Page 1

X-Rack Owner’s Manual

Page 2

Page 3

Solid State Logic

S O U N D

||

V I S I O N

SUPERANALOGUE

X - R A C K

Super-Analogue™ Outboard

Owner’s Manual

82S6XR010C

Page 4

X-Rack Owner’s Manual

As research and development is a continual process, Solid State Logic reserves the right

to change the features and specifications described herein without notice or obligation

E&OE

Solid State Logic

S O U N D

| |

V I S I O N

Begbroke, Oxford, England, OX5 1RU • +44 (0)1865 842300

320 West 46th Street, 2nd Floor, New York, NY 10036, USA • +1 (1) 212 315 1111

Suite 401, 5757 Wilshire Blvd, Los Angeles, CA 90036, USA • +1 (1) 323 549 9090

3-55-14 Sendagaya, Shibuya-Ku, Tokyo 151-0051, Japan • +81 (0)3 5474 1144

7 bis, rue de la Victoire, le Blanc Mesnil, Paris 93150, France • +33 (0)1 48 67 84 85

Via Timavo 34, 20124 Milano, Italy • +39 (0)39 2328 094

Visit SSL at URL: http://www.solid-state-logic.com

© Solid State Logic

All Rights reserved under International and Pan-American Copyright Conventions

Solid State Logic, SSL and XLogic are trademarks of Solid State Logic

All other product names and trademarks are the property of their respective owners

No part of this publication may be reproduced in any form or

by any means, whether mechanical or electronic, without the

written permission of Solid State Logic, Oxford, England

Added Mic Amp and EQ Modules (Rev. 0B), April 2006

Added Line Return and Master Modules (Rev. 0C), October 2006

Initial Release (Rev. 0A), September 2005

Page 5

Contents

1. Introduction 3

2. Safety Considerations 4

2.1 Definitions 4

2.2 Electrical Safety Warning 4

2.3 Installation 4

2.4 Graphical Symbols 4

3. X-Rack Installation 6

3.1 Assembling the X-Rack 6

3.2 Mounting 6

3.3 Connection 7

3.3.1 Power Connection 7

3.3.2 Audio Connection 7

3.3.3 Connection to an AWS 900 7

3.3.4 MIDI Connection 7

3.3.5 Mix Bus Link 7

4. X-Rack Operation – Total Recall 8

4.1 Overview 8

4.2 Standalone Mode 8

4.2.1 Saving Stores to Internal Memory 8

4.2.2 Recalling Stores 8

4.2.3 Exiting Display Mode 8

4.2.4 Copy/Swap 9

4.2.5 Deleting Stores 9

4.2.6 Delete all Stores 9

4.3 AWS Remote Mode 9

4.3.1 System Requirements 9

4.3.2 Operation 9

4.4 Setup/MIDI mode 10

4.4.1 Overview 10

4.4.2 MIDI Save and Load 11

4.4.3 Write Protect 12

4.4.4 Remote Mode 12

4.4.5 Address Setting 12

4.4.6 Show Version 12

4.4.7 Test Mode 13

4.5 Software Download and Installation 13

5. Miscellaneous 16

5.1 Internal Links and Fuses 16

5.2 Connector Details 16

5.3 Physical Specification 17

5.4 Environmental Specification 17

A Mic Amp Module A-1

B EQ Module B-1

D Dynamics Module D-1

E Line Return Module E-1

F Master Module F-1

Page 1

Page 6

Page 2

X-Rack Owner’s Manual

Solid State Logic

OXFORD • ENGLAND

ogic

XL

SUPERANALOGUE

X - R A C K

SETUP/

MIDI

SAVE

Push to Select

COPY/

DEL

TOTAL RECALL

Empty

Wr Prot

SEL

XR621

MIC

INST

IMP

+48V

PAD

LINE

LINE

fl

HF

IN

IN

IN

REC

REC

L

R

GND

LIFT

INSTRUMENT

OUTPUT

SIGNAL

LF

Z

LO HI

dB

+75 +12

+20 -20

dB

KHz

9 6

3 50

30 4

30 600

60

160 300

SEL

XR621

MIC

INST

IMP

+48V

PAD

LINE

LINE

fl

HF

IN

IN

IN

REC

REC

L

R

GND

LIFT

INSTRUMENT

OUTPUT

SIGNAL

LF

Z

LO HI

dB

+75 +12

+20 -20

dB

KHz

9 6

3 50

30 4

30 600

60

160 300

SEL

XR625

HF

dB

HMF

LMF

dB

dB

LF

dB

Q

Q

- +

- +

- +

- +

IN

G-EQ

KHz

KHz

22 1.5

10 5

2 15

7 .6

3 2

1 5

Hz

KHz

2.0 .2

1.0 .6

.3 1.6

600 40

220

60

SEL

XR625

HF

dB

HMF

LMF

dB

dB

LF

dB

Q

Q

- +

- +

- +

- +

IN

G-EQ

KHz

KHz

22 1.5

10 5

2 15

7 .6

3 2

1 5

Hz

KHz

2.0 .2

1.0 .6

.3 1.6

600 40

220

60

SEL

+10 -30

COMPRESSOR

GATE/

EXPANDER

KEY

4

0.1

RELEASE

0.1

4

+10

THRESHOLD

-20

RATIO

1

∞

RANGE

0 40

PK

FAST

ATT

LINK

RELEASE

THRESHOLD

IN

EXP

20

14

10

6

3

HOLD

0 4

FAST

ATT

XR618

SEL

+10 -30

COMPRESSOR

GATE/

EXPANDER

KEY

4

0.1

RELEASE

0.1

4

+10

THRESHOLD

-20

RATIO

1

∞

RANGE

0 40

PK

FAST

ATT

LINK

RELEASE

THRESHOLD

IN

EXP

20

14

10

6

3

HOLD

0 4

FAST

ATT

XR618

SEL

XR623

LEVEL

PAN

INS

REC

SOLO

LINE 1

LEVEL

PAN

INS

REC

SOLO

LINE 2

LEVEL

PAN

INS

REC

SOLO

LINE 3

LEVEL

PAN

INS

REC

SOLO

LINE 4

SEL

XR622

MIX LEVEL

AFL

LEVEL

MIX

REC

MONITOR

SUM

MON

SUM

INS

INS

REC

MIX

EXT

ALT

MONO

SOLO

DIM

CUT

MONITOR

0

369

121518

2430364248

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

This equipment must be Earthed. Refer

to manual for installation instructions.

CAUTION! Disconnect all power sources

before removing any panel(s).

WARNING! Unearthed metal parts may be

present inside enclosure. Check for

hazardous voltages before touching.

For protection against risk of fire - replace

only with same type/rating of fuse.

Do not expose to rain or moisture.

No user-servicable parts inside - to be

serviced only by qualified personnel.

12345678

TOTAL RECALL

LINK IN

MIDI IN

MIDI OUT

TOTAL RECALL

LINK OUT

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received,

including interference that may cause undesired operation.

This class A digital apparatus complies with Canadian ICES-003

MIX BUS LINK

OUT

IN

+4dBu

-10dBV

KEY

OUT

IN

+4dBu

-10dBV

KEY

OUT

IN

+4dBu

-10dBV

OUT

IN

+4dBu

-10dBV

IN

OUT

LINE

IN

OUT

LINE

LINE IN

INSERT

SEND/

RTN

1 - 4

INS RTN

EXT

MON

ALT MON

INS SND

MIX

REC

FOL MON

TESTED

DATE INITIALS

(IEC 127)

Model

Serial No.

Solid State Logic

Oxford ¥ England

FUSE risk of fire, u se same type

and rating

250V

250V

Ratings: AC ~ 5 0/60Hz

Volts

Amps

629935X1

XRK001

100-240 0.5-0.2

NONE

Page 7

Introduction

1. Introduction

Overview

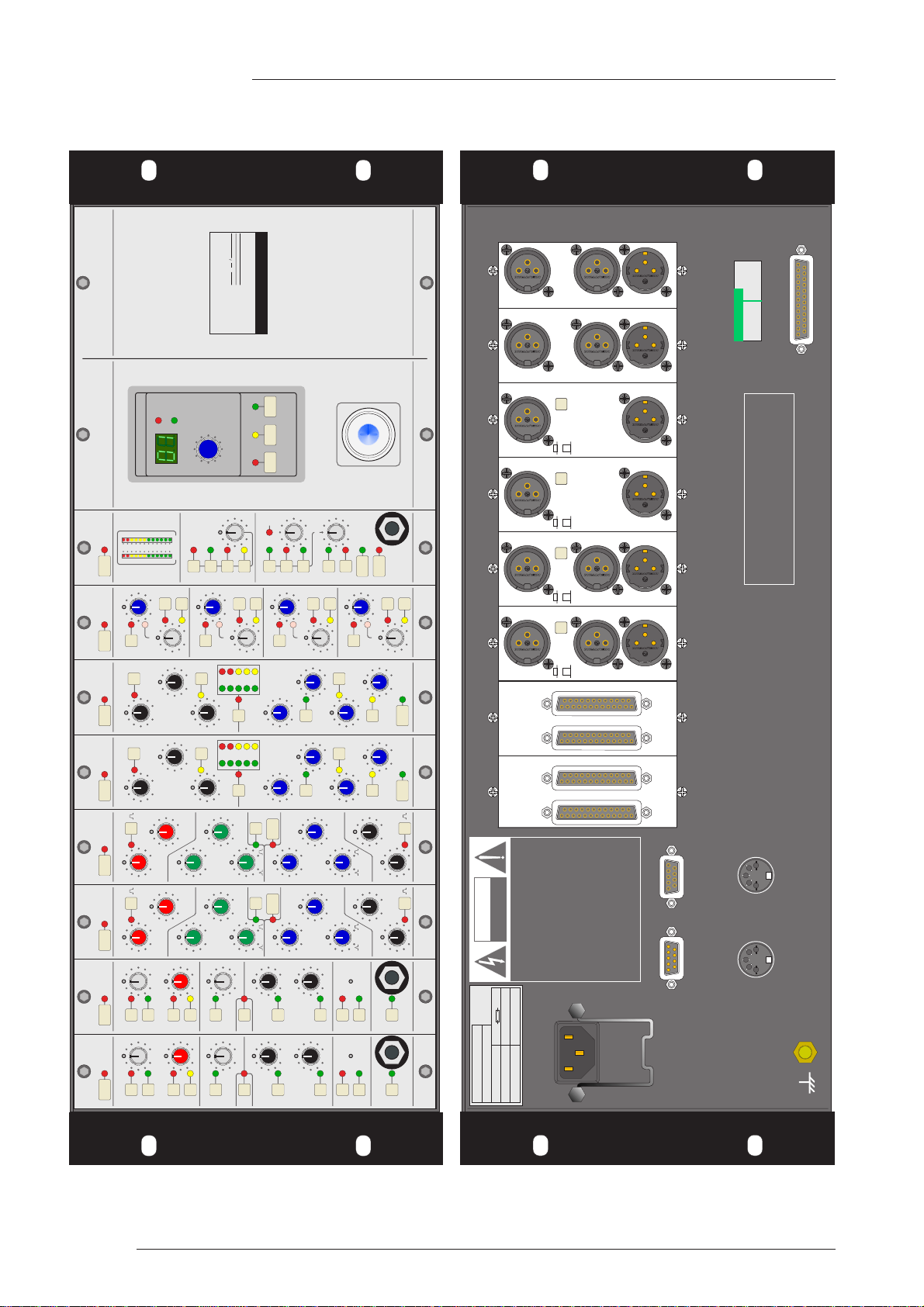

The Solid State Logic X-Rack unit has been developed from the successful range of XLogic outboard equipment

nd provides a flexible solution to those engineers requiring a larger number of processing units in a compact

a

package.

The additional space provided by the X-Rack allows the processing modules to be vertically orientated,

providing a more familiar interface to users of Solid State Logic’s renowned range of mixing consoles, and makes

it possible to include Solid State Logic’s Total Recall system - the first time this has been available on an analogue

outboard unit.

This Manual

The object of this manual is to provide purchasers of the X-Rack unit with information in the following areas:

• Operation of the unit

• Safety considerations

• Installation requirements

• Electrical connections and cabling

• Connector pin-outs

• Specifications and physical dimensions

This manual is applicable to X-Rack units from serial number XRK110 onwards and assumes that the X-Rack unit

is running V1.2/0 or later software. Please refer to Section 4 of this manual for instructions on how to check the

current software version and how to obtain and install a newer version if required.

Warranty

The warranty period for this unit is 12 months from date of purchase.

