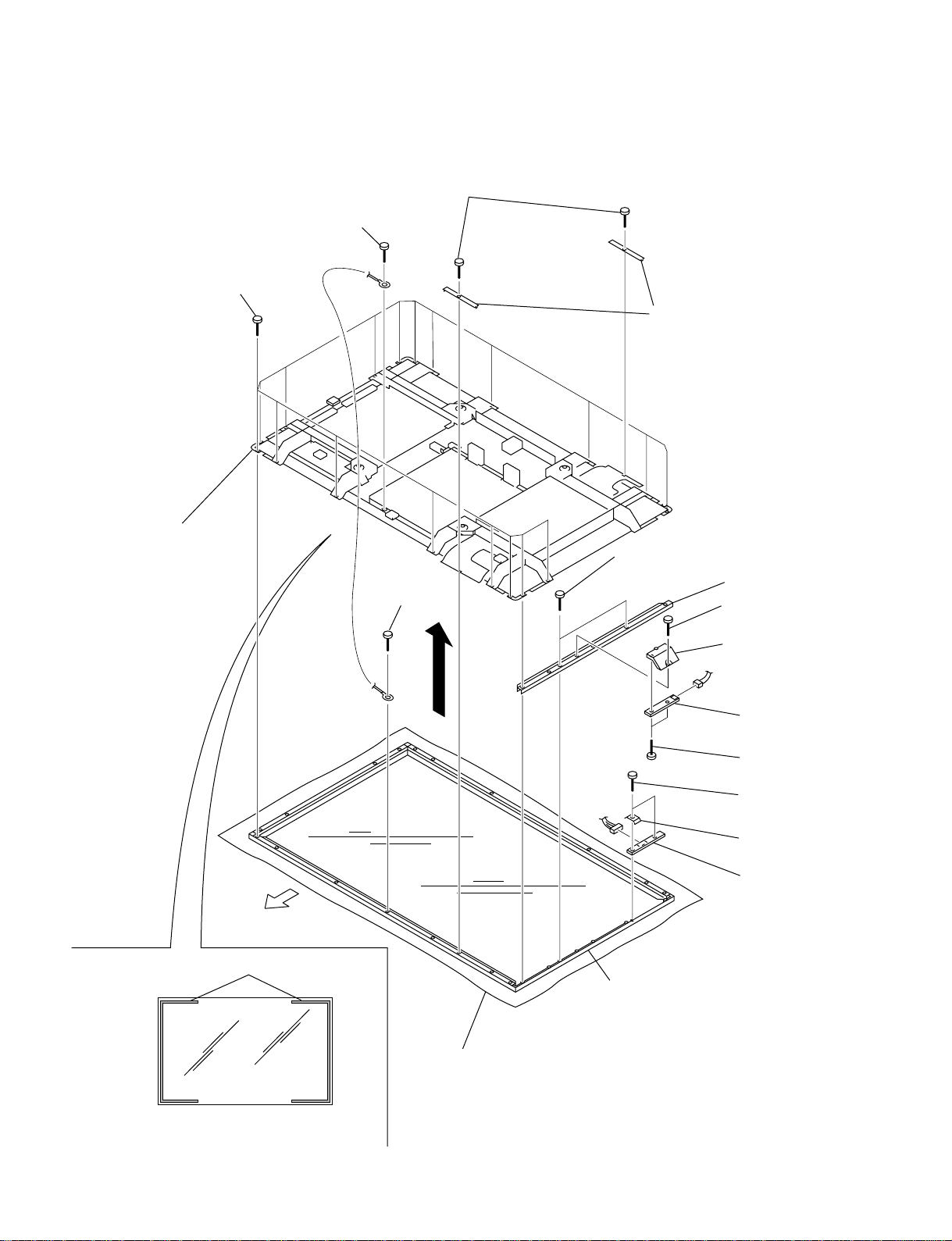

1-2-9. Plasma Display Panel Unit Removal (2/2)...............................1-10

1-2-10. Plasma Display Panel Unit Packing

When Sending it to FUJITSU ..................................................1-11

1-2-11. Power Cord...............................................................................1-12

1-3. Service Position.........................................................................................1-13

2. Electrical Adjustments

2-1. Equipment Required....................................................................................2-1

2-2. Electrical Adjustments Using the Service Mode ........................................2-1

2-3. White Balance Adjustment .......................................................................2-25

2-4. A/D Calibration Adjustment .....................................................................2-25

2-5. Video Processor Adjustment.....................................................................2-26

2-6. Watch Error Adjustment ...........................................................................2-26

2-7. Switching Regulator (APS-179) Adjustment............................................2-27

2-7-1. Oscillating Frequency Adjustment........................................... 2-27

2-7-2. Voltage Adjustment with Minimum Load ...............................2-27

3. Trouble Shooting

3-1. Judging Method When Image Does Not Appear ........................................3-1

3-1-1. Flow chart...................................................................................3-1

3-1-2. How to Distinguish the Trouble of the PDP Unit. .....................3-2

3-2. Self Diagnosis Function .............................................................................. 3-3

3-2-1. Outline ........................................................................................3-3

3-2-2. Criteria for Judgment of Abnormality........................................3-3

PFM-42B2/42B2E

1

4. Semiconductors................................................................................. 4-1

5. Spare Parts

5-1. Notes on Repair Parts..................................................................................5-1

5-2. Exploded Views ..........................................................................................5-2

5-3. Electrical Parts List .....................................................................................5-8

5-4. Supplied Accessories ................................................................................ 5-36

6. Block Diagrams

B (1/6), QA(1/2).......................................................................................... 6-1

B (2/6), QA (2/2), B1 ..................................................................................6-2

B (3/6) .........................................................................................................6-3

B (4/6) .........................................................................................................6-4

B (5/6), S1, YA, YB.................................................................................... 6-5

B (6/6) .........................................................................................................6-6

APS-179 ...................................................................................................... 6-7

7. Diagrams

7-1. Frame Schematic Diagram ..........................................................................7-2

Frame...........................................................................................................7-2

7-2. Schematic Diagrams and Printed Wiring Boards........................................7-3

Schematic Diagrams

QA ...............................................................................................................7-3

B (1/13) .......................................................................................................7-7

B (2/13) .......................................................................................................7-8

B (3/13) .......................................................................................................7-9

B (4/13) .....................................................................................................7-10

B (5/13) .....................................................................................................7-11

B (6/13) .....................................................................................................7-12

B (7/13) .....................................................................................................7-13

B (8/13) .....................................................................................................7-14

B (9/13) .....................................................................................................7-15

B (10/13) ...................................................................................................7-16

B (11/13) ...................................................................................................7-17

B (12/13) ...................................................................................................7-18

B (13/13) ...................................................................................................7-19

B1 ..............................................................................................................7-25

YA ............................................................................................................. 7-26

2

PFM-42B2/42B2E

YB .............................................................................................................7-26

S.................................................................................................................7-27

APS-179 (1/4) ...........................................................................................7-28

APS-179 (2/4) ...........................................................................................7-29

APS-179 (3/4) ...........................................................................................7-30

APS-179 (4/4) ...........................................................................................7-31

Printed Wiring Boards

QA ...............................................................................................................7-3

B .................................................................................................................. 7-4

B1 ..............................................................................................................7-24

YA .............................................................................................................7-26

YB .............................................................................................................7-26

S.................................................................................................................7-27

APS-179 .................................................................................................... 7-32

PFM-42B2/42B2E

3

1-1. Board Layout

Section 1

Service Informations

S

YA

YB

B1

S

SWITCHING

REGULATOR

(APS-179)

QA

S

S

B

PFM-42B2/42B2E

1-1

1-2. Disassembly

1-2-1. QA Board Removal

4 Blank panel

* Only AEP model.

3 Two screws

(+PSW3 x 8)

1 Loosen two panel

stopper screws.

2 QA board

Connector

1-2

PFM-42B2/42B2E

1-2-2. Rear Cover Assy Removal

1 Four screws

(+PSW6 x 20)

4 Four screws

(+BVTP4 x 16)

3 Fourteen screws

(+BVTP4 x 16)

2 Four knobs

5 Two screws

(+PSW3 x 8)

6 Screw

(+PSW3 x 8)

7 Three screws

(+PSW3 x 8)

