Page 1

Page 2

Page 3

S

o

li

s

20

Page 4

SOLIS 20 OPERATOR MANUAL

Page 5

EIGENAAR EN TRACTOR DETAILS

EIGENAARS

NAAM &

ADR

ESS

TEL.NO

.

Model

:

Afleverdatum

:

Chassis No

. :

Factuur No. /

Datum

:

Motor No. :

Dynamo

Gemaakt

/ Sr. No. :

Batterij G

emaakt

/ Sr. No. :

Start motor

Gemaakt

/ Sr. No. :

FIP Sr. No. :

Hydraulische Pomp Gemaakt

/ Sr. No. :

Banden

Gemaakt

Maat

Sr. No.

Voor

(Links)

Voor

(Rechts)

Achter (Links)

Achter (Rechts)

Ik ga akkoord met alle voorwaarden ten behoeven van het onderhoud van de trekker, de garantievoorwaarden,

de systemen, de geregelde diensten & ik begrijp de werking van de trekker in het veld en met het gebruik

tijdens andere verrichtingen.

Ontving een nieuwe defectvrije tractor Chassis No. ............................................................................................

Motor No. ....................................................................... & ben volkomen tevreden met de transactie.

HANDTEKENING EIGENAAR

HANDTEKENING DEALER

TEL. NO. .................................... DATUM: .....................

* BELANGRIJKE INFORMATIE VOOR DE AFNEMER: Voor hulp met betrekking tot ons

product, neem dan contact op met onze geautoriseerde dealer of erkend servicecentrum.

Page 6

Page 7

EIGENAAR EN TRACTOR DETAILS

EIGENAARS

NAAM &

ADR

ESS

TEL.NO

.

Model

:

Afleverdatum

:

Chassis No

. :

Factuur No. /

Datum

:

Motor No. :

Dynamo

Gemaakt

/ Sr. No. :

Batterij G

emaakt

/ Sr. No. :

Start motor

Gemaakt

/ Sr. No. :

FIP Sr. No. :

Hydraulische Pomp Gemaakt

/ Sr. No. :

Banden

Gemaakt

Maat

Sr. No.

Voor

(Links)

Voor

(Rechts)

Achter (Links)

Achter (Rechts)

Ik ga akkoord met alle voorwaarden ten behoeven van het onderhoud van de trekker, de garantievoorwaarden,

de systemen, de geregelde diensten & ik begrijp de werking van de trekker in het veld en met het gebruik

tijdens andere verrichtingen.

Ontving een nieuwe defectvrije tractor Chassis No. ............................................................................................

Motor No. ....................................................................... & ben volkomen tevreden met de transactie.

HANDTEKENING EIGENAAR

HANDTEKENING DEALER

TEL. NO. .................................... DATUM: .....................

* BELANGRIJKE INFORMATIE VOOR DE AFNEMER: Voor hulp met betrekking tot ons

product, neem dan contact op met onze geautoriseerde dealer of erkend servicecentrum.

Page 8

Page 9

INLEIDING

Geachte Afnemer, wij verwelkomen u met veel plezier in uw toetreding tot de ITL familie en

bedanken u voor het vertrouwen dat in ons heeft door uw zorgvuldige keuze te laten vallen

op een van onze tractoren. Voor het gebruik van deze tractor wordt u sterk aanbevolen om

deze handleiding zorgvuldig door te lezen. Elke persoon die regelmatig of incidenteel uw

tractor gebruikt wordt geacht deze instructies door te lezen.

Werkzaamheden als dagelijks en routineonderhoud, kunnen eenvoudig worden uitgevoerd

met behulp van deze handleiding. Onze dealers staan altijd klaar om u te assisteren met het

onderhoud van uw tractor en de zuinige afstelling ervan.

Gebruik alleen originele Sonalika onderdelen van erkende dealers en leveranciers. Zo bent

u verzekert van een betrouwbare en optimaal presterende tractor.

De informatie verstrekt in deze handleiding is correct op het moment van drukken.

Verbetering en aanpassingen zijn een continue proces bij International Tractor Limited (ITL),

en zijn voorbehouden wijzigingen door te voeren zonder voorafgaande kennisgeving.

u kunt uzelf de trotse eigenaar van dit product noemen. In het geval dat u enige hulp of

ondersteuning vereist, aarzel dan niet om contact op te nemen met een van onze dealers.

Service Department (IB)

INTERNATIONAL TRACTORS LIMITED

V

ill Cha

k G

ujran

, P.O. P

iplanwala 146022

J

alandhar Road, Hoshiarpur

, P

unjab

.

P

hone: 01882-302-288

/

289

/

299

, Fax:

01882-302-555

.

E

-mail: export@sonalika.com

SOLIS 20 OPERATOR MANUAL

Page 10

UW RECHTEN

Tijdens de afname van een nieuwe “Solis 20” Tractor,

kunt U de dealer While taking delivery of new ?

SOLIS

20"Tractor, kindly ask the dealer to give following

items:

1.

Tool kit which includes

Grease Gun (Optional) 1pc

D-spanner 10x 11 1pc

D-spanner 12X 13 1pc

D-spanner 14X 17 1pc

D-spanner 18X 19 1pc

D-spanner 20X 22 1pc

D-spanner 30X 32 1pc

Ring spanner 16X 17 1pc

Battery Guarantee card 1pc

Ring Spanner 24X 27

2. Farmer Kit

Fuel Filter Catridge (703008219a ) 3

Oil Filter Assy. 3 Cyl.(803007059a) 2

Fan Belt (703006099a) 1

Linch Pin (10080109ab) 3

Fuel Tank Cap With Key (10071015ac) 1

Tyre Pressure Gauge (10026665aa) 1

Fuses For Farmer Kit (10071358aa) 1

Hose Pipe For Air Cleaner(10051220ba) 1

Cap For Radiator (10026958aa) 1

3. To avail the services

.

4.

To call dealers any time for any breakdown

.

5. Additional Accessories as Standard fitment

Safety Reflector

Plough Lamp (1pc) (Optional)

Rear View Mirror

SOLIS 20 OPERATOR MANUAL

Page 11

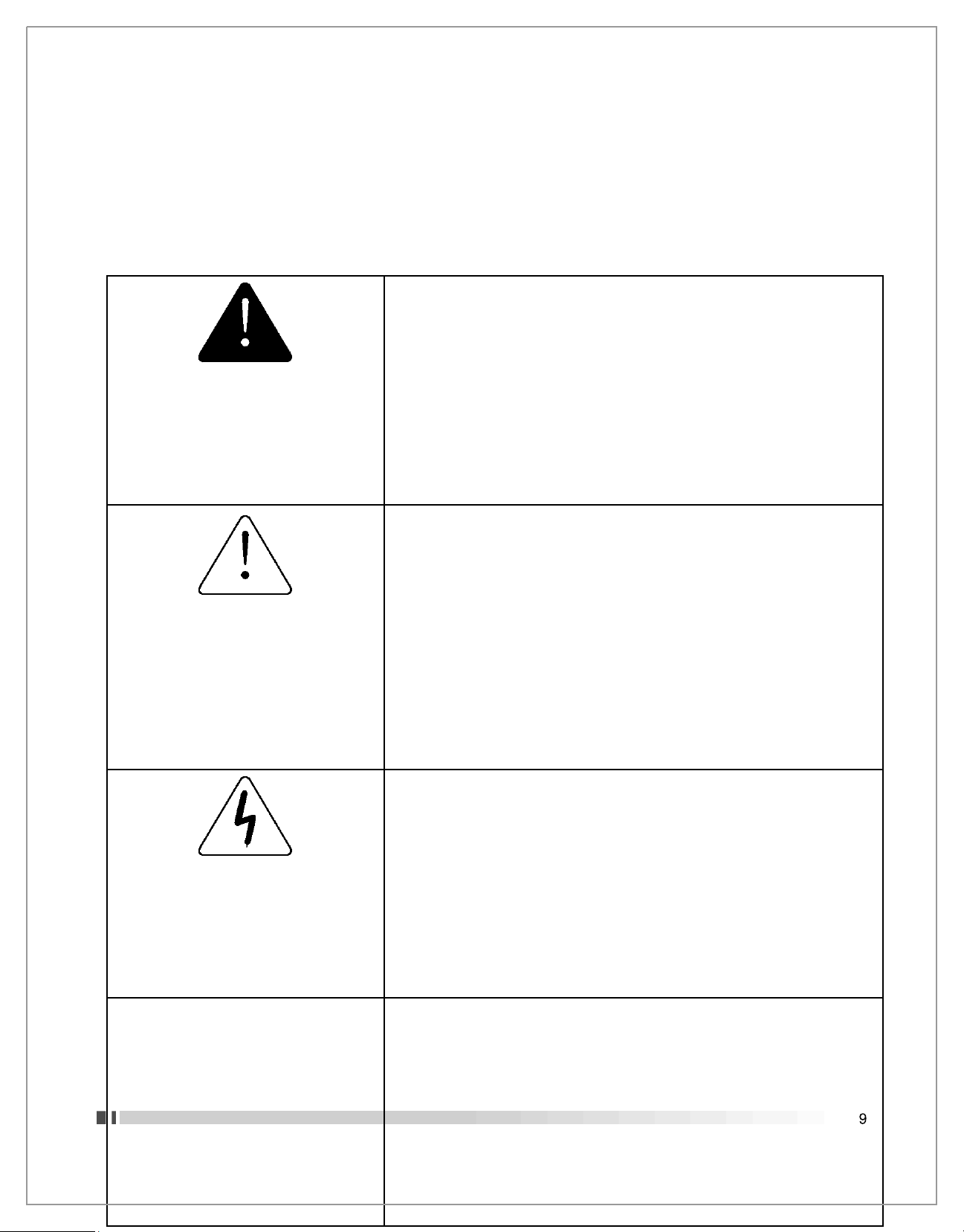

DANGER

Dit symbool en het

woord

“

DAN

GER” duiden op een

onmiddellijke gevaarlijke situatie,

die indien niet vermeden, zal leiden

tot de DOOD of ZEER ERNSTIG

LETSEL.

1.

Bescherm uw gezicht van een radiator onder druk als de motor

warm is. Verwijder de dop voorzichtig en alleen als de motor koud

is.

2.

Laat nooit kinderen of onbevoegden uw tractor bedienen, en houd

anderen altijd op afstand wanneer het apparaat in werking is.

WARNING

Dit symbool en het woord

“WARNING” duiden op een

potentieel gevaarlijke situatie. Als

de instructies of procedures niet

correct gevolgd worden kan dit

leiden tot de DOOD of ZEER

ERNSTIG LETSEL

1.

Verwijder nooit de “Danger”, “Warning”, en “Caution” of instructie

labels.

2.

Een exploitant mag nooit onder invloed zijn van drank of drugs, die

zijn alertheid of coördinatie beïnvloeden.

3.

