SONY 0108 Service Manual

Chapter 1

Routine maintenance and servicing

Air cleaner element renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Alternator drivebelt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Automatic transmission fluid level check . . . . . . . . . . . . . . . . . . . . .27

Automatic transmission selector mechanism check . . . . . . . . . . . .28

Battery check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Brake components check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Brake fluid renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Contact breaker points adjustment - models with contact

breaker distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Contact breaker points renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Coolant renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Crankcase emission control filter renewal . . . . . . . . . . . . . . . . . . . .35

Distributor lubrication - models with contact breaker distributor . .12

Driveshaft check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Engine oil and filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Exhaust manifold nut check - RS Turbo models . . . . . . . . . . . . . . . .9

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Fluid leak check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Fluid level checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Front brake disc pad check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Fuel filter renewal - fuel injection engines . . . . . . . . . . . . . . . . . . . .36

Hinge and lock check and lubrication . . . . . . . . . . . . . . . . . . . . . . .31

Idle speed and mixture adjustment . . . . . . . . . . . . . . . . . . . . . . . . .10

Ignition system components check . . . . . . . . . . . . . . . . . . . . . . . . .11

Ignition timing check - models with contact breaker distributor . . .14

Intensive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Manual transmission oil level check . . . . . . . . . . . . . . . . . . . . . . . . .26

Oil filler cap cleaning - OHV and HCS engines . . . . . . . . . . . . . . . . .7

Rear brake shoe lining check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Road test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Roadwheel check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Seat belt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Spark plug renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Spark plug renewal - RS Turbo models . . . . . . . . . . . . . . . . . . . . . .15

Suspension and steering check . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Timing belt renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Turbocharger-to-manifold nut check - RS Turbo models . . . . . . . .23

Tyre checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Valve clearance adjustment - OHV and HCS engines . . . . . . . . . . .21

1•1

Easy, suitable for

novice with little

experience

Fairly easy, suitable

for beginner with

some experience

Fairly difficult, suitable

for competent DIY

mechanic

Difficult, suitable for

experienced DIY

mechanic

Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

Contents

1

Engine

Oil filter type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C104

Valve clearances (cold):

OHV engines:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.22 mm (0.008 in)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.59 mm (0.023 in)

HCS engines:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.22 mm (0.008 in)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.32 mm (0.012 in)

Cooling system

Recommended antifreeze concentration . . . . . . . . . . . . . . . . . . . . . . . . 45% by volume

Fuel system

Idle speed:

Carburettor models:

All except Weber 2V TLDM carburettor . . . . . . . . . . . . . . . . . . . . . 750 to 850 rpm

Weber 2V TLDM carburettor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 700 to 800 rpm

Bosch K-Jetronic fuel injection models . . . . . . . . . . . . . . . . . . . . . . . 750 to 850 rpm

Bosch KE-Jetronic fuel injection models:

1985 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800 to 900 rpm

1986 models onwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 920 to 960 rpm

Electronic Fuel Injection (EFI) models . . . . . . . . . . . . . . . . . . . . . . . . . 900 ± 50 rpm

Idle mixture CO content:

Bosch K-Jetronic fuel injection models . . . . . . . . . . . . . . . . . . . . . . . 1.0 to 1.5 %

Bosch KE-Jetronic fuel injection models:

1985 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 to 0.75%

1986 models onwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 to 1.1%

Electronic Fuel Injection (EFI) models . . . . . . . . . . . . . . . . . . . . . . . . . 0.8 ± 0.25% (cooling fan running)

Air filter element type:

1.1 litre and 1.3 litre OHV engines . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W153

1.1 litre and 1.3 litre HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W225

1.1 litre and 1.3 litre CVH engines . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W127

1.4 litre CVH engine:

Carburettor engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W179

Central Fuel Injection (CFI) engines . . . . . . . . . . . . . . . . . . . . . . . . Champion W201

1.6 litre CVH engine (except XR3 models):

Up to 1986 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W169

1986 to October 1988 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W201

October 1988 on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W226

1.6 litre CVH engine (XR3 models) . . . . . . . . . . . . . . . . . . . . . . . . . Champion W201

Ignition system

Contact breaker points gap:

Bosch distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.40 to 0.50 mm (0.016 to 0.02 in)

Lucas distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.40 to 0.59 mm (0.016 to 0.023 in)

Dwell angle (contact breaker ignition system) . . . . . . . . . . . . . . . . . . . . 48º to 52º

Ignition timing *:

OHV engines:

Up to 1984 (contact breaker) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12º BTDC at idle speed

1984-on (contact breaker) and all electronic ignition . . . . . . . . . . . . . 6º BTDC at idle speed

CVH engines (all models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12º BTDC at idle speed

* Note:

Ignition timing on models with either a Distributorless Ignition Sytem (DIS) or a programmed ignition system (ESC) cannot be adjusted.