8 Rear cover assy

PFM-42B2/42B2E

Top side

Conductive cushion

Main chassis

1-3

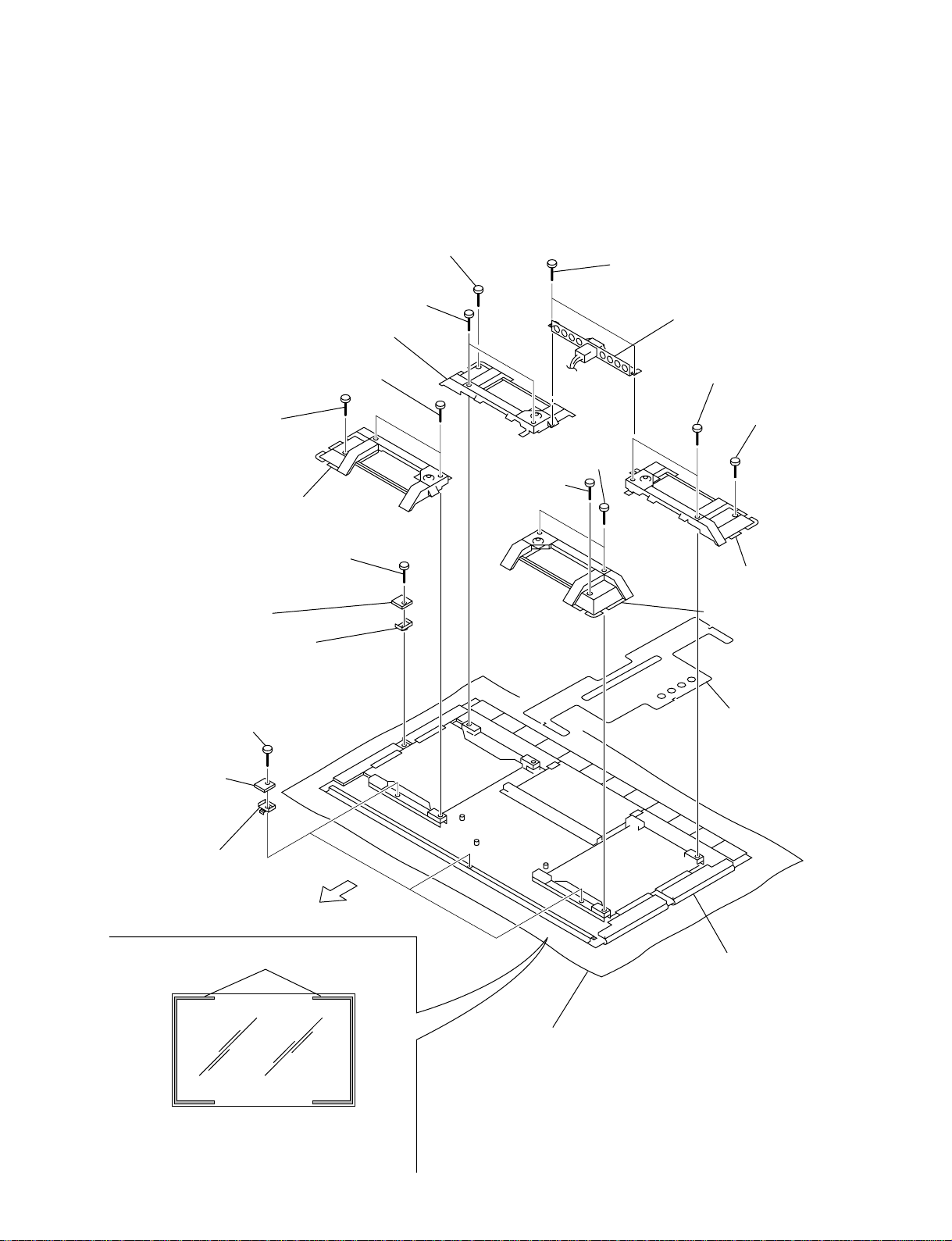

1-2-3. Bezel Assy and YA, YB Boards Removal

5 T wo screws

(+BVTP4 x 16)

7 Screw

(+PSW4 x 8)

9 Eighteen screws

(+BVTP4 x 16)

0 Main chassis

8 Screw

(+BVTP4 x 16)

6 Retainer

!= T wo screws

(+BVTP4 x 16)

!- Filter bracket (V)

1 Screw

(+BVTP4 x 16)

2 YB board bracket

CN8601

Top side

Wire (for reference)

Note) If two wires attached on the glass surface of

plasma display panel, be careful not to cut them.

Conductive cushion

CN8501

!- Bezel assy

4 YB board

3 T wo screws

(+P2 x 5)

![ T wo screws

(+BVTP3 x 12)

!] Earth plate

!\ Y A board

1-4

PFM-42B2/42B2E

1-2-4. B Block Assy Removal

CN110

CN106

Removal of Lithium Battery

Remove the lithium battery

in the direction of arrow.

Lithium

battery (CR2025)

Battery holder

CN112

CN109

CN8001

2 S/C cover

CN102

CN103

4 Screw

(+PS3 x 6)

1 Four screws

(+BVTP3 x 12)

GND

5 B block assy

PFM-42B2/42B2E

Top side

Conductive cushion

3 Two PC board hinges

Main chassis

1-5

1-2-5. B and B1 Boards Removal

* Remove the B block assy. (Refer to 1-2-4.)

8 Fan bracket

!- B1 board

9 Six screws

(+PS3 x 6)

0 B board

7 Screw

(+PS3 x 6)

6 S/C panel

1 Three screws

(+PS3 x 6)

2 Two screws

(+PS2 x 6)

3 Two screws

4 Two screws

5 Two screws

1-6

PFM-42B2/42B2E

1-2-6. Extension Board Connection

Extension board

(Mounted circuit board, Z

Part No : A-1391-125-A)

Main chassis

S/C cover

B1 board

Top side

Conductive cushion

Connector (CN6102)

PFM-42B2/42B2E

1-7

1-2-7. Switching Regulator (APS-179 board) Removal

5 Screw

(+PSW3 x 8)

4 Two screws

(+PSW3 x 8)

1 Screw

(+PSW4 x 16)

7 Switching regulator

(APS-179 board)

CN7

CN68

CN23

6 Two DC fan,

Two DC fan bracket (R) (L)

CN33

CN42

CN52

CN9003

CN9002

CN9001

CN9004

2 S board

3 S board bracket

Top side

Conductive cushion

Main chassis

1-8

PFM-42B2/42B2E

1-2-8. Plasma Display Panel Unit Removal (1/2)

* Remove the Bezel assy. (Refer to 1-2-3.)

* Remove the B block assy. (Refer to 1-2-4.)

* Remove the switching regulator. (Refer to 1-2-7.)

Remove those parts according to

numbers 1 through @/.

9 Two screws (+PSW5 x 40)

!- Corner bracket (B)

4 Two screws (+PSW5 x 40)

5 Screw (+PSW4 x 8)

6 Corner bracket (A)

!\ Screw (+PSW3 x 16)

!; S board

!' S board bracket

0 Screw (+PSW4 x 8)

2 Screw

(+PSW4 x 8)

7 Two screws

(+BVTP4 x 16)

8 Inlet bracket

!= Two screws

(+PSW5 x 40)

![ Screw

(+PSW4 x 8)

1 Two screws

(+PSW5 x 40)

!] Corner bracket (A)

3 Corner bracket (B)

!, Three screws

(+PSW4 x 16)

!. Three S boards

@/ Three S board brackets

Top side

Wire (for reference)

Note) If two wires attached on the glass surface of

plasma display panel, be careful not to cut them.

@- Shield sheet

Main chassis

Conductive cushion

PFM-42B2/42B2E

1-9

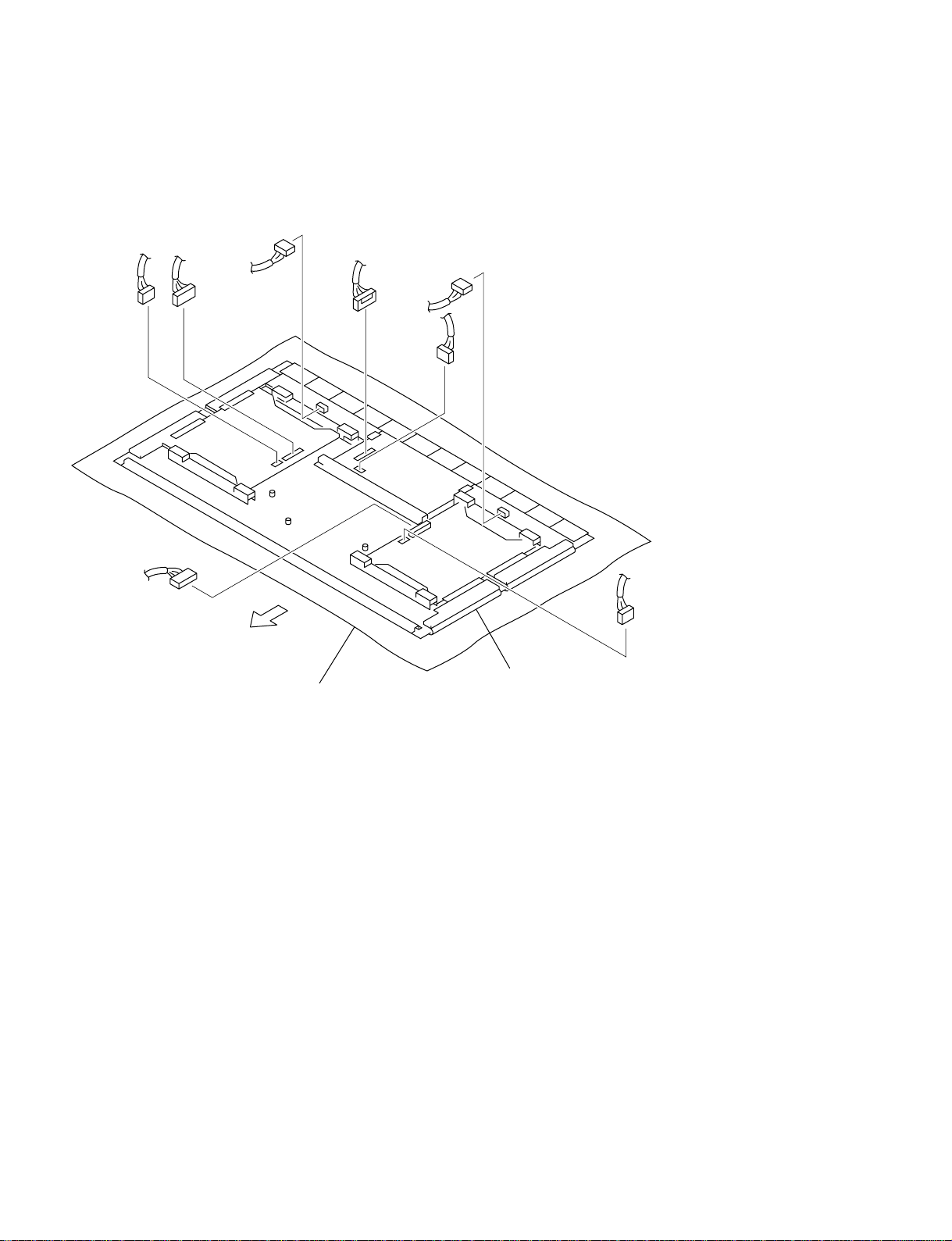

1-2-9. Plasma Display Panel Unit Removal (2/2)

Disconnect all of the connectors specified in the illustration. After that, package it

according to Section 1-2-10.

