http://listado.mercadolibre.com.mx/_CustId_67027869

rodcasti@gmail.com

I

3

2002

IMPREZA SERVICE MANUAL

GENERAL INFOMATION

SECTION

This service manual has been prepared

to

provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

c-

.

for maintenance, disassembling, reassembling, inspection and adjustment of

components and diagnostics for guidance of experienced mechanics.

Please peruse and utilize this manual

fully

to

ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement

repair work is needed, be sure

SUBARU genuine parts.

of

parts during

to

QUICK REFERENCE INDEX

use

All information, illustration and specifications contained in this manual are

based on the latest product information

available at the time of publication

approval.

FUJI

HEAVY

INDUSTRIES LTD.

G1830BE1

I

FOREWORD

1

.

Foreword

....

.. . .

...

. . .. . . .. .... .

.

..

. . . ..

~~~~

...

.

...

. .

...

. . .. .

...

. . .. . . .. . . .

..

. .. . .

FWa

Page

..

. . .. . . . . . .. .

... ...

. .. . .. ...

.

.2

FOREWORD

FOREWORD

~

1.

Foreword

A:

FOREWORD

These manuals are used when performing mainte-

nance, repair or diagnosis of the Subaru IMPREZA.

2001

Applied model: GG***** and GD***** from

The additional manuals below are also available:

AUTOMATIC TRANSMISSION SERVICE MANUAL (Pub. No. G0853ZE)

The manuals contain the latest information at the

time

of

publication. Changes in the specifications,

methods, etc. may be made without notice.

MY.

FW-2

HOW

TO

USE

How

1.

THIS MANUALS

to

Use

This

Manuals

...........................................................................

HU

Paae

--

2

I

HOW TO USE THIS MANUALS

HOW

TO

USE

THIS

MANUALS

1.

How

A:

HOW

1.

STRUCTURE

Each section consists of SCT that are broken down

into

SC

ponent. The specification, maintenance and other

information for the components are included, and

the diagnosis information has also been added

where necessary.

2.

INDEX

The first page has an index with tabs. And at the

end of each section is an alphabetical index.

3.

COMPONENTS

For each component, a composition drawing is included.

4.

SPECIFICATIONS

to

Use

TO

that are divided into sections for each com-

This

Manuals

USE THIS MANUALS

ff

necessary, specifications are also included

5.

INSPECTION

Inspections are included to be carried out before

and after maintenance.

6.

MAINTENANCE

Maintenance instructions are provided for each

component. When multiple components comprise

one process, refer to the instructions for that process for each component.

7.

DIAGNOSIS

Tables showing a step-by-step process make it

easy to conduct diagnosis.

8.

SI

UNITS

Measurements in these manuals are according to

the

SI

units. Metric and yard/pound measurements

are also included.

H

U-2

SPECIFICATIONS

SPC

1

.

lmpreza

...

.

. .

. .

. .

. . . . . .

. . .

,

. . .

. .

. .

.

. .

.

.

. . . . , . . . .

. . .

,

. . .

. . . . . . . . .

. .

. .

,

.

. . . .

. . , .

. . . . . . . ..

. . . .

. .

.

. . ..

.

...

. . . . . . .

Page

.2

a

SPECIFICATIONS

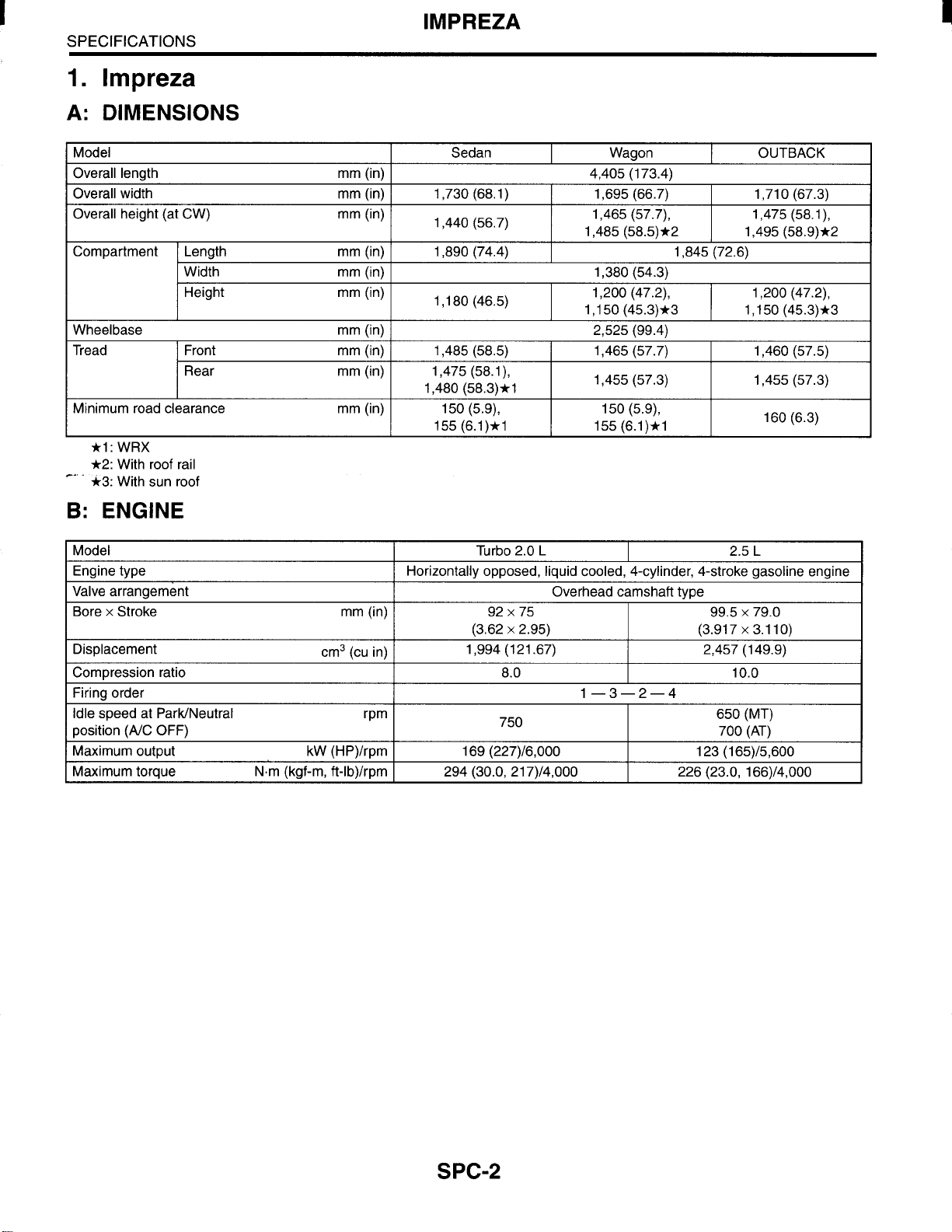

1.

lmpreza

A:

DIMENSIONS

IMPREZA

Model

Overall lennth mm (in)

Overall width mm (in)

Overall height (at CW)

Compartment Length mm (in)

Width mm (in)

I

Height

Tread

Minimum road clearance mm (in)

B:

ENGINE

Model

I

valve arranqement

Bore x Stroke mm (in)

Displacement cm3 (cu in)

ComDression ratio

I

Firinq order

Idle speed at Park/Neutral

I

position (NC OFF)

Maximum output

Maximum torque

I

Front mm (in)

Rear mm (in)

N.m (kgf-m, ft-lb)/rpm 294

mm (in)

mm

rpm

kW (HP)/rpm 169 (227)/6,000

(in)

\I

Sedan Waaon OUTBACK

I

1,730 (68.1) 1,695 (66.7) 1,710 (67.3)

1,440 (56.7)

1,890 (74.4) 1,845 (72.6)

I

1

,I

80 (46.5)

I

1.485 (58.5)

,\,

1,475 (58.1

1,480 (58.3)*1

150 (5.9), 150 (5.9),

155 (6.1)*1 155 (6.1)*1

),

Turbo 2.0

L

I

92

x

75

(3.62

x

2.95)

1,994 (121.67)

8.0

I

(30.0,

750

217)/4,000

I

4,405 (173.4)

1,465 (57.7), 1,475 (58.1),

1,485 (58.5)*2 1,495 (58.9)*2

1,380 (54.3)

1,200 (47.2), 1,200 (47.2),

I

1,150 (45.3)*3

1.465 (57.7) 1.460 (57.5)

.\,

1,455 (57.3) 1,455 (57.3)

Overhead camshaft tvDe

1-3-2-4

I

2.5

99.5

(3.91 7

2,457

10.0

650 (MT)

700 (AT)

123 (165)/5,600

226 (23.0, 166)/4,000

1,150 (45.3)*3

I\,

160 (6.3)

L

x

79.0

x

3.1

IO)

(1

49.9)

-1

1

SPC-2

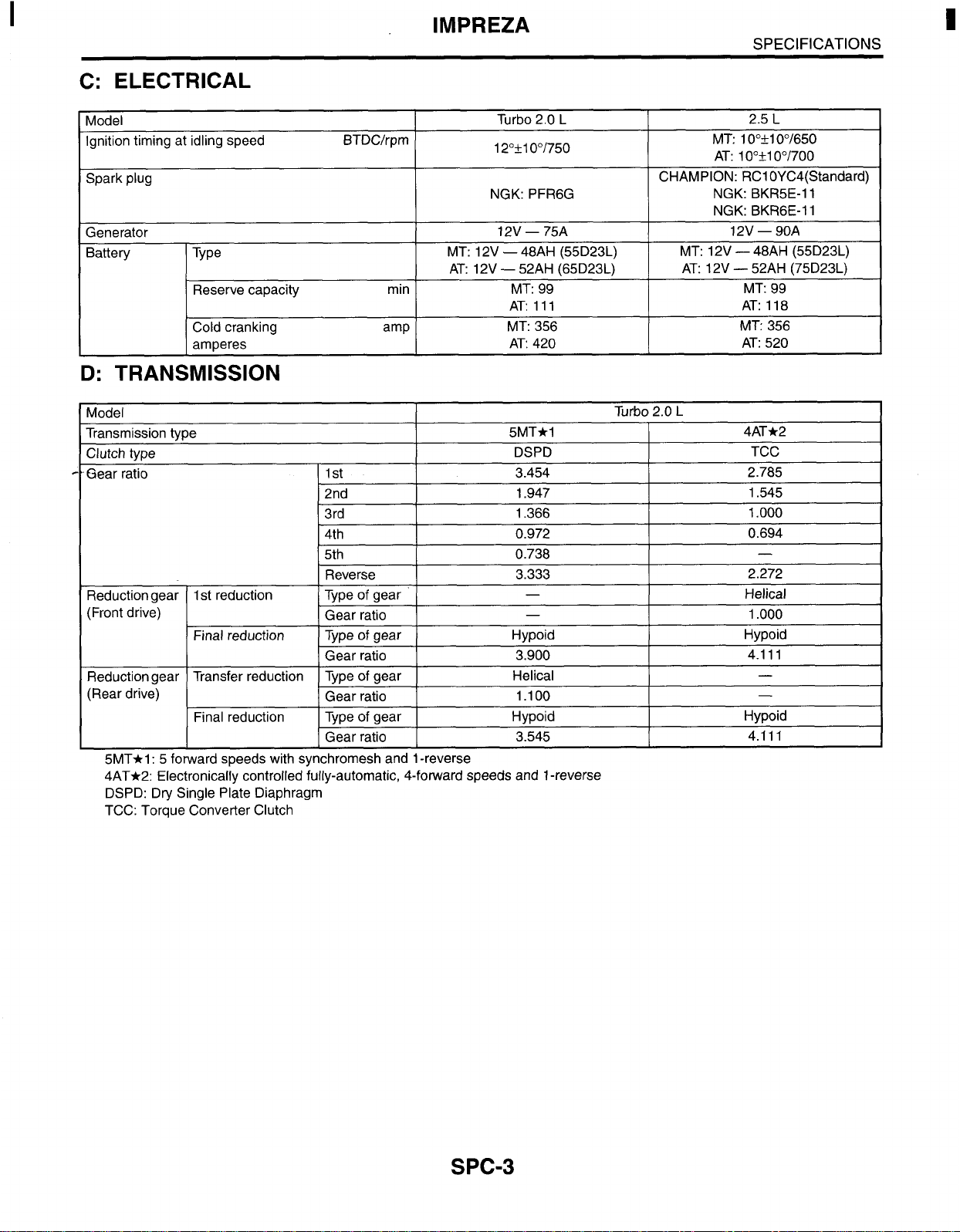

C:

ELECTRICAL

IMPREZA

I

SPECIFICATIONS

Model Turbo 2.0 L

Ignition timing at idling speed BTDC/rpm

Spark plug

Generator

Battery Type

Reserve capacity min

Cold cranking amp

amperes

rMm

Transmission type

Clutch type

-'

Gear ratio

I

I

I

'

Reduction gear

,

(Front drive) Gear ratio

I

Reduction gear

(Rear drive)

~

1

st

reduction Type

Final reduction Type

I I

Transfer reduction Type

Final reduction Type

I

1st 3.454 2.785

L

1

3rd

L

14th

5th 0.738

Reverse

of

of

Gear ratio

of

Gear ratio 1.100

of

Gear ratio 3.545 4.111

I

12"+10"/750

NGK: PFR6G NGK: BKR5E-11

-

12V

MT: 12V

AT: 12V

-

48AH (55D23L)

-

52AH (65D23L)

MT: 99 MT: 99

AT:

MT: 356 MT: 356

AT: 420 AT: 520

I

5MTSrl 4ATlr2

DSPD TCC

I

I

I

I

gear

gear Hypoid Hypoid

I

gear Helical

gear Hypoid Hypoid

1.366

0.972

3.333 2.272

-

-

3.900

75A

111

I

CHAMPION: RCI OYC4(Standard)

MT: 12V

AT: 12V

Turbo

2.0

L

I

I

I

2.5

MT: 1 O"k1 0°/650

AT: 1 O"k1 0"/700

NGK: BKR6E-11

12V

-

-

48AH (55D23L)

-

52AH (75D23L)

AT: 118

1

.ooo

0.694

-

Helical

1.000

I

4.1

11

-

-

L

90A

I

4

I

I

I

I

SPC-3

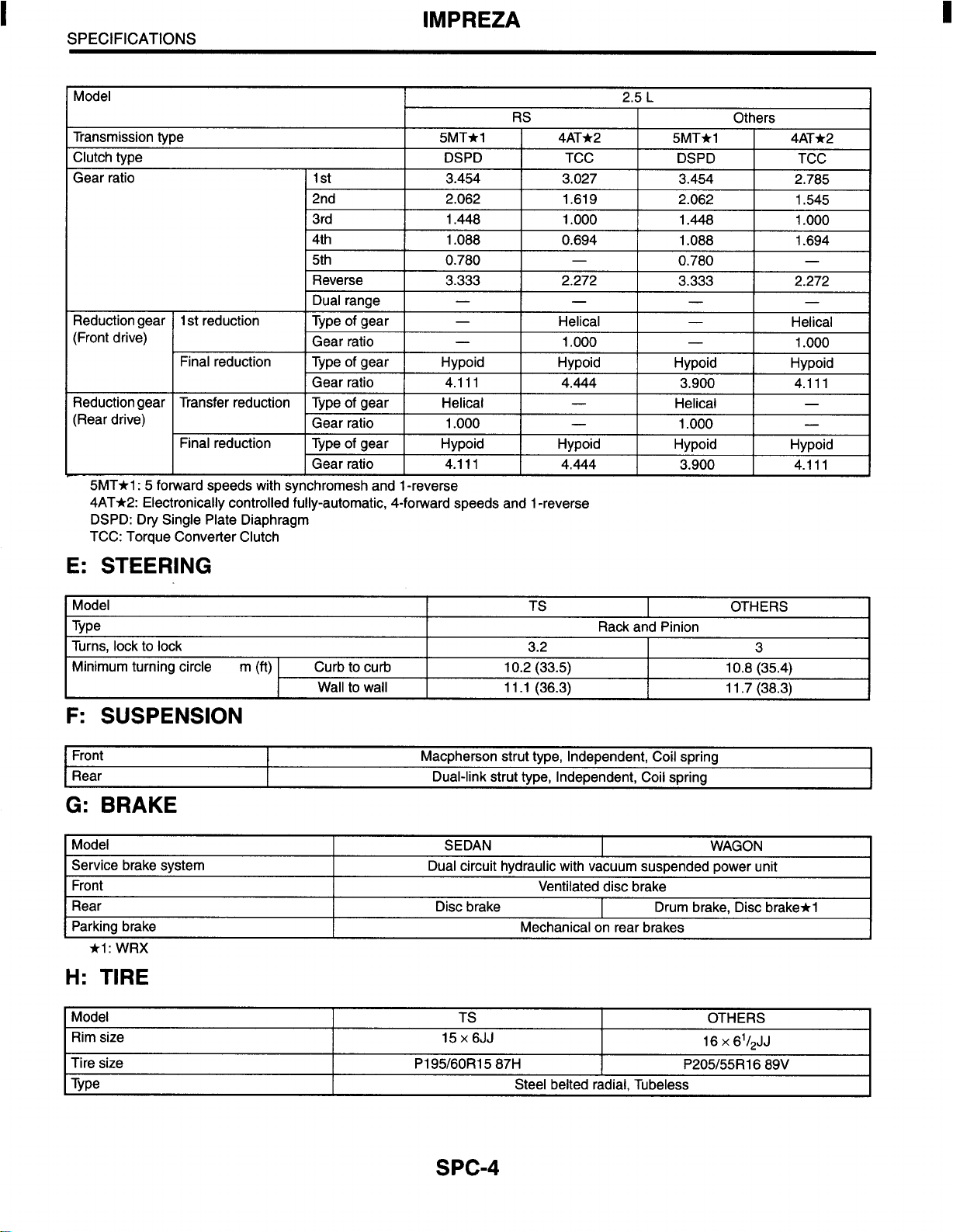

IM

PREZA

SPECIFICATIONS

Model

Transmission type

Clutch type

I

1st

2nd

3rd

4th

5th

I

Reverse

Dual range

1

st

reduction Reduction gear

(Front drive)

Final reduction

r

Reduction gear

(Rear drive)

r

I

5MTM : 5 forward speeds with synchromesh and I -reverse

4AT+2: Electronically controlled fully-automatic, 4-forward speeds and

DSPD: Dry Single Plate Diaphragm

TCC: Torque Converter Clutch

Transfer reduction

Final reduction

Type of gear

Gear ratio

Type of gear

Gear ratio

Type

of

gear

Gear ratio

Type of gear

Gear ratio

5MT*1 4ATlr2 5MTlrl 4AT*2

DSPD TCC DSPD TCC

I

3.454

2.062 1.619 2.062 1.545

1.448

1.088 0.694 1.088 1.694

0.780

I

3.333

- - - -

-

-

Hypoid Hypoid Hypoid

11

4.1

I

ical

He

1

.ooo

Hypoid Hypoid

11

4.1

RS

I

I

2.5

L

3.027

1

.ooo

-

2.272

Helical

1

.ooo

4.444 3.900

I

I

-

-

4.444 3.900

1

-reverse

Others

3.454

1.448

0.780

3.333

-

-

He I ical

1.000

Hypoid Hypoid

I

I

2.785

