Page 1

7151

COMPUTING MULTIMETER

MAINTENANCE MANUAL

Issue 1: June 1984

SOLARTRON

Schlumberger

Solartron pursues a policy of continuous development and product improvement

The specification in this document may therefore be changed without notice

Solartron Instruments, Victoria Road, Farn bo rough

Hampshire, England GU14 7PW Telephone: Farnborough (0252) 544433

Telex: 858245 Solfar G Cables: Solartron Famborough

A division of Schlumberger Electronics (UK) Ltd

PartNo. 71510011

19©84

Page 2

n

Page 3

7151 COMPUTING MULTIMETER

MAINTENANCE MANUAL

1642g/0072g

Page 4

Page 5

CONTENTS

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

General

Calibration Procedures

Dismantling & Reassembly

Circuit Descriptions & Diagrams

Fault Diagnosis Guide

Parts Lists &

Component Layout

1642g/0072g

Page 6

r

Page 7

Chapter 1 General

1642g/0072g

Page 8

f

Page 9

CHAPTER 1

1. GENERAL

The Solartron 7151 Computing Multimeter performs all common

functions, and offers: a library of

measurements;

The instrument is suitable for general purpose bench work, or for use

within a system where 7151 would

control interfaces. The interfaces provided are the IEEE 488 (1978) STD

system and the RS232C V24 serial system.

2. SAFETY

The 7151 multimeter has been designed in accordance with the

recommendations of IEC 348. To ensure the user's safety, and the

continued safe operation of the instrument, it is advisable to fully

observe the procedures and specifications given in the Operating Manual

(Part No. 71510010).

An Earth wire is provided to ensure the user's safety. Therefore, if an

extension mains cable is used, check that the Earth connection is

maintained throughout the length of the extension.

When using 7151 on

(e.g. inductive circuitry giving high back emf's such as

a large mains transformer), it is most important that 7151's test leads

are disconnected from the equipment before

that harmful back-emf's do not reach 7151. Care should

exercised when handling the input leads, especially where

are known to be present, or where

and a programmable power-on status.

equipment which is capable

programs;

be operated via

high transients could

clock controlled

one of

of delivering

switched it off. This ensures

measurement

its remote

high voltages

the secondary

always be

high

occur.

voltages

of

Whenever it is likely that the safety of the instrument has been impaired

- e.g. if it shows visible signs of damage, if it fails to perform

correctly, or if the specifications have been exceeded in any way - it

should be made inoperative and referred to a suitable repair depot. Any

maintenance, adjustment or repair of the multimeter must be carried out

by

skilled personnel only, in accordance with the procedures and

precautions detailed in this Maintenance Manual (part no. 71510011).

A

Wherever this symbol appears on the front or rear panel it is

advisable to consult the appropriate section of

further information.

3. SUMMARY OF OPERATION

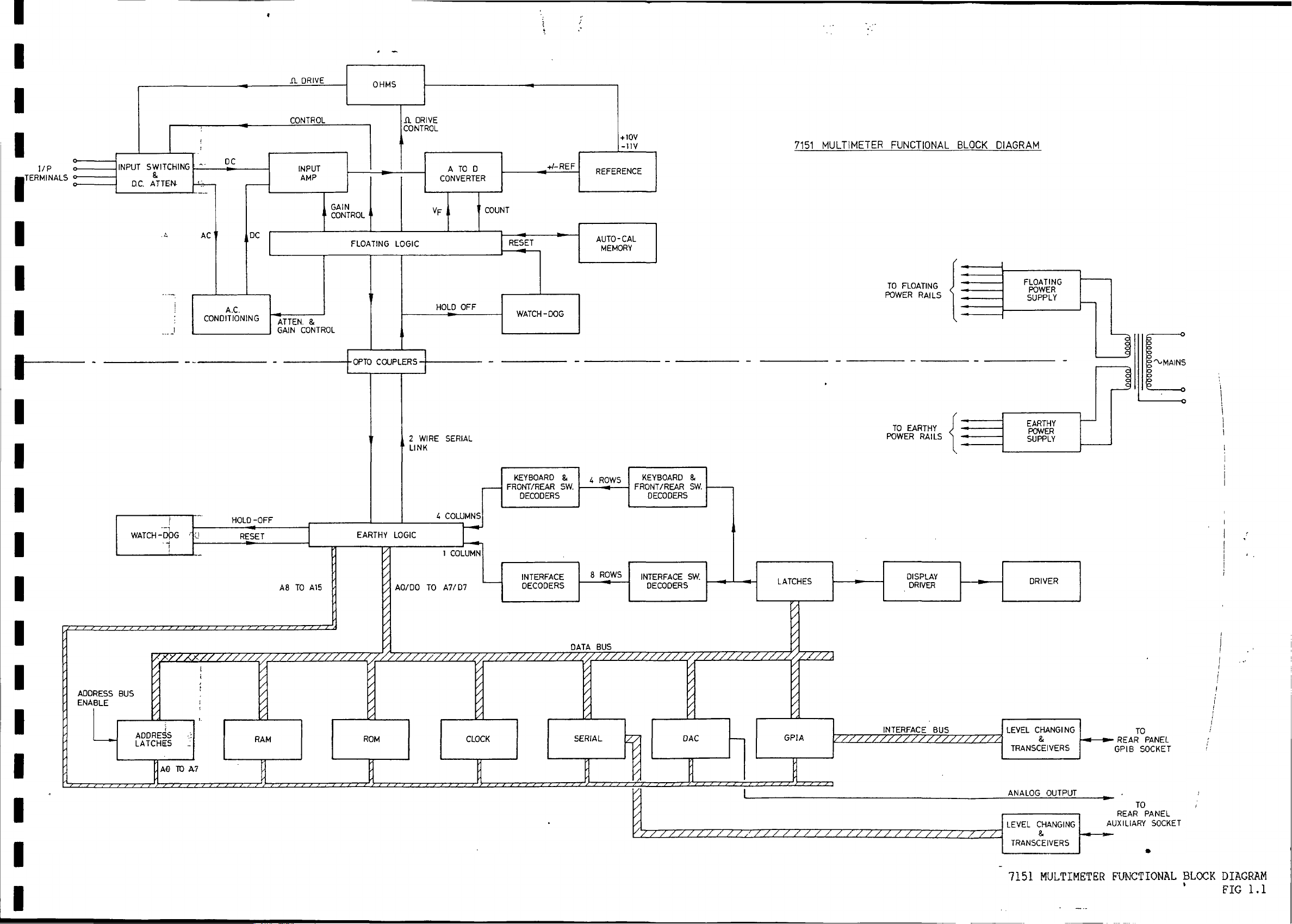

A schematic block diagram of the 7151 is shown in Fig. 1.1. 7151 is

essentially a

technique of analog to digital conversion.

All inputs to the instrument are first converted to dc voltages before

being passed to the input amplifier. This is simple enough for current

(dc) and resistance, but ac inputs also undergo rms conversion to dc.

All inputs are suitably scaled by the input amplifier and passed to the

voltage measuring instrument which uses the pulse width

the Operating Manual for

0072g/1634g

1.1

Page 10

analog to digital converter (ADC). With no input,

balanced pulse trains of

received, the

opposite

then

manner, proportional to the size of the input. These trains are

converted to a single end and gated into a reversible counter. The

mark-space ratios of the trains respond in an

mark space ratio 1:1. When an input is

the

ADC produces two

equal and

nett result is a pulse count proportional to the measure of the input.

The measuring circuits are controlled by what is termed the 'floating'

logic and

'Piggyback' ROM. The other circuits of 7151 are organised in a

arrangement which is controlled by the 'earthy' logic and consists

essentially

between the floating and earthy logic is acheived by

links. It is the

of

measurements, processing, remote

displays, and so

consists essentially of a 8-bit microprocessor

with

of another 8-bit microprocessor. Isolated communication

opto coupled serial

earthy logic

which is responsible for effective control

control, the real time clock, the

on.

bus

0072g/1634g

1.2

Page 11

A DRIVE

OHMS

I/P

TERMINALS »

CONTROL

A DRIVE

CONTROL

7151 MULTIMETER FUNCTIONAL BLOCK DIAGRAM

o-

INPUT SWITCHING

A.C.

CONDITIONING

INPUT

AMP

ATTEN. &

GAIN CONTROL

GAIN

CONTROL

FLOATING LOGIC

OPTO COUPLERS

CONVERTER

HOLD OFF

2 WIRE SERIAL

LINK

COUNT

RESET

+/-REF

WATCH-DOG

REFERENCE

AUTO-CAL

MEMORY

TO FLOATING

POWER

RAILS

TO EARTHY

POWER RAILS

FLOATING

POWER

SUPPLY

EARTHY

POWER

SUPPLY

ADDRESS BUS

ENABLE

WATCH-DPG

ADDRESS

LATCHES

At) TO A7

HOLD -OFF

RESET

A8 TO A15

EARTHY LOGIC

AO/DO TO A7/D7

4 COLUMNS

1 COLUMN

CLOCK

KEYBOARD 8.

FRONT/REAR SW.

DECODERS

INTERFACE

DECODERS

4 ROWS

8 ROWS

DATA BUS

SERIAL

KEYBOARD &

FRONT/REAR SW.

DECODERS

INTERFACE SW.

DECODERS

LATCHES

GPIA

DISPLAY

DRIVER

INTERFACE BUS

DRIVER

LEVEL CHANGING

TRANSCEIVERS

TO

■ REAR PANEL

GPIB SOCKET

ANALOG OUTPUT

TO

LEVEL CHANGING

TRANSCEIVERS

REAR PANEL

AUXILIARY SOCKET

7151 MULTIMETER FUNCTIONAL BLOCK

*

DIAGRAM

FIG 1.1

Page 12

Chapter

Calibration

Procedures

1642g/00'72g

Page 13

{

I

(

{

1

Page 14

CHAPTER 2

Setting-Up And Calibration Procedures

General

These procedures enable the instrument to be set-up

factory

despatch

standards

.

and

calibrated to the

The procedures are categorised into the following sections:

1. Setting-up procedures

2. Initial calibration

3. Final calibration

procedures

procedures

Safety

The instrument must be disconnected from the mains supply when

dismantling it to gain access to the preset controls and also

being reassembled (see

Chapter 4 for dlssembly instructions)

when it is

.

When adjusting preset controls beware of high test voltages, the guard

potential on the guard plate and also the mains input supply.

Calibration Method

Owing to the automatic calibration circuits incorporated in 7151, it can

only be calibrated by connecting it to a remote controller and then using

the appropriate calibration commands.

program can be used which is a

Solartron

can

supply, on tape cassettes, a calibration program for the

much faster method of calibrating 7151.

Alternatively, a calibration

more common types of controllers.

The user is advised to re-calibrate 7151 annually.

If the instrument's existing

satisfactory, the user can

constants by sending the REFRESH

state of calibration is judged to be

simply re-write the existing calibration

command to 7151 once it is in the

calibration mode.

Calibration Source

It is recommended that the calibration source has an accuracy of at least

two times better than the accuracy specified for the various 7151

functions. The 7151 specification is given in the Operating

Manual and

the important percentage accuracies are as follows:-

DC Volts

DC Current

AC Volts

AC Current

Resistance

0.002%

0.02%

0.05%

0.05%

0.002%

0072g/1624g

2.1

Page 15

ENTERING CALIBRATION MODE

Insert a shorted 2.5mm jack plug Into the rear panel

the front panel CAL Indicator to repeatedly flash. The short may be

CAL socket, causing

within the plug Itself, or externally via a switch. The plug must remain

fitted throughout the calibration, and can be removed after calibration

is complete.

Note: Do not switch mains power on or off when the shorting plug Is

fitted, otherwise the Internal calibration

Using the controller, send the command CALIBRATE

Into the

calibration

mode. The

CAL Indicator should then be steady.

Also displayed Is the word, 'CAL'. Once the calibration mode

constants may be

ON to 7151, putting It

altered.

has been

selected, the following conditions apply:

(a) Three commands cannot be used: TRIG

TRACK

NULL

'OFF' status Is adopted.

'OFF' status Is adopted,

all nulls being deleted.

(b) Four commands become available: HI

LO

WRITE

REFRESH

for refreshing

existing

cal. constants.

0072g/1624g

2.2

Page 16

CALIBRATING MEASUREMENT RANGE

Using the controller, select the function and range to be calibrated by

sending the appropriate MODE and RANGE commands.

