Page 1

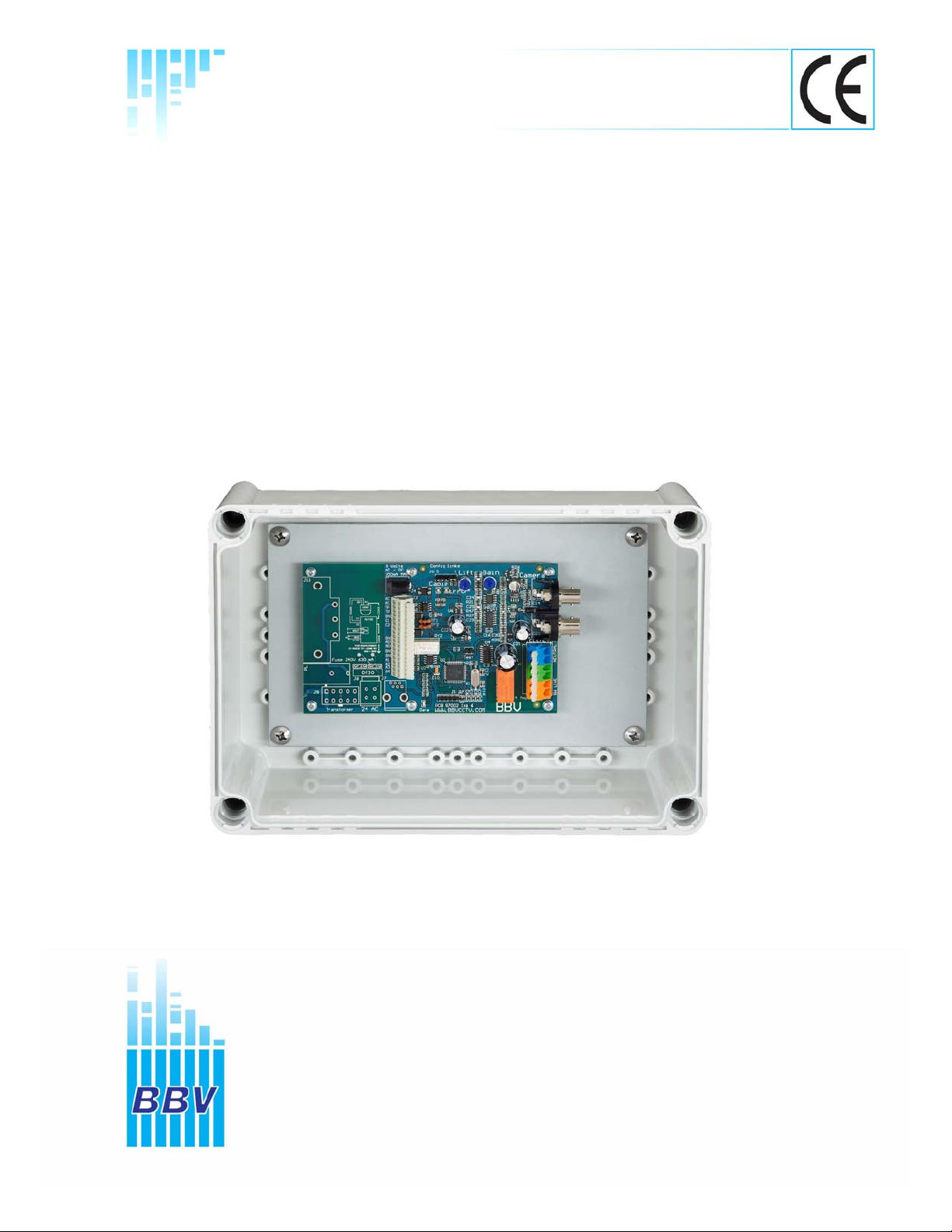

RX100

Dome Interface Receiver

Installation

Guide

Building Block Video Ltd.,

17 Apex Park,

Diplocks Industrial Estate,

Hailsham, East Sussex, BN27 3JU UK.

Tel: +44(0)1323 842727

Fax: +44(0)1323 842728

Support: +44(0)1323 444600

www.bbvcctv.com

Page 2

TABLE OF CONTENTS

1. Pre-installation Checks and Safety Procedures 3

Unpacking 3

Important safety precautions 3

2. Introduction 5

General 5

Rx100 Technical specification 5

Transmitter compatibility chart 6

Cable connection method 7

Fig. 1 Wago cable connectors

Cable types 7

3. Installation 8

Operating voltage 8

Rx100 connections 8

Fig. 2 Rx100 pcb connections

4. Setup 9

Diagnostic aids 9

Cable length compensation 9

Fig. 3 Launch amplifier

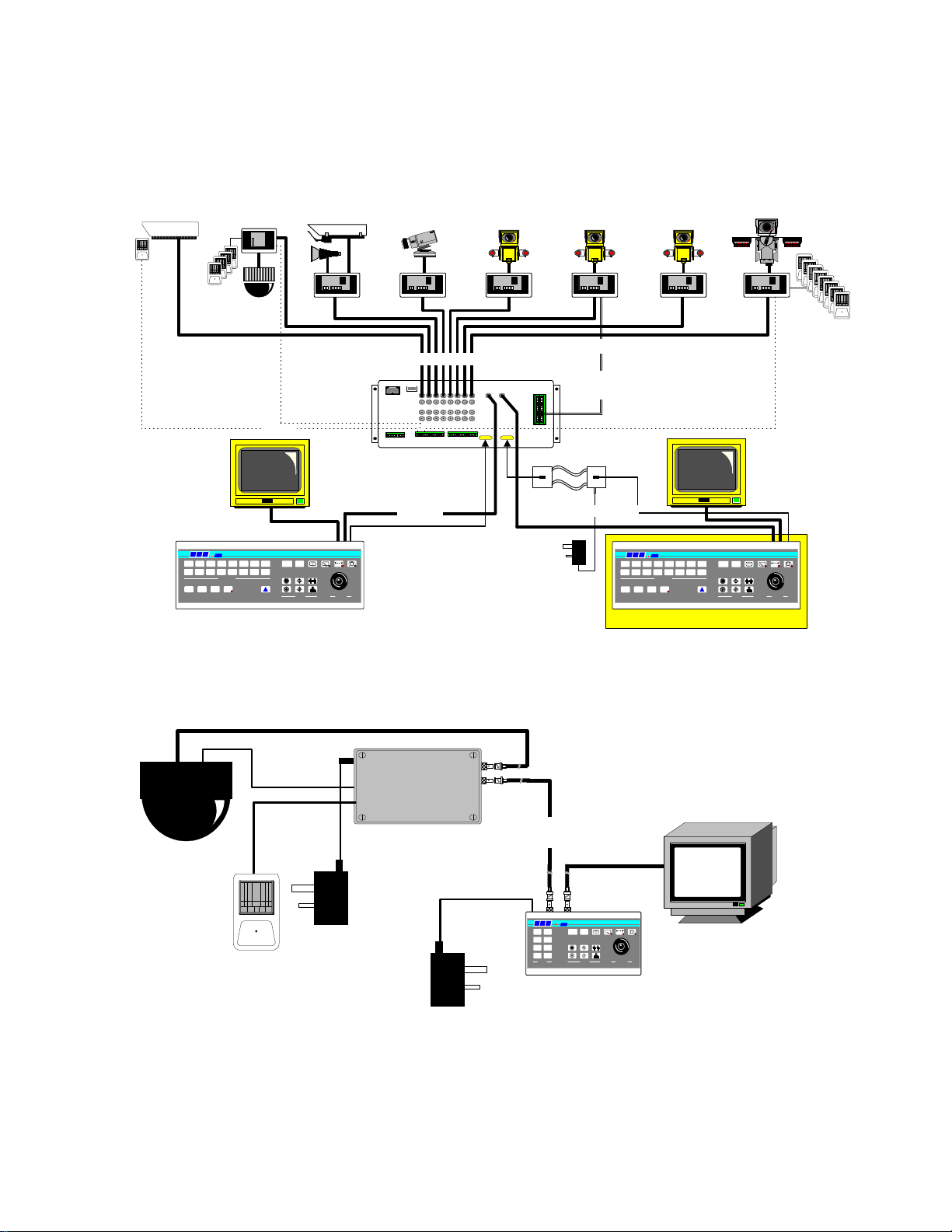

5. System schematic diagrams 10/11

Fig. 4 Integration of dome into Tx1500 system

Fig. 5 Integration of dome into Tx1000 system

Fig. 6 Simple single camera system

Appendix A - Dome Connection Details 12

Appendix B - Troubleshooting 40

Version 1.17 29 Aug 08 Update Dennard page Customer pointed out that the address switches were

not mentioned.

Version 1.16 1 May 08 Update version numbers and J6 links for change to 16F887 processor.

Various corrections and amendments made.

Version 1.15 15 May 07 Removed old Borsatec and putting new Borsatec BT2790FF Dome

Version 1.14 22 Jan 06 Added page for Videcon VCP451 camera software V5V1.

Removed Mitsubishi CCD400 and Star MD100

Version 1.13 25 Mar 05 Added page for Videcon dome software V4V1.

Forward Vision MIC1 zoom proportional pan/tilt speed enabled F1V6

Removed RX100/24 issue 4 pcb page as obsolete

Modified back page products list.

Version 1.12 24 Nov 04 Added page for Kalatel Cyberdome software K1V1.

Also removed page for obsolete Bischke camera

Version 1.11 20 Oct 04 Added page for Vista PowerDome software V3V1

Version 1.10 22 Sept 04 Updated installation notes for FORWARD VISION and LILIN domes.

Rx100 installation manual V1.17 29 Aug 08.doc Page 2

Page 3

1. PRE-INSTALLATION CHECKS AND SAFETY PROCEDURES

UNPACKING

Check Packaging - Upon taking delivery of the unit, inspect the packaging for signs of damage. If damage has

occurred, advise the carriers and/or the suppliers immediately.

Check Contents - Upon taking delivery of the unit, unpack the unit carefully and check that all the items are

present and correct. If any items are missing or damaged, contact your equipment dealer.

Retain Packaging - The shipping carton is the safest container in which to transport the unit. Retain

undamaged packaging for possible future use.

IMPORTANT SAFETY PRECAUTIONS

Read Instructions - All relevant safety, installation and operating instructions should be read before attempting

to install, connect or operate the unit.

Retain Instructions - All safety, installation and operating instructions should be retained for future reference.

Heed Warnings - All warnings on the unit and in any relevant safety, installation or operating instructions

should be adhered to.

Cleaning - Unplug the unit from the power outlet before cleaning. Do not use liquid cleaners or aerosol

cleaners. Use a damp cloth for cleaning.

Attachments - Do not use attachments not recommended by the product manufacturer as they may cause

hazards.

Water and Moisture - Do not expose the internal electronics of this unit to water or dampness; for example, in

an unprotected outdoor installation, or in any area classified as a wet location. The unit as supplied conforms to

ingress protection rating IP 67. This rating will be affected by any holes made in the enclosure. Cable entry

points should be protected by the use of suitably rated glands and/or flexible conduit. It is not necessary to

make further holes in the enclosure for mounting purposes, as mounting holes are provided at the corners of the

enclosure outboard of the seal between enclosure and lid.

Accessories - Do not attach this unit to an unstable stand, bracket or mount. The unit may fall, causing serious

injury to a person and serious damage to the unit.

Power Sources - This unit should be operated only from the type of power source indicated on the

manufacturer’s label. If you are not sure of the type of power supply you intend to use, consult your equipment

dealer or local power company. For units intended to operate from battery power or other sources, refer to

operating instructions.

Power Connector - This unit is equipped with coaxial power connector mounted at the edge of the PCB for low

voltage power input. Do not attempt to alter this connector in any way.

Power Cord Protection - Power supply cords should be routed so that they are not likely to be trapped, pinched

or otherwise damaged by items in close proximity to them, whether inside the unit or outside it. Particular

attention should be paid to cords at plugs, connection units and the point of exit from the unit.

Overloading - Do not overload outlets and extension cords, as this can result in fire or electric shock.

Object and Li quid Entry - Never push objects of any kind into the unit, as they may touch dangerous voltage

points or short out parts that could result in fire or electric shock. Never spill liquid of any kind on or inside the

unit.

Servicing - Servicing of the unit should only be undertaken by qualified service personnel, as opening or

removing covers may expose you to dangerous voltages or other hazards.

Rx100 installation manual V1.17 29 Aug 08.doc Page 3

Page 4

Damage Requiring Service - Servicing by qualified personnel should be carried out under the following

conditions:

(a) When the power-supply cord or plug is damaged.

(b) If liquid has been spilled or objects have fallen into the unit

(c) If the internal electronics of the unit have been exposed to rain or water

(d) If the unit does not operate normally by following the operating instructions. Adjust only those

controls that are covered by the operating instructions, as improper adjustment of other controls may

result in damage and will often require extensive work by a qualified technician to restore the unit to

normal operation.

(e) If the unit has been dropped or the enclosure is damaged.

(f) If the unit exhibits a distinct change in performance. This indic ates a need for service.

Replacement Parts - If replacement parts are required, ensure that only replacement parts recommended by the

product manufacturer are used.

