Page 1

GE Fanuc Automation

Programmable Control Products

Genius

t

Hand-held Monitor

User’s Guide

GFK-0121E June 1994

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to

equipment, a Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL–002

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding

and operating the equipment.

This document is based on information available at the time of its publication. While

efforts have been made to be accurate, the information contained herein does not

purport to cover all details or variations in hardware or software, nor to provide for

every possible contingency in connection with installation, operation, or maintenance.

Features may be described herein which are not present in all hardware and software

systems. GE Fanuc Automation assumes no obligation of notice to holders of this

document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or

statutory with respect to, and assumes no responsibility for the accuracy, completeness,

sufficiency, or usefulness of the information contained herein. No warranties of

merchantability or fitness for purpose shall apply.

The following are trademarks of GE Fanuc Automation North America, Inc.

Alarm Master CIMSTAR Helpmate PROMACRO

Series Six CIMPLICITY GEnet Field Control

Logicmaster Series One Series 90 CIMPLICITY 90–ADS

Genius Modelmaster Series Three VuMaster

CIMPLICITY P owerTRA C Genius PowerTRA C ProLoop Series Five

W orkmaster

e

Copyright 1994 GE Fanuc Automation North America, Inc.

All Rights Reserved

Page 3

Preface

Content of this Manual

Chapter 1. Introduction: Chapter 1

describes the Hand-held Monitor. This

chapter lists catalog numbers and

specifications. It also explains

compatibility between different versions

of the Hand-held Monitor and various

other products.

Chapter 2. Hardware Setup: Chapter 2

gives instructions for powering the HHM,

changing its EPROM, and changing its

battery pack. It also describes how to

install the HHM on a panel, and how to

install a separate HHM connector on a

bus.

Chapter 3. Getting Started: Chapter 3

explains how turn on the Hand-held

Monitor, and how to set up its features for

your application. Chapter 3 also explains

how to test the Hand-held Monitor’s

operation.

Chapter 4. Device Configuration:

Overview: Chapter 4 gives basic

instructions for using the Hand-held

Monitor to configure Genius devices.

Chapter 5. Monitoring the Bus and its

Devices: Chapter 5 explains how to use the

Hand-held Monitor to displ ay data and

status information from other devices on

the bus. It also expl ai ns how to clear faults,

switch a dual bus , ex ecute Pulse Testing,

and display the bus scan time.

Chapter 6. Reading CPU Memory:

Chapter 6 explains how to use the HHM

to read the contents of specified memory

locations in CPUs on the bus.

Chapter 7. Error Messages: Chapter 7

defines messages that may be displayed

during HHM startup or operation, or

device configuration.

Related Publications

For more information, refer to these

publications:

Genius I/O System User’s Manual

(GEK-90486–1). Reference manual for

system designers, programmers, and

others involved in integrating Genius I/O

products in a PLC or host computer

environment. This book provides a

system overview, and describes the types

of systems that can be created using

Genius products. Datagrams, Global Data,

and data formats are defined.

Genius Discrete and Analog Blocks User’s

Manual (GEK-90486–2). Reference

manual for system designers, operators,

maintenance personnel, and others using

Genius discrete and analog I/O blocks.

This book contains a detailed description,

specifications, installation instructions,

and configuration instructions for all

currently–available discrete and analog

blocks.

Series 90-70 Remote I/O Scanner User’s

Manual (GFK-0579). Reference manual

for the Remote I/O Scanner , which

interfaces a drop containing Series 90-70

modules to a Genius bus. Any CPU

capable of controlling the bus can be used

as the host. This book describes the

Remote I/O Scanner features,

configuration, and operation.

Genius Bus Interface Unit and Field

Processor User’s Manual (GFK-0825).

Reference manual for the Bus Interface

Unit and the Field Processor, which

interface a station containing Field

Control modules to a Genius bus. Any

CPU capable of controlling the bus can be

used as the host. This book describes the

features, configuration, and operation or a

Bus Interface Unit or Field Processor.

Field Control I/O Modules User’s Manual

(GFK-0826). Reference manual for system

GFK-0121

E

Index-3

Page 4

Preface

designers, operators, maintenance

personnel, and others using Field Control

I/O modules. This book contains a

detailed description, specifications, and

installation instructions for all

currently–available I/O modules.

Series 90-70 Bus Controller User’s

Manual (GFK-0398). Reference manual

for the Bus Controller, which interfaces a

Genius bus to a Series 90-70 PLC. This

book describes the installation and

operation of the Bus Controller. It also

contains the programming information

needed to interface Genius I/O devices to

a Series 90-70 PLC.

Series 90-30 Bus Controller User’s

Manual (GFK-1034). Reference manual

for the Bus Controller, which interfaces a

Genius bus to a Series 90-30 PLC. This

book describes the installation and

operation of the Bus Controller. It also

contains the programming information

needed to interface Genius I/O devices to

a Series 90-30 PLC.

Series Six

Manual (GFK-0171). Reference manual

for the Bus Controller, which interfaces a

Genius bus to a Series Six PLC. This book

describes the installation and operation of

the Bus Controller. It also contains the

programming information needed to

interface Genius I/O devices to a Series Six

PLC.

Bus Controller User’s

describes the installation and operation of

the Bus Controller. It also contains the

programming information needed to

interface Genius I/O devices to a Series

Five PLC.

Genius I/O PCIM User’s Manual

(GFK-0074). Reference manual for the

PCIM, which interfaces a Genius bus to a

suitable host computer. This book

describes the installation and operation of

the PCIM. It also contains the

programming information needed to

interface Genius I/O devices to a host

computer .

Genius I/O Single-slot PCIM User’s

Manual (GFK-0881). Reference manual

for the Single-slot PCIM, which interfaces

a Genius bus to a suitable host computer.

This book describes the installation and

operation of the PCIM. It also contains the

programming information needed to

interface Genius I/O devices to a host

computer .

We Welcome Your Comments

and Suggestions

At GE Fanuc automation, we strive to

produce quality technical documentation.

After you have used this manual, please

take a few moments to complete and

return the Reader’s Comment Card

located on the next page.

Index-4

Series Five Bus Controller User’s

Manual (GFK-0248). Reference manual

for the Bus Controller, which interfaces a

Genius bus to a Series Five PLC. This book

Hand-held Monitor User’s Guide – June 1994

Jeanne L. Grimsby

Senior Technical Writer

GFK-0121E

Page 5

Contents

Chapter 1 Introduction 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hand-held Monitor Description 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HHM Compatibility 1-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HHM Specifications 1-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ordering Information 1-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Hardware Setup 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power for the Hand-held Monitor 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the PROM 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Permanent Installation 2-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing a Separate Hand-held Monitor Connector 2-9 . . . . . . . . . . . . . . . . . . .

Chapter 3 Getting Started 3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Device Configuration: Overview 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Monitoring the Bus and its Devices 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitor Block Display for Discrete I/O and Input Blocks 5-4 . . . . . . . . . . . .

Monitor Block Display for Discrete Relay Output Blocks 5-5 . . . . . . . . . . . .

Monitor Block Display for Analog Blocks 5-5 . . . . . . . . . . . . . . . . . . . . . . . . .

Monitor Block Display for RTD or Thermocouple Blocks 5-5 . . . . . . . . . . . .

Monitor Block Display for a High-speed Counter Block 5-6 . . . . . . . . . . . . .

Monitor Block Display for a P owerTRAC Block 5-7 . . . . . . . . . . . . . . . . . . . .

Monitor/Control Reference Display for a Discrete, Relay , or High-speed Counter

Block 5-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitor/Control Reference Display for an Analog, RTD, or Thermocouple Block

5-10

Monitor/Control Reference Displays for a P owerTRA C Block 5-11 . . . . . . . .

Chapter 6 Reading CPU Memory 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7 Error Messages 7-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GFK-0121E

Table of Contents i

Page 6

Restarts for autonumbers that do not restart in each

chapter .

figure bi level 1, reset

table_big level 1, reset

chap_big level 1, reset1

app_big level 1, resetA

figure_ap level 1, reset

table_ap level 1, reset

figure level 1, reset

table level 1, reset

these restarts must be in the header frame of chapter 1.

a:ebx, l 1 resetA

a:obx:l 1, resetA

a:bigbx level 1 resetA

a:ftr level 1 resetA

c:ebx, l 1 reset1

c:obx:l 1, reset1

c:bigbx level 1 reset1

c:ftr level 1 reset1

Reminders for autonumbers that need to be restarted

manually (first instance will always be 4)

let_in level 1: A. B. C.

letter level 1:A.B.C.

num level 1: 1. 2. 3.

num_in level 1: 1. 2. 3.

rom_in level 1: I. II. III.

roman level 1: I. II. III.

steps level 1: 1. 2. 3.

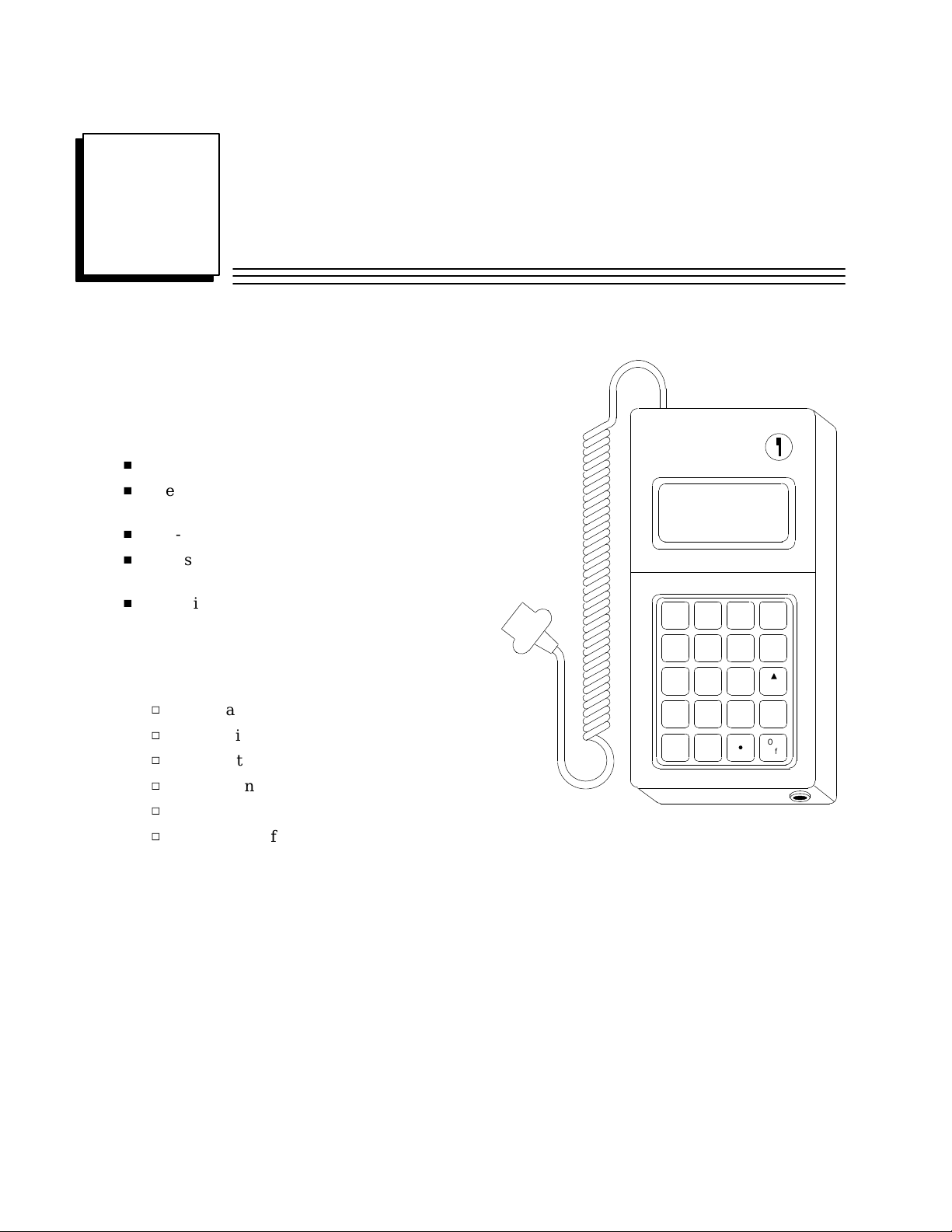

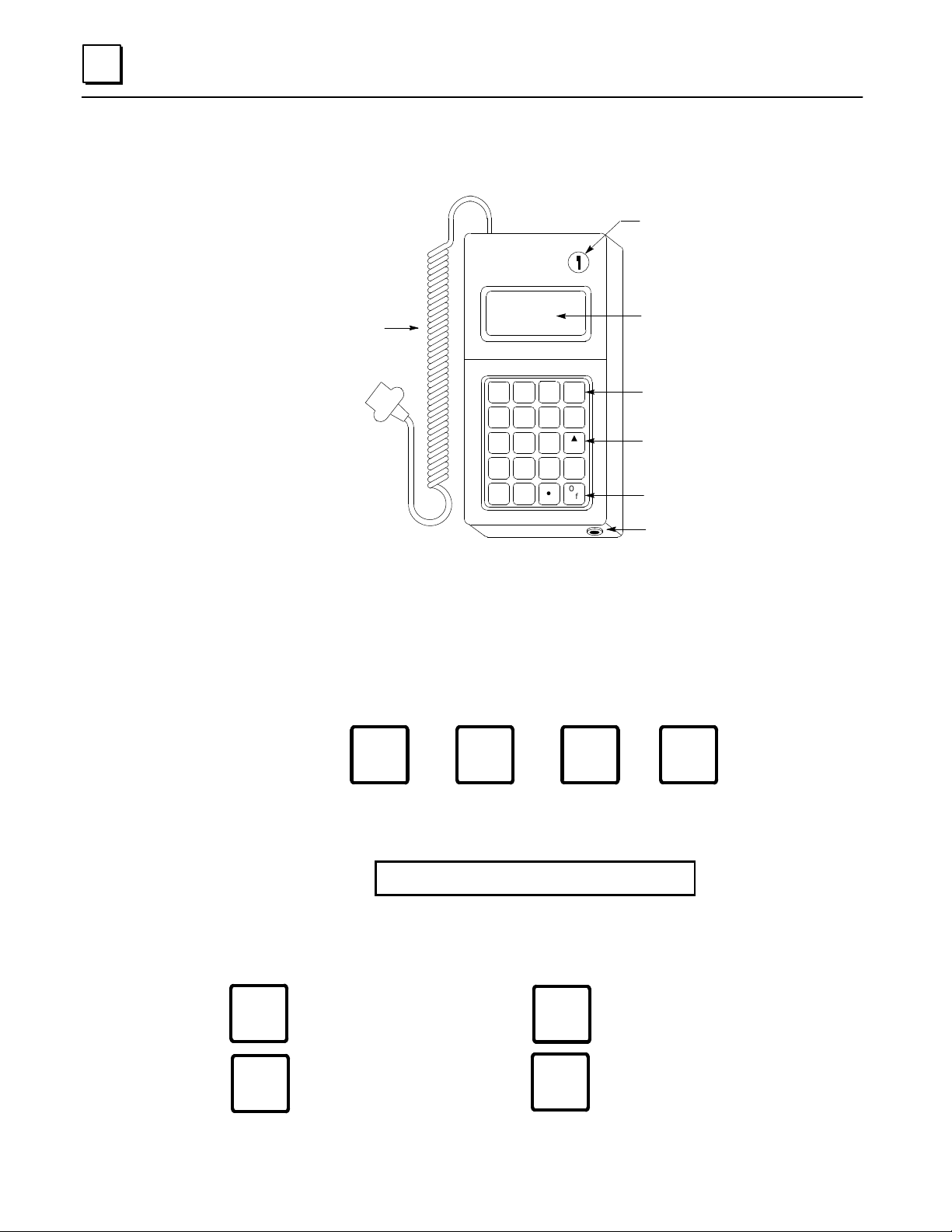

Chapter 1 Introduction

1

The Hand-held Monitor (HHM) is a convenient operator

interface device that can be used to set up and monitor a Genius

I/O and communications system.

