Page 1

SCD-XA5400ES

SERVICE MANUAL

Ver. 1.0 2008.08

SPECIFICATIONS

When a Super Audio CD is played

Playing frequency range 2 Hz to 100 kHz

Frequency response 2 Hz to 50 kHz (–3 dB)

Dynamic range 110 dB or more

Total harmonic distortion rate

0.0012 % or less

Wow and flutter Value of measurable limit

(±0.001 % W. PEAK) or

less

When a CD is played

Frequency response 2 Hz to 20 kHz (±0.5 dB)

Dynamic range 100 dB or more

Total harmonic distortion rate

0.0017 % or less

Wow and flutter Value of measurable limit

(±0.001 % W. PEAK) or

less

Output jacks

Jack type Output

ANALOG

OUT UNBALANCED

ANALOG

OUT

BALANCED

HDMI HDMI

DIGITAL

OUT (CD)

OPTICAL*

DIGITAL

OUT (CD)

COAXIAL*

PHONES Stereo

* Outputs only the audio signals of the CD

Phono

jacks

XLR 2 Vrms

Square

optical

output

connector

Coaxial

output

connector

phone jack

US Model

Canadian Model

AEP Model

Model Name Using Similar Mechanism NEW

Mechanism Type CDM66F-DVBU101

Optical Pick-up Block Name KHM-313CAB

General

level

2 Vrms

(at 50

kilohms)

(at 50

kilohms)

–18 dBm (Light

0.5 Vp-p 75 ohms

5 mW 32 ohms

Load

impedance

Over 10

kilohms

Over 600

ohms

emitting

wave

length: 660

nm)

Laser Diode Properties

Emission duration:

Continuous

Laser Output*: Less than

44.6 μW

* This output is the value

measurement at a

distance of 200 mm from

the objective lens surface

on the Optical Pick-up

Block with 7 mm

aperture.

Power requirements North America:

120 V AC, 60 Hz

Europe:

230 V AC, 50/60 Hz

Power consumption 25 W

Power consumption (during standby mode)

0.5 W

Dimensions (w/h/d) 430 × 124 × 390 mm

(17 × 5 × 15 3/8 inch) incl.

projecting parts

Mass (approx.) 10.2 kg (22 lb 8 oz)

Supplied accessories

Audio connecting cord Red and White plugs (1)

Remote commander RM-ASU042 (1)

AC power cord (1)

Battery R6 (size-AA) (2)

9-889-205-01

2008H05-1

2008.08

©

Design and specifications are subject to change

without notice.

SUPER AUDIO CD PLAYER

Sony Corporation

Audio&Video Business Group

Published by Sony Techno Create Corporation

Page 2

SCD-XA5400ES

NOTES ON CHIP COMPONENT REPLACEMENT

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

FLEXIBLE CIRCUIT BOARD REPAIRING

• Keep the temperature of soldering iron around 270 °C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specifi ed herein may result in hazardous radia-

tion exposure.

This appliance is

classified as a CLASS

1 LASER product.

This marking is

located on the rear

exterior.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

SAFETY-RELATED COMPONET WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

AC

1.5 kΩ0.15 μF

Earth Ground

voltmeter

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE

PAR DES PIÈCES SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

Page 3

TABLE OF CONTENTS

1. SERVICING NOTES ............................................. 4

2. GENERAL .................................................................. 6

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 8

3-2. Case ................................................................................. 8

3-3. Loading Panel Assy ........................................................ 9

3-4. Front Panel Assy ............................................................. 9

3-5. MAIN Board ................................................................... 10

3-6. Mechanism Deck (CDM66F-DVBU101) ....................... 10

3-7. MOTOR Board, Motor (L) Assy (Loading) ................... 11

3-8. Base Unit Block .............................................................. 11

4. TEST MODE ............................................................ 12

5. ELECTRICAL ADJUSTMENT ........................... 16

6. DIAGRAMS

6-1. Block Diagram - SA-CD/CD SERVO Section - ............. 17

6-2. Block Diagram - HDMI Section - ................................... 18

6-3. Block Diagram - MAIN Section - ................................... 19

6-4. Block Diagram

- PANEL, POWER SUPPLY Section - ........................... 20

6-5. Printed Wiring Board - MAIN Section (1/2) - ................ 22

6-6. Printed Wiring Boards - MAIN Section (2/2) - .............. 23

6-7. Schematic Diagram - MAIN Section (1/4) - ................... 24

6-8. Schematic Diagram - MAIN Section (2/4) - ................... 25

6-9. Schematic Diagram - MAIN Section (3/4) - ................... 26

6-10. Schematic Diagram - MAIN Section (4/4) - ................... 27

6-11. Printed Wiring Board - AUDIO Section (1/2) - .............. 28

6-12. Printed Wiring Boards - AUDIO Section (2/2) - ............ 29

6-13. Schematic Diagram - AUDIO Section (1/2) - ................. 30

6-14. Schematic Diagram - AUDIO Section (2/2) - ................. 31

6-15. Printed Wiring Boards - PANEL Section - ..................... 32

6-16. Schematic Diagram - DISPLAY Board - ........................ 33

6-17. Schematic Diagram - KEY Section - .............................. 34

6-18. Schematic Diagram - POWER Board - .......................... 35

6-19. Schematic Diagram - STANDBY Board - ...................... 36

6-20. Printed Wiring Boards - POWER Section - .................... 37

SCD-XA5400ES

7. EXPLODED VIEWS

7-1. Case Section .................................................................... 47

7-2. DISPLAY Board Section ................................................ 48

7-3. Front Panel Section ......................................................... 49

7-4. MAIN Board Section ...................................................... 50

7-5. AUDIO Board Section .................................................... 51

7-6. Chassis Section ............................................................... 52

7-7. Mechanism Deck Section (CDM66F-DVBU101) .......... 53

7-8. Base Unit Section ............................................................ 54

8. ELECTRICAL PARTS LIST .............................. 55

Accessories are given in the last of the electrical parts list.

3

Page 4

SCD-XA5400ES

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The fl exible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc refl ective surface by the objective lens in the optical

pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

Compatible Disc Types

You can play the following types of discs on this player.

• Super Audio CDs

• Audio CDs

• DSD Discs

This player cannot play the following discs.

• CD-ROMs (MP3, JPEG, etc.)

• DVDs

• DTS-CDs

• DualDiscs, etc.

If you try to play CD-ROMs/DVDs, the error message

“

Cannot Play” or “No Disc” will appear.

For DTS-CDs/DualDiscs, refer to their respective notes below.

Music discs encoded with copyright protection

technologies

This product is designed to play back discs that conform to the Compact

Disc (CD) standard.

Recently, various music discs encoded with copyright protection

technologies are marketed by some record companies. Please be aware

that among those discs, there are some that do not conform to the CD

standard and may not be playable by this product.

Notes on CD-R/CD-RW playback

Discs recorded on CD-R/CD-RW drives may not be played back because

of scratches, dirt, recording condition, or the drive’s characteristics.

Besides, the discs, which are not yet finalized at the end of recording,

cannot be played back. In these cases, “Reading” will remain or

“Cannot Play” will appear on the display.

Note on DTS-CDs

DTS signals are output from the DIGITAL OUT (CD) jacks only.

The DTS signals must be decoded on a DTS-compliant digital device to

be listened to.

Note on DualDiscs

A DualDisc is a two sided disc product which mates DVD recorded

material on one side with digital audio material on the other side.

However, since the audio material side does not conform to the Compact

Disc (CD) standard, playback on this product is not guaranteed.

NOTE OF REPLACING THE IC1103 ON THE MAIN

BOARD

IC1103 on the MAIN board cannot exchange with single. When

this part is damaged, exchange the entire mounted board.

MODEL IDENTIFICATION

– Rear View –

Part No.

Model Part No.

US and Canadian models

AEP model

3-873-299-1[]

3-873-299-2[]

4

Note on DSD Discs

A DSD Disc is a disc recorded in the DSF file format.

This player can play DSF files that you have recorded on DVD-ROM

compatible DVD-R, DVD-RW, DVD+R and DVD+RW discs. For details

on DSD Discs.

Page 5

HOW TO OPEN THE TRAY WHEN POWER SWITCH TURNS OFF

SCD-XA5400ES

#

Pull out the tray

in the direction of arrow #.

Rotate the cam (66)

with a tapering driver

in the direction of arrow ".

"

– BOTTOM VIEW –

cam (66)

MAIN BOARD SERVICE POSITION

In checking the MAIN board, prepare jig (extension cable J-2501-102-A: 1 mm Pitch, 13 cores, Length 300 mm).