Safety Check - Upon completion of any service or repairs to the unit, safety checks should be performed to

ensure that the unit is in proper operating condition.

Pre-installation Checks - It is recommended that the unit be bench-tested prior to installation on the site.

Safety During Installation or Servicing - Particular care should be taken to isolate the dome in order to prevent

operation while engineering work is being carried out on the Rx100.

Adhere to Sa fety Standa rds - All normal safety precautions as laid down by British Standards and the Health

and Safety at Work Act should be observed.

WARNING

TO PREVENT DANGER OF FIRE OR SHOCK, DO NOT EXPOSE THE INTERNAL COMPONENTS OF THIS

EQUIPMENT TO RAIN OR MOISTURE.

The “lightning flash with arrowhead” symbol inside an equilateral triangle is used to warn the user of this

equipment that there are sufficiently high voltages within the enclosure to constitute a risk of electric shock.

The “exclamation point” symbol inside an equilateral triangle is used to alert the user of this equipment to

important operating and maintenance (servicing) instructions in the literature accompanying the appliance.

Rx100 installation manual V1.17 29 Aug 08.doc Page 4

Page 5

2. INTRODUCTION

GENERAL

The Rx100 telemetry interface is designed to allow control of a variety of integrated dome cameras using BBV’s

range of up-the-coax telemetry transmitters. See appendix A for a complete list of supported domes.

The Rx100 interface is supplied in an IP67 rated enclosure. It will be necessary to make suitable holes in the

enclosure to permit cable entry and exit. Adequately rated cable glands and or flexibl e conduit should be used at

all times to avoid compromising the protection afforded by the enclosure as supplied. Any holes made in the

enclosure for any other purpose should be sealed with a non-hardening waterproof sealant, taking care to ensure

that the internal electronics are not contaminated.

Rx100 TECHNICAL SPECIFICATION

Power Requirements: RX100 9-12V ac/dc – plug mounted PSU provided

RX100/24 – 24Vac or 230Vac

Current Consumption: RX100 - 100mA @ 12Vdc maximum

RX100/24 – 630mA @ 230Vac maximum

Features: • Serial data output 2 wire RS485/RS422.

• 4 alarm inputs.

• 1 N/C alarm output.

• Up to 16 pre-set positions can be stored within the Rx100.

• Relay capable of switching 1Kw of lighting.

Engineering Facilities: • Unit auto-tunes to the coaxial telemetry signal.

• LED readout for continual system status.

• Video launch amplifier provided with Gain and Lift controls.

• Colour-coded cage clamp terminals. Mains terminal connections:

Live, Neutral and Earth and Low Voltage.

Telemetry Signals: Telemetry signals either:

• up-the-coax (max distances, 250M of RG59 or 500M of CT125/RG11).

• or twisted pair 0-20mA current loop.

Video Input: 1v p-p 75Ω terminated input via BNC socket.

Video Output: 1v p-p to 4v p-p 75Ω impedance via BNC socket.

Up to 16 full-scene preset positions can be stored within the interface depending upon the model of dome.

Dimensions (external): RX100/WBX RX100/24/WBX

Width: 190 mm Width: 190mm

Length: 280 mm Length: 380mm

Height: 130 mm Height: 130mm

Weight: 1.0Kg 3.6Kg

Temperature range: -10° Celsius to +40° Celsius

Rx100 installation manual V1.17 29 Aug 08.doc Page 5

Page 6

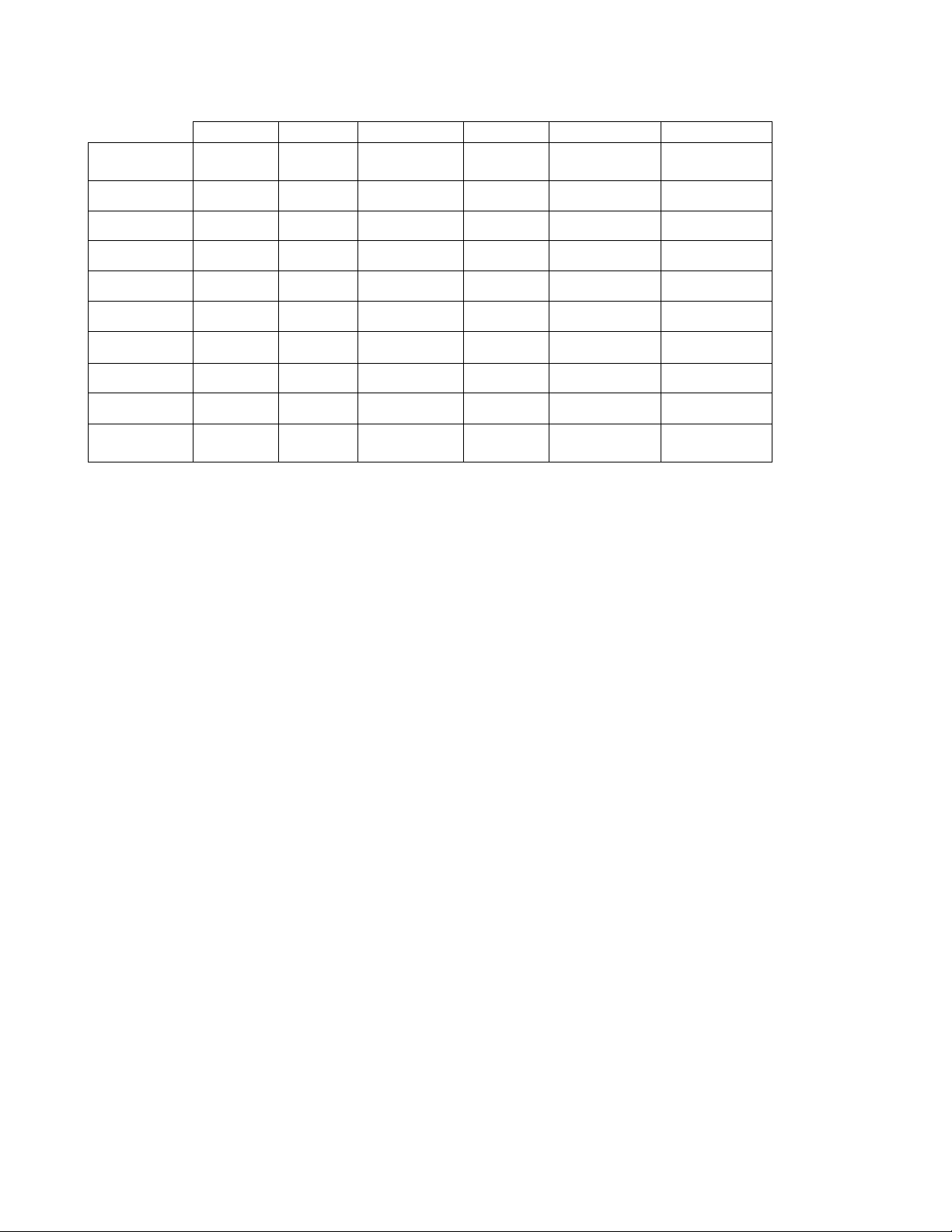

TRANSMITTER COMPATABILITY CHART

Tx300 Tx400 Tx400DC Tx1000 Tx1000DC Tx1500

Variable

Speed

Fixed Speed

Zoom

Focus

Iris

Pre-sets

Patrols

Lights

Autopan

Camera

Functions

2 Speeds 2 Speeds

Proportional

Joystick

2 Speeds

9 9 9 9 9 9

9 9 9 9 9 9

9 9 9 9 9 9

9 9 9 9 9 9

- 8 8 16 16 16

- 2 2 2 2 2

9 9 9 9 9 9

-

-

9 9 9 9 9

9 9 9 9 9

Proportional

Joystick

Proportional

Joystick

Rx100 installation manual V1.17 29 Aug 08.doc Page 6

Page 7

CABLE CONNECTION METHOD

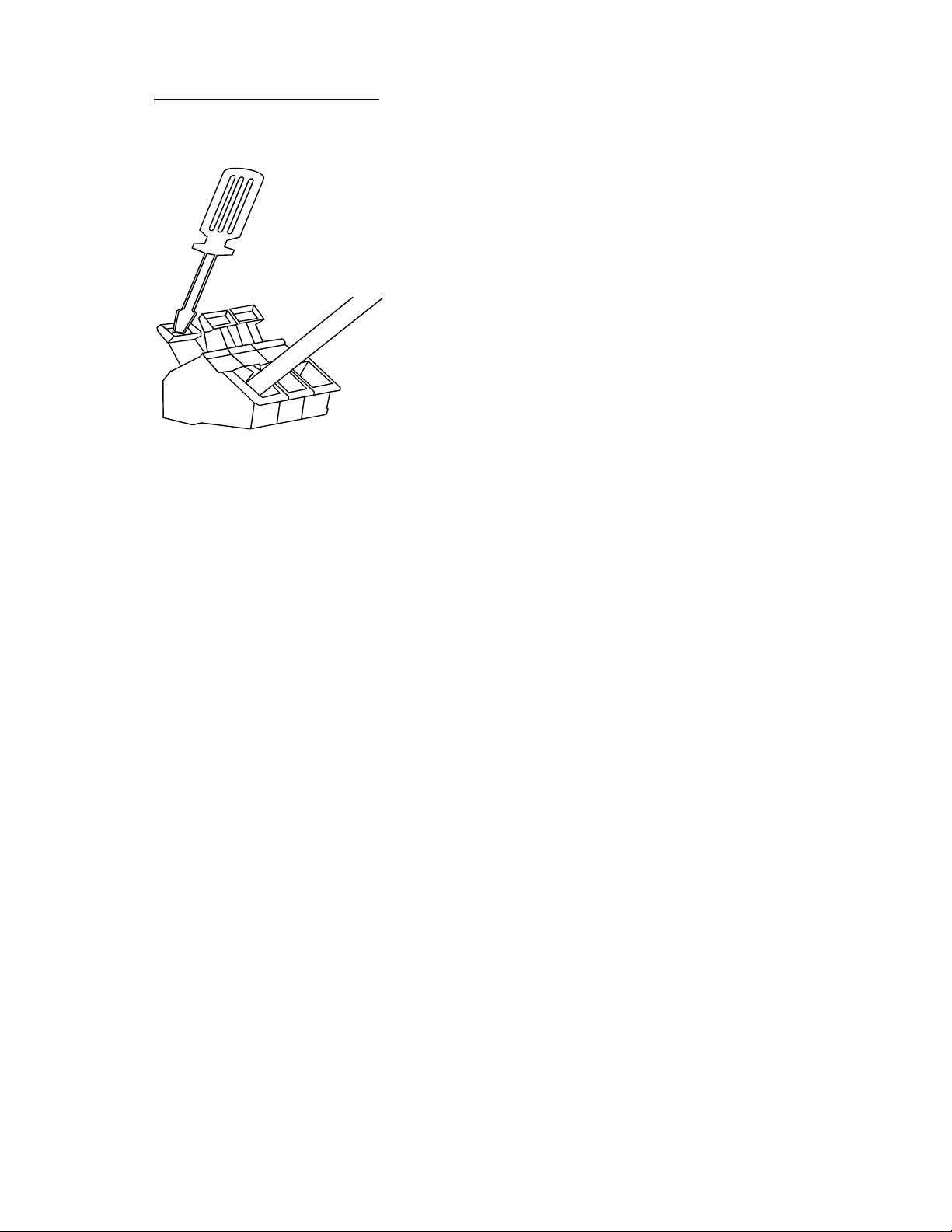

Fig. 1: cage clamp connectors

The cage clamp PCB terminal block is a simple-to-use method of

attaching cables to PCBs quickly and easily. Prepare cables as

follows:

• Use only cable between 0.08 and 2.5 mm²

• Strip the cable to a length of 5 to 6 mm (0.23 in)

The correct method of attachment is as follows:

1. Press down the relevant terminal block lever with a suitable

screwdriver;

2. Insert wire;

3. Remove screwdriver.

The procedure for detaching wires is the reverse of the 3 attachment

steps, ensuring that power is disconnected before starting.

CABLING RECOMMENDATIONS FOR THE Rx100 INTERFACE.