The HHM features:

H

An LCD display with four lines of 16 characters each.

H

Selectable display language: English, German, French, or

Italian.

H

A 20-key sealed-membrane keypad.

H

A keyswitch that can be used to restrict operator access to

certain functions, as selected for the application.

H

Operation from its battery pack, or by 115 volt AC

or 230 volt AC power .

The Hand-held Monitor screen is the operator’s

window to the Genius bus and all of its devices. It can

be used to display:

h

I/O data for any device on the bus.

h

Diagnostics.

h

Bus scan time.

h

Descriptions of all devices on the bus.

h

Global Data addresses.

h

Memory data from CPUs on the bus.

The Hand-held Monitor can also be used for device configuration, fault clearing, and forcing I/O circuits

and dual bus selection. It can also be set up to prevent the use of any of these capabilities.

A k ey feature of the Hand-held Monitor is its ability to communicate with I/O blocks and to force discrete

and analog I/O, whether or not there is a PLC or computer connected to the bus. This greatly simplifies

system check-out prior to full-scale system operation.

GENIUS

Hand Held Monitor

GE Fanuc

F1 F2 F3 F4

789Home

456

123Clear

+

0

–

mon

cfg

Y

Menu

On

D

Off

GFK -0121E

1-1

Page 7

1

Hand-held Monitor Description

GENIUS

Hand Held Monitor

GE Fanuc

Mode Select Keyswitch

mon

cfg

HHM Cable

F1 F2 F3 F4

789Home

456

123Clear

+

–

Menu

0

D

Y

On

Off

LCD Display

Function Keys

Decimal Keys

Operation Keys

Connection for

Charger/Adapter

The HHM Keypad

The Hand-held Monitor keypad has three types of keys: function keys (F1 - F4), decimal

keys, and operation keys.

Function K eys: The four keys in the top row (F1, F2, F3, and F4) have functions that

change as the display changes.

F1 F2 F3 F4

1-2

The bottom line of the screen shows the current functions of these keys. For example:

n x t p r v a c t v b u s

Decimal Keys: The decimal keys are used to enter numbers and change sign.

Operation Keys: The four keys on the right side of the keypad are used to control HHM

operations:

Home

∆

Menu

displays the Home menu.

displays the previous screen.

Clear

On

Off

clears HHM error messages,

clears Genius faults,

deletes HHM keypad entries.

turns the HHM on or off.

Hand-held Monitor User’s Guide – June 1994

GFK-0121E

Page 8

The HHM Display

The Hand-held Monitor has a 4-line LCD screen. On a new Hand-held Monitor,

displays are in English. The display language can easily be changed to French, German,

or Italian. (Instructions for changing the display language are on page 3-5).

In addition to alphanumeric characters, the display uses the following special characters:

tri-state input.

I

T

Output with Feedback, or block with both inputs and outputs.

O

T

circuit is forced OFF .

4

circuit is forced ON.

1

relay block point is forced open.

O

relay block point is forced closed.

C

circuit controls a Bus Switching Module.

B

S

reference address or Device Number not yet assigned.

?

reference address is out of range for the presently-selected HHM host.

*

For a list of other HHM abbreviations and their meanings, select F3 (HELP) from the

HHM Utilities menu.

1

K eyswitch

The Hand-held Monitor’s keyswitch can be used to restrict access to certain features of

the HHM.

With the key present, the switch can be placed in either “configure” (cfg) or “monitor”

(mon) position.

cfg with the switch in Configure position, all HHM functions are available. In this

mode, the Hand-held Monitor can be configured to determine which of its features will be usable once the key is removed.

mon: with the keyswitch in Monitor position, the HHM can monitor bus and block

data. Additional HHM functions, such as clearing faults or configuring I/O

blocks, can be used in Monitor mode only if the HHM has been set up to permit

their use.

The key must be present to move the switch from Monitor to Configure mode position;

it can only be removed in MON position. Two identical keys are supplied with each

Hand-held Monitor . The key should be removed if system security is a concern.

Accessories

The Hand-held Monitor comes with:

H

A sturdy removable leather case. The case has a rear tab with snap closure for

carrying the HHM on a belt. The handle can be pivoted back to stand the

Hand-held Monitor upright on a table.

GFK-0121E

H

A rechargeable battery pack.

H

A battery charger/adapter with 8-ft cord.

H

Two keys for the mode-selection keyswitch.

H

A removable 5 ft (1.5 meter) coiled communications cable.

Chapter 1 Introduction

1-3

Page 9

1

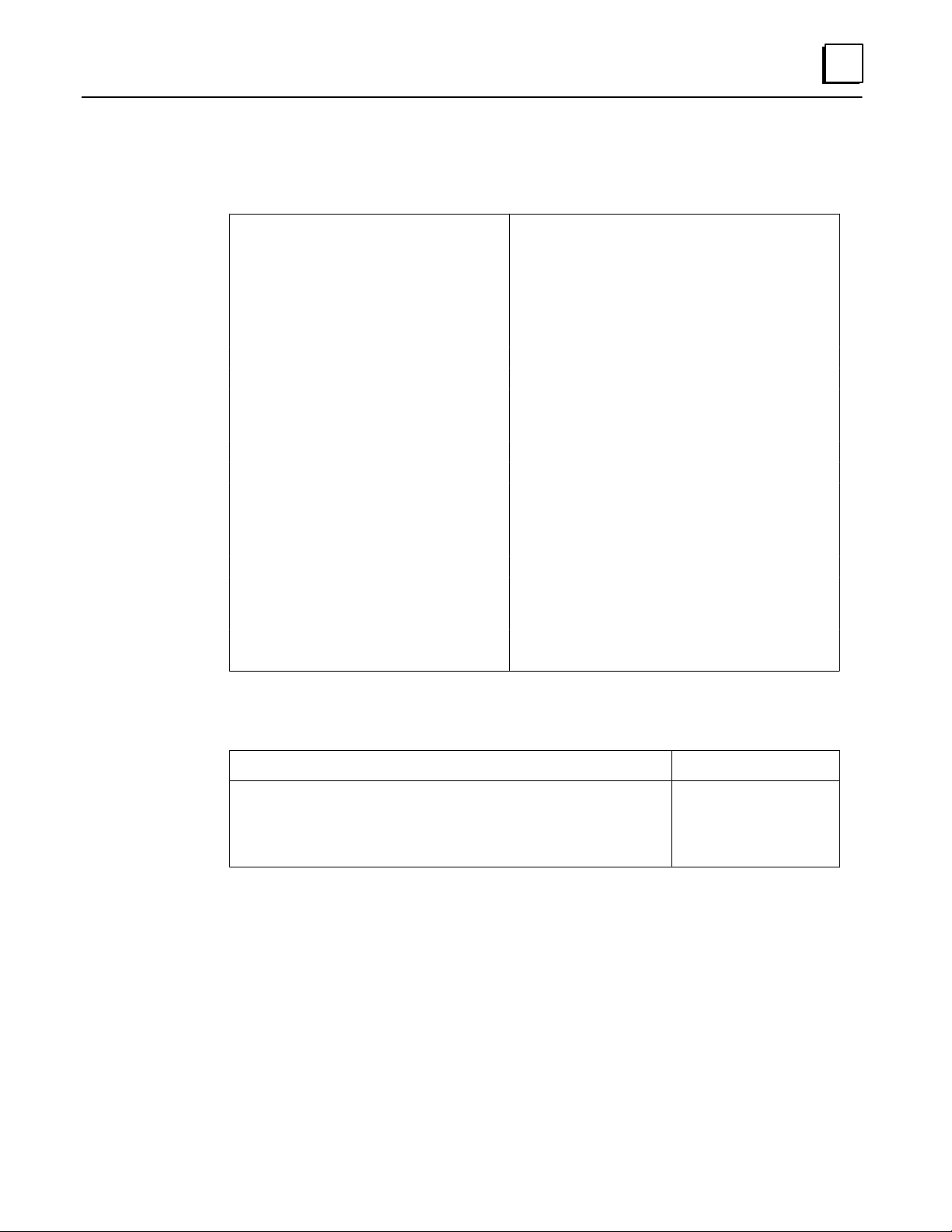

HHM Compatibility

The following table shows which Hand-held Monitor versions are compatible with

specific Genius I/O, Field Control, and related products.

Note that the functionality of an older Hand-held Monitor can be upgraded by replacing

its firmware PROM. (PROM installation instructions are in chapter 2).

Product

Type

24/48VDC Analog 4 Input/2 Output block

24/48VDC RTD 6 Input block

24/48VDC Thermocouple 6 Input block

24/48VDC Current-Source Analog 4 Input/2 Output block

24/48VDC Current-Source Analog 6 Output block

115V A C Analog 4 Input/2 Output block

115V A C/125VDC RTD 6 Input block

115VA C/125VDC Thermocouple 6 Input block

115V A C/125VDC Current-Source Analog 4 Input/2 Output block

115V A C/125VDC Current-Source Analog 6 Output block

24/48VDC Source 16 I/O block

24/48VDC Sink 16 I/O block

24VDC Source 16 I/O block

24VDC Sink 16 I/O block

12/24VDC Source 32 I/O block

5/12/24VDC Sink 32 I/O block

115V A C 8 I/O block

115V A C 8 I/O Low Leakage block

115VA C 16 Input block

115V AC/10-30VDC High-Speed Counter block, v1.x

115V AC/10-30VDC High-Speed Counter block, v2.0

115/230VAC Relay Normally-closed 16 Output block

115/230VAC Relay Normally-open 16 Output block

115V AC/125VDC 8 I/O Isolated Block with Failed Switch Diagnostic

115V AC/125VDC 8 I/O Isolated without Failed Switch Diagnostic

115-230V A C/125VDC PowerTRAC block, v .2.2 or earlier

115-230VA C/125VDC PowerTRAC block, v.2.3

Product

Catalog

Number

IC660BBA020

IC660BBA021

IC660BBA023

IC660BBA024

IC660BBA025

IC660BBA100

IC660BBA101

IC660BBA103

IC660BBA104

IC660BBA105

IC660BBD020

IC660BBD021

IC660BBD022

IC660BBD023

IC660BBD024

IC660BBD025

IC660BBD100

IC660BBD101

IC660BBD110

IC660BBD120

IC660BBD120D

IC660BBR100

IC660BBR101

IC660BBS100

IC660BBS101

IC660BPM100

IC660BPM100C

Requires this Hand-

held Monitor Ver-

sion (or later)

any

IC660HHM501B (v2.0)

IC660HHM501D (v3.5)

IC660HHM501E (v3.7)

IC660HHM501G (v4.0)

any

IC660HHM501B (v2.0)

IC660HHM501D (v3.5)

IC660HHM501E (v3.7)

IC660HHM501G (v4.0)

any

any

any

any

IC660HHM501B (v2.0)

IC660HHM501B (v2.0)

any

any

IC660HHM501B (v2.0)

IC660HHM501D (v3.5)

IC660HHM501G (v4.0)

IC660HHM501B (v2.0)

IC660HHM501B (v2.0)

any

any

IC660HHM501D (v3.5)

IC660HHM501G (v4.0)

Series Five Genius Bus Controller

Series 90-70 Genius Bus Controller

Series Six Genius Bus Controller with Diagnostics

Series Six Genius Bus Controller without Diagnostics

Series 90-30 GENIUS Communications Module

GENIUS Network Interface (GENI) module

IBM PC Interface Module (PCIM)

GENIUS Network Interface (GENI) module with inverted connector

Series 90-70 Remote I/O Scanner IC697BEM733 IC660HHM501G (v4.0)

24/48VDC Bus Switching Module (BSM)

115V AC/125VDC Bus Switching Module (BSM)

Field Control products (all) IC670xxxxxx IC660HHM501J (v4.6)

1-4

Hand-held Monitor User’s Guide – June 1994

IC655BEM510

IC697BEM731

IC660CBB902

IC660CBB903

IC693CMM301

IC660ELB905

IC660ELB906

IC660ELB910

IC660BSM021

IC660BSM115

IC660HHM501C (v3.0)

IC660HHM501F (v3.8)

any

any

IC660HHM501C (v3.0)

any

any

any

any

GFK-0121E

Page 10

HHM Specifications

Operating temperature 0–60 C(32–140 F)

Storage temperature –40 to +70 C(–40 to 158 F)

Humidity 5-95% (non-condensing)

Weight: without case 1.3 lbs (0.6 Kg)

with case 1.8 lbs (0.8 Kg)

Size (HxWxD): without case 8.00” x” 3.75 x” 1.25 (cmx)

with case 10.85” x 4.30” x 2.25”

Requir ed AC power (for battery charger) 115/230VAC 15%, 47-63 Hz

Fully charged operation 6 hours

Display characters 4 lines each of 16 LCD (0.2” - 5 mm high)

K eyboard 20 sealed keys with tactile feedback

Featur es Performs Genius I/O block configuration, monitors

Display language English, German, French, or Italian

Drop T est Survives drop from 4 feet (1.2 meters) to concrete

Data Rates 153.6 Kbaud standard, 153.5 Kbaud extended, 76.8

1

(16-hour charging period for IC660BPM500B.