Refer to Chapter 5, Part B for further information.

Spark plugs:

Type:

OHV and HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion RS9YCC or RS9YC

CVH engines:

Carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion RC7YCC or RC7YC

Bosch K-Jetronic fuel injection and

Electronic Fuel Injection (EFI) models . . . . . . . . . . . . . . . . . . . . . . . Champion C6YCC or RC6YC

Bosch KE-Jetronic fuel injection models . . . . . . . . . . . . . . . . . . . . Champion C61YC

Central Fuel Injection (CFI) models . . . . . . . . . . . . . . . . . . . . . . . . . Champion RC7YCC or RC7YC4

Electrode gap:

All except HCS and CFI models:

RS9YCC, RC7YCC, C6YCC spark plugs . . . . . . . . . . . . . . . . . . . . 0.8 mm (0.032 in)

RS9YC, RC7YC, RC6YC, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.7 mm (0.028 in)

HCS and CFI models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 mm (0.039 in)

1•2 Servicing Specifications

Servicing Specifications 1•3

1

Brakes

Minimum front brake disc pad thickness . . . . . . . . . . . . . . . . . . . . . . . . 1.5 mm (0.06 in)

Minimum rear brake shoe lining thickness . . . . . . . . . . . . . . . . . . . . . . . 1.0 mm (0.04 in)

Tyres

Tyre pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See “Weekly checks” on page 0•16

Torque wrench settings Nm lbf ft

Exhaust manifold nuts - RS Turbo models . . . . . . . . . . . . . . . . . . . . . . . 14 to 17 10 to 13

Turbocharger-to-manifold nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 to 26 15 to 19

Spark plugs:

OHV and HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 to 20 10 to 15

CVH engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 38 18 to 28

Seat belt anchor bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 to 41 21 to 30

Roadwheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 to 100 52 to 74

Capacities

Engine oil (drain and refill)

OHV engine:

With filter change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.25 litres (5.7 pints)

Without filter change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.75 litres (4.8 pints)

CVH engine:

Carburettor engines with filter change:

Pre-July 1982 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.75 litres (6.6 pints)

July 1982 onwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.50 litres (6.2 pints)

Carburettor engines without filter change:

Pre-July 1982 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.50 litres (6.2 pints)

July 1982 onwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.25 litres (5.7 pints)

Fuel-injected engines with filter change . . . . . . . . . . . . . . . . . . . . . . . 3.85 litres (6.8 pints)

Fuel-injected engines without filter change . . . . . . . . . . . . . . . . . . . . 3.60 litres (6.3 pints)

Fuel tank

All models (except XR3i and Van) pre-May 1983 . . . . . . . . . . . . . . . . . . 40 litres (8.8 gallons)

All other models (except Van) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 litres (10.6 gallons)

Van . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 litres (11.0 gallons)

Cooling system

1.1 litre OHV engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7 litres (11.8 pints)

1.1 litre CVH engine:

With small radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.2 litres (11.0 pints)

With large radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.2 litres (12.6 pints)

1.3 litre OHV engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.1 litres (12.5 pints)

1.3 litre CVH engine:

Pre-1986 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.1 litres (12.5 pints)

1986 onwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.6 litres (13.3 pints)

1.4 litre CVH engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.6 litres (13.3 pints)

1.6 litre CVH engine:

Pre-1986 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.9 litres (12.1 pints)

1986 onwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.8 litres (13.7 pints)

Transmission

4-speed manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.8 litres (4.9 pints)

5-speed manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1 litres (5.5 pints)

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.9 litres (13.9 pints)

The maintenance intervals in this manual are provided with the

assumption that you, not the dealer, will be carrying out the work. These

are the minimum maintenance intervals recommended by the

manufacturer for vehicles driven daily. If you wish to keep your vehicle

in peak condition at all times, you may wish to perform some of these

procedures more often. We encourage frequent maintenance, because

it enhances the efficiency, performance and resale value of your vehicle.

If the vehicle is driven in dusty areas, used to tow a trailer, or driven

frequently at slow speeds (idling in traffic) or on short journeys, more

frequent maintenance intervals are recommended.

When the vehicle is new, it should be serviced by a factoryauthorised dealer service department, in order to preserve the factory

warranty.

