Page 1

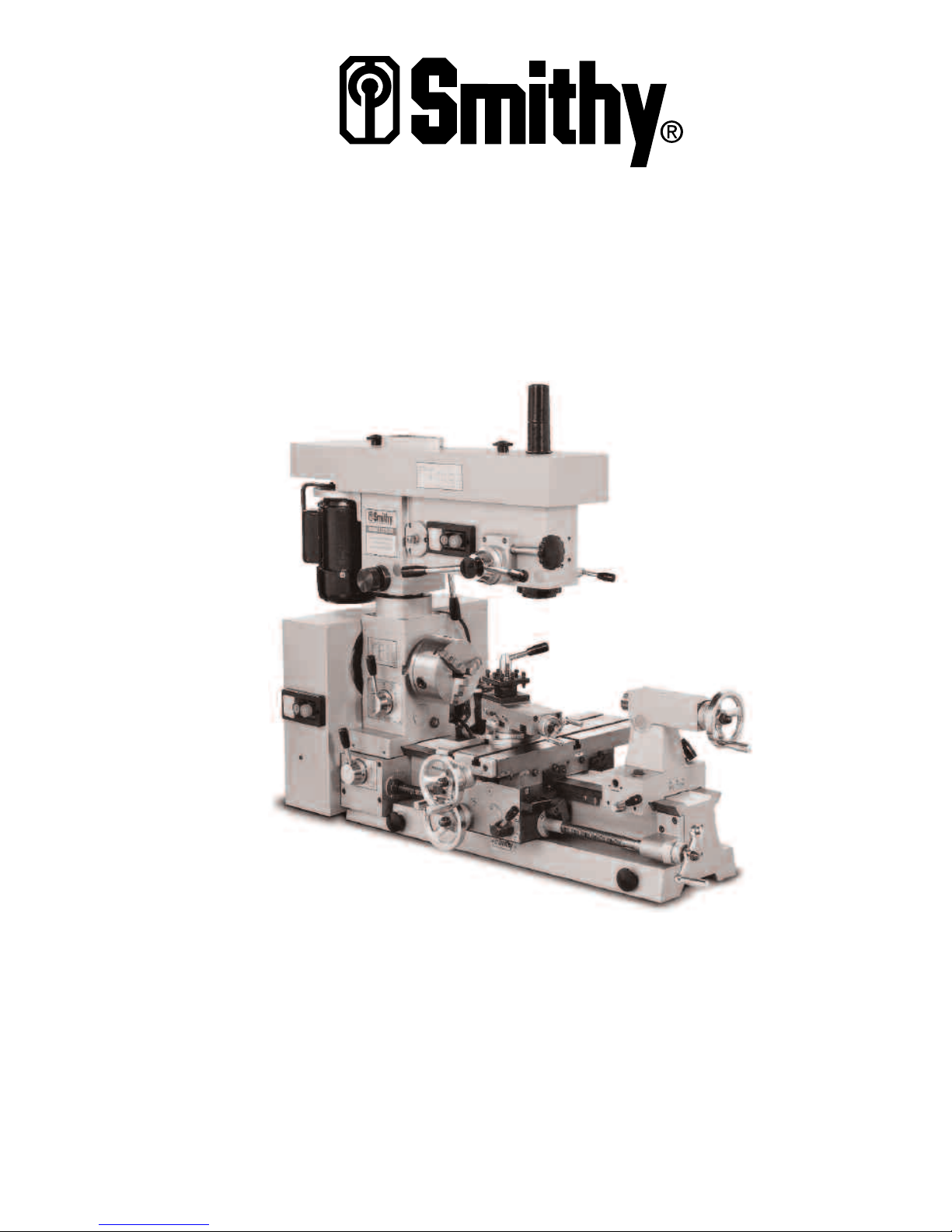

MIDAS 1220 & 1230 LTD

Combination Lathe - Mill - Drill

OPERATOR’S MANUAL

Updated Feb. 2019

170 Aprill Dr., Ann Arbor, MI, USA 48103

1-800-476-4849

www.smithy.com

Page 2

Smithy - All rights reserved (Revision 1).

© 2019

170 Aprill Dr., Ann Arbor, Michigan, USA 48103

Toll Free Hotline: 1-800-476-4849

International: 734-913-6700

All images shown are from Midas 1220 LTD machine.

All rights reserved. No part of this manual may be reproduced or transmitted in any form by

any means, electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of Smithy Co. For information on getting permission for

reprints and excerpts, comments, or suggestions, contact info@smithy.com

While every precaution has been taken in the preparation of this manual, Smithy Co. shall not

have any liability to any person or entity with respect to any loss or damage caused or

alleged to be caused directly or indirectly by the instructions contained in this manual. Please

see section on warranty and safety precautions before operating the machine.

Printed and bound in the United States of America.

Page 3

Table of Contents

Chapter 1: Introduction

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Chapter 2: Safety

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Chapter 3: Caring For Your Machine

Caring for you machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Chapter 4: Basic Parts of the MI-1220 LTD

Basic Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Chapter 5: Uncrating and Setting Up the MI-1220 LTD

Moving the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Uncrating and Positioning the machine . . . . . . . . . . . . . . . . . . . . . .5-1

Millhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Tailstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Three Jaw Chuck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Selecting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Cleaning and Lubricating the MI-1220 LTD . . . . . . . . . . . . . . . . . . . .5-4

Oiling the Ways . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Oiling the Millhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Oiling the Headstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Oiling the Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Oiling the Compound Angle Toolpost . . . . . . . . . . . . . . . . . .5-5

Oiling the Apron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Oiling the Leadscrew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Oiling the Tailstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Oiling the Mill/Drill Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Adjusting Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Mill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Page 4

Lathe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Adjusting Gibs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Reducing Backlash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Running in the MI-1220 LTD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Millhead Run in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Lathe Run in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Setting Lathe and Mill Speeds for the MI-1220 LTD . . . . . . . . . . .5-10

Chapter 6: Turning

Turing Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Gear Ratios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Chapter 7: Metal Theory

Tool Sharpness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Chapter 8: Grinding Cutter Bits for Lathe Tools

High Speed Steel Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Materials Other than Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Bits for Turning and Machining Brass . . . . . . . . . . . . . . . . . . . . . . . .8-3

Special Chip Craters and Chipbreakers

Using a Center Gauge to Check V-Thread Forms . . . . . . . . . . . . . .8-4

Acme or Other Special Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

Carbide-Tipped Cutters and Cutter Forms . . . . . . . . . . . . . . . . . . . . .8-5

. . . . . . . . . . . . . . . . . . . . . . .8-4

Chapter 9: Setting Up Lathe Tools

Cutting Tool Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Turning Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Threading Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

Cutoff, Thread Cutting and Facing Tools . . . . . . . . . . . . . . . . . . . . . .9-3

Boring and Inside Threading Tools . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

Chapter 10: Setting Up with Centers, Collets and Chucks

Centering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

Mounting Work between Centers . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

Using a Clamp Dog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

Using Faceplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

Setting Up Work on Mandrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-5

Steady Rest and Follow Rest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

Steady Rest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

Follow Rest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-7

Page 5

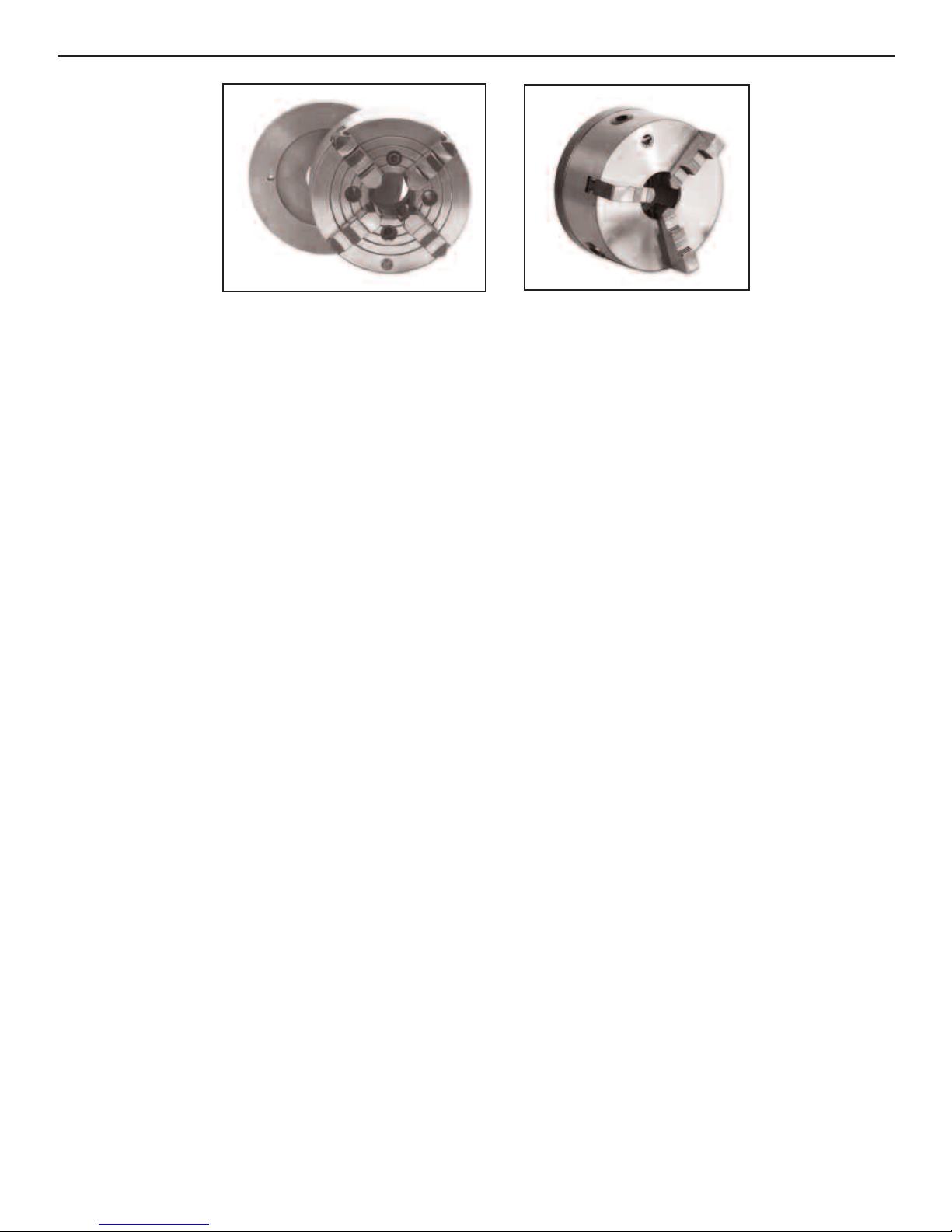

Setting Up Work in a Chuck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-7

Mounting Work in a Four-Jaw Independent

Lathe Chuck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-8

Mouting Work in a Three-Jaw Universal Chuck . . . . . . .10-9

Toolpost Grinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-11

Chapter 11: Lathe Turning

Rough Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

Finish Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

Turning to Shapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

Machining Square Corners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-3

Finishing and Polishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-3

Taper Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-4

Chapter 12: Lathe Facing and Knurling

Facing Across the Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

Knurling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-2

Chapter 13: Cutting Off or Parting with a Lathe

Cutting Off or Parting with a Lathe . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

Chapter 14: Lathe Drilling and Boring

Lathe Drlling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

Reaming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

Boring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-2

Cutting Internal Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-3

Cutting Special Form Internal Threads . . . . . . . . . . . . . . . . . . . . . .14-4

Chapter 15: Changing Gears on Your MI-1220 LTD

Changing Gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-1

Chapter 16: Cutting Threads on Your MI-1220 LTD

Threading Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-1

Cutting Right Hand Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-3

Using the Threading Dial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-4

Cutting Multiple Threads

What Not To Do When Cutting Threads . . . . . . . . . . . . . . . . . . . . .16-5

Finishing Off a Threaded End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-5

Cutting Threads on a Taper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16-5

16-5

Page 6

Chapter 17: Milling

Milling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-1

Holding Milling Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-2

Arbors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-2

Collets and Holders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-2

Adaptors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-3

Milling Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-4

End Mill Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-4

Plain Milling Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-6

Side Milling Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-6

Slitting Saws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-6

Angle Milling Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-7

Form Relieved Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-7

Flycutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-7

Using Cutting Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-8

Tool Grinding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-8

Speeds and Feeds for Milling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-8

Feeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-9

Up Milling

Down Milling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-10

Common Milling Operations

Milling Flat Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-12

Squaring a Workpiece . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-12

Milling a Cavity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-13

Tapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-12

Chapter 18: Workholding

Mounting to the Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-1

Using a Vise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-1

Dividing Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-2

Rotary Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-2

Chapter 19: Troubleshooting

Powerfeed and Thread Cutting

Carriage and Milling Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-2

Lathe Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-3

Milling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-4

Drilling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-4

Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-1

Chapter 20: Removing the Quill and Quill Feed Assembly

Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20-1

Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20-2

Page 7

Page 8

Chapter 1

Introduction

Congratulations on purchasing a Smithy lathe-mill-drill. We are pleased you chose Smithy

to fulfill your machining needs.

The purpose of this manual is to give the machinist, beginning or advanced, the

information he need to operate the Smithy Midas 1220 LTD. It will teach you about the

machine’s parts and how to care for them. We’ll explain how to grind cutters, set up lathe

tools, hold work pieces, and do all basic machining operations.

