Page 1

_Safety Instructions& Operator's Manual for

LT12D41 SERIES LAWN

TRACTORS

& MOWER

ATTACHMEN'r

Thank you for buying a SNAPPER product! Before operating your mower, read

and follow the Important Safety Instructions(on page 2), the other instructions

contained in this manual and the accompanying booklet, "About Power Mower

Safety". Lawnmowers, and all power equipment, can be potentially dangerous

if used improperly. REMEMBER: SAFETY REQUIRES CAREFUL USE IN

ACCORDANCE WITH INSTRUCTIONS AND COMMON SENSE.

SNAPPER POWEREQUIPMENT

McDonough, Georgia 30253

ADivismnof Fuqualndustrles :_/_ I_I

(Rev. 2. 4/90) M,_NUAL #2-3211

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: This powerful cutting machine is capable of

amputating hands and feet and can throw objects that can

cause injury and damage! Failure to observe the following

safety instructions could result in serious injury. Carefully

read this manual and question your dealer if something is

not clear. Should the dealer be unable to answer to your

satisfaction, write or call the Customer Service Depart-

ment at SNAPPER Power Equipment, McDonough,

Georgia 30253 (phone 404-957.9141).

PROTECTION FOR CHILDREN

1,

2.

DO NOT allow children in yard when machine is

operated.

DO NOT allow children to ride on machine or on at-

tachments.

3. DO NOT allow pre-teenage children to operate

machine.

4. Only responsible teenagers with mature judgement

shall be allowed to operate machine and only under

close supervision.

PROTECTION AGAINST TIPOVERS

1.

2,

DO NOT operate machine on slopes exceeding 15°

(27% grade),

On slopes above 10° (18% grade); exercise extreme

caution; turn blade OFF when traveling uphill;

reduce speed , ayoid sharp turns.

3,

4.

Avoid uphill starts. If machine is stopped going

uphill, turn blade off and back slowly down the slope.

DO NOT mow under any condition where traction or

stability is doubtful without first test driving over the

terrain with blade OFF.

5. Stay alert for holes and other hidden hazards and

keep away from ditches, washouts, culverts, fences

and protruding objects.

6. DO NOT mow back and forth across face of slopes.

7. KEEP A SAFE DISTANCE (at least three feet) away

from edge of ditches and other drop offs.

OTHER IMPORTANT PRECAUTIONS

1. Read and follow operator's manuals and instructions

furnished with attachments.

2. Only mature, responsible persons shall operate the

machine.

3,

4.

5.

6.

7.

Mount and dismount machine from left side.

Wear appropriate protective clothing when mowing

such as long pants and substantial footwear, not

barefoot or with open sandals.

Practice operation of machine with blade OFF to

learn controls and develop skill.

Persons under the influence of alcohol or drugs must

not operate machine.

Know how to stop blade and engine quickly in

preparation for emergencies.

8,

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

2

Keep people and pets a safe distance from machine.

Shields, deflectors, switches, blade controls and

other safety devices must be in proper position and

functional.

Clear area to be worked of wire, rocks and other ob-

jects that could cause injury if thrown by blade.

STOP blade, stop engine and remove key when leaw

ing machine.

DO NOT operate machine unless properly seated

with feet on foot rests or pedal.

Keep hands and feet away from rotating blade

underneath deck. Never place foot on ground while

blade is ON or when machine is in motion!

Turn blade OFF, stop engine and wait for blade to

stop before attempting to unclog grass or leaves to

prevent loss of fingers or hand.

Blade must be OFF except when cutting grass.

Set cutter in highest position When mowing over

rough ground.

Deflector or arass catcher must be in eosition. Never

point discharge at people, passing cars, windows or

doors. Watch out for traffic when crossing or near

roadways.

Operate in reverse only after careful observation of

entire area behind the machine. DO NOT mow in

reverse unless absolutely necessary.

Service machine and make adjustments only when

engine is stopped.

Have machine serviced by an authorized Snapper

dealer at least once a year and have the dealer install

any new safety devices.

Use only genuine Snapper replacement parts to

assure that original standards are maintained.

Tighten all nuts, bolts, screws, frequently and check,

adjust, repair or replace brakes as needed.

Lubricate machine at intervals specified in manual to

prevent controls from binding.

Mow only in daylight or with good artificial light.

Handle gasoline with care! Never remove cap while

engine is running. Fill tank outdoors only with engine

stopped and cool. Clean spilled gasoline from

machine. Store gasoline in approved container, out

of the reach of children, in well ventilated, unoc-

cupied building.

DO NOT change engine governor speed settings or

overspeed engine.

Check grass catcher components frequently for

signs of wear or deterioration and replace as needed

to prevent injury from items going through weak or

worn spots.

Exercise caution when pulling loads. Limit loads to

those you can safely control and attach loads to

hitch plate as specified with Snapper attachment in-

structions.

