AN236

X-10® Home Automation Using the PIC16F877A

Author: Jon Burroughs

Microchip Technology Inc.

INTRODUCTION

X-10 is a communication protocol designed for sending

signals over 120 VAC wiring. X-10 uses 120 kHz bursts

timed with the power line zero-crossings to represent

digital information. Plug-in modules available from various vendors enable users to create home automation

systems by using the AC wiring already installed within

a home. Readers who would like an overview of the

X-10 signal format may refer to Appendix A.

®

PICmicro

conjunction with X-10 technology to create home

automation applications. The specific PICmicro

microcontroller (MCU) used should be selected based

on RAM, ROM, operating frequency, peripheral, and

cost requirements of the particular application. The

PIC16F877A was selected for this application because

of its versatility as a general purpose microcontroller,

its FLASH program memory (for ease of development),

data EEPROM, and ample I/O.

This application note discusses the implementation of

X-10 on a PICmicro MCU to create a home controller

that can both send and receive X-10 signals. The

reader may implement the home controller as is, or

adapt the circuits and firmware to other applications. A

library of X-10 functions is provided to facilitate development of other X-10 applications using PICmicro

MCUs (see Appendix E).

Operating instructions for the home controller are

included in Appendix B.

microcontrollers can easily be used in

HARDWARE OVERVIEW

The home controller application described in this application note allows the user to program on and off times

for up to sixteen devices, using a 2 x 16 liquid crystal

display and five push buttons. A built-in light sensor can

be used to turn on lights at dusk, and turn them off at

dawn.

The home controller is designed to facilitate experimentation with home automation using the

PIC16F877A. In addition to the PIC16F877A, the board

will accept any other PICmicro MCU that shares the

same pinout, such as the PIC18F452. Therefore,

experimenters may expand on the application using the

higher performance of the PIC18 family of parts without

changing the hardware.

With care, engineers and home control enthusiasts can

experiment with home automation using the

MPLAB

or in-circuit emulator. However, proper circuit isolation

precautions must be taken to avoid damage to your

computer or development tools. See Figure 1 and the

warning note!

®

ICD and MPLAB®ICD 2 development tools

WARNING: VSS or ground on the application circuit is

tied to neutral of the 120 VAC. To safely connect your

development tools or computer to the home controller, you must power it through an isolation transformer

and leave wall ground (the green wire in most cases)

disconnected. Any test instruments (such as an oscilloscope) that you hook up to the application circuit,

should be powered through the isolation transformer

as well, with wall ground disconnected. In addition,

the entire circuit should be enclosed within a suitable

case to prevent unintentional contact with the mains

voltage!

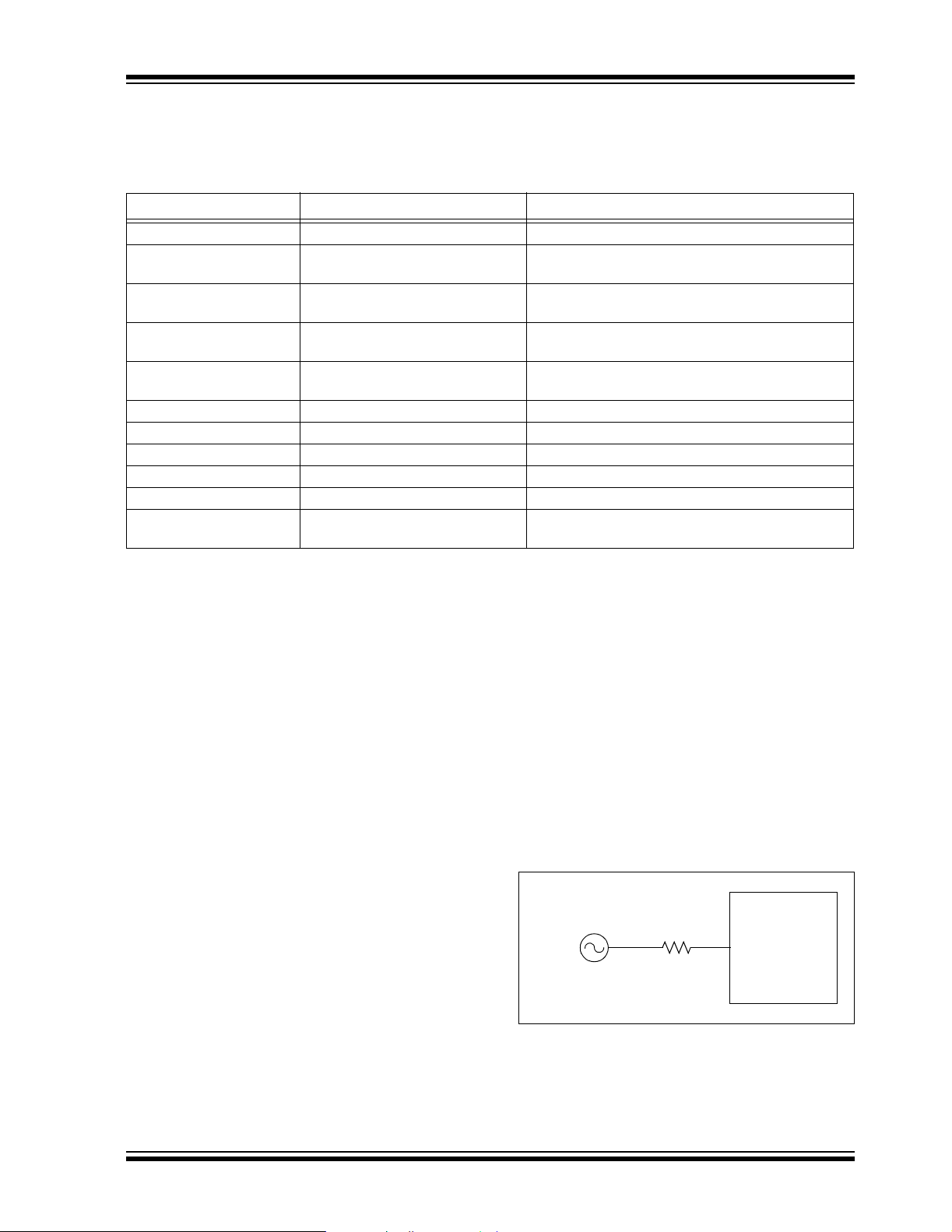

FIGURE 1: TEST SETUP WHEN USING DEVELOPMENT TOOLS

X-10

Isolation

Transformer

Computer,

development tools,

and the isolation

transformer should

be plugged into

the wall outlet.

2002 Microchip Technology Inc. DS00236A-page 1

Board

X-10

Lamp

Module

Oscillo-

scope

X-10

Lamp

Module

X-10 modules and

any test

instruments should

be plugged into

the isolation

transformer.

To m a i nt a in

isolation, leave

ground

disconnected.

