Page 1

Solid State Logic

Super-Analogue™ Outboard

Owner’s Manual

82S6XL070A

S U P E R A N A L O G U E

C H A N N E L A D C

Page 2

As research and development is a continual process, Solid State Logic reserves the right

to change the features and specifications described herein without notice or obligation

E&OE

Revision 0A, May 2004

Minor changes, November 2004

Minor changes, June 2005

Solid State Logic

Begbroke, Oxford, England, OX5 1RU • +44 (0)1865 842300

320 West 46th Street, 2nd Floor, New York, NY 10036, USA • +1 (1) 212 315 1111

Suite 401, 5757 Wilshire Blvd, Los Angeles, CA 90036, USA • +1 (1) 323 549 9090

3-55-14 Sendagaya, Shibuya-Ku, Tokyo 151-0051, Japan • +81 (0)3 5474 1144

7 bis, rue de la Victoire, le Blanc Mesnil, Paris 93150, France • +33 (0)1 48 67 84 85

Via Timavo 34, 20124 Milano, Italy • +39 (0)39 2328 094

Visit SSL at URL: http://www.solid-state-logic.com

© Solid State Logic

All Rights reserved under International and Pan-American Copyright Conventions

Solid State Logic, SSL and XLogic are trademarks of Solid State Logic

All other product names and trademarks are the property of their respective owners