Page 3

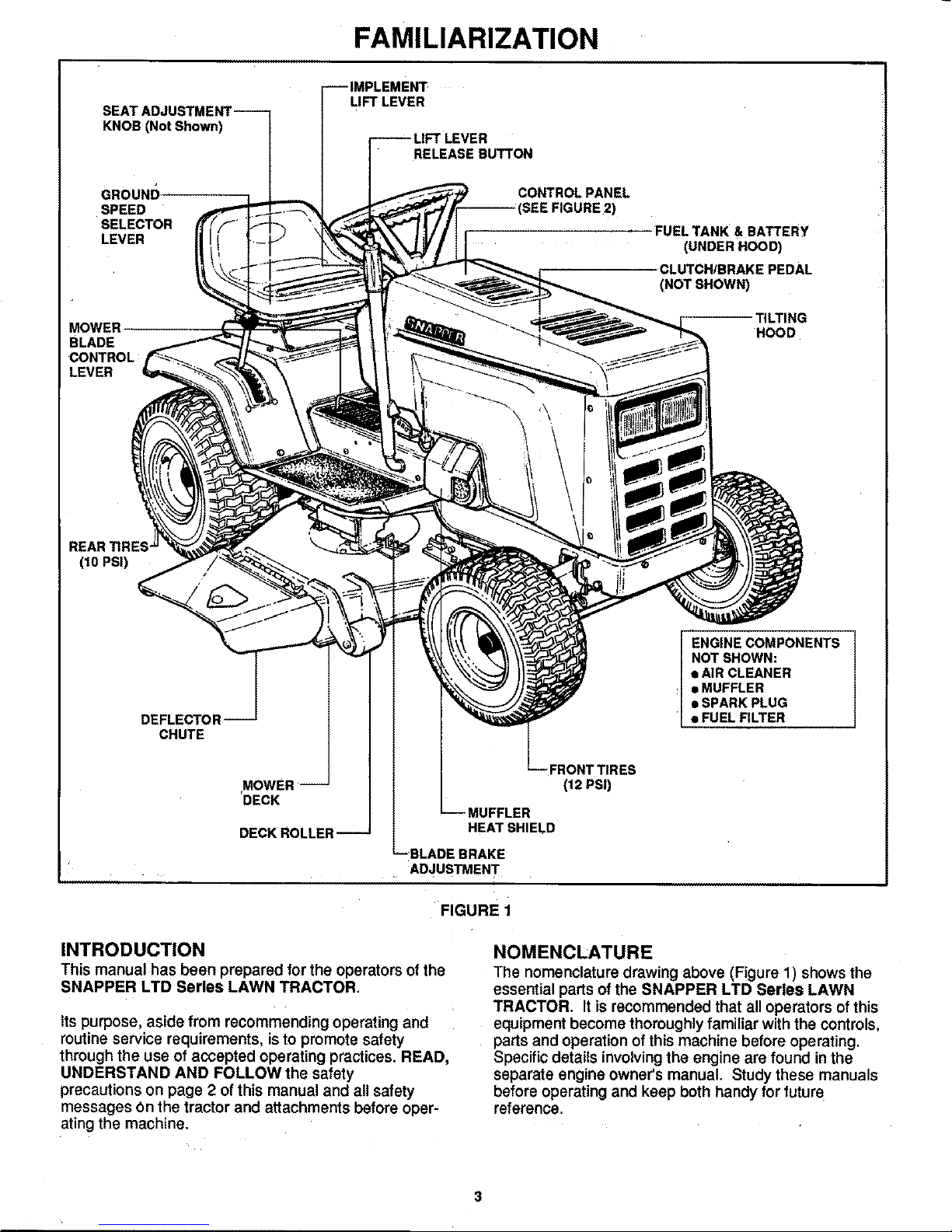

FAMILIARIZATION

SEAT ADJUSTMENT--

KNOB (Not Shown)

GROUND

SPEED

SELECTOR

LEVER

MOWER

BLADE

CONTROL

LEVER

MFTLEVER

RELEASE BUTTON

CONTROL PANEL

_)

FUEL TANK & BATTERY

(UNDER HOOD)

CLUTCH!BRAKEPEDAL

(NOTSHOWN)

TILTING

HOOD

(10 PSI)

/

DEFLECTOR

CHUTE

MOWER

DECK

DECK ROLLER--

MUFFLER

HEAT SHIELD

BLADE BRAKE

ADJUSTMENT

' FIGURE i

INTRODUCTION

This manual has been prepared for the operators of the

SNAPPER LTD Series LAWN TRACTOR.

Its purpose, aside from recommending operating and

routine service requirements, is to promote safety

through the use of accepted operating practices. READ,

UNDERSTAND AND FOLLOW the safety

precautions on page 2 of this manual and all safety

messages On the tractor and attachments before oper-

ating the machine.

ENGINE COMPONENTS

NOT SHOWN:

• AIR CLEANER

• MUFFLER

• SPARK PLUG

• FUEL FILTER

(12 PSI)

NOMENCLATURE

The nomenclature drawing above (Figure 1) shows the

essential parts of the SNAPPER LTD Series LAWN

TRACTOR. It is recommended that all operators of this

equipment become thoroughly familiar with the controls,

parts and operation of this machine before operating.

Specific details involving the engine are found in the

separate engine owner's manual. Study these manuals

before operating and keep both handy for future

reference.

Page 4

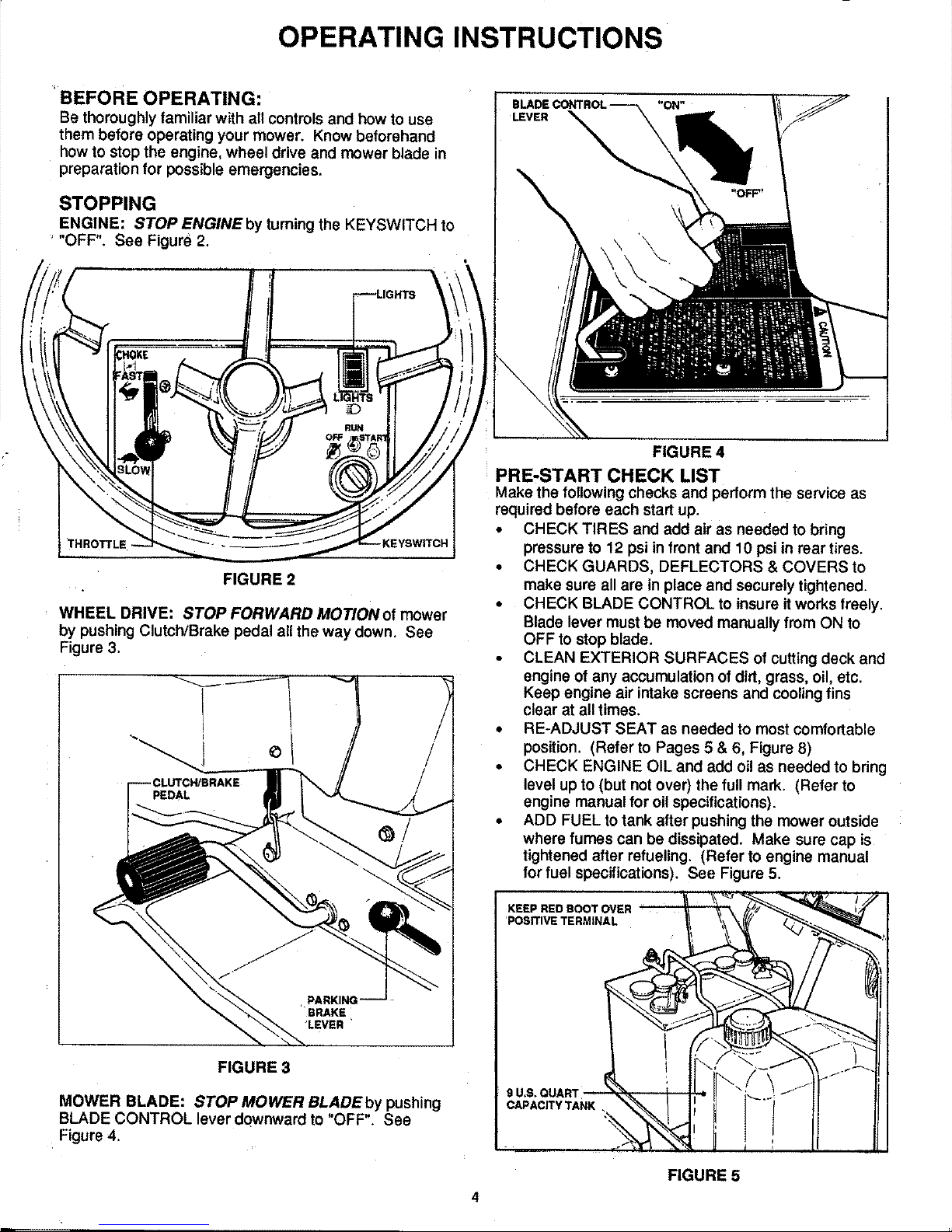

OPERATING INSTRUCTIONS

BEFORE OPERATING:

Be thoroughly familiar with all controls and how to use

them before operating your mower. Know beforehand

how to stop the engine, wheel drive and mower blade in

preparation for possible emergencies.