AN236

HARDWARE DESCRIPTION

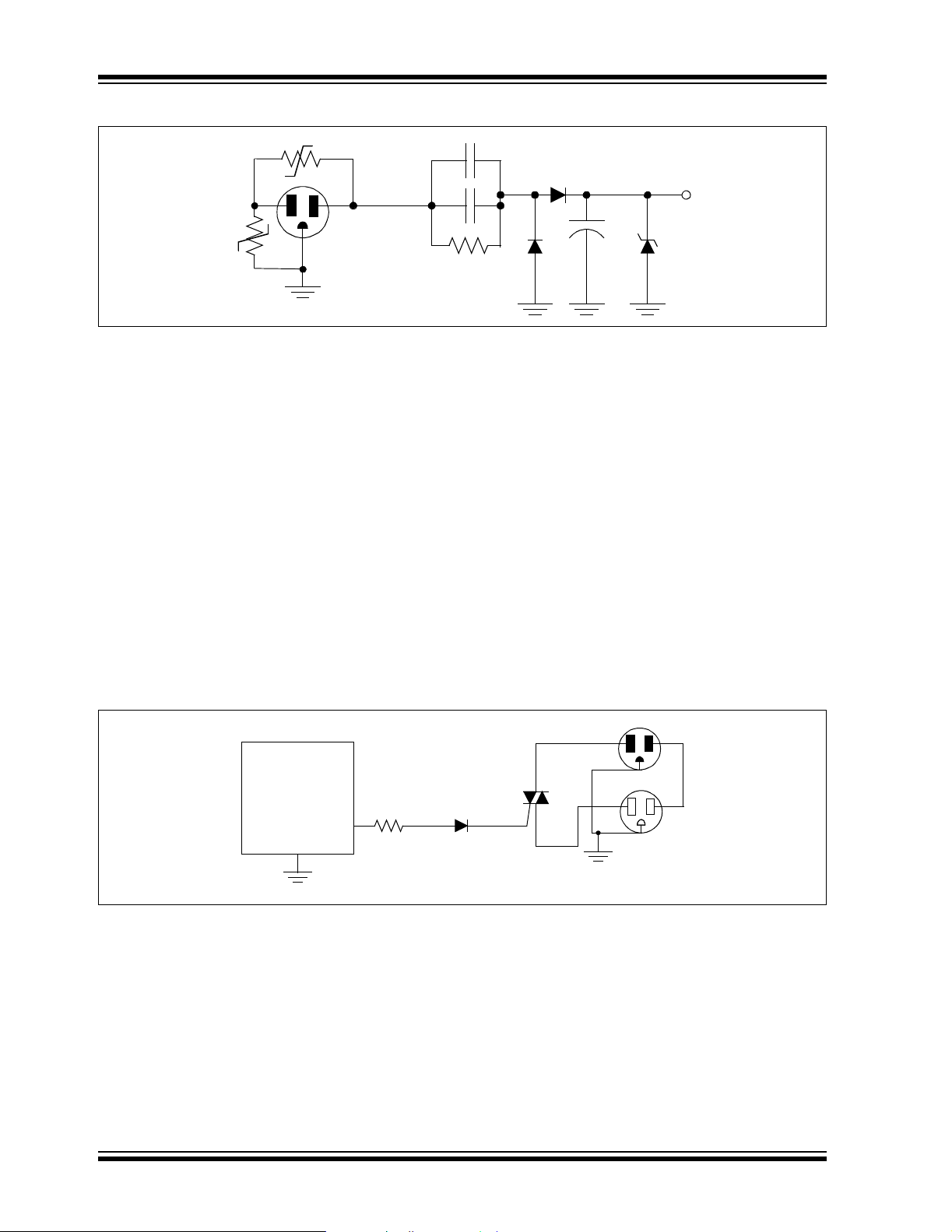

An overview of the home controller application

hardware is shown in Figure 2.

The hardware functionality of X-10 circuitry can be

divided into four functional blocks:

• Zero-crossing detector

• 120 kHz carrier detector

• 120 kHz signal generator

• Transformerless power supply

FIGURE 2: APPLICATION BLOCK DIAGRAM

X-10 FUNCTIONS

Zero-crossing Detector

120 kHz Carrier Detector

120 kHz Carrier Generator

There are several application functions that are not

directly associated with the X-10 interface. User

interface functions are accomplished with an LCD

display and five push buttons. A real-time clock is

created using Timer1 and an external 32 kHz oscillator.

User modified control data, such as unit on and off

times, are stored in the PICmicro MCU’s built-in

EEPROM. A light sensor and load switch are also used

in this application.

APPLICATION SPECIFIC FUNCTIONS

Light

Sensor

Real-time Clock Control Data

Load

Switch

Storage

USER INTERFACE

LCD Key Switches

TRANSFORMERLESS POWER

SUPPLY

DS00236A-page 2 2002 Microchip Technology Inc.

AN236

A summary of resource use can be seen in Table 1.

Details of the functional sections are discussed below.

TABLE 1: SUMMARY OF MICROCONTROLLER RESOURCE USE

Resource Function Description

External interrupt on RB0 Zero-crossing Detect Generates one interrupt every zero-crossing.

CCP1/Timer2 in PWM

mode

Timer2 interrupt through

postscaler

Timer1 interrupt Real-time Clock Used as time keeping clock and key scan clock.

Timer0 interrupt 120 kHz Envelope Timing Times duration of 1 ms bursts and onset of second

ADC Light Sensor Used to detect dawn and dusk.

PORTB<1:5> Key Press Inputs Five push buttons are used for menu navigation.

PORTB<6:7> Reserved for ICD Isolation precautions required. See warning note!

PORTD<0:7> LCD Data pins 8 data lines for LCD.

PORTE<0:2> LCD Control pins 3 control lines for LCD.

DATA EEPROM Non-volatile Control Data Storage Stores on and off times and other user

120 kHz Modulation TRISC is used to enable/disable 120 kHz output.

Main oscillator is 7.680 MHz.

Triac Dimmer Timing Generates dimmer timing increments for controlling

Triac.

One interrupt/25 ms, 40 interrupts/1 sec.

and third phase bursts.

programmable information.

Zero-Crossing Detector

In X-10, information is timed with the zero-crossings of

the AC power. A zero-crossing detector is easily created by using the external interrupt on the RB0 pin and

just one external component, a resistor, to limit the

current into the PICmicro MCU (see Figure 3).

In the United States, Vrms = 117 VAC, and the peak

line voltage is 165V. If we select a resistor of 5 MΩ,

Ipeak = 165V/5 MΩ =33µA, which is well within the

current capacity of a PICmicro MCU I/O pin.

Input protection diodes (designed into the PICmicro

MCU I/O pins) clamp any voltage higher than V

lower than V

the negative half of its cycle, the RB0 pin will be

clamped to V

logic zero. When the AC voltage rises above the input

threshold, the logical value will become a ‘1’.

In this application, RB0 is configured for external interrupts, and the input buffer is a Schmitt trigger. This

makes the input threshold 0.8 V

edge and 0.2 V

SS. Therefore, when the AC voltage is in

SS - 0.6V. This will be interpreted as a

DD = 4V on a rising

DD = 1V on a falling edge.

DD or

Upon each interrupt, the Interrupt Edge Select bit within

the OPTION_REG register is toggled, so that an interrupt occurs on every zero-crossing. Using the following

equation, it is possible to calculate when the pin state

will change relative to the zero-crossing:

V = Vpk*sin(2*π*f*t), where Vpk = 165V and f = 60 Hz

On a rising edge, RB0 will go high about 64 µs after the

zero-crossing, and on a falling edge, it will go low about

16 µs before the zero-crossing.

More information on interfacing PICmicro MCUs to AC

power lines can be found in the application note

AN521, “Interfacing to AC Power Lines”, which is

available for download from the Microchip web site.

