Page 1

OPERATOR’S

MANUAL

NHSystem Number: Description:

5600001 IS500Z, & IS1500Z, 44” Mower Deck - 2 Bag System

5600002 IS1500Z & S150X, 48” Mower Deck - 2 Bag System

5600003 IS1500Z & S150X, 48” Mower Deck - 3 Bag System

5600004 IS1500Z & S150X, 52” Mower Deck - 3 Bag System (S/N: 2012628762 & Below)

5600005 IS3000ZL, 61” Mower Deck - 3 Bag System

5600006 IS3000Z & IS3000ZX, 61” Mower Deck - 3 Bag System (S\N 3631 & Above)

5600007 IS1000Z, 52” Mower Deck - 3 Bag System (S\N 2531 & Above)

5600008 IS1000Z, 61” Mower Deck - 3 Bag System (S\N 2899 & Above)

5600009 IS4500Z, 61” Mower Deck - 3 Bag System

5600057 IS2000Z & S200X, 61” Mower Deck - 3 Bag System

5600060 IS3100Z, 61” Mower Deck - 3 Bag System

5600061 IS2000Z, 52” Mower Deck - 3 Bag System (S/N: 2012628762 & Below)

5600083 IS3100ZBS, 61” Mower Deck - 3 Bag System

5600148 IS1500Z & S150X, 52” Mower Deck - 3 Bag System (S/N: 2012628763 & Above)

5600150 IS2000Z, 52” Mower Deck - 3 Bag System (S/N: 2012628763 & Above)

FAST-Vac

Grass Collection Systems

with Setup Instructions

IMPORTANT NOTE:

These FAST-Vac Systems fit 2005

and newer Model Year product

equipped with the rubber

discharge chute.

5100063

Revision K

Rev. Date: 10/2007

TP 100-7219-K-AT-UV

Page 2

Thank you for purchasing this quality-built Ferris product. We’re pleased that

you’ve placed your confidence in the Ferris brand. When operated and

maintained according to the instructions in this manual, your Ferris product will

provide many years of dependable service.

This manual contains safety information to make you aware of the

hazards and risks associated with this machine and how to avoid them. This

machine is designed and intended to be used and maintained according to the

manual for finish cutting of established lawns and is not intended for any other

purpose. It is important that you read and understand these instructions

thoroughly before attempting to start or operate this equipment.

DATE PURCHASED / FECHA COMPRADA

Briggs & Stratton Yard Power Products Group

Copyright © 2007 Briggs & Stratton Corporation

Milwaukee, WI, USA. All rights reserved.

The Ferris logo is a trademark of Briggs & Stratton

Corporation Milwaukee, WI, USA.

Contact Information:

Briggs & Stratton Yard Power Products Group

5375 N. Main St.

Munnsville, NY 13409-4003

(800) 933-6175

www.ferrisindustries.com

Page 3

1

Table of Contents

SAFETY RULES & INFORMATION .....................2

Safety Decals..........................................................3

GENERAL OPERATING INSTRUCTIONS...........4

Before Operation.....................................................4

Mowing with the Double / Triple Catcher ................4

After Operation........................................................5

Storing the Grass Catcher ......................................5

Mowing Without the Blower ....................................5

INSTALLATION.....................................................6

Suspension Adjustment ..........................................6

Ball Joint Replacement ...........................................7

Blower Assembly.....................................................8

Mower Deck Preparation ......................................12

Blower Installation.................................................17

Collector Installation..............................................19

Weight Mount Installation

1000Z Series ...................................................27

Weight Mount Installation

IS1000Z Series................................................28

Weight Mount Installation

IS3000Z Series & IS3100Z Series ..................29

Weight Mount Installation

IS500Z & IS1500Z Series ...............................30

Weight Mount Installation

IS2000Z Series................................................31

Weight Mount Installation

IS4500Z Series................................................32

Weight Mount Installation

S150X & S200X Series ...................................33

BLOWER & COLLECTOR REMOVAL ...............34

REGLAS E INFORMACIÓN DE SEGURIDAD...36

Calcomanías de seguridad ...................................36

INSTRUCCIONES GENERALES

DE OPERACIÓN.................................................37

Antes de la operación...........................................37

Podar con el receptor doble o triple......................37

Después de la operación......................................38

Almacenar el receptor de pasto............................38

Podar sin el soplador............................................39

REMOCIÓN DEL SOPLADOR Y RECEPTOR...39

Safety

Operation

Installation

Removal Seguridad

Operación

ES GB

Spanish English

Page 4

2 www.ferrisindustries.com

Safety

GENERAL WARNINGS

• Know the mower controls, safety rules and how to

stop quickly. READ AND UNDERSTAND THE

MOWER OPERATOR’S MANUAL.

• Read and obey all safety decals.

• Wear appropriate ear, eye and breathing

protection.

• Only allow responsible adults, who are familiar

with the instructions, to operate the unit.

• Disengage the electric clutch (PTO). Shut off the

engine and wait for all moving parts to stop before

attaching, adjusting, or disconnecting any part of

the collection system.

• Check the collection system to make sure it is

bolted tightly to the rider.

• DO NOT operate the mower without either the

entire grass catcher or the deflector in place.

• Turn off the PTO switch to disengage the blades

when not mowing.

• DO NOT mow in reverse. Always look down and

behind before and while travelling in reverse.

• DO NOT turn sharply when travelling alongside a

building or any object. Slow down before turning.

• DO NOT carry passengers on the rider.

• When blower assembly is removed from the

mower deck, the deflector must be properly

installed.

• Collector bags are subject to deterioration and

wear during normal use. Inspect the bag

periodically for tears, holes or weak spots and

replace with a new bag that meets manufacturer’s

durability standards.

• If the mower stalls or the turbo blower chute plugs:

1. Disengage the electric clutch (PTO);

2. Stop the engine and remove the key;

3. Set the parking brake, and wait for all moving

parts to stop.

4. Remove the foreign object or clear the chute

with a piece of wood before restarting the

engine. NEVER place hands into blower

housing to clear jammed object. Blower

may rotate when object is removed.

• For added rider stability and to prevent tipping or

loss of control:

a. Use reduced speed on uneven ground and

when turning corners.

b. Reduce loads on hillsides. It is recommended

that the collection system be kept no more than

half full when negotiating any slopes. Start

mowing on slopes when the collection system

is empty.

c. Mow across the face of slopes; not up and

down.

• Never operate on slopes greater than 17.6%

(10°).

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of

control of unit, severe personal injury or death to you, or bystanders, or damage to property or

equipment. This mo

wing deck is capable of amputating hands and feet and throwing objects.

The triangle in text signifies important cautions or warnings which must be followed.

Safety Rules & Information

Page 5

3

Safety

GB

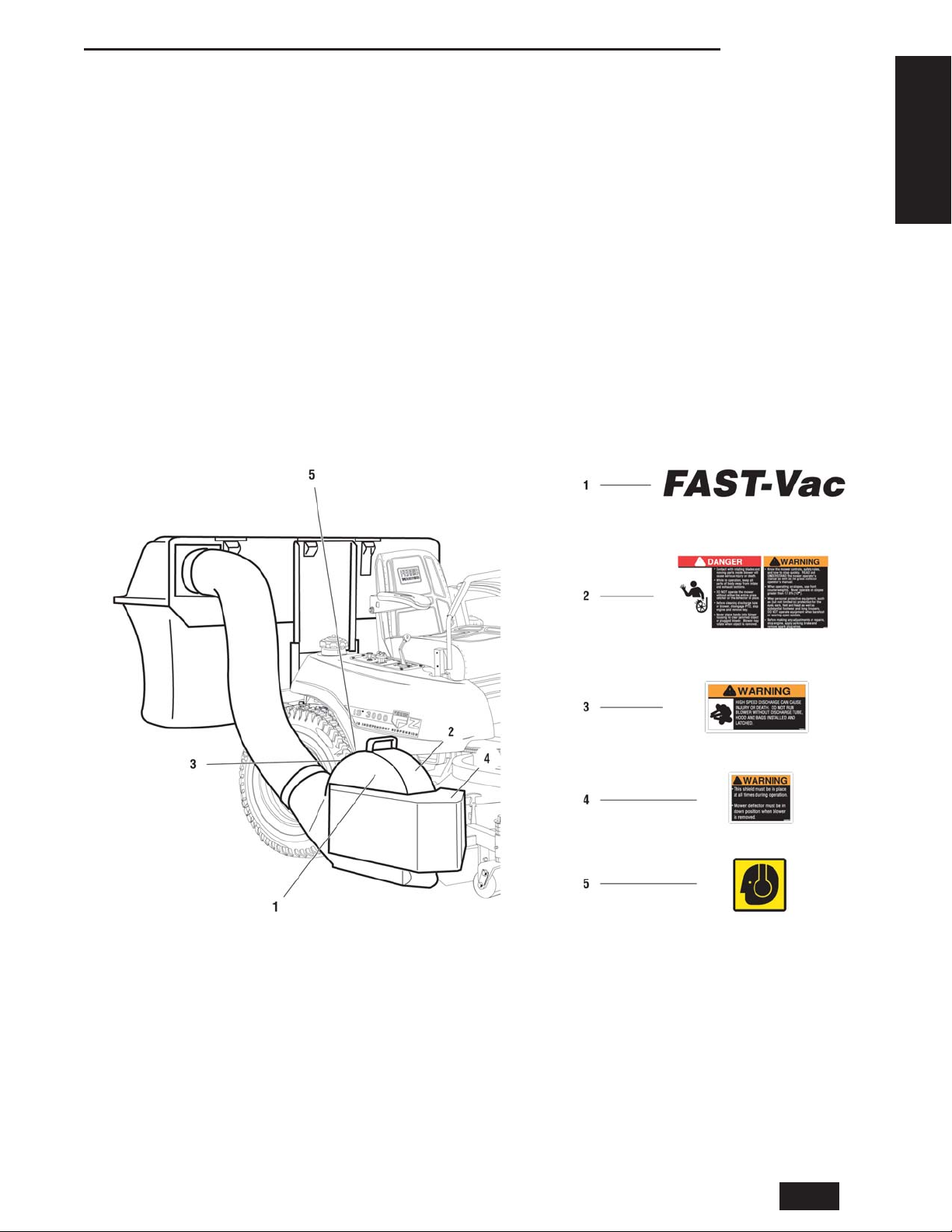

SAFETY DECALS

This unit has been designed and manufactured to

provide you with the safety and reliability you would

expect from an industry leader in outdoor power

equipment manufacturing.

Although reading this manual and the safety

instructions it contains will provide you with the

necessary basic knowledge to operate this equipment

safely and effectively, we have placed several safety

labels on the unit to remind you of this important

information while you are operating your unit.

All DANGER, WARNING, CAUTION and

instructional messages on your rider and mower

should be carefully read and obeyed. Personal bodily

injury can result when these instructions are not

followed.The information is for your safety and it is

important! The safety decals below are on your rider

and mower.

If any of these decals are lost or damaged, replace

them at once. See your local dealer for replacements.