Please read this operator’s manual carefully. If you don’t understand how your machine

works, you may damage it, your project, or yourself. If you want to learn more about

machining practices, Smithy offers books that meet the needs of machinists at all levels

of experience. We also suggest using your local library as a resource. Enrolling in a

machining class wi

If you have any questions not covered in this manual, please call Smithy. Our trained

technicians will help you with any machining problems you may have. Dial our toll free

number 1-800-476-4849 Monday through Friday, 8:00 am to 5:00pm Eastern Time. You

can also find Smith

service bulletins.

ll give you the best knowledge of machining.

y on the Internet at www.smithy.com. Check for service updated and

We are always interested in your suggestions to improve our products and services. Feel

free to contact us by phone or email us at

about this operator’s manual, or if you have a project you’d like to share with other Smithy

owners, contact Smithy Co., PO Box 1517, Ann Arbor, Michigan 48106-1517.

We look forward to a long working relationship with you. Thank you again for putting your

trust in Smithy.

our Smi

This manual should r

include the owner’s manual with the machine.

Model No.:__________________________________________________

erial No

S

(at the back of the lathe bed)

Purchase Date:______________________________________________

ery Date:_______________________________________________

iv

Del

Sales Technician:____________________________________________

emain wi

.:__________________________________________________

th y

info@smithy.com. If y

thy machine. If ownership changes, please

ou have comments

Or V

isit www

.smithy.com

1-1

Page 9

Chapter 2

Safety

Your workshop is only as safe as you make it. Take responsibility for the safety of all who

use or visit it. This list of rules is by no means complete, and remember that common

sense is a must.

1. Know your machine. Read this manual thoroughly before attempting to operate your

machine. Don’t try to do more than you or your machine can handle. Understand the

hazards of operating a machine tool. In particular, remember never to change speeds or

set-ups until the machine is completely stopped, and never operate it without first rolling

your sleeves or tying them at your wrists.

2. Ground the machine. The MI-1220 LTD has three-conductor cords and three-prong

grounding-type receptacles. Never connect the power supply without properly grounding

the machine.

3. Remove all adjusting keys and wrenches from the machine before operating. A chuck

key or misplaced Allen wrench can be safety hazard.

4. Keep your work area clean and organized. Cluttered work areas and benches invite

accidents. Ha

5. Keep children away from the machine while it is in use. Childproof your shop with

padlocks, master swi

have access to it.

6. Wear appropriate clothing. Avoid loose-fitting clothes, gloves, neckties, or jewelry that

could get caught in moving parts. If you have long hairs, tie it up or otherwise keep it

from getting into the machine.

7. Use safety glasses, goggles, or a face shield at all times. Use glasses designed for

machinery operation; regular glasses will not do. Have extras for visitors. Know when to

wear a f

8. Check for damaged parts. Make sure the machine will run properly before operating it.

9. Disconnect the machine before servicing and when changing accessories. Shut power

f before making changes, removing debris, or measuring your work. Don’t reach over

of

the machine when it’s operating. Keep your hands out of the way.

oid ac

v

10. A

ve a place for everything and put everything in place.

tches, and starter keys, or store the machine where children do not

acemask and earplugs, as wel

cidental starts. T

urn the swi

l.

tch to OFF bef

ore plugging in the machine.

11. Secure your work. Flying metal is dangerous. Loose work can also bind tools.

12. Use the recommended accessories. Understand how to use them before trying them

out.

2-1

For Assistance: Call Toll Free 1-800-476-4849

Page 10

13. Use the correct tool for the job. Don’t try to make a tool into something it isn’t.

14. Keep your mind on your work. Pay attention to these simple rules and you will spend

many safe, enjoyable houses in your workshop.

Note: Your safety depends largely on your practices.

2: Safety

Or V

isit www

.smithy.com

2-2

Page 11

Chapter 3

Caring For Your Machine

Your machine is a delicate, precision tool with hardened ways and hand-scraped bearing

surfaces under the table and carriage. Any rust spot or battering of the ways, any chips

or grit between close-fitting parts, will affect the accuracy of this fine tool. Follow these

guidelines whenever you use your Smithy machine:

1. When you finish working, wipe machined surfaces with a clean, oily rag. Never leave

the machine without this thin film of protective oil all over parts that might rust,

especially ground finished parts.

2. Never lay wrenches, cutting tools, files, or other tools across the ways of your lathe.

The slightest dent or burr will impair its accuracy.

3. Before inserting collars, centers, adapters, or drawbar attachments in either the

spindle or tailstock spindle, wipe them a clean, oi

carefully with an oily rag on a ramrod. Chips or dirt on the centers or in the spindle nose

can scratch or mark surfaces and interfere with the assembled part’s alignment.

ly rag. Also, wipe all internal surfaces

4. Lubricate the machine before each use as seen on Section 5.4.

5. Use good 10W 30 weight non-detergent oil on your machine.

6. Cover your machine to protect it from dust and moisture.

Note: An old machinist trick is to leave camphor in the toolbox and on the machine to

prevent rust. Newer compounds that also protect machines that will unused for some

time are BoeShield, developed by the Boeing Company and CRC Lubricants. There are

also specialty oils that may be purchased.

3-1

For Assistance: Call Toll Free 1-800-476-4849

Page 12

Chapter 4

Basic Par ts of the MI-1220 LTD

Learn the operation of your machine, you have to know the names and functions of its

basic units.

5

8

13

9

3

4

18

6

7

17

1

16

15

12

2

14

10

11

Figure 4.1 Midas 1220 LTD

1. Bed. The bed is the machine’s foundation. It is heavy, strong, and built for absolute

rigidity. The two ways on the top are the tracks on which the carriage and tailstock

vel. To maintain an exact relationship between tool point and work piece from one end

a

tr

of the machine to the other, the ways must be absolutely true and accurately aligned to

the line of centers and to one other.

2. Carriage. The carriage consists of the saddle and apron. It moves by hand or power

along the bed, carrying the cr

support the cut

into place by tightening the carriage lock with the setscrew on the backside of the

carriage.

ting tool rigidity and move it along the bed for different operations. It locks

ide, compound rest, and toolpost. Its function is to

oss sl

.smithy.com

isit www

Or V

4-1

Page 13

Midas 1220 LTD Operator’s Manual

3. Compound Rest. Mounted on the cross slide, the compound rest swivels to any angle

horizontal to the lathe axis to produce bevels and tapers. Cutting tools fasten to a

toolpost on the compound rest. The calibration on the front of the base are numbered in

degrees from 60 right to 60 left.

4. Cross Slide. The T-slotted cross slide moves crosswise 90 degrees to the lathe axis by

manual turning of the cross feed screw hand wheel. It also serves as the milling table.

5. Drill Press and Fine Feed Clutch. Pushing in the drill press clutch (engages the fine

feed). To work the clutch, release the spring tension by rotating the drill press handles

clockwise. Pull the clutch out to sue it as a drill press or push it in to use the fine feed.

Use the fine fee hand wheel to move the quill up and down.

6. Forward/OFF/Reverse Switch. This is the main switch used to operate the lathe. It is

simply a forward/reverse switch for the motor. The motor turns counterclockwise for

normal lathe operation and clockwise for normal milling and drilling operation. The

MI-1220 LTD has two switches, one located on the millhead and one on the right side of

the gearbox.

7. Gearbox. The gearbox houses the belts that deriv

e the spindle and change gears for

the powerfeed. Select the thread pitch (for threading) or the feed rate (for turning) by

changing the four change gears on the right side of the gearbox.

8. Headstock. The headstock, which is secured to the bed, houses the gears the drive

the powerfeed and the taper that secure the lathe spindle.

9. Lathe Spindle. The end of the lathe spindle facing the tailstock is the spindle nose. The

spindle nose, which has an MT4 taper, rotates the work piece and drives the lathe chicks

and other workholding devices. Al

l attachments (like three-jaw chucks, four-jaw chucks,

faceplates, etc.) bolt to the spindle flange either directly or via an adapter plate.

10. Leadscr

ew.

The leadscr

ew, which runs the length of the bed, moves the carriage for

lathe turning or thread cutting. It works both manually and under power. You can also

use it manually with the mill.

11. Locks. Locks on the cross slide, carriage, quill, and tailstock (two) keep them from

moving. During machining, lock all axes except the one you want to move.

12. Micr

ossf

cr

ometer Contr

eed, drill calibrated in millimeters. The compound feed and crossfeed are

ol and Calibration.

Just inside the handles of the tai

lstock

calibrated in two thousandths, the tailstock in thousandths, the leadscrew in two

thousandths, and the drill press in forty thousandths.

Note: These micr

ometer dial col

This independent motion is cal

slide, tailstock, longitudinal and mill feeds. They let you zero the collars at any point and

read the feed travel from that point on the dial for increased accuracy.

13. Mill Spindle. The mill spindle attaches to the quill, which moves in and out of the

head. The qui

l lock k

l

eeps the qui

milling horizontally. Usually, tools fir into collets that attach through the spindle via

drawbars.

4-2

ound the handle shafts.

e independent

lars can mo

v

led float. The MI

-1220 L

ly ar

TD has floating dials on the cr

ll still when you install or remove tools from it and while

For Assistance: Call Toll Free 1-800-476-4849

oss

Page 14

4: Basic Parts o thef Midas 1220 LTD

14. Half-nut Lever. This lever transmits power to the carriage for threading.

15. Power Longitudinal Feed. Push the lever down to engage the power of the long feed

for general cutting.

16. Power Cross Feed. Push the lever down to engage the cross feed and pull it up to

disengage.

17. Powerfeed Speed Selector. The two-speed selector for powering the leadscrew is on

the front of the headstock. The leadscrew turns twice as fast in the II position as in the

I position.

18. Tailstock. The tailstock, which provides right-end support for the work, moves along

the bed and can stop at any point on it. It holds centers, drills, reamers, taps, and other

tools. To move the tailstock spindle, which has an MT3 taper, turn the tailstock hand

wheel. The scale of offset calibrations on the back of the tailstock is in millimeters.

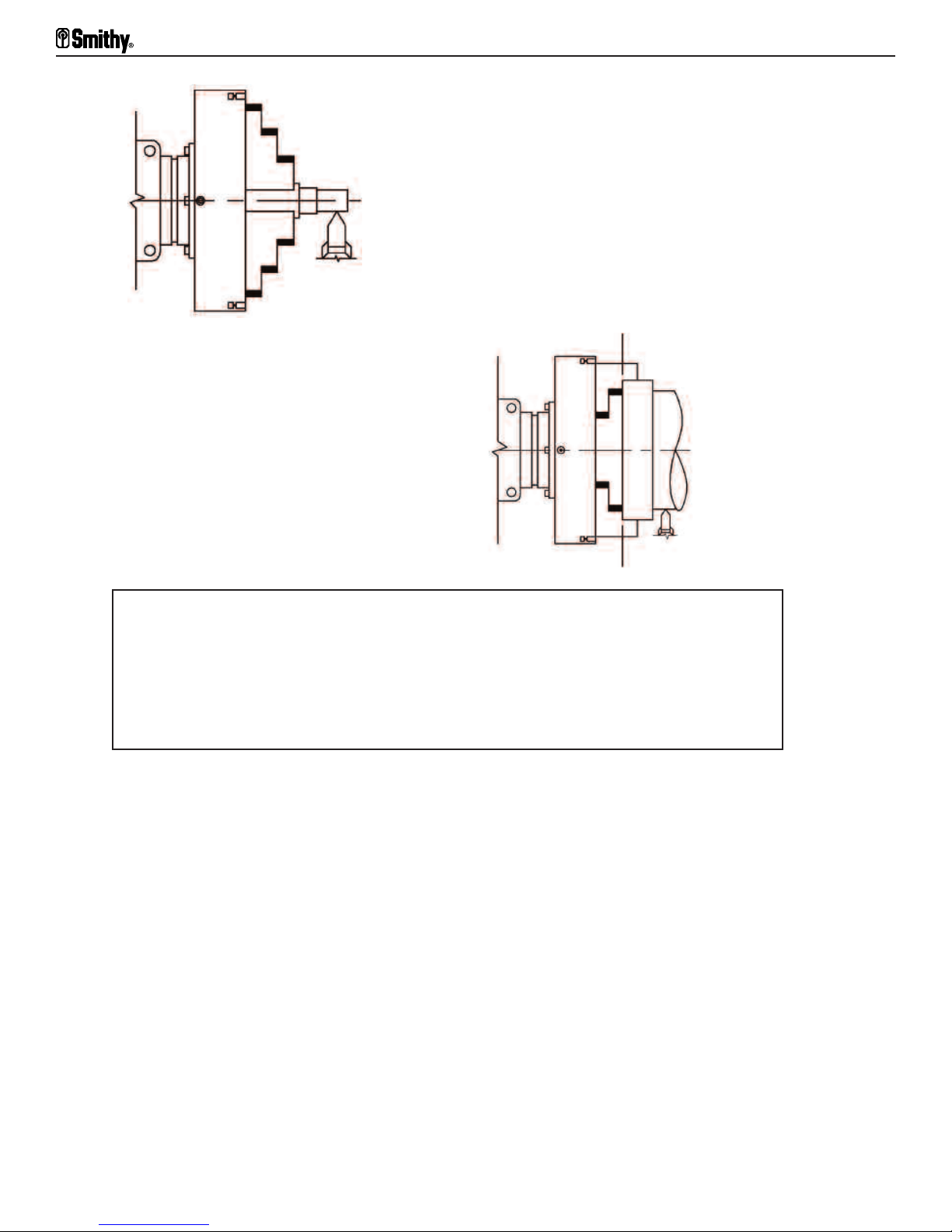

Note: To offset the tailstock, loosed the four base locking bolts. To offset to the left,

loosed the left adjusting bolt and tighten the right and do the same on the other side

.2.

when you want to of

fset to the right. See figur

e. 4

Rgiht

Treslte

Setscrew

Setover

Screw

Figure 4.2 Tailstock base locking bolts.