Nooit staan of toestaan dat iemand anders op of tussen de tractor

en het werktuig staat, tenzij de motor is uitgeschakeld, de

versnelling in neutraal staat, en alle uitrusting of werktuigen zijn

neergelaten op de grond.

4.

Ontkoppel nooit de koppeling en probeer niet te schakelen,

wanneer u een helling afrijdt.

5.

Overbelasting is altijd gevaarlijk. Controleer dus altijd het

laadvermogen van uw tractor en overbelast deze nooit.

6.

Koppel nooit de hydraulische aansluitingen los en pas nooit een

werktuig aan met een draaiende motor of de aftakas in werking. Dit

zou kunnen leiden tot ernstig letsel of de dood.

CAUTION

Dit symbool en het woord “Caution”

duiden op een potentieel

gevaarlijke situatie, die indien niet

vermeden, kan leiden tot LICHT

LETSEL.

1.

Laat een lopende tractor nooit ongestuurd achter, en houd ten alle

tijden een stevige grip op het stuur.

2.

Voordat u van de tractor afstapt, wordt u geacht de aftakas te

ontkoppelen, alle uitrusting en werktuigen neer te laten, de

versnelling in zijn neutraal te zetten, de handrem aan te trekken, de

motor uit te zetten en de sleutel te verwijderen.

3.

Rook niet tijdens het tanken van de tractor, en houd elke vorm van

open vuur weg.

RICHTLIJNEN OVER VEILIGHEIDSTEKENS

Erken Veiligheid Informatie:

Dit is het waarschuwingssymbool. Elk symbool op uw machine of in deze handleiding, waarschuwt u voor een

mogelijke kans om persoonlijk letsel op te lopen. Volg de aanbevolen voorzorgsmaatregelen en een veilige

bedrijfsvoering.

SOLIS 20 OPERATOR MANUAL

Page 12

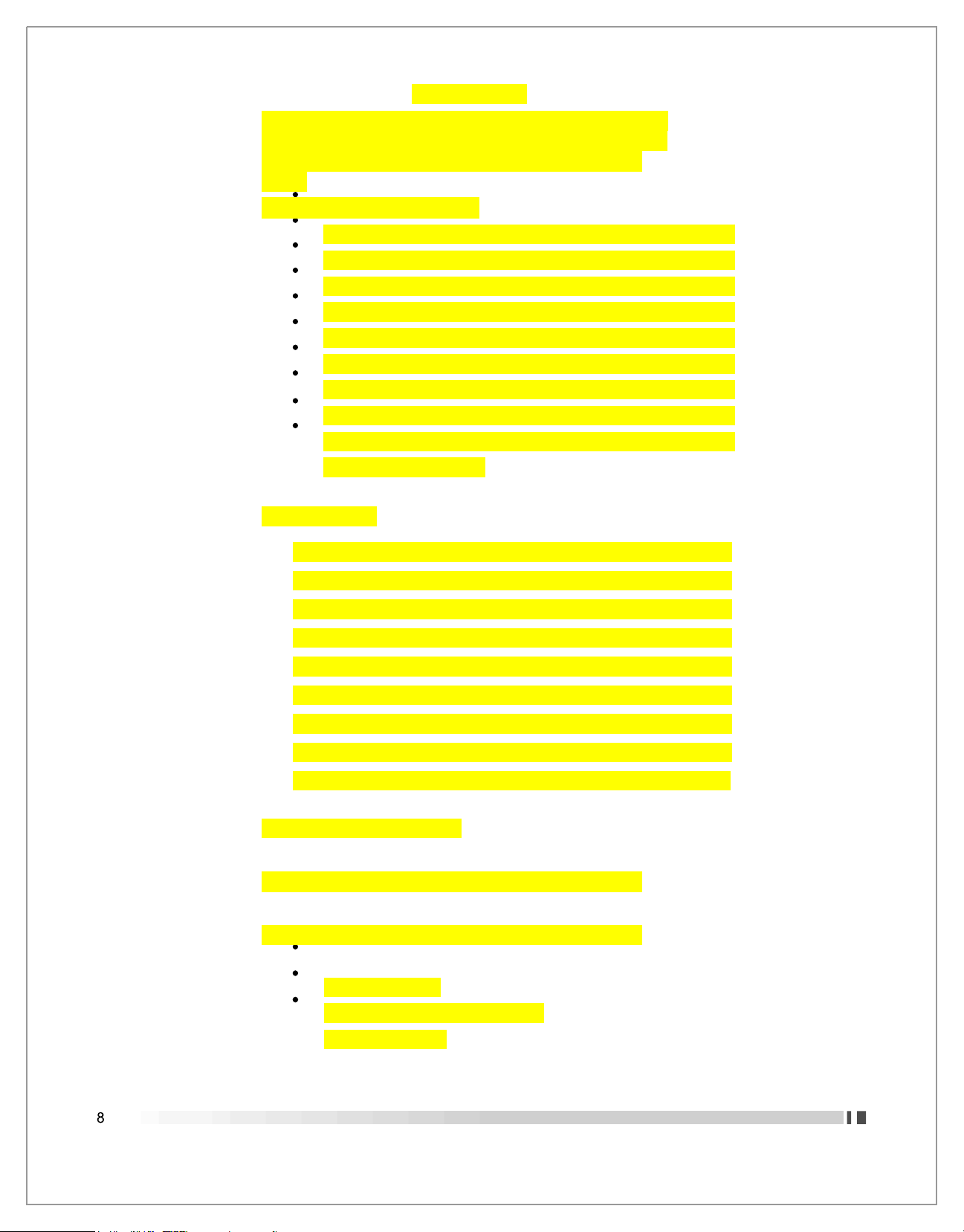

No Parking

No Stopping or Standing

Staggered

Instersection

Cattle

Ferry

One Way Signs

Vehicles Prohibited in

One Direction

One Way Signs

Vehicles Prohibited in

One Direction

Y-Intersection

Y-Intersection

Y-Intersection

T-Intersection

Straight

Prohibited

or No Entry

Right Turn

Prohibited

Left Turn

Prohibited

U-turn

Prohibited

ROAD SAFETY SIGNS

Rechtse

bocht

School Ahead

Linkse

bocht

Men at Work

Right Hand Pin

Bend

Cross Road

Left Hand Pin

Bend

Gap in

Median

Narrow

Bridge

Side Road

Right

Pedestrian

Crossing

Side Road

Left

Staggered

Instersection

Major Road

Ahead

Major Road

Ahead

Right Reverse

Bend

Left Reverse

Bend

Narrow Road

Ahead

Road Widens

Ahead

SOLIS 20 OPERATOR MANUAL

Page 13

VEILIG GEBRUIK

Voorzichtig gebruik is uw beste verzekering tegen ongelukken.

Lees deze gebruiksaanwijzing aandachtig door, voordat u de tractor bestuurd.

Alle gebruikers, ongeacht de desbetreffende ervaring, worden geacht deze gebruiksaanwijzingen te lezen

voordat men gebruik maakt van de tractor.

Het is de eigenaar zijn verplichting om elke verdere gebruiker in te lichten over het veilige gebruik van de tractor.

1

. VOOR HET GEBRUIK VAN DE TRACTOR

LEES DE VEILIGHEIDSINSTRUCTIES

Lees de veiligheidsinstructies in deze gebruiksaanwijzing aandachtig

door. Het nalaten van een van de volgende veiligheidsovereenkomsten

kan leiden tot erge verwondingen of de dood. Houd alle

veiligheidstekens in goede conditie, en vervang beschadigde of kapotte

veiligheidstekens.

Houd uw tractor in goede conditie en sta ongeautoriseerde wijzigingen

aan uw tractor niet toe, wat de werking, veiligheid, en levensduur van uw

tractor kan beïnvloeden.

Het besturen van de tractor

1

. Kijk uit waar je rijd vooral bij het einde van rijen, op wegen, bij bomen en andere bij andere obstakels.

2

. Voorkom tegenslagen, door de tractor zorgvuldig te besturen en een veilige snelheid aan te houden. Dit

geldt voornamelijk bij het werken op ruw terrein en hellingen, het oversteken van sloten, en bij het maken

van bochten

3

. Vergrendel beide rempedalen van de tractor, wanneer de tractor wordt getransporteerd over wegen.

4

. Houd de tractor in dezelfde versnelling wanneer u bergafwaarts gaat als bij het bergop rijden, en ga nooit

bergafwaarts zonder dat de tractor in zijn versnelling staat.

5

. Elk getrokken voertuig of aanhangwagen waarvan het totale gewicht hoger is dan het gewicht van de

trekkende tractor, moet worden uitgerust met eigen remmen voor een veilig gebruik.

6

. Wanneer de tractor vast raakt of wanneer deze is vast gevroren aan de grond, , back

ou

t to

prevent upse

t.

7

. Kijk met het rijden en vooral met het vervoeren van de tractor ook altijd naar de

desbetreffende toegestane hoogte op de weg.

SOLIS 20 OPERATOR MANUAL

Page 14

VEILIGHEIDS TIPS TIJDENS ONDERHOUD

1

. Check dagelijks het oliepeil, het waterpeil in de radiator en de accu op genoeg

vermogen, en verricht het onderhoud volgens de onderhoudsinstructies.

2

. Zorg altijd voor een gelijke en correcte bandenspanning voor de desbetreffende

uitgevoerde taken.

3

. Kijk altijd goed na of alle bedieningselementen en aansluitingen van de tractor en het

desbetreffende werktuig correct zijn aangesloten en naar behoren werken.

4

. Zorg ervoor dat er altijd voldoende gereedschap aanwezig is voor het verrichten van

onderhoud en kleine reparaties.

5

. Zorg er altijd voor dat onderhoud en reparaties aan de tractor worden uitgevoerd op

een vlakke en harde ondergrond.

Voer geen onderhoudswerkzaamheden uit aan de tractor totdat deze is uitgeschakeld,

de handrem is aangetrokken en de wielen zijn geblokkeerd. Wanneer de tractor in een

gesloten ruimte word onderhouden, zorg er dan voor dat de ruimte goed word

geventileerd wanneer de motor aan staat, omdat de uitlaatgassen schadelijk zijn en

uiteindelijk kunnen leiden tot de dood.

6. Werk nooit onder opgeheven werktuigen of wanneer werktuigen nog in werking zijn.

7. Zorg ervoor dat bij het verwisselen van de wielen of banden, er een geschikt standaard

onder de as van de tractor is geplaatst en de wielen zijn geblokkeerd voordat het

desbetreffende wiel of band is verwijderd.

8

. Wanneer afschermende onderdelen die dienen voor diens bescherming tijdens het

gebruik van de tractor verwijderd moeten worden voor onderhoud of reparatie, zorg er

dan altijd voor dat u deze afschermende onderdelen weer op de desbetreffende manier

installeert voordat u gebruikt maakt van de tractor.

