Page 1

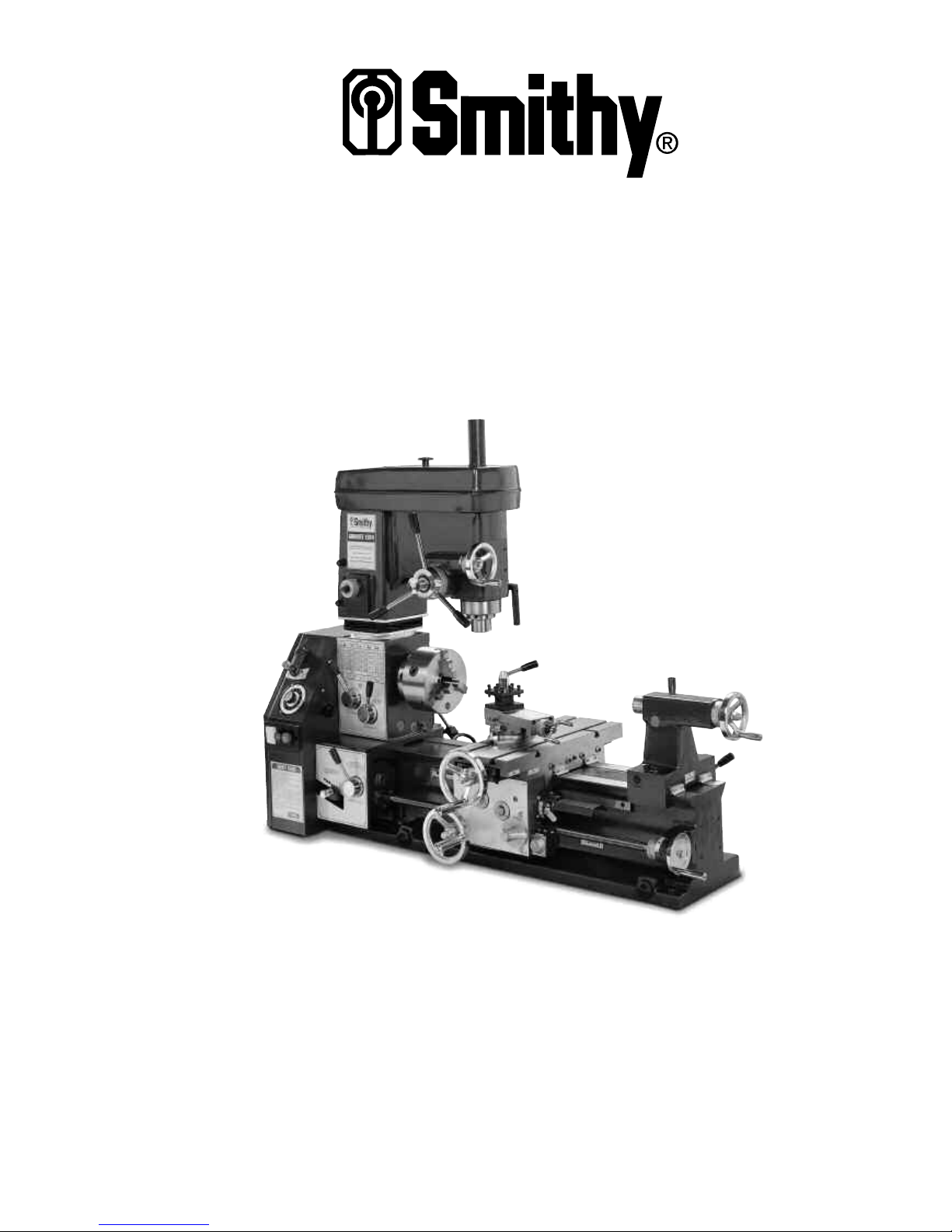

GRANITE 1300 SERIES

COMBINATION LATHE/MILL/DRILL

OPERATOR’S MANUAL

Updated April, 2008

170 Aprill Dr., Ann Arbor, MI, USA 48103

Toll Free 1-800-476-4849

www.smithy.com

Page 2

© 2008 Smithy Co. All rights reserved (Revision 3).

170 Aprill Dr., Ann Arbor, Michigan, USA 48103

Toll Free Hotline: 1-800-476-4849

Fax: 1-800-431-8892

International: 734-913-6700

International Fax: 734-913-6663

All images shown are from Granite Classic 1324 model.

All other images for other Granite models are specified.

All rights reserved. No part of this manual may be reproduced or transmitted in any form

by any means, electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of Smithy Co. For information on getting permission for

reprints and excerpts, comments, or suggestions, contact info@smithy.com

While every precaution has been taken in the preparation of this manual, Smithy Co. shall not

have any liability to any person or entity with respect to any loss or damage caused or

alleged to be caused directly or indirectly by the instructions contained in this manual.

Please see section on warranty and safety precautions before operating the machine.

Printed and bound in the United States of America.

Page 3

Table of Contents

Chapter 1: Introduction

Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Contact Information and Customer Information . . . . . . . . . . . . . . . .1-2

Chapter 2: Safety

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Symbols Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Shop Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Machine Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Chapter 3: Inventory Check List

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Items Mounted to your machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Items Packed in the larger Smithy Box . . . . . . . . . . . . . . . . . . . . . . .3-2

Items Packed in smaller Smity Box

. . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Items Packed in Plastic Bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Additional Items for GN-IMX Series . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Chapter 4: Machine Overview

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Major Features Identified . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Millhead Components and Functions . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Powerhead Components and Functions . . . . . . . . . . . . . . . . . . . . . .4-5

Pulley Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Carriage Asssembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Carriage Assembly - Compound Angle Toolpost . . . . . . . . . . . . . .4-11

Tailstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

For Granite MAX and IMX Series Machine . . . . . . . . . . . . . . . . . .4-13

Chapter 5: Preparing Your Machine For Operation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Assembly of Minor Components

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1

Drill Chuck and Arbor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1

Arbor Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Mill Spindle Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Cleaning and Lubricating Your Machine . . . . . . . . . . . . . . . . . . . . . .5-3

Lubrication Schedule

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Page 4

Ways . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Carriage Assembly - Saddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Carriage Assembly - Cross-Slide Table . . . . . . . . . . . . . . . . . . . . . . .5-6

Compound Angle Toolpost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Cross-Slide Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Leadscrew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Oil Drip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Quick Change Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Tailstock Barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Mill/Drill Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Adjusting Gibs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Carriage Assembly - Saddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Carriage Assembly - Cross-Slide Table . . . . . . . . . . . . . . . . . . . . . .5-10

Compound Angle Toolpost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

Tailstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Adjusting Backlash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Cross-Slide Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Cross-Slide Screw to the Front Screw Mount . . . . . . . . . . . . . . . .5-13

Cross-Slide Screw to Brass Nut and Nut to the Saddle . . . . . . . .5-14

Longitudinal Leadscrew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Half-Nut to Leadscrew Backlash . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Mill Feed Backlash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-16

Adjusting the fit between the Worm Gear

and Pinion Gear Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Adjusting the fit of the Quill Gear to the Quill Rack . . . . . . . . . . . .5-17

Adjusting Drive Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

Adjusting Millhead Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

Adjusting Lathe Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

Becoming Familiar with Operating Your Smithy Granite . . . . . . .5-20

Running in the Lathe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-21

Running in the Mill/Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-22

Chapter 6: Tooling Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Setting-up Lathe Turning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Lathe Spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Removing D1-4 Camlock Tooling from the Lathe Spindle . . . . . . . .6-2

Installing D1-4 Camlock Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Installing Tailstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Installing Compond Angle Toolpost . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Installing Tooling into the Compound Angle Toolpost . . . . . . . . . .

6-3

Setting-up Tooling in the Mill/Drill Spindle . . . . . . . . . . . . . . . . . . . .6-4

Aligning Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Installing R-8 Tooling with the Drawbar . . . . . . . . . . . . . . . . . . . . . .6-4

Removing R-8 Tooling from the Drawbar . . . . . . . . . . . . . . . . . . . . .6-5

Page 5

Chapter 7: Manual Operations

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Changing Between Lathe and Mill Operation . . . . . . . . . . . . . . . . . .7-1

Manual Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Mill/Drill Spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Coarse Feed Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Fine Feed Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Cross-Slide Table and Carriage Assembly . . . . . . . . . . . . . . . . . . . .7-3

Cross-Slide Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Carriage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Chapter 8: Speeds and Feeds

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Speed and Feed Rates Defined . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Setting the Spindle Rotational Speed . . . . . . . . . . . . . . . . . . . . . . . .8-2

High Range Speed Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Mid Range Speed Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Low Range Speed Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

Feed Chart Explained . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

Sample Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

Chapter 9: Powerfeeding

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Powerfeeding Defined . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

The Jog Knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

Step-by-Step Lathe Powerfeeding . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

Step-by-Step Mill Powerfeeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

Chapter 10: Threading

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

Leadscrew Safety Clutch Adjustment . . . . . . . . . . . . . . . . . . . . . . .10-1

Basic Threading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

Changing Gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

Cutting Inch Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

Using the Threading Dial to Cut Inch Threads . . . . . . . . . . . . . . . .10-5

Cutting Metric Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

Chapter 11: Machine Maintenance Schedule

Overview

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-1

Before Each Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

After Each Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

10 Hours (Daily) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-2

25 Hours (Daily) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

110 Hours (Yearly)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

Page 6

Chapter 12: Troubleshooting

Powerfeed and Thread Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

Carriage/Milling Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-2

Lathe Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-3

Milling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-4

Drilling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-4

Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-5

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

Chuck and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

Leadscrew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-8

Granite Series Leadscrew Handwheel

Fabrication and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-18

Chapter 13: Machine Specifications

Granite 1324 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

Granite 1340 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-3

Chapter 14: Diagrams and Parts List

Lathe Bed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

Lathe Bed and Handwheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-2

Motor and Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-3

Headstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-4

Headsctock Clutch Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-7

Pulley Box for Models Prior to May 2003 . . . . . . . . . . . . . . . . . . . .14-8

Pulley Box for Models After May 2003 . . . . . . . . . . . . . . . . . . . . . .14-9

Pulley Box (Prior to May 2003) List . . . . . . . . . . . . . . . . . . . . . . . . .14-10

Pulley Box (After May 2003) List . . . . . . . . . . . . . . . . . . . . . . . . . . .14-11

Mill/Drill Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-12

Compound Angle Toolpost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-17

Tailstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-19

Carriage Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-22

Apron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-25

Gearbox

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-30

Speed Reduction Pulley 40-300G . . . . . . . . . . . . . . . . . . . . . . . . . .14-34

Granite 1340 Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-35

Page 7

Appendix A: Machining Reference Guide

How to Determine Speeds and Feeds for

Lathe Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Turning Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Cutting Speed and Feed for High Speed Steel Tools . . . . . . . . . . .A-3

How to Determine Speeds and Feeds for Milling . . . . . . . . . . . . . .A-5

Feeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Up Milling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Down Milling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Feed Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

How to Form Blank Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

High Speed Steel Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Materials Other Than Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Bits for Turning and Machining Brass . . . . . . . . . . . . . . . . . . . . . . .A-9

Special Chip Craters and Chip Breakers . . . . . . . . . . . . . . . . . . . . .A-9

Using a Center Gauge to Check V-Thread Forms . . . . . . . . . . . . . .A-9

Acme or Other Special Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-10

Carbide-Tipped Cutters and Cutter Forms . . . . . . . . . . . . . . . . . . .A-10

When To Use Differnt Kinds of Endmills . . . . . . . . . . . . . . . . . . . . .A-11

Endmill Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-11

Plain Milling Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-12

Side Milling Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-13

Slitting Saws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-13

Angle Milling Cutters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-13

Form-Relieved Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-14

Flycuttters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-14

How to do Threading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-14

Cutting Right-hand Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-16

Cutting Left-hand Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-17

Cutting Multiple Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-17

Cutting Internal Threads

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-17

Cutting Speed From Internal Threads . . . . . . . . . . . . . . . . . . . . . . .A-18

Cutting Threads on a Taper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-18

Appendix B: Inch Feed Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Machine Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Page 8

Welcome

Congratulations on the purchase of your Smithy Granite machine. We welcome

you to the Smithy family. Smithy strives to provide you with the best in machine

tools. Please read through this manual carefully to ensure that you get the most

out of your Granite 3-in-1 lathe-mill-drill.

The purpose of this manual is to give beginning thru advanced machinists the

information needed to operate the Smithy Granite 1300 series. It will teach you

about the machine’

s parts and how to care for them. Most of the photographs

in this manual show the GN-1324 model. Individual model variations will be

noted as necessary. This manual is complete and current at the time of

printing*. In our continuing effort to bring you the best in machine tools,

changes may be made. Please visit us at

www.smithy.com for the latest

updates.

This manual—and any other manuals associated wi

th this Smithy machine—

should remain with the machine. If ownership changes, please include the Quick

Start Manual and the Operating Manual with the machine.