Or V

isit www

.smithy.com

4-3

Page 15

Chapter 5

Uncrating and Setting Up the MI-1220 LTD

Moving the Machine

Moving a machine tool can be dangerous. Improper techniques and methods may injure

you and/or damage the machine. To find a professional to move and site your Smithy

machine, look in your local Yellow Pages under “Machine Tools, Moving and/or Rigging”.

If there is no such listing or your community does not have a rigging specialist, a local

machine shop or machinist may be able to provide referral.

When you pick up the machine at the shipping terminal, bring a crowbar, tin snips for

cutting the metal straps, and a hammer. If there is obvious shipping damage to the crate,

you’ll be able to inspect the machine before signing for it. Note any damage on the bill

of lading (shipping document). Fill out the claims forms and notify both Smithy Co. and

the shipping terminal about the damage. Failure to notify both parties can complicate

and/or invalidate a claims process.

Trucking company terminals usually have forklifts to assist customers. It’s most

convenient to transport the machines in trucks without canopies and large vans.

Uncrating and Positioning the Machine

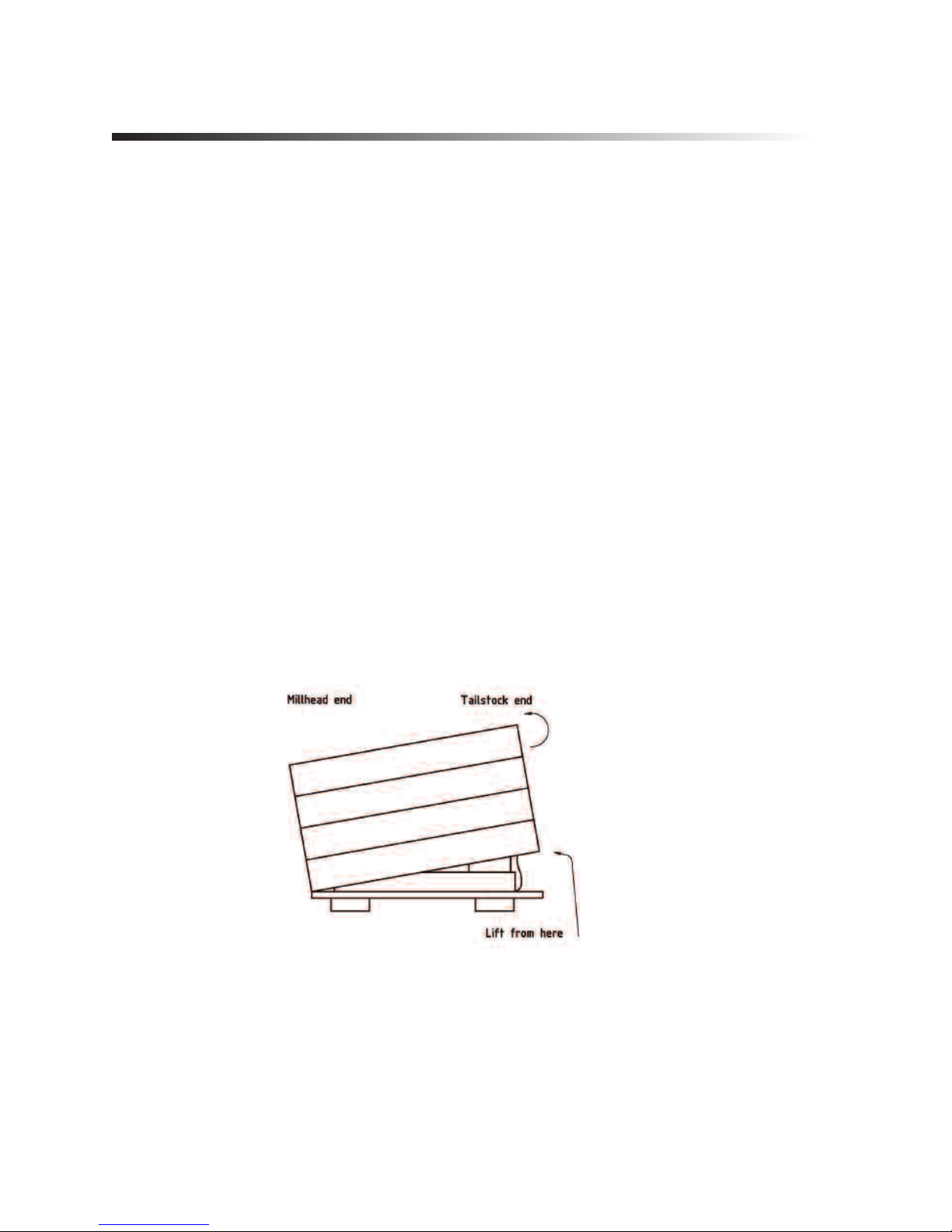

Figure 5.1 Tip the crate from the tailstock end up and over the machine.

The machine is assembled, inspected, and ready to do in its stand. It’s wrapped in a water

and greaseproof cover, strongly braced, and crated. A box of accessories is also in the

crate.

The metal bands that encir

gloves, cut the metal bands with tin snips.

5-1

cle the cr

For Assistance: Call Toll Free 1-800-476-4849

ate are under tension. Wearing eye protection and

Page 16

5: Uncrating and Setting Up the MI-1220 LTD

Caution

The cut edges are sharp. The bands secure the crate top to the base.

After removing the straps, lift off the crate top. Tip the crate from the tailstock end up

and over the machine (Figure 5.1). Do not damage the crate. You may need it another

time to transport the machine.

Once your crate cover is removed it is time to put your machine on its bench. The

machine is just less than 500 pounds so make sure you have some extra hands to help.

There are four lifting pints that pull out from the bed of the lathe. You can use chains or

a tow rope to wraparound these pins and the aid of a lifting device such as an engine

hoist to list the machine on to a bench rated to support the machine’s weight.

Without a mechanical device to aid in your lifting you can lighten the machine by

removing a few or all of the following:

Millhead

1. Remove the four hexagon socket-head screws at the base of the millhead support

column. If a scr

remove it too.

2. Lock the millhead-locking handle.

3. Lift the millhead and column off the lathe head. You may have to rock it back and forth

while lifting it. Make sure that the mill head is locked to the column before removing the

millhead.

ew runs through the belt box into the flange of the support column,

Tailstock

1. Loosen the tailstock lock and pull the tailstock off the end of the bed. The gib and

all out. Be careful no to lose them.

l f

locking pin wi

l

Bolts

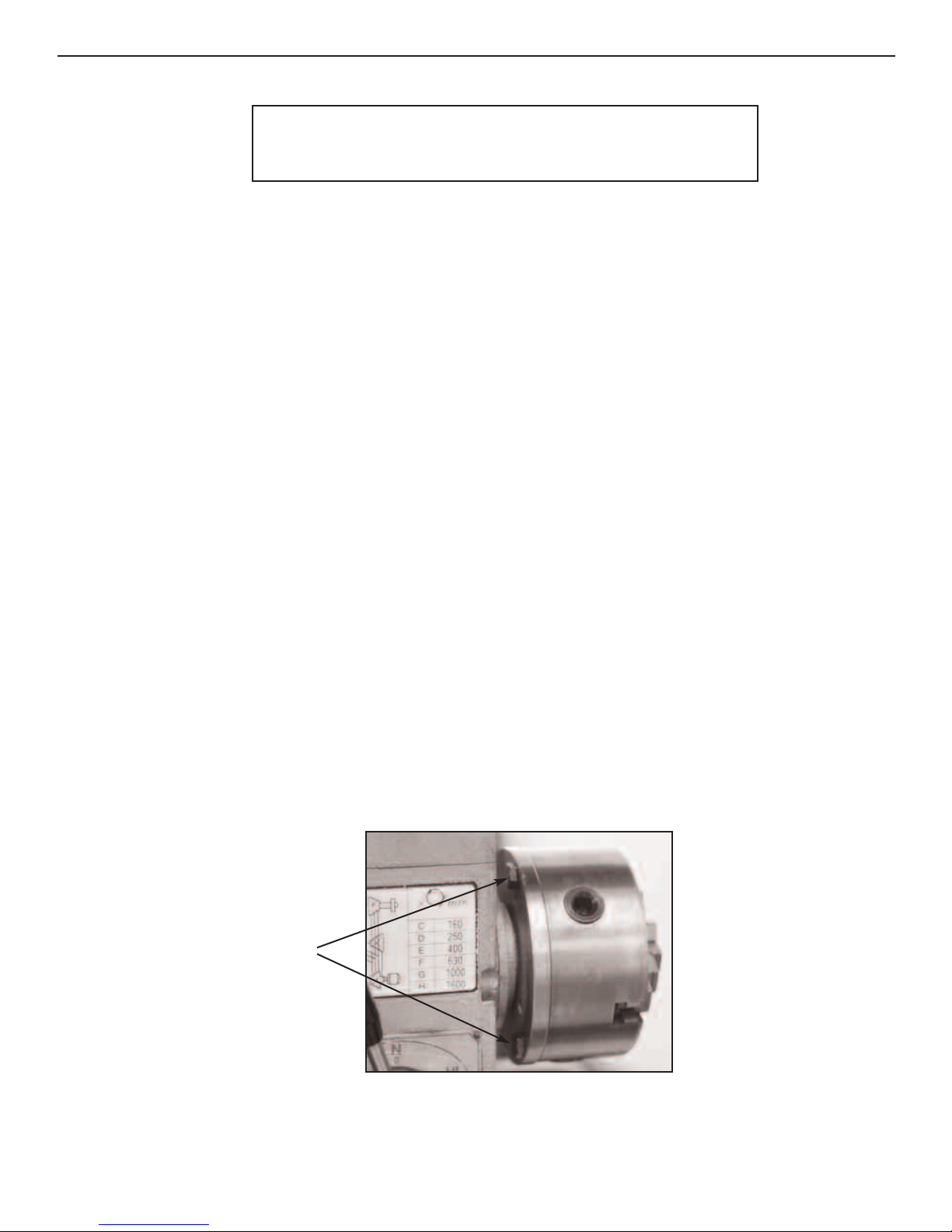

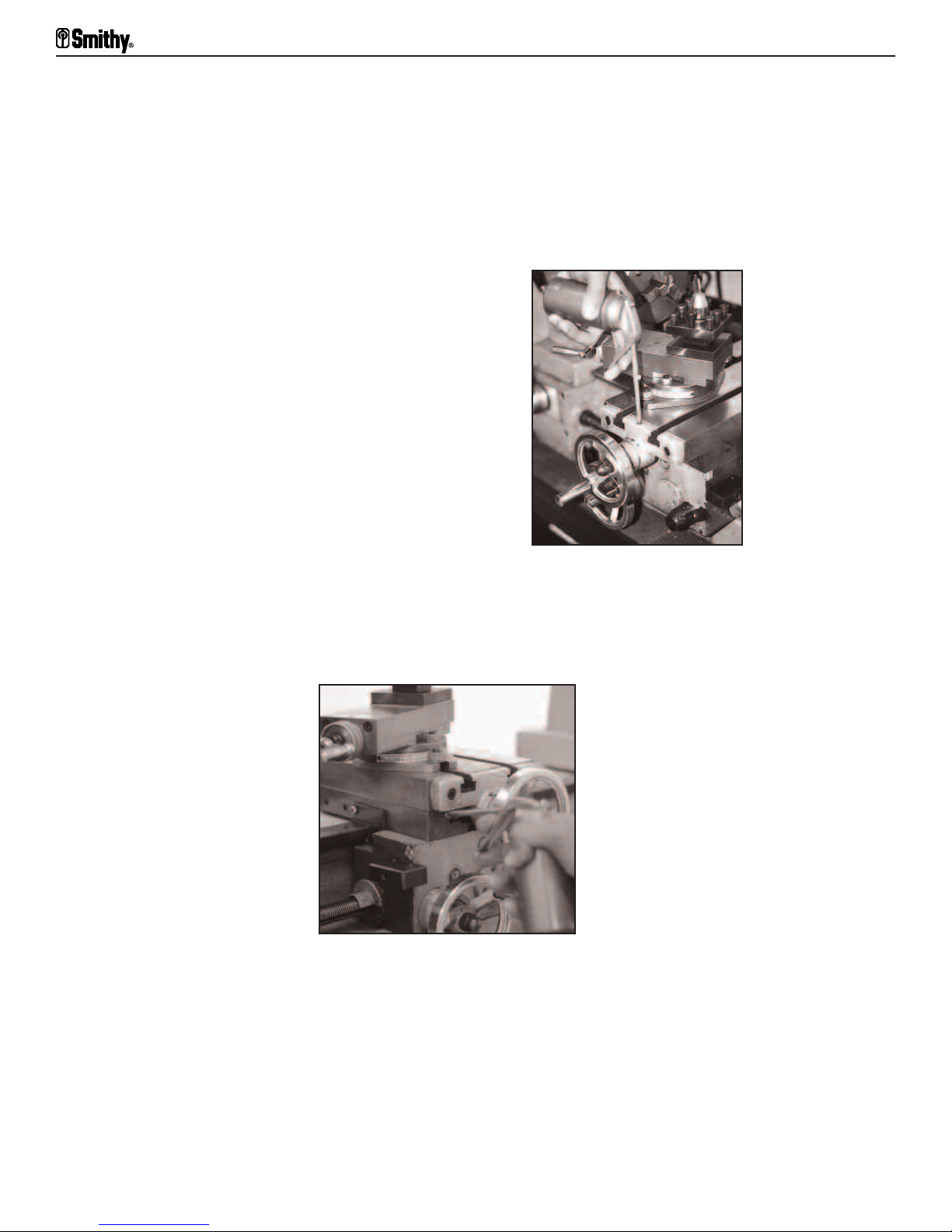

Figure 5.2 The chuck attaches to the spindle flange with three bolts.

