Page 1

1250

1250

Frequency Response

Analyzer

OPERATING MANUAL

Page 2

1250 Frequency Response Analyzer

1250

Solartron is a division of Solartron Group Ltd. Any reference to Schlumberger or

Schlumberger Instruments (the name of the company until November 1993) implies no

liability on the part of Schlumberger.

Solartron Solartron

Victoria Road, Farnborough 19408 Park Row, Suite 320

Hampshire, GU14 7PW England Houston, Texas 77084-4860, USA

Telephone: +44 (0)1252 376666 Telephone: +1 281 398 7890

Fax: +44 (0)1252 544981 Fax: +1 281 398 7891

Toll-free: 1-800 CALL SOL

Solartron Solartron

37 Rue du Saule Trapu Beijing Liasion Office

91882 MASSY, Cedex Room 327 Ya Mao Building

France No. 16, Bei Tu Chen Xi Road

Telephone: +33 (0)1 69 53 63 53 Beijing 100101, PR China

Fax: +33 (0)1 60 13 37 06 Telephone: +86 10-6238 4687

Fax: +86 10-6202-8617

E-mail: solartron@solartron.com

Web: http://www.solartron.com

For details of our agents in other countries, please contact our Farnborough, UK, office.

Solartron pursues a policy of continuous development and product improvement.

The specification in this document may therefore be changed without notice.

Page 3

1250 Frequency Response Analyzer

1250

DECLARATION OF CONFORMITY

The directives covered by this declaration

73123/EEC Low voltage Equipment Directive, amended by 93/68/EEC

89/336/EEC Electromagnetic Compatibility Directive, amended by 92/31/EEC & 93/68/EEC

Product(s)

1250A Frequency Response Analyzer

The following products are included in this declaration:

1250B, 1250E and 1254 Frequency Response Analyzers;

12501A, 12502A, 12506A, 12506B, 12506C Option modules.

Basis on which conformity is being declared

The product(s) identified above comply with the requirements of the EU directives

by meeting the following standards:

BS EN50081-1:1992 Electromagnetic Compatibility - Generic Emission Standard

Part 1: Residential, commercial and light industry.

BS EN50082-1:1992 Electromagnetic Compatibility - Generic Immunity Standard

Part 1: Residential, commercial and light industry.

EN61010-1:1993 Safety requirements for electrical equipment for

measurement, control and laboratory use.

Accordingly the CE mark has been applied to this product.

Signed

For and behaIf of Solartron, a division of Solartron Group Limited

Authority: Engineering Manager

Date: December 1995

REGISTERED IN ENGLAND No.2852989. REGISTERED OFFICE: BYRON HOUSE,

CAMBRIDGE BUSINESS PARK, CAMBRIDGE, CB4 4WZ

Approved to BS EN ISO 9001:1994 and BS EN 123000, MOD Registered Company

A Roxboro Group company

Solartron

a division of Solartron Group Ltd

Victoria Road, Farnborough

Hampshire GUI4 7PW England

Tel +44 (0) 1252 376666

Fax +44 (0) 1252 543854

Page 4

1250 Frequency Response Analyzer

1250

GENERAL SAFETY PRECAUTIONS

The equipment described in this manual has been designed in accordance with EN61010

“Safety requirements for electrical equipment for measurement, control and laboratory use”,

and has been supplied in a safe condition. To avoid injury to an operator or service

technician the safety precautions given below, and throughout the manual, must be strictly

adhered to, whenever the equipment is operated, serviced or repaired. For specific safety

details, please refer to the relevant sections within the manual.

The equipment is designed solely for electronic measurement and should be used for no

other purpose. Solartron Instruments accept no responsibility for accidents or damage

resulting from any failure to comply with these precautions.

ENVIRONMENT

This instrument must always be used within the environmental conditions (temperature,

humidity, vibration, etc.), given in the Specification.

GROUNDING

To minimize the hazard of electrical shock it is essential that the equipment is connected to

a protective ground whenever the power supply, measurement or control circuits are

connected, even if the equipment is switched off. The protective ground for ac and dc

supplies is connected separately.

AC GROUND is connected via the ac supply cord. The cord must be plugged into an ac line

outlet with a protective ground contact. When an extension lead is used, this must also

contain a ground conductor. Always connect the ac supply cord to the supply outlet before

connecting the control and signal cables; and, conversely, always disconnect control and

signal cables before disconnecting the ac supply cord. The ac ground connection must be

capable of carrying a current of 25A for a minimum of one minute.

AC SUPPLY VOLTAGE

Never operate the equipment from a line voltage or frequency in excess of that specified.

Otherwise, the insulation of internal components may break down and cause excessive

leakage currents.

FUSES

Before switching on the equipment check that the fuses accessible from the exterior of the

equipment are of the correct rating. The rating of the ac line fuse must be in accordance

with the voltage of the ac supply.

Should any fuse continually blow, do not insert a fuse of a higher rating. Switch the

equipment off, clearly label it “unserviceable” and inform a service technician.

EXPLOSIVE ATMOSPHERES

NEVER OPERATE the equipment, or any sensors connected to the equipment, in a

potentially explosive atmosphere. It is NOT intrinsically safe and could possibly cause an

explosion.

Continued overleaf.

Page 5

1250 Frequency Response Analyzer

1250

SAFETY PRECAUTIONS (continued from previous page)

SAFETY SYMBOLS

For the guidance and protection of the user, the following safety symbols appear on the

equipment:

SYMBOL MEANING

Refer to operating manual for detailed instructions of use. In

particular, note the maximum voltages permissible at the input

sockets, as detailed in the Specification.

Hazardous voltages.

NOTES, CAUTIONS AND WARNINGS

For the guidance and protection of the user, Notes, Cautions and Warnings appear

throughout the manual. The significance of these is as follows:

NOTES highlight important information for the reader’s special attention.

CAUTIONS guide the reader in avoiding damage to the equipment.

WARNINGS guide the reader in avoiding a hazard that could cause injury or death.

AVOID UNSAFE EQUIPMENT

The equipment may be unsafe if any of the following statements apply:

• Equipment shows visible damage.

• Equipment has failed to perform an intended operation.

• Equipment has been subjected to prolonged storage under unfavorable conditions.

• Equipment has been subjected to severe physical stress.

If in any doubt as to the serviceability of the equipment, don’t use it. Get it properly checked

out by a qualified service technician.

LIVE CONDUCTORS

When the equipment is connected to its measurement inputs or supply, the opening of

covers or removal of parts could expose live conductors. The equipment must be

disconnected from all power and signal sources before it is opened for any adjustment,

replacement, maintenance or repair. Adjustments, maintenance or repair, must be done

only by qualified personnel, who should refer to the Maintenance Manual.

EQUIPMENT MODIFICATION

To avoid introducing safety hazards, never install non-standard parts in the equipment, or

make any unauthorized modification. To maintain safety, always return the equipment to

Solartron for service and repair.