AUDIO board

(CN151)

connect jig (extension cable J-2501-102-A) to

MAIN board

(CN1100)

MAIN board (CN501, CN1100) and

AUDIO board (CN151, CN152).

insulator sheet

Note: insert the insulator sheet to prevent short.

PRECAUTION WHEN REMOVING OPTICAL PICK-UP BLOCK OR DMB-FIT BOARD

CAUTION

Be sure to execute a solder bridge as a measure against

static electricity when removing the optical pick-up or

DMB-FIT board.

(Otherwise, the OP block will be destroyed.)

mechanism deck

AUDIO board

(CN152)

MAIN board

(CN501)

– BOTTOM VIEW –

5

Page 6

SCD-XA5400ES

Front Panel

SECTION 2

GENERAL

This section is extracted

from instruction manual.

" / (power) switch

Turns the power of the player on or off.

To let the play er enter power-saving mode

(standby mode), press =/ (power) on the remote

or on the player.

# TIME/TEXT button

Switches the playing time of the track, the

remaining time of the disc, or TEXT information

on the display.

$ MULTI/2CH button

Selects the playback area when a disc with the 2channel area and the multi-channel area (page 8) is

loaded.

% SA-CD/CD button

Switches between the Super Audio CD layer and

the CD layer of a hybrid disc.

Rear Panel

& HDMI button/lamp

Sets whether the audio signal is output from the

HDMI OUT jack or not.

When the lamp is lit, sound is output from th e

HDMI OUT jack.

When the lamp is not lit, sound is output from the

ANALOG OUT jacks and DIGITAL OUT (CD)

jacks.

' Disc tray

Holds a disc.

( " button

Opens and closes the disc tray.

) / button and lamp

Plays a disc. The lamp lights up during playback.

* 9 button and lamp

Pauses playback. The lamp lights up during

playback pause.

+ Y button

Stops playback

, AMS dial (AMS: Automatic Music

Sensor)

Selects a track.

- Display window

Displays information on the disc or current track.

. Remote sensor

Receives the signal from the remote.

/ PHONE LEVEL

Adjusts the headphones volume.

0 PHONES jack

Connects the headphones.

" IR REMOTE IN jack

Equipped on the models for the U.S. and Canada

only.

Connects an IR repeat er.

# ANALOG OUT BALANCED L/R jacks

Connects a component with XLR input jacks, such

as stereo amplifiers, etc., using an XLR (balanced)

cable (not supplied).

$ HDMI PRIORITY MULTI/2CH switch

When both multi-channel area and 2-channel area

are recorded on a Super Audio CD layer, sets the

area that is given priority to be played back.

% HDMI OUT jack

Connects components with HDMI jacks, su ch as

HDMI-compliant amplifiers, etc.

6

& DIGITAL OUT (CD) COAXIAL jack

Connects a component with the coaxial digital

input jack, such an MD deck, etc.

' DIGITAL OUT (CD) OPTICAL jack

Connects a component with the optical digital

input jack, such an MD deck, etc.

( DIGITAL OUT (CD) ON/OFF switch

Sets whether audio signals are output from the

DIGITAL OUT (CD) jacks or not.

) AC IN jack

Connects the supplied AC power cord (mains

lead).

* ANALOG OUT UNBALANCED L/R jacks

Connects a component with analog input jacks,

such as stereo amplifiers, etc., using an audio

connecting cord.

About the IR REMOTE jack

You can operate the player without pointing the

remote toward the remote sensor of the player if

you connect an IR repeater (not supplied) to the

IR REMOTE jack.

Use an IR repeater when you install the player in

aplacewheresignalsfrom theremotecannot

reach.

IR repeater

SCD-XA5400ES

(not supplied)

RM-ASU042

Page 7

SCD-XA5400ES

Remote

" / (power) switch

Turns the power of the player on or off.

To let the player enter power-saving mode

(standby mode), press =/ (power) on the remote

or on the player.

# SA-CD/CD button

Switches between the Super Audio CD layer and

the CD layer of a hybrid disc.

$ HDMI button

Sets whether the audio signal is output from the

HDMI OUT jack or not.

% REPEAT button

Performs Repeat Play.

& SHUFFLE button

Performs Shuffle Play.

' ENTER button

Select a track directly.

( / button

9 button

Y button

Plays back discs, pauses playback, and stops

playback.

) AMS buttons (AMS: Automatic

Music Sensor)

Selects a track.

* N. buttons

Fast-forwards or fast-reverses the track during

playback.

+ DISPLAY button

Turns the display information off or on.

, TIME/TEXT button

Switches the playing time of the track, the

remaining time of the disc, or TEXT information

on the display.

- CLEAR button

Resumes Continuous Play from Repeat Play or

Shuffle Play.

. Number buttons

Select a track directly.

/ CONTINUE button

Resumes Continuous Play from Shuffle Play.

0 MULTI/2CH button

Selects the playback area when a disc with the 2channel area and the multi-channel area is loaded.

1 ; button

Opens or closes the disc tray.

Inserting batteries into the

remote

Insert two R6 (size-AA) batteries into the

battery compartment with the + and – correctly

oriented to the markings. When using the

remote, point it at the remote sensor on the

player.

Tip

Under normal conditions, the batteries should last for

about 6 months. When the remote no longer operates

the player, replace both batteries with new ones.

Notes

• Do not leave the remote in an extremely hot o r a

humid place.

• Do not drop any foreign object into the remote

casing, particularly when replacing the batteries.

• Do not use a new battery with an old one.

• Do not expose the remote sensor to direct sunlight or

lighting apparatus. Doing so may cause a

malfunction.

• If you do notintend touse the remote foran extended

period of time, remove the batteries to avoid possible

damage from battery leakage and corrosion.

7

Page 8

SCD-XA5400ES

DISASSEMBLY

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. CASE

(Page 8)

SECTION 3

3-3. LOADING PANEL ASSY

(Page 9)

3-4. FRONT PANEL ASSY

(Page 9)

Note: Follow the disassembly procedure in the numerical order given.

3-5. MAIN BOARD

(Page 10)

3-6. MECHANISM DECK

(CDM66F-DVBU101)

(Page 10)

3-7. MOTOR BOARD,

MOTOR (L) ASSY (LOADING)

(Page 11)

3-2. CASE

two screws

(BVST4 × 8)

case

3-8. BASE UNIT

BLOCK

(Page 11)

flat head screw

(TP)

two screws

(BVST4 × 8)

8

Page 9

3-3. LOADING PANEL ASSY

in the direction of arrow #.

loading panel assy

SCD-XA5400ES

Pull out the tray

two screws

(BVTP2.6 (3CR))

3-4. FRONT PANEL ASSY

two screws

(BVTP3 × 8)

#

"

Rotate the cam (66)

with a tapering driver

in the direction of arrow ".

two cushions

– BOTTOM VIEW –

cam (66)

wire (flat type) (19 core)

(CN502)

two brackets

(panel)

six screws

(BV/ring)

front panel assy

connector

(CN291)

connector

(CN103)

9

Page 10

SCD-XA5400ES

3-5. MAIN BOARD

wire (flat type) (24 core)

(CN1101)

wire (flat type) (13 core)

(CN1100)

six screws

(BVTP3 × 8)

connector (CN506, CN1201, CN1202)

R

wire (flat type) (19 core)

(CN502)

wire (flat type) (13 core)

(CN501)

two screws

(BVTP3 × 8)

screw

(B3 × 6)

MAIN board

3-6. MECHANISM DECK (CDM66F-DVBU101)

three screws

mechanism deck

(CDM66F-DVBU101)

(BVTP3 × 8)

(CN010)

connector

connector

(CN1201)

wire (flat type) (24 core)

(CN1101)

10

Page 11

3-7. MOTOR BOARD, MOTOR (L) ASSY (LOADING)

gear (LD)

connector

(CN012)

cushion

two claws

tray (66F)

belt (LD)

two screws

(B2.6 × 4)

SCD-XA5400ES

3-8. BASE UNIT BLOCK

– BOTTOM VIEW –

cam (66)

MOTOR board

R

motor (L) assy

RB

(loading)

Remove two solders.

base unit block

floating screw (DIA.12)

base unit block

11

Page 12

SCD-XA5400ES

SECTION 4

TEST MODE

Note 1: According to the following procedures when you ship it

(Return it to the customer).

1. SERVICE MODE of step 6 and 7

(DVD EEPROM clearness)

2. COLD RESET

Note 2: “DVD” displayed by the test mode shows "super audio

CD”.

COLD RESET

The cold reset clears data stored in microcomputer’s RAM to initial conditions.

Procedure:

1. Press three buttons of [x], [A] and [

] on the set simultane-

?/1

ously.