The one bolt located on the other side of the spindle does not show.

Or V

isit www

.smithy.com

5-2

Page 17

Midas 1220 LTD Operator’s Manual

Three-Jaw Chuck

1. Remove the three bolts behind the chuck that hold it to the spindle flange (Figure 5.2).

The chuck will come off. Don’t let it fall onto the ways. Placing a board between the chuck

and ways will protect the ways.

Place the machine on a strong, rigid table 40” long, 24” wide and 28” to 33” high. We

recommend you to bolt down the MI-1220 LTD machine using the holes in the base of

the bed or using the lifting handles as they held the machine to the shipping pallet.

Selecting a Location

There are several major considerations for selecting a location for your Smithy.

Operation is from the apron side, so allow at least 40” to 48” clearance in front of the

machine.

The machine should be on a 20supply. Try not to use an extension cord. If you must use one, check with an electrician

about the proper size.

Provide ample working light over the operator’s shoulder.

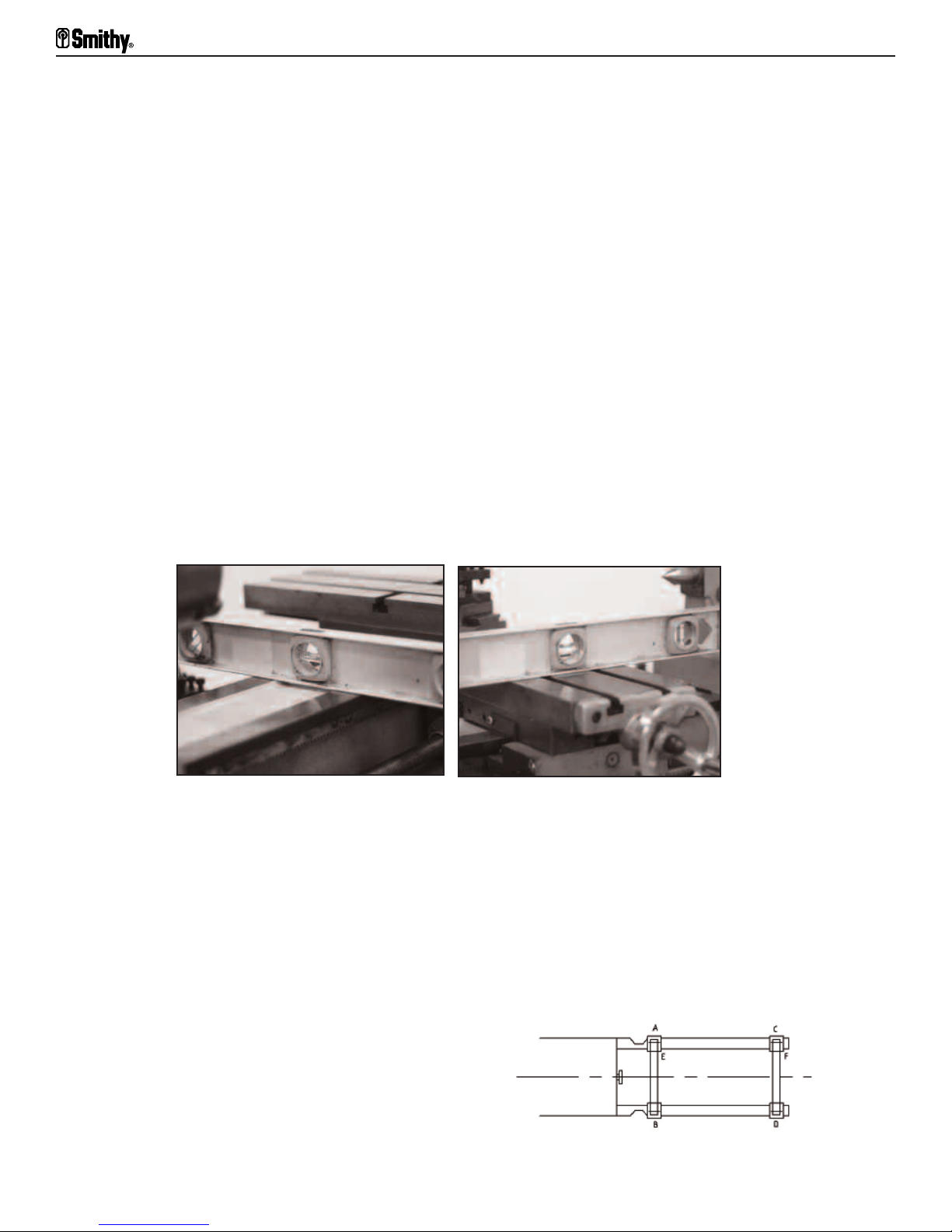

Figure 5.3 Check along and across the bed to make sure it is level.

Place the machine on a solid foundation, concrete if possible. If you must put it on a

wood floor, make sure it is adequate. Brace it if necessary to prevent sagging or settling.

amp circuit, positioned as close as possible to the power

e allowances at the back of the machine tool as at its end and above it for later

Mak

addi

tions, at

stock to be fed through the spindle. If you are considering placing more than one machine

in an area, allow enough floor space to feed long bar stock to each machine.

tachments, and/or accessories. Provide clearance on the left end for bar

Notice To check bench and bed level accuracies,

successively place level at A, B, C, D

(longitudinal positions) and E and F (transverse

positions). Bedways alignment in the longitudinal place

should be better than 0.0016/40”; alignment in the

traverse plane should be better than 0.0024/40”.

5-3

For Assistance: Call Toll Free 1-800-476-4849

Page 18

5: Uncrating and Setting Up the MI-1220 LTD

Cleaning and Lubricating the MI-1220 LTD

Smithy machines are shipped with protective grease coating called cosmoline. Use

WD-40 or non-corrosive kerosene to remove the cosmoline.

Once you have your MI-1220 LTD set up and positioned correctly, you are ready for

lubricating. You must do this carefully and thoroughly before starting the machine. Use a

pressure oil can and a supply of good quality SAE No.10 weight oil.

To be thorough and complete, follow this routine:

Oiling the Ways

Run the carriage as far to the left as possible. Put a few

drops of oil on the ways. Run the carriage to the extreme

right and repeat. You may want to use Way Lube, special

oil formulated for the ways.

Oiling the Millhead Quill

Using your mill handles or your fine feed crank to lower

the mi

work it down and up until it runs smoothly.

llhead down. Apply a thin layer of oil to the quill and

Oiling the Headstock

Figure 5.4 Oiling the ways

Figure 5.5 Oiling the

Millhead Quill

Figure 5.6 Oil the button behind the D gear.

.smithy.com

isit www

Or V

5-4

Page 19

Midas 1220 LTD Operator’s Manual

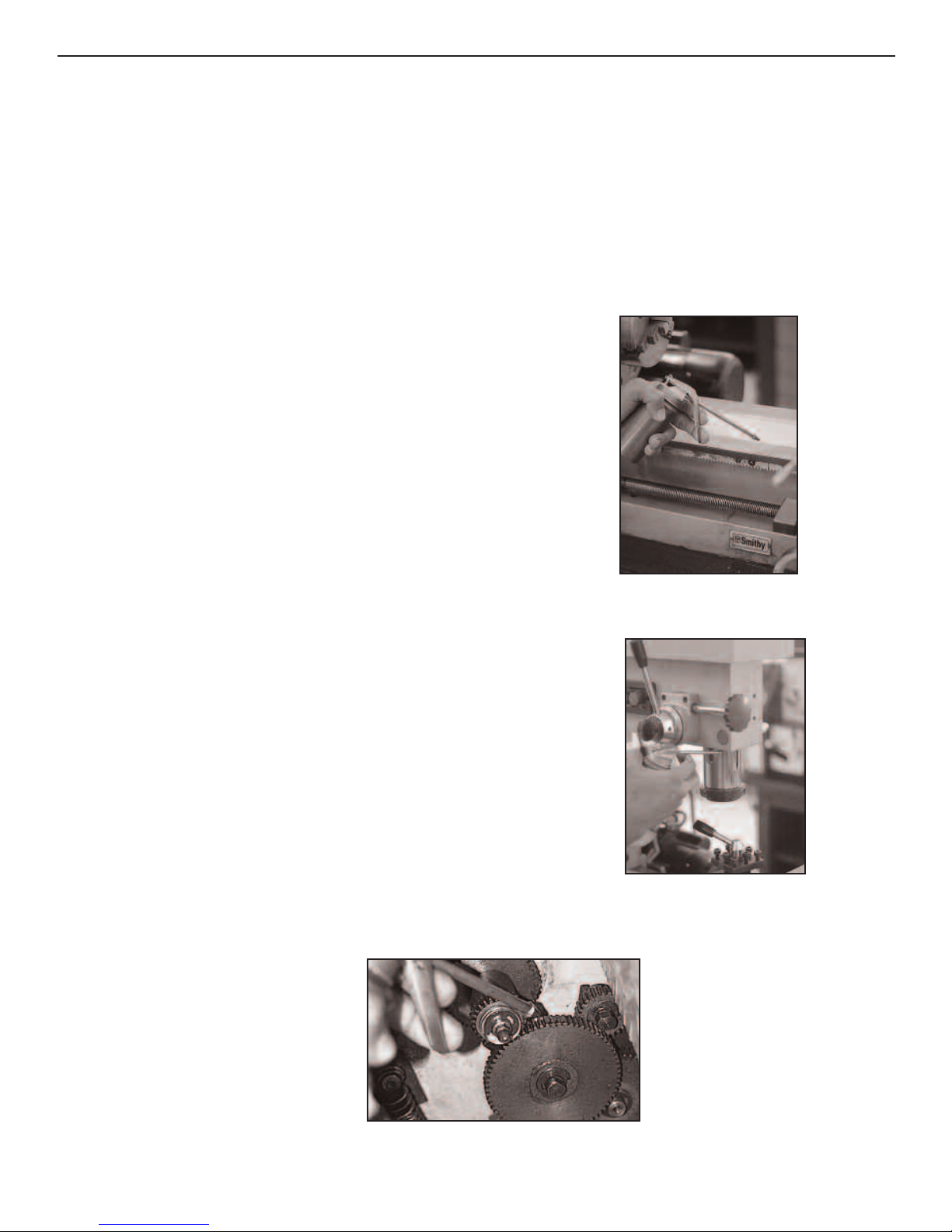

Open the gearbox door to expose the pick-off gears. Oil the button in the casting behind

the D gear. Then put a few drops of oil on the teeth of all the gears. Grease the zerk on

the A gear shaft.

Check the sight glass under the chuck. If necessary, add oil until it is half full. The oil fill

plug is at the back of the headstock above the motor. Be careful not to overfill it. The

gearbox requires only 8 to 10 ounces of oil.

Oiling the Carriage

Lubricate the oil buttons in the cross feed table.

There are two buttons on the left of the saddle for

the bedways and two on the front of the cross slide

for the cross slide ways.

Oil the button in the center of the cross slide.

Put a few drops of oil on the compound slides.

Oiling the Compound Angle Toolpost

Figure 5.8 Oil the buttons along the cross feed table.

l two buttons on top of the compound angle toolpost.

Oi

Figure 5.7 Oiling the table

Oiling the Apron

Put oil in the button just behind the cross slide hand wheel.

5-5

For Assistance: Call Toll Free 1-800-476-4849

Page 20

P

ut oil on the button at the back of the cross slide.

Oiling the Leadscrew

Put oil in the oil buttons on the left trestle.

Put oil in the support for the right end of the leadscrew.

Oiling the Tailstock

5: Uncrating and Setting Up the MI-1220 LTD

Figure 5.9 Oil the two buttons on the top of the tailstock.

Oil the buttons on top of the tai

lstock.

Oiling the Mill/Drill Clutch

Figure 5.10 Oil the clutch housing button.

Put oil in the button on top of the clutch housing.

To keep your machine in peak condition, lubricate it daily after removing any debris.

Do not fill the gearbox sight glass more than half way. Too much oil will make the

motor lug and sling oil out form behind the chuck and inside the belt box.

Or V

isit www

Notice

.smithy.com

5-6

Page 21

Midas 1220 LTD Operator’s Manual

Adjusting Belt Tension

The MI-1220 LTD has two belt tensioners

installed by the factory. One for the

millhead and the other one for the pulley

box.