CN42

CN52

CN22

CN33

CN23

CN1

CN6

CN32

Top side

Main chassis

Conductive cushion

1-10

PFM-42B2/42B2E

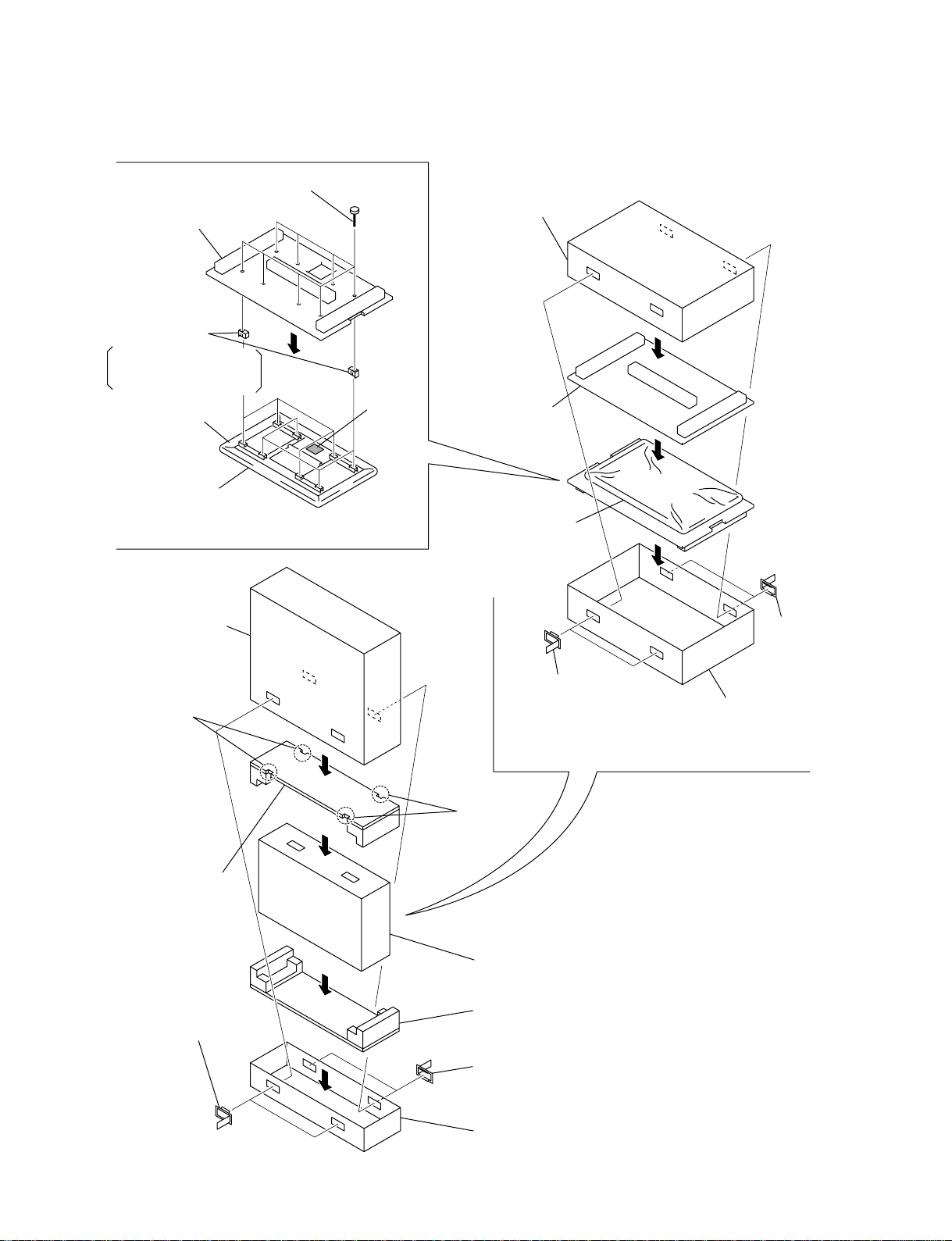

1-2-10.Plasma Display Panel Unit Packing When Sending it to FUJITSU

3 Eight screws (M5 x 50)

2 Lower pad (B)

1 Eight spacers

Type : FPF11R-KM6

Name : Spacer for fixing

bracket (100 unit)

Polyethylene sheet

4 Plasma display panel unit

* Glass side is lower.

Silica gel

6 Plasma display panel unit

* Glass side is upper.

8 Inner box (Cap)

7 Upper pad (B)

!\ Outer box (Cap)

Notch

!] Upper pad (A)

!; Two joint parts

0 Two joint parts

9 Two joint parts

5 Inner box (bottom)

Notch

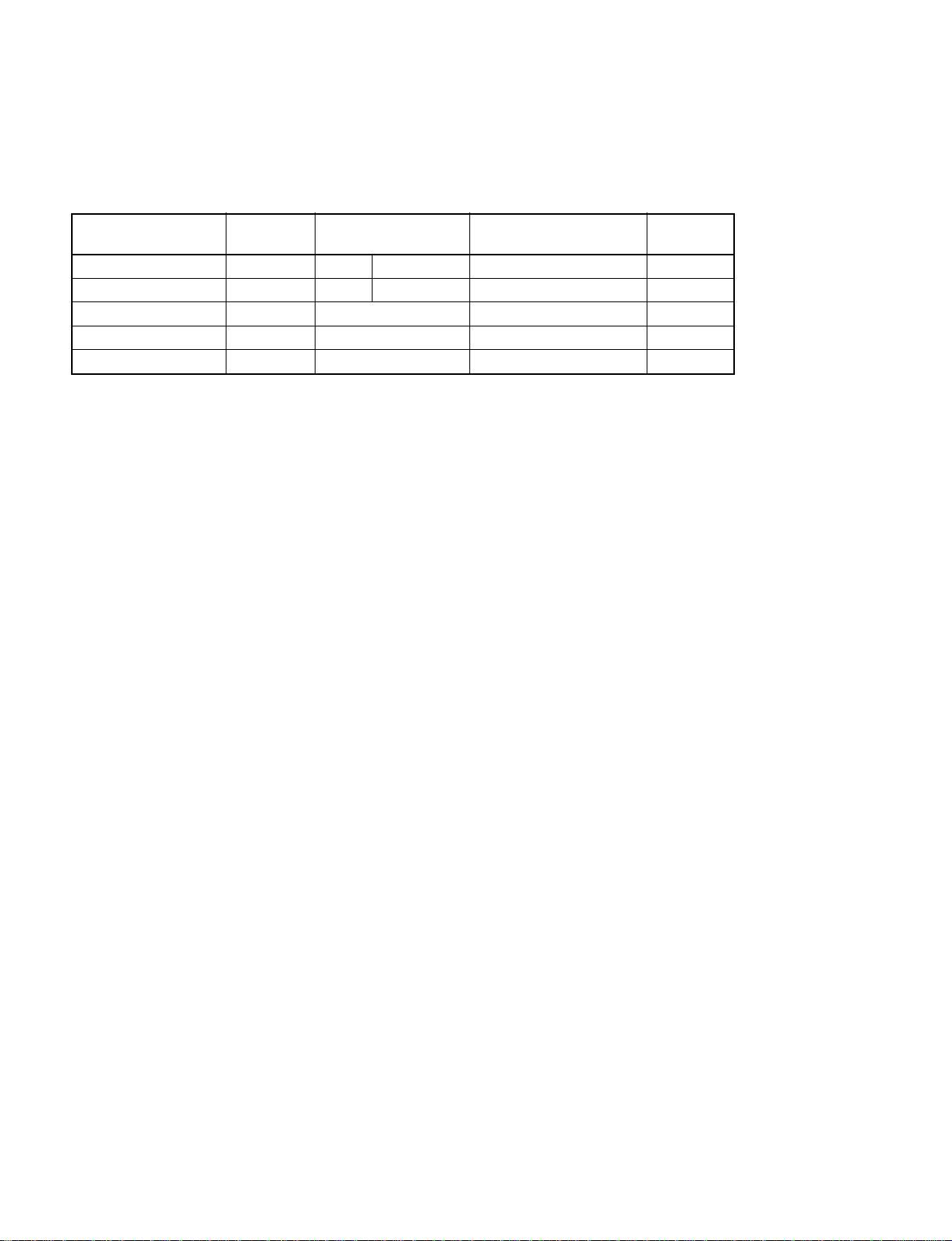

1-2-11.Power Cord

Warning on power connection

Use the proper power cord for your local power supply.