Ford Escort maintenance schedule

1•4 Maintenance schedule

Every 6000 miles (10 000 km) or

6 months – whichever comes first

In addition to all the items in the 250 mile (400 km) service, carry

out the following:

mm Renew the engine oil and filter (Section 6)

mm On OHV and HCS engines, remove and clean the oil

filler cap (Section 7)

mm Check the hoses, hose clips and visible joint gaskets for

leaks and any signs of corrosion or deterioration (Section 8)

mm Visually check the fuel pipes and hoses for security,

chafing, leaks and corrosion (Section 8)

mm Check the fuel tank for leaks and any sign of damage or

corrosion (Section 8)

mm On RS Turbo models check the tightness of the

exhaust manifold retaining nuts (Section 9)

mm Check and if necessary adjust the idle speed and

mixture settings (Section 10)

mm Clean the distributor cap, coil tower and HT leads and

check for tracking (Section 11)

mm On contact breaker point distributors lubricate the

distributor shaft and cam (Section 12)

mm On contact breaker point distributors check and if

necessary adjust the points gap (dwell angle), then

check the ignition timing (Sections 13 and 14)

mm On RS Turbo models renew the spark plugs (Section 15)

mm Check the front disc pad thickness (Section 16)

mm Check the rear brake shoe lining thickness (Section 17)

mm Check the steering and suspension components for

any signs of damage and wear (Section 18)

mm Check the security of the front suspension lower arm

balljoint (Section 18)

mm Check the seat belt webbing for cuts or damage and

check the seat belt operation (Section 19)

mm Carefully inspect the paintwork for damage and the

bodywork for corrosion (Chapter 11)

mm Check the condition and adjustment of the alternator

drivebelt (Section 20)

Every 12 000 miles (20 000 km) or

12 months - whichever comes first

In addition to all the items in the 6000 mile (10 000 km) service,

carry out the following:

mm On OHV and HCS engines check and if necessary

adjust the valve clearances (Section 21)

mm Check the exhaust system condition and security

(Section 22)

mm On RS Turbo models check the tightness of the

turbocharger-to-manifold nuts (Section 23)

mm Renew the spark plugs (Sections 24 and 15)

mm On contact breaker point distributors renew the contact

breaker points (Section 25)

mm Check and if necessary top-up the manual transmission

oil (Section 26)

mm Check the automatic transmission fluid level - where

applicable (Section 27)

mm Check the operation of the automatic transmission

selector mechanism (Section 28)

mm Check the driveshafts for damage or distortion and

check the condition of the constant velocity joint

bellows (Section 29)

mm Inspect the roadwheels for damage (Section 30)

mm Check the tightness of the roadwheel bolts (Section 30)

mm Lubricate all hinges, door locks, check straps and the

bonnet release mechanism (Section 31)

mm Check the operation of all door, tailgate, bonnet release

and window regulator components (Section 31)

mm Carry out a road test (Section 32)

Every 36 000 miles (60 000 km) or

3 years - whichever comes first

In addition to all the items listed in the previous services, carry out

the following:

mm On CVH engines renew the timing belt (Section 37)

mm Make a thorough inspection of all brake components

and rubber seals for signs of leaks, general

deterioration and wear (Section 38)

mm Renew the brake fluid (Section 39)

Every 24 000 miles (40 000 km) or

2 years - whichever comes first

In addition to all the items in the 12 000 mile (20 000 km) and

6000 mile (10 000 km) services, carry out the following:

mm Renew the coolant (Section 33)

mm Renew the air cleaner element (Section 34)

mm On CVH engines renew the crankcase emission control

filter (Section 35)

mm On fuel-injected engines renew the fuel filter (Section 36)

Every 250 miles (400 km) or weekly

mm See "Weekly checks"