These labels are easily applied and will act as a

constant visual reminder to you, and others who may

use the equipment, to follow the safety instructions

necessary for safe, effective operation.

Safety Decals

Page 6

4 www.ferrisindustries.com

Operation

BEFORE OPERATION

Clear the lawn of all sticks, stones, wire and other

debris which may be caught or thrown by the mower

blades.

Check grass condition. If wet, wait until later in the

day. If grass is wet, the grass catcher is likely to

become plugged.

For efficient bagging, air circulation under the

mower deck, through the chute and into the bag

is very important.

For this reason, BEFORE YOU BEGIN MOWING

you should make certain the underside of the mower

and the underside of the catcher lid are free from

grass and debris.

Make sure that there is a snug fit between mower

deck, blower housing, tubes, and grass catcher

cover.

MOWING WITH THE DOUBLE /

TRIPLE CATCHER

Always operate with throttle at full speed when

mowing.

Always wear hearing protection when operating

grass catcher.

Grass should be cut often, and not too short. If grass

is too long or lush it may be necessary to keep

ground speed to a minimum or to cut only half the

width of the mower to prevent clogging. If grass is

long, operate with mower in high cutting position for

first pass, cutting again in a lower position on a

second pass.

Do not open the cover with mower engaged.

If a large amount of cut grass is spilling out from

under deck, the tube may be plugged or the bags

may be full— discontinue mowing, stop the rider,

disengage the PTO and then empty the catcher or

clear the tube.

WARNING

ALWAYS shut off the tractor. disengage the

PTO, and allow all moving parts to stop

BEFORE disconnecting or clearing tube, or

emptying catcher.

Before leaving the operator’s position for any

reason, engage the parking brake, disengage

the PTO, stop the engine and remove the key.

To reduce fire hazard, keep the engine, rider

and mower free of grass, leaves and excess

grease. Do not stop or park rider over dry

leaves, grass or combustible materials.

CAUTION

This machine produces sound levels in

excess of 85 dBA at the operator’s ear

and can cause hearing loss though

extended periods of exposure.

Wear hearing protection when operating this

machine.

General Operating Instructions

Page 7

5

Operation

GB

AFTER OPERATION

Remove any debris from the the screen on the

underside of the lid.

Note: The lid screen can be

partially removed for easier cleaning and should be

cleaned regularly.

The blower housing and tube should be removed for

cleaning.

Inspect the grass bags for wear or damage. Make

sure that there is a snug fit between mower deck,

blower housing, tubes, and grass catcher cover.

STORING THE GRASS CATCHER

Clean the grass catcher thoroughly using a mild

detergent (other products may damage the tube).

Remove any debris from the the screen on the

underside of the lid. The screen can be partially

removed for easier cleaning.

If paint has been scratched on metal parts, touch up

with paint, or apply a thin film of oil to prevent

corrosion.

Store in a dry area. Hang the catcher and catcher

bags to dry thoroughly before storing for a long period

of time. Always store away from moisture.

MOWING WITHOUT THE BLOWER

For operation without the blower, the deflector must

be properly installed in the down position.

To remove the blower, reverse the installation steps.

General Operating Instructions

Page 8

6 www.ferrisindustries.com

Installation

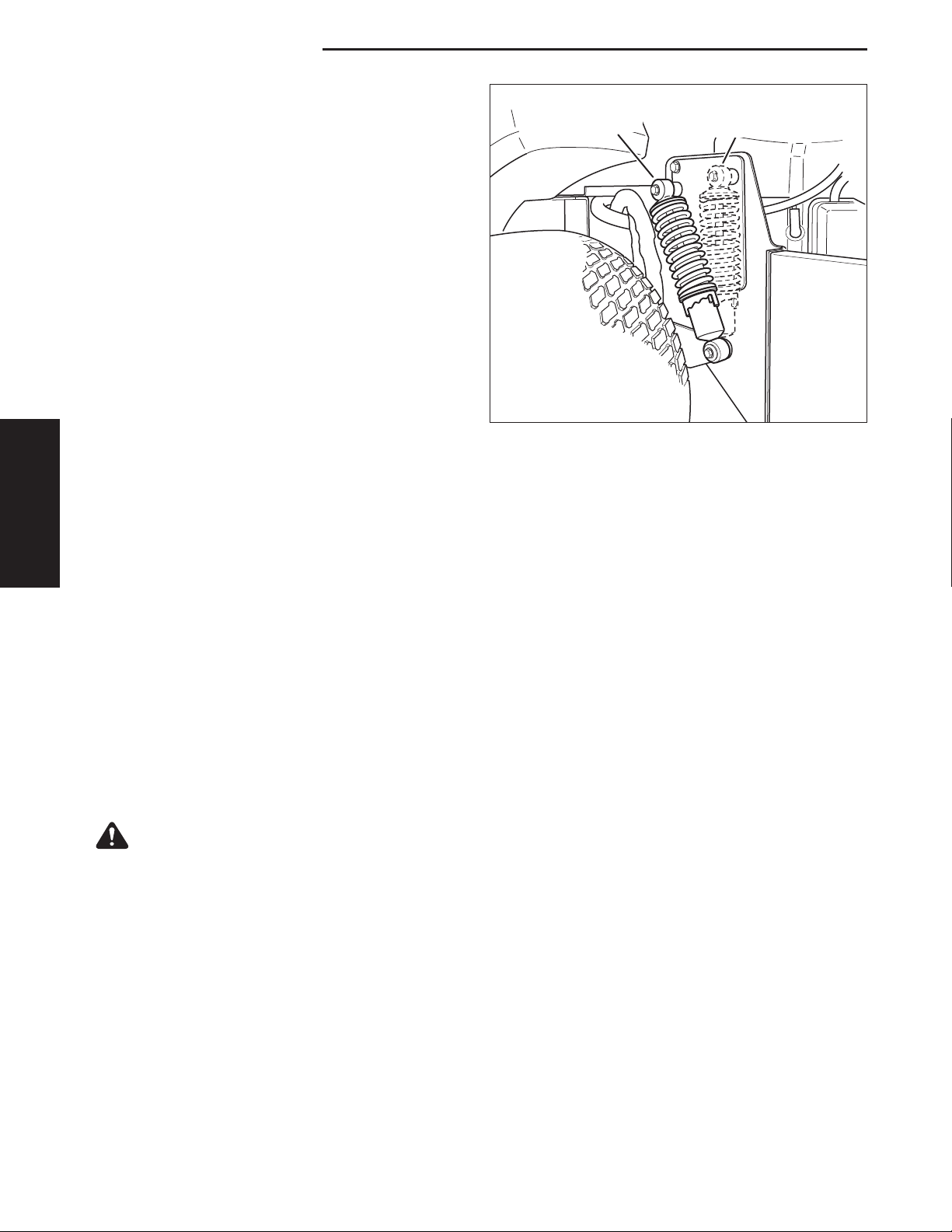

Figure 1. Rear Suspension Adjustments

POSITION #1

(FACTORY SET)

POSITION #2

(GRASS BAGGER)

Suspension Adjustment

REAR SUSPENSION ADJUSTMENT

For IS1500Z & IS2000Z Models:

The upper mounting position #2 (See Figure 1)

should be used when a rear-mount grass bagger

system is installed.

To adjust the upper mounting position:

1. Park machine on a flat, level surface. Disengage

the PTO, stop the engine and engage the parking

brake.

2. Raise the rear of the machine and secure with

jackstands. The jackstands must be under the

bumper. Chock the front wheels to prevent the

machine from rolling.

3. Position the jack under the cross member that ties

the suspension arms together and slowly raise the

rear suspension to relieve the pressure on the

upper shock mounting bolts.

NOTE: This will require small adjustments to the

jack’s position. The shock should move freely on the

mounting bolt when the pressure is relieved.

4. Remove the upper shock mounting hardware and

pivot the shock to the position #2 (see Figure 1).

Adjust the jack to align the shock mounts to the

shocks.

5. Reinstall the upper shock mounting hardware and

tighten securely.

6. Remove the jack from under the suspension cross

member.

7. Remove the jackstands from under the machine.

For All Models:

More spring pre-load should be used with heavy

weight operators.

To adjust the spring pre-load:

1. Park machine on a flat, level surface. Disengage

the PTO, stop the engine and engage the parking

brake.

2. Raise the rear of the machine and secure with

jackstands. Chock the front wheels to prevent the

machine from rolling.

3. Remove the rear drive tires.

WARNING

Use two hands when adjusting the shock

springs. This will prevent the wrench from

slipping while pressure is being applied.

4. See Figure 1. Using the supplied spanner wrench

(p/n 5022853), insert the tip of the wrench into the

notch in the pre-load adjuster. While holding the

wrench in place with one hand, turn COUNTERCLOCKWISE to increase the pre-load, turn

CLOCKWISE to decrease the pre-load. Make

sure both shocks are set to the same amount of

pre-load.

5. Reinstall the rear drive tires. Torque the lug bolts

to 85-95 ft/lbs. (115-129 Nm). Remove the

jackstands from under the machine.

NOTE: Spanner wrench is located under the seat on

the right-hand side of the machine.