2. “COLD RESET” appears on the fl uorescent indicator tube. Af-

ter that, the fl uorescent indicator tube becomes blank then the

system becomes standby states.

PANEL TEST

Procedure:

1. Press the [

2. Press three buttons of [

and [

?/1

] button to turn on.

?/1

x], [. AMS >, PUSH ENTER]

] on the set simultaneously.

3. All segments turned on.

4. When [x] button on the set is pressed after half segments in

fl uorescent indicator tube light up. If you press [

x] button on

the set again, another half segments in fl uorescent indicator

tube light up. Pressing [

x] button on the set again would cause

all segments in fl uorescent indicator tube light up.

5. Press [N] button on the set, in the key check mode, the fl uo-

rescent indicator tube displays “K0 J0”.

6. Each time an another button is pressed, “KEY” value increases. However, once a button is pressed, it is no longer taken into

account. When all keys are pressed correctly, “K10” and “OK”

are alternately displayed.

7. When the [

. AMS >, PUSH ENTER] dial on the set is

turned in the direction of right,“J0” is changed to “J1”, then ...

“J9”. When the [

. AMS >, PUSH ENTER] dial on the

set is turned in the direction of left, “J0” is changed to “J9”,

then ... “J0”.

8. To release from this mode, press three buttons in the same

manner as step 1.

CDM TEST

Aging test mode of CDM.

Procedure:

1. Press three buttons of [X], [A] and [

] on the set simultane-

?/1

ously.

2. After the “Open” display blinks, “SINGLE LOADING” is displayed on the fl uorescent indicator tube.

3. Press [

. AMS >, PUSH ENTER] and then aging starts.

4. To stop aging, Press [x] button.

5. To release from this mode, press three buttons of [

[

] on the set simultaneously.

?/1

X], [A] and

SERVICE MODE

When HDMI is connected in this mode, various information is displayed on the fl uorescent indicator tube. Refer to the following

table for displayed various information.

EEPROM CLEAR

Procedure:

1. Press two buttons of [x] and [A] on the set simultaneously for

3 seconds.

2. Various information is displayed on the fl uorescent indicator

tube.

3. When [

R] button is pressed of the remote commander. Reboot-

ing emergence fuctor appears of toggle article number on the

fl uorescent indicator tube.

4. When [

t] button is pressed of the remote commander. MTK

communication error factor appears of toggle article number

on the fl uorescent indicator tube.

5. When [r] button is pressed of the remote commander. Power

ON/OFF error factor appears of toggle article number on the

fl uorescent indicator tube.

6. Press the button in order of the [4] t [Time/Text] t [CLEAR]

on the remote commander of attachment.

7. The message “Complete” is displayed on the fl uorescent indi-

cator tube, and DVD EEPROM is cleared.

8. To release from this mode, disconnect the power cord.

Note: Don't press the [

Necessarily disconnect the power cord. The set doesn't operate

when turning off power with [

] button when to release from this mode.

?/1

] button of the set.

?/1

12

Page 13

List of trouble log

Note: “nnn” of toggle article number is a generation frequency of the error.

SCD-XA5400ES

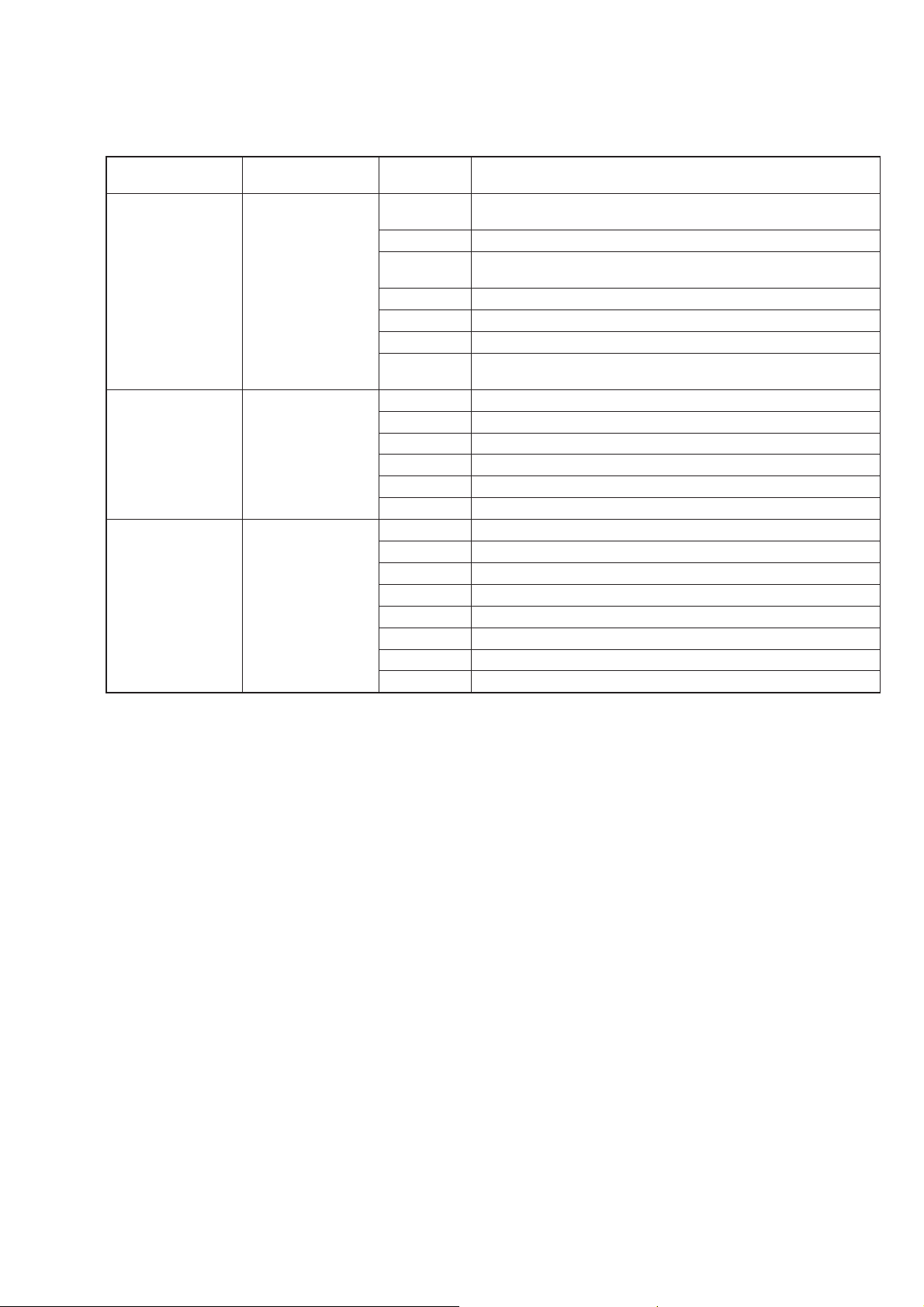

Type

Rebooting emergence

(Rebooting emergence

factor)

Serial communications

(MTK communication

error factor)

MTK power control

(Power ON/OFF error

factor)

Test key

(Remote commander)

Test key2 (R)

Test key3 (t)

Test key2 (r)

Toggle article

number

2Annn

2Bnnn Compulsion power off demand was received from MTK

2Cnnn

2Dnnn Fails in the start of MTK

2Ennn Fails in the switch of the input mode of MTK

2Fnnn Input mode of MTK changed without permission

2Gnnn

3Annn It was not possible to communicate with MTK with 48ms

3Bnnn A non-standard packet length was received (Excluding 16 bytes)

3Cnnn Checksum NG

3Dnnn Type of the communication header is NG

3Ennn PEQ data reading operation (8032tDVDLIB) terminated abnormally

3Fnnn PEQ data writing operation (DVDLIBt8032) terminated abnormally

4Annn Fails in AC ON Initial

4Bnnn Fails in power on of MTK

4Cnnn Initialization response of CDM is abnormal

4Dnnn CDM mechanism error notifi cation is received

4Ennn Input mode is NG MTK is started

4Fnnn MTK input mode switch at time fails usually

4Gnnn Fails in power off of MTK

4Hnnn Fails in power off of CDM

It was not possible to communicate with MTK fi ve seconds more continu-

ously

Only MTK reset it

(Distination, model and region for are the disagreements)

Reacts to the key notifi cation no though the communication with MTK is

alive

Content

13

Page 14

SCD-XA5400ES

DVD SERVICE MODE

Note: DVD SERVICE MODE is a service mode of super audio

CD.

When the DVD service mode is operated, the following, remote

commander is necessary.