Page 6

1

Contents

Section Page

Chapter 1 General Information

1.1 Introduction 1.3

1.2 Basic measuring set-up 1.3

1.3 The instrument essentials 1.4

1.4 Additional facilities 1.5

1.5 1250 Variants 1.7

1.6 Options 1.8

Chapter 2 Installation

2.1 Safety 2.2

2.2 General Safety Precautions 2.2

2.2.1 Electromagnetic Compatibility 2.3

2.3 Connecting the ac mains 2.4

2.3.1 Safety precautions: Earthing 2.4

2.3.2 Procedure 2.4

2.4 Accessories 2.5

2.5 Rack Mounting 2.5

2.5.1 Rack Dimensions 2.6

2.5.2 Ventilation 2.6

2.5.3 Fitting Telescopic Slide Mounting Kit 12505B (Accuride) 2.6

2.5.4 Fitting Telescopic Slide Mounting Kit 12505C (Jonathan) 2.11

Chapter 3 Switching on and Initialising

3.1 Switch On 3.2

3.2 Initialising 3.3

3.3 Resetting 3.4

Chapter 4 Making Measurements: The Generator

4.1 Simple Measurements 4.2

4.2 Setting the Generator 4.2

4.2.1 Introduction 4.2

4.2.2 Setting the Generator Menu 4.2

4.2.3 Waveform 4.2

4.2.4 Frequency 4.3

4.2.5 Clear 4.4

4.2.6 Amplitude 4.4

4.2.7 Bias 4.4

4.2.8 Modulated Carrier 4.4

4.3 Checking Generator Settings: Using the Status Displays 4.4

4.4 Starting the Generator 4.5

4.4.1 Generator Start Key 4.5

4.4.2 Generator Waveform Starting Point 4.5

4.5 Rack Stopping the Generator 4.5

4.5.1 Introduction 4.5

4.5.2 Generator Stop Key 4.5

Page 7

Contents 1250 Frequency Response Analyzer

2 1250

4.5.3 Generator Stop @ Key 4.6

4.5.4 Applications of the Stop @ Key 4.6

4.5.5 Generator Overload Protection 4.7

Chapter 5 Making Measurements: The Analyzers

5.1 Introduction 5.2

5.2 Setting the [ANALYZER COMMON] Menu 5.2

5.2.1 ∫ Time 5.2

5.2.2 Delay 5.3

5.2.3 Harmonic 5.3

5.2.4 Order 5.4

5.2.5 Auto ∫ 5.4

5.2.6 Application of Auto Integration 5.4

5.3 Setting Individual Analyzers 5.6

5.3.1 Range 5.6

5.3.2 Demod 5.6

5.3.3 Coupling 5.6

5.3.4 Input 5.6

5.4 Measurement Start 5.7

5.5 Stopping the Analyzer; Stop and Break Keys 5.8

5.6 Changing Menus during Recycle 5.8

5.7 Measurement Start Point 5.8

5.7.1 Implementation of Delay 5.8

Chapter 6 The Sweep Facility

6.1 Introduction 6.2

6.2 Logarithmic Sweep 6.2

6.3 Linear Sweep 6.2

6.4 Setting Up a Logarithmic or Linear Sweep 6.3

6.5 Executing the Sweep 6.3

6.6 Automatic Sweep Time 6.3

6.7 End of Sweep Conditions 6.4

6.8 Further Sweeps 6.4

6.9 Stopping and Re-staring the Sweep 6.4

6.9.1 Introduction 6.4

6.9.2 Commands Which Produce “Sweep Stop” Status 6.4

6.9.3 Commands Which Produce “Sweep Idle” or “Hold” Status 6.5

6.10 Changing Parameters in Mid-Sweep 6.5

6.11 Harmonic Sweep 6.5

6.11.1 Introduction 6.5

6.11.2 Perfoming a harmonic Sweep 6.6

6.11.3 Error 21 6.6

6.11.4 Sweep Termination Conditions 6.6

Chapter 7 The Display Menu and Mini Status

7.1 Introduction 7.2

7.2 Sources 7.3

7.3 Co-Ordinates 7.3

Chapter 8 Menu Summary

8.1 Introduction 8.2

Chapter 9 Additional Generator Controls

9.1 The Variable Key 9.2

9.1.1 Introduction 9.2

Page 8

1250 Frequency Response Analyzer Contents

1250 3

9.1.2 Methods of Use 9.2

9.1.3 Method 1, With Analyzers Stopped 9.2

9.1.4 Method 2, With Analyzers Running 9.3

9.1.5 Using Variable with the Generator STOP @ Key 9.4

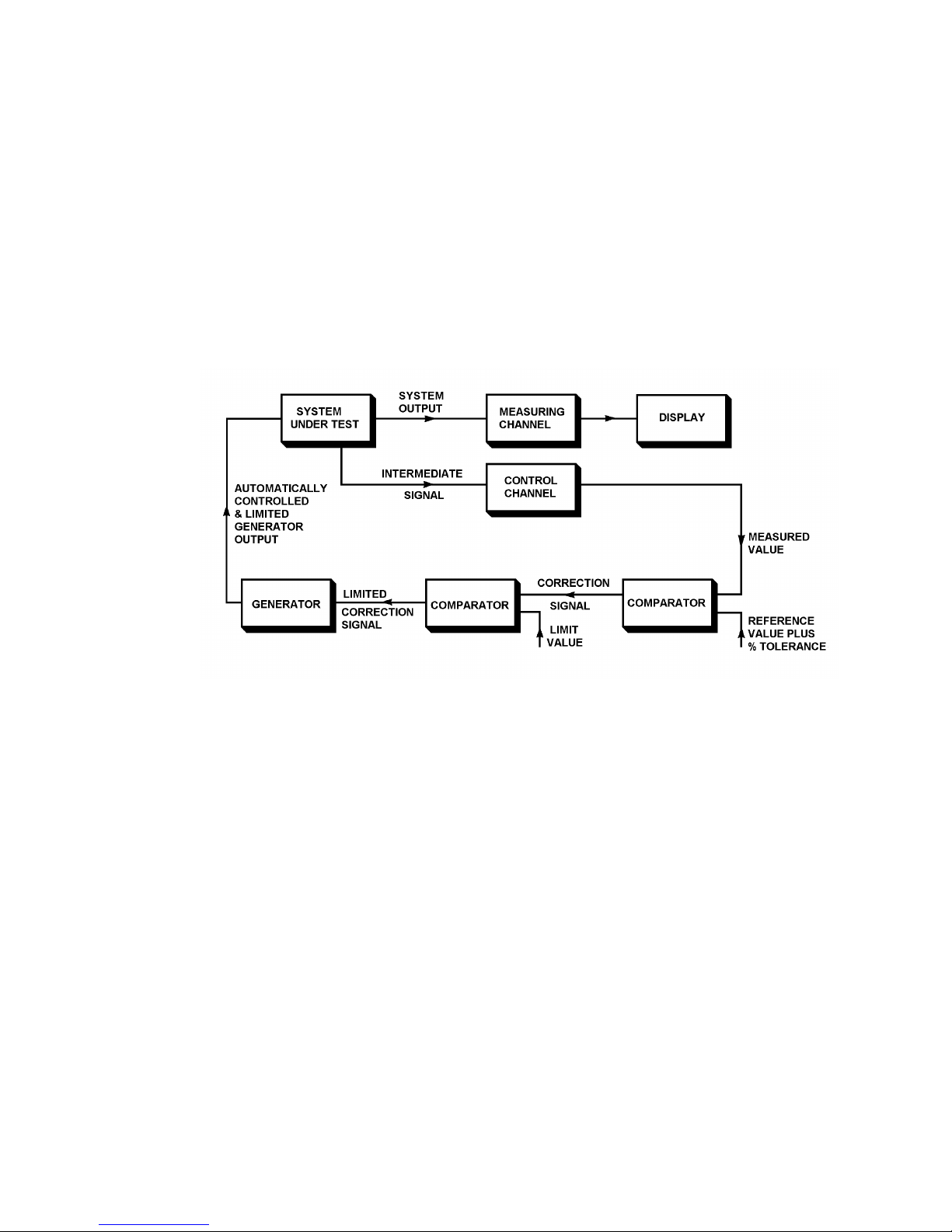

9.2 Amplitude Compression 9.5

9.2.1 Introduction 9.5

9.2.2 Principle of Operation 9.5

9.2.3 Generator Output Limit 9.7

9.2.4 Setting the Menu 9.8

9.2.5 Error 84 9.8

9.2.6 Use of the File 9.8

Chapter 10 Facilities For More Complex Measurements

10.1 The Function Key 10.2

10.1.1 Introduction 10.2

10.1.2 Angle Information 10.3

10.1.3 Multiplication Factors: Xωn 10.4

10.1.4 Scaling 10.5

10.1.5 Limits 10.6

10.1.6 Function Key Summary 10.7

10.2 Data Flow Schematic 10.8

Chapter 11 Additional Displayed Information

11.1 The Status Key 11.2

11.1.1 Introduction 11.2

11.1.2 Using the Key 11.2

11.1.3 Main Status 11.3

11.1.4 Other Status 11.5

11.1.5 Printed Record 11.8

11.2 Error Codes 11.9

11.2.1 Introduction 11.9

11.2.2 Error Codes: Summary 11.9

11.3 Error Codes: Details 11.11

11.3.1 Introduction 11.11

11.3.2 Group 0. Errors Pertaining to Command Structure 11.11

11.3.3 Group 1. Errors Pertaining to the Learnt Program 11.12

11.3.4 Group 2. Parametric Interaction Errors. 11.12

11.3.5 Group 3. Generator Warnings and Errors 11.12

11.3.6 Group 4. Learnt Program, File and Variable 11.13

11.3.7 Group 5. Missing Boards 11.13

11.3.8 Group 6. Illegal I/O Manipulation 11.14

11.3.9 Group 7. System Errors 11.14

11.3.10 Group 8. Measurement Validity is Suspect 11.14

Chapter 12 Recording, Learning and Storing Facilities

12.1 The Data Output Key 12.2

12.1.1 Introduction 12.2

12.1.2 [DATA OUTPUT] 12.2

12.1.3 [FORMAT]: Heading and Reformat 12.3

12.1.4 Heading 12.3

12.1.5 Reformat 12.4

12.1.6 Menu Changes Activating the Heading and Reformat Functions 12.5

12.1.7 Channel and Range Column Conventions 12.5

12.1.8 [GPIB CONFIGURE] 12.6

12.1.9 Parallel and Poll Sense 12.6

12.1.10 Serial Poll 12.6

Page 9

Contents 1250 Frequency Response Analyzer

4 1250

12.1.11 Terminator and Separator 12.6

12.2 The File 12.7

12.2.1 Introduction 12.7

12.2.2 Maximum File Size 12.7

12.2.3 Selecting File Size 12.7

12.2.4 Overwriting the Size of the File 12.7

12.2.5 Starting a File 12.8

12.2.6 Reading from the File 12.8

12.3 Learnt Programs 12.9

12.3.1 Introduction 12.9

12.3.2 Learning a Program: From the Front Panel 12.9

12.3.3 Learning a Program: From an External Device 12.10

12.3.4 Executing a Program 12.11

12.3.5 Editing a Program: From the Front Panel 12.11

12.3.6 Editing a Program: From an External Device 12.12

12.3.7 Copying a Program 12.12

12.3.8 Program Pause/Continue Key 12.13

12.3.9 Example Programs 12.13

12.3.10 Error Messages Displayed During Program Running 12.13

12.4 X - Y Plotter 12.14

12.4.1 Introduction 12.14

12.4.2 Setting up a Plot: Non-Plotter Menus 12.14

12.4.3 The [PLOTTER COMMON] menu 12.15

12.4.4 The [PLOTTER X-AXIS] and [PLOTTER Y-AXIS] menus 12.16

12.4.5 The [PLOTTER SCALING] menu 12.17

12.4.6 Performing a Plot 12.18

12.4.7 Bode and Nyquist Plots 12.19

12.4.8 Adjusting the Plotting Field to suit Preprinyed Chart Paper 12.20

12.4.9 Pen Selection with two Pen Plotters 12.21

12.4.10 Plotting Data from the File 12.21

Chapter 13 The RS423 and GPIB Ports. Remote Control

13.1 Introduction 13.3

13.1.1 GPIB Capacity Code 13.3

13.2 Connections 13.4

13.3 RS423 Baud Rate 13.4

13.4 RS423 Input Command Terminator Character; RS423 Character

Frame 13.4

13.5 GPIB Switches 13.5

13.5.1 Address switches 13.6

13.5.2 Input Command Terminator Character Switches 13.6

13.5.3 Talk Only Switch 13.6

13.5.4 GPIB Switch Example 13.6

13.6 REMOTE/LOCAL Facility 13.7

13.6.1 Local Lock-Out 13.8

13.7 Command Codes 13.9

13.7.1 Introduction 13.9

13.7.2 Command Code Format 13.9

13.7.3 Generator Commands 13.10

13.7.4 Synchroniser Commands 13.10

13.7.5 Amplitude Compression Commands 13.11

13.7.6 Auxiliary Generator Commands 13.11

13.7.7 Analyzer Commands 13.11

13.7.8 Sweep Commands 13.12

13.7.9 Display Commands 13.12

Page 10

1250 Frequency Response Analyzer Contents

1250 5

13.7.10 Plotter Commands 13.12

13.7.11 Status Commands 13.13

13.7.12 Variable Commands 13.13

13.7.13 File Commands 13.13

13.7.14 Program Commands 13.14

13.7.15 Data Output Commands 13.14

13.7.16 RS423/GPIB Commands 13.14

13.7.17 Function Commands 13.15

13.7.18 Miscellaneous Commands 13.15

13.7.19 Self Test Commands 13.16

13.7.20 Commands in Alphabetical Order 13.16

13.8 GPIB Controller: Language Used in Program Examples 13.19

13.9 Command Query 13.19

13.10 Measurement Output Selection 13.20

13.10.1 Via RS423 Port 13.20

13.10.2 Via GPIB Interface 13.21

13.11 Measurement Output Rate 13.21

13.11.1 Via RS423 Port 13.21

13.11.2 Via GPIB Interface 13.21

13.12 Measurement Output Format 13.21

13.12.1 RS423 Port 13.21

13.12.2 GPIB Talk Only Mode 13.21

13.12.3 GPIB Normal Mode 13.22

13.12.4 Dump Mode 13.23

13.12.5 Floating Point Format 13.23

13.12.6 Output Terminators and Separators 13.24

13.13 Serial Poll/Parallel Poll 13.25

13.13.1 Serial Poll 13.25

13.13.2 Parallel Poll 13.26

13.14 Learnt Programs. External Storing and Reloading 13.27

13.14.1 RS423 Port, Device Control Characters 13.27

13.14.2 Procedure for Storing a Learnt Program Externally, via RS423 13.28

13.14.3 Procedure of Loading a Learnt Program into the 1250,

Via RS423 Port 13.28

13.14.4 Procedure of Loading a Learnt Program into the 1250,

Via GPIB Port 13.28

13.14.5 Example of Controller Program for Transferrring Learnt program 1

from 1250 via GPIB Port, Without Handshake 13.29

13.14.6 Example of Controller Program for Transferrring Learnt program 1

from 1250 via GPIB Port, With Handshake 13.29

13.14.7 Reloading a Learnt Program to 1250 Via GPIB 13.29

13.15 File Output 13.30

13.15.1 Procedure to Outputt File Via RS423 Port by External Command 13.30

13.15.2 Procedure to Output the File Via GPIB Port 13.30

13.15.3 Example of Controller program for Copying the File to the GPIB

Without Handshake 13.31

13.15.4 Example of Controller program for Copying the File to the GPIB

With Handshake 13.31

13.16 GPIB Plotting 13.31

13.16.1 Operating Sequence for GPIB Plotter, Using a Controller 13.32

13.17 Combinations of RS423 and GPIB Devices 13.32

Chapter 14 Break, Self Test, Time Display and Power Fail

14.1 The Break Key 14.2

14.2 Self Test 14.2

14.3 Time Display 14.4

Page 11

Contents 1250 Frequency Response Analyzer

6 1250

14.4 Power Fail 14.5

Chapter 15 Options

15.1 Synchroniser Unit 12501 15.2

15.1.1 Introduction 15.2

15.1.2 Description 15.2

15.1.3 Installation 15.2

15.1.4 Connecting Up 15.2

15.1.5 Modes of Operation 15.3

15.1.6 The Synchroniser Menu 15.5

15.1.7 Procedure for Establishing the Sync. Locked State 15.8

15.1.8 Synchroniser Status 15.9

15.1.9 Measuring Harmonics: Use of Order Analysis 15.11

15.2 Modulator/Demodulator Unit 12502 15.12

15.2.1 Introduction 15.12

15.2.2 Installation 15.12

15.2.3 Connections 15.12

15.2.4 Setting Up 15.12

15.3 Analog Plotter Interface 12503 15.13

15.2.1 Introduction 15.13

15.2.2 Installation 15.13

15.2.3 Preset Controls 15.14

15.2.4 Setting Up and Performing a Plot 15.14

15.4 Auxiliary generator Unit 12505 15.15

15.4.1 Introduction 15.15

15.4.2 Description 15.15

15.4.3 Installation 15.15

15.4.4 Setting Up 15.16

Chapter 16 The 1251 Multichannel Analyzer System

16.1 Introduction 16.2

16.2 Description 16.2

16.3 System Configuration 16.2

16.3.1 1250-1251 Interface Bus 16.2

16.3.2 IEEE 488 Interface Bus 16.2

16.3.3 1250 Series Options 16.2

16.4 Connecting Up 16.4

16.4.1 Safety: Connecting the ac Mains 16.4

16.4.2 Connecting up the 1250-1251 Interface Bus 16.4

16.5 1251 Unit Identification Switches 16.5

16.5.1 Analyzer Channel Numbering 16.5

16.6 Manual Operation of the System 16.5

16.6.1 Introduction 16.5

16.6.2 Manual Setting up of the 1251 System 16.5

16.6.3 Setting up the 1251 Analyzers 16.6

16.6.4 Displaying and Plotting data from the 1251 Analyzers 16.6

16.6.5 Checking the Analyzer and Display/Plotter Menu Settings 16.7

16.7 Remote Operation of the System 16.7

16.7.1 Introduction 16.7

16.7.2 GPIB Capability Code 16.7

16.7.3 Setting up the GPIB Configure Menu 16.8

16.7.4 Data Transfer Speeds 16.8

16.7.5 GPIB Output Buffers 16.8

16.7.6 GPIB Addresses 16.9

16.7.7 1251 Multichannel Analyzer Output: Complete Block Format 16.9

16.7.8 ASII Format 16.9

Page 12

1250 Frequency Response Analyzer Contents

1250 7

16.7.9 Dump Mode Format 16.10

16.8 1251 Multichannel Analyzer Specification 16.11

Chapter 17 Specification

Index

Page 13

CWB / 1260_Op / Issue 9 1-1

1

General Information

Section Page

1.1 Introduction 1.3

1.2 Basic measuring set-up 1.3

1.3 The instrument essentials 1.4

1.4 Additional facilities 1.5

1.5 1250 variants 1.7

1.6 Options 1.8

Page 14

General Information 1250 Frequency Response Analyzer

1-2 CWB / 1250_Op / Issue 9

Page 15

1250 Frequency Response Analyzer Menu Terms

CWB / 1250_Op / Issue 9 1-3

1.1 INTRODUCTION

The 1250 Frequency Response Analyzer measures the gain and phase characteristics

of the system under test, when stimulated by a known sinusoid. Ease of use is provided

by the touch-sensitive front panel keys. Many advanced features are incorporated,

making full use of microprocessor technology.

Standard interfaces allow full remote control. Readings can be stored for future

processing or fed to external recording devices. The instrument can be either freestanding or rack-mounted. Diagrams showing the front and rear panels are shown at the

end of this Chapter.

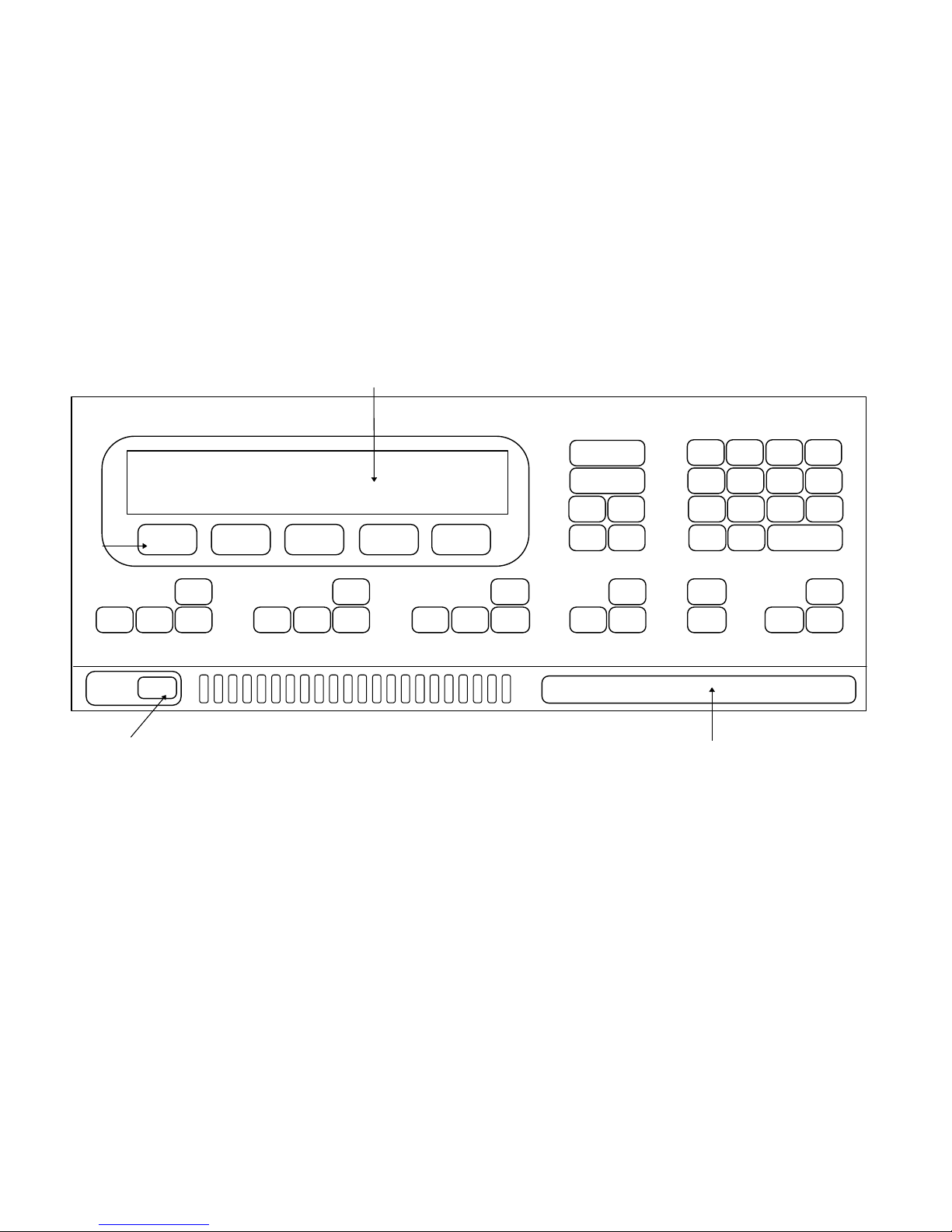

Figure 1.1 - 1250 Frequency Response Analyzer

1.2 BASIC MEASURING SET-UP

Figure 1.2 - Basic Measuring Set-up

Page 16

General Information 1250 Frequency Response Analyzer

1-4 CWB / 1250_Op / Issue 9

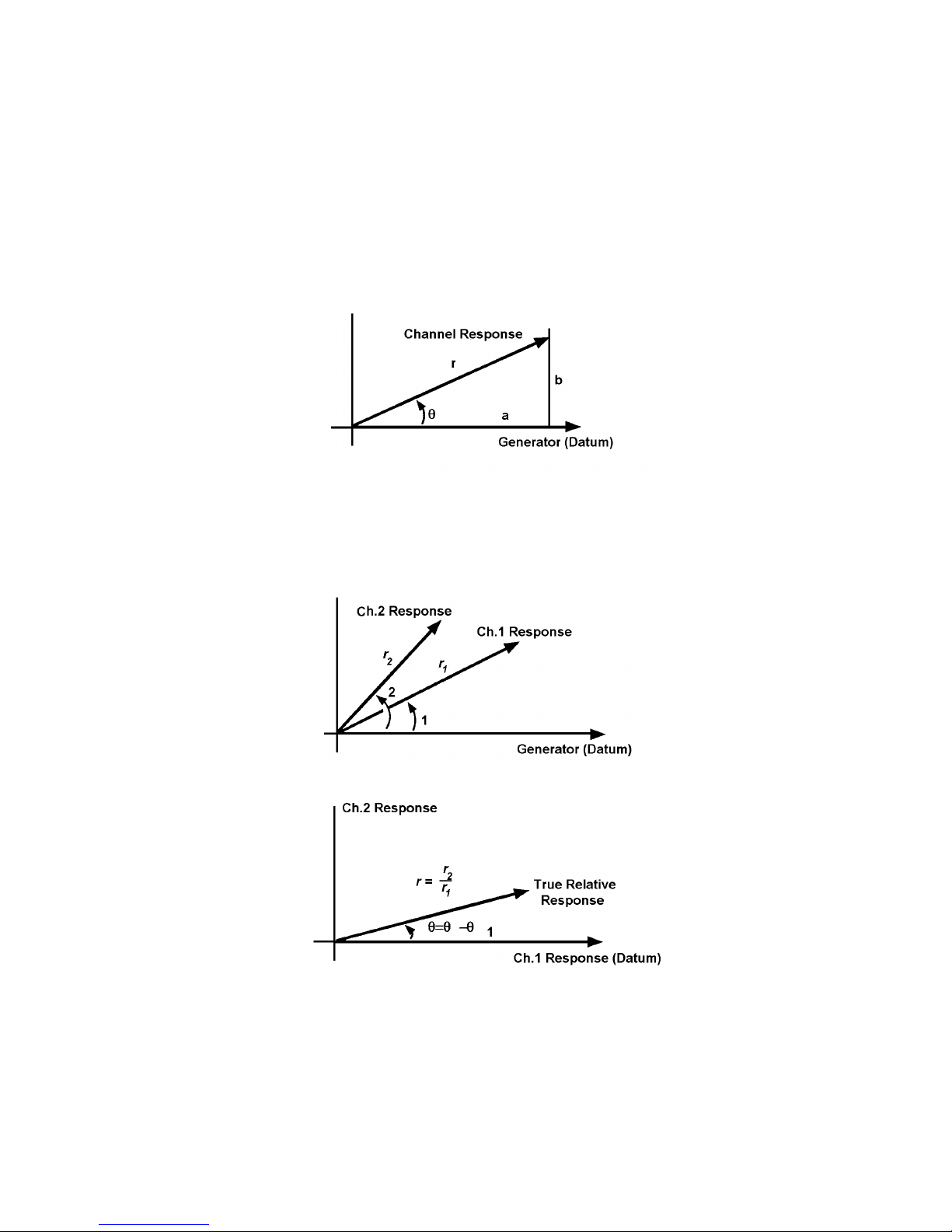

1.3 THE INSTRUMENT ESSENTIALS

The three main sections of the 1250 are:

1. A Generator which produces a sinusoidal, square, or triangular-wave electrical

stimulus for the system on test.