STOPPING

ENGINE: STOP ENGINE by turning the KEYSWITCH to

"OFF". See Figure 2.

FIGURE 2

WHEEL DRIVE: STOP FORWARD MOTION of mower

by pushing Clutch/Brake pedal all the way down. See

Figure 3.

/

/

FIGURE 3

MOWER BLADE: STOP MOWER BLADE by pushing

BLADE CONTROL lever downward to "OFF" See

Figure 4.

FIGURE 4

PRE-START CHECK LIST

Make the following checks and perform the service as

required before each start up.

,, CHECK TIRES and add air as needed to bring

pressure to 12 psi in front and 10 psi in rear tires.

• CHECK GUARDS, DEFLECTORS & COVERS to

make sure all are in place and securely tightened.

• CHECK BLADE CONTROL to insure it works freely.

Blade lever must be moved manually from ON to

OFF to stop blade.

• CLEAN EXTERIOR SURFACES of cutting deck and

engine of any accumulation of dirt, grass, oil, etc.

Keep engine air intake screens and cooling fins

clear at all times.

• RE-ADJUST SEAT as needed to most comfortable

position. (Refer to Pages 5 & 6, Figure 8)

• CHECK ENGINE OIL and add oil as needed to bring

level up to (but not over) the full mark. (Refer to

engine manual for oil specifications).

• ADD FUEL to tank after pushing the mower outside

where fumes can be dissipated. Make sure cap is

tightened after refueling. (Refer to engine manual

for fuel specifications). See Figure 5.

KEEP REDBOOT OVER

'POSITIVETERMINAL

FIGURE 5

4

Page 5

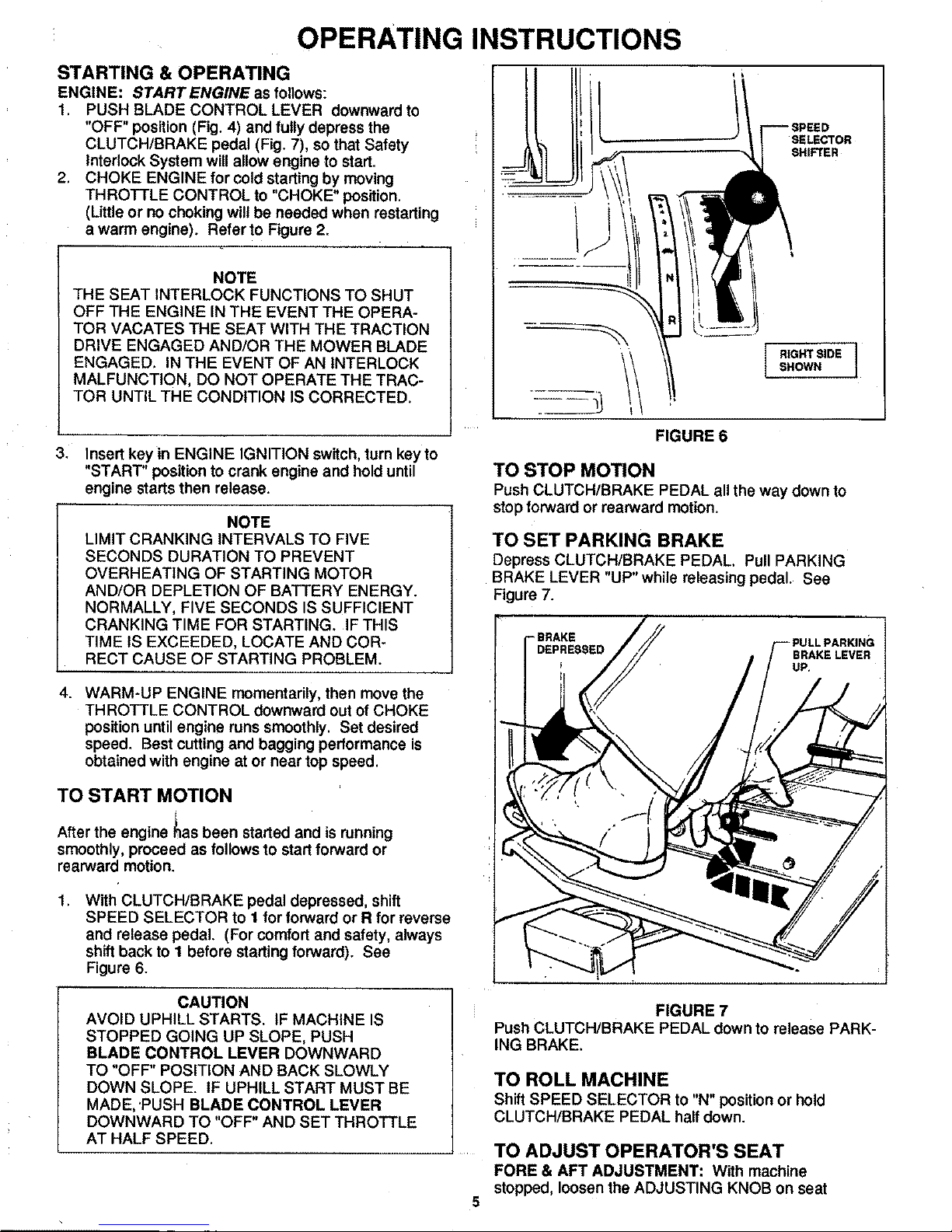

OPERATING INSTRUCTIONS

STARTING & OPERATING

ENGINE: START ENGINE as foliows:

1. PUSH BLADE CONTROL LEVER downward to

"OFF" position (Fig. 4) and fully depress the

CLUTCH/BRAKE pedal (Fig. 7), so that Safety

Interlock System will allow engine to start.

2. CHOKE ENGINE for cold starting by moving

THROTTLE CONTROL to "CHOKE" position.

(Little or no choking will be needed when restarting

awarm engine). Referto Figure 2.