Page 9

Installation

Ball Joint Replacement

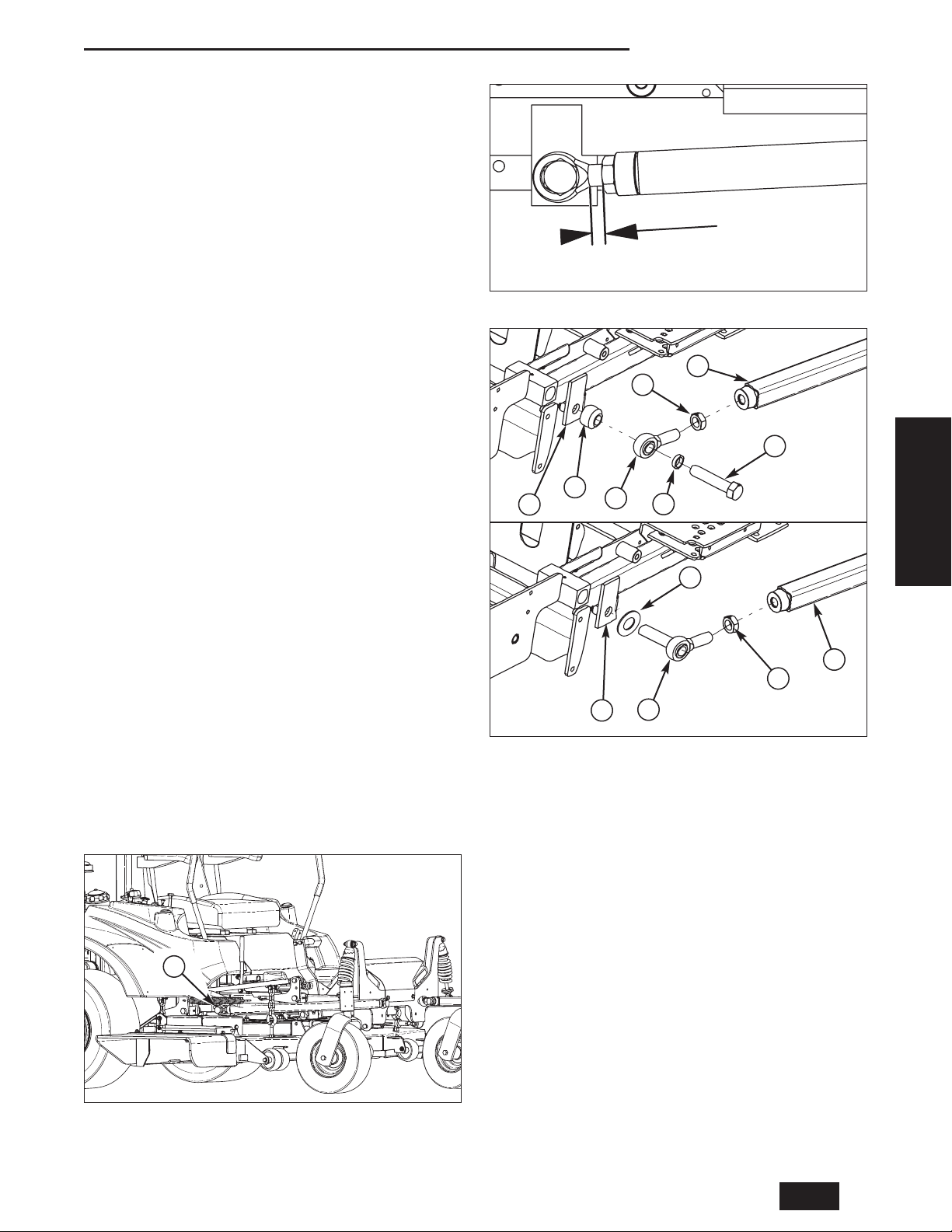

BALL JOINT REPLACEMENT

For IS2000Z Models with 52” Mower Deck:

The existing ball joint (A, Figure 2) on the right-hand

front suspension arm has to be replaced with the ball

joint provided in the kit. This change is necessary to

provide clearance for the blower unit and must be

completed before blower unit installation.

To replace the ball joint:

1. Lower the front of the mower deck down on to

wooden blocks to relieve the tension on the front

deck hanger chains. Jack up the front of the

tractor frame until the weight is lifted off of the

front caster wheels.

2. Measure the amount of threads showing on the

shank of the existing ball joint. See Figure 3.

3. Remove 3/4” bolt (E, Figure 4) that attaches the

ball joint to the tractor frame (A). Discard the

spacers (H and I) and 3/4” bolt (E).

4. Remove the ball joint (B) from the suspension arm

(D).

5. Remove the jam nut (C) from the existing ball joint

and thread onto the ball joint provided with kit (F).

Discard the existing ball joint (B). Thread new ball

joint into the suspension arm to the approximate

measurement taken in step 2, allowing for correct

orientation (Refer to Figure 4) of the ball joint to

the tractor frame.

6. Install the ball joint stud through the 3/4” washer

(G) and the tractor frame and tighten securing nut.

Tighten jam nut on the shank of the ball joint

against the suspension arm.

7. Lower the machine back down onto the caster

wheels and remove the jack. Raise the mower

deck to the transport position and remove the

wooden blocks.

Figure 2. Location of Ball Joint

A. Ball Joint To Be Replaced

A

Figure 3. Measure Threads

Figure 4. Ball Joints

A. Frame

B. Existing Ball Joint

C. Jam Nut

D. Suspension Arm

E. 3/4” Bolt

F. Ball Joint Provided In Kit

G. 3/4” Washer Provided In Kit

H. Spacer, .75 x 1.75 x 1.00

I. Spacer, .75 x 1.00 x .25

B

C

D

F

C

E

D

A

A

7

G

GB

H

I

MEASURE HERE

Page 10

8 www.ferrisindustries.com

Installation

Blower Assembly

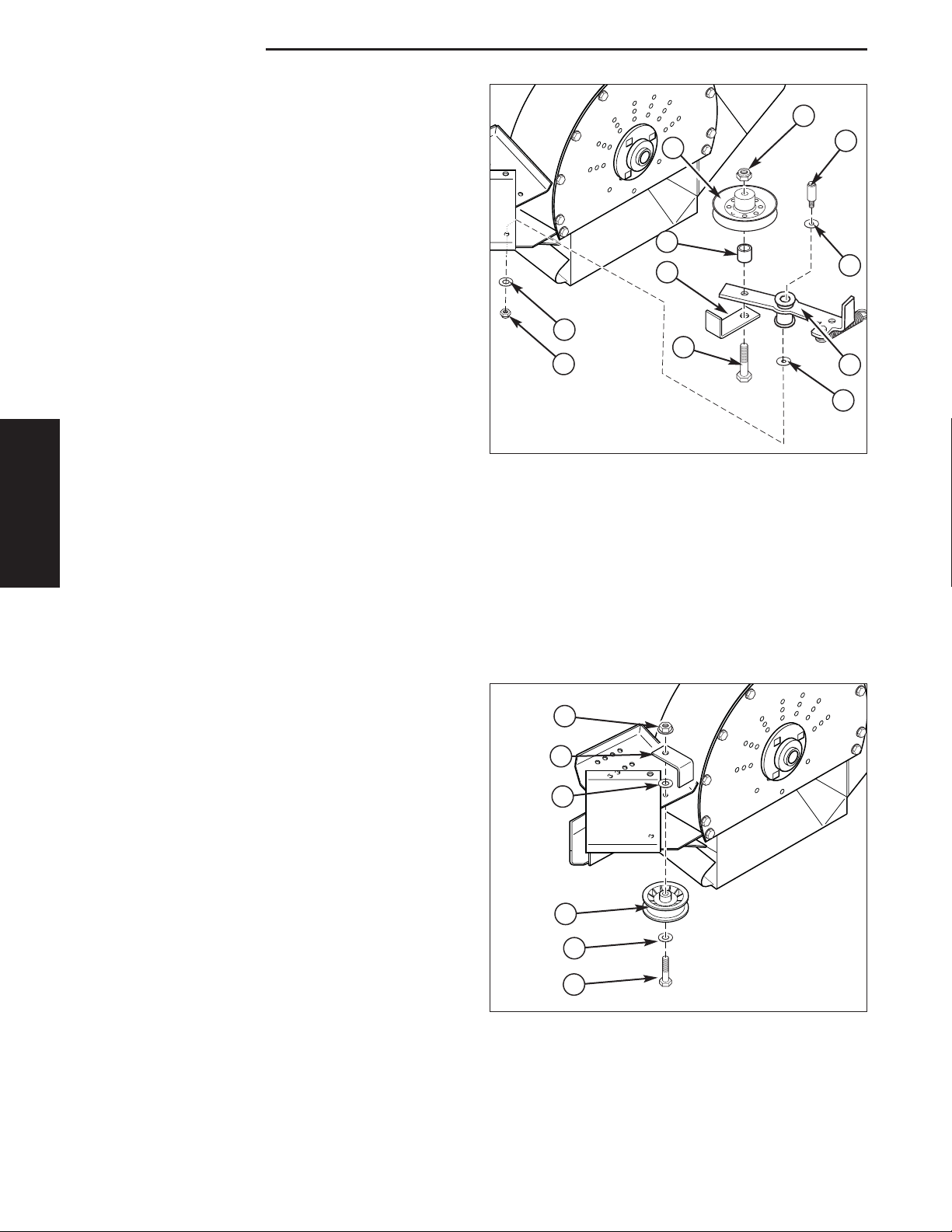

BLOWER ASSEMBLY

Preparing the Mower Deck (IS4500Z Models Only)

1. Loosen the 3/8-24 hex nut (A, Figure 5) that

secures the idler arm (C) to the blower assembly.

Remove the idler arm assembly from the blower

assembly.

2. Loosen the 1/2” hardware that secures the idler

pulley (G) to the idler arm assembly. Remove the

idler pulley from the idler arm assembly. Discard

the bolt that secured the idler pulley to the idler

arm assembly.

3. Refer to figure 6. Install the new 1/2-13 X 2-3/4”

bolt (J) through the belt keep (I), which should be

positioned with the tab facing up, then through the

idler arm (C), then through the idler pulley spacer

(H), and then through the idler pulley (G) which

should be positioned wiht the hub facing up, and

secure with the 1/2-13 hex nylon nut (F).

4. Set the idler arm assembly aside for reinstallation

later.

Figure 5. Updating the Idler Arm Assembly

A. 3/8-24 Hex Nut

B. 3/8 Lock Washer

C. Idler Arm

D. 9/16 Narrow Flat Washer

E. Idler Stud

F. 1/2-13 Hex Nylon Lock Nut

G. Idler Pulley

H. Idler Pulley Spacer, .52 X 1.00 X .44

I. Belt Keep

J. 1/2-13 x 2-3/4” Bolt

A

B

D

C

D

E

F

H

I

J

G

Figure 6. Installing the New Washer

A. 3/8-16 Hex Serrated Flange Nut

B. Belt Keep

C. .41 X 1.75 X .14 Washer

D. Fixed Idler Pulley

E. 3/8” SAE Washer

F. 3/8-16 X 2” Bolt

F

E

D

C

B

A

5. Loosen the 3/8-16 hex serrated flange nut (A,

Figure 6) that secures the fixed idler pulley (D),

and belt keep to the blower assembly.

6. Remove the 3/8-16 hex serrated flange nut (A)

and the belt keep (B) from the 3/8-16 X 2” bolt (F).

7. Refer to figure 6. Install the .41 X 1.75 X .14

washer (C) onto the bolt above the top of the

blower assembly. Reinstall the belt keep (B) with

the tab facing down, and secure with the 3/8-16

hex serrated flange nut (A).

Page 11

9

Installation

GB

Figure 7. Installing the New Support Plate

A. 3/8-16 Hex Serrated Flange Nut

B. Support Plate

C. 3/8-16 X 3/4 Bolt

D. Adjustable Idler Pulley

E. 3/8” SAE Washer

F. .39 X .75 X .38 Spacer

G. Belt Keep

H. 3/8-16 x 2-1/2” Bolt

A

B

C

D

E

G

H

F

Outer

Row

Inner

Row

Drill

Here

8. Loosen the 3/8-16 hex serrated flange nut (A,

Figure 7) that secures the adjustable idler pulley

(D) to the blower assembly. Remove the 3/8-16

hex serrated flange nut (A), and all the

components the nut secured. Discard the 3/8-16 X

2” bolt.

9. Place the support plate (B) on the blower

assembly. Line up the two rows of holes in the

support plate with the two rows of holes on the

blower assembly.

10. Refer to figure 7. Place a 3/8-16 X 3/4 Bolt (C) up

through the blower assembly in the front most

hole of the inner row, through the support plate

(B) and secure with a 3/8-16 hex serrated flange

nut (A).