Maintenance - Component location 1•5

1

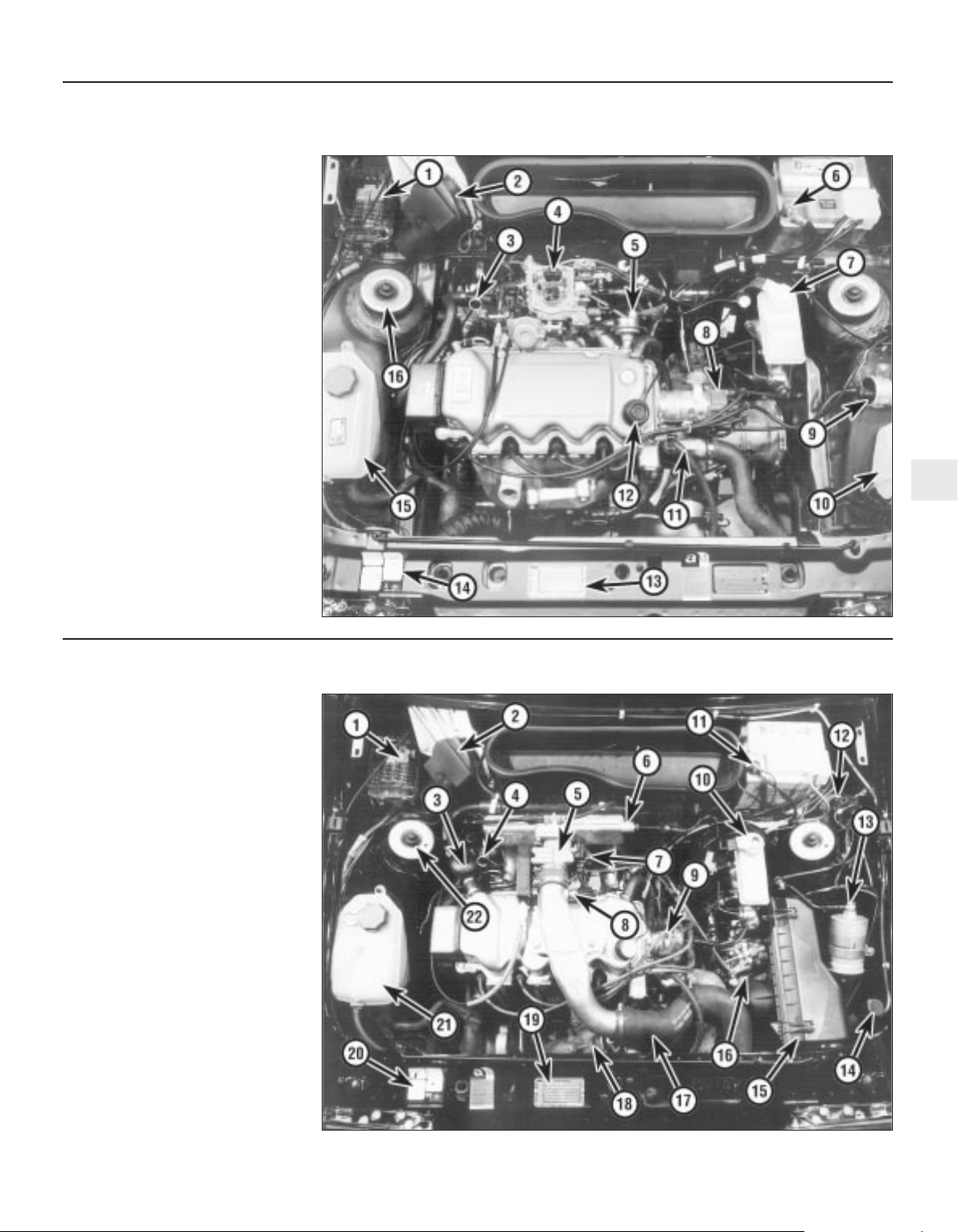

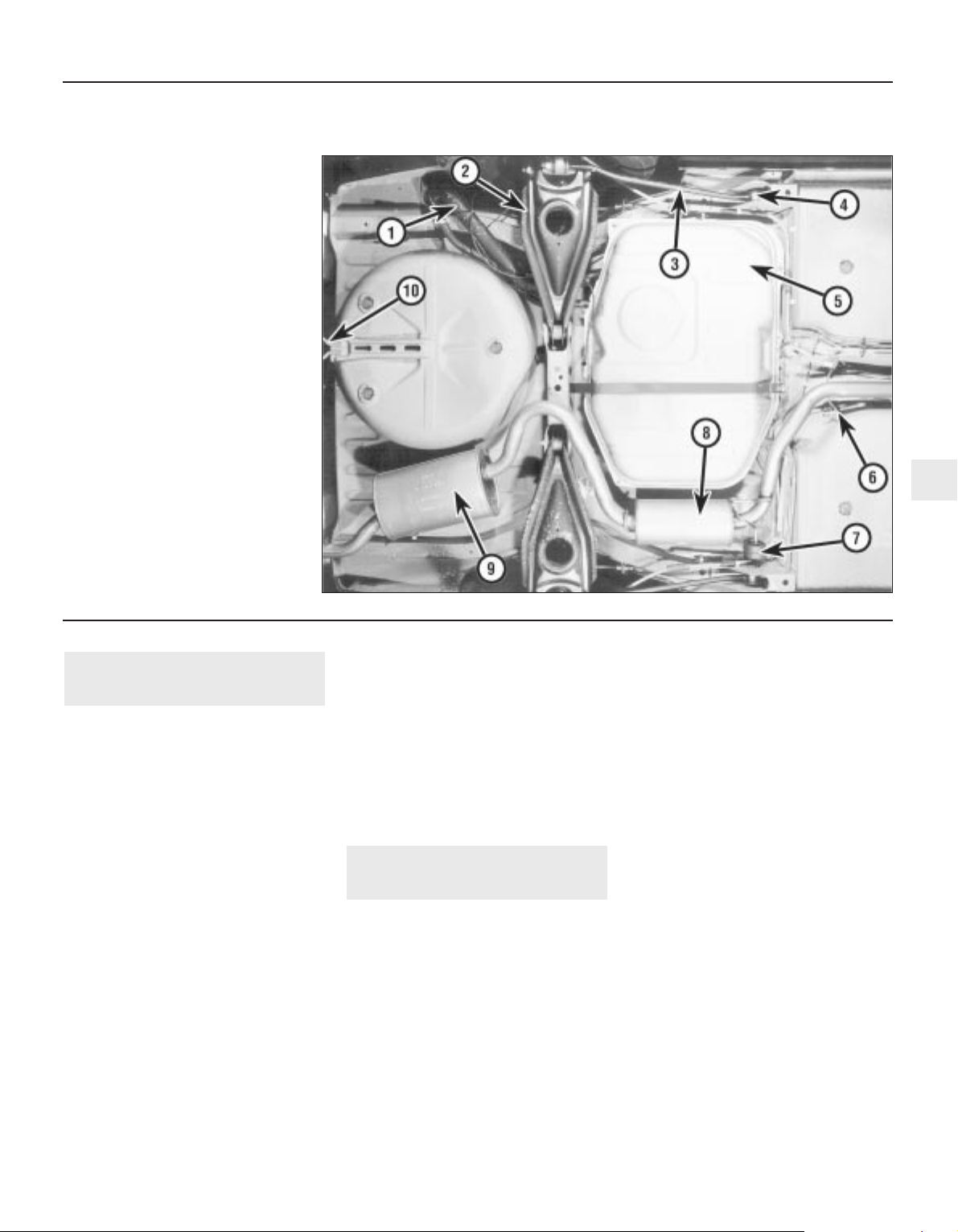

1 Fuse and relay box

2 Windscreen wiper motor

3 Engine oil dipstick

4 Carburettor

5 Fuel pump

6 Battery negative terminal

7 Brake master cylinder reservoir

8 Distributor

9 Ignition coil

10 Washer reservoir

11 Thermostat housing

12 Oil filler cap

13 Vehicle identification plate

14 Engine tuning decal

15 Cooling system expansion tank

16 Suspension strut top mounting

Engine and under bonnet component location on 1986 1.4 litre models (air cleaner removed for clarity)