7151 must then be supplied with two precisely known reference inputs

(non-negative) one at approximately nominal full scale (referred to as

the Hi point), and

one at approximately zero (referred to as the Lo

point), in the case of ac ranges the Lo point should not be less than

approximately 5% of nominal full scale rather than zero. This ensures

that all inputs are within the optimum part of 7151's

linear range.

After a reference input is applied, 7151 must be informed of the precise

value of the input. This is achieved by using the HI command for a Hi

point, and the LO command for a Lo point. These commands must be

accompanied by an integer argument number, of up to six digits in length,

which expresses the applied input in terms of 5 x 9's count.

An integer value of 200000 corresponds to nominal full scale for any

range

For example, applying 2V on the 2V range, enter 200000

.

applying 20V on the 20V range, enter 200000

applying 5V on the 200V range, enter 005000

Apply the Hi point input to 7151 for the requisite function/range.

For example, 2.00843V on 2V dc range.

Using the controller, send the HI command to 7151.

For example, HI200843.

7151 responds by displaying 'Hi Pt' for about 1.5 seconds, during which

time it measures the applied reference input. When finished, the

instrument displays (and outputs) its measured count, e.g. 214576. It is

of no consequence if the displayed count differs from the applied input.

Repeat the above

(short circuit), and send the LO command. For example LOO (leading

zeroes need

Having

command

specified the Hi point and Lo point (in any order), send the

WRITE to 7151 (no argument required). This causes the

calibration constants for the selected range/function to be calculated

and

stored in memory. If successful, the message 'Good' is displayed.

If unsuccessful, an error message will be displayed and output to the

procedure for the Lo point. For example, reference = OV

not be specified).

controller.

Repeat the above instructions for each function/range to be calibrated.

0072g/1624g

2.3

Page 17

RESTORING THE MEASUREMENT FUNCTIONS

Using the controller, send 7151 the command CALIBRATE OFF. The CAL

indicator will then flash indicating that the CAL shorting plug is still

fitted.

Withdraw the CAL

shorting plug. The

CAL indicator should then be

invisible, the instrument being ready for normal use.

SUMMARY

(a) Insert CAL shorting plug (2.

(b) Select the calibration mode by sending the CALIBRATE ON

5mm) in rear panel socket

.

command.

(c) Select the requisite function and range to be calibrated and perform

the calibration sequence. Repeat for each range/function to be

calibrated.

(d) De-select the calibration mode by sending the

CALIBRATE OFF

command.

(e) Remove CAL plug.

0072g/1624g

2.4

Page 18

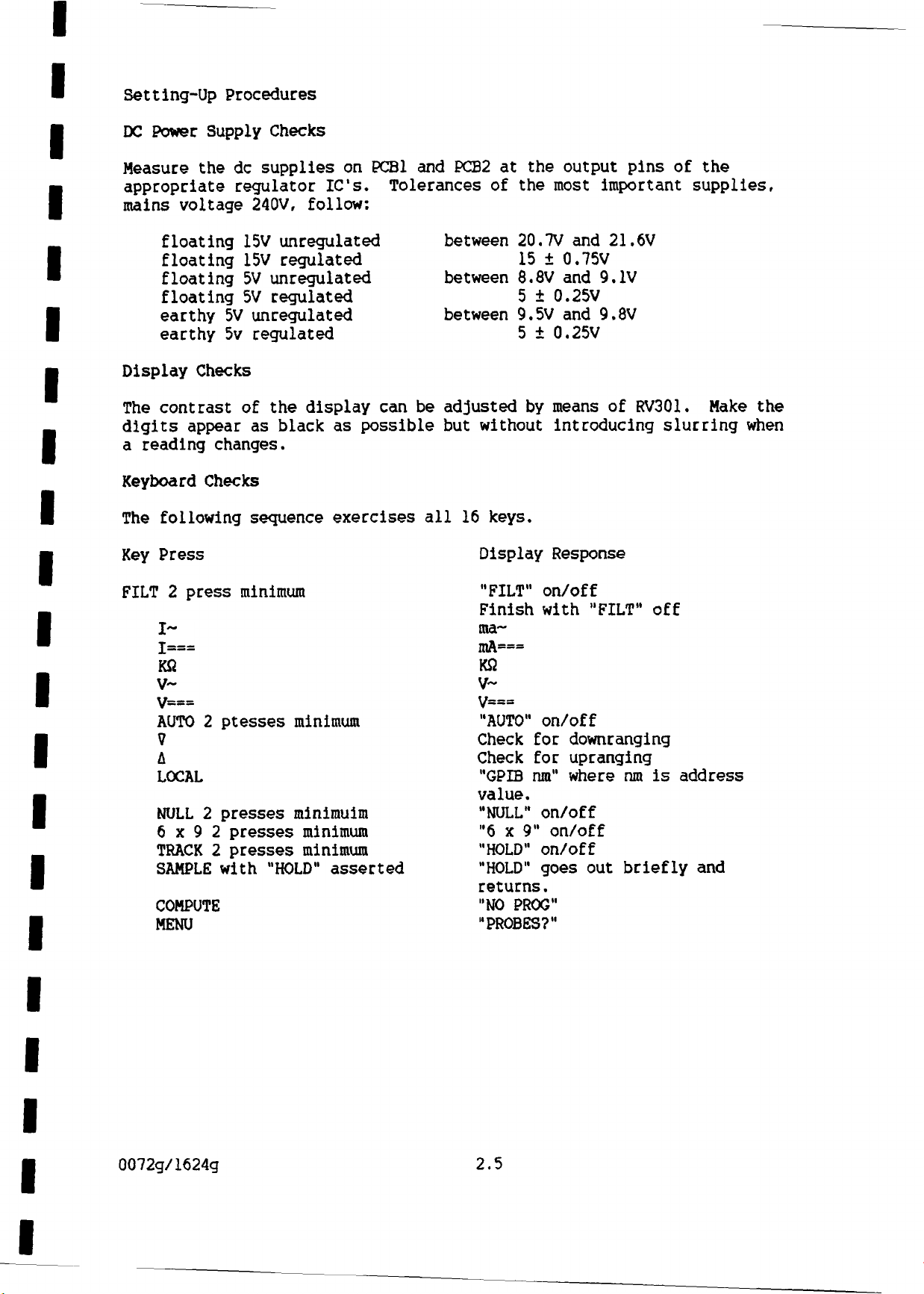

Setting-Up

Procedures

DC Power Supply Checks

Measure the dc supplies on PCB1 and PCB2 at the output pins of the

appropriate regulator IC's. Tolerances of the most important supplies,

mains voltage 240V, follow:

floating 15V unregulated

floating 15V regulated

floating 5V unregulated

floating 5V regulated

earthy 5V unregulated

earthy 5v regulated

between 20.7V and 21.6V

15 ± 0.75V

between 8.8V and 9.1V

5 + 0.25V

between 9.5V and 9.8V

5 ± 0.25V

Display Checks

The contrast of the display can be adjusted

by means of RV301. Make the

digits appear as black as possible but without introducing slurring when

a reading changes.

Keyboard Checks

The following sequence exercises all 16 keys.

Key Press

FILT 2 press minimum

Display Response

"FILT" on/off

Finish with "FILT" off

ma-

mA===

K£2

V~

V===

AUTO 2

V

A

LOCAL

presses

minimum

KQ

V~

V===

"AUTO" on/off

Check for downranging

Check for upranging

"GPIB nm" where nm is address

value.

NULL 2 presses minimuim

6x92

TRACK 2

presses

presses

minimum

minimum

SAMPLE with "HOLD" asserted

COMPUTE

MENU

"NULL" on/off

"6x9" on/off

"HOLD" on/off

“

HOLD" goes out briefly and

returns

.

"NO PROG"

“

PROBES?"

0072g/1624g

2.5

Page 19

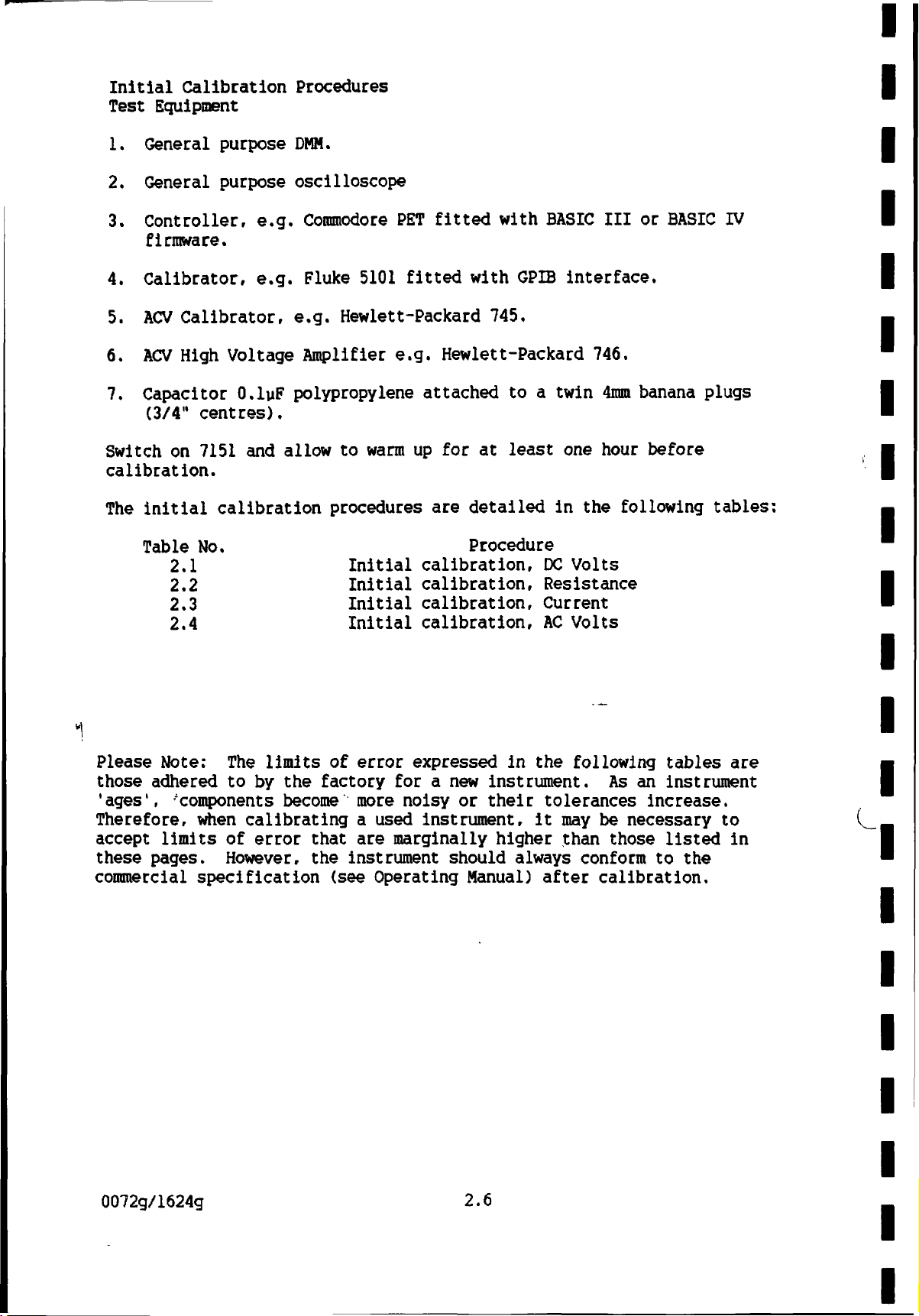

Initial

Calibration

Procedures

Test Equipment

1. General purpose DMM.

2. General purpose oscilloscope

3. Controller, e.g. Commodore PET fitted with BASIC III or BASIC IV

firmware.

4. Calibrator, e.g. Fluke 5101 fitted with GPIB interface.

5. ACV Calibrator, e.g. Hewlett-Packard 745.

6. ACV High Voltage

7. Capacitor O.lyF polypropylene attached to a twin 4mm banana

(3/4" centres)

Switch on 7151 and

Amplifier e.g. Hewlett-Packard 746.

.

allow to warm up for at least one hour before

plugs

calibration.

The initial calibration

Table

2.1

No.

2.2

2.3

2.4

procedures are detailed in the following tables:

Procedure

Initial

Initial

Initial

Initial

calibration, DC

calibration, Resistance

calibration. Current

calibration, AC Volts

Volts

Please

Note: The limits of error expressed in the following tables are

those adhered to by the factory for a new instrument. As an instrument

'ages', "components become more noisy or their tolerances increase.

