Page 1

Safety Instructions & Operator’s Manual for

NIR5003B

INTERMEDIATE

REAR TINE TILLER

SERIES 3

MODEL

IR5003B

MODEL DESIGNATION ENGINE MODEL

REAR TINE MODEL SERIES DESIGNATION

ENGINE HP

I – Intermediate Size Model 50 – 5 HP Engine (Horse Power) 3 - Series Designation B – Briggs Engine

R – Rear Tine Type Model

Thank you for buying a SNAPPER product! Your Tiller was designed and built to provide long and s atisfactory service.

Study this manual carefully before operating the Tiller and pay particular attention to the Im portant Safety Instructions

found herein. Keep in mind that a Tiller, like any other mechanical device, can be potentially dangerous if used

improperly. Following the instructions in this and the engine manual will help you continue to enjoy the trouble-free

operation expected of a SNAPPER.

MODEL NUMBER EXPLANATION

I R 50 03 B

COPYRIGHT © 1999

SNAPPER INC.

ALL RIGHTS RESERVED

MANUAL No. 2-8701 (REV. 2, 5/18/99)

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: This powerful machine is capable of amputating hands and feet and can throw objects that can

cause injury and damage! Failure to comply with the following instructions may result in serious injury to the

operator or other persons. The owner of the tiller must understand these instructions and, furthermore, must

allow only persons who understand these instructions to operate tiller. Each person operating the tiller must be

of sound mind and body and must not be under the influence of any substance, which might impair vision,

dexterity, or judgment. If you have any questions pertaining to your tiller which your dealer cannot answer to

your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough, Georgia, 30253.

Phone: (1-800-935-2967).

PROTECTION FOR CHILDREN

1. DO NOT allow children in area when tiller is

being operated.

2. DO NOT allow pre-teenage children to operate

tiller.

3. Allow only responsible teenagers or adults with

mature judgment to operate tiller and only under

close supervision.

4. Keep the area clear of all persons, particularly

small children, and pets.

5. Know how to ST OP the tiller and disengage the

controls quickly.

PREPARATION

1. Read this manual, get to know w here all cont rols

are located and practice how t o use them before

starting for the first time, and at the beginning of

each season. Be thoroughly familiar with the

controls and proper use of the equipment. Pay

attention to Warning and Instructional Decals on

engine and tiller.

2. Never operate tiller without proper guards, drag

shield, plates, safety switches, or other safety

protective devices in place and properly

connected. Inspect to determine that these safety

devices are installed properly, are in good repair,

and operate properly. If the condition or

operation of these d ev ices are qu estio nab le, t hey

must be repaired or replaced before using the

tiller.

3. Thoroughly inspect the area where the tiller is to

be used and remove all stones, sticks, wire,

bones and other foreign objects. Also, note the

location of holes, stumps, and other possible

hazards.

4. DO NOT operate tiller when barefoot or wearing

open sandals. Always wear long pants and

substantial footwear with good traction.

5. Fill fuel tank outdoors and replace fuel cap

before starting engine. Use approved fuel

container. DO NOT smoke near open fuel

container. DO NOT fill fuel tank indoors or when

engine is running. Allow engine to cool for at

least ten minutes before refilling. Wipe off any

spilled fuel before starting engine. DO NOT run

engine indoors.

6. Make sure that clutch is disengaged and

transmission is in neutral (if so equipped) before

starting engine.

OPERATIONAL PRECAUTIONS

1. DO NOT change engine governor settings or

over speed engine.

2. DO NOT put hands or feet near or under rotating

parts.

3. Exercise CAUTION when crossing g ravel drives,

walks, or roads, and under any conditions when

tiller is transported. Look behind and use care

when backing.

4. After striking a foreign object or if tiller vibrates

abnormally, STOP the engine, disconnect and

secure spark plug wire aw ay from plug. Inspect

the tiller for any damage and repair the damage.

5. When leaving tiller unattended, disengage clutch,

shift transmission to neutral (if so equipped) and

stop the engine.

6. Before removing debris or cleaning tines,

repairing or inspecting make certain engine,

tines and all moving parts have STOPPED.

Disconnect and secure spark plug wire away

from plug to prevent accidental starting.

7. Exercise CAUTION when changing directions

while operating tiller. DO NOT till in areas w here

stability or traction is in doubt.

8. DO NOT overload the machine capacity by

attempting to till too deep at too fast a rate.

9. Be extra careful when tilling hard ground. Use

less tine engagement to maintain control of tiller.

10. Till only in daylight or in good artificial light.

11. Nev er operate tiller in wet areas. Always be sure

of your footing; keep a firm hold on the handle.