Although BBV do not specify any particular type, manufacturer or supplier of cables, the following ESD

Electronic Services (01279 626777) cables have been used successfully for production and testing:

ESD Part Number: Description:

0222586G Coax Cable (Minimum Specification)

(100 m) RG59B/U ESD radio frequency coax cable to BS2316 and MIL-C-17

1/0.58mm copper-covered steel wire conductor with solid polythene dielectric, bare

copper wire braid and PVC sheath

Characteristic impedance: 75 Ohm

Capacitance: 22pF/ft

020966D Orange-Coloured Lighting Output Power Cable (1000 w)

(100 m) 3183Y PVC-insulated, 3-core cable

1.25mm

Current rating: 13 amp

0140467H 20mA Twisted Pair Cable (Minimum Specification)

(100 m) British Telecom spec CW 1308

2-core 1/0.5mm PVC-insulated

Maximum conductor resistance at 20 degrees Celsius: 97.8 ohms/km

² 40/0.2mm annealed copper conductor

Rx100 installation manual V1.17 29 Aug 08.doc Page 7

Page 8

3. INSTALLATION

OPERATING VOLTAGE

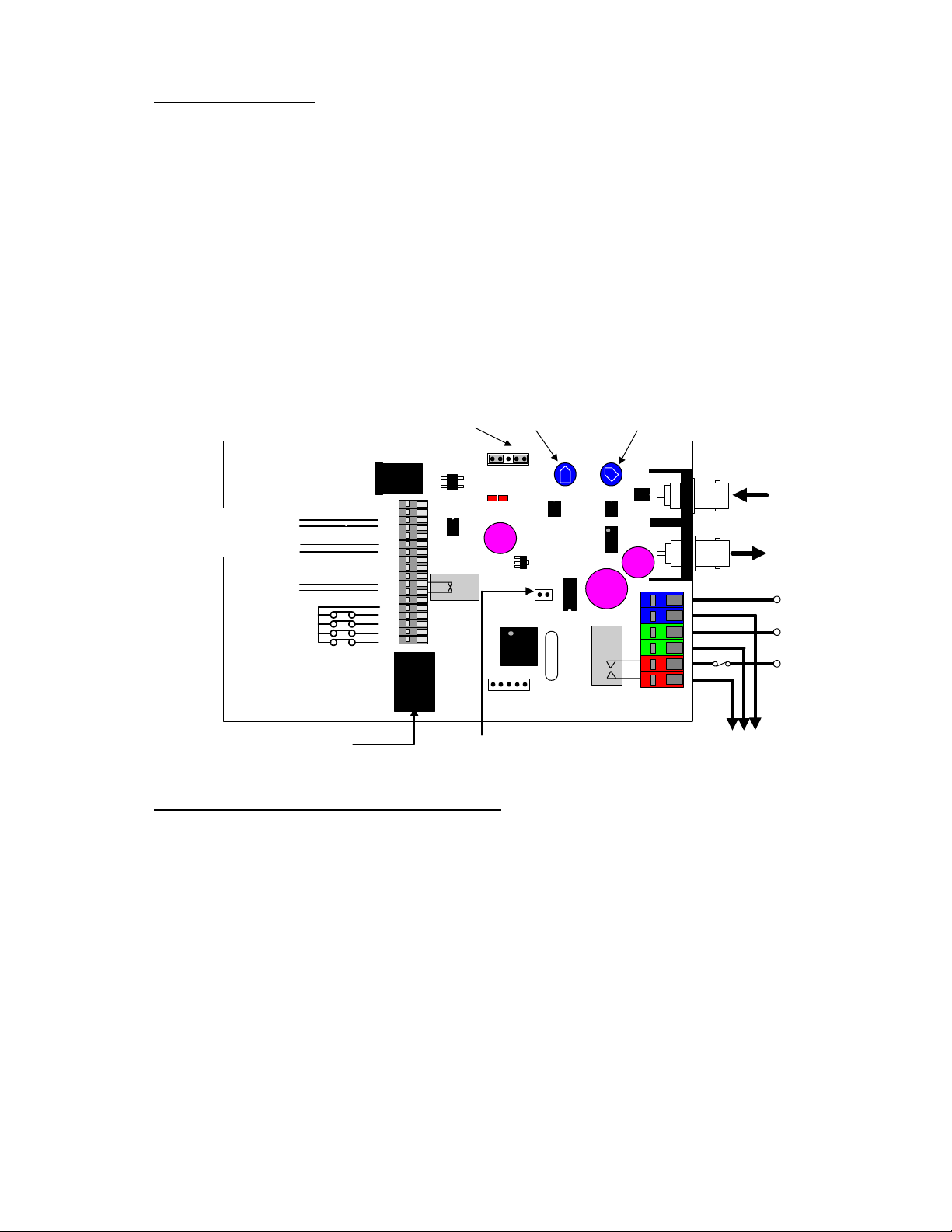

The Rx100 requires all connections to the PCB to be made by the installer, and via terminal blocks or by plug

and socket. These connections are: power in, video in, video out, and serial data to dome. In addition

connections for alarm in, alarm out and lights if required are provided. See fig.2 below for correct connections.

The Rx100 is supplied pre-configured to suit the application for which it is intended, i.e. to control an integrated

dome camera.

IMPORTANT NOTE – If link J6/4-5 is removed it must be refitted to J6/3-4 position or the RX100 will

assume it is still fitted.

Fig. 2 Rx100 Iss6 PCB connections

J6 OPTION LINKS

POWER 9 - 12 V AC/DC

100mA MAX

J4

9-12V

supply

Twisted Pair IN from

telem transmitter

RS485 OUT to dome

N/C Alarm

OUT

Alarm

contacts IN

N/C

AC

AC

TP

TP

GND

C1

C2

C3

C4

GND

AOUT

AOUT

GND

GND

A1

A2

A3

A4

J3

J3

J7

Test LinkRS485 to Panasonic domes

Function Connector Type

Power In J4 2.1mm coaxial

or J3/AC-AC Grey WAGO

Video In CAMERA BNC SOCKET

Video Out TELEMETRY BNC SOCKET

Twisted Pair Telemetry J3/TP-TP Grey WAGO

Serial to dome J3/C1-C4-GND Grey WAGO

or J7 FCC68 (Fitted for Panasonic versions)

Alarm 1 contact in J3/A1-GND Grey WAGO (optional if alarm input required)

Alarm 2 contact in J3/A2-GND Grey WAGO (optional if alarm input required)

Alarm 3 contact in J3/A3-GND Grey WAGO (optional if alarm input required)

Alarm 4 contact in J3/A4-GND Grey WAGO (optional if alarm input required)

Alarm contact out J3/AOUT-AOUT Grey WAGO (optional if alarm input required)

Lighting relay J5 Coloured WAGO (optional if lights control required)

(clean contact between orange connectors)

Rx100 installation manual V1.17 29 Aug 08.doc Page 8

HF Lift Gain

J6/1-2

J6/4-5

5

1

CABLE

ERROR

Test

J1

pcb 97002 Iss 6

www.bbvcctv.com

GAINLIFT

RY1

BBV

CAMERA

TELEMETRY

J5

4 Amp 250V MAX

Lights Supply

SW LIVE EARTH NEUTRAL

Lights

Feed

Video In

from dome

Video Out

to transmitter

Neutral

Earth

Live

Page 9

4. SETUP

DIAGNOSTIC AIDS

Two red LEDs and one Green LED are mounted on-board to give simple system status information. Their

functions are as follows:

Cable LED

Regular Blinking - Telemetry and video signa ls are OK.

Blinking but mainly ON - No Telemetry from the transmitter.

Blinking but mainly OFF - No video from the camera.

Error LED

On - Telemetry transmission error.

Both LEDs

Off - No power or major PCB fault.

Data LED (Iss PCB 4 onwards only) - Will flash on and off very fast when data

is

being sent to the dome.

Test Link - Is used to confirm correct operation of the

Rx100 and dome and also that the RS485

connection is correct. Shorting the link after the

Rx100 is powered up will cause the dome to pan

left and zoom in. Removing the link will stop the

pan left and will zoom out the lens. This is

dependant on dome type.

All BBV equipment is designed to auto-tune and compensate for any discrepancies in the transmitted telemetry

signal; there are no further adjustments that need to be made.

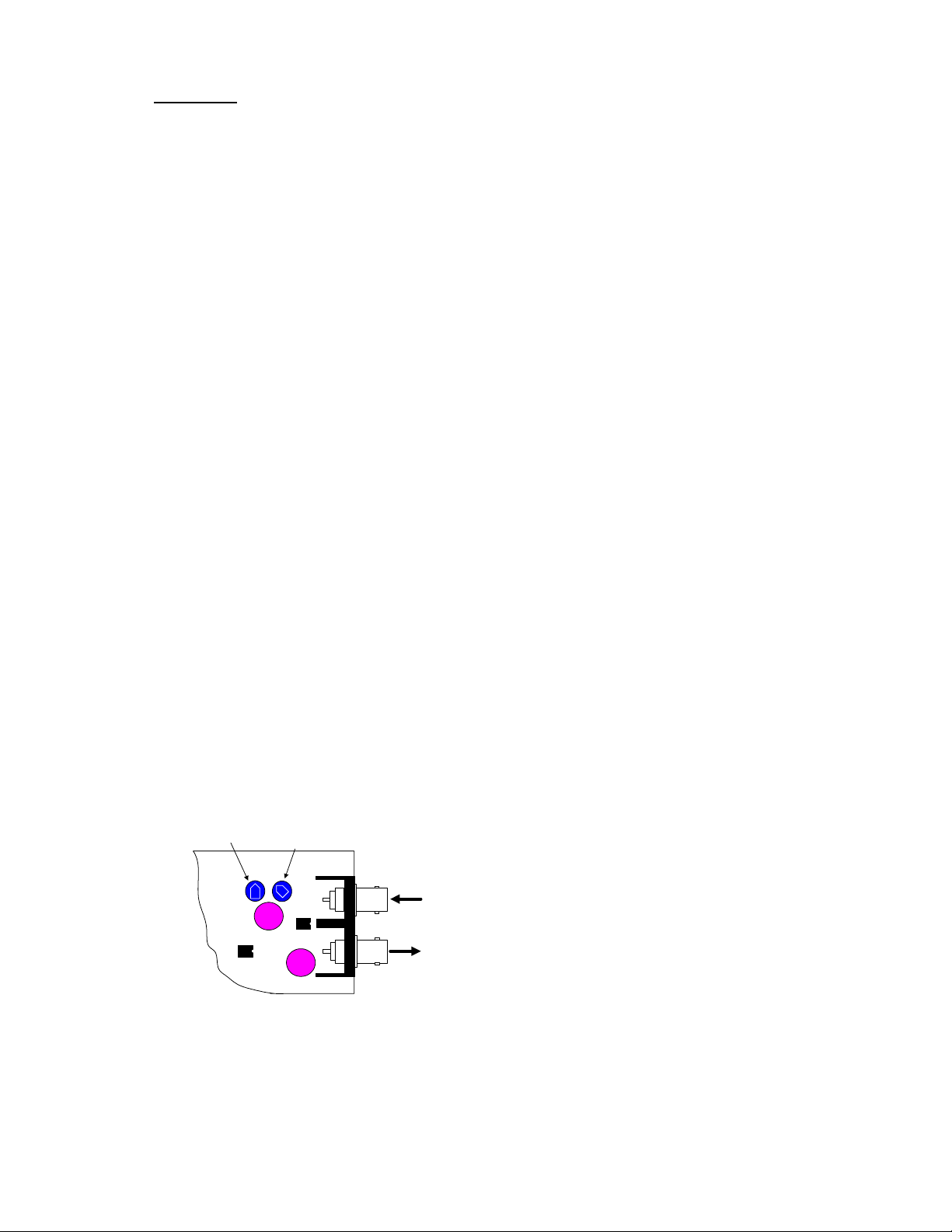

VIDEO LAUNCH AMPLIFIER AND CABLE LENGTH COMPENSATION

The interface features a video launch amplifier with two variable controls situated close to the BNC connectors:

Lift and Gain. These are pre-adjusted for a cable distance of 500m of CT125, and are adjustable to compensate

for video detail or signal losses if and when longer or shorter cable lengths are used to connect the telemetry

transmitter to the interface.

Fig. 3 Launch Amplifier

HF Lift

LIFT

Gain

GAIN

CAMERA

TELEMETRY

Video

from

dome

Video

to

transmitter

Default position adjusted for 500M of CT125.

For shorter cable lengths, turn the Gain control anti-clockwise until 1V p-p is present at the telemetry

transmitter. For longer cable lengths, turn the Gain control clockwise until 1V p-p is present at the telemetry

transmitter.

The purpose of each control is:

GAIN varies the overall signal level.

LIFT boosts the high frequency component of the video

signal. If the high frequency component is too low, picture

appears ‘washed out’ and lacking detail.