Please read the operating manual carefully and closely follow the procedures

described. If y

ou don’t understand how your machine works, you risk injury to

yourself or others. Misuse of the machine can lead to damaging it or your

pr

oject. To learn more about general machining practices, Smithy offers books

that meet the needs of machinists with varying levels of experience. We also

suggest your local library as a resource. Enrolling in a machining class will give

y

ou the best knowledge of machining.

*Last Update: 06/16/2008

Version 1.02

1-1

1

Introduction

Page 9

Granite 1300 Series Operator’s Manual

1-2

For

Assistance: Call

Toll Free 1-800-476-4849

Suggestions or Comments

We are interested in any suggestions you might have to improve our products

and services. Feel free to contact us with your suggestions by phone or in

writing. If you have comments about this operator’s manual, or if you have a

project you’d like to share with other Smithy owners, contact the Smithy

Company, P.O. Box 1517, Ann Arbor, MI 48106-1517. You can also e-mail

info@smithy.com 24 hours a day.

Questions?

If you have questions not covered in the manuals, please call our toll-free number:

11--880000--447766--44884499

Our friendly service technicians are available Monday through Friday from 8:00 a.m. to

5:00 p.m. Eastern Standard Time. Y

ou can also e-mail your questions 24 hours a day to

info@smithy.com.

Customer Information

Please r

ecor

d the information below about your Smithy machine. Having this information

readily available will save time if you need to contact Smithy for questions, service,

accessories, or replacement parts.

Model number:_____________________________________

Serial Number: ____________________________________

Purchase Date: ____________________________________

Delivery Date: ____________________________________

We look forward to a long working relationship with you, and thank you again

for putting your trust in Smithy.

Page 10

Overview

Smithy machines are proven to be safe and reliable; however, if abused or operated

improperly, any machine can cause injury. Please read this manual carefully before you

start machining. Proper use will create a safe working environment and prolong the life

of your machine.

Symbols Used In This Manual

In this manual, the symbols below draw attention to specific operating issues.

Potential hazard, unsafe

situation, or potential

equipment damage that ma

y

result in injury to yourself or

damage to your machine.

Hazardous situation which if not

avoided could r

esul

t in series

injury or death.

P

otential hazard, unsafe

situation, or equipment damage

could result in death or serious

injury

.

Alerts user to helpful and proper

operating instructions.

2

Safety

CAUTION

DANGER

WARNING

! NOTICE !

2-1

Or V

isit www

.smithy.com

Page 11

Shop Safety Rules

Your workshop is only as safe as you make it. Take responsibility for the safety of those

who use or visit it. This list of rules is by no means complete, so remember that common

sense is a must.

Smithy strongly discourages the use of casters or wheels on metal-working machine

benches. The weight of the machine could result in the bench tipping while being moved.

Once the machine is mounted, consider your workbench to be permanent. If you must

move the machine, first remove it from the bench

1. Read this manual thoroughly before operating your machine. Don’t try to do

more than you or your machine can handle. Understand the hazards of operating a

machine tool. I

n particular

, remember never to change speeds or setups until the machine

is completely stopped and nev

er operate it without first rolling up your sleeves.

2. Wear proper clothing. Avoid loose-fi

tting clothes, gloves, neckties, or jewelry that

could get caught in moving parts. If you have long hair, tie it up or otherwise keep it from

getting into the machine. Always wear non-slip footwear.

3. Protect yourself. Use ANSI approved safety glasses, goggles, or a face shield at all

times. Use safety glasses designed for machinery operation; regular glasses will not do.

Have extras available for visitors. Know when to wear a face mask or earplugs as well.

4.

Keep your work area clean and organized.

Clut

tered work areas and benches

invite accidents. Have a place for everything and put everything in its place.

5. Childproof your work area and keep children away from the machine while

it is in use. Childproof your shop with padlocks, master switches, and starter keys or

stor

e the machine wher

e chi

ldr

en do not ha

ve access to it.

6. Never operate your machine under the influence of drugs and alcohol.

7. Keep track of tools. Remove adjusting keys and wrenches from the machine before

operating. A chuck key or misplaced Allen wrench can be a safety hazard.

8.

Avoid accidental starts. Turn the switch to the

OFF posi

tion before plugging in the

machine. Turn the speed dial to zero before starting your machine.

9. Ground your machine. The machine has a three-conductor cord and three-prong,

gr

ounding-t

ype plug. Nev

er connect the power supply without proper grounding

10. Keep your mind on your work. By paying attention to what you are doing and

avoiding distractions you will spend many safe, enjoyable hours in your workshop.

11. Never leave your machine running unattended.

DANGER

Granite 1300 Series Operator’s Manual

2-2

For

Assistance: Call

Toll Free 1-800-476-4849

WARNING

Page 12

Machine Safety Rules

1. Stop the machine before servicing. Stop the machine before making changes,

removing debris, or measuring your work.

2. Don’t over reach. Don’t reach over the machine when it’s operating. Keep your hands

out of the way.

3. Turn the switch OFF. Turn the switch to off before plugging in the machine. Turn

the speed dial to zero before starting your machine.

4. Use proper tooling. Use only recommended accessories and understand how they

should be used before trying them out. Don’t try to make a tool into something it isn’t or

attempt to use a tool in inappropriate ways. Remember to always use the proper tooling

for the material you are cutting. Reference a general machining guide such as Machinist

Ready Reference for recommended tooling for your material.

5.

Secure your work.

Before starting y

our machine, be certain that your workpiece is

properly and securely mounted. Flying metal is dangerous!

6. Do not run you machine beyond its limits of travel. Befor

e starting your

pr

oject, ensure that your work area does not go beyond the limits of travel on your

machine. Going beyond the limits of travel will cause serious damage to your machine

which wi

ll not be covered by your warranty.

7. Run your machine at recommended spindle speeds and feed rates. Always

cut at the r

ecommended speed and feed rates for the type of metal that you are cutting

for optimum performance. Do not begin your cut until the machine has reached the full

and proper speed.

8.

Do not change the direction of the spindle rotation or leadscrew rotation

while your machine is running.

Changing the rotation direction of the spindle or

leadscrew while your machine is running could cause serious damage to your machine.

9. Do not stop the spindle by hand. Always use your on/off switch to stop the spindle from rotating.

10. Do not clear chips by hand. Metal chips are very sharp and can easily cut your

hand. Use a brush to clear chips.

11. Protect bed ways. When removing or installing tooling from your lathe spindle,

place a piece of wood or other material across the bed to protect the ways from being

damaged if the tooling is dropped.

12.

Keep your machine maintained.

Alw

a

ys r

eplace worn or damaged parts bef

ore

using y

our machine to pr

event damage to your machine or the operator. Follow the

maintenance schedule outline in this manual for peak performance.

2: Safety

WARNING

2-3

Or V

isit www

.smithy.com

Page 13

Overview

It is a good idea to take inventory of the parts of your machine soon after it is

unpacked. By doing so, you can quickly determine if any parts are missing. In addition,

should you find it necessary to return the machine to Smithy for any reason, the

inventory will ensure that all the parts you received have been returned.

A third reason to perform an inventory is to become familiar with the names of all of

the parts of your Smithy machine. To aid with this, the following parts lists have

individual photos of the items listed.

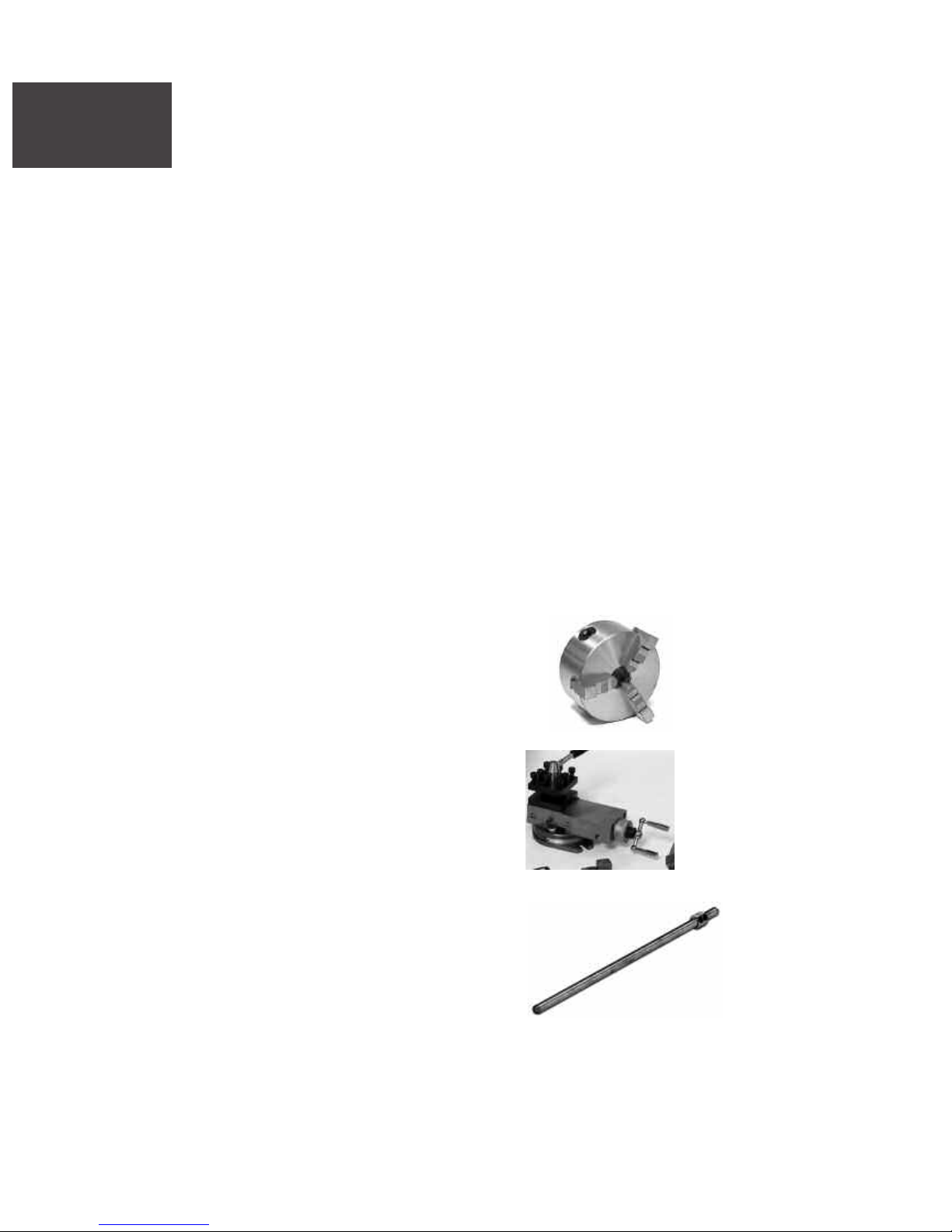

Items Mounted To Your Machine

The items listed below are shipped mounted on the Smithy Granite. Kindly check if the

following items are present. Use the box before the item as your reference.

