Page 1

INTRODUCTION

PN. 33-2855

I N S T A L L A T I O N I N S T R U C T I O N S

SONANCE SYMPHONY EXTREME T

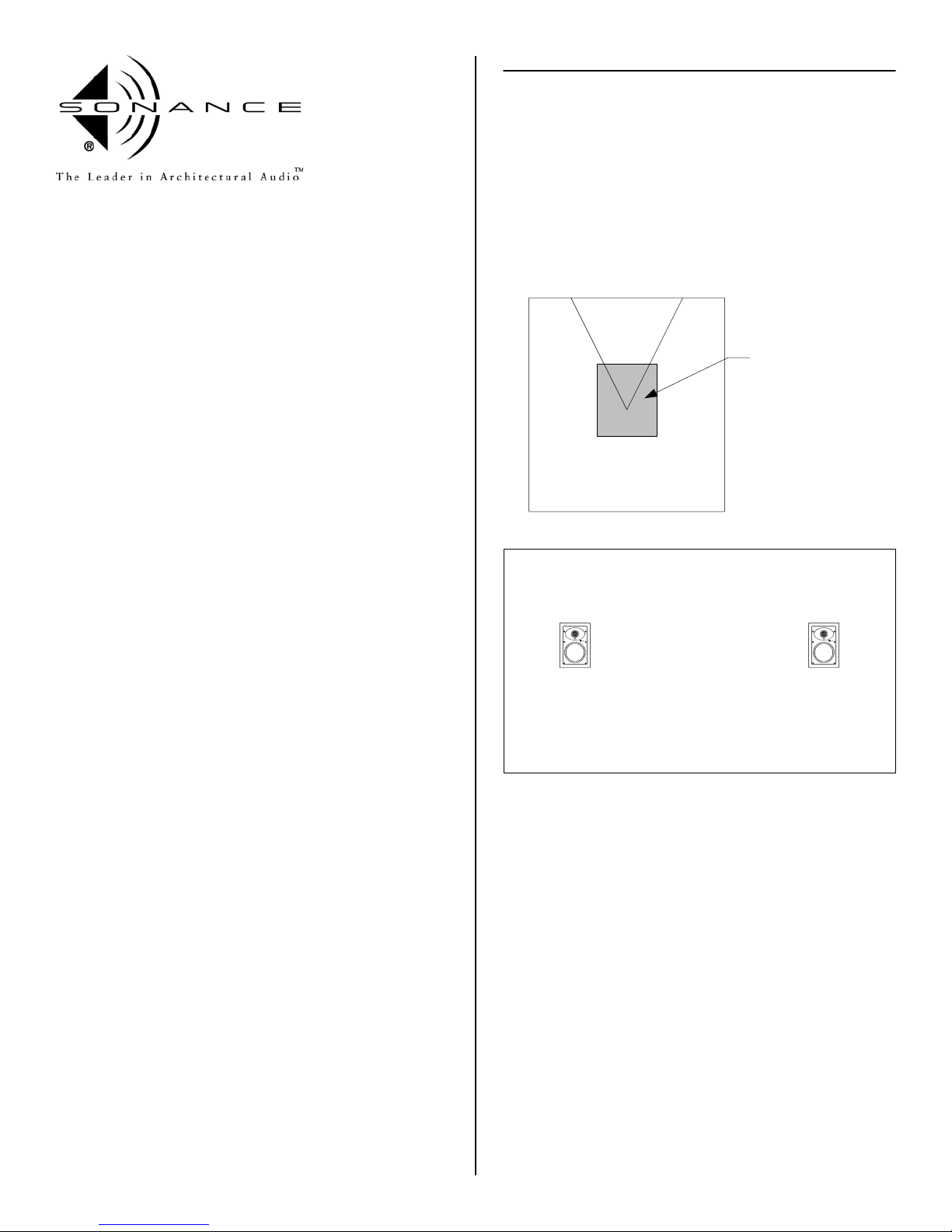

2 - CHANNEL AUDIO PLACEMENT

For best performance, the center of the Sonance Symphony Extreme

XT speakers should be placed around ear level. This would be

approximately 40" for a seated listener and 62" for a standing listener.