Therefore, when calibrating a used instrument, it may

be

necessary to

accept limits of error that are marginally higher than those listed in

these pages. However, the instrument should always conform to the

commercial specification (see Operating Manual) after calibration.

0072g/1624g

2.6

Page 20

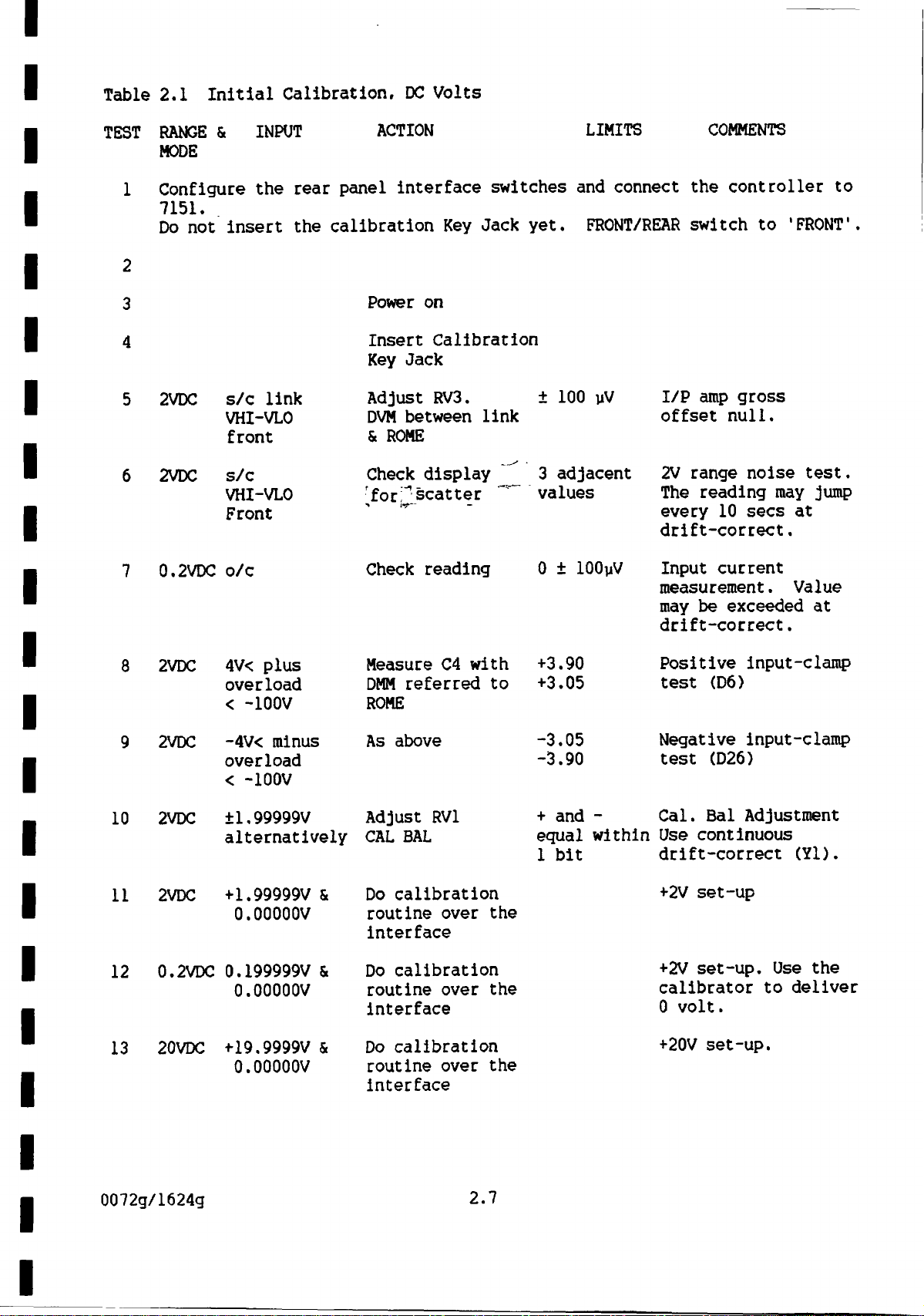

Table 2.1 Initial Calibration, DC Volts

TEST RANGE & INPUT

ACTION

LIMITS

COMMENTS

MODE

1 Configure the rear panel interface switches and connect the controller to

7151.

Do

not insert the calibration Key Jack yet. FRONT/REAR switch to 'FRONT'.

2

3

4

5

6

7

2VDC

2VDC

0.2VDC

s/c link

VHI-VLO

front

s/c

VHI-VLO

Front

o/c

Power on

Insert Calibration

Key Jack

Adjust RV3.

DVM between link

& ROME

Check display ^

'for2scatter

Check reading

± 100 yV

3 adjacent

values

0 ± lOOyV

I/P amp gross

offset null.

2V range noise test.

The reading may jump

every 10 secs at

drift-correct

Input current

measurement.

may be exceeded at

drift-correct

.

Value

.

10

11

12

13

8

9

2VDC

2VDC

2VDC

2VDC

0.2VDC

20VDC

4V< plus

overload

< -100V

-4V< minus

overload

< -100V

±1,99999V

alternatively

+

1.99999V &

0.00000V

0.

199999V &

0.00000V

+19.

9999V &

0.00000V

Measure C4 with

DMM referred to

ROME

As above

Adjust RV1

CAL BAL

Do calibration

routine over the

interface

Do calibration

routine over the

interface

Do calibration

routine over the

interface

+3.90

+3.05

-3.05

-3.90

+ and -

equal within

1 bit

Positive input-clamp

test (D6)

Negative input-clamp

test (D26)

Cal. Bal Adjustment

Use continuous

drift-correct (Yl)

.

+2V set-up

+2V set-up. Use the

calibrator to deliver

0 volt

.

+20V set-up.

0072g/1624g

2.7

Page 21

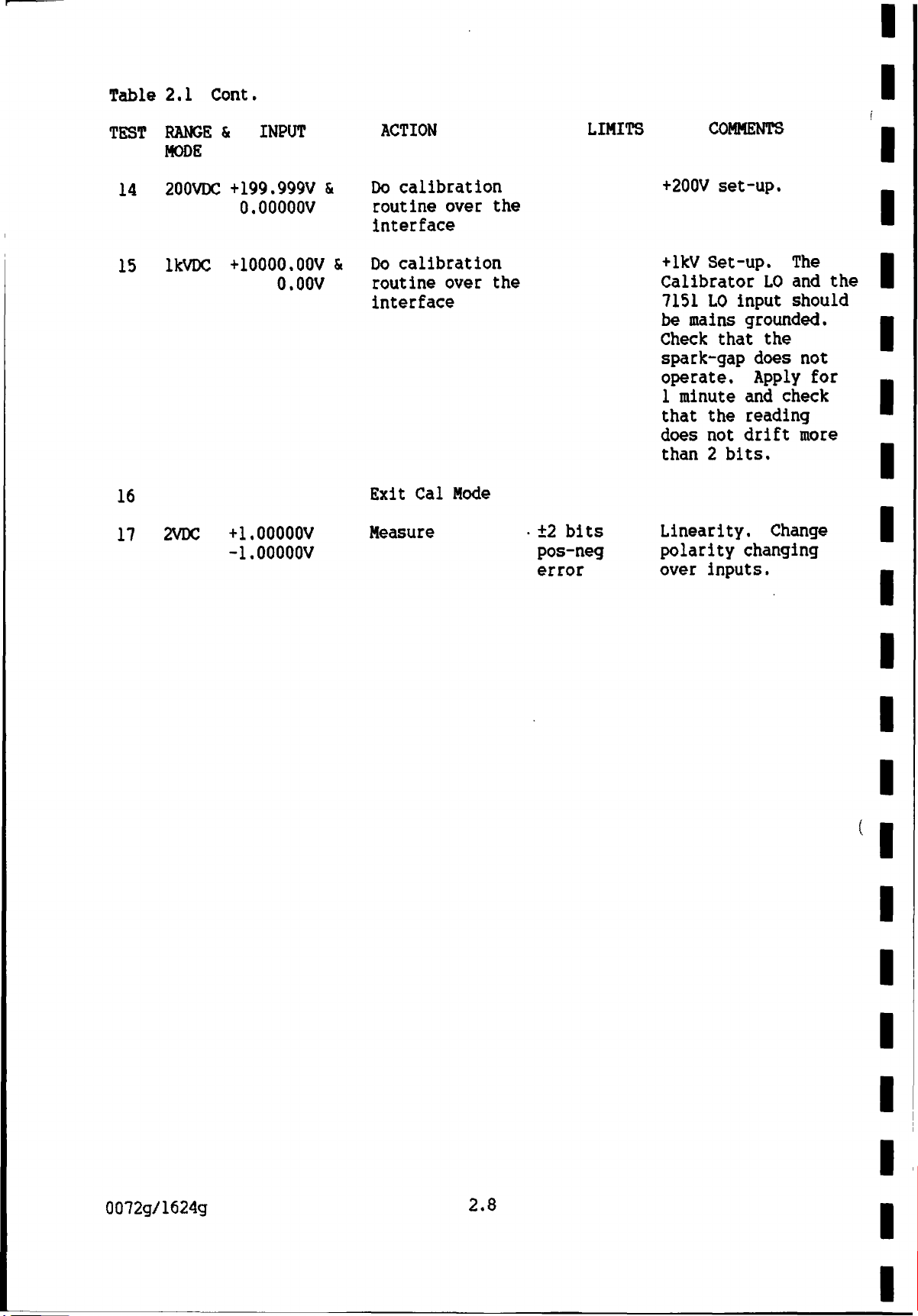

Table 2.1 Cent.

TEST RANGE & INPUT

MODE

14 200VDC +199.999V &

0.00000V

15 IkVDC +10000.

00V &

0.00V

16

17 2VDC +1.00000V

-1.00000V

ACTION

Do calibration

routine over the

LIMITS

COMMENTS

+200V set-up.

interface

Do calibration

routine over the

interface

+lkV Set-up. The

Calibrator LO and the

7151 LO input should

be mains grounded.

Check that the

spark-gap does not

operate. Apply for

1 minute and check

that the reading

does not drift more

than 2 bits.

Exit Cal Mode

Measure

+2 bits

pos-neg

error

Linearity. Change

polarity changing

over inputs.