In Warranty Repairs

In the event of a fault during the warranty period the unit must be returned to your local distributor who will

arrange for it to be shipped to Solid State Logic for repair. All units should be shipped to Solid State Logic in their

original packaging. Solid State Logic cannot be held responsible for any damage caused by shipping units in

other packaging. In such cases Solid State Logic will return the unit in a suitable box, which you will be charged

for. Please do not send manuals, power leads or any other cables – Solid State Logic can not guarantee to return

them to you. Please also note that warranty returns will only be accepted as such if accompanied by a copy of the

receipt or other proof of purchase.

Out of Warranty Repairs

In the event of a fault after the warranty period has expired, return the unit in its original packaging to your local

distributor for shipment to Solid State Logic. You will be charged for the time spent on the repair (at Solid State

Logic's current repair rate) plus the cost of parts and shipping.

Page 3

Page 8

X-Rack Owner’s Manual

2. Safety considerations

his section contains definitions and warnings, and practical information to ensure a safe working environment.

T

Please take time to read this section before undertaking any installation work.

2.1 Definitions

‘Maintenance’

All maintenance must be carried out by fully trained personnel. Note: it is advisable to observe suitable ESD

recautions when maintenance to any part is undertaken.

p

‘Non-User Adjustments’

Adjustments or alterations to the equipment may affect the performance such that safety and/or international

compliance standards may no longer be met. Any such adjustments must therefore only be carried out by fully

trained personnel.

‘Users’

This equipment is designed for use solely by engineers and competent operators skilled in the use of professional

audio equipment.

‘Environment’

This product is a Class A product intended to form an integrated component part of a professional audio

recording, mixing, dubbing, film, TV, radio broadcast or similar studio wherein it will perform to specification

providing that it is installed according to professional practice.

2.2 Electrical Safety Warning

When installing or servicing any item of Solid State Logic equipment with power applied, when cover

and/or blank panels are removed, HAZARDOUS CONDITIONS CAN EXIST.

These hazards include: High voltages

High energy stored in capacitors

High currents available from DC power busses

Hot component surfaces

Any metal jewellery (watches, bracelets, neck-chains and rings) that could inadvertently come into contact

with uninsulated parts should always be removed before reaching inside powered equipment.

2.3 Installation

Voltage Selection and Fusing

The X-Rack unit has an auto-sensing power supply that can operate on 100 – 230V without adjustment.

The X-Rack power supply module is internally fused. If the fuse should fail for any reason the unit should be

returned to Solid State Logic for repair/replacement as appropriate.

Safety Earth Connection

Any mains powered item of Solid State Logic equipment that is supplied with a 3-core mains lead (whether

connectorised or not) should always have the earth wire connected to the mains supply ground. This is the safety

earth and grounds the exposed metal parts of the racks and cases and should not be removed for any reason.

Note that the earth stud provided on the rear of the equipment is a functional earth not a safety earth.

Page 4

Page 9

Safety Considerations

Mains Supply and Phases

Solid State Logic equipment is designed for connection to single phase supplies with the Neutral conductor at

arth potential – category TN – and is fitted with a protective fuse in the Live conductor only. It is not designed

e

for use with Phase (Live) and Neutral connections reversed or where the Neutral conductor is not at earth

otential (TT or IT supplies).

p

Mains cables will be coded with the following colour scheme:

IVE: Brown

L

NEUTRAL: Blue

EARTH: Yellow/Green

Mains Isolation and Over-Current Protection

An external disconnect device is required for this equipment; a detachable power cord, as fitted to this

equipment, is a suitable disconnect device. Note that the socket outlet used for the detachable power cord should

be installed near the equipment and should be easily accessible.

An external over-current protection device is required to protect the wiring to this equipment which must be

installed according to current wiring regulations. The fusing or breaking-current is defined in the environmental

specification in Section 5.0 of this manual. In certain countries this function is supplied by use of a fused plug.

CE Certification

Note that the majority of cables supplied with Solid State Logic equipment are fitted with ferrite rings

at each end. This is to comply with current European CE regulations and these ferrites should not be

removed. If any of the equipment metalwork is modified in any way the CE certification status of the

product may be adversely affected.

Note that a frame or chassis terminal stud (functional earth) has been fitted to this equipment to provide a

convenient low impedance bonding point for interconnected equipment, should it be required.

FCC Certification

The XLogic unit has been tested and found to comply with the limits for a Class Adigital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his own expense.

Instructions for Disposal of WEEE by Users in the European Union

The symbol shown here is on the product or on its packaging, which indicates that this product

must not be disposed of with other waste. Instead, it is the user’s responsibility to dispose of

their waste equipment by handing it over to a designated collection point for recycling of waste

electrical and electronic equipment. The separate collection and recycling of your waste

equipment at the time of disposal will help to conserve natural resources and ensure that it is

recycled in a manner that protects human health and the environment. For more information

about where you can drop off your waste equipment for recycling, please contact your local city

office, your household waste disposal service or where you purchased the product.

2.4 Graphical Symbols

The following symbols may be used either on the product or in this manual:

General hazard – refer to user or service

manual for details.

Protective Earth (ground).

Electrical hazard.

Frame or Chassis terminal.

(Functional Earth)

Page 5

Page 10

X-Rack Owner’s Manual

3. X-Rack Installation

3.1 Assembling the X-Rack

The X-Rack unit is normally shipped either as an empty rack (SSL Part No. 729935X1), a part filled (custom)

ack or as a fully loaded unit; for example, a unit fitted with eight 729618X1 Dynamics modules (SSL

r

Part No. 729935X2) – if you have purchased a fully loaded unit you should skip the rest of Section 3.1.

In the case of empty or part filled racks, any empty module slots will be covered by blank panels which

will need to be removed before fitting additional modules.

Note. Do not attempt to fit or remove modules with power applied. Always switch the rack off and remove the power cord

prior to working on this unit. When fitting or removing modules, it is advisable to observe suitable ESD precautions.

Take care when handling modules and blank panels; sharp corners may be present.

Modules are fitted from the front of the X-Rack, normally starting from the left hand end. Note that it is

recommended that any required blank panels (SSL Part No. 729618X2) are fitted prior to fitting modules.

Each module plugs into the backplane; use the two 8mm M3 counter sunk screws supplied with the

module or blank to fix the item to the front of the rack – a 2mm AF hex key is supplied with the X-Rack

unit. The rear connector panel or blank should be screwed to the rear of the case using the two 8mm M3

button head screws supplied with the module. The end result should be a unit that is fully loaded with

modules and/or blank panels. For ease of fitting, do not tighten the screws until all modules and/or blank

panels have been fitted.

Note. To ensure peak operating performance, please ensure all rear panel fixing screws are securely tightened; warping on

the rear of the chassis may be observed – this is no cause for concern.

3.2 Mounting

The X-Rack unit is designed to be rack mounted or free standing. It is 4RU (178mm/7 inches) high. Its

depth is:

180 mm/7.2 inches

255 mm/10.2 inches including connectors

The unit does not require rack shelves. A 1RU space should normally be provided above the unit.

The unit is supplied fitted with both feet and rack ears. If the unit is to be rack mounted the feet should be

removed using the supplied 2.5 mm AF hex driver. The same driver can be used to remove the rack ears

if the unit is to be free standing.

Feet and rack ears are fixed using M4 x 8mm screws.

Do not replace them with longer screws as this may damage the rack electronics.

Page 6

Page 11

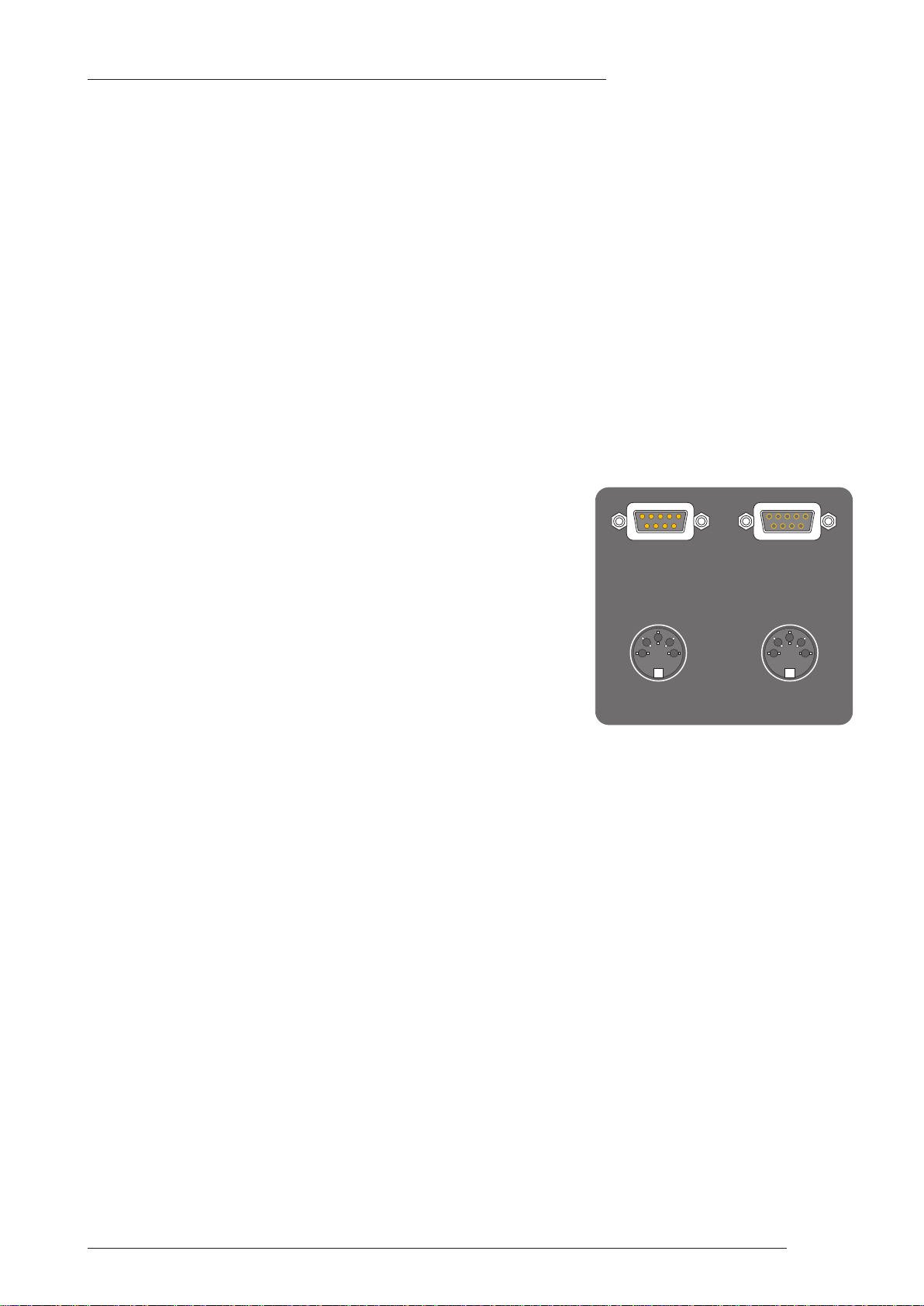

TOTAL RECALL

LINK IN

MIDI IN MIDI OUT

TOTAL RECALL

LINK OUT

X-Rack Installation and Operation

3.3 Connection

.3.1 Power Connection

3

The X-Rack unit has an auto-sensing power supply that can operate on 100 – 230V without adjustment.

The power connection is made via a standard IEC mains cord to an un-switched IEC mains socket on the

rear panel and a latching power switch is provided on the front panel of the unit.

3.3.2 Audio Connection

Generally, each module will have an input connector (normally a female XLR) and an output connector

(normally a male XLR). Depending upon the type of module other connectors, such as key inputs, may be

present also. Connect the module inputs to the insert sends of your console or to your workstation outputs.

Connect the module outputs to the corresponding insert returns or to your workstation inputs.

Once the unit is connected switch it on, then route a signal to each channel in turn and check that it is

returned to the correct input on your console or workstation.

Some module input and output gains can be set to operate at a nominal level of +4dBu or –10dBV using a

switch on the connector panel. Select the appropriate level for the equipment you are connecting to. If in

doubt either refer to the section of this manual specific to the particular module or experiment!

3.3.3 Connection to an AWS 900

If the X-Rack is being used with an AWS 900 or AWS 900+,

connect the TOTAL RECALL LINK IN connector (a 9 pin D-

type) to Serial Port 1 on the conole’s connector panel using the

supplied 2 metre cable. This may be extended to a maximum of

15 metres using a suitable pin to pin extension cable.

If you have more than one X-Rack unit connect the

TOTAL RECALL LINK IN connector on the second unit to the

TOTAL RECALL LINK OUT connector on the first unit using

the supplied cable. A third unit may be connected to the second

unit in the same way.