9

. Tank nooit in de buurt van een open vlam of een oververhitte motor. En zorg er altijd

voor dat u de motor heeft uitgeschakeld voor het tanken.

10

. Het koelsysteem van de tractor werkt onder druk. Zorg bij het verwijderen van de

radiator dop dat de motor is afgekoeld, om brandwonden veroorzaakt door stoom of

heet water te voorkomen. Voeg ook nooit water toe in de radiator wanneer de motor

warm is, maar zorg ervoor dat u wacht tot deze volledig is afgekoeld.

11

. Om ontvlamming te voorkomen, zorg er dan ten alle tijden voor dat u de tractor en

motor schoon houdt en ontvlambaar materiaal en brandstoffen verwijderd.

12

SOLIS 20 OPERATOR MANUAL

Page 15

BESCHERMING VAN KINDEREN

Houdt kinderen en onbevoegden uit de buurt van de tractor indien in werking.

- Kijk voordat u achteruit rijdt naar achter of het vrij is van obstakels.

- Laat kinderen en onbevoegden nooit de tractor of een werktuig besturen.

VOORZORGSMAATREGELEN OM KANTELEN TE VOORKOMEN

Rijd niet op plekken waar de tractor mogelijk kan wegglijden of omvallen.

Blijf altijd alert voor gaten en andere obstakels.

Verlaag je snelheid bij het maken van scherpe bochten.

Het voorwaarts wegrijden uit een greppel of verzakking kan er voor

zorgen dat de tractor naar achter kantelt. Voorkom dit ten alle tijden.

PARKEER DE TRACTOR VEILIG

Nadat u gebruik heeft gemaakt van de tractor:

- Laat alle werktuigen zakken.

- Stop de motor en haal de sleutel uit het contact.

HOUD PASSAGIERS VAN DE TRACTOR

Sta geen mede-inzittende toe op de tractor.

Mede-inzittende kunnen zwaar gewond raken door beknelling, bewegende

onderdelen, of het vallen van de tractor.

V

EILIG TANKEN EN VOORKOM BRAND

Behandel brandstof met adat u gebruik heeft gemaakt van de tractor:

- Laat alle werktuigen zakken.

- Stop de motor en haal de sleutel uit het contact.

STAY CLEAR OF ROTATING SHAFTS

Entanglement inrotatingshaftcancauseseriousinjury or death.

Keep PTOshield inplaceat all times.

Wearclose fitting clothing.Stop the engineand to surePTO drive isstopped

before makingadjustments,connections,or cleaning outPTO driven equipment.

SOLIS 20 OPERATOR MANUAL

13

Page 16

ALWA

YS USE SAFETY LIGHTS

AND DR

IVES

Use of hazard warning lights and turn signals are recommended when

towing equipment on public roads unless prohibited by state or local regulations.

Use slow moving vehicle (SMV) sign when driving on public road during both day &

nigth time, unless prohibited by law.

P

RACTIC

E SAFE MAINTE

NANC

E

Understand service procedure before doing work.

Keep the surrounding area of the Tractor clean and dry.

Do not attempt to service Tractor when it is motion.

Keep body and clothing away from rotating shafts.

Always lower equipment to the ground. Stop the engine.

Remove the key equipment to the ground. Stop the engine.

Securely support any Tractor elements that must be raised for service work.

Keep all parts in good condition and properly installed.

Replace worn or broken parts. Replace damage/missing decals.

Remove any buildup of grease or oil form the Tractor.

Disconnect battery ground cable (

)

before making adjustments on electrical

system or welding on Tractor.

A

VOID HIGH-PRESSURE FLUIDS

Escaping fluid under pressure can penetrate the skin causing serious injury. Keep

hands and body away from pinholes and nozzies, which eject fluids under high

pressure. If ANY fluid is injected into the skin. Consult your doctor immediately.

PREVENT BATTERY EXPLOSIONS

Keep sparks, lighted matches, and open flame away from the top of battery.

Battery gas can explode.

Never check battery charge by placing a metal object across the poles.

SERVICE T

RACTOR SA

FELY

Do not when a necktie, scarf or loose clothing when you work near moving parts. If

these items were to get caught, severe injury could result.

Remove rings and other jeweler to prevent electrical shorts and entanglement in

moving parts.

14

SOLIS 20 OPERATOR MANUAL

Page 17

PREVENT ACID

BURN

S

Sulfuric acid in battery electrolyte is poisonous. It is strong enough to burn skin,

cause holes in clothing and cause blindness if found entry into eyes.

For adequate safety always.

1. Fill batteries in a well-ventilated area.

2. Wear eye protection and acid proof hand gloves

3. Avoid breathing direct fumes when electrolyte is added.

4. Do not add water to electrolyte as it may splash off causing server burns.

If you spill acid on your self.

1. Flush your skin with water.

2. Flush your eyes with water for 10-15 minutes.

Get medical attention immediately.

WORK IN VENTILATED AREA

Do not start the Tractor in an enclosed building unless the doors &

windows are open for proper ventilation, as tractor fumes can cause

sickness or death. If it is necessary to run an engine in an enclosed

area remove the exhaust fumes by connecting exhaust pipe extensions.

Safety Starter Switch is to be replaced after every 2000 hours/4years,

whichever is earli

T

RACTOR RUNAWA

Y

1. The tractor can start even if the transmission is engaged position causing Tractor to runaway and

serious injury to the people standing nearby the tractor. For additional safety keep the pull to slop knob

(fuel shut off control) in fully pulled out position.

Transmission in neutral position. Foot brake engaged and PTO lever in disengaged position while

attending to Safety Starter Switch or any other work on Tractor.

SAFETY STARTER SWITCH

1. Clutch operated safety switch is provided on all Tractors which allow the starting system to become

operational only when the Clutch pedal is fully pressed.

2. Do not By-pass this safety switch or work on it. Only Authorized Dealers are recommended to

work on safety starter switch.

SOLIS 20 OPERATOR MANUAL

15

Page 18

S.No.

DESCR

IPTIO

N

1

. IDENTIFICATION OF T

RACTOR

............................................................................................19

2

. INTRO

DUC

TION & DESCRIPTION........................................................................................20

3

. OPERATIONS.........................................................................................................................21

3.1

In

strumenta

l Panel................................................................................................................22

T

emperature Gauge

................................................................................................................

22

E

ngine Oil Pressure Indicator

..................................................................................................22

RPM cum Hour Recorder

........................................................................................................23

F

uel Gauge

.............................................................................................................................23

Battery

Charge Indicator

.........................................................................................................23

High Beam Indicator

...............................................................................................................23

Le

ft S

ide Indicator

...................................................................................................................23

Righ

t S

ide Indicator

.................................................................................................................24

PTO Lever Posit

ion Indication

................................................................................................24

G

ear Lever Position Indication

................................................................................................

24

3.2

El

ectrical Contr

ol :................................................................................................................25

Hazard Ligh

t Switch...............................................................................................................25

S

ide Indicator Switch

..............................................................................................................25

Combination Switch

................................................................................................................25

Start

ing Ke

y Switch................................................................................................................26

E

ngine

Stop K

nob

..................................................................................................................26

Fuse Box.................................................................................................................................26

Revolving ligh

t Switch.............................................................................................................

26

3.3

El

ectrica

l Equipments...........................................................................................................27

Battery & its

Maintenance

.......................................................................................................27

Alt

ernator

.................................................................................................................................27

V-Belt

Checking and Adjustmen

t.............................................................................................

27

Starter Motor............................................................................................................................27

G

eneral Maintenance o

f Electrical System.............................................................................28

Precaut

ions before Connecting Welding Apparatu

s...............................................................

28

3.4

Sh

eet Metal :

..........................................................................................................................28

Proc

edure to open the Top Hood

............................................................................................

28

3.5 Controls :

...............................................................................................................................29

Main Gear Shifter Lever

.........................................................................................................29

High -Low Lever

.....................................................................................................................29

2WD/4

WS Lever....................................................................................................................29

P

ower Take

Off Shifter Lever.................................................................................................30

Differential Lo

ck P

edal

...........................................................................................................30

Clutch Pedal

..........................................................................................................................30

Method to Che

ck the

Clutch Pedal Free Pla

y........................................................................

30

16

SOLIS 20 OPERATOR MANUAL

Page 19

S.No. DESCRIPTION

Foot Brake P

edal

..........................................................................................................30

Method for Che

ck Brakes.............................................................................................30

Park

ing Brake

...............................................................................................................31

Foot Acc

elerator

............................................................................................................31

Hand Throttle Lever

...................................................................................................... 31

Driver Sea

t................................................................................................................... 31

Travel A

djustmen

t.........................................................................................................31

Back A

djustmen

t...........................................................................................................31

T

ool Bo

x.....................................................................................................................

31

Seven Pin Socket..........................................................................................................32

Posit

ion Control Lever

...................................................................................................32

P

ower Take

Off............................................................................................................. 32

Registration Plate

......................................................................................................... 32

Ligh

ts............................................................................................................................32

3.6 Engine......................................................................................................................... 33

Start

ing the Engine

...................................................................................................... 33

Proc

eed a

s F

ollow

s..................................................................................................... 33

Running the Engine

......................................................................................................34

T

urning

Off the E

ngine

..................................................................................................33

3.7

Fuel S

ystem :

.............................................................................................................. 34

F

uel Saving Tip

s...........................................................................................................34

3.8 Hydra

ulic :....................................................................................................................35

Hydrauli

c System......................................................................................................... 35

Response Valve

............................................................................................................35

T

hree Point Linkage

......................................................................................................35

Quick

Release coupling

................................................................................................35

Directional Control Valve

...............................................................................................35

3.9 Wheel and T

yres :

........................................................................................................36

In f

ield operation

s......................................................................................................... 36

In

Road Operation

s...................................................................................................... 36

Recommended Load carrying Capaci

ty........................................................................36

B

allasting o

f Tractor.......................................................................................................37

F

ron

t W

heel

TOE IN.................................................................................................... 37

Checking and Adjustment o

f TOE IN............................................................................37

Rear Wheel Tra

ck Width A

djustmen

t............................................................................38

G

eneral Suggestion

s....................................................................................................38

Che

ck W

heel Nu

t Bolt...................................................................................................38

SOLIS 20 OPERATOR MANUAL

17

Page 20

S.No.