The distance from the listener to the speakers and the distance

between the speakers should be the same, see diagram. Distance A, B

and C should be the same.

Thank you for purchasing Sonance Symphony Extreme T in-wall

speakers. When properly installed, this product will provide you with

years of entertainment pleasure.

To obtain the full potential of your new speakers, please read all

instructions before starting the installation. If you do not have the

necessary skills to install the speakers yourself, contact your authorized

Sonance dealer for installation options.

PARTS LIST

Each Extreme T speaker package includes the following items:

(2) Sonance Extreme XT speakers

(2) Paintable grilles

(2) Plastic paint plugs to protect speakers during painting

(1) Mounting cutout template ( in packaging )

OPTIONAL ACCESSORIES

New Construction Bracket - part number 90-0700

Plastic template to reserve hole in new construction.

A

CB

Ideal Listening Zone

FlexBracket - part number 90-1193

Plastic template to reserve hole in new construction.

Designed to be used with the FlexbarJ mounting system.

Staple Template - part number 90-0651

Thin plastic template for new construction to reserve hole in

new construction. Designed to be used with the FlexbarJ

mounting system.

Coverplate - part number 90-0693

Designed to cover hole made by FlexBracket, New

Construction Bracket or Staple Template until the speaker is

installed.

Acoustic Enclosure - part number 91687

A 3/4" medium density fiberboard enclosure designed

specifically for the C and Symphony series speakers.

Fire Rate Back Can - part number 91709

A metal can designed for the C and Symphony series

speakers that meets the following fire testing criteria;

ASTM E119, CAN/ULC S101, NFPA 251, UBC 7-1, UL 263.

ENVIRONMENTAL SPECIFICATIONS

Maximum Heat

104 degrees C = (220.0 degrees Fahrenheit)

Maximum Cold

-40 degrees C = (-40.0 degrees Fahrenheit)

Maximum Humidity and Temperature

99% humidity @ 49 degrees C = (120.0 degrees Fahrenheit)

95% humidity @ -40 degrees C = (-40.0 degrees Fahrenheit)

The Extreme speakers meet or exceed the following:

Salt Spray - ASTM-B117

UV Test - ASTM-G23H

IEC / CEE Water Splashing Test - IP-X4

Vibration Test - ASTM D5112-98 and ASTM D3580-95

1

Page 2

WIRE GAUGE AND QUALITY

The total wire resistance should be less than 10% of the speaker

impedance. If using an 8 ohm speaker, your total wire resistance

should be no more than 0.8 ohms.

In simple terms, the extra resistance from the wire will have a very

negative effect on the sound quality of the speaker. The sound can be

less dynamic, definition of bass frequencies can be reduced, and in

extreme cases, the high frequencies can be attenuated. Amplifier

power is also wasted in the wire, reducing the maximum output level

of the system.

Please refer to the following chart when deciding on the appropriate

wire gauge for your installation.

Wire resistance in Ohms vs. length of cable run

Distance in Feet

20 gauge

18 gauge

16 gauge

14 gauge

12 gauge

10 gauge

50' 100' 150' 200' 250' 300'