~~~

1

.ooo

-

2.272

Helical

1

.ooo

...

Hypoid

11

4.1

-

-

11

4.1

I

I

1

E: STEERING

Type

Turns, lock

Minimum turning circle m

Front

Rear

Model

Service brake system

Front

Rear

Parking brake

H:

to

TIRE

lock

(ft)

Curb

Wall

to

to

curb

wall

Rack and Pinion

3.2 3

10.2 (33.5)

11

.I

(36.3) 11.7 (38.3)

Macpherson strut type, Independent, Coil spring

Dual-link strut type, Independent, Coil spring

SEDAN WAGON

Dual circuit hydraulic with vacuum suspended power unit

Ventilated disc brake

Disc brake Drum brake, Disc brakelrl

Mechanical on rear brakes

I

10.8

(35.4)

Rim size

Tire size

Type

15 x 6JJ

PI 95/60R15 87H P205/55R16 89V

Steel belted radial, Tubeless

16

x

6’/2JJ

SPC-4

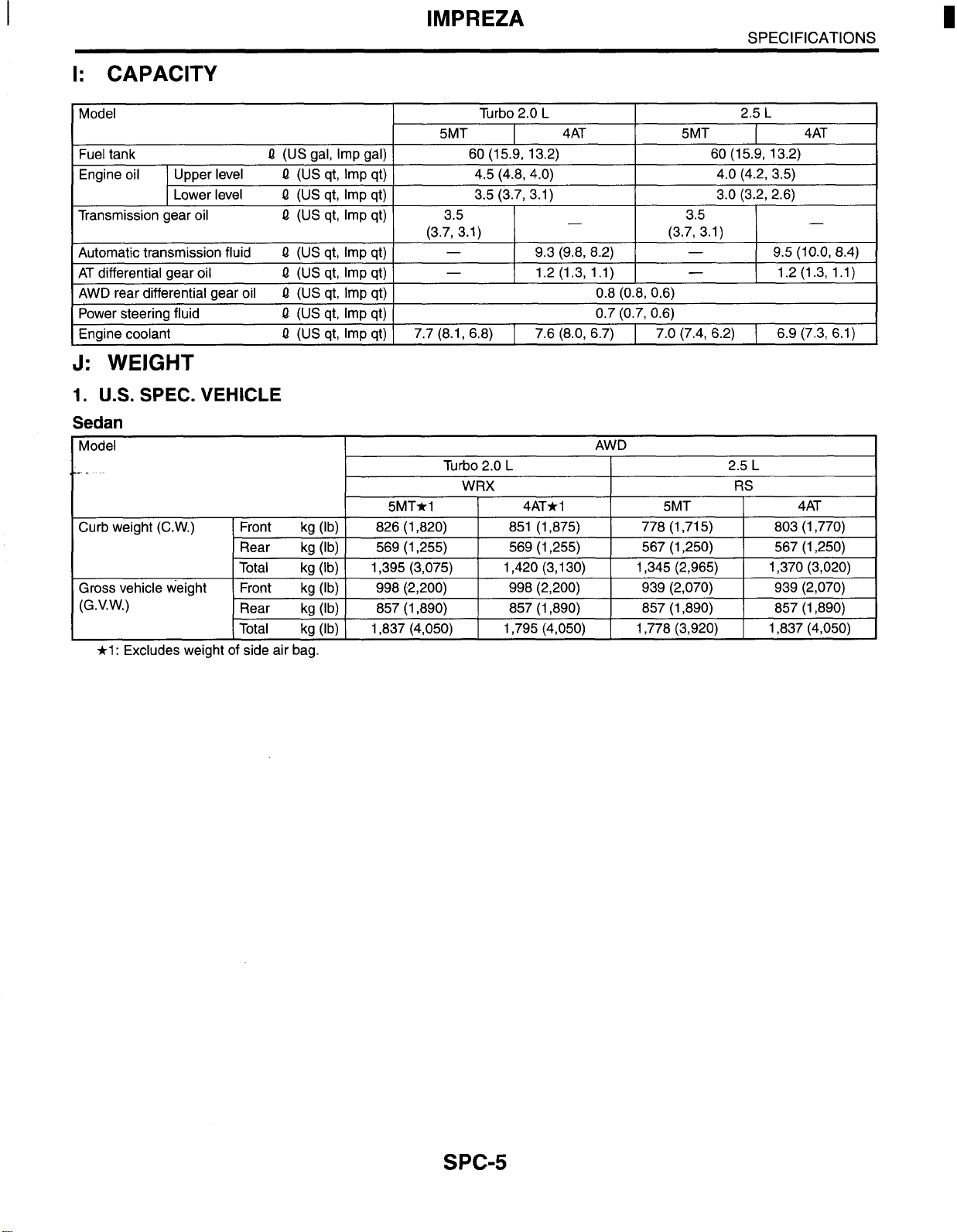

I:

CAPACITY

IMPREZA

SPECIFICATIONS

Fuel tank

Engine oil Upper level

Lower level

Transmission gear oil

Automatic transmission fluid

AT differential gear oil

AWD rear differential gear oil

Power steering fluid

Engine coolant

Model

Q

t-

Curb weight

I

Gross vehicle weight

.V.

W.)

(G

(C.W.)

Front kg (Ib)

Rear

I

Total ka (Ib) I 1,395 (3,075)

Front

Rear

Total

(US gal, Imp gal)

Q

(US qt, Imp qt)

Q

(US qt, Imp qt)

Q

(US qt, Imp qt)

Q

(US qt, Imp qt)

Q

(US qt, Imp qt)

Q

(US qt, Imp qt)

Q

(US qt, Imp qt)

Q

(US qt, Imp qt)

I

826 (1,820) 851 (1,875)

ka

(Ibl

w.

kg (Ib)

kg (Ib)

kg (Ib)

569 (1.255) 569 (1.255)

I1

998 (2,200) 998 (2,200)

857 (1,890) 857 (1,890)

1,837 (4,050) 1,795 (4,050)

I

5MTlrl 4ATJrl

5MT

3.5

(3.7, 3.1) (3.7, 3.1)

-

-

7.7 (8.1, 6.8)

Turbo 2.0

WRX

..

I

I

I

60 (1 5.9, 13.2)

4.5 (4.8, 4.0)

3.5 (3.7, 3.1)

4AT

-

9.3 (9.8, 8.2)

1.2 (1.3, 1 .I)

I

7.6 (8.0, 6.7)

L

I I

I

I. I I.

1,420 (3,130)

I

0.8 (0.8, 0.6)

0.7 (0.7, 0.6)

I

AWD

1

1,345 (2,965)

1,778 (3,920) 1,837 (4,050)

5MT

3.5

-

-

7.0 (7.4, 6.2)

5MT 4AT

778 (1,715) 803 (1,770)

567 (1.250) 567 (1,250)

939 (2,070) 939 (2,070)

857 (1,890) 857 (1,890)

I

60 (1 5.9, 13.2)

4.0 (4.2, 3.5)

3.0 (3.2, 2.6)

9.5 (10.0, 8.4)

1.2 (1.3, 1.1)

1

6.9 (7.3, 6.1)

2.5 L

RS

.

I

I

1,370 (3,020)

4AT

-

I

I

I

SPC-5

SPECIFICATIONS

IM

PREZA

I

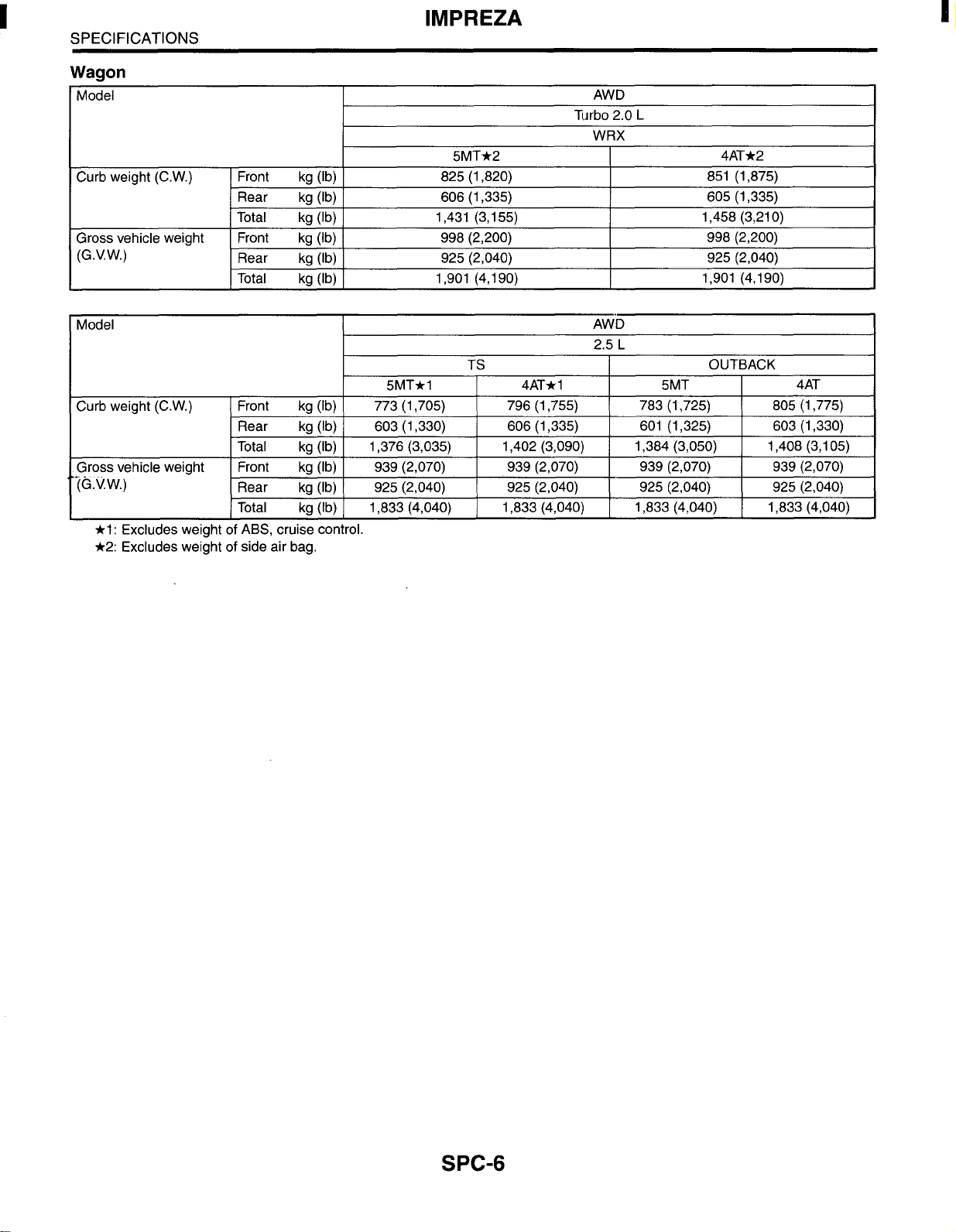

Model

Curb weight (C.W.) Front kg (Ib)

Rear ka (Ib)

~~

~

Gross vehicle weight

.