! 6” 3 Jaw Chuck

Part # G03046

Quantity 1

! Compound Angle Toolpost

Part # 45-110

Quanti

t

y 1

! 7/16” Drawbar

Part # K99-168

Quanti

t

y 1

3

Inventory Check List

3-1

For

Assistance: Call

Toll Free 1-800-476-4849

Page 14

3-2

Or V

isit www

.smithy.com

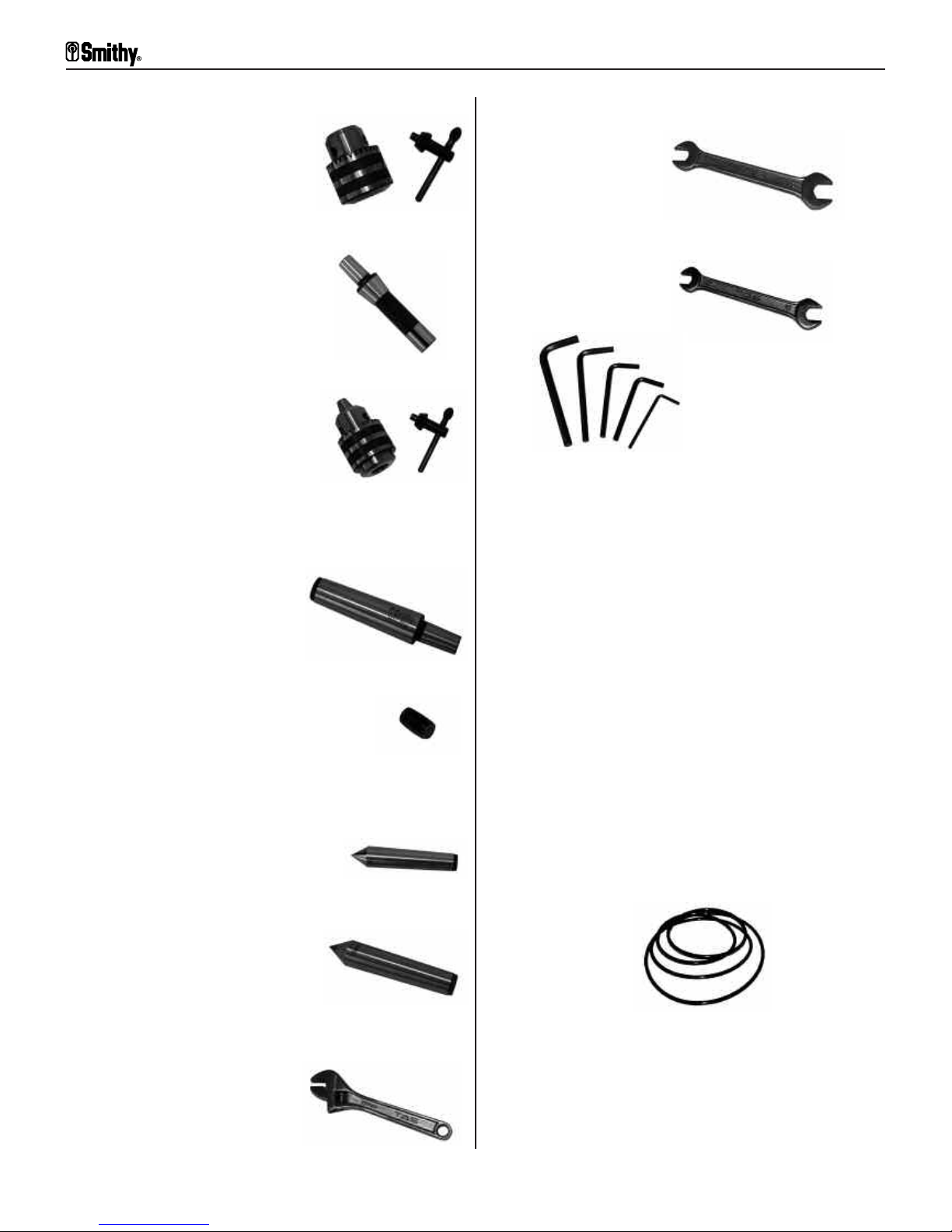

Items Packed in the Larger Smithy Box

The following items are packed in the larger of the two Smithy boxes.

3: Inventory Check List

! Air Mask

Part # 15-020

Quantity 1

! Protective Goggles

Part # 15-015

Quantity 1

! Ear Plugs

Part # 15-025

Quantity 1 Set

! Oil Can

Part # 80-100

Quanti

ty 1

! 7/16” T-Slot Nuts

P

art # 35-105

Quanti

ty 2

! Vise, 0-90º Adjustable Angle

Part # 32-110

Quantity 1

! End Mill, 4 FL HSS

1/4” w/3/8”

Shank

Part # 50-402

Quantity 1

! End Mill, 4 FL HSS

3/8” w/3/8” Shank

Part # 50-406

Quantity 1

! End Mill, 4 FL HSS

1/2” w/3/8” Shank

Part # 50-410

Quantity 1

! End Mill

Adapter R-8

P

art # 65-028

Quantity 1

! Lathe Bit Set

P

art # 43-000

Quantity 1 Set

(AR-8,AL-8,BR-8,

BL

-8 & E8)

! Lathe Chuck Key

Part # C30532

Quantity 1

Page 15

! Drill Chuck,

J

T3, 0.8-16 mm

with key

(for millhead)

Part # 72-003

Quantity 1

! Drill Chuck Arbor,

R-8/JT3

Part # 73-080

Quantity 1

! Drill Chuck,

JT33, 0.8-13 mm

with key

(for tailstock)

Part #72-001

Quanti

ty 1

! Drill Chuck Arbor,

MT3/JT33

Part # C30523

Quantity 1

! Arbor Plug

(M12 x 1.5 x 20 mm

setscrew)

Part # S12898

Quantity 1

! MT3 Dead Center

Part #41-003

Quantity 1

! MT4 Dead Center

Part # 41-004

Quantity 1

! 6” Adjustable Wrench

Part # G20006

Quantity 1

! 13/16 mm Open End

W

rench

Part # G20131

Quantity 1

! 10/12 mm Open End

Wrench

Part # G20101

Quantity 1

! Allen Wrench, 3 mm

Part # G20003

Quantity 1

! Allen Wrench, 4 mm

Part # C30540

Quantity 1

! Allen Wrench, 5 mm

Part # C30542

Quantity 1

! Allen Wrench, 8 mm

P

art # C30536

Quantity 1

! Allen Wrench, 10 mm

Part # G20002

Quantity 1

! Belt Set Millhead Belt

(Shipped On Machine)

Part # G05042 -A900 Or

P

art # G05042A 1/2”

Quantity 1

3-3

For

Assistance: Call

Toll Free 1-800-476-4849

Granite 1300 Series Operator’s Manual

Page 16

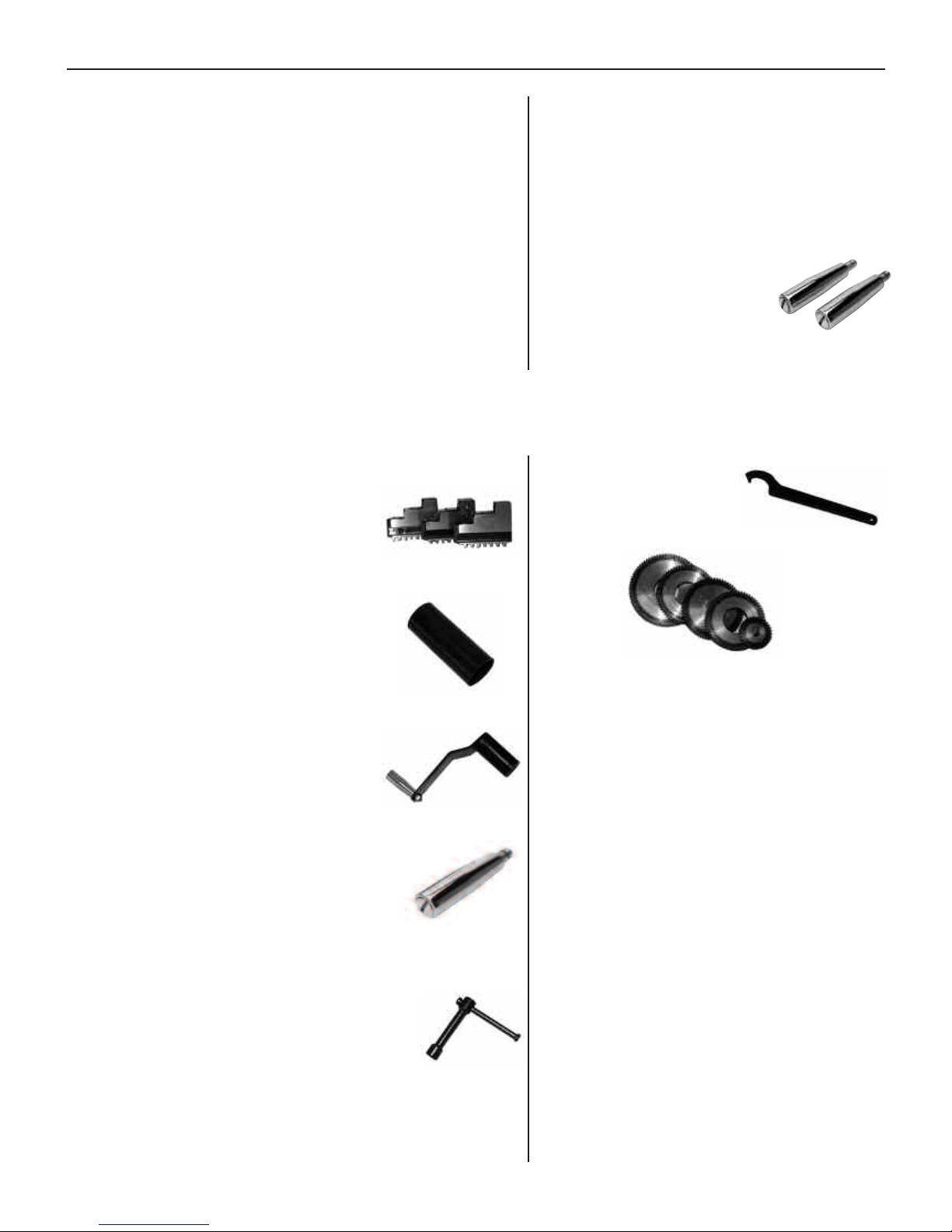

3: Inventory Check List

3-4

Or V

isit www

.smithy.com

! S

pindle to Speed Reduction

Pulley Belt

Part # G02043-A630 Or

Part # G02043A 1/2” x 27

Quantity 1

! Speed Reduction Pulley To Motor

Pulley Belt

Part # G02034-A710 Or

Part# G02034A-1/2” X 30

Quantity 1

! Outside Jaws for

Lathe Chuck

Part #

Quantity 1

! Spindle Cover

Part # G05057

Quantity 1

! Millhead Crank

Part # G05123

Quantity 1

! Handle for

Leadscrew

Handwheel

P

art # G01028

Quanti

t

y 1

! Wrench, Compound

Angle Toolpost

Part # G06039

Quantity 1

! Spanner Wrench

Part # G20001

Quantity 1

! Metric Gear Set

Gear,33 Teeth

Part # G10116

Quantity 1

! Gear,63 Teeth

P

art # G10117

Quantity 1

! Gear,64 Teeth

Part # G10118

Quantity 1

! Gear,66 Teeth

Part # G10119

Quantity 1

! Gear,80 Teeth

P

art # G10120

Quantity 1

! Spindle to Motor Pulley Belt

(

Shipped On Machine)

Part # G03020 Or

Part # G03020A-1/2” x 41”

Quantity 1

! Crossfeed Handle &

Rack & Pinion

Travel Handle

Part # G08031

Quantity 2

Items Packed in Smaller Smithy Box

Page 17

! DVD, Machine

Tool Basics

Part # 12-003

Quantity 1

! Manual Cover

Part # 83-942

Quantity 1

! Quick Change

Toolpost*

(Mounted)

Part # 45-271

Quanti

ty 1

! Chuck Guard

(Mounted)

Part # 15-610

Quantity 1

! Operator’s Manual

Part # 83-950

Quantity 1

! Live Center**

(Large Box)

Part # 41-103

Quantity 1

! 3” Superlock Vise***

(Large Box)

Part # K99-310

Quantity 1

Items Packed in Plastic Bag

Additional Items for GN-IMX Series

* Quick Change Toolpost replaces standard turret for IMX series.

** Live Center additional item for IMX series.

***

Superlock Vise r

eplaces angle vise f

or IMS series.

Missing Items?

If y

ou find that an i

tem is missing or def

ectiv

e from your Quick Start Tool Pack

Call Us TOLL FREE 1-800-476-4849

or send an e-mail to info@smithy.com

within 30 days of receiving your machine so that we may assist you immediately.

Our sales and service technicians are available 8am to 5pm ET, Mondays to Fridays.

3-5

For

Assistance: Call

Toll Free 1-800-476-4849

Granite 1300 Series Operator’s Manual

Page 18

4-1

Or V

isit www

.smithy.com

Overview

This chapter will help you to familiarize yourself with the Smithy Granite 1300 models and

standard accessories. Figures 4.1 through 4.15 identify the major components and

functions of your machine. The photographs in this section depict a Granite 1324 model.

Distinguishing features are noted.