DESCR

IPTION

4

. GENERAL MAINTE

NANC

E................................................................................................39

4.1

Engine :........................................................................................................................39

E

ngine Lubrication

System...........................................................................................39

Che

ck E

ngine Oil Level

.................................................................................................39

Changing o

f E

ngine Oil

& Oil Filter...............................................................................39

Replacement o

f F

uel Filter

............................................................................................40

Air B

leeding From Fuel Injection

s System/F

uel Filter Replacemen

t............................ 40

4.2 Air Cleaner :

............................................................................................................... 40

Oil bath type

air cleaner

................................................................................................40

Cleaning of pre cleaner (Dry)

........................................................................................40

Air c

leaner bowl

&

elemen

t c

leaning (wet)

................................................................... 41

After every 50 hrs......................................................................................................... 41

4.3 Radiator :

........................................................................................................................42

Coollant Level in Radiator (Hot)

................................................................................... 42

Radiator Draining and Flushing (When Cold)

...............................................................42

Radiator Fins Cleaning

.................................................................................................42

Radiator Cap

................................................................................................................ 42

4.4 Hydra

ulic :........................................................................................................................43

T

ransmission/Hydrauli

c Oil Level..................................................................................43

Change Transmission Oil

............................................................................................. 43

Change

St

eering Gear Bo

x Oil.....................................................................................43

Checking Specification Gravi

ty of Battery Elect

rolyte

...................................................43

F

ron

t Axie Oil Level.......................................................................................................43

5

. Oth

ers

.................................................................................................................................44

Tec

hnical Parameter

s...................................................................................................44

Recommended Grade of Lubrican

ts

and grease

s........................................................47

Service Sc

hedule

......................................................................................................... 48

G

reasing

P

oin

ts............................................................................................................49

W

iring Diagram

............................................................................................................ 50

W

arran

ty........................................................................................................................51

6

. Do'S

AND DON

'TS...................................................................................................... 52

7

. T

RACTOR INSTALLA

TION CERTIFICATE................................................................ 56

8

. FREE SERVICE COUPONS........................................................................................ 59

9

. TROUBLE SHOOTING.................................................................................................67

10

. MATCHING IMPLEMENT.............................................................................................69

Specifi

cat

ions.................................................................................................. 69

Cultivator

...........................................................................................................69

Rotavator

.......................................................................................................... 70

12

. SERVICE RECORD......................................................................................................75

13

. NOTES......................................................................................................................... 76

18

SOLIS 20 OPERATOR MANUAL

Page 21

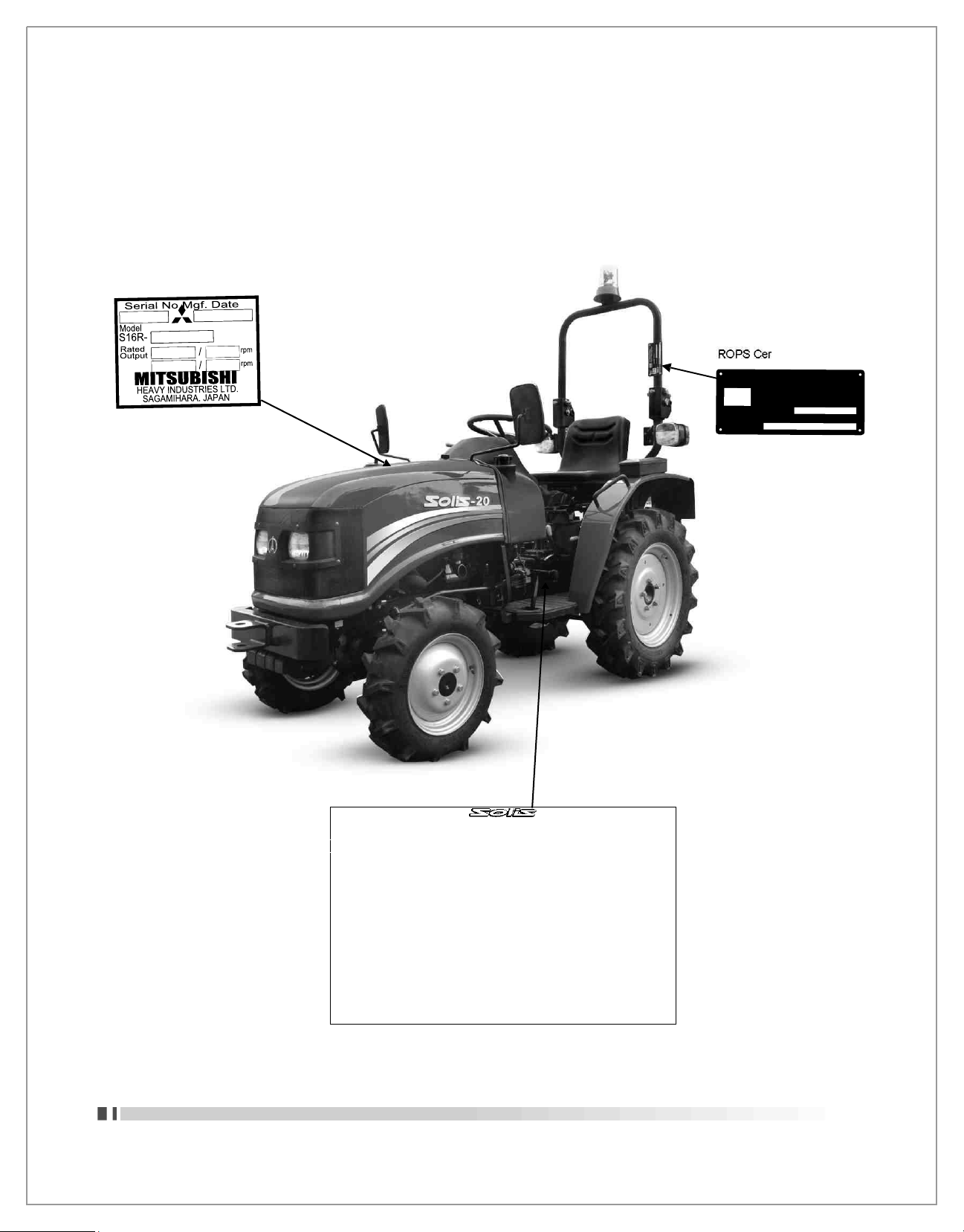

INTERNATIONAL TRACTORS LTD.

Type :

EEC number :

Identification number :

Total Permissible mass (*) :

Permissible front axle load (*) :

Permissible rear axle load (*) :

to

to

to

kg

kg

kg

(*) depending on the tyres.

Permissible towable mass:

Unbraked towable mass:

Independently-braked towable mass:

kg

Inertia-braked towable mass:

kg

Towable mass fitted with an assisted braking system:

kg

(hydraulic or pneumatic)

INTERNATIONAL TRACTORS LIMITED

HOSHIARPUR, PUNJAB (INDIA)

1

. IDENTIFI

CA

TION OF T

RAC

TO

R

Solis 20, Homologation

Certificate

E

11*2010/22*0209*00

Revis

ion 00 issued by the vehicle

certificat

ion agency on the approval

authority

in the United Kingdom

SV

e11

rtificate Plate

INTERNATIONAL

TRACTORS LIMITED

TRACTOR TYPE T 2

3003

Serial No.

Tractor Model

Solis 20 4WD

SOLIS 20 OPERATOR MANUAL

19

1

kg

Page 22

2. INTRODUCTION & DESCRIPTION

T

RACTOR AN INTRODUC

TION

The

word

, 'Tractor' has

been derived from

'Tract

ion' which means pulling

.

A Tractor is

required to pull or haul an equipmen

t,

implement or trolley which are coupled to the

Tractor

bod

y t

hrough suitable linkage

. ATractor can also be used as a

prime mover as it has power

outle

t s

ource which is also called Power Take o

ff or PTO shaft.

In this

book the operating, maintenance and

st

orage instruction

s for S

olis-20 Tractor has been

c

omplied

. This mat

erial has been prepared in detail to help you in the better understanding o

f

maintenance and efficient operation o

f the mac

hine

.

If you

need any information not given in this manual or require the services of a trained machani

cs,

please get in touch with the

ITL

Dealer/Distributor in your locali

ty,

Dealer/Distributors are kep

t

informed o

f the latest met

hods o

f servic

ing Tractor

s. They stock

genuine spare par

ts

and are backed

b

y the

Compan

y's f

ull suppor

t.

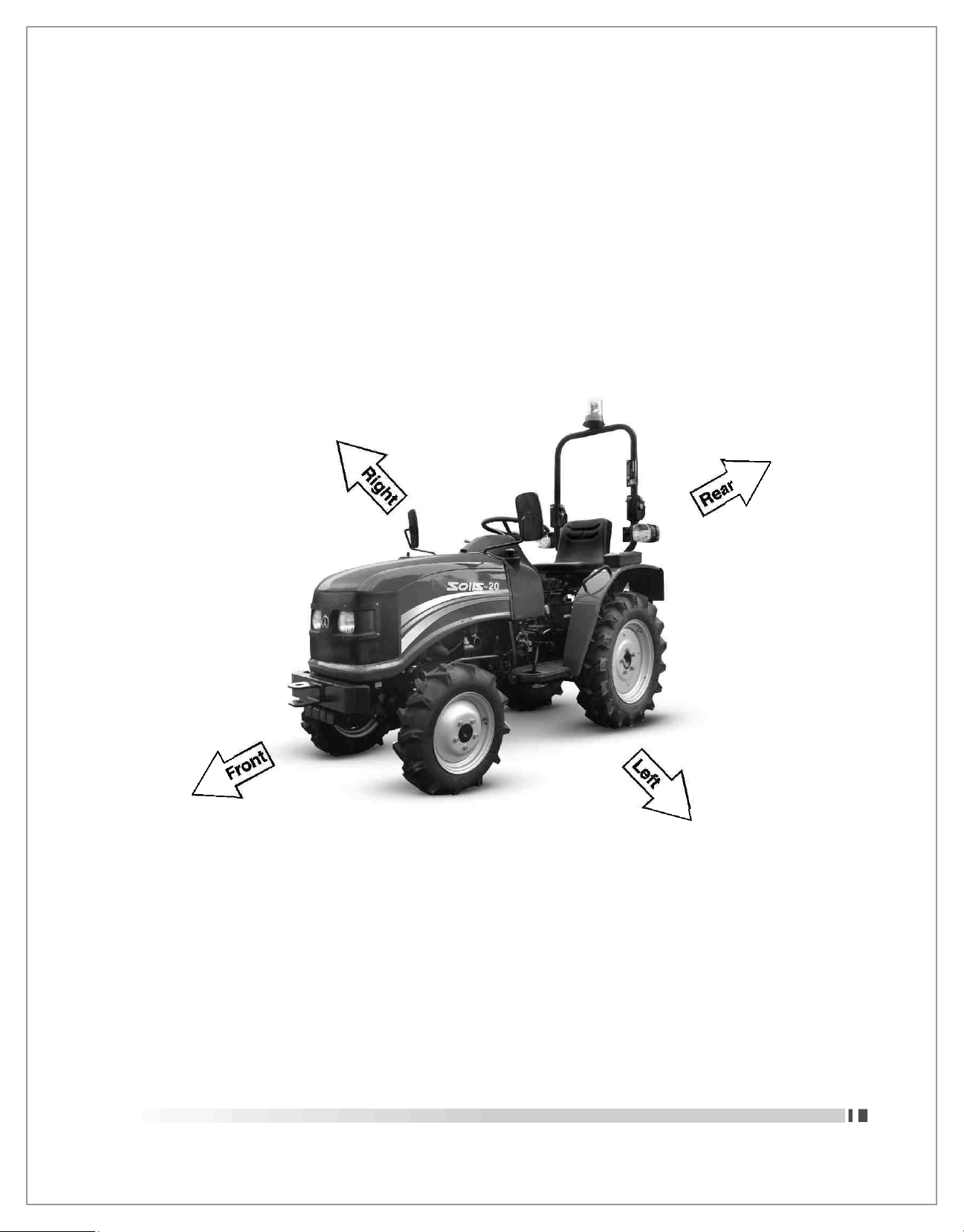

(Front, Rear

, L

eft, R

ight Portion)

T

hrough this manual

. The use of the t

erms L

EFT, RIGHT, FRONT

and REAR mu

st be

understood

, to

avoid an

y confus

ion when following the introduction

s. The LEFT

and RIGHT means le

ft

and righ

t

s

ides o

f the Tractor

when facing forward in the driver

's s

eal, Reference to the FRONT indicate

s the

radiator end o

f the Tractor,

while the REAR, indicate

s the

drawbar end

.