(The DVD service mode cannot be operated by remote commander

to which this machine is attached)

Remote commander (RM-ASP003) (for US, Canadian models):

Part No. 1-479-272-11

Remote commander (RM-ASP004) (for AEP model):

Part No. 1-479-272-21

Note: Above-mentioned remote commander is one example. If it is the

one printed under a remote commander as "DVD", any remote commander can be operated.

1. DVD Service Mode General Description

This mode let you make diagnosis and adjustment easily by using the remote commander and the TV screen for HDMI input.

The instructions, diagnostic results, etc. are given on the on-screen

display.

Be sure to execute the IOP measurement when a base unit is replaced.

2. Enterring DVD Service Mode

Procedure:

1. Press the [?/1] button to turn the power on.

2. Press two buttons of [x] and [A] on the set simultaneously for

3 seconds

3. The message “SERVICE IN” appears on the fl uorescent in-

dicator tube and top menu of the Remocon Diagnosis Menu

appears on the on-screen display on the TV screen for HDMI

input as follows. The model name, IF-con version and Syscon

version are displayed at the bottom of the on-screen display.

Remocon Diagnosis Menu

0. External Chip Check

1. Servo Parameter Check

2. Drive Manual Operation

3. Emergency History

4. Version Information

Model Name :xxxx_xx

IF-con:Ver.xx.xx(xxxx)

Syscon:Ver.x.xxx

4. To execute each function, press its number by using numeric

button on the remote commander.

5. To release from this mode, disconnect the power cord.

Note: Don't press the [

Necessarily disconnect the power cord. The set doesn't operate

when turning off power with [

] button when to release from this mode.

?/1

] button of the set.

?/1

3. Executing IOP Measurement

In order to execute IOP measurement, the following standard procedures must be followed.

Procedure:

1. From the top menu of Remocon Diagnosis Menu, select “2

Drive Manual Operation” by pressing the [2] button on the

remote commander. The following screen appears on the onscreen display

Drive Manual Operation

1. Servo Control

2. Track/Layer Jump

3. Manual Adjustment

4. Mecha test mode

5. MIRR time Adjust

0. Return to Top Menu

2. Select “3. Manual Adjustment” by pressing the [3] button on

the remote commander. The following screen appears on the

on-screen display.

Manual Adjust

1. Track Balance Adjust:

2. Track Gain Adjust:

3. Focus Balance Adjust:

4. Focus Gain Adjust:

5. Eq Boost Adjust:

6. Iop:

7. TRV. Level:

8. S curve(FE) Level:

9. RFL(PI) Level:

0. MIRR Time:

[V][v] Change Value

[RETURN]Return to previous menu

3. Select “6. Iop:” by pressing [6] button on the remote commander.

4. Wait until a hexadecimal number appear in the on-screen display as below.

Manual Adjust

1. Track Balance Adjust:

2. Track Gain Adjust:

3. Focus Balance Adjust:

4. Focus Gain Adjust:

5. Eq Boost Adjust:

6. Iop: xx

7. TRV. Level:

8. S curve(FE) Level:

9. RFL(PI) Level:

0. MIRR Time:

[V][v] Change Value

[RETURN]Return to previous menu

14

5. Convert data from hexadecimal to decimal by using conversion table.

6. If the value is smaller than 93 (decimal), then it is OK. However if the value is higher than 93, then BU (base unit) is defective and need to be change.

Page 15

SCD-XA5400ES

7. Press the [O RETURN] button on the remote commander to

return to previous menu.

8. Press the [0] button on the remote commander to return to the

top menu of Remocon Diagnosis Menu.

9. Disconnect the power cord to turn off.

Note: Don't press the [

Necessarily disconnect the power cord. The set doesn't operate

when turning off power with [

] button when to release from this mode.

?/1

] button of the set.

?/1

4. Checking Emergency History

To check the emergency history, please follow the following procedure.

Procedure:

1. From the top menu of Remocon Diagnosis Menu, select “3.

Emergency History” by pressing the [3] button on the remote

commander. The following screen appears on the on-screen

display.

Emg. History Check

Laser Hours CD 999h 59min

DVD 999h 59min

01. 01 05 04 04 00 92 46 00

00 00 00 00 00 00 23 45

02. 02 02 01 01 00 A9 4B 00

00 00 00 00 00 00 23 45

52. Open kick spindle error

60: Focus on error

61: Seek fail error

62: Read Q data/ID error

70: Lead in data read fail

71: TOC read time out (CD)

80: Can’t buffering

81: Unknown media type

B. Parameter of error code

This is the detail of error code.

Example of Error code

01. 01 05 04 04 00 92 46 00

00 00 00 00 00 00 23 45

C. Time of error code

This is the laser time when an error occurred.

Example of Error code

01. 01 05 04 04 00 92 46 00

00 00 00 00 00 00 23 45

To Clear the Laser Hour

Press the [DISPLAY] button on the remote commander and then

press the [CLEAR] button on the remote commander. The data for

both super audio CD and CD data are reset.

[Next]Next page [Prev]Prev page

[0]Return to Top Menu

2. You can check the total time when the laser is turned on during

playback of super audio CD and CD from the above menu. The

maximum time, which can be displayed are 999h 59min.

3. You can check the error code of latest 10 emergency history

from the above menu. To view the previous or next page of

emergency history, press the [

.] or [>] button on the re-

mote commander. The error code consists of three kinds of

error codes.

A. Error code

Example of Error code

01. 01 05 04 04 00 92 46 00

00 00 00 00 00 00 23 45

The meaning of error code is as below:

01: Communication error (No reply from syscon)

02: Syscon hung up

03: Power OFF request when syscon hung up

19: Thermal shutdown

24: MoveSledHome error

25: Mechanical move error (5 changer)

26: Mechanical move stack error

30: DC motor adjustment error

31: DPD offset adjustment error

32: TE balance adjustment error

33. TE sensor adjustment error

34. TE loop gain adjustment error

35. FE loop gain adjustment error

36. Bad jitter after adjustment

40. Focus NG

42. Focus layer jump NG

51: Spindle stop error

Emg. History Check

Laser Hours CD 0h 0min

DVD 0h 0min

01. 01 05 04 04 00 92 46 00

00 00 00 00 00 00 23 45

02. 02 02 01 01 00 A9 4B 00

00 00 00 00 00 00 23 45

[Next]Next page [Prev]Prev page

[0]Return to Top Menu

To Clear the Emergency History

Press the [TOP MENU] button on the remote commander and then

press the [CLEAR] button on the remote commander. The error

code for all emergency history would be reset.

Emg. History Check

Laser Hours CD 999h 59min

DVD 999h 59min

01. 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00

02. 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00

[Next]Next page [Prev]Prev page

[0]Return to Top Menu

15

Page 16

SCD-XA5400ES

SECTION 5

ELECTRICAL ADJUSTMENT

To Execute the Initialize Setup Data

Procedure:

1. Press the [MENU] button on the remote commander and then

press the [CLEAR] button on the remote commander. The following screen appears on the on-screen display.

Emg. History Check

Laser Hours CD 999h 59min

DVD 999h 59min

Initialize setup data...

[Next]Next page [Prev]Prev page

[0]Return to Top Menu

2. The screen after a while returns to former display.

To Return to the Top Menu of Remocon Diagnosis

Menu

Press the [0] button on the remote commander.

When the base unit is replaced, perform the adjustment and the

measurement as shown below in this order.

EXECUTING IOP MEASUREMENT (See page 14)

5. Checking Version Information

To check the version information, please follow the following procedure.

Procedure:

1. From the top menu of Remocon Diagnosis Menu, select “4.

Version Information” by pressing the [4] button on the remote

commander. The following screen appears on the on-screen

display.

Version information

Firm(Main): Ver. X.XXXX

Firm(Sub): XX.XX

RISC: XXXXXX

8032: XXXXXX

Audio DSP: XX.XX.XX.XX

Servo DSP: XX.XX.XX.XX

[0]Return to Top Menu

2. To return to the top menu of Remocon Diagnosis Menu, press

the [0] on the remote commander.

16

Page 17

SCD-XA5400ES

SCD-XA5400ES

1717

SECTION 6

DIAGRAMS

6-1. BLOCK DIAGRAM - SA-CD/CD SERVO Section -

MULTIPLEXER

IC1901

LEVEL SHIFT

IC1703

OPTICAL

TRANSMITTER

IC1701

11Y

BDTL

PDT

SBCK

PLRCK

PBCK

20Y R-CH

Ycom

15

9C10

B

PDT, BDTR, PBCK,

PLRCK, SBCK

J1701

LEVEL SHIFT

IC1702

DIGITAL

OUT(CD)

COAXIAL

OPTICAL

R-ch is omitted due to same as L-ch.