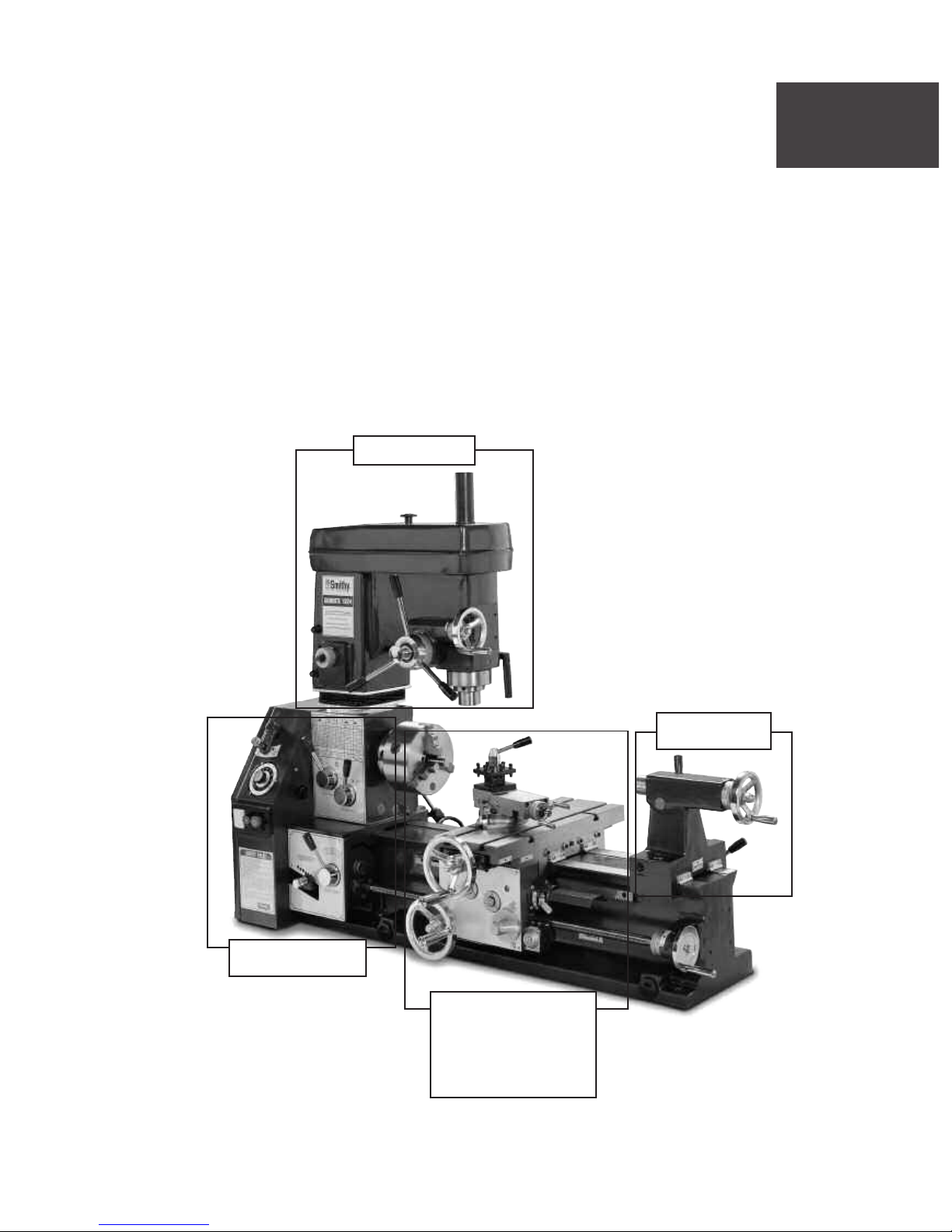

Major Features Identified

4

Machine Overview

Millhead

Powerhead

Carriage

Assembly &

Compound

Angle Toolpost

Figure 4.1 Granite 1324 Front View

Tailstock

Page 19

Figure 4.2 Granite 1324 Back View

Tailstock

Millhead

Carriage

Assembly

Motor

Assembly

Granite 1300 Series Operator’s Manual

4-2

For

Assistance: Call

Toll Free 1-800-476-4849

Page 20

Millhead Components & Functions

The photos below show the front and back of the millhead of the Smithy Granite machine.

The millhead holds the tooling necessary to perform milling and drilling operations. The

following section identifies the components and functions of the millhead.

A. Spindle Cover - The spindle cover protects the spindle from dust and debris. It also

protects the operator from injury. The spindle cover should be in place whenever the

machine is in operation. The drawbar is located under the spindle cover.

B. Millhead Cover - The Mi

l

lhead co

v

er pr

otects the belt and pulleys of the millhead.

The co

v

er should always be in place when the machine is in operation.

C. Quill Lock - The quill lock locks the mill/drill quill in place during a horizontal milling

operation or while changing tools.

D. Mill/Drill Spindle - The mi

l

l dri

l

l spindle is an R-8 taper. It holds and rotates the the

tool

ing used during milling and drilling operation. The spindle also moves in and out of

the millhead quill. The quill is an internal part which is not seen in this picture.

E. Drill Press Handles - The drill press handles move the quill in and out of the mill

head during a dri

l

l

ing operation. Rotating the handles in a clockwise direction moves the

qui

l

l downward, out of the millhead casting.

F. Coarse Feed/Fine Feed Clutch - Pulling out the coarse feed/fine feed clutch knob

engages the drill press handles/coarse feed. Pressing the knob in engages drill/mill fine

feed hand wheel. To easily engage/disengage the clutch, rotate the drill press handles

slight

ly while pulling/pushing the knob.

A

B

C

D

E

F

G

H

I

J

Figure 4.3 Granite Millhead (Front & Back)

4: Machine Overview

4-3

Or V

isit www

.smithy.com

Page 21

G. Drill/Mill Fine Feed Handwheel - The handwheel controls the fine feed movement

of the quill in and out of the millhead.

H. Height Adjustment Drive - The height adjustment drive works with the millhead

crank to raise and lower the millhead. Insert the millhead crank over the stud, as in

Figure 4.4, rotate clockwise to raise the millhead and counter clockwise to lower the

millhead.

One revolution of the crank handle will move the millhead 0.25 inches.

I. Millhead Locking Studs - The locking studs secure the mi

llhead in posi

tion. Insert

the mi

llhead crank over the upper stud, rotate counterclockwise to unlock the stud.

Repeat the process on the lower stud. Position the millhead in the desired position and

lock BOTH locking studs before starting your machine.

J. Bellows - Bellows keep debris off of the Z-Axis column and rack.

Figure 4.4 Adjusting Millhead Height

Granite 1300 Series Operator’s Manual

4-4

For

Assistance: Call

Toll Free 1-800-476-4849

Page 22

Powerhead Components & Functions

A. Lathe/Mill Clutch - This clutch engages the mi

ll portion of the Smith

y Granite LatheMill-Drill when pulled out and moved to the left. When moved to the right the lathe is

engaged. Center position is neutral.

B. Speed Dial - The speed dial contr

ols the motor rpm. Rotating clockwise increases the

speed.

C. Forward/Reverse & On/Off Switch - The red toggle button underneath the yellow

cover reverses the direction of the motor. The green middle button is the “power-on”

but

ton. The large red button is the stop button and cuts power to the machine.

D. Powerfeed Function Lever - Moving the lever to the left, powers the lathe

powerfeed. Moving the lever to the right powers the mill powerfeed.

E. Leadscrew Rotation Direction Handle - Positioning this handle to the right

causes the leadscrew to rotate clockwise. Positioning to the left causes the leadscrew to

r

otate counter

clockwise.

F. Selector Lever 1-7 - Used in conjunction with Selector Lever I-III to set feed rate or

pitch setting for cutting threads.

G. Selector Lever I-III - Used in conjunction wi

th S

elector Lev

er I

-7 to set f

eed r

ate

or pi

tch set

ting f

or cut

ting threads.

H. Jog Knob - Assists in meshing gears inside the quick change gear box which is

controlled by selector levers 1-7 and I-III. Rotating the knob helps align gears

I. Oil Level/Sight Glass - Normal oi

l lev

el is at the hal

f w

ay point, add oil if the level

of oi

l in the sight glass dr

ops below this level.

J. Quick Change Gear Box - Houses the gears that determine f

eed r

ates and gear

settings for cutting threads.

Figure 4.5 Granite Powerhead Parts (Front View)

A

B

C

D

E

F

G

H

I

J

4: Machine Overview

4-5

Or V

isit www

.smithy.com

Page 23

A. Oil Fill Port - Located direct

ly abo

ve the motor, it holds 8-10 oz of 30 weight oil.

Remove the screw to add oil as necessary.

B. Belt Tension - Mo

ves the motor pulley up and down releasing tension on the belts.

Pull the lever down to loosen the tension on the belt and push the lever up to add

tension to the belts.

C. DC Motor - Runs on standard 110 volt power.

A

B

C

Figure 4.6 Granite Powerhead Parts (Back View)

Granite 1300 Series Operator’s Manual

4-6

For

Assistance: Call

Toll Free 1-800-476-4849

Page 24

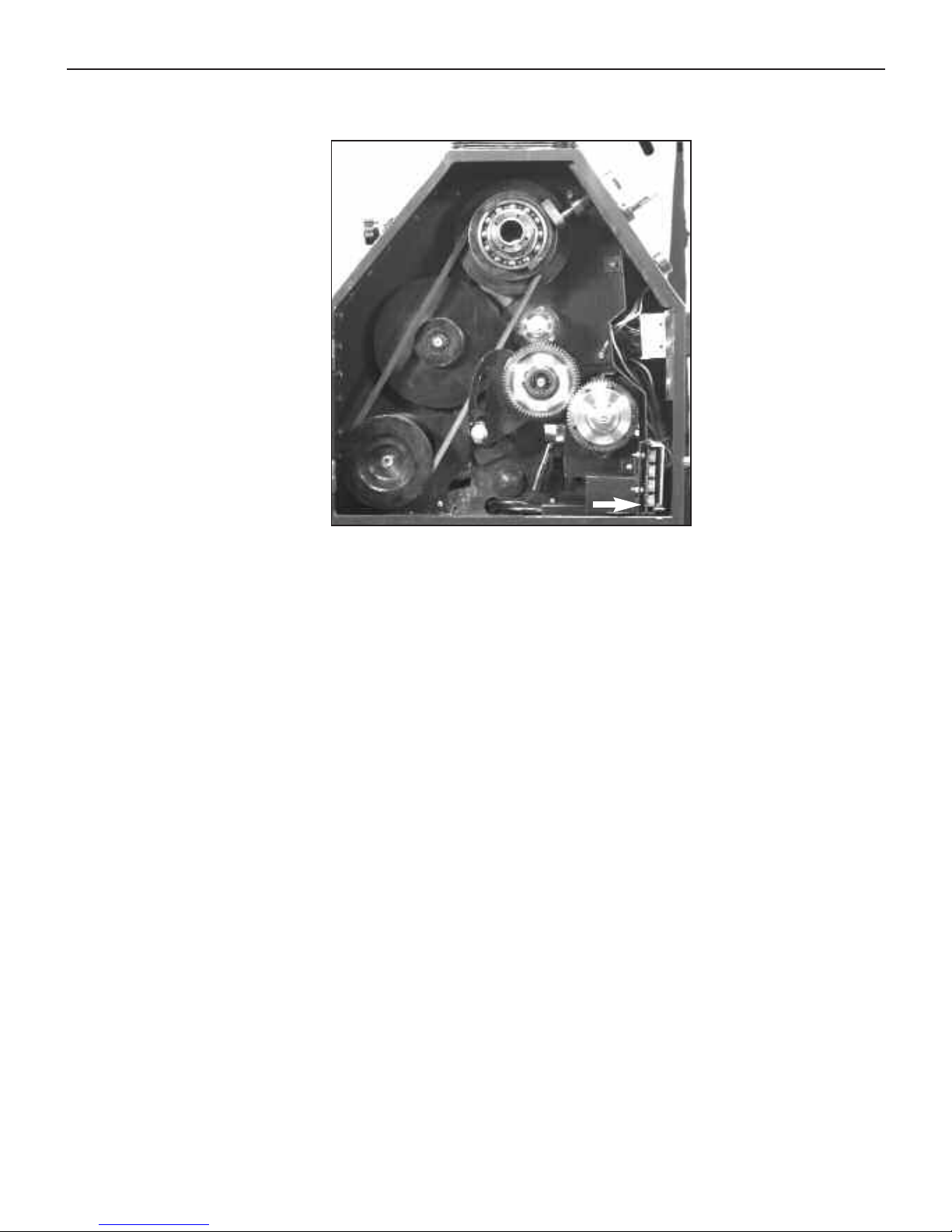

Pulley Box

The pulley box houses the drive pulleys, gears and power components.

L-1. Motor Pulley - A three-step pulley attached to the shaft of the motor.

L-2. Speed Reduction Pulley - Sits between the motor and spindle pulley and is used

for low speed operations when increased torque is desired.

L-3. Spindle Pulley - A two-step pulley attached to the main lathe spindle.

L-4. Change Gear A - A 30-tooth gear instal

led at the f

actory

. The change gears only

need to be reconfigured when cutting metric threads.

L-5. Change Gear B - A 60 tooth gear installed at the factory. The change gears only

need to be reconfigured when cutting metric threads.

L-6. Change Gear C - A 66

tooth gear that rides behind change gear B (60 tooth gear)

and is instal

led at the factory. The change gears only need to be reconfigured when

cutting metric threads.

L-7. Change Gear D - A 60 tooth gear instal

led at the f

actory

.

L-8. SCR Module - Converts the AC power coming into the machine to DC power for the

motor.

L-9. Inch/Metric Selector - Used when cutting threads. Pull the lever out toward the

oper

ator when cut

ting metric threads. When cutting inch (SAE) threads, make sure the

lev

er is pushed in toward the machine.

Figure 4.7 Granite Pulley Box (Inside)

L-1

L-2

L-3

L-8

L-4

L-5

L-6

L-7

L-9

L-10

4: Machine Overview

4-7

Or V

isit www

.smithy.com

Page 25

L-10. Leadscrew Clutch- Is designed to slip to reduce damage to the machine

apron if the carriage is accidentally run into the head of the machine.