12. Do not operate on slopes

MAINTENANCE AND STORAGE

1. Keep all nuts, bolts, and screws tight and be sure

tiller is in safe operating condition.

2. Never store tiller with fuel in tank inside of a

building where fumes may reach an open flame

or spark. Allow engine to cool before storing in

any enclosure.

3. To reduce fire hazard, keep engine free of spilled

fuel, debris and excessive grease.

4. Have your tiller inspected and serviced each year

by an authorized Snapper dealer. Determine if

any additional devices are av ailable which might

upgrade the safety of your tiller.

5. Factory specified Snapper replacement parts

must be used to assure adequate protection

against injury.

2

Page 3

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ................................................... 2

TABLE OF CONTENTS............................................................................ 3

SECTION 1 - FAMILIARIZATION..............................................................4

SECTION 2 - OPERATING INSTRUCTIONS.........................................5-7

Transmission Positions ............................................................... 5

Pre-Start Checklist........................................................................ 5

Starting & Stopping ................................................................... 5-6

Handlebar Adjustment.................................................................. 6

Transporting.................................................................................. 6

Tilling Procedure........................................................................ 6-7

SECTION 3 - ADJUSTMENTS & REPAIR........................................... 8-10

Service Parts & Assistance.......................................................... 8

Standing Tiller On End ................................................................. 8

Tiller Lubrication........................................................................... 8

Tiller Tines..................................................................................... 9

Belt Adjustment & Replacement.................................................. 9

Off Season Storage..................................................................... 10