5.18

4.32

3.45

1.73

1.30

.85

.54

.34

.22

2.59

1.94

1.28

.81

.51

.33

2.59

1.71

1.08

.68

.44

3.24

2.14

1.35

.85

.56

3.89

2.56

1.62

1.02

.67

.86

.65

.43

.27

.17

.11

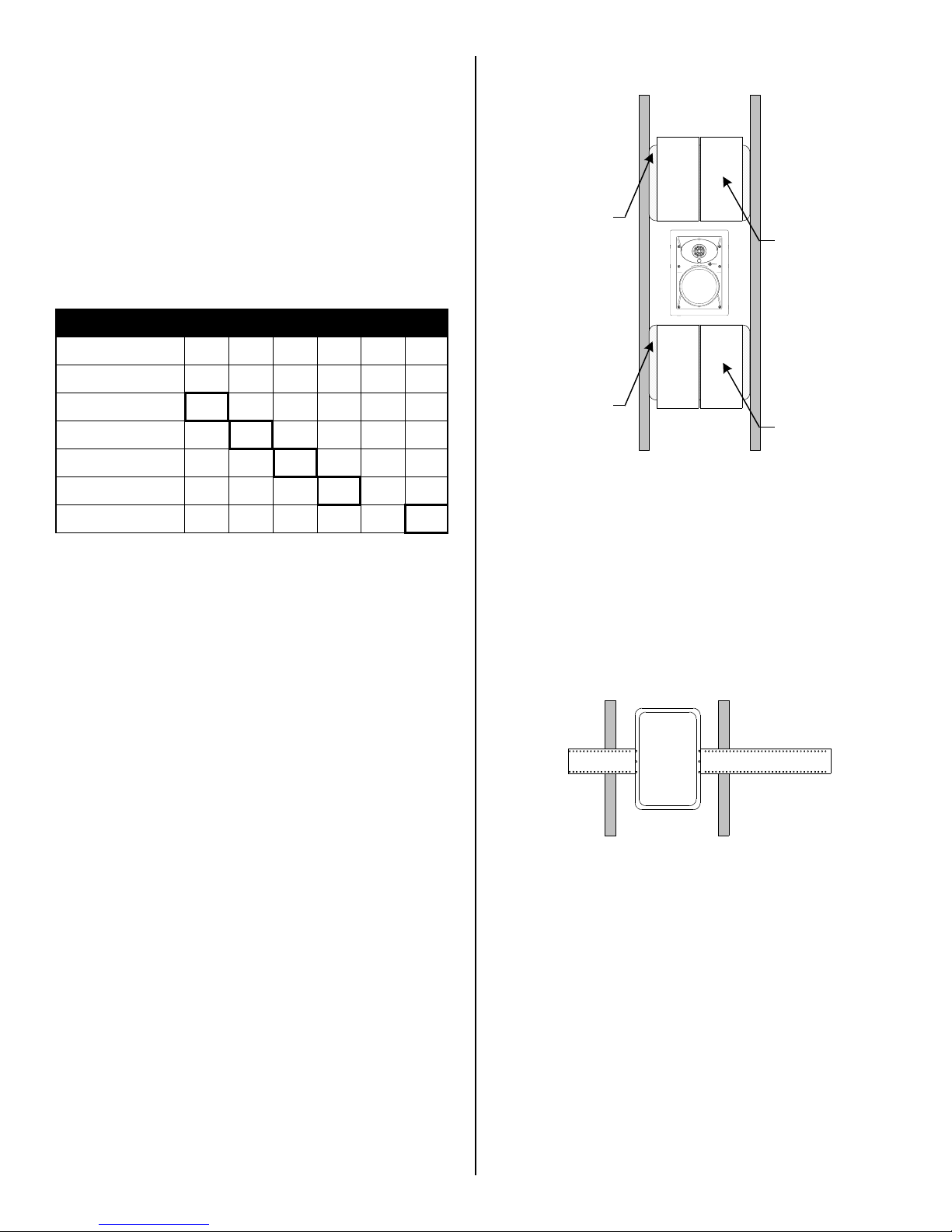

PREPARING THE INSTALLATION LOCATION

Acoustic Pillow

Damping Tiles

Acoustic Pillow

Damping Tiles

The Sonafill System

New Construction

The Extreme XT speakers feature an integral Rotolock mounting

system for quick mounting into walls. The Symphony / C series

FlexBracket and New Construction Bracket are only necessary in new

construction installations when reserving a location for the speaker is

desired.