V.

W.

)

(G

Curb weight (C.W.) Front kg (Ib)

Gross vehicle weight Front kg (Ib)

-(

G

.

v.

w.

)

tl:

Excludes weight

t2: Excludes weight

htai ka ob)

Front kg (Ib)

Rear kg (Ib) 925 (2,040)

Total kg (Ib) 1,901 (4,190)

Rear kg (Ib)

Total

Rear kg (Ib)

Total kg (Ib) [ 1,833 (4,040)

of

ABS,

of

side air bag.

kg

(Ib)

-

cruise control.

AWD

Xirbo 2.0

5MTt2 4ATt2

825 (1,820) 851 (1,875)

606

(1.335) 605 (1,335)

1

-

5MTtl 4ATt

773 (1,705)

603 (1,330)

1,376 (3,035) 1,402 (3,090) 1,384 (3,050)

939 (2,070) 939 (2,070)

925 (2,040)

1,431 (3,155)

998 (2,200)

TS

796 (1,755) 783 (1,725)

606 (1,335) 601 (1,325)

925 (2,040) 925 (2,040)

I

1,833 (4,040)

1

WRX

I

2.5

I

L

L

939 (2,070)

1,833 (4,040)

1,458 (3,210)

998 (2,200)

925 (2,040)

1,901 (4,190)

OUTBACK

5MT 4AT

805 (1,775)

603 (1,330)

1,408 (3,l 05)

939 (2,070)

925 (2,040)

I

1,833 (4,040)

SPC-6

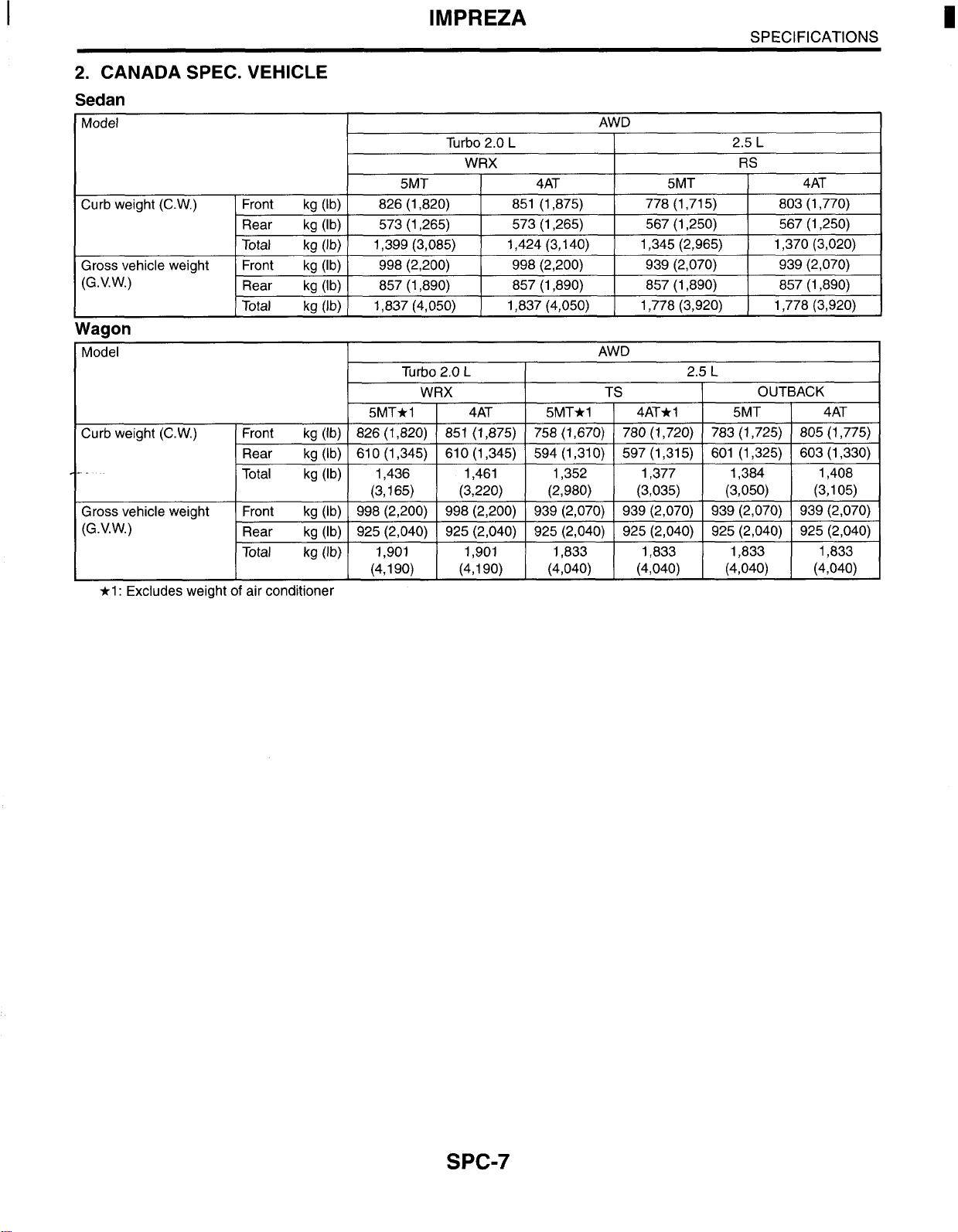

2.

CANADA SPEC. VEHICLE

Sedan

Model

Curb weight

Gross vehicle weight

.V.

W.

(G

(C.W.)

)

Front

Rear

Total

Front

Rear

Total

Wagon

.-

IMPREZA

5MT

kg (Ib)

kg (Ib) 573 (1,265)

kg (Ib)

kg (Ib)

kg (Ib)

kg Ob)

826 (1,820)

1,399 (3,085)

998 (2,200) 998 (2,200)

857 (1,890) 857 (1,890)

1,837 (4,050) 1,837 (4,050)

Turbo 2.0

WRX

SPECIFICATIONS

2.5

L

4AT 5MT

851 (1,875) 778 (1,715) 803 (1,770)

573 (1,265) 567 (1,250)

1,424 (3,140) 1,345 (2,965) 1,370 (3,020)

939 (2,070) 939 (2,070)

857 (1,890)

1,778 (3,920) 1,778 (3,920)

L

RS

4AT

567 (1,250)

857 (1,890)

I

*1: Excludes weight

of

air conditioner

SPC-7

SPECIFICATIONS

IMPREZA

c-

.

SPC-8

PRECAUTION

Precaution

1

.

...........

..................

PC

Page

......................................................................

I

2

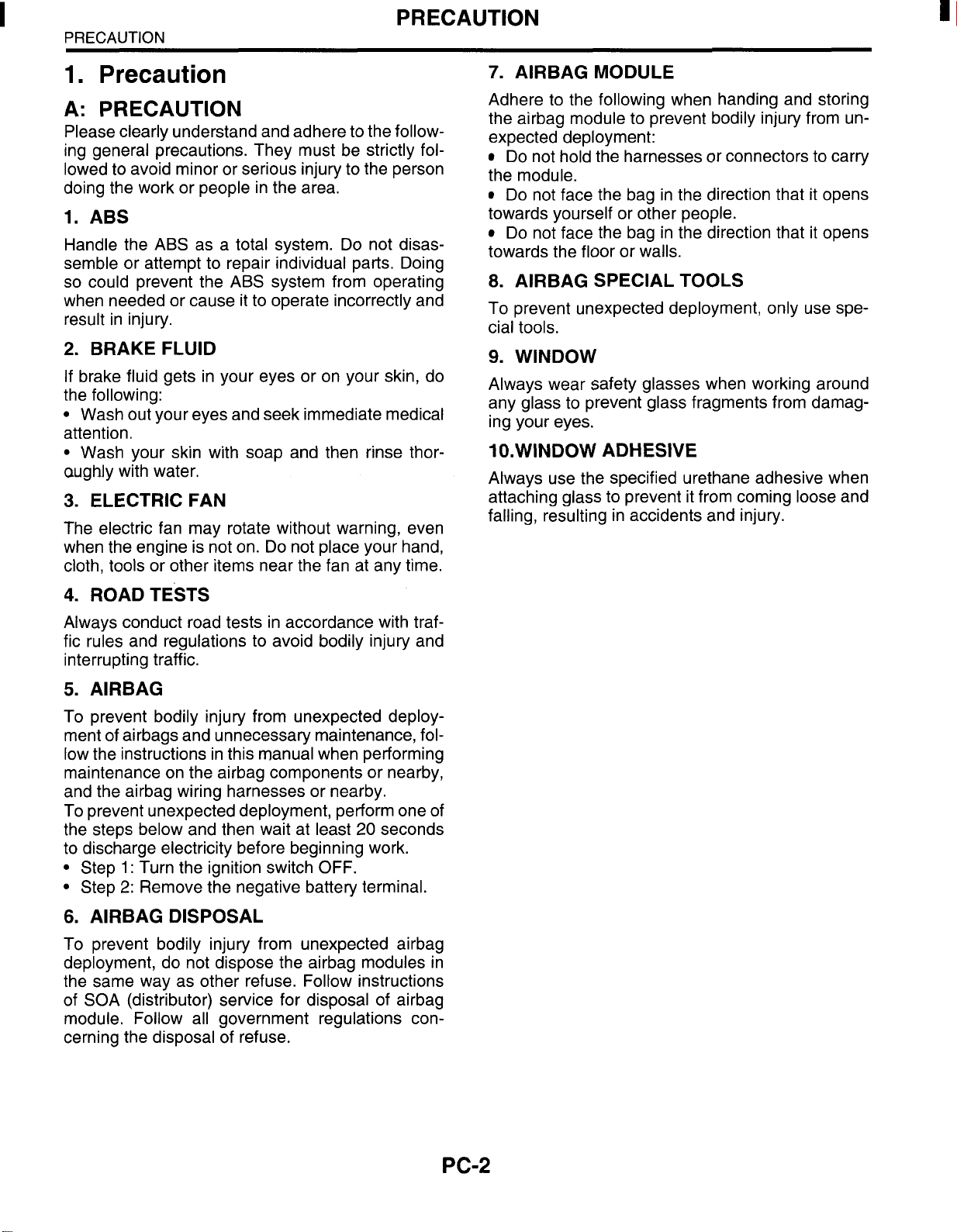

PRECAUTION

PRECAUTION

1.

Precaution

A:

PRECAUTION

Please clearly understand and adhere to the following general precautions. They must be strictly followed to avoid minor or serious injury to the person

doing the work or people in the area.

1. ABS

Handle the ABS as a total system. Do not disas-

semble or attempt to repair individual parts. Doing

so

could prevent the ABS system from operating

when needed or cause it to operate incorrectly and

result in injury.

2.

BRAKE FLUID

If

brake fluid gets in your eyes or on your skin, do

the following:

Wash out your eyes and seek immediate medical

attention.

Wash your skin with soap and then rinse thor-

oughly with water.

3.

ELECTRIC FAN

The electric fan may rotate without warning, even

when the engine is not on. Do not place your hand,

cloth, tools or other items near the fan at any time.

7.

AIRBAG MODULE

Adhere to the following when handing and storing

the airbag module to prevent bodily injury from unexpected deployment:

Do

not hold the harnesses or connectors to carry

the module.

Do not face the bag in the direction that it opens

towards yourself or other people.

Do not face the bag in the direction that it opens

towards the floor or walls.

8.

AIRBAG SPECIAL TOOLS

To

prevent unexpected deployment, only use spe-

cial tools.

9.

WINDOW

Always wear safety glasses when working around

any glass to prevent glass fragments from damaging your eyes.

1O.WINDOW ADHESIVE

Atways use the specified urethane adhesive when

attaching glass to prevent it from coming loose and

falling, resulting in accidents and injury.

4.

ROADTESTS

Always conduct road tests in accordance with traffic rules and regulations to avoid bodily injury and

interrupting traffic.

5.

AIRBAG

To prevent bodily injury from unexpected deployment of airbags and unnecessary maintenance, follow the instructions in this manual when performing

maintenance on the airbag components or nearby,

and the airbag wiring harnesses or nearby.

To

prevent unexpected deployment, perform one of

the steps below and then wait at least

to discharge electricity before beginning work.

Step

1

:

Turn the ignition switch OFF.

Step

2:

Remove the negative battery terminal.

6.

AIRBAG DISPOSAL

To prevent bodily injury from unexpected airbag

deployment, do not dispose the airbag modules in

the same way as other refuse. Follow instructions

of SOA (distributor) service for disposal of airbag

module. Follow all government regulations concerning the disposal of refuse.

20

seconds

PC-2

NOTE

1

.

NT

Note

.............................................................................................................

I

Page

2

NOTE

1.

Note

A:

NOTE

This is the information that can improve the effi-

ciency of maintenance and assure the sound work.

1.

FASTENER NOTICE

Fasteners are used to prevent the parts from damage and dislocation due to looseness. Fasteners

must be tightened to the specified torque.

Do not apply paint, lubricant, rust retardant or other

substances to the surface around bolts, fasteners,

etc. Doing

rect torque and result in looseness and other problems.