WARRANTY............................................................................................ 11

PRIMARY MAINTENANCE................................................................12-15

NOTES ...............................................................................................16-17

3

Page 4

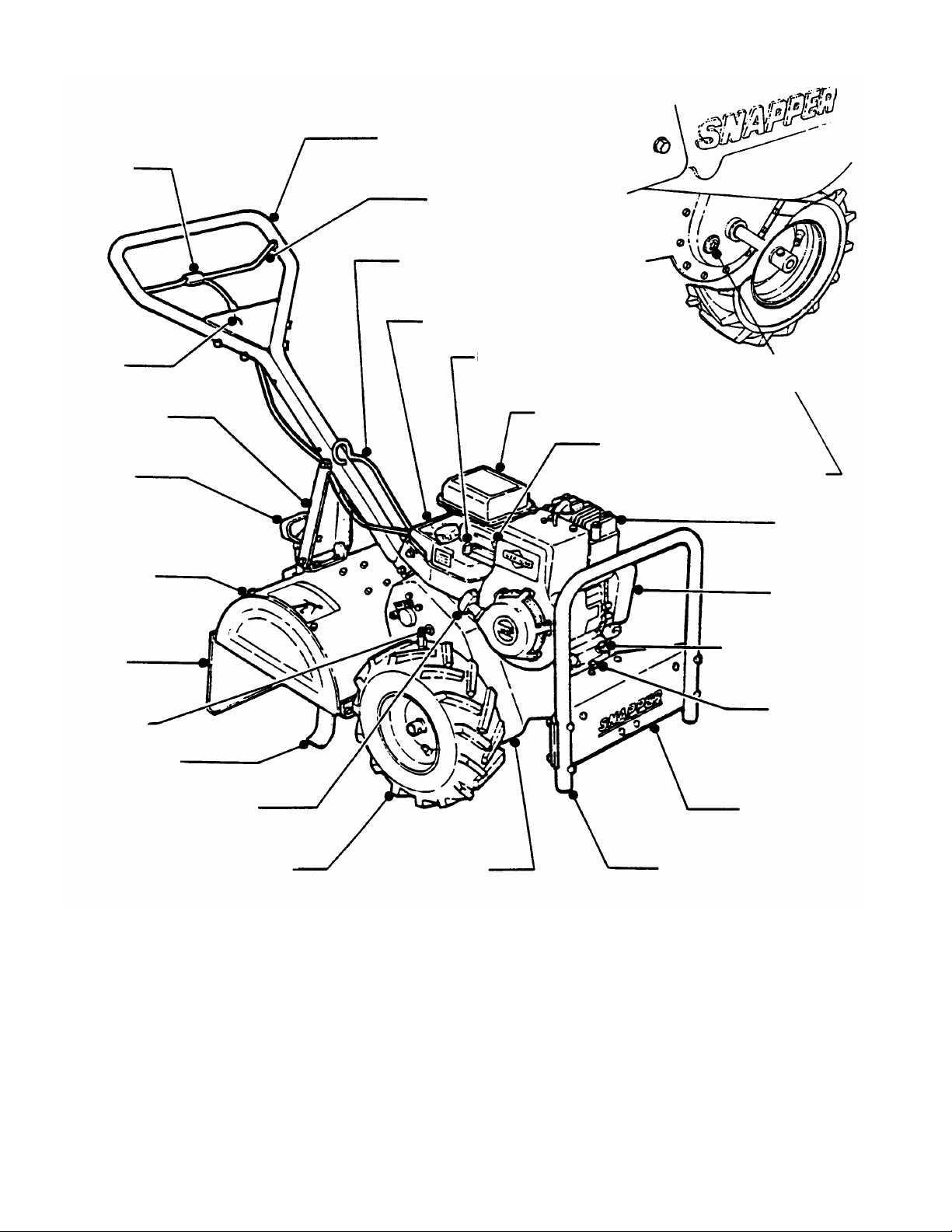

Section 1 - FAMILIARIZATION

CLUTCH

CABLE

COVER

DASH

PANEL

HANDLE

BRACKET

DEPTH

BAR

TINE

COVER

HANDLEBAR

WHEEL & TINE

CONTROL BAIL

WHEEL & TINE

SHIFT LEVER

SHIFT COVER

THROTTLE CONTROL

LEFT SIDE SHOWN TO

VIEW CHECK PL UG

ENGINE AIR FILTER

CHOKE CONTROL

MAIN CASE GREASE

CHECK PLUG

ENGINE

DRIVE

BELT

GUARD

DRAG

SHIELD

MAIN CASE

FILL PLUG

TINE

STARTER ROPE

TIRE & WHEEL

TRANSMISSION

CHAIN CASE

STAND-UP

BAR

ENGINE OIL

CHECK/FILL

PLUG

OIL DRAIN

PLUG

WEIGHT

BOX

FIGURE 1

1.1 INTRODUCTION: This manual covers the recommended operating procedure and

routine service requirements on SNAPPER Intermediate Rear Tine Tiller Model IR5003B.

It is recommended that all operator’s of this Tiller become thoroughly familiar with the

controls and proper operation of the unit before operating. Specific details involving the

engine are found in the separate engine owner’s manual. Study these manuals before

operating and keep both handy for future reference. Refer to Figure 1 above for location

of controls and other essential components.

4

Page 5

Section 2 - OPERATING INSTRUCTIONS

2.1 BEFORE OPERATING:

Be thoroughly familiar with the operation of ALL controls

and how to use them BEFORE operating your Tiller.

Transmission shifting is done by shifting the WHEEL

and TINE SHIFT LEVER into the desired position.

Refer to Figure 3.

2.1.1 TRANSMISSION POSITIONS

The Tiller has four transmission positions:

NOTE: The four diff erent transmiss ion positions shown on

the cover are clos e to ac tual positions of s hift lever but are

not exact. Use positions as a reference.

1. FWD & TIL - (FORWARD and TILL) (Wheels and

Tines

are engaged).

2. FWD - (FORWARD) (Only the Wheels are engaged).

3. NEU - (NEUTRAL) (Wheels and Tines are disengaged).

4. REV - (REVERSE) (Rearward Wheel rotation).

2.2 PRE-START CHECKLIST

Make the following checks and perform services as

required before each start up. NOTE: Before check ing

oil level place 2x4 piece of wood under both wheels to

level engine.

2.2.1 CHECK ENGINE OIL and bring level up to full.

(Refer to engine manual for oil specifications).

2.2.2 CHECK AIR CLEANER and service according to

instructions in engine manual.

2.2.3 CHECK EXTERNAL SURFACES and remove dirt

and dust accumulation and clean tines as needed.

2.2.4 CHECK GUARDS to make sure all are in proper

position and securely tightened.

2.2.5 FILL FUEL TANK where fumes will be safely

dissipated. Refer to engine manual for fuel specifications.