3.3.4 MIDI Connection

The MIDI port can be used for several functions:

• Archiving of the 32 internal stores as SysEx (System Exclusive) dumps

• Remote control of the ‘soft’ functions of the XR622 Master module

• Updating the system software

If you wish to use this facility connect the X-Rack MIDI IN connector to a spare MIDI out connector on

your MIDI interface and the X-Rack MIDI OUT connector to the corresponding MIDI input.

A separate connection is required for each X-Rack.

3.3.5 Mix Bus Link

Some X-Rack modules can route signals onto the X-Rack’s internal mix busses. This 25-way ‘D’ type

connector is provided to enable access to these buses and, using this connector, multiple X-Racks may be

connected together enabling a large stereo mix system to be constructed. The pinout for this connector is

detailed in Section 5.2.

Page 7

Page 12

X-Rack Owner’s Manual

4

21454

5

Push to Select

SAVE

3

SETUP/

MIDI

SAVE

Push to Select

COPY/

DEL

TOTAL RECALL

Empty

Wr Prot

1

76543

2

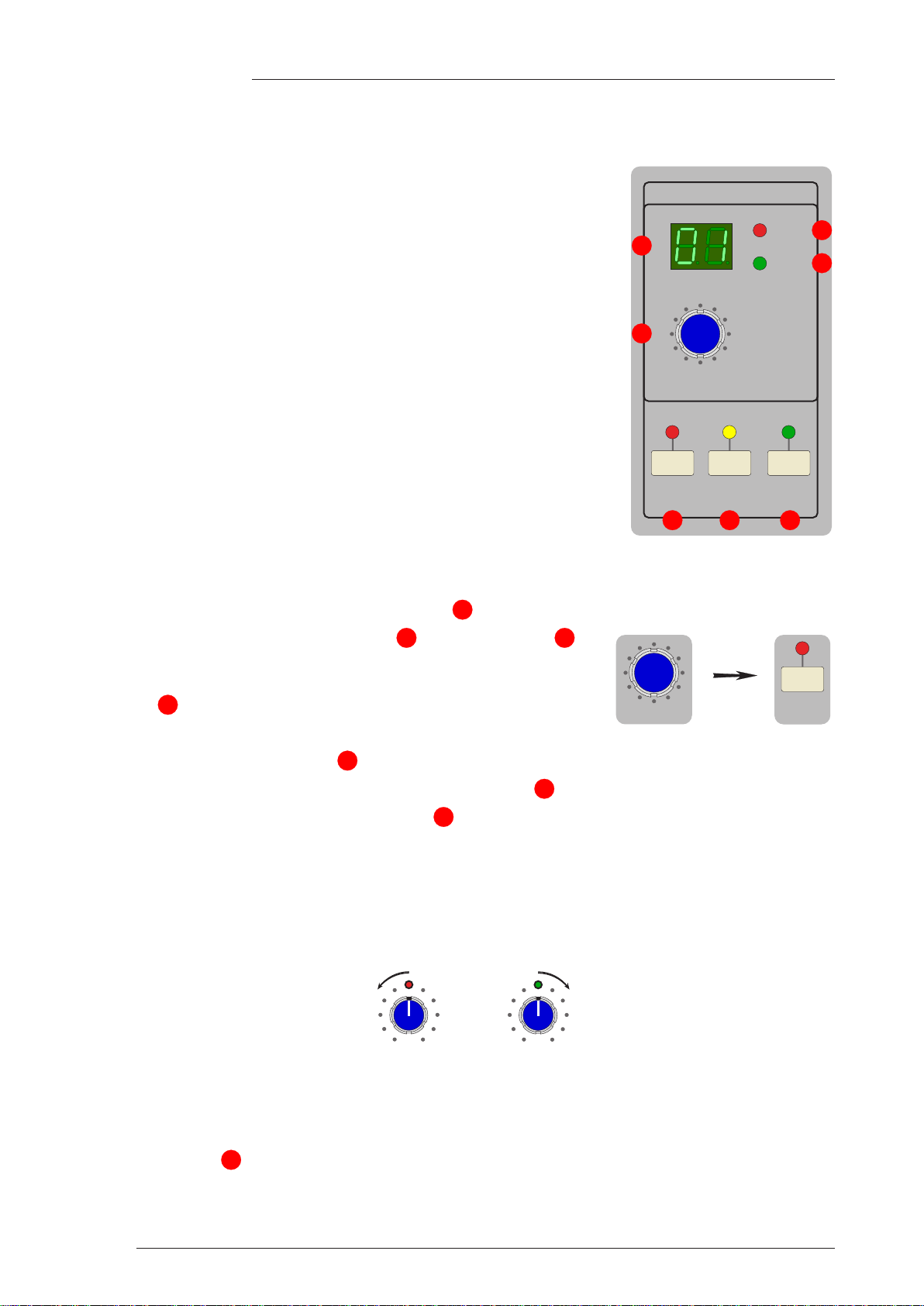

4. Operation - Total Recall

4.1 Overview

The Total Recall computer stores all of the switch and rotary control

positions for each X-Rack module in one of thirty two internal stores.

These can be recalled and compared with the current settings using

front panel LEDs to show which controls do not match. If the module

layout has changed since the snapshot was taken, only the modules

that match will be recalled.

The contents of all the stores can be archived and restored as a MIDI

system exclusive data dump.

Additionally the X-Rack can interface with the Total Recall system on

an AWS 900 or AWS 900+. This allows the settings of up to three X-Rack

units to be stored along with the AWS 900 settings.

Note. Through the rest of this manual, references to ‘AWS 900’ apply equally to

‘AWS 900+’.

4.2 Stand-alone Mode

4.2.1 Saving Stores to Internal Memory

A maximum of 32 stores can be saved in internal non-volatile memory, provided the stores have not been

write-protected – indicated by the ‘Wr Prot’ LED being illuminated.

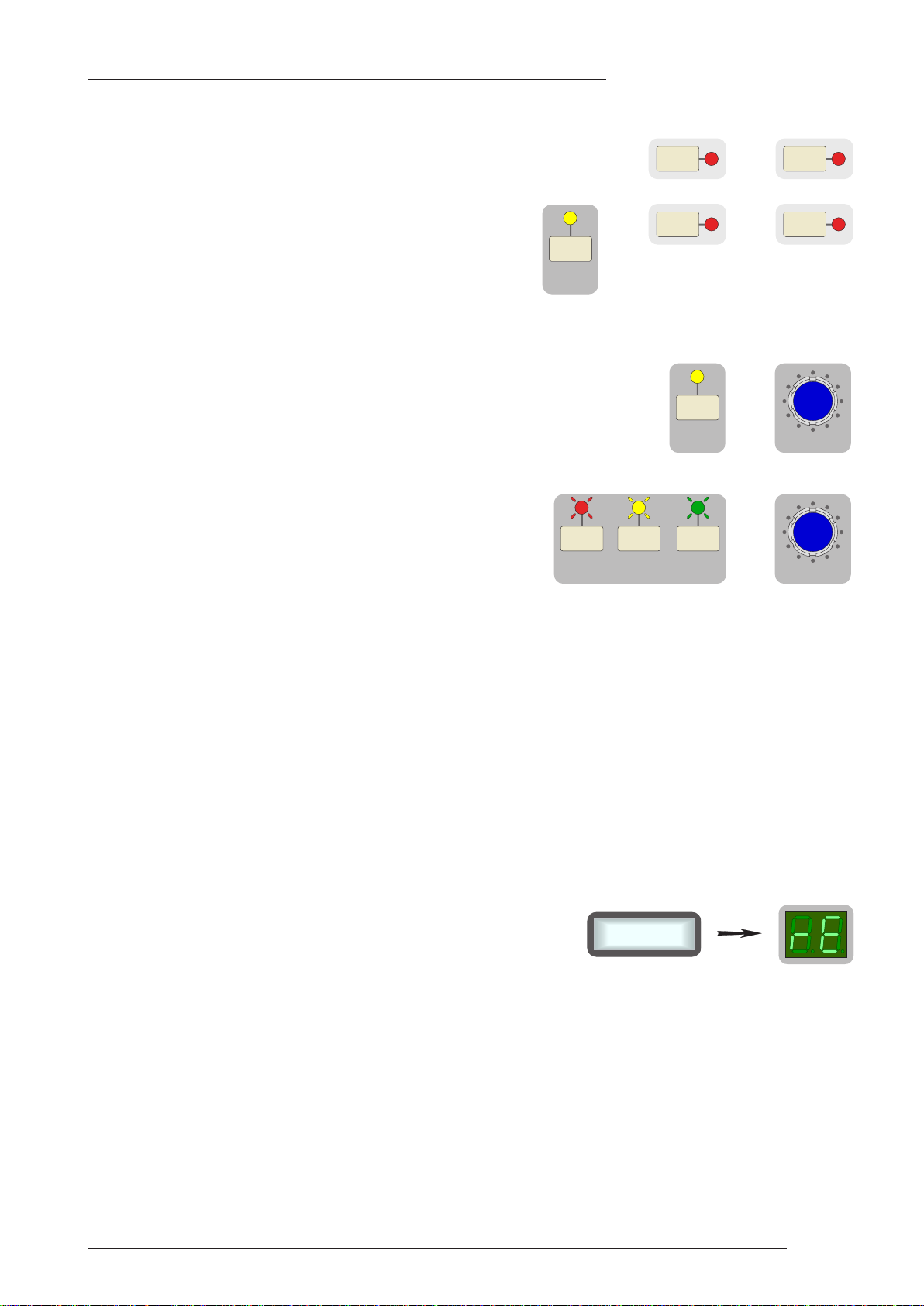

First select a store by turning the D-Pot , then press SAVE to

store all of the current control positions.

If the store has already been used the SAVE LED will flash. Press the

SAVE switch a second time to overwrite the store.

4.2.2 Recalling and Displaying Stores

To select a store using the D-Pot then press the D-Pot to select that store.

The current store is displayed on the dual 7-segment display .

If the selected store is empty the ‘Empty’ LED lights and the unit will not switch to display mode.

With a valid store selected, the X-Rack module SEL LEDs will light if the module type in the store (EQ,

Dynamics etc.) matches the module currently fitted in that slot. A flashing SEL LED indicates that some controls

on that module do not match the stored positions. A steady LED shows that all controls are matched. The

switch LEDs will light if the current switch position does not match the stored positions. Press or release

the switch as required to extinguish the LED.

Above each rotary control is a bi-colour LED:

The LED lights red if

the control needs

turning anti-clockwise.

or

The LED lights green if

the control needs

turning clockwise.

The LED extinguishes when the control matches the stored position.

If a store is already being displayed when you select a different store the display will flash and the new

store will not become active until you press the D-Pot for a second time.

4.2.3 Exiting Display Mode

Push the D-Pot a second time to exit display mode.

All SEL LEDs will extinguish and the channel switch LEDs will now show the position of their respective

switches.