11. Reassemble the adjustable idler pulley

components as shown in Figure 7. Install the 3/816 X 2-1/2” bolt (H) up through the belt keep (G)

which should be positioned with the tab facing up,

through the .39 X .75 X .38 spacer (F), through

the 3/8 SAE washer (E), through the adjustable

idler pulley (D), which should be positioned with

the hub facing up, then through the blower

assembly, then through the support plate (B) and

secure with a 3/8-16 hex serrated flange nut (A).

12. Using a 3/8” drill bit, drill a 3/8” hole through the

blower assembly using the left rear hole (see

Figure 7) as a guide.

13. Install a 3/8-16 X 3/4 bolt (C) up through the

blower assembly in the newly drilled hole, through

the support plate (B) and secure with a 3/8-16 hex

serrated flange nut (A).

14. Reinstall the idler arm assembly to the blower

assembly as shown in Figure 8. Install the idler

stud (A, Figure 8) down through a 9/16 narrow flat

washer (B) then down through the idler arm

assembly (C), then down through another 9/16

narrow flat washer (B), then down through the

blower assembly, then down through the 3/8 lock

washer (D), and secure with the 3/8-24 hex nut

(E).

D

E

B

C

B

A

Figure 8. Updating the Idler Arm Assembly

A. Idler Stud

B. 9/16 Narrow Flat Washer

C. Idler Arm Assembly

D. 3/8 Lock Washer

E. 3/8-24 Hex Nut

Blower Assembly

Page 12

10 www.ferrisindustries.com

Installation

Blower Assembly

Blower Assembly

1. Remove the existing 5/16-18 x 5/8” flange head

bolts (B, Figure 9) from the blower housing (A).

2. Install the blower mount plate (C) onto the blower

housing and reinstall the 5/16-18 x 5/8” flange

head bolts. Tighten securely.

3. Install three (3) 3/8-16 x 1” bolts and nylon lock

nuts (D) through the blower mount plate and

blower. The bolt heads must be installed on the

inside of the blower housing.

Figure 9. Install Blower Mount Plate

A. Blower Housing

B. 5/16-18 x 5/8” Bolts (existing)

C. Blower Mount Plate

D. 3/8-16 x 1” Bolts & Nylon Lock Nuts (3X)

B

D

C

B

A

4. Loop the idler spring (A, Figure 10) through the

1/4” x 2” eyebolt (B). Install the eyebolt through

the L-bracket on the blower mount and install the

1/4-20 nylock flange nut (C). Tighten the nut until

the eyebolt contacts the L-bracket.

Note: For 52” decks, the spring anchor bolt (D) has to

be reversed. So that the idler spring can be attached

to anchor bolt above the idler arm (E).

C

A

B

Figure 10. Install Idler Spring

A. Idler Spring

B. 1/4” x 2” Eyebolt

C. 1/4-20 Nylock Flange Nut

D. Spring Anchor Bolt

E. Idler Arm

E

D

Page 13

11

Installation

GB

5. Remove the blower belt guard and set aside.

IS500Z, 1000Z, IS1000Z, IS1500Z, IS2000Z,

IS3000Z, IS3100Z, S150X, S200X Series Models:

6. Install the impeller drive pulley (A, Figure 11) onto

the impeller shaft (B) as described in Figure 11.

Install the 1/4” x 1-1/2” long key (not shown) in the

pulley.

7. Align the pulley groove with the appropriate slot as

described in Figure 11. Tighten the set screws in

the pulley.

8. Reposition the 3/8-16 x 6” bolt if required to line

up with the pulley groove.

IS4500Z Models:

9. Loosely install the tapered hub (A, Figure 12) into

the blower pulley (D). Install the blower pulley onto

the impeller shaft (E) and slide the blower pulley in

towards the blower assembly.

10. Position the new blower drive belt (B, Figure 12) in

the blower drive pulley.

11. Position the blower pulley (D, Figure 12) so it is

center with the belt keeper bolt (F). Install the 1/4”

X 1-1/2” long key (C) into the blower pulley (D).

12. Install the two (2) 1/4-20 X 1” bolts (B) into the

tapered hub (A) and tighten evenly. Torque the

1/4” bolts to 8 ft. lbs. (10,9 Nm).

All Models:

13. Check the position of the idler pulley (A, Figure

13). The position must be aligned with the

position of the pulley (outer row of holes for pulley

hub pointing in, inner row of holes for pulley hub

pointing out). Reposition if necessary.

Inner Slot

Align pulley groove

with slot (outer slot

with pulley hub in

OR inner slot with

pulley hub out)

Inner Row

Outer Row

Figure 11. Install Impeller Drive Pulley

Figure 13. Check Idler Pulley Position

A. Idler Pulley

A

Hub pointing OUT:

52” Models

All other 61” Models

Hub pointing IN:

44” Models

48” Models

61” IS3000ZL Model ONLY

61” IS3100Z Models

Blower Assembly

Outer Slot

Figure 12. Install Impeller Drive Pulley (IS4500Z

Models Only)

A. Tapered Hub

B. 1/4-20 X 1” Bolt

C. 1/4 X 1-1/2” Long Key

D. Blower Pulley

E. Impeller Shaft

F. Belt Keeper Bolt

A

B

C

D

E

F

Page 14

12 www.ferrisindustries.com

Installation

A

Figure 16. Mower PTO Belt

A. Idler Arm

B. Stationary Idler Pulley

B

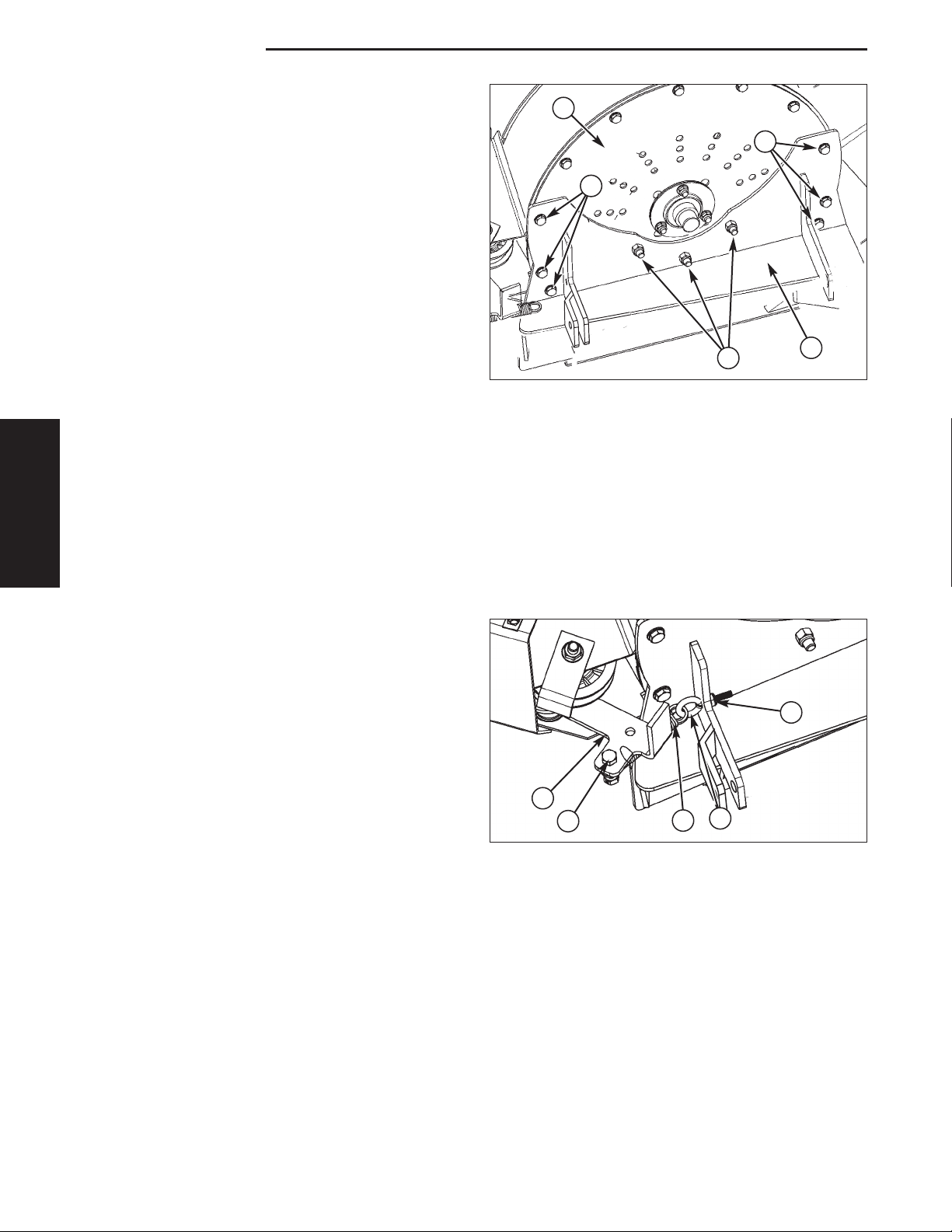

Remove the Spindle Belt

IS500Z & IS1500Z Series:

1. Using a 1/2” breaker bar, place the square end in the

square hole located in the end of the idler arm (A,

Figures 16). Carefully rotate the breaker bar

clockwise, which will relieve the tension on the belt

exerted from the idler arm.

2. Slide the drive belt over the edge of the stationary

idler pulley (B). Carefully release the tension on the

breaker bar. Remove the belt from the right-hand

(discharge side) spindle pulley.

Remove the Discharge Chute

1. Remove the discharge chute (A, Figure 14), chute

mount rod (B) and mounting hardware.

2. Remove the chute lock bolt (C) and nut.

3. Remove the deck guard (D). Save the bolts and

washers, as they will be required in a later step.

Figure 14. Remove Chute & Guard

A. Discharge Chute

B. Chute Mount Rod

C. Chute Lock Bolt

D. Guard

A

B

D

C

4. Examine the discharge chute mount bracket on

the mower deck (see Figure 15). If the hole

pattern looks like the one shown, you must drill a

3/8” hole in the location specified in Figure 15.

Figure 15. Discharge Chute Mount

WARNING

IS500Z, 1000Z, IS1500Z, IS2000Z, IS3000Z,

IS3100Z, IS4500Z, S150X & S200X Models:

Use extreme caution when rotating the idler

arm with the breaker bar, due to the increased

tension in the spring as the idler arm is being

rotated. Injury may result if the breaker bar is

prematurely released while the spring is under

tension.

Mower Deck Preparation

1-1/2"

(3,8 cm)

5/8"

(1,6 cm)

3/8" Drill

Page 15

13

Installation

GB

IS2000Z Series (52” Model):

1. Using a 1/2” breaker bar, place the square end in

the square hole located in the end of the idler arm

(A, Figures 18). Carefully rotate the breaker bar

counter-clockwise, which will relieve the tension

on the belt exerted from the idler arm.

2. Slide the drive belt over the edge of the stationary

idler pulley (B). Carefully release the tension on

the breaker bar. Remove the belt from the righthand (discharge side) spindle pulley.