Rx100 installation manual V1.17 29 Aug 08.doc Page 9

Page 10

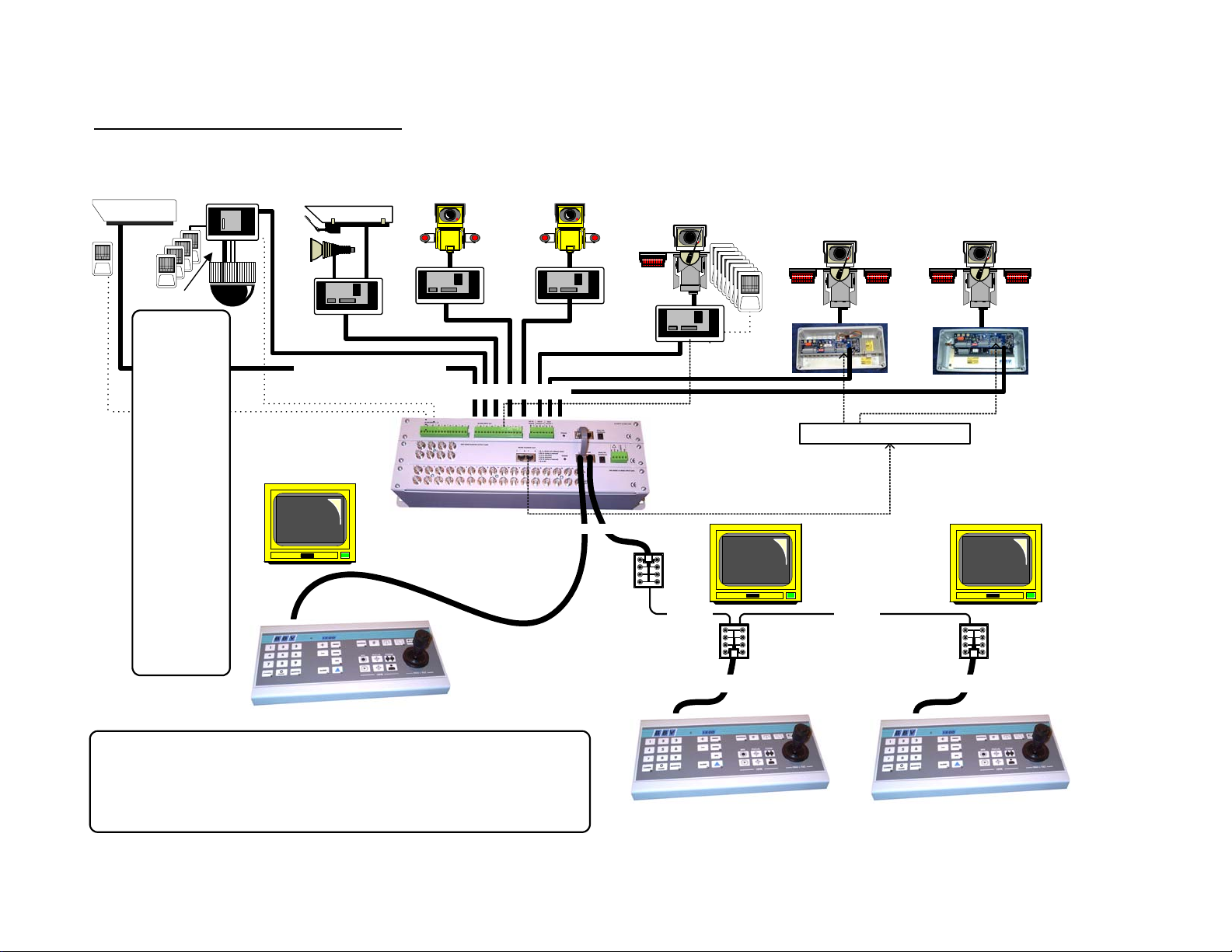

4. SYSTEM SCHEMATIC DIAGRAMS

static camera

STATIC

Rx100

dome camera

4 local alarms

Rx200

static camera with

lights/wash/wipe

Rx300

AC P/T Zoom/Focus

1 Aux.

Rx400P

AC P/T Zoom/Focus

16 Presets with 4 Aux.

Rx400DC

High & Variable speed

P/T Zoom/Focus

16 Preset with 3 Aux.

8 Local alarms

Fig.4

Expandable up to 96 cameras i n puts. 4 control positions including remote control via RS232/485 interface unit.

Up to 96 alarm inputs using 16 i nput alarm modules. BBV up-the- coax and RS485 telemetry as standa r d.

The STARCARD/CONVETER allows RS485 control of domes etc.

Simple control protocol to al low integration with 3rd part equipment.

video & data

Dome library includes:

Alltec Apollo

Chugai/Computar SMD

Dennard type 2050

Ulltrak/Diamond KD6

Dynacolor

Forward Vision MIC

*JVC TK-C675/675B

Kalatel Cyberdome

(1/1/02 or later)

Kenko Daiwa DMP15H1

Kenko Daiwa DMP16H3

MarkMercer D250MPT

Merit Li-Lin PIH717X

Panasonic WV-CSR400

Panasonic WV-CSR600

Panasonic WV-CSR650

Panasonic WV-CS850

Pelco SD5 'Spectra'

*Philips G3 (RS232)

Sanyo VCC9200P

Sensormatic Speed dome

Sony EVI-31D

Star MD100 & MD200

VCL TP domes

*Vicon Surveyor 2000

Videcon dom e

Vista PowerDome

*Rx100/24 230Vac

powered with 24Vac 100VA

output.

Call BBV for info.

Up-the-coax telemetry

250M RG59 / 500M CT125

TX1500/KBD

video in - coax

TX1500/16/8/16AL Matrix

Monitor 1-4 with OSD

Monitor 5-8 without OSD

B-BUS multidrop 4 wire RS422

Supplied 2M CAT5 cable

Poweres 1st keyboard.

Use RJ45 breakout boxes if > 2M

Cat5 RJ45 patch cable

RJ45 Breakout

Box

RS485 twisted pair

twin UTP twin UTP

RJ45 Breakout

Box

Cat5 RJ45 patch cable

TX1500/KBD

Rx45X AC

BBV RS485

AC Fixed Speed

P/T Zoom/Focus

32 Preset with 4 Aux.

8 Local alarms

RS485 twisted pair

RS485 StarCard

8 outputs

RJ45 Breakout

Box

Cat5 RJ45 patch cable

TX1500/KBD

Rx55X DC

BBV RS485

High & Variable speed

P/T Zoom/Focus

32 Preset with 3 Aux.

8 Local alarms

SYSTEM SCHEMATIC SHOWING INTEGRATION OF DOME INTO Tx1500 SYSTEM

Page 11

Fig.5

SYSTEM SCHEMATIC SHOWING INTEGRATION OF DOME INTO Tx1000 SYSTEM.

Rx300M

AC P/T Mitsubishi

CCD400 control

2 Aux.

static camera

STATIC

Rx100

dome camera

4 local alarms

Rx200

static camera with lights/

wash/wipe

Rx200

simple AC panner

Rx300

AC P/T Zoom/Focus

1 Aux.

Rx400P

AC P/T Zoom/Focus

16 Presets with 3 Aux.

Rx400DC

High & Variable speed

P/T Zoom/Focus

16 Preset with 3 Aux.

8 Local alarms

alarm cable

RS232 control Max distance - 50M

Optional TxLD available for extended

BBV

1000

910111213141516

CAMERA SELECT

MONITOR

PRESETPATROLSEQ

PROGRAM

87564312

IRIS FOCUS

#

BBV

LENS

LENS

AUTOPAN

ZOO

M

PAN +TILT

300

KEYBOARD 1

Fig. 6 SIMPLE SINGLE CAMERA SYSTEM

Video

Data

video in - coax

Optional Alarm Package

Tx1000/8 or 16 Base Unit

video out - coax

distances.

up-the-coax telemetry 250M-RG59, 500M-CT125

Twisted Pair telemetry.

Optional

Twisted Pair

Loop resistance < 300R

TxLD TxLD

Twin Twisted Pair

Optional TxLD link. Distance > 50M.

9V plug PSU

BBV

1000

910111213141516

CAMERA SELECT

MONITOR

PRESETPATROLSEQ

PROGRAM

87564312

IRIS FOCUS

OPTIONAL 2ND KEYBOARD

#

BBV

LENS

LENS

AUTOPAN

ZOO

M

PAN +TILT

300

Alarm

contact

Rx100 Interface

9V

PSU

250M-RG59

500M-CT125

BBV

400

12

43

56

87

PRESETS

PROGRAM

IRIS FOCUS

#

AUTOPAN

ZOOM

LENS

PAN +TILT

MONITOR

Tx400DC

9V

PSU

Page 12

Appendix A - Dome addendums & connection details

Rx100/24 iss. 4 pcb 13

360 Vision VisionDome 14

Borsatec BT2790FF Dome 15

Chugai SMD-08ll, SMD-12, SMD-12ll, SMD-20 31

Dennard 2050 16

Diamond-Smartscan 36

Dynacolor 7720 17

Forward Vision MIC1300 18

Gardiner Security Juno 14

JVC TK-C675E / TK-C675BE 19

Kalatel Cyberdome (1/1/2002 or later firmware) 20

Li-Lin PIH-717X/7000/7600/7625 21

Mark Mercer D250MPT 22

Panasonic WV-CSR400, WV-CSR600. WV-CSR650 23

Panasonic WV-CS850 24

Pelco Spectra dome & Esprit head (P protocol) 25

Philips AutoDome (RS232/485) 26/27

Samsung SCC-641 28

Sanyo VCC-9200P 31

Sensormatic speeddome (RS422 Only) 29

Sony EVI-D31, 1000 30

Star MD-800, MD-1200S, MD-1200H, MD-2000 31

Ultrak KD6 32

VCL-TP 33

Vicon Surveyor 34

Videcon Dome 35

Videcon VCP451 Camara 36

Vista PowerDome 37

Rx100 installation manual V1.17 29 Aug 08.doc Page 12

Page 13

BBV Rx100/24 Supply Additional information (iss. 6 pcb)

The RX100/24 can be powered from either 230Vac or 24Vac. The diagrams below shows the connections that

should be made for each supply voltage. Please note that when powered from 24Vac the 230Vac terminals will be

at mains voltages. To prevent the risk of shocks the fuse must be removed from the fuse holder and no connections

made to L and N. The 24Vac supply must be fused with a 315mA to protect the supply wiring.

Fig 9. RX100/24 iss. 6 pcb Connection details when operating from a 230Vac supply.

Important! When

operating the unit

230Vac Supply

24Vac 100VA

output to power dome

Fig 10. RX100/24 iss. 6 pcb Connection details when operating from a 24Vac supply.

from 24Vac, the fuse

from the 230Vac

connector fuse holder

must be removed. No

connections must be

made to this connector,

as it will have 230Vac

across the L & N

terminals.

24Vac

IMPORTANT! Remove fuse from fuseholder

and make no connection as these terminals

!

Rx100 installation manual V1.17 29 Aug 08.doc Page 13

will have 230Vac across L and N.

315mA Fuse

Supply

Page 14

BBV Rx100 Interface Receiver

Addendum to manual for the following domes:

360 Vision VisionDome

Gardiner Security Juno

Rx100 software RX1_31V2

Application Notes

The RX 100 provide the following functionality when controlling the above mentioned domes

Variable speed Pan/Tilt.

Zoom/Focus, Focus/Iris Override returning to auto after Zoom In/Out.

16 Full scene presets.

2 preset patrols.

Slow preset tour. Started by pressing AUTOPAN (As patrol 1 but slow speed movement and 10 second dwell)

5 minute datum/park driving to preset 1 or slow preset tour. Disabled by removing link J6/1-2

Program up to 16 privacy zones

Additional commands:

AUTOPAN: Pressing the AUTOPAN key will run the domes preset tour at slow speed between the patrol 1 pres et positions.

Advanced Features Tx400 Tx1000 Tx1500 DM DS/DS2/BX2 Mux

180 degree pan flip ‘#’ 1 '#' WASH 1 ’#’ *889 002 or *889 10 10 2

Privacy SET (enable) ‘#’ 2 '#' WIPE 2 ’#’ *889 003 or *889 10 10 3

Privacy CLEAR (disable) ‘#’ 3 '#' AUTOPAN 3 ’#’ *889 004 or *889 10 10 4

Reset dome param eters ‘#’ 4 '#' LIGHTS 4 ’#’ *889 005 or *889 10 10 5

The dome and Rx100 are linked using RS485 for control and video for the camera signal.

Rx100 Description Dome connection

J3-C1 TX-/B DJ3-C2 TX+/A D+

Notes:

The dome address must be set at 1 for all the camera s that are controlled using a Rx100. Check with the dome manual if you ha ve any doubts.

The alarm output relay ope ns for approx 5 seconds upon power up and following any active alarm input.

If the slow preset tour is running, start patrol 1 & 2 is inhibited. The dome will be driven to a preset following an alarm activation. 60 seconds after alarm, the

tour will restart. A manual goto preset and lens control will stop the tour leaving the AUTOPAN led on until the next manual pan command.

A datum/park mode is offered that drives the dome to preset 1 following 5 minutes of inactivity. This can be disabled by removing the link fitted across J6/pin

4 & 5. and refitting to J6/pin 3 & 4.

Privacy zone programming

The keystrokes shown assume use of a TX1500. Use the keystroke shown above if using another controller.

Programming a zone

The Rx100 can be used to program 16 privacy zones. The same procedure that is used to program a preset position is used to program or clear a privacy zone.

To instruct the Rx100 to program a privacy zone press 2# followed by program preset 1 – 16. The screen will then go blank showing that the privacy zone has

been set.

Clearing a zone

To clear/delete a privacy zone press 3# followed by program preset 1 – 16. The relevant privacy zone will then be disabled and the dome will move to show the

zone that has been disabled so that the zone can easily be re-enabled if disabled in error.

J6 Links

J6/1-2 fitted to enable the 5 minute datum mode. After 5 minutes of inactivity the dome will be driven to either preset 1 or a slow preset tour is started

depending upon link J6/4-5. J6/4-5 fitted = goto preset 1,J6/3-4 = start slow preset tour.

Intended for up-the-coax control.

When using 20mA TP telemetry control maybe slightly sluggish.

.

Rx100 installation manual V1.17 29 Aug 08.doc Page 14

Page 15

BBV Rx100 Interface Receiver

Addendum to manual for the following domes:

Borsatec BT2790FF Dome

Rx100 software RX1_B3V2

Application Notes

The RX100 provides the following functionality when controlling the above mentioned dome:

Variable speed Pan/Tilt.