Page 8

Page 13

4.2.4 Copy/Swap

SELECT

SETUP/

MIDI

SAVE COPY/

DEL

Push to Select

C

OPY/

DEL

P

ush to Select

COPY/

DEL

SEL +SEL

SEL

SEL

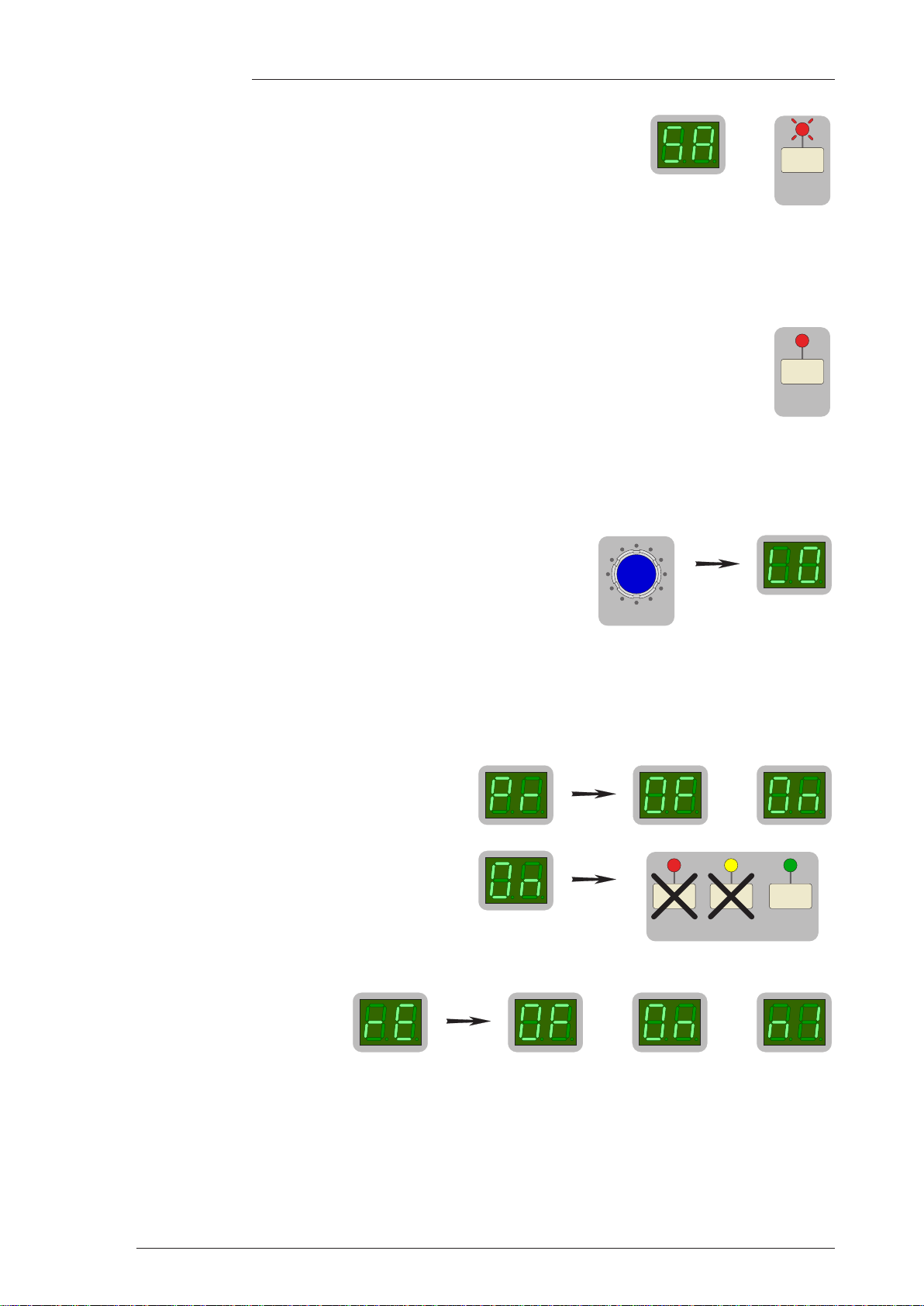

While displaying a TR setup pressing and holding a module SEL switch

nd then pressing a second SEL switch will swap the setting of the two

a

channels.

Selecting COPY/DEL and then doing the same will copy

settings from the first channel to the second.

ote that Copy/Swap is only allowed between similar

N

modules; the unit will not allow you to swap settings

etween an EQ module and a Dynamics module for

b

instance!

4.2.5 Deleting Stores

Stores can be cleared (to remove unwanted stores before a SysEx dump) by

holding down COPY/DEL till it’s LED flashes and pressing the D-Pot

switch (while still holding down the COPY/DEL switch). Additional stores

can be deleted by holding down the COPY/DEL switch, selecting the

second store with the D-Pot and pressing the D-Pot again.

4.2.6 Delete All

All stores can be cleared by holding down all three

switches until their LEDs flash, then pressing the D-Pot

switch.

X-Rack Installation and Operation

+

&

+

+

4.3 AWS Remote Mode

4.3.1 System Requirements

The X-Rack ‘TOTAL RECALL LINK IN’ connector must be connected to AWS 900 serial port 1 – see

Section 3.3 for more details.

If more than one X-Rack is connected each X-Rack must have a different address – refer to the Setup/MIDI

Section.

The AWS 900 must be running V1.2/6 or higher software and have Total Recall enabled for this to function.

This software can be downloaded from the SSL website.

4.3.2 Operation

Pressing the Total Recall STORE switch on the AWS 900 will send a message to all attached X-Racks asking

for the current control settings to be returned. The returned settings are appended to the AWS 900 Total

Recall stores and are automatically archived and restored as part of the AWS 900 Total Recall system.

Similarly pressing SELECT in the AWS TR page will return the

selected Total Recall setup to the X-Rack unit(s). The remote

load command will always replace the current setup and the XRack display will read ‘re’.

To display the new settings, press the D-Pot as in ‘Standalone’ mode and to exit display mode press the

D-Pot a second time. If the AWS 900 store does not contain valid data (for example if it was saved on an

AWS 900 not connected to an X-Rack) the ‘Empty’ LED will light and it will not be possible to select display

mode.

Settings can be saved to the local stores and recalled at any time by turning the D-Pot (though see the

Remote option in the Setup menu section). Pressing STORE in the TR page on the AWS 900 will always

save the current state of the unit and pressing SELECT will replace the store to be displayed with the store

from the AWS 900.

See the Remote and the Address options in the Setup/MIDI Section.

Page 9

Page 14

X-Rack Owner’s Manual

S

ETUP/

MIDI

4.4 Setup/MIDI Mode

.4.1 Overview

4

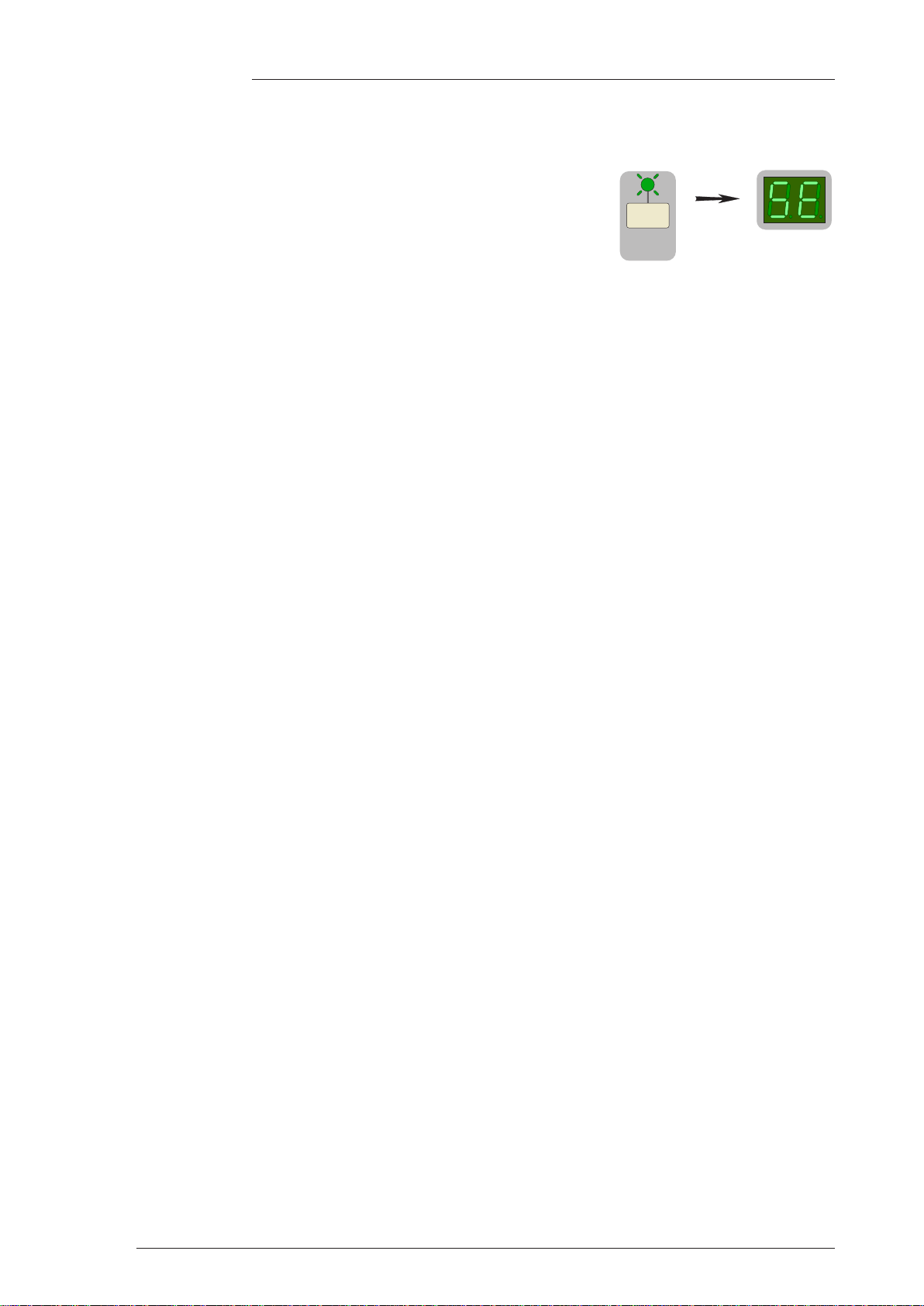

Enter SETUP/MIDI mode by holding down the SETUP/MIDI switch

till the display reads ‘5e’. The SETUP/MIDI LED flashes to show you

are in this mode. Press and hold the same switch to return to normal

operation.

Navigating in the Setup menu

he setup menu contains a number of options. These each contain a number of sub-options. Turn the

T

D-Pot to scroll through the main list of options and push the D-Pot to select an option for editing. The DPot will now scroll through the available list of possible settings for that option. Pressing the D-Pot again

will save the currently selected setting and return to the normal option menu. The options are:

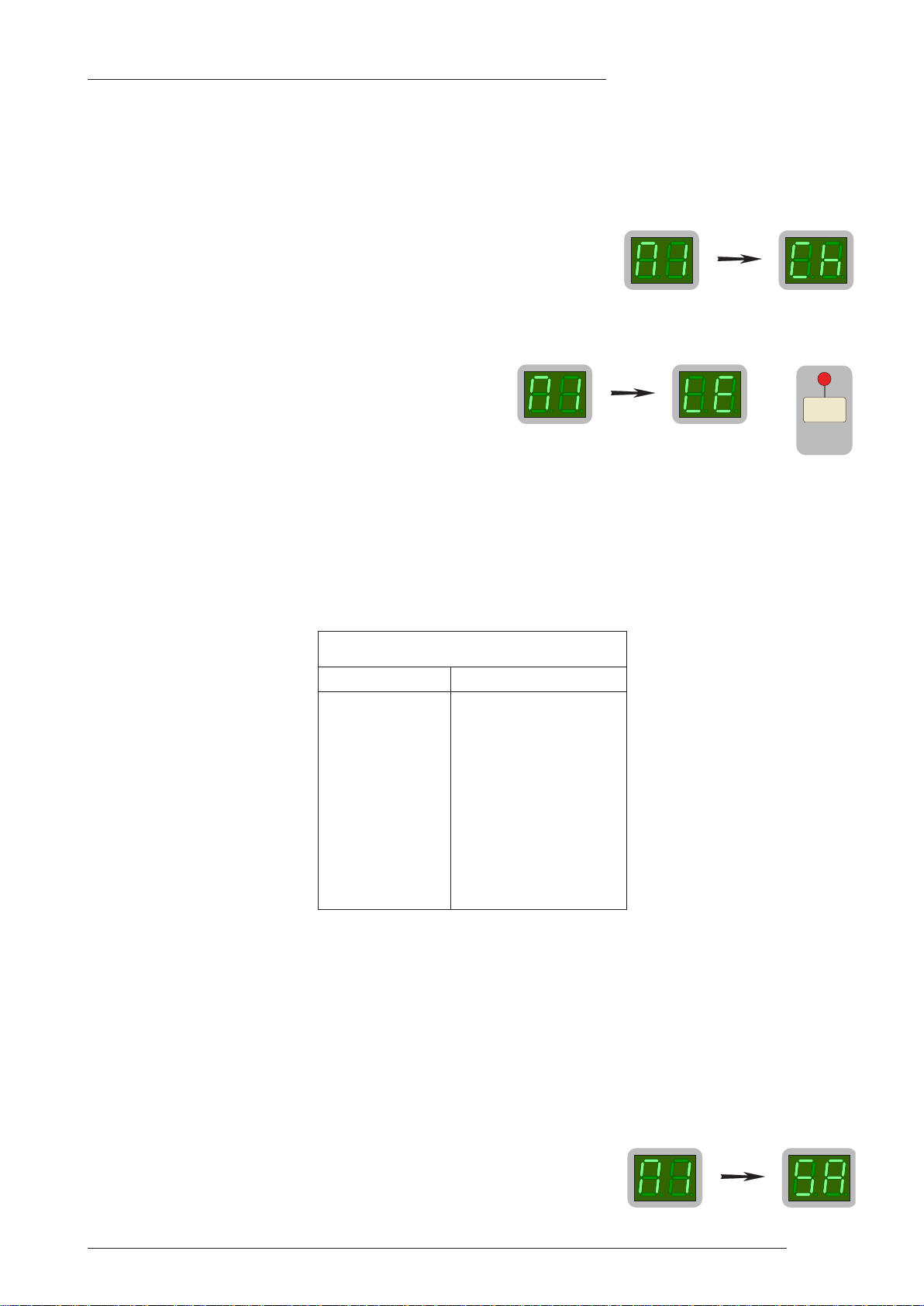

Option Display Setting Notes

Enter Setup 5e None

MIDI m1 MIDI Channel (ck) Select the MIDI channel to listen to for

remote control of the XR622 Master

module (01 to 16 or al for all)

MIDI Learn (le) Define which MIDI controls operate

the XR622 Monitor module controls

Save (sa) and Load (l0) Send or receive SysEx data to save or

load all internal stores to a MIDI

sequencer or librarian

Write Protect pr Off (0f) and On (0n) Toggles write protect on and off

Remote re Off (0f), On (0n) or MIDI (m1) Toggles remote Total Recall mode on

and off or enables MIDI remote control

of the XR622 Monitor module controls

Set Address ad a1, a2, a3, a4 Sets X-Rack address for AWS Total

Recall interface

Show Version ve Displays software version

Test te Test LEDs (tl) All module LEDs flash

Test switches (t5) Press TR computer switches to light

corresponding LEDs

Test pots (tp) Shows position of pots

Update Software fl Program upgrade mode (te) The only exit from this mode, without

updating the X-Rack software, is to

power-cycle the unit.