Mower Deck Preparation

IS1000Z Series (52” Model):

1. Loosen the spring compression nut (B, Figure 17)

to release the belt tension.

2. Slide the drive belt over the edge of the idler

pulley and then remove the belt from the righthand (discharge side) spindle pulley.

A

Figure 17. Mower PTO Belt

A. Belt Tension Spring

B. Spring Compression Nut

B

Figure 18. Mower PTO Belt

A. Idler Arm

B. Stationary Idler Pulley

A

B

Figure 19. Mower PTO Belt

A. Idler Arm

B. Stationary Idler Pulley

1000Z Series (61” Model), IS2000Z Series (61”

Model), IS3000Z Series & IS3100Z Series, S150X

Series:

1. Using a 1/2” breaker bar, place the square end in

the square hole located in the end of the idler arm

(A, Figures 19). Carefully rotate the breaker bar

counter-clockwise, which will relieve the tension

on the belt exerted from the idler arm.

2. Slide the drive belt over the edge of the stationary

idler pulley (B). Carefully release the tension on

the breaker bar. Remove the belt from the righthand (discharge side) spindle pulley.

A

B

Page 16

14 www.ferrisindustries.com

Installation

Mower Deck Preparation

IS4500Z Series:

1. Using a 1/2” breaker bar, place the square end in

the square hole located near the end of the idler

arm (A, Figures 21). Carefully rotate the breaker

bar clockwise, which will relieve the tension on the

belt exerted from the idler arm.

2. Remove the belt from the trim side spindle pulley

(B).

3. Carefully release the tension on the breaker bar.

4. Remove the belt from the right-hand (discharge

side) spindle pulley.

Figure 21. Spindle Drive Belt Removal

A. Idler Arm

B. Trim Side Spindle Pulley

B

A

A

B

B

Figure 20. Mower PTO Belt

A. Idler Arm

B. Stationary Idler Pulley

S200X Series:

1. Using a 1/2” breaker bar, place the square end in

the square hole located in the end of the idler arm

(A, Figures 20). Carefully rotate the breaker bar

counter-clockwise, which will relieve the tension

on the belt exerted from the idler arm.

2. Slide the drive belt over the edge of the stationary

idler pulley (B). Carefully release the tension on

the breaker bar. Remove the belt from the righthand (discharge side) spindle pulley.

Page 17

15

Installation

GB

Mower Deck Preparation

Remove the Spindle Pulley

IS500Z Series, 1000Z Series, IS1000Z Series,

IS1500Z, IS2000Z, IS3000ZF & ZX Series, S150X &

S200X Series:

1. Remove the 3/4-16 hex nut & 3/4” spring washer

(A & B, Figure 22) securing the spindle pulley (C)

to the spindle shaft. Use a 1” wrench on the flats

of the blade end of the spindle shaft to prevent the

shaft from spinning. Save the 1/4” key (D).

IS3000ZL Series, IS3100Z Series, & IS4500Z

Series:

1. Measure and record the distance between the

bottom of the spindle pulley and the top of the

mower deck. This will be required when installing

the new pulley.

2. Remove the 1/4-20 x 1” bolts (E) securing the

tapered hub (F) to the spindle pulley (G) and

shaft.

3. Reinstall the bolts in the tapped holes of the

tapered hub and tighten evenly to remove the hub

from the pulley and shaft. Use a 1” wrench on the

flats of the blade end of the spindle shaft to

prevent the shaft from spinning. Save the 1/4” key

(D).

Figure 22. Remove Spindle Pulley

A. 3/4-16 Hex Nut

B. 3/4” Spring Washer

C. Spindle Pulley

D. 1/4” Key

E. 1/4-20 x 1” Bolts

F. Tapered Hub

G. Spindle Pulley (tapered bore)

Install the Double Spindle Pulley

IS500Z Series, 1000Z Series, IS1000Z Series,

IS1500Z, IS2000Z, IS3000ZF & ZX Series, S150X &

S200X Series:

1. Install the double spindle pulley (C, Figure 22) and

1/4” key (D) onto the spindle shaft.

2. Install the 3/4” spring washer (B) with the cone

facing up (see insert, Figure 22). Install the 3/4-16

hex nut (A) and torque to 85-90 ft. lbs (115-122

Nm). Use a 1” wrench on the flats of the blade

end of the spindle shaft to prevent the shaft from

spinning.

IS3000ZL Series, IS3100Z Series, & IS4500Z

Series:

1. Remove the 1/4-20 x 1” bolts (E) from the tapered

hub (F). Install the bolts through the clearance

holes in the hub and into the new double spindle

pulley (G).

2. Install the pulley, hub and 1/4” key (D) onto the

spindle shaft.

3. Hold the pulley at the height measure previously

and tighten the 1/4” bolts evenly. Torque the 1/4”

bolts to 8 ft. lbs. (10.9 Nm). Use a 1” wrench on

the flats of the blade end of the spindle shaft to

prevent the shaft from spinning.

Figure 23. Install Double Spindle Pulley

A. 3/4-16 Hex Nut

B. 3/4” Spring Washer

C. Double Spindle Pulley

D. 1/4” Key

E. 1/4-20 x 1” Bolts

F. Tapered Hub

G. Double Spindle Pulley (tapered bore)

A

D

C

G

F

E

D

A

B

C

D

E

F

G

D

B

Page 18

16 www.ferrisindustries.com

Installation

Mower Deck Preparation

Reinstall the Spindle Belt

Refer to the belt removal instructions on Page 10,

11, & 12 and reverse the order for reinstalling the

belt.

Install the Deck Guard

1. Install the new deck guard onto the mower deck

and secure with the hardware previously removed

(see Figure 24).

NOTE: The IS2000Z with 52” deck has a 2-piece

deck guard. Install as shown in Figure 25.

NOTE: The IS4500Z Series has a 3-piece deck

guard. Install as shown in Figure 26.

Figure 24. Install Guard

Figure 26. Install Guard - IS4500Z Series

Figure 25. Install Guard - IS2000Z with 52” Deck

Page 19

17

Installation

GB

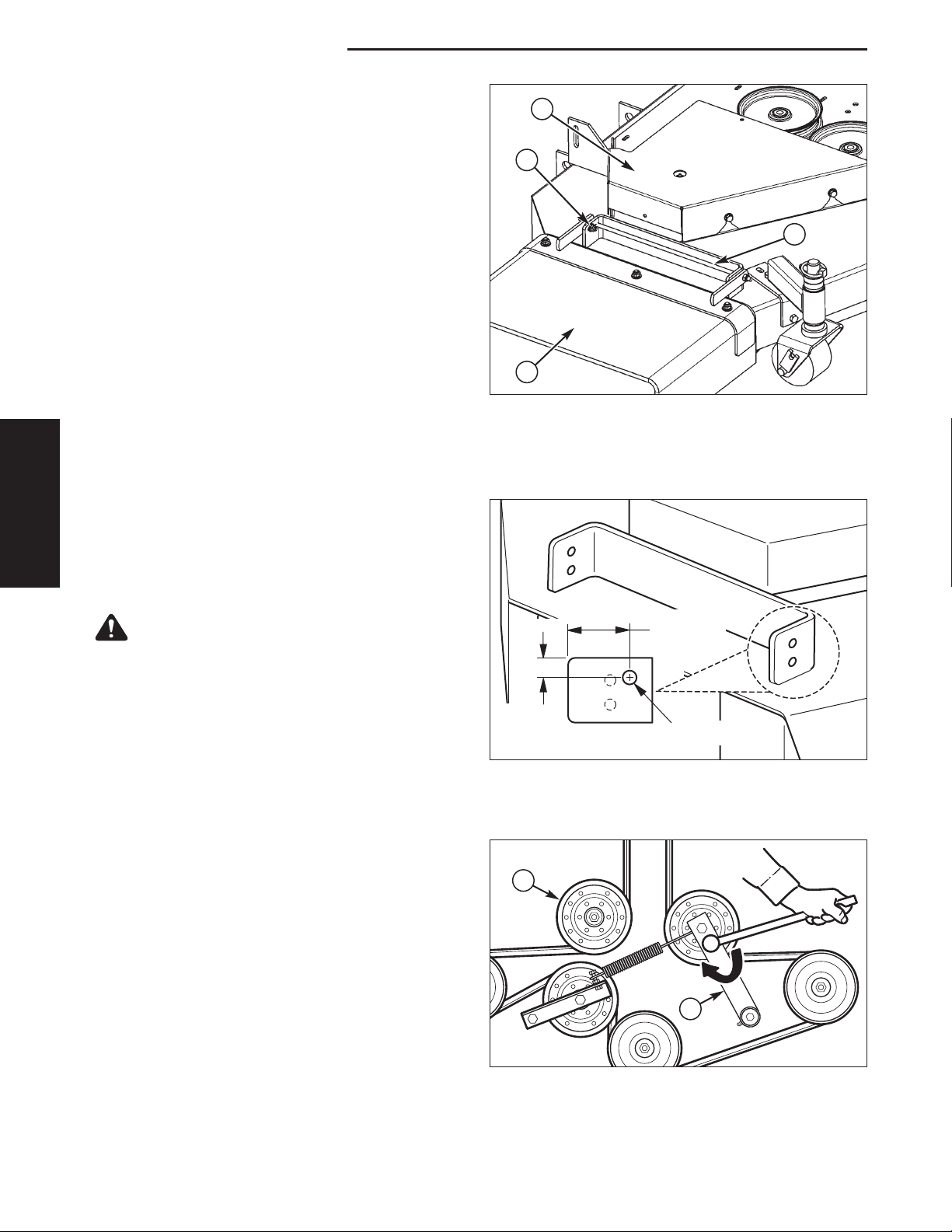

Blower Installation

1. Install the blower onto the mower deck. Refer to

Figure 27 for the position of the quick pins in

relationship to the chute mount bracket on the

mower deck. The quick pins fit into the same

holes that the chute mount rod was installed.

2. Install the blower drive belt. Refer to Figure 28 for

the proper belt routing. It may be required to

loosen the idler pulley mounting hardware to get

the belt past the belt keeps.

IMPORTANT NOTE: The gray area denotes the flat

side of the belt. V-side of belt must contact v-groove

pulleys, flat side of belt must contact flat pulleys.

Figure 27. Install Blower On Deck (Notice Pin

Orientation)

Figure 28. Install Belt

44” & 48” Decks

52” & 61” Decks

Page 20

18 www.ferrisindustries.com

Installation

Blower Installation

3. Check the belt tension by measuring the distance

from the center of the v-idler pulley (A, Figure 29)

mounting bolt and the blower housing. This

should measure between 3 - 3-3/8” (7,6 - 8,6 cm).

4. If measurement falls outside of this range, you

must move the idler pulley (B) either forward or

back to achieve the proper belt tension.

NOTE: If pulley position needs to be adjusted, make

sure that it is reinstalled in the same row of holes as

determined in the blower assembly (Step 13, page

11).