16 Full scene presets.

2 RX100 preset patrols.

Pattern 1 learn and playback

2 preset patrols.

4 alarm inputs moving to preset 1 - 4

Additional commands:

Advanced Features Tx400 Tx1000 Tx1500 DM DS/DS2/BX2 Mux

Dome MENU ‘#’ 1 '#' WASH 1 ’#’ *889 002 or *889 10 10 2

(Preset 95)

Start Patten 1 ‘#’ 2 '#' WIPE 2 ’#’ *889 003 or *889 10 10 3

(Preset 81)

B L C. On OFF ‘#’ 3 '#' AUTOPAN 3 ’#’ *889 004 or *889 10 10 4

(Preset 93)

DAY NIGHT MODE ‘#’ 4 ‘#’ LIGHTS 4 ‘#’ *889 005 or *889 10 10 5

(Preset 152)

AUTOPAN calls scan - goto preset 66

LIGHTS operates the dome AUX 1 relay - goto preset 94

WIPER Disabled

WASH Disabled

RS485 control of dome using the following connections:

Rx100 Description Dome

J3-C1 TX/RX- Data- RX J3-C2 TX/RX+ Data+ RX+

Notes:

The alarm output relay ope ns for approx 5 seconds upon power up. This can be used to signal pow er loss, etc.

Set the Dome address to 1, SW1 1 ON, 2-8 OFF

Protocol - Protocol and Baud, SW2 1-7 OFF, 8 ON, P elco D - 2400 Baud

Shorting the TEST link after power up will pan the dome LEFT and ZOOM IN. Releasing the short will stop pan and zoom out. This is allows confirmation of

correct wiring and switch settings at the dome.

Link J6/3-4 – Dome enters preset pat rol after 5minutes of inactivity. Link J6/4-5 disabled.

Rx100 installation manual V1.17 29 Aug 08.doc Page 15

Page 16

BBV Rx 100 Interface Receiver

Addendum to manual for the following domes:

Dennard type 2050/2055/2060 dome.

Rx100 software RX1_D2V12

Application Notes

Variable speed Pan/Tilt.

Zoom/Focus, Autofocus

16 full scene presets (additional presets can be programmed using dome's menu)

2 preset patrols

4 alarm inputs driving to preset 1 - 4 or dome sequence 001 - 004, link selectable

Advanced Features Tx400DC Tx1000 Tx1500 DM Mux

Dome User Menu 1 ‘#’ '#' WASH 1 ‘#’ *889 002 or *889 10 10 2

Dome Supervisor Menu 2 ‘#’ '#' WIPE 2 ‘#’ *889 003 or *889 10 10 3

Dome Service Menu 3 ‘#’ '#' AUTOPAN 3 ‘#’ *889 004 or *889 10 10 4

The domes internal Sequence 001 can be started by pressing AUTOPAN. The sequence must be programmed

from the dome supervisor menu.

RS485 control of dome using the following co nn e ctions:

Rx100 Description Dome (old) Dom e (current) 7 pin socket

J3-C1 TX- Bs (White) Bs (Green) Pin 3

J3-C2 TX+ As (Orange) As (Yellow) Pin 4

The Dome must be addressed as 1 this is achieved by setting BLUE rotary sw. to 0 & YELLOW rotary sw. to 1

Notes:

The alarm output relay ope ns for approx 5 seconds upon power up and following local alarm activation.

Accessing the dome menus.

Press relevant key combination to display menu. To select highlighted menu item, perform a goto preset 1 function as follows:- Tx1000 Hold the PRESET key

and tap the CAM1 key, Tx400 press the PRESET1 key.

The cursor can be moved using the standard pan/tilt keys or joystick. If the cursor direction is reversed, the pan and tilt cursor directions can be reversed from

the SUPERVISOR, USER OPTIONS, CURSOR CONTROL REVERSE menu.

Presets positions greater than 17 can be programmed using the dome's menu and can be built into dome sequences. Please refer to dome manual for specific

instructions regarding programming of sequences.

Local alarm can trigger either a dome preset sequence or goto a preset position depending upon the link J6/4-5. Complex alarm handling can be offered using a

combination when used with the do me sequences. Eg wh en the lin k is f itted, an alarm can fo rce the d ome to a specific preset for a period. The dome can then

move to another preset position at a programmed speed. Useful if an alarm area is say a fence line or building line with several doors/windows. Please view

our web site for more information. www.bbvcctv.com

Links Function

J6/1-2 Enable datum mode if fitted (goto preset 1 after 2 minutes if inactivity)

J6/3, 4, 5 Select between presets or sequence following local alarm. Fitted to 4&5 = sequence 1-4, Fitted to 3&4 = preset 1-4

A TEST link is used to confirm correct operation of the Rx100 and dome and also that the RS485 connection is correct. Shorting the link after the Rx100 is

powered up will cause the dome to zoom in. Removing the link cause the dome to zoom out. The green data led should also flash to indicate RS485 sent to the

dome.

If the TEST link is shorted when power is applied to the Rx100 will cause a receiver self test function to start. This is an advanced function that BBV support

engineers may request during fault diagnosis. To stop the self test, remove the link and power the Rx100 off and on again.

To prevent difficulty when navigating through the dome menu local alarm input 1 is disabled for 4 minutes after the menu is

displayed. To enable the alarm when out of the menu ple ase press zoom in or zoom out. The alarm will then be re-enabled.

Rx100 installation manual V1.17 29 Aug 08.doc Page 16

Page 17

BBV Rx 100 Interface Receiver

Addendum to manual for the following dome:

Dynacolor 7720

COAXIAL TELEMETRY ONLY NOT 20mA

Rx100 software RX1_D4V7

Application Notes

Variable speed Pan/Tilt (single function at a time, pan or tilt or zoom or focus)

Zoom/Focus

16 full scene presets

2 preset patrols

4 alarm inputs driving to preset 1 – 4

Additional Features Tx400 Tx1000 Tx1500 DM Sprite DM/DS/DSL/DS2

Dome Menu and ENTER

Exit Dome Menu ‘#’ 2 ‘#’ WIPE 2 ‘#’ *889 003 *889 10 10 3

Dome Reset

Menu access – example using the Tx1500 system

Press 1# 1# will display the dome’s menu and put the Rx100 in menu mode. In this mode the joystick allows navigation and either IRIS

OPEN or IRIS CLOSE or 1# is used when ENTER is required. After exiting the menu, press 2# to set the Rx100 back into normal mode and

the joystick will then revert to pan/tilt control.

Dome Reset

This command will cause the dome to carry out a system reset, including erasing any preset positions and programming. This command must

be used with extreme caution. To activation the dome reset, the command must entered 3 times, eg for the Tx1500, press 4# 4# 4#.

Cruise

Recording: The dome has a built in cruise facility allowing the operator to record and playback a period of manual dome movement. The

exact procedure varies depending upon the control equipment and version of dome firmware. The example shown assumes that the dome is

controlled using a Tx1500.

To record the cruise, you must enter the dome menu using 1# 1# and navigate to the RECORD START entry within the CRUISE menu.

After pressing the ENTER command using 1# you must exit the dome menu using 2# to allow the joystick to be used to move the dome

around the intended area. To complete the cruise, press the Dome Menu command twice using 1# 2# to allow the joystick to be used to

navigate to the RECORD E ND line. Pressing t he ENTER command usin g 1# saves the crui se. Navigate ou t of the menu an d exit the dome

menu using 2#.

Playback: The cruise can be started by pressing the AUTOPAN key on the controller.

Return to home: Link J6/pin 4-5 if fitted will cause the dome to return to preset 8 after 5 minutes of inactivity. If function not required refit

link to J6/pin 3-4.

Speed select: Two versions of dome protocol are published. The early version has uses speeds 0 – 8 and the later version has speeds 0 – 15.

Link J6/1-2 when fitted selects the later version and removed the earlier version. If the dome speed controls are very ‘sluggish’ then try

operation with the link in the other position.

RS485 control of dome. Data rate, 96 00 Ba ud , No parity, 8 Data bits, 1 Stop bits

Connection details:

Dome Description Rx100

D- RS485 Data - J3/C1

D+ RS485 Data+ J3/C2

Notes:

The alarm output relay opens for approx 5 seconds upon power up. This can be used to signal power loss, etc.

Check with the DM multiplexer manual for exact procedure for entering * commands.

Dome switch settings:

(3 times) ‘#’ 4 ‘#’ LIGHTS 4 ‘#’ *889 005 *889 10 10 5

(twice) ‘#’ 1 '#' WASH 1 '#' *889 002 *889 10 10 2

Rx100 installation manual V1.17 29 Aug 08.doc Page 17

Page 18

Early dome - Set dome address to 1: 8 way switch 1 ON, 2-7 OFF. 4 way switch 1-3 ON, 4 OFF.

Later dome – Dome ID switch: 1 ON, 2-8 OFF. Duplex/Simplex switch:1-2 OFF. Dynacolor protocol S2:1-4 OFF, S1:1-3 ON

BBV Rx 100 Interface Receiver

Addendum to manual for the following domes:

Forward Vision protocol

including MIC1 300/400 series dome

and compatible equipment.

Rx100 software RX1_F1V8

Application Notes

Variable 16 speed Pan/Tilt.

Zoom/Focus

16 full scene presets

2 preset patrols

4 alarm inputs driving to preset 1 - 4

Advanced Features Tx400 Tx1000 Tx1500 DM Mux DSL/DS2/BX2

AUTO/MANUAL FOCUS TOGGLE ‘#’ 1 ‘#’ WASH 1 ‘#’ *889 002 or *889 10 10 2 (twice)

DIGITAL ZOOM ON/OFF ‘#’ 2 '#' WIPE 2 '#' *889 003 or *889 10 10 3

MANUAL/AUTO EXPOSURE ‘#’ 3 '#' AUTOPAN 3 '#' *889 004 or *889 10 10 4

IR FILTER IN/OUT ‘#’ 4 ‘#’ LIGHTS 4 ‘#’ *889 005 or *889 10 10 5

Version V4 of software has added su pp ort for PRIVACY ZONE programming. (TX1500 keystrokes shown)

ENABLE ALL SCENE 1 ‘#’ PROGRAM 1 PRESET (Whole screen)

DISABLE ALL SCENE 1 ‘#’ PROGRAM 2 PRESET (Whole screen)

TOGGLE CURSOR ON/OFF 1 ‘#’ PROGRAM 3 PRESET

ENABLE AROUND CURSOR 1 ‘#’ PROGRAM 4 PRESET (Centre of screen)

DISABLE AROUND CURSOR 1 ‘#’ PROGRAM 5 PRESET (Centre of screen)

DM DS2 example to ENABLE ALL SCENE as privacy.

*889 10 10 2 [PRESS AND HOLD ‘PRESET’] 1 [ENTER]

RS485 control of dome using the following co nn e ctions:

Rx100 Description Dome

J3-C1 RS485 IN(A) Yellow

J3-C2 RS485 IN(B) White

Notes:

The alarm output relay ope ns for approx 5 seconds upon power up and following local alarm activation.

A local alarm opening contact will cause the dome to move to the respective preset position. After 60 seconds the dome will revert to preset patrol if the patrol

was active before the alarm occurred.

Links Function

J6/4-5 Enable datum mode: Goto preset 1 or start Patrol 1 2 minutes after last activity. J6/3-4 = Function disabled.

J6/1-2 Select datum function: Fitted = goto preset 1, Removed = start Patrol 1

TEST link when shorted will drive the dome LEFT and ZOOM IN. Removing the short will stop pan and ZOOM OUT. This is used to gain confidence that the

wiring between Rx100 and dome is correct. The GREEN DATA le d will flash when a command is sent to the dome.

VERSION 6 now enables zoom proportional pan/tilt speed to improve manual control.

For correct operation, ensure that the dome/head address is set to 01.

Please contact Forward Vision for exact procedure on +44(0)870 011 3131.

Rx100 installation manual V1.17 29 Aug 08.doc Page 18

Page 19

BBV Rx 100 Interface Receiver

Addendum to manual for the following dome:

JVC TK-C655B/676/675B combination cameras

Rx100 software RX1_J2V4

Application Notes

The RX 100 provides the following functionality when controlling the above mentioned domes

Variable speed Pan/Tilt.

Zoom/Focus, Autofocus can be enabled/disabled from the dome menu.

16 Full scene presets.

2 preset patrols.

Slow patrol or dome autopan from controller AUTOPAN key

4 alarm inputs driving to preset 1 - 4.

Additional commands:

TK-C676 Tx400DC Tx1000 Tx1500 DM System Sprite, DS, DS2, BX2

OPEN MENU and BACK (Twice) ‘#’1’ #' WASH 1 ‘#’ *889 002 or *889 10 10 2

SET '#' 2 '#' WIPE 2 ‘#’ *889 003 or *889 10 10 3

Togggle ExDR '#' 3 '#' AUTOPAN 3 ‘#’ *889 004 or *889 10 10 4

Cycle Mono Mode '#' 4 '#' LIGHTS 4 ‘#’ *889 005 or *889 10 10 5

RS485 control of dome using the following connec tions:

Rx100 Description Dome connection

J3-C1 TX- CONTROL RX- (D)

J3-C2 TX+ CONTROL RX+ (C)

Notes:

The alarm output relay ope ns for approx 5 seconds upon power up. This can be used to signal pow er loss, etc.