United States, Continental United Kingdom, Ireland, Japan

Canada Europe Australia, New Zealand

Plug type VM0233 COX-07 636 _

Female end VM0089 COX-02 VM0310B VM303B VM1313

Cord type SVT H05VV-F CEE (13) 53rd (O. C) HVCTF

Minimum cord set rating 10A/125V 10A/250V 10A/250V 10A/125V

Safety approval UL/CSA VDE VDE DENTORI

a) Note : Use an appropriate rating plug which is applied to local regulations.

a)

VM1296

1-12

PFM-42B2/42B2E

1-3. Service Position

n

When you are going to set up the PDP panel in the service position, remove the rear cover first, and then

set up the PDP panel in the service position.

Main chassis

2 Four knobs

3 Four screws

(+PSW 6 x 20)

1 S/C cover

Main chassis

5 Insert the four knobs

into the holes of the stand.

4 Stand (SU-42B)

Main chassis

PFM-42B2/42B2E

Stand (SU-42B)

1-13

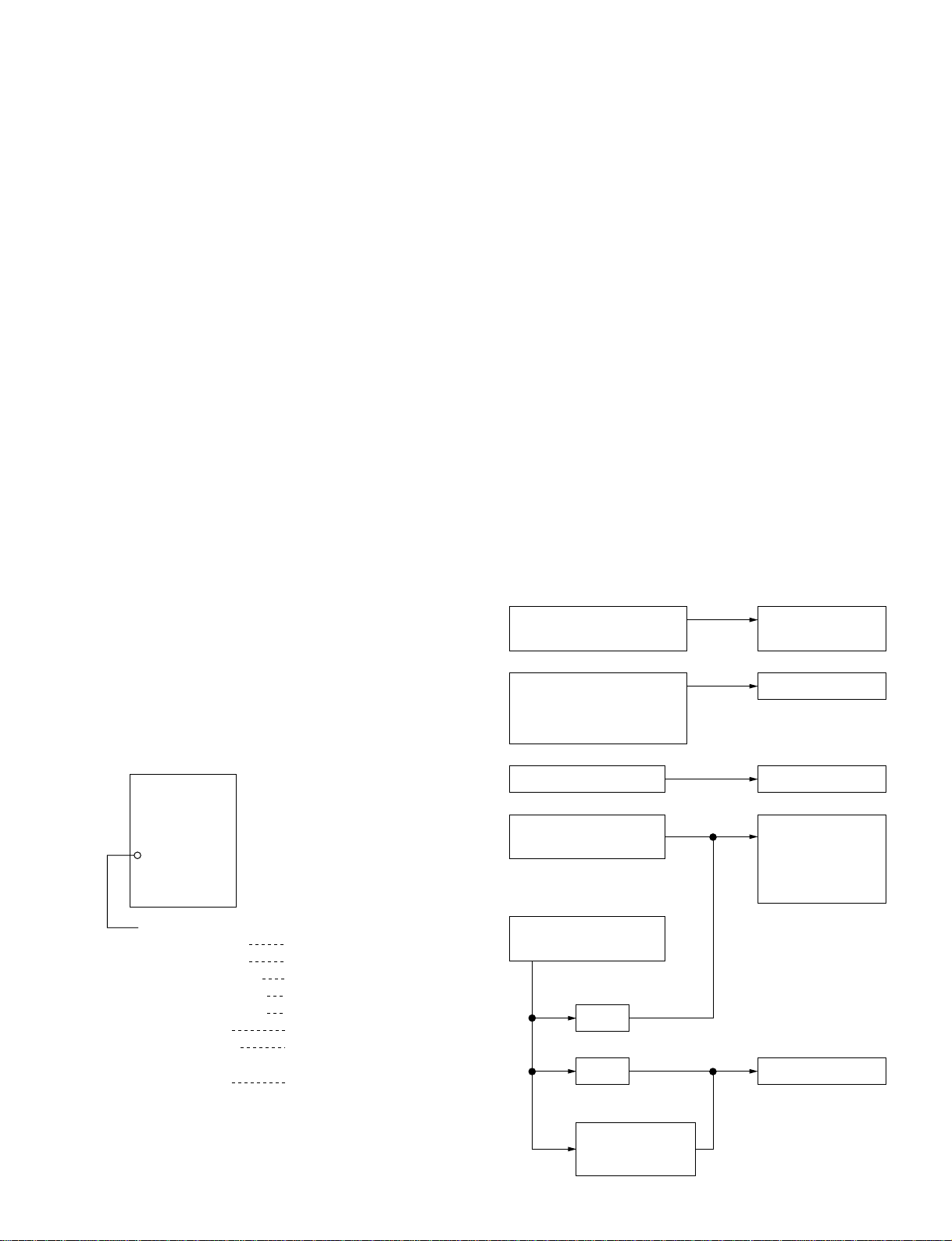

Section 2

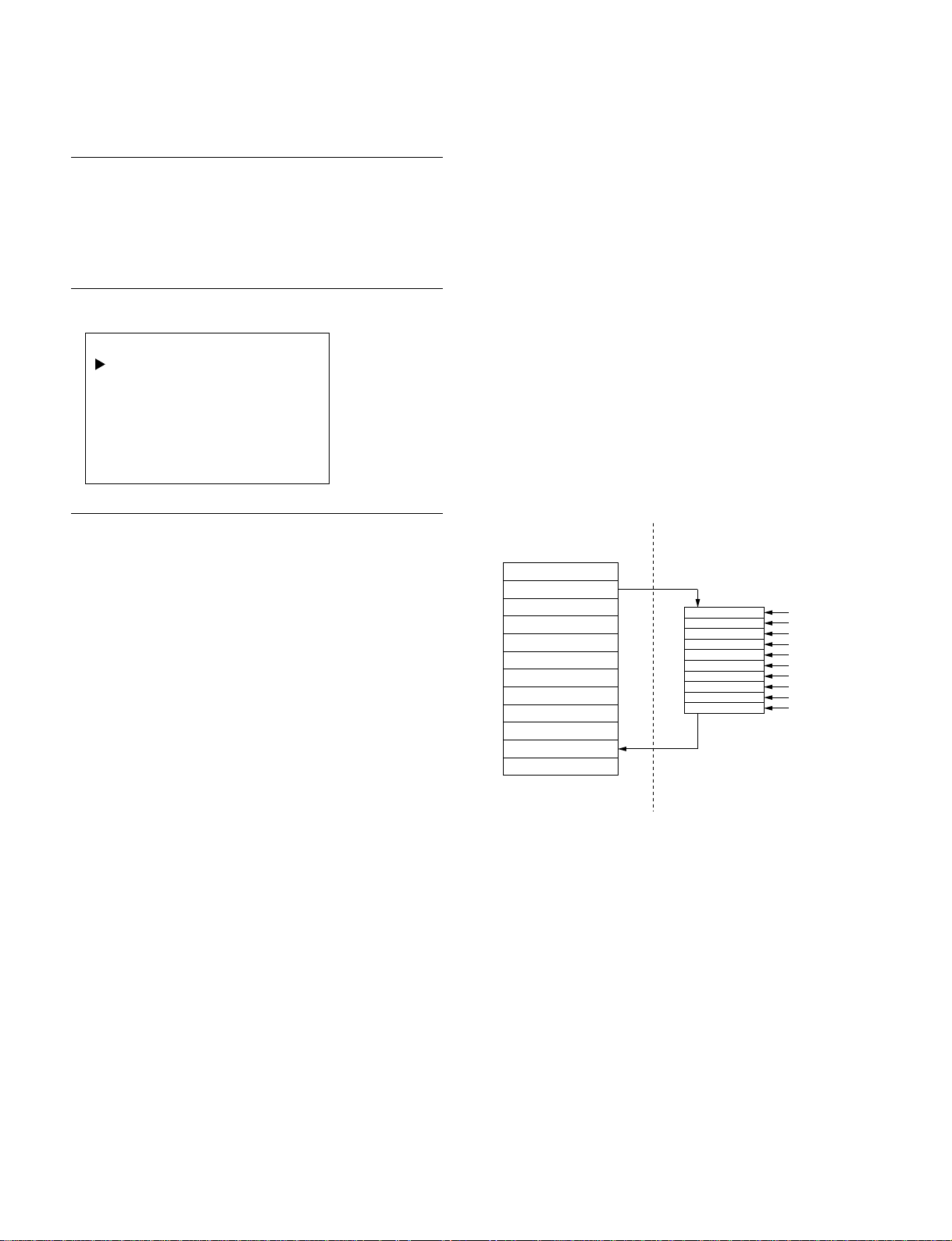

Operation check only

When IC200 and its peripheral

parts (the parts that are

shown in schematic diagram

B (3/13) ) are replaced.

When PDP is replaced.