Figure 5.11 Mill belt

Mill

Locate the “L shaped” lever and a thumbscrew at the top of the mill motor. Loosen the

thumbscrew and then rotate the lever to increase or decrease the belt tension.

Re-tighten the thumbscr

ew when the desired tension is achieved.

Figure 5.12 Lathe belt tensioner.

Lathe

Locate the belt tensioner handle on the motor mount. To tighten the lathe belts, move

the tensioner handle upward so that the handle points toward the lathe head. Turn the

knurled knob clockwise to tighten the bel

t and counter

clockwise to loosen it.

Adjusting the Gibs

The MI-1220 LTD machines have straight gibs. Before using the machine, adjust the gibs

evenly. First tighten the screws all the way. This will lock the movement. Then loosen

each screw one quarter turn and check it. Tighten the gib, the more accurate it will be.

es the tolerances.

v

ving and pol

emo

R

With the gibs properly adjusted, review the following instructions on how to reduce the

backlash, or lost motion in the screw, which also depends on the type of job you’re doing

and/or individual preference.

5-7

ishing the gibs also impr

For Assistance: Call Toll Free 1-800-476-4849

o

Page 22

5: Uncrating and Setting Up the MI-1220 LTD

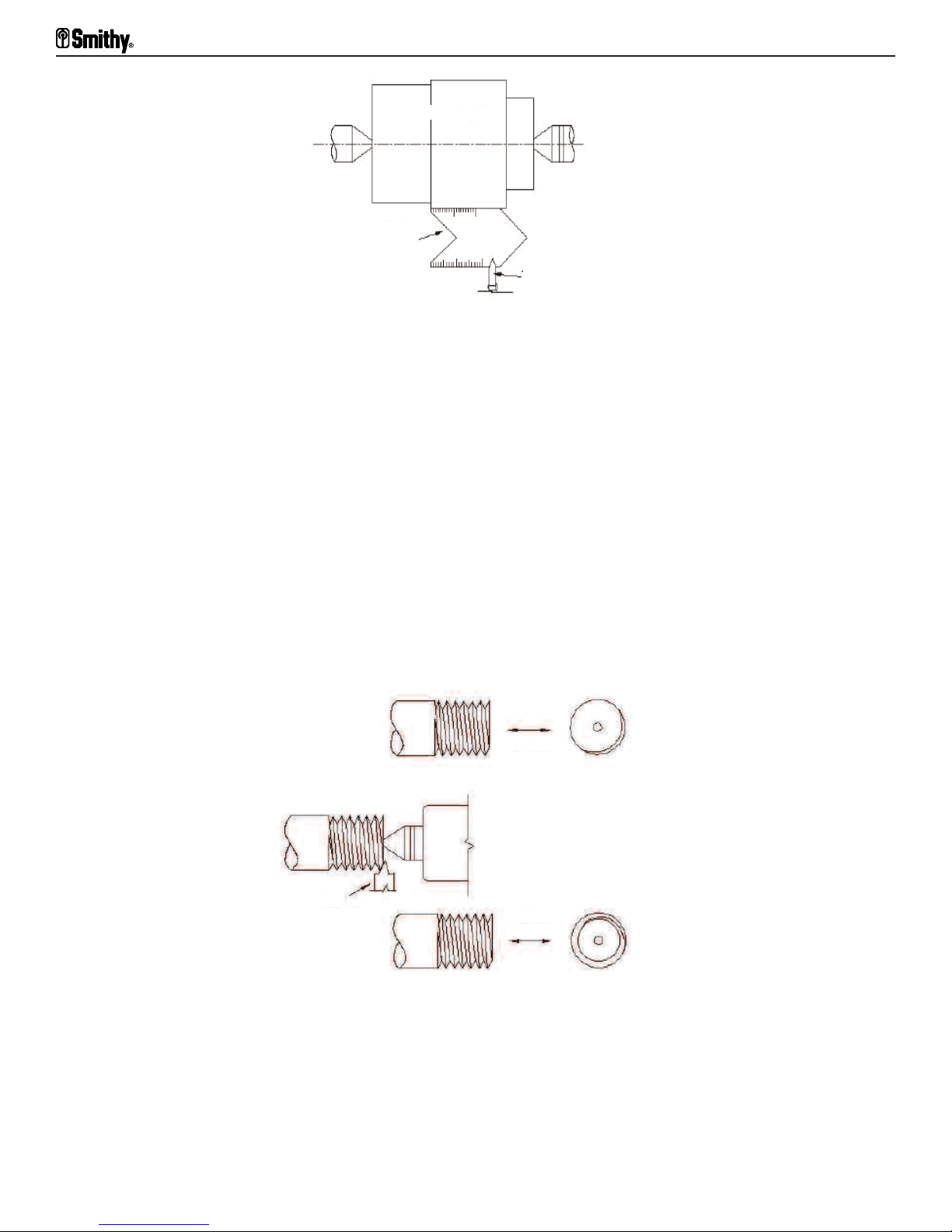

Reducing Backlash

Backlash of 0.008-0.015” as measured on the dial is normal. If you have more backlash

than that in your crossfeed table, refer to the schematics at the back of this manual, if

necessary and follow these directions:

1. Tighten the cap nut in the center of the cross feed hand wheel securely.

2. Tighten the set screw inside the T-slot so the brass nut cannot move.

3. Tighten the screw in the base of the brass nut. This will remove play between the

threads in the cross feed screw and nut. Do not over tighten it or there will be excess

wear on the nut.

If there is still excess backlash, place one or more shim washers between the large

shoulder of the cross feed screw and the bush bearing. Ask a Smithy technician about our

antibacklash shim washer kit, Item number K99-190.

Figure 5.13 To reduce backlash, tighten the setscrew so the

bush bearing will be secured.

To install shims, turn the hand wheel clockwise to move the cross table away from the

screw seat. Loosen the setscrew. Then pull out on the hand wheel until the bush bearing

is free of the seat. Remove the cap nut, hand wheel, dial, keys, and bush bearing. Install

one or mor

e shim washers and reassemble.

Running in the MI-1220 LTD

thy machines are run at the factory and again before shipping, it is wise

Though al

l Smi

to put your machine through a break-in run before putting it to work. After oiling the

machine, check the belts to make sure the tensioners are correct. Do not plug your

machine yet.

Follow these steps:

Millhead Run-in

1. Make sure that the power switch for the lathe motor and the mill motor are both in the

tion.

f posi

of

2. Close the door of the gearbox before starting your machine.

3. Plug the machine into a grounded 20-amp circuit.

Or V

isit www

.smithy.com

5-8

Page 23

Midas 1220 LTD Operator’s Manual

4. Start the mill motor by pushing in the green start button. After a few minutes, push in

the red stop button and allow the motor to stop. Flip the yellow switch cover and switch

it to the opposite position and repeat the above procedure.

5. Start the lathe by pushing the green button on the lathe control panel.

6. Engage the half nut by pushing down the half nut handle, pull up to disengage. Do the

same with the cross feed and the longitudinal feeds.

7. Push the lathe stop button and allow the motor to stop. Move the direction selector to

the left and flip the yellow cover and switch the red toggle switch to the opposite

position and repeat the above procedure.

During the run-in, try all of the controls. Get a feel for your machine before you start to

work.

Caution

This machine is equipped with power crossfeed and longitudinal feed.

Caution must be taken to not run the power feeds past their limits of travel. As part of

normal operation procedures, run each axis through the entire length of the proposed

machining oper

travel to accomplish the desired task. Failure to do so could result in running one of the

power feeds to the end of its mechanical limits. This is what is known as a “CRASH”. A

ash can cause damage to the work piece and severe damage to the machine.

cr

Remember that becoming familiar with your machine is the best safety insurance you can

have.

ation bef

ore engaging any of the power feeds to assure there is sufficient

Lathe Run-in

1. Start the lathe by pushing the green button on the lathe control panel.

2. Engage the half nut by pushing down on the half nut handle, pull up to disengage. Do

the same with the cross feed and the longitudinal feeds.

3. Push the lathe stop button and allow the motor to stop. Move the direction selector to

the left and flip the yellow reversing switch to the opposite position and repeat the above

ocedure.

pr

During the run-in, try all of the controls. Get the feel for your machine before you start

to work.