RF

OPTICAL PICK-UP

BLOCK

(KHM-313CAB)

Q1102-1

AUTO POWER

CONTROL (FOR CD)

DVDRFIP

10

SPDIF

DVDA

VOA/A

VOB/B

VOC/C

VOD/D

VOF/F+H

VOE/E+G

VC

LIMIT

PD

LD (780)

6

DVDB

7

DVDC

8

DVDD

9

TNI

17

TPI

18

NA

11

NB

12

MC

13

MD

14

V2O

LIMIT SW

28

LDO1

22

MDI1

19

MDI2

53

20

Q1102-2

AUTO POWER

CONTROL (FOR SA-CD)

IC1201

FOCUS/TRACKING COIL DRIVE,

SPINDLE SLED, LOADING MOTOR DRIVE

VREF

IN+3

IN4+

MUTE123

MUTE4

TSD_M

PS

IC1101 (1/2)

RF AMP, SERVO DSP,

HDMI TRANSMITTER

IC501 (1/4)

SYSTEM CONTROLLER

BUFFER

VR (650)

VR (780)

MSW

Q1103

VCC

LD (650)

LDO2

MSW

21

D+3.3V

DVD_SCO

37

DVD_SOD

32

DVD_SID

31

DVD XIFCS

37

STT_D/P

43

DMUTE

45

STT_M/2

44

OCSW

84

CKSW

83

DVD_XIFBUSY

(CHUCKING)

SW010

(DISC IN/OUT)

SW011

34

98

FMO

37

FOO

41

DMO

36

TRO

40

V REFO

29

RFRAPC

FWD

94

REV

95

IOPMON

39

OP_INP

35

MUTE123

MUTE

TSD_M

42

25

21

22

20

19

45

7

6

17

40

16

13

12

10

9

4

3

1

48

43

15

24

41

54

REG01

REG02

FCS+

FCS-

TRK+

TRK-

SP-

SP+

SLSL+

BUFFER

46

47

MCS

BUFFER

32

31

30

29

SPINDLE MOTOR

DRIVE

27

28

SLED MOTOR

DRIVE

FOCUS COIL

DRIVE

36

37

TRACKING COIL

DRIVE

35

34

(LOADING)

M001

MM

130

158

157

252

215

IFCK

99

xIFCS

97

IFSDO

xIFBSY

11 0

IFSDI

100

TRG_SW

DSEL

210

WIDE

209

ASDATA

226

ASDATA3

222

KMOD

213

ALRCK

205

ABCK

204

211

• SIGNAL PATH

: CD PLAY (ANALOG)

: SA-CD PLAY

: CD PLAY (DIGITAL)

A

Q1101-2

SA-CD ON

SWITCH

Q1101-2

CD ON

SWITCH

(Page 19)

Page 18

SCD-XA5400ES

SCD-XA5400ES

1818

6-2. BLOCK DIAGRAM - HDMI Section -

X501

5MHz

27M

MTK_RST

3

22

CSC_RX_IN

CEC_TX_OUT

239

XTALI

180TX2P

179TX2N

177TX1P

176TX1N

174TX0P

173TX0N

171TXCP

170TXCN

162HTPLG

CN1701

1

TMDS DATA2+

3

TMDS DATA2–

4

TMDS DATA1+

6

TMDS DATA1–

7

TMDS DATA0+

9

TMDS DATA0–

10

TMDS CLOCK+

12

TMDS CLOCK–

19

HPD

HDMI OUT

SW+6V

IC1103

EEPROM

IC1705

LEVEL SHIFT

IC1102

FLASH ROM

IC1101 (2/2)

REAMP, SERVO DSP, HDMI TRANSMITTER

IC501 (2/4)

SYSTEM CONTROLLER

IC1104

SD-RAM

IC1707

+5V REGULATOR

WE

EEWP

SCL

SDA

18

+5V POWER

13

CEC

15

SCL

16

SDA

Q9724, 9726, 9728, 9729

CEC DATA SWITCH

7

101

112

102

xSYSRST

108

DDC_CLK

161

DDC_DAC

159

CLKE

37

UDQM

39

LDQM

15

WE

11

OE

28

CE

26

45

12

CAS

17

RAS

18

WE

16

CS

19

CLK

38

BA1

21

BA0

20

CKE

147

DQM1

132

DQM0

111

_CAS

134

_RAS

135

_RWE

133

_RCS

136

DRCLK

146

BA1

138

BA0

137

XWR

66

XRD

78

XROMCS

76

SCL

6

SDA

5

Q1701

LEVEL SHIFT

140, 141, 143, 144

23 – 26,

29 – 34, 22, 35

121-119,117-113,

129-122155, 150, 139, 149

2,4,5,7,8,10,11,13,42,

44,45,47,48,50,51,53

RD0 – RD15

RA0 – RA11

DQ0 – DQ15

A0 – A11

97, 56 – 62, 74 – 67,

91, 63, 64, 75, 87

29, 31, 33, 35,

38, 40, 42, 44

25 – 18, 8 – 1,

48, 17, 16, 9, 10

79, 80, 82 – 86, 89

HD0 – HD7

HA0 – HA21

DQ0 – DQ7

A0 – A19,

N.C

DQ15/A-1

RESET

Q1105

B+ SWITCH

B

166AVDD3

165AVDD3

• SIGNAL PATH

: SA-CD PLAY

38

XOUT

13

XIN

15

SW+3.3V

(Page 19)

Page 19

SCD-XA5400ES

SCD-XA5400ES

1919

6-3. BLOCK DIAGRAM - MAIN Section -

• SIGNAL PATH

: SA-CD

A

B

BDTR

PBCK

PLRCK

PDT

PDT, BDTR, PBCK,

PLRCK, SBCK

27M

C

AC_DET

SWITCHING

IC206

SBCK

INVERTER

IC292

CLOCK

BUFFER

IC152

X151

22.5792MHz

D-FLIP FLOP

IC155

CLOCK GENERATOR

IC151

COUNTER

IC156

15CLKP

REF

2

PBCK

PLRCK

6

AB CK

3

SCK

7

RST

14

MS

10

PDATA

5

DSDL

1

DSDRR-CH

2

4

MDI

MDO

12

11

1

SCL2SDA

78

PLL_IC_ISC_SCL

77

PLL_IC_I2C_SDA

87

DAC_CS288DAC_CS1

30

DAC_DATA

28

DAC_CLK

85

DAC_INT

6

XAMUTE

19

ASDMUTE

17IOUTR+

18IOUTR-

RY252

BUFFER

IC253

LOW-PASS FILTER

IC255

RELAY DRIVE

Q252, 253

1

2

4

3

4

J252

R

25IOUTL+

26IOUTL-

RY202

BUFFER

IC203

LOW-PASS FILTER

IC205

D/A CONVERTER

IC202

SYSTEM CONTROLLER

IC501 (3/4)

LINE AMP

IC291

BUFFER

IC204

RELAY DRIVE

Q202, 203

1

2

3

J202

L

PHONE LEVEL

ANALOG OUT

UNBALANCED

R

L

RY201

RV801

PHONES

J801

-1

-2

RELAY DRIVE

Q201, 204

RELAY

CONTROL

Q151, 293

J251

J201

R-ch is omitted due to same as L-ch.

(Page 17)

(Page 18)

(Page 20)

Page 20

SCD-XA5400ES

SCD-XA5400ES

2020

6-4. BLOCK DIAGRAM - PANEL, POWER SUPPLY Section -

DAC+3.3V

AC_DET

C

(AC IN)

L51

LINE FILTER

RECT

D52 – 55

T002

SUB POWER

TRANSFORMER

PT002

MAIN POWER

TRANSFORMER

AC

DETECT

Q51

RESET

SWITCH

Q503

RELAY DRIVE

Q52

D56, 57

RECT

D101 – 104

RECT

D113 – 116

+4V

REGULATOR

IC51

+4V

REGULATOR

IC103

+1.8V

REGULATOR

IC1110

RECT

D105 – 108

+6V

REGULATOR

IC101

RY01

F002

PT003

MAIN POWER

TRANSFORMER

RECT

D117 – 120

E3.3V

E3.3V

+3.3V

REGULATOR

IC506

+3.2V

REGULATOR

IC52

RESET SIGNAL

GENERATOR

IC503

DSP+1.8V

DISPLAY-27V

+3.3V

DSP+3.3V

RF+3.3V

SW+5V

SW+6V

M+9V

FL+6V

FL+3.3V

RECT

D109 – 112

+10V

REGULATOR

IC102

+6V

REGULATOR

IC104

RECT

D121 – 124

CL+3.3V

+5V

REGULATOR

IC105

+3.3V

REGULATOR

IC201

RY+3.3V

+3.3V

REGULATOR

IC153

+3.3V

REGULATOR

IC154

RECT

D121 – 124

AMP+12V

+9V

REGULATOR

IC504

+3.3V

REGULATOR

IC803

+12V

REGULATOR

IC106

AMP–12V

–12V

REGULATOR

IC107

+5V

REGULATOR

IC505

SYSTEM CONTROLLER

IC501 (4/4)