W

hen spare par

ts

are required, alwa

ys specify the Tractor

and engine serial number when ordering

these

par

ts. This

will facilitate faster delivery and help ensure tha

t the c

orre

ct

par

ts of

your particular

Tractor s

erial number is punched on a plate attached to the le

ft

hand side o

f the

engine bod

y. For easy

reference, we sugge

st you to

write the number in the space provided in the owner

's

personal data

.

20

SOLIS 20 OPERATOR MANUAL

Page 23

3. OPERATIONS

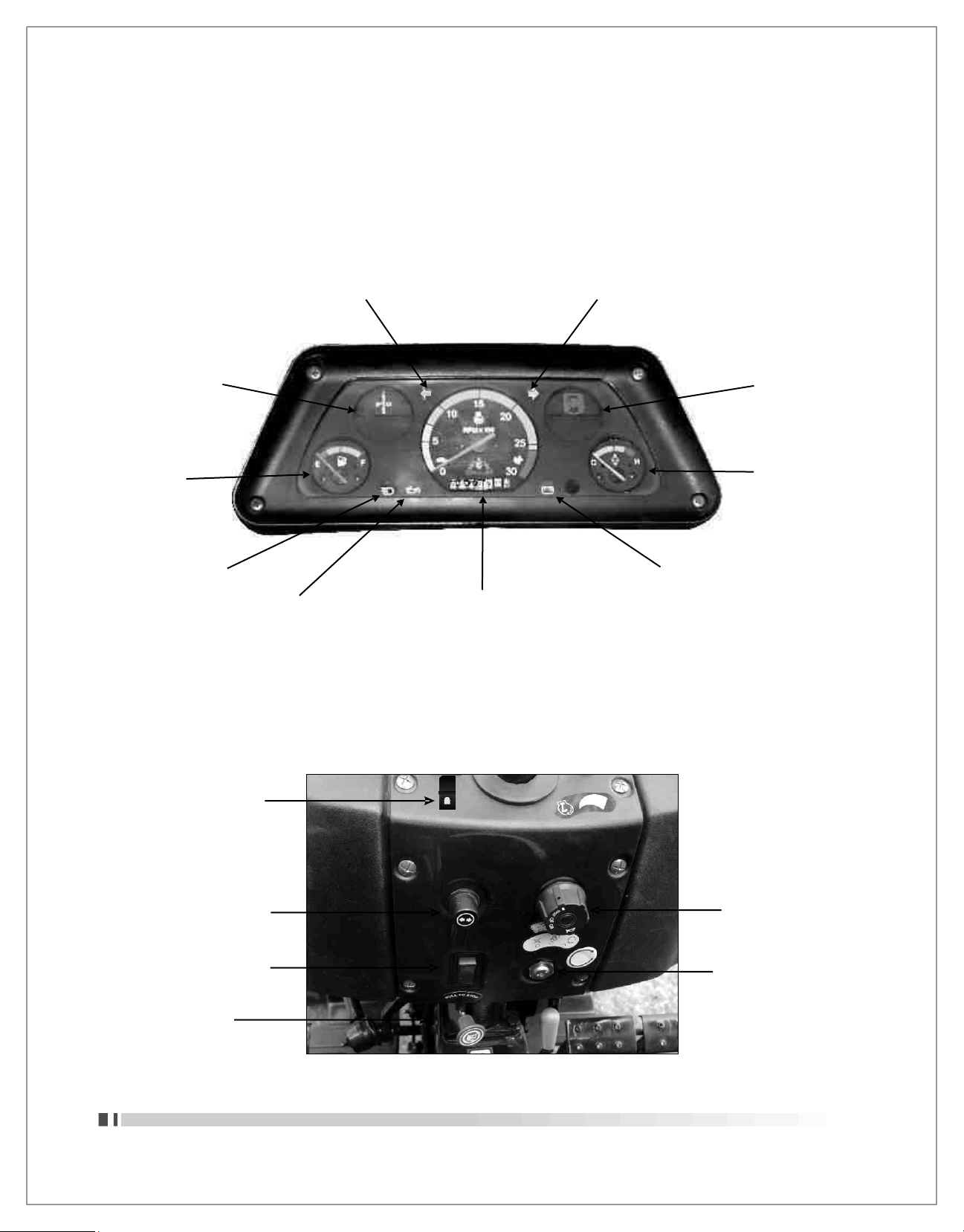

3.1 INSTRUMENT PANEL

Left Turn Indicator

Right Turn Indicator

PTO Lever Position

Indication

Fuel Gauge

High/Low Beam

Oil Pressure Indicator

Engine RPM cum

Hmr. Meter

Gear Lever Position

Indication

Temperature

Gauge

Battery Indicator

3.2 ELECTRICAL CONTROLS

Revolving Light Switch

Turn Indicator Switch

Hazard Warning Switch

Combination Switch

Ignition Switch

Pull to Stop Lever

SOLIS 20 OPERATOR MANUAL

21

Page 24

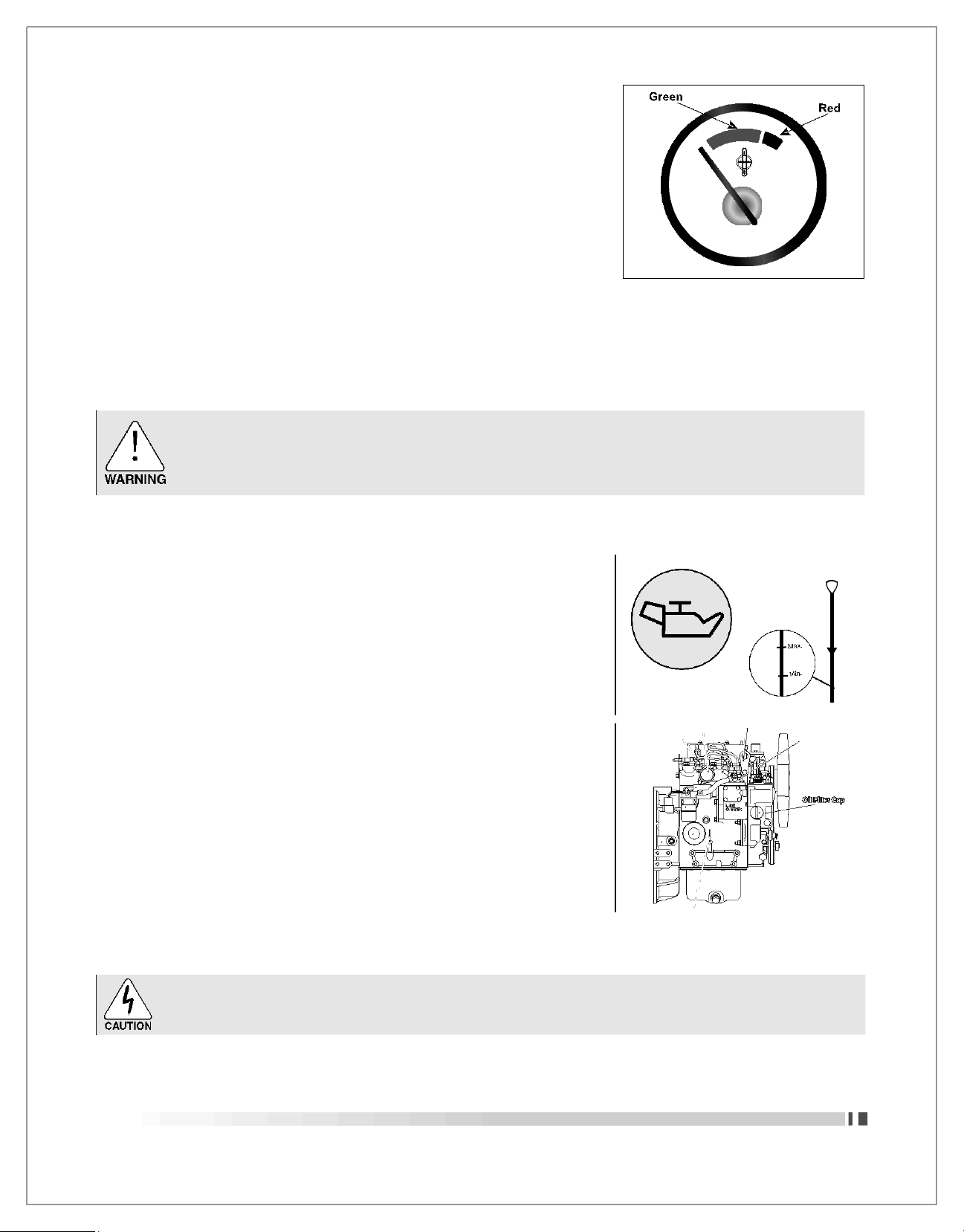

3.1.1

TEMPERATURE GAUGE :

This

gauge indicate

s t

emperature of engine coolan

t, GREEN z

one

indicates normal temperature and RED Zone indicates engine

overheating

. If the

needle moves beyond normal range

,

t

owards RED zone

, f

ollow the procedure

.

C H

1. Drive safel

y to the s

ide of road and

stop y

our tractor

.

2

. A

llow the engine to run idle

.

3

. If the t

emperature does not go down

, shut it off

and allow

suffic

ien

t t

ime for i

t to c

ool

.

4

. Vis

ually inspe

ct the fan

bel

t for

loosene

ss,

breakage and all

water hose connection

s for

lea

k.

5

. If the fan

belt i

s OK

and no coolant leak is noticed che

ck the

c

oolant level

.

6

. Add c

oolant if required otherwise conta

ct y

our neare

st

dealer

.

Do not remove the radiator cap when the engine and radiator are ho

t. B

oiling ho

t c

oolant and

st

eam may blow out under pressure, which could cause serious injur

y. The cap

should only be

taken off

when the coolan

t t

emperature has lowered

.