All Sonance speakers are designed to be relatively insensitive to

changes in enclosure volume. To achieve the ultimate performance

from the Extreme XT speakers, a section of the stud bay can be

sectioned off to form a back box. Building this enclosure will create a

dramatic improvement in the quality of bass response and power

handling.

Back box volume requirements:

Insulating the wall cavity

Speaker performance can be enhanced by insulating the cavity with

fiberglass insulation.

When installing speakers in a wall, it is best to insert a sheet of

unfaced fiberglass insulation above and below the speaker.

To further improve the sound quality, install insulation in the bays

adjacent to the speaker location. This will reduce noise produced by

the unsupported drywall.

Sonafill

Sonafill is a retrofitable acoustical treatment for loudspeakers that

virtually eliminates the noise produced by resonating drywall and

dramatically improves mid-bass sound quality. Sonafill also reduces

room-to-room noise especially in multi-channel installations where

many speakers are installed.

The Sonafill system consists of two pillows and four tiles. Installation is

accomplished by first adhering the tiles to the inside of the cavity, then

stuffing the two pillows in place behind the tiles.

Extreme XT 1.00 cubic feet (28.3 liters)

®

The FlexBracket and New Construction Bracket will serve as a guide for

the drywaller when cutting holes for in-wall speakers. The FlexBracket

or New Construction Bracket is nailed or screwed to the studs so that

the hole is in the desired location once the drywall is installed.

Symphony / C series FlexBracket

Retrofit

With the Flexbar system, the speaker can be installed directly into

existing walls. Once the hole is cut and the cable is run, the speakers

can be installed in a matter of seconds.

Once you have determined the area you would like to locate your

speakers, you will need to do an obstruction survey. Before you cut the

hole for the speaker, be certain no studs, conduit, pipe, heating duct

or air return will interfere with the speaker.

The cutout for the Extreme XT is 6 3/4" (171mm) x 11" (279mm).

There must also be 2-1/2" (63.5mm) of depth within the wall for the

speaker.

A cut out template is provided in the packaging of the speaker.

Position the template where the speaker is to be located and pencil an

outline on the wall. If you are unsure about obstructions, drill a small

hole in the center of the cutout and insert a coat hanger into the hole

to feel for possible obstructions. If no obstructions are found, proceed

with cutting the hole using a drywall saw and run the speaker wires.

2

Page 3

INSTALLING THE SPEAKERS

Step 1

Remove the paint plug from the

speaker. Attach the wire from your

amplifier to the terminals on the back of

the speaker. Double check the polarity

of the speaker wires, amplifier + to

speaker + and amplifier - to speaker -.

Proper polarity is critical in home theater

installations.

Step 2

Make sure the Roto-Lock clamps are in

the full clockwise position so that all the

clamps are tucked within the cutout

border. Insert the speaker into the hole

in the ceiling.

Note: The maximum clamp thickness is

1-1/4" (32mm). The minimum clamping

thickness is 1/8" (3.2mm)

Step 3

Tighten the six screws on the front of

the baffle. The Roto-Lock clamps will

rotate into position automatically and

begin clamping. When you notice

resistance on the four screws, the

speaker has been clamped successfully.

The flange is designed to flex and

conform to any small imperfections in

the wall surface. The screws should not

be tightened so far that the flange bows

out.

Step 4

After the speaker is installed, the grille

can be installed. Insert about half of the

grille into the groove at the edge of the

speaker. Gently fit the remaining half of

the grill into the speaker by working

your hands around the speaker fitting

the grille into the groove as you go

along.

PAINTING THE SPEAKERS AND GRILLES

Speakers and grilles can be painted before installation, which will

eliminate the "paint scar" if the speaker needs to be removed for

service. Speakers may also be painted after installation, but before the

grilles are attached. All speakers come from the factory fitted with a

plastic "paint plug." Use the paint plug to protect the drivers while the

flange is being painted with the wall.