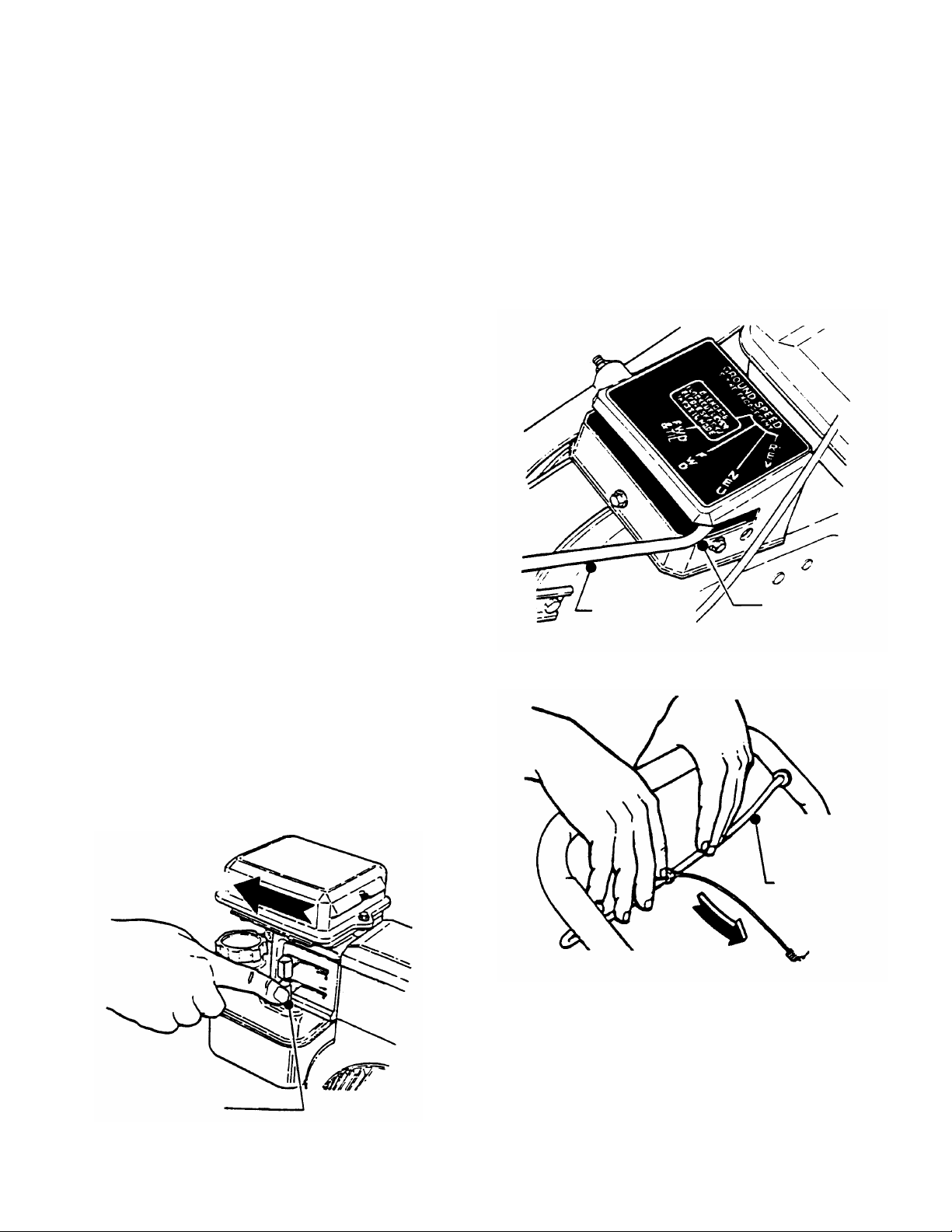

2.3 STARTING - STOPPING

Know beforehand how to stop the tines, wheel drive and

engine in preparation for possible emergencies. The

engine is stopped by pulling the engine. THROTTLE

CONTROL to the rear to STOP. See Figure 2.

When activated, the tines rotate in a rearward (Reverse)

direction ONLY. With the engine running, shift into the desired

transmission position and pull the WHEEL and TINE

CONTROL BAIL against the handle bar to start wheel or

wheel and tine rotation.

Wheel or wheel and tine rotation is STOPPED by releasing

the W HEEL and TINE CONTROL BAIL. W hen the bail is

released, rotation should STOP even with the W HEEL and

TINE SHIFT LEVER in an engaged position. See Figures 3

and 4.

FIGURE 2

WHEEL & TINE

SHIFT LEVER

FIGURE 3

NEUTRAL

POSITION

TO STOP WHEEL

STOP

& TINE DRIVE

RELEASE

WHEEL & TINE

CONTROL BAIL

FIGURE 4

THROTTLE

CONTROL

5

Page 6

Section 2 - OPERATING INSTRUCTIONS

2.4 ENGINE STARTING PROCEDURE

Step 1: Place the W HEEL and T INE SHIFT LEVER in

the NEUTRAL position and make sure the WHEEL and

TINE CONTROL BAIL is in the released position.

Step 2: For cold st arts, m ove the CHOKE CONTROL

on the engine forward into CHOKE position.

See Figure 5.

PUSH FORWARD

TO CHOKE

CHOKE

LEVER

FIGURE 5

Step 3: Move THROTTLE CONTROL to RUN

position.