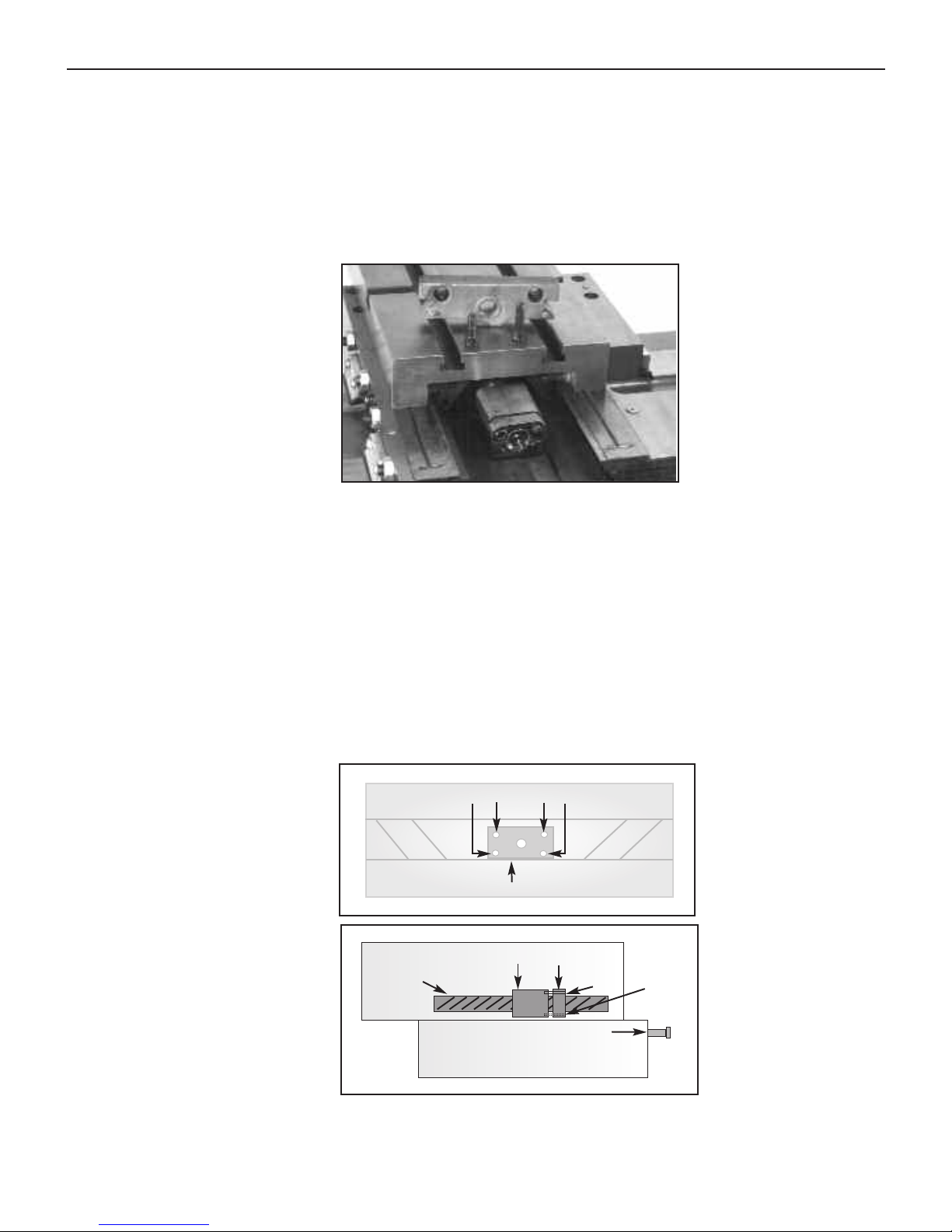

Carriage Assembly

The carriage assembly consists of:

• Crossslide table

• Carriage; the lower portion of the table that rides on the bed ways,

• Apron; the portion that hangs from the cross-slide table in front of the

machine.

The carriage moves by hand or by power along the bed ways. Its function is to support

the cutting tool rigidly while in the lathe mode and to secure the workpiece while in the

mill mode. The carriage can be locked into place with the lock found on the back of the

carriage.

The figure to the above right identifies and defines the major components of the carriage

assembly.

A. Cross-SlideTable - The top portion of the carriage assembly. It supports the

compound angle toolpost (not pictured) which holds the lathe cutters and tooling. The

table also supports y

our workpiece when oper

ating the mill. The cross-slide table has four,

7/16” sized t-slots for securing tooling and mounting workpieces.

! NOTICE !

There is a neutral position with this selector. Be sure that it is completey

engaged in either the metric or inch mode before you begin your threading

operation.

Figure 4.8 Granite Carriage Assembly

A

B

C

D

E

F

G

H

I

Granite 1300 Series Operator’s Manual

4-8

For

Assistance: Call

Toll Free 1-800-476-4849

Page 26

B. Cross-Slide Handwheel - This handwheel moves the table toward and away from

the operator along the Y-Axis. Rotating the handwheel clockwise moves the table away

from the operator while moving it counterclockwise moves the table toward the operator.

C. Longitudinal Handwheel - This handwheel is located at the bottom left of the

carriage assembly. Manually rotating the handwheel clockwise will move the carriage

assembly along the X-Axis towards the tailstock end of the machine. Rotating the

handwheel counter clockwise will move the the carriage assembly towards the headstock

end of the machine.One revolution moves the assembly approximately .040”.

NOTE:

This handwheel is for coarse movements only. Use the handwheel at the end of

the leadscrew for fine movement (0.001”)

D. Half-Nut Engagement Lever - This lever closes the half-nut on to the leadscrew.

When the half-nut is engaged, in the down position, the table assembly will be powered

to move right and left along the X-Axis leadscrew.

E. Longitudinal and Lateral Powerfeed Selector - This selector determines whether

the carriage will be power

ed to move along the X-Axis (longitudinal axis) or the Y-Axis

(lateral axis). When the lever is in the upper position the table will move along the Y-Axis.

When moved into the lower position, the table will move along the X-Axis. Center

posi

tion is neutral.

F. Threading Dial - The threading dial is used to coor

dinate consecutive cuts when

cut

ting threads. Restarting each cut from the same point on the dial ensures that each

cut follows the same path, leading to accurately machined threads.

G. Saddle - The saddle supports the cr

oss-sl

ide table and mo

v

es along the X

-

Axis of the

machine.

H. Apron - The apron houses the gear mechanism for the X and Y-Axis powerfeed.

! NOTICE !

The hal

f-nut engagement lever is only engaged for rapid

travel or threading operations.

! NOTICE !

The threading dial can only be used when cutting inch

(S

AE) threads.

4: Machine Overview

4-9

Or V

isit www

.smithy.com

Page 27

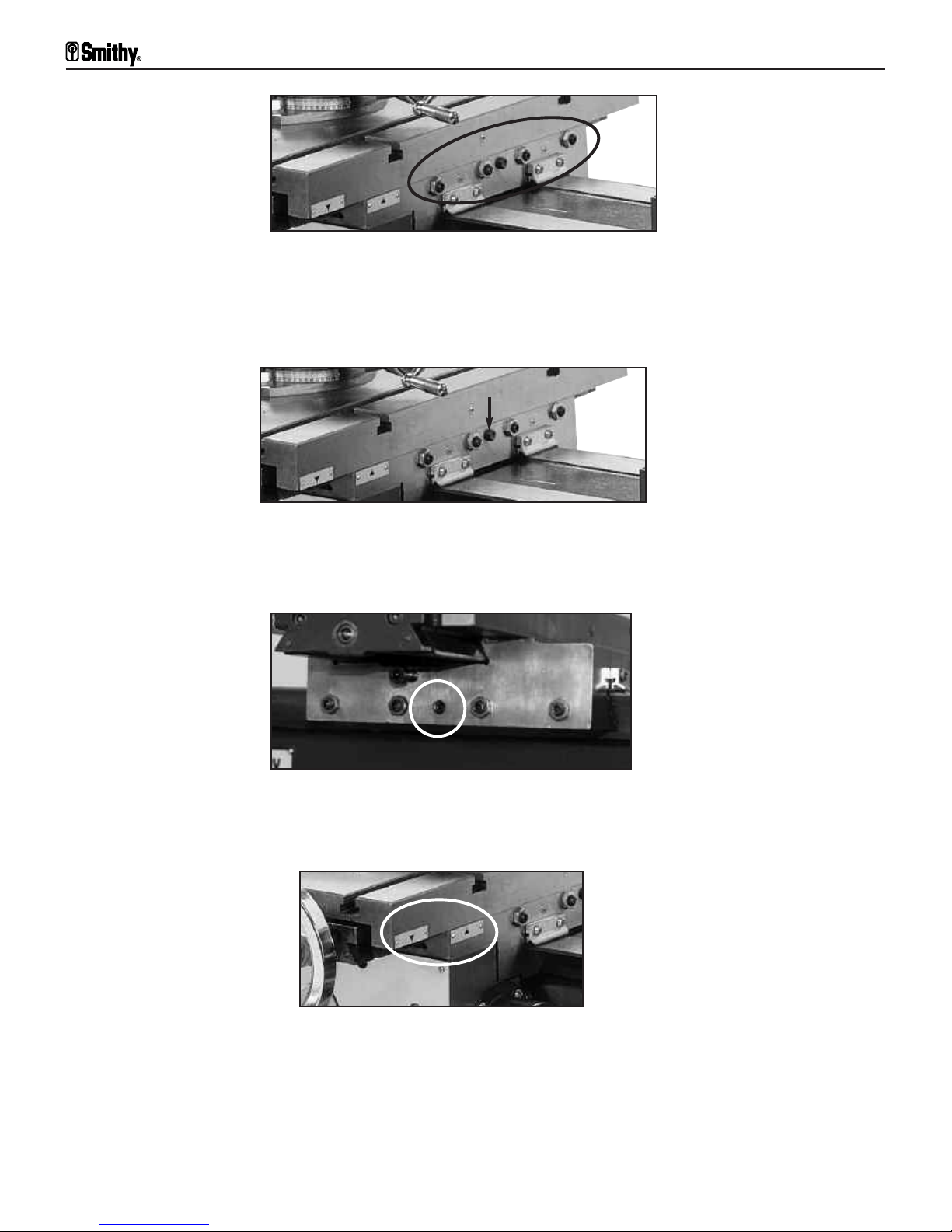

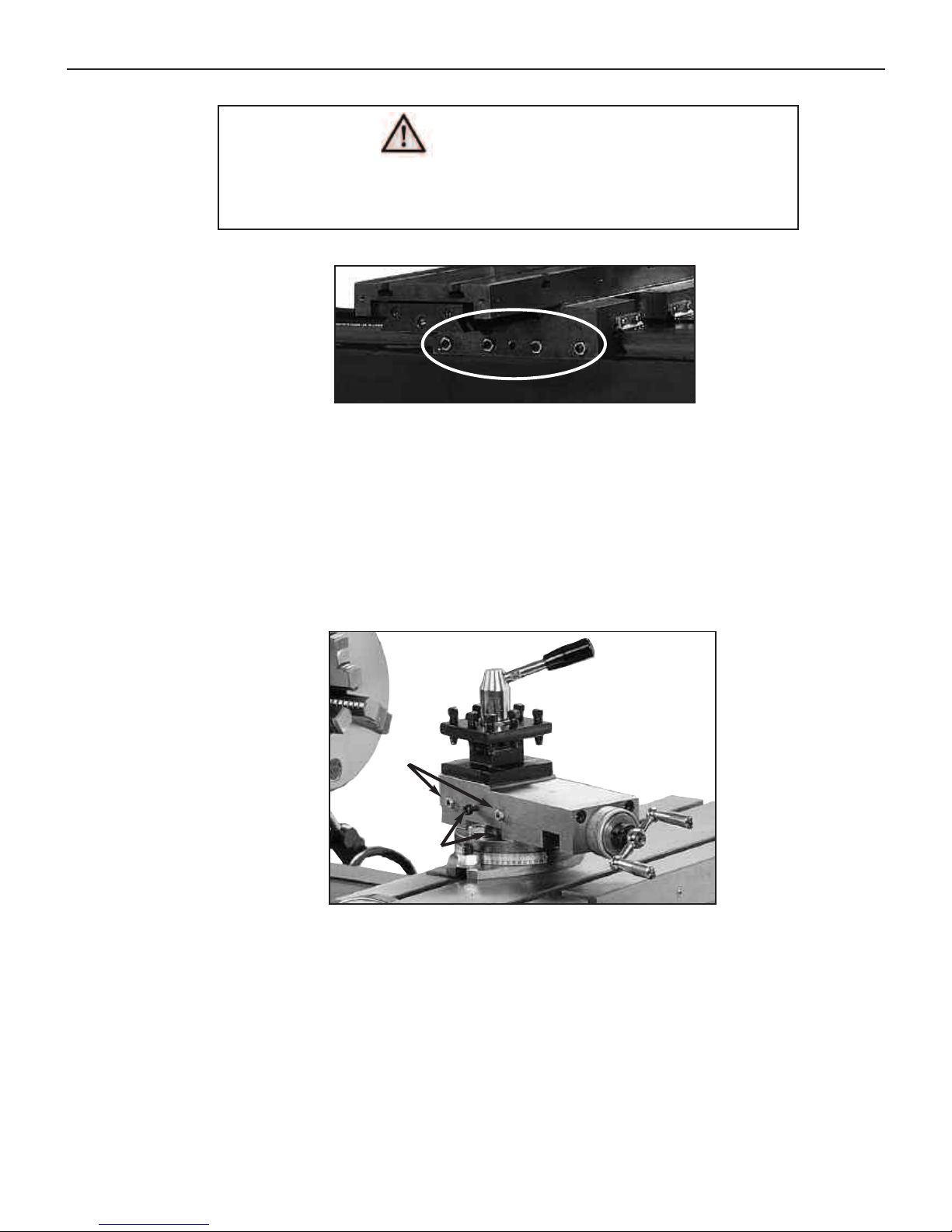

I. Carriage Gib Adjustment Screws - These screws press a small metal plate (the gib)

to the ways of the bed, increasing or decreasing the tension when moving the cross-slide

assembly. (Figure 4.9)

J. Carriage Lock (Y-Axis) - is an M8 screw. Turning the screw clockwise will prohibit

movement of the carriage along the Y-Axis. (Figure 4.10)

K. Carriage Lock X-Axis - is an M8 screw located on the back side of the carriage.

Turning this screw clockwise locks the carriage to the bedways.