0072g/1624g

2.8

Page 22

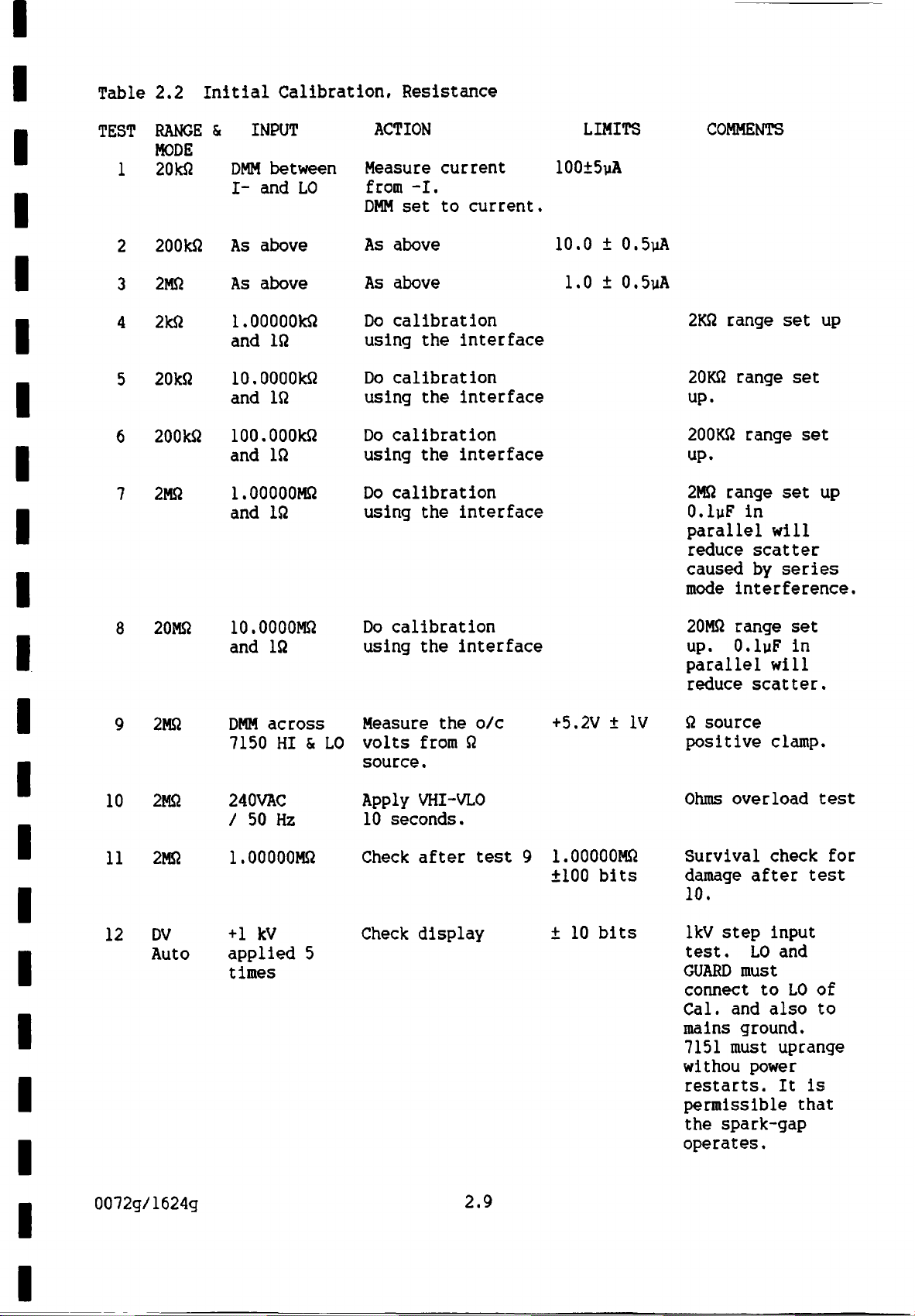

Table 2.2 Initial Calibration, Resistance

TEST

1

2

3

4

5

6

7

RANGE

MODE

20kfl

200kfl

2Mfi

2k£2

20kfi

200kfi

2Mft

5. INPUT

DMM between

I- and LO

As above

As above

l.OOOOOkfl

and IQ

lO.OOOOkQ

and IQ

lOO.OOOkQ

and IQ

1.00000MQ

and IQ

ACTION

Measure current

LIMITS

100±5yA

COMMENTS

from -I.

DMM set to current.

As above

As above

Do calibration

10.0 ± 0.5uA

1.0 ± 0,5yA

2KQ range set up

using the interface

Do calibration

using the interface

Do calibration

using the interface

Do calibration

using the interface

20KQ range set

up.

200KQ range set

up.

2MQ range set up

O.lyF in

parallel will

reduce scatter

caused by series

mode interference.

10

11

12

8

20MS2

10.0000MQ

and IQ

Do calibration

using the interface

20MQ range set

up. O.lyF in

parallel will

reduce scatter.

9

2M$2

DMM across

7150 HI & LO

2M£2

240VAC

/ 50 Hz

2Mfi

1.00000MQ

Measure the o/c

volts from Q

source

.

Apply VHI-VLO

10 seconds.

Check after test 9

+5.2V ± IV

1.00000MQ

±100 bits

Q source

positive clamp.

Ohms overload test

Survival check for

damage after test

10.

DV

Auto

+1 kV

applied 5

times

Check display

± 10 bits

IkV step input

test. LO

GUARD must

connect to LO of

Cal. and also to

and

mains ground.

7151 must uprange

withou power

restarts. It is

permissible that

the spark-gap

operates.

0072g/1624g

2.9

Page 23

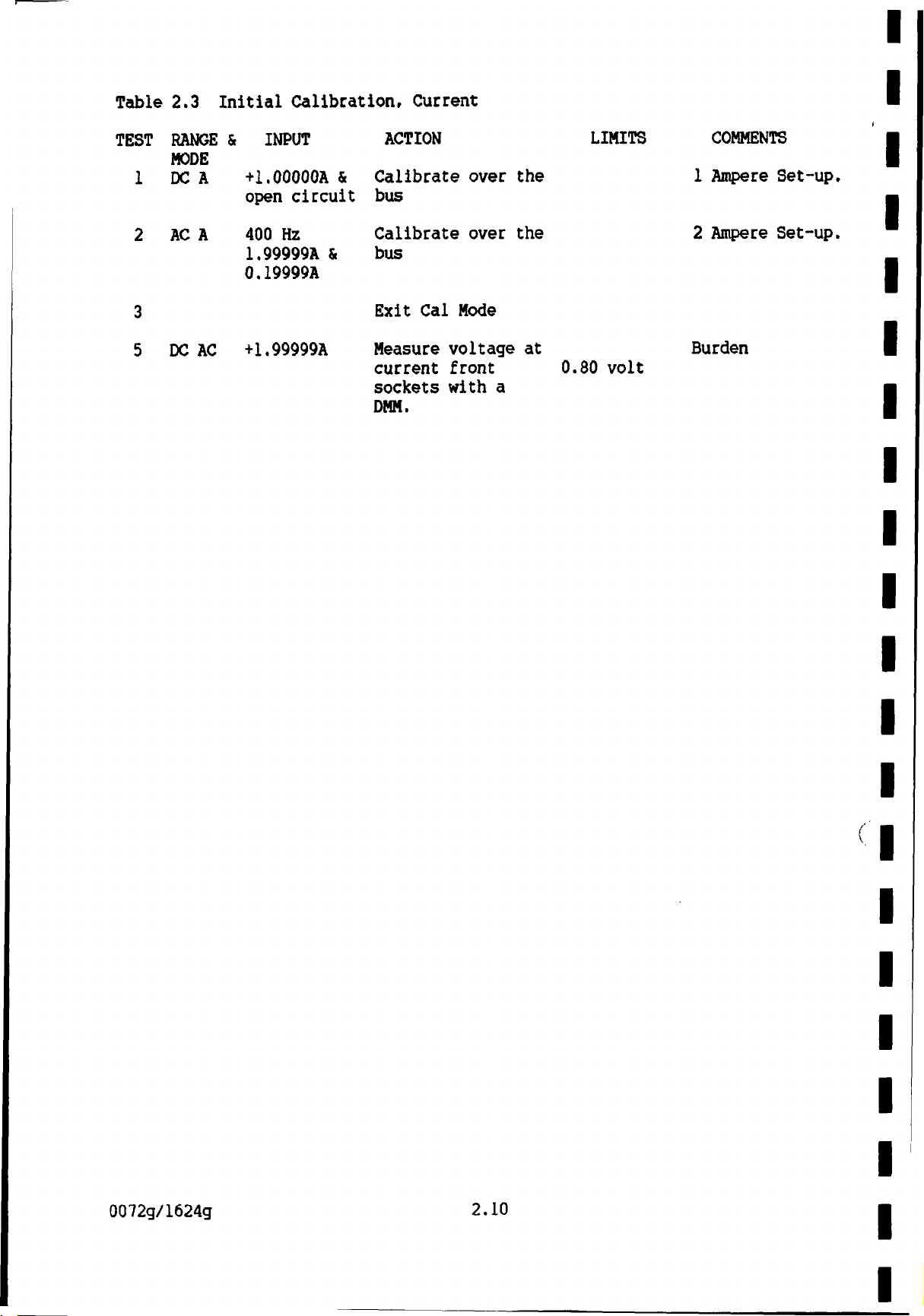

Table 2.3 Initial Calibration, Current

TEST

1

2

3

5

RANGE

MODE

DC A

AC A

DC AC

& INPUT

+1.00000A &

open circuit

400 Hz

1.99999A &

0.19999A

+1.99999A

ACTION

Calibrate over the

LIMITS

COMMENTS

1 Ampere Set-up

bus

Calibrate over the

2 Ampere Set-up

bus

Exit Cal Mode

Measure voltage at

current front

sockets with

a

0.80 volt

Burden

DMM.

0072g/1624g

2.10

Page 24

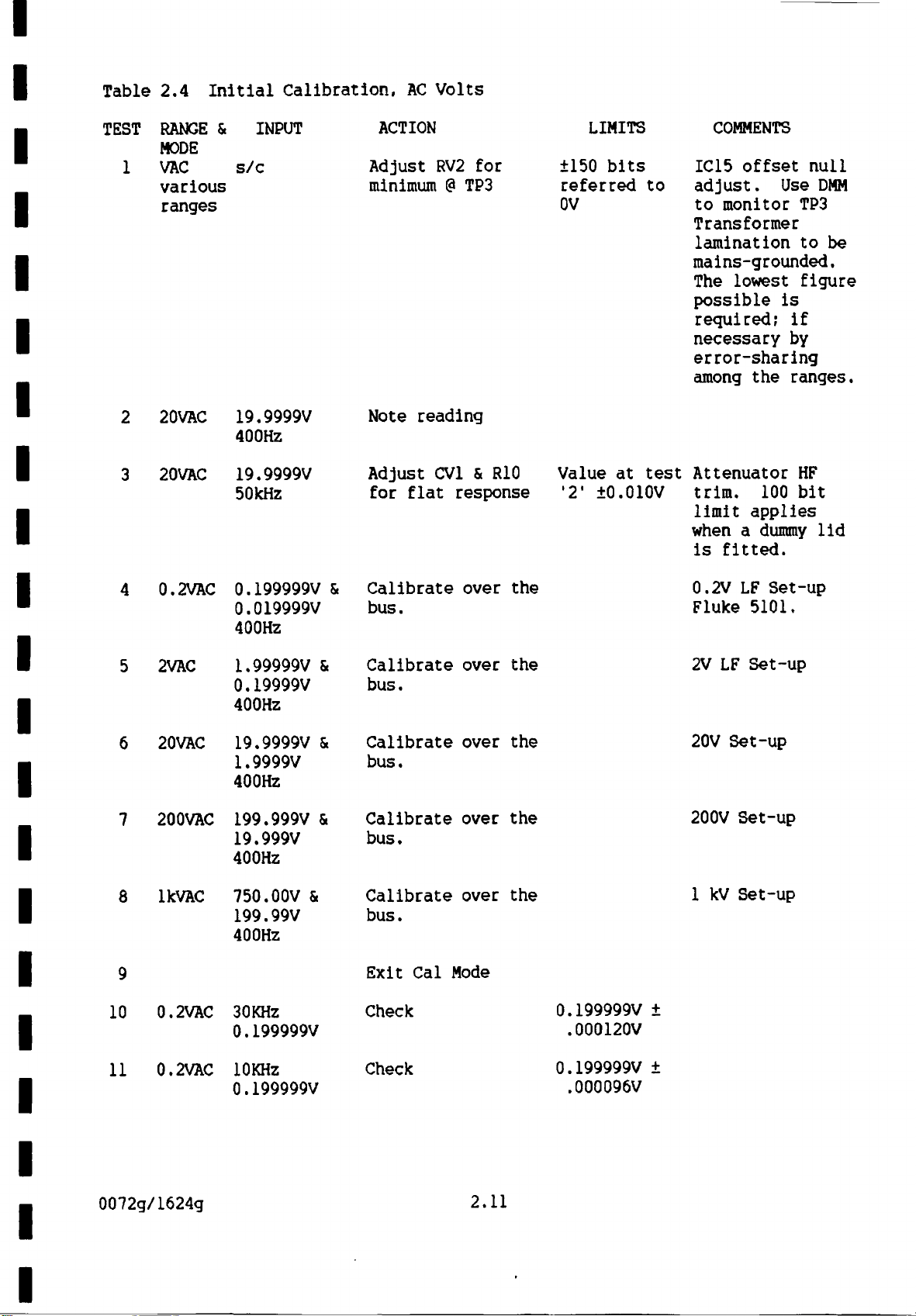

Table 2.4 Initial Calibration, AC Volts

TEST

1

2

3

RANGE &

MODE

VAC

various

ranges

20VAC

20VAC

INPUT

s/c

19.9999V

400Hz

19.9999V

50kHz

ACTION

Adjust RV2 for

minimum @

TP3

Note reading

Adjust CV1 St R10

for flat response

LIMITS

±150 bits

referred to

OV

Value at test

12'

±0.0

10V

COMMENTS

IC15 offset null

adjust.

to monitor TP3

Transformer

Use

DMM

lamination to be

mains-grounded.

The lowest figure

possible is

required; if

necessary by

error-sharing

among the ranges

Attenuator HF

trim. 100 bit

limit applies

when a dummy lid

is fitted.

.

10

4

5

6

7

8

9

0.2VAC

2VAC

20VAC

200VAC

IkVAC

0.2VAC

0.199999V &

0.019999V

400Hz

1.99999V &

0.19999V

400Hz

19.9999V S>

1.9999V

400Hz

199.999V S.

19.999V

400Hz

750.00V &

199.99V

400Hz

30KHz

0.199999V

Calibrate over the

bus.