Camera switch settings:

MACHINE ID – set both rotary switches to ‘0’

8 way DIL switch, all OFF apa rt from 8 which should be ON to enable the RS485 termination, point-to-point, simplex.

On screen display of preset position, HOME - P16 or MANUAL during manual control. The on screen display can be enabled/disabled using dome switch

SW3, ON = Display off, OFF = Display on.

J6 links.

J6/1-2: Link fitted across J6/1 and J6/2 (default) to allow the ExDR and MONO mode status to be displayed. Remove this link if you are programming a dome

camera title and do not want to display the ExDR and MONO sta t us.

J6/4-5: Fitted (default) dome will perform a slow patrol between programmed presets when AUTOPAN pressed. Removed and fitted to J6/3-4 will send

autopan start to the dome.

DOME MENU

Pressing #1 twice will display the dome’s menu. The joystick is then used to navigate through the dome menu. #2 sends a SET command to the dome and #1

twice whilst the menu is displayed sends a BACK command.

If the #1 command doesn’t work press a foc us key before sending #1.

Pressing #1 FOUR times within 2 seconds will displa y the dome’s service menu.

PRESET POSITIONS

The dome has a home preset position which is preset 00.

To enable this preset to be programmed when using the Rx100/JVC676 program ming preset 1. BBV Presets 2 – 16 re fer to the dome presets 2 – 16.

Rx100 installation manual V1.17 29 Aug 08.doc Page 19

Page 20

BBV Rx100 Interface Receiver

Addendum to manual for the following domes:

Kalatel Cyberdome (Firmware 1/1/02 or later)

Rx100 software RX1_K1V2

Application Notes

Variable speed Pan/Tilt.

Zoom/Focus/Iris

16 Full scene presets.

2 preset patrols. (PATROL1 = RX100 patrol and PATROL 2 = dome’s TOUR 03)

Shadow TOUR 1 playback using AUTOPAN key.

Menu navigation including programm i ng privacy zones etc

Advanced Features Tx1000 Tx1500 DM DS/DS2/BX2 Mux

Toggle MENU ON/OFF '#' WASH 1 ’#’ *889 002 or *889 10 10 2

Toggle PTZ/CURSOR '#' WIPE 2 ’#’ *889 003 or *889 10 10 3

(see GOTO PRESET 16 BELOW)

The dome and Rx100 are linked using RS485 for control and video for the camera signal.

Rx100 Description Dome connection

J3-C1 TX-/B RS485 B J3-C2 TX+/A RS485 A +

Notes:

The dome address must be set at 1 for all the cameras that are controlled using a Rx100. Check with the dome manual if you

have any doubts.

The alarm output relay opens for approx 5 seconds upon power up and following any active alarm input.

The dome will be driven to a preset following a local alarm activation. 60 seconds after alarm, the shadow tour will restart if

running when the alarm occured. A manual goto preset and lens control will stop the tour leaving the AUTOPAN led on until

the next manual pan command. If PATROL 1 was running when a local alarm occurs after 60 seconds the patrol will be

resumed.

The dome’s TOUR 3 must be programmed from within the domes menu. Please refer to the dome manual for details. 2

PATROL from TX1500 or PATROL 2 from TX1000 to start this tour.

Programming preset 1 will also program the dome’s home preset – 00.

Navigating the dome’s menu requires several key presses that may not be available with all controllers.

These key presses are simulated using GOTO PRESET commands as follows.

<1> – <9> = GOTO PRESET 1 – 9 <0> = GOTO PRESET 10

<SEQ> = GOTO PRESET 11 <ALARM> = GOTO PRESET 12 <1

<CLEAR> = GOTO PRESET 14 <SET> = GOTO PRESET 15

ST

> = GOTO PRESET 13

GOTO PRESET 16 - This is used to toggle the joystick between dome movement and cursor movement which is needed for

some menus eg preset and area titles.

The TEST link can be used to prove correct data connection between the RX100 and dome. When the link is fitted the dome

should pan left. Removing the link will stop the pan. Ensure that the link is removed before powering the RX100 on as this is

to enter diagnostics mode.

Due to the number of presets required to navigate in the dome menu the TX400 and TX400DC, which have 8 presets, will not

be able to navigate the menu fully.

Rx100 installation manual V1.17 29 Aug 08.doc Page 20

Page 21

BBV Rx 100 Interface Receiver

Addendum to manual for the following dome:

Merit Li-Lin

PIH-717X/7000/7600/7625 series

Rx100 software RX1_L1V8

Application Notes

Variable speed Pan/Tilt.

Zoom/Focus, Autofocus

16 full scene presets

2 preset patrols

4 alarm inputs driving to preset 1 - 4

Advanced Features Tx400 Tx1000 Tx1500 DM Sprite/DS/DSL/DS2/BX2

Toggle Menu display ‘#’ 1 ‘#’ WASH 1 ‘#’ *889 002 or *889 10 10 2

Enable Auto-Iris ‘#’ 2 '#' WIPE 2 ‘#’ *889 003 or *889 10 10 3

Dome reset step 1 ‘#’ 3 '#' AUTOPAN 3 '#' *889 004 or *889 10 10 4

Exit menu ‘#’ 4 '#' LIGHTS 4 '#' *889 005 or *889 10 10 5

Procedure to program preset positions. The procedure must be followed to program new preset positions and also to reprogram existing positions.

The keystrokes shown below assume use of a Tx1000.

1) Select GOTO PRESET number to program eg 1

Hold PRESET tap 1

2) Move dome to new position using joystick and lens keys.

3) Select PROGRAM PRESET to save new position.

Press PROGRAM 1 1

To stop dome from running its own internal Autopan move joysti c k then press AUTOPAN.

RS485 connections between Rx100 and dome.

PIH717(DB15) or PIH7000/7600 Description Rx100

Pin 14 TXDI- -Data J3/C1

Pin 15 TXDI+ +Data J3/C2

Notes:

The alarm output relay ope ns for approx 5 seconds upon power up. This can be used to signal pow er loss, etc.

A 2 minute datum mode is available. 2 minutes after the last manual command, the dome will either move to preset 1 or start an autopan. Fit link J6/1-2 to

enable this feature. J6/4-5 fitted = autopan, J6/3-4 fitted = goto preset 1.

All dome preset positions can be deleted using #3 followed by #4 within 1 second.

Check with the DM multiplexer manual for exact procedure for entering * commands.

IMPORTANT: Dome settings: Select dome address #1.

To aid diagnostics and confirm correct connection between the Rx100 and dome, the TEST link when shorted will drive the

dome LEFT until the short is removed. Whilst the Rx100 is sending data to the dome the GREEN DATA will flash.

V6 software – 1# now used to toggle menu display on/off. In previous versions this was used to toggle AUTOPAN which is

now not required with current generation of LiLin dome.

Rx100 installation manual V1.17 29 Aug 08.doc Page 21

Page 22

BBV Rx 100 Interface Receiver

Addendum to manual for the following domes:

Mark Mercer 150 and D250/500 series

Rx100 software RX1_M1V6

Application Notes

Variable speed Pan/Tilt.

Zoom/Focus override, Iris override

16 full scene presets

2 preset patrols

4 alarm inputs driving to preset 1 – 4

2 minute datum (park) mode, link selectable as either preset 1 or slow preset patrol.

Advanced Features Tx400 Tx1000 Tx1500 DM Mux/DS/DSL/DS2/BX2 etc

Pan ‘U’-turn (180deg flip) ‘#’ 1 '#' WASH 1 ‘#’ *889 002 or *889 10 10 2

Dome Reset ‘#’ 4 ‘#’ LIGHTS 4 ‘#’ *889 005 or *889 10 10 5

A slow preset patrol can be started by pressing AUTOPAN. The preset dwell is fixed at 20 seconds with a dome speed of 1.

RS485 control of dome using the following co nn e ctions:

Rx100 Description Dome 6 pin connector

J3-C1 TX/RX- RS485 B Pin 4 (RED)

J3-C2 TX/RX+ RS485 A Pin 3 (GREEN)

Notes:

The alarm output relay ope ns for approx 5 seconds upon power up and following a local alarm activation.

Links Function

J6/1-2 Enable 2 minute inactivity datum mode if the link is fitted.

J6/3,4,5 Select datum operation, J6/4-5 = goto prese t 1, J6/3-4 = start slow preset patrol.

Only operational whilst the dome is not running a patrol.

Rx100 installation manual V1.17 29 Aug 08.doc Page 22

Page 23

BBV Rx 100 Interface Receiver

Addendum to manual for the following domes:

Panasonic WV-CSR400 series.

WV-CSR600 series.

WV-CSR650 series.

Rx100 software RX1_P1V5B

Application Notes

Variable speed Pan/Tilt.

Zoom/Focus, Autofocus, Iris Open/Close (AutoFocus with 600 & 650 series)

16 full scene presets (600 & 650 series dome)

2 preset patrols (600 & 650 series dome)

4 alarm inputs driving to preset 1 - 4. (600 & 650 series dome )

Autopan

Advanced Features Tx400 Tx1000 Tx1500 DM Sprite/DSL/DS2/BX2

Entry/Exit Dome Menu ‘#’ 1 '#' WASH 1 ‘#’ *889 002 or *889 10 10 2

SET (select menu item) ‘#’ 2 '#' WIPE 2 ‘#’ *889 003 or *889 10 10 3

ESC (back to previous menu) ‘#’ 3 '#' AUTOPAN 3 ‘#’ *889 004 or *889 10 10 4

SPECIAL2 (for special menus) ‘#’ 4 '#' LIGHTS 4 ‘#’ *889 005 or *889 10 10 5

Autopan is started by selecting Autopan on the Transmitter. The Autopan stops can be programmed from within the dome

menu. Please refer to dome user manual for exact details.

RS485 control of dome. Connect dome FCC-68 plug into J7 of Rx100. If the dome cable requires extending, connect cores as

follows:

Dome Cable Description Rx100

Yellow Data- J3/C1

Green Data+ J3/C2

Notes:

The alarm output relay ope ns for approx 5 seconds upon power up. This can be used to signal pow er loss, etc.

Accessing the dome menus.

Press either '#'WASH , '#'1 or *889 002 key strokes to Enter Menu. Use Pan/Tilt to highlight item. Press either '#'WIPE, '#'2 or *889 003 key strokes to select

menu item. To exit from menu, press either '#'WASH, '#'1 or *889 002.

Check with the multiplexe r manual for exact procedure for ente ring * commands.

IMPORTANT: Dome settings: Select dome address 01. Communications must be 19200, N, 8, 1. If dome cannot be controlled, see dome manual section to

reset dome to factory default.

The Panasonic CS-850 can be controlled using an Rx100 with Rx1_P1V6 software order code RX100/Panasonic CS850.

The TEST link will pan the dome left whilst shorted. The video out BNC must be disconnected before the TEST link is fitted.

The GREEN DATA flashes when data is sent from the Rx100.

Rx100 installation manual V1.17 29 Aug 08.doc Page 23

Page 24

BBV Rx 100 Interface Receiver

Addendum to manual for the following domes:

Panasonic WV-CS850 / 860

Rx100 software RX1_P1V10

Application Notes

Variable speed Pan/Tilt.

Zoom/Focus, Autofocus, Iris Open/Close (Hold for auto-iris)

16 full scene presets

2 preset patrols

4 alarm inputs driving to preset 1 – 4

Autopan/Patrol learn-play using autopa n key

Advanced Features Tx400 Tx1000 Tx1500 DM Sprite/DS/DS2/BX2

ENTRY/EXIT Dome Menu ‘#’ 1 '#' WASH 1 ’#’ *889 002 or *889 10 10 2

SET (select menu item) ‘#’ 2 '#' WIPE 2 ’#’ *889 003 or *889 10 10 3

ESC (back to previous menu) ‘#’ 3 '#' AUTOPAN 3 ’#' *889 004 or *889 10 10 4

SPECIAL2 (for special menus) ‘#’ 4 '#' LIGHTS 4 '#' *889 005 or *889 10 10 5

A dome RESET ALL command can be sent by holding either ‘#’LIGHTS or ‘#’4 for 5 seconds when not within the menu. Care must be used with this

command as the dome is set to default and user settings are erased.

The dome’s internal PATROL can be LEARNED using the dome menu. Setting the AUTO PAN KEY to PATROL will allow the patrol to be PLAYED by

pressing AUTOPAN on the controller.

RS485 control of dome. Connect dome FCC-68 plug into J7 of Rx100. If the dome cable requires extending, connect cores as follows:

Dome Cable Description Rx100

Yellow Data- J3/C1

Green Data+ J3/C2

Notes:

The alarm output relay ope ns for approx 5 seconds upon power up. This can be used to signal pow er loss, etc.

Accessing the dome menus.