2. Two analyzers which measure the response to the stimulus at two points in the

system, enabling either of the following to be calculated and displayed:

a) Single Point measurements (i.e., the absolute voltage of either Channel, and its

phase with respect to the Generator) as shown in Fig. 1.3:

Figure 1.3 - Single Point Measurements

b) Point-to-Point measurements (e.g., the response of Ch.2 with respect to Ch.1, in

terms of gain and phase shift) as shown in Fig. 1.4:

Figure 1.4 - Point-to-Point Measurements

Page 17

1250 Frequency Response Analyzer Menu Terms

CWB / 1250_Op / Issue 9 1-5

3. The Display, (which is not fitted to 1250B), shows the results of the measurements in

any one of the following co-ordinate systems:

a. Cartesian (a, jb)

b. Polar (r, θ )

c. Log Polar (log r, θ )

The results may also be stored within the instrument for further processing. Additionally,

results may be passed to a plotter or computer.

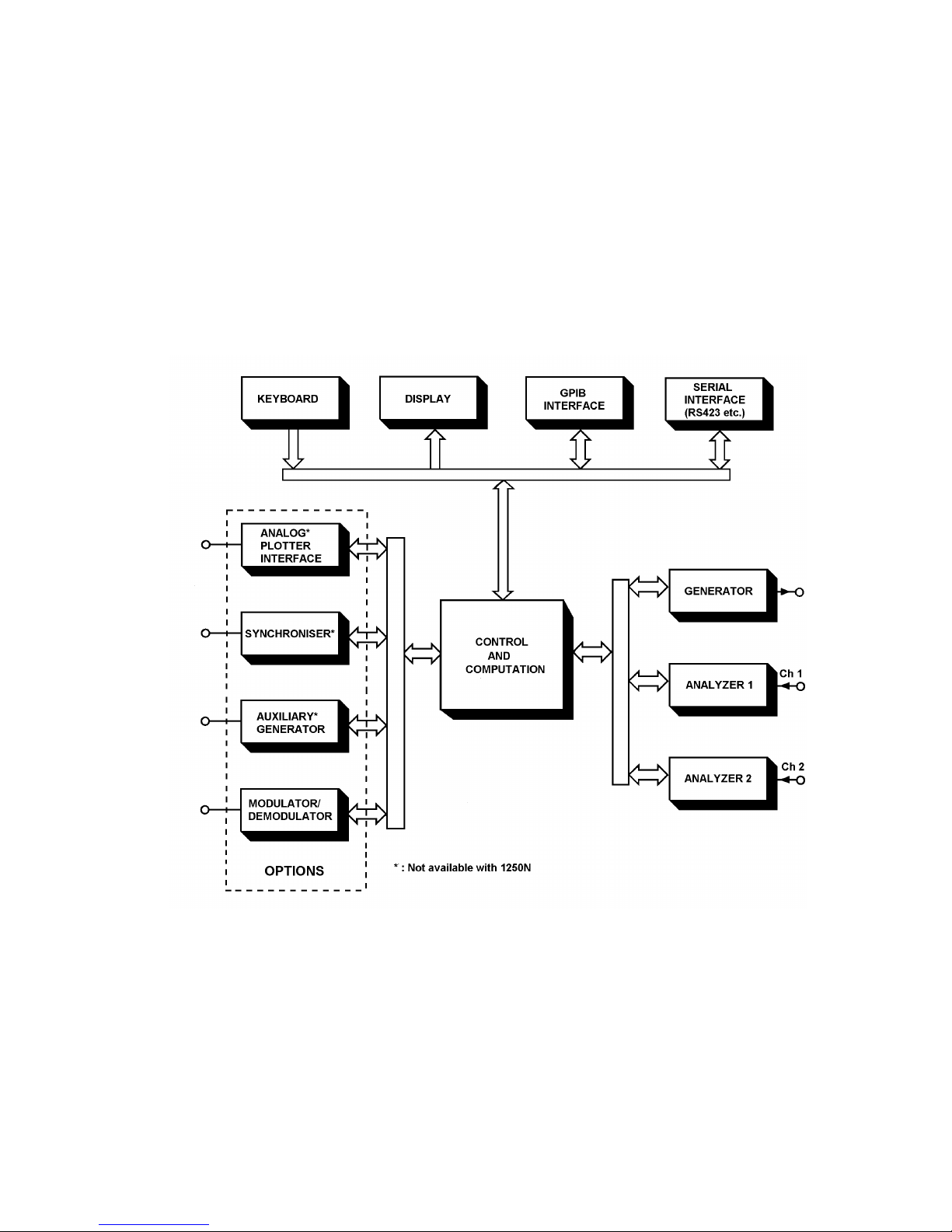

1.4 ADDITIONAL FACILITIES

These are shown in Fig. 1.5

Figure 1.5 - 1250 Block Schematic

Page 18

General Information 1250 Frequency Response Analyzer

1-6 CWB / 1250_Op / Issue 9

Keyboard. The keyboard on the front panel uses membrane switches and consists of a

number of function keys, used in conjunction with a numeric keypad. (See Fig. 1.7).

The function keys are known as `hard` keys in order to distinguish them from the five

keys immediately below the display which are called `soft` keys. Each hard key is

dedicated to one specific task, whereas the soft keys have many different roles assigned

to them, according to which hard key has just been operated. These roles are identified

by titles which appear in the display immediately above the relevant soft key.

For example, the major programmable sections of the 1250 are each controlled by a

menu. If the GENERATOR MENU key is pressed, the lower half of the display will

assign titles to the five soft keys as shown in Fig. 1.6:

Figure 1.6 - Softkey titles

Display. The display is a vacuum fluorescent alpha numeric type, each character being

formed on a 7 x 5 dot matrix. There are two rows of forty characters each.

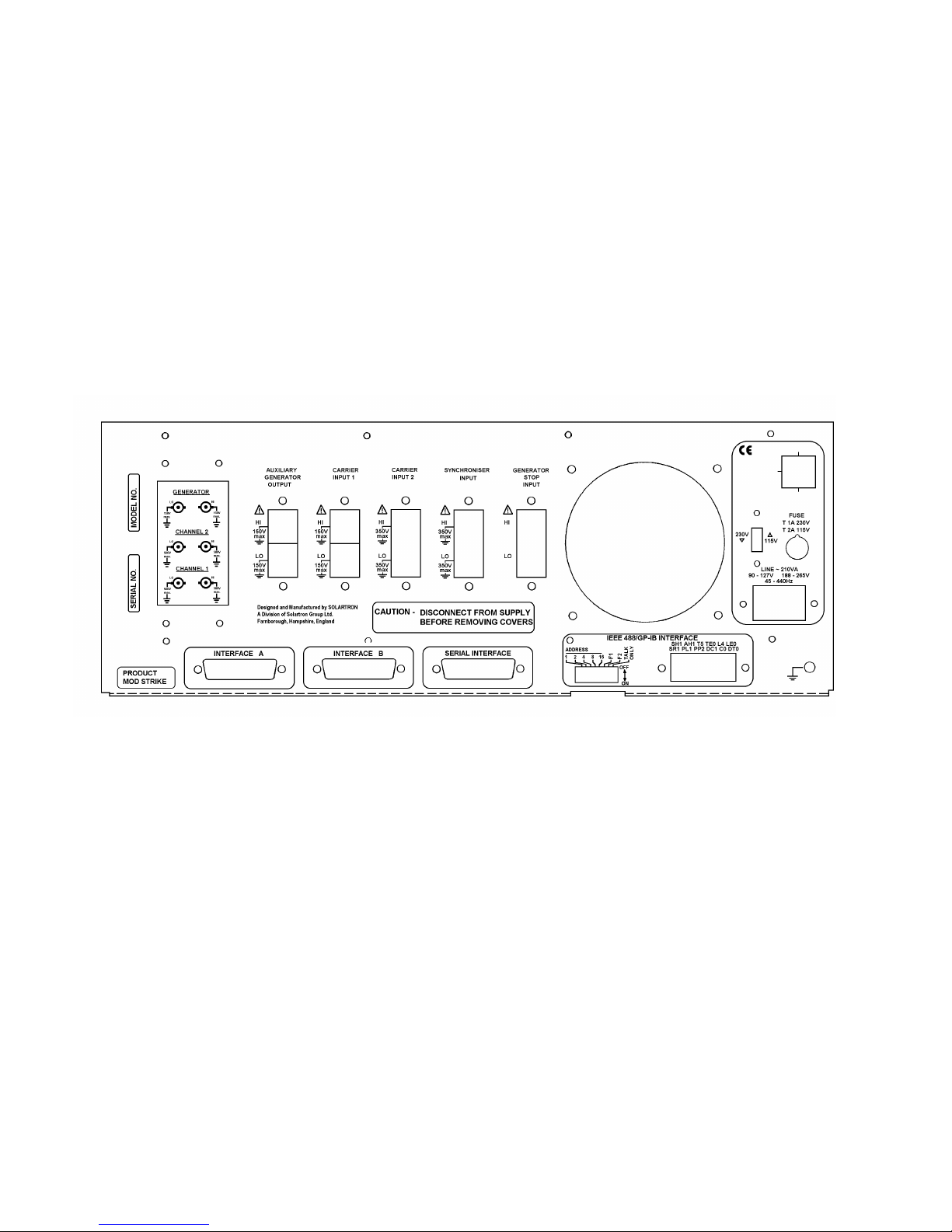

Keyswitch. The keyswitch on the rear panel of the 1250 enables/disables writing to the

permanent memory, when switched to Supervisor/Normal respectively. The keyswitch

is a three position switch, with the Operator position reserved for future use.

GPIB Interface. Permits any device conforming to IEEE 488 (1978) to be connected,

e.g., a digital plotter to display results or a computer to process them.

Serial Interface. Enables most EIA RS232C and RS423 compatible peripherals to be

connected.

Control and Computation. This section controls the functioning of the whole

instrument and computes the results of the measurements. All the functions are under

microprocessor control and the entire instrument is run synchronously to preserve the

highest possible accuracy and repeatability of results. There are stores to hold previous

readings, parameter settings, and a number of learnt programs.