No part of this publication may be reproduced in any form or

by any means, whether mechanical or electronic, without the

written permission of Solid State Logic, Oxford, England

Page 3

Contents

1. Introduction 3

Warranty

2. Safety Considerations 4

Definitions

Electrical Safety Warnings

Installation

3. Installation 6

Supplied Parts

Tools Required

Procedure

4. Operation 11

Synchronisation

Sample Rates

Appendices 15

A. Internal Links

B. Connector Details

C. Electronic Specification

D. Physical Specification

E. Environmental Specification

Contents

Page 1

Page 4

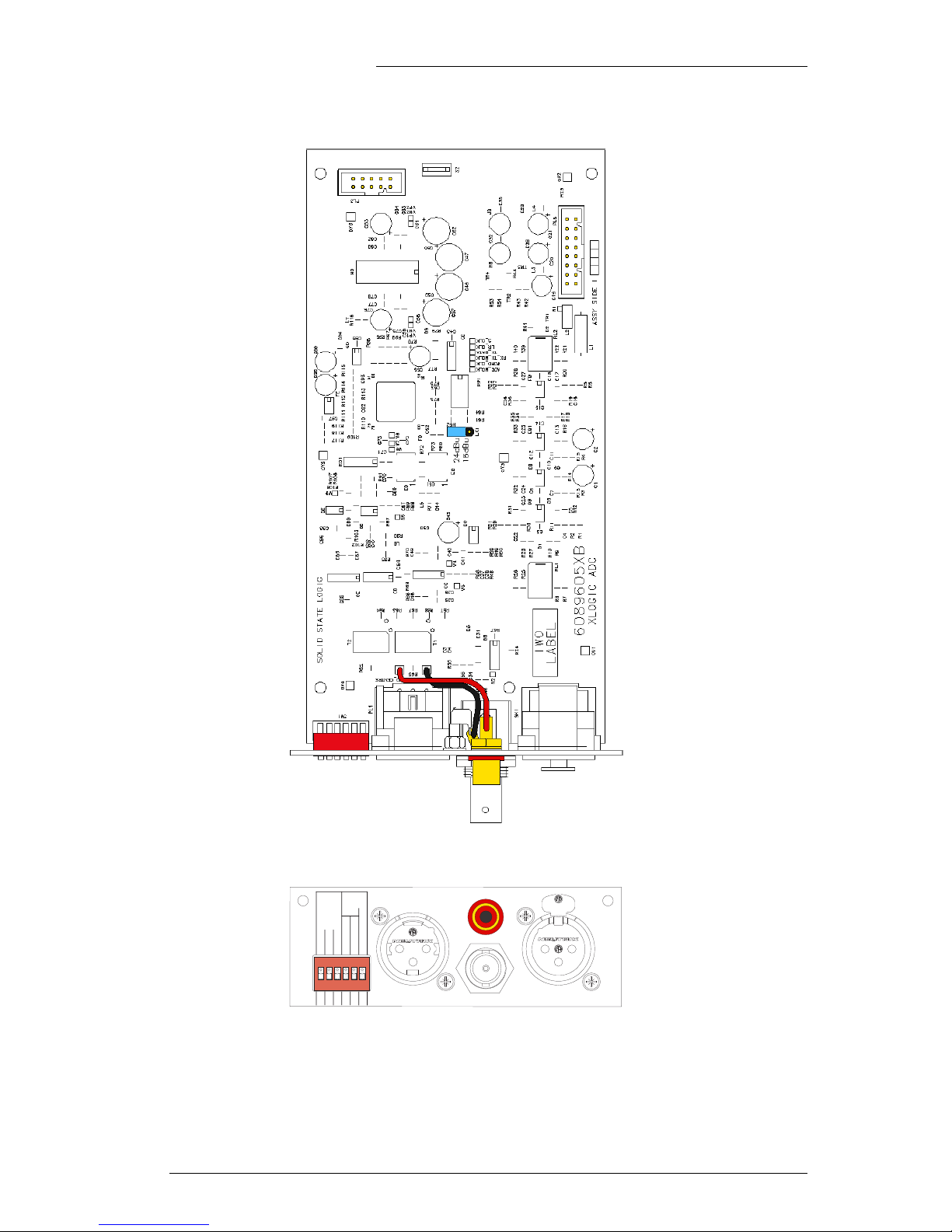

Plan (top) and elevation (lower) of the 629605 Channel ADC card

XLogic Channel ADC Owner’s Manual

Page 2

AES OUT SPDIF OUT

SYNC IN RIGHT IN

SAMPLE

RATE

SYNC

Fs x

44.1

1/4

1/2

AES

Fs

INT

Fs = 48

4 SINGLE / 2

4 SINGLE / 4

WD CLK

256 x Fs

EXT

ON

123456

Page 5

1. Introduction

The XLogic Channel ADC card is a small PCB assembly containing a high quality 24-bit stereo ADC.

The card is intended to be fitted inside the XLogic Channel unit to provide immediate A to D

conversion at any of the common sample rates between 44.1kHz and 192kHz. The ADC can be

synchronised either to internal crystal or an external word clock or AES/SPDIF sync source. Digital

output from the card is provided in both balanced AES and un-balanced SPDIF formats.

Because the XLogic Channel unit is a mono unit, a second balanced line-level input to the ADC card is

provided. This allows connection of, for example, a second XLogic Channel unit to enable full use of

the AES/SPDIF stereo data stream.

The object of this manual is to provide purchasers of the XLogic Channel ADC card with information

in the following areas:

• Safety considerations

• Installation instructions

• Operational instructions

• Connector pin-outs

• Specifications and physical dimensions

Please Note

The XLogic Channel ADC card is a hardware upgrade for the XLogic Channel unit – it must be

installed before it can be used. Full instructions to achieve this are provided within this

document, however, if you are unsure about performing this please contact your local Solid State

Logic distributor who will be happy to arrange to install it for you. Do note that a charge may be

levied for this service.

Warranty

The warranty period for this card is 12 months from date of purchase.

In Warranty Repairs

In the event of a fault during the warranty period the unit must be returned to your local distributor

who will arrange for it to be shipped to Solid State Logic for repair. All units should be shipped to Solid

State Logic in their original packaging. Solid State Logic can not be held responsible for any damage

caused by shipping units in other packaging. In such cases Solid State Logic will return the unit in a

suitable box, which you will be charged for. Please do not send manuals, power leads or any other

cables - Solid State Logic can not guarantee to return them to you. Please also note that warranty

returns will only be accepted as such if accompanied by a copy of the receipt or other proof of purchase.

Out of Warranty Repairs

In the event of a fault after the warranty period has expired, return the unit in its original packaging to

your local Solid State Logic distributor for shipment to Solid State Logic. You will be charged for the

time spent on the repair (at Solid State Logic's current repair rate) plus the cost of parts and shipping.

Introduction

Page 3

Page 6

2. Safety considerations

This section contains definitions and warnings, and practical information to ensure a safe working

environment. Please take time to read this section before undertaking any installation work.

Definitions

‘Maintenance’

All maintenance must be carried out by fully trained personnel. Note: it is advisable to observe suitable

ESD precautions when maintenance to any part is undertaken.

‘Non-User Adjustments’

Adjustments or alterations to the equipment may affect the performance such that safety and/or

international compliance standards may no longer be met. Any such adjustments must therefore

only be carried out by fully trained personnel.