Press either '#'WASH , '#'1 or *889 002 key strokes to Enter Menu. Use Pan/Tilt to highlight item. Press either '#'WIPE, '#'2 or *889 003 key strokes to select

menu item. ‘#’WASH , ‘#’3 or *889 004 is used to ESCAPE back to previous menu. SPECIAL2 menus are accessed using ‘#’LIGHTS, ‘#’4 or *889 005. To

exit from menu, press either '#'WASH, '#'1 or *889 002.

Check with the multiplexe r manual for exact procedure for ente ring * commands.

Dome Switch settings: The following procedure must be followed to ensure that the dome is set-up correctly for terminated 4 wire RS485 at 19200 Baud and

address 1. Remove the dome from it’s base before each step and reconnect to the base after changing the switches.

Step 1: Address switches 2,4 and 5 ON

Step 2: Address switches 1,3,4 and 5 ON

Step 3: Address switches 1 and 8 ON. 4 Way switch 1 ON to select 4 wire, terminated RS485.

Panasonic WV-CSR400/600/650 domes can be controlled using a different version of Rx100 software. Please contact BBV for further information or check out

our web site www.bbvcctv.com

Rx100 installation manual V1.17 29 Aug 08.doc Page 24

Page 25

BBV Rx 100 Interface Receiver

Addendum to manual for the following dome:

Pelco Spectra (P-mode RS485 protocol)

Rx100 software RX1_P2V10

Application Notes

Variable speed Pan/Tilt.

Zoom/Focus, Autofocus

16 full scene presets

2 preset patrols

4 alarm inputs driving to preset 1 - 4

Dome Pattern definition and playback

Advanced Features Tx1000 Tx400 DM-Sprite DM-DSL/DS/DS2

Display dome menu (preset 95) '#' WASH '#' 1 *889 002 *889 10 10 2

Enter within menu (iris open ) '#' WIPE '#' 2 *889 003 *889 10 10 3

Pattern define start '#' AUTOPAN '#' 3 *889 004 *8 89 10 10 4

Pattern define stop ‘#’ LIGHTS ‘#’ 4 *889 005 *889 10 10 5

To record a Pattern, direct the camera to the required starting position. Hold '#' and tap 'AUTOPAN'. The dome will now record pan/tilt

and lens movement up to a time limit. To stop the recording, hold '#' and tap 'LIGHTS’. To play the recorded Pattern, press the AUTOPAN

key only. The dome will repeatedly run the Pattern until either the joystick is moved or an alarm occurs.

(The example shows Tx1000 keystrokes, please substitute the keystroke for the controller used.)

Menu access:

Use ‘#’ WASH to display menu. Navigate using the joystick and IRIS OPEN to select. When used with control systems without iris keys,

eg DM Digital Sprite Lite, use *889 003 or *889 10 10 3

Return to home: Can be prog r a mmed from the Dome menu.

RS485 control of dome. Data rate, 96 00 Ba ud , No parity, 8 Data bits, 1 Stop bits

Connection details:

Dome Description Rx100

RX- RS485(B) input J3/C1

RX+ RS485(A) input J3/C2

Notes:

The alarm output relay opens for approx 5 seconds upon power up. This can be used to signal power loss, etc.

Check with the DM multiplexer manual for exact procedure for entering * commands.

Dome settings: Select dome address 1, P-MODE PROTOCOL and 9600, N, 8, 1.

Link J6/1-2 is used to select the function that is used to drive the Esprit AUX outputs.

Function Link fitted Esprit AUX No Link removed Esprit AUX No

LIGHTS 1 2

WIPER 2 1

WASHER 3 3

Link J6/4-5 is used to enable 5 minute datum time to start preset patrol.

Link fitted = datum disabled and link removed = datum enabled.

Rx100 installation manual V1.17 29 Aug 08.doc Page 25

Page 26

BBV Rx 100 Interface Receiver

Addendum to manual for the following dome:

Philips AutoDome including G3A and G3B

(RS232 control only, not Bi-Phase compatible)

Rx100 software RX1_P3V11

Application Notes

Variable speed Pan/Tilt.. Zoom/Focus, Autofocus. 16 full scene presets. 2 preset patrols. 4 alarm in pu ts driving to preset 1 – 4.

Dome AutoPlay record & playback. Preshot title, Zone title, Menu Access

Advanced Features Tx400DC Tx1000 Tx1500 DM Sprite DS/DSL/DS2/BX2

Display Menu (

Program Zone Title

Record AutoPlay start/stop

RESET DOME!

RS232 control of dome. Data rate, 96 00 Ba ud , No parity, 8 Data bits, 1 Stop bits

Connection details:

Dome Description Rx100 or DMP100/124

RxD RS232 I/P J3/C1

Gnd Gnd J3/GND

Notes:

Configuration links:

J6/pin 1-2 is used to select the address that the unit outputs. Fitted(Default) = Address 1, Removed = Address 10,000.

Removing the link allows the receiver to be used as an alarm input unit for domes that are controlled using bi-phase telemetry. This will work with late model

domes with post 2002 software.

J6/pin3-4 – preset title text is programmed following a save preset command by autom at ically issuing a aux(62) command.

J6/pin4-5 (Default) – the preset text command is not sent and the existing text is retained.

The alarm output relay opens for approx 5 seconds upon power up. This can be used to signal power loss, etc.

The dome must be RS232 controllable. BI-PHASE domes cannot be controlled.

Dome settings: Select dome address #0 or #1. Communications must be 9600, N, 8, 1. The G3 Basic address is software programmable, however as default

the dome is addressed as #0. If the dome address is not #0 or #1 then the dome will require reprogramming using a Philips controller or removing link J6/1-2.

A TEST link is used to confirm correct operation of the Rx100 and dome and also that the RS485 connection is correct. Shorting the link after the Rx100 is

powered up will cause the dome to pan left and zoom in. Removing the link cause the dome to zoom out and stop panning left. The green data led should also

flash to indicate RS485 sent to the dome.

If the TEST link is shorted when power is applied to the Rx100 will cause a receiver self test function to start. This is an advanced function that BBV support

engineers may request during fault diagnosis. To stop the self test, remove the link and power the Rx100 off and on again.

Using the advanced features wh en u sin g a BBV Tx1000DC

Menu Access

Use the joystick to navigate the cursor. FOCUS FAR or FOCUS NEAR can be pressed to enter the next menu item or to return press either

IRIS OPEN or IRIS CLOSE. When completely out of the menu issue a goto preset command to put the interface into normal mode. Press

and HOLD PRESET whilst taping 1 will move to preshot 1.

Program Zone Title: Press and HOLD # and tap WIPE will allow the title for the current zone to be programmed.

Use the joystick as described on screen. Use the following keystrokes to program the text:

FOCUS NEAR – Select a current character, FOCUS FAR – Clear character, IRIS CLOSE – Backspace and IRIS OPEN – Return

Record Autoplay: Press and HOLD # and tap AUTOPAN will allow autoplay ‘A’ to be recorded.

Press FOCUS FAR or FOCUS NEAR to start the recording or IRIS CLOSE to abandon recording. Once recording has started, use the

joystick and focus keys as required. To end the recording, press and HOLD # and tap AUTOPAN. The recording can be replayed

continuously be pressing t he AUTOPAN key.

Reset dome def aults: Press and HOLD # and tap LIGH TS TWICE to display the dome’s software version. Repeating the key

strokes for a THIRD

USE WITH EXTREME CARE AS ALL THE DOME PROGRAMMING WILL BE LOST.

Programming preshot text

preshot 1 press PROGRAM 1 1. To program preshot 2 press PROGRAM 1 2. To program preset 14 press PROGRAM 1 14. After the

preshot has been programmed the interface issues an AUX 62 to display the preshot text menu. The same keystrokes are used to program

preshot text as when programming zone titles.

Rx100 installation manual V1.17 29 Aug 08.doc Page 26

Aux 46) '#' 1 ‘#’ WASH 1'#' *889 002 *889 10 10 2

(Aux 63) '#' 2 ‘#’ WIPE 2'#' *889 003 *889 10 10 3

(Aux 100) '#' 3 ‘#’ AUTOPAN 3'#' *889 004 *889 10 10 4

(Set 899) '#' 4 ‘#’ LIGHTS 4'#' *889 005 *889 10 10 5

: Press and HOLD # and tap WASH TWICE will display the dome ’s me nu .

time will issue a SET 899 to reset the dome including ALL PRESET POSITIONS.

. To program a preshot position press PROGRAM then 1 followed by number of the preshot. EG to program

Page 27

Using the advanced features wh en u sin g a BBV Tx400DC

Menu Access

Use the joystick to navigate the cursor. FOCUS FAR or FOCUS NEAR can be pressed to enter the next menu item or to return press either

IRIS OPEN or IRIS CLOSE. When completely out of the menu issue a goto preset command to put the Rx100 into normal mode. Press 1

will move to preshot 1.

: Press and HOLD # and tap 1 TWICE will display the dome’s menu

Program Zone Title: Press and HOLD # and tap 2 will allow the title for the current zone to be programmed.

Use the joystick as described on screen. Use the following keystrokes to program the text:

FOCUS NEAR – Select a current character, FOCUS FAR – Clear character, IRIS CLOSE – Backspace and IRIS OPEN – Return

Record Autoplay: Press and HOLD # and tap 3 allow autoplay ‘A’ to be recorded.

Press FOCUS FAR or FOCUS NEAR to start the recording or IRIS CLOSE to abandon recording. Once recording has started, use the

joystick and focus keys as required. To end the recording, press and HOLD # and tap 3. The recording can be replayed continuously be

pressing the AUTOPAN key.

Reset dome defaults: Press and HOLD # and tap 4 TWICE to display the dome’s software version. Repeating the key strokes for a

THIRD

time will issue a SET 899 to reset the dome including ALL PRESET POSITIONS.

USE WITH EXTREME CARE AS ALL THE DOME PROGRAMMING WILL BE LOST.

Programming preshot text

EG to program preshot 1 press and HOLD PROGRAM then tap 1. To program preshot 2 press and HOLD PROGRAM and tap 2. To

program preset 8 press and HOLD PROGRAM and tap 8. After the preshot has been programmed the Rx100 issues an AUX 62 to display

the preshot text menu. The same keystrokes are used to program preshot text as when programming zone t i t le s .

. To program a preshot position press and HOLD PROGRAM then tap the preshot require, 1 – 8.

Using the advanced features when us ing a DM S p rite an d Digital Sp rite keyboard.

The DM units use a series of * commands to access the advanced features. The Digital Sprite or DS does not have a ‘0’ key

instead the ‘10’ key is used when ever the ‘0’ key is mentioned. Eg to access the dome menu on a System Sprite you would

key *889 002 and on the Digital DS you would key in *889 10 10 2. The examples below assume control from the Digital

Sprite keyboard. If a System Sprite is used then please use the ‘0’ key whenever the ‘10’ key is mentioned.

Menu Access

Use the joystick to navigate the cursor. FOCUS FAR or FOCUS NEAR can be pressed to enter the next menu item or to return use *889 10

10 3 which simulates an iris command. When completely out of the menu issue a goto preset command to put the Rx100 into normal mode.

Pressing PRESET followed by 10 1 will goto preshot 1.

: *889 10 10 2 repeated TWICE will display the dome’s menu

Program Zone Title: *889 10 10 3 will allow the title for the current zone to be programmed.

Use the joystick as described on screen. Use the following keystrokes to program the text:

FOCUS NEAR – Select a current character, FOCUS FAR – Clear character, *889 10 10 4 – Backspace and *889 10 10 3 – Return

Record Autoplay: *889 10 10 4 will allow autoplay A to be recorded.

Press FOCUS FAR or FOCUS NEAR to start the recording or *889 10 10 3 to abandon recording. Once recording has started, use the

joystick and focus keys as required. To end the recording, press *889 10 10 4. The recording can be replayed continuously be pressing the

AUTOPAN key.

Reset dome defaults: *889 10 10 5 repeated TWICE to display the dome’s software version. Repeating the key strokes for a

THIRD

time will issue a SET 899 to reset the dome including ALL PRESET POSITIONS.

USE WITH EXTREME CARE AS ALL THE DOME PROGRAMMING WILL BE LOST.

Programming preshot text. To program a preshot position press and hold the PRESET button until the display asks for preset number.

Use the camera keys to enter a 2 digit number from 01 – 16. Use the 10 key to represent 0. After the preshot has been programmed the

Rx100 issues an AUX 62 to display the preshot text menu. The same keystrokes are used to program preshot text as when programming zone

titles. EG to program preshot 2, press and hold PRESET, wait for the display, press 10 then 2.

Control from DM Digital Sprite 2 systems

The new DM Digital Sprite 2 (DS2) keyboard now supports iris directly again. Therefore navigation through the menus will be ea sier.