Figure 29. Check Belt Tension

A. V-Idler Pulley

B. Idler Pulley

B

A

A

B

C

C

Figure 30. Install Guards

A. Blower Belt Guard

B. Deck Guard Top

C. Knob

5. Install the blower belt guard (A, Figure 30) and

secure with the flange head bolts previously

removed.

6. Install the deck guard top (B) and secure with the

supplied knobs (C).

(7,6 - 8,6 cm)

3" - 3-3/8"

Page 21

19

Installation

GB

Collector Installation

Install Collector Mount Plate

(1000Z & IS1000Z Series)

1. Remove the hardware securing the rear bumper

screen (A, Figure 31) to the top and bottom

bumpers (A, B). Save the 3/8” bolts and washers

from the lower bumper.

2 .Install the collector mount plate (A, Figure 32) on

to the lower bumper and secure with the

previously removed 3/8” bolts, 3/8” washers (B)

and new 3/8-16 nylock flange nuts (E).

3. Install the 3/8-16 x 1-1/2” bolts and 3/8” washers

(C) through the top mount holes as shown in

Figure 31. Install the support bar (D) and secure

with the 3/8-16 nylock flange nuts (E).

A

E

B

C

D

A

B

Figure 31. Remove Bumper Screen

A. Screen

B. Top Bumper

C. Lower Bumper

E

Figure 32. Install Collector Mount Plate

A. Mount Plate

B. 3/8” Bolts & Washers (previously removed)

C. 3/8-16 x 1-1/2” Bolts & 3/8”Washers

D. Support Bar

E. 3/8-16 Nylock Flange Nuts

C

Page 22

20 www.ferrisindustries.com

Installation

Install Collector Mount Plate

(IS500Z Series, IS1500Z Series, IS2000Z Series, &

IS4500Z Series)

IMPORTANT NOTE: If the collector system is being

installed on an IS4500Z Series model, the Extreme

Duty Rear Bumper Kit (5600019) must be installed

first.

1. Install the collector mount plate (A, Figure 33) and

mount tabs (B) on to the bumper. Install two of

the 3/8-16 U-bolts (C) over the top bumper tube

and through the mount tabs and loosely secure

with the 3/8-16 nylock flange nuts (F).

NOTE: On IS500Z models use the inner mounting

holes when installing the collector mount plate and

mount tabs to the bumper with the 3/8-16 U-bolts

2. Install the remaining 3/8-16 U-bolt bolt (C) over

the middle bumper tube and loosely secure with

the 3/8-16 nylock flange nuts (E).

3. Center mount plate on the bumper and tighten all

the hardware securely.

4. Temporarily install the collector mount posts (A,

Figure 34) into the collector plate and install the

hitch pins (B). This will insure that the holes are

properly aligned for easy installation and removal.

5. Tighten the top nuts (C) securely and remove the

hitch pins and mount posts.

Figure 33. Install Collector Mount Plate

A. Mount Plate

B. Mount Tab

C. 3/8-16 U-Bolts

D. 3/8-16 Nylock Flange Nuts

B

A

Figure 34. Install Mount Posts & Hitch Pins

A. Mount Post

B. Hitch Pin

C. 3/8-16 Nylock Flange Nuts

A

C

D

B

D

B

D

C

Collector Installation

Page 23

21

Installation

GB

Remove the Rear Engine Shield

(IS3100Z with 4-Tube Rear Bumper)

1. If the engine is hot, allow sufficient time for the

muffler to cool to prevent a burn injury during

installation.

2. Remove the rear engine shield (C, Figure 35) from

the top of the rear bumper (D) by removing the

3/8” hardware (A, B, & E) securing the shield to

the bumper.

Install Collector Mount Plate

(IS3100Z Series with 5-Tube Rear Bumper)

1. Install the collector mount plate (A, Figure 37) on

to the bumper. Install two of the 3/8-16 U-bolts

(C) over the second tube down from the top of the

bumper and through the mounting plate and

loosely secure with the 3/8-16 nylock flange nuts

(B).

2. Install the remaining 3/8-16 U-bolt bolt (C) over

the forth tube down from the top of the bumper

and loosely secure with the 3/8-16 nylock flange

nuts (B).

3. Center mount plate on the bumper and tighten all

the hardware securely.

B

C

A

Figure 35. Remove the Rear Engine Shield

A. 3/8-16X1” Bolts

B. 3/8” Washers

C. Rear Engine Shield

D. Rear Bumper

E. 3/8” Nylon Flange Nuts

C

D

E

A

B

A

C

B

Install Collector Mount Plate

(IS3100Z Series with 4-Tube Rear Bumper)

1. Install the collector mount plate (A, Figure 36) on

to the bumper. Install two of the 3/8-16 U-bolts

(C) over the top bumper tube and through the

mounting plate and loosely secure with the 3/8-16

nylock flange nuts (B).

2. Install the remaining 3/8-16 U-bolt bolt (C) over

the third tube down from the top of the bumper

and loosely secure with the 3/8-16 nylock flange

nuts (B).

3. Center mount plate on the bumper and tighten all

the hardware securely.

Figure 37. Install Collector Mount Plate

A. Mount Plate

B. 3/8-16 Nylock Flange Nuts

C. 3/8-16 U-Bolts

Figure 36. Install Collector Mount Plate

A. Mount Plate

B. 3/8-16 Nylock Flange Nuts

C. 3/8-16 U-Bolts

Collector Installation

Page 24

22 www.ferrisindustries.com

Installation

Install Collector Mount Plate

(IS3000Z Series)

1. Install the collector mount plate (A, Figure 38) and

mount tabs (B) on to the bumper. Install the 3/816 x 2-3/4” bolts (C) through the mount tabs and

loosely secure with the clamp bars (D) and 3/8-16

nylock flange nuts (F).

2. Install the 3/8-16 x 2-1/2” bolts (E) through the

bottom mounting holes and loosely secure with

the clamp bars (D) and 3/8-16 nylock flange nuts

(E).

3. Center mount plate on the bumper and tighten all

the hardware securely.

4. Temporarily install the collector mount posts (A,

Figure 39) into the collector plate and install the

hitch pins (B). This will insure that the holes are

properly aligned for easy installation and removal.

5. Tighten the top mounting bolts (C, Figure 38)

securely and remove the hitch pins and mount

posts.

A

B

D

D

F

E

E

C

Figure 38. Install Collector Mount Plate

A. Mount Plate

B. Mount Tab

C. 3/8-16 x 2-3/4” Bolt

D. Clamp Bar

E. 3/8-16 x 2-1/2” Bolt

F. 3/8-16 Nylock Flange Nut

B

C

Figure 39. Install Mount Posts & Hitch Pins

A. Mount Post

B. Hitch Pin

A

B

Collector Installation

Page 25

23

Installation

ES GB

Install Collector Mount Plate

(S150X & S200X Series)

1. Remove the carb. shield plate from top of the rear

bumper.

2. Install the collector mount plate (A, Figure 40) and

mount tabs (B) on to the bumper. Install the 3/816 x 1-1/4” bolts (C) and 3/8” SAE washers (F)

through the mount tabs and loosely secure with

the 3/8-16 nylock flange nuts (E).

3. Install the 3/8-16 x 1” bolts (D) and 3/8” SAE

washers (F) through the bottom mounting holes

and loosely secure with the 3/8-16 nylock flange

nuts (E).

4. Tighten the bottom mounting bolts securely.

5. Temporarily install the collector mount posts (A,

Figure 41) into the collector plate and install the

hitch pins (B). This will insure that the holes are

properly aligned for easy installation and removal.

6. Tighten the top mounting bolts (C, Figure 37)

securely and remove the hitch pins and mount

posts.

A

B

Figure 40. Install Collector Mount Plate

A. Mount Plate

B. Mount Tab

C. 3/8-16 x 1-1/4” Bolt

D. 3/8-16 x 1” Bolt

E. 3/8-16 Nylock Flange Nut

F. 3/8” SAE Washers

B

Figure 41. Install Mount Posts & Hitch Pins

A. Mount Post

B. Hitch Pin

A

B

E

E

C

F

F

D

D

Collector Installation

Page 26

24 www.ferrisindustries.com

Installation

Collector Installation

Assemble Collector Hood

1. Install the inlet tube (B, Figure 42) to the collector

back plate (A) and secure with the 5/16-18 x 3/4”

bolts (C) and 5/16-18 nylock flange nuts (D).

2. Install the mount posts (E) on the back plate and

loosely secure with the 3/8-16 x 1” bolts (F) and

3/8-16 nylock flange nuts (G).

NOTE: On the 3-bag collector back plate, install the

eight (8) supplied hole plugs in the remaining

mounting holes not used.

Figure 42. Assemble Collector Hood

A. Collector Back Plate

B. Inlet Tube

C. 5/16-18 x 3/4” Bolt

D. 5/16-18 Nylock Flange Nut

E. Collector Mount Post

F. 3/8-16 x 1” Bolt

G. 3/8-16 Nylock Flange Nut

B

A

A

B

C

D

C

D

E

E

F

G

F G

2 Bag Collector

3 Bag Collector

3. Install the collector onto the mount plate and

secure with the hitch pins as shown in Figure 38.

Again, this will insure that the holes are properly

aligned for easy installation and removal.. Tighten

the 3/8-16 x 1” bolts securing the posts to the

back plate.

NOTE: It is recommended that the rear suspension

be adjusted stiffer due to the added weight of the

collection system (see operators manual for

procedure).

Page 27

25

Installation

ES GB

Collector Installation

Install Collector Bags

1. Raise the collector hood and slide the collector

bags (A, Figure 43) onto the frame rails (B).

NOTE: The collector bags are constructed with three

mesh panels and one solid panel. Install the bag with

the solid panel towards the front of the machine.

Figure 43. Install the Collector Bags

A. Collector Bag

B. Frame Rails

2. Lower the hood and push the lock pin (B, Figure

44) through the hood lock plate (A).

Figure 44. Lock Hood

A. Hood Lock Plate

B. Lock Pin

A

B

B

B

A

Page 28

26 www.ferrisindustries.com

Installation

Collector Installation

Install Hose

1. Lower the mower deck to the lowest cutting

position.

2. See Figure 45. Install the hose (A) onto the

blower and secure with the removable clamp (with

knob) (B). At least two bands must cover the

outlet of the blower (C).

3. Cut the hose to fit properly between the blower

and collector as shown in Figure 45. At least two

bands must cover the inlet of the collector (D).

Secure with the stationary clamp (E).

Figure 45. Install Hose

A. Hose

B. Removable Clamp (with knob)

C. Blower Outlet

D. Collector Inlet

E. Stationary Clamp

A

A

D

E

A

C

B

Page 29

27

Installation

ES GB

Weight Mount Installation

(1000Z Series)

Install Weight Carrier

1. Remove the hairpin clip and clevis pin and remove

the deck lift foot pedal. Lift the floor plate.

2. Install the weight carrier (E, Figure 46), mount

plates (B & C) and fasten with the 3/8-16 x 3”

bolts (A) and 3/8-16 nylon lock nuts (D). Tighten

securely.