‘Users’

This equipment is designed for use solely by engineers and competent operators skilled in the use

of professional audio equipment.

‘Environment’

This product is a Class A product intended to form an integrated component part of a professional

audio recording, mixing, dubbing, film, TV, radio broadcast or similar studio wherein it will

perform to specification providing that it is installed according to professional practice.

Electrical Safety Warning

When installing or servicing any item of Solid State Logic equipment with power applied, when

cover panels are removed, HAZARDOUS CONDITIONS CAN EXIST.

These hazards include: High voltages

High energy stored in capacitors

High currents available from DC power busses

Hot component surfaces

Any metal jewellery (watches, bracelets, neck-chains and rings) that could inadvertently come

into contact with uninsulated parts should always be removed before reaching inside powered

equipment.

XLogic Channel ADC Owner’s Manual

Page 4

Page 7

Installation

Voltage Selection and Fusing

The XLogic Channel ADC card is fitted internally to the XLogic Channel unit and so does not require

a mains supply.

CE Certification

Modifying any of the metalwork of the XLogic Channel unit to which this assembly is fitted in any way

may adversely affect the CE certification status of the product.

FCC Certification

The XLogic Channel unit, with an ADC card fitted, has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

The above certifications are valid provided the ADC card is fitted to an XLogic Channel assembly, as instructed

within this document.

Safety Considerations

Page 5

Page 8

XLogic Channel ADC Owner’s Manual

Page 6

3. Installation

This section details how to install the XLogic Channel ADC card in an XLogic Channel unit. Before you

begin, please consider these points:

• Carefully read through these instructions first.

• Check that all of the component parts of the kit are present.

• Check that you have the required tools to hand before attempting installation.

• Consider if you need to adjust the operating level of the card. There are two options, set by an

internal jumper:

+24dBu (position ‘1-2’) 0dBu ≈ –24dB FS (SMPTE standard and factory default)

+18dBu (position ‘2-3’) 0dBu ≈ –18dB FS (EBU standard)

Supplied Parts

The following hardware is supplied with the XLogic Channel ADC Card kit:

Qty Item Part Number & Description Notes

10 51DD20CB - Screw M3 x 6mm Csk Pozi Zp Spares, for the top cover…

6 51DD25CB - Screw M3 x 6mm Pan Pozi Zp ADC Card fixings

4 51DDNH5Z - Washer M3 Fibre Internal ADC Card fixings

2 51DDNQ5B - Washer M3 Crinkle Shakeproof Zp External ADC Card fixings

Also included in this kit are one of each of the following:

• 629605X1 - S/A XLogic ADC

This card should be left in its sealed,

anti-static bag, until you are ready to

install it.

Along with the card there should also be a short ribbon cable

(either loose or plugged into PL5 on the ADC card).

• 82S6XL070A - XLogic Channel ADC Installation Guide

(this document)

Solid State Logic

Super-Analogue™ Outboard

Owner’s Manual

82S6XL070A

S U P E R A N A L O G U E

C H A N N E L A D C

Page 9

Tools Required

Other than any tools which may be required to remove the XLogic Channel unit from any racking or

studio furniture, the following tool is all that is required to install this card:

Qty Part No. Description Notes

1 80C2CECC 1-point pozi-drive screwdriver This is not a ‘philips’ screwdriver!

Do however, please note the following:

• The geometry of ‘philips’ and ‘pozi-drive’ screws and screwdrivers are

subtly different and so the two types of screw and screwdriver are not

inter-changable. It is however normally quite simple to differentiate

between the two types of screwdriver as the tip of a ‘pozi-drive’

screwdriver is quite blunt and has additional ‘flutes’ between each of the

four blades that make up the head, as shown in the illustration to the

right – a ‘philips’ screwdriver will be missing the flutes and has a much

sharper tip.

• Most ‘pozi-drive’ screws have an echo of the additional ‘flutes’ marked

on the head of the screw - take a look at the illustrations opposite and the

screws that we have supplied.

• The tip of any screwdriver should firmly locate in the screwhead – if it

does not then it is either the wrong type, the wrong size or worn out.

• If you neither possess nor can obtain a 1-point pozi-drive screwdriver

locally, it should be possible to obtain one from your local Solid State

Logic distributor.