Step 4: Move to the right side of Tiller and place

your foot on top of the right wheel (See starting

procedure decal located on top of the tine cover),

hold handle bar, then pull the ROPE STARTER

HANDLE in smooth, steady motion until the engine

starts. To prolong the life of the rope, guide the

handle back to the engine rather than allowing it to

snap back.

Step 5: Allow a brief warm-up period, then move

the CHOKE CONTROL rearward and the

THROTTLE CONTROL to the desired speed

setting. Refer to the tilling procedure column on

this page.

Step 6: To STOP the engine, pull the THROTTLE

CONTROL on engine rearward into STOP position.

2.5 HANDLE BAR A DJUSTMENT

Remove retaining screw and nut from handle bar

bracket. Adjust handle bar “UP” or “DOWN” as

required. Reinstall screw and nut. See Figure 6.

REMOVE

SCREW TO

ADJUST

HANDLEBAR

HANDLE

BRACKET

2.6 TRANSPORTING

2.6.1 FORWARD/REVERSE: To transport the T iller to

a new tilling site using its own power, raise the tines to clear

lawn and paved surfaces to prevent gouging. Releas e the

WHEEL and T INE CONTROL BAIL and lif t the rear of the

Tiller to take the weight off the DEPTH BAR (see Figure 7),

then push the DEPTH BAR downward into notch setting

that allows the tines to clear the ground surfac e. Place the

WHEEL and TINE SHIFT LEVER in FWD or REV. Pull the

WHEEL and TINE CONTROL BAIL back against the

handlebar to engage the wheel drive and transport the unit.

2.6.2 To transport the Tiller to a new tilling site by

pushing it, place the W HEEL and TINE SHIFT LEVER in

the NEUTRAL position, and with the bail released, push the

unit with the handle bar. The Tiller m ay be pushed with the

engine running or shut off.

ADJUST UP OR

DOWN TO

DESIRED

TILLING DEPTH

2.7 TILLING PROCEDURE

Tines are engaged ONLY when the W HEEL and TINE

SHIFT LEVER is in the FWD & TIL position and the

WHEEL and T INE CONTROL BAIL is held against the

handle bar.

1. Set HANDLE BAR in desired position before

beginning operation.

2. Set DEPTH BAR in highest position for deepest tilling

depth or in intermediate notches for lesser depth.

See Figure 7.

FIGURE 6

DEEP

TILL

SHALLOW

TILL

FIGURE 7

LOW

MEDIUM

HIGH

DEPTH

BAR

PULL SPRING

BACK TO

RELEASE

TENSION

6

Page 7

Section 2 - OPERATING INSTRUCTIONS

2.7 TILLING PROCEDURE

(Continued from previous page)

3. Set SPEED by moving the THROTTLE

CONTROL to desired setting.

4. To star t TILLING action, move the W HEEL and

TINE SHIFT LEVER to the FWD & TIL position

(See Figure 8). Step behind the Tiller and rais e

the WHEEL and TINE CONTROL BAIL up

against the handlebar to start for ward m ovem ent

of the Tiller and rearward rotation of the tines.

MOVE SHIFT LEVER

TO FWD & TIL

POSITION

FWD & TIL

POSITION

FIGURE 8

2.7.1 TILLING HINTS: Let the Tiller do the work!

DO NOT try to hold it back. If forward motion ceases

while tilling deep, lift up slightly on the handle bar to

resume moving forward.

2.7.2 ROUGH TERRAIN HINT: If tilling over very

rough, uneven ground, till at a shallow depth setting

on the first path to smooth the surface. On

especially rough terrain, the Tiller could hang up

underneath with the wheels spinning freely. Under

this condition, lift the handle bar, then tur n the tiller

diagonally uphill to regain traction.

7

Page 8

Section 3 - ADJUSTMENTS & REPAIR

3.1 SERVICE PARTS & ASSISTANCE

To retain the original quality of your Tiller, use only

genuine SNAPPER replacement parts. Spec ify the

model and serial number as found on the

nameplate of your Tiller when contacting your

SNAPPER Dealer for parts or service assistance.

3.2 STA NDING THE TILLER ON END

WARNING

ALWAYS STOP the engine and DISCONNECT the spark

plug wire BEFORE standing the TILLER on end to

prevent accidental start ing! NEVER stand Tiller on end

with the engine running!

WARNING

If the fuel tank is over half full when the Tiller is placed on

end, gasoline may leak from the carburetor vent hole and

drip down the outside surface of the engine creating a

potential FIRE HAZARD! Gasoline may also leak unnoticed

into the engine cylinder and wash away lubricating oil

causing engine damage. T ake all neces sary precautions to

prevent fuel leakage BEFORE standing the Tiller on end.