NOTE

THE SEAT INTERLOCK FUNCTIONS TO SHUT

OFF THE ENGINE IN THE EVENT THE OPERA-

TOR VACATES THE SEAT WITH THE TRACTION

DRIVE ENGAGED AND/OR THE MOWER BLADE

ENGAGED, IN THE EVENT OF AN INTERLOCK

MALFUNCTION, DO NOT OPERATE THE TRAC-

TOR UNTIL THE CONDITION IS CORRECTED.

3. Insert key in ENGINE IGNITION switch, turn key to

"START" position to crank engine and hold until

engine starts then release.

NOTE

LIMIT CRANKING INTERVALS TO FIVE

SECONDS DURATION TO PREVENT

OVERHEATING OF STARTING MOTOR

AND/OR DEPLETION OF BATTERY ENERGY.

NORMALLY, FIVE SECONDS IS SUFFICIENT

CRANKING TIME FOR STARTING. IF THIS

TIME IS EXCEEDED, LOCATE AND COR-

RECT CAUSE OF STARTING PROBLEM.

4=

WARM-UP ENGINE momentarily, then move the

THROTTLE CONTROL downward out of CHOKE

position until engine runs smoothly. Set desired

speed, Best cutting and bagging performance is

obtained with engine at or near top speed.

TO START MOTION

L

After theengine hasbeen startedand is running

smoothly, proceedas follows to startforward or

rearward motion.

,

With CLUTCHIBRAKE pedal depressed, shift

SPEED SELECTOR to I for forward or R for reverse

and release pedal. (For comfort and safety, always

shift back to I before starting forward). See

Figure 6.

II SELECTOR

SHIFTER

FIGURE 6

I RIGHT SIDE

SHOWN

TO STOP MOTION

Push CLUTCH/BRAKE PEDAL all the way down to

stop forward or rearward motion.

TO SET PARKING BRAKE

Depress CLUTCH/BRAKE PEDAL Pull PARKING

BRAKE LEVER "UP"while releasing pedal. See

Figure 7.

SRAKE

DEPRESSED

CAUTION

AVOID UPHILL STARTS. IF MACHINE IS

STOPPED GOING UP SLOPE, PUSH

BLADE CONTROL LEVER DOWNWARD

TO "OFF" POSITION AND BACK SLOWLY

DOWN SLOPE. IF UPHILL START MUST BE

MADE, 'PUSH BLADE CONTROL LEVER

DOWNWARD TO "OFF" AND SET THROTTLE

AT HALF SPEED.

FIGURE 7

Push CLUTCH/BRAKE PEDAL down to release PARK-

ING BRAKE.

TO ROLL MACHINE

Shift SPEED SELECTOR to "N" position or hold

CLUTCH/BRAKE PEDAL half down.

TO ADJUST OPERATOR'S SEAT

FORE & AFT ADJUSTMENT: With machine

stopped, loosen the ADJUSTING KNOB on seat

5

Page 6

OPERATING INSTRUCTIONS

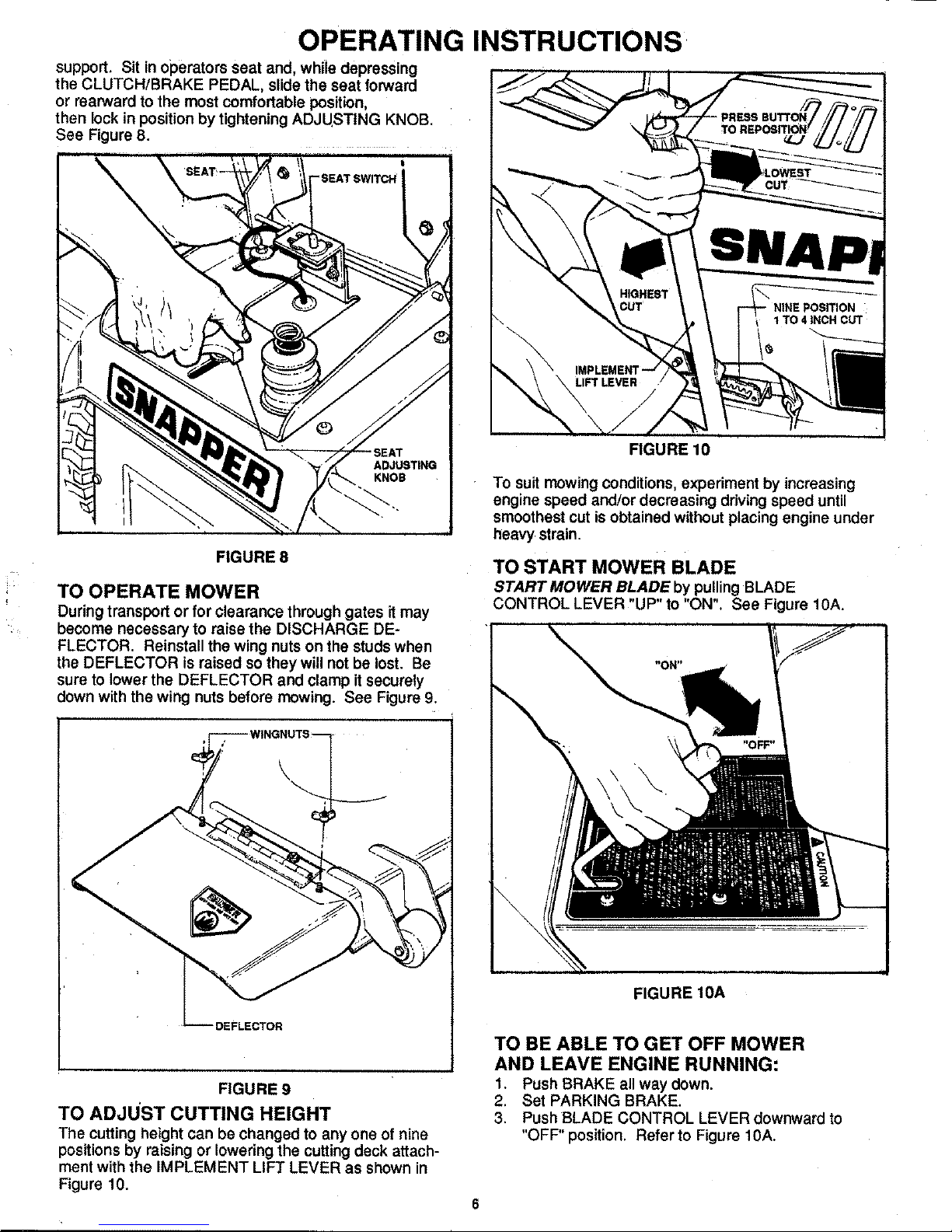

support. Sit in operators seat and, while depressing

the CLUTCH/BRAKE PEDAL, slide the seat forward

or rearward to the most comfortable position,

then lock in position by tightening ADJUSTING KNOB.

See Figure 8.