Dim Level d1 –3 (03) to –30 (30) dB Sets the ‘DIM’ level for the XR622

Monitor module

Page 10

Page 15

X-Rack Installation and Operation

SAVE

4.4.2 MIDI (m1)

Under this menu it is possible to set the MIDI controls which can control parts of the X-Rack XR622 Master

module and also to save and load all internal stores to and from a MIDI sequencer or librarian as a SysEx

dump.

MIDI Remote Channel (ck)

Under the MIDI menu, use the D-Pot to select MIDI Channel.

Then press the D-Pot and turn it to select the required channel (‘01’

to ‘16’ or ‘al’ for all/any channel). This is the MIDI channel that will

e used for remote control of the XR622 Master module. By default

b

X-Rack will listen on all channels.

MIDI Remote Learn (ck)

Under the MIDI menu, use the D-Pot to select

MIDI Learn (le) and press SAVE. The green

‘Wr Prot’ LED will flash to indicate you are in MIDI

Learn mode. Operating any one of the ‘soft’ controls

on the XR622 Master module will cause the LED of

the selected control to flash (the module ‘SEL’ LED

will flash if either of the potentiomenters have been chosen) – indicating it has been chosen. Assign a MIDI

controller to the selected function by operating the required MIDI controller. To cancel or change the

assignment either operate the Master module control again, or operate a different control. A successful

assignment will be indicated by the flashing LED changing to just being illuminated steadily.

+

To exit MIDI Learn mode, press the D-Pot – the green ‘Wr Prot’ LED will stop flashing. Switch assignments

can be reset to the system defaults by pressing COPY/DEL when in MIDI Remote Learn mode; the ‘Empty’

LED indicating when the assignments have been deleted.

Default MIDI Controller Mapping

MIDI Controller Master Module Control

1 MIX

2 REC

3 EXT

4 ALT

5 MONO

6 DIM

7 CUT

8 AFL Level

9 Monitor LEVEL

MIDI Save and Load

In order to use the MIDI save and load utility the X-Rack must be connected to a computer running a

suitable sequencer or MIDI librarian package.

All the stored setups can be saved as a System Exclusive dump to any software package that supports

MIDI SysEx dumps. In practice this includes most packages and you would normally save the TR setups

to an additional track in your current DAW project so that your setups are stored with the rest of the

project.

Saving Setups to a Mac or PC (sa)

With the X-Rack in Setup Mode, saving TR setups to Mac or PC can be achieved as follows:

• Under the MIDI menu, use the D-Pot to select MIDI Save.

Page 11

Page 16

X-Rack Owner’s Manual

SAVE

S

AVE

Push to Select

SETUP/

MIDI

SAVE COPY/

DEL

• The display will show ‘5a’ and both the ‘SAVE’ LED and display flash.

• Create an additional MIDI track in your DAW program. Select its input and output to be the MIDI port

connected to your X-Rack.

• If available select the track to store System Exclusive data and record enable the MIDI track.

Press Play and Record on the DAW to put the MIDI track into record.

•

• Press the SAVE switch to start transmission of all saved Total Recall setups.

A ‘rotatingsegment’ display will start and run until all data has been transmitted

• Once the display changes to ‘m1’ stop the DAW to end recording.

An unlimited number of Total Recall setups can be stored in this way.

Loading Setups from a Mac or PC (l0)

Restoring setups from a Mac or PC is even simpler:

&

• Enter MIDI mode as before, and turn the D-Pot until the display

changes to ‘l0’ and begins to flash.

• Locate the DAW to just before the SysEx data containing the setups you wish to load.

• Play through the SysEx block of data. The display will show a rotating segment while data is received.

As soon as the X-Rack detects the start of valid data it will delete all the current setups and replace them

with the stored ones from the MIDI track.

4.4.3 Write Protect Mode (pr)

Write Protect prevents existing stores being over

written or deleted, providing an extra level of

or

protection for units that have been programmed

with particular settings.

When set to ‘0n’ the Save and Delete functions are

disabled. When set to ‘0f’ they are enabled. The

‘Wr Prot’ LED lights to show this mode has been

selected.

4.4.4 Remote Mode (re)

This mode enables remote

control of X-Rack, either from an

or or

AWS 900 for saving and

recalling Total Recall snapshots

or from a MIDI controller for control of the XR622 Master module.

Page 12

When Remote Mode is ‘0n’, selecting a TR setup on the AWS 900 Total Recall page will change the current

X-Rack setup to the one saved in the AWS 900. The X-Rack display will change to read ‘re’ (remote).

Pressing the D-Pot will display the TR setup as normal. When Remote Mode is ‘0f’, turning the D-Pot will

change the current X-Rack setup to one of the internal stores but when Remote Mode is set to ‘0n’ the DPot is disabled once the X-Rack has received a setup from an AWS 900. This also prevents saving or

deleting of local stores.

Page 17

X-Rack Installation and Operation

When Remote Mode is set to MIDI (‘m1’), the ‘soft’ controls on the XR622 Master module may be remotely

operated as MIDI controls. The Master module controls will continue to function until a valid MIDI packet

has been received, after which all of the ‘soft’ controls will be locked out – operating these controls under

hese conditions will result in an ‘re’ message on the X-Rack display. Which MIDI channels and controls

t

are used is set through the MIDI learn process (see above).

Note. Setting Remote Mode to MIDI will disable the AWS 900 Total Recall connection.

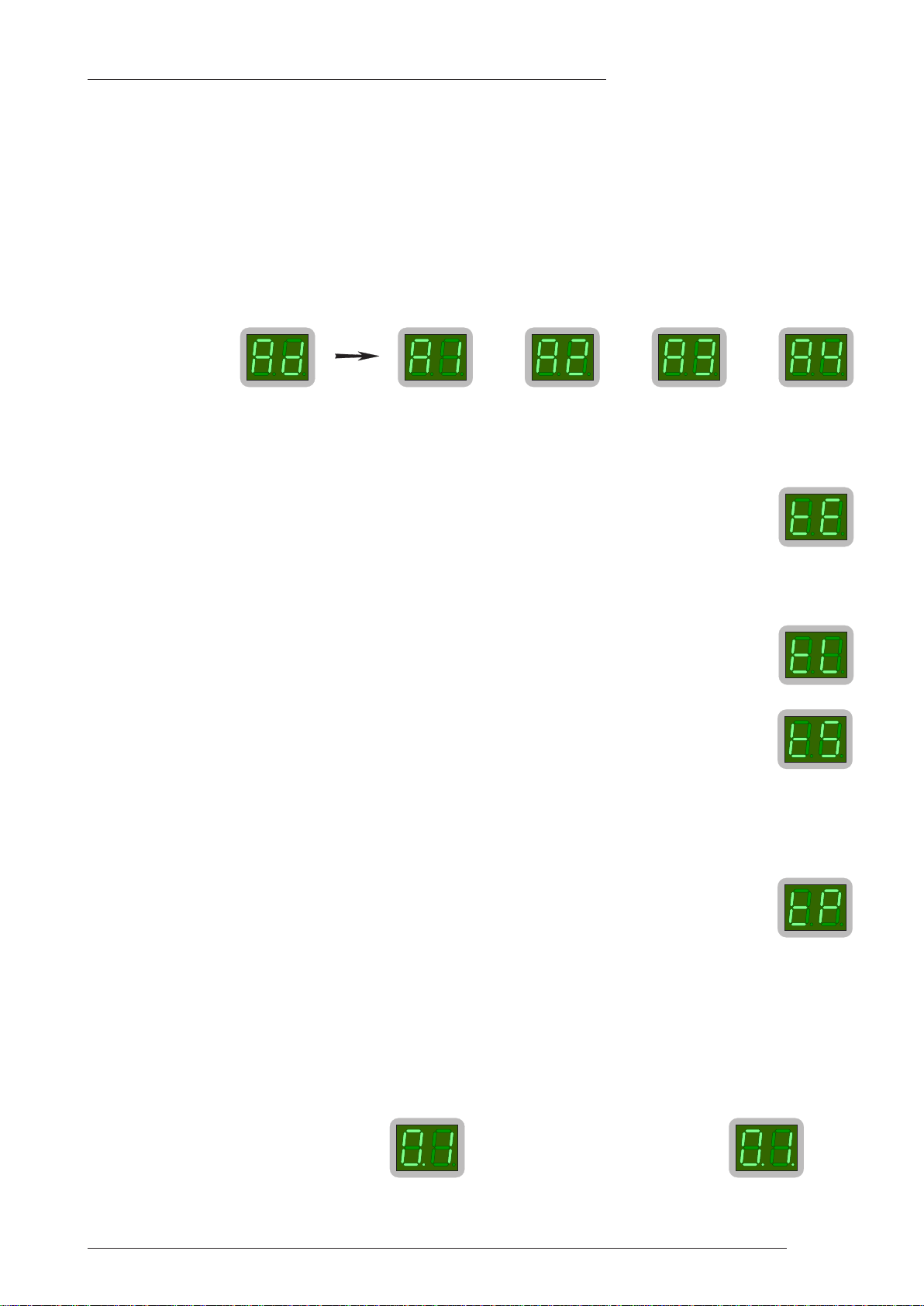

4.4.5 Address Setting (ad)

If more than one X-Rack is to be connected to an AWS 900 then each must have a different address. Enter

Address mode and turn the D-Pot so the display reads ‘a1’, ‘a2’, ‘a3’ or ‘a4’ then press the D-Pot to save

the address:

ororor

The order of addressing is not important, but we recommend you address the racks in the order they are

connected to the AWS 900. This will increase the chances of data being correctly mapped if you move to a

different facility.

4.4.6 Test Mode (te)

This mode is used for testing the front panel switches and LEDs.

There are three test modes available, selected using the D-Pot as for the other Setup functions:

Test LEDs (tl)

This toggles the bi-colour LEDs above the pots between red and green.

Test Switches (t5)

This mode flashes all the channel switch LEDs. Pressing any switch (apart from SEL)

should make the corresponding LED flash out of time with the other LEDs on the front

panel.

Pressing a SEL switch should light the corresponding LED.

Pressing any of the switches on the TR computer section should flash the corresponding LED. Pressing the

D-Pot should turn off the flashing ‘Empty’ LED and flash the ‘Wr Prot’ LED.

Test Pots (tp)

This mode scans all the modules from the top left to the bottom right of the unit and

displays the value of the last rotary control not turned fully counter clockwise. If all controls

are turned counter clockwise then the display shows ‘tp’.

To use this diagnostic first turn all controls fully counter clockwise. The module SEL LEDs will flash on all

modules with a control not in the correct position and the individual pot LEDs will light green on all

controls not in the correct position. Turning any control should make the display change from ’02’ to ‘255’.

Note that ‘02’ is the lowest value that can be read before the pot is skipped.