Page 19

1250 Frequency Response Analyzer Menu Terms

CWB / 1250_Op / Issue 9 1-7

1.5 1250 VARIANTS

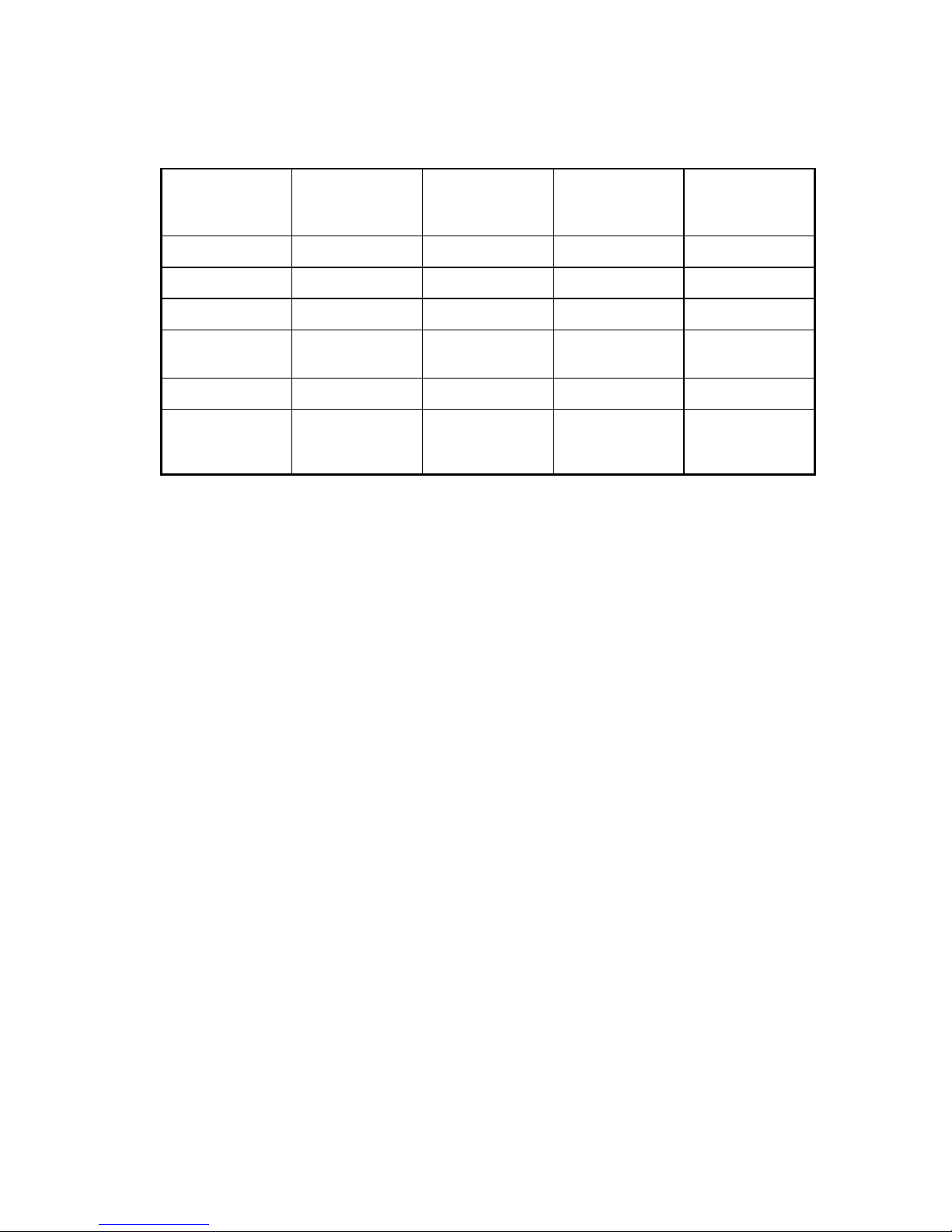

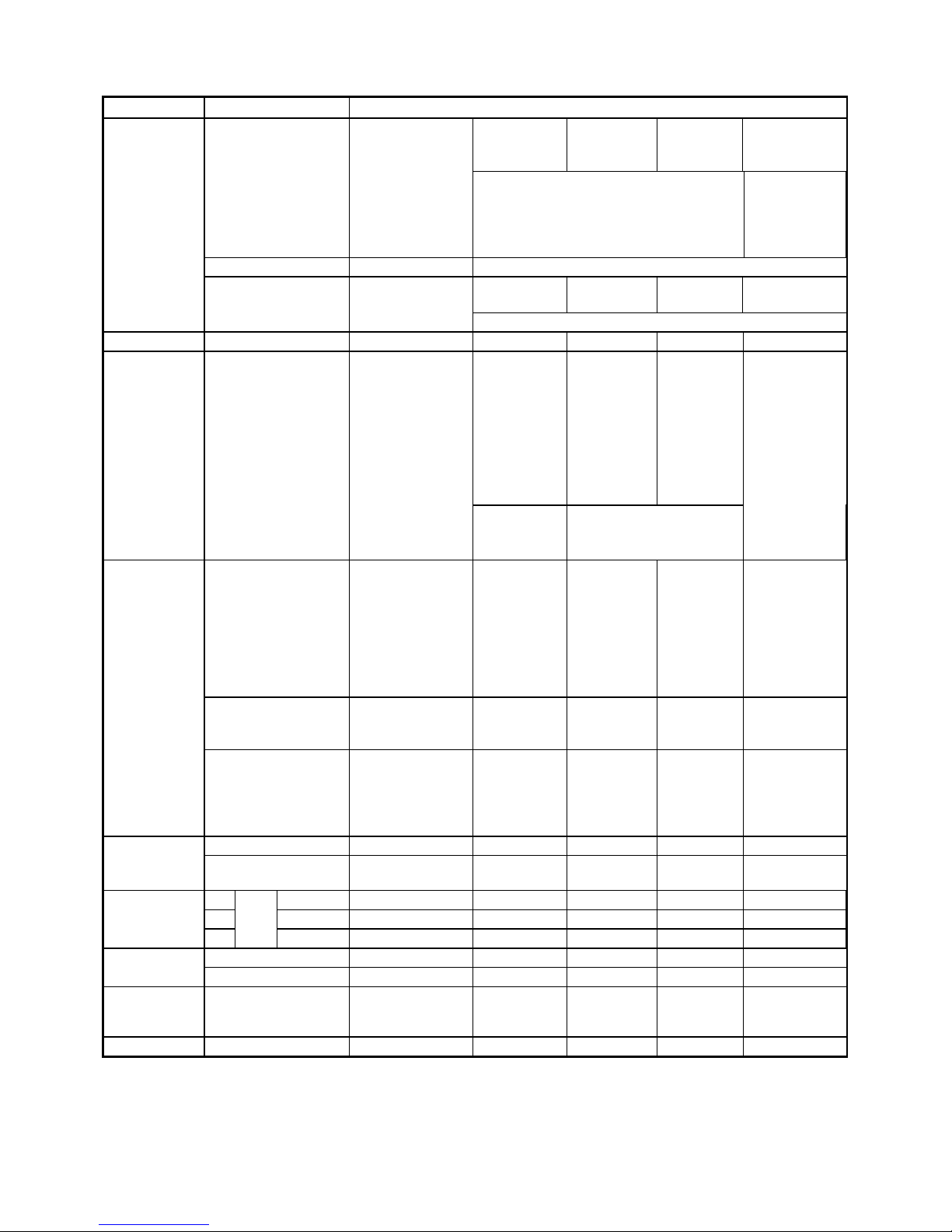

The 1250 is available in several versions, as shown in the table:

Model Number of

Channels

Front Panel

control

Compliant with

European EMC

Regulations

Notes

1250A 2 Yes No

1250B 2 No Yes

1250E 2 Yes Yes

1250N 2 Yes No Low impedance

generator output

1254A 4 Yes Yes

1251A Multiple n/a No Multi-channel

extension for

1250

Page 20

General Information 1250 Frequency Response Analyzer

1-8 CWB / 1250_Op / Issue 9

1.6 OPTIONS

All these are controllable from the 1250 Keyboard, as are the GPIB and Serial Interface.

1. Synchroniser (12501A)*: enables the 1250 to be synchronised to an external

source.

2. Modulator/Demodulator (1250A): enables the 1250 to be directly interfaced with

systems that require ac carrier inputs, or which produce ac carrier outputs.

3. Plotter Interface (12503A)*: enables the 1250 to plot the measured results on an

analog plotter. A digital plotter may be driven from the GPIB.

4. Auxiliary Generator*: an additional generator, synchronised to the main generator

but producing a signal in quadrature with it. If required, however, the two generators

can be in phase. Three variants of the Auxiliary Generator are available:

Cosine (Quadrature) - 12506A

Sine (In phase) - 12506B

Antiphase - 12506C

* - these options are not available with the 1250N. In the manual, any references to the

options are not therefore applicable to 1250N.

1250A, B and E can be fitted with up to three options, plus one auxiliary generator.

1254A can only be fitted with any one of the available options, and cannot use an

auxiliary generator.

With the exception of the 12503A (which is no longer available in Europe), all the

options are compliant with European EMC standards. Therefore 1250B, 1250E and

1250A remain compliant when fitted with these options.

Page 21

CWB / 1260_Op / Issue 9 1-9

Figure 1.7 - 1250E Front Panel

Alpha-numeric display

Front Input connections

(not available on 1250E, 1250B or 1254A)

Soft keys

Power switch

SI1250

FREQUENCY RESPONSE ANALYZER

POWER

OFF ON

STOP

STOP

@

START

MENU

STOP SINGLE RECYCLE

MENU

STOP HOLD

START/

CONTINUE

MENU

STOP PLOT

MENU

DATA

OUTPUT

FUNCTION

PAUSE/

CONTINUE

EXECUTE

LEARN

3 +/-

6

EXP

9

CLEAR

1 2

4 5

7 8

ENTER

. 0

STATUS VIEWFILE

LOCAL BREAK

VARIABLE

SELECT

[ ]

self test

GENERATOR ANALYSER SWEEP

DISPLAY/

PLOTTER

PROGRAM

Page 22

General Information 1250 Frequency Response Analyzer

1-10 CWB / 1250_Op / Issue 9

Note: The rear panel shown is for 1250E or 1250B. Other versions of 1250 may have a slightly different appearance.

Figure 1.8 - Rear panel layout

Page 23

1250 Frequency Response Analyzer Installation

CWB / 1250_Op / Issue 9A 2-1

2

Installation

Section Page

2.1 Safety 2.2

2.2 General Safety Precautions 2.2

2.2.1 Electromagnetic Compatibility 2.3

2.3 Connecting the ac mains 2.4

2.3.1 Safety precautions: Earthing 2.4

2.3.2 Procedure 2.4

2.4 Accessories 2.5

2.5 Rack Mounting 2.5

2.5.1 Rack Dimensions 2.6

2.5.2 Ventilation 2.6

2.5.3 Fitting Telescopic Slide Mounting Kit 12505B (Accuride) 2.6

2.5.4 Fitting Telescopic Slide Mounting Kit 12505C (Jonathan) 2.11

Page 24

Installation 1250 Frequency Response Analyzer

2-2 CWB / 1250_Op / Issue 9A

2.1 SAFETY

The 1250 has been designed in accordance with EN61010, "Safety requirements for

electrical equipment for measurement, control and laboratory use", and has been

supplied in a safe condition. This operating manual contains information and warnings

which must be followed by the user to ensure safe operation and to retain the equipment

in a safe condition.

The operating instructions include safety precautions where appropriate, but the

principal ones are also listed below.

2.2 GENERAL SAFETY PRECAUTIONS

1. Before switching on, ensure that the mains lead is connected to the ac supply in

accordance with the colour code.

2. Ensure that the mains voltage selector is correctly set.

3. Ensure that the mains plug is connected only to a mains outlet which has a protective

earth contact. This applies equally if an extension lead is used; the lead must

contain an earth conductor.

4. To effect earthing, the mains plug must be inserted before connections are made to

measuring and control circuits. The mains plug or external earth (as appropriate)

must remain connected until all measuring and control circuits have been

disconnected.

5. Any interruption of the earth connection (inside or outside the 1250) is prohibited.

6. When the 1250 is connected to its supply the opening of covers or removal of parts

could expose live conductors. The 1250 should be disconnected from all voltage

sources before it is opened for any adjustment, replacement, maintenance or repair.

Adjustments, maintenance or repair of the 1250 when it is powered should not be

attempted by the user. Consult a Solartron Service Centre if repairs are necessary.

7. Ensure that only fuses of the correct rating and of the specified type are fitted.

Makeshift fuses and short-circuiting of fuseholders is prohibited.

8. Whenever it is likely that the protection of the 1250 has been impaired, it should be

made inoperative and secured against any unintended operation. Protection could be

impaired if the 1250:

i) shows visible damage;

ii) has not been used as specified;

iii) has been operated outside the stated temperature range;

iv) fails to perform the intended measurements;

v) has been subjected to prolonged storage under unfavourable conditions;

vi) has been subjected to severe transport stress.

9. This symbol on the 1250 means 'Refer to the Operating Manual' for detailed

instructions or safety precautions.

In particular, care must be taken not to apply voltages in excess of the maximums

specified for each input and output. A summary of these is listed in the table below:

Page 25

1250 Frequency Response Analyzer Installation

CWB / 1250_Op / Issue 9A 2-3

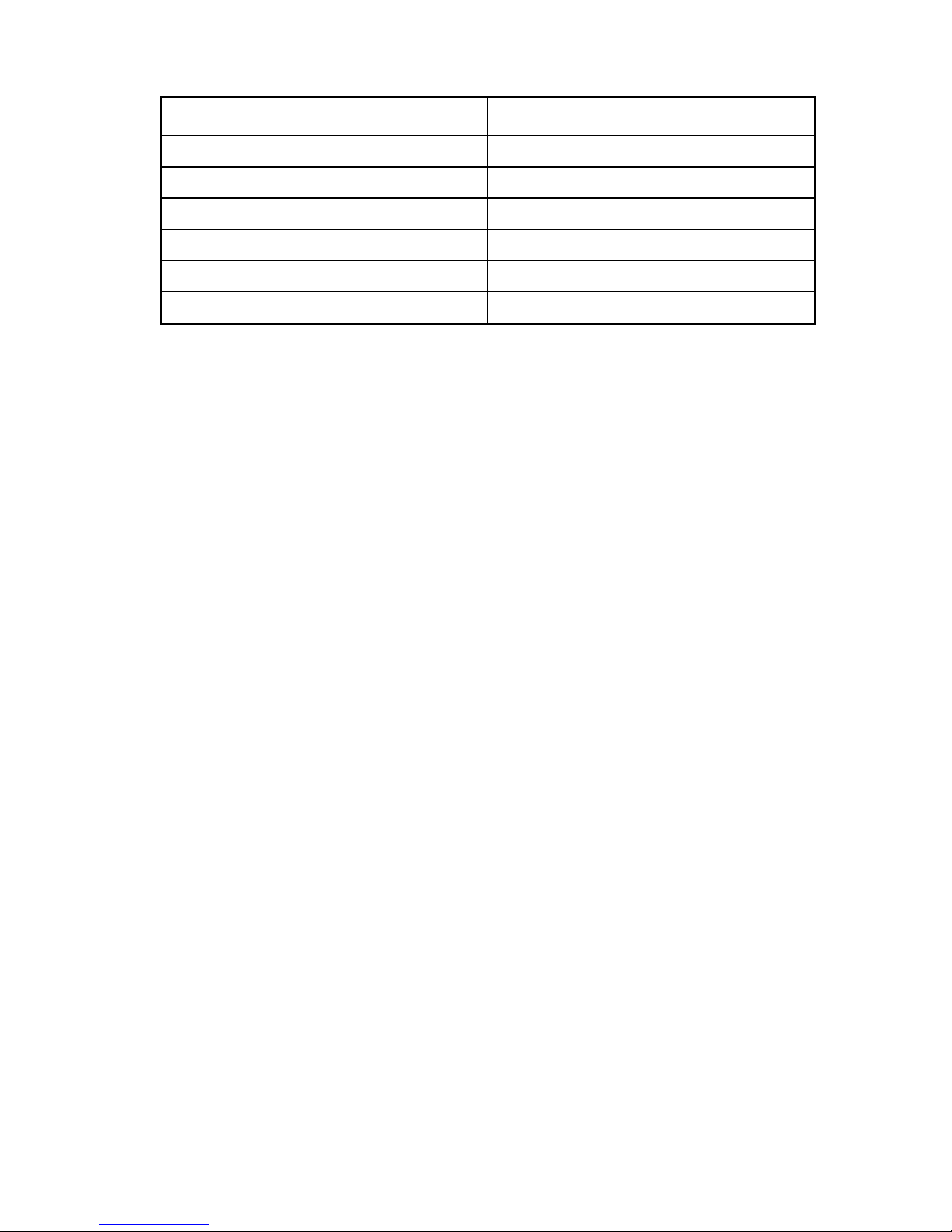

Input / Output Maximum Voltage

Generator outputs 150V, HI or LO to Gnd

Channel inputs 500 V, HI or LO to Gnd

Auxiliary Generator output 150V, HI or LO to Gnd

Modulator/Demodulator carrier inputs 350V peak, 250V rms, HI or LO to Gnd

Synchroniser input 350V peak, 250V rms, HI or LO to Gnd

Generator Stop inputs +7V to Gnd

2.2.1 Electromagnetic Compatibility

When used as described in this manual the 1250B, 1250E and 1254A models meet the

requirements of the EMC Directive, (see Specification in Chapter 17). The 1250 must

not be operated with the inner metal screens removed and any replacement

components must be of the correct type.

When conducting tests where there is a radio-frequency common mode voltage present,

it is strongly recommended that the Synchroniser, Carrier 1 and Carrier 2 inputs use the

differential connection, that is, with both HI and LO connections connected to their

respective sources by screened cables. In this way the signal leads will be screened by

a ground which originates at the 1250 and continues to the signal source.

Data cables connected to the Serial, GPIB and Interface B connectors should have a

braided outer screen, which should be grounded.

Page 26

Installation 1250 Frequency Response Analyzer

2-4 CWB / 1250_Op / Issue 9A

2.3 CONNECTING THE AC MAINS

2.3.1 SAFETY PRECAUTIONS: EARTHING

For reasons of safety an earth connection is essential whenever measurement and

control circuits are connected, even if the 1250 is switched off. Earthing is achieved by

connecting the 1250 to a mains outlet, or other suitable earthing point. This earth

should be capable of carrying 25A and conform to the regulations in 'British Standard

Code of Practice CP1013 1965. Earthing'.

2.3.2 PROCEDURE

The 1250 is powered from 115V or 23OV ac mains. Before connecting the supply:

1. Ensure that the mains voltage selector switch on the rear panel is set at 115V or

230V as appropriate. Also on the rear panel, check that the mains fuse rating is

correct: 2A SLO BLO for 115V. 1A SLO BLO for 230V.

2. Ensure that the Power On/Off switch in the bottom left-hand corner of the Front

Panel is Off.