2.

STATIC ELECTRICITY DAMAGE

Do

not touch the

and other such parts when there is a risk of static

electricity. Always use a static electricity prevention

cord or touch grounded metal before conducting

work.

so

will make it difficult to obtain the cor-

ECM,

connectors, logic boards

NOTE

3.

IGNITION

When removing the battery cables, always be sure

to turn the ignition off to prevent electrical damage

to the

4.

mance and maintenance, when conducting repairs.

Subaru/FHI will not be responsible for poor performance resulting from the use of parts not specified

by a genuine dealer.

ECM

SERVICE PARTS

Use authentic service parts for maximum perfor-

OFF

BATTERY

from rush current.

NT-2

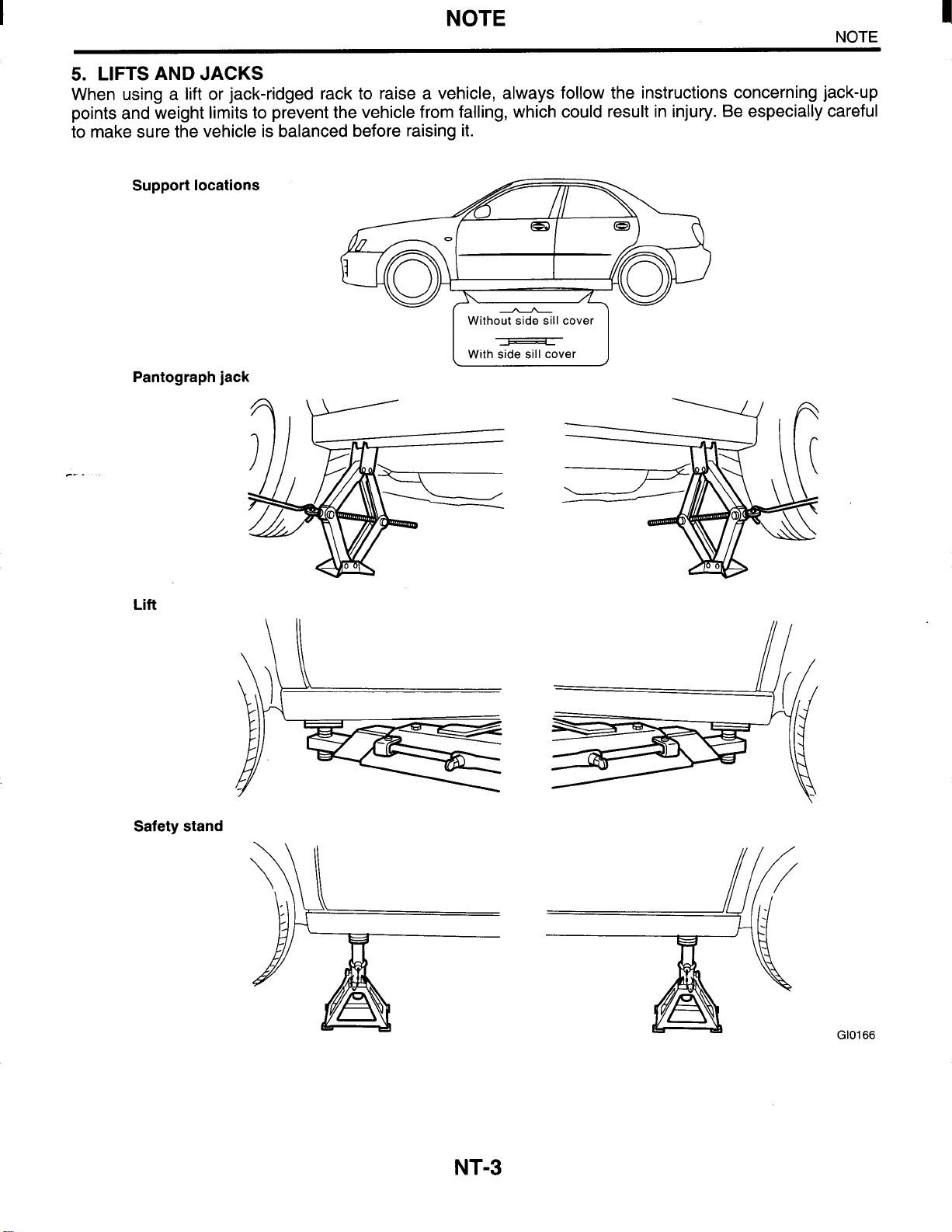

NOTE

NOTE

5.

LIFTS

When using a lift or jack-ridged rack to raise a vehicle, always follow the instructions concerning jack-up

points and weight limits to prevent the vehicle from falling, which could result in injury. Be especially careful

to make sure the vehicle is balanced before raising it.

AND

JACKS

Support locations

Pantograph jack

A

Without side sill cover

I

With-ver

fi.w

I

Lift

Safety stand

GI0166

NT-3

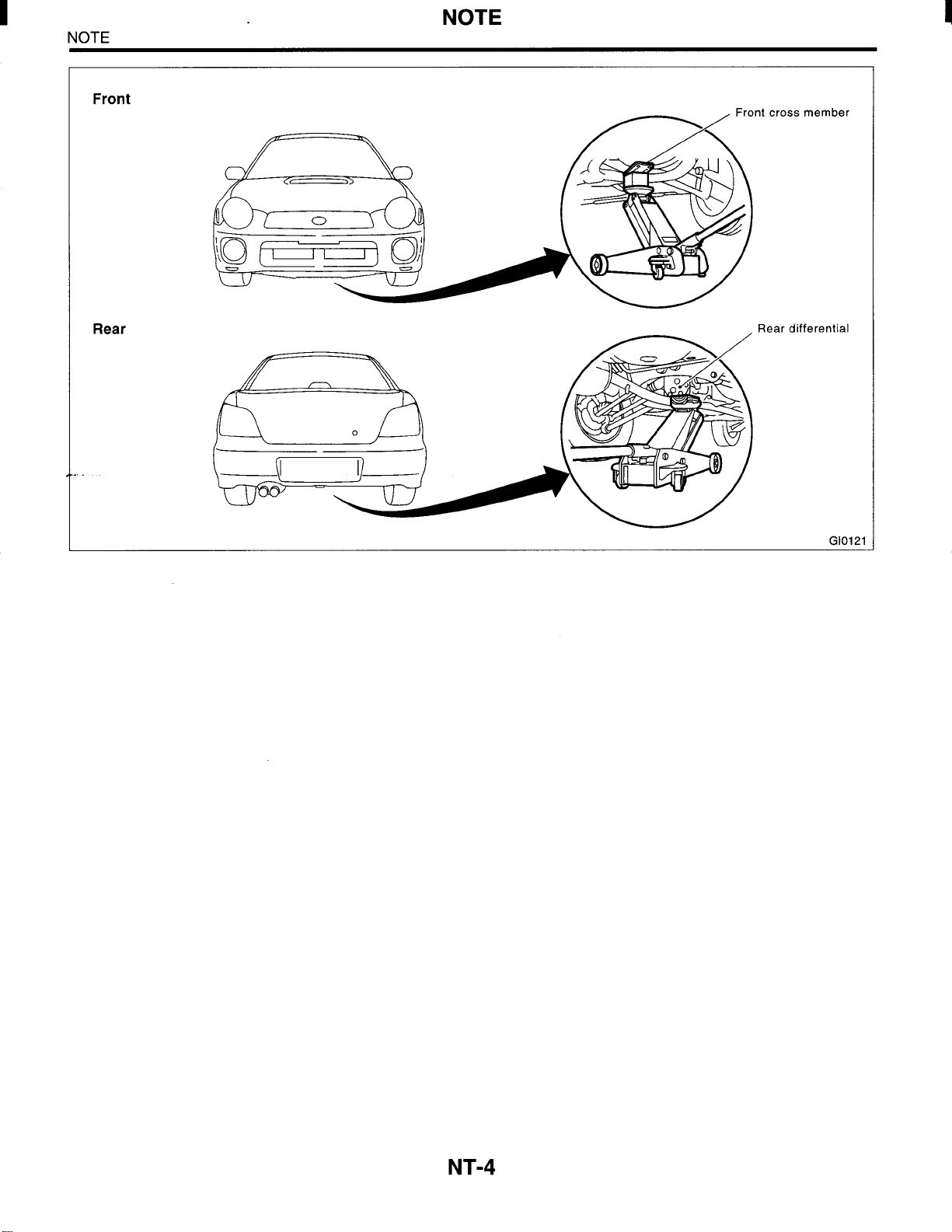

NOTE

NOTE

I

Front

Rear

nt

cross member

Rear differential

GI0121

NT-4

NOTE

NOTE

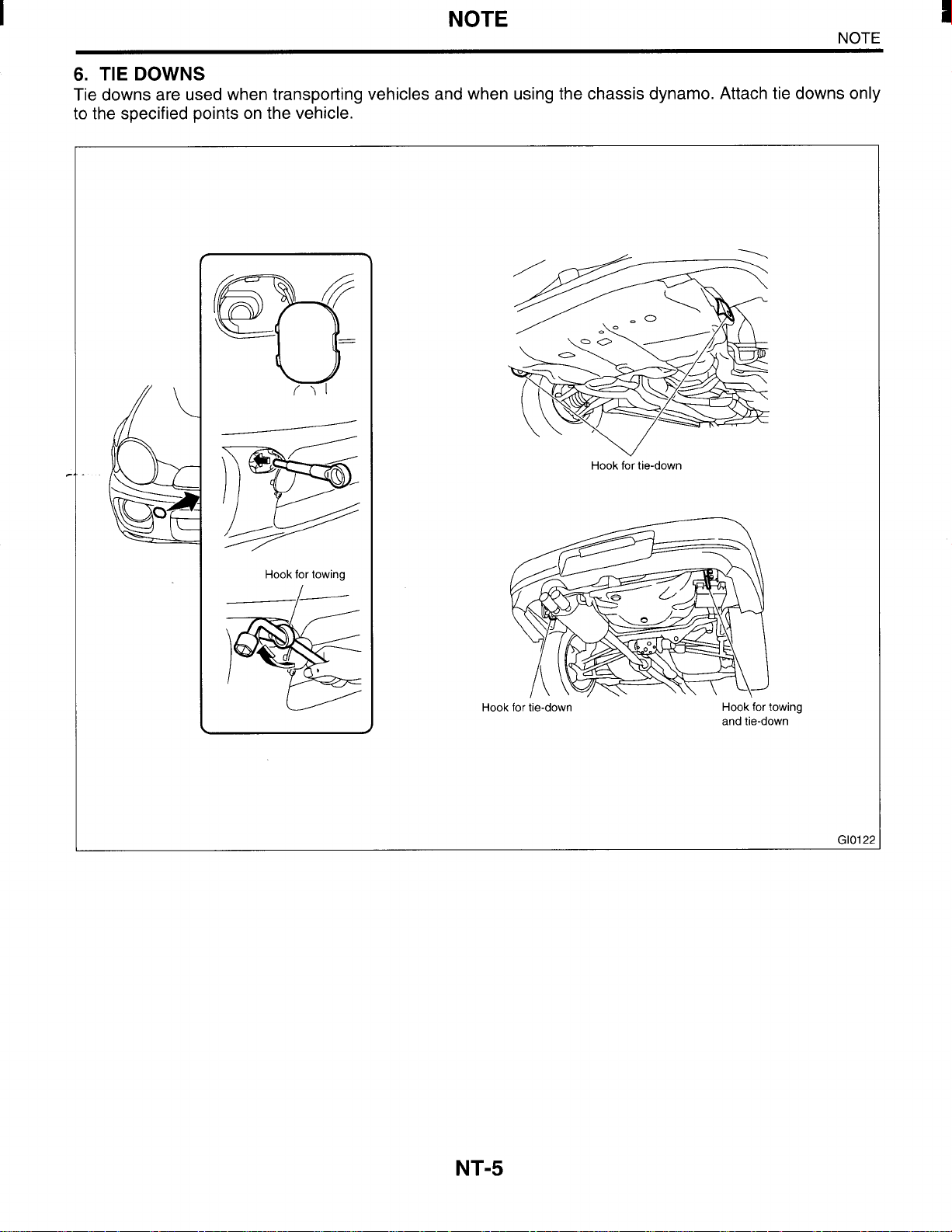

6.

TIE

DOWNS

Tie downs are used when transporting vehicles and when using the chassis dynamo. Attach tie downs only

to the specified points on the vehicle.

Hook

for

tie-down

3

Hook

for

1-

towing

Hook

for

tie-down

Hook

for

towing

and tie-down

GI0122

NT-5

I

NOTE

NOTE

I

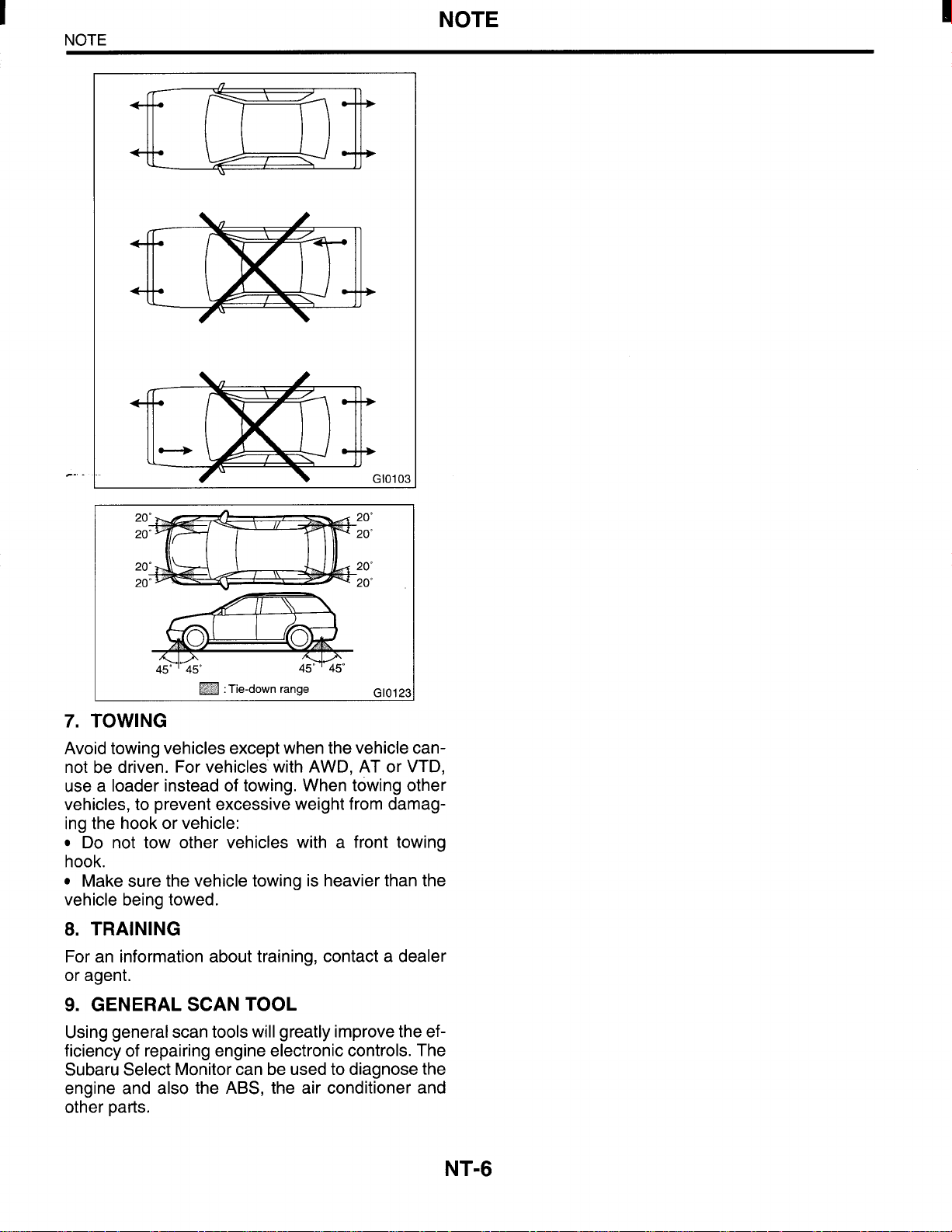

20 20’

20 20”

20 20”

20

7.