8-hour charging period for IC660BPM500A, now

discontinued.)

I/O data on Genius bus, displays diagnostic information.

floor landing on any surface or corner without affecting its operation.

Kbaud, 38.4 Kbaud

Ordering Information

GFK-0121E

Description Catalog Number

Hand-Held Monitor (includes all items listed below) IC660HHM501

Cable from HHM to I/O Block IC660HHC005

Battery P ack IC660BPM500

Battery Charger IC660BCM501

Optional Accessories

External HHM Connector: A panel-mountable or DIN rail-mountable HHM connector

(catalog number 44A736310-001-R001) is available. It can be used to provide a

permanent HHM connection point on a Genius bus. See chapter 2 for a description.

230VAC Power A dapter: An optional 230V AC P ower A dapter (IC660MCA512) can be

used to connect the Hand-held Monitor Charger to variety of 230 VAC power outlets by

means of a standard computer cable (not supplied). See chapter 2 for a description.

Extra HHM Keys: For applications requiring extra keys for the Hand-held Monitor, a

group of five sets can be ordered separately. The catalog number is IC660MKS511.

Chapter 1 Introduction

1-5

Page 11

Chapter 2 Har dwar e Setup

2

Power for the Hand-held Monitor

The Hand-held Monitor can be operated using its built-in battery, or connected to either

115 volt or 230 volt AC power. A battery pack must always be installed to operate the HHM,

even when using AC power.

A n optional 230VAC Power A dapter can be used to connect the Hand-held Monitor Charger

to variety of 230 VA C power outlets. See page 2-2 for more information.

Charging the Battery Pack for AC Operation

To operate the HHM using AC power , if the battery pack is new or has become fully

discharged by operating the HHM on battery power, it must be charged for at least 20

minutes. If it is necessary to restore temporary operation before charging is complete:

H

Plug the adapter cable into the HHM.

H

Wait 15 seconds and power up the HHM. It may be necessary to remove the battery pack

for 15 seconds, then reinstall it.

GFK-0121E

Note that continuall y usi ng the Hand-held Monitor in AC mode for an extended period of

time causes the battery pack to deteriorate. A fter up to two years of AC operation of the

HHM, the battery pack may not be able to accept enough charge to operate the HHM

independently. However, it can still be used for AC operation.

Selecting 120 VAC or 230 VAC

Before plugging the adapter into AC power to operate or charge the Hand-held Monitor,

be sure the switch at the base of the adapter is correctly set to match the incoming

power (120 volts AC or 230 volts A C).

120V

position

230V

position

The Hand-held Monitor will operate while the adapter is connected.

120V

230V

2-1

Page 12

2

Using the 230VAC Power Adapter

The optional 230VAC Power Adapter (IC660MCA512) can be used to connect the Handheld Monitor Charger to variety of 230 VAC power outlets by means of a standard computer cable (not supplied).

The Adapter has a receptacle on the top for the Hand-held Monitor Charger and an IEC

320 receptacle on the side for the computer cable.

HHM Charger receptacle in

top of Adapter

IEC 320 receptacle in

side of Adapter

Instructions

1. Se t the powe r selection switch on the Han d-held Monitor Charger to the 230V position.

120V

230V

position

2. Plug the Hand-held Monitor Charger into the top receptacle on the Power A dapter

unit.

3. Plug the computer cable into the IEC receptacle on side of the Power Adapter unit.

4. Connect the computer cable to a suitable 230VAC power source.

During normal operation, it is best to connect and disconnect the cable at the outlet, not

at the Adapter.

230V

2-2

Hand-held Monitor User’s Guide – June 1994

GFK-0121E

Page 13

Battery Operation

The HHM’s battery pack provides up to 6 hours of operation. To maximize battery life,

allow the battery to discharge fully between charges. The battery should be allowed to

fully discharge once a month.

Low Battery Power

Low battery power may cause this message:

**LOW BATTERY**

**HHM HALTED**

Please Recharge

Or the display may blank, or two black lines may appear briefly. Low battery power

suspends the current operation.

Charging the Battery Pack

When you receive a new Hand-held Monitor, its battery pack is not charged. Before

using a new battery pack to power the HHM for the first time, charge it by plugging the

adapter into a power source for 24 hours. After this initial charging, subsequent

rechanges will require only 16 hours.

Maintaining spare battery packs will allow the HHM to operate using one battery pack

while another is being charged.

If the battery pack won’t take a charge, it usually indicates a faulty battery pack, not a

faulty Hand-held Monitor. Try another batter y pack. Replacement (uncharged) batter y

packs are available.

If a battery pack is left uncharged for a long time, it may be necessary to remove the

battery pack from the HHM and charge it while removed for up to 15 minutes.

2

GFK-0121E

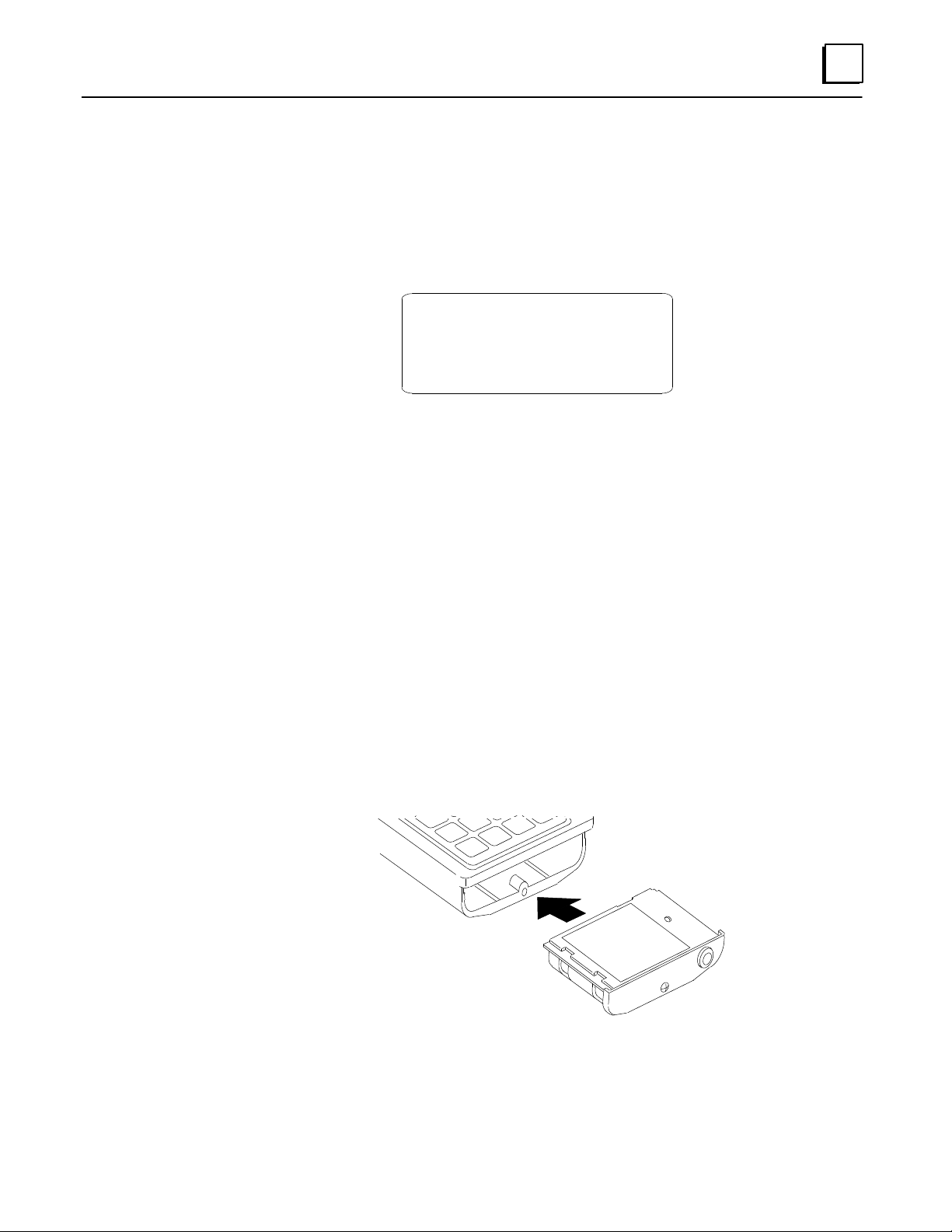

Replacing the Battery Pack

To replace the battery pack, use a Phillips screwdriver (size 0 or 1) to release the retaining

screw at the bottom of the HHM. Slide the battery pack out, insert another, and tighten

the screw.

Automatic Shutoff

To conserve power, the Hand-held Monitor automatically shuts off 10 minutes after the

last key is pressed. For applications where continual operation is preferred, the

automatic shutoff feature can be disabled. See page 3-5 for more information.

Chapter 2 Hardware Setup

2-3

Page 14

2

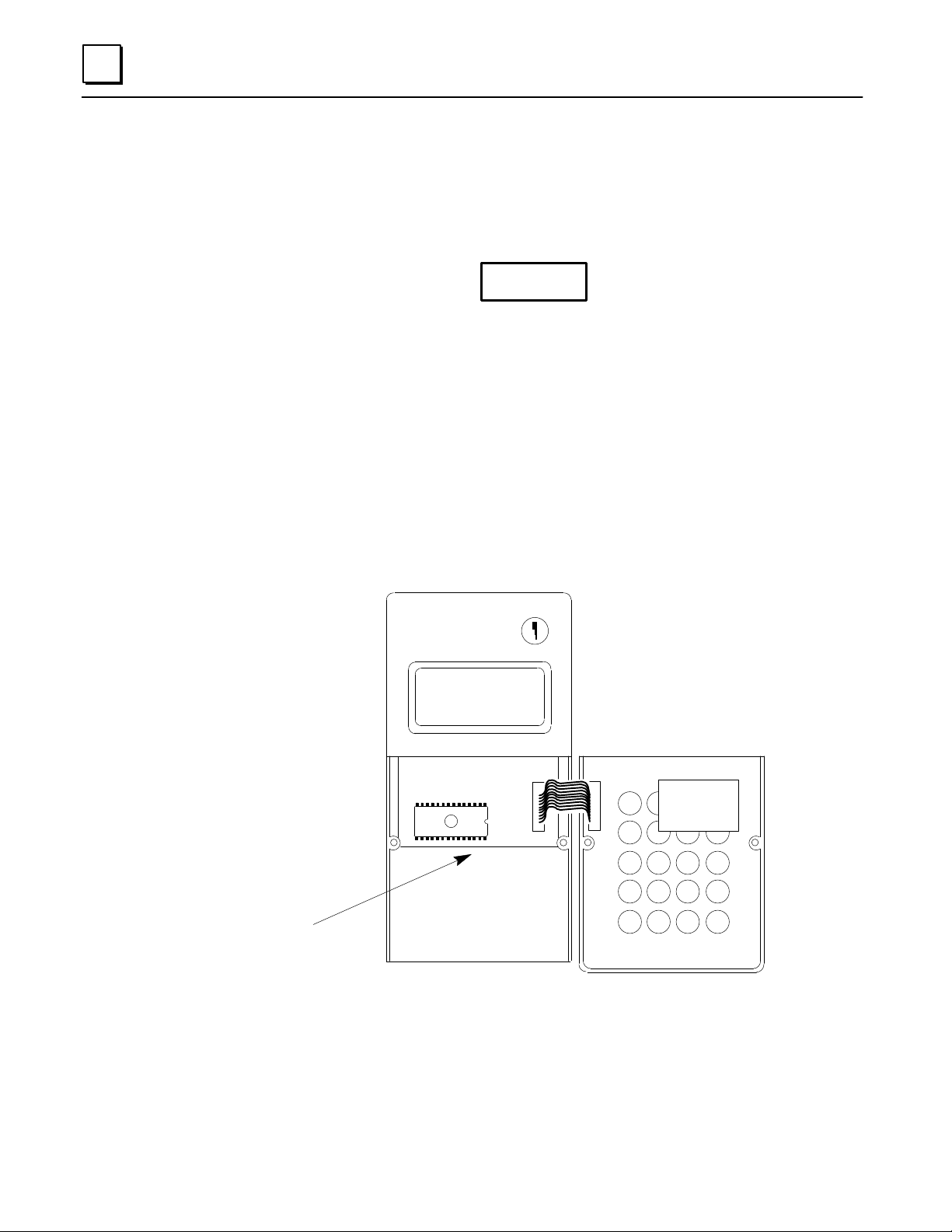

Changing the PROM

New features can be added to upgrade a Hand-held Monitor by replacing its PROM as

described below .

To prevent possible damage to the Hand-held Monitor, this operation should be

performed in an area equipped with suitable electrostatic discharge protection.

1. If the HHM is connected to AC power, disconnect it.

2. Remove the HHM battery pack as described on the previous page.

3. On the front of the Hand-held Monitor, remove the two Phillips-head screws located

near the 7 and HOME keys.

4. Gently raise the keyboard up from the bottom to release the lip between the

keyboard and the display.

Caution

5. Once this lip is free, open the keyboard to the right, as illustrated below. It is not

necessary to remove the ribbon connector .