STATUS/TEST

B board

Power supply board

(APS-179)

When memory (IC511) on

the B board is replaced.

WHITE BALANCE

ADC CALIBRATION

ADC CALIBRATION

WHITE BALANCE

EEPROM RESET

WHITE BALANCE

ADC CALIBRATION

MAINTENANCE

STATUS/TEST

S1 board

When any of the following

boards is replaced.

When any repairs that

are related to picture quality

are performed.

Electrical Adjustments

2-1. Equipment Required

. Oscilloscope

Tektronix 2465 or equivalent

(band width : 350 MHz or more)

. VG (Programmable video signal generator)

VG814 or equivalent

. Frequency counter

Advantest TR5821AK or equivalent

. Digital voltmeter

Advantest TR6845 or equivalent

. Potential transformer

. Regulated DC power supply

. Remote commander (RM-42B)

n

Perform the following adjustments at least 5 minutes after

turning on the power.

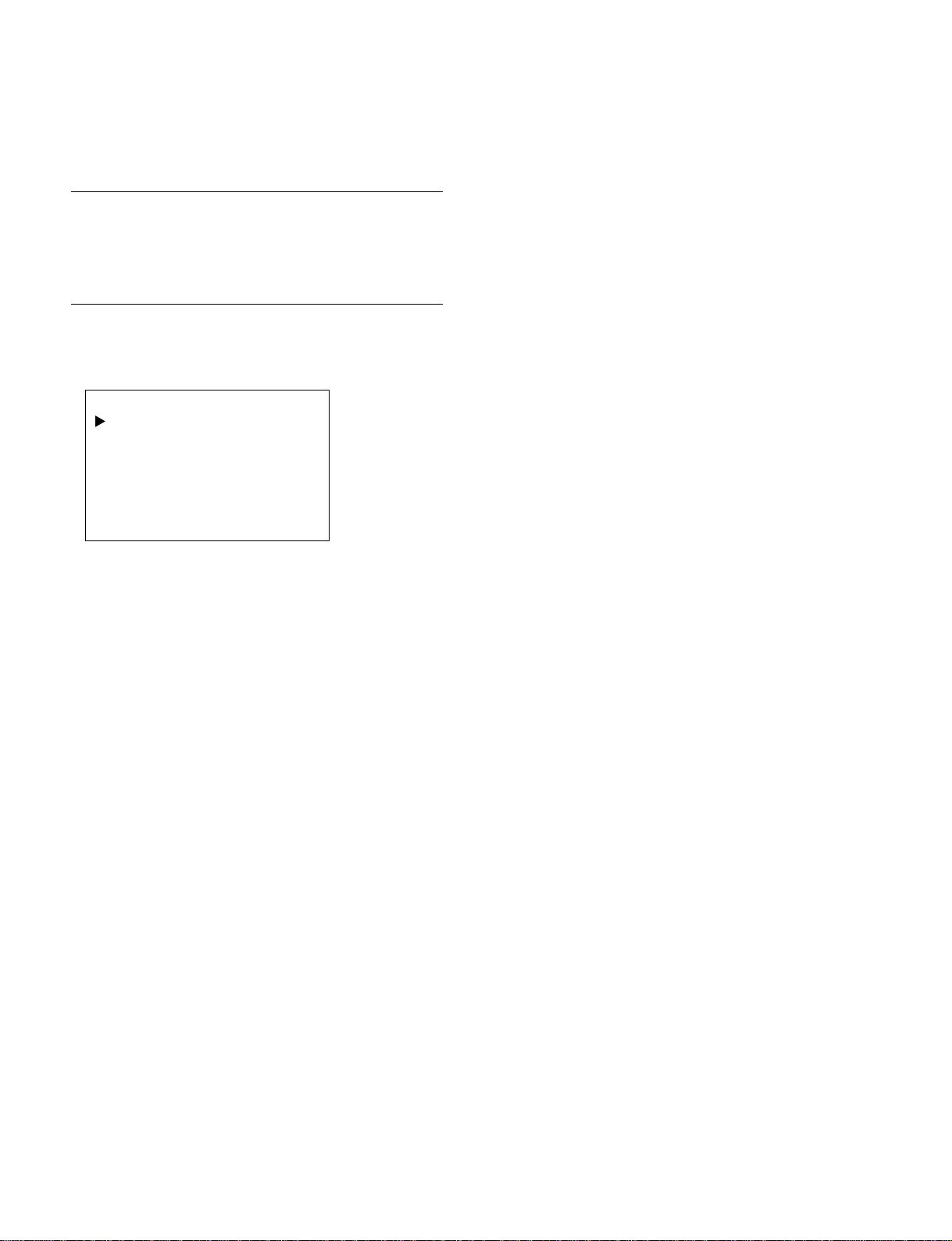

2-2. Electrical Adjustments Using the

Service Mode

The electrical adjustments can be performed using the remote

commander RM-42B supplied with the PFM-42B2/B2E. The

remote commander has the Service Mode. Select the Service

Mode to perform the electrical adjustments as listed below.

How to enter the Service Mode using the commanders

other than RM-42B:

In the STAND-BY state, press the keys in the following

order.

[DISPLAY] → [5] → [

VOL+

] → [

POWER

]How to exit the

Service Mode :

Press the ON key once and back on to enter the STAND-BY

state or turn off the main power to exit the Service Mode.

..

. Operation of remote commander in the Service

..

Mode

The four keys of MENU, ENTER, SELECT+ and SELECT_ are the basic operation keys in the same manner as

in the user adjustment. The other keys can be operated in

the same manner as in the user adjustment.

..

. The electrical adjustments using the Service

..

Mode become necessary in the following cases.

When any of the following repairs is performed, adjustment using the service mode becomes necessary.

..

. Service Menu

..

When you enter the Service Mode, the mode menu appears

as shown below. The mode menu contains the three menus

of MAIN MENU, SERVICE MENU and MANUAL

MENU as shown. Select the SERVICE MENU to perform

the electrical adjustments.

MODE SELECT

MAIN MENU

SERVICE MENU

MANUAL MENU

SERVICE MENU

EEPROM RESET

WHITE BALANCE

ADC CALIBRATION

VIDEO PROCESSOR

SPECIAL FUNCTION

PRESET EDIT

MAINTENANCE

STATUS/TEST

How to enter the Service Mode using the RM-42B:

In the STAND-BY state, press the keys in the following

order.

[DISPLAY] → [5] → [BRT+] → [ON]

PFM-42B2/42B2E

: This is the user’s menu. Use the

MAIN MENU when user adjustment items

such as operation checks upon completion

of adjustments, are going to be made.

: This is the menu that is used for electrical

adjustments. This section of this manual

describes how to use the SERVICE MENU.

: This menu is used in production factory.

Do not make any attempts to use this menu

and do not make any operations using this menu.

Initialization of EEPROM

Gain adjustment

Calibration of A/D converter

Level adjustment of video processor circuit

Setting the special functions

Editing the preset signals

Setting the data that are unique

to the particular machine

Internal status and function test

2-1

SERVICE MENU

1. EEPROM RESET

EEPROM Configuration

Table 1 shows the configuration of EEPROM. The entire

area or the respective areas of the EEPROM can be

separately initialized.

Menu Structure

Select the desired area of EEPROM to be initialized using

the following menu.

EEPROM RESET

WHOLE AREA

COMMON

COLOR TEMP

PROG. PRESET

FIXED PRESET

LAST MEMORY

USER MEMORY

FACTORY

To initialize the desired area, firstly select the desired item

from the EEPROM RESET menu. Change the selected

item from CANCEL to EXECUTE. Then press ENTER.

a) WHOLE AREA

The entire area of the EEPROM is initialized. Initializing the entire area of the EEPROM has the same result

as all menu items of COMMON, COLOR TEMP,

PROG. PRESET, FIXED PRESET, LAST MEMORY,

USER MEMORY and FACTORY are executed.

b) COMMON

Only the COMMON area of the EEPROM as shown in

Table 1 is initialized.

When the COMMON area is initialized, the data that is

unique to the particular machine and the common data

(CONFIG MENU, REMOTE MENU) are initialized.

c) COLOR TEMP

Only the COLOR TEMP area of the EEPROM as

shown in Table 1 is initialized.

When the COLOR TEMP area is initialized, the color

temperature data in HIGH, LOW and the user setup

data from 1 to 6 are initialized to 255. The users

names are also initialized to “1” to “6”.

d) PROG. PRESET

Only the PROG. PRESET area of the EEPROM as

shown in Table 1 is initialized.

When the PROG. PRESET area is initialized, the

preset area (for 20 types) that is reserved as spare is

initialized.

e) FIXED PRESET

Only the FIXED PRESET area of the EEPROM as

shown in Table 1 is initialized.

When the FIXED PRESET area is initialized, the basic

preset area is initialized to the built-in standard value

that is stored in the system controller.

f) LAST MEMORY

Only the LAST MEMORY area of the EEPROM as

shown in Table 1 is initialized.

When the LAST MEMORY area is initialized, only

the last memory data of every signal that is adjusted by

user is initialized.

g) USER MEMORY

Only the USER MEMORY area of the EEPROM as

shown in Table 1 is initialized.

When the USER MEMORY area is initialized, all of

the 20 types of adjustment data that is saved by the

MEMORY function of the user menu are initialized to

EMPTY.

h) FACTORY

Only the FACTORY area of the EEPROM as shown

in Table 1 is initialized.