TOWING

Avoid towing vehicles except when the vehicle cannot be driven. For vehicles with AWD, AT or VTD,

use a loader instead of towing. When towing other

vehicles, to prevent excessive weight from damaging the hook or vehicle:

Do not tow other vehicles with a front towing

hook.

Make sure the vehicle towing is heavier than the

vehicle being towed.

8.

TRAINING

For an information about training, contact a dealer

or agent.

20”

9. GENERAL SCAN TOOL

Using general scan tools will greatly improve the ef-

ficiency of repairing engine electronic controls. The

Subaru Select Monitor can be used to diagnose the

engine and also the ABS, the air conditioner and

other parts.

NT-6

IDENTIFICATION

Identification

1

.

....

. ... .

....

.. . .

...

. .

... . ...

....

.

...

. . .. . . .. . .. . .

...

.

....

. .. . .. .

. .. . . .

...

ID

. ..

...

... .

.. . ..

Page

.....

.

.2

IDENTIFICATION

I

DE

NTI

F I CAT1 0 N

1.

Identification

A:

IDENTIFICATION

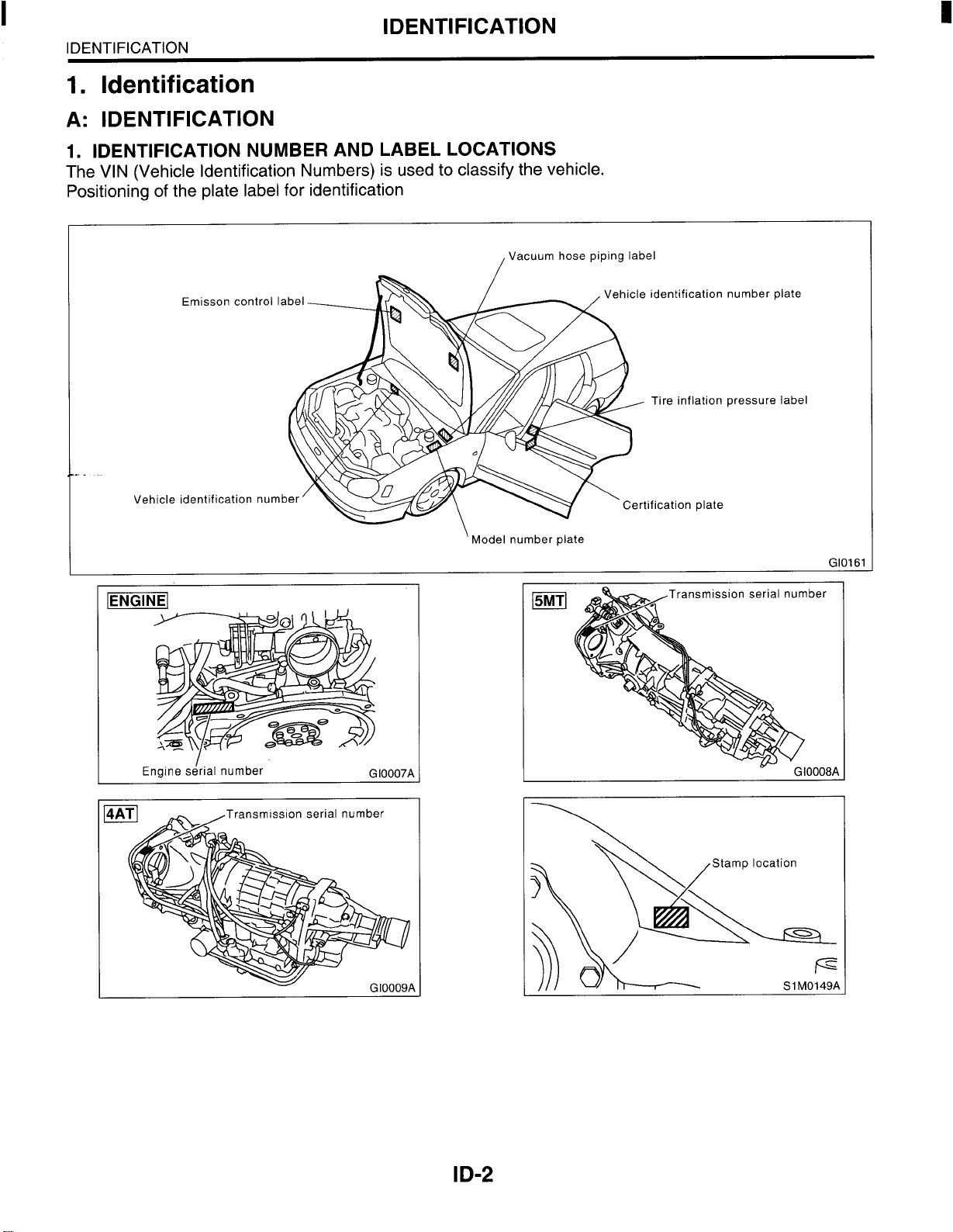

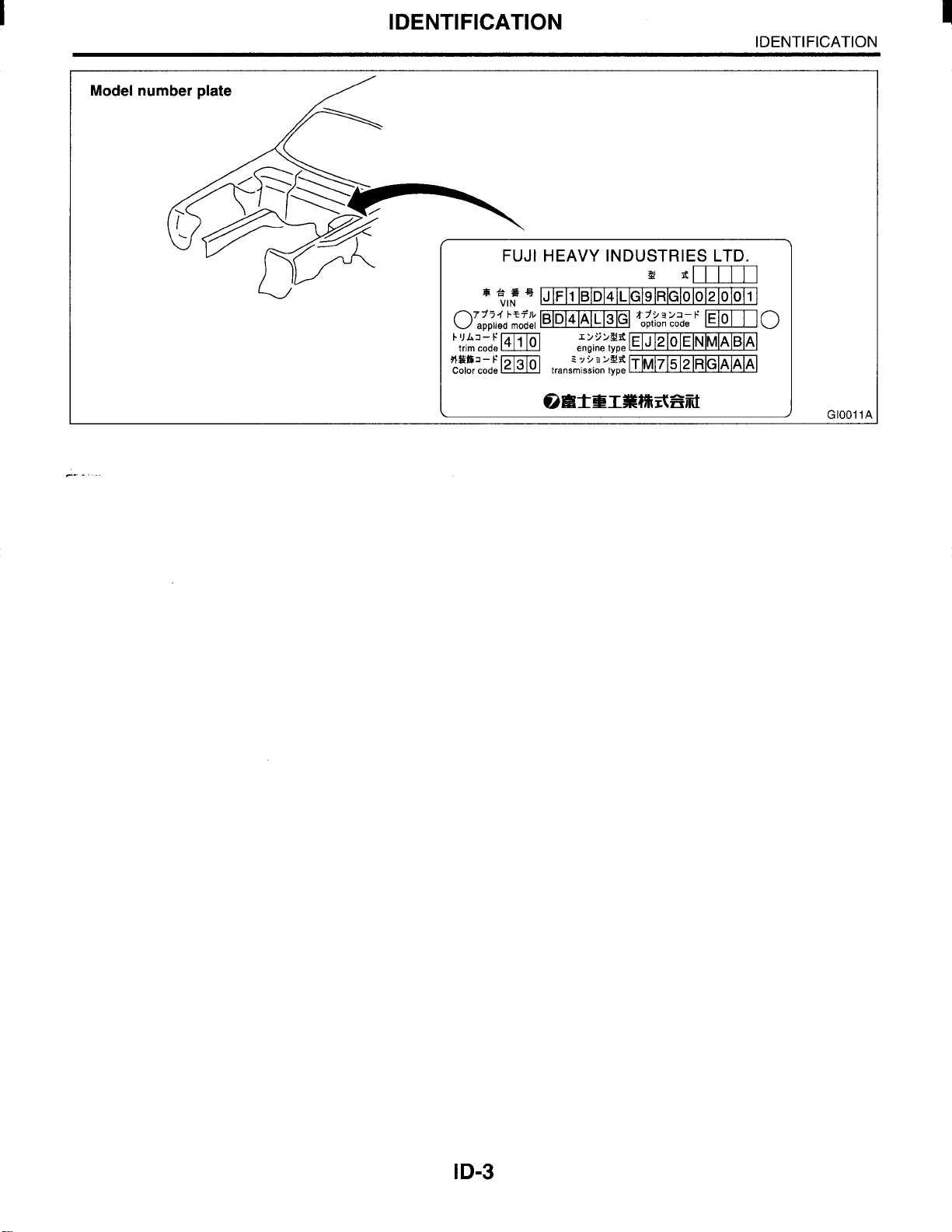

1.

IDENTIFICATION NUMBER AND LABEL LOCATIONS

The VIN (Vehicle Identification Numbers) is used to classify the vehicle.

Positioning of the plate label for identification

Vacuum hose piping label

/

..

I

number plate

pressure label

Vehicle

Engine sdrial number G l0007A

'

Model number plate

I

Transmission serial number

o.

G10008A

GI0161

I

I

D-2

I

DENTI FlCATlON

I

IDENTIFICATION

Model number

plate

U

/

b

'I

L3

F

trim code engine

9+#L2-F

2

3

0

r'z"'!it

sv53>w

type

E

J

2

0

ENMABA~

GlOOllA

I

D-3

IDENTIFICATION

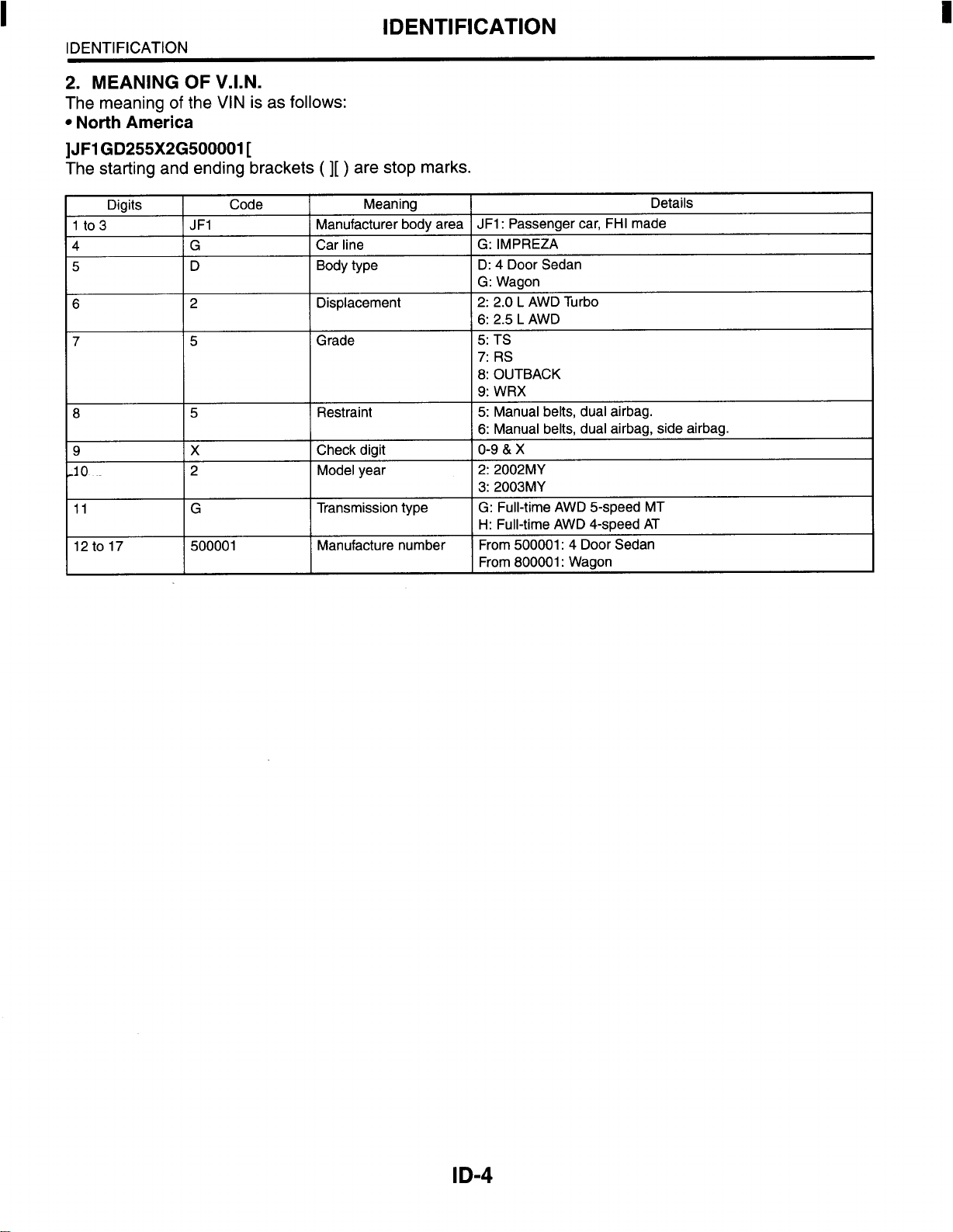

2.