GENIUS

Hand Held Monitor

GE Fanuc

mon

cfg

Install PROM

with notch to

right as shown

2-4

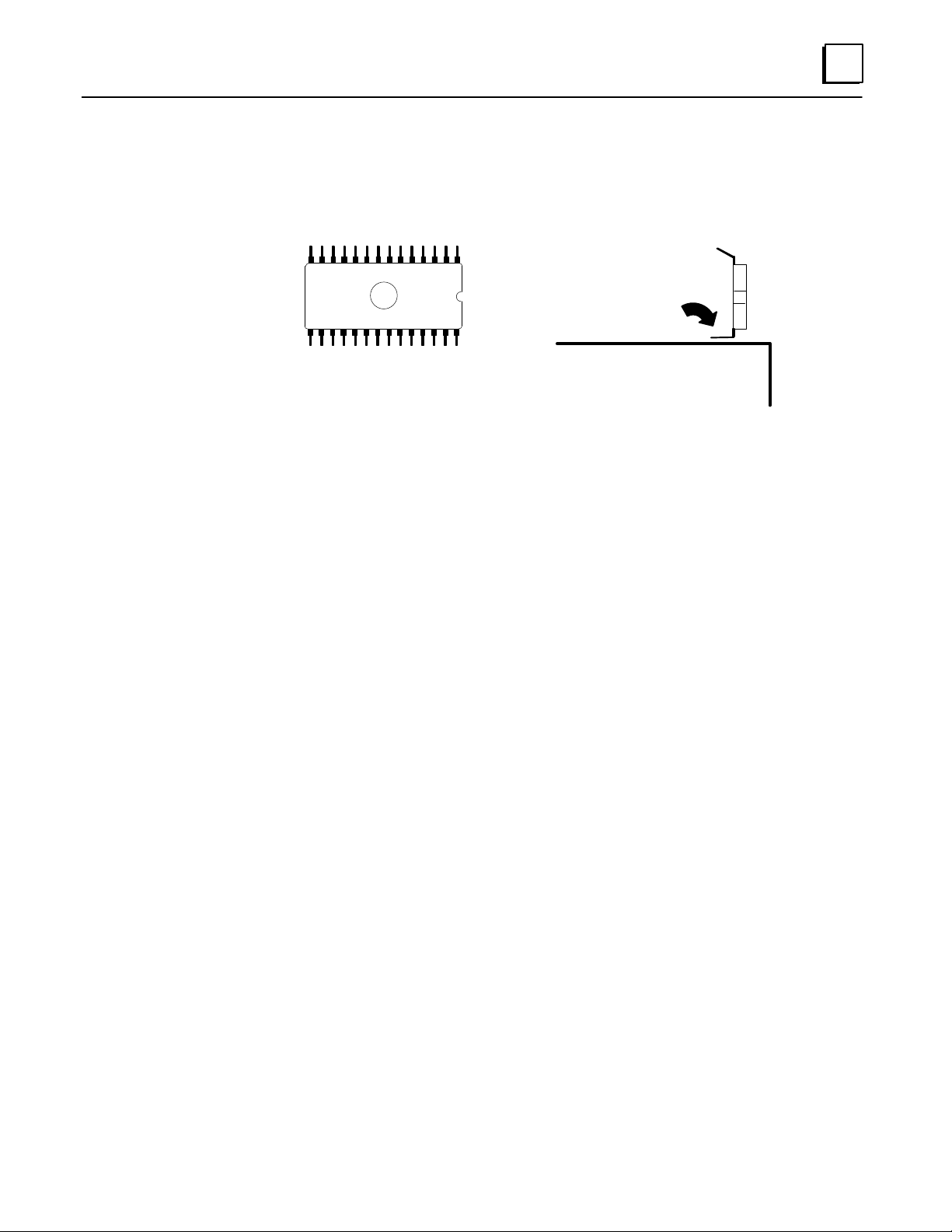

6. Remove the old PROM. If you don’t have a PROM extraction tool, a small screwdriv-

er can be used instead, carefully working from side to side.

Hand-held Monitor User’s Guide – June 1994

GFK-0121E

Page 15

7. If necessary, bend the pins on the PROM so they line up properly with the holes in

the socket. Bend the pins by pressing each side against a clean desk or table top as

shown below. If possible, a conductive mat should be used.

46024

Conductive mat

8. Insert the EPROM or Battery-Backed RAM into the socket.

IMPORTANT: Inserting the PROM backward can damage the Micro PLC and

destroy the PROM.

2

Newer PROMs may be physically longer, but all PROMs must be inserted flush with

the left edge of the socket, with the notch toward the ribbon connector.

9. Reposition the keyboard in its lip and tighten the two screws.

10. Reinstall the battery pack.

GFK-0121E

Chapter 2 Hardware Setup

2-5

Page 16

2

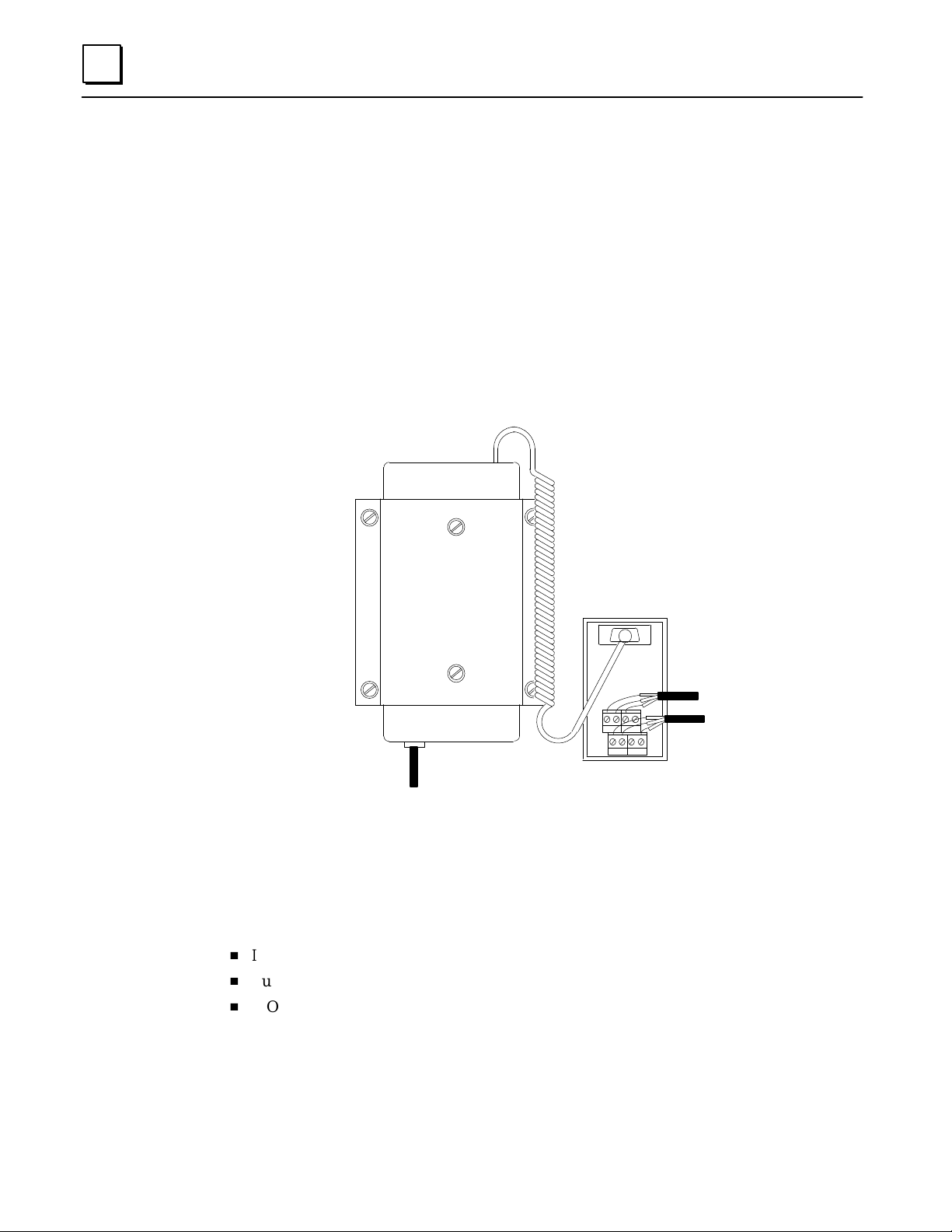

Permanent Installation

If the Hand-held Monitor is to be installed using the metal bracket provided, follow the

instructions below. Do not install the HHM yet if it will be used to configure I/O blocks.

The mounting bracket provid ed can be used to install the Hand-held Monitor behind a

panel. You will need to make a cutout in the panel for the HHM (see next page).

You will also need to install a connector for the Hand-held Monitor within reach of the

HHM’s cable. The extra D-shell connector provided with the Hand-held Monitor

requires a panel cutout, with the bus cable and Hand-held Monitor located on the

opposite sides of the panel (see page 2-8).

An optional panel-mountable or DIN rail-mountable connector is also available. It does

not require a cutout. See page 2-9 for details.

Behind PanelBack of HHM

Bracket

To Power Source

Optional HHM

Connector

Bus In

Bus Out

Configuring a Permanently-installed HHM

Ordinarily, a Hand-held Monitor installed on a panel serves as an operator station. Its

configuration may be different from that of a portable HHM.

H

Its Device Number must be changed from 0 to some other number .

H

Automatic shutoff may be disabled.

H

I/O block configuration and other features may also be disabled.

After the HHM is configured, its keyswitch should be placed in MON position, and the

key removed.

2-6

Hand-held Monitor User’s Guide – June 1994

GFK-0121E

Page 17

HHM Installation Instructions

1. Select a suitable location for the HHM. Environmental specifications are listed on

page 1-5. The location must have 115 VAC or 230 VAC power.

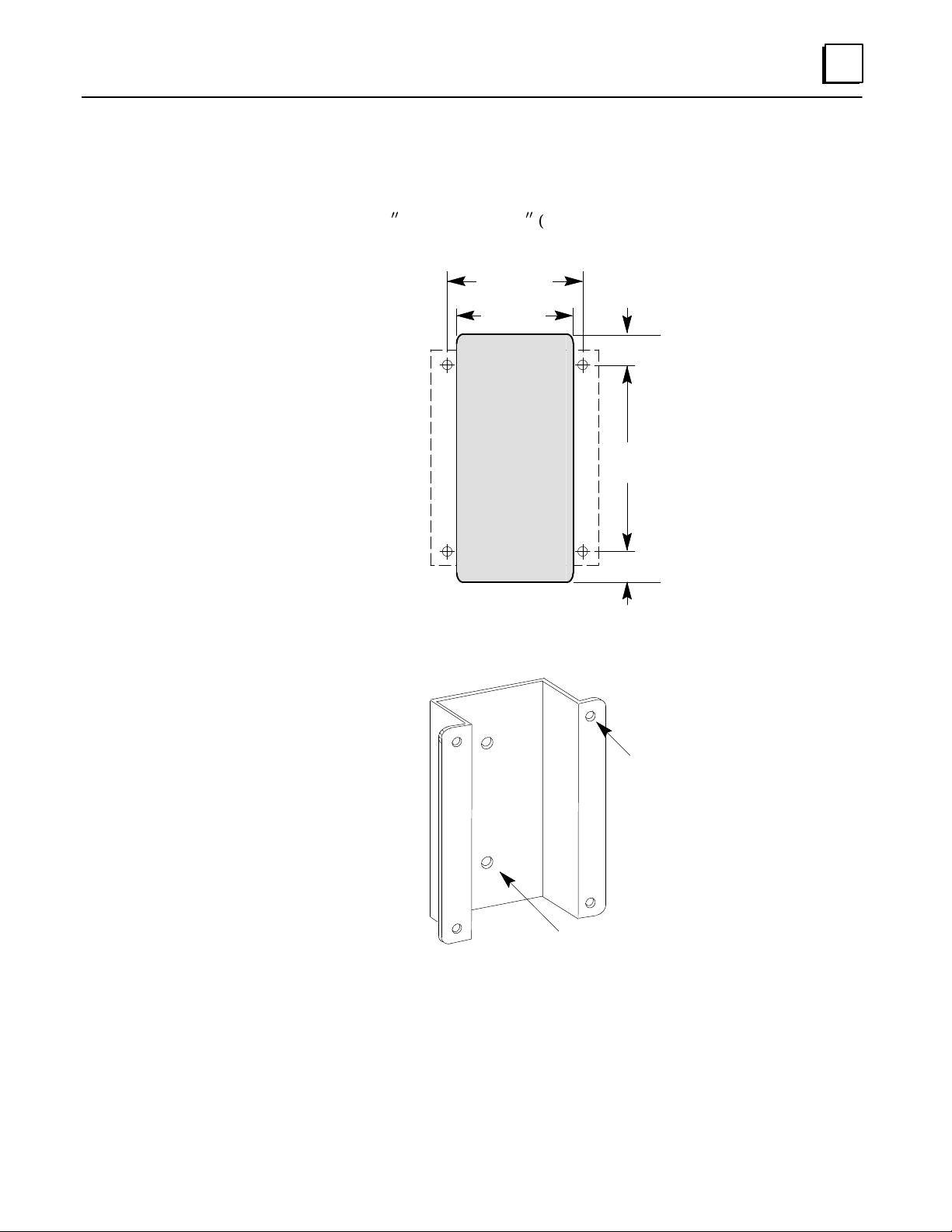

2. Cut an opening 3.75I (9.53cm) wide x 8I (20.32cm) high in the panel. Drill four

mounting holes as shown below.

4.38in

(11.13cm)

3.75in

(9.53cm)

1.00in (2.54cm)

Cutout

6.00in

(15.24cm)

2

1.00in (2.54cm)

3. Attach the bracket to the HHM with the screws, washers, and lockwashers provided.

(4) holes for

mounting on

panel

(2) holes for mounting to

back of Hand-held Monitor

4. Using appropriate hardware (not provided), mount the HHM and bracket in the

cutout.