3. Connect the mains lead.

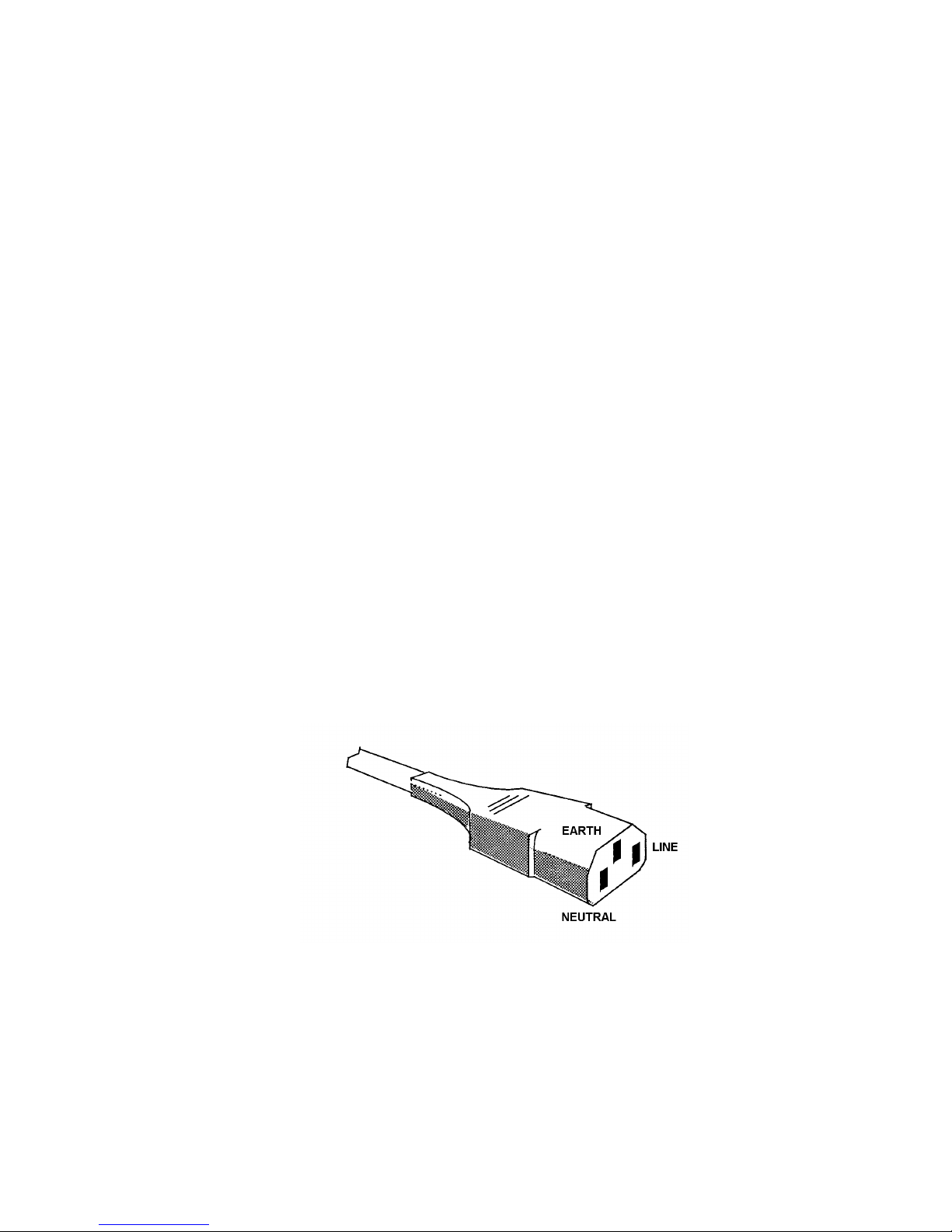

An ac supply cable, complete with a mating connector socket for the IEC plug on the

1250, is supplied. This cable should be connected to the user's ac supply in accordance

with the following colour code:

BROWN : LINE

BLUE : NEUTRAL

GREEN/YELLOW : EARTH

If the user already has available a supply cable terminated with an IEC socket, then this

can be plugged directly into ac supply plug on the 1250. It should be ensured. however,

that the socket is correctly wired, as shown in Fig. 2. 1.

Figure 2.1 - IEC power socket connections

4. Press the Power switch to On.

Page 27

1250 Frequency Response Analyzer Installation

CWB / 1250_Op / Issue 9A 2-5

2.4 ACCESSORIES

The 1250 accessories are supplied in a polythene bag packed with the instrument. The

accessory bag should contain:

a. 1 fuse, 1A SLO BLO, for 240V ac supply

b. 1 fuse. 2A SLO BLO, for 115V ac supply

c. 2 rack mounting brackets ("ears")

d. 1 slide mounting bar, part no. 12502024B, for telescopic slide rack mounting

e. 4 screws, M4 X 12 countersunk, to fix item d

f. 3 cable assemblies, terminated for front panel connections

An appropriate ac mains cable is packed with the instrument. If ordered with the 1250, a

telescopic rack slide mounting kit (Option 12505B, or 12505C for U.S.A.) is also packed.

2.5 RACK MOUNTING

The 1250 can be rack mounted in two ways: either by using fixed rails in the rack to

support the underside of the case, or by using telescopic slides to support the 1250 and

allow easy withdrawal for servicing.

With either method, the pair of rack mounting cars included in the accessory kit is

substituted for the finisher trims on the 1250; screws inserted through the ears and into

the rack keep the unit in place.

Note 1: The rack mounting ears must be used only to prevent the 1250 sliding out of the

rack. They are not designed to support the whole weight of the instrument.

Note 2: When the 1250 is rack mounted on telescopic slides, ensure that the rack will

not tip over when the slides are fully extended.

Two slide mounting kits are available as optional accessories:

1. kit 12505B (Accuride; UK), containing:

a. 1 telescopic slide kit, plus fixings

b. 14 screws, M4 X 6 panhead, to fix slide inner members to the mounting bars

c. 14 washers, M4 crinkle

d. 4 screws, M6 satin chrome, to fix front panel to rack

e. 4 washers. M6 plain

f. 4 caged nuts, M6, to fix front panel to rack

This kit is suitable only for 30 ins deep IMHOF IMRAK Series 80 or dimensionally similar

cabinets.

2. kit 12505C (Jonathan; USA), containing:

a. 1 replacement case top, part no. 12500241A

b. 1 replacement case bottom, part no. 12500242A

c. 4 feet, self-adhesive, to support pcb's inside item b

Jonathan slides and fixings are not supplied by Solartron.

Page 28

Installation 1250 Frequency Response Analyzer

2-6 CWB / 1250_Op / Issue 9A

2.5.1 RACK DIMENSIONS

The internal rack dimensions required for fitting the 1250 are:

610mm (24 ins) deep X 485mm (19 ins) wide for fixed rail mounting, and

760mm (30 ins) deep X 485mm (19 ins) wide for telescopic slide mounting (using either

kit)

2.5.2 VENTILATION

Ensure that the rack in which a 1250 is mounted has adequate ventilation, either by an

extractor fan or by having the rear of the rack open.

2.5.3 FITTING TELESCOPIC SLIDE MOUNTING KIT 12505B (ACCURIDE)

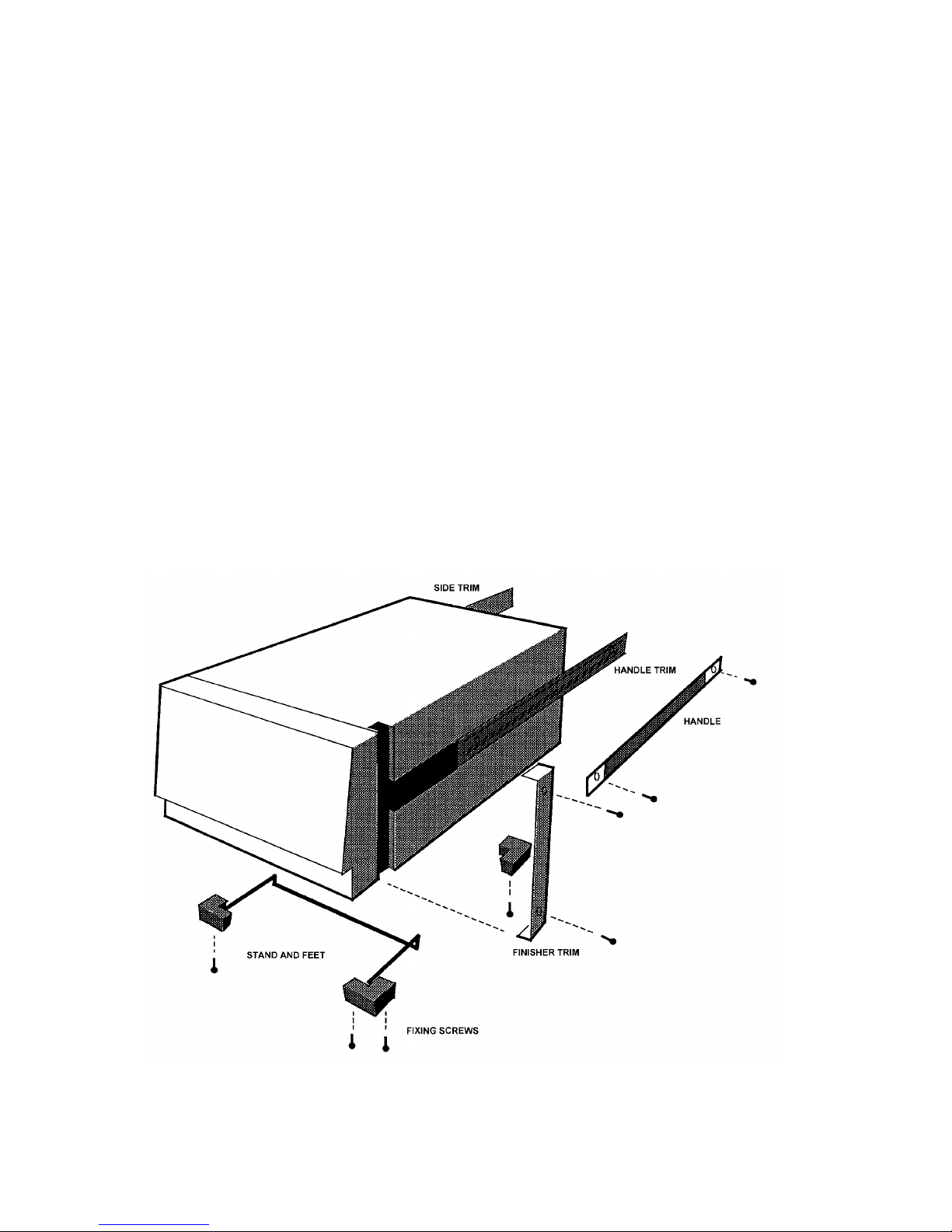

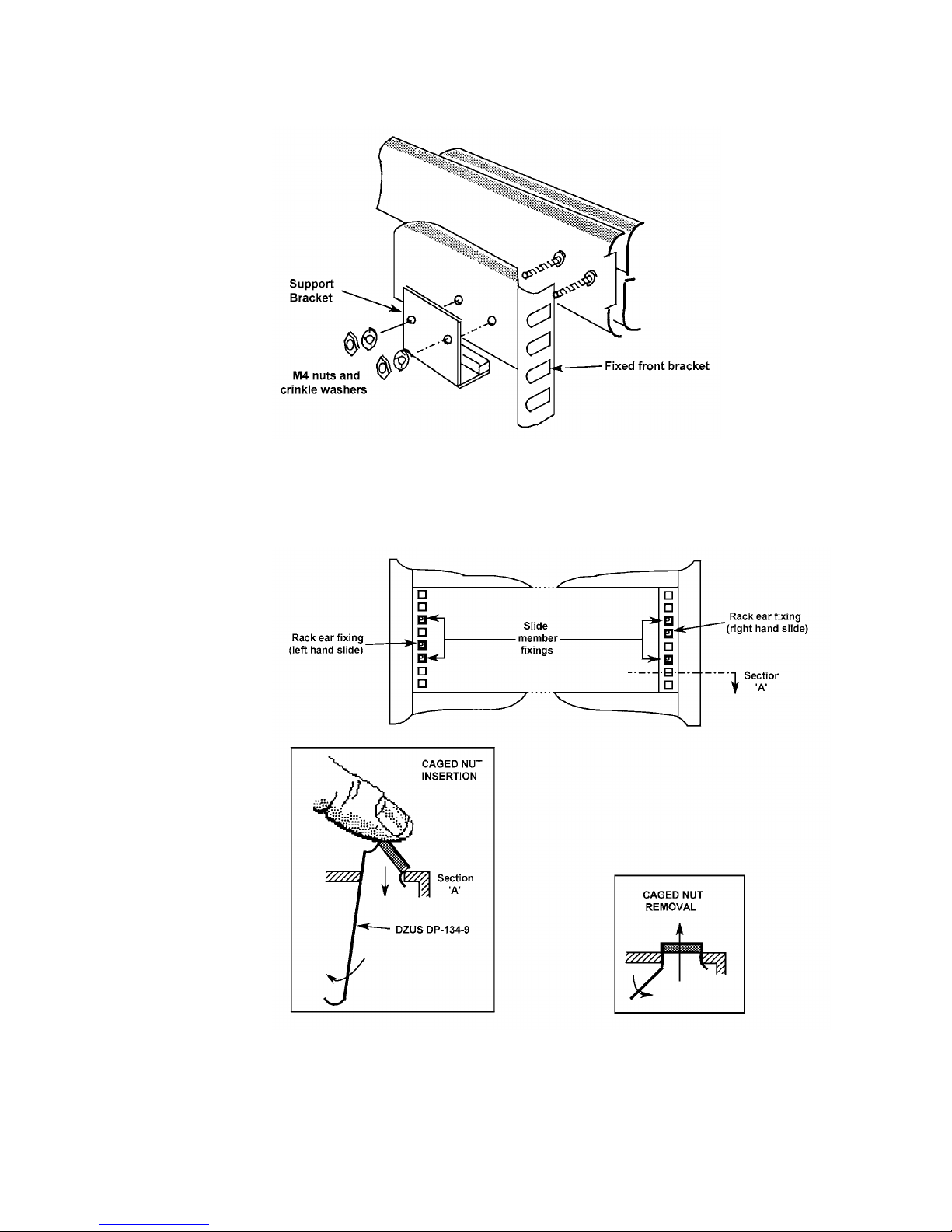

1. Remove the following items from the unit, as shown in Fig. 2.2:

a. Finisher Trim (two off)

Retain the four M4 x 16 panhead screws and M4 crinkle washers for securing the

rack ears.

b. Handle and Handle Trim

c. Side Trim

Located on the opposite side to the handle, it is normally secured by a pip on the

finisher trim, and slides out backwards.

d. Feet (four off) and Tilt Bar

The tilt bar is secured by the two front feet.

Figure 2.2 - Removal of trims, handle, feet, and tilt bar

Page 29

1250 Frequency Response Analyzer Installation

CWB / 1250_Op / Issue 9A 2-7

2. Fit the following items to the unit, as shown in Fig. 2.3:

a. Rack Ears (two off)

Fit the rack ears in place of the finisher trim, using the same fixings.

The ears may he fitted as illustrated, or with their flanges facing the rear of the

1250, which causes the unit to stand out further in the rack, allowing use of racks

too shallow for normal mounting.

b. Slide Mounting Bar

Screw the bar to the chassis in the former position of the handle, using the four

M4x12 csk screws provided. The bar fits correctly only one way round, with

threaded holes nearest the front.

The corresponding mounting bar on the left-hand side of the unit is supplied

already fitted behind the side trim (part no. 12502019B), it is slightly narrower than

the right-hand bar.

Figure 2.3 - Fitting rack ears and telescopic slide inner members

Page 30

Installation 1250 Frequency Response Analyzer

2-8 CWB / 1250_Op / Issue 9A

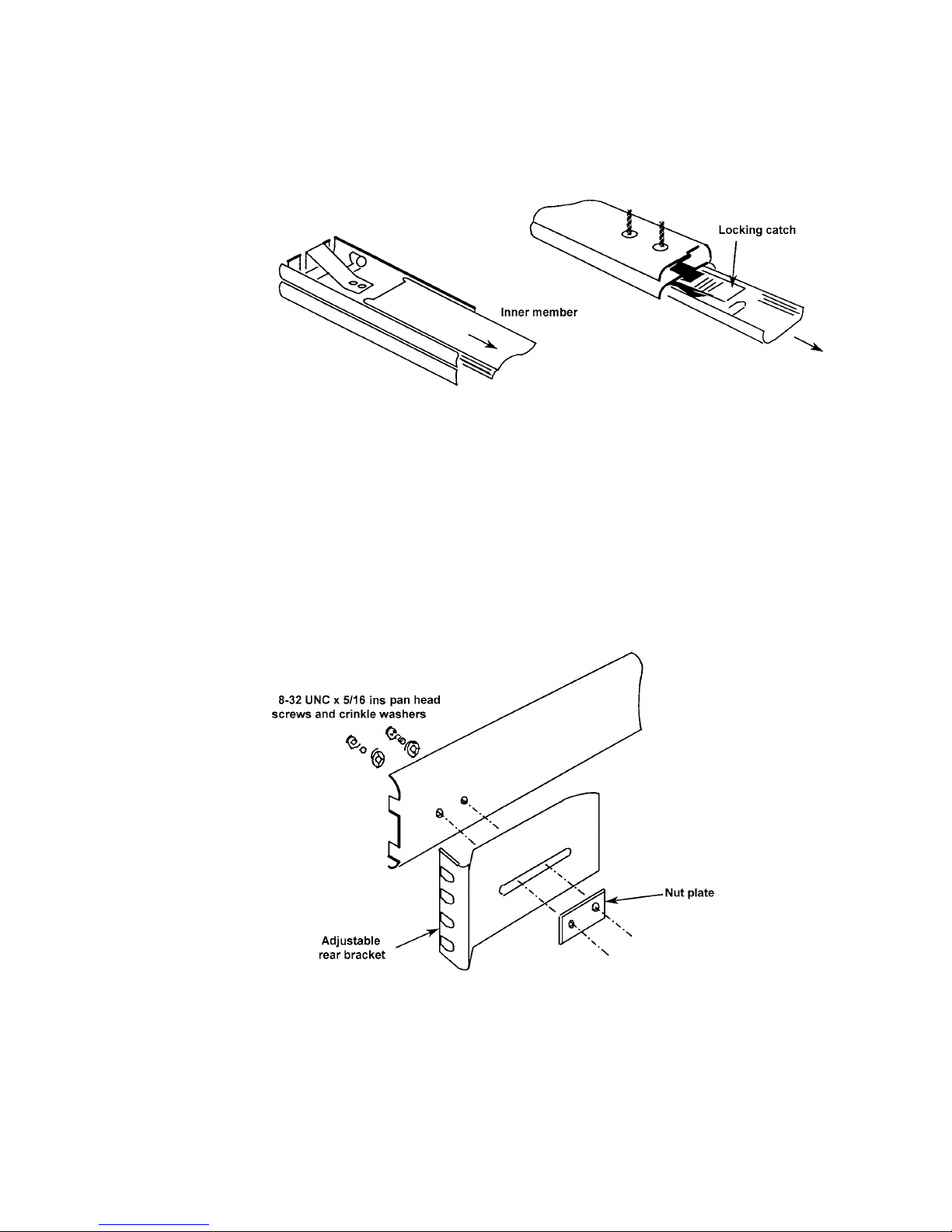

c. Telescopic Slide Inner Members (two off)

The telescopic slides are supplied with inner and outer members, slotted

together. Slide out the inner member as shown in Fig. 2.4. depressing the

locking catch at the halfway point.