Installation

Page 7

Additional

‘flutes’

Blunt tip

Page 10

Procedure

Remove the XLogic Channel unit from any racking or studio furniture, and place it on a suitable clean,

flat work surface. Ensure that the work area is adequately illuminated and then proceed as follows:

1. Using a 1-point pozi-drive screwdriver, remove the 15 M3 x 6mm csk screws which secure the top

cover to the unit. Lift the cover off and place it safely to one side.

2. Turn the unit around and using the same screwdriver, remove the two M3 x 6mm panhead screws

which fix the ADC blanking plate to the rear of the unit. The blank plate, screws and washers

removed can be discarded although it is recommended that they be retained in case it is found

necessary to remove the ADC card at a later date.

XLogic Channel ADC Owner’s Manual

Page 8

Remove:

15 x

Remove ADC Blanking Plate

Remove:

2 x , plus 2 x

Page 11

Installation

Page 9

3. Remove the ADC card from its sealed anti-static bag, either fold back or remove and place to one

side the short ribbon cable attached to PL5. Slide the ADC card through the apperture in the rear

of the XLogic unit that was revealed in step 2. above. It may be necessary to lift the ‘OUTPUT’ and

‘Gnd’ (S1) cables on the main PCB to avoid them snagging under the ADC card.

4. The ADC card is retained in the XLogic unit by a total of six screws; two for the rear plate and four

for the PCB. Loosely fit four M3 x 6mm panhead screws and fibre washers in the PCB holes,

followed by two M3 x 6mm panhead screws and wave washers to the rear panel.

Slide the ADC Card

into the XLogic unit

Take care not to snag

the ‘Gnd’ (S1) and

‘OUTPUT’ cables

Fold back or remove the

ribbon cable from PL5 before

sliding the ADC card in.

Fit:

4 x

Fit:

2 x

Page 12

XLogic Channel ADC Owner’s Manual

Page 10

5. Check that the rear plate of the ADC card is flush to the rear panel of the XLogic unit and tighten

the six screws; these screws need only be lightly tightened – the ADC card isn’t going to be

escaping out of the box by itself…

6. Connect the short ribbon cable removed in step 3. above between PL5 on the ADC card and PL5

on the main PCB. Be sure to push these connectors fully home; they have about 5mm of travel and

there should be a light ‘click’ as they are seated.

7. Check that link LK1 on the ADC card is set to the correct position – if in doubt, leave it at the

factory (+24dBu) setting.

8. Refit the top cover to the XLogic unit and replace the 15 M3 x 6mm Csk screws – we have supplied

a few replacements if any were damaged (or missing). Like the ADC card, these screws should not

be over-tightened - they should be little more than finger tight. When the top cover is fitted, the

test and warning labels should all be visible - if they are not, you have put it on upside down!

9. Before refitting the XLogic unit to any racking or studio furniture it would be prudent to check it

for correct operation – Section 4. of this document details the operational features of the ADC card.

Click!

Click!

Ribbon Cable

PL5 on the

ADC card

PL5 on the

main PCB

+24dBu ≈ 0dB FS

(Factory Default)

+18dBu ≈ 0dB FS

Page 13

4. Operation

On the rear panel of the ADC card are four sockets and one multi-position DIP switch. Their functions

are as follows:

The front panel of the XLogic Channel unit carries no controls associated

with the ADC card although it does have a ‘Lock’ indicator, located

immediately below the ‘Power’ indicator. The various states of this

indicator are as follows:

State Function

Off The ADC card is not locked.

Yellow The ADC card is set to internal sync.

Red The ADC card is set to external sync and is locked.

Synchronisation

There are four possible synchronisation options, selected with switches 1 to 3 as follows:

Function Switch(es) Detail

Internal sync In this mode, with switch 1 ‘off’ (down), the ADC card will free-

run at the sample rate determined by the setting of switches 4 to

6 (see over leaf).

AES sync With switches 1 and 3 set this way, an external un-balanced

(75Ω) AES sync source may be used – switches 4 to 6 will need

to be set to match the nominal rate being applied.

Word Clock In this mode the ADC card will lock to an external TTL level

word clock at any nominal sample rate between 44.1kHz and

192kHz – again, set switches 4 to 6 to match the nominal rate

being applied.