FIGURE 8

TO OPERATE MOWER

During transport or for clearance through gates it may

become necessary to raise the DISCHARGE DE-

FLECTOR. Reinstall the wing nuts on the studs when

the DEFLECTOR is raised so they will not be lost. Be

sure to lower the DEFLECTOR and clamp it securely

down with the wing nuts before mowing. See Figure 9.

FIGURE 10

To suit mowing conditions, experiment by increasing

engine speed and/or decreasing driving speed until

smoothest cut is obtained without placing engine under

heavy strain.

TO START MOWER BLADE

START MOWER BLADE by pulling BLADE

CONTROL LEVER "UP" to "ON". See Figure 10A.

\

DEFLECTOR

FIGURE 9

TO ADJUST CUTTING HEIGHT

The cutting height can be changed to any one of nine

positions by raising or lowering the cutting deck attach-

ment with the IMPLEMENT LIFT LEVER as shown in

Figure 10.

FIGURE 10A

TO BE ABLE TO GET OFF MOWER

AND LEAVE ENGINE RUNNING:

1. Push BRAKE all way down.

2. Set PARKING BRAKE.

3. Push BLADE CONTROL LEVER downward to

"OFF" position. Refer to Figure 10A.

Page 7

SERVICE

To retain the quality of your tractor, use Genuine

_APPER Replacement Parts only. Contact your local

SNAPPER Dealer for parts and service assistance. For

the correct part or information for your particular mower,

always mention model and serial number. We reCo-

mmend returning the tractor to an authorized SNAPPER

Dealer on a yearly basis for inspection and addition of

any new devices which might upgrade the safety of your

mower. For the nearest SNAPPER Dealer, check the

yellow pages under the heading LAWN MOWERS, For

engine parts and service, look for the engine manufact-

urer's dealers under the heading ENGINES-gasoline.

DRAINING ENGINE OIL

MAINTENANCE & LUBRICATION

_eCHEDULE

fer to the Engine=Owner's Manual for service spaci-

fications on the engine itself, The following applies

primarily to the tractor and optional mower attacWnents.

Clean fittings before greasing,

FIRST 5 HOURS (NEW UNIT)

• ENGINE: Change oil in crankcase. Refer to

Engine Owner's Manual, and Draining Engine

Oil on this page.

• TRACTOR: Check all fasteners and retighten as

needed.

NOTE

RAISE HOOD. (IT MAY BE MORE CONVEN-

IENT TO REMOVE HOOD FOR EASIER

ACCESS WHEN FILLING WITH OIL. SEE

"HOOD REMOVAL", PAGE 12.

1. Disconnect spark plug wire,

2. Fashion an oil drain trough from metal or cardboard

as shown in Figure 11.

I--7[

BEND UP 90" AT CENTER I" _"

4 TO 6 INCH_ -_

FIGURE 11

.

i

4.

Loosen oil _lrain plug. Place trough under plug.

Place a flat container (2 qt. Min. Capacity) beneath

end of oil drain trough.

NOTE

TO ACHIEVE PROPER OIL DRAINAGE,

IT MAY BE NECESSARY TO PLACE

BLOCKS UNDER LEFT WHEELS OF MOWER.

Loosen oil filLcap and remove oil drain plug, Allow

engine oil to drain completely. See Figure 12,

EVERY 25 OPERATING HOURS

• FRONT WHEEL BEARINGS: Lubricate bear-

ingsthrough the fitting on hub of front wheels.

See Figure 13.

BEARINQ

FITTING

FIGURE 13

REAR LEFT AXLE BEARING: Lubricate through

fitting with 2 shots of bearing grease. Right

hand bem'lng is lubricated by transmission.

FRONT AXLE PIVOT & SPINDLE BUSHINGS:

Lubricate the center pivot fitting on underside

of the front axle and each spindle fitting located

on rear of front axle (toward operator). See

Figure 14. (Continued on next page)

DRAIN

TROUGH

[" LOOSEN OiL FILL CAP I

FIGURE 12

5. Reinstall oil plug, remove fill cap ar_l refillcrankcase

with oil. Refer to the Engine Owner's Manual for

engine oil specifications.

FRONTAXLE

PIVOT FITTING

BUSHING

FITTING

/

7

FIGURE 14

Page 8

SERVICE (Continued)

• CHANGE OIL IN ENGINE CRANKCASE with oil

of weight and grade specified in Engine Owner's

Manual.

• ENGINE AIR CLEANER: Refer to Engine Own-

er's Manual for details.

END OF EACH SEASON

(OR EVERY 100 HOURS)

• TRANSMISSION DIFFERENTIAL: Remove

rear panel or fender seat pan to gain access

to differential. See Figure 15.

• TO REMOVE REAR PANEL:

1. Remove six (6) screws.

2. Remove REAR PANEL.

• TO REMOVE FENDER SEAT PAN:

1. Remove shift handle knob,

2. Disconnect wires to seat switch,

3, Remove four (4) top screws.

4, Remove two (2) lower fender screws.

5, Remove FENDER SEAT PAN from

mower,

REARPANEL_-

/

!

REMOV

REMOVE SHIFT KNOB

FE_DERSCREWS

RSEATPAN

CHECK'

PLUG

CORRECT

LUBE

LEVEL

FIGURE 16

• MOWER ATTACHMENT SPINDLE(S):

Lubricate fitting for BLADE SPINDLE BEARINGS

with two shots only of bearing grease once each

year.

• SERVICE Engine air cleaner element and spark

plug.

• SERVICE FUEL FILTER as instructed below.

FUEL SYSTEM SERVICE

Check the in-line fuel filter at frequent intervals and

replace before the screen becomes clogged with sedi-

ment. Make sure the replacement is correctly installed

with IN marking toward the tank and OUT toward the

engine. Check the fuel system components fre-

quently and replace any parts showing worn spots or

cracks. See Figure 17.

TOWARD

ENGINE

FIGURE 15

• Remove CHECK PLUG on inside of unit shown

in Figure 16 to check level of oil. Add

SNAPPER "O" grease as needed thru upper

fill hole to bring the level up to the lower edge of

the CHECK PLUG HOLE. Reinstall NEW plugs

after servicing.

• CHAIN CASE: Remove plug and check. If dry,

add'0ne ounce of SNAPPER "O" grease - do

not overfill. Total capacity must not exceed 2

ounces.

FIGURE 17

FUELTANK

S'

BATTERY SERVICE

Check the battery once each month. Remove the caps

and add distilled water as necessary to bring the level of

the electrolyte up to about 3/32" over plates in each cell.

DO NOT FILL TO THE RINGS. Carefully reinstall

battery caps. In freezing weather, charge the battery

after adding water to thoroughly mix the water in the

electolyte. Keep the terminals and straps clean and tight

and make sure the red boot (shown infigure 5) remains

in position over the positive terminals. Always

disconnect negative (-) terminal first and reconnect last!