5-9

For Assistance: Call Toll Free 1-800-476-4849

Page 24

5: Uncrating and Setting Up the MI-1220 LTD

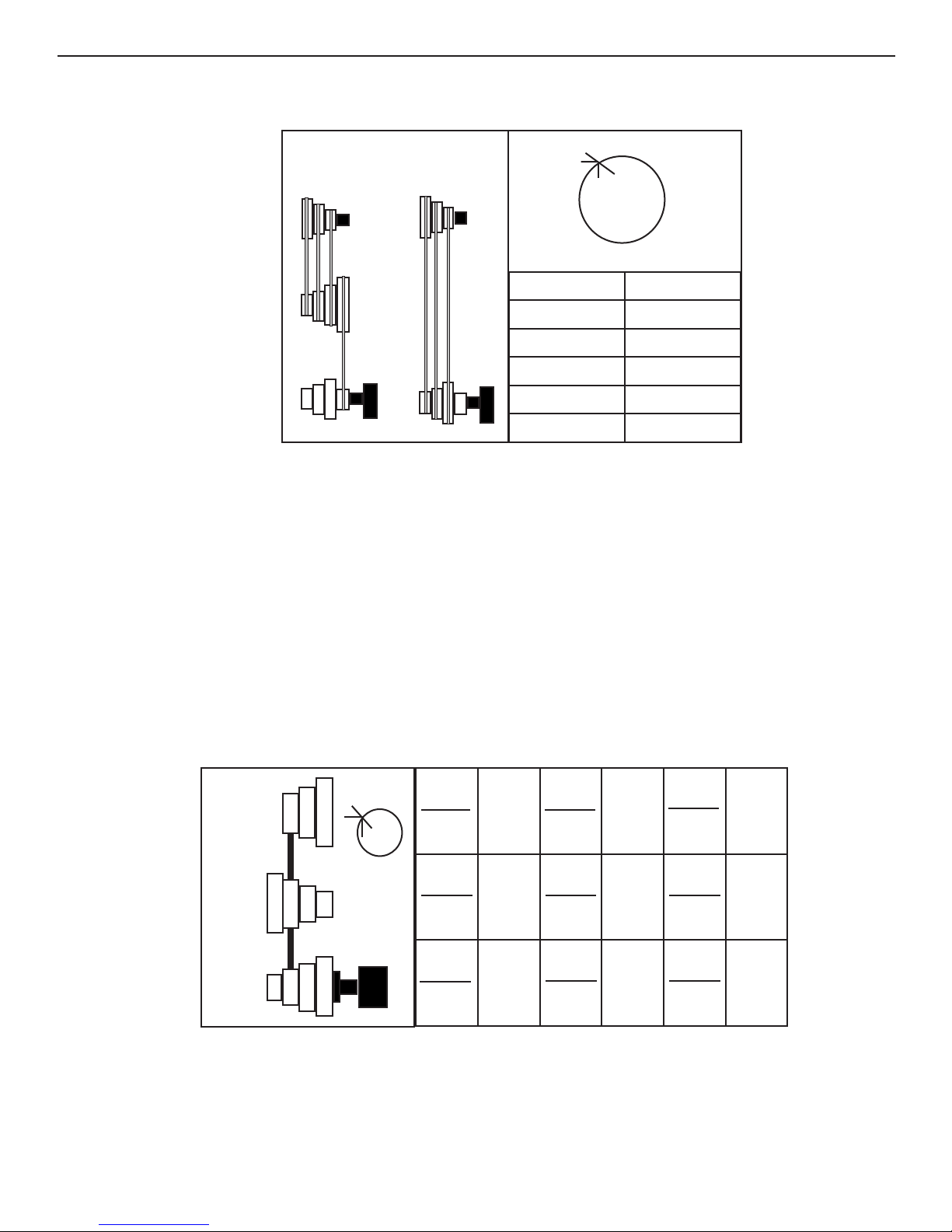

Setting Lathe and Mill Speeds for the MI-1220 LTD

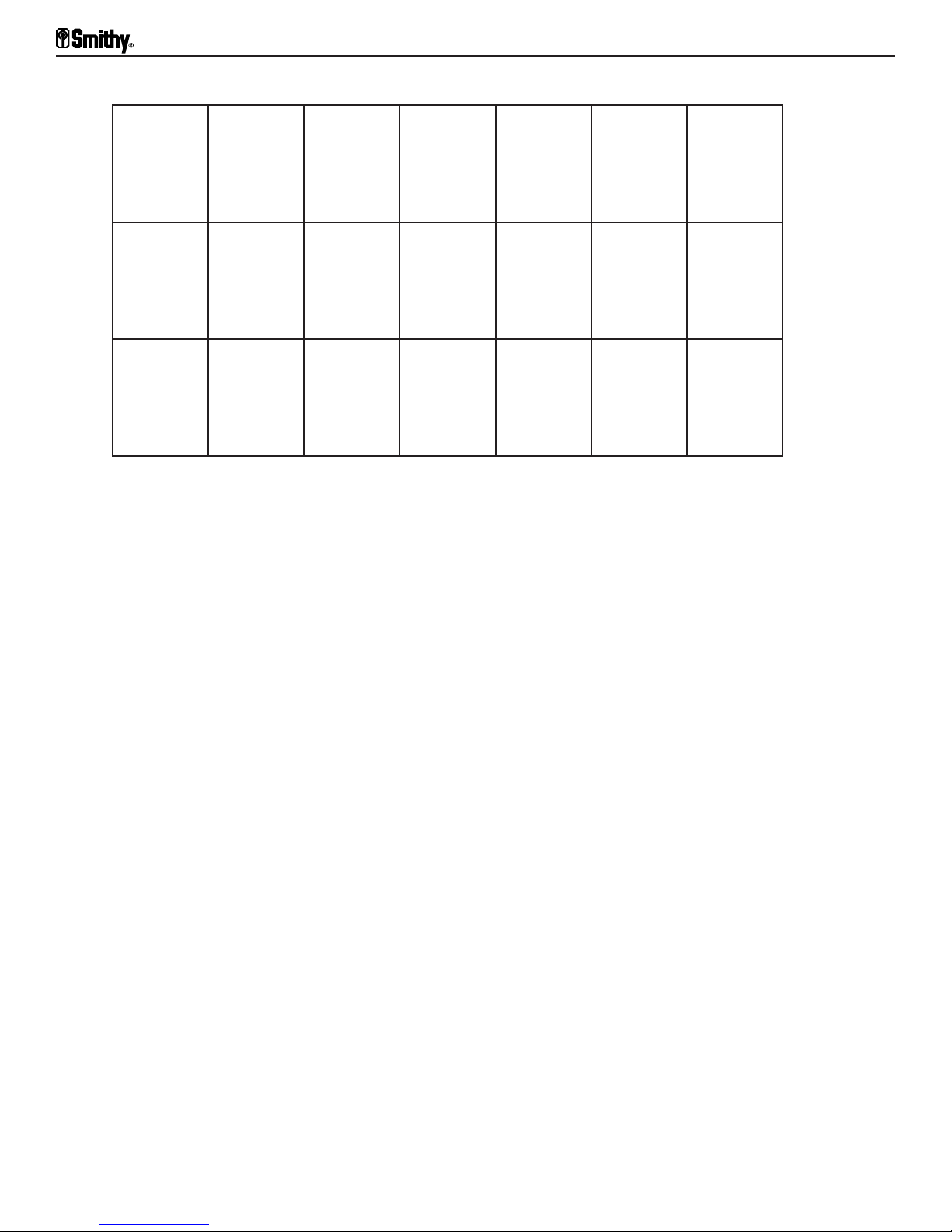

LOW HIGH

C D E

F G H

X

C 160

D 250

E 400

F 630

G 1000

H 1600

Figure 5.14 Setting Lathe Speeds (RPM)

Changing belts changes lathe speeds. The lower speeds use the two short belts. There is

only one position for the motor pulley to idler pulley belt. It goes on the smallest sheave

of the motor pulley (behind the largest sheave, Figure 5.14) and on the largest sheave of

the idler pulley. For 160 RPM, se the idler pulley to lathe spindle pulley belt on the

smallest sheave of the idler pulley to the largest sheave of the spindle pulley (position C).

Move it in once sheave for 250 RPM (position D) and one more for 400RPM (position E).

For the higher speeds, remove the two small belts and use the single long belt from the

motor pulley to the spindle pulley. For 630 RPM (position F), run the belt from the outside sheave (closest to the door) on the motor pulley. Move it one sheave for 1000 RPM

(position G). For 1600 RPM (position H), run it from the largest motor pulley sheave to

the smallest spindle pulley sheave.

C

321

A4 X B1

B4 C1

315

A3 X B1

B3 C1

630

A2 X B3

B2 C3

1250

X

A4 X B2

B

4

2

1

3

A

4

321

B4 C2

A4 X B3

B4 C3

400

500

A2 X B1

B2 C1

A3 X B2

B3 C2

800

1000

A1 X B2

B1 C2

A1 X B3

B1 C3

1600

2000

Figure 5.15 Setting Mill/Drill Speeds (RPM)

Set mill speeds using various combinations of the mill belts. For 315 RPM, place belt A/B

in posi

mo

tion 4 and bel

e the B/C belt to position 3.

v

t B/C in posi

tion 1. For 500 RPM, leave belt A/B belt in position 4 and

Or V

isit www

.smithy.com

5-10

Page 25

Chapter 6

Turning

The lathe rotates a workpiece against a cutting edge. With its versatility and numerous

attachments, accessories, and cutting tools, it can do almost any machining operation.

The modern lathe offers the following:

• The strength to cut hard, tough materials

• The means to hold the cutting point tight

• The means to regulate operating speed

• The means to feed the tool into or across, or into and across, the work, either

manually or by engine power, under precise control

• The means to maintain a predetermined ratio between the rates of rotating

works and the travel of the cutting point or points.

Turning Speeds

When metal cuts metal at too high a speed, the tool burns up. You can machine soft

metals like aluminum at fast speeds without danger or trouble, but you must cut hard

steels and other metals slowly

You must also consider the diameter of the workpiece (Figure 6.1). A point on a 3"

diameter shaft will pass the cutting tool three times as fast as a point on a 1 " diameter

shaft rotating at the same speed. This is because the point travels a tripled

ence.

er

cumf

cir

For work in any given material, the larger the diameter, the slower the speed in spindle

revolutions needed to get the desired feet-per-minute (fpm) cutting speed.

Lathes cut thr

ator's needs. The MI

oper

In thread cutting, the carriage carries the thread-cutting tool and moves by rotating the

leadscrew . The basic principle is that the revolving leadscrew pulls the carriage in the

desired direction at the desired speed. The carriage transports the toolrest and the

eading tool, which cuts the scr

thr

eads in v

arious numbers per inch of material thr

.

-1220 L

ding to the

eaded, ac

TD cuts metric threads and inch threads standards.

ew thr

ead into the metal being machined.

cor

The faster the leadscrew revolves in relation to the spindle, the coarser the thread. This

is because the threading tool moves farther across the revolving metal with each

workpiece revolution.

6-1

For Assistance: Call Toll Free 1-800-476-4849

Page 26

The lathe spindle holding the workpiece revolves at a selected speed (revolutions per

minute, or rpm) according to the type and size of the workpiece. The leadscrew, which

runs the length of the lathe bed, also revolves at the desired rpm. There is a definite and

changeable ratio between spindle and leadscrew speeds.

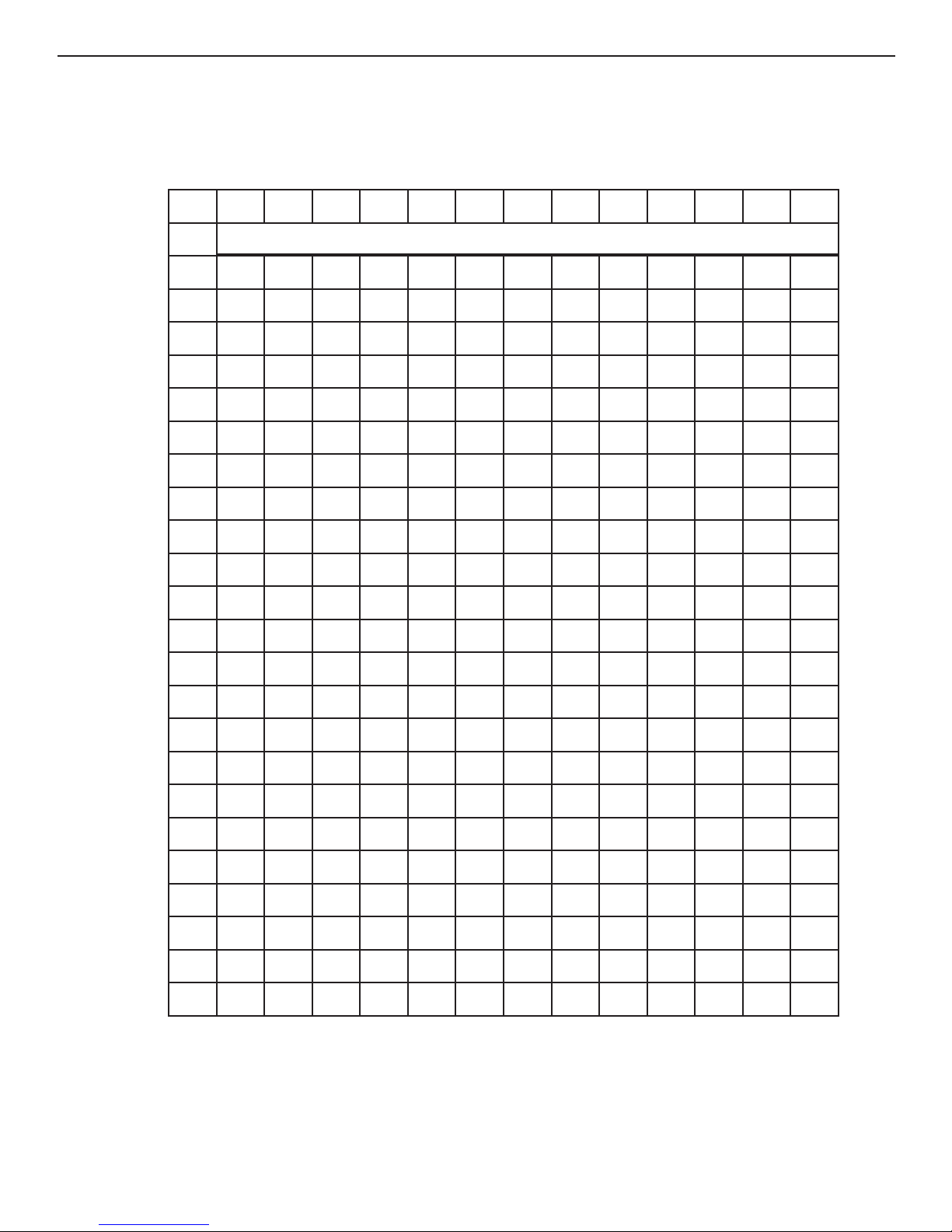

FPM 50 60 70 80 90 100 110 120 130 140 150 200 300

6: Turning

DIAM

1/16”

1/8”

3/16”

1/4”

5/16”

3/8”

7/16”

1/2”

5/8”

3/4”

7/8”

1”

1-1/8”

RPM

3056 3667 4278 4889 5500 6111 6722 7334 7945 8556 9167 12229 18344

1528 1833 2139 2445 2751 3056 3361 3667 3973 4278 4584 6115 9172

1019 1222 1426 1630 1833 2037 2241 2445 2648 2852 3056 4076 6115

764 917 1070 1222 1375 1538 1681 1833 1986 2139 2292 3057 4586

611 733 856 978 1100 1222 1345 1467 1589 1711 1833 2446 3669

509 611 713 815 917 1019 1120 1222 1324 1426 1528 2038 3057

437 524 611 698 786 873 960 1048 1135 1222 1310 1747 2621

382 458 535 611 688 764 840 917 993 1070 1146 1529 2293

306 367 428 489 550 611 672 733 794 856 917 1223 1834

255 306 357 407 458 509 560 611 662 713 764 1019 1529

218 262 306 349 393 426 480 524 568 611 655 874 1310

191 229 267 306 366 372 420 458 497 535 573 764 1146

170 204 238 272 306 340 373 407 441 475 509 679 1019

1-1/4”

1-3/8”

1-1/2”

1-5/8”

1-7/8”

2-1/4”

2-1/2”

2-3/4”

Table pr

account. Determine the desir

machine.

153 183 216 244 275 306 336 367 397 428 458 612 918

139 167 194 222 250 278 306 333 361 389 417 556 834

127 153 178 204 229 255 280 306 331 357 382 510 765

117 141 165 188 212 235 259 282 306 329 353 470 705

102 122 143 163 183 204 224 244 265 285 306 408 612

2”

95 115 134 153 172 191 210 229 248 267 287 382 573

85 102 119 136 153 170 187 204 221 238 255 340 510

76 91 107 122 137 153 168 183 199 214 229 306 459

69 82 97 111 125 139 153 167 181 194 208 278 417

3”

64 76 89 102 115 127 140 153 166 178 191 254 371

Table 6.1 Cutting Speeds for Various Diameters

vides exact speeds (rpm). It does not tak

o

e machine speed l

ate of speed and find the closest speed a

ed r

tations into

imi

vailable on your

Or V

isit www

.smithy.com

6-2

Page 27

Midas 1220 LTD Operator’s Manual

• The means to hold the cutting point tight

• The means to regulate operating speed

• The means to feed the tool into or across, or into and across, the work, either

manually or by engine power, under precise control

• The means to maintain a predetermined ratio between the rates of rotating

works and the travel of the cutting point or points.

Gear ratios

The lathe lets you use various indicated gear combinations to cut the desired number of

threads per inch (TPI), or the metric equivalent, or to advance the tool a specified amount

each revolution (feed rate expressed as inches per revolution [ipr]).

The MI-1220 LTD has pick-gear gearboxes; gears are picked and placed to change the

gear ratios. The gearbox mechanism determines the leadscrews rotation rate in relation

to the spindles f

gears per Figure 6.2.

or threading, turning, and facing. To change the feed rate, replace the

e 6.2 (missing)

Figur

6-3

For Assistance: Call Toll Free 1-800-476-4849

Page 28

Chapter 7

Metal Theory

Tool sharpness

Instead of being the all-important factor in determining tool performance, keenness of

the cutting edge is just one of many factors. On rough or heavy cuts, it is far less

important than strength, because a false cutting edge or crust usually builds up on the

tool edge, and though the edge dulls, its angle often increases the cutting tool's

efficiency by increasing its wedging action. Cutter shape is usually more important than

edges, which generally are rough-ground and usually must be honed for fine finishing

cuts or work in soft, ductile materials like brass or aluminum.