Any draining of fuel mus t be done outside with the engine

cool and away from ignition sources. If the Tiller is stored on

end for any length of time, check it frequently for signs of fuel

and/or oil leakage.

NEVER stand Tiller on end with

engine running!

3.2.1 ENGINE SERVICE: Refer to the engine

owner’s manual for details. Engine oil is drained by

removing front f iller plug and standing Tiller on end.

See Figure 9.

3.2.2 SERVICE NOTE: Since a Tiller normally

operates under extrem ely dusty or dirty conditions,

the air cleaner, engine oil and cooling fins m ust be

serviced as specified in the engine manual at

frequent intervals. The Tiller itself should be

serviced as follows:

WARNING

3.3 TILLER LUBRICATION

CHAIN CASE: Check the level of the greas e in the

chain case at the beginning of each tilling season.

Remove clevis pin and cotter pin that secures left

hand tire/wheel to axle. Remove wheel. Check

grease level by removing the plastic plug located

beside the axle shaf t on the lower left hand side.

See Figures 9A. The level should be up to the edge

of the opening. To add grease, remove the filler

plug located just forward of the pulley shaft on the

right hand side. See Figure 10. Add Snapper Part

No. 2-9577 Benalene 900 grease (4 oz. Bottle) as

needed to bring level up to bottom edge of the

check plug opening. The total capac ity of the case

is about 48 ounces. DO NOT exceed this amount.

Reinstall check plugs after checking. NOTE: Also

available Snapper Part No. 2-9296 Benalene 900

grease (32 oz. Bottle).

GREASE CHECK PLUG

(REMOVE TO CHECK

GREASE LEVEL)

REMOVE L.H.

TIRE/WHEEL

ASSEMBLY

PROPER

GREASE

LEVEL

FIGURE 9A

STAND

TILLER

ON END

TO DRAIN

ENGINE

OIL

OIL DRAIN

PLUG

FIGURE 9

CHAIN

CASE

RIGHT

HAND

WHEEL

MAIN CASE

FILL PLUG

FIGURE 10

8

Page 9

Section 3 - ADJUSTMENTS & REPAIR

3.4 TILLER TINES

Your Snapper Tiller has right hand and left hand

tines. Replace both tines if blades becom e bent or

are badly worn or otherwise damaged. Use correct

Snapper replacement tines. The tines are secured

to the tine shaft with a shear bolt, Part No. 2-8725

and Lock Nut Part No. 9-0222 on each side. NO TE:

Two extra nuts and two bolts com e with tiller. Keep

spares on hand in case a bolt shears off or

becomes lost while tilling. See Figure 11. DO NOT

over tighten these shear bolts as this will cause

premature failur e. (Recommended torque is 5 to 8

foot pounds maximum). NOTE: Failure to use the

correct shear bolts c ould result in serious damage

to your Tiller. Use only the genuine Snapper

replacement bolts and lock nuts specified above.

These bolts are designed to shear at a specific

stress to prevent damage. DO NOT use substitutes!