Page 9

SERVICE (Continued)

BATTERY CHARGING

The engine is equipped with a flywheel alternator to

charge the battery, Ifthe tractor is not run regularly,

connect the battery to a charger monthly to maintain the

specific gravity at 1.250 or higher. Ifthis reading falls

below 1.175, the battery liquid may freeze when temp-

eratures drop to around zero degrees F.

To charge, connect per instructions furnished with

charger. If time allows, slow charge at 1 amp for ten

hours or as an alternate, fast charge at 3 amps for four

hours. Observe all precautions while charging.

TO ADJUST TIRE PRESSURE

Check tire pressure at frequent intervals, A low tire on

one side causes uneven mowing. Pressure in front

tires should be maintained at 12 psi while rear tire

pressure should be 10 psi.

DRIVEN DISC SERVICE

If the drive does not engage after extended use, it may

be that the driven disc is excessively worn and is not

contacting the drive disc. The driven disc must be

replaced if the rubber iswom down to 1/16" above the

metal. Replacethe robber driven discwhen excessively

worn or unevenly worn. To replace, remove the rear

cover plate, shift the drive into neutral, remove the four

nuts from the hub, remove the old disc and replace it with

new disc (see Figure 18). Refer to Page 15 for

TRACTION LOSS ADJUSTMENT procedure.

FIGURE 18

WHEEL BRAKE TEST & READJUSTMENT

t. Test the wheel braking action at frequent intervals to

insure proper stopping in the event of poss-

.

CAUTION I

MOWERISNOT

I ENDEDTORE1

ToooONENO J

RETURN SPRING

; NOTE:

| MOWER DECK SHOWN

| REMOVED FOR CLARITY

[

FIGURE 19

3. After adjusting, put the Speed Selecting lever in

sixth (6th) position. Depress the CLUTCH/BRAKE

pedal slowly as you roll the mower. There should be

a place where the CLUTCH is disengaged and the

brakes not yet applied, allowing the machine to roll.

This should occur in the first half of the pedal travel.

4. Retest braking action as described in Step 1.

MOWER DRIVE BELT ADJUSTMENT

Normally, within the first few hours of operation, the

MOWER DRIVE BELT will seat into the pulleys and be-

- come slack. To regain correct belt tension, follow steps

ible emergencies. Normally, the mower should stop

from top forward speed within approximately three

feet after the CLUTCH/BRAKE pedal has been fully

depressed.

To adjust the braking action: !

Loosen Locknut and adjust the cable housing toward '

the rear of the mower to increase cable tension. See'

Figure 19.

1 thru 5_

1. Lower MOWER DECK to lowest position.

2. Push BLADE CONTROL lever downward to

"OFF" position.

3. Remove BLADE CABLE spring from hole in

BRAKE ARM, Reattach spring in next hole

forward. See Figure 20. (Continued on next Page)

Page 10

SERVICE (Continued)

MOST

BELT LEAST

TENSION BELT

TENSION

BLADE CABLE

SPRING

FIGURE 20

4. Pull BLADE CONTROL lever up to "ON" •

position, then check belt tension.

5. If belt is stilltoo slack, move spring to another

hole until tension is correct.

MOWER DRIVE BELT SERVICE

To install or replace the MOWER DRIVE BELT, follow

steps I thru g.

1. Lower MOWER DECK to lowest position.

2..Loosen screw on slotted side of belt covers and

swing covers away from pulleys.

3. Loosen pulley screw on stationary IDLER PULLEY

until BELT RETAINER can be moved away from

belt.

4. Loosen pulley screw on BRAKE ARM IDLER

PULLEY until belt can be removed from between

BELT RETAINER and PULLEY.

5. Remove old belt.

6. Route new belt around pulleys as shown in

Figure 21.

i PULLEY

BRAKE ARM

,OL_StDE PULLEY

BELT COVER

LOOSEN SCREW

AND SWING BELT _ PULLEY

COVER OUT OF WAY

FIGURE 21

"10

7. Retighten BRAKE ARM IDLER PULLEY screw.

8. Readjust BELT RETAINER on stationary IDLER

PULLEY, then retighten pulley screw.

9. Reinstall belt covers on outside pulleys. Tighten

retaining screws.

MOWER SERVICE & ADJUSTMENTS"

Keep the topside of the mower freeof grass cuttings.

Buildupof clippings could cause belt problems and also

might present potential fire hazard especially when dryl

If uneven cutting is noted, check the tire pressure first

as this is the most common cause. If tire pressure is

correct and uneven cutting persists, move the tractor

to a flat level surface, such as a garage floor, and check

the deck level. (See "LEVELING MOWER", Page 13).

To prolong the life and efficiency of your mower, keep

the underside of deck clean and free of accumulated

grass clippings by washing it down with a hose and/or

scraping with awire brush and scraper. Make sure this

isdone at the end of the cutting season before placing

the mower in storage.

BLADE BRAKE ADJUSTMENT

The BLADE BRAKE assembly is designed to stop blade

rotation within 3 seconds after the BLADE CONTROL

lever has been pushed downward to "OFF". Should the

blades not stop within 3 seconds, the BLADE BRAKE

must be adjusted as follows:

1. Lower deck to lowest position.

2. Push BLADE CONTROL lever doward to "OFF"

position.

3. Loosen retaining nut on R.H. OUTSIDE PULLEY

BELT COVER and swing cover out of way.

4. inspect BRAKE BAND closely in order to determine

approximate amount of adjustment required.

i 5. Tighten BRAKE BAND by loosening jam nut and

turning T-nut, on end of eyeboit, clockwise 1 to 2

turns, or until brake band tightens. Make sure

flanged lip on T-nut is positioned vertically to fit

over top edge of anchor. See Figure 22.

T-NUT

EYE-BOLT

FIGURE 22

NOTE I

MAKE SURE THAT BRAKE BAND DOES

NOT DRAG AFTER ADJUSTMENT.

(Continuedonne_ Page)

Page 11

SERVICE (Continued)

6. A_er adjusting BLADE BRAKE, start mower,

engage blade and then disengage blade to

check stopping time, Readjust if necessary.

CUTTING BLADE SERVICE

Check at frequent intervals to make sure the blade is

securely tightened and that if is in good condition.

Replace blade if badly chipped, bent, out of balance,

or as soon as notch starts wearing in the tip between

the flat surface and upturned liftas depicted in Figure

23. This type wear pattern occurs more rapidly under

sandy soil conditions.

CAUTION

AVOID CUTTING YOURSELF ON CUTTING

BLADEI PROTECT YOUR HANDS FROM CUTS

WHILE HANDLING BLADE.