Lack of clearance, which lets a tool drag on the work below the cutting edge, is a brake

e on the cutting point and interfering with tool

ly reducing pr

on the lathe, gr

performance more than edge dullness. At the same time, excessive clearance weakens a

tool because of insufficient support to the cutting edge. Such an edge will break off if you

use the tool on hard materials.

Clearance requirements change with almost every operation, but there are certain

standar

cutting edge; there must also be end and side clearance. To help the chip pass with

minimum resistance across the top of the tool, i

determine the shapes and rakes to which you'll grind your tools by the tool holder you

use. TheCB-1220 XL LTD have a four-sided turret toolpost that accommodates four

high-speed-steel (HS

ds for all aspects of the cutting tool. You must not only provide clearance from the

eat

S), carbide-tipped, or indexable carbide turning tools.

essur

t should often have top r

ake as well. You

Heat

The ener

the ener

ceramic tools, this heat created a serious machining problem. Machining could be done

only under a steady flow of coolant, which kept the tool from heating to its annealing

point, softening, and breaking down.

th HSS, you can usually cut dry unless a small lathe is running at extremely high speeds

Wi

on continuous, hea

hot. They do not dissipate the heat, however, or in any way prevent the workpiece from

heating up. Because steel expands when heated, it is a good idea, especially when

working on long shafts, to check the tightness of the lathe centers frequently and make

sur

gy expended at the lathe's cut

gy expended is great, the heat is intense. Before today's HSS, carbide, and

vy-duty production work. HSS tools are self-hardening even when red

e workpiece expansion does not cause centers to bind.

ting point con

.smithy.com

isit www

Or V

verts largely into heat, and because

7-1

Page 29

Midas 1220 LTD Operator’s Manual

Low-Carbon

Steel

Speed (sfm)

Roughing

Finishing

90

120

Feed (ipr)

Roughing

Finishing

0.010-0.202

0.003-0.005

Table 7.1 Cutting Speeds and Feeds for High-Speed-Steel Tools

High-

Carbon

Steel

Annealead

50

65

0.101-0.020

0.003-0.005

Alloy Steel

Normalized

45

60

0.010-0.020

0.003-0.005

Aluminum

Alloys

200

300

0.015-0.030

0.005-0.010

Cast Iron Bronze

70

80

0.010-0.020

0.003-0.010

100

130

0.010-0.020

0.003-0.010

In everyday lathe operations like thread cutting and knurling, always use cutting oil or

other lubricant. On such work, especially i

a brush in oil occasionally and holding it against the workpiece will provide sufficient

lubrication. For continuous, high-speed, heavy-duty production work, however, especially

on tough al

essential if you're using a non-HSS cutting tool.

When you use coolant, direct it against the cutting point and cutter. Consider installing a

coolant system if you don't have one.

Table 7.1 lists cutting speeds and feeds for HSS cutters so you can set up safe rpm rates.

The formula is as follows:

rpm=CSx4 / D"

where:

CS = cut

D" = diameter of the workpiece in inches.

To use this formula, find the cutting speed you need on the chart and plug that number

into the CS portion of the formula. After calculating the rpm, use the nearest or next lower

speed on the lathe and set the speed.

loy steels, using a cutting oi

eet per minute (sf

ting speed in surf

ace f

f the cut is light and lathe speed low, dipping

l or coolant will increase cutting efficiency. It's

m)

If you were to make a finish cut on a piece of aluminum 1" in diameter, for example, you

would see the desired sfm per Figure 7.3 is 300. Then:

rpm = 300 sfm x 4 / 1

rpm = 1200 / 1

7-2

For Assistance: Call Toll Free 1-800-476-4849

Page 30

7: Metal Theory

rpm = 1200 or next slower speed.

For high-carbon steel, also 1" in diameter,

rpm = 50 sfm x 4 / 1

rpm = 200 / 1

rpm = 200 or next slower speed.

The four-turret toolpost lets you mount up to four different tools at the same time. You

can install all standard-shaped turning and facing tools with 1" or smaller shanks. The

centerline is approximately 5/8" above the bottom of the turret. Smithy also offers

quick-change tool sets that greatly speed up lathe operations. Contact a Smithy

technician for details.

Or V

isit www

.smithy.com

7-3

Page 31

Chapter 8

Grinding Cutter Bits for Lathe Tools

High Speed Steel Cutters

The advantage of HSS cutter bits is you can shape them to exact specifications through

grinding. This lets you grind a stock shape into any form. Stock shapes come in an

assortment of types, including squares, flats, and bevels. Many shops buy their cutters as

ready-ground or ready-to-grind bits or blades.

Ready-to-grind bits and blades are of specially selected HSS, cut to length and properly

heat-treated. They are fine tools in the rough and generally superior to HSS shapes sold

by the pound.

ou have five major goals:

In grinding HS

• A strong, keen cutting edge or point

• The proper cutting form (the correct or most convenient shape for a specific

operation)

S cutter bi

ts, y

• Front clearance away from the toolpoint

• Clearance away from the side of the tool (side rake)

ee chip movement over the tool and away from the cutting edge.

• Fr

Keenness angles can vary from 60° for mild softness to 90° for hard steels and castings

(Figure 8.1).

Side

Rake

Side Clearance

o

3-10

Angle of

Keenness

Figure 8.1 Keenness angles vary from 60 to 80 degrees.

8-1

For Assistance: Call Toll Free 1-800-476-4849

Page 32

8: Grinding Cutter Bits for Lathe Tools

Front clearance must always be sufficient to clear the work. If it is too great, however,

the edge weakens and breaks off (Figure 8.2). Side and back-rake requirements vary with

the material used and operation performed. Back rake is important to smooth chip flow,

which is needed for a uniform chip and good finish, especially in soft materials. Side rake

directs the chip flow away from the point of cut.

Figure 8.2 The edge weakens if front clearance is too great.

Grind cutters on a true-surfaced, good-quality, medium-grit grinding wheel (preferably an

8", 46-60A-grit or 68A-grit Carborundum wheel) at 6000 or 6500 rpm. When starting with

an ungrounded cutter bit, the procedure (Figure 8.3) is usually to:

1. grind the left-side clearance

2. grind the right-side clearance

3. grind the end form or radius

4. grind the end clear

ance

5. grind the top rake, touching in a chipbreaker.

If you are honing the cutting edge (for fine finishing or machining soft materials), draw

the cutter away from the cutting edge across the oilstone as shown in Figure 8.4.

Cutter Bit

Grinding Wheel

1. Left Side

Clearance

2. Rigt Side

Clearance

3. End

Clearance

4. Radius 5. Top Rake

Figure 8.3 Grinding sequence for an unground cutter bit.

Or V

isit www

.smithy.com

8-2

Page 33

Midas 1220 LTD Operator’s Manual

ilstone

O

Figure 8.4 When honing, draw the cutter away from the cutting edge across the oilstone.

Materials Other Than Steel

As pointed out earlier, when grinding HSS cutters, we determine cutting angles primarily

by strength requirements, not keenness requirements. Angles and rakes for general

industrial shop use are established. In machining steel, the softer the steel, the keener

the angle of the cutting edge. For soft steels, angles as acute as 61° are possible.

Figure 8.5 With soft steels, 61 degree angles are possible.

The same general rule applies to cast iron. Chilled or very hard cast iron requires tools

with cutting-edge angles as great as 85°. For ordinary cast iron, you obtain greatest

efficiency with a more acute cutting edge-approximately 71°.

Figure 8.6 With cast iron, a 71 degree angle is most efficient.

Bits for Turning and Machining Brass

Brass tends to pull or drag when machined. It's best to machine it on dead center with

the top rake in the horizontal plane of the lathe centers. Softer than steel, brass needs

less support f

or the cut

ting edge. Brass cutters require an almost flat top angle and can

8-3

For Assistance: Call Toll Free 1-800-476-4849

Page 34

8: Grinding Cutter Bits for Lathe Tools

gain greater angle keenness only in increased side and end rakes. It is often advisable to

hone the cutting edges of cutters used to machine brass.

Note: All roundnose cutters are ground with flat tops and equal side rakes because they

are fed across the work, to both right and left.

Special Chip Craters and Chipbreakers

When grinding cut-off blades, and occasionally on other cutter bits where the material's

extreme hardness or toughness makes it difficult to control the chip leaving the work, it

sometimes helps to grind a smooth, round crater just behind the cutting edge. This serves

as a chip guide and starts the chip curling smoothly.

Figure 8.7 A crater starts the chip curling smoothly.

Using a Center Gauge to Check V-Thread Forms

It may be convenient to grind a standard cutter bit for thread cutting, especially for

cutting standard 60° V-threads. When grinding an ordinary square cutter into a thread

ting tool, tak

cut

dinary center gauge for a standard V-thread tool or a special thread gauge for special

or

e care to ensur

e a true thread f

thread forms.

To grind a cutter for an ordinary V-thread, grind first the left side of the tool, then the

right side, to 30°. Be careful to grind equally from both sides to center the toolpoint. Then

test for true form by inserting the newly ground point in the closest-sized V in a standard

center gauge (Figure 8.8). Examine the gauge and cutter before a light. When the cutter

is ground perfectly, no light streak shows between tool and gauge. Use a grinding chart

es.

or other r

f

ak

orm. The easiest way is to use an

Figure 8.8 Insert the point into the nearest seized V in the center gauge.

Or V

isit www

.smithy.com

8-4

Page 35

Midas 1220 LTD Operator’s Manual

Acme or Other Special Threads

Thread gauges are available for all standard threads. Before grinding such cutters,

ascertain the correct pitch angle of the particular thread profile. For example, the pitch

of an acme thread is 29° to a side, and the toolpoint is ground back square to an exact

thread profile that requires a different end width for each thread size.

Thread forms must be accurate if threads are to fit snugly and smoothly. Every

resharpening of this type of cutter requires regrinding the entire form. It is far better,

when doing any amount of threading, to use a threading tool with a special form cutter.

Sharpening such cutters requires only flat, top grinding, which does not alter the cutting

profile.

Carbide-Tipped Cutters and Cutter Forms

Carbide is a compound of carbon and a metal. In cutting tools, it is usually carbon and

tungsten. The hardness of carbide cutting materials approaches that of diamond. While

carbides permit easy machining of chilled cast iron, hard and tough steels, hard rubber,

Bakelite, glass, and other difficult or "unmachinable" materials, its primary use in

industry is for long production runs on ordinary steels. On such work, carbide-tipped tools

permit higher running speeds and much longer runs between resharpenings. The cutting

edge of carbide tools stands up 10 to 200 times as long as the edge of HSS tools (Figure

8.9).

The advantage of carbide is that it tolerates much higher heat than HSS or other alloys

so you can run at higher speeds. The disadvantage is that it is more brittle than HSS and

must ha

ve adequate support in the toolpost to prevent vibration and breakage.

Application Use Grade

Cast Iron Roughing cuts C-1

Non-ferrous, non-metallic, high-temperature

alloys

200 and 300 Series stainless steels

General purpose C-2*

Light finishing

Precision boring

Roughing cuts

General Purpose

C-3

C-4

C-5

C-6*

Alloy steels Finishing cuts C-7

400 Series stainless steel, high velocity Precision boring C-8

Table 8.1 Carbide Types and Cutting Tool Applications

8-5

For Assistance: Call Toll Free 1-800-476-4849

Page 36

Chapter 9

Setting Up Lathe Tools

After selecting a cutter, insert it in the toolholder. Allow the cutter bit to project just

enough to provide the necessary clearance for the cutting point. The closer the cutter is

to the toolpost, the more rigid the cutting edge. Allen-head capscrews hold the tool in the

toolpost. To assure maximum rigidity, don't let the tool extend too far beyond the end of

the toolpost turret.