1 Fuse and relay box

2 Windscreen wiper motor

3 Crankcase emission control filter

4 Engine oil dipstick

5 Throttle housing

6 Inlet manifold

7 Throttle position sensor

8 Charge air temperature sensor

9 Distributor

10 Brake master cylinder reservoir

11 Battery negative terminal

12 Ignition coil

13 Fuel filter

14 Washer reservoir

15 Air cleaner

16 Fuel distributor

17 Inlet air hose

18 Turbocharger

19 Vehicle identification plate

20 Engine tuning decal

21 Cooling system expansion tank

22 Suspension strut top mounting

Engine and under bonnet component locations on 1986 RS Turbo models

1•6 Maintenance - Component location

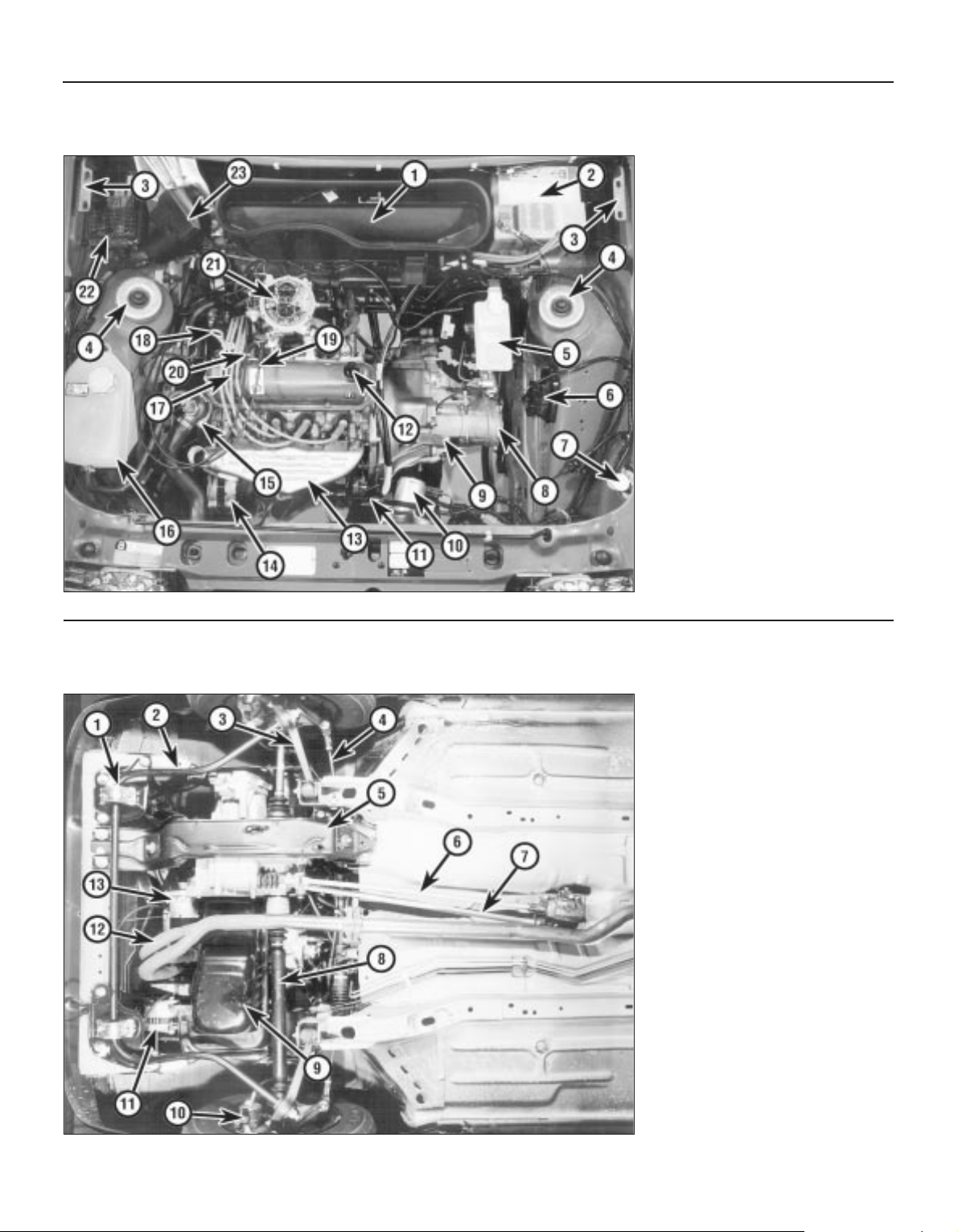

1 Ventilation air inlet duct

2 Battery

3 Bonnet hinge

4 Suspension strut upper mounting

5 Brake system fluid reservoir

6 Ignition system ESC module

7 Windscreen washer reservoir filler cap

8 Transmission housing

9 Clutch release lever

10 Cooling fan motor

11 Starter motor

12 Engine oil filler neck (cap removed)

13 Exhaust manifold shield

14 Alternator

15 Coolant thermostat and fan thermal

switch

16 Coolant expansion tank

17 Spark plug HT leads

18 Engine oil dipstick

19 Throttle cable

20 Choke cable

21 Carburettor

22 Fusebox

23 Windscreen wiper motor

Engine and underbonnet components location on 1989 1.3 litre HCS model (air cleaner removed for clarity)

1 Anti-roll bar clamp

2 Anti-roll bar

3 Front suspension lower arm

4 Steering tie-rod

5 Transmission support crossmember

6 Gearchange rod

7 Gearchange stabiliser

8 Driveshaft

9 Engine oil drain plug

10 Brake caliper

11 Alternator

12 Exhaust front pipe

13 Starter motor

Front underbody view of a 1986 1.4 litre Saloon model

Maintenance procedures 1•7

1

General information

This Chapter is designed to help the home

mechanic maintain his/her vehicle for safety,

economy, long life and peak performance.

The Chapter contains a master

maintenance schedule, followed by Sections

dealing specifically with each task on the

schedule. Visual checks, adjustments,

component renewal and other helpful items

are included. Refer to the accompanying

illustrations of the engine compartment and

the underside of the vehicle for the locations

of the various components.

Servicing of your vehicle in accordance with

the mileage/time maintenance schedule and

the following Sections will provide a planned

maintenance program, which should result in

a long and reliable service life. This is a

comprehensive plan, so maintaining some

items but not others at the specified service

intervals will not produce the same results.

As you service your vehicle, you will

discover that many of the procedures can and should - be grouped together because of

the particular procedure being performed, or

because of the close proximity of two

otherwise unrelated components to one

another. For example, if the vehicle is raised

for any reason, the exhaust can be inspected

at the same time as the suspension and

steering components.

The first step in this maintenance program

is to prepare yourself before the actual work

begins. Read through all the Sections relevant

to the work to be carried out, then make a list

and gather together all the parts and tools

required. If a problem is encountered, seek

advice from a parts specialist, or a dealer

service department.