L. Travel Indicators - mark the limit of travel on the crossfeed table. Running the top

portion of the indicator located on the tai

lstock side of the cr

oss-sl

ide table past the lower

indicator on the bot

tom portion of the table (carriage) wi

ll cause serious damage to your

machine.

Figure 4.9 Granite Carriage Gib Adjustment Screws (Quantity 4)

Figure 4.11 Granite Carriage Lock X-Axis (Rear View)

Figure 4.12 Granite Carriage Travel Indicators

Figure 4.10 Granite Carriage Lock Y-Axis

Granite 1300 Series Operator’s Manual

4-10

For

Assistance: Call

Toll Free 1-800-476-4849

Page 28

M. Carriage Gib Adjustments Screws - when screwed in, these screws press a small

metal plate (the gib) to the ways of the bed, incr

easing or decreasing the tension when

moving the carriage assembly along the bed ways.

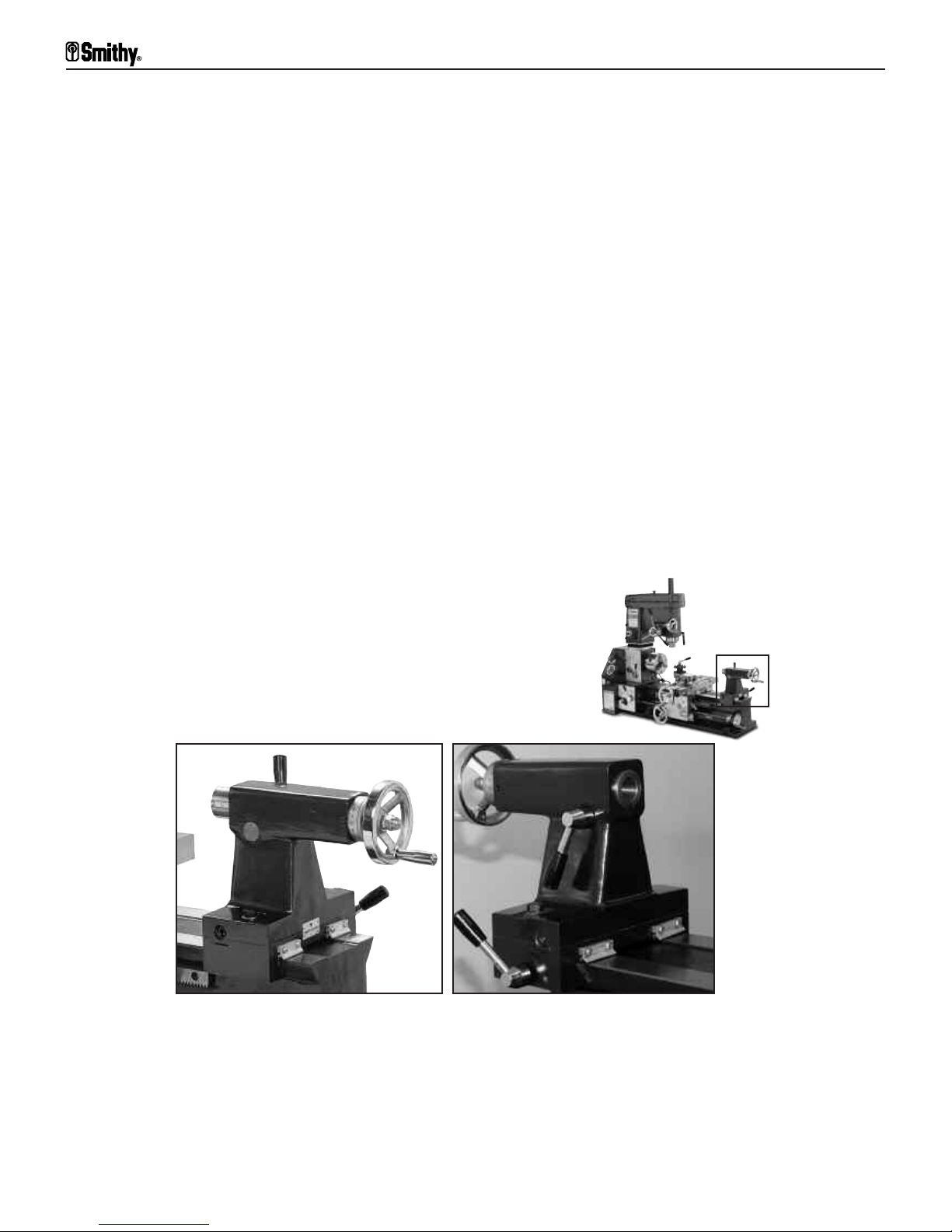

Carriage Assembly-Compound Angle Toolpost

The compound angle toolpost is bol

ted to the cr

oss-sl

ide table wi

th 10mm T

-B

olts. The

compound angle toolpost swiv

els to an

y angle horiz

ontal to the lathe axis. The

calibrations on the swivel base are in degrees, (60º-0º-60º). The following section

identifies and explains the functions of the toolpost.

A. CATP (Compound Angle Toolpost) Lock down handle - The handle r

otates

counter

clockwise to loosen the tension on the f

our position turret, allowing the user to

turn the turr

et 90º per turn.

Figure 4.13 Granite Carriage Gib Adjustment Screws (Rear View)

Figure 4.14 Granite Compound Toolpost

Do not let the top indicator mark travel past the bottom indicator

mark on the right side (side facing tailstock) of the carriage assembly.

WARNING

A

B

C

D

E

F

G

H

I

4: Machine Overview

4-11

Or V

isit www

.smithy.com

Page 29

B. Turret Bolts - These bolts secure your tooling to the turret.

C. 4 Position Turret - The turret holds up to 1/2” tooling. The turret can support up to

4 tools.

D. Compound Slide - The compound slide moves the tooling in towards and away from

the workpiece.

E. Floating Dial - The floating dial can be repositioned to zero at any point to measure

tool feed in or out.

F. CATP Carriage -The carriage supports the compound slide and is bolted directly to

the swivel base.

G. Swivel Base - The swivel base secures the CATP and allows it to rotate 360º in either

direction. A calibrated scale at the bottom of the base shows positioning in degrees from

60º-0º-60º.

H. Slide lock - This slide lock locks the compound slide to the carriage to secure the slide

in position.

I. Compound Gib Adjustment Screws - These screws press a small metal plate (the

gib) to the w

ays of the bed, increasing or decr

easing the tension when mo

ving the

compound slide.

Tailstock

The tailstock holds tool

ing that supports the end of a workpiece. It also holds tool

ing such

as center dri

l

ls, reamers and taps. It moves along the bed of the machine and can be

stopped and locked in position at any point on the bedways. The photos above depict the

tailstock of the Granite machine. This section will identify and define major components

and functions of the Granite tailstock.

A

C

D

E

F

G

B

Figure 4.15 Granite Tailstock (Front & Back)

Granite 1300 Series Operator’s Manual

4-12

For

Assistance: Call

Toll Free 1-800-476-4849

Page 30

A. Tailstock Body - This is the main casting of the tailstock.

B. Off-Setting Lock Bolts -These bolts lock the top base of gthe tailstock and prevent

it from moving off center.

C. Tailstock Handwheel -This handwheel moves the tailstock barrel in and out of the

tailstock body.

D. Tailstock Lock -This locks the tailstock body to the bed ways.

E. Tailstock Barrel Lock -This locks the barrel into position.

F. Tailstock Barrel -The barrel holds the MT3 tooling that supports the end of the

workpiece.

G. Tailstock Off-Setting Bolts -These bolts allow the user to offset the toolpost for

cutting tapers.

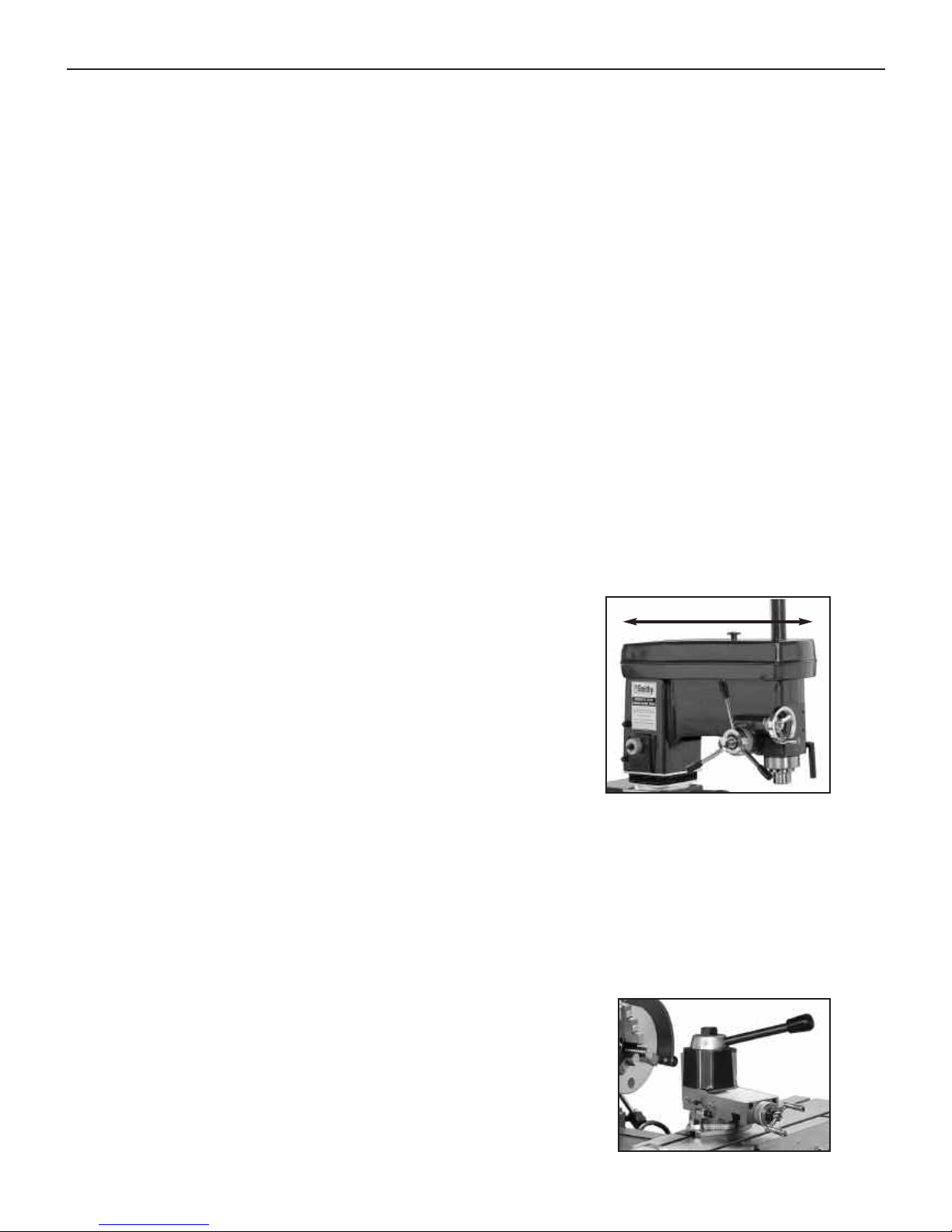

For Granite MAX and I-MAX Series Machines

The following are some of the modifications and improvements for the Granite MAX and

Granite Industrial MAX machine series.

A. 30% Longer Millhead - An extended millhead to

accept larger workpieces for more efficient milling

operations.

B. Crash Protection System (Y-Axis) - A unique shear pin design that protects your

machine from major damage if the machine is run past its limits of travel. Found inside

the carriage assembly

.