MEANING

The meaning

North

America

of

OF

the

V.I.N.

VIN

is

as

follows:

]JF1 GD255X2G500001[

The starting and ending brackets

(

I[

IDENTIFICATION

)

are

stop

marks.

Digits Code

1

to3

4 G

5

JFI

ID

6

7

8

9

10

11

12

to

17

2 Displacement

5

5

X Check digit

2 Model year

G

500001

Meaning

Manufacturer body area

Car line

Grade

Restraint

Transmission type

Manufacture number

Details

JFI: Passenger car, FHI made

G: IMPREZA

D: 4 Door Sedan

G: Waaon

2: 2.0 L AWD Turbo

6:

2.5 LAWD

5:

TS

7:

RS

8:

OUTBACK

9:

WRX

5:

Manual belts, dual airbag.

6:

Manual belts, dual airbag, side airbag.

0-9

&

x

2: 2002MY

3:

2003MY

G:

Full-time AWD 5-speed MT

H:

Full-time AWD 4-speed AT

From

500001

800001 : Waaon

From

:

4 Door Sedan

I

D-4

IDENTIFICATION

IDENTIFICATION

3.

MODEL NUMBER

The model number plate indicates: the applied model, the option code, the trim code, the engine type, the

transmission type, and the exterior color code. This information is helpful when placing orders for parts.

GDEAY4R

PLATE

2

5

7

Digits

3

and 4

5

6

7

8

9to10

Digits

Code

Series

Body style

ID

Engine displacement

Drive system

Sumension svstem

Minor chanae

IY

IR

Code Meaning Details

25 Displacement 20: 2.0

1

A Exhaust reuulations US Federal

Destination

Grade

Transmission, fuel feed

system

Fuel feed system

Transmission

Iw

3

AB

Minor change 3: 3 is applied for this vehicle.

Detailed specifications

Meaning

G: IMPREZA

D:

4

Door Sedan

G: Wagon

A: 2.0

L

E: 2.5

L

A: Initial

Y:

Left-hand drive for United States and Canada

4:

TS

6: RS

7:

OUTBACK

8:

WRX

R:

SOHC MPI 4-speed AT

P: DOHC

J: SOHC MPI 5-speed MT AWD

D: DOHC B MPI 5-s~eed MT AWD

L

25: 2.5

5: MPI Turbo

L

1:

D-MPI SOHC-A

I

Used when ordering parts. See the parts catalog for details.

AWD Turbo

AWD

B

MPI 4-speed AT

&

California

Details

I

D-5

I

IDENTIFICATION

Transmission

TV1 A421 AA

I

DENTI FlCATlON

Z

AA

Code

I

No

Viscous

Digits

I

3

and 4

5

14

6

7

8

to

10

Rear differential

EH

Code Reduction LSD

I

EG

I1

I

aear ratio

13.900

4.1

11

4.1

11

Meaning

Transmission

Transmission type

Classification

Series IMT 14:5MT

Transmission specifications

Minor change

Detailed specifications I Used when ordering parts. See the parts catalog for details.

T: Transmission

Y:

Full-time AWD MT center differential

V: Full-time AWD AT center differential

Z:

Full-time AWD AT MPT

75:

MT

1A: AT

AT 14: New AT

V: Full-time AWD 5-speed MT with viscous coupling center dif-

ferential single range

Z:

Full-time AWD 4-speed AT with MPT

Y:

Full-time AWD 4-speed AT with VTD

I

I:

Initial

Details

I

I

I

I

I

D-6

RECOMMENDED MATERIALS

Recommended

1

.

Materials

,...

...

..

. . .. . . .. . . . .. . . . . . , .

. . . . . . . .. .

RIM

..

. . . . . . . . . . . . . . .. . . . .. . . .. .

Page

.

.

. .. .

.

.

I

.2

I

RECOMMENDED MATERIALS

RECOMMENDED MATERIALS

~

1.

Recommended

A:

RECOMMENDED MATERIALS

1.

GENERAL

To

insure the best performance, always use the

specified oil, gasoline, adhesive, sealant, etc. or

that of equivalent quality.

2.

FUEL

Always use a gasoline of the same or higher octane

value than specified in the owner's manual. Ignoring the specifications below will result in damage

poor operation of the engine and fuel injection system. Use the specified gasoline to correct performance.

Unleaded gasoline

Materials

or

Use unleaded gasoline and

vehicles with a catalytic converter installed to reduce air pollution. Using leaded gasoline will dam-

age ihe catalytic converter.

not

leaded gasoline on

RM-2

RECOMMENDED MATERIALS

RECOMMENDED MATERIALS

3.

LUBRICANTS

Use either the lubricants in the table below or equivalent lubricants. See the table below to choose the correct

SAE

viscosity.

Lubricant

API

Spec. ACEA Spec.

Engine oil

Manual transmission oil GL-5

Front differential GL-5

Rear differential GL-5

SJ

Grade “Energy conserving” API:

Recommended Alternative

A1

,

A2

or

A3

GlOOOl

GI0002

-

-

SH

or SG

-

SAE viscosity

Engine oil

SAE viscosity

<

No.

and applicable temperature SAE

J300

5W-30 Recommend

I

G10003A

RM-3

RECOMMEND ED MATER I ALS

RECOMMENDED

MATERIALS

SAE viscosity

Manual transmission oil

3ear differential

'ront differential

SAE viscosity No. and applicable temperature SAE J300

("C)

(OF)

7

('C)

(OF)

-30

-22

I I I

ll

-30

-22

-20

-4 14

I I

I

I

-20

-4 14

-1

-1

0 0

I

32

I

I

85W

80W

I I I

75W-90

0

0

32

10

50

I I I I

10

50

20 30

68 86

90

I

20 30

68 86

I

40

104

40

104

>

/

2

G10004A

4.

FLUID

Use the fluids specified in the table below. Do not mix two different kinds or makes

Fluid Recommended

Automatic transmission fluid DEXRON

Power steerina fluid DEXRON

Brake fluid

Clutch fluid FMVSS No.

5.

COOLANT

FMVSS No. 1 16 DOT3 FMVSS No. 116 DOT4

Ill

Ill

1

16 DOT3

Alternative Remarks

-

-

FMVSS No. 116 DOT4

of

fluid.

Use the genuine coolant to protect the engine. The table below shows the ratio of coolant

Coolant

Coolant

Water for dilution

Air conditioner

Refrigerant

Compressor oil

Recommended Item number Alternative

SUBARU coolant 00001 621

Distilled water

Recommended

HFC134a

DH-PR

Item number Alternative

8

-

-

-

G10005A

to

distilled water.

None

Tap water

None

None

RECOMMENDED MATERIALS

7.

GREASE

Use the grease and supplementary lubricants shown in the table below.

I

RECOMMENDED MATERIALS

Grease

Supplementary lubricants

Grease

._

Application point

02 sensor

Bolts. etc.

MT main shaft

Clutch master cylinder

push rod

Steering shaft bush

(Toe board)

Gear shift bush

Steering gear box

Disc brake

~~

Drum brake

Brake pad

Brake shoe

Front axle

Front axle EBJ

Rear axle EBJ

(Turbo model)

Rear axle BJ

(Non-turbo model)

Rear axle DOJ

Control cable

Throttle linkage

Water pump

Door latch

Door striker

SFJ

Recommended Item number

SUBARU CRC

I

FX clutch clrease

Slicolube G-40M 004404003

SU NLIGHT2 00360201

Valiant grease M-2 003608001

Niglube RX-2 003606000 or

I

Molvkote No. 7439

1

Molykote AS-880N 26298AC000

SSG-6003 28093TAOOO

NTG 2218 28093AA000

NTG 2218 28093AA000

Molylex No. 2 72322301

VU-3A702 23223GA050

Slicolube G-30M 004404002

I

I

004301 003

000040901

7251 91 040

7251 9460

Alternative

-

I

0

I

-

-

-

-

-

-

I

-

-

-

0

-

-

-

8.

ADHESIVES

Use the adhesives shown in the table below, or equivalent.

Adhesive

9.

SEAL MATERIAL

Windshield and body Essex Chemical Crop’s Ure-

thane E

Soft vinyl Cemedine 540

Momentarv sealant Cemedine 3000

I

Enaine case

Transmission oil pan

Torque converter clutch

case

Rear differential

Rear differential

I

Weatherstrip

Steering adjusting screw

SOHC cam cap

I

Three Bond 121

Three Bond 12178 K0877YA020

Three Bond 12158 004403007 Dow Corning’s No. 7038

Three Bond 1324 004403042

Three Bond 11 05 00440301

I

Starcalking B-33A I000018901

Three Bond 11 02 004403006

Three Bond 12808 K0877YA018

5

-

-

-

I004403007

Sunstar 580

3M’s EC-776 EC-847 or EC-1022

(Spray type)

Armstrona’s Eastman 91

I

Dow Corning’s No. 7038

0

I

Butyl Rubber sealant

0

I

-

-

-

I

-

-

RM-5

I

RECOMMENDED MATERIALS

RECOMMENDED MATERIALS

1

c-

RM-6

PRElDELlVERY INSPECTION

1.

Pre-delivery Inspection

......................

........................

PI

Page

..................................

I

2

I

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION

1.

Pre-delivery Inspection

A: GENERAL

The purposes of the pre-delivery inspection (PDI)

are as follows.

Remove the additional parts used for ensuring

the vehicle quality during transportation and restore

to

the vehicle

Check if the vehicle before delivery is in a normal

state.

Check for any damage or missing parts that may

have taken place during transportation or storage.

Make sure

customer.

Because

must always carry

vehicle.

In addition, all franchised shops and PDI centers

must check the status of every vehicle received

identify who is responsible for any possible defects.

its normal state.

to

provide a complete vehicle to the

of

the above reasons, all dealerships

out

the PDls before delivering a

to

PI-2

PRE-DELIVERY INSPECTION

B:

PDI PROCEDURE

Follow the procedures shown in the table below.

Static Checks Just After Vehicle Receipt

PRE-DELIVERY INSPECTION

Step

I.

Appearance check

2.

Tire check

3.

Fuse installation

Eheck the doors for locklunlock and openlclose

iperations.

5.

Power window oDeration check

ii+ Check the trunk lid openlclose operations.

7.

Check the rear gate for locklunlock and open1

:lose operations.

3.

Operation check of trunk lid release handle

3.

Operation check of fuel lid opener lock release

ever

10.

Accessory check

11. Operation check of hood lock release system

12. Connection of air conditioner harness

13. Battery

14. Brake fluid

15. Engine oil

16. Transmission fluid

17.

AT front differential oil

18. Coolant

19. Clutch fluid

20. Window washer fluid

21. Hood latch check

Check point

(1) If the vehicle is covered with protective coating, visually check the vehicle

body for damage and dents.

visually check the body paints for small areas of damage or stains.

(2) Visually check the glass and light lenses for any damage and cracks or

excessive gaps to the body sheet metal.

(3) Visually check the plated parts for any damage.

(4)

Check the tires for damage, abnormal conditions, and dents on the

wheels.

f5) Check the tire air Dressure.

~

(6)

If the vehicle is about to be delivered to the customer, attach a room lamp

fllRF!

(7) Using the key, check

(8) Open and close all doors

(9) Operate the power door locking switch

and unlocked normally.

(1

0)

Check the power window for correct operations.

(1 1) Operate the trunk lock release lever to check that the trunk opens normally.

(12) Using the key, check if the trunk lid can be unlocked normally.

(1 3) Open and close the trunk lid to see that there are no abnormal condi-

tions.

(14) Using the key, check

(15) Open and close the rear gate to see that there are no abnormal conditions.

(16) Operate the power door locking switch to check that the rear gate is

locked and unlocked normally.

(17) Operate the trunk lid release lever to check the trunk is unlocked normally.

(18) Operate the fuel lid opener to check that the fuel lid is unlocked normally.

Check the following accessories are provided:

Owner's manual

Warranty booklet

Service booklet

Spare key

Jack

Tool set

Spare tire

(1) Operate the hood lock release lever to check that the hood opens normallv.

~

(2)

If

the vehicle is about to be delivered to the customer, connect the air con-

ditioner harness.

(3) Check the battery for any abnormal conditions such as rust and trace of

battery fluid leaks.

(4) Check the fluid amount.

(5) Check the oil amount.

(6) Check the fluid amount.

(7)

For AT, check the front differential oil.

(8) Check the AT front differential oil amount.

f9) Check the coolant amount.

(10)

Check the clutch fluid amount.

(1 1) Check the window washer fluid amount.

(12) Check that the hood is closed and latched securely.

If

the protective coating has been removed,

if

the door can be locked and unlocked normally.

to

see that there are no abnormal conditions.

to

check that all doors is locked

if

the rear gate can be lock and unlocked normally.

PI-3

PRE-DELIVERY

INSPECTION

PRE-DELIVERY INSPECTION

I

Step

22. Keyless entry system

23. Securitv svstem

124.

Seat

125. Seat belt

126. Wheel alignment

Checks with the Engine Running

I

27. Read memory and test mode connectors

28. Starting condition

29. Exhaust system

30. Indicator liaht

I

31. Clock

132. Radio

33. Cigarette lighter

34. Lighting system

35. Window washer

36. WiDer

I

Step

Pynamic Test with the Vehicle Running

Step

37. Brake test

38. Parkina brake

MAT

I

shift control

40. Heater & ventilation

41. Air conditioner

42. Cruise control

Check point

(1 3) Check that the keyless entry system operates normally.

(14) Check that the securitv svstem operates normallv.

(15) Check the seat surfaces for smears or dirt.

(1 6) Check the seat installation conditions and functionality.

I

(17) Check the seat belt installation conditions and functionality.

I

(18) Check that the wheel alignments are properly adjusted.

I

(1) Read memory and test mode connectors

(2) Start the engine and check that the engine starts smoothly.

(3) Check that the exhaust noise is normal and no leaks are found.

(4) Check that all indicator liahts operate normally.

I

(5)

Check that the clock operates normally.

I

(6) Check that the radio system operates normally.

(7) Check that the cigarette lighter operates normally.

(8) Check that the lighting systems operate normally.

(9)

Check that the window washer system operates normally.

(10) Check that the wiper svstem oDerates normally.

~.

(1) Check that the foot brake operates normally.