LED_PLAY

89

ND801

FLUORESCENT

INDICATOR TUBE

FLUORESCENT INDICATOR

TUBE DRIVER

IC802

AD1, S1 – 35G2 – 15

DAT FL_O_OUT

2463

CLK FL_CLK

2162

XCS FL_STB

2361

XRST

G1

40

60

40 – 54 4 – 39

GRID DRIVE

Q802

LED DRIVE

Q803

D802

/

LED_PAUSE

90

LED DRIVE

Q804

LED_HDMI

91

KEY0

97

KEY1

95

KEY3

94

XDOUT_EN

55

MULTI_PRIO

56

EN_A

10

EN_B

11

LED DRIVE

Q801

ROTARY

ENCODER

S805

D803

9

(US, Canadian)

(AEP)

D502

F001

+3.3V

REGULATOR

IC1105

+3.3V

REGULATOR

IC1107

RESET

12

AC_OUT

20

P_CONT0

41

P_CONT1

39

S801 – 804

S807 – 810

AMS

PUSH ENTER

S805

HDMI

SIRCS_IN

4

REMOTE CONTROL

RECEIVER

IC801

REMOTE CONTROL

RECEIVER

IC693

D890

J691

IR REMOTE

IN

S501

OFF

ON

DIGITAL

OUT(CD)

7

6

1

SIRCS

SELECT SWITCH

IC692

REMOTE

CONTROL

TRANSMITTER

CH1

COM

CH0

S502

MULTI

2CH

HDMI

PRIORITY

-27V

REGULATOR

Q101

(Page 19)

Page 21

SCD-XA5400ES

SCD-XA5400ES

2121

• Circuit Boards Location

For Schematic Diagrams.

Note:

• All capacitors are in μF unless otherwise noted. (p: pF) 50

WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specifi ed.

• f : internal component.

• C : panel designation.

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

• A : B+ Line.

• B : B– Line.

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : SA-CD PLAY

( ) : CD PLAY

• Voltages are taken with VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : SA-CD PLAY

J : CD PLAY (ANALOG)

c : CD PLAY (DIGITAL)

• Abbreviation

CND : Canadian model

For Printed Wiring Boards.

Note:

• X : Parts extracted from the component side.

• Y : parts extracted from the conductor side.

• f : internal component.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Note:

The components identifi ed by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specifi ed.

Note:

Les composants identifi és

par une marque 0 sont

critiques pour la sécurité.

Ne les remplacer que par

une piéce portant le numéro spécifi é.

Caution:

Pattern face side:

(Conductor Side)

Parts face side:

(Component Side)

Parts on the pattern face side seen from

the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

• AUDIO and MAIN boards are multi-layer printed board.

However, the patterns of intermediate layers have not

been included in diagrams.

• Indication of transistor.

C

Q

B

E

Q

B

CE

These are omitted.

These are omitted.

MOTOR board

KEY-L board

HP board

STANDBY board

DISPLAY board

OUT-SW board

JOG board

MAIN board

AUDIO board

POWER board

LED board

KEY-R board

Page 22

SCD-XA5400ES

SCD-XA5400ES

2222

6-5. PRINTED WIRING BOARD - MAIN Section (1/2) -

• : Uses unleaded solder.

• See page 21 for Circuit Boards Location.

Note: IC1103 cannot exchange with single. When this part

is damaged, exchange the entire mounted board.

1

19

D1

G2

S2

G1

D2

S1

241

25

48

5

8

1

4

1

8

9

16

BE

1

12

13

48

24

25 36

37

1

2

13

12

191

182

19

B

E

B

E

B

E

BE

224

1

23

1

2

13

12

D1

G2S2

G1

D2

S1

C1E1B1B2E2

C2

BE

D

G

S

C1118

C1119

CN1701

C1120

C1121

C1122

C1123

CL2118

C1124

CL2119

R601

R602

C1703

R603

C1704

R604

C1705

Q1701

C1706

R1102

R1107

R1108

IC1101

R1109

IC1102

C1132

CL2127

IC1103

C1133

CL2128

IC1104

CL2129

C1135

IC1105

C1136

IC1107

C1137

C1138

R1110

C1139

R1111

R1112

R1113

CL2130

R1114

CL2131

R1115

CL2132

R1116

R1117

R1118

IC1110

C1145

C1147

R1120

C1148

C1725

R1121

C1727

R1123

R1124

C1728

C1729

R1125

R1126

C1730

IC1702IC1703

IC1705

IC1707

R1135

R1136

R1137

CL2154

R1138

CL2155

R1139

IC1901

R1142

R1143

R1146

R650

CL500

L1801

CL501

CL502

CL503

CL504

R1151

CL505

CL506

CL507

CL508

CL509

R1156

R1159

C1182

C1183

C1184

CL510

CL511

C1186

CL512

C1187

CL513

R1160

CL514

R1161

R2101

CL515

CL516

CL517

CL518

CL519

R1742

R1744

C1190

C2130

C1192

R1746

R1747

C1193

R1748

C1195

R2110

C1198

R2114

R2115

R1752

R1754

R1757

CL1201

R1185

CL1202

CL1203

CL1204

CL1205

CL1206

CL1207

CL1208

R693

R694

R695

R1191

R696

R697

Q503

R2133

R1193

CL1213

RB1103

RB1104

RB1105RB1106

RB1107RB1108

RB1109

R1783

R1784

R1785

R1786

RB1110

RB1111

RB1112

RB1113

RB1114

RB1115

EB503

C691

C692

C693

R2176

R2177

C1203

C1205

C1206

C1208

C1209

R2187

C1210

C1211

C1212

C1213

C1214

C1215

C1217

C1218

R501

C1219

R504

R506

C1220

R508

R509

C1221

C1222

FB1106

C1223

FB1108

C1224

C1801

C1225

C1802

C1226

R510

R511

R512

R513 R514

R1204

R515

FB1111

R516

R1206

R1207

R518

R1208

R519

IC1201

R1209

C1233

CN501

CN502

R520

R1210

CN504

R521

R522

R1212

R523

R524

R1214

R525

R1215

R526

R1216

R527

R528

R529

R1219

R530

R1220

D1801

R531

R1221

D1802

R532

R533

R1223

R534

R1224

R1801

R535

R1225

R536

R1226

R538

R1229

D693

Q9724

R1230

R1231

R542

Q9726

R543

R1233

R544

Q9728

R545

Q9729

R1236

R546

R1237

R1238

R1239

C510

X501

D9712

C515

R551

L1701

L1702

R1243

L1703

L1704

R556

R1246

R557

R1247

R559

IC692

C520

C521

C522

C523

R561

R562

R563

R564

R1254

R565

R566

R567

R568

R569

R9920

C531

C533

R9924

R9928

R9929

R9934

R9935

R583

R584

R585

R586

R587

R588

CL1101

R589

R9941

CL1105

CL1106

CL1107

CL1108

R590

R9945

CL1301

C9972

R596

CL1302

R597

CL1303

CL1110

R598

CL1304

R599

CL1305

CL1112

CL1113

CL1114

D501

CL1115

CL1116

D502

CL1117

CL1118

D505

CL1121

CL1123

CL1702

CL1900

IC501

IC503

JL577

CN1101

C1101

C1103

CN1110

C1105

Q1101

Q1102

Q1103

Q1105

CL1160

CL2101

CL1161

CL2102

CL1162

CL2103

CL1163

C1110

CL2104

CL1164

C1111

CL1165

C1112

CL1166

C1113

CL1167

CL1168

CL2109

C1117

1354135

4

1

3

5

4

1

64

192

193

256

128

65

129

1

3

1 4

1 4

8 5

5

4

B

AUDIO BOARD

CN152

G

DISPLAY BOARD

CN803

A

AUDIO

BOARD

CN151

127

54

28

MAIN BOARD (COMPONENT SIDE)

1-877-065-

11, 12

(11, 12)

HDMI OUT

(NC)

81

100

50

51

80

30 1

31

(CHASSIS)

OPTICAL PICK-UP

BLOCK

(KHM-313CAB)

(1/2)

(AEP)

(US, CND)

1

3

5

4

1

3

1 32

5

4

1

3

54

A

B

C

D

E

12345678910

(Page 28)

(Page 32)

(Page 28)

Ref. No. Location

• Semiconductor Location

Ref. No. Location Ref. No. Location Ref. No. Location

D501 B-8

D502 D-9

D505 C-9

D693 B-9

D1801 B-2

D1802 B-2

D9712 C-6

IC501 C-8

IC503 B-8

IC692 B-9

IC1101 C-4

IC1102 C-6

IC1103 B-6

IC1104 B-5

IC1105 C-3

IC1107 D-3

IC1110 D-3

IC1201 D-6

IC1702 B-2

IC1703 B-2

IC1705 B-4

IC1707 B-4

IC1901 C-2

Q503 B-8

Q1101 E-5

Q1102 E-3

Q1103 E-5

Q1105 B-4

Q1701 B-4

Q9724 C-6

Q9726 C-6

Q9728 C-6

Q9729 C-6

Page 23

SCD-XA5400ES

SCD-XA5400ES

2323

6-6. PRINTED WIRING BOARDS - MAIN Section (2/2) -

• : Uses unleaded solder.