GFK-0121E

5. Connect the power cord to the HHM, and connect the signal cable to the connector.

Chapter 2 Hardware Setup

2-7

Page 18

2

Installing the D -Shell HHM Connector

Follow the instructions below if you are installing the supplied D-shell connector on the

bus.

1. Using the mounting plate as a template, cut an opening in the panel for the mating

connector. Also drill two holes for the mounting hardware.

2. Attach the mounting plate and mating connector to the panel using the mounting

hardware supplied.

3. Secure the two ends* of the serial bus cable to the back of the panel using strain

relief brackets.

4. Strip the ends of the wires. Twist the two Serial 1 wires together and attach them to

pin 5 of the connector. Twist the Serial 2 wires together and attach them to pin 9.

Similarly, attach the Shield wire(s)* to pin 4.

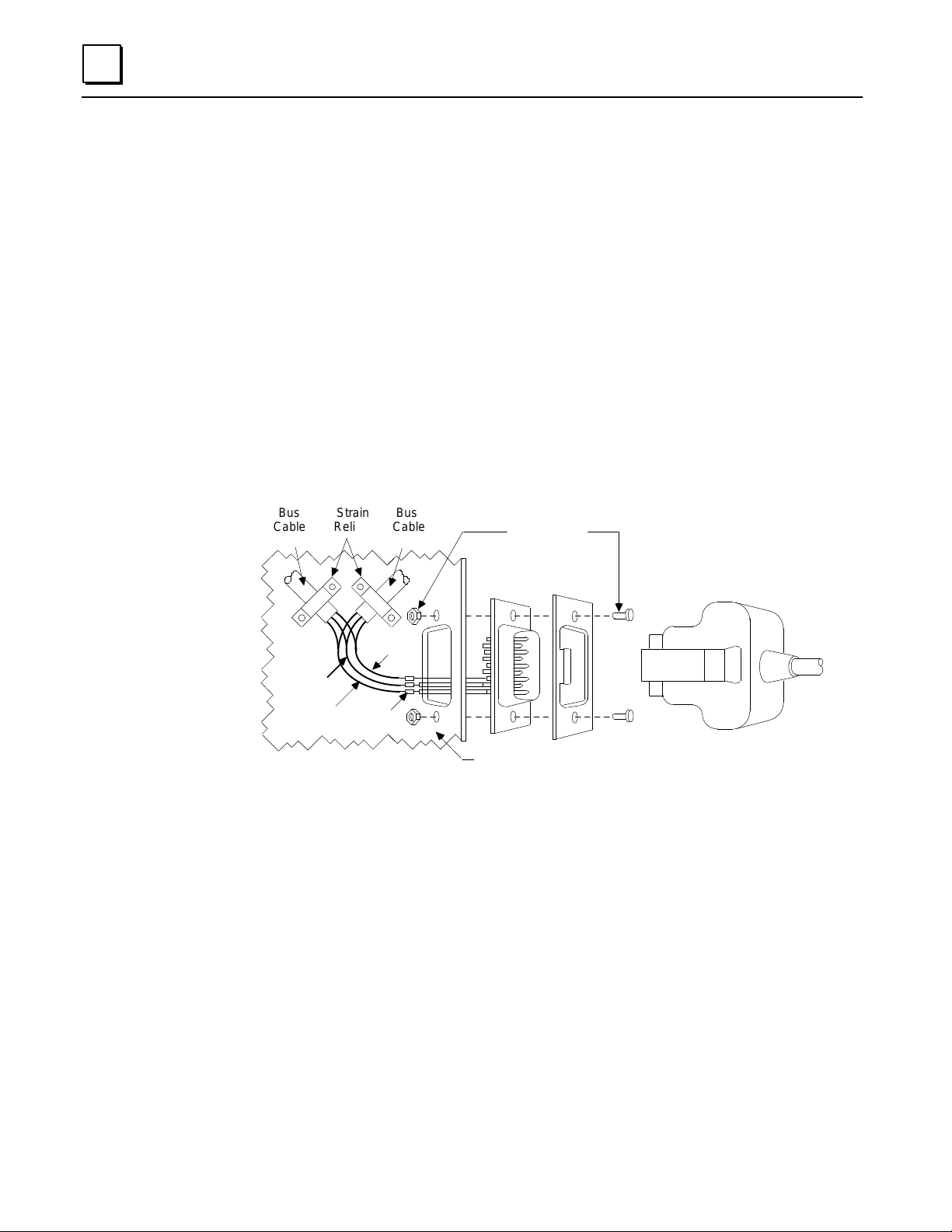

The following illustration shows connections for incoming and outgoing serial bus

cable. As with other devices, the HHM connector may be at either end of its bus. If it

is, there will only be one bus cable attached.

Bus

Cable

SER 2

(Pin 9)

Strain

Reliefs

SER 1

(Pin 5)

Crimp

(Qty. 3)

Bus

Cable

Shield

(Pin 4)

Mounting

Hardware

Mating

Connector

Mounting Surface

(rear view)

Mounting

Plate

a42240c

Hand-held

Monitor

Connector

When making bus connections, the maximum exposed length of bare wires should

be two inches. For added protection, each shield drain wire should be insulated with

spaghetti tubing to prevent the Shield In and Shield Out wires from touching each

other.

* If the HHM connector is at either end of its bus, it is necessary to install an

appropriate terminating resistor across the Serial 1 and Serial 2 wires. The Genius I/O

System and Communications User’s Manual lists appropriate terminating resistors for

each recommended bus cable type.

2-8

Hand-held Monitor User’s Guide – June 1994

GFK-0121E

Page 19

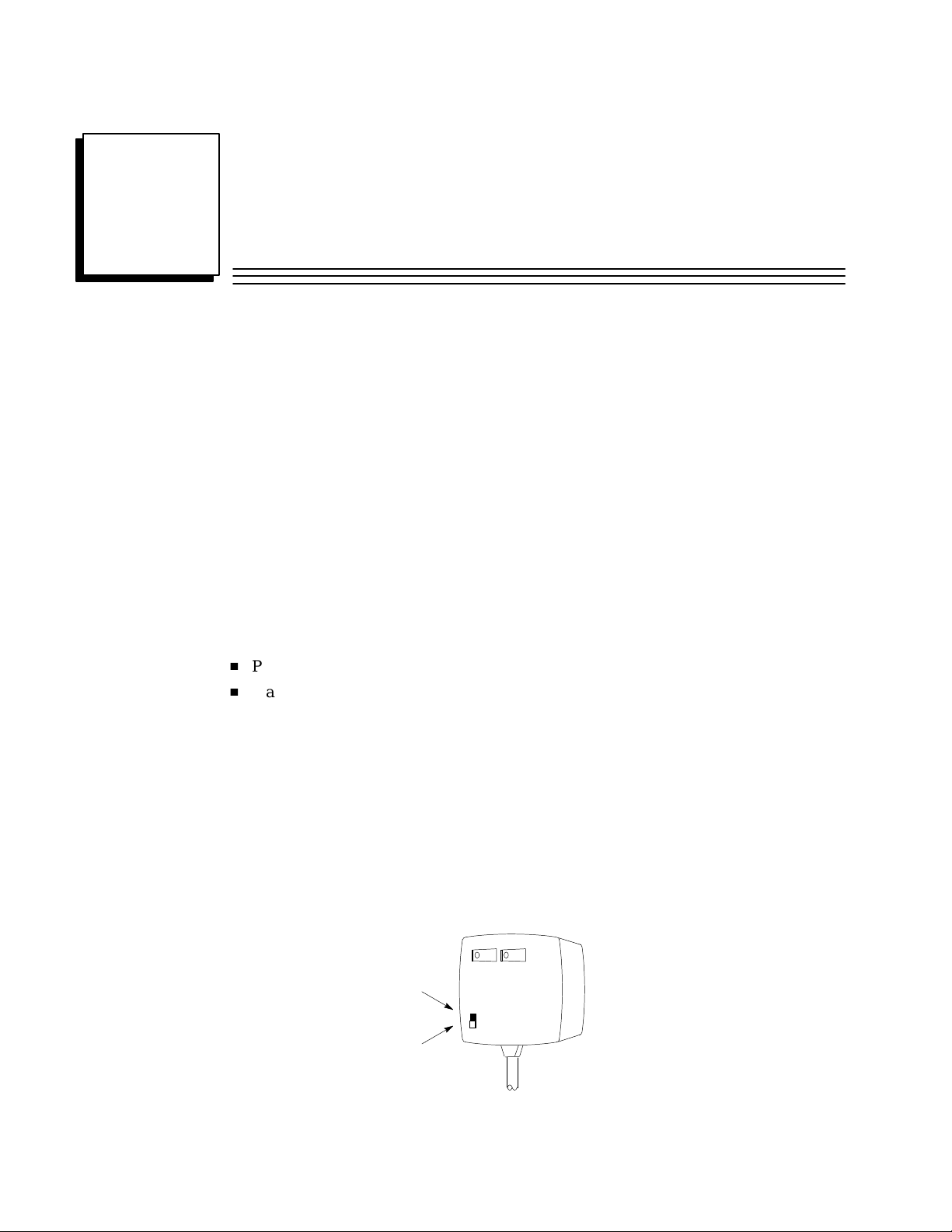

Installing a Separate Hand-held Monitor Connector

You can add a connector to the bus for a permanently-mounted Hand-held Monitor, or

to provide an additional attachment point for a portable HHM.

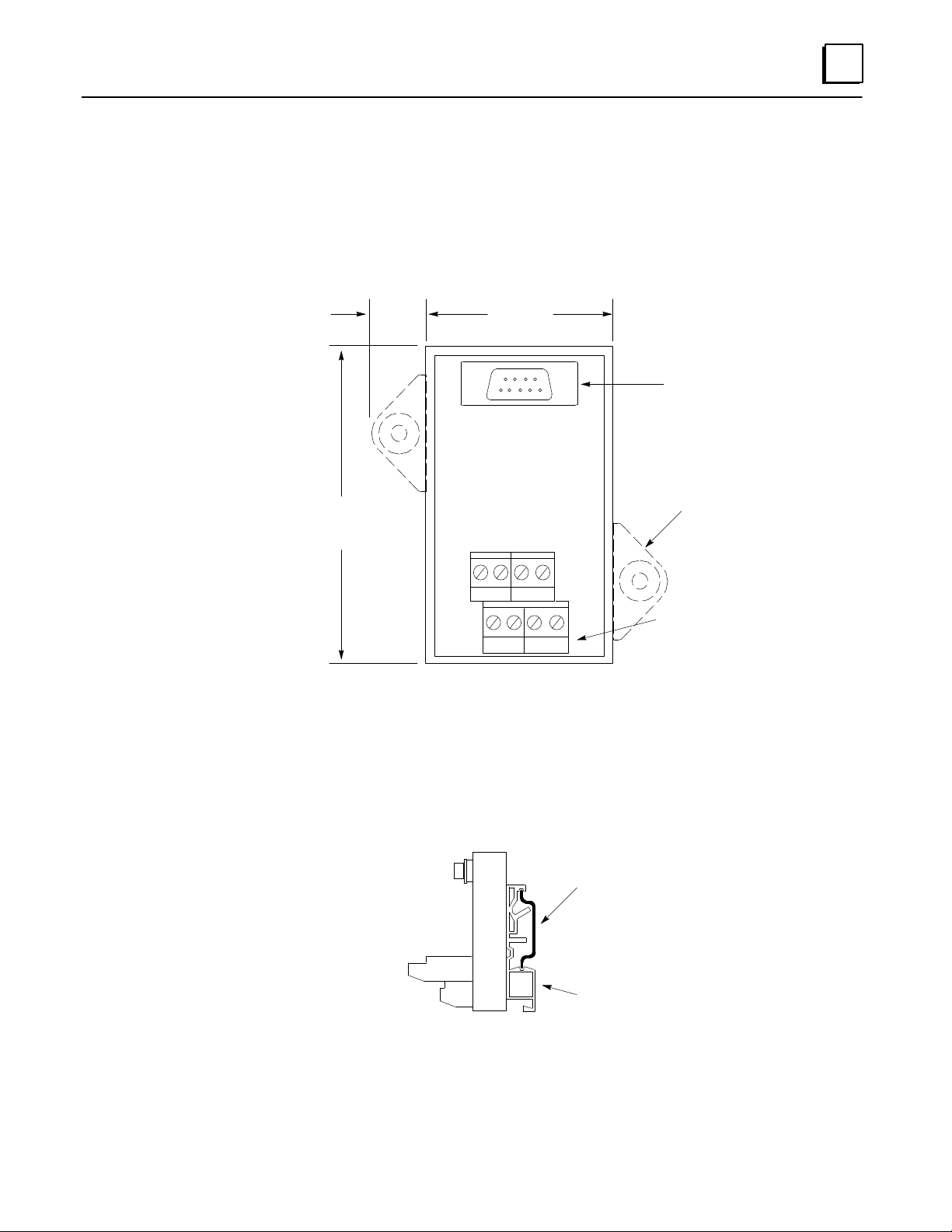

The unit shown below (catalog number 44A736310-001-R001) provides a Hand-held

Monitor connector and serial bus terminals.