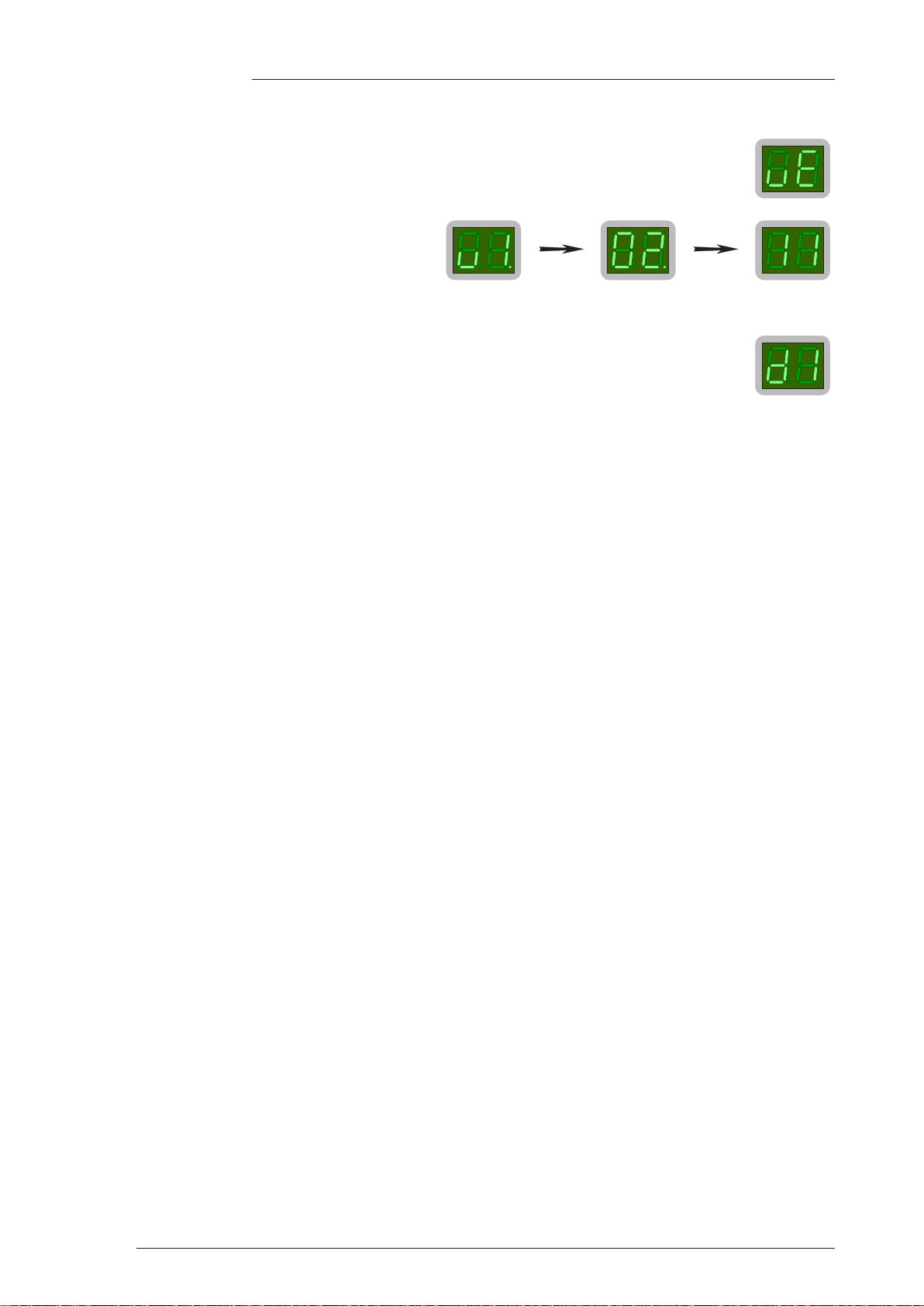

The decimal points on the two displays are used to show numbers greater than ‘99’. The left hand decimal

point lights to indicate that you should add a 100 to the displayed value and both decimal points light to

show that you should add 200 to the displayed value, hence:

‘101’ will display like this: whilst ‘201’ will display like this:

Page 13

Page 18

X-Rack Owner’s Manual

4.4.7 Show Version (ve)

Select Show Version by turning the D-Pot till the display shows ‘ve’.

Press the D-Pot to show the software version

in three blocks. As an example, software

version ‘V1.2/11’ will display in this sequence

before returning to display ‘ve’.

4.4.8 Set DIM Level (d1)

Select DIM Level by turning the D-Pot till the display shows ‘d1’.

Press the D-Pot to show the current DIM level. The level can be varied from –3dB (‘03’) to –30dB (‘30’).

Press the D-Pot once more to change the DIM level.

Page 14

Page 19

X-Rack Installation and Operation

4.5 Software Download and Installation

Software to upgrade your X-Rack unit can be downloaded from the SSL website (http://www.solid-state-

ogic.com/plus/utilities.html). To access this page will you will need to be registered with us and logged into the website.

l

The X-Rack software is packaged as a 50kB (approximately) Java archive file, the format of which is compatible

with both PC and Macintosh (OS X only) platforms. Some users may need to install additional files on their computer

before continuing – see System Requirements overleaf.

nce the software package has been downloaded, it will need to be moved onto a Mac or PC that is connected

O

to the X-Rack via MIDI after which you will be ready to install the new software. The following steps detail this

rocess:

p

1. Ensure that the X-Rack is turned on and connected to a MIDI port on your PC/Mac.

2. Enter Setup mode and turn the D-Pot until the display shows ‘fl’

(‘Flash’).

Press the D-Pot and the display should change to read ‘te’ (‘Test’).

To exit from this mode without updating software turn the unit off and on.

3. Close all current applications on your PC/Mac.

4. Double click on the X-Rack Software Update File. You should see the SSL X-Rack Software Update

window appear:

5. Go to the In MIDI Port menu. Select the MIDI IN port which is connected to your X-Rack from the drop

down list. In the example shown below this was ‘port 1’ on an 8-Port interface. If nothing appears in the

list check that you have installed the files listed in the System Requirements section over leaf.

Page 15

Page 20

X-Rack Owner’s Manual

. Go to the Out MIDI Port menu. Select the MIDI OUT port which is connected to your X-Rack:

6

Note that the Macintosh will show all MIDI Inputs at the top of the list, MIDI Outputs at the bottom.

You must scroll to the middle of the list to see the MIDI Out ports.

7. Click on the Test button. This transmits a packet of data to the X-Rack which should return

an acknowledgment to the computer. If the test was successful the message ‘Comms test

passed, now use send’ will be displayed and the display on the X-Rack should change to

read ‘se’.

If the test fails check that the correct MIDI port has been selected and that the X-Rack is in software

download mode, then repeat the test.

8. Once you have established a valid connection click on the Send button. The new code will now be

transferred to memory on the X-Rack. This process will take approximately 20 seconds. A progress bar and

transfer counter will be displayed on screen to enable you to observe the transfer progress and the X-Rack

displays will show a rotating segment.

Note. During this time it is important that power to the X-Rack is not interrupted.

9. Once the software has been saved a message will appear ‘Software update completed’ and the X-Rack

will re-boot using the new software. Click on ‘Exit’ to close the Update Utility.

System Requirements

PC users should ensure that they have the latest version of Java installed. This can be downloaded from

http://www.java.com

Mac OS X users may need to download the ‘plumstoneserv.jar’ file, available from the SSL website

(http://www.solid-state-logic.com/plus/utilities.html

folder then restart the Macintosh before running the upgrade utility.

Page 16

. There is a link to this address on the download page.

). Drag this file into the ‘/Library/Java/Extensions’

Page 21

X-Rack Installation and Operation

MIDI In

Location:

Rear Panel

Conn' Type:

5-pin DIN Female

Pin

Description

1

n/c20V3n/c4Signal +ve

5

Signal –ve

MIDI Out

Location:

Rear Panel

Conn' Type:

5-pin DIN Female

Pin

Description

1

n/c2n/c3n/c4Signal +ve

5

Signal –ve

Total Recall Link In

Location:

Rear Panel

Conn' Type:

9-pin 'D' Type Male

Pin

Description

10V2RX3TX4

DTR (linked to DSR)

50V6

DSR (linked to DTR)

7

RTS (linked to CTS)

8

CTS (linked to RTS)

9

0V

Total Recall Link Out

Location:

Rear Panel

Conn' Type:

9-pin 'D' Type Female

Pin

Description

10V2TX3RX4

DTR (linked to DSR)

50V6

DSR (linked to DTR)

7

RTS (linked to CTS)

8

CTS (linked to RTS)

9

0V

5. Miscellaneous

5.1 X-Rack Internal Links and Fuses

.1.1 Fuses (Mains Inlet)

5

The power supply module is internally fused. In the event of this fuse failing the entire unit should be

returned to your nearest SSL Service agent.

5.1.2 Internal Fuses

The internal power rail fuses will automatically reset once the fault condition has been removed and

should not need to be replaced.

5.1.3 Links

There are no user settable links.

5.2 X-Rack Connector Details

Page 17

Page 22

X-Rack Owner’s Manual

X-Rack Connector Details (cont.)

Mix Bus Link

Location: Rear Panel

Conn’ Type: 25-pin ‘D’ Type Female

in

P

1 Chassis

14 AFL/Solo Bus Left (–ve)

2 AFL/Solo Bus Left (+ve)

15 Chassis

3 AFL/Solo Bus Right (–ve)

16 AFL/Solo Bus Right (+ve)

4 Chassis

17 Mix Bus Left (–ve)

5 Mix Bus Left (+ve)

18 Chassis

6 Mix Bus Right (–ve)

19 Mix Bus Right (+ve)

7 Chassis

20 Record Bus Left (–ve)

8 Record Bus Left (+ve)

21 Chassis

9 Record Bus Right (–ve)

22 Record Bus Right (+ve)

10 Chassis

23 AFL/Solo Enable

11 n/c

24 n/c

12 n/c

25 n/c

13 n/c

escription

D

Page 18

Page 23

X-Rack Installation and Operation

5.3 Physical Specification *

Depth: 180mm / 7.2 inches excluding front panel knob(s) and connectors

255mm / 10.2 inches including connectors, excluding front panel knob(s)

Height: 178mm / 7 inches (4 RU) excluding feet

Width: 440mm / 17.4 inches excluding rack ears

483mm / 19 inches including rack ears

Weight: 2.8kg / 6.2 pounds without modules fitted

3.5kg / 7.7 pounds with blank panels fitted

5.0kg / 11 pounds with modules fitted

Power: 50 Watts / 60VA with 8 modules fitted

Boxed size: 540mm x 300mm x 270mm / 21.25" x 12" x 10.63"

Boxed weight: 4.3kg / 9.5 pounds without modules fitted

5.0kg / 11 pounds with blank panels fitted

6.5kg / 14.3 pounds with modules fitted

* All values are approximate

5.4 Environmental Specification

Temperature Operating: 5 to 30 Deg. C

Non-operating: –20 to 50 Deg. C

Max. gradient: 15 Deg. C/Hour

Relative Humidity Operating: 20 to 80 %

Non-operating: 5 to 90 %

Max. wet bulb: 29 Deg. C (non-condensing)

Vibration Operating: < 0.2 G (3 - 100Hz)

Non-operating, power off: < 0.4 G (3 - 100Hz)

Shock Operating: < 2 G (10mSec. Max.)

Non-operating: < 10 G (10mSec. Max.)

Altitude Operating: 0 to 3000m (above sea level)

Non-operating: 0 to 12000m

Page 19

Page 24

X-Rack Owner’s Manual

Notes

Page 20

Page 25

Page A-1

X-Rack Mic Amp Module

A. The Mic Amp Module

A.1 Connection

The rear panel of the module carries the Mic (‘IN’) and Line input (‘LINE’) XLRs along

with a single output (‘OUT’) XLR. The Line input and output operate at a nominal

level of +4dBu although the gain of the Line input can be varied by a front panel

control. Also contained on the front panel is an additional mono Jack socket for a high

impedance Instrument input.

A.2 Operation

The X-Rack Mic module contains three seperate input amplifiers; a Microphone

amplifier, an Instrument input and a Line input, any one of which may be selected

at any one time. A set of High and Low Pass filters are also provided.

A.2.1 MIC Section

Normally, the Microphone input on the rear of the module will be selected (‘LINE’

and ‘INST’ switches released); pressing the ‘INST’ switch selects the mono jack

instrument input on the front of the module. This is a very high impedance

unbalanced input intended to be used with guitar pickups etc. To help alleviate

‘hum’, a ground lift (‘GND LFT’) switch has been provided which places a 1k2Ω

impedance in series with the sleeve of this connector and audio ground in the

module. The gain of these inputs is continuously variable between +12dB and

+75dB.

The impedance of the Microphone input can be varied between ≈1k2Ω and ≈10kΩ

by selecting the ‘IMP IN’ switch and adjusting the ‘Z’ control. This allows the

connection of line level signals to the Microphone input if required, and pr ovides an

alternative input impedance for some dynamic microphones.

The ‘PAD’ switch reduces the signal level of both the Microphone or Instrument

inputs by 20dB. Phantom power , for microphones r equiring this, can be switched on

using the ‘+48V’ switch. Please note that X-Rack units prior to serial number XRK0110

are not normally enabled for +48V. However, a field retrofit kit (629620XR) is available for

these units. Any in-warranty X-Rack units can be upgraded free-of-charge; for units out of

warranty a charge will be made. Please contact your local distributor to order this kit, if

required.