3. Install the counter weights (H) in the weight carrier

and secure with the retaining pin (F) and hair pin

clips (G).

4. Lower floor plate and reinstall deck lift foot pedal,

clevis pin and hair pin clip.

Figure 46. Install Weight Carrier

A. 3/8-16 x 3” Bolts

B. Mount Plate

C. Mount Plate

D. 3/8-16 Nylon Lock Nuts

E. Weight Carrier

F. Retaining Pin

G. Hairpin Clip

H. Weight

A

A

A

A

B

C

B

D

D

D

D

E

F

H

G

Page 30

28 www.ferrisindustries.com

Installation

Weight Mount Installation

(IS1000Z Series)

Install Weight Carriers

1. Install the left-hand and right-hand weight carriers

(E & H, Figure 47), bar clamps (F) and fasten with

the 5/16-18 x 2-1/2” bolts (B) and 5/16-18 nylon

lock nuts (G). Make sure carriers are tight against

the outside of the suspension arm and do not

interfere with the shock/spring assembly. Tighten

securely.

2. Install the counter weights (A) in the weight carrier

and secure with the clevis pins (D) and hair pin

clips (C).

Figure 47. Install Weight Carriers

A. Weight

B. 5/16-18 x 2-1/2 Bolt

C. Hairpin Clip

D. Clevis Pin

E. Weight Carrier-LH

F. Bar Clamp

G. 5/16-18 Nylon Lock Nuts

H. Weight Carrier-RH

B

A

A

C

B

D

E

F

F

G

G

H

D

C

Page 31

29

Installation

ES GB

Figure 48. Hole Location

Figure 49. Weight Rack Installation

Figure 50. Weight & Retainer Rod Installation

5”

(12,7cm)

1-1/4”

(3,18cm)

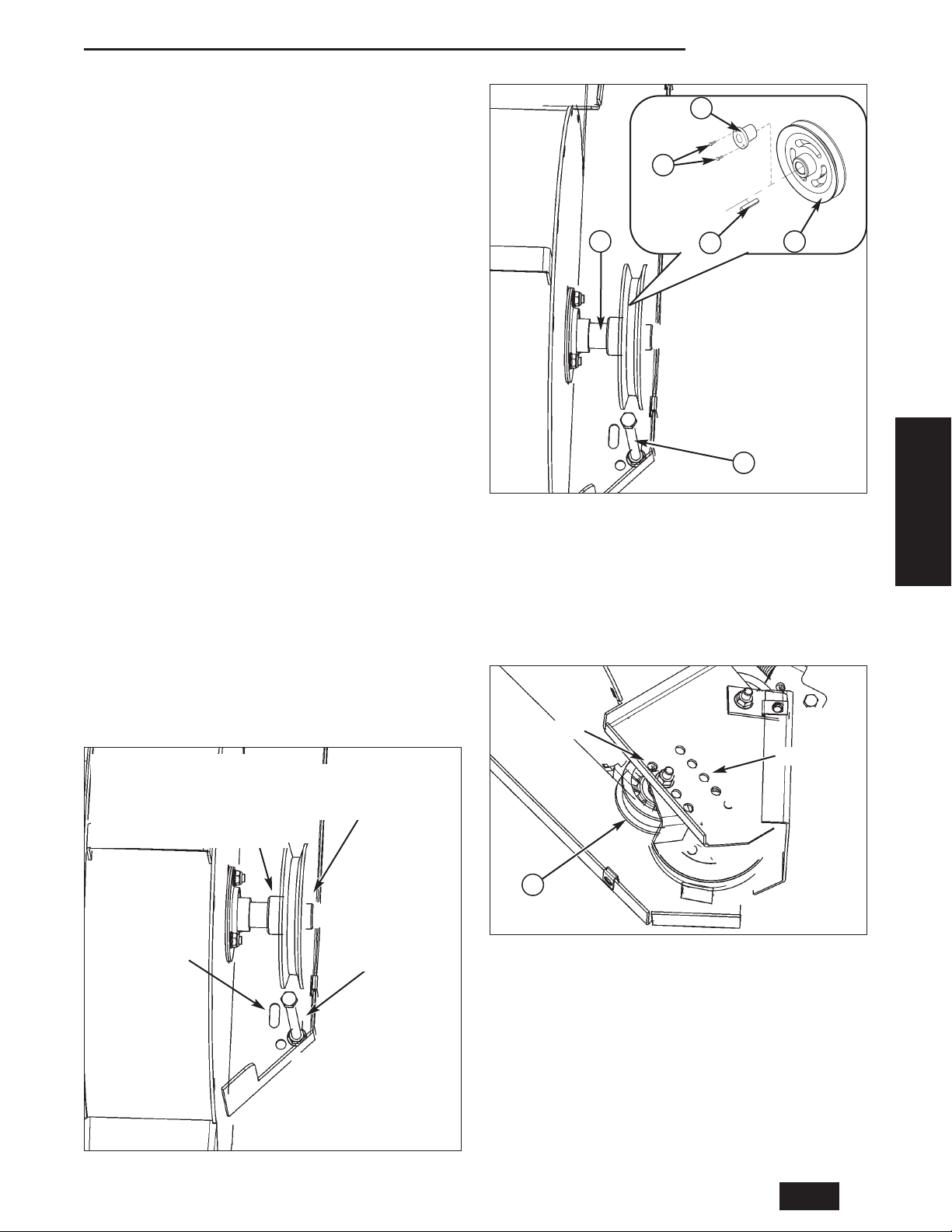

Install Weight Mount Rack

1. Measure and mark the front main frame tubes to

the dimensions shown in Figure 48.

2. Using a 3/8” drill bit, drill one (1) hole in each of

the main frame tubes from the outside surface of

the tube.

3. Slide the weight mount rack into the main frame

tubes and align with the holes drilled through the

frame (see Figure 49). It may require you drive

the arms into the frame tubes using a wooden

block and hammer.

4. Finish drilling through the opposite wall of the

frame tubes using the weight rack as a guide.

5. Install the 3/8” bolts from the inside of the frame

rail and fasten securely with the nylon lock nuts.

6. Install the counter weights supplied with the grass

collector on the weight mount rack (see Figure

50).

7. Install the weight retainer rod through the weight

mount rack and secure with the hairpin clips (see

Figure 50).

Weight Mount Installation

(IS3000Z Series & IS3100Z Series)

Page 32

30 www.ferrisindustries.com

Installation

Install Weight Carrier

1. Install the weight carrier (A, Figure 51) onto the

front of the unit and secure with the 1/2-20 x 11/4” bolts (B), 1/2” washers (C) and 1/2-20 nylon

lock nuts (D).

NOTE: Use outer holes in the weight carrier for the

IS1500Z Series (shown) and the inner holes for the

IS4500Z Series.

2. Install the counter weights (E) in the weight carrier

and secure with the retaining pin (F) and hairpin

clips (G).

Figure 51. Install Weight Carrier

A. Weight Carrier

B. 1/2-20 x 1-1/4” Bolt

C. 1/2” SAE Washer

D. 1/2-20 Nylon Lock Nut

E. Weight

F. Retaining Pin

G. Hairpin Clip

A

C

B

D

F

G

E

Weight Mount Installation

(IS500Z & IS1500Z Series)

Page 33

31

Installation

ES GB

Weight Mount Installation

(IS2000Z Series)

Install Weight Carrier

1. Install the weight carrier (A, Figure 52) onto the

front of the unit and secure with the 3/8-16 x 11/4” bolts (C), 3/8” washers (B) and 3/8-16” nylock

flange nuts (G).

NOTE: Use top holes in the weight carrier for the

IS2000Z Series (as shown in Figure 52).

2. Install the counter weights (D) in the weight carrier

and secure with the retaining pin (E) and hairpin

clips (F).

Figure 52. Install Weight Carrier

A. Weight Carrier

B. 3/8” SAE Washer

C. 3/8-16X1-1/4” Bolt

D. Weight

E. Retaining Pin

F. Hairpin Clip

G. 3/8-16 Nylock Flange Nut

A

B

D

F

E

C

G

Page 34

32 www.ferrisindustries.com

Installation

Install Weight Carrier

1. Support the front of the frame in the center of the

unit with a jackstand.

2. Remove the 1/2-13 x 5” bolts (B, Figure 53) and

1/2-13 nylon lock nuts (C) securing the front

suspension arms to the frame.

3. Install the weight carrier (A) onto the front of the

unit and secure with the 1/2-13 x 5” bolts and 1/213 nylon lock nuts previously removed.

4. Install the counter weights (D) in the weight carrier

and secure with the retaining pin (E) and hairpin

clips (F).

Figure 53. Install Weight Carrier

A. Weight Carrier

B. 1/2-13 x 5” Bolt

C. 1/2-13 Nylon Lock Nut

D. Weight

E. Retaining Pin

F. Hairpin Clip

B

E

F

D

A

C

Weight Mount Installation

(IS4500Z Series)

Page 35

33

Installation

ES GB

Install Weight Carrier

1. Install the weight carrier (A, Figure 54) onto the

front of the unit and secure with the 3/8-16 x 11/4” bolts (C), 3/8” washers (B) and 3/8-16” nylock

flange nuts (G).

NOTE: Use top holes in the weight carrier for the

IS2000Z Series (as shown in Figure 54).

2. Install the counter weights (D) in the weight carrier

and secure with the retaining pin (E) and hairpin

clips (F).

Figure 54. Install Weight Carrier

A. Weight Carrier

B. 3/8” SAE Washer

C. 3/8-16X1-1/4” Bolt

D. Weight

E. Retaining Pin

F. Hairpin Clip

G. 3/8-16 Nylock Flange Nut

A

B

D

F

E

C

G

Page 36

34 www.ferrisindustries.com

Removal

1. Remove the knobs (A, Figure 55) securing the

deck guard top (B) to the deck guard.

2. Pull the blower idler arm lever (C) forward to

release the belt tension and remove the belt from

the spindle pulley.

3. Reinstall the deck guard top and secure with the

knobs.

4. Loosen the lower clamp securing the hose to the

blower outlet and remove the hose from the

blower. See Figure 56.

5. Pull the quick pins on the blower mount and

remove the blower from the mower deck.

Blower & Collector Removal

B

A

A

Figure 55. Remove the Belt

A. Knob

B. Deck Guard Top

C. Idler Arm Lever

C

Figure 56. Remove the Hose

A. Lower Clamp (with knob)

A

Page 37

35

Removal

ES GB

Figure 58. Remove the Hitch Pins

A. Mount Post

B. Hitch Pin

A

B

A

C

B

C

Figure 57. Reinstall the Discharge Chute

A. Discharge Chute

B. Quick Attach Rod

C. Hairpin Clip

6. Reinstall the discharge chute (A, Figure 57) and

secure with the supplied quick attach rod (B) and

hairpin clips (C).

7. Empty the grass collector bags and reinstall in the

bagger frame.