2

.5 in

1.27 cm

7.198 cm

2.834 in

1.673 in

4.249cm

X1

X2 SA SB

X1 X2

SA SB

shown at 100% of actual size

46357

Hand-held Monitor

Connector

Panel Mounting Ear

Serial Bus Terminals

X1 Serial 1

X2 Serial 2

SA Shield In

SB Shield Out

GFK-0121E

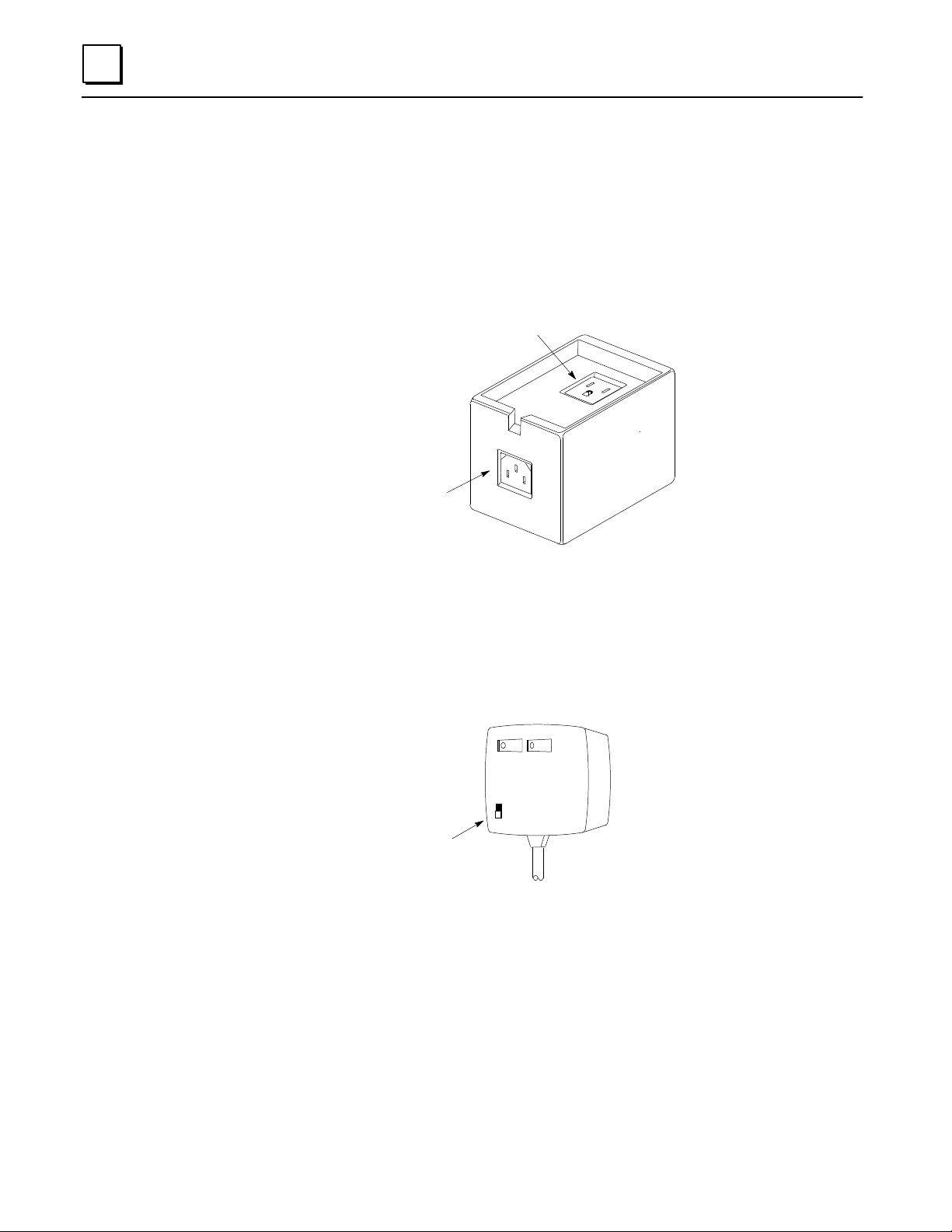

Mounting the HHM Connector

This unit can be easily mounted on a rail such as a standard 35mm (shown below) or

15mm DIN rail. The panel-mounting ears are not used if the unit is installed on a DIN

rail.

46358

35mm DIN rail

(Removable) DIN rail

Mounting Feet

side view: shown at 50% of actual size

Alternatively, it can be installed directly on a panel using screws through its mounting

ears. The DIN rail feet on the back of the unit are removed when the unit is

panel-mounted.

Chapter 2 Hardware Setup

2-9

Page 20

2

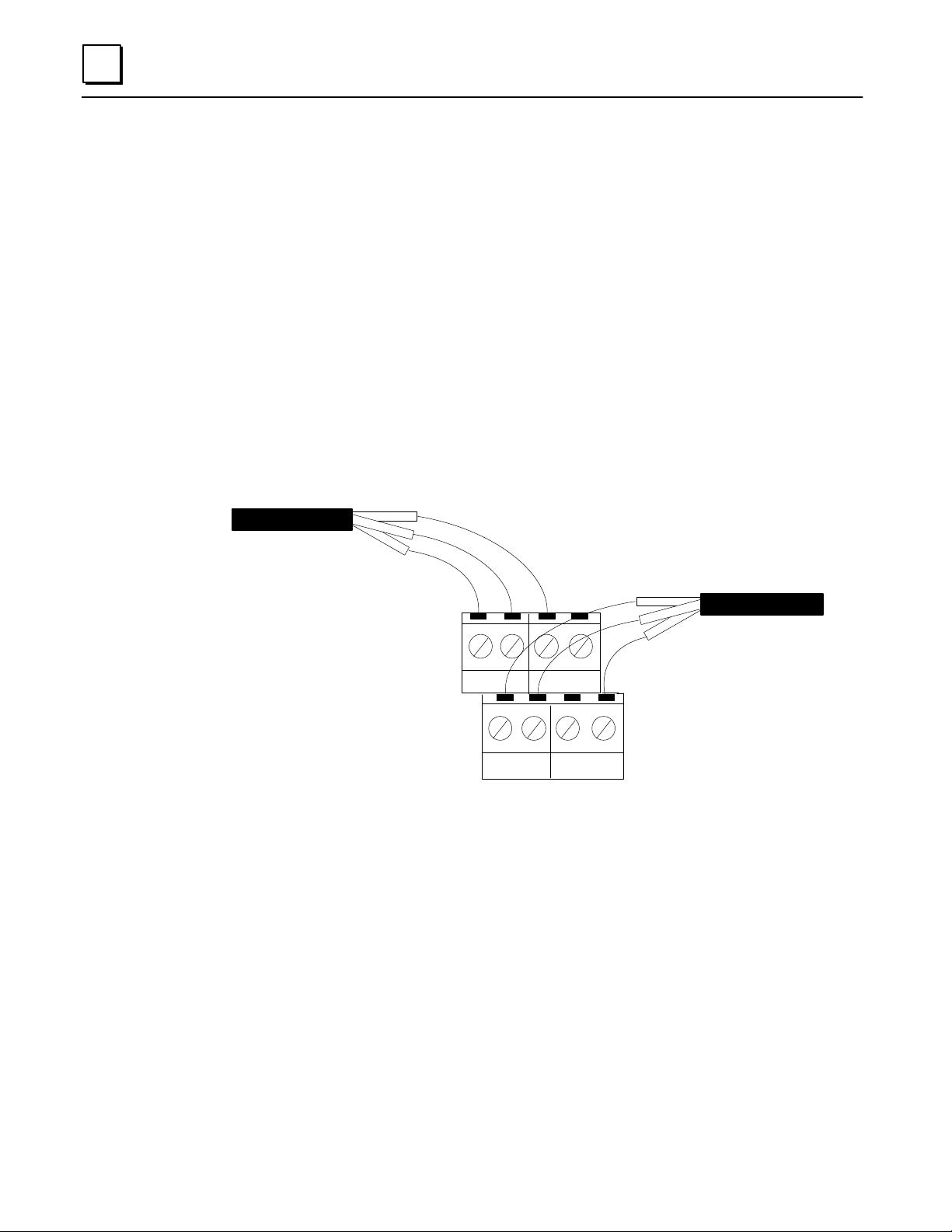

Making the Bus Connections

The HHM connector has two sets of terminals; one for incoming cable and the other for

outgoing cable.

Connect the Serial 1, Serial 2, and Shield In terminal of either connector to the previous

device. Connect the Serial 1, Serial 2, and Shield Out terminal of the other connector to

the next device.

When making bus connections, the maximum exposed length of bare wires should be

two inches. For added protection, each shield drain wire should be insulated with

spaghetti tubing to prevent the Shield In and Shield Out wires from touching each other.

The following illustration shows connections for incoming and outgoing serial bus cable.

As with other devices, the HHM connector may be at either end of its bus. If it is, there

will only be one bus cable attached.

46366

Bus In

Bus Out

X1

X2 SA SB

X1 Serial 1

X2 Serial 2

X1 X2

SA SB

SA Shield In

SB Shield Out

As with other devices, if the HHM Connector is at either end of its bus, install an

appropriate terminating resistor across the Serial 1 and Serial 2 terminals. The Genius I/O

System and Communications User’s Manual lists appropriate terminating resistors for each

recommended bus cable type.

2-10

Hand-held Monitor User’s Guide – June 1994

GFK-0121E

Page 21

Chapter 3Getting Started

3

This chapter explains how to:

H

Turn on the Hand-Held Monitor

h

Set the HHM Baud Rate

h

Display the Home Menu

H

Change the Hand-held Monitor ’s configuration:

h

the HHM Device Number

h

the HHM Display Language

h

the Host CPU

h

automatic shutoff

h

ability to Change Block ID Parameters

h

ability to Change the Baud Rate of Devices on the Bus

h

ability to Configure Devices on the Bus

h

ability to Force I/O Circuits

h

ability to Clear Faults

H

H

GFK-0121E

Test the operation of the Hand-held Monitor.

h

the Keypad

h

the Display Screen

h

the Internal Electronics

Display an alphabetical list of definitions for the definitions used on the HHM screen.

3-1

Page 22

3

Turning on the Hand-Held Monitor

With the battery pack charged, or with the HHM

connected to a suitable AC power source, press the

ON/Off key to turn the Hand-held Monitor on.

Caution

Do not connect or disconnect the

HHM to/from another device or connector while it is ON.

Connecting or disconnecting the

HHM while it is ON may disrupt

communications on the bus.

Each time you turn on the Hand-held Monitor, it

executes a brief self-test.

GENIUS HHM (version)

COPR. (date)

GE Fanuc N.A.

SELFTEST WORKING

1. If the baud rates match, press F4 (Ok).

If the baud rates do not match, press F2

(Change) instead. The HHM screen changes to

allow you to select a different baud rate:

HHM BAUD RATE

ACTIVE=(baud rate)

PROG =(baud rate)

tgl entr ok

A. With the key in CFG position, press F2

(Toggle). The selection changes to 76.8K,

38.4K, 153.6K extended, and back to 153.6K

standard.

B. When the correct baud rate appears on line

3, press F3 (Enter). Press F4 (Ok) to return

to the first baud rate screen.

2. Press F4 (Ok) to display the Home menu.

Powerup Error Messages

Setting the HHM Baud Rate

Before the HHM completes the self-test, this

screen appears:

HHM BAUD RATE

ACTIVE=153.6K ST

MUST MATCH BUS

chng ok

It shows the baud rate that is currently set up for

the Hand-held Monitor. The baud rate

.

Chapter 7 lists error messages that may appear at

powerup.

Sometimes, an error message appears although

the HHM has powered up normally.

POWERUP ERROR #4 or #5 may be caused by

excessive noise on the bus, or by an attempt to use

different baud rates on the same bus.

3-2

Hand-held Monitor User’s Guide – June 1994

GFK-0121E

Page 23

Displaying the Home Menu

3

This is the Hand-held Monitor’s Home menu:

F 1 : H H M U T I L I T I E S

F 2 : A N A L Y Z E

F 3 : C O N F I G U R A T I O N

F 4 : D E V I C E M E M O R Y

Display the Home menu by either:

A. Pressing F4 (Ok) from the first baud rate

screen, or

The Main HHM Screens

F1: HHM CONFIG

F2: SELF–TEST

F3: HELP

F1

HHM CONFIG

BLOCK NO. 0

chng nxt

See page 3-4 for

instructions.

F2

F1: KEYPAD TEST

F2: DISPLAY TEST

F3: TEST INTRNALS

F4:

See page 3-7 for

instructions.

F3

(help screens)

F1: MONITOR BLOCK

F2: MNTR/CTRL REF

F3: BLOCK/BUS STS

F4: PULSE TEST

F1

REFS O

3 4 5 6 7 8 9 0

O O O O O O O

A 1 0 0 0 1 1 1

See page 5-4 for

instructions.

F2

MNTR/CNTL O

STATE: 0

NO FAULTS

> on off reles

See page 5-9 for

instructions.

F3

REFS O

DC16K 15 v2.0ACT

FORCED, NO FAULTS

nxt prv actv bus

See page 5-2 for

instructions.

F4

PULSE TEST

REFS 0

NO FAULTS

exec

See page 5-17 for

instructions.

B. Pressing the Home key or DMenu key from a

Use the Home menu to get to any other HHM

function, as shown below.

Notice that different screens appear, depending on

the type of device that is currently communicating

with the HHM.

F1: HHM UTILITIES

F2: ANAL YZE

F3: CONFIGURATION

F4: DEVICE MEMORY

F3F2F1

F1: PROG BLOCK ID

F2: CONFIG BLOCK

F3: COPY CONFIG

F1

PROG BLOCK ID

I/O

BLOCK NO.

ref blk nxt

See page 4-4 for

instructions.

F2

(individual feature

configuration

screens)

See Genius I/O

Blocks Manual or

individual block

manual for

instructions.

F3

COPY CONFIG

FROM : TO :

chng entr

See page 4-6 for

instructions.

For Most

Genius Devices

lower-level screen.

F2

F1: MONITOR

F2: CONFIGURATION

F1

F1 Monitor I/O

F2:Faults

F3 Previous Menu

See page 5-15 for

instructions.

F2

F1: GENIUS CONFIG

F2: Module Config

F3: Previous Menu

See page 4-7 for

instructions.

F4

DEVICE MEMORY #

(reference)

tgl chng entr SBA

See chapter 6 for

instructions.

For Field

Control

GFK-0121E

Chapter 3 Getting Started

3-3

Page 24

3

Configuring the Hand-held Monitor

You can change the following operating

characteristics of the Hand-held Monitor:

H

PLC reference format.

H

153.6 Kbaud “standard” baud rate.

H

Device Number set to 0.

H

English language displays.

H

Shutdown after 10 minutes of inactivity.

H

I/O block configuration enabled.

H

I/O circuit forcing enabled.

H

Fault clearing enabled.

Select F1 (HHM Utilities) from the Home menu to

access the HHM Utilities menu:

F1:HHM CONFIG

F2:HHM SELF TEST

F3:HELP

F4

To change the configuration of the Hand-held

Monitor, select F1 (HHM Config) from the HHM

Utilities menu.