FIGURE 3: ZERO-CROSSING DETECTOR

PIC16F87XA

120 VAC

R = 5 M

Ω

RB0/INT

2002 Microchip Technology Inc. DS00236A-page 3

AN236

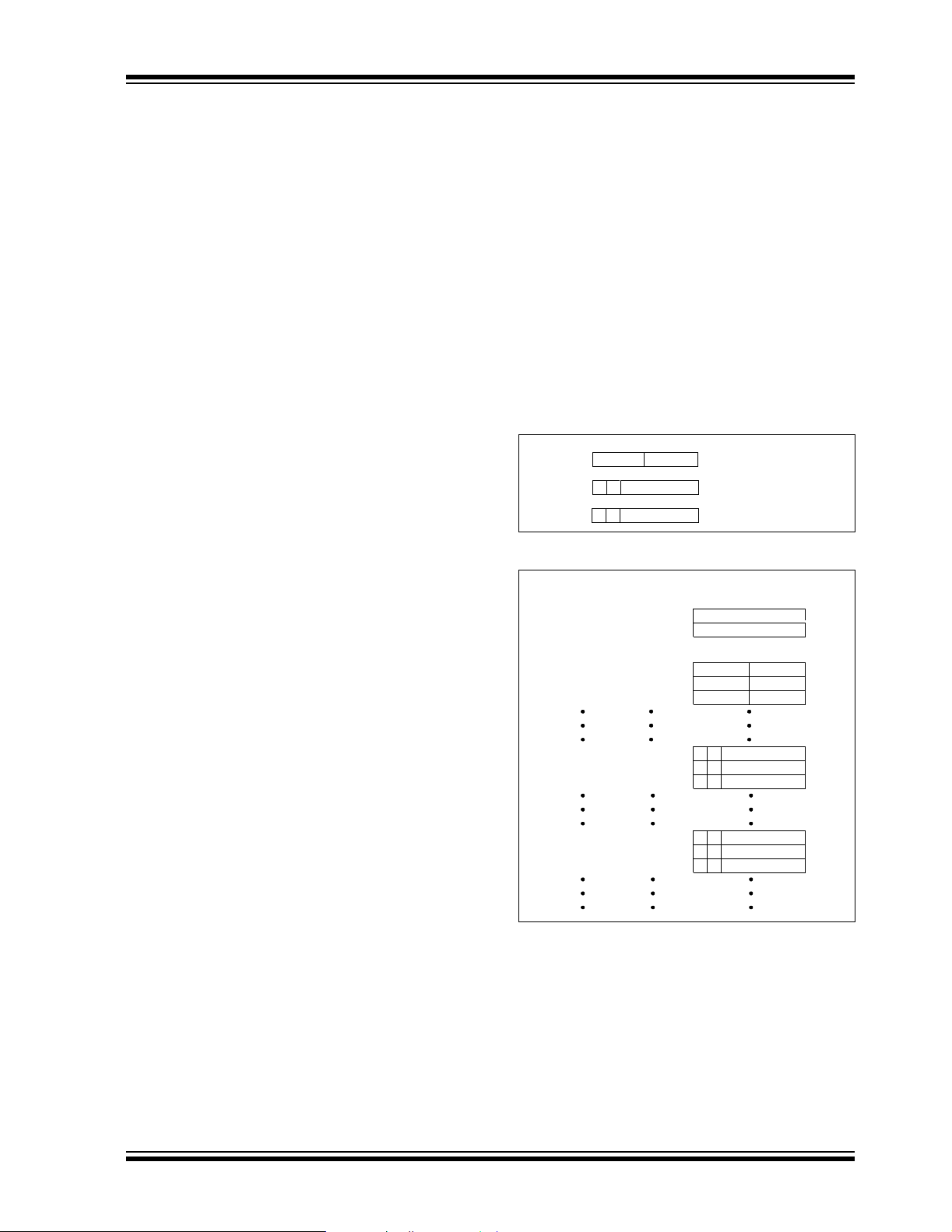

120 kHz Carrier Detector

To receive X-10 signals, it is necessary to detect the

presence of the 120 kHz signal on the AC power line.

This is accomplished with a decoupling capacitor, a

high-pass filter, a tuned amplifier, and an envelope

detector. The components of the carrier detector are

illustrated in Figure 4.

Because the impedance of a capacitor is:

Zc = 1/(2*π*f*C), a 0.1 µF capacitor presents a low

impedance (13Ω) to the 120 kHz carrier frequency, but

a high impedance (26.5 kΩ) to the 60 Hz power line frequency. This high-pass filter allows the 120 kHz signal

to be safely coupled to the 60 Hz power line, and it doubles as the coupling stage of the 120 kHz carrier

generator described in the next section.

Since the 120 kHz carrier frequency is much higher

than the 60 Hz power line frequency, it is

straightforward to design an RC filter that will pass the

120 kHz signal and completely attenuate the 60 Hz. A

high-pass filter forms the first stage of the High-Pass

Filter and Tuned Amplifier Block, shown on sheet 5 of

the schematics in Appendix C.

FIGURE 4: 120 kHz CARRIER DETECTOR

For a simple high-pass filter, the -3 db breakpoint is:

ƒ3 db = 1/(2*π*R*C). For C = 150 pF and R = 33 kΩ,

ƒ3 db = 1/(2*π*150 pF *33 kΩ)=32kHz.

This ƒ3 db point assures that the 60 Hz signal is completely attenuated, while the 120 kHz signal is passed

through to the amplifier stages. Next, the 120 kHz signal is amplified using a series of inverters configured as

high gain amplifiers. The first two stages are tuned

amplifiers with peak response at 120 kHz. The next two

stages provide additional amplification. The amplified

120 kHz signal is passed through an envelope detector, formed with a diode, capacitor, and resistor. The

envelope detector output is buffered through an

inverter and presented to an input pin (RC3) of the

PIC16F877A.

Upon each zero-crossing interrupt, RC3 is simply

checked within the 1 ms transmission envelope to see

whether or not the carrier is present. The presence or

absence of the carrier represents the stream of ‘1’s and

‘0’s that form the X-10 messages described in

Appendix A.

Decoupling

Capacitor

0.1

µF

X2 Rated

1 M

Ω

Note 1: See schematic in Appendix C.

High-Pass

Filter & Tuned

Amplifier

(1)

+5 VDC

10K

Envelope Detector

10 nF

PIC16F87XA

RC3

DS00236A-page 4 2002 Microchip Technology Inc.

AN236

120 kHz Carrier Generator

X-10 uses 120 kHz modulation to transmit information

over 60 Hz power lines. It is possible to generate the

120 kHz carrier with an external oscillator circuit. A single I/O pin would be used to enable or disable the oscillator circuit output. However, an external oscillator

circuit can be avoided by using one of the PICmicro

MCU’s CCP modules.

The CCP1 module is used in PWM mode to produce a

120 kHz square-wave with a duty cycle of 50%.

Because X-10 specifies the carrier frequency at

120 kHz (+/- 2 kHz), the system oscillator is chosen to

be 7.680 MHz, in order for the CCP to generate precisely 120 kHz. Calculations for setting the PWM

period and duty cycle are shown in the code listing

comments for the function InitPWM.

After initialization, CCP1 is continuously enabled, and

the TRISC bit for the pin is used to gate the PWM output. When the TRISC bit is set, the pin is an input and

the 120 kHz signal is not presented to the pin. When

the TRISC bit is clear, the pin becomes an output and

the 120 kHz signal is coupled to the AC power line

through a transistor amplifier and capacitor, as

depicted in Figure 5.

Since the impedance of a capacitor is Zc = 1/(2*π*f*C),

a 0.1 µF capacitor presents a low impedance to the

120 kHz carrier frequency, but a high impedance to the

60 Hz power line frequency. This high-pass filter allows

the 120 kHz signal to be safely coupled to the 60 Hz

power line, and it doubles as the first stage of the

120 kHz carrier detector, described in the previous

section.

To be compatible with other X-10 receivers, the maximum delay from the zero-crossing to the beginning of

the X-10 envelope should be about 300 µs. Since the

zero-crossing detector has a maximum delay of

approximately 64 µs, the firmware must take less than

236 µs after detection of the zero-crossing to begin

transmission of the 120 kHz envelope.