Necessary precaution to be taken while opening the radiator cap

.

3.1.2

ENGINE OIL PRESSURE INDICATOR

This

indicator indicates pressure of lubricating oil in the engine

. If the

indicator glow

, stop the

engine and follow the procedure

:

1

. Stop y

our tractor to the side of road on leveled surface

.

2

. Wait for suffic

ien

t t

ime after

st

opping the engine to get down the

oil from galler

y to

oil sump

.

3

. P

ull ou

t the

dipsti

ck,

wipe o

ff

oil with a clean cloth

.

4

. Insert the

dipsti

ck, f

ully into the oil level gauge guide

, t

hen pull

ou

t the

gauge again

. The c

orre

ct

oil level is between the M

AX.

&

Min. mar

ks on the

dipsti

ck.

5

. If the

oil level is low, remove the oil filler cap and add oil o

f the

specif

ied

type to the MAX. level.

6

. Inst

all the oil filler cap after a topup

.

7. Chec

k the

oil pan and other parts for oil leakage

.

8

. Start the

engine, allow i

t to

run idle and don

't race it

immediatel

y

if again the red light glow

s, t

hen conta

ct y

our neare

st

dealer

.

Do not operate the engine if there is no oil pressure indication.

22

SOLIS 20 OPERATOR MANUAL

Page 25

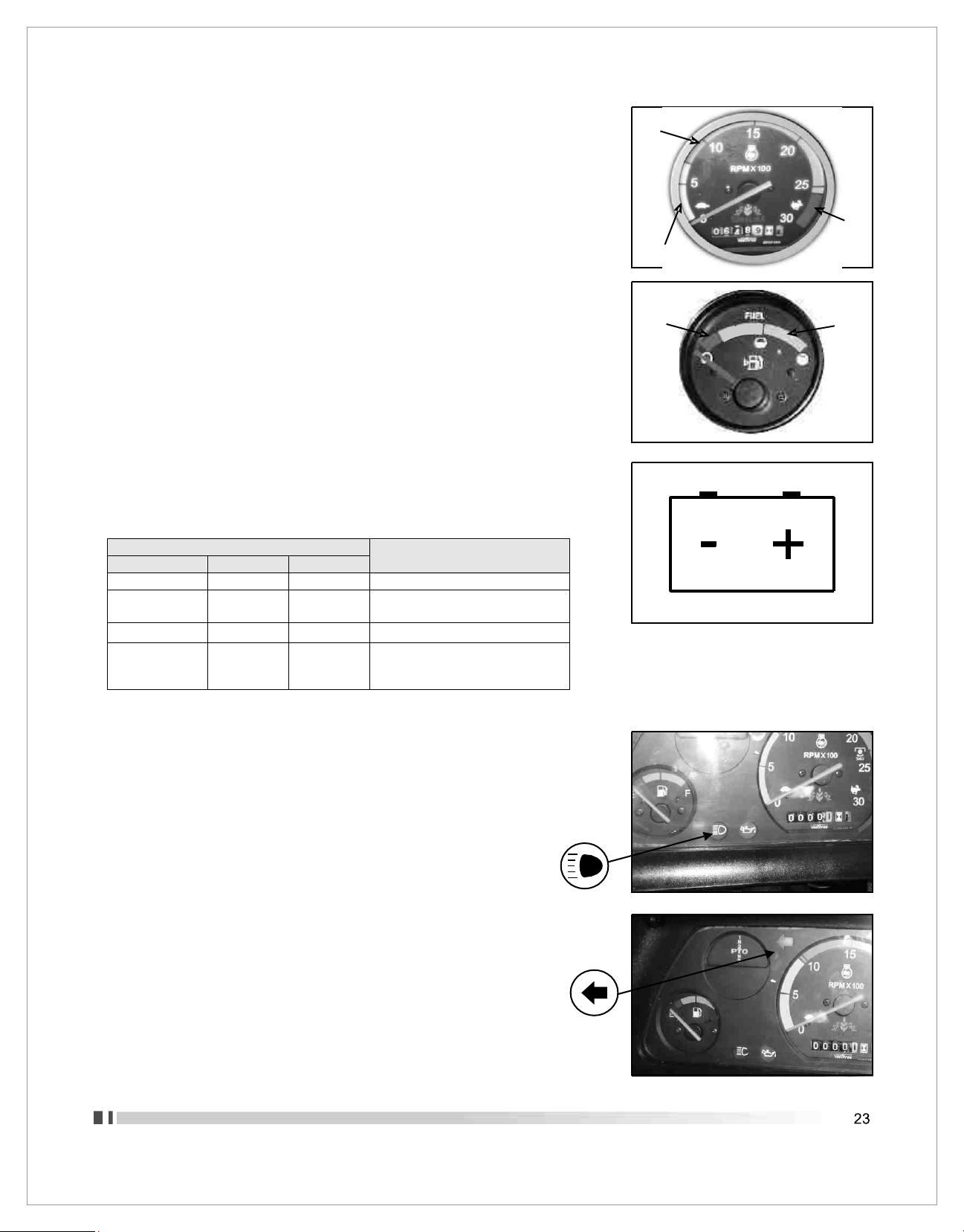

3.1.3 RPM CUM HOUR RECORDER

Green

Needle o

f this meter

indicate

s s

peed of engine in revolution per minute

and the recorder meter indicate

s the

number of hour

s clocked by the

engine

.

G

reen Zones i

s safe for

operation

.

Red

Yellow

3.1.4 FU

EL GAUGE

F

uel gauge gives an approximate indication o

f the

quanti

ty of f

uel in

f

uel tan

k. If the

needle enters in RED zone, refill the fuel tan

k.

Ens

ure Min. 5 Ltr. o

f F

uel in Fuel Tan

k to av

oid air locking

F

uel Tank Capaci

ty 30 Ltr.

Red

Green

3.1.5 BATTERY CHARGE INDICATOR

This indicator indicates that either battery is being charged or not.

Refer the below given observations with respect to different

CONDITIONS

Battery Charging

System Functioning

IGNITION SWITCH

ENGINE

INDICATOR

ON

OFF

GLOW

OK

ON

OFF

OFF

Charging System/Battery is defective,

Get both thing checked from electrician

ON

Start/Running

OFF

Battery being Charged

ON

Start/Running

GLOW

Charging System is defective/Battery

is draining out, get the charging system

checked from electrician.

3.1.6 HIGH BEAM INDICATOR

This blue light glows when Head Lights are in high beam mode.

3.1.7 LEFT SIDE INDICATOR

It glow when the left side indicator is switched ON

SOLIS 20 OPERATOR MANUAL

Page 26

3.1.8 RIGHT SIDE INDICATOR

It

glow when the righ

t s

ide indicator i

s switc

hed ON

3.1.9 PTO LEVER POSITION INDICATOR

This is

onl

y for

awarene

ss

abou

t Posit

ions o

f PTO Lever to get 3-S

peed

s

i.e. C1, C2, C3

.

1

N

2

PTO

N

3

3.1.10 GEAR LEVER POSITION INDICATOR

This is

only for awareness about Positions of Gear Lever to select the

desired gear speed

.

1

2

N

R

3

SOLIS 20 OPERATOR MANUAL

Page 27

3.2 ELECTRICAL CONTROLS

Turn Indicator Switch

Hazard Warning Switch

Combination Switch

Ignition Switch

Engine Stop Knob

3.2.1 HAZARD LIGHT SWITCH:

Purpose of the hazard switch is as follows.

1. All the four lights blinking Indicates that driver has no control on tractor.

2. Mechanical defects in the tractor.

Push this switch to blink all indicators in HAZARD situation to alert others.

3.2.2 SIDE INDICATOR SWITCH:

This switch is used for

indicating the vehicle turn. Move turn signal lever le

ft to

indicate le

ft

hand turn or righ

t for

right hand turn

. I

ndicator ligh

ts in cluster

will flash

accordingl

y.

Left

Right

3.2.3 COMBINATION SWITCH:

This switch illuminates all lights (Parking Light, Head Light, High Beam, Low Beam)

with the clockwise rotation as well act as horn switch.

HORN : Press the combination switch to blow the Horn.

OFF Position

All lights are off.

1st Position

(Clockwise)

With 1st click Stop

parking lights,

Instrument panel lights

and tail lights will glow.

2nd Position

(Clockwise) :

With 2nd click Stop

Head lights (Low

beam), Instrument

panel lights, Parking

lights and tail light will

3rd Position

(Clockwise) :

With 3rd click Stop

Head lights (High beam)

Instrument panel lights,

Parking lights and tail

light will glow.

Horn :

Press the

combination switch

to blow the Horn.

OFF

1st

2nd

3rd

Horn

SOLIS 20 OPERATOR MANUA

L

Page 28

3.2.4 STARTING KEY SWITCH:

Functioning of starting key switch is as below:

Ist Position (OFF) : All

the electrical systems

remain disconnected in

this position.

2nd Position (ON) : The

warning lights (Battery, Oil

Pressure indicator & other

Cluster Lights will be

functional in this position.

This is normal running

position after the engine is

started.

3rd Position (Use of

Heater):

Turn the key slightly

clockwise and hold in

between ON & START

position for 3-5 Seconds so

that glow plugs can heat up

the air in the cylinders.

4th Position (START):

Immediate after the

use of air heater turn

the key furthe r

clockwise to Start

position to start the

engine.

O

N H

EATE

R

START

NOTE : Do not keep the starter engaged more than 5-8 seconds. If engine stalls/fails to start then wait for 5-10 seconds

before re-engaging the starter, otherwise you may damage it.

Keep the switch in OFF condition when engine is also in OFF condition.

3.2.5 ENGINE STOP KNOB:

To stop the engine release the accelerator lever and pull the stopping

knob. After stopping the engine push it back to its original position.

3.2.6 FUSE BOX:

Fuse box is mounted under the right side of Fuel Tank. If an electrical

failure occurs, check for a blown fuse and replace with specified fuse

only.

CAUTION: Never install a wire instead for proper fuse.

3.2.7 Revolving Light Switch

Revolving light as show in the figure is used as the precession light

during working of the tractor in the field. ON/OFF switch is located on

dash board in control figure.

SOLIS 20 OPERATOR MANUAL

Page 29

3.3 ELECTRICAL EQUIPMENTS

3.3.1 BATTERY AND ITS MAINTENANCE

12,V, 50 AH is mounted at front of the tractor.

1. CHECK ELECTROLYTE LEVEL

It must be as per the recommendation of battery manufacturer.

If required top up with distilled water. Never add acid.

2. CHECK CAREFULLY BATTERY CHARGING

Protect against freezing. Insure that terminals are clean and tight. Check

electrolyte battery charge. This operation is carried out using a battery

hydrometer. The value of a fully charged electrolyte is 1265. If below 1215

recharge the battery.