Calibrate over the

bus.

Calibrate

bus.

Calibrate over the

bus.

Calibrate over the

bus.

Exit Cal Mode

Check

over the

0.

.000120V

199999V ±

0.2V LF

Fluke 5101.

2V LF Set-up

20V Set-up

200V Set-up

1 kV

Set-up

Set-up

11

0072g/1624g

0.2VAC

lOKHz

0.199999V

Check

2.11

0.

199999V ±

,000096V

Page 25

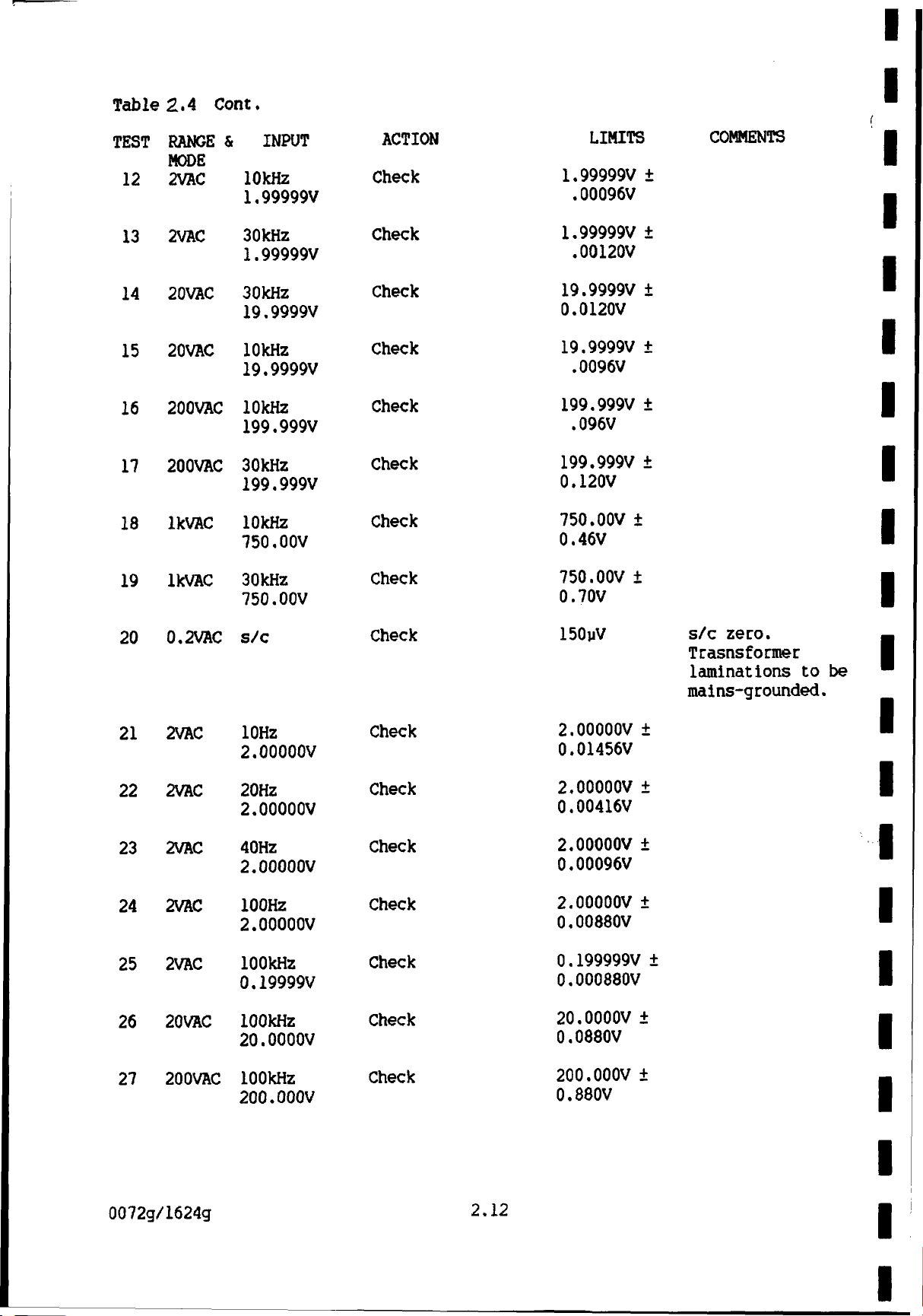

Table 2.4 Cent.

TEST

12

13

14

15

16

17

18

19

RANGE &

MODE

2VAC

2VAC

20VAC

20VAC

200VAC

200VAC

IkVAC

Ik VAC

INPUT

10kHz

1.99999V

30kHz

1.99999V

30kHz

19.9999V

10kHz

19.9999V

10kHz

199.999V

30kHz

199.999V

10kHz

750.00V

30kHz

750.00V

ACTION

Check

Check

Check

Check

Check

Check

Check

Check

LIMITS

1.99999V ±

.00096V

1.99999V ±

.00120V

19.9999V ±

0.0120V

19.9999V ±

.0096V

199.999V +

.096V

199.999V ±

0.120V

750.00V +

0.46V

750.00V +

0.70V

COMMENTS

20

21

22

23

24

25

26

27

0.2VAC

2VAC

2VAC

2VAC

2VAC

2VAC

20VAC

200VAC

s/c

10Hz

2.00000V

20Hz

2.00000V

40Hz

2.00000V

100Hz

2.00000V

100kHz

0.19999V

100kHz

20.0000V

100kHz

200.000V

Check

Check

Check

Check

Check

Check

Check

Check

150yV

2.00000V ±

0.01456V

2.00000V ±

0.00416V

2.00000V ±

0.00096V

2.00000V ±

0.00880V

0.199999V ±

0.000880V

20.0000V ±

0.0880V

200.000V ±

0.880V

s/c zero.

Trasnsformer

laminations to be

mains-grounded.

0072g/1624g

2.12

Page 26

Table 2.4 Cent

.

TEST RANGE & INPUT

MODE

24 2VAC

Auto

750V/400HZ Check

applied 5

times

ACTION

LIMITS

750.00 ±

0.46V

COMMENTS

750VAC

Autocange

test. Lo and

GUARD

must

connect to LO of

Calibrator and

also mains

ground. 7151

must uprange with

no signs of

distress.

0072g/1624g

2.13

Page 27

Final Calibration Procedures

7151 should be fully cased and

four hours and switched on for at least two hours prior to final

calibration. GUARD and LO should

placed in a

20,,C

environment for at least

be mains-grounded to minimise

series-mode interference. For this reason, use of the screened leads is

essential for HI fi measurement.

Note that the four screws which retain the top

be fully tightened to make the case screening

section of the case

effective.

must

The final calibration procedures are detailed in the following tables;

Table

2.5

2.6

2.7

2.8

2.9

2.10

No.

Final

Final

Final

Final

Final

Other

Procedure

calibration, DC Volts

calibration. Resistance

calibration, AC Volts

calibration, Current

calibration, Recheck

Checks

Q072g/1624g

V.

2.14

Page 28

Table 2.5 Final Calibration, DC Volts

TEST

1

2

3

4

5

RANGE &

MODE

0.2VDC

2VDC

20VDC

200VDC

IkVDC

INPUT

+0.100000V &

0.000000V the bus

+

1.9999V &

0.000000V

+19.

9999V &

0.000000V

+199.

+1000.00V

Sc

999V Sc

0.000000V

o.oov

ACTION

Calibrate over

Calibrate over

the bus

Calibrate over

the bus

Calibrate over

the bus

Calibrate over

the bus.

LIMITS

200mV range Cal. zero

volts to be

commanded from

Calibrator.

2V range

volts from

Calibrator on its 2

volt range.

20V range

volts from

Calibrator on its 20

volt range

200V range Cal. zero

volts from

Calibrator.

COMMENTS

IkV range

Cal. zero

Cal. zero

.

Cal.

0072g/1624g

2.15

Page 29

Table 2.6 Final Calibration, Resistance

TEST

1

2

3

4

5

RANGE &

MODE

2KS2

20142

200142

2M£2

20M$2

INPUT

1K$2 & IQ

10142 5. IQ

100142 &

IS

IMS &

IB

10MB &

IB

ACTION

Do calibration

over the bus

Do calibration

over the bus

Do calibration

over the bus

Do calibration

over the bus

Do calibration

over the

bus

LIMITS

COMMENTS

4 terminal connection

4 terminal connection

to be used.

Use screened lead

Use screened lead

0072g/1624g

2.16

Page 30

Table 2.7 Final Calibration, AC Volts

TEST RANGE & INPUT

MODE

1 0.2VAC 0.

2 2VAC

3 2QVAC 19.9999V

4 200VAC 199.999V

5 IkVAC 750.00V

199999V

& 0.0199999V

400Hz

1.99999V

& . 19999V <a

400Hz

& 1.9999V @

400Hz

& 19.999V @

400Hz

& 199.99V

400Hz

ACTION

Do calibration

over the bus

Do calibration

over the bus

Do calibration

over the bus

Do calibration

over the bus

Do

over the bus

calibration

LIMITS

COMMENTS

0072g/1624g

2.17

I

Page 31

Table 2.8 Final Calibration, Current

TEST

1

2

RANGE &

MODE

2ADC

2A AC

INPUT

1.00000A

and o/c

1.99999A

& 0.19999A

400Hz

ACTION

Do

calibration

LIMITS

COMMENTS

over the bus

Do calibration

over the bus

0072g/1624g

2.18

Page 32

Table 2.9 Final Calibration

Recheck (Filter In)

TEST

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

RANGE & MODE

2ADC

2AAC

2k®

20k$2

200k£2

2MS2

20MS2

0.2VAC

2VAC

20VAC

200VAC

Ik VAC

0.2VAC

20VAC

0.2VDC

2VDC

20VDC

200VDC

1 kVDC

1 kVDC

200VDC

20VDC

2VDC

0.2VDC

INPUT

1.00000A

1.9999A/400HZ

l.OOOOOKfi

lO.OOOOkQ

lOO.OOOkfi

l.OOOOOMfl

lO.OOOOMfi

0.199999V 400Hz

1.99999V 400Hz

19.9999V 400Hz

199.999V 400Hz

750.00V 400Hz

IQ (short circuit)

19.9999V 50kHz

+0.

199999V

+

1.99999V

+19.9999V

+199.

999V

+1000.

-10000.

00V

00V

-199.999V

-19.9999V

-1.99999V

-0.199999V

LIMITS

20 bits

100 bits

4 bits

4 bits

5 bits

5 bits

40 bits

100 bits

100 bits

100 bits

100 bits

46 bits

250 bits

300 bits

6 bits

6 bits

6 bits

6 bits

4 bits

4 bits

6 bits

6 bits

6 bits

6 bits

0072g/1624g

2.19

Page 33

Table

2.10 Other Checks

TEST

1

2

3

4

5

6

RANGE &

MODE

DC Auto

AC Auto

INPUT

1.5kV max.

See Fig.

See Fig.

25 Ampere

5 seconds

1.5kV rms

2.1

2.2

ACTION

Do flash test

Check

Display

Check Display

Perform earth

continuity test

Fit mains fuses

appropriate to

supply voltage.

Flash Test LO to

Earth.

LIMITS

0 + 500yV

0 ± 340yV

0.5Q

250mA SLO

BLO or 100mA

SLO-BLO

COMMENTS

Safety test to IEC

348. Refer to

Solartron

Specification

09/00/105.02. Power

switch

DC Common

ON.

Mode

Rejection 120dB.

AC Common Mode

Rejection 120dB.

As Test 1.

Q072g/1624g

2.20

Page 34

Figure 2.1 DC Common Mode Rejection

+ O

500V

Figure 2.2 AC

Mains O

Line

Common Mode

lOkfi

IkQ

Rejection

external

LINK

7 V HI

9

v

LO

^ GUARD

> V

HI

7151

MULTIMETER

7151

MULTIMETER

Ikfi

3 V LO

S GUARD

0072g/1624g

2.21

Page 35

Page 36

Chapter 3

Dismantling & Reassembly

1642g/0072g

Page 37

(

Page 38

CHAPTER 3

DISMANTLING AND REASSEMBLY

3.1 GENERAL

The 7151 must be disconnected from the mains supply before proceeding

with these Instructions.

3.2 DISMANTLING

1. Pivot the

carrying handle to the rear of the case. Pull out the

handle lugs from the pivot points on each side of the case and remove

the handle.

2. Remove the four screws from

the bottom of the case and then

withdraw

the top section of the case to expose the copper track side of PCB 1.