Transformerless Power Supply

The PIC16F877A and other board circuits require a 5V

supply. In this application, the X-10 controller must also

transmit and receive its data over the AC line. Since

X-10 components are intended to be plugged into a

wall outlet and have a small form factor, a transformerless power supply is used. Two characteristics of transformerless supplies that should be kept in mind are

limited current capacity, and lack of isolation from the

AC mains (see the warning note)!

WARNING: This circuit is not isolated from 120 VAC.

Act with caution when constructing or using such a

circuit, and ensure that it is contained within a suitable

insulated enclosure. Follow isolation precautions to

avoid personal injury or damage to test equipment

and development tools.

Figure 6 illustrates the transformerless power supply

used in this application. To protect the circuit from

spikes on the AC power line, a 130V VDR (voltage

dependent resistor) is connected between Line and

Neutral. A Positive Temperature Coefficient (PTC)

device acts as a resettable fuse, which limits current

between Ground and Neutral. The 47Ω resistor limits

current into the circuit, and the 1 MΩ resistor provides

a discharge path for the voltage left on the capacitor

when the circuit is unplugged from the wall. Two diodes

rectify the voltage across the 1000 µF capacitor and

5.1V Zener diode to produce a 5V supply.

The reader may wish to refer to the technical brief

TB008, “Transformerless Power Supply”, available for

download from the Microchip web site, for additional

information on transformerless power supply design.

FIGURE 5: 120 kHz CARRIER GENERATOR

+5 VDC

PIC16F87XA

7.680 MHz

2002 Microchip Technology Inc. DS00236A-page 5

OSC2

RC3/CCP

OSC1

200Ω

50Ω

High-Pass Filter

0.1 µF

X2 Rated

Ω

1 M

120 VAC

AN236

FIGURE 6: TRANSFORMERLESS POWER SUPPLY

VDR

LN

PTC

G

Load Switch

A load switch is included on the home controller so that

it may act as a lamp module, with its own house and

unit address. A Triac was selected as the load switch,

because its medium power switching capacity and

rapid switching capability make it well-suited for lamp

control and dimming.

A Triac is an inexpensive, three-terminal device that

basically acts as a high speed, bi-directional AC switch.

Two terminals, MT1 and MT2, are wired in series with

the load. A small trigger current between the gate and

MT1 allow conduction to occur between MT1 and MT2.

Current continues to flow after the gate current is

removed, as long as the load current exceeds the latching value. Because of this, the Triac will automatically

switch off near each zero-crossing as the AC voltage

falls below the latching voltage.

1N4005

A Teccor

1N4005

1000 µF

®

L4008L6 Triac was selected because it has

+5 VDC

5.1V Zener

2.25 µF

2.25 µF

1.1M

a sensitive gate that can be directly controlled from the

logic level output of the PICmicro MCU I/O pin. The

sensitive gate Triac can control AC current in both

directions through the device, even though the

PICmicro MCU can provide only positive voltages to

the gate.

A variable dimmer is created by including a delay

between the time of each zero-crossing and the time

that the trigger current is provided to the Triac from the

PICmicro MCU.

The design and control of a lamp dimmer using a

PICmicro MCU is discussed in detail in PICREF-4

Reference Design, “PICDIM Lamp Dimmer for the

PIC12C508”.

FIGURE 7: LOAD SWITCH/DIMMER (TRIAC)

PIC16F87XA

1N4148470Ω

RA5

VSS

L4008L6

Gate

Return Hot

MT1

MT2

120 VAC In

120 VAC Out

DS00236A-page 6 2002 Microchip Technology Inc.

AN236

LCD Module

The 2-line x 16-character display uses the HD44780U

Display Controller. Eight data lines and three control

lines are used to interface to the PICmicro MCU. If

fewer I/O pins are available, the LCD can be operated

in Nibble mode using only four data lines, with some

additional software overhead. A basic LCD library is

included in this application, which provides the

necessary functions for controlling this type of LCD.

Real-Time Clock

A real-time clock is implemented using Timer1. The

real-time clock keeps track of the present time using a

routine called UpdateClock. It also determines the

rate that the buttons are read by a routine called

ScanKeys.

Timer1 is set to cause an interrupt each time it

overflows. By adding a specific offset to Timer1 each

time it overflows, the time before the next overflow can

be precisely controlled. The button reading routine,

ScanKeys, is called each time a Timer1 interrupt

occurs. Since ScanKeys performs debouncing of the

button presses, a suitable rate to check the buttons is

once every 25 ms.

With a 32 kHz crystal, the counter increments once

every 31.25 µs when the prescaler is set to 1:1. In order

for Timer1 to generate an interrupt once every 25 ms,

TMR1H:TMR1L are pre-loaded with 0xFCE0h.

The Timer1 interrupt interval, or tick, can be seen in the

following equation:

(FFFFh – FCE0h)*1/32 kHz = .025 s = 1 tick

Each time ScanKeys is called (every 25 ms), it calls

UpdateClock. UpdateClock keeps track of the time

unit variables: ticks, seconds, minutes, and hours.

Since every 25 ms equals one tick, seconds are incremented every 40 ticks. Minutes and hours are

incremented in a similar fashion.

development tool, without taking first isolating the

entire application from wall power (see the previous

warning notes)!