Install sharpened or replacement blade with compo-

nents in same sequence as removed. Make sure that

the tumed-up dins in the center of blade fit over the

edges of the blade drive hub when installing. Do not

substitute any components here. Tighten the blade

retaining capscraw to 20-30 loot pounds torque value.

See Figure 25.

CAUTION

NEVER OPERATE THE MOWER WITH BLADE

WORN TO THE EXTENT SHOWN IN VIEW C AS

THE TIP COULD FLY OFF CAUSING PERSONAL

INJURY OR PROPERTY DAMAGE.

E-WEAR

LIMIT

CUTTING EDGE

WORN

DO NOT USE ON MOWERI

_ DANGER

FIGURE 23

Sharpen blade when the cutting edges become dull if

the blade is in otherwise good condition. When dull,

the grass cut ends will be ragged and usually turn

brown soon after mowing. For best results, remove

the blade and sharpen if on a grinding wheel at an angle

of 22 to 28 degrees, The cutting surface should extend

in about 2 1/2" from the tips. Check the blade after

sharpening to determine that it isstill balanced. It will

cause excessive vibration if unbalanced. See Figure 24,

2-1/2

"PLUS OR MINUS

3 DEGREES

- #1-2063

CONE WASHERS

FIGURE 25

CAPSCREW

TORQUE CAINJCREW

30 to 30 ft. IbL

REMOVING & INSTALLING MOWER

The mower is attached to the tractor and leveled at the

factory, ifthe mower isto be removed for cutting blade

service, or to install another attachment, be sure that

the mower settings remain unchanged.

TO REMOVE MOWER:

1. Lower deck to lowest position.

2, Remove hairpin from LIFT BRACKET CABLE clevis

pin. See Figure 26.

\

\

FIGURE 24

FIGURE 26

11

Page 12

SERVICE (Continued)

3. Remove hairpins and washers from REAR LIFT

ARM CHAINS. See Figure 27.

ARM

4.

CHAINS

(REAR)

FIGURE 27

Remove hairpins and clevis pins from FRONT LIFT

ARMS. See Figure 28.

CLEVISPIN

FRONT LIFT

ARM _'"

FIGURE 28

5. Afte_deck has been lowered to ground, turn

tractor's front wheels to the left and slide the mower

out from the right side. Reverse steps 1 thru 5 to

reinstall mower.

HOOD REMOVAL

To service engine (changing oil, spark plug, etc.). It is

recommended that the hood be removed. Hood re-

moval is as follows:

1. With hood in closed position, unhook latches at

bottom rear of hood.

2. Disconnect headlight wire at lower left front of

hood.

3. With hood level, lift straight up to clear pivot pins

at front front. See Figure 29.

4. Remove hood and lay aside until maintenance is

completed. Reinstall hood in reverse order.

LIFt

STRAIGHT

FIGURE 29

ADJUSTING STEERING

If steering develops excessive free-play, then the eccen-

tric steering bolt must be adjusted. Proceed as follows:

1. Working from the left side of the tractor, use a 7/16"

wrench to loosen nut on top of carriage bolt. See

Figure 30.

2. Push eccentric clockwise (towards R.H. side of

tractor) until free-play in steering wheel is minimized.

3. Retighten nut.

NUT

FIGURE 30

12

Page 13

SERVICE (Continued)

LEVELING MOWER

With the blades sharpened and properly aligned, a level

mower deck will insure a clean, even cut. The mower

should be checked for level as follows:

1. Check the air pressure in the tiros and correct

pressure as needed (12 psi front and 10 psi rear

tires).

2. Move the tractor to a smooth, flat and level area such

as garage floor.

3. Move the lift lever to #5 notch.

4. Place a 2 x 4" block on edge under the front lipof

the deck in the exact center between the front lift

arms.

5. Loosen the jam nut on the front liftcable and adjust

until the front lip of the deck rests on the 2 x 4 block

and the cable istight. Tighten the cable jam nut and

remove the block. See Figure 31.

FRONT LIFT CABLE _,,_

6. Place a 3" high block under the exact center of the

rear lip of the deck.

7. Pullthe pins and remove the chains from the rear lift

arms.

8. Turn the outside blades perpendicular to the tractor

frame.

9. Loosen nuts on eccentric bolt and pivot bolt and .

level the deck side to side by turning the eccentric

adjusting bolt. The distance from floor to each blade

tip should be within 1/8" of each other.

10. Loosen the jam nuts and adjust both rear lift chain

eyebolts so that the top link of the chain just slides

over the rear arm pins. Tighten jam nuts. Reinstall

the flat washers and hairpins. Recheck level.

I

(CONNECTED TO

MOWER FRAME)

OUTER PULLEY

BELTGUARDS

PIVOT BOLT

ECCENTRIC BOLT

BELT

_FRONTLIFTARM

CABLE

_'x4" WOODEN BLOCK

(STANDONEDGE)

MOWER DECK

CENTEROFREAR

DECK LIP

3" HIGH WOODEN

BLOCK

LEADING

BLADE

MULT*I-BLADE LEVEL CHECK ;

CHUTE DEFLECTOR

FIGURE 31

13,

Page 14

SERVICE (Continued)

LEVELING MOWER

With the blade sharpened and properly aligned, a level

mower deck will insure a clean, even cut. The mower

should be checked for level as follows:

1. Check the air pressure in the tires and correct

pressure as needed (12 psi front and 20 psi rear

tires).

2. Move the tractor to a smooth, flat and level area

such as garage floor.

3. Move the lift lever to #5 notch,

A. SIDE TO SIDE LEVEL ADJUSTMENT

(1) Place a piece of angle iron under center

of deck. See Figure 31,

(2) Pull the pins and remove the CHAINS

from the REAR LIFT ARMS.

(3) Measure distance between the floor

and outside center edges of the deck.

NOTE

A DECK IS CONSIDERED LEVEL IF MEASURE-

MENTS ARE WITHIN 1/8" FROM SIDE-TO-SIDE.

S*

(4) If required, adjust side-to-side level of

mower deck by loosening SHOULDER

SCREW on side of lift arm ECCENTRIC

BOLT. See Figure 31.

(5) Turn the ECCENTRIC BOLT "UP" or

"DOWN" to level deck within 1/8" side-

to-side.

(6) When deck is level, tighten SHOULDER

SCREW.

(7) Re-attach CHAINS to REAR LIFT ARMS.

(8) If either CHAIN is slack, adjust EYEBOLT

until both CHAINS have equal tension.

Recheck deck level, See Figure 31.

FRONT TO REAR LEVEL ADJUSTMENT

(1) Measure distance between the floor and the

front and rear edges of the mower deck.

Measurements should be the same or 1/8"

lower at the rear.