3. PRECAUTIONS

1. The electrolyte in the battery contains sulphuric acid. Which is

dangerous and burn the skin take all necessary precautions (protective

clothing)

2. If accidentally splash yourself with acid, take care not to breath in

the fumes, rinse throughly and consult a doctor immediately.

3. Keep the battery well away from any naked flame or sparks

3.3.2 ALTERNATOR

Alternator is fitted on Left side of engine and generates current which

charges battery for healthy electrical back up.

Rating: 12V, 30A

3.3.3 V-BELT CHECKING AND ADJUSTMENT

CHECKING:

1. Ensure for V-Belt free from defects such as wear, cuts or surface

separations, otherwise replace with genuine specified belt.

2. Inspect belt tension as instructed below:

Push the belt downward with approx. 98 N (10kgf) (22lbf) force midway

otherwise adjust the belt tension

ADJUSTING :

1. Removal belt cover the covers V-belt.

2. Loosen all retaining bolts of the alternator and adjusting plate.

3. Insert a bar between the alternator and cylinder block and use leverage

to move that alternator to have proper v-belt tension.

4. While V-belt tension is appropriate, retighten all the retaining bolts of the

alternator and adjusting plate.

5. Reinstall the belt cover.

3.3.4 STARTER MOTOR

Starter motor is mounted on the left side of the engine.

• The starting motor rotates the engine crankshaft for starting.

• Capacity and Rating: 12V, 1.8KW

SOLIS 20 OPERATOR MANUAL

Page 30

3.3.5 GENERAL MAINTENANCE OF ELECTRICAL SYSTEM

Never Patch up the electrical circui

ts.

Never replace a blown fuse by a higher capaci

ty fuse. It c

ould

cause a

f

ire

.

Never work on componen

ts such as the alt

ernator or

starter motor

when

the

engine is running

.

Lastly when

you

are

c

leaning

the tractor

and using

the

pressure

s

pra

y, take c

are no

t to

damage

the c

onnections on

the v

ariou

s

electrical cable

.

3.3.6 PRECAUTIONS BEFORE CONNECTING WELDING

APPARATUS:

•

In case of any electrical welding on tractor, first disconnect battery

earth connection.

3.4 SHEET METAL

3.4.1 PROCEDURE TO OPEN THE TOP HOOD

Press the knob (at the centre of the bonnet) towards steering wheel and lift

the bonnet upwords to full open position.

SOLIS 20 OPERATOR MANUAL

Page 31

L

ock

3.5 CONTROLS

2WD & 4WD Lever

Differe

Lever HI

PTO Lever

Main Gear

Dipstick

Shifter Lever

3.5.1 MAIN GEAR SHIFTER LEVER

Main gear shifter lever enables to get the required speed (6 Forward and 2

Reverse) by selecting the particular gear with combination of hi-low gear

lever. Refer photo for gear shifting arrangements.

Before changing the tractor movement from forward to reverse or reserve to

forward direction wait for the tractor to stop.

Release accelerator pedal and declutch. Select required gear, release the

clutch gradually and accelerate the engine.

NOTE: When traveling downhill always remain in gear. Never declutch. The gear selected should be same as would be

used to climb. For engaging/disengaging gear always depress the clutch

3.5.2 HIGH-LOW LEVER

This lever is used to change the low speed into high speed or vice versa when

tractor is moving. According to requirement you can use it with combination

with main gear lever.

Speed Selection:

1. Neutral Position: Lever in the middle cut

2. High Speed: Move the lever out of the cut and shift towards rear end.

3. Slow Speed: Move the lever out of cut and shift towards front end.

Select the speed before tractor movement.

3.5.3 2WD/4WD LEVER

This lever decides whether tractor move in 2WD or 4WD mode.

2WD MODE: By engaging the lever in 2WD position the power is transmitted

to rear wheels only. Shift the lever towards rear (driver seat) to select 2WD

mode.

4WD MODE: With the lever in 4WD position the power is simultaneously

transmitted to all 3 wheels (Front & Rear) of tractor. Shift the lever towards

front to select 3WD mode.

NOTE: 4WD Mode is for field operation and 2WD mode is for road running.

SOLIS 20 OPERATOR MANUAL

4WD

2WD

Page 32

3.5.4 POWER TAKE OFF SHIFTER LEVE

R

T

here are three position

s for PTO lever. In the 'N' it is c

alled Neutral position

.

and other three speed are also selected b

y shift

ing this lever to particular

position

PTO Lever Position

PTO RPM

@engine rated RPM

1

630

2700

2

930

3

1605

3.5.5 D

IFFERENTIAL LOCK PEDAL

W

hen you pre

ss

pedal differential lo

ck

will work and both the wheel rotate a

t

s

ame speed

.

Note : Differential lock operation should be in straight position only and

should be disengaged at turnings to avoid any damage of differential

assembly.

Do not apply differential lock while tractor speed is more than 6 kmph

on turning.

3.5.6 CLUTCH

PEDAL

By

pressing clutch pedal the motion and power or engine will be disengage

f

rom gearbo

x.

Release the clutch pedal slowl

y for t

ransfer the engine power

to

gear bo

x.

3.5.7 METHOD

TO CHECK CLUTCH PEDAL FREE PLAY

Press down the clutch pedal and measure the distance between the footrest

and pad. The distance should be 25 to 30 mm. If the distance is less than

25 mm or higher than 30mm then get it adjusted.

NOTE: Do not keep foot on clutch pedal while tractor is in running condition. It may cause excessive wear of clutch

and clutch falls before its life time

3.5.8 FOOT

BRAK

E PEDALS

Use independent brake in the field operation

s. In f

ield you will turn more

s

harply by pressing brake pedal for the side wheel on the turn

. The

pedal

s

mu

st be locked for

road use

.

3.5.9 METHOD TO CHECK BRAKES

Release the hand brake. Uncouple the two pedal

s

Press

down

the

right hand pedal and measure

the distance bet

ween

the

pad

s & footrest. The distance s

hould be between 25-30 mm

.

If the f

ree play is le

ss t

han 25mm or higher than 30mm then adju

st the both

hex nut on actuator tie rod until free pla

y c

ome

s to 25 to 30 mm.

Now, pre

ss

down the le

ft

hand pedal

. If the v

alues are not equal with the right hand pedal

t

hen repea

t the s

ame procedure until values come equal

.

N

OTE: Ens

ure locking of both break padles while driving on road

.

Note: Difference in the free play will lead to unbalanced brake

s. the tractor can s

lew, in the event o

f v

iolent braking

. the

wheel on which the brakes are applied lo

cks

and the

tyre

wears out quickl

y.

During Road Operation

s Both the

brake

P

edal

s s

hould be locked

SOLIS 20 OPERATOR MANUAL

Page 33

3.5.10 PARKING BRAK

E

Park

ing brake lever is mounted on R.H

.S. foot

board and should alwa

ys be

engaged while tractor is parked

.

Press the foot

break pedal and shi

ft the

parking brake lever towards driver

seat to

engage the parking brake

.

Press the foot

break pedal and shi

ft the

parking brake lever toward

s f

ron

t to

release the parking brake

.

3.5.11

FOOT

ACC

ELERATO

R

Foot acc

elerator is used for control the tractor speed as per requiremen

t,

Only use foot acc

elerator while moving on road

.

3.5.12 HAND THR

OTTLELEVE

R

Hand throttle lever mounted on dashboard (Panel) is used in field application

to inc

rease the speed of engine, pull down the lever and to decrease pull up

the lever.

3.5.13 DR

IVER SEAT

Driver sea

t can be

adjusted according to your convenience in following wa

ys

3.5.14

SEAT PAN TRAVEL

ADJUSTMEN

T

Seat can be moved f

orward

& back

ward to three different locations as per

requiremen

t. A

dju

st the seat as

per requirement b

y shift

ing the pin as indicated

direction

.

3.5.15

SEAT

BACK ADJUSTMEN

T

Seat can be

adjusted upward/downward by loosening the four bol

ts

mounted

on the ba

ck s

ide o

f the seat.

Loose the four mounting

sc

rews o

f seat back. S

lide the seat ba

ck to des

ired

height and religh

t the sc

rew

s.

3.5.16

TOOL BOX

T

ool box is mounted at below of driver sea

t.

To

open the tool bo

x tilt the seat t

oward

s f

ron

t t

hen unscrew then knob (A) and

li

ft the cover of t

ool bo

x.

SOLIS 20 OPERATOR MANUAL

Page 34

3.5.17

SEVEN PIN SOCKET

7 Pin socket is mounted on ba

cks

ide of driver sea

t to attach the t

railer

c

onnection as per following Connector

s.

1

Eart

h 2

Work

ing ligh

t

3 Le

ft I

ndicator

5 Righ

t I

ndicator

7

For Extra

Connection

4

Park

ing ligh

t

6

Brake

ligh

t

3.5.18

POSITION CONTROL LEVE

R

This

bla

ck c

olour lever is mounted on R.H

.S. of

driver seat which enable

s

raising or lowering the implement/li

ft.

3.5.19

POWER TAKE OFF

P

ower take o

ff is

mounted at rear side o

f tractor. This is used for s

upplying

power directl

y to

implemen

t f

rom engine

. P

ower take o

ff shaff has st

andard

06 Spline on 540 rpm

. PTO can be

engaged or disengaged b

y PTO shifter

lever. 3 - speed

s can be obt

ained by putting the

PTO Lever in diff

eren

t t

hree

.Posit

ion (i.e. 1,2,3)

3.5.20 R

EGISTRATION PLATE

A v

ehicle registration plate or number plate is mounted at rear end of righ

t

f

ender as per country rule

.

3.5.21

LIGHTS

The v

ehicle is equipped with

E

marked front and rear tail ligh

ts.

SOLIS 20 OPERATOR MANUAL

Page 35

3.6

Engin

e:

3.6.1 S

tart

ing the Engin

e:

Starter Switch: The starter switch is used to start the

engine

OFF POSITIO

N

W

hen the key i

s t

urned to this position, power suppl

y to the

electri

c circuits is

cut off,

and the ke

y can be

removed or inserted in this position

. To stop the

engine

, t

urn the ke

y to this posit

ion and pull the

'P

ull to

stop k

nob

'

ON:

W

hen the key i

s t

urned in to this position, power i

s s

upplied to the

electri

c circuits. After the

engine

starts , the key is

held in thi

s

position

.

HEAT:

This is an int

ermediate position between

the 'ON'

and

'Start'

position

. W

hen the key i

s t

urned to this position

, the

glow plug

s

would become hot and allow ea

sy startup of a c

old engine

.

START:

W

hen the key i

s t

urned to thi

s f

inal position

, the starter c

ran

ks the

engine and

the

engine

starts. W

hen

the key is

released, i

t

automatically return

s to the 'ON' posit

ion

.