8. Remove the hitch pins (B, Figure 58) securing the

bagger mount posts (A) to the mount plate.

9. Lift the bagger unit up and off of the mount plate.

Blower & Collector Removal

Page 38

36 www.ferrisindustries.com

Seguridad

ADVERTENCIAS

GENERALES

• Conozca los controles de la podadora, las reglas

de seguridad y cómo detenerla rápidamente. LEA

Y COMPRENDA EL MANUAL DEL OPERADOR

DE LA PODADORA.

• Lea y obedezca todas las calcomanías de

seguridad.

• Use la protección adecuada para oídos, ojos y

respiración.

• Sólo permita que un adulto responsable, que esté

familiarizado con las instrucciones, opere la

unidad.

• Desactive el embrague eléctrico (PTO). Apague el

motor y permita que se detengan todas las piezas

móviles antes de anexar, ajustar o desconectar

alguna parte del sistema de recepción.

• Compruebe que el sistema de recepción esté

fijamente atornillado al montable.

• NO opere la podadora si no está el receptor de

pasto completo o el deflector en su lugar.

• Apague el interruptor PTO para desactivar las

cuchillas cuando no esté podando el pasto.

• NO pode el pasto en reversa. Mire siempre hacia

abajo y hacia atrás antes de echarse en reversa y

mientras lo hace.

• NO gire bruscamente cuando conduzca en

reversa junto a un edificio o algún objeto. Reduzca

la velocidad antes de girar.

• NO lleve pasajeros en el montable.

• Cuando se quita el conjunto de soplador de la

cubierta de la podadora, debe instalar

debidamente el deflector.

• Las bolsas recolectoras son susceptibles de

deterioro y desgaste durante el uso normal.

Inspeccione la bolsa periódicamente para

comprobar que no tenga rasgaduras, agujeros o

puntos débiles y reemplácela con una bolsa

nueva, que cumpla con las normas de durabilidad

del fabricante.

• Si se atasca la podadora o se obstruye la tolva del

soplador turbo:

1. Desactive el embrague eléctrico (PTO);

2. Detenga el motor y quite la llave;

3. Ponga el freno de mano y espere a que se

detengan todas las piezas móviles.

4. Quite el objeto extraño o limpie la tolva con un

pedazo de madera antes arrancar nuevamente

el motor. NUNCA ponga las manos en la caja

del soplador para quitar un objeto

atascado. El soplador puede girar al quitar

el objeto.

• Para dar mayor estabilidad al montable y evitar

que se vuelque o que pierda el control sobre él:

a. Reduzca la velocidad en terrenos desnivelados

y al girar en las esquinas.

b. Reduzca la carga en las laderas. Se

recomienda que llene el sistema de recepción

sólo a la mitad cuando franquea una

pendiente. Empiece a podar el pasto en la

pendiente con el sistema de recepción vacío.

c. Pode el pasto de la pendiente de un lado a

otro, pero no hacia arriba o abajo.

• Nunca opere en pendientes con una

inclinación superior a 17.6% (10°).

Lea estas reglas de seguridad y sígalas con cuidado. Hacer caso omiso de ellas puede ocasionar la pérdida del control

sobre la unidad, lesiones corporales graves o la muerte a usted o a los espectadores, o daños a la propiedad o al

equipo.

Esta cubier

ta de la podadora puede amputar manos y pies y arrojar objetos.

El triángulo en el texto denota precauciones o advertencias importantes que deben tomarse en cuenta.

Reglas E Información De Seguridad

Page 39

37

Seguridad

ES GB

CALCOMANÍAS DE SEGURIDAD

Esta unidad fue diseñada y fabricada para brindarle

seguridad y confiabilidad, características que usted

esperaría de un líder en la industria de la fabricación

de equipos motorizados para el exterior.

Aunque leer este manual, y las medidas de seguridad

que contiene, le proporcionará el conocimiento básico

necesario para operar este equipo sin percances y de

modo eficaz, hemos colocado varias etiquetas de

seguridad en la unidad para recordarle esta

importante información mientras usted la opera.

Debe leer cuidadosamente y obedecer todos los

mensajes de PELIGRO, ADVERTENCIA,

PRECAUCIÓN y las instrucciones en su podadora y

su montable. Hacer caso omiso de las instrucciones

puede ocasionar lesiones corporales. La información

es para su seguridad y es importante. Las

calcomanías de seguridad que presentamos abajo

están pegadas en su podadora y en su montable.

Si pierde o se daña alguna de estas calcomanías,

reemplácela inmediatamente. Busque a su

distribuidor local para reponerlas.

Estas etiquetas son fáciles de pegar y servirán como

constantes recordatorios visuales para usted, y otros

que puedan llegar a usar el equipo, para que sigan

las medidas de seguridad necesarias para una

operación eficaz y sin percances.

Calcomanías de seguridad

5

1

2

2

3

1

4

3

4

5

Page 40

38 www.ferrisindustries.com

Operación

ANTES DE LA OPERACIÓN

Despeje el jardín de las ramas, piedras, alambres y

otros despojos que puedan quedar atrapados en las

cuchillas de la podadora o que puedan ser lanzados

por las mismas.

Revise la condición del pasto. Si está húmedo,

espere hasta más tarde durante el día. Si el pasto

está húmedo, es probable que se obstruya el

receptor de pasto.

Para que la recepción del pasto en la bolsa sea

eficiente, es muy importante la circulación de

aire debajo de la cubierta de la podadora, a

través de la tolva y hacia la bolsa.

Por eso, ANTES DE EMPEZAR A PODAR

asegúrese de que la parte inferior de la podadora y

de la tapa del receptor estén exentos de pasto o

despojos.

Asegúrese que la cubierta de la podadora, la caja

del soplador, los tubos y la tapa del receptor de

pasto estén debidamente ajustados.

PODAR CON EL RECEPTOR DOBLE

O TRIPLE

Opere siempre con el acelerador en velocidad

máxima cuando pode el pasto.

Use siempre protectores para oídos cuando opere

el receptor de pasto.

Debe poder el pasto con frecuencia y no dejarlo

demasiado corto. Si el pasto es demasiado largo o

abundante, quizá sea necesario mantener la

velocidad de avance al mínimo o cortar sólo la mitad

del ancho de la podadora para evitar que se

obstruya. Si el pasto está muy largo, opere la

podadora en la posición de corte más alta en la

primera pasada, y córtelo de nuevo en la posición

más baja en la segunda pasada.

No abra la cubierta mientras la podadora está

activada

Si sale una gran cantidad de pasto cortado por

debajo de la cubierta, es posible que esté obstruido

el tubo o que las bolsas estén llenas: interrumpa la

actividad, detenga el montable, desactive el PTO y

vacíe el receptor o despeje el tubo

ADVERTENCIA

Apague SIEMPRE el tractor, desactive el PTO y

permita que se detengan las piezas móviles

ANTES de desconectar o despejar el tubo o de

vaciar el receptor.

Antes de dejar el puesto del operador por el

motivo que sea, accione el freno de mano,

desactive el PTO, detenga el motor y quite la

llave.

Para reducir el peligro de un incendio,

mantenga el motor, el montable y la podadora

libre de pasto, hojas y aceite excesivo. No

detenga ni estacione el montable sobre hojas

secas, pasto o materiales combustibles.

PRECAUCIÓN

Esta máquina produce niveles de sonido

por encima de 85 dBA cerca del oído del

operador y pueden originar la pérdida

auditiva cuando se expone al ruido por

períodos prolongados. Protéjase siempre los

oídos al operar esta máquina.

Instrucciones generales de operación

Page 41

39

Operación

ES GB

DESPUÉS DE LA OPERACIÓN

Quite cualquier despojo de la pantalla en la parte

inferior de la tapa. Nota: puede quitar parcialmente la

pantalla de la tapa para limpiarla con mayor facilidad

y debe hacerlo con regularidad.

Debe quitar la caja del soplador y el tubo para

limpiarlos.

Inspeccione las bolsas de pasto para ver si presentan

desgaste o daños. Asegúrese que la cubierta de la

podadora, la caja del soplador, los tubos y la tapa del

receptor de pasto estén debidamente ajustados.

ALMACENAR EL RECEPTOR DE

PASTO

Limpie a fondo el receptor de pasto usando un

detergente suave (otros productos pueden dañar el

tubo). Quite cualquier despojo de la pantalla en la

parte inferior de la tapa. Puede quitar parcialmente la

pantalla para limpiar con mayor facilidad.

Si la pintura en las piezas metálicas está rayada,

retoque con pintura o aplique una capa delgada de

aceite para evitar la corrosión.

Almacénese en una zona seca. Cuelgue el receptor

y las bolsas para que se sequen totalmente antes de

almacenarlos por un período largo de tiempo.

Almacene las piezas en un lugar sin humedad.

PODAR SIN EL SOPLADOR

Para operar la podadora sin el soplador, instale

debidamente el deflector apuntando hacia abajo.

Para quitar el soplador, invierta los pasos de la

instalación.

Instrucciones generales de operación

Page 42

40 www.ferrisindustries.com

Operación

B

A

A

Figura 59. Remoción de la correa

A. Perilla

B. Parte superior de la guarda de la cubierta

C. Palanca del brazo tensor

1. Quite las perillas (A, Figura 59) y fije la parte

superior de la guarda de la cubierta (B) a la

guarda misma.

2. Jale hacia adelante la palanca del brazo tensor

del soplador (C) para liberar la tensión de la

correa y retirar la correa de la polea del huso.

3. Instale nuevamente la parte superior de la guarda

de la cubierta y fíjela con las perillas.

4. Afloje la abrazadera inferior que sujeta la

manguera a la conexión de salida del soplador y

quite la manguera del soplador. Vea la Figura 60..

5. Jale los pasadores de desenganche en el

soplador y quite el soplador de la cubierta de la

podadora.

C

Figura 60. Remoción de la manguera

A. Abrazadera inferior

A

Remoción del soplador y receptor

Page 43

41

Operación

ES GB

Figura 62. Remoción de los pasadores de

enganche

A. Poste de soporte

B. Pasador de enganche

A

B

6. Instale nuevamente la tolva de expulsión (A,

Figura 61) y sujétela con el brazo de sujeción

rápida (B) y los pasadores de horquilla (C),

incluidos.

7. Vacíe las bolsas del receptor de pasto e instálelas

nuevamente en la estructura.

8. Quite los pasadores de enganche (B, Figura 62)

fijando los postes de soporte de las bolsas (A) a

la placa de soporte

9. Levante la unidad con la bolsa hasta que deje de

entrar en contacto con la placa de soporte.

A

C

B

C

Figura 61. Nueva instalación de la tolva de

expulsión

A. Tolva de expulsión

B. Brazo de sujeción rápida

C. Pasador de horquilla

Remoción del soplador y receptor

Page 44

FAST-Vac

Grass Collection Systems

Briggs & Stratton Yard Power Products Group

5375 North Main Street

Munnsville, NY 13409

800-933-6175

www.ferrisindustries.com

Loading...

Loading...