‘Super Clock’ With switches 1 to 3 all set ‘on’ (up), the card will synchronise to

a 256x ‘Super Clock’ as provided from ProTools™ – switches 4

to 6 should be set to match the nominal rate being used (sample

rates greater than 96kHz are not supported).

ON

123456

ON

123456

ON

123456

ON

123456

GAIN

1260-12-24 2418

MTR

INPUT

+20

-20

OUTPUT

ADC LOCK

POWER

XL

SUPER ANALOGUE

C H A N N E L

ogic

Operation

Page 11

D

L

KEY INOUTPUT

AES OUT SPDIF OUT

SYNC IN RIGHT IN

SAMPLE

RATE

SYNC

Fs X

44.1

1/4

1/2

AES

Fs

INT

Fs = 48

4 SINGLE / 2

4 SINGLE / 4

WD CLK

256 x Fs

EXT

ON

123456

Synchronisation

Options

Sample Rates

AES/EBU and SPDIF

Outputs

External Analogue Input.

A signal applied to this connector will

feed the right hand side of the A to D

converter in all ‘stereo’ modes.

External Sync Input.

Either AES/EBU or

TTL wordclock are

accepted.

ADC Lock

Indicator

Page 14

Sample Rates

There are eight possible preset sample rate options ranging between 44.1kHz and 192kHz. The

different rates are selected with switches 4 to 6 as follows:

Sample Rate Switch(es) Detail

44.1kHz With all three switches ‘off’ (down), this sets the ADC to run at

44.1kHz stereo. For external sync at this rate, the applied AES or

Word Clock sync should be 44.1kHz whilst ‘Super Clock’ should

be 11.2896MHz.

48kHz This sets the ADC to run at 48kHz stereo. For external sync at

this rate, the applied AES or Word Clock sync should be 48kHz

whilst ‘Super Clock’ should be 12.2880MHz.

88.2kHz This sets the ADC to run at 88.2kHz stereo. For external sync at

this rate, the applied AES or Word Clock sync should be

88.2kHz whilst ‘Super Clock’ should be 22.5792MHz.

96kHz This sets the ADC to run at 96kHz stereo. For external sync at

this rate, the applied AES or Word Clock sync should be 96kHz

whilst ‘Super Clock’ should be 24.5760MHz.

176.4kHz This sets the ADC to run at 176.4kHz stereo. For external sync at

this rate, the applied AES or Word Clock sync should be

176.4kHz – ‘Super Clock’ is not supported.

192kHz This sets the ADC to run at 192kHz stereo. For external sync at

this rate, the applied AES or Word Clock sync should be 192kHz

– ‘Super Clock’ is not supported.

176.4kHz mono This sets the ADC to run at 176.4kHz in mono or ‘two wire’

mode. In this mode only a single channel of data is available and

so the second analogue input is not available. For external sync

at this rate, the applied AES sync should be 88.2kHz or Word

Clock at 176.4kHz – ‘Super Clock’ is not supported.

192kHz mono With all three switches ‘on’ (up), this sets the ADC to run at

192kHz in mono or ‘two wire’ mode. In this mode only a single

channel of data is available and so the second analogue input is

not available. For external sync at this rate, the applied AES sync

should be 96kHz or Word Clock at 192kHz – ‘Super Clock’ is not

supported.

ON

123456

ON

123456

ON

123456

ON

123456

ON

123456

ON

123456

ON

123456

ON

123456

XLogic Channel ADC Owner’s Manual

Page 12

Page 15

Appendix

Page 13

Notes

• The external analogue input is DC coupled and electronically balanced. It will feed the right hand

side of the A to D converter in all of the ‘stereo’ AES modes – when the ADC card is set to run at

either 176.4kHz mono or 192kHz mono this input can not be used.

• The AES/EBU and SPDIF digital outputs are independant of each other. They are both transformer

isolated.

• The Sync Input is a 75Ω BNC and will accept either TTL wordclock (≈5V pk-pk) or unbalanced 75Ω

AES/EBU (≈1V pk-pk). Conversion from balanced to un-balanced AES/EBU is best achieved with

a third-party in-line transformer. These are widely available – your local Solid State Logic

distributor should be able to supply these. Alternatively, a standard 110Ω balanced feed can be

used, albeit at the expense of increased jitter due to the level/impedance mis-match.

• The ‘Lock’ indicator shows that the ADC card is locked to the selected sync source. Whilst this also

implies that the correct sample rate has been selected on the DIP switches on the rear of the unit,

it does not necessarily mean that valid AES/EBU data is being produced.