When the FACTORY area is initialized, all areas of

the MEMORY except the areas that are listed below

are initialized.

Items that are not initialized by the “FACTORY” RESET

function.

..

. EEPROM ID CODE

..

..

. INDEX NUMBER

..

..

. MODEL NAME

..

..

. SERIAL NUMBER

..

..

. AUTO PLL SETUP

..

..

. AUTO PLL PIXEL

..

..

. H/V SHIFT

..

..

. VIDEO SHARP SW

..

..

. AUTO FT CANCEL

..

..

. WATCH ERROR

..

..

. Y GAIN

..

..

. R-Y GAIN

..

..

. B-Y GAIN

..

..

. RED CUTOFF

..

..

. BLUE CUTOFF

..

..

. GREEN C//O SW

..

..

. ADC R GAIN

..

..

. ADC G GAIN

..

..

. ADC B GAIN

..

..

. ADC R BIAS

..

..

. ADC G BIAS

..

..

. ADC B BIAS

..

..

. RED GAIN

..

..

. GREEN GAIN

..

..

. BLUE GAIN

..

..

. SUB BRIGHT

..

2-2

PFM-42B2/42B2E

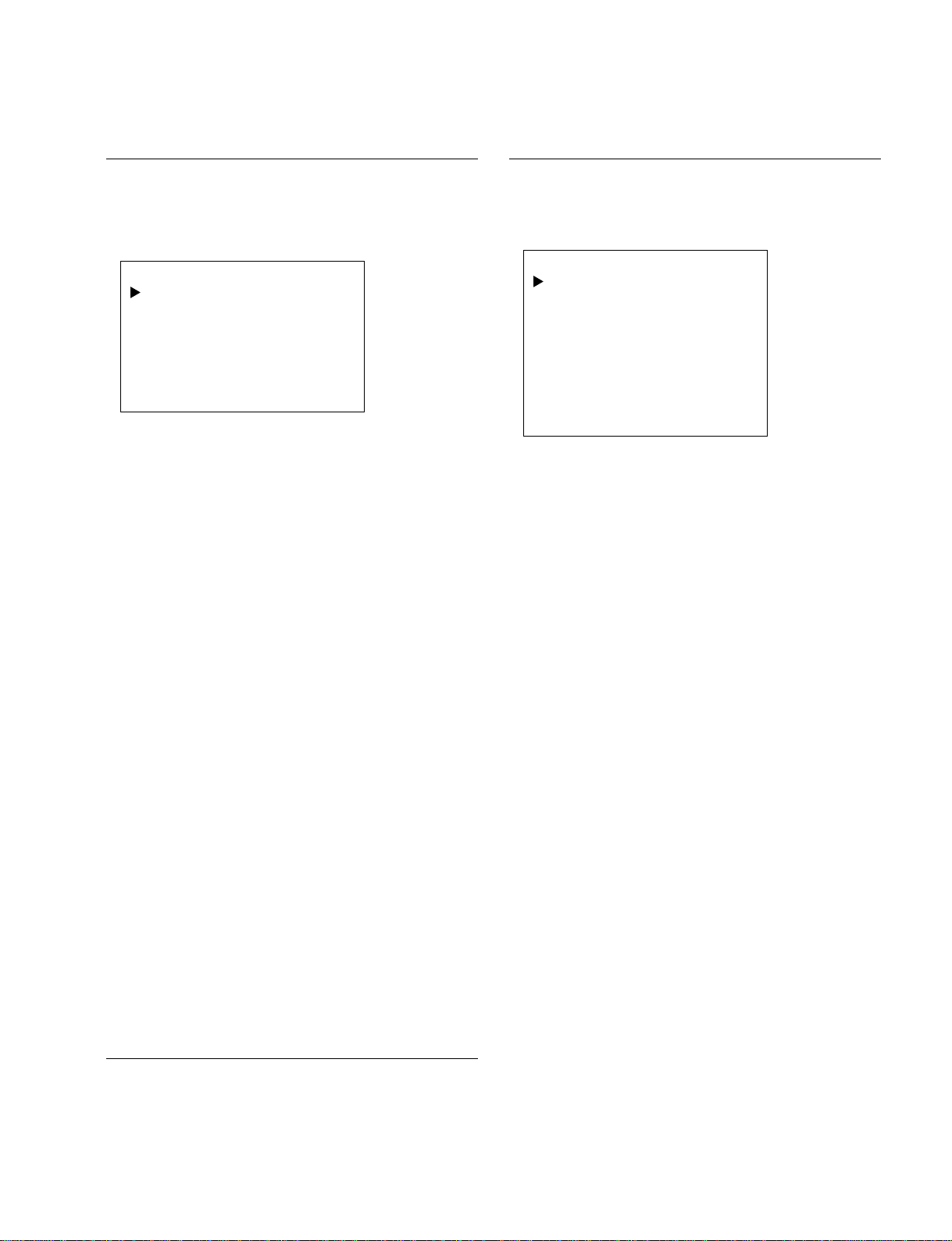

2. WHITE BALANCE

3. ADC CALIBRATION

Menu Structure

Adjust the white balance of the desired color temperature

by selecting the items of the WHITE BALANCE menu

and by adjusting the R, G, B gain.

WHITE BALANCE

WINDOW

COLOR TEMP

RED GAIN

GREEN GAIN

BLUE GAIN

SUB BRIGHT

: OFF

: HIGH

: 103

: 141

: 128

: 151

a) WINDOW

The PFM-42B2/B2E has the built-in window signal

for white balance adjustment. There are two sizes that

are the large and small windows. Select the optimum

size of window for white balance adjustment.

OFF : Window does not appear.

TYPE1 : Small window

TYPE2 : Large widow

n

When white balance is going to be adjusted using an

external signal, perform the A/D converter calibration

(referring to the next paragraph 3) ADC CALIBRATION) before starting the white balance adjustment.

b) COLOR TEMP

To adjust the white balance, firstly select the desired

color temperature from HIGH, LOW, 1, 2, 3, 4, 5 or 6

on the COLOR TEMP sub-menu. Color temperature

of items 1 to 6 are the same as those of the user menu.

c) RED GAIN

Adjust the red gain of the selected color temperature.

The range of adjustment is from 000 to 255.

d) GREEN GAIN

Adjust the green gain of the selected color temperature.

The range of adjustment is from 000 to 255.

e) BLUE GAIN

Adjust the red blue of the selected color temperature.

The range of adjustment is from 000 to 255.

White Balance Adjustment

Refer to section “2-3. White Balance Adjustment”.

Menu Structure

Calibrate the A/D converter (IC200) until non-uniformity between

the R, G and B channels of the A/D converter is removed.

ADC CALIBRATION

AUTO

CAL MODE

RED GAIN

GREEN GAIN

BLUE GAIN

RED BIAS

GREEN BIAS

BLUE BIAS

R : — — — G : — — — B : — — —

: OFF

: 128

: 128

: 128

: 128

: 128

: 128

a) AUTO

The A/D converter is automatically calibrated.

n

When sufficient adjustment accuracy cannot be

obtained by the automatic calibration, perform basically the manual calibration using the following ADC

CALIBRATION menu items.

b) CAL MODE

The A/D converter has the calibration mode as its operating mode as follows.

* The A/D converter has the R, G, B GAIN adjust-

ments and the R, G, B BIAS adjustments. The

GAIN adjustments of the A/D converter are used for

CONTRAST adjustment in the machine. The R, G,

B BIAS adjustments of the A/D converter are used

for BRIGHTNESS adjustment in the machine.

CAL MODE - OFF : Standard display state

The R, G, B GAIN values and the R, G, B BIAS values are

controlled by the CONTRAST/BRIGHT data of the user

menu. The R, G, B GAIN values and the R, G, B BIAS

values of this menu cannot be adjusted independently.

CAL MODE - OFF : Calibration mode

The R, G, B GAIN values and the R, G, B BIAS values

of this menu can be adjusted independently. The R, G,

B data that appear in the most-bottom part of the menu

in cyan, change from the indication “___” to the indication of any digital output data of the A/D converter.

c) RED GAIN/GREEN GAIN/BLUE GAIN

The respective R, G, B GAIN values can be adjusted

independently.

The range of adjustment is from 000 to 255.

d) RED BIAS/GREEN BIAS/BLUE BIAS

The respective R, G, B BIAS values can be adjusted

independently.

The range of adjustment is from 000 to 255.

PFM-42B2/42B2E

2-3

A/D Calibration Adjustment

5. SPECIAL FUNCTION

Refer to section “2-4. A/D Calibration Adjustment”.

4. VIDEO PROCESSOR

Menu Structure

The following items of the video processor can be adjusted

using this menu. However, all items of the video processor

have the default values on which normal operations are performed. Therefore, the video processor normally needs no

adjustment.

VIDEO PROCESSOR

Y GAIN

R-Y GAIN

B-Y GAIN

RED CUTOFF

BLUE CUTOFF

GREEN C/O SW : ON

: 111

: 082

: 128

: 143

: 100

a) Y GAIN

The range of adjustment is from 000 to 255.

Default value : 111

b) R-Y GAIN

The range of adjustment is from 000 to 255.