If, from the time the vehicle is new, the

routine maintenance schedule is followed

closely and frequent checks are made of fluid

levels and high wear items, as suggested

throughout this manual, the engine will be

kept in relatively good running condition and

the need for additional work will be minimised.

It is possible that there will be times when

the engine is running poorly due to the lack of

regular maintenance. This is even more likely

if a used vehicle, which has not received

regular and frequent maintenance checks, is

purchased. In such cases, additional work

may need to be carried out, outside of the

regular maintenance intervals.

If engine wear is suspected, a compression

test will provide valuable information

regarding the overall performance of the main

internal components. Such a test can be used

as a basis to decide on the extent of the work

to be carried out. If for example a

compression test indicates serious internal

engine wear, conventional maintenance as

described in this Chapter will not greatly

improve the performance of the engine, and

may prove a waste of time and money, unless

extensive overhaul work is carried out first.

The following series of operations are those

most often required to improve the

performance of a generally poor-running

engine.

a) Clean, inspect and test the battery

(Section 5).

b) Check the levels of all the engine related

fluids (Section 3).

c) Check the condition and tension of the

alternator drivebelt (Section 20).

d) Check the condition of the spark plugs

and renew if necessary (Section 15).

e) Check the condition of the air cleaner

element, and renew if necessary (Section 34).

f) Check the condition of all hoses and

check for fluid leaks.

g) Check and if necessary adjust the idle

speed (where possible) (Section 10).

2 Intensive maintenance

1 Introduction

1 Fuel filler pipe

2 Suspension lower arm

3 Tie-bar

4 Tie-bar front mounting

5 Fuel tank

6 Handbrake cable adjuster

7 Exhaust mounting

8 Exhaust intermediate silencer

9 Exhaust rear silencer

10 Rear towing eye

Rear underbody view of a 1986 1.4 litre Saloon model

1 Frequent oil and filter changes are the most

important preventative maintenance

procedures that can be undertaken by the DIY

owner. As engine oil ages, it becomes diluted

and contaminated, which leads to premature

engine wear.

2 Before starting this procedure, gather

together all the necessary tools and materials.

Also make sure that you have plenty of clean

rags and newspapers handy to mop up any

spills. Ideally, the engine oil should be warm,

as it will drain better and more built-up sludge

will be removed with it. Take care, however,

not to touch the exhaust or any other hot

parts of the engine when working under the

vehicle. To avoid any possibility of scalding,

and to protect yourself from possible skin

irritants and other harmful contaminants in

used engine oils, it is advisable to wear rubber

gloves when carrying out this work. Access to

the underside of the vehicle will be greatly

improved if it can be raised on a lift, driven

onto ramps or jacked up and supported on

axle stands (see “Jacking and Vehicle

Support”). Whichever method is chosen,

make sure that the vehicle remains as level as

possible, to enable the oil to drain fully.

3 Remove the oil filler cap from the rocker cover,

then position a container beneath the sump.

4 Clean the drain plug and the area around it,

then slacken it using a suitable socket or

spanner (see illustration). If possible, try to

keep the plug pressed into the sump while

unscrewing it by hand the last couple of turns.

As the plug releases from the threads, move it

away sharply so the stream of oil issuing from

the sump runs into the container, not up your

sleeve!

5 Allow some time for the old oil to drain,

noting that it may be necessary to reposition

the container as the oil flow slows to a trickle.

6 After all the oil has drained, wipe off the

drain plug with a clean rag and check the

condition of the sealing washer. Renew the

washer if necessary. Clean the area around

the drain plug opening, then refit and tighten

the plug to the specified torque setting.