3. Compress the two plastic snap fasteners, located on

side of PCB 1 (as viewed from the unit front) to release the pcb.

Pivot the pcb outwards to gain access to the board components and to

the right hand

expose the screening pcb and the mains transformer.

4. Remove the two screws from the holes located in the mains transformer

laminations and withdraw the complete instrument assembly from the

bottom section of

the plastic stand-off fasteners which retain the screening

the case. PCB 2 can now be accessed by unclipping

board to

PCB 2.

5. At the left of the front panel assembly, remove the self-tapping

screw which secures the front panel assembly to a clip on PCB 2.

Unplug the front panel assembly from PCB 2.

6. To gain access to PCB 3, remove the six screws

to the front panel. Note that PCB 3 remains attached to the front

which

secure the pcb

panel by the keyboard ribbon cable.

3.3 REASSEMBLING

1. Fit PCB 3 to the front assembly using the six screws.

2. Carefully plug the front panel assembly into PCB 2. Check that all

of the connecting

pins on the front panel assembly are correctly

inserted into the socket pins on PCB 2.

3. Fit the self-tapping screw which secures the front panel assembly to

PCB 2.

4. Attach the screening pcb to PCB 2 by use of the plastic stand-off

fasteners.

5. Insert the complete instrument assembly into the bottom section of

the case. Insert the two screws into the holes on the mains

transformer laminations and tighten to secure the

bottom section of

the case.

00072g/1626g

3.1

Page 39

F

6. Secure PCB 1 by

use of the two plastic snap fasteners located on

right hand side of the pcb.

7. Dress the cables on the top

in the

board which locate the extended lugs in the top section

of the screening board clear of the holes

case.

8. Insert the top section

of the case onto the instrument assembly and

secure the top section to the bottom section by the four screws

inserted into the

bottom section

of the case.

NOTE: It is important that these four screws are fully tightened

otherwise the case screening is made ineffective and consequently the

ac calibration

9. Fit the

handle by lining up the locating lugs on the handle with the

could be impaired.

pivot points on each side of the case and then press the handle lugs

into the pivoting points on the case.

the

of the

00072g/1626g

3.2

Page 40

REAR PANEL SECTIONS

f

The instrument pictured is not 7151, but a similar instrument and is

intended only to show the functional assembly

.

7151

DISMANTLED

FIG 3.1

Page 41

Chapter 4 Circuit Descriptions & Diagrams

Page No.

4.1

4.2

4.3

4.4

Contents

General

Measurement of voltage, dc

Measurement of voltage, ac

Measurement of resistance

Measurement of current

Input amplifier

Drift correction

Input protection

Analogue to digital converter

Reference supply

4.5

4.6

1642g/0Q72g

Floating

Logic

Earthy Logic

Page 42

Page 43

CHAPTER 4

1. GENERAL

CIRCUIT DESCRIPTIONS AND DIAGRAMS

All multimeter inputs are at some stage processed

by the Analog to

Digital Converter (ADC) whose operating range is limited to ±2.6V. The

range of measurement is extended beyond this figure by

to the 2V range. For example, a

would

be seen by the ADC as only 2V. Non-dc inputs must of course

200V

input scaled

by a

scaling all inputs

factor of 0.01

undergo conversion to dc as well as attenuation and scaling.

2. MEASUREMENT OF VOLTAGE, DC

The dc voltage input attenuator consists of the resistors R1A to RID.

The attenuator is switched by FETs TR7, TR8, and relay

range control inputs from the floating logic. The attenuator setting,

RLK in response to

xl, xO.Ol, xO.OOl depends upon the selected voltage range, i.e.

Range(V)

0.2

,

2

20

,

200

1000

Attenuation

xl

xO.Ol

xO/001

Circuit Path

Direct to input amp. via RLE

RLK, TR7, with RLE open

RLK, TR8, with RLE

open

The attenuated outputs are then amplified by the input amplifier, whose

gain is arranged to

be xl or xlO to ensure satisfactory scaling at

the

ADC.

Input switching - The dc voltage inputs to the input amplifier are

selected via the series FET TR7 and the shunt FET TR6. With TR5 on, TR6

is off, and vice versa.

TR6 is switched

current measurement,

on during ac

and

during 'drift correct

(voltage or current) measurement,

'.

during dc

3. MEASUREMENT OF AC VOLTAGE

For Vac operations, inputs are first scaled to the 2V range

by the ac

signal conditioning circuits and then converted into a dc voltage.

AC inputs are subject to the ac input attenuator which is switched by

IC18, TR1, TR2, and by the op. amp. IC15. It's gain is set,

via IC18 to

be either xl or xlO. For inputs on the 2V range, no conditioning is

required; quad analog switch IC18 selects the gain of IC15 (via the

matched resistors R21A and R21B) to be set at unity, with inputs to the

amplifier passed through RLA, RLE and RLF contacts. The overall circuit

gain for other input ranges is selected by TR1 and IC18 in response to

range and control inputs from the floating logic.

Range(V)

0.2

2

20

200

1000

Attenuation

xl

xl

xO.Ol

xO.Ol

xO.OOl

Amp. I/P(V)

0.2

2

0.2

2

1

Gain

xlO

xl

xlO

xl

xl

Amp 0/P(V)

2

2

2

2

1

IC21. The

DC conversion is performed by the

true rmsto dc

maximum 2V output from this IC is switched to the dc input

converter

amplifier IC1 via the shunt input FET TR6 and via quad analog switch ICS.

1639g/0072g

4.1

Page 44

4. MEASUREMENT OF RESISTANCE

This is achieved by measuring the voltage developed across the unknown

resistance when a

voltage is then measured by the dc voltage measurement circuit.

Current Generator

IC3 is a

supply from the reference circuit. The

reference. Thus IC3 drives TR3, maintaining a IV differential across the

resistors R73, R74, R75 and R15. Control inputs from the logic circuitry

switch this resistor chain (via TR4, TR9, and

currents. The test currents for the various ranges are:

Mhen checking

available at the Hi ohms source terminal is returned via the Lo ohms

source terminal.

For the ranges other than 20MS2, the logic control, via IC2, also

switches in the resistor chain R7, R27 and R56

the Lo ohms source terminal and the -3.1V reference. This part of the

circuit acts as a calibrated

precision operational amplifier to

Nominal Range

20MQ

200k$2

20kS2

4-wire

Circuit

2MQ

2kQ

known

current is passed through it. The resultant

which is connected the +1QV

other amplifier input is the +11V

RLD) to define four test

Test Current

lOOnA

luA

10uA

lOOvA

lOOuA

measurement circuits ensure that all current

which is connected between

current sink for the test current generator.

Protection

R4 (22k) which is in series with both the 1+ and V+ input terminals.

Diodes D2 and D25 limit the

-2.6V.

5. MEASUREMENT OF CURRENT

This is achieved

resistance when the unknown current passes through it. The voltage

obtained can be measured by the dc input amplifier directly or for ac

inputs, via the AC-DC

DC Current Input

Resistor R3 is a 0.1$) shunt through

flows. The

via the quad switch ICS and shunt FET TR6. The gain

for dc current; the amplifier output is thus correctly scaled on the 2V

range for

AC Current Input

For ac inputs, the potential across resistor R3 is switched, via the quad

switch IC18 and FET TR2, to the ac operational amplifier IC15. The gain

of IC15 is set to xlO for ac current inputs; thus the inputs to the AC to

DC converter are scaled to the 2V range. After AC to DC conversion, the

output voltage is switched to the dc input amplifier via the quad switch

ICS and shunt FET TR6.

of the resistance

by

measuring the potential produced across a known

converter.

potential across R3 is switched to the dc input amplifier IC1

A to D conversion.

measurement circuit is provided by resistor

voltage of

TR3 and R4 to between +5.3V and

which the current to

be measured

of IC1 is set to xlO

Protection agains excessive current is by the 2A fuse, FI.

1639g/0072g

4.2

Page 45

6. INPUT AMPLIFIER

Input amplifier IC1 is a precision FET input operational amplifier.

Signals for IC1 are firstly amplified

by the dual FET pre-amplifier,

TR13, whose bias is provided by transistor TR14 and diode D7.

Inputs to the pre-amplifier are selected

(series FET) or TR6 (shunt FET) depending on the selected multimeter

function. For dc measurement functions (including resistance) TR5

either by switching on

TR5

conducts; for ac functions, or during drift corrections, TR6 conducts.

The gain of the pre-amplifier is controlled by IC2 in response to range

control signals from the floating logic. IC2 is a quad

analog

switch

connected across IC1 feedback resistors R18 and R19. The switching of

IC2 sets the overall gain of the pre-amplifier and IC1 to be xl or xlO

depending on the selected input range or measurement function. The gain

settings can be summarised as follows;

for DC

voltage

ranges

for DC

current range

Range (V)

0.2

2

20

200

1000

Range (mA)

2000

Gain

xlO

xl

xlO

xl

xl

Gain

xlO

for AC

current range

Range (mA)

2000

Gain

xl

7. DRIFT CORRECTION

A 'drift correct1 is

originating in the input amplifier or from

necessary in order to compensate for any drift

the ADC. Typically, drift

results from component aging or temperature fluctuations.

During a drift correct cycle, the input amplifier is isolated from any

measured input (series FET TR5 off) and connected to signal OV (shunt FET

TR6 on). With

due to drift. This is subsequently subtracted from a

zero input to the amplifier, any resultant count is then

measurement count

to provide a final count (i.e. result) free from error.

8. INPUT PROTECTION

Protection against voltage overload of the input amplifer is by spark-gap

SG2 (1400V nominal) which is connected across the VHI and VLO terminals.

Resistors R9 and R25 form a

current limiter, and

diodes D6 and D26 limit

series inputs to the amplifier to ±2.6V.

1639g/0072g

4. 3

Page 46

9. ANALOGUE TO DIGITAL CONVERTER (ADC)

This circuit converts the

digital pulses.

These

analogue output from

are used to gate

clock into a reversible counter

the input amplifier into

in the MPU, IC103, to produce a count proportional to the measured input

The Integrator

The integrator, ICS has the following inputs connected to its summing

point:

1. The input to

be measured

2. The forcing waveform

3. + reference or - reference

With zero input applied to the

waveform applied continuously to the integrator, the

alternately positive and

negative through the thresholds of the

multimeter and a 300Hz forcing square

output is driven

comparators IC9 and IC10.

The states of the two comparators are followed by the bistable, IC11

which

synchronises the transistors to a clock. The outputs from IC11

control the analogue switch IC16 which switch the + and - reference

supplies (through OV) to the integrator input. This closed loop feedback

arrangement ensures that the output is always dynamically balanced about

zero.

.

The synchronised output of the bistable, IC11, is also

passed to IC103 where the

pulses are counted.

NANDed by IC17 and

10. REFERENCE SUPPLY

This circuit generates the +10V

generator and the + and -3.1V supplies for the ADC. The reference

D20, together with the resistor network R38, R42, R17 and RV1, ensures

and +11V supplies for the ohms current

diode,

the input to IC4 is held at 3.1V. D20 also forms the + reference supply,

via IC6a and IC16, for the

ADC. The output of IC4 forms the -3.1V

reference supply.

All references are with respect to the 0V ROME.

The + reference voltage is also used as the input to IC6b. This is an

amplifier which drives a current through-R14, R57 and R16 in

order to

maintain the reference at balance. The resistor chain is tapped to

provide the +10V and +11V reference voltages for the

generator

.

ohms current

1639g/0072g

4.4

Page 47

11. FLOATING LOGIC

This circuit includes the floating logic microprocessor (MPU),

This IC communicates with the earthy logic MPU

via a 2-wire optically

IC103

.

coupled serial link. The circuit can be considered to have four separate

functions:

1. Controls range and

mode switching on

the analogue pcb.

2. Generates the forcing waveform for the ADC.

3. Counts the pulsed output from the ADC.

4. Stores calibration constants and checksum for use during auto-cal

procedures

Note:

The circuit automatically resets to a known state in the event

.

of a system lockout.

11.1 Analogue Control Lines

These MPU outputs are connected to drivers, comparators and bi-lateral

switches on the analogue pcb. The outputs, via their respective

switching

devices, correctly configure the circuits for the selected

multimeter range and function.

11.2 Forcing Waveform

The "timer-out"

generate the forcing

signal is converted into a 0 to 8V

signal from the MPU is a 300Hz waveform which is used to

waveform for the A to D converter.

square wave by

the bi-lateral switch

The TTL level

ICS in the analog circuit.