SHEAR BOLT

(TORQUE TO

8 FT. LBS.)

TINE

COVER

TINE

ASSEMBLY

FIGURE 11

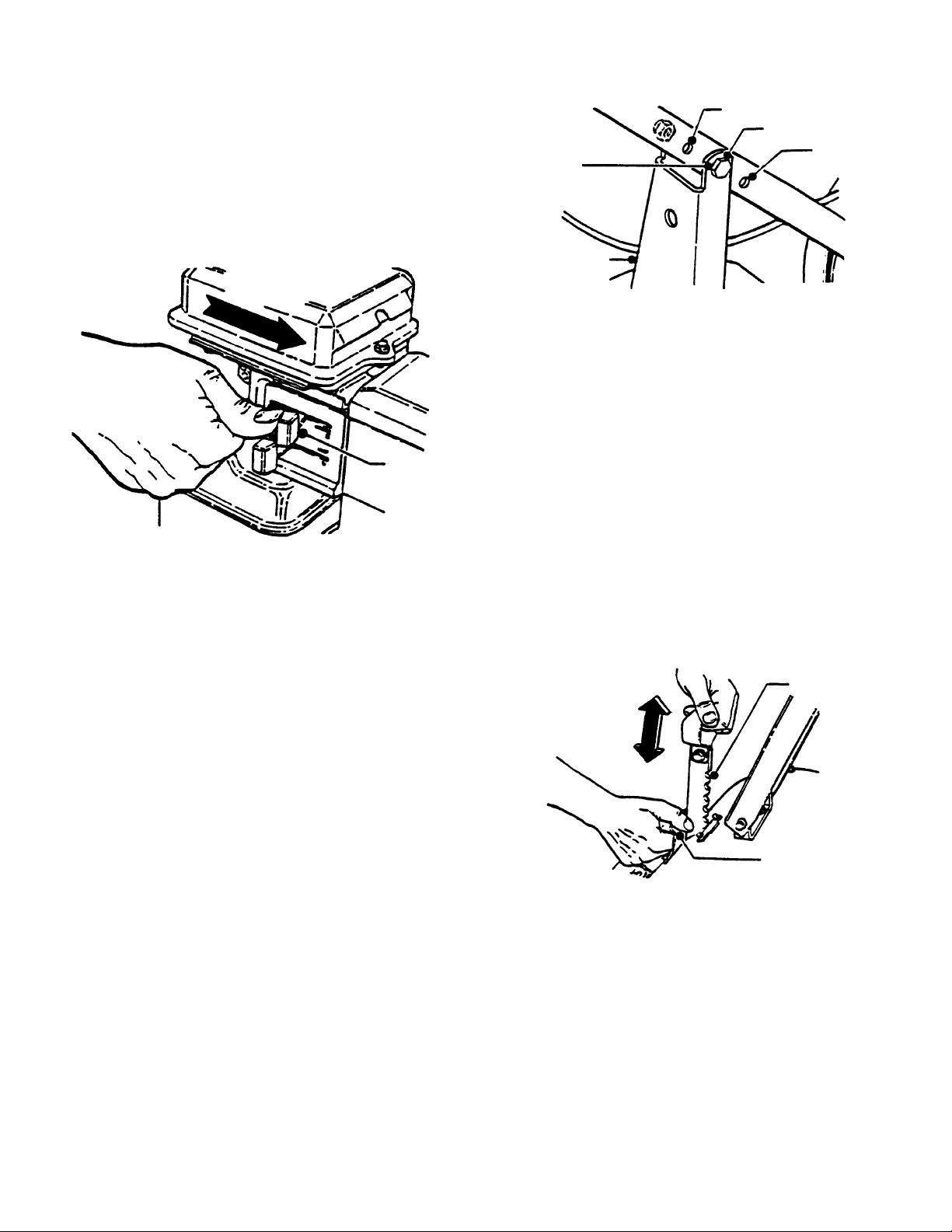

3.5 BELT ADJUSTMENT - REPLACEMENT

BELT TENSION ADJUSTMENT: Remove the cotter

pin that secures clevis pin to left wheel hub. Rem ove

clevis pin from lef t wheel hub and slide wheel out on

axle about 1”. Remove belt guard. Measure the

length idler pulley spring at the end of the control

cable in a relaxed position. Then move wheel and

tine control bail up to the handle bar and measure

the extended length of the spring. When properly

adjusted, the spring will extend 1/4” to 1/2”. See

Figure 12. To adjust, loosen and reposition the two

jam nuts on the threaded end of c able located on the

dash panel. Move jam nuts toward the end of

threaded end of cable for more tension. Move jam

nuts in a direction away from the end of threaded

end of cable for less tension. See Figure 13. After

adjustment, retighten both jam nuts against dash

panel. Reinstall belt guard. Slide wheel back into

operating position and reinstall clevis pin and sec ure

with hair pin.

LOCK

NUT

BELT

GUIDE

IDLER

PULLEY

3.5.1 TENSION TEST: Start the engine with tiller in

neutral. Shift transmiss ion into FW D & TILL and pull the

wheel and tine control bail up against the handle bar.

Tines and wheels will s tart to r otate. Releas e c ontrol bail.

Tines and wheels should stop rotating immediately. If

rotation continues after release of c ontrol bail then clutch

spring tension is to great and will have to be readjusted

as described in BELT TENSION ADJUSTMENT Section.

3.5.2 BELT REPLACEMENT: Pull the clevis pin from

the left wheel and slide the wheel out 1”, remove belt

guard and then the old belt. NOTE: Replacement belt

must go over the top of the idler and be within the belt

guide as shown in Figure 14. Check belt tension as

described in BELT TENSION ADJUSTMENT Section.

Reinstall guard, push left wheel back into position and

secure with clevis pin and insert and secure cotter pin.