(2) Adjust chain EYEBOLTS the same number of

turns to raise or lower rear of

deck. Adjust until deck is properly

leveled.

WASHER

CHAIN

EYEBOLT

ADJUSTING

NUTS

PLACED UNDER

CENTER REAR

OFDECK

REARLIFT

ARM

LIFT ARMS

FIGURE 31

13

Page 15

SERVICE (Continued)

DRIVE BELT SERVICE

To remove and replace the DRIVE BELT, follow steps

1 thru 11.

1. Raise mower hood and disconnect spark plug wire.

2. Lower MOWER DECK to lowest position

j CAUTION

THE IDLER SPRING iS UNDER TENSION. TO

AVOID INJURY, USE CARE WHEN DISCON-

NECTING SPRING FROM FRAME.

7. Remove hairpin from front of CONTROL ROD then

lower CONTROL ROD, See Figure 34.

3. Remove REAR COVER PLATE. See Figure 32.

six (e)

RETAINING

SCREWS

PLATE

//

/

/

FIGURE 32

4. Depress CLUTCH/BRAKE PEDAL and lock into

position by pulling PARKING BRAKE LEVER "UP".

5. Shift SPEED SELECTOR to 6th position.

NOTE

ALTHOUGH IT IS POSSIBLE TO REMOVE AND

REPLACE THE DRIVE BELT WITH THE MOWER

DECK ATTACHED, IT IS RECOMMENDED THAT

THE DECK BE REMOVED TO MAKE BELT IN-

STALLATION EASIER. SEE "REMOVING &

INSTALL!NG MOWER", PAGES 11 & 12.

6. Disconnect IDLER SPRING. See Figure 33.

FIGURE 34

j NOTE

IF REMOVING/REPLACING DRIVE BELT WITH

DECK ATTACHED, THEN REMOVE MOWER

BELT FROM FRONT DRIVE PULLEY AT THIS

TIME.

8,

Remove DRIVE BELT from engine pulley by

rotating MOWER DRIVE PULLEY and holding

down on DRIVE BELT at same time. Allow belt

to remain on hub between pulleys at this time.

See Figure 35.

PULLEY

TRACTION

DRIVE

PULLEY

FIGURE 33

WHILE ROTATING

PULLEY

14

FIGURE 35

LOCKED.NOTESHIFTER 'i

B RAKEJCLUTCH MUST

BE DEPRESSED AND

MUST RE IN 6th

PosmoN. I

Page 16

.

Working at the rear of the mower, rotate the DRIVE

DISC while holding down on the DRIVE BELT until

belt is clear of disc. See Figure 36.

SERVICE (Continued)

TRACTION LOSS ADJUSTMENT

If the robber on the driven disc ring wears enough to

cause loss of traction, readjust the yoke stop (see

Figure 37) to restore good contact. With engine

"OFF" and drive shifted into "NEUTRAL", loosen the

jamnuts and turn the bolt clockwise about 2 turns. Check

to see that rubber ring turns freely in the center or

"NEUTRAU' groove - turn bolt in more if needed to

achievu this, then secure bolt by tightening both jamnuts,

FIGURE 36

10. Remove DRIVE BELT from front pulley.

11. Install DRIVE BELT in reverse order of above,

i

CAUTION

MAKE SURE THE BELT BEING INSTALLED

IS ABOVE REAR LIFT ARM.

t

TURN SCREW

CLOCKWISE

f

NEUTRAL

GRGOVE

FIGURE 38 I

SCHEMATIC WIRING DIAGRAM

FIGURE 37

KEYSWITCH-

7,5AMP

FUSE

12V-- 1

BATTERY

e.

KILL WIRE

_CABLE

(Soleno_toBatte_)

LIGHTS

PTO

CABLE -- SWITCH

(Solenoid to Stener) TO

ALTERNATOR CLUTCH

........ SWITCH .......

15

Page 17

SNAPPER LT12D41 SE

GENERAL SPECIFICATIONS

DRIVE TRAIN

Friction Disc System provides 6 forward speeds and 1

reverse.

ENGINE

Refer to Engine Manufacturer's Manual for specifications.

Brake: Drum ELECTRICAL SYSTEM

Starter 12 volt gear drive

TIRES ignition Magnetmn

Front: 15 x 6.50 x 6 Alternator Tri-cimuit

Rear 18 x 8.50 x 8 FUEL SYSTEM

APPROX.,WEIGHT 490 LBS. Fuel Capacity: 9 U.S. Quarts (2 1/4 U.S. GALS)

Air Cleaner: Paper filter cartridge

MANUFACTURER'S 2 YEAR LIMITED WARRANTY

For two (2) Years from purchase date for the original purchaser's residential, non-commercial use.

[ninety (90) days from purchase date for the original purchaser's commercial, rental, or other non-

residential use], SNAPPER POWER EQUIPMENT, through any SNAPPER dealer will replace, free of

charge, any part or parts found upon examination by the factory at McDonough, Georgia, to be

defective in material or workmanship or both.

All transportation Cost incurred by the purchaser in submitting material to a SNAPPER dealer for

replacement under this warranty must be borne by the purchaser.

This warranty does not apply to engines and their components, as these items are warranted

separately by their manufacturers, and does not apply to batteries which are covered separately.

This warranty does not apply to parts that have been damaged by accident, alteration, abuse,

improper lubrication, normal wear, or other cause beyond our control.

There is no other express warranty.

Implied warranties, including those of merchantability and fitness for a particular purpose, are

limited to two (2) years from purchase date for the original purchaser's residential, non-commercial

use [ninety (90) days from purchase for the original purchaser's commercial, rental or other non-

residential use], and to the extent permitted by law any and all implied warranties are excluded. This

is the exclusive remedy. Liabilities for consequential damages, under any and all warranties are

excluded.

Some states do not allow limitations on how long an implied warranty lasts,or do not allow the ex-

clusion or limitation of incidental or consequential damages, so the above limitation or exclusion

may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

WARNING: THE USE OF REPLACEMENT PARTS OTHER THAN GENUINE SNAPPER PARTS MAY

IMPAIR THE SAFETY OF SNAPPER PRODUCTS AND WILL VOID ANY LIABILITY AND

WARRANTY BY SNAPPER ASSOCIATED WITH THE USE OF SUCH PARTS.

IMPORTANT: Please fill out the attached SNAPPER Product Registration Card immediately and

mail to: SNAPPER POWER EQUIPMENT, McDONOUGH, GEORGIA 30253

SNAPPER POWER EQUIPMENT I /TI U UAI

McDonough, GA., 30253 U.S.A. / J- %_-_-'_"

MANUAL #2-3211 REVISION 2, 4/90 Issue)

Printed In U,S.A,

Loading...

Loading...