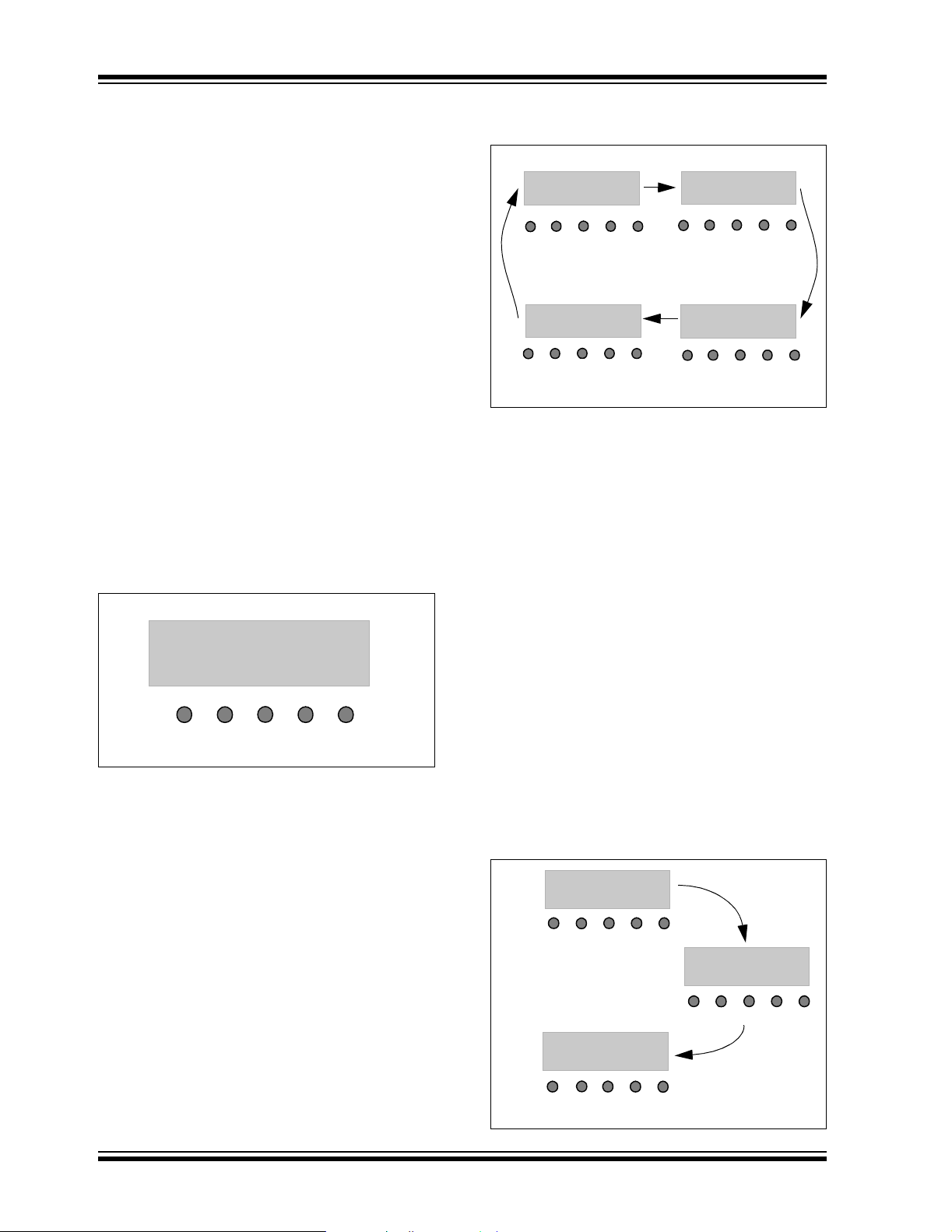

Control Data Storage

Certain control data that is programmable by the user

must be stored in non-volatile memory. The PICmicro

MCU’s built-in EEPROM is well-suited to this task.

To use EEPROM memory space most efficiently (by

avoiding wasted bits), on/off times and light sensor

control flags are stored using the format shown in

Figure 8. Figure 9 shows the location of on/off times

and other information within the data EEPROM. Using

this data organization, only 48 bytes of EEPROM are

required to store the on/off times and light sensor

control flags for 16 units.

FIGURE 8: ON/OFF TIME STORAGE

4 bits 4 bits

EEHours

EEOnMinutes

EEOffMinutes

On Hour Off Hour

11

A

11

C D

6 bits

BOnMin

6 bits

Off Min

FIGURE 9: EEPROM DATA

Address Unit

0x001

0x002

0x010

0x011

0x012

0x020

0x021

0x022

System

System

Unit 1

Unit 2

Unit 3

Unit 1

Unit 2

Unit 3

A = AM/PM bit for On Hour

B = Control bit for On at Dusk

C = AM/PM bit for Off Hour

D = Control bit for Off at Dawn

Data

House Address

Unit Address

OnHour OffHour

OnHour OffHour

OnHour OffHour

B OnMinA

B OnMinA

B OnMinA

Push Buttons

Five push buttons, connected to RB1-RB5, are used for

user interaction with the application. Each normally open

push button will pull a port pin low when it is pressed.

0x030

0x031

0x032

Unit 1

Unit 2

Unit 3

B OffMinA

B OffMinA

B OffMinA

Light Sensor

To detect the ambient light level, a CdS photoresistor is

used in conjunction with an 820Ω resistor to create a

voltage divider. The voltage on the divider varies with

the intensity of ambient light and is connected to an

analog channel (AN0) of the microcontroller.

In-Circuit Debugger

RB6 and RB7 have been reserved for In-Circuit Serial

Programming

(ICD). However, do not connect the ICD or any other

2002 Microchip Technology Inc. DS00236A-page 7

TM

(ICSPTM) and the in-circuit debugger

Each time that minutes are incremented within the

UpdateClock routine, a flag is set that enables a routine called CheckOnOffTimes to be called from the

main loop. CheckOnOffTimes compares the present

time with the unit on and off times stored in EEPROM

memory. If there is a match, then a flag is set to either

turn the unit on or off, by sending it the appropriate X-10

command when the routine ControlX10Units is

called.

AN236

APPLICATION FIRMWARE OVERVIEW

The firmware is divided into several different files to

facilitate adaptation of the code to other applications.

Following is a summary of the files associated with this

application note:

• x10lib.asm Defines X-10 functions.

• x10lib.inc Defines X-10 constants and

macros.

• x10hc.asm Main application code for the

home controller.

• x10demo.asm Example code that shows how

to use the X-10 library macros.

• lcd.asm Defines the routines necessary

for driving the LCD.

• p16f877A.lkr Standard linker file for

PIC16F877A parts.

• p16f877A.inc Standard include file for

PIC16F877A parts.

Detailed descriptions of operation can be found in the

comments within the code listing. The X-10 library

functions and macros are described in the next section.

X-10 LIBRARY

A simple library of commands was developed and used

for the home controller. It can be used with little or no

modification in a user’s application. The library consists

of two files: x10lib.asm and x10lib.inc.

To use the library, a user need only understand the

function of the macros defined in x10lib.inc. The

macros greatly simplify the use of the library by eliminating the need for the user to understand every X-10

function in x10lib.asm. Examples of how the macros

are used are included in the file x10demo.asm.

The macros are explained below:

InitX10

This macro is used to initialize the peripherals that provide X-10 functionality. It must be called in the application program before any of the below macros will work.

It is used as follows:

InitX10

SkipIfTxReady

Before sending an X-10 message, it is necessary to

make sure that another message is not already being

sent, which is signified by the X10TxFlag being set.

This macro simply checks that flag and skips the next

instruction if it is okay to begin a new transmission.

Otherwise, there is a chance that a new transmission

will interrupt an ongoing transmission.

It is used as follows:

SkipIfTxDone

GOTO $-1 ;loop until ready to

;transmit next message

SendX10Address (House, Unit)

This macro is used to send an X-10 address for a particular unit. It requires two arguments, a house address

and unit address. The definitions for all house and unit

addresses are defined in x10lib.inc. To use this

macro to send the address for unit 16 at house P, one

simply types:

SendX10Address HouseP, Unit16

SendX10AddressVar

This macro is used to send an X-10 address, defined

by variables rather than constants. To send an address

contained in the user variables MyHouse and MyUnit,

the following sequence would be applied:

MOVF MyHouse, W ;contains a value

;from 0-16

MOVWF TxHouse

MOVF MyUnit, W ;contains a value

;from 0-16

MOVWF TxUnit

SendX10AddressVar

DS00236A-page 8 2002 Microchip Technology Inc.

AN236

SendX10Command (House, Function)

This macro is used to send an X-10 command. It

requires two arguments, the house address and function code. The definitions for all house addresses and

function codes are defined in x10lib.inc. To use this

macro to send the command ‘All Lights On’ to all units

at house A, one types:

SendX10Command HouseA, AllLightsOn

SendX10CommandVar

This macro is used to send an X-10 command, defined

by a variable rather than a constant. To use this macro

to send the command stored in the user variable

MyCommand to all units at MyHouse, one types:

MOVF MyHouse, W ;contains a value

;from 0-16

MOVWF TxHouse

MOVF MyCommand, W ;any X-10

;function

;defined in

;x10lib.inc

MOVWF TxFunction

SendX10CommandVar

SkipIfRxDone

Before reading an X-10 message, it is necessary to

make sure that a complete message has been

received. This is signified by the X10RxFlag being set.

This macro simply checks that flag and skips the next

instruction if a new X-10 message has been received.

It is used as follows:

SkipIfRxDone

GOTO $-1 ;loop until message

;received

SkipIfAddressRcvd

It may be necessary to make sure that an address was

received by using this macro, which checks to see if the

RxCommandFlag is clear.

It is used as follows:

SkipIfAddressRcvd

GOTO $-1 ;loop until address

;received

SkipIfCommandRcvd

Or, it may be necessary to make sure that a command

was received by using this macro, which checks to see

if the RxCommandFlag is set.

It is used as follows:

SkipIfCommandRcvd

GOTO $-1 ;loop until command

;received

ReadX10Message

This macro is called to read a received X-10 message,

which may be either an address or a command. If the

message was an address, then the received house and

unit codes will be stored in the variables RxHouse and

RxUnit, respectively. If the message was a command,

then the received house address and function code will

be stored in the variables RxHouse and RxFunction.