• See page 21 for Circuit Boards Location.

6

15

6

15

6

15

C1701

C1125

C1702

C1126

C1127

C1128

R1101

C1129

R1103

R1105

JL2101

R1106

JL2102

JL2103

C1130

JL2104

JL2105

JL2106

JL2107

JL2108

JL2109

JL2110

JL2111

JL2112

JL2113

C1140

JL2114

JL2115

JL2116

JL2117

C1144

JL2118

JL2119

C1146

C1149

JL2120

R1701

JL2121

R1702

JL2122

JL2123

JL2124

R1128

C1151

JL2125

JL2126

C1154

C1155

C1156

C1158

C1159

R1132

R1133

JL2130

JL2133

C1160

C2100

JL2134

C1161

JL2135

C1162

JL2136

C1163

JL2137

C1164

JL2138

C1165

JL2139

R1140

C2108

C1169

R1141

JL2140

R1145

JL2141

JL2142

R1147

JL2143

R1148

C1170

JL2144

C1171

JL2145

C1172

JL2146 JL2147

C1174

C2114

JL2148

C1175

C2115

JL2149

C1176

C2116

C2117

C2118

C1179

C2119

R1152

C2502

R1153

C2503

R1730

R1154

JL600

JL2150

R1155

JL601

JL2151

JL602

JL2152

JL603

JL2153

C1180

JL604

C1181

JL605

JL606

JL607

JL608

JL609

JL610

JL611

JL2161

JL612

JL2162

JL613

JL2163

JL614

JL2164

C1191

JL615

JL616

JL617

JL618

R1749

JL619

C1197

C1199

R1750

JL620

R1175

R1751

JL621

JL622

R1753

JL623

JL624

R2119

JL625

JL626

JL627

JL628

JL629

JL630

R1186

R2129

JL638

R691

CL1209

R692

R2134

CL1210

CL1211

CL1212

JL642

JL643

R1198

JL644JL645JL646 JL647 JL648 JL649 JL650

JL1201

R1781

JL1202

R1782

JL1203

JL1204 JL1205

JL1206

JL1207

JL1208

JL1209

R2150

R2151

R2152

JL1210

JL1211

R2155

JL1212

R2156

JL1213

R2157

R2158

R2159

R2160

R2178

R2180

R2184

FB505

R2185

FB508 FB510

FB1107

FB1109

R1205

FB1112

R517

FB1113

FB1115

FB1116

FB1117

FB1118

R1213

D691

R539

C501

C502

C503

R540

R1232

C507

C508

R1234

C517

C518

R558

JL500

JL501

JL502

JL503

JL504

JL505

JL506

JL507

R560

S501

JL508

JL509

R9918

FB2101

FB2103

JL510

JL511

JL514

JL515

R9922

JL516

JL517

R570

R2200

JL518

R571

JL519

C538

R574

JL520

R579

JL521

JL522

JL523

JL524

JL525

JL526

JL527

R580

JL528

R581

JL529

R582

JL530

JL531

JL532

JL533

JL534

JL535

JL536

JL537

JL538

JL539

R592

JL541

JL542

JL543

JL544

JL545

JL546

JL547

JL548

JL549

JL550

JL551

JL552

JL553

JL554

JL555

JL556

JL1107

JL557

JL1108

JL558

JL1109

JL559

C577 C578

JL1110

JL560

JL1111

JL561

JL1112

JL562

JL1113

JL563

JL564

C581

JL565

C582

JL566

JL567

JL568

IC504

JL569

IC505IC506

JL570

JL571

JL572

JL573

JL574

C591

JL1701

JL575

C592

JL576

JL578

JL579

JL580

JL1130

JL581

JL1131

JL582

JL1132

JL583

JL1133

JL584

JL1134

JL585

JL1135

JL586

JL1136

JL587

JL588

JL589

C1106

C1108

C1109

JL590

JL591

JL592

JL593

JL594

JL595

JL596

JL597

C1114

JL598

C1115

JL599

C1116

231

1

4

IC1701

C2110

CN1801

J1701

L1705

1

7

1

6

1

11

1

6

C2109

EB501

CN1201

CN1202

CN506

C526

C527

C528

C579C580

C583C584C593C594

CN1105

C1177

EB502

D692

IC693

S502

J691

12

CN012

SW011

CL015

CL016

CL010

CL011

CL012

CL013

CL014

1

5

21

CN010

CN011

SW010

MAIN BOARD (CONDUCTOR SIDE)

F

POWER BOARD

CN104

(CHASSIS)

1-877-065-

11, 12

(11, 12)

(CHASSIS)

D692

REMOTE

CONTROL

TRANSMITTER

IR REMOTE

IN

OPTICAL PICK-UP

BLOCK

(KHM-313CAB)

(2/2)

(NC)

(NC)

COAXIAL

MDMI PRIORITY

OPTICAL

OFF ONMULTI 2CH

DIGITAL OUT (CD)

OUT SW BOARD

1-877-109-

11

(11)

(DISC IN/OUT)

MOTOR BOARD

1-877-108-

11

(11)

(CHUCKING)

M001

(LOADING)

M

(US, CND)

1

3

2

A

B

C

D

E

F

G

12345678910

(Page 37)

Ref. No. Location

• Semiconductor

Location

D691 B-2

D692 B-1

IC504 D-4

IC505 D-3

IC506 D-3

IC693 B-2

IC1701 B-9

Page 24

SCD-XA5400ES

SCD-XA5400ES

2424

6-7. SCHEMATIC DIAGRAM - MAIN Section (1/4) -

5

(2/4)

BOARD

MAIN

6

(2/4)

BOARD

MAIN

3

(3/4)

BOARD

MAIN

1

(3/4)

BOARD

MAIN

2

(3/4)

BOARD

MAIN

8

(4/4)

BOARD

MAIN

4

(3/4)

BOARD

MAIN

1.422.105

1.4

2.9

2.9

1.7

9.2

9.2

4.6

0

1.4

1

0

3.2

3.2

3.2

3.2

3.2

3.2

9.2

4.5

4.4

4.5

4.5

4.9

3.5

4.5

4.5

3.3

5.8

4.8

1.4

1.4

1.4

1.4

1.4

3.2

3.2

2.2

1.4

1.4

1.4

1.4

0.01

C1212

100kR1223

33k

R1208

220p

C1205

56k

R1221

15k

R1231

27k

R1219

16V

10

C1218

1.2k

R1204

0.033

C1211

0.01

C1203

1000p

C1226

12k

R1216

0.01

C1219

15k

R1214

56k

R1226

0.01

C1213

0.01

C1210

1k

R1237

4700p

C1233

16V

10

C1220

33k

R1209

10kR1205

10k

R1206

18k

R1232

1000p

C1225

82k

R1230

100kR1225

0.033

C1209

0.1

C1223

1k

R1236

10k

R1224

0.01

C1208

1k

R1247

47k

R1210

10k

R1234

0.01

C1224

10k

R1212

6.8k

R1213

12k

R1215

4.7k

R1246

1k

R1220

220p

C1206

0.01

C1215

1000p

C1214

2.7k

R1207

JL1206

JL1205

JL1203

JL1204

JL1202

JL1201

1

2

3

4

5

6

7

8

9

10

11

12

13 14 15 16 17 18 19 20 21 22 23 24

25

26

27

28

29

30

31

32

33

34

35

36

373839404142434445464748

FIN

FIN

FIN

FIN

IC1201

FAN8036L

JL1207

JL1208

JL1209

JL1210

JL1211

JL1212

JL1213

CL1213

SPFG

TRO

VREFO

CKSW

FMO

D3.3V

TSD_M

OCSW

FWD

REV

DMO

OCSW1

5V

FCS-

D-GND

LIMITSW

FCS+

TRK+

MUTE123

FOO

TRK-

REG02

IOP

IOPMON

RF+3.3V

MUTE

REG01

M+9V

M-GND

0.1

C1222

CL1201

CL1202

CL1203

CL1204

CL1205

CL1206

CL1207

CL1208

CL1209

CL1210

CL1211

CL1212

0.1

C1221

33k

R1233

1k

R1239

1k

R1238

47

R1243

1

3

4

5

6

7

7P

CN1201

SP-

SP+

2NC

LIMIT

(GND)LMIT

SL-

SL+

16V

47

C1217

R1254

10k

1

3

4

5

6

6P

CN1202

LDM+

LDM-

2

NC

GND

CKSW

OCSW

12k

R1229

FCS-

FCS+

TRK+

TRK-

FCS+

TRK+

TRK-

SL+

SP-

SP+

SL-

FCS-

SP-

SP+

SL-

SL+

IC1201

FOCUS/TRACKING COIL DRIVE

SPINDLE/SLED/LOADING MOTOR DRIVE

(1/4)