Page 16

XLogic Channel ADC Owner’s Manual

Page 14

Page 17

Appendix

Page 15

Appendix A – Internal Links

There is one internal link on the ADC card:

LK1 Sets the operating level as follows:

1-2 +24dBu ≈ 0dB FS (factory default)

2-3 +18dBu ≈ 0dB FS

Appendix B – Connector Details

SPDIF Out

Location:

Rear Panel

Conn' Type:

RCA Phono

Pin

Description

Tip

Signal

Sleeve

Chassis

AES Out

Location:

Rear Panel

Conn' Type:

XLR Male

Pin

Description

1

Chassis

2

Signal +ve

3

Signal -ve

Sync In

Location:

Rear Panel

Conn' Type:

75Ω BNC

Pin

Description

Tip

Signal

Sleeve

Chassis

Right In

Location:

Rear Panel

Conn' Type:

XLR Female

Pin

Description

1

Chassis

2

Audio +ve

3

Audio -ve

Page 18

XLogic Channel ADC Owner’s Manual

Page 16

Appendix C – Performance Specification

Following are audio performance specification figures for the XLogic Channel ADC card, when fitted

to an XLogic Channel unit. No other Solid State Logic products, including the XLogic Channel unit

with which this card operates, are covered by this document and the performance of other Solid State

Logic products can not be inferred from the data contained herein.

Measurement Conditions

For all of these measurements, signal for the left hand channel is applied via PL5 and for the right hand

channel via SK1. Measurements are taken from the AES output. For all measurements the gain of the

ADC card is set at +24dBu ≈ 0dB FS.

Measurement References

Unless otherwise specified the references used in this specification are as follows:

• Reference frequency: 1kHz

• Reference level: 0dB FS (+24dBu)

• Source impedance of Test Set: 50Ω

• Unweighted measurements are specified as 22Hz to 22kHz band limited RMS and are expressed

in units of dB FS

• All distortion measurements are bandwidth limited in the digital domain at no more than half the

sample frequency specified and are expressed as a percentage

• Jitter is quoted in terms of ‘Unit Interval’ where 1 UI = Sample Period/128 (ref. AES-3-1995)

• Unless otherwise quoted all figures have a tolerance of ±0.5dB or 5%

ADC Performance

Gain Link selectable between +18dBu ≈ 0dB FS and +24dBu ≈ 0dB FS

Input Impedance 10kΩ @ +24dBu, 5kΩ @ +18dBu

THD + Noise < 0.0035% from 20Hz to 20kHz, irrespective of sample rate

Frequency Response ±0.05dB from 20Hz to 20kHz @ 44.1kHz

±0.05dB from 20Hz to 40kHz @ 96kHz

Usable Dynamic Range > 110dB

Common Mode Rejection > 55dB from 20Hz to 20kHz

Resolution 24bit

Jitter < 0.025 UI (700Hz to 100kHz filter, internal sync)

Group Delay 64 samples, irrespective of sample rate

Page 19

Appendix

Page 17

Appendix D – Physical Specification *

Depth: 180mm/7.0 inches PCB only

203mm/8.0 inches including rear panel and connectors

Height: 36mm/1.4 inches including rear panel

Width: 90mm/3.5 inches PCB only

100mm/3.9 inches including rear panel

Weight: 150g/5.5 ounces

Boxed size: 190mm x 290mm x 70mm (7.5" x 11.5" x 2.5")

Boxed weight: 350g/12 ounces

* All weights and dimensions are approximate

Appendix E – Environmental Specification

Temperature Operating: 5 to 30 Deg. C

Non-operating: –20 to 50 Deg. C

Max. Gradient: 15 Deg. C/Hour

Relative Humidity Operating: 20 to 80 %

Non-operating: 5 to 90 %

Max. wet bulb: 29 Deg. C (non-condensing)

Vibration Operating: < 0.2 G (3 - 100Hz.)

Non-operating, power off: < 0.4 G (3 - 100Hz.)

Shock Operating: < 2 G (10mSec. Max.)

Non-operating: < 10 G (10mSec. Max.)

Altitude Operating: 0 to 3000m (above sea level)

Non-operating: 0 to 12000m

Page 20

XLogic Channel ADC Owner’s Manual

Page 18

Notes

Loading...

Loading...