Note. Please note that connecting a microphone to the X-Rack Mic module with phantom power

switched on is not advised as it may cause damage to either the microphone or the input

stage of the X-Rack module. Take care not to connect line level sources (keyboards etc.) to the

microphone input with phantom power switched on as this may damage the output stage of

the connected unit.

A.2.2 LINE Section

The Line input on the rear of the module is selected by pressing the ‘LINE’ switch. The gain of this input

can be varied by ±20dB from the nominal 0dB.

The Ø (Phase) switch reverses the phase of the selected input.

2

1

SEL

XR621

MIC

INST

IMP

+48V

PAD

LINE

LINE

Ø

HF

IN

IN

IN

REC

REC

L

R

GND

LIFT

INSTRUMENT

OUTPUT

SIGNAL

LF

Z

LO HI

dB

+75 +12

+20 -20

dB

KHz

9 6

3 50

30 4

30 600

60

160 300

IN

OUT

LINE

1

2

Page 26

Page A-2

X-Rack Owner’s Manual

A.2.3 HF/LF Section

This section contains simple high and low pass filters as follows:

HF (Low Pass): Frequency range 50kHz – 3kHz (–3dB point)

Slope: 12dB/Octave

LF (High Pass): Frequency range 30Hz – 600Hz (–3dB point)

Slope: 18dB/Octave

The two filters can be switched into circuit independently.

A.2.4 OUTPUT Section

This small section contains a tri-colour signal present indicator and two routing

switches (‘REC L’ and ‘REC R’) which route the module signal onto a common

internal record bus.

The signal present indicator measures signals immediately prior to the output

amplifier. It will light GREEN for output signals above the lower threshold of

–60dBu, AMBER for signals between +4dBu and +24dBu and lights RED for signals

above +24dBu.

The record bus is not currently used but may be used by forthcoming X-Rack

modules (such as the XR622 Mix/Monitor Module, due late 2006).

4

SEL

XR621

MIC

INST

IMP

+48V

PAD

LINE

LINE

Ø

HF

IN

IN

IN

REC

REC

L

R

GND

LIFT

INSTRUMENT

OUTPUT

SIGNAL

LF

Z

LO HI

dB

+75 +12

+20 -20

dB

KHz

9 6

3 50

30 4

30 600

60

160 300

334

Page 27

Page A-3

X-Rack Mic Amp Module

A.3 Performance Specification

The following pages contain audio performance specification figures for the X-Rack Mic Amp module. No

other Solid State Logic products are covered by this document and the performance of other Solid State

Logic products can not be inferred from the data contained herein.

A.3.1 Measurement Conditions

For each set of figures on the following pages, the specific unit and test setup will be stated at the

beginning of that section. Any changes to the specified setup for any particular figure(s) will be detailed

beside the figures to which that difference applies.

A.3.2 Measurement References

Unless otherwise specified the references used in this specification are as follows:

• Reference frequency: 1kHz

• Reference level: 0dBu, where 0dBu ≈ 0.775V into any load

• Source impedance of Test Set: 50Ω

• Input impedance of Test Set: 100kΩ

• All unweighted measurements are specified as 22Hz to 22kHz band limited RMS and are expressed in

units of dBu

• All distortion measurements are specified with a 36dB/Octave low pass filter at 80kHz and are

expressed as a percentage

• The onset of clipping (for headroom measurements) should be taken as 1% THD

• Unless otherwise quoted all figures have a tolerance of ±0.5dB or 5%

• All measurements are made with the operating level switch set for +4dBu

A.3.3 Microphone Amplifier Performance

Signal applied to Microphone Input and measured at Output. Pad switched out and Input Gain control

set to +12dB (minimum).

Gain Continously variable from +12dB to +75dB

Independently switchable 20dB Pad available

Input Impedance Continously variable from ≈1k2Ω to ≈10kΩ

Output Headroom > +26dBu at onset of clipping

THD + Noise < 0.003% at 1kHz

(-18dBu applied, +28dB gain) < 0.006% at 10kHz

Frequency Response +0.05dB/-0.1dB from 20Hz to 20kHz

–3dB at 150kHz

Equivalent Input Noise < –127dB at maximum gain

(input terminated with 150Ω) < –90dB at 0dB gain (+20dB with Pad ‘IN’)

Common Mode Rejection > 75dB from 50Hz to 1kHz

(-10dBu applied, +30dB gain) > 70dB at 10kHz

Page 28

Page A-4

X-Rack Owner’s Manual

A.3.4 Instrument Input Performance

Un-balanced signal applied to Instrument Input and measured at Output. Pad switched out and Input

Gain control set to +12dB (minimum).

Gain Continously variable from +12dB to +75dB

Independently switchable 18dB Pad available

Input Impedance 1MΩ

Output Headroom > +26dBu at onset of clipping

THD + Noise < 0.03% at 1kHz

(-18dBu applied, +28dB gain) < 0.05% at 10kHz

Frequency Response +0.05dB/-0.1dB from 20Hz to 20kHz

–3dB at 150kHz

Equivalent Input Noise < –82dB at +12dB (minimum) gain

(Input terminated with 150Ω) < –88dB at +28dB gain (mid’ position)

A.3.5 Line Input Performance

Signal applied to Line Input and measured at Output. Input Gain control set to 0dB (indent).

Gain Continuously variable from –20dB to +20dB

Input Impedance > 10kΩ

THD + Noise < 0.005% from 20Hz to 20kHz

(+24dBu applied, 0dB gain)

Frequency Response ±0.1dB from 20Hz to 20kHz

–3dB at 150kHz

Equivalent Input Noise < –90dB

(Input terminated with 150Ω)

Page 29

Page A-5

X-Rack Mic Amp Module

A.4 Calibration Information

The X-Rack Mic Amp module is factory calibrated and should only need calibration if a potentiometer or

other component has been replaced or if it is suspected that there is a problem with calibration.

In each of the following instructions it is assumed that the lid of the X-Rack has been removed and that

power has been applied. It is also assumed that unless otherwise specified, all switches are released and

all front panel potentiometers are at unity or minimum position as appropriate. The required accuracy for

each adjustment will be specified along with the target value. All level and distortion measurements

should be made with audio-band 20Hz to 20kHz filters unless otherwise specified.

All presets are accessible from the top of the unit.

A.4.1 Microphone Input

Equipment Required: Calibrated audio oscillator and audio level meter

Test Signal: 50Hz sinewave @ –12dBu, common mode

Input and Output: Oscillator to Mic Input and Output to the audio level meter

Unit Setup: Set the Mic Gain to ‘36dB’ (mid-position)

CMRR Trim

Adjustment: Adjust VR7 (CMRR) for minimum level (normally < –40dBu)

A.4.2 Line Input

Equipment Required: Calibrated audio oscillator and audio level meter

Test Signal: 1kHz sinewave @ 0dBu

Input and Output: Oscillator to Line Input and Output to the audio level meter

Unit Setup: Set the Line Gain to indent (0dB) and select ‘LINE’

Level Trim

Adjustment: 1. Adjust VR6 (0dB) for 0dBu ±0.05dB.

A.4.3 Output Balance

Equipment Required: Calibrated audio oscillator, audio level meter and a ‘balance’ adaptor (see

below)

Test Signal: 1kHz sine wave at +24dBu

Input and Output: Oscillator to Line Input and Output to the audio level meter via the

‘balance’ adaptor

Unit Setup: Set the Line Gain to indent (0dB) and select ‘LINE’

Adjustment: Adjust VR8 (BAL) for minimum level (< 55dBr)

A.4.4 ‘Balance’ Adaptor

For the output balance adjustment, a ‘balance’

adaptor such as that illustrated here will be

required. This adaptor consists of a pair of close

tolerance resistors in an in-line cable and is

used to sum together a balanced output in

order to correctly adjust the level balance of the

measured output; perfect balance should result

in complete signal cancellation.

5K01**

5K01**

2

3

1

2

3

1

0V

+

–

0V

+

–

To measuring

equipment

From unit

under test

1

2

1

Resistor tolerance should ideally be 0.01%

Absolute level measured will depend upon the input

impedence of the measuring equipment.

1.

2.

Note

Page 30

Page A-6

X-Rack Owner’s Manual

A.5 Connector Details

A.6 Physical Specification *

Depth: 200mm / 7.9 inches including front panel knobs, excluding connectors

275mm / 10.9 inches including front panel knobs and connectors

Height: 171mm / 6.75 inches

Width: 35mm / 1.4 inches front/rear panels

49mm / 1.9 inches overall width (front and rear panels are offset)

Weight: 260g / 9.5 ounces

Boxed size: 190mm x 290mm x 70mm / 7.5" x 11.5" x 2.5"

Boxed weight: 460g / 16.5 ounces

* All values are approximate

A.7 Environmental Specification

As per X-Rack – see page 19.

Instrument Input

Location:

Front Panel

Conn' Type:

Mono 1/4" Jack Socket

Pin

Description

Tip

Guitar Input

Sleeve

Chassis

Audio Output

Location:

Rear Panel

Conn' Type:

XLR Male

Pin

Description

1

Chassis

2

Audio +ve

3

Audio -ve

Audio Input

Location:

Rear Panel

Conn' Type:

XLR Female

Pin

Description

1

Chassis

2

Audio +ve

3

Audio -ve

Page 31

Page B-1

X-Rack EQ Module

B. The EQ Module

B.1 Connection

The module input and output gains can be set to operate at a nominal level of either

+4dBu or –10dBV, using a switch on the connector panel. To select the appropriate

level for the equipment you are connecting to, please check the operating manual for

your mixer or DAW. The switch should be released for +4dBu operation: push it in for

–10dBV operation.

B.2 Operation

The EQ module is a 4-band equaliser that can be switched between two different

sets of curves, one based on the latest version of the classic SSL E Series EQ and the

other based on SSL’s G Series EQ.

The G-EQ button switches the EQ from ‘E’ operation to ‘G’ operation.

The IN button switches the entire section in and out of circuit.

B.2.1 Frequency Sections

The different frequency sections are as follows:

HF Section: Frequency range 1.5kHz – 22kHz

Gain ±20dB

LF Section: Frequency range 40Hz – 600Hz

Gain ±16.5dB

The HF and LF sections provide shelving equalisers with variable turnover

frequency and a gentle slope. Selecting the ‘G-EQ’ button provides a slightly steeper

slope for both sections with a degree of overshoot/undershoot (depending on

whether you are boosting or cutting) below the selected HF frequency (or above the

selected LF frequency). Selecting ‘ ’ (‘Bell’) in either mode switches the equaliser

to a peaking curve.

HMF Section: Centre frequency 600Hz – 7kHz

Gain ±20dB

Continuously variable Q (0.7 – 2.5)

LMF Section: Centre frequency 200Hz to 2.5kHz

Gain ±20dB

Continuously variable Q (0.7 – 2.5)

Normally, at any Q setting, the bandwidth of the HMF and LMF sections varies with

gain, whereby an increase in boost or cut increases the selectivity of the EQ. This

type of EQ can sound effective when used at moderate settings; the gentle Q curve lends itself to the

application of overall EQ on combined sources and subtle corrective adjustments to instruments and

vocals.

When the EQ is switched to ‘G-EQ’ operation, at any given Q setting the bandwidth of the HMF and LMF

sections varies with gain such that an increase in boost or cut increases the selectivity of the EQ. This type

of EQ can sound effective when used at moderate settings; the gentle Q curve lends itself to the application

of overall EQ on combined sources and subtle corrective adjustments to instruments and vocals.

2

1

SEL

XR625

HF

dB

HMF

LMF

dB

dB

LF

dB

Q

Q

- +

- +

- +

- +

IN

G-EQ

KHz

KHz

22 1.5

10 5

2

15

7 .6

3 2

1 5

Hz

KHz

2.0 .2

1.0 .6

.3 1.6

600 40

220

60

OUT

IN

+4dBu

-10dBV

1

2

Page 32

Page B-2

X-Rack Owner’s Manual

Page 33

Page B-3

X-Rack EQ Module

B.3 Performance Specification

The following pages contain audio performance specification figures for the X-Rack EQ Module. No other

Solid State Logic products are covered by this document and the performance of other Solid State Logic

products can not be inferred from the data contained herein.

B.3.1 Measurement Conditions

For each set of figures on the following pages, the specific unit and test setup will be stated at the

beginning of that section. Any changes to the specified setup for any particular figure(s) will be detailed

beside the figures to which that difference applies.