Changing the HHM Device Number

The Device Number (serial bus address) assigned

to the Hand-held Monitor appears on line 2 of the

first HHM configuration screen.

HHM CONFIG

BLOCK NO. O

chng nxt

Each device on a Genius bus must have a unique

serial bus address number. A new HHM has

number 0. If multiple HHMs will be used on the

same bus, each of them must be assigned a

different Device Number.

If you want to change the HHM Device Number,

follow these steps:

H

Press the ON key. Go to the Home menu. Select F1 (HHM Utilities), then F1 (HHM Config).

H

From the HHM Configure menu, press F2

(Change) to clear the existing Device Number.

Enter the new number and press F3 (Enter).

Note

The HHM key must be in the keyswitch, turned to CFG position.

After setting up the configuration, you can prevent

changes by turning the keyswitch to the MON

position and removing the key.

Pressing F4 from the buad rate screen will advance

you through additional HHM configuration

screens. Press Home if you want to return to the

Home menu, or use the DMenu key to go back to

the previous screen.

3-4

Hand-held Monitor User’s Guide – June 1994

GFK-0121E

Page 25

3

Changing the HHM Display Language

The next display shows the current language

selection.

HHM CONFIG

LANGUAGE

ENGLISH

tgl entr nxt

Press F2 (TGL) to change the display language

(French, German, Italian, English). Press F3

(Enter) to save the change.

Selecting the Host CPU

The next display shows the Hand-held Monitor’s

host CPU selection. The choices are: Series Six,

Series Five, PCIM/QBIM/GENI, or Series 90.

SELECT HOST CPU

SERIES SIX

Enabling/Disabling Automatic Shutoff

The next screen shows whether automatic shutoff

is selected.

AUTO OFF = 1Omin

ENABLED

This feature conserves battery power by shutting

off the Hand-held Monitor 10 minutes after the

last key press. To change the current selection,

press F2 (Toggle), then F3 (Enter).

Enabling/Disabling the Ability to Change Block

ID Parameters

The next display shows whether the Hand-held

Monitor is able to configure the Block Number

(serial bus address) of bus devices, as well as the

I/O circuit mix of some types of I/O blocks.

To change the host CPU type, press the F2 (TGL)

key, then press F3 (Enter).

CHNG BLK ID

ENABLED

This selection also determines whether the HHM

is able to assign the Reference Address of I/O

blocks, or change the I/O mapping of a Remote

I/O Scanner (for the modules in its remote drop).

To enable or disable this capability , press F2 (TLG),

then F3 (Enter).

GFK-0121E

Chapter 3 Getting Started

3-5

Page 26

3

Enabling/Disabling the Ability to Change the

Baud Rate of Devices on the Bus

The next configuration screen shows whether the

HHM is able to change the baud rate of bus

devices.

CHNG BLK BAUD

ENABLED

To change the current selection, press F2 (Toggle),

then press F3 (Enter).

Enabling/Disabling the Ability to Configure

Devices on the Bus

The next display shows whether the HHM is able

to change the other configurable features of bus

devices.

Enabling/Disabling the Ability to Force I/O

Circuits

The next display shows whether the HHM can be

used to force I/O circuits.

CIRCUIT FORCING

ENABLED

To change the current selection, press F2 (Toggle),

then press F3 (enter).

Enabling/Disabling the Ability to Clear Faults

The next display shows whether the HHM can

clear faults on bus devices.

CLEAR BLK FAULTS

ENABLED

CHNG BLK CONFIG

ENABLED

To change the current selection, press F2 (Toggle)

then press F3 (Enter).

3-6

Hand-held Monitor User’s Guide – June 1994

GFK-0121E

Page 27

Testing Operation of the Hand-held Monitor

3

If you want to test the Hand-held Monitor display,

keypad, or internal electronics, select F2 (HHM

SELF- TEST) from the HHM Utilities menu. This

menu of tests appears:

F1:KEYPAD TEST

F2:DISPLAY TEST

F3:TEST INTRNALS

F4:

Testing the Keypad

Press F1 (KEYPAD TEST). The HHM prompts:

KEYPAD TEST

STRIKE ANY KEY

KEY=

MON/CFG KEY=CFG

H

Press any key you want to test. Each key press

is shown on the display. The HOME, D

MENU, and ON/OFF keys are tested by their

operation.

H

To test keyswitch operation, turn the key and

observe the bottom line of the display.

H

Press D MENU to perform another test, or

press HOME to return to the Home menu.

Testing the Display Screen

Press F2 (DISPLA Y TEST) from the HHM Utilities

menu. The screen first displays uppercase letters

and special characters:

Testing the Internal Electronics

Press F3 (TEST INTRNALS) from the Self -Test

menu. After a moment, the HHM displays:

TEST INTRNALS

SELFTEST WORKING

exec

If an error occurs, one of the following messages

will appear instead.

E : P R O C E S S O R F A I L

E : R A M F A I L U R E

E : E P R O M F A I L U R E

E : E E P R O M F A I L U R E

E : C O M M E R R O R

Press the Clear key and try the test again. If the

message returns, replace the HHM. Otherwise,

continue.

An EEPROM failur e will not pr event use of the

Hand-held Monitor. However, the HHM will not be

able to retain changes to its default configuration

through a power cycle.

The COMM ERROR message may indicate that

the Hand-held Monitor is not attached to a

correctly-terminated bus.

GFK-0121E

DISPLAY TEST

ABCDEFGHIJKLMNOP

QRSTUVWZYZO12345

6789:>?–./1O

Next, a screen of lowercase letters appears,

followed by a continuous test pattern, which

checks pixel operation. When the test pattern is

finished, press DMENU to perform another HHM

test, or press HOME to return to the Home menu.

Chapter 3 Getting Started

OII

T

3-7

Page 28

Chapter 4Device Configuration Overview

4

The Hand-held Monitor can be used to configure (establish the operating characteristics for) a wide

variety of other devices. Some configurable devices are:

H

Genius I/O Blocks, High-speed Counter Blocks, and P owerTRAC Blocks

H

the Series 90-70 Remote I/O Scanner and its remote drop

H

Field Control stations.

The Hand-held Monitor displays a unique set of configuration screens for each type of configurable

device.

Because of the wide assortment of configuration features provided by the HHM, it has not been possible

to include them all here. You should refer to the more detailed configuration instructions in the User’s

Manual for the type of device you are configuring.

GFK-0121E

4-1

Page 29

4

Online or Offline Configuration

Devices can be configured before or after

installation on a properly-terminated serial bus. If

a new device is to be added to an existing bus

running at a baud rate other than 153.6 Kbaud

standard, the device must first be configured

offline. Be careful adding new devices to existing

systems. Be sure the baud rate configured for the

new device matches that of the system - never mix

baud rates on a bus.

Online Configuration

When configuring a device on an operating bus,

the Hand-held Monitor must be the ONLY HHM

plugged into a device on the bus. If devices are

configured online, the HHM automatically check

for PLC reference address conflicts.

Offline Configuration

It may be most convenient to configure devices

off-line at a central location. Each device will need

to be connected to an appropriate source of power

and to earth ground. To prepare a device for

off-line configuration:

1. Connect a 75 ohm resistor across the Serial 1

and Serial 2 terminals, or use the 75 ohm

terminator plug (IC660BLM508).

Warnings

If the device is not properly grounded,

hazardous voltages may exist. Death or

injury may result.

DO NOT TOUCH the connectors or

wiring after powering up the device.

Hazardous voltages exist, and death or

injury may result.

Starting Configuration

Note: To assign a serial bus address, the

Hand-held Monitor must be directly attached to

the device being configured. Additional features

can be configured with the Hand-held Monitor

connected at any point on the bus. In that case, the

device being configured must be selected as the

active device (on the Block/Bus Status screen).

1. Begin with the Hand-held Monitor turned off.

Attach the HHM to the device (see below) or

to another bus connection point.

a42307

2. Attach a grounding strap to the device’s

ground screw. Be sure that the strap is

connected to earth ground.

a42468

Attach

Ground

Strap

Terminator

Plug

1

2

3

4

H

N

3. Wire the device to the power source and apply

power.

4-2

Hand-held Monitor User’s Guide – June 1994

2. Turn the Hand-held Monitor on. After the

HHM completes its powerup sequence, the

Home menu appears. The Hand-held

Monitor’s Change Block Configuration option

must be enabled to complete the instructions

in this section. For a new device, the HHM’s

Change Block ID and Change Block Baud

options must also be enabled.

GFK-0121E

Page 30

Displaying the Configuration Menus

4

The illustration below shows how to reach the

HHM’s device configuration menus from the Main

Menu.

H

For all devices, you will need to select F3 (Configuration) then F1 (Program Block ID) to configure a block’s required features.

h

Device Number (serial bus address).

h

I/O type for input/output blocks.

h

CPU references.

h

Baud rate.

For new blocks, this must be done first.

H

To configure Genius blocks, select F3 (Configuration) from the Main Menu, then F2 (Configure Block) to view and modify other features.

Detailed configuration instructions for each

type of device are provided in its User’s Manual.

You can use F3 (Copy Configuration) to copy a

configuration from one block on the same bus

to another.

H

To configure a remote drop, continue from the

Program Block ID screens to enter the remote

map (I/O References) and Drop ID. Then go to

the Configure Block screens to configure redundancy and Configuration Protection.

H

For a F ield Control device, select either F2

(Analyze) or F3 (Configuration) from the Main

Menu. The HHM will then display a special set

of screens for Field Control. (The currently-active device must be the Field Control device for

these screens to appear. See page 4-7 if you

need instructions to select the active device).

If the message E: CONFIG PROTECT appears,

you can remove Configuration Protection by:

1. Going through the configuration screens to

reach the Configuration Protection screen.

2. Pressing F2 (Toggle) to select either DISABLED

or ENABLED.

3. Pressing F3 (Enter) to save the selection.

4. Pressing F4 (Next) to go to the first configura-

tion display , D MENU to return to the Configuration menu, or HOME to return to the Home

menu.

Displaying the HHM

Configuration Menus

F 1 : P R O G B L O C K I D

F 2 : C O N F I G B L O C K

F 3 : C O P Y C O N F I G

F 4 :

F1

All Devices

P R O G B L O C K I D

I / O (device references)

B L O C K N O . (device)

r e f b l k n x t

Configure a Remote

Map

Remote I/O Scanner

F 1 : H H M U T I L I T I E S

F 2 : A N A L Y Z E

F 3 : C O N F I G U R A T I O N

F3

Configure an

Genius Blocks

and Remote I/O Scanner

F 4 : D E V I C E M E M O R Y

F2

C O P Y C O N F I G

F R O M : n T O :

c h n g e n t r

I/O Block

F2 or F3

F 1 : M o n i t o r

F 2 : C o n f i g u r a t i o n

F3

Field Control

Devices

F 1 : G E N I U S C O N F I G

F 2 : M o d u l e C o n f i g

F 3 : P r e v i o u s M e n u

GFK-0121E

Chapter 4 Device Configuration: Overview

4-3

Page 31

4

Completing the Program Block ID Screens

Select F1 (Program Block ID) from the

Configuration menu to complete the mandatory

part of a device’s configuration. (The HHM’s

CHNG BLK ID capability must be enabled).

When the HHM is set up for a PLC host, the

Program Block ID screen looks like this:

PROG BLOCK ID

I / O (device references)

BLOCK NO. (device #)

ref blk nxt

If there are ? symbols on the screen, the

reference address and/or Device Number have not

yet been configured. If there are * symbols on the

screen, a reference address was previously

assigned, but is out of range for the host CPU

currently set up for the HHM. If this happens,

check the host CPU setup in the HHM Utilities.

When the HHM is set up for a PCIM/QBIM/GENI

host, references are not used. Instead, the second

line describes the device:

To Complete the Program Block ID Screen: The

Program Block ID screen is used to configure

additional features for some devices. These vary

from device to device; you should refer to the

device’s User’s Manual if you need more

information.

To Change the Device’s Baud Rate: press F4

(Next) from the Program Block ID screen. (The

HHM’s CHNG BLK BAUD capability must be

enabled).

SELECT BAUD RATE

ACTIVE=153.6K ST

PROG =153.6K ST

tgl entr nxt

The bus will not operate unless all devices are set for the

same baud rate. Check the baud rate before

introducing blocks onto an operating bus.

H

To change the device’s baud rate, press F2

(Toggle), then press F3 (Enter).

H

Cycle power to all devices on the bus at the

same time to use the new baud rate.

PROG BLOCK ID

I S O L 8 (device #)

BLOCK NO. (device #)

ref blk nxt

To Enter or Change the Device Number: the

Hand-held Monitor must be connected directly to

the device.

1. Press F2 (blk). Then, enter the intended number (1-30). If you make a mistake, press F2

twice again, then enter the correct number.

2. Press the F3 (Enter) key. If the device is on-line

and the number has already been used, an error message appears.

To Set the I/O Map for a Remote I/O Scanner:

The next screen is used to assign data types and

lengths for a Series 90-70 Remote I/O Scanner. See

the next page.

4-4

Hand-held Monitor User’s Guide – June 1994

GFK-0121E

Page 32

Configuring a Remote I/O Scanner

4

After selecting the baud rate, the next Program

Block ID screen is used to assign data types and

lengths for a Series 90-70 Remote I/O Scanner.

PROG REMOTE MAP

%I

LENGTH(PTS)

tgl ref send nxt

Configuration Notes

The Remote I/O Scanner User’s Manual explains

remote drop configuration in detail. You should

use it as a reference during remote drop

configuration.

Also, look over the information below. Especially,

note that it is not always possible or desirable to

use a HHM for remote drop configuration.

H

If the remote drop includes any Analog Expander Modules, Logicmaster 90 must be used for

configuration; do not use a HHM.

H

When a remote drop is configured with a

HHM, all I/O modules will operate in default

mode; module options can only be configured with

the Logicmaster 90-70 software.