BELT

GUIDE

DRIVE

PULLEY

DASH PANEL

BELT OVER

TOP OF IDLER

1/4” TO 1/2”

FIGURE 12

LOOSEN

JAM NUTS

FIGURE 13

FIGURE 14

IDLER

PULLEY

SPRING

HANDLEBAR

CLUTCH

CABLE

MOVE NUTS

TOWARD END

OF CABLE

FOR MORE

TENSION

SHIFT

LEVER

DRIVEN

PULLEY

REMOVE

LEFT HAND

WHEEL &

BELT

GUARD

9

Page 10

Section 3 - ADJUSTMENTS & REPAIR

3.6 OFF SEASON STORAGE

Thoroughly clean all external surfaces and tines before

storing the Tiller. The Tiller may be stored on end,

however, the following steps must be taken:

1. Drain gasoline from fuel system and drain the engine

crankcase oil (refer to engine manual for details).

2. After standing the Tiller on end, chec k the plugs in the

chain case for leakage. After extended period, s ome

grease may seep thru upper bearing races.

3. Remove both wheels and grease wheel shafts.

Reinstall wheels. Remove both tines and grease tine

shafts. Reinstall tines. Greas e these shafts when tiller

is stored for long periods of time to prevent rust

buildup. Rust buildup will cause wheels and tines

difficult to remove.

4. At the start of the new season, replenish engine

crank-case oil and add gasoline to the f uel tank after

returning the Tiller to its wheels.

5. Before starting, move the ENGINE CONTROL to

STOP and pull rope starter slowly several times. If

excessive resistance is felt, remove the spark plug

and pull rope starter rapidly to spin the engine and

clear oil from the cylinder. Clean and reinstall spark

plug before attempting to start the engine.

10

Page 11

3 YEAR LIMITED WARRANTY

For three (3) years from purchas e date for the original purchas er's r esidential, non-c om m ercial us e, SNAPPER, through

any authorized SNAPPER dealer will replace, free of charge (except for taxes where applic able), any part or parts found

upon examination by the factory at McDonough, Georgia, to be defective in material or workmanship or both.

For ninety (90) days from purchase date for the or iginal purchaser's comm ercial, rental, or other non-residential use,

SNAPPER, through any authorized SNAPPER dealer will replace, free of charge, any part or parts found upon

examination by the factory at McDonough, Georgia, to be defective in material or workmanship or both.

All transportation costs incurred by the purchaser in submitting material to an authorized SNAPPER dealer for

replacement under this warranty must be paid by the purchaser.

This warranty does not apply to engines and their c omponents, and batteries , as these items are warranted separately.

This warranty does not apply to parts that have been damaged by accident, alteration, abuse, improper lubrication,

normal wear, or other cause beyond the control of SNAPPER. This warranty does not cover any machine or com ponent

part that has been altered or modified changing safety, performance, or durability.

Batteries have a one (1) year prorated warranty period with free replacement if required during the first ninety (90) days

from the original purchas e date. SNAPPER will not be responsible for any installation cost incurred. The battery warranty

only covers original equipment batteries and does not cover dam age to the battery or machine caused by neglect or

abuse, destruction by fire, explosion, freezing, overcharging, improper maintenance, or use of improper electrolyte.

There is no other express warranty.

DISCLAIMER OF WARRANTY

Implied warranties, including those of merchantability and fitness for a particular purpose, are limited to three

(3) years from purchase date for the original purchaser's residential or other non-commercial use, and ninety

(90) days from purchase for the original purchaser's commercial, rental or other non-residential use, and to the

extent permitted by law, any and all implied warranties are excluded. This is the exclusive remedy. Liabilities for

consequential damages, under any and all warranties are excluded.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

WARNING: THE USE OF REPLACEMENT PARTS OTHER THAN GENUINE SNAPPER PARTS MAY IMPAIR THE

SAFETY OF SNAPPER PRODUCTS AND WILL VOID ANY LIABILITY AND WARRANTY BY SNAPPER

ASSOCIATED WITH THE USE OF SUCH PARTS.

IMPORTANT: Please fill out the attached SNAPPER Product Registration Card immediately and mail to:

Snapper’s Product Registration Ce nter, P.O. Box 1379, McDonough, Georgia 30253

11

Page 12

PRIMARY MAINTENANCE

12

Page 13

PRIMARY MAINTENANCE

13

Page 14

PRIMARY MAINTENANCE

14

Page 15

PRIMARY MAINTENANCE

15

Page 16

SERVICE NOTES

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

16

Page 17

SERVICE NOTES

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

17

Page 18

Safety Instructions & Operator’s Manual for

INTERMEDIATE

REAR TINE TILLER

SERIES 3

MODELS IR5003B & NIR5003B

WARNING:

The engine exhaust from this product cont ains chemicals known to the Stat e

of California to cause cancer, birth defects or other reproductive harm.

COPYRIGHT © 1999

SNAPPER INC.

ALL RIGHTS RESERVED

MANUAL No. 2-8701 (REV. 2, 5/18/99)

18

Loading...

Loading...