11.3 Counting Circuit

Timer-in is an input to the MPU which is derived from the ADC. The input

is a single, clock synchronised

alternatively, the length of

pulse-train; the pulse widths indicating

time the + and - reference voltages were

applied in order to balance the integrator. Within the MPU, these pulses

are used to gate clock into a reversible counter to produce a nett count

proportional to the measured input

.

11.4 Non-Volatile Memories

IC’s 105 and 106 are EAROMs which hold the automatic calibration program

for the multimeter and the calibration constants for each mode/range

selected.

11.5 Reset Watchdog

This circuit causes the floating MPU to be reset in the event of system

lockout.

The circuit operation is similar to that described for the

earthy logic reset circuit (page 2.11).

A 1.2288 MHz clock derived output from the MPU is divided by a 12-bit

binary counter IC 107. The 300Hz (3.33ms period) output from

this IC is

counted by the 4-bit counter, IC108.

The serial link TX DATA line from the ea

IC108. This input holds off the RESET output unless the RX DATA line is

inactive for more than 26.664ms (8x

period)

rthy

MPU, is also connected to

.

With the RESET line active, bistable IC112 (see ADC) is also reset,

thus

MPU pin 8 (TIMER IN) is set to a logic 1 state. Pins 8, 9, and 10 are

set to this state at initialisation.

1639g/0072g

4. 5

Page 48

12. EARTHY LOGIC

This includes the microprocessor set, the remote control interfaces, the

watch-dog reset circuitry, the analog to digital converter (analog

output),

clock and the interface switch decoders

.

MPU set

This consists of

IC 212 :

IC 207 :

IC 208 :

8 bit MPU

16K x 8 bit ROM

8K x 8 bit RAM

GPIB Interface

This consists of

IC 203 :

IC 202 :

IC 201 :

IC 203 consists essentially of 15

into by the

to RS2, 8 can be read by

MPU and, depending on the state of

the MPU.

The transceivers IC201 and 202 are bidirectional and consist of eight

driver/receiver pairs

each. Each driver/receiver is enabled by a

send/receive input (T/Rl and T/R2) with the disabled

general purpose interface adaptor

octal transceiver

octal transceiver

registers, 7 of which

control lines R/W and RSO

output forced to a

can be written

high impedance state. All GPU) signals are TTL level.

12.2 RS232 Interface

This consists of IC 204 : RS232 interface adaptor

IC 218 : RS232 line driver

IC 219 : RS232 line receiver

IC204 is essentially a

reversible 8 to 1 line decoder for the

transmission and reception of data via the TxD and RxD lines. IC218 and

219 serve to

buffer and level-shift the various signals to/from

RS232

levels (±12V).

12.3 Analog Output

This is generated by the 8-bit digital to

voltage

between the

Hi and Lo lines should bot exceed +10V, or be less

analog

converter, IC205. The

than OV.

12.4 Address

The

MPU addresses the various bus connected devices and the watch-dog

reset circuitry via the decoder, IC209. The ROM, IC207, is addressed

separately by the

Decoders

A15 (inverted) address line.

12.5 Clock

IC206 is a real time clock which is responsible for generating accurate

time signals for the MPU

and provides control signals for other

circuits. The clock frequency is factory adjusted to exactly 32.768kHz.

If the frequency is to

directly

across the crystal as this will produce a false reading.

Instead, the frequency

suitably buffered and divided by four. i.e. 8.1920kHz±0.1Hz. The

frequency can

be adjusted with C217.

be

checked, test probes must not be placed

should be

measured at

IC206/pin 21 where it is

Whilst the instrument is switched-off,

(pin 22) by the

1639g/0072g

back-up

battery, BAT 201 (approx. 4.5V).

standby power is supplied to IC206

4.6

Page 49

12.6 Reset Watchdog

This resets the MPU and the display in the event of a system lockout. A

0.6144MHz clock derived

12-bit binary counter IC216. The 150Hz (6.6ms period) resultant output

is checked

by the counter, IC217.

output from the MPU is further divided by

the

12.7 Display and Keyboard

This circuit has two main functions:

1. to decode display and command data

2. to transfer keyboard selections to the MPU

12.8 Display

The display circuit includes custom

undergoes selt-test for approx. 2 secs. The display is of the matrix

type

where it takes both column and

segments (see diagram of display layout).

pulses that alternate about 0V; this ensures that the crystals do not

LCD X301. At switch-on, the display

row

signals to activate

The display is driven by

particular

become permanently polarised.

The driver for the display is IC301 and is serially interfaced with the

'earthy* logic via pins 8->13. With CS (chip select), data can be sent

on the serial input (SI) line. A data bit is sent for every +ve going

transition of SCK; on the eight on, the BUSY line is made low until the

IC is ready to accept more data.

The serial input may just be data for display, in which case the control

data (C/D) line remains in its active low state. However, for driver

commands,

such as blanking or flashing the display, C/D is set to active

high.

12.9 Keyboard

The (vertical) column outputs from the keyboard are connected directly to

the

MPU and, with no selections made, held in the logic 1 state via

pull-up resistors on the earthy logic pcb. Keyboard (horizontal) rows

are scanned via output latch IC210 and BCD-to-decimal decoder,

IC302.

12.10 Power Supplies

Both PCB1 and PCB2 have on-board power-supply regulation, supplied by a

common

the regulated 5V

derived from PCB2's unregulated 5V

mains transformer. The display board logic derives its power from

supply

of PCB2

whilst the display backlighting

power is

supply. The -25V supply of PCB1 can

only be enabled by insertion or a shorted CAL plug, and is reguired to

re-program the calibration constants held in the EAROMs (ICs 105 & 106).

1639g/0072g

4. 7

Page 50

aep-fA*

Page 51

I

PCBl,

SHT 1 OF 3,

FLOATING ANALOGUE

DIAGRAM 4,1

Page 52

BROWN WIRE TO PHS01/11 O-

ORANOE WIRE TO PH50W3 1 O-

/ ^

PH >01

/I

fieo

WIRE TO PH601/?

YELLOW WIRE TO PH501K.

PH1Q1

IL

(

POWER SUPPLY

-cf>

C151

NEGATIVE

NON - VOLATILE

MEMORIES

270

)

IS CONNECTED

3 IS OPEN CIRCUIT

1

PIN NUMBERS

+ 5V OVP -5V -2SV

14

7,21

7

'6

*

-

'

-

>

-

6

-

7

-

-

-

■

-

-

P37 -

P36 i

P35 :

P34 -

P32 ■

P3I j

P30 ■

1C N« DEVICE TYPE

76LS04

10?

HO68P01VOS

103

- IC13/7

» TC14/A

S CONTROL

ANALOGUE

*35,106

107

*36

NC 7033

404066

74LS197

PCB1,

SHT 2 OF 3,

FLOATING ANALOGUE

DIAGRAM 4.2

Page 53

1C15I

-IC154

IC15I

IC152

1C156

!C153 h

,C,”o7

IC154

IC153

}FD

GROUND

GROUND

^OUTPUT

j

ICI55

IC1S7

WIRES TO PCS

2

j FLOATING'ANALOGUE POWER SUPPLIES

DIAGRAM

4.3

Page 54

?

5

l

1C214

k

5

5

i

IC215

♦SvfFLOATI

f

- BROWN WIRE

1

1

1

:

Opol7

i

|

-ORANGE WIRE

1C No

201,202

203

206

205

206

207

208

209

210

211

212

213

216

217

218

219

220

221

222

223

226

225

Type4

MC3667

MCS36B8

SY6S51A

A0558

HOU60I8

27128-6

HD6266P15

74US139

76LS376

76W5373

H06301

76LSH5

MC140408

74LS197

SN75190

SN75152

LM339

MCH071B

74 L

500

76L504

76 L5

03

MC16068B

PIN NUMBERS

ov

3V

24

12

20

1

1

IS

—

12

12

—

u

29

— —

16

20

10

20

10

21

1

16

B

16

8

14

—

—

12

—

7

14

16

H

7

16

7

-17V+

—

—

—

—

—

—

—

—

—

—

—

—

— —

9

—

—

—

—

—

—

12V

CMOS POWER

—

—

—

11

—

—

—

—

—

—

— —

—

—

6

16

—

—

— —

—

—

—

-

—

—

—

—

24

—

28

—

—

—

—

—

—

—

—

—

14

—

—

—

1C217

C232

OyOA7

IC222

1C223

1C22-

1

C228

0p0C7

C229

OpOA7

g>-

oe IC220d

SPARE GATES

po

ji>

ov IC221C

R207 NOT USED

PCB2, EARTHY LOGIC

DIAGRAM 4.4

Page 55

N2V SCHAFFNER FN372-2/

21

QRANQg WIRE

FUSES

SLO-BLO 1

1100/120: 250mA

220/240

:100mA

RED WIRE

> CABLE FORM TO PCBt

IC253

IC25!

IC251

IC257

1

I

i

i

i

DISPLAY BOARD

BACKLIGHTING

EARTHY LOGIC POWER SUPPLIES (5= MAINS POWER)

DIAGRAM 4.5

Page 56

UNRECULATEO

VOO VDO

IC303(A)

IC303;

T

i

acposs “

ins

fc

AKO 75F inoi

bi

isa'iosof

I

:c302

IC30I

LIQUID CRYSTAL DISPLAY X30I

PLUGS ATI SiO02 AND SK30;

IC302

anna

nnan

□□□□

□□□□

ARE NOT USED

Qe

FRONT VIEW OF PCS

f:ex!9l

£

C0NN5CTQ?

APPROACHES

SK1CLFPCM

THE RIGHT

PIN NUMBERING FOR FLEXI -CONNECTOR

KEYBOARD VlEV.EO

FROM FROfif <«<£ /PADl

□ □ □ □

FACE

□ □an

□ □ □ □

□ □ □ □

PCB3,

DISPLAY AMD KEYBOARD

DIAGRAM 4.6

Page 57

tDO

&

A

J LJ

-A

j

~7~

^

—7 ™

___z_____

nOA AUTO-HOLD FILT CAL NULL COMP ERR 6X0

7

4

50

26

backpl

ane

®

=

crossover

DISPLAY

DIAGRAM 4.7

segment

plane

WIRING.

Page 58

^T

OUTER SR&iO

nr

OUTER BRAIO

m

PCB1/0P6 AMI

PC8W0P2 VH[

PCBV0P5 GUARD

PCBW0P3 10

PCB1/0P1 H

PCBVDPA [-

, P/fi LOGIC INPUT

PC93/PAD'S'

TOP VIEW OF SWITCH

o 1

i

FRONT/REAR SWITCH

WIRING

DIAGRAM 4.8

Page 59

Chapter 5

Fault Diagnosis Guide

1642g/0072g

Page 60

(

Page 61

Chapter 5

Symptom

Possible Fault

Procedure

Instrument 'dead*

Fuses keep blowing

'Fail 1' displayed

at power-up

'Fail 2' displayed

at power-up

No mains power

A

good check is to look for the display

backlights. If no lights check fuses

and supply

Rectifier, regulator Correct current drawn from the

or smoothing

for 240V on 240V

voltages.

mains

setting: approx 60mA,

capacitor faulty. for 120V on 120V setting: approx 120mA.

Under fault conditions (regulator

blown) current may typically

be in

order of 500mA. Look for correct

output from each regulator IC.

Communication

breakdown

between

Check opto-couplers IC214 & IC215,

IC102, and the connecting wires and

floating and earthy plugs (to PCB 1). Look for activity on

logic

Problem with

Real- Leave 7151 switched on for 24 Mrs,

time clock IC206,

possibly caused by

battery BAT201 being and on again. If 'Fail 2' still

discharged.

the TX and RX lines.

displaying 'Fail 2', to recharge battery

(or fit a good replacement). Switch

displayed, switch off, remove turret

lug link (if no link, remove battery)

and momentarily

0V to reset the

short IC206 pin 22 to

chip. Also check that

pin 21 is exactly 8.192kHz (derived

from X203)

.

off

Amps range

'does not work'

Display inoperative

Display 'sluggish'

or too faint

7151 doesn't

perform 'correctly'

via remote control,

i.e. perhaps

occasional errors

occur.

2A fuse on rear

Check fuse,

panel blown.

Poor connections

Remake all connections and

verify 100%

between display and contact. Look for the following shaped

IC301, or of the

header PL301 in

socket SK204

waveform on the IC301 outputs

_

SCHS31:

.

Also check the control lines of IC301

(e.g. ensure that RESET is not 'stuck').

Display not

Check setting of RV301 (see P2.5).

correctly driven

Poor contacts in

switch S201, or

fault in interface

chips, IC201, 202,

203 (for GPIB)

or IC218, 219, 204

(for RS232).