(2) Check that the parkina brake operates normally.

I

(3) Check that the AT shift patterns are correct.

I

(4)

Check that the heater & ventilation system operates normally.

(5)

Check that the air conditioner operates normally.

(6) Check that the cruise control system operates normally.

.-

Check point

Check point

I

I

I

I

I

I

I

I

43. ATF level

44. Power steerina fluid level

I

45. Fluid leak check

146. Water leak check

47. Appearance check 2

Step

.8

I

I

(1) Check that the ATF level is normal.

I

12)

Check that the Dower steerina fluid level is normal.

,\I

I

13) Check for fluid/oil leaks.

\,

I

(4) Sprav the vehicle with water and check for water leaks.

(5)

Remove the protective coating (if any).

(6)

Check the body paints for damage and smears.

(7) Check the plated parts for damage and rust.

Check point

I

I

1

PI-4

PRE-DELIVERY INSPECTION

1.

APPEARANCE CHECK

If

the vehicle is covered with protective coating,

visually check the vehicle body for damage and

dents.

If

there is no protective coating, check the body

paints for small areas of damage or stains and repair as necessary.

Check the window glass, door glass, and lights

for any cracks or damage and repair or replace the

parts as necessary.

Check the plated parts, such as the grilles and

door knobs, for damage or

or replace the parts as necessary.

2.

TIRECHECK

Check the tire outer faces for any damage.

Check the tire air pressure by referring to the following table.

Tire size Tire inflation pressure

PI 95/60R1587H

P205/55R1689V

220 (2.2, 32) 200 (2.0, 25)

220 (2.2. 32) 200 (2.0, 25)

loss

kPa (kg/cm2,

Front

of gloss and repair

psi)

PRE-DELIVERY

4.

CHECK THE DOOR OPERATIONS,

INSPECTION

LOCWUNLOCK AND OPENELOSE, AS

FOLLOWS.

Using the key, lock and unlock the door several

times to check for normal operation. Open and

close the door several times for smooth movement.

GI0148

Operate the power door locking switch on the front

door arm rest, and check that all doors lock and un-

lock normally.

1

3.

FUSE INSTALLATION

A

vehicle just- delivered has no fuses for the room

lamp circuit to prevent battery discharge. Attach a

15

A fuse as shown in the figure.

(A)

G10084A

5. POWER WINDOW OPERATION CHECK

Manipulate the power window switches one by one

to check that each of the power windows goes up

and down with no abnormal noises.

PI-5

I

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION

6.

CHECK THE TRUNK LID OPERATIONS,

OPEN/CLOSE, AS FOLLOWS.

Operate the trunk lock release lever and verify

that the trunk lid opens.

Using the key, open the trunk lid several times to

check for normal operation.

Open and close the trunk lid several times for

smooth movement.

7.

CHECK THE REAR GATE OPERATIONS,

kOCWUNLOCK AND OPEN/CLOSE, AS

FOLLOWS.

Using the key, lock and unlock the rear gate sev-

eral times to check for normal opeartion.

Open and close the rear gate several times for

smooth movement.

8.

OPERATION CHECK

OF

TRUNK LID RE-

LEASE HANDLE

1)

Use a screwdriver with a thin blade. Slide the

screwdriver blade from the slit aperture of the lock

to

assembly fully

places the latch in the locked position.

Locked

I

the end until you hear a click. This

GI0157

mni

w

171

Operate the power door locking switch to check

that the rear gate is locked and unlocked normally.

2)

Move the release handle from outside the vehi-

to

cle, in the direction of the arrow

is released.

check if the latch

PI-6

I

GI0160

I

PRE-DELIVERY INSPECTION

PRE-DELIVERY

I

INSPECTION

9.

OPERATION CHECK OF FUEL LID

OPENER LOCK RELEASE LEVER

Operate the fuel lid opener and verify that the fuel

lid opens normally. Check that the filler cap is se-

curely closed.

1O.ACCESSORY CHECK

Check that the following accessories are provided

in the luggage compartment or cargo area.

Owner's manual

Warranty booklet

Service booklet

Spare key

Jack

Tool

set

Spare tire

11 .OPERATION CHECK OF HOOD LOCK

RELEASE SYSTEM

Unlatch and open the hood while checking that

abnormal conditions are found. Then, support the

hood with the hood stay.

no

P

GI0151

1-7

I

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION

I

12.CONNECTION OF AIR CONDITIONER

HARNESS

A vehicle just delivered has its air conditioner harness disconnected to protect the air conditioner

compressor. Connect the harness as shown in the

figure.

13.BATTERY

Check the battery terminals to make sure that no

rust or corrosions due to fluid leaks are found.

check that the battery caps are securely tightened.

16.TRANSMISSION FLUID

Check the transmission fluid amount.

is insufficient, check that no leaks are found. Then,

add the necessary amount of the specified fluid.

Oil

level gauge

I

_-

If

the amount

Upper level

Lower level

G10088A

I

17.AT FRONT DIFFERENTIAL OIL

Check the AT front differential oil amount.

amount is insufficient, check that no leaks are

found. Then, add the necessary amount of the

specified AT front differential oil.

If

the

14.BRAKE FLUID

Check the brake fluid amount.

sufficient, carry out a brake line test to identify

brake fluid leaks and check the brake operation. After that, refill the brake fluid tank with the specified

type of fluid.

If

the amount is in-

15.ENGINE OIL

Check the engine oil amount.

ficient, check that no leaks are found. Then, add

the necessary amount of the specified engine oil.

If

the amount is insuf-

P Upper level

About

1

.O

us

Imp

e

qt,

qt)

(1.1

0.9

Lower level

-

Upper level

_I

-Lower level

1

GlOO89Al

18.COOLANT

Check the coolant amount on the reservoir.

amount is insufficient, check that no leaks are

found. Then, add the necessary amount of coolant

with the specified concentration.

If

the

19.CLUTCH FLUID

Check the clutch fluid amount.

sufficient, check that no leaks are found. Then, add

the necessary amount of the specified fluid.

I

If

the amount is in-

I

G10087A

I

PI-8

PRE-DELIVERY INSPECTION

PRE-DELIVERY

I

INSPECTION

20.WlNDOW WASHER FLUID

Check the window washer fluid amount.

amount is insufficient, check that no leaks are

found. Then, add the necessary amount of washer

fluid commercially available.

If

the

21.HOOD LATCH CHECK

Retract the hood stay and close the hood. Check

that the hood is securely latched.

22.KEYLESS ENTRY SYSTEM

Check the keyless entry system operations as follows:

Fully open all the door windows.

Remove the key from the ignition switch and

close all the doors including rear gate (wagon).

Press the “LOCWARM” button on the transmitter

if

momentarily once and check

locked and the horn chirps once.

I

all the doors are

Press the “LOCWARM” button on the transmitter

momentarily once with one of the doors including

the rear gate (wagon) open and check

if

the horn

chirps three times to warn of a door ajar.

Then, bring all the doors including the rear gate

(wagon) in closed condition and check

if

all the

doors are locked and the horn chirps once.

Press the “LOCK side of the power door locking

switch with any one of the doors including the rear

gate (wagon) open. Then, bring all the doors including the rear gate (wagon) in the closed condition and check if all the doors are locked and the

horn chirps once.

LOCK

GI0091

Press the “UNLOCWDISARM” button on the

transmitter momentarily once and check if the driver’s door is unlocked, the horn chirps twice and the

dome light illuminates.

I

I

GI0092

Press the “UNLOCWDISARM” button on the

transmitter momentarily once again within five seconds and check if all the doors including the rear

gate on wagon are unlocked.

Press the “LOCWARM” button on the transmitter

a little bit of time (approx.

sec.) and check

if

a

1.5

panicking condition occurs; the horn sounds continuously. Also, check

if

that condition lasts for

30

sec-

onds or until any button of the transmitter is

pressed.

Check selecting audible signal operation.

Using the horn, the system will give you an audi-

ble signal when the doors lock and unlock.

If

desired, you may turn the audible signal off.

To turn the audible signal off, carry out the unlock-

ing procedure of keyless entry system, then simul-

taneously depress LOCWARM and UNLOCW

DISARM buttons for more than two seconds.

The horn will sound two times to inform you that the

audible signal has been turned off.

To turn the audible signal on, carry out the unlock-

ing procedure of keyless entry system, then simultaneously depress LOCWARM and UNLOCW

DISARM buttons for more than two seconds.

The forn will sound one time

to

inform you that the

audible signal has been turned on.

I

PRE-DELIVERY INSPECTION

PRE-DELIVERY

INSPECTION

23.SECURITY SYSTEM

Check the security system operations as follows:

Fully open all the door windows.

Remove the key from the ignition switch and

close all the doors including rear gate (wagon).

Press the “LOCWARM” button on the transmitter

momentarily once and check if all the doors are

locked, the horn chirps once, the parking lights

flash once and the security indicator light flashes

to

slowly

brought into the arming state.

c-

Press the “UNLOCWDISARM” button on the

transmitter momentarily once and check

er’s door is unlocked, the horn chirps twice, the

parking light flash twice, the dome light illuminates

and the security indicator light goes off to ensure

that the system has been brougt into the disarming

state.

Press the “UNLOCWDISARM” button on the

transmitter momentarily once again within five seconds and check if all the doors including the rear

gate on wagon are unlocked.

Press the “LOCWARM” button on the transmitter

a little bit of time (approx.

panicking condition occurs; the horn sounds continuously, the parking lights flash and the security in-

dicator light flashes rapidly. Also, check if that

condition lasts for

the transmitter is pressed.

Press the “LOCWARM” button on the transmitter

momentarily once with one of the doors including

the rear gate (wagon) open and check if the horn

chirps three times to warn of a door ajar.

ensure that the security system has been

I

1.5 sec.) and check if a

30

seconds or until any button of

GI0091

if

the driv-

GI0092

I

Then, bring all the doors including the rear gate

(wagon) in closed condition and check if the arming

condition is brought about; all the doors are locked,

the horn chirps once and the parking lights flash

once.

Press the “LOCK’ side of the power door locking

switch with any one of the doors including the rear

gate (wagon) open. Then, bring all the doors in-

cluding the rear gate (wagon) in the closed condition and check if all the doors are locked, the horn

to

chirps once and the parking lights flash once

ensure that the security system has been brought into

the arming state.

LOCK

Unlock a door using the inner lock knob or the

key and open the door while the security system is

in the arming state. Check to ensure that the alarming condition occurs, i.e. the horn sounds continu-

ously, the parking lights flash and security indicator

30

light flashes rapidly, and that it lasts for

seconds

or until the “UNLOCWDISARM” button on the

to

transmitter is pressed. Also, check

to

turning the ignition key

the “START position in

ensure that

the arming state does not cause the starter motor

to

turn, thus the engine being prevented from start-

ing.

Apply a shock

to

the vehicle body with the security system in arming state, and check to ensure

that the alarming condition occurs.

Troubleshoot the security system if any one of

the above-mentioned checks does not meet the re-

qui remen

ts.

24.SEAT

Check that each seat provides full functionality in

sliding and reclining. Check all available functions

of the rear seat such as a trunk-through center arm

rest.

25.SEAT BELT

Pull out the seat belt and then release it. Check

that the belt webbing retracts smoothly.

Check the seatbelt warning light and chime oper-

ations.

PI-I

0

PRE-DELIVERY INSPECTION

1

PRE-DELIVERY INSPECTION

26.WHEEL ALIGNMENT

Check the wheel alignments. <Ref. to

Alignment.> and <Ref. to

.>

RS-9,

FS-8,

Wheel

Wheel Alignment,

27.READ MEMORY AND TEST MODE CONNECTORS

Turn the ignition switch

check-engine light starts blinking.

return the ignition key to LOCK and disconnect the

test mode connector. Then, turn the ignition key to

ON

again.

If

the check-engine light blinks at that

time in spite of the disconnected test mode connector, carry out an engine diagnosis.

to

ON

and check that the

If

the light blinks,

35. LIGHTING SYSTEM

Check the headlight operations.

Check the brake light operations.

Check the other lights for normal operations.

Check the daytime running light system opera-

tions.

Check the illumination brightness control system

operations.

36.WINDOW WASHER

Check that the

washer fluid to the specified area of the windshield

shown in the figure.

Front Injection position:

A:

257”

B:

512”

window washer system injects

(IO.

12

in)

(20.16

in)

___

28.KEY WARNING SYSTEM

Check that the chime sounds when the driver’s

door opens and the key is in the “LOCK’ or “ACC”

position.

29. STA RTI N G CON DIT1 0 N

Start the engine and check that the engine starts

smoothly.

found, recharge or replace the battery.

If

any battery voltage problems are

If

any abnormal noises are observed, immediately stop the

engine and check and repair the necessary components.

30.EXHAUST SYSTEM

Listen to the exhaust noise to see if no abnormal

noises are observed.

31 .INDICATOR LIGHT

Check that all the indicator lights are off.

32.CLOCK

Check the clock for normal operations and enough

accuracy.

Rear Injection position:

A:

39

mm

(2.36

in)

B:

72”

I\

I\

1?K

(/

I\

Nozzle

33.RADIO

Check the radio for full functionality and normal

noise level. Also check the CD unit operations.

34.CIGARETTE LIGHTER

Check the cigarette lighter operations.

PI-I

1

I

PRE-DELIVERY

INSPECTION

PRE-DELIVERY

INSPECTION

40.AT SHIFT CONTROL

Set the AT selector lever to each gear position

while checking that the demanded gear position is

correctly attained.

Selector lever gate pattern

Selector Gear

Position

Yes Yes Yes

Yes Yes Yes

2

I

Yes

I

1

I

Yes

Check the shift lock system operations.

Check the key interlock system operations.

I

I

Yes

Position

I

41 .HEATER & VENTILATION

Operate the heater and ventilation system to check

for normal airflow and heating capacity.

42.AIR CONDITIONER

Operate the air conditioner. Check that the A/C

compressor operates normally and enough cooling

is provided.

43.CRUISE CONTROL

Operate the cruise control system. Check that the

system is activated and deactivated correctly.

44.ATF LEVEL

Check that the ATF level is normal.

check that no leaks are found. Then add the necessary amount of the specified ATF.

Lower level

If

insufficient,

<-upper

1-

Lower level

level

G10098A

45.POWER STEERING FLUID LEVEL

Check that the power steering fluid level is normal.

If

insufficient, check that no leaks are found. Then

add the necessary amount of the specified power

steering fluid.

46.FLUID LEAK CHECK

Check the entire areas of the vehicle for any trace

of coolant/oil/fluid leaks.