B.3.2 Measurement References

Unless otherwise specified the references used in this specification are as follows:

• Reference frequency: 1kHz

• Reference level: 0dBu, where 0dBu ≈ 0.775V into any load

• Source impedance of Test Set: 50Ω

• Input impedance of Test Set: 100kΩ

• All unweighted measurements are specified as 22Hz to 22kHz band limited RMS and are expressed in

units of dBu

• All distortion measurements are specified with a 36dB/Octave low pass filter at 80kHz and are

expressed as a percentage

• The onset of clipping (for headroom measurements) should be taken as 1% THD

• Unless otherwise quoted all figures have a tolerance of ±0.5dB or 5%

• All measurements are made with the operating level switch set for +4dBu

B.3.3 Performance

Signal applied to Input and measured at Output. EQ switched In. All EQ contr ols set centre as appr opriate.

THD + N < 0.005% at +20dBu 1kHz

< 0.007% at +20dBu 10kHz

Frequency Response ±0.5dB from 20Hz to 20kHz

–3dB at 200kHz

Output Headroom > +26dBu at onset of clipping

Noise < –83dBu (+4dBu operating level)

< –92dBu (–10dBV operating level)

B.3.4 Curves

Each channel contains a four band equaliser that can be switched between two different sets of curves, one

based on the latest version of the classic SSL E Series EQ and the other based on SSL’s G Series EQ. High

and low pass filters are also available.

HF Band controls:

Frequency Variable from 1.5kHz to 22kHz

Gain Variable between ±20dB

‘Q’ 2.5 (on ‘ ’ setting)

HMF Band controls:

Frequency Variable from 600Hz to 7kHz

Gain Variable by > ±20dB

‘Q’ Variable from 0.5 to 2.5 (may also vary with gain)

Page 34

Page B-4

X-Rack Owner’s Manual

LMF Band controls:

Frequency Variable from 200Hz to 2.5kHz

Gain Variable by > ±20dB

‘Q’ Variable from 0.5 to 2.5 (may also vary with gain)

LF Band controls:

Frequency Variable from 40Hz to 600Hz

Gain Variable between ±16.5dB

‘Q’ 2.5 (on ‘ ’ setting)

The LF and HF bands have variable turnover frequency with switchable bell/shelving and selectable

response curves:

• Normal (‘E type’) curves with the ‘G-EQ’

switch OUT follow conventional cut or

boost characteristics.

• ‘G type’ curves with the ‘G-EQ’ switch IN,

have a modified slope with a degree of

overshoot/undershoot for increased

selectivity.

The two parametric bands have selectable characteristics which affect the relationship between frequency

bandwidth and gain:

• With the ‘G-EQ’ switch OUT, the frequency

bandwidth is constant at all gains.

• With the ‘G-EQ’ switch IN, the frequency

bandwidth reduces with increased gain,

thereby increasing the selectivity of the EQ

as the gain is increased.

• At full boost or cut both are identical.

10 100 1k 10k 20k

-25.0

-20.0

-15.0

-10.0

-5.0

0.0

5.0

10.0

15.0

20.0

25.0

Amplitude (dBr) v Frequency (Hz)Channel Equaliser Curves

’G type’

’E type’

Both

0.0

25.0

-25.0

20 100 1k 10k 100k

-20.0

-15.0

-10.0

-5.0

5.0

10.0

15.0

20.0

Amplitude (dBr) v Frequency (Hz)Channel Equaliser Curves

’G type"

’E type’

Page 35

Page B-5

X-Rack EQ Module

B.4 Calibration Information

The X-Rack EQ module is factory calibrated and should only need calibration if a potentiometer or other

component has been replaced or if it is suspected that there is a problem with calibration.

In each of the following instructions it is assumed that the lid of the X-Rack has been removed and that

power has been applied. It is also assumed that unless otherwise specified, all switches are released and

all front panel potentiometers are at unity or minimum position as appropriate. The required accuracy for

each adjustment will be specified along with the target value. All level and distortion measurements

should be made with audio-band 20Hz to 20kHz filters unless otherwise specified.

All presets are accessible from the top of the unit.

Note. The unit should be allowed to warm up with power applied for at least 15 minutes prior to making any adjustments.

B.4.1 EQ Alignment

Equipment Required: Calibrated audio oscillator and audio level meter

Test Signal: Sine wave @ –6dBu, frequencies as specified below

Input and Output: Oscillator to Input, Output to the audio level meter

Unit Setup: 1. Switch the EQ IN and release all other EQ switches.

2. Release the +4dBu/–10dBV switch on the rear panel.

3. Set all of the Q and Frequency controls fully anti-clockwise and all Gain

controls to their centre indent.

HF EQ - Maximum Gain

Adjustment: 1. Set HF Gain to maximum and select HF . Set the audio oscillator for

12kHz and adjust HF Frequency to find the maximum level on the audio

level meter.

2. Adjust VR13 (HF Q) for +20dBu ±0.25dB.

3. Reset HF Gain to its centre indent position, de-select HF and re-check

the audio level meter for 0dBu.

HMF EQ - Maximum Gain

Adjustment: 1. Set HMF Gain to maximum and HMF Q fully anti-clockwise. Set the

audio oscillator for 3kHz and adjust HMF Frequency to find the

maximum level on the audio level meter.

2. Adjust VR11 (HMF Q) for +21dBu ±0.25dB.

3. Reset HMF Gain to its centre indent position, re-check the audio level

meter for 0dBu.

LMF EQ - Maximum Gain

Adjustment: 1. Set LMF Gain to maximum and LMF Q fully anti-clockwise. Set the audio

oscillator for 1kHz and adjust LMF Frequency to find the maximum level

on the audio level meter.

2. Adjust VR12 (LMF Q) for +21dBu ±0.25dB.

3. Reset LMF Gain to its centre indent position, re-check the audio level

meter for 0dBu.

(continued)

Page 36

Page B-6

X-Rack Owner’s Manual

LF EQ - Maximum Gain

Adjustment: 1. Set LF Gain to maximum and select LF . Set the audio oscillator for

80Hz and adjust LF Frequency to find the maximum level on the audio

level meter.

2. Adjust VR14 (LF Q) for +16.5dBu ±0.25dB.

3. Reset LF Gain to its centre indent position, de-select LF and re-check

the audio level meter for 0dBu.

B.4.2 Output Balance

Equipment Required: Calibrated audio oscillator, audio level meter and a ‘balance’ adaptor (see

below).

Test Signal: 1kHz sine wave at +24dBu.

Input and Output: Oscillator to the Input of the channel being tested, Output to the level

meter via the ‘balance’ adaptor.

Unit Setup: Ensure that all front panel switches are off and all controls are set fully

anti-clockwise.

Adjustment: Connect the test equipment to the each channel in turn and adjust VR15

(BAL) for minimum level (< 55dBr).

B.4.3 ‘Balance’Adaptor

For the output balance adjustment, a ‘balance’

adaptor such as that illustrated here will be

required. This adaptor consists of a pair of close

tolerance resistors in an in-line cable and is

used to sum together a balanced output in

order to correctly adjust the level balance of the

measured output; perfect balance should result

in complete signal cancellation.

5K01**

5K01**

2

3

1

2

3

1

0V

+

–

0V

+

–

To measuring

equipment

From unit

under test

1

2

1

Resistor tolerance should ideally be 0.01%

Absolute level measured will depend upon the input

impedence of the measuring equipment.

1.

2.

Note

Page 37

B.5 Connector Details

B.6 Physical Specification *

Depth: 200mm / 7.9 inches including front panel knobs, excluding connectors

275mm / 10.9 inches including front panel knobs and connectors

Height: 171mm / 6.75 inches

Width: 35mm / 1.4 inches front/rear panels

49mm / 1.9 inches overall width (front and rear panels are offset)

Weight: 260g / 9.5 ounces

Boxed size: 190mm x 290mm x 70mm / 7.5" x 11.5" x 2.5"

Boxed weight: 460g / 16.5 ounces

* All values are approximate

B.7 Environmental Specification

As per X-Rack – see page 19.

Audio Output

Location:

Rear Panel

Conn' Type:

XLR Male

Pin

Description

1

Chassis

2

Audio +ve

3

Audio -ve

Audio Input

Location:

Rear Panel

Conn' Type:

XLR Female

Pin

Description

1

Chassis

2

Audio +ve

3

Audio -ve

Page B-7

X-Rack EQ Module

Page 38

Page B-8

X-Rack Owner’s Manual

Page 39

Page D-1

X-Rack Dynamics Module

D. The Dynamics Module

D.1 Connection

The module input and output gains can be set to operate at a nominal level of either

+4dBu or –10dBV, using a switch on the connector panel. Select the appropriate level

for the equipment you are connecting to. If in doubt experiment!

To check the input and output gains, set the compressor Ratio and Threshold controls

fully clockwise and send a signal close to the nominal operating level of your mixer or

DA W to the dynamics module. The lower three LEDs of the compr ession meter should

light if the input level matches the selected operating level. Release the switch for

+4dBu operation: push it in for –10dBV operation.

D.2 Operation

Each dynamics module comprises a compressor/limiter and a gate/expander, both

of which use the same gain element.

The IN button switches the entire section in and out of circuit.

D.2.1 Compressor/Limiter Section

RATIO – When turned to 1:1, the compressor/limiter section is inactive. Turning

the control clockwise increases the compression ratio, giving a true limiter at the

fully clockwise position. The compressor normally has an ‘over-easy’ characteristic.

Pressing the PK button switches this to peak sensing, and replaces the ‘over-easy’

characteristic with a hard knee.

THRESHOLD – Whenever a signal exceeds the level set by this control, the

compressor will start to act at the ratio set by the RATIO control. The

THRESHOLD and RATIO controls also provide automatic make-up gain, so as

you lower the threshold and introduce more compression, the output level is

increased, maintaining a steady output level regardless of the amount of

compression.

FST A TK– Normally the attack time is program dependent (3mS – 30mS). Press this

button to select a fixed fast attack time (3mS for 20dB gain reduction).

RELEASE – Sets the time constant (speed) with which the compressor returns to

normal gain settings once the signal has passed its maximum.

D.2.2 Gate/Expander Section

This section can act as a ∞:1 Gate or as a 2:1 Expander when the EXP button is

pressed.

RANGE – Determines the depth of gating or expansion. When turned fully

anticlockwise (Range = 0), this section is inactive. When turned fully clockwise, a

gate depth of 40dB can be obtained.

THRESHOLD – Determines the level at which the gate opens or below which gain reduction begins (EXP

selected), adjustable from +10dBu to –20dBu. Variable hysteresis is incorporated in the threshold circuitry

to prevent spurious triggering of the gate when the signal is close to the threshold level. This means that

the signal has to decay roughly 2dB below the threshold level before the gate will start to close.

3

2

1

SEL

+10 -30

COMPRESSOR

GATE/

EXPANDER

KEY

4

0.1

RELEASE

0.1

4

+10

THRESHOLD

-20

RATIO

1

∞

RANGE

0 40

PK

FAST

ATT

LINK

RELEASE

THRESHOLD

IN

EXP

20

14

10

6

3

HOLD

0 4

FAST

ATT

XR618

OUT

IN

+4dBu

-10dBV

KEY

1

3

2

Page 40

Page D-2

X-Rack Owner’s Manual

FST ATK – Normally, a controlled linear attack time of 1.5ms per 40dB is provided.

Press this button to select a fast attack time (100µs per 40dB). The attack time is the

time taken for the Gate/Expander to ‘recover’ once the signal level is above the

threshold. When gating signals with a steep rising edge, such as drums, a slow

attack may effectively mask the initial ‘THWACK’, so you should be aware of this

when selecting the appropriate attack time.

RELEASE – This determines the time constant (speed), variable from 0.1 to 4

seconds, at which the Gate/Expander reduces the signal level once it has passed

below the threshold. Note that this control interacts with the Range control.

HOLD – Determines the time after the signal has decayed below the threshold

before the gate starts to close. Variable from 0 to 4 seconds.

KEY – Switches the Dynamics side chain to the ‘KEY’ input on the rear panel of the

unit.

LINK – The side chain control signals of multiple modules can be linked by

pressing the LINK switch on those modules you wish to gang. When two (or more)

Dynamics sections are linked, the control voltages of each section sum together, so

that whichever section has the most gain reduction will control the other section.

Don’t try to link two gates using the LINK button when you want the signal on one

to open the other. If you need to achieve this effect, take a keying signal from one

section to trigger the other. The easiest way to do this is by patching from the

‘source’ signal to the Key input of the ‘destination’ channel, and selecting KEY (see

above) on this channel.

SEL

+10 -30

COMPRESSOR

GATE/

EXPANDER

KEY

4

0.1

RELEASE

0.1

4

+10

THRESHOLD

-20

RATIO

1

∞

RANGE

0 40

PK

FAST

ATT

LINK

RELEASE