It is simply called as follows:

ReadX10Message

Please refer to the example code in x10demo.asm to

see how each of these macros is used in a simple

application.

2002 Microchip Technology Inc. DS00236A-page 9

AN236

Memory Usage

Memory usage for the X-10 portion of the application is

summarized in Table 2.

TABLE 2: SUMMARY OF MEMORY USAGE FOR X-10 FUNCTIONALITY

Memory Type Used Available on PIC16F877A Percent Used

FLASH Program Memory 437 words 8453 words 5%

Data Memory (RAM) 62 bytes 368 bytes 17%

EEPROM Data Memory 0 bytes 256 bytes 0%

Memory usage for the entire home controller

application is summarized in Table 3.

TABLE 3: SUMMARY OF MEMORY USAGE FOR THE HOME CONTROLLER

Memory Type Used Available on PIC16F877A Percent Used

FLASH Program Memory 3762 words 8453 words 44.5%

Data Memory (RAM) 168 bytes 368 bytes 45.6%

EEPROM Data Memory 51 bytes 256 bytes 20%

DS00236A-page 10 2002 Microchip Technology Inc.

AN236

CONCLUSION

The PICmicro MCU is well-suited to X-10 applications.

With its plethora of on-chip peripherals and a few external components, a PICmicro MCU can be used to

implement an X-10 system that can transmit and

receive messages over the AC power line wiring. The

small code size of the X-10 library leaves ample space

for the user to create application specific code.

PICmicro MCUs, such as the PIC16F877A, have plenty

of additional resources for creating more complex X-10

applications, while smaller PICmicro MCUs can be

selected for economical use in simpler X-10

applications.

USEFUL WEB REFERENCES

• http://www.abacuselectrics.com/x10.htm

This web site describes how to build an appliance

module that utilizes the PIC16C52 or PIC16F84.

Parts of this project’s receiver circuit, designed by

Phil Plunkett, were adapted to the home controller

application.

• http://www.microchip.com

The Microchip web site features data sheets, product

information, and more. Helpful technical

documentation available here include:

AN521 “Interfacing to AC Power Lines”

TB008 “Transformerless Power Supply”

PICREF-4 “PICDIM Lamp Dimmer for the

PIC12C508”

• http://www.x10.com/support

TM

The X10 Wireless Technology, Inc.

tures technical information and FAQs pertaining to

the X-10 communication protocol.

web site fea-

2002 Microchip Technology Inc. DS00236A-page 11

AN236

APPENDIX A: HOW DOES THE X-10

PROTOCOL WORK?

X-10 transmissions are synchronized with the

zero-crossings on the AC power line. By monitoring for

the zero-crossings, X-10 devices know when to transmit or receive X-10 information. A binary ‘1’ is represented by a 1 ms long burst of 120 kHz, near the

zero-crossing point of the AC. A binary zero is

represented by the lack of the 120 kHz burst.

FIGURE A-1: X-10 TRANSMISSION TIMING

(1)

(1)

120 kHz

60 Hz

1 ms

2.778 ms

5.556 ms

8.333 ms

Note 1: These 120 kHz carrier bursts are timed to coincide with the zero-crossing of the other phases,

when implemented.

A complete X-10 message is composed of a start code

(1110), followed by a house code, followed by a key

code. The key code may be either a unit address or a

function code, depending on whether the message is

an address or a command. Table A-1 and Table A-2

show the possible values of the house and key codes.

(1)

(1)

DS00236A-page 12 2002 Microchip Technology Inc.

AN236

TABLE A-1: HOUSE CODES

House

Addresses

A 0110

B 1110

C 0010

D 1010

E 0001

F 1001

G 0101

H 1101

I 0111

J 1111

K 0011

L 1011

M 0000

N 1000

O 0100

P 1100

H1 H2 H4 H8

House Codes

TABLE A-2: KEY CODES

Unit Addresses

1 01100

2 11100

3 00100

4 10100

5 00010

6 10010

7 01010

8 11010

9 01110

10 11110

11 00110

12 10110

13 00000

14 10000

15 01000

16 11000

All Units Off 00001

All Units On 00011

Bright 01011

All Lights Off 01101

Extended Code 01111

Hail Request 10001

Hail Acknowledge 10011

Function Codes

Pre-set Dim 101X1

Extended Code

(Analog)

Status = On 11011

Status = Off 11101

Status Request 11111

D1 D2 D4 D8 D16

On 00101

Off 00111

Dim 01001

Key Codes

11001

When transmitting the codes in Table A-1 and

Table A-2, two zero-crossings are used to transmit

each bit as complementary bit pairs (i.e., a zero is represented by 0-1, and a one is represented by 1-0). For

example, in order to send the house code A, the four-bit

code in Table A-1 is 0110, and the code transmitted as

complimentary bit pairs is 01101001. Since house and

key codes are sent using the complimentary format, the

start code is the only place where the pattern 1110 will

appear in an X-10 data stream.

The key code, which is 5-bits long in Table A-2, takes

10 bits to represent in the complimentary format.

Because the last bit of the key code is always zero for

a unit address and one for a function code, the last bit

of the key code can be treated as a suffix that denotes

whether the key code is a unit address or function

code.

A complete block of data consists of the start code,

house code, key code and suffix. Each data block is

sent twice, with 3 power line cycles, or six

zero-crossings, between each pair of data blocks.

For example, to turn on an X-10 module assigned to

house code A, unit 2, the following data stream would

be sent on the power line, one bit per zero-crossing.

First, send the address twice:

1110 01101001 10101001 01

START HOUSE A UNIT 2 Suffix

1110 01101001 10101001 01

START HOUSE A UNIT 2 Suffix

Next, wait for three cycles (six zero-crossings):

000000

Then, send the command twice:

1110 01101001 01011001 10

START HOUSE A ON Suffix

1110 01101001 01011001 10

START HOUSE A ON Suffix

Lastly, wait for three cycles (six zero-crossings) before

sending the next block:

000000

There are exceptions to this format. For example, the

bright and dim codes do not require the 3-cycle wait

between consecutive dim commands or consecutive

bright commands. For a complete discussion of all

X-10 messages, please refer to the X10 Wireless

Technology, Inc. web site (see the "USEFUL WEB

REFERENCES" section).

2002 Microchip Technology Inc. DS00236A-page 13

AN236

APPENDIX B: HOME CONTROLLER

OPERATING

INSTRUCTIONS

Welcome Screen

The home controller user interface consists of five buttons and a 2 x 16 LCD. Upon power-up, the Welcome

screen is displayed. This screen displays a welcome

message and the time. Immediately, the seconds begin

incrementing and the PICmicro MCU begins keeping

track of the time.

Figure B-1 shows the Welcome screen and the location

and functionality of each button. Depending on the

screen viewed, each of the five buttons performs a

different function.

When the Welcome screen is displayed, the buttons

enable access to the following functions:

•Press menu to enter the Select Function screen.

•Press up to brighten the lamp that is plugged into

the home controller.

•Press down to dim the lamp.

•Press enter to turn the lamp on.

•Press exit to turn the lamp off.

FIGURE B-1: WELCOME SCREEN

FIGURE B-2: SELECT FUNCTION

SCREENS

Select Function

Set System Time

menu up down

Select Function

Program Unit

menu up down

exit

enter

1

enter

exit

4

Select Function

Set System Addr

menu up down

2

Select Function

Set Light Sensor

menu up down

3

enter

enter

exit

exit

Set System Time Screen

Use the Set System Time screen to set the time.