Figure 2.4 - Separating the inner and outer slide members, prior to fixing

Screw the slide inner members to the mounting bars, using the fourteen M4X6

panhead screws supplied, seven each side.

3. Fit the following items to the telescopic slide outer members, as shown in Fig. 2.5

and 2.6:

c. Adjustable Rear Brackets (two off)

Fit one rear bracket to each outer member, but do not fully tighten the screws

until the 1250 is fitted into the rack (step 6).

Figure 2.5 - Fitting a rear bracket

Page 31

1250 Frequency Response Analyzer Installation

CWB / 1250_Op / Issue 9A 2-9

d. Fixed Front Brackets together with Support Brackets (two off each)

Figure 2.6 - Fitting a front bracket and support bracket

4. Fit the M6 caged nuts for outer slide member and rack ear fixing into the rack in

positions shown in Fig. 2.7. How to insert and remove caged nuts is shown in the

figure detail.

Figure 2.7 - Cage nut insertion in Imrak Series 80 (and similar) cabinets

Page 32

Installation 1250 Frequency Response Analyzer

2-10 CWB / 1250_Op / Issue 9A

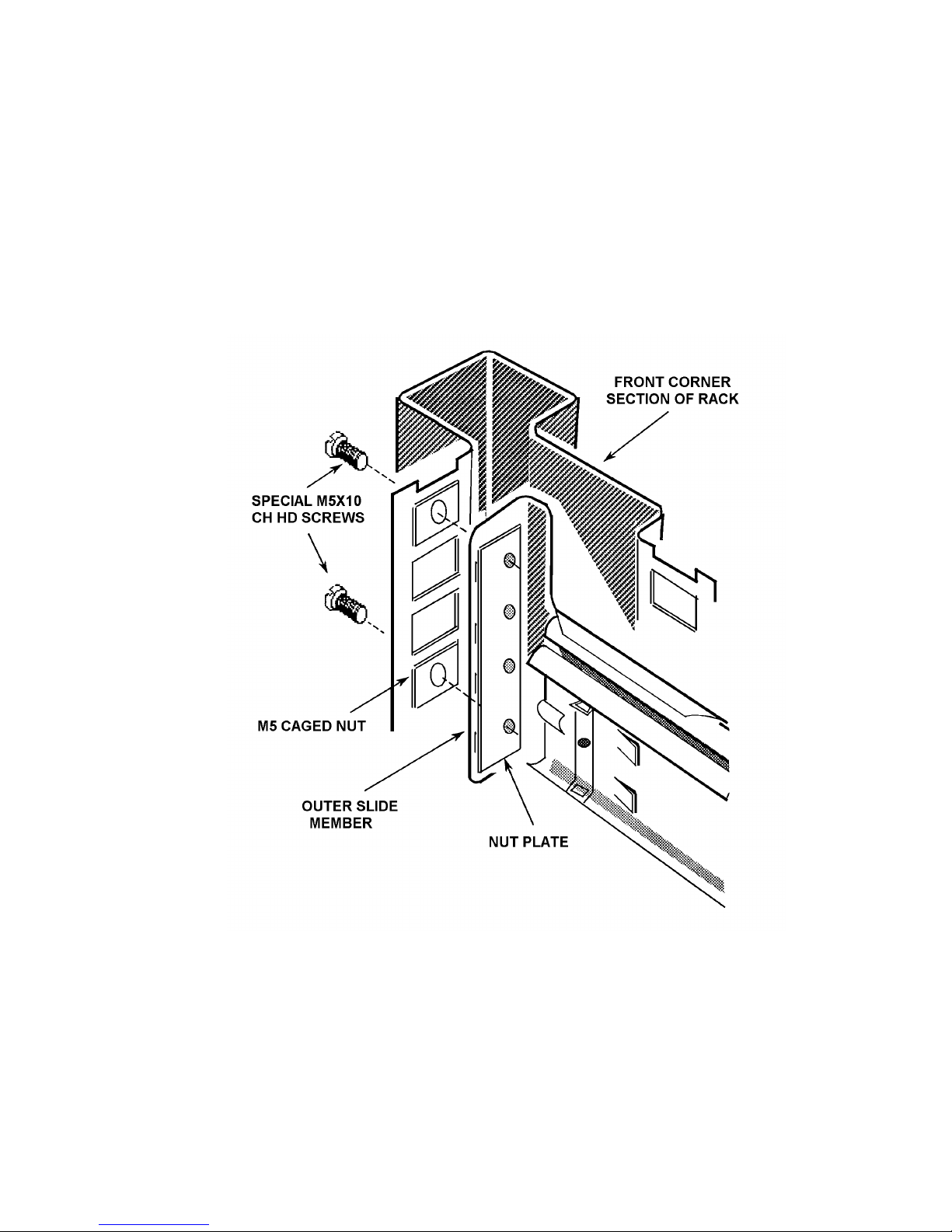

5. Fit the Outer Slide Members (two off) to the rack, as shown in Fig. 2.8

Note that the tapped holes in the nut plate are off centre to provide maximum

lateral adjustment. Fit the plates, as shown, with the holes offset towards the

rack exterior.

Fitting one end of an outer member is facilitated if the other end is supported,

by hooking the bracket at the other end over an M5 screw pushed into the top

caged nut.

Tighten the M5 screws securing each member until it is held moderately firmly

in the rack, approximately in the centre of its travel. The members must,

however, be free enough to take up any adjustment when the 1250 is first

fitted into the rack.

Figure 2.8 - Fitting the outer slide members into the rack

Page 33

1250 Frequency Response Analyzer Installation

CWB / 1250_Op / Issue 9A 2-11

6. Finally, fit the 1250 into the rack, as follows:

a. Offer the 1250 up to the rack and feed the inner telescopic slide members into the

outer members, pushing the unit into the rack until the locking catches engage

and lock.

b. Depress both catches and push the unit fully into the rack, ensuring that no cables

are trapped.

c. Tighten the screws on the outer slide members in the following order:

1. The M5 screws securing the rear bracket to the rack.

2. The M5 screws securing the front bracket to the rack.

3. The 8-32 UNC screws securing the rear bracket to the outer slide member.

2.5.4 FITTING TELESCOPIC SLIDE MOUNTING KIT 12505C (JONATHAN)

Remove the following items from the unit. as shown in Fig. 2.9:

a. Finisher Trim (two off)

Retain the four M4X16 panhead screws and M4 crinkle washers for securing the

rack ears.

b. Handle and Handle Trim

Figure 2.9 - Removal of trims, handle, top and bottom cases

Page 34

Installation 1250 Frequency Response Analyzer

2-12 CWB / 1250_Op / Issue 9A

c. Side Trim

Located on the opposite side to the handle, it is normally secured by a pip on the

finisher trim, and slides out backwards.

Check that the threaded bar supplied already fitted behind the side trim is part

no. 12502019B.

d. Case Top and Case Bottom

Retain the five screws and washers for securing the replacement cases.

2. Fit the Self-adhesive Feet (4 off) to the inside of the Replacement Case Bottom in

the positions corresponding to those in the original case bottom.

3. Fit the following items to the unit, as shown in Fig. 2.10 overleaf:

a. Rack Ears (2 off)

Fit the rack ears in place of the finisher trim, using the same fixings. The flanges

must face the rear of the 1250.

b. Slide Mounting Bar

Screw the bar to the chassis in the former position of the handle, using the four

M4x12 countersunk screws provided. The bar fits correctly only one way round,

with the threaded holes nearest the front.

c. Replacement Case Top and Case Bottom

Use the original five screws and washers.

Fit the Jonathan Telescopic Slide (not supplied), e.g. Tru-Glide 110QD-2, and mounting

brackets to the unit and fit it into the rack. See the Manufacturer's slide specification

sheets for details of the fixings, brackets and mounting accessories.

Page 35

1250 Frequency Response Analyzer Installation

CWB / 1250_Op / Issue 9A 2-13

Figure 2.10 - Fitting rack ears, slide mounting bar and replacement cases

Page 36

Installation 1250 Frequency Response Analyzer

2-14 CWB / 1250_Op / Issue 9A

Page 37

Switching On and Initialising 1250 Frequency Response Analyzer

3-1 AMK / 1250 / 3

3

Switching On and Initialising

Section Page

3.1 Switch On 3.2

3.2 Initialising 3.3

3.3 Resetting 3.4

Page 38

Switching On and Initialising 1250 Frequency Response Analyzer

3-2 AMK / 1250 / 3

3.1 SWITCH ON

The mains on/off switch is under the bottom left hand corner of the front panel. Press in

to switch on, press again to switch off.

When the instrument is switched on, the Display setting is set to [All] (see Chapter 12

Section 2) regardless of its original setting. Therefore when power is switched on the

display will always show one of the following two messages:

Figure 3.1 - Power-up Message a.

This signifies that the 1250 has correctly remembered the settings for the Generator

etc., from the last time it was used. Also, any Learnt programs are still available, and

readings stored in the File have not been corrupted. Therefore the instrument may

continue to be used as if it had not been switched off. (A fuller explanation of this

feature is given in Chapter 14 Section 4 Power Fail).

The Time display, in hours, minutes and seconds, shows time elapsed since the

instrument was switched on, starting from zero. The time-of day can be entered in this

display from the Front Panel or externally, see Chapter 14 Section 3 Time Display.

Figure 3.2 - Power-up Message b.

This signifies that errors have been detected in the previous 1250 settings. Therefore

the control circuitry has erased the contents of the parameter store and returned all

settings to their default state. The contents of the File and the Learnt Programs 1 to 9

will also be erased, but Learnt Programs 10 to 18 will not be erased even if the

keyswitch is in the Supervisor position.

The configuration of the printed circuit boards (pcbs) present is also checked and the

"initialised" message displayed if:

a. Any of the essential pcbs are missing:

b. Any pcbs have been fitted or removed during the "power-off" period, e.g. option

boards.

The TIME display is reset to zero, as in "POWER RESTORED".

Page 39

1250 Frequency Response Analyzer Switching On and Initialising

AMK / 1250 / 3 3-3

3.2 INITIALISING

The 1250 can remember its previous settings for at least 100 hours whilst switched off.

Therefore it is most likely that POWER RESTORED will be displayed when the

instrument is switched on again. If the next measurement to be made is similar to the

one preceding switch-off, the 1250 is already virtually set up, and will need only slight

adjustment.

However, if a markedly different type of measurement is to be made, it is advisable to

“erase" all existing settings to ensure that no unwanted facilities, e.g. Bias, are

inadvertently left active. This is achieved by initialising, which returns all controls to

the default state, and also erases the File plus all Learnt programs (Note: To erase

Learnt Programs 10 to 18 the keyswitch must be in the Supervisor position). The default

states are given in Chapter 8, Menu Summary.

To initialise press "self test" on the front panel. Five softkeys will be assigned as shown

in Fig. 3.3:

Figure 3.3

Press INIT. Initialisation takes about 14 seconds to complete in Supervisor mode, and

about 250ms in Normal mode, (see Chapter 1, Section 4: Keyswitch). When initialisation

is complete, the Display will be as shown in Fig. 3.4.

Figure 3.4

The 1250 is now in an identical state to that shown in Fig. 3.2, except that Learnt

Programs 10 to 18 will also have been erased if the keyswitch is in the Supervisor

position. Numerical values, e.g. Generator Amplitude, will read "not entered" on the

Display when interrogated, but are actually set to their default values. The TIME display

is set to zero.

Page 40

Switching On and Initialising 1250 Frequency Response Analyzer

3-4 AMK / 1250 / 3

3.3 RESETTING

To return all settings to the default state, without erasing the File and Learnt Programs,

press the RESET soft key instead of INIT.

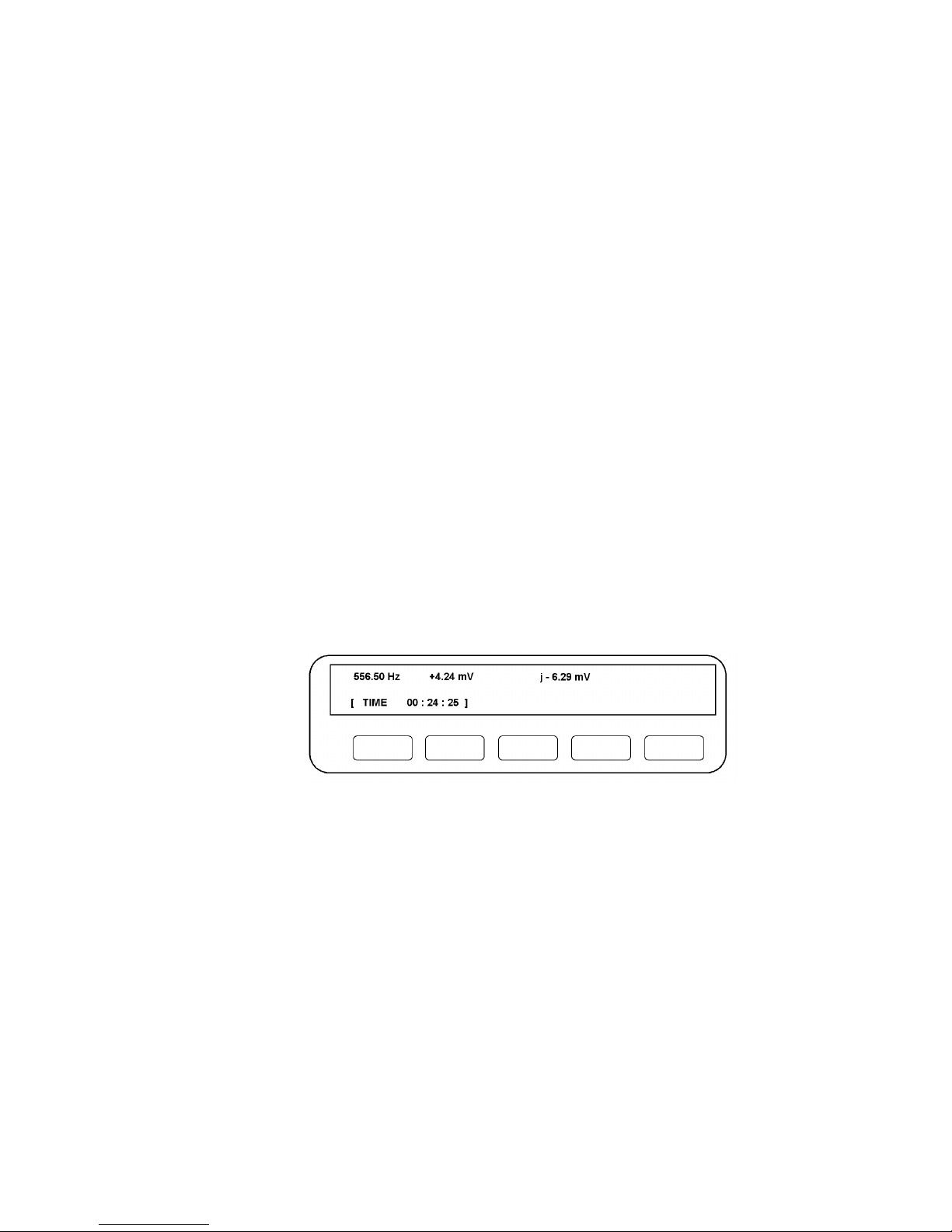

When resetting is complete, the Display will be as shown in Fig. 3.5.