Default value : 082

c) B-Y GAIN

The range of adjustment is from 000 to 255.

Default value : 128

d) RED CUTOFF

The range of adjustment is from 000 to 255.

Default value : 143

e) BLUE CUTOFF

The range of adjustment is from 000 to 255.

Default value : 100

f) GREEN C/O SW

This switch is set to ON normally.

However, if white balance cannot be obtained at the

CUTOFF position, set this switch to the OFF position

and adjust the white balance.

Menu Structure

Various special functions as listed in the SPECIAL

FUNCTION menu can be independently set as required.

SPECIAL FUNCTION

AUTO ASPECT

AUTO PLL SETUP

AUTO PLL PIXEL

H/V SHIFT

VIDEO SHARP SW

AUTO FT CANCEL

a) AUTO ASPECT (Japanese Model only)

When the BKM-B11 is installed, the aspect ratio is

automatically switched by the identification signal at

the D terminal.

ON : Aspect ratio is automatically switched by the

identification signal

OFF : Automatic switching of aspect ratio is

prohibited.

Set the AUTO ASPECT item to the ON position

normally.

b) AUTO PLL SETUP

Sets enable/disable of automatic execution of the

PIXEL ADJUST function.

ON :When the AUTO PLL SETUP is set to ON,

the PIXEL ADJUST is automatically executed

when the main power is turned on or when the

input signal is switched. (Be noted that about

10 seconds are required to output the video

signal after switching the input signal when this

function is kept to the ON position.)

OFF : The automatic PIXEL ADJUST is executed

only when AUTO item of the user menu

PIXEL ADJUST is activated.

This function becomes valid only when the signal that

enables the PIXEL ADJUST is inputted to the

42B2/B2E

.

PFM-

Set the AUTO PLL SETUP item to the OFF position

normally.

Video Processor Adjustment

Refer to section “2-5. Video Processor Adjustment”.

(Perform the service menu adjustment of the video processor only when the specifications cannot be satisfied by section “2-5. Video Processor Adjustment”.)

2-4

PFM-42B2/42B2E

c) AUTO PLL PIXEL

Selects the functions that are automatically adjusted

when PIXEL ADJUST is executed.

ON : Both the TOTAL H PIXEL and DOT PHASE

are automatically adjusted.

OFF : Only the DOT PHASE is automatically

adjusted.

In the case that the

PFM-42B2/B2E

is used under the

environment where input signal contains much noise,

there are cases that the PIXEL ADJUST mis-operations. Therefore, set the AUTO PLL PIXEL to the

OFF position. In such a case, the TOTAL H PIXEL

can be adjusted only manually.

This function becomes valid only when the signal that

enables the PIXEL ADJUST is inputted to the

42B2/B2E

.

Set the AUTO PLL PIXEL item to the ON position

normally.

d) H/V SHIFT

Selects the method to control the horizontal and

vertical picture shift.

EDGE : When EDGE is selected, a picture is shifted

by changing the starting position when

reading data into memory. Using this

function, the entire area including blanking of

all pictures can be displayed by shifting. The

variable range of shifting is 1 horizontal and

vertical period respectively.

CAPT : When CAPT is selected, the picture that is

already written into memory is shifted by a

scan converter. Using this function, a picture

can be shifted as much as ± 50 % of a

picture. When a picture is partly lacked at an

end of a picture, the lacked portion of a

picture cannot be displayed.

Set the H/V SHIFT item to the EDGE position normally.

PFM-

e) VIDEO SHARP SW

Sets analog aperture ON or OFF.

The two methods are used for the aperture correction

of the video signals (NTSC/PAL/SECAM/NTSC4.43/

PAL60/PAL-M and YUV signal having horizontal

frequency of 15 kHz). These two methods are the

scaling filter and the analog aperture of the scan

converter.

ON : Both the scaling filter and the analog aperture

of the scan converter are used for aperture

correction.

OFF : Only the scaling of the scan converter is used

for aperture correction.

This function becomes valid only when the signal

(NTSC/PAL/SECAM/NTSC4.43/PAL60/PAL-M and

YUV signal having horizontal frequency of 15 kHz) is

inputted to the

PFM-42B2/B2E

.

Set the VIDEO SHARP SW item to the ON position

normally.

f) AUTO FT CANCEL

Sets the FT (field tearing) cancel circuit ON or OFF.

The

PFM-42B2/B2E

has the FT (field tearing) prevention circuit caused by the overrun of memory while it

is displaying the moving picture (video and DTV).

However, there can be cases that noise appears on

screen when the FT (field tearing) prevention is being

executed.

ON : The FT (field tearing) is cancelled in every

picture size and in every shift conditions as

long as the

PFM-42B2/B2E

is receiving the

moving picture. When this item is set to ON,

noise may appear only once after the size/

shift is adjusted. (Noise does not last long

but appears only once when the size/shift

adjustment is complete.)

OFF : The FT (field tearing) cancel circuit is

disabled. When OFF is selected, there can be

a case that the FT (field tearing) appears on

screen depending on the adjustment conditions of picture size/shift. However, the noise

due to operation of the processing circuit

does not occur.

Set the AUTO FT CANCEL item to the ON position

normally.

PFM-42B2/42B2E

2-5

6. PRESET EDIT

Preset Data Configuration

Memory map of the preset data area is shown in Table 1

(PROG. PRESET/FIXED PRESET). The areas from 1 to

20 are assigned to store the additional signal. The areas

from 21 to 74 are assigned to store the internal signal.

Menu Structure

PRESET EDIT

ORIGINAL DATA SELECT

DATA EDIT

SAVE AREA SELECT

How To Edit The Preset Data

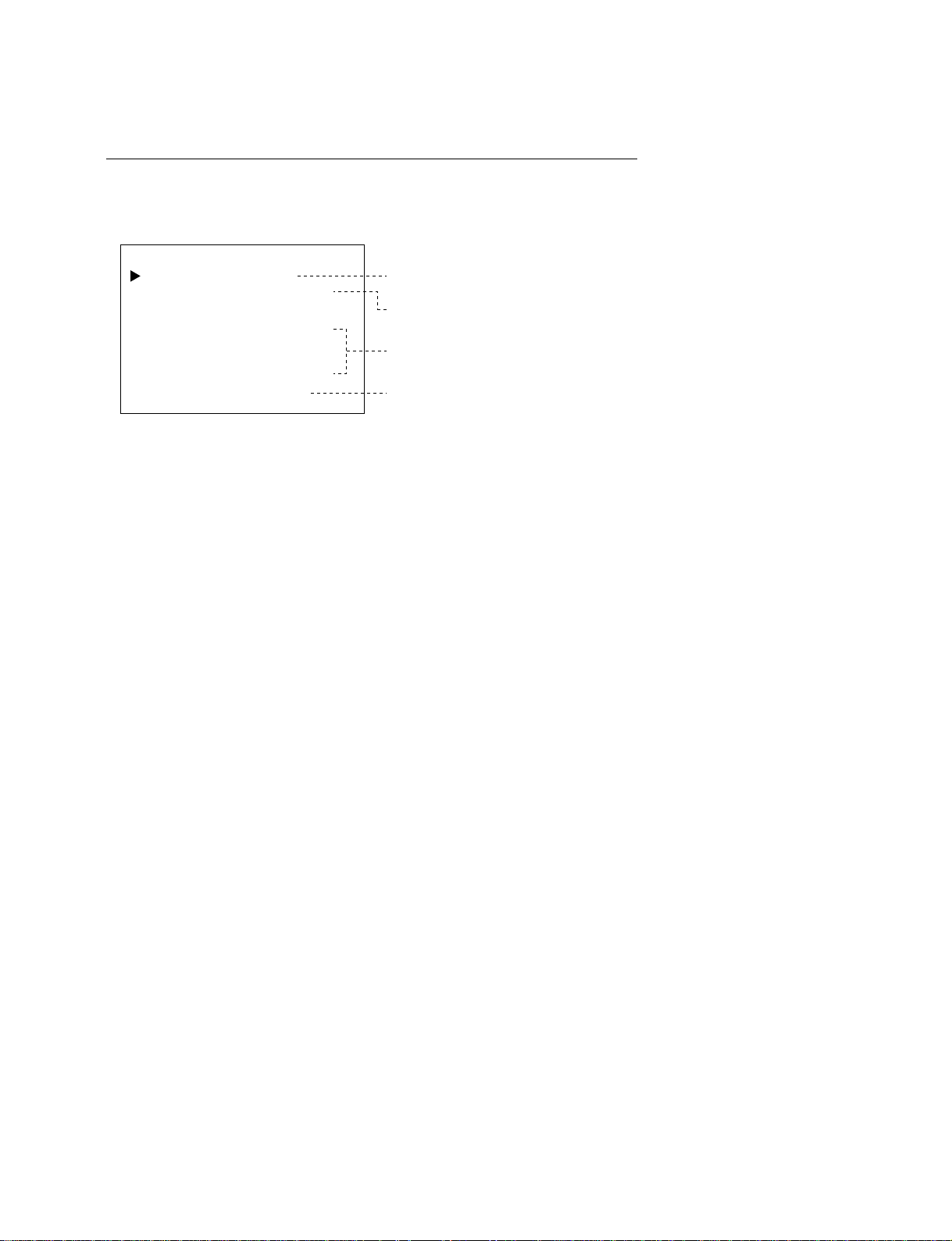

As shown in the illustration, the system controller contains

the memory area (i.e., Editing RAM) that is assigned only

for data editing. The source data that is used for editing

must be firstly copied to the Editing RAM. Edit then the

copied data as desired. Finally save the result of editing in

the specified preset area of the EEPROM.