7 Move the container into position under the

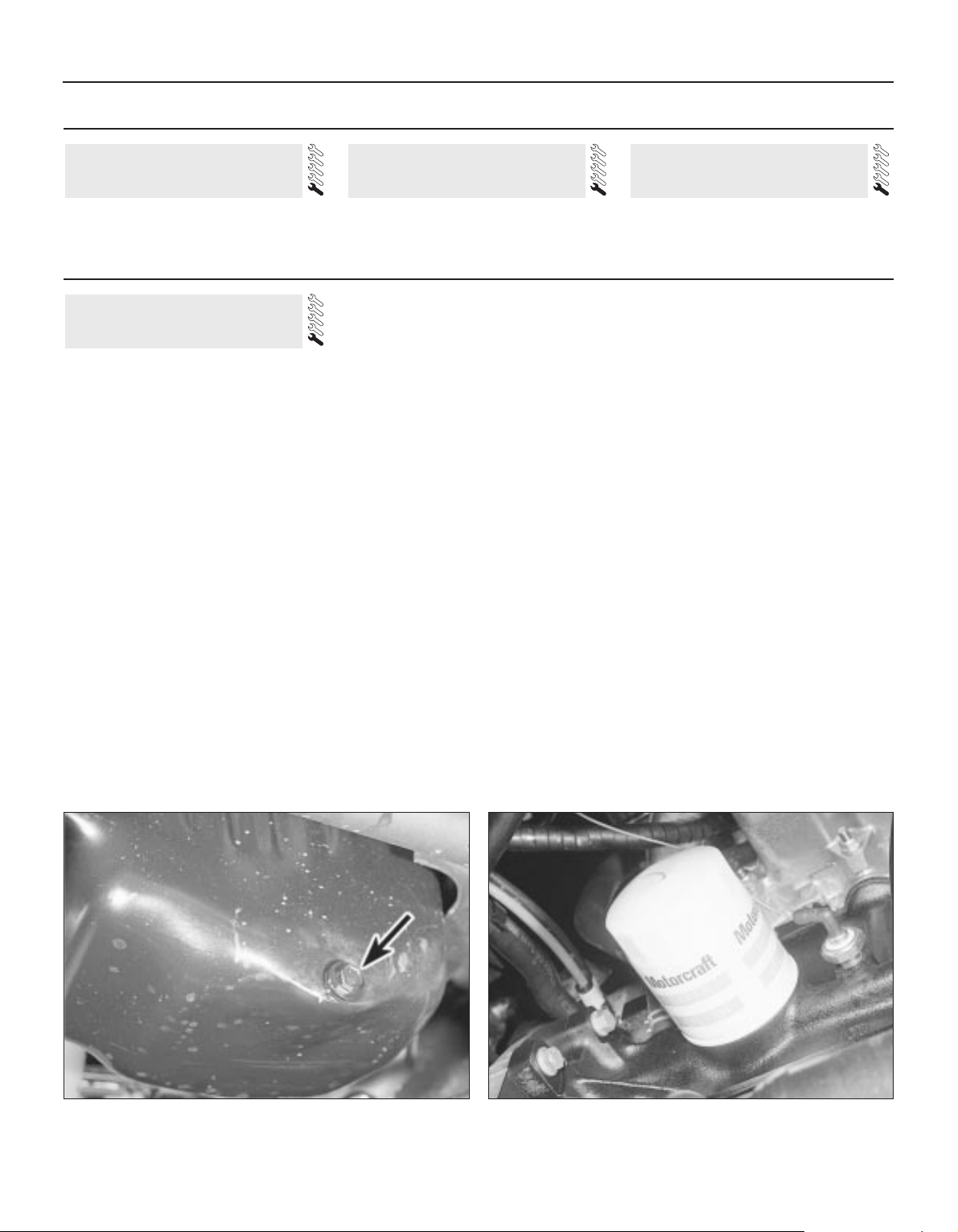

oil filter. The oil filter is located at the rear of

the cylinder block, and is accessible from

under the vehicle (see illustration)

8 Using an oil filter removal tool, slacken the

filter initially. Loosely wrap some rags around

the oil filter, then unscrew it and immediately

position it with its open end uppermost to

prevent further spillage of oil. Remove the oil

filter from the engine compartment and empty

the oil into the container.

9 Use a clean rag to remove all oil, dirt and

sludge from the filter sealing area on the

engine. Check the old filter to make sure that

the rubber sealing ring hasn’t stuck to the

engine. If it has, carefully remove it.

10 Apply a light coating of clean oil to the

sealing ring on the new filter, then screw it into

position on the engine. Tighten the filter firmly

by hand only - do not use any tools. Wipe

clean the exterior of the oil filter.

11 Remove the old oil and all tools from

under the vehicle, then (if applicable) lower the

vehicle to the ground.

12 Fill the engine with the specified quantity

and grade of oil, as described in “Weekly

checks”. Pour the oil in slowly, otherwise it

may overflow from the top of the rocker cover.

Check that the oil level is up to the correct

level on the dipstick, then refit and tighten the

oil filler cap.

13 Run the engine for a few minutes, and

check that there are no leaks around the oil

filter seal and the sump drain plug.

14 Switch off the engine and wait a few

minutes for the oil to settle in the sump once

more. With the new oil circulated and the filter

now completely full, recheck the level on the

dipstick and add more oil if necessary.

15 Dispose of the used engine oil safely with

reference to “General repair procedures” in

the Reference Sections at the end of this

manual.

6 Engine oil and filter renewal

Every 6000 miles or 6 months

1•8 Maintenance procedures

See “Weekly checks” starting on Page 0•10. See “Weekly checks” starting on Page 0•10. See “Weekly checks” starting on Page 0•10.

5 Battery check4 Tyre checks3 Fluid level checks

Weekly checks

6.7 Oil filter location - CVH engine6.4 Engine oil drain plug (arrowed) -

CVH engine

Loading...

Loading...