SETTING SYSTEM TIME

1. Starting from the Welcome screen, press menu

until the Set System Time screen is displayed

and press enter.

2. Press up/down to set the hours.

Welcome Home

12:00:00 AM

menu up down

Select Function Screen

When viewing the Welcome screen, the menu button

enables access to the Select Function screen. Each

successive press of the menu button cycles through

the four main functions of the user interface: setting the

system time, setting the system address, setting the

light sensor, or programming the unit on and off times,

as illustrated in Figure B-2.

enter

exit

3. Press enter when the correct hour, including AM

or PM, has been selected.

4. Repeat this process to set the minutes.

5. If the time is correct, select Y (the default) using

the up/down buttons and press enter. This

returns to the Welcome screen with the new

time displayed.

6. If the time is not correct, select N and press

enter. This will return the user to step 2 so the

correct time can be entered.

7. Press exit at any time to return the user to the

Welcome screen without saving the new time.

FIGURE B-3: SET SYSTEM TIME SCREENS

Set System Time

12:00 AM Set hrs

menu up down

1

Set System Time

12:00 AM Okay? Y

enter

exit

Set System Time

12:00 AM Set min

menu up down

enter

2

exit

menu up down

DS00236A-page 14 2002 Microchip Technology Inc.

enter

exit

3

AN236

Select System Address Screen

Use the Set System Address screen to set the house

address and unit address of the home controller.

SETTING HOUSE/UNIT ADDRESS

1. From the Welcome screen, press menu until the

Set System Addr screen is displayed and press

enter.

2. Press up or down to set the house address (a

letter from A - P).

3. Press enter when the house address has been

selected.

4. Repeat steps 2 and 3 to set the unit address (a

number from 1 - 16).

5. If the house and unit addresses are correct,

select Y (the default) using the up/down buttons

and press enter. This returns to the Welcome

screen with the new address stored in

non-volatile memory.

6. If the address is not correct, select N and press

enter. This will return the user to step 2.

7. Press exit at any time to return the user to the

Welcome screen without saving the new

address.

FIGURE B-4: SET SYSTEM ADDRESS

SCREENS

Set System Addr

A-01 Set House

menu up down

1

Set System Addr

A-01 Okay? Y

menu up down enter

3

enter

exit

Set System Addr

A-01 Set Unit

menu up down

exit

enter

exit

2

Set Light Sensor Screen

Use the Set Light Sensor screen to select whether

units turn on at dusk, or off at dawn.

SETTING THE LIGHT SENSOR

1. From the Welcome screen, press menu until the

Set Light Sensor screen is displayed and press

enter.

2. Press up or down to select the desired unit. The

house address will already be set to the system

house address.

3. Press enter when the desired unit address has

been selected.

4. Press up or down to select whether or not the

unit should turn on at dusk, and press enter.

5. Repeat this process to set other units as

desired.

6. Press exit to return to the Welcome screen.

Pressing exit while the “On at Dusk” or “Off at

Dawn” prompt is displayed will return the user to

the Welcome screen without modifying that

parameter.

FIGURE B-5: SET LIGHT SENSOR

SCREENS

Set Light Sensor

A-01 Set Unit

menu up down

1

Set Light Sensor

Off at Dawn? Y

menu up down enter

3

enter

exit

Set Light Sensor

On at Dusk? Y

menu up down

exit

exit

enter

2

2002 Microchip Technology Inc. DS00236A-page 15

AN236

Program Unit Screen

Use the Program Unit screen to program on and off

times for different units.

PROGRAMMING UNIT ON AND OFF TIMES

1. From the Welcome screen, press menu repeatedly until the Program Unit screen is displayed

and press enter.

2. Press up or down to select the desired unit. The

house address will already be set to the system

house address.

3. Press enter when the unit address has been

selected.

4. Press up or down to set the ‘on’ time hours.

Hours set to ‘00’ means that the unit will not be

turned on at any time.

5. Press enter when the correct hour, including AM

or PM, has been selected.

6. Repeat this process to set the ‘on’ time minutes.

If the hour has been set to ‘00’, then the minutes

will be set to ‘00’ automatically.

7. If the time is correct, select Y (the default) using

the up/down buttons and press enter. The user

will be prompted to program the ‘off’ time in a

similar fashion.

8. If the time is not correct, select N and press

enter. This allows the user to re-enter the hour

and minutes by returning to step 2.

9. Repeat this process to set the ‘on’ and ‘off’ time

for other units as desired.

10. Press exit to return to the Welcome screen.

Pressing exit while the “Set Hours” or “Set Min”

prompt is displayed will return the user to the

Welcome screen without modifying any

parameters.

FIGURE B-6: PROGRAM UNIT ‘ON’ TIME

SCREENS

Program Unit

A-01 Set Unit

menu up down

Program On-Time

00:00AM Set hrs

menu up down

Program On-Time

00:00AM Set min

menu up down

Program On-Time

00:00AM Okay? Y

N

menu up down

Program Off-Time

00:00AM Set hrs

menu up down

Y

enter

enter

enter

enter

enter

exit

exit

exit

exit

exit

Program Off-Time

00:00AM Set min

menu up down

Program Off-Time

00:00AM Okay? Y

N

menu up down

Y

DS00236A-page 16 2002 Microchip Technology Inc.

enter

enter

exit

exit

APPENDIX C: X-10 SCHEMATICS

FIGURE C-1: SHEET 1 OF 5

AN236

RE2

RE1

RE0

RD7

RD6

RD5

U1

CDS

MCLR

RD4

RD3

RD2

RD1

RD0

TRIAC

ZEROX

XIN

XOUT

UP

MENU

DOWN

EXIT

ENTER

2002 Microchip Technology Inc. DS00236A-page 17

AN236

FIGURE C-2: SHEET 2 OF 5

EXIT

ENTER

RD0

RD1

RD2

RD3

RD4

RD5

RD6

RD7

DOWN

UP

MENU

LCD1

RE2

RE1

CDS

RE0

DS00236A-page 18 2002 Microchip Technology Inc.

FIGURE C-3: SHEET 3 OF 5

AN236

TRIAC

+5V

XIOCIRCUITS

2002 Microchip Technology Inc. DS00236A-page 19

AN236

FIGURE C-4: SHEET 4 OF 5

ZEROX

XIOCIRCUITS

CARRIERDATA

XOUT

DS00236A-page 20 2002 Microchip Technology Inc.