(The illustration shows an example that the data in the

preset area No. 02 is once copied to the Editing RAM

where data is edited. The edited data is sent back to the

preset area No. 11 where the edited data is saved.)

EEPROM Preset areas System controller

Preset Area 01

Preset Area 02

Preset Area 03

Preset Area 04

Preset Area 05

Preset Area 06

Preset Area 07

Preset Area 08

Preset Area 09

Preset Area 10

Preset Area 11

Preset Area 12

Editing RAM

Editing

2-6

PFM-42B2/42B2E

a) ORIGINAL DATA SELECT

Menu Structure

Select the source data that is used for editing. Then the selected source data is

copied to the Editing RAM.

ORIGINAL DATA SELECT

CURRENT DATA SELECT

FORMAT TABLE

- ORIGINAL FORMAT H FREQUENCY

V FREQUENCY

SYNC POL (H/V)

: PROGRAM1

: 31.47 [kHz]

: 60.00 [Hz]

: NEGE/NEGA

(1) The signal that is being inputted at present

is selected as the source data.

(2) The signal that is already stored in the preset

area is selected as the source data.

(3) Frequency of the signal that is selected

as the source data is displayed.

EDIT MODE

: DIRECT

(4) Type of the signal that is selected as the

source data is displayed.

(1) CURRENT DATA SELECT

When an editing is performed using the signal that is being inputted at present is

selected as the source data, move the cursor to this item and press ENTER. The

selected data is copied to the Editing RAM.

(2) FORMAT TABLE : PROGRAM 1

When an editing is performed using the signal that is already stored in the preset

area is selected as the source data, move the cursor to this item and press

ENTER. Select the desired area from Table 1 by pressing the +/_ keys. The

selected data is copied to the Editing RAM.

(3) - ORIGINAL FORMAT -

Frequency of the signal that is selected as the source data in step (1) or (2) is

displayed.

Use the frequency data as the fundamental information when selecting a source

data.

(4) EDIT MODE

When the signal that is being inputted at present is selected as the source data,

the message DIRECT appears. When the signal that is already stored in the

preset area is selected as the source data, the message TABLE appears.

n

The editing items that can be editing here are different in the DIRECT mode and the

TABLE mode. Refer to the next sub-section “b) DATA EDIT” for the editing items.

< When DIRECT mode is used for editing >

… The DIRECT mode is used when editing is performed while watching the

picture on screen in the case that the specifications of the signal are not known. …

When DIRECT mode is selected, select the desired adjustment item referring to

the next sub-section “b) DATA EDIT” by pressing the +/_ keys. Press the ENTER key. Then the result of data adjustment is reflected on the display screen.

(Pressing the MENU key returns to the previous menu display.)

However, the three adjustment items H FREQUENCY, V FREQUENCY and

SYNC POL cannot be changed by the menu operation.

< When TABLE mode is used for editing >

… The TABLE mode is used when the specifications of the signal to edit are

already known. …

All adjustment items adjusted by the menu but result of adjustment is not

reflected on the actual picture. Data can be edited only.

PFM-42B2/42B2E

2-7

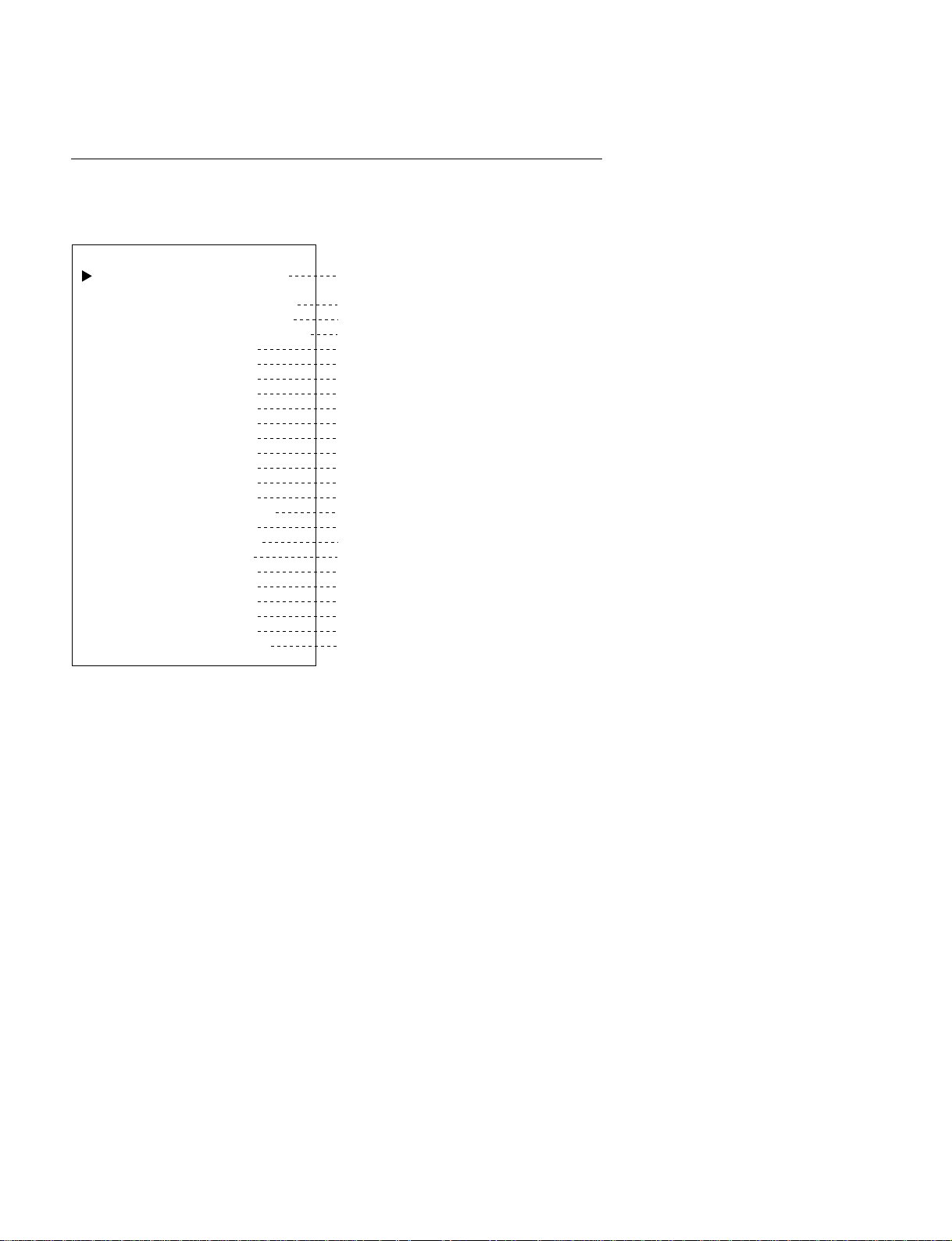

b) DATA EDIT

Menu Structure

The following items of the source data that is copied to the Editing RAM can be

modified as described below.

DATA EDIT

INPUT SELECT

INPUT SELECT2

H FREQUENCY

V FREQUENCY

SYNC POL (H/V)

TOTAL H PIXEL

LEFT EDGE

H RESOLUTION

TOP EDGE

V RESOLUTION

DOT PHASE

CP PLACEMENT

CP DURATION

INTERLACE MODE

FILED MODE

FRAMELOCK MODE

MATRIX SELECT

PICTURE AGC

ASPECT

ZOOM

APERTURE INIT

APERTURE HIGH

APERTURE MID

APERTURE LOW

AUTO PLL

SYNC WIDTH (µs)

: 01100000

: 00000101

: 31.47 [kHz]

: 60.00 [Hz]

: NEGA/NEGA

: 800

: 140

: 640

: 35

: 480

: 128

: 005

: 016

: OFF

: OFF

: OFF

: ITU709

: ON

: 4 × 3

: × 1

: MID

: 000

: 002

: 004

: ON

: 003.81

(1) Acceptable type of input signal

(2) Horizontal frequency

(3) Vertical frequency

(4) Sync signal polarity

(5) Total number of horizontal dots

(6) Horizontal dot position to start reading

(7) Horizontal resolution (Number of dots)

(8) Vertical dot position to start reading

(9) Vertical resolution (Number of dots)

(10) Dot phase

(11) Clamp pulse width (Number of dots)

(12) Clamp pulse position (Number of dots)

(13) Interlace setting

(14) In-field processing setting

(15) Vertical sync setting

(16) Color difference matrix setting

(17) Automatic brightness adjustment setting

(18) Aspect ratio setting

(19) Zoom setting

(20) Aperture initial value setting

(21) Aperture data setting

(22) Aperture data setting

(23) Aperture data setting

(24) Automatic PIXEL ADJUST setting

(25) Horizontal sync signal width

n

A maximum of 8 lines of the above menu can be displayed on screen. The other

menu items can be displayed by scrolling the display by moving the cursor up or

down.

2-8

PFM-42B2/42B2E

Loading...

Loading...