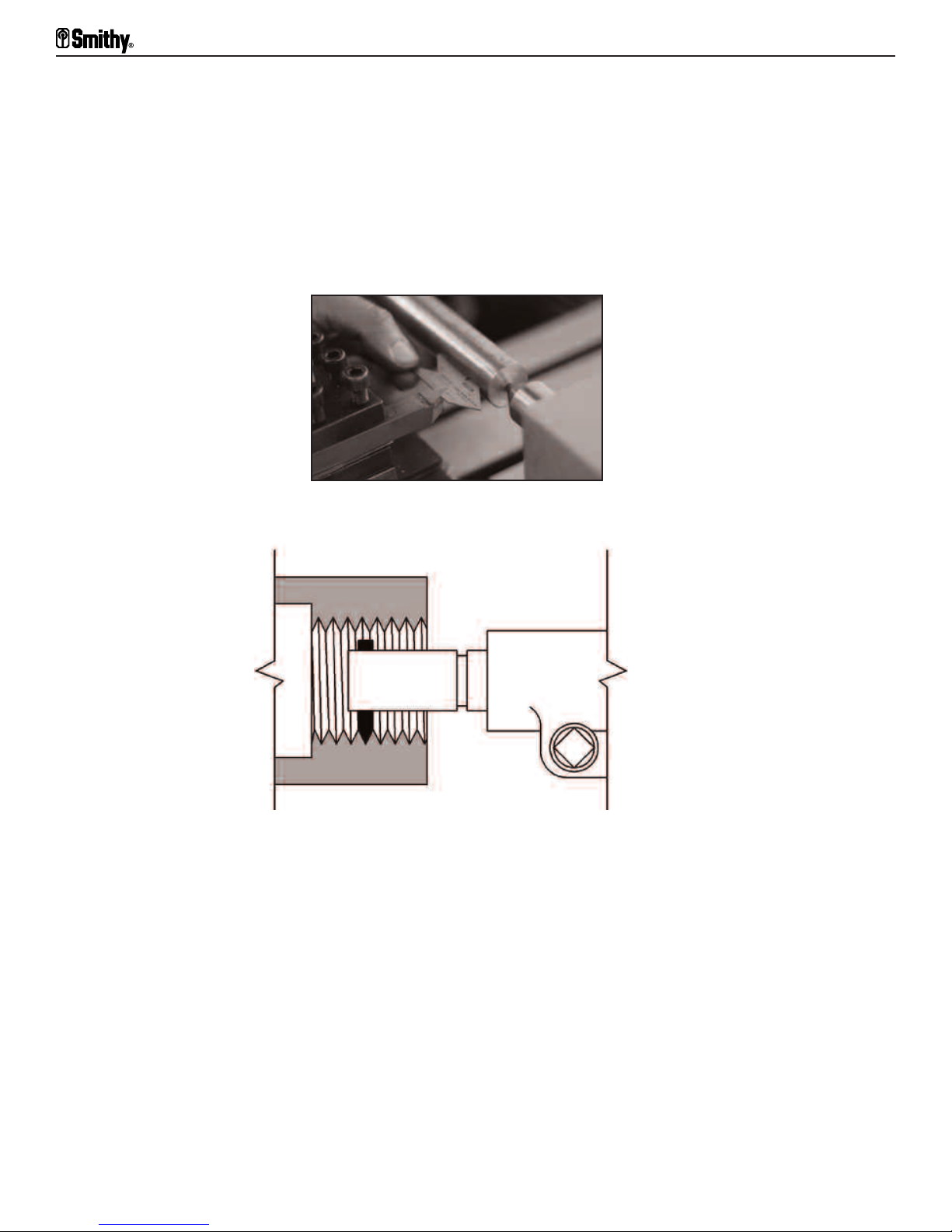

Cutting Tool Height

After inserting the cutting tool into the toolpost, adjust the height of the cutting edge in

relation to the lathe center. Insert a center in the tailstock. Then run the tool and center

together.

The cutting edge on the tool should meet the point on the center. It may be necessary

to use shims, which can be of various thicknesses and materials (Figure 9.1). Many

seasoned cutting-tool height machinists use pieces of old hacksa

toolbit is too high, shim the back of the toolbit. If it's too low, shim the entire tool.

w blades as shims. If the

Figure 9.1 Placing shims under the tool can correct cutting too height.

Turning Tools

For general turning operations, set the point of the cutter bit slightly above the

centerl

9.2, left).

Exceptions are soft brass, aluminum, and materials that tend to pull or tear. When

machining these materials, set the cutter on dead center (Figure 9.2, right).

ine of the work. I

n steel, the har

isit www

Or V

der the material, the less abo

.smithy.com

e center (Figur

v

e

9-1

Page 37

Midas 1220 LTD Operator’s Manual

Figure 9.2 The harder the steel (left),the less above center you set the cutter point.

For soft brass and aluminum (right), set the cutter on dead center.

When cutting toward the headstock on most turning and threading operations, swing the

compound rest to hold the shank of the toolholder at an angle. The angle should be

approximately 29-1/2° left of perpendicular to the line of centers, except for extremely

heavy, rough-forcing cuts close to the limits. For such work, use a straight-shanked tool

held perpendicular to the line of lathe centers in the right side of the toolpost. The tool

will tend to swing out of the cut rather than hog into the work if you reach a stalling

point.

Figure 9.3 The tool will swing out of the cut (left) rather than hog into the work (right)

if you reach a stalling point. Note the tool is in the right-hand side of the toolpost.

Threading Tools

eading tools should alw

Thr

l affect the thread profile (Figure 9.4).

below wi

9-2

l

y deviation above or

ys engage the work on dead center

a

. An

Figure 9.4 Threading tools engage the work on dead center.

For Assistance: Call Toll Free 1-800-476-4849

Page 38

9: Setting Up Lathe Tools

Cutoff, Thread Cutting and Facing Tools

For cutoff, thread cutting, and facing, feed the cutter to the work on dead center (Figure

9.5). For the beginner, the average feed should not exceed 0.002 inches per revolution

(ipr).

Chip Curve

Figure 9.5 Feed the cutter on dead center for cutoff, thread cutting and facing.

Boring and Inside Threading Tools

For boring and inside threading, the cutter point engages the work on dead center (Figure

9.6). For greater cutting efficiency, position the bar while parallel to the line of lathe

centers sufficient

ly below center to give the cutter a 14-1/2 degree approach angle. For

internal threading, grind the top face of the cutter to compensate for this angle, giving a

flat, true form top face.

Some machinists prefer to position the tool slightly above center when boring. With the

bit above center, if a tool chatters it deflects down into empty space instead of into the

workpiece.

Figure 9.6 For boring and inside threading, the cutter point is at dead center.

Or V

isit www

.smithy.com

9-3

Page 39

Chapter 10

Setting Up with Centers, Collets, and Chucks

Before setting work up on centers, make sure the spindle and tailstock centers align

accurately. Do this by inserting a center into the nose spindle and inserting the tailstock

center into the tailstock ram. Then move the tailstock toward the headstock until the

centers touch (Figure 10.1). You can correct any lateral alignment error by adjusting the

tailstock set over screws (Figure 4.8).

Figure 10.1 When aligning spindle and tailstock centers, move the

tailstock toward the headstock until the centers touch.

For most turning operations, work is held in the lathe between the lathe centers by means

of holes drilled in the ends of the stock to be machined. Your machining accuracy depends

primari

Locating these holes is called

ly on how precisely y

ou locate these holes at the center of the bar or block.

centering

.

Centering

You can improve centering greatly by first squaring or facing the ends of the workpiece

(Section 12.1). This gives you a true cross section in which to locate the centering holes.

First, chuck the stock in the appropriate chuck. Let the stock protrude about an inch.

Place a right-hand side tool (or a straight turning tool with a facing cutter) in the

ly adjust the cut

ul

toolpost. Car

the toolpost. If you don't do this, a small tit or projection will remain in the center of the

stock and perhaps cause the center drill to run off center.

Start your lathe on the slowest speed. Bring the tool into the cutting position against the

center of the workpiece. F

yourself, using the hand cr

end roughened by the hacksaw. After facing one end, reverse the work and face the

opposite end.

ef

ossf

ting edge so i

eed the tool f

eed. One or two light cuts is usually enough to true up an

t is exact

om the center of the stock outw

r

ly on center, then tighten it into

d, tow

ar

ard

You can center on round stock (Figure 10.2) with calipers, dividers, or special centering

10-1

For Assistance: Call Toll Free 1-800-476-4849

Page 40

10: Setting Up with Centers, Collets, and Chucks

instruments (Figure 10.3). Centering square or rectangular stock is done by scribing lines

from opposite corners. The intersection of these lines is the center (Figure 10.4).

Figure 10.2 Centering on round stock and

Figure 10.4 Centering on square or rectangular stock.

Figure 10.3 Use centering instruments include calipers and dividers.

After locating the center of each end, drive a starting depression for the drill into the stock

th a center punch. Check centering ac

wi

curacy by placing the workpiece between the

spindle and tailstock centers. Revolve the headstock slowly against the tip of a tool or a

piece of rigidly held chalk.

The chalk should touch just the high spots (Figure 10.5). If the center is off 0.002" or

more, correct the position of the center by repunching at an angle.

Chalk Marks

Chalk

Compound

Figure 10.5 When you revolve the headstock against a piece of chalk,

the chalk should just touch the high spots.

Next, drill and countersink the centers to conform to the profile of the lathe centers. This

is best done with a combination center drill/countersink held in the tailstock arbor chuck.

The centers now wi

l

e the lathe centers wi

l tak

Or V

isit www

thout pla

.smithy.com

y or chat

ter.

10-2

Page 41

Midas 1220 LTD Operator’s Manual

If a combination drill is not available, you can drill centers with a small drill and

countersink them with a drill of sufficient diameter ground to a 60° point. A 60° taper is

standard for lathe center points. Correct center depth is given in Figure 10.6. Take care

to get an accurate 60° countersink in the center (Figure 10.7).

Too Shallow

Correct Path

Too Deep

Figure 10.6 The correct depth of center is illustrated above.

If it's too deep (bottom), only sharp outer edges will contact the center

.

Center

Work

Hole

Work

Work

Lathe

A

Center

B

C

Point

Figure 10.7 Counterbore centers with a drill to a 60° point so they fit the lathe centers (A).

Too obtuse (B) or too acute (C) a counterbore will give insufficient bearing,

and destroy the lathe centers.

Mounting Work Between Centers

e the chuck from the lathe, bolt the faceplate to the spindle if l angle (Figure 10.8),

v

emo

R

and put in both headstock and tailstock centers. Fasten a lathe dog (Figure 10.9) to one

end of the work. For ease of operation, use a live or rotating center in the tailstock end

so you won't need lubrication.

Before centers starting the lathe, make sure the centers don't hold the workpiece too

tight

. Heat ma

ly

y cause the workpiece to expand, so w

tailstock center so the work turns freely but without end play.

If, after partially machining the workpiece, you find you must machine the stock under

the lathe dog, remove the workpiece from the lathe and place the lathe dog on the

machined end. Then turn this new tai

diameter or f

orm.

10-3

For Assistance: Call Toll Free 1-800-476-4849

lstock center end of the shaft down to the desir

atch for binding. Adjust the

ed

Page 42

10: Setting Up with Centers, Collets, and Chucks

Figure 10.8 Bolt the faceplate to the spindle flange

Using a Clamp Dog

Standard lathe dogs drive round, or near-round, shapes. Rectangular or near-rectangular

stock requires clamp dogs. In a properly made clamp dog, the under face of the heads

of tightening screws are convex and fit into concave seats, while the holes in the upper

bar are elongated. This design allows a firm grip of off-square shapes without bending

the screws. Top and bottom bars should also have V-notches to give a firm grip on

triangular or other odd-shaped stock. You can use clamp dogs or special V-jaw dogs also

to hold highly polished round bars.

Using Faceplates

For work setup, faceplates serv

centers. Second, they hold workpieces shaped so you can't chuck them or mount them

on centers.

Faceplates for driving workpieces on centers are generally small. They're notched and

slotted to receive the tail of the lathe or clamp dog, bolt drive, or other driving tool

(Figur

e10.9). F

aceplates f

die parts, for example) are usually larger and have varied designs. They may be

T-slotted, drilled all over, or slotted and drilled. Workpieces mount on such faceplates with

-slot or standar

T

d bolts, strap clamps, angle plates, or other standard setup tools.

e two purposes. First, they drive workpieces held between

or holding workpieces (irr

egularly shaped casting, machine, or

Figure 10.9 Fasten a lathe dog to one end of the work piece.

Or V

isit www

.smithy.com

10-4

Page 43

Midas 1220 LTD Operator’s Manual

Note: Before starting to machine work set up on centers, check to see the lathe dog tail

is free in the faceplate slot so it won't lift stock off its true line of centers, as in Figure

10.10. Also, be sure lathe centers fit closely into the center holes to eliminate side play

but not so tightly they bind. If you're working on a long workpiece, check it frequently to

be sure the center does not bind. Also, balance unbalanced setups with counterweights

to overcome any "throw" as the work revolves (Figure 10.11).

Tail of Lathe Dog

Figure 10.10 Make sure the lathe dog tail is free in the faceplate slot

so it won't lift off the true line of centers.

Figure 10.11 Counterweights can help with unbalanced setups.

Setting Up Work on a Mandrel

ou can machine cyl

Y

indrical or bor

by mounting them first on a mandrel (Figure 10.12). Then mount them between centers.

The solid mandrels, which are driven into the hole of the work-piece, must be tight

enough to turn the workpiece against the tool without slippage. Oil them lightly before

driving them into the workpiece. Otherwise, the workpiece may freeze to the mandrel,

making it impossible to r

emo

10-5

ed pipe work or cored castings too long to fit in a chuck

e the mandrel without damaging both workpiece and

v

For Assistance: Call Toll Free 1-800-476-4849

Page 44

10: Setting Up with Centers, Collets, and Chucks

mandrel. When removing a mandrel, drive it back out of, instead of through, the hole.

You can purchase hardened steel mandrels, which have a slight (0.003") ground taper

and an expanding collar, to facilitate mounting and demounting (Figure 10.13). Mandrels

with compressible ends for holding single or ganged pieces are also available. When a

workpiece is mounted on a mandrel, machine it as you would a solid shaft. You can drill

eccentric centers in mandrel ends to permit eccentric turning.

Figure 10.12 Mount workpieces too long for a chuck on a mandrel.

Figure 10.13 Hardened steel mandrels have a slight ground taper and expanding collar.

Steady Rests and Follow Rests

Rests are for setting up (1) work that is relatively long in proportion to its diameter or (2)

work whose dead end must be left f