MAIN BOARD

PICK-UP

BLOCK

(KHM-313CAB)

(1/2)

OPTICAL

1

2

3

4

5

LDM+

LDM-

GND

CKSW

OCSW

5P

CN010

SW010

(CHUCKING)

CL010

CL011

CL012

CL013

CL014

1

2

GND

OCSW

2P

CN011

MOTOR BOARD

M001

(LOADING)

M

SW011

(DISC IN/OUT)

CL015

CL016

12OSCW

GND

2P

CN012

OUT-SW BOARD

4

B

6911

D

H

1035 12

C

F

1

E

8

G

14

A

2 13

I

7

(Page 26)

(Page 25)

(Page 25)

(Page 27)

(Page 26)

(Page 26)

(Page 26)

Page 25

SCD-XA5400ES

SCD-XA5400ES

2525

6-8. SCHEMATIC DIAGRAM - MAIN Section (2/4) -

• See page 38 for waveforms. • See page 38 for IC Block Diagrams. • See page 41 for IC Pin Function Description.

BOARD

F

POWER

CN104

BOARD

12

MAIN

(3/4)

BOARD

11

MAIN

(4/4)

BOARD

10

MAIN

(4/4)

BOARD

6

MAIN

(1/4)

BOARD

7

MAIN

(3/4)

BOARD

9

MAIN

(4/4)

CN803

DISPLAY

G

BOARD

BOARD

CN152

B

AUDIO

(1/2)

BOARD

5

MAIN

(1/4)

IC B/D

IC B/D

IC B/D

IC B/D

IC B/D

1

0

1.8

000

0

1.7

1.6

3.2

3.2

0

3

2.8

0

2.6

0

3.3

3.2

0

0

3.2

3.3

3.2

3.3 (2.7)

3.3 (2.7)

0

3.3

0

0

3.2

3.2

3.2 (0)

3.2

3.3

0.2

3.2

3.2

3

3.2

3.3 (0)

3.200

0

0.4 (∗)

0.1

3.3

2.2

3.2 (2.8)

3.2 (2.8)

3.3 (3)

3.2 (3)

3.2

3.1

3.3 (0)

0

0

3.3 (0)

0 (3.3)

0

3.6

0

3.2

3.2

3.2

0.9

3.343.2

0

5

5.9

3.2

0

9

10.1

3.2

1

2

3

4

5

6

7

8

9

9P

CN504

D-GND

RESET

CNVSS

RXD1

CLK1 (NC)

E3.3V

RTS1

TXD1

D-GND

VCC

OUT

GND

NJL23H400A

IC693

123

CEC_RX_IN

JL501

JL577

10k

R512

JL500

JL584

R506 10k

100

R650

JL583

0.1

C507

JL539

1.5k

R598

5

43

2

1

PST3635NR

IC503

OUT

VDD

GND NC

CD

12k

R584

CL519

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

19P

CN502

LED_LAT

LED_PLAY

LED_PAUSE

LED_HDMI

NC

EN_A

NC

EN_B

D-GND

KEY2

E+4V

KEY1

SIRCS

KEY0

D-GND(FL)

P_CONT1

FL_CS

FL_DATA

FL_CLK

R586

1k

R581 100

R521 10k

JL560

JL515

47k

R557

5V

FWD

JL533

R518 10k

JL624

CL512

JL547

10k

R587

SID307BRTP19

D692

0.22

C522

E

EB501

D-GND

JL618

JL629

JL649

0.01

C581

OCSW

JL520

JL601

JL588

0.22

C520

R590

1k

JL642

JL561

100

R697

JL528

0.1

C501

JL503

IFSDI

JL585

10k

R583

E

EB503

JL551

JL617

0.1C582

1M

R538

R504 10k

JL509

CL511

CL513

FB508

1k

R513

JL646

JL589

JL575

JL510

10k

R514

R566 100

6.8k

R589

R532 1k

100k

R695

R522

10k

R544

10k

10k

R516

JL565

JL628

6.3V

1000

C528

0.1

C515

CL508

JL546

R508

0

0.1

C502

JL596

JL582

JL598

R542

10k

JL650

R565 100

R564

100

JL530

10k

R596

JL611

XIFBSY

JL522

JL543

JL621

JL606

JL615

JL517

JL586

JL597

CL505

JL554

JL552

M+9V

CL500

JL506

IFSCK

123465

SI-3010KM-TLS

IC504

VCONT

VIN

GND

VOUT

SENSE

JL562

10k

R694

R546

10k

R540 10k

0.1

C508

R531

10k

R592

0

47k

R562

47k

R570

33k

R588

JL525

JL544

MA2J1110GLS0

D693

JL527

JL564

JL559

E

EB502

1

3

4

5

6

7

8

9

10

11

11P

CN506

M-GND

M10V

2

NC

D_GND

D_GND

D6V

D4V

D4V

P_CONT0

E4V

P_CONT1

R603

0

68k

R585

JL537

E3.3V

JL620

REV

JL605

S502

10V

100

C583

C527

2200

6.3V

0.1

C503

JL592

R559 10k

JL599

JL505

M-GND

JL595

JL600

CL516

100k

R561

CL514

10k

R527

JL538

JL531

JL581

10k

R563

FB505

STT_M/2

JL602

JL578

8765

4321

TC7W53FK(TE85R)

IC692

COM

INH

VEE

GND A

CH1

CH0

VCC

JL534

JL609

JL536

JL630

0.01

C592

JL627

R519 10k

JL558

JL535

XSYSRST

100R530

CL517

JL648

10k

R515

10

R692

JL576

50V

C693

2.2

JL574

JL502

CL518

JL521

JL556

22k

R597

MC2836

D502

R569 100

123465

SI-3010KM-TLS

IC506

VCONT

VIN

GND

VOUT

SENSE

R568 100

2SC3052EF-T1-LEF

RESET SWITCH

Q503

47k

R556

JL644

100

R579

JL563

CEC_TX_OUT

JL508

0

R536

JL616

JL550

CL502

10k

R691

100R526

0.1

C523

10V

100

C584

J691

JL607

JL542

JL573

1M

R501

123465

SI-3010KM-TLS

IC505

VCONT

VIN

GND

VOUT

SENSE

JL590

16V

100

C579

100k

R693

DMUTE

JL568

JL541

IFSDO

JL587

JL626

JL549

0.01

C577

100

R580

R604 0

JL647

0.1

C531

JL625

100R533

FB510

R599

1k

0.1

C692

100R551

JL514

JL569

10kR558

JL610

CKSW

10V100

C593

JL523

R567 100

MA2J1110GLS0

D501

JL545

0.1C510

JL567

JL507

JL548

JL579

D3.3V

JL518

JL519

CL507

JL623

JL580

CL501

CL503

JL532

+6V

STT_D/P

JL613

XIFCS

R545

10k

JL614

JL622

JL572

10k

R510

JL594

10V

100

C594

1

2

3

4

5

6

7

8

9

10

11

12

13

13P

CN501

DGND

XAMUTE

SA/CD

MU/ST

DAC_INIT

DAC_DATA

DAC_CLK

DAC_CS1

DAC_CS2

ASDMUTE

SDA

SCL

DGND

JL516

JL571

1000p

C538

JL526

JL645

JL529

0.1

C518

JL555

R601

100

0.01C578

JL557

10k

R517

JL570

JL553

MC2836

D505

10kR539

JL511

123456789101112131415161718192021222324252627282930

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

515253545556575859606162636465666768697071727374757677787980

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

IC501

R5F3640DDFAR