For S

tart

ing

:-

A

Che

ck that the

gear shifter lever and range selector lever are in neutral

.

B

Move the low/ high speed selector lever to neutral position

.

C Move the hand throttle lever to about halfway position

.

D Depre

ss the clutch

pedal all the wa

y.

Warning: The E

ngine Should not Crank i

f the

above conditions are not met -

If this

happens have

the tractor

repaired b

y y

our dealer or

authorized service center

.

Cold Weather

start

ing (Temperature below 0 °C or 32

° F):

W

hen outdoor temperature drop

s to

around or below 0 °C (32

° F),

check the c

ooling

system

and if necessary add the recommended

antifreeze

.

Warning: Do not

inje

ct f

luids (Ether) to make the engine easier to

start in c

old

weather

.

3.6.2

. Pro

ceed as

Follow

s:

1 Perform operation

s A, B,C

and D as instructed above

.

2 Turn the

Starter Key to '

Hea

t' posit

ion and keep i

t t

here for few second

s

and then turn the ke

y to start posit

ion

.

3

If the

engine fail

s to start

repea

t Step 2,

wait a further 10 to 15 seconds and

t

hen turn the ke

y to start posit

ion again

.

Note:

1

If the

engine fail

s to start after two or t

hree attemp

ts

and smoke can be

s

een coming out o

f the ex

hau

st,

repea

t the start

ing procedure with le

ss

t

ime glow plug heater

.

2 Do no

t k

eep the ke

y t

urned to

start posit

ion for more than 15 seconds at a

t

ime

.

SOLIS 20 OPERATOR MANUAL

Page 36

3

Wait at

lea

st

one minute between ever

y two att

emp

ts of start

ing the

tractor.

If the

engine does no

t start

regularly and easil

y, do not cont

inue a

s for you may

run down the batter

y. B

leed any air that may have accumulated in the fuel

system

and, i

f the

problem persi

sts check that:

1 Fuel filters are not blocked

2 The battery and Heater Plugs are working efficientl

y.

Note-: Before

start

ing a cold engine in cold weather fir

st cover the

radiator with

a radiator cover. Remove the cover a

s s

oon as a normal working temperature

is achieved

.

3.6.3. R

unning in:- It is essent

ial to take the following precautions during the

running in period

:

1 During this period, do no

t s

ubje

ct the tractor to

loads greater than those i

t

will have to deal with during the re

st of its

working life

.

2 Engage low gears when towing hea

vy

load

s.

3

W

hen running in

, check

regularl

y that

all

sc

rew

s, nuts

and bol

ts

are tigh

t.

4 To ensure prolonged clutch life, run in the clutch di

scs c

orrectl

y.

3.6.4

. Turning off the engin

e:

1 Turn the engine accelerator to idle position

2 Turn the starting Ke

y to 'Off' posit

ion

3

Stop the

engine by pulling the fuel cut-o

ff lever t

ill engine

stops.

3.7

FUELSYSTE

M

3.7.1 FU

ELSAVING TIPS

Maintain your tractor

. B

adly maintained tractor wastes 25% of preciou

s f

uel

.

A

lwa

ys top up tank at the

end of da

y to av

oid water contamination in fuel tan

k

due to moisture

.

Change fuel filter regularly as per maintenance

sc

hedule. Use genuine fuel

filter av

ailable at authorized dealer

. Also c

lean feed pump

, filter

and drain ou

t

water from filters as per

sc

hedule

.

Prevent f

uel leakage

.

For better

performance o

f tractor f

ollow running in proce

ss

mentioned in thi

s

manual

Do not ride the clutch

.

Run tractor with appropriate speed and gear combination

.

Do lengthwise field operation

.

A

lwa

ys k

eep the specified

tyre

pressure for road and field operation

.

Switch off the

engine when the tractor is not in use

.

Av

oid wheel slippage

Attac

hed tractor trolley at appropriate heigh

t.

Do not over load tractor beyond capaci

ty.

34

SOLIS 20 OPERATOR MANUAL

Page 37

3.8 HYDRAULIC

3.8.1 HYDRAULIC

SYSTE

M

In this tractor live hy

drauli

c system is

provided

. In

which hydraulic pump i

s

driven by engine and mounted a

t cover of

engine

. As the

engine run

, the

hydraulic pump also

starts

working

. T

ransmission lubrication oil is used a

s

hydraulic oil

.

3.8.2 T

RAN

SPORT LO

CK

It acts as safely device

during transportation of implemen

ts. It is located on f

ron

t

s

ide of Hydraulic Rear Cover below driver sea

t.

Use

: For safety lock f

ull

y t

ighten the response valve by rotating in clockwise

direction

Response Valve should always be closed during implements transportation.

3.8.3 THREE POINT LI

NKA

GE

T

hree-point linkage is used to moun

t the

implemen

t,

which i

s f

ully mounted

,

or semi-mounted and used for differen

t f

ield operation

. T

hree-point linkage

i

s cont

rolled by hydraulic lever

. In this two

lower link are available, of which

one side o

f the

lower link is attached with differential housing and other i

s

used to hitch the lower pin o

f the

implemen

t. Lift

rods are mounted on li

ft

arm

that is

operated

t

hrough ro

ckshaft.

Loose

s

ide o

f Top

link is used

for

attaching upper hitch pin of implemen

t. Top

link is adjustable for proper

sett

ing of implement and ease a

t the t

iming of joining

.

3.8.3.1

LIFT RODS (A &

B)

If lift

rod i

s fitted with lift

arm and lower lin

k, the

length of li

ft

rod (

A&B) c

anno

t

be adjusted

.

3.8.3.2

TOP LINK

(C)

For

length adjustment o

f top

lin

k, fix the top

link other end and turn the lever

for inc

reasing or decreasing the length. During field operation lo

ck the t

ube

to av

oid unnecessar

y t

urning

.

3.8.3.3

LOWER LINKS

(C)

Lower Lin

ks

are provided for hitching the implemen

t.

3.8.3.4 ATTACHIN

G IMPLEMENT TO 3 POINT LI

NKA

GE

Posit

ion the tractor to align corresponding linkage with the hitch poin

ts of

implemen

ts. K

eep the implement on hard

& lev

eled surface and attach a

s

per given below instruction

s :

First attach with Left

lower link (E) and Right Lower Link (F)

T

hen at Last attach with Top Link (C)

3.8.3.5 DIREC

TIONAL CONTROL VALVE

(DCV)

The tractor is

equipped with single acting directional control valve

. The

operator is with a lever located on LHS of driver sea

t. And the c

oupler (qui

ck

attach) is at rear side o

f tractor.

Use only single action cylinder implement.

SOLIS 20 OPERATOR MANUAL

Page 38

TYRE

TYRE SIZE

Pressure

(kPa)

80 100 120 140 160

REAR

8 - 18

4 Ply

Rating

345 395 440 480 520

FRONT

5 - 12

115 135 150 160 175

3.9 WHEELS AND TYRES

Tyres Play vital

role in transportation and agriculture operation

s. It is the most

importan

t factor in the effic

ient performance

o

f tractor it s

hould be used only as per company recommendation. Here we will discu

ss

only pneumati

c tyres.

On any tyre t

here i

s s

ome marking which represen

ts its size & c

apaci

ty e.g. Tyre

marking is 8x18, 4 ply rating i.e. 8 inch i

s

the sect

ion width, 18 inch i

s the

bead diameter

. Ply rat

ing doe

sn’t s

how tha

t the s

ame No. of plies are inserted in

tyre. It is

onl

y c

omparative measure o

f the

load carrying capaci

ty (L.C.C) of tyre. As

more ply rating shows more L.C.C. a

t the s

ame

t

ime as L.C.C. increase the sho

cks abs

orption capaci

ty dec

rease

s.

In

general

, tractor is cons

idered for two

types of

wor

k:

Work on soft s

oil where maximum adhesion is needed

. In this case t

here will be use of lowe

st

pressure compatible with the

load carried

.

Work on

hard ground and road

s, t

owing e

tc. In this case t

here will be use of maximum pressure

.

3.9.1 IN

FIELD OPERATIONS

(Recommended

Tyre Press

ure

: F

ront - 1.75 Kg/cm

2

&

Rear .84 Kg/cm2)

Correct Pressure

G

ood adherence by dirt grouser

s.

G

ood cleaning o

f the t

read

Insufficient P

ressure

Reduce adherence through la

ck of

tyre

grip

.

Deterioration o

f tyre cas

ing b

y

tract

ion force

s.

O

ver Pressure

Reduce group due to la

ck of

c

leaning

Deterioration due to compacted

ground

.

3.9.2 ON ROAD

OPERATIONS

(Recommended

Tyre Press

ure

: F

ront - 2.15 kg/cm

2

&

Rear 1.57 kg/cm2)

Correct Pressure

Resistance to Wear

Insufficient P

ressure

Reduce adherence through la

ck of

tyre

grip

.

Deterioration o

f tyre cas

ing b

y

tract

ion force

s.

O

ver Pressure

Reduce group due to la

ck of

c

leaning

Deterioration due to compacted

ground

.

3.9.3 RECOMMENDED

LOAD

CARRYING CAPAC

ITY

NOTE: Tyre pressure should never maximum pressure as recommended the tyre could burst. Change / repair any worn

or faulty tyre (cuts, cracks etc.) immediately to prevent the problem become more severe

SOLIS 20 OPERATOR MANUAL

Page 39

3.9.4 BALLASTING OF TRACTOR

P

roper ballasting is an importan

t factor in tractor

performance

. For better

performance o

f tractor, the

weight o

f tractor can be dec

reased as per

requiremen

t. Max

imum productivi

ty can be ac

hieved only i

f tractor

weight i

s

appropriate for the job

. B

alla

st is

required for traction and

st

abili

ty. F

ollowing

factors det

ermine amount of balla

st.

S

oil surface loose or firm

Type of

implemen

t

Travel s

peed and tractor power output partial or full load

.

3.9.5 FRONT WHEEL TOE IN

After sett

ing the tra

ck

width is necessar

y to

adju

st toe in of the f

ront axle

.

3.9.6 CHECKING AND ADJUSTMENT OF TOE-IN

Firstly

par

k the tractor on level surface. T

urn the

st

eering wheel so tha

t f

ron

t

wheels are in the

st

raight-ahead position

. Stop the

engine. Measure distance

(A) between tyres at hub level in front of axle. Record measurement and

mar

k the

points on

tyres. Move tractor back

about 1 meter so that mark on the

tyre is at

hub level behind the axle

.

A

gain measure distance between

tyres at s

ame point on

tyre. Rec

ord the

measurem en

t. Det

ermine

the diff

erence between

f

ront and rear

measuremen

t. If the f

ront measurement i

s s

maller toe i

s 'In'. If the

rear i

s

s

maller

, toe is 'Out'. DIstance (A) at f

ront or tyre

s s

hould be 3-6 mm le

ss t

han

distance measured at rear o