Sonance suggests always painting the grilles separate from the

speaker. The grilles may be lightly sprayed with thin paint (5 parts

thinning agent to 1 part paint), but be careful not to plug the holes.

Too much paint will adversely affect the sound of the speaker.

Once the grilles and flange are painted and dry, remove the paint plug

from the flange and install the grilles.

Note: The torque applied to the

mounting screws can be adjusted for

proper grille fit.

3

Page 4

TECHNICAL ASSISTANCE AND SERVICE

Extreme XT

Tweeter 1.0" (25mm) Polyurethane dome

Woofer 6-1/2" (165mm) Black anodized aluminum cone with a

Frequency Response 55Hz - 20kHz + 3dB

Impedance 8 ohms nominal - 6 ohms minimum

Power Handling 5 - 60 Watts

SPL 89 dB

Grille Powder coated Stainless steel

Dimensions WxHxD 8-1/8" (206mm) x 12-3/16" (310mm) x 2-1/2" (63.5mm)

Cutout Dims WxH 6-3/4" (171mm) x 10-7/8" (276mm)

Shipping Weight 9 lbs (4.1 KG) per pair

rubber surround

The Technical Assistance Department at Sonance is available at (800)

582-0772 or (949) 492-7777 to answer any questions concerning the

operation and installation of your speakers between the hours of 7:00

AM and 5:00 PM Pacific time, Monday through Friday, except holidays.

In the event your unit should need repair or service, you may return

the unit to your authorized dealer or use the following guidelines:

1. Be prepared to state the model number and / or serial number,

date of purchase and dealer's name and address when calling.

2. Contact Sonance directly at (800) 582-0772 or (949) 492-7777 or

at www.sonance.com

3. If you are returning the product directly to Sonance, call us to

obtain a return authorization number before shipping. YOU MUST

HAVE PRIOR AUTHORIZATION TO RETURN YOUR UNIT.

4. The original packaging must be used. If the original packaging is

unavailable, replacements can be obtained from Sonance for a

small fee.

5. Ship the product via United Parcel Service, Federal Express, or

RPS. Please do not use the U.S. Mail service.

6. Write the return authorization number on the outside of the box.

7. Ship to:

Attn: Quality Assurance Department

Sonance

212 Avenida Fabricante

San Clemente, CA 92672-7531

8. FREIGHT COLLECT SHIPMENTS WILL BE REFUSED !

WARRANTY COVERAGE ( U.S. ONLY )

If, within five (5) years from the date shown on the bill of sale, the unit

fails due to a defect in workmanship or material, Sonance will, at its

option and at no charge, repair or replace the components of such unit

which prove to be defective. For this warranty to be effective, the bill

of sale must show that the unit was purchased from an "Authorized

Sonance Dealer". This warranty shall apply exclusively to the original

purchaser and shall not apply to units purchased for industrial or

commercial use.

Furthermore, this warranty shall not apply if:

1. Damage to the unit was caused by accident, abuse or misuse;

2. The unit was opened, modified, or repaired by unauthorized

personnel.

3. The unit was not used as outlined in the operating instructions.

EXCLUSIONS AND LIMITATIONS

The warranty set forth above is in lieu of all other warranties,

expressed or implied, of merchantability, fitness for a particular

purpose, or otherwise. The warranty is limited to Sonance products

registered herein and specifically excludes any damage to loudspeakers

and other allied or associated equipment which may result for any

reason from use with this product. Sonance shall in no event be liable

for incidental or consequential damages arising from any breach of this

warranty or otherwise. This warranty gives you specific legal rights,

and you may have rights which vary from state to state.

Sonance $ 212 Avenida Fabricante $ San Clemente, CA 92672-7531, USA $ (800) 582-7777 or (949)492-7777 $ FAX: (949) 361-5151 $ Technical Support: (800) 582-0772

c

2003 Sonance. Sonance , Roto-Lock, and Sonafill are trademarks of Sonance.

www.sonance.com

Loading...

Loading...