Figure 3.5

For details of other “self test” functions, see Chapter 14 Section 2 Self Test.

Page 41

4-1

4

Making Measurements:

The Generator

Section Page

4.1 Simple Measurements 4.2

4.2 Setting the Generator 4.2

4.2.1 Introduction 4.2

4.2.2 Setting the Generator Menu 4.2

4.2.3 Waveform 4.2

4.2.4 Frequency 4.3

4.2.5 Clear 4.4

4.2.6 Amplitude 4.4

4.2.7 Bias 4.4

4.2.8 Modulated Carrier 4.4

4.3 Checking Generator Settings: Using the Status Displays 4.4

4.4 Starting the Generator 4.5

4.4.1 Generator Start Key 4.5

4.4.2 Generator Waveform Starting Point 4.5

4.5 Stopping the Generator 4.5

4.5.1 Introduction 4.5

4.5.2 Generator Stop Key 4.5

4.5.3 Generator Stop @ Key 4.6

4.5.4 Applications of the Stop @ Key 4.6

4.5.5 Generator Overload Protection 4.7

Page 42

Making Measurements: The Generator 1250 Frequency Response Analyzer

4-2 AMK / 1250 / 4

4.1 SIMPLE MEASUREMENTS

As the 1250 is so versatile, very comprehensive measuring sequences can be set up.

Before attempting these however, it is recommended that the user acquire familiarity

with the basic controls by making a few simple measurements first. Refinements such

as Sweep, Recording of Data, Scaling of readings etc. can then be added as experience

is gained.

The simplest way to start is to initialise, then couple the Generator output directly to the

Analyser Channel 1 input. The Generator and Analyser Menus can now be set up for a

single-frequency measurement, and the resulting readings will be shown on the Display

in Cartesian form.

A summary of all menus is given in Chapter 8.

4.2 SETTING THE GENERATOR

4.2.1 INTRODUCTION

Setting up the Generator Menu is explained in detail in the following section. The other

Menus are set in similar fashion, the salient points being explained under the relevant

headings. For quick reference, all the Menus are listed together in Chapter 8.

The following sections describe the making of measurements by using only the Front

Panel controls. Remote programming is described in Chapter 13.

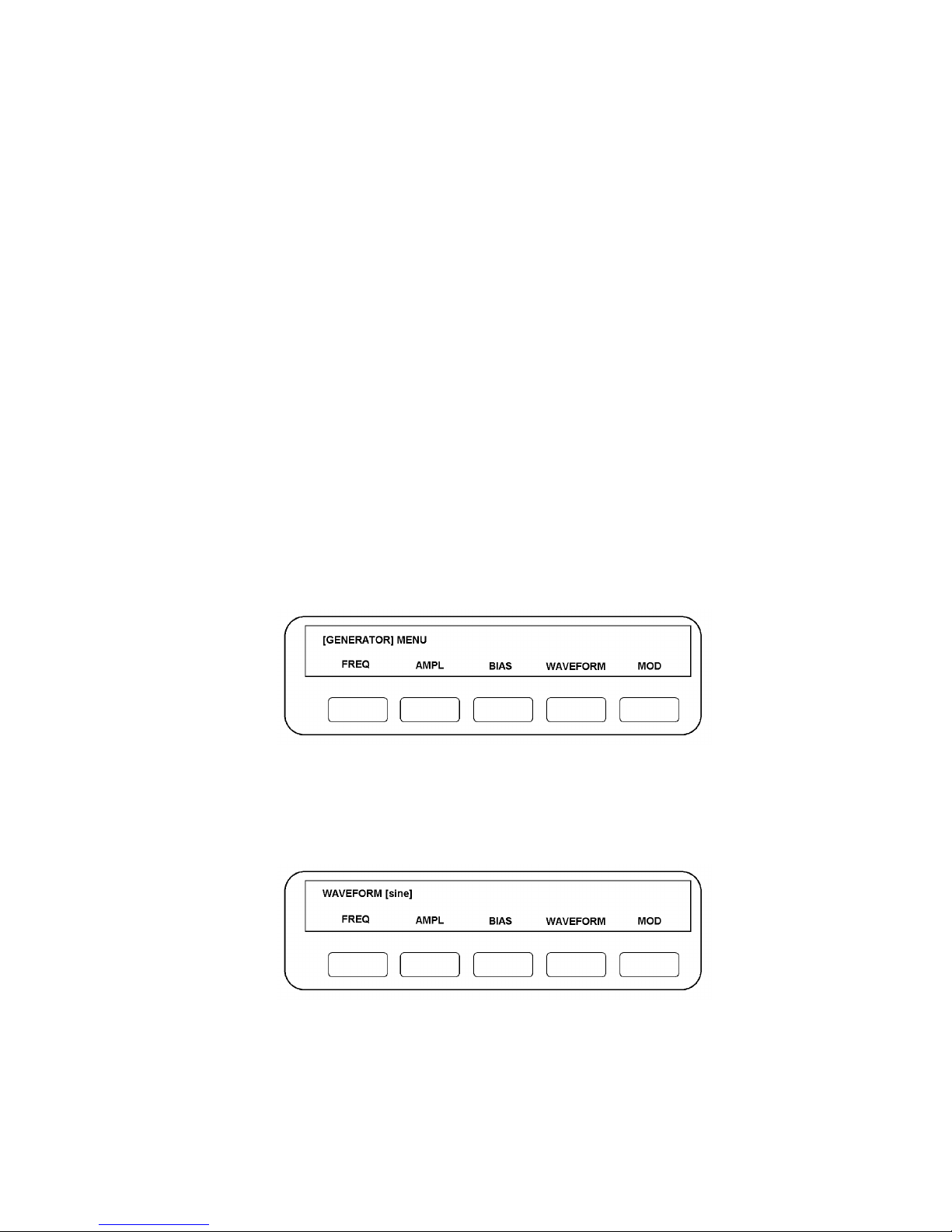

4.2.2 SETTING THE GENERATOR MENU

Press GENERATOR MENU. The five soft keys will be assigned functions as per Fig.

4.1:

Figure 4.1

4.2.3 WAVEFORM

For simplicity, start by establishing the required waveform. Press WAVEFORM: the

Display will change to the form shown in Fig. 4.2.

Figure 4.2

The word in the square brackets identifies the waveform currently commanded from the

Generator: [sine] is the default state, [square] and [triangle] are the alternatives. The

Page 43

1250 Frequency Response Analyzer Making Measurements: The Generator

AMK / 1250 / 4 4-3

square brackets signify that the user has a choice as to which word or symbol shall

appear between them. Successively operate the SELECT key until the chosen word

appears in the square brackets.

Press ENTER, the new command will not be accepted by the 1250 until ENTER is

pressed. The Display will revert to that shown in Fig. 4. 1.

To verify that the new command has been accepted, simply press WAVEFORM again.

If [square] has been entered the Display should now be as shown in Fig. 4.3.

Figure 4.3

4.2.4 FREQUENCY

Press FREQ. The Display should now resemble Fig. 4.4.

Figure 4.4

The top left-hand section, here labelled "Current Data", displays the current frequency,

represented by FREQ + xxx.xx Hz. If no frequency has been entered since an

initialisation, the Current Data section will show "not entered" although the value will in

fact have defaulted to 100Hz.

Key in the new frequency from the numeric key pad. The figures will appear after the

"+" sign between the round brackets, in the section labelled "New Data" in Fig. 4.4. The

flashing cursor indicates where the next character typed will be placed.

The maximum number of characters that can be displayed between the round brackets,

excluding any exponent entry (described later), is six, or five digits plus decimal point. If

further digits are typed, they do not displace those already displayed, and will usually be

ignored by the 1250 if they exceed the specified resolution.

The units of frequency, Hz in Fig. 4.4, appear in square brackets and can therefore be

altered by operating the SELECT key, the choices being mHz, Hz and kHz.

Alternatively, range may be expressed in exponent notation, by using the EXP key. The

1250 accepts exponents in the range 10-9 to 10+9, these being keyed in as E-9 to E+9,

the sign of the exponent being changed by the +/- key.

Page 44

Making Measurements: The Generator 1250 Frequency Response Analyzer

4-4 AMK / 1250 / 4

The exponent must always be expressed with respect to the units in the square

brackets.

Having set the required value plus units and/or exponent in the New Data section,

ENTER must be pressed for the change to be actioned. The Display will again revert to

that shown in Fig. 4.1. If FREQ is pressed again, the new frequency will now appear in

the Current Data section.

Note that the format may have been altered by the transition from New to Current Data

status, e.g. if 0.25 kHz is entered, this will appear as 250 Hz in the Current Data section.

4.2.5 CLEAR

If an error is made whilst keying information into the New Data section, pressing CLEAR

erases the contents of the round brackets. As with "Setting the Waveform", the contents

of the New Data section has no effect on the 1250 settings until ENTER has been

pressed.

4.2.6 AMPLITUDE

Press AMPL. The Display will be similar to Fig. 4.4 for frequency, but show AMPL, with

units of rms voltage. Key in the new amplitude as described for frequency and ENTER.

Note. The 1250N Generator source impedance is low, at approximately 1.5 Ω. So, for

low impedance loads, multiply the amplitude required by a scale factor to get the

amplitude you must program.

The scale factor = load impedance + 1.5

load impedance

4.2.7 BIAS

Press BIAS. The Display will be similar to Fig. 4.4 for frequency, but show BIAS, with

units of dc voltage. As bias can be of either polarity, select the one required by the +/key, set the required voltage and ENTER.

4.2.8 MODULATED CARRIER

This is available only when the optional Modulator/Demodulator Unit is fitted in the

1250. Connecting the Unit and the use of the MOD key are described in Chapter 15

"Options". The default state is "off”, so if no unit is fitted, the MOD key is not used.

If an attempt is made to enter any state other than "off" via the MOD key, when no Unit

is present, an Error Code Number will appear in the Display, accompanied by a warning

"beep". The Error Codes are listed in Chapter 11.

This completes the setting up of the basic Generator menu. The remaining facilities

accessible via the GENERATOR MENU key do not need setting up for simple

measurements and are described in later sections.

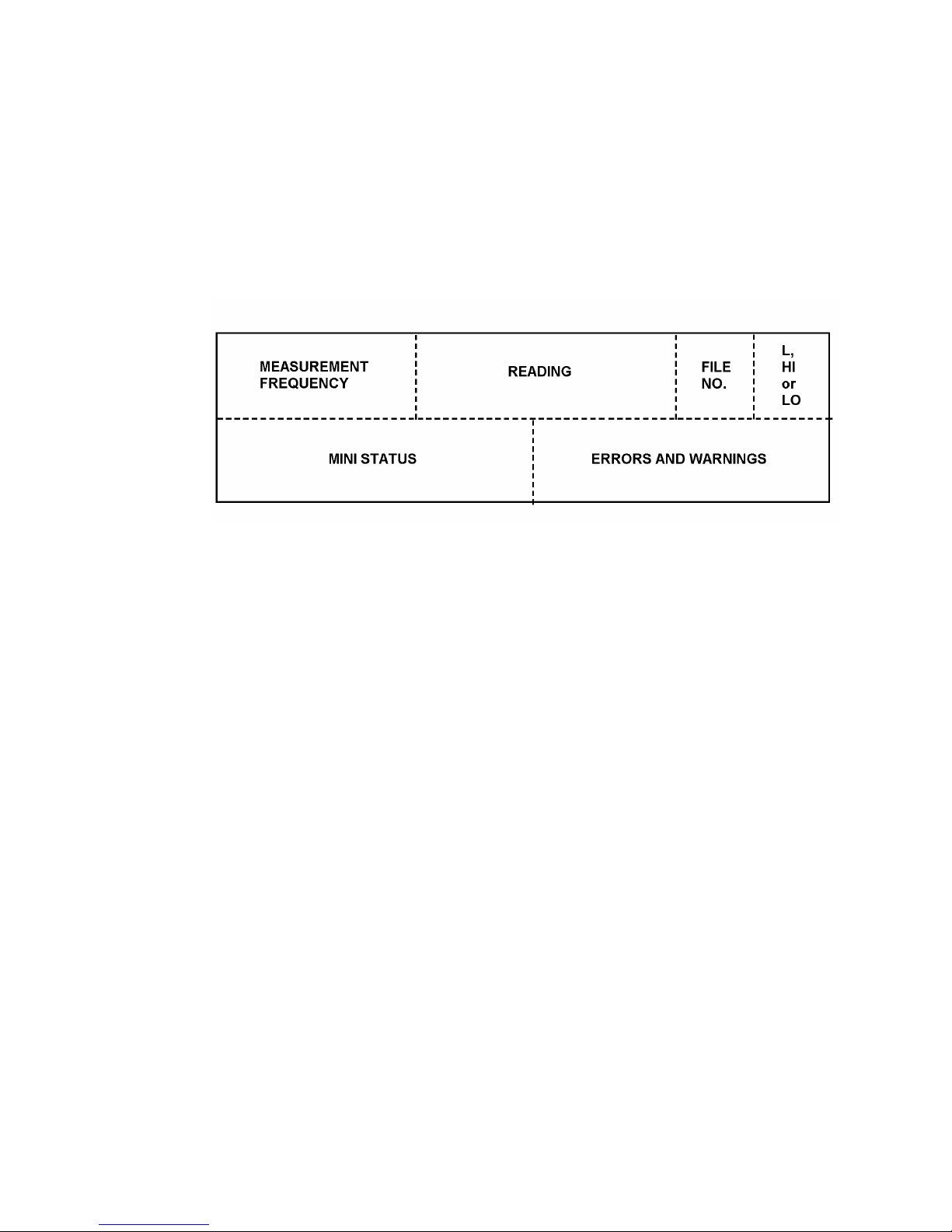

4.3 CHECKING GENERATOR SETTINGS: USING THE STATUS

DISPLAYS

To cheek that the Generator, or any other section of the 1250, has been set up correctly,

the user could step through all the Menus again. However, a better method is to use the

STATUS key, as described in Chapter 11.

Attention is also drawn to the Mini-Status Display, described in Chapter 7.

Page 45

1250 Frequency Response Analyzer Making Measurements: The Generator

AMK / 1250 / 4 4-5

4.4 STARTING THE GENERATOR

4.4.1 GENERATOR START KEY

As a general rule, when setting up a new measurement after initialisation, the Generator

should be the last item in the sequence to be started. The GENERATOR START key

thus becomes the Measurement Start control. By this means, all output devices such as

plotter, printer and computer can be enabled in advance; any scaling etc. can be set up

and sweep details entered. All these facilities are then held waiting, so that when the

Generator is finally started, everything begins at the same time, and no readings are

lost.

Bearing this in mind, the Generator can, in fact, be started at any time, by simply

pressing GENERATOR START. For simple measurements, it does not usually matter

which is `started` first, the Generator or the Analyzer, but both must be running for

readings to be taken.

4.4.2 GENERATOR WAVEFORM STARTING POINT

For most applications of single sinewave measuring techniques, the Generator

waveform starting point is not critical. The power-up reset that occurs when the 1250 is

switched on, and the initialising routine both ensure that the Generator waveform

commences at 0° the next time that START is pressed.

However, if the Generator has been left halted as the result of a 'stop' command of any

kind, the waveform may not start again from 0°. See Section 5 'Stopping the Generator'

for details.

4.5 STOPPING THE GENERATOR

4.5.1 INTRODUCTION

Apart from using a remote controller, the Generator can be stopped by:

1. Pressing GENERATOR STOP.

2. Connecting the HI and LO GENERATOR STOP INPUT sockets on the rear panel

to each other; or connecting the HI socket to 0V.