FIGURE C-5: SHEET 5 OF 5

AN236

XIN

CARRIERDATA

2002 Microchip Technology Inc. DS00236A-page 21

AN236

APPENDIX D: PARTS LIST

Count Reference Value Description

2 D7, D8 6.8V Zener Diode

2 D4, D5 1N4005 Diode

2 D3, D9 1N4148 Diode

1 D6 5.1V Zener Diode

1 Q2 2N2222 NPN Transistor

1 J2 Power In Connector

2 J1 Power Out Connector

1 U2 CD4069 HEX Inverters

8 C1, C2, C3, C8, C9, C10, C11, C12 0.1 µF Capacitor

4 C4, C5, C6, C7 15 pF Capacitor

1 C13 0.1 µF Capacitor

2 C14, C15 2.25 µF, 250V x2 Capacitor

2 C21, C22 3.3 nF Capacitor

2 C25, C26 4.7 nF Capacitor

1 C20 10 nF Capacitor

2 C23, C24 10 pF Capacitor

1 C27 100 pF Capacitor

2 C18, C19 150 pF Capacitor

1 C16 1000 µF, 25V Capacitor

1 C17 0.1 µF, 275 VAC x2 Capacitor

1 Y2 7.680 MHz Crystal

1Y1 32 kHz Crystal

2 L1, L2 220 µH Axial Lead Inductor

1 LCD1 CG161 HD44780-based 2x16 Liquid Crystal Display

2 D1, D2 LTL-94PEKTA LEDs

1 U1 PIC16F877A Microcontroller

1R6 20 kΩ Potentiometer

1PTC1 CdS Cell

1 PTC2 Resettable PTC's Resistor

1 R18 1 MΩ Resistor

1 R14 1.1 MΩ Resistor

1 R13 2 MΩ Resistor

1 R17 5 MΩ Resistor

7 R1, R4, R5, R7, R8, R9, R21 10 kΩ Resistor

1 R22 33 kΩ Resistor

1 R25 47 kΩ Resistor

1 R19 50 kΩ Resistor

1 R16 100 kΩ Resistor

2 R15, R23 100 kΩ Resistor

1 R20 200Ω Resistor

1 R24 220 kΩ Resistor

2 R2, R3 680Ω Resistor

1 R10 820Ω Resistor

1R11 470Ω Resistor

1 R12 470 kΩ Resistor

1 R26 10 MΩ Resistor

6 S1, S2, S3, S4, S5, S6 Push Button Switches

7 P1, P2, P3, P4, P5, P6, P7 Test Points

1 Q1 TIC206D Sensitive Gate Triac

1 VDR1 130V Varistor (Voltage Dependent Resistor)

DS00236A-page 22 2002 Microchip Technology Inc.

APPENDIX E: SOURCE CODE

Due to size considerations, the complete source code

for this application note is not included in the text. A

complete version of the source code, with all required

support files, is available for download as a Zip archive

from the Microchip web site, at:

www.microchip.com

AN236

2002 Microchip Technology Inc. DS00236A-page 23

AN236

NOTES:

DS00236A-page 24 2002 Microchip Technology Inc.

Note the following details of the code protection feature on PICmicro® MCUs.

• The PICmicro family meets the specifications contained in the Microchip Data Sheet.

• Microchip believes that its family of PICmicro microcontrollers is one of the most secure products of its kind on the market today,

when used in the intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our knowledge, require using the PICmicro microcontroller in a manner outside the operating specifications contained in the data sheet.

The person doing so may be engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable”.

• Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of

our product.

If you have any further questions about this matter, please contact the local sales office nearest to you.

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with

express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, K

EELOQ,

MPLAB, PIC, PICmicro, PICSTART and PRO MATE are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

FilterLab, microID, MXDEV, MXLAB, PICMASTER, SEEVAL

and The Embedded Control Solutions Company are

registered trademarks of Microchip Technology Incorporated

in the U.S.A.

dsPIC, dsPICDEM.net, ECONOMONITOR, FanSense,

FlexROM, fuzzyLAB, In-Circuit Serial Programming, ICSP,

ICEPIC, microPort, Migratable Memory, MPASM, MPLIB,

MPLINK, MPSIM, PICC, PICDEM, PICDEM.net, rfPIC, Select

Mode and Total Endurance are trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2002, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999

and Mountain View, California in March 2002.

The Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro

devices, Serial EEPROMs, microperipherals,

non-volatile memory and analog products. In

addition, Microchip’s quality system for the

design and manufacture of development

systems is ISO 9001 certified.

®

8-bit MCUs, KEELOQ

®

code hopping

2002 Microchip Technology Inc. DS00236A - page 25

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200 Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Rocky Mountain

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7966 Fax: 480-792-4338

Atlanta

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770-640-0034 Fax: 770-640-0307

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-692-3848 Fax: 978-692-3821

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-818-7423 Fax: 972-818-2924

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538-2250 Fax: 248-538-2260

Kokomo

2767 S. Albright Road

Kokomo, Indiana 46902

Tel: 765-864-8360 Fax: 765-864-8387

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263-1888 Fax: 949-263-1338

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436-7955

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Canada

Tel: 905-673-0699 Fax: 905-673-6509

ASIA/PACIFIC

Australia

Microchip Technology Australia Pty Ltd

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-9868-6733 Fax: 61-2-9868-6755

China - Beijing

Microchip Technology Consulting (Shanghai)

Co., Ltd., Beijing Liaison Office

Unit 915

Bei Hai Wan Tai Bldg.

No. 6 Chaoyangmen Beidajie

Beijing, 100027, No. China

Tel: 86-10-85282100 Fax: 86-10-85282104

China - Chengdu

Microchip Technology Consulting (Shanghai)

Co., Ltd., Chengdu Liaison Office

Rm. 2401, 24th Floor,

Ming Xing Financial Tower

No. 88 TIDU Street

Chengdu 610016, China

Tel: 86-28-86766200 Fax: 86-28-86766599

China - Fuzhou

Microchip Technology Consulting (Shanghai)

Co., Ltd., Fuzhou Liaison Office

Unit 28F, World Trade Plaza

No. 71 Wusi Road

Fuzhou 350001, China

Tel: 86-591-7503506 Fax: 86-591-7503521

China - Shanghai

Microchip Technology Consulting (Shanghai)

Co., Ltd.

Room 701, Bldg. B

Far East International Plaza

No. 317 Xian Xia Road

Shanghai, 200051

Tel: 86-21-6275-5700 Fax: 86-21-6275-5060

China - Shenzhen

Microchip Technology Consulting (Shanghai)

Co., Ltd., Shenzhen Liaison Office

Rm. 1315, 13/F, Shenzhen Kerry Centre,

Renminnan Lu

Shenzhen 518001, China

Tel: 86-755-82350361 Fax: 86-755-82366086

China - Hong Kong SAR

Microchip Technology Hongkong Ltd.

Unit 901-6, Tower 2, Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2401-1200 Fax: 852-2401-3431

India

Microchip Technology Inc.

India Liaison Office

Divyasree Chambers

1 Floor, Wing A (A3/A4)

No. 11, O’Shaugnessey Road

Bangalore, 560 025, India

Tel: 91-80-2290061 Fax: 91-80-2290062

Japan

Microchip Technology Japan K.K.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Korea

Microchip Technology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea 135-882

Tel: 82-2-554-7200 Fax: 82-2-558-5934

Singapore

Microchip Technology Singapore Pte Ltd.

200 Middle Road

#07-02 Prime Centre

Singapore, 188980

Tel: 65-6334-8870 Fax: 65-6334-8850

Taiwan

Microchip Technology (Barbados) Inc.,

Taiwan Branch

11F - 3, N o. 2 07

Tung Hua North Road

Taipei, 105, Taiwan

Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

EUROPE

Austria

Microchip Technology Austria GmbH

Durisolstrasse 2

A-4600 Wels

Austria

Tel: 43-7242-2244-399

Fax: 43-7242-2244-393

Denmark

Microchip Technology Nordic ApS

Regus Business Centre

Lautrup hoj 1-3

Ballerup DK-2750 Denmark

Tel: 45 4420 9895 Fax: 45 4420 9910

France

Microchip Technology SARL

Parc d’Activite du Moulin de Massy

43 Rue du Saule Trapu

Batiment A - ler Etage

91300 Massy, France

Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Germany

Microchip Technology GmbH

Steinheilstrasse 10

D-85737 Ismaning, Germany

Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Italy

Microchip Technology SRL

Centro Direzionale Colleoni

Palazzo Taurus 1 V. Le Colleoni 1

20041 Agrate Brianza

Milan, Italy

Tel: 39-039-65791-1 Fax: 39-039-6899883

United Kingdom

Microchip Ltd.

505 Eskdale Road

Winnersh Triangle

Wokingham

Berkshire, England RG41 5TU

Tel: 44 118 921 5869 Fax: 44-118 921-5820

10/18/02

DS00236A-page 26 2002 Microchip Technology Inc.

Loading...

Loading...