Toggle switches S201 to clear their

contacts and set as required. If no

improvement check chips by substitution.

In the case of the

GPIB, ensure that the

correct cables are being used, and

disconnect all instruments other than

the controller to

verify if 7151 is

faulty.

1643g/0072g

5.1

Page 62

Symptom

Possible Fault

Procedure

After calibrating New cal. constants

7151, it is still haven't been stored

out of

Very

be very difficult to decide where to start looking. However, for PCB1 and

PGB2 there are some basic checks that can be carried out to

search.

Board

PGB 1

calibration, in IC105 & 106.

often a fault will not fall into one of the above categories and it can

Check

All power supplies are within tolerance (see Chapter 2).

Waveform E at

TX and RX of

pins 11 & 12. It is sufficient just to look for activity

on the signal lines.

Forcing waveform of 300 Hz is generated by IC103 pin 9.

Reference

-3.1V respectively.

IC103 pin 40 is 1.2288 MHz.

data from PCB 2 (via opto couplers) on IC103

voltages at IC16 pins 9 & 6 should be 3.1V

Check that -25V is produced

pin 5 when the CAL plug is fitted, and

that it reaches IC105 & 106 pin 1.

help narrow

by IC157

the

and

PCB 2

Waveform at TP4 (IC 16 pin 10) should look like:

|_

RESET from IC 103 pin 6 for activity.

etc.

(

All power supplies.

Waveform E at IC212 pin 40 is 1.2288MHz,

TX and RX of

pins 11 & 12. It is sufficient just to look for activity

on the signal lines.

RESET from IC212 pin 6 for activity.

Pin 21 of IC206 (Real time clock) should be

8.192kHz,

data from PCB 1 (via opto couplers) on IC212

exactly

1643g/0072g

5.2

Page 63

Chapter 6 Parts Lists &

Component Layout

Page

6.1

6.2

6.9

6.12

6.12

No.

Contents

Parts List abbreviations

PCB 1

PCB 2

PCB 3

Miscellaneous

1642g/0072g

Page 64

?ri

ir

no£j::e,yqz.:Zi

!?i f1;

5v."iJ i V

3bb;C

orj.'.'WT', t':r'

b.'j.uow. r- '

i.?C*

Page 65

CHAPTER 6

PARTS LISTS

AND LAYOUT

DIAGRAMS

INTRODUCTION

This section contains component layout diagrams and detailed parts lists

for each of the three printed circuit boards and the front and rear

panels. When ordering

spare parts, it is essential to quote the

instrument serial number located on the rear panel as well as the full

description

of the item given in the appropriate parts list.

A description of the abbreviations used in the parts list is given as

follows:

COMPONENT PARTS LIST ABBREVIATIONS

CIRCUIT REFERENCES

B

C

D

FS

IC

L

LK

PL

R

RL

S

SK

T

TP

TR

X

Battery

Capacitor

Diode

Fuse

Integrated

Circuit

Inductor

Link

Plug

Resistor

Relay

Switch

Socket

Transformer

Terminal Post (or Test Point)

Transistor

Other Components

Also Used:

RV

Variable Resistor

COMPONENT TYPES

Fixed Resistors

CACP

MEFM

MEGL

MEOX

POWW

PRWW

TKFM

Variable

CMPM

0072g/1636g

Carbon Composition

Metal Film

Metal Glaze

Metal Oxide

Power Wirewound

Precision Wirewound

Thick Film

Resistors

Cermet Preset Multiturn

Capacitors

ALME

CARS

GERM

ESTF

ESTM

PTFE

TAND

6,1

Aluminimum Electrolytic

Polycarbonate

Ceramic

Polyester Foil

Polyester Metallised

PTFE

Tantalum Dry

Page 66

r

PCS

l

(71510501) Floating Logic and Analogue

Cct.

Rl

R2

R3

R4

85

86

67 •

68

89 <

810

811

812

813

814

R15

816

817

818

819

821

Bef.

CAD

1776

Ik

0.1

22k

10k

1.2k

30.9k

100k

47k

990k

9k+lk

3.3k

Ik

1452 1

9k

CAD1776

10k

9k

Ik

9k+lk

J

0.25W

3W

0.5W

0.125W

0.125W

0.25W

3W

2W

0.2W

0.25W

0.25W

matched

P^lr

0.125W

matched

pair

0.2W

General Description

TKFM

5%

0.5%

5%

10%

0.5%

0.25%

5%

2%

0.5%

0.1%

5%

5%

MEOX

PRW

MEGL

CACP

MEFM

MEFM

MEOX

MEGL

MEFM

TKFM

MEOX

MEOX

0.25%

£

TKFM

0.5%

MEFM

0.25%

0.1%

TKFM

Solartron

Part No.

195631000

160300506

176442200

172341000

192731202

192843094

198651000

175244700

160400487

160400582

195633300

195631000

169617201

•

160400583

192741002

169617001

160400582

820

824

822

823

825

826

827

828

829

830

831

832

833

834

635

636

83?

838

R3y

840

100k O

67k J

33k

30k

47k

33k

' 280k

Ik

100

100k

100k

22k

Ik

100

4.7k

4.7k

470k

10k

33k

33k

matched

pair

0.25W

0.125W

3W

0.25W

0.

125V

0.25W

0.25W

0.25W

0.25W

0.25W

0.25 V

0.25W

0.25W

0.25W

0.5W

0.125W

0.25W

0.25W

0.25%

5%

0.5%

2%

5%

0.25%

5%

5% ?

5%

5%

5%

5%

5%

5% -

5%

10%

0.5%

5% t

5%

MEOX

MEFM

MEGL

MEOX

MEFM . ;

MEOX "

■ *

i-''

MEOX "J;

MEOX,x

meox

;;:

MEOX

MEOX :

MEOX

MEOX « ;

MEOX

CACP

MEFM =

MEOX -

MEOX

...

Ci

1

169617101

195643300

••

192743002

175244700

195643300

192852804

195631000

P

c

n

vy:

j

V

'\ ‘‘:

kS.

we.

VJcS.

Wf1"''1 -

i>r:, r

.

-

(t

‘

o

,

c

c

195621000

195651000

195651000

195642200

195631000

195621000

195634700

195634700

172354700

192741002

195643300

195643300

0072g/1636g

•1 e-V-

6.2

Page 67

PCB

Get.

R41

R42

R43

R44

R45

R46

R47

R48

R49

R50

R51

R52

R53

R54

R55

R56

R57

R59

R61

R62

R63

R64

R65

R66

R67

R68

R69

R70

R71

R72

R73

R74

R75

R76

R77

R78

1 (cont

Ref.

33k

100

4.7k

470k

100k

Ik

1M

100k

200k

1M

62k

33k

Ik

56

10k

2.7M

10k

27k

180

180

10k

22k

22k

82k

22k

22k

Ik

4.7k

15k

1M

10k

90k

900k

1.0M

1 .OH

1.0M

.)

0.25W

0.125W

3W

0.5W

0.25W

0.25W

0.5W

0.25W

0.125W

0.25W

0.

125W

0.25W

0.25W

0.25W

0.5W

0.25W

0.125W

0.

125W

0.25W

0.25W

0.25W

0.25W

0.25W

0.25W

0.125W

0.

125W

0.25W

0.125W

0.125W

0.5W

0.2W

0.2W

0.3W

0.25W

0.25W

0.25W

'

"' -

General Description

5%

0.5%

5%

10%

5%

5%

5%

5%

0.5%

0.5%

0.5%

5%

5%

5%

10%

10%

0.5%

0.5%

5%

5%

5%

5%

5%

5%

0.5%

0.5%

5%

0.5%

0.5%,.

5% '

0.25%

0.01% '

0.25%

10%

10%

10% x

HEOX

HEFH

HEOX . .

CACP

HEOX

HEOX '

HEOX . ;

HEOX''

HEFH

HEFH

HEFH • •0

HEOX '

HEOX

HEOX

CACP

CACP

HEFH

HEFH

HEOX

HEOX

HEOX

HEOX

HEOX

HEOX

HEFH

HEFH

HEOX

HEFH

HEFH

HEOX

PRWW r:

PRWW

PRWW

CACP

CACP

CACP

"

r

r--u;tc,r

'' ' •

w “

kcC.O

"

r--

-

r

:

.

k

w

-

V..

0

'■

;

-'*=

u' '3 '

192752002

198261002 «?

192746202V1

' 195643300^

195631000

195615600'-

172341000“13

172062700'"

192741004

192742702'

195621800^0

195621800 '»

195641000

195642200

195642200

195648200 -9

192742202

192742202 %

195631000 ^

- 192734702

192741502

193561000 Sfi

160300505 M

160300438 1

160300504

172061000 TJd

172061000

172061000

•

Solartron

Part No.

195643300

192721002 ^

193734700 Sfl

172354700 CH

!>2

195651000

195631000 «!H

193561000

195651000 'S

8A

1

ik

<sl2

'H

•*

^

"Sii

a6?

5T

5.T8

£%

-fl

R79

R80

R81

R82

0072g/1636g

1 .OH

100

100

33

0.25W

0.25W

0.25W

0.125W

10%

5%

5% f

0.5%’'

CACP

HEOX

HEOX

HEFH '

■r*

6.3

172061000

'■

195621000

195621000 v.-.

192713302

»*

Ur'

Page 68

PCS 1

(cont

.)

Cctl

R101

R103

R104

R105

R106

R151

R152

RV1

RV2

RV3;

RLA

RLE

RLC

RLD

RLE

RLE

RLK .

Ref.

,

15k

270

1.5k

100

100

47k

180

200

200k

2k

relay

relay

relay

relay

relay

relay

relay

0.25W

0.25W

0.25W

0.5V

0.25W

0.25 V

0.25V

0.5V

0.5V

0.5V

GOTO

GOTO

GOTO

GOTO

GOTO

4000

7002

7002

7002

4000

RS12

GOTO 7002-

General Description

5%

5%

5%

1%

5%

5%

5%

10%

10%

10%

MEOX

MEOX

MEOX

MEOX

MEOX "

MEOX

MEOX

multiturn

multiturn

multiturn

-0002

-5005

-5085

-5086

-0002

-5085

cermet preset

cermet preset

cermet preset

Solartron

Part No.

195641500

195622700

195631500

195421000

195621000

195644700

195621800

130922000

110016220

130932000

301203400

301203300

301203500

301203600

301203400

300652190

301203500

Cl

C2

C3

C4

C5, ,

C6

C7

C8

C9

CIO

Cll

C12

Cl 3

C14

CIS

C16

C17(0,

C18 ^

CIS ,

C20 \

C21

C22 ' 5

C23,

C24"1'

200pF

0.22vF

lOnF

470pF

22nF

15nF

0.47uF

0.22vF

15nF

47nF

47nF

lOOpF

47nF

47nF

47nF

luF

2.2yF

47nF

47nF

47nF

47nF

lOyF

.„t,.10yF

>1 6.8pF

500V

400V

1000V

400V

100V

100V

100V

400V

25V

25V

160V

25V

25V

25V

100V

100V

25V

25V

25V

25V

25V

25V

500V

20%

20%

10%

10%

10%

10%

10%

10%

25%

25%

20% >

25%

25%

25%

10%

10%

25%

25%

25%

25%

20% •*

20%

20%

GERM

ESTM

ESTF

ESTF

ESTM

ESTM

ESTM

ESTF

GERM r

GERM

GARB

germ

GERM ‘

GERM

ESTM *

ESTM *

GERM

GERM

GERM

GERM - •

TAND

TAND

3 GERM

241322200

226152200

222841000

208100201

222342200

225441500

225454700

225452200

222341500

—

241944700

241944700

#

v(u.

'

V f

v

ci

208900004

241944700

241944700

241944700

-

W*

\fri'

-S

V;-:

225461000

225462200

241944700

241944700

241944700

a

:

Vf

i

241944700

'•-

208700108

208700108

v';

"-

241306800

0072g/1636g

6.4

Page 69

1 (cont.)

PCB

•c-) I g>:

Get.

C25

C26

C27

C28

C29

C30

C31

C32

C33

C34

C3 5

C36

C37

C38

C39

040

041

042

C101

0102

Ref.

47nF

47pF

150pF

47pF

3.3yF

47nF

47nF

lOnF

lOnF

lOnF

lOnF

220pF

220pF

220pF

220pF

lOnF

47nF

3.3nF

33pF

33pF

0103 22uF

0104

0105

0106

0107

0108

0109

C110