H

Unless the Remote I/O Scanner is configuration

protected, pressing F3 (send) from the Remote

Map configuration screen causes the HHM to

automatically configure the remote drop. This

configuration will REPLACE any existing I/O

configuration (including one entered using Logicmaster 90-70), and return I/O module options to their original defaults.

H

Remote drops configured with Logicmaster

90-70 are automatically protected. Please check

carefully before removing configuration protection with a Hand-held Monitor.

H

The Hand-held Monitor automatically creates a

configuration for a nine-slot rack, regardless of

the actual rack size. If the remote drop has a

five-slot rack, the HHM will later assume that

there are unfilled slots. If this is a problem, Logicmaster 90-70 can be used for configuration,

or to edit an automatic configuration done with

a Hand-held Monitor. Then, the configuration

can be stored to the Remote I/O Scanner.

Configuring the Remote Drop

To configure the remote drop with the HHM:

1. Enter a starting address and length for: %I (discrete inputs), %Q (discrete outputs), %AI (analog inputs), %AQ (analog outputs) on the

screen shown at left. The data lengths must

not add up to more than 128 bytes of inputs

and 128 bytes or outputs. If they do, an error

message will appear when you attempt to send

the data to the Remote I/O Scanner.

2. Next, press F2 (drop) and enter a Remote Drop

ID (between 16 and 254).

PROG REMOTE MAP

DROP ID _____________

tgl drp send nxt

3. Press the F3 (send) key to download these

selections to the Remote I/O Scanner.

Note: Do not perform this step if you want to

preserve a configuration entered using the Logicmaster software.

The HHM configures the I/O references of Series 90-70 I/O modules (only) in the remote

drop. It assigns references in ascending order,

starting with the slot next to the Remote I/O

Scanner. The leftmost module of each type (%I,

%Q, %AI, or %AQ) in the rack receives the first

available reference of the appropriate type.

4. Press F4 (nxt) to go to the Program Block ID

screen.

5. After completing these screens, press F2 (Configure Block) to complete the Genius configuration screens, or to display information about

the I/O modules in the remote drop.

The module description screens that appear

during the configuration sequence are readonly; boards cannot be configured here.

Go through these block description screens to

configure:

H

BSM Present

H

BSM Controller

H

CPU Redundancy

H

Configuration Protection

GFK-0121E

Chapter 4 Device Configuration: Overview

4-5

Page 33

4

Configuring Genius Blocks

To configure individual features of a Genius block,

the block must be the “active” device.

Selecting the Active Device

1. F rom the Analyze menu, select F3 (Block/Bus

Status).

2. Press F1 (Next) or F2 (Previous), to reach the

device’s description screen.

3. When the desired device appears, press F3 (Ac tive) to make it the active device. (On a dual

bus, the HHM must be on the same bus as the

active block. If it is not, either move the HHM

or force the bus selection as described on

page 5-3).

4. Press D MENU twice to return to the Main

Menu.

Configuring Block Features

Select F3 (Configuration), then F2 (Config Block).

For Genius blocks, the HHM shows the first

configuration display. For example:

PULSE TEST

REFS (block references)

ENABLED

tgl entr nxt

The HHM shows the feature to be configured (in

the example above, it is the Pulse Test option). It

also shows the current status of that feature.

When the Hand-held Monitor is set up for a PLC

host, line 2 shows the references assigned to the

device being configured. If there are ? symbols on

the screen, the device’s reference address has not

yet been configured. If there are * symbols on the

screen, a reference address was previously

assigned, but it is out of range for the host CPU

currently set up for the Hand-held Monitor. If this

happens, check the host CPU setup in the HHM

Utilities.

When the HHM is set up for a PCIM/QBIM/GENI

host, line 2 shows the device type and Device

Number (serial bus address) instead.

Because there are so many different device

configuration screens, it is not possible to show

O

I

them all here. You should refer to the User ’s

Manual for the device you are configuring for

descriptions of its configuration screens and

detailed instructions for completing them.

Configuration Instructions

1. To advance through the HHM configuration

displays making changes as needed, use the F4

(Nxt)key. You can pass through feature displays without making entries.

2. To change a feature, use the TGL and CHNG

keys to select choices or enter other values. On

screens used to enter individual I/O circuit options, use the F1 ( > ) key to choose a circuit,

then select the option using the TGL or CHNG

key. On some displays, you can enter new values from the keypad.

3. Press the F3 (Enter) key to save each change.

Copying a Configuration

If there are similar devices on an operating bus,

you can use the Copy Configuration feature to

copy the configuration from one to the another.

Both of the devices must have a Device Number

already configured, and they must be operating at

the same baud rate. The device to be copied TO

must not be Configuration Protected.

The device to be copied FROM must be the active

device (move the HHM to that block or select it

from the Block/Bus Status screen).

1. To begin, press F3 (Copy Configuration) from

the Configuration menu. The HHM shows:

COPY CONFIG

FROM: n TO:

chng entr

2. The Device Number of the active device appears next to the word FROM. Enter the Device Number of the device being copied TO.

Press F3 (Enter).

3. Press the F4 (Execute) key. The configuration is

copied.

4-6

Hand-held Monitor User’s Guide – June 1994

GFK-0121E

Page 34

Configuring Field Control Station

4

1. From the HHM Main Menu, display the special

set of menus for Field Control.

A. If the Bus Interface Unit or Field Processor is

the current-selected device, press F2 (analyze) twice or F3 then F2.

B. If it is NOT the currently-selected device:

H

Select F2 (analyze) then F3 (Block/Bus

Status).

H

Press the F1 (nxt) or F2 (prev) key repeatedly to reach the serial bus address of the

BIU or Fiel d Processor. Press F3 to make it

the active de vice. The n, press ∆Menu, followed by F2 (Monitor/Control Ref).

F1:Monitor

F2:Configuration

From this menu, press F2 (Configuration). This

menu appears:

F1:GENIUS CONFIG

F2:Module Config

F3:Previous Menu

H

Press F1 to configure the BIU/Field Processor.

H

Press F2 to configure individual modules.

Change the Bus Address

When you press F1 (Genius Configuration) from

the Configuration menu, the HHM shows the

serial bus address previously configured for the

BIU or Field Processor:

1. If you want to change the address, enter the

new address using the keypad.

2. Press F4 (entr). An error message appears if

the number has been used for another device.

Select a PLC Reference Address

If the host is not a Series Six PLC or Series Five

PLC, no entry is necessary here.

If the host is a Series Six PLC or Series Five PLC,

assign an I/O or register reference address.

S t a t T b l Addr

OOOOO

< > I O 6 e n t r

shows reference type

1. Use the F3 key to toggle the selection of Series

Six I/O memory, Series Five I/O memory, or

register memory. (See the BIU/F ield Processor

User’s Manual for information about memory

usage in the Series Five and Series Six PLC).

If I/O memory is used, the amount required is

equal to the number of bits of discrete data

PLUS analog data. Each analog reference used

consumes 16 points.

If register memory is used, an amount is required that is equal to the total number of bytes

of input data PL US all of the output data

2. Key in the number of the block’s beginning I/O

or register reference. This may be:

Series Six I/O 1 to 993

Series Five I/O 1 to 2041

Registers 1 to 16383

3. Press the F4 (Entr) key.

D e v i c e S B A

1 4

P r v > e n t r

If the bus address is correct, press F2 to go on.

Note: If a BIU or Field Processor has a Serial Bus

Address conflict on an operating bus, it will not

scan the modules in the station until the fault is

cleared.

GFK-0121E

Chapter 4 Device Configuration: Overview

Configure Additional Features

On the screens that follow, select these features:

H

Fault Reporting

H

Genius bus redundancy

H

BSM Controller

H

Output default time (for redundancy)

H

CPU redundancy

H

Duplex redundancy: default mode for outputs

H

Configuration protection

4-7

Page 35

4

Configuring Individual Field Control Modules

Go to the Field Control configuration menu:

F 1 : G E N I U S C O N F I G

F 2 : M o d u l e C o n f i g

F 2 : P r e v i o u s M e n u

From this menu, press F2 to configure the

individual modules in the station.

Disable the I/O Scan

While you configure the modules in the station,

you may want to disable I/O scanning. (The Bus

Interface Unit or Field Processor begins scanning

I/O as soon as it is powered up).

I O S c a n

D I S A B L E D *

P r v > t g l e n t r

Configure Data Addresses and Lengths

The next screens are used to assign the starting

addresses and lengths for I, then Q, then AI, then

AQ data.

If the host is a Series 90 PLC, these should

correspond to the memory assignments made for

the BIU or Field Process o r during PL C c onfi g uration.

If the host is a Series Six or Series Five PLC, only

the length selected here is used; the entry made

on the starting address screen is not used by the

PLC. For those PLC types, the starting address was

assigned on an earlier screen.

1. For each data type, enter a starting address for

disc rete input data (I). For example:

Blk Map Start 1

IOOOO1

< > e n t r

2. Press F4 to accept the value. Then, enter a

length in bits for I data. For example:

When the I/O scan is disabled, previously

unconfigured module inputs and outputs default

to 0. For previously-configured modules, inputs

and outputs either default or hold their last state

or value, as configured.

1. If you want to change the present selection,

press F3 (tgl).

2. Press F4 (entr). If you want to go to the next

screen without changing the selection, press F2

( > ).

B l k M a p L n g t h

6 4

< > e n t r

3. Press F4 (entr) to accept the value.

4. Continue as above, entering starting addresses

and lengths for the other data types.

The lengths entered must not add up to more

than 128 bytes of inputs (discrete + analog)

and 128 bytes of outputs (discrete + analog).

5. Press F1 ( > ) after entering the length for AQ

data (the fourth data type).

If you changed any starting address or length

entries, the HHM displays this screen:

M a p h a s c h a n g e d

A c c e p t ?

n o y e s

6. To accept the changes and continue to the next

menu, press F4 (yes).

4-8

Hand-held Monitor User’s Guide – June 1994

GFK-0121E

Page 36

4

Add Modules and Assign References

The first module configuration screen looks like this:

Rack

number

R O :S1 EMPTY

< > t g l r e a d

Use F1 and F2 to display

another slot (module)

The Rack Number is always 0.

The Slot Number refers to the location of the

module relative to the BIU or Field Processor.

Read a Module Identification

If there is a module in the currently-selected slot,

pressing F4 (read) from the “empty slot” screen

brings up the module identification screen:

Slot

number

Assign I/O References for the Module

After you “accept” a module into the slot, a screen

like this appears:

R O :S1 I16

I_

e n t r

Specify the I/O references to be used by the

module. For most applications, you can simply

have the BIU/Field Processor assign the next

available references in that memory type.

A. To assign the next available references, just

press F4 (entr).

B. If you want to assign specific references, enter

the starting address. Press F4 (entr).

Module references are automatically assigned by

the BIU or Field P rocessor based on its configured

data addresses and the number of points

appropriate for the module type.

R O :S1 Mod type?

D i s c r e t e O u t 1 6

t g l e n t r

H

If you want to change the module type displayed, press F3 (tgl) to list other module types.

H

To accept the module type, press F4 (entr).

Module

type

Select a Module Type

If a module is not present in the selected slot, press

F3 (tgl) to select Generic I/O or Special I/O. Then

press F4 (entr).

R O :S1 I/O type?

G e n e r i c I / O

t g l e n t r

H

Use the F3 (tgl) key again to go through the

module names.

H

When the correct module name appears, press

F4 (entr).

Editing a Module Configuration

To edit the module’s configurati on, press F4 (zoom).

Refer to the module configuration instructions in the

BIU/Field Processor User’s Manual.

Delete an Existing Module Configuration

To delete the configuration of the module in the

present slot, press F3 (delete) then F4 (enter). Note

that this removes the entire module configuration.

Configuring Module Features

Configure additional module features as described in

the BIU/Field Processor User’s Manual. For example:

H

Change the module’s reference address.

H

Module F ault Reporting (discrete)

H

Default inputs (or outputs) or Hold Last State

(discrete and analog)

H

Channel Fault Reporting (analog)

H

Channel Active (analog)

H

Input Current/Voltage Ranges (analog)

H

Input or output scaling (analog)

H

Alarm thresholds (analog)

H

Output default values (analog)

GFK-0121E

Chapter 4 Device Configuration: Overview

4-9

Page 37

Chapter 5Monitoring the Bus and its Devices

5

This chapter explains how to perform monitoring and control operations with the Hand-held Monitor.

Di s p la y in g Inform at i on A b o u t Bu s De v ic es (p age 5-2).

h

Selecting the Active Device (page 5-2) .

h

Cl ea r ing Fau l t s ( pa ge 5- 3) .

Display for a Bus Controller (page 5-3).

Monitoring the Bus Status (page 5-3).

Switching a Dual Bus (page 5-3).

Monitoring a Genius Block (page 5-4).

h

Discrete I/O and Inpu t Bl o c k s (p a g e 5- 4) .

h

Discr ete Relay Output Blocks (page 5-5).

h

A nal og Blocks (pa ge 5-5).

h

RT D or Thermocoupl e Blocks (pag e 5-5).

h

Hi g h - s pe e d Co u nt e r Bl o ck ( p a g e 5- 6) .

h

Power TRAC Bloc k ( page 5-7).

Monitoring and Operation

HHM Menus

F 1 : M O N I T O R B L O C K

F 2 : M N T R / C N T L R E F

F 3 : B L O C K / B U S S T S

F 4 : P U L S E T E S T

Monitoring and Controlling Individual Circuits on a

Genius Block (page 5-8).

h

Discr ete, Relay, High-speed Counter Block (p. 5-9).

– F o r cing an Input or Output (page 5-9).

– Clea r i n g Ci r c u i t F a u l t s (p a g e 5- 9) .

h

A nalo g, RTD, or Thermocou ple Block (page 5-10).

– F o r cing an Anal o g Value (page 5-10).

– Clearing Circuit Faults (page 5-10).

h

Power TRAC Bloc k ( page 5-11).

– F orc ing P o werT RAC Data (page 5-12).

– Diagnostics (page 5-12).

Monitoring /Controlling Remote Drop Data (page 5-13).

– Forcing a Circuit (page 5-1 4).

– Dis pl ay ing and Clear ing Fa ul ts (pag e 5-14).