3. Using the STOP @ key, as explained in Section 5.3.

If methods 1 or 2 are used, the Generator waveform will remain at the level reached

when the command was actioned. If not initialised, or switched off then on again in the

interim, the next START command will cause the waveform to continue from wherever it

had stopped.

4.5.2 GENERATOR STOP KEY

Because of its immediate action, the GENERATOR STOP key can be used as a 'Panic

Switch' to stop the measurement if things seem to be getting out of control!

If it is essential to know the exact start point, and re-setting in any form is inconvenient,

use the STOP @ key, as explained in Section 5.3.

There is no need to stop the Generator before changing the settings of frequency,

amplitude etc.

Page 46

Making Measurements: The Generator 1250 Frequency Response Analyzer

4-6 AMK / 1250 / 4

4.5.3 GENERATOR STOP @ KEY

This control enables the Generator to be stopped at any of the four cardinal points

shown in Fig. 4.5. When the key is pressed, four soft keys will be assigned, one to each

Stop point.

Figure 4.5

When the required soft key is pressed, the next time that the Generator waveform

reaches the selected Stop point, it will halt there and stay until START is pressed again

(unless the 1250 is initialised, or switched on and off again in the meantime).

When START is operated again, the STOP @ command is cancelled, and the

Generator will continue running from the cardinal point at which it had been instructed to

stop.

4.5.4 APPLICATIONS OF THE STOP @ KEY

Apart from enabling the user to ensure that the Generator waveform always starts from

a known point, this control has several other applications in sine wave mode:

1. STOP @ 0° enables any offsets in the system under test to be adjusted to zero,

before testing commences.

2. If a large piece of machinery is being controlled by the Generator, e.g. a

hydraulic jack, this can be brought gently to rest by using STOP @ 0°, instead of

being stopped in some arbitrary position from which it abruptly returns to zero,

as could occur if GENERATOR STOP were used and then the equipment

switched off.

3. STOP @ 90° or 270° enable maximum amplitudes to be determined empirically,

see Chapter 9 'VARIABLE' Section 1.5 for a typical procedure.

Page 47

1250 Frequency Response Analyzer Making Measurements: The Generator

AMK / 1250 / 4 4-7

4.5.5 GENERATOR OVERLOAD PROTECTION

Accidental Short-Circuit

The Generator is protected against accidental short-circuiting of its HI and LO terminals.

The 1250N (low source impedance) uses feedback within the power amplifier to limit the

current to ∼300mA into a short-circuit. The 1250 relies on its higher source impedance

(50 Ω) to limit the current to a similar value. No error message is displayed.

Excessive External Voltage at Generator Terminals

If an external voltage of between ∼ ± 18V (∼ ±22V for 1250N) and ∼ ±30V is applied

across the Generator HI and LO terminals, Error 31 'Generator Overload' is displayed

and the output is held open-circuit until the overload is removed.

For overloads greater than ∼ ±30V the 1250 and 1250N behave differently.

1250. An S.C.R. clamp is triggered which short-circuits the Generator terminals via 33Ω

for ∼ 5ms before open-circuiting them and displaying Error 31. Remove the overload to

restore normal operation.

1250N. An S.C.R. clamp is triggered which short-circuits the Generator terminals. Then:

a) If the overloading source can supply more than ∼ 800mA, an internal protection fuse

blows which open-circuits the Generator output. Error 31 is displayed. Replace the fuse

to restore normal operation.

The fuse is an 800mA anti-surge, 20mm X 5mm cartridge type, Part No. 360106110 and

is located on Option 12506D (Board 16). To access, remove the heat sink (4 screws).

b) If the overloading source cannot supply more than ∼ 800mA, the fuse does not blow

and the Generator output remains short-circuited even after the overload is removed.

Error 31 is not displayed. Switch the 1250N 'off then 'on' to restore normal operation.

During the short-circuit, the Generator output is fully protected.

Page 48

AMK/1250/3 5-1

5

Making Measurements: The Analyzers

Section Page

5.1 Introduction 5.2

5.2 Setting the [ANALYZER COMMON] Menu 5.2

5.2.1 ∫ Time 5.2

5.2.2 Delay 5.3

5.2.3 Harmonic 5.3

5.2.4 Order 5.4

5.2.5 Auto ∫ 5.4

5.2.6 Applications of Auto Integration 5.4

5.3 Setting Individual Analyzers 5.6

5.3.1 Range 5.6

5.3.2 Demod 5.6

5.3.3 Coupling 5.6

5.3.4 Input 5.6

5.4 Measurement Start 5.7

5.5 Stopping the Analyzer; Stop and Break Keys 5.8

5.6 Changing Menus during Recycle 5.8

5.7 Measurement Start Point 5.8

5.7.1 Implementation of Delay 5.8

Page 49

Making Measurements: The Analyzers 1250 Frequency Response Analyzer

5-2 AMK/1250/3

5.1 INTRODUCTION

Having completed the Generator Menu, the Analyzers may now be set up. Channels 1

and 2 are connected to Analyzers 1 and 2 respectively. The numbering of any

additional Analyzers is explained in Chapter 16, The 1251 Multichannel Analyzer

System.

5.2 SETTING THE [ANALYZER COMMON] MENU

Press ANALYZER MENU. The Display will show [ANALYZER COMMON]. The term

'COMMON' indicates that the values entered here will apply to all the Analyzers in the

system. Five soft keys are assigned as described below.

5.2.1 ∫∫ TIME (where ∫ is the symbol for integration).

Enter the required numerical value here, plus the chosen units, i. e. time [sec] or cycles

[cyc]. If the signal to be analysed is noisy, the rms error in the readings due to the noise

tends to zero as the integration time is increased. Hence the longer the integration time

that can be tolerated, the closer the final reading will approach to the true value of the

wanted signal.

The integration time chosen usually has to be a compromise between speed of

measurement and acceptably small errors in the reading.

The ability of the Analyzers to reject unwanted frequencies, especially harmonics is

illustrated in Fig. 5.1

Figure 5.1

The curves indicate that one cycle of integration will give a reasonable reading where

the signal contains little random noise, but may have some harmonic distortion.

Page 50

1250 Frequency Response Analyzer Making Measurements: The Analyzers

AMK/1250/3 5-3

For measurements where the random noise level is high, however, the number of cycles

of integration needs to be increased to improve the signal to noise ratio.

The minimum values that can be set are 10 ms or 1 cycle of the fundamental frequency,

whichever is the longer, up to 655 Hz. Above this, the values are 10 ms or 61 cycles of

the fundamental frequency, whichever is the longer (61 periods at 655 Hz = 93 ms).

If a time value is entered, the 1250 automatically rounds this up to give an exact

number of cycles, or blocks of 61 cycles, according to frequency. Hence the user would

normally enter a time value only as an approximate setting.

If no entry is made after initialising, a default value will be assigned automatically,

depending upon the frequency of the Generator. This value will be as per the minima

specified above.

If the user enters an integration time of less than the period of 1 cycle of the Generator

frequency, the 1250 will not reject it, but will automatically set the relevant minimum

integration time for the frequency concerned.

When the Analyzer is set to measure the nth harmonic, over x cycles of integration, the

1250 always interprets this as meaning x cycles of the fundamental frequency, and not

the harmonic.

One technique for evaluating the effect of different integration times, once

measurements are being made, is to observe the scatter on the displayed readings, with

the Analyzer on RECYCLE. If the current integration time is too short to allow

observation of the readings, add in a delay, as explained under Section 2.2 'DELAY'. If

the scatter is due to noise, or other spurious components, increasing the ∫ TIME value

should cause a decrease in the scatter.

5.2.2 DELAY

This facility enables a time delay to be interposed between applying the Generator

waveform to the system under test and taking a reading.

Two applications of this are:

1. To allow the system under test to 'settle' after a change to the input stimulus, e.g.

after each change of frequency when performing a sweep.

2. To enable scatter on readings to be observed on the Display, when using only a short

∫ TIME value.

Note: The 1250 itself does not require any delay to allow it to settle. However, on

receipt of a command to start, either from the front panel or by remote control, it takes

approximately 10 ms to action the command.

As with ∫ TIME, the required delay is entered as a number, plus units of time or cycles,

but the 1250 converts all delays into time values. See Section 4 'Measurement Start' for

the implications of this. There is no minimum delay, and the default value is zero.

5.2.3 HARMONIC

The 1250 can be set to analyze the response of the system under test at any harmonic

of the fundamental up to the 16th, provided that the frequency of the harmonic does not

exceed 65.535 kHz. Enter the required harmonic number, between 1 and 16, in the

round brackets in the Display. The default value is 1, i.e. the fundamental frequency.

Page 51

Making Measurements: The Analyzers 1250 Frequency Response Analyzer

5-4 AMK/1250/3

5.2.4 ORDER

Using Order Analysis, the 1250 computes the response of the system under test at the

first 16 harmonics of the analysis frequency, all within a single measurement period.

This is effectively a 'fast' harmonic analysis, since in the normal harmonic mode only the

selected harmonic response is computed within one measurement period. However,

Order Analysis does not work with AUTO ∫, and cannot be used when the analysis

frequency is greater than 650 Hz (or 400 Hz when Synchronising).

If Harmonic Analysis has also been set up, Order Analysis computes the 16 harmonics

of the chosen harmonic, rather than of the fundamental (generator) frequency.

For example, if HARMONIC (10) has been selected, then Order Analysis computes the

10th, 20th, 30th ..... 150th, and 160th harmonics of the measurement frequency,

provided that HARMONIC (10) is less that 650 Hz (or 400 Hz when Synchronising).

Setting up ORDER (2), for example, then displays the second of the 16 values viz: the

20th harmonic.

The Order Analysis facility is particularly useful in conjunction with the Synchroniser

Unit, Option 12501 (see Chapter 15, Section 1 for further explanation).

Note: REFORMAT (accessed via the DATA OUTPUT menu) must be 'on' when the

ORDER facility is in use.

5.2.5 AUTO ∫∫

When a signal contains random noise or other spurious components, it may be difficult

to decide how long an integration is required in order to give a result with acceptably

small error. The crude approach of providing plenty of time may entail a test sequence

that is unnecessarily lengthy, particularly if a succession of signals cover a wide

dynamic range and thus require different integration times.

With auto-integration the measurement is continued until either the variation in the

running average result becomes sufficiently small or the maximum time allowed has

expired. Two levels of acceptable variation are available, chosen by integrating for a

'short' or 'long' time, the readings being averaged until the Standard Deviation falls

below the limits:

short: = ±10% of reading ± 0.01% of full scale;

long: = ±1.0% of reading ± 0.001% of full scale.

Students 't' test is applied to the Standard Deviation to ensure a 90% confidence level.

The maximum time that the user is prepared to allow should be entered using the ∫

TIME key. If the 1250 has just been initialised, and no new value is entered here, the

default value is automatically increased when AUTO ∫ is enabled, to the longer of 3

cycles or 1 second. This is now the minimum time that can be set, i.e. auto-integration

relies on at least 3 readings.

If the maximum integration time is reached before the measured deviation has fallen

below the selected limit, a reading will still be displayed, but with ERROR 82 flagged as

a warning that the specified confidence level has not necessarily been achieved.

5.2.6 APPLICATIONS OF AUTO INTEGRATION

Where more than one Analyser is being used, auto-integration could usefully be

assigned to the channel with the worst signal-to-noise ratio. Once the chosen Standard

Deviation limit has been achieved on this channel, the measurement will terminate. It is

now probable that the readings on the less noisy channels will have even smaller

Standard Deviations.

Page 52

1250 Frequency Response Analyzer Making Measurements: The Analyzers

AMK/1250/3 5-5

Auto-integration can also be used to reduce sweep time when the signal-to-noise ratio

varies widely across the swept spectrum. Consider the points plotted in Fig. 5.2.

Figure 5.2 - Plot of readings from a sweep measurement

Either side of the band marked "noise", a fairly clear curve is indicated, as represented

in Fig. 5.3. A short integration time will suffice here.

Figure 5.3 - Idealised curve from Fig. 5.2

As the scatter on the readings increases as shown towards the centre of Fig. 5.2, the

integration time must be lengthened until it is at a maximum where the wanted signal is

completely obscured by noise. This process will yield a plot which approaches the

idealised curve of Fig. 5.3.

If a fixed integration time is chosen, this must be long enough to cope with the noisiest

part of the signal. Hence it will be unnecessarily long where the signal is relatively

clean. Auto-integration solves this problem as illustrated by the following example.

Example

With fixed integration time. Suppose that this must be 10 seconds in the noisiest

region. If the sweep consists of 60 steps, the sweep time would therefore be

60 X 10 = 600 seconds = 10 minutes

Page 53

Making Measurements: The Analyzers 1250 Frequency Response Analyzer

5-6 AMK/1250/3

With auto-integration. Not all the steps in the sweep will need the full 10 seconds. A

typical simplified allocation could be:

20 points at 10 seconds each = 200 seconds

15 points at 5 seconds each = 75 seconds

25 points at 1 second each = 25 seconds

TOTAL 300 seconds = 5 minutes

i.e. half the previous time.

5.3 SETTING INDIVIDUAL ANALYZERS

Having completed the setting up of the common features of the Analyzers, the last

operation of the ENTER key should have left the Display showing [ANALYZER

COMMON). Successive operations of the SELECT key will call up the specific Analyzer

menus, each of which will assign four soft keys as follows:

5.3.1 RANGE

Pressing this key offers the user a choice of several fixed ranges from 30mV to 300V.

See the full Specification, Chapter 17 for details of these.

There is also an auto-ranging feature whereby the 1250 itself selects the range which

will produce an accurate result with the best possible resolution. Measurements start on

the most sensitive range and as soon as an overload is detected, the measurement is

terminated, the range is changed and the measurement restarted. This process

continues until the correct range has been found.

On termination of the measurement, the Analyzer automatically resets to the most

sensitive range, so if on Recycle, the auto-ranging process is repeated for every

measurement. The default state is auto-range.

5.3.2 DEMOD

This key is used only when the optional Modulator/Demodulator Unit is fitted.

Instructions for its use will be found in Chapter 15, Options. The default state is off. The

Unit is not required for simple measurements.

If an attempt is made to enter any state other than off via the DEMOD key, when no

Unit is present, an Error Code Number will appear in the Display, accompanied by a

warning "beep". The Error Codes are listed in Chapter 11.

5.3.3 COUPLING

The default state gives direct [dc] coupling of the signal to the Analyzer input. This

mode should be used wherever possible, as it introduces minimum phase shift,

particularly at low frequencies.

On the other hand, if the incoming signal has an unwanted direct component, such as dc

bias, this could necessitate using the Analyzer on a relatively insensitive range, which

would impair the resolution of the ac component. In this case, ac coupling may he used

to block the dc component.

5.3.4 INPUT

On 1250A, 1250N, the Analyzer input can be routed via the 4mm sockets on either the

front or rear; this is selectable via the front panel or a remote command code. The

default is Front. For 1250B and 1250E, the inputs are hard-wired to the rear panel

sockets, and are unaffected by the front panel setting or remote commands.

Page 54

1250 Frequency Response Analyzer Making Measurements: The Analyzers

AMK/1250/3 5-7

5.4 MEASUREMENT START

The Generator and Analyzer are assumed to have been fully set up for making simple

measurements, as described in the previous sections.

As explained under 'Starting the Generator', it is recommended that the Analyzer be

enabled now, before the Generator is started. However, the user may choose either of

the following methods:

1. With the Generator stopped

a. Enable the Analyser by pressing either SINGLE if only one reading is to be

taken, or RECYCLE if a continuous series of readings is required. The Analyzer

Status will change from ANALYZER STOP to ANALYZER IDLE, i.e. the

Analyser is now ready to make a measurement, but cannot do so until the

Generator has started.

b. Press GENERATOR START. The Display will now be updated to show the

latest reading, and the Generator Status will change from STOP to RUN.

c. If the Analyser is on RECYCLE, its Status will change to RUN, but if a Delay has

been entered, the Status will alternate between DELAY and RUN.

If the Analyser is on SINGLE with a Delay, the Status will first show DELAY,

change to RUN whilst the measurement is being made, then revert to STOP on

completion.

2. With the Generator already running