47.WATER LEAK TEST

Spray the vehicle with water and check that no wa-

ter enters the passenger compartment.

Before performing the water leakage test, re-

move anything that may obstruct the operation or

which must be kept dry.

Close all of the windows completely, and then

close all of the doors tightly. Close the hood and

trunk lid before starting the test.

Connect a hose to a tap, and spray water on the

vehicle. The rate of water discharge must be ap-

6.6

prox. 20 to 25 liters (5.3 to

Imp gal) per minute.

When spraying water on areas adjacent to the floor

and wheel house, increase the pressure. When di-

recting water on areas other than the floor portion

and wheel house, decrease the pressure. But the

force of water must be made strong occasionally by

pressing the end of the hose.

NOTE:

Be sure to keep the hose at least

from the vehicle.

Check the following areas:

Front window and body framework mating

portion

Door mating portions

Glass mating portions

Rear quarter window mating portions

Rear window and body framework mating

portion

Around roof drips

US gal, 4.4 to

10 cm

(3.9

5.5

in)

PI-I

2

I

PRE-DELIVERY INSPECTION

If

any dampness in the compartments is discov-

ered after the water has been applied, carefully

check all areas that may have possibly contributed

to

the leak.

48.APPEARANCE CHECK 2

Check the vehicle body paints, plated faces, glass,

for

and lenses

any dirt or damage.

I

PRE-DELIVERY INSPECTION

PI-I

3

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION

I

PI-I

4

PERIODIC MAINTENANCE SERVICES

General Description

1

.

Schedule

2

.

Engine Oil

3 .

Engine Oil Filter

4 .

Spark Plugs

5 .

Drive Belt(s)

6 .

Camshaft Drive Belt

7 .

Fuel Line

8

.

Fuel Filter

9

.

Air Cleaner Element

..

10 .

Cooling System

11

.

Coolant

12 .

Idle Mixture

13 .

Clutch System

14 .

Transmission Oil

15 .

ATF 23

16

.

Front

17 .

Brake Line

18 .

Brake Fluid

19 .

20 .

21

22

23 .

24 .

25 .

26 .

Disc Brake Pads and Discs

Brake Linings and Drums

.

Suspension 31

.

Wheel Bearing

Axle Boots

Steering System (Power Steering)

Supplemental Restraint System

.....................................................................................................

....................................................................................................

.................................................................................................

................................................................................................

...................................................................................................

..................................................................................................

......................................................................................................

................................................................................................

...........................................................................................................

&

Rear Differential Oil

.................................................................................................

................................................................................................

...............................................................................................

&

Joints

....................................................................................

...........................................................................................

..................................................................................

..................................................................................

.........................................................................................

...........................................................................................

.......................................................................................

......................................................................

.......................................................................

..........................................................................

...........................................................................................

...................................................................................

............................................................ 35

................................................................

PM

Page

2

3

5

7

8

9

11

14

15

16

17

18

20

21

22

24

25

27

28

29

33

34

38

GENERAL DESCRIPTION

PERIODIC MAINTENANCE SERVICES

1.

General Description

A:

GENERAL

Be sure to perform periodic maintenance in order to

maintain vehicle performance and find problems

before they become serious.

I

P

M-2

SCHEDULE

I

PERIODIC MAINTENANCE SERVICES

--I1

--Clutch system

12

Transmission oil

13

ATF

14

Front

8,

rear

differential oil

15

Brake line

16

Brake fluid

17

Disc brake pads

discs

18

Brake linings and

drums

19

Parking brake

20

Suspension

21

Wheel bearing

22

Axle boots &joints

23

Tire rotation

24

Steering system

(Power steering)

25

Supplement

restraint system

Symbols used:

R:

Replace

I:

Inspection

(R)

or

(I):

Recommended service for safe vehicle operation.

NOTE:

(1)

This inspection is not required

EPA’s in-use compliance program.

(2)

When the vehicle is used in extremely dusty conditions, the air cleaner element should be replaced more often.

(3)

ATF filter is maintenance free part. ATF filter needs replacement, when it has physically damaged or

(4) A tire should be replaced when the tread wear indicator appears as a solid band across the tread. The indicators appear when

the remaining tread has been worn to

&

I

I

I

I

I

I I I

I

to

maintain emission warranty eligibility and it dose not affect the manufacturer’s obligations under

1.6

I

I I I

I I

I

I

R R R

I I

I

I

I

I

I

I

I

mm

(0.063

I

I

I

I

I

I I

I

Inspect every

in) or less.

I

I

I

I

I

I

I

I

I

I

I

I

10

years

I

I

I

I

I

I

I

I

I

I I

I

I I

I

I

I

I

I

I

I

I

I

I

I

I

I I I

I

ATF

leaked.

I

I

I

Note

I

R

I

I

I

(1)

I

INote(4)

I

(3)

PM-3

I

PERIODIC MAINTENANCE SERVICES

B:

MAINTENANCE SCHEDULE

SCHEDULE

2

Item

Engine oil

Engine oil filter

Fuel filter

Fuel line

Transmission oil

-.

AT

F

Front & rear

differential oil

Brake line

Brake fluid

3.75 months

6,000

km

3,750 miles

15 months

24,000 km

15,000 miles

15 months

24,000 km

15,000 miles

15 months

15,000 miles

15 months

24,000 km

15,000 miles

15 months

24,000 km

15,000 miles

15 months

R

High humid- Repeat towity or moun- ing trailer

road drive

used or

coastal area

tain area

R

R

I

I

Disc brake pads

&

discs

Brake linings

and drums

Parking brake

Suspension

Axle boots

joints

Steering system

(Power steering)

&

15,000 miles

15 months

24,000 km

15,000

15 months

ziGlK-7

15,000 miles

7.5 months

7,500 miles

-izzzGl

7,500 miles

7.5

months

12,000 km

7,500 miles

miles

I

I

I

I

I

I

I

I

I

I

I I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

1

I

I-

I

T

PM-4

ENGINE

3.

Engine Oil

A:

REPLACEMENT

1)

Drain the engine oil by loosening engine oil drain

Plug.

2) Open the engine oil filler cap for quick draining of

the engine oil.

Upper level

1.0

us

Imp

L

qt,

qt)

About

(1.1

0.9

Lower level

OIL

PERIODIC MAINTENANCE SERVICES

5)

Fill the engine oil through filler pipe up to the upper point on level gauge. Make sure that the vehicle

is placed level when checking oil level. Use engine

oil of proper quality and viscosity, selected in accordance with the table in figure.

Engine oil capacity (Non-TURBO model):

Upper level

4.0

0

(4.2

US

qt, 3.5 Imp qt)

Lower level

0

(3.2

US

3.0

Engine oil capacity (TURBO model):

Upper level

0

4.5

(4.8

Lower level

0

3.5

(3.7

SAE Viscosity

("C)

-30 -20-15

(OF)

-22

I

qt, 2.6 Imp qt)

US

qt, 4.0 Imp qt)

US

qt, 3.1 Imp qt)

No.

and

4

5

II

32

Applicable Temperature

0

I I

15

59

30

40

86 104

II

G10015A

I

3)

Replace the drain plug gasket.

U

G10013A

4) Tighten the engine oil drain plug after draining

engine oil.

Tightening torque:

44 N-m (4.5 kgf-m, 33 fi-lb)

Thc

proper viscosity helps vehicle get good cold

and hot starting by reducing viscous friction and

thus increasing cranking speed.

NOTE:

When replenishing oil, it does not matter

to

be added is a different brand from that in the en-

if

the oil

gine; however, use oil having the API classification

and SAE viscosity

If

vehicle is used in desert areas with very high

No.

designated by SUBARU.

temperatures or for other heavy duty applications,

the following viscosity oils may be used:

SJ

or

API classification:

SAE Viscosity

No.:

SH

30,

40, 1OW-50, 2OW-40, 20W-

50

6)

Close the engine oil filler cap.

7)

Start the engine and warm it up for a time.

PM-5

I

ENGINE

PERIODIC MAINTENANCE SERVICES

8)

After the engine stops, recheck the oil level.

If

necessary, add the engine oil up to the upper lev-

el on level gauge.

Oil

level

gauge

I-&

Notch mark

Upper level

About

1.OL

(1.1

us

0.9

qt,

Imp

qt)

Lower level

G10016A

OIL

B:

INSPECTION

1)

Park vehicle on a level surface.

2)

Remove the oil level gauge and wipe it clean.

3)

Reinsert the level gauge all the way. Be sure that

the level gauge is correctly inserted and in the

proper orientation.

4)

Remove it again and note the reading.

gine oil level is below the

the level up to the

5)

After turning off the engine, wait a few minutes

“F

line.

“L”

line, add oil to bring

for the oil to drain back into the oil pan before

checking the level.

6) Just after driving or while the engine is warm, the

engine oil level may show in the range between the

‘IF”

line and the notch mark. This is caused by ther-

mal expansion of the engine oil.

7)

To prevent overfilling the engine oil, do not add

the oil above the

‘IF’

line when the engine is cold.

If

the en-

PM-6

I

ENGINE OIL FILTER

4.

Engine Oil Filter

A:

REPLACEMENT

1)

Remove the oil filter with ST.

ST 498547000 OIL FILTER WRENCH

2)

Get a new oil filter and apply a thin coat of engine

oil to the seal rubber.

3) Install the oil filter by turning it by hand, being

careful not to damage seal rubber.

4)-Tighten more (approximately

ter the seal rubber contacts the oil pump case.

not tighten excessively, or oil may leak.

5)

After installing oil filter, run the engine and make

sure that no oil is leaking around seal rubber.

NOTE:

The filter element and filter case are permanently

joined; therefore, interior cleaning is not necessary.

6)

Check the engine oil level. <Ref. to PI-3, PDI

PROCEDURE, P re-delivery Inspection

2/3

to 3/4 turn) af-

.>

Do

PERIODIC MAINTENANCE

1

SERVICES

PM-7

I

SPARK PLUGS

PERIODIC MAINTENANCE SERVICES

5.

Spark

A:

REPLACEMENT

1)

Remove the intake duct and intake chamber.

2)

Remove the washer tank and put it aside.

3)

Disconnect the spark plug cord.

4) Remove the spark plug with a plug-wrench.

5) Set the new spark plug.

c-

Recommended - spark plug

Non-Turbo model

CHAMPION RClOYC4 (Standard)

NGK BKRSE-11

NGK BKRGE-11

Spark plug gap

1.0

-

Turbo model

NGK PFRGG

Spark plug gap

0.7- 0.8

6)

Tighten the spark plug lightly with hand, and then

secure with a plug-wrench

Plugs

:

1.1

mm (0.039 - 0.043 in)

mm

(0.028

-

0.03 1 in)

to

the specified torque.

Tightening torque:

20.6

N.m

(2.10

kgf-m, 15.19 ft-lb)

NOTE:

Be sure to place the gasket between the cylinder

head and spark plug.

If

the torque wrench is not available, tighten

spark plug until gasket contacts cylinder head; then

1/4

to

1/2

tighten further

turns.

PM-8

DRIVE BELT(S)

1

PERIODIC MAINTENANCE SERVICES

6.

Drive

A:

INSPECTION

1)

Replace the belts,

found.

2)

Check the drive belt tension and adjust it if necessary by changing generator installing position

and/or idler pulley installing position.

Belt tension

Belt(s)

if

cracks, fraying or wear is

(4

replaced:

reused: 9.0

(9)

*

replaced: 7.5

reused: 9.0

*:

There is no belt

ditioner.

7

-

9 mm (0.276 - 0.354 in)

-

10.0 mm (0.354 - 0.394 in)

-

8.5 mm (0.295 - 0.335 in)

-

10.0 mm (0.354 - 0.394 in)

(B)

on models without an air con-

98

N

(10

ka.

22

Ib)

B: REPLACEMENT

1.

V-BELT COVER

1)

Remove the V-belt cover.

2.

FRONT SIDE BELT (DRIVING POWER

STEERING

NOTE:

Wipe off any oil or water on the belt and pulley.

1)

Loosen the lock bolt

2)

Loosen the slider bolt

3)

Remove the front side belt

4)

Install a new belt, and tighten the slider bolt so as

to

obtain the specified belt tension.

5) Tighten the slider bolt

6)

Tighten the lock bolt

OIL

PUMP AND GENERATOR)

(A).

(B).

(C).

(B).

(A).

C/P

GEN Generator

P/S

A/C

I/P

Crankshaft pulley

Power steering oil pump pulley

Air

conditioning compressor pulley

Idler pulley

Tightening torque:

Lock bolt, through bolt:

25 N-m (2.5 kgf-m, 18 ft-lb)

Slider bolt:

8 N.m (0.8 kgf-m, 5.8 ft-lb)

G10021A

PM-9

I

DRIVE

PERIODIC MAINTENANCE SERVICES

3.

REAR

TIONER)

NOTE:

Wipe

Before removing the rear side belt, remove the

front side belt.

1)

Loosen the lock nut

2)

Loosen the slider bolt (9).

3)

Remove the rear side belt.

4)

Install a new belt, and tighten the slider bolt

to obtain the specified belt tension.

5)

Tighten the slider bolt (9).

6)

Tighten the lock nut

Tightening torque:

22.6

SIDE

off

any oil or water on the belt and pulley.

N*m

BELT (DRIVING AIR CONDI-

(A).

(A).

(2.3 kgf-m, 16.6

ff-lb)

so

BELT(S)

as

PM-10

CAMSHAFT DRIVE BELT

7.

Camshaft

A:

REPLACEMENT

1.

SOHC

1) Remove the radiator fan <Ref. to CO-9, Radia-

tor Main Fan System.> and air conditioner fan.

<Ref. to CO-17, Radiator Sub Fan System.>

2) Remove the V-belt cover.

MODEL

Drive

Belt

PERIODIC MAINTENANCE SERVICES

10)

Turn the crankshaft and align alignment marks

on crankshaft, and left and right camshaft sprockets with notches of belt cover and cylinder block:

ST 499987500 CRANKSHAFT SOCKET

Notch

ent

mark

Notch

1

3)Remove the V-belts. <Ref. to ME(S0HC)-43, Vbelt.>

4) Remove the air conditioning compressor drive

belt tensioner.

5)

Remove the pulley bolt. To lock crankshaft use

ST.

ST 499977t00 CRANKSHAFT PULLEY

WRENCH

6)

Remove the crankshaft pulley.

7) Remove the left side belt cover.

8) Remove the front belt cover.

9) Remove the timing belt guide. (MT vehicle only)

G10025A

11) Remove the belt idler.