Rx100 installation manual V1.17 29 Aug 08.doc Page 27

Page 28

BBV Rx100 & Rx100/24

Addendum to manual for the following domes:

Samsung SCC-641 Interface

Rx100 software RX1_S5V3

Application Notes

The Rx100 allows control of the following dome features: Variable speed Pan/Tilt, Zoom/Focus/Iris, 16 full scene presets,

2 preset patrols, 4 alarm inputs driving to preset 1 – 4, Dome Pattern 1 playback using the AUTOPAN key ,Menu Access

Advanced Features BBV Tx1000 BBV Tx400 DM Sprite DS/DSL

Display Menu (Twice) ' # ' WASH '#' 1 *889 002 *889 10 10 2

Turn Menu Off '#' WIPE '#' 2 *889 003 *889 10 10 3

ENTER within menu '#' AUTOPAN '#' 3 *8 89 00 4 *889 10 10 4

Dome FACTORY RESET '#' LIGHTS '#' 4 *889 005 *889 10 10 5

RS485 control of dome. Data rate link selectable using J6/1-2. Fitted = 9600,N,8,1 and removed = 19200,N,8,1

Connection details:

Dome RX100

RX- J3/C1

RX+ J3/C2

Notes:

J6/pin 1-2 is used to select the baud rate to drive the dome, either 9600 or 19200 baud.

Fitted(Default) = 9600,N,8,1 Removed = 19200,N,8,1(used if experience run on problems with 20mA telemetry)

The dome’s SW500 and SW501 switches must be set as follows:

SW500 sets the dome’s address to 01. 1 = ON, 2,3,4,5,6,7, 8 = OFF

SW501 is used to set the dome’s RS485 baud rate, Termination and protocol selection.

For 9600 baud set as follows: 1,2,3,5 = ON 4,6,7,8 = OFF

For 19200 baud set as follows: 1,2,3,4 = ON 5,6,7,8 = OFF

Menu Access when using a BBV Tx1000DC

Display Menu: Press and HOLD # and tap WASH TWICE

Use the joystick to navigate the cursor and HOLD # and tap AUTOPAN as ENTER.

Turn Menu Off: Press and HOLD # and tap WIPE

Dome FACTORY RESET: Press and HOLD # and tap LIGHTS THREE

Menu Access when using a BBV Tx400DC

Display Menu: Press and HOLD # and tap 1 TWICE

Use the joystick to navigate the cursor and HOLD # and tap 3 as ENTER.

Turn Menu Off: Press and HOLD # and tap 2

Dome FACTORY RESET: Press and HOLD # and tap 4 THREE

Menu Access when using DM DS/DSL/DS2

Display Menu: *889 10 10 2 TWICE

Use the joystick to navigate the cursor and *889 10 10 4 as ENTER.

Turn Menu Off: *889 10 10 3

Dome FACTORY RESET: *889 10 10 5 THREE

CAUTION – READ BEFORE PERFORMING A DOME FACTORY RESET!

USE WITH EXTREME CARE AS ALL THE DOME PROGRAMMING INCL UDING PRESET POSITIONS WILL BE

LOST.

Rx100 installation manual V1.17 29 Aug 08.doc Page 28

will display the dome’s menu.

times to return the dome to factory defaul ts.

will display the dome’s menu.

times to return the dome to factory defaults.

will display the dome’s menu.

times to return the dome to factory defaults.

Page 29

BBV Rx 100 Interface Receiver

Addendum to manual for the following domes:

Sensormatic Speeddome

Rx100 software RX1_S3V6

Coaxial telemetry ONLY. Not twisted pair!

Application Notes

Variable speed Pan/Tilt.

Zoom/Focus, Autofocus, Iris Open/Close

7 full scene presets

2 preset patrols

4 alarm inputs driving to preset 1 – 4

Pattern 1 define – play using Autopan key

Advanced Features Tx1000 Tx400 DM DS/DS2/BX2

Start/Stop PATTERN1 Definition '#' WASH '#' 1 *889 002 or *889 10 10 2

(Press AUTOPAN to Run Pattern1)

Dome Menu '#' LIGHTS '#' 4 *889 005 or *889 10 10 5

RS485 control of dome 4800 Baud, No parity, 8 data bits, 2 stop bits.

Dome Cable Description Rx100

RS422 IN-/Data In- Data-(B) J3/C1

RS422 IN+/Data In+ Data+(A) J3/C2

Notes:

The alarm output relay ope ns for approx 5 seconds upon power up. This can be used to signal pow er loss, etc.

Accessing the dome menus.

Press either '#'LIGHTS , '#'4 or *889 005 key strokes to Enter Menu. Use Pan/Tilt/zoom/focus functions are then used to navigate through menu structure.

Please refer to individual dome manual for exact operation of menu.

Check with the multiplexe r manual for exact procedure for ente ring * commands.

IMPORTANT:

Dome settings: Select dome address 01 or 001.

Communications must be 4800, N, 8, 2 – RS422, NOT SensorNet.

The interface software is based on 1997 protocol and has been tested with Ultradome IV, Ultradome VI and original Speeddome.

Link J6/1-2 used to enable/disable datum mode to start preset patrol.

Link fitted = datum disables

Link removed = datum enabled, start preset patrol after 60 seconds of inactivity

Rx100 installation manual V1.17 29 Aug 08.doc Page 29

Page 30

BBV Rx 100 Interface Receiver

Addendum to manual for the following camera:

Sony EVI-D31 Webcam

Rx100 software RXS4V3

Coaxial telemetry ONLY. Not twisted pair.

Application Notes

Variable speed Pan/Tilt.

Zoom/Focus, Autofocus with manual override (returns t o auto following zoom command)

6 full scene presets

2 preset patrols

4 alarm inputs driving to preset 1 – 4

Advanced Features Tx400 Tx1000 Tx1500 DM Sprite/DS2/BX2

Toggle Backlight compensation '#' ‘1’ ‘#’ WASH 1 ‘#’ *889 002 or 10 10 2

Cycle White Balance ‘#’ ‘2’ ‘#’ WIPE 2 ‘#’ *889 003 or 10 10 3

AUTO, INDOOR, OUTDOOR

Toggle AutoExposure/Bright mode ‘#’ ‘3’ ‘#’ AUTOPAN 3 ‘#’ *889 004 or 10 10 4

Iris keys used in Bright mode

Reset dome to default ‘#’ ‘4’ ‘#’ LIGHTS 4 ‘#’ *889 005 or 10 10 5

RS232 control of dome 9600 Baud, No parity, 8 data bits, 1 stop bit. The camera uses a sub-miniature 8 pin DIN socket. A

Sony supplied VISCA to DB9 RS232 cable may help with installation.

Connection details:

Camera Pin Description Rx100

5 Receive Data J3/C1

4 or 6 Ground J3/GND

Notes:

Link J6/1-2 selects a 5 minute datum mode. If fitted and no activity for 5 minutes, the camera will drive to either preset 1 or start PATROL 1 depending on link

J6/3,4,5, Fitted to J6/4&5 = Goto Preset 1 or fitted to J6/3&4 = start PATROL 1.

The alarm output relay ope ns for approx 5 seconds upon power up. This can be used to signal pow er loss, etc.

Check with the multiplexe r manual for exact procedure for ente ring * commands.

IMPORTANT:

Ensure that CAMERA NO switch on the camera rear panel is set to 1.

As communications is RS232 please limit cable from Rx100 to camera to less than 5M.

Rx100 installation manual V1.17 29 Aug 08.doc Page 30

Page 31

Rx 100 Interface Receiver

Addendum to manual for the following domes:

Chugai SMD-08II, SMD-12, SMD-12II, SMD-20

Sanyo VCC-9200P

Star MD-800, MD-1200S, MD-1200H, MD-2000

Rx100 software RX1_S2V6

Application Notes

The RX 100 provide the following functionality when controlling the above mentioned domes

Variable speed Pan/Tilt, from 0.8deg/sec to 120deg/sec.

Zoom/Focus, Autofocus following a Zoom In/Out.

(Autofocus enabled with link fitted on J6 pin 1&2)

16 Full scene presets.

2 preset patrols.

4 alarm inputs.

Additional commands:

AUTOPAN: Pressing the AUTOPAN key will run the domes in-built swing feature. Preset positions 1 & 8 must be

programmed before the swing is started. Preset 1 is the right hand stop, preset 8 is the left hand stop. Tilt and lens can be

adjusted whilst the dome is swinging.

180deg PAN AUTO FLIP is accomplished by pressing either '#'WASH on Tx1000 or '#'1 on Tx400.

DOME REMOTE RESET can be started by pressing either '#'LIGHTS on Tx1000 or '#'4 on Tx400.

RS485 control of dome using the following connections:

Rx100 Description Dome mounting bracket

J3-C1 TX/RX- Data- Pin 2

J3-C2 TX/RX+ Data+ Pin 1

Notes:

The alarm output relay ope ns for approx 2 seconds upon power up. This can be used to signal pow er loss, etc.

When programming a preset position, control is prohibited until the dome has stored the position into it's eeprom memory, approx 1-2 seconds.

Following a goto preset command, all further commands are ignored until the dome has reached it's preset position including any alarm input.

If swing is running, start patrol 1 & 2 is inhibited. The dome will be driven to a preset following an alarm activation. 60 seconds after alarm, swing will restart.

If a manual goto preset is pressed, the dome will stop swinging and move to the preset position. The AUTOPAN led will be on until the next manual pan

command.

Rx100 installation manual V1.17 29 Aug 08.doc Page 31

Page 32

BBV Rx100 Interface Receiver

Addendum to manual for the following dome:

Diamond/Ultrak KD6 Dome

Rx100 software RX1_D1V5

up-the-coax telemetry only. Not twisted pair

Application Notes

Variable speed Pan/Tilt.

Zoom/Focus, Iris override, Auto exposure ON/OFF

16 Full scene presets.

2 preset patrols.

4 alarm inputs driving to preset 1 - 4.

Advanced Features Tx400 Tx1000 TX1500 DM Mux or DS/DS2/BX2

DOME MENU (pshot 90) ‘#’1 '#' WASH 1’#’ *889 002 or *889 10 10 2

Auto Exposure (auto-iris) toggle (pshot 92) '#' 2 '#' WIPE 2’#’ *889 003 or *889 10 10 3

Program PTZ Tour1 toggle (pshot 83/86) '#' 3 ‘#' AUTOPAN 3’#’ *889 004 or *889 10 10 4

Start PTZ Tour1 (pshot 80) ‘#’ 4 ‘#’ LIGHTS 4’#’ *889 005 or *889 10 10 5

VectorScan 0 is started by pressing AUTOPAN and is programmed using the dome menu (see notes).

A datum or home facility is provided. This is link selectable to either move to preset 1 or start VectorScan 0. Link J6/1-2 fitted enables datum mode. Link

J6/4-5 fitted selects preset 1 and removed selects VectorSc an 0. The timeout is fixed at 5 minutes after the last movement command.

RS485 control of dome using the following connec tions:

Rx100 Description Dome connection

J3-C1 TX/RX- RXJ3-C2 TX/RX+ RX+

Notes:

The alarm output relay ope ns for approx 5 seconds upon power up. This can be used to signal pow er loss, etc.

Whilst within PATROL1, PATROL2, VECTORSCAN or PTZ Tour a local alarm input will drive the dome to the active alarm preset position at full speed.

The dome will remain in this position for approx 60 seconds, after which time the patrol, VectorScan etc will resume. Additionally, if the dome is running

PATROL1 or 2 a manual preset command will move the dome to this preset position for 60 seconds before continuing with the patrol.

The dome must be configured as follows:

Select 9600 Baud communications. To use the dome’s advanced features including the menu, select MAXPRO telemetry. The exact switch setting for

MAXPRO telemetry depends on the dome’s internal firmware version as below:

Version S4-1 S4-2 S4-3 S4-4

J/K closed open open open

H open closed open open

G closed open open closed

Three rotary switches set the dome address to 000. S1 = ‘0’, S2 = ‘0’, S3 = ‘0’.

The dome menu allows setting of several internal dome features. Once activated using ‘#’WASH etc, navigate using the pan/tilt direction keys/joystick.

Generally the IRIS OPEN key is used as a ENTER key and the IRIS CLOSE key is used as an ESCAPE key. The dome manual should explain in greater detail.

On screen text can be e nabled using the dome menu.

It is recommended that the dome is operated with the auto exposure set to ON to allow automatic compensation for varying lighting conditions.

Due to the dome protocol requirements, telemetry control is up-the-coax only

Rx1_D1V5)

. 20mA twisted pair telemetry is not currently supported. (Software version

Rx100 installation manual V1.17 29 Aug 08.doc Page 32

Page 33

BBV Rx 100 Interface Receiver

Addendum to manual for the following domes:

VCL TP protocol Microsphere/Orbiter range.

Rx100 software RX1_V1V10

Application Notes

The RX 100 provide the following functionality when controlling the above mentioned domes

Variable speed Pan/Tilt.

Zoom/Focus, Autofocus following a Zoom In/Out.

16 Full scene presets.

2 preset patrols.

Slow preset tour. Started by pressing AUTOPAN

5 minute datum/park driving to preset 8 disabled by removing link J6/4-5

Program up to 16 privacy zones

Additional commands:

AUTOPAN: Pressing the AUTOPAN key will run the domes preset tour at slow speed between the patrol 1 preset positions.

Advanced Features Tx400 Tx1000 Tx1500 DM DS/DS2/BX2 Mux

180 degree pan flip ‘#’ 1 '#' WASH 1 ’#’ *889 002 or *889 10 10 2

Privacy SET (Toggle Mono/Colour) ‘#’ 2 '#' WIPE 2 ’#’ *889 003 or *889 10 10 3