C. Electrical Overload Protection - Improvement on the powerhead section of the

machine that safely shut offs the machine for prolonged motor life.

D. Extended Tailstock Travel - Dri

l

l or r

eam deeper wi

th 3” travel, also reach farther

across the table with the center securely placed in the tailstock.

E. Quick Change Toolpost (For Idustrial MAX Series

Only)

- The fastest, most convenient way to change a tool.

4: Machine Overview

4-13

Or V

isit www

.smithy.com

Page 31

Overview

The Quick-Start Manual you received before delivery of your Smithy machine

provides detailed instructions for mounting and locating your machine. Please

complete those instructions if you have not already done so. As you unpack, it

is a good idea to inventory the parts. (See chapter 3 for a complete list.) Before

operating your machine, you should assemble the remaining components of

your machine, clean the machine, and lubricate it. This section will guide you

through those steps.

Assembly of Minor Components

The installation of the drill chuck, arbor and arbor plug; mill spindle covers; and several

handles should be completed according to the procedures described below.

Drill Chuck and Arbor

Before proceeding both the arbor and the chuck should be thoroughly cleaned to ensure

a good fit. Once cleaned attach the chucks to the respective arbors. Follow the steps

below to achieve the best possible fit.

Step 1: Place the arbor in a f

reezer for about 1 hour to slightly shrink the metal.

Step 2: Remove the cold arbor from the freezer and place it into the drill chuck.

Step 3: Use a soft mallet or a block of wood to tap the end of the arbor.

Step 4: Allow the arbor to return to room temperature.

5

Preparing Your Machine

For Operation

Figure 5.1 Installing Arbor into Chuck

5-1

For

Assistance: Call

Toll Free 1-800-476-4849

Chuck

Jacobs Taper

MT3 Arbor

Page 32

Mill Spindle Cover

The mill spindle cover slides over the flange on the top of the millhead.

! NOTICE !

Arbor Plug

Install the plug setscrew (S12898 into the tailstock arbor before inserting the

arbor into the tailstock. A plug is installed in the tailstock arbor (the MT3 to JT33

arbor

, part number C30523), which allows the ejector pin inside the tailstock to

eject the arbor when the tailstock barrel is retracted.

Morse Taper 3 (MT3) tooling is used in the tailstock of the machine. R-8

tooling is used in the millhead of the machine and used in conjunction with a

dr

awbar.

Figure 5.2 Installing Arbor Plug

Figure 5.3 Installing Mill Spindle Cover

Do not operate your machine without the mill spindle

cover. Doing so could cause harm to yourself or your

machine.

WARNING

5

: Preparing Your Machine For Operation

5-2

Or V

isit www

.smithy.com

MT3 Arbor

Plugs

Page 33

Handles

Install any handles or handwheels that have been removed for shipping. Handles can be

hand installed and tightened with a flat-head screwdriver. Remove and reverse the

tailstock handwheel.

Cleaning & Lubricating Your Machine

Smithy machines are shipped with a light protective grease coating that must be removed

prior to use. Use a noncorrosive kerosene or white mineral spirits to remove the coating.

WD-40® also works well.

Once cleaned, your Smithy must be lubricated. Make sure to lubricate carefully and

thoroughly before starting the machine. Use a pump oil can and a supply of good

qual

ity SAE30 weight nondetergent oil or 30-weight compressor oil. Lubricants can be

obtained at most home and building supply stores. A lubrication point chart can be found

on the backside of the millhead.

Lubrication Schedule

Lubrication depends a lot on the use of your machine and your climate. The schedule

below is intended to be used as a guide, use your best judgement for lubricating your

machine based on your use and environment.

Check Oil Before each use

Oil Ports Before each use

Add Oil As Needed

See Chapter 11 for a complete maintenance schedule.

Lubrication Points

Follow the instructions on the next page and refer to the lubrication chart on the

backside of the mi

l

lhead.

Figure 5.4 Installing Handles

Granite 1300 Series Operator’s Manual

5-3

For

Assistance: Call

Toll Free 1-800-476-4849

Page 34

Gearbox

Open the gearbox door. Lightly grease the gears with a good quality molybdenum or

lithium grease or motorcycle-chain lubricant.

Check the oil sight glass under the chuck. If necessary, add oil until the sight glass is half

full. The oi

l-fill plug is at the back of the headstock above the motor. Be careful not to

overfill, the gearbox requires only 8 to 10 ounces of oil.

Figure 5.5 Brush a thin layer of lithium grease over

the gear quadrant in the pulley box

Figure 5.6 The oil level should be half way in the oil site glass

located under the lathe spindle.

Figure 5.7 Add oil through the oil port located

on the back side of the headstock.

Oil should be at

the mid point in the

site glass.

5: Preparing Your Machine For Operation

5-4

Or V

isit www

.smithy.com

Page 35

Ways

Run the carriage as far to the left as possible. Put a few drops of oil on the ways. Run

the carriage to the extreme right and repeat.

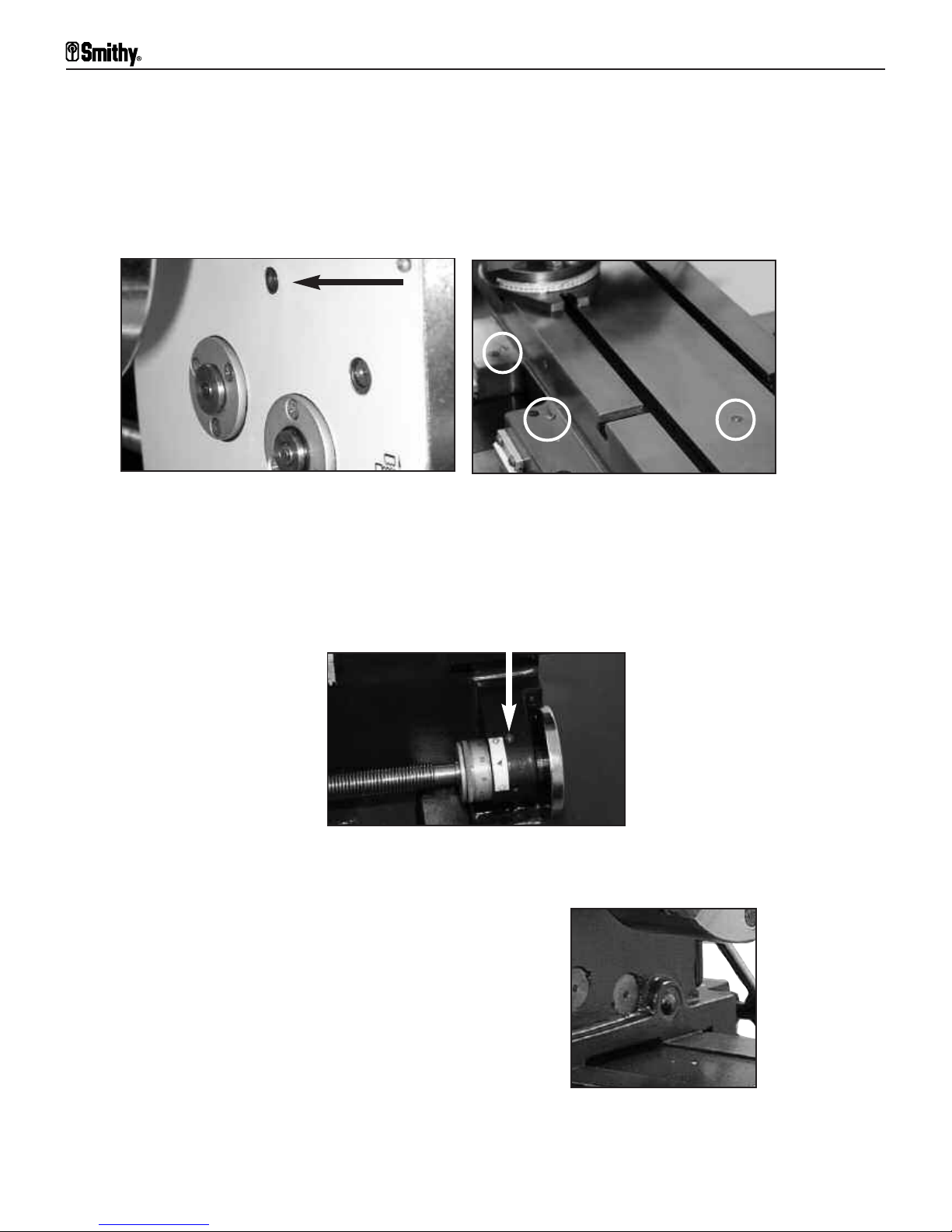

Carriage Assembly-Saddle

Lubricate the four oil buttons of the cross-slide table

There are two buttons on both the right (tailstock) side and left side (head stock) of the

carriage for the ways.

Figure 5.8 Carriage Assembly Saddle Oil Points

Granite 1300 Series Operator’s Manual

5-5

For

Assistance: Call

Toll Free 1-800-476-4849

Page 36

Carriage Assembly-Cross-Slide Table

There is one button on each side of the cross slide for the cross-slide ways.

Compound Angle Toolpost

Oil the two buttons on the top of the compound rest.

Figure 5.9 Carriage Assembly Cross Slide Table Points

Figure 5.10 Oil the Compound Angle Toolpost at its oil points

5: Preparing Your Machine For Operation

5-6

Or V

isit www

.smithy.com

Page 37

Cross-Slide Screw

Oil the cross-slide screw. The first oil button is located on the apron next to the crossslide dial and the other is found on the top of the cross-slide table.

Oil the buttons between the cross-slide and longitudinal-feed handwheels (at right).

Leadscrew

Oil the support for the right end of the leadscrew. Put a few drops of oil along the

leadscrew itself.

Oil Drip

Oil the end of the oil-drip trough from inside the gear box.

Figure 5.11 A & B Cross-Slide Screw Apron Oil Points

and Cross-Slide Screw Table Oil Points

Figure 5.12 Leadscrew Oil Point

Figure 5.13 Oil Drip

Granite 1300 Series Operator’s Manual

5-7

For

Assistance: Call

Toll Free 1-800-476-4849

Page 38

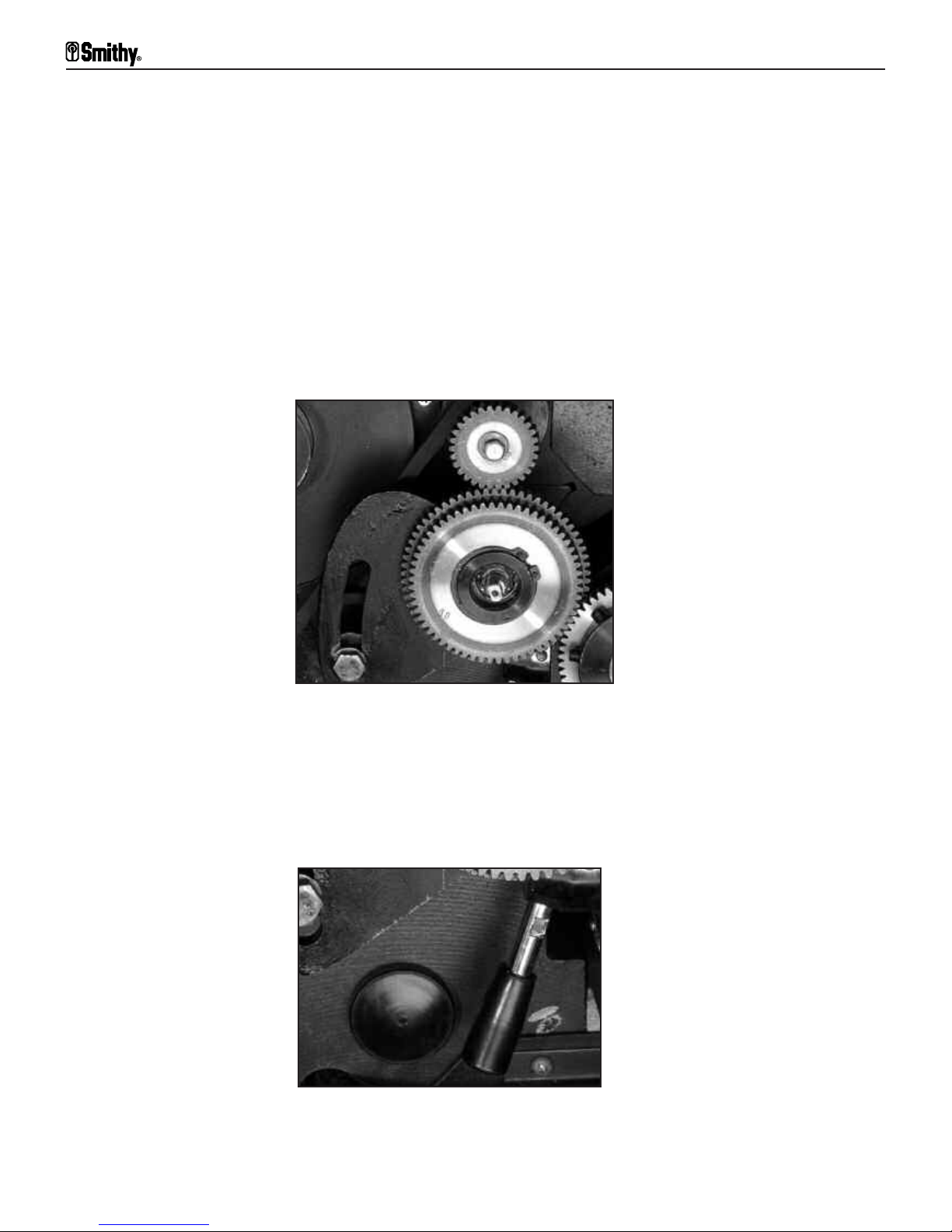

Quick Change Gear Box

Use a spray can of lithium grease or motorcycle-chain lubricant. Spray inside the

quick-change gearbox through the slot for the powerfeed (1-7) selector.

Tailstock Barrel

Oil the two buttons on top of the tailstock.

Mill/Drill Clutch, Fine Feed

Oil the button on top of the mill/drill clutch housing.

Figure 5.14 Oil the Quick Change Gear Box through the Powerfeed Slot

Figure 5.15 Tailstock Barrel Oil Points

Figure 5.16 Mill/Drill Clutch Oil Points

5: Preparing Your Machine For Operation

5-8

Or V

isit www

.smithy.com

Page 39

Adjusting Gibs

The Granite 1300 models have a series of straight gibs. The gibs are found on the

carriage, the cross-slide table, compound angle toolpost and the tailstock. These gibs

should be adjusted periodically to maintain accuracy and smooth operation.

Carriage Assembly-Saddle

Adjust the gibs on the saddle assembly using the procedure below.

Step1: Loosen the four jam nuts on the back side of the saddle with the 6” adjustable

wrench that was shipped with your machine.

Step 2: Back out the gib adjusting screws found on the back side of the saddle two turns

wi

th the 4 mm al

len wr

ench.

Step 3: Using the 4 mm Allen wrench, tighten each of the four gib adjustment screws

until they are lightly touching the gib.

Step 4: B

ack the gib adjustment scr

ews out 1/8 to 1/4 turn.

Step 5: With the adjustment screws now set at roughly the same position, make the

fine adjustments on each individual screw. Starting with one of the inner screws, slowly

tighten the screw while moving the carriage assembly by turning the leadscrew

handwheel unti

l y

ou f

eel sl

ight r

esistance.

! NOTICE !

Always make sure your machine is well lubricated before

adjusting the gibs.

Do not apply excessive force.

Figure 5.17 Carriage Gibs

CAUTION

Granite 1300 Series Operator’s Manual

5-9

For

Assistance: Call

Toll Free 1-800-476-4849

Page 40

Step 6: Once slight resistance is felt, hold the gib adjustment screw in position and

t

ighten the jam nut.

Step 7: Repeat steps 5 and 6 with the other inner screw and then with the two outer

screws.

Adjusting the Gibs on the Carriage Assembly Cross-Slide Table

Adjust the gibs on the cross-slide table using the procedure below.

Step 1: Loosen the four jam nuts on the tailstock side on the table with the 6” adjustable

wr

ench that was shipped with y

our machine.

Step 2: Back out the gib adjusting screws two turns.

Step 3: Using the 4 mm Al

len wrench, tighten each of the four gib adjustment screws

until they are lightly touching the gib.

Step 4: B

ack the gib adjustment scr

ews out 1/8 to 1/4 turn.

Step 5: With the adjustment screws now set at roughly the same position, make the

fine adjustments on each individual screw. Starting with one of the inner screws, slowly

tighten the screw while moving the cross-slide table by turning the cross-slide handwheel

unti

l y

ou f

eel slight resistance.

Step 6: Once slight resistance is felt, hold the gib adjustment screw in position and

tighten the jam nut.

Step 7: Repeat steps 5 and 6 with the other inner screw and then with the two outer

scr

ews.

Do not apply excessive force.

Figure 5.18 Gib Adjustment Screws - Cross-Slide Table

CAUTION

5: Preparing Your Machine For Operation

5-10

Or V

isit www

.smithy.com

Page 41

Adjusting the Gibs on the Compound Angle

Toolpost

Adjust the gibs on the compound-angle toolpost using the procedure below.

Step 1: Loosen the jam nuts on the side of the compound-angle toolpost with the

6 inch adjustable wrench.

Step 2: Back out the gib adjustment screws out two turns .

Step 3: Using the a flat-head screw driver, tighten the two gib adjustment screws until

they are lightly touching the gib.

Step 4: Back the gib adjustment screws out 1/8 to 1/4 turn.

Step 5: With the adjustment screws now set at roughly the same position, make the

fine adjustments on each individual screw. Starting with the screw closest to the handle,

slowly tighten the screw while moving the compound angle toolpost by turning the

compound-slide handle until you feel

slight

resistance.

Step 6: Once slight resistance is felt, hold the gib adjustment screw in position and

tighten the jam nut.

Step 7: Repeat steps 5 and 6 with the remaining gib adjustment screw.

Figure 5.19 Gib Adjustment Screws - Compound Angle Toolpost

Do not apply ex

cessiv

e force.

CAUTION

Granite 1300 Series Operator’s Manual

5-11

For

Assistance: Call

Toll Free 1-800-476-4849

Page 42

Adjusting the Gibs on the Tailstock

Adjust the gibs on the tailstock using the procedure below.

Step 1: Unlock the tailstock.

Step 2: Remove the outer setscr

ews with the 4 mm Allen wrench provided.

Step 3: Using the 4 mm Al

len wrench, tighten each gib adjustment screw until it

touches the gib lightly.

Step 4: Back each gib adjustment screw out 1/4 turn.

Step 5: Reinstall each outer setscrew and bottom it against the inner screws to lock the

corresponding inner screw in place.

Step 6: Repeat steps 2 through 5 on the remaining screw.

Figure 5.20 Gib Adjusting Screws - Tailstock (Shown with tailstock lock removed)

! NOTICE !

Ther

e ar

e two setscrews in each hole. To tighten the

tailstock gibs the outer setscrews need to be removed.

! NOTICE !

Unlike the carriage, cross-slide and compound-angle toolpost gib

adjustments, you will not feel a slight resistance when moving the

tai

lstock. The tai

lstock wi

l

l be lock

ed to the w

a

ys with the tailstock

lock. The objectiv

e of adjusting the tai

lstock is to ensur

e that the

tailstock remains parallel to the ways.

5: Preparing Your Machine For Operation

5-12

Or V

isit www

.smithy.com

Page 43

Adjusting Backlash

Backlash is lost motion in the screw. The user will notice an initial small movement in the

handwheel before the screw responds. The procedures in this section will help minimize

backlash.

Adjusting Backlash from the Cross-Slide Screw

Before making any adjustments to the cross-feed screw system, all the gibs on the table

and carriage system should be checked and adjusted as described previously.

Excessive backlash in the cross-slide can come from three different places.

• The fit of the cross-slide screw to the front screw mount

• The fit of the cross-slide screw into the brass crossfeed nut

• The fit of the br

ass cross-feed nut into the carriage casting

There are adjustments for each of these areas. Follow the procedures below to make

each adjustment.

Adjusting Backlash Cross-Slide Screw to the Front

Screw Mount

Step 1: Loosen the two nuts that hold the cross-slide handwheel on to the end of the

cross-slide screw.

Step 2: Tighten the inner nut slowly whi

le checking the ease of movement of the

cross-slide handwheel. When the screw starts to become difficult to turn, loosen the nut

slightly so that the screw turns freely.

Step 3: Hold the inner nut in place with a wrench and tighten the outer nut against the

inner nut to lock both nuts in position.

Step 4: Recheck the backlash.

Figure 5.21 Loosen the two outer nuts holding the handwheel

Granite 1300 Series Operator’s Manual

5-13

For

Assistance: Call

Toll Free 1-800-476-4849

Page 44

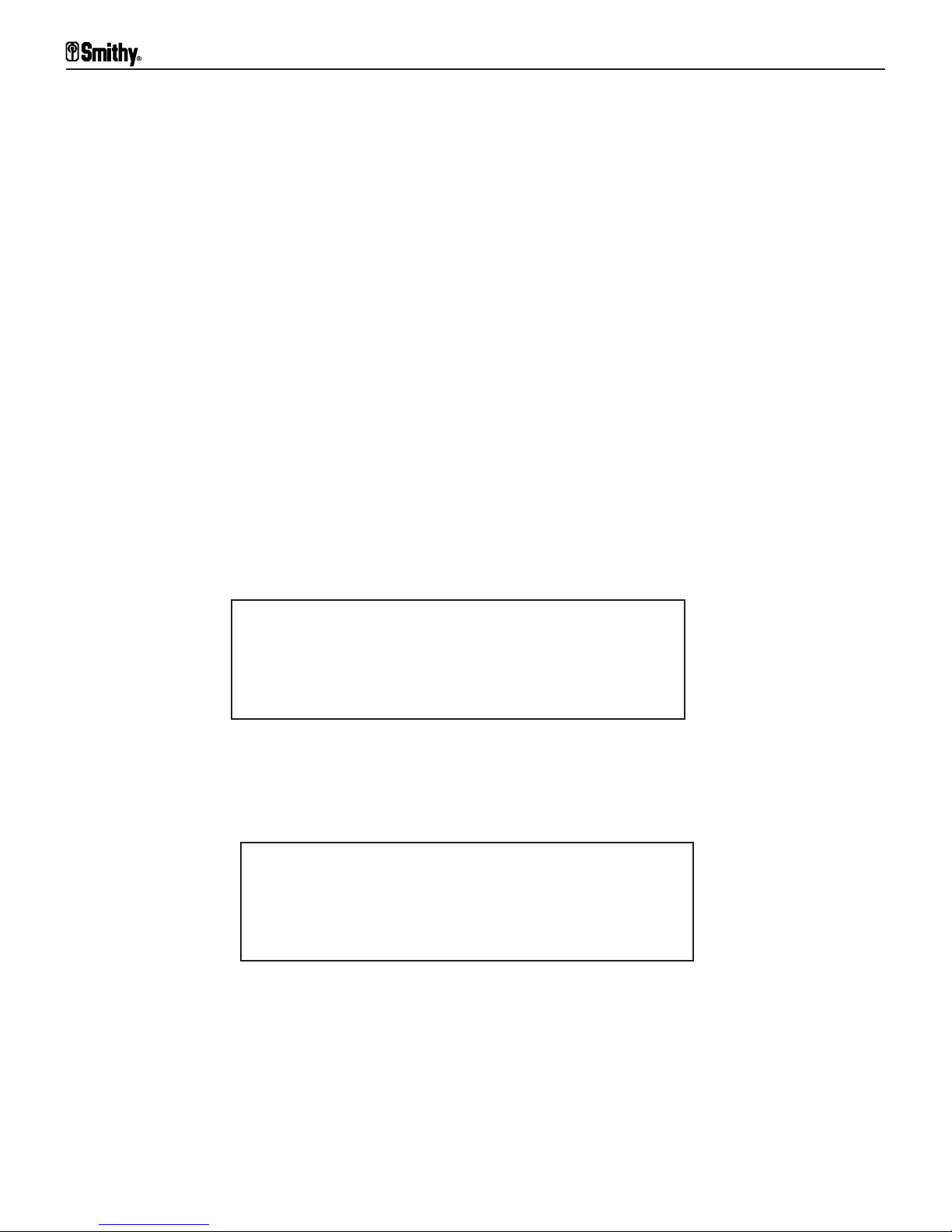

Cross-Slide Screw to Brass Nut & Nut to Saddle

If there is still excess backlash after the previous adjustment, the backlash is either

between the cross-slide screw and the brass nut or between the brass nut and the

saddle. The following procedure covers both adjustments.

Step 1: Remove the rear support on the backside of the cross-slide table.

Step 2: Loosen the allen bolt that locks the brass nut into the saddle. (See Figure 5.23)

Step 3: Use the handwheel to mo

ve the cross-slide table toward the operator side of

the machine. Watch under the table from the backside and stop before the cross-slide

scr

ew comes out of the brass nut.

Step 4: Slowly tighten the four adjusting screws on the brass nut, one at a time, until

a sl

ight drag is felt while turning the cross-slide handwheel. It is best to continue

turning the handwheel back and forth while adjusting the nut to balance ease of

operation and backlash.

Figure 5.22 Remove mount on backside of the table

to access the brass cross slide nut

Figure 5.23 Tighten the adjusting screws on the brass nut

Cross-slide table

Cross-slide screw

2 Piece Brass Nut

Adjusting Screws

Saddle

Locking Bolt

Saddle

Brass Nut

Adjusting Screws

Table view from

rear of machine.

5: Preparing Your Machine For Operation

5-14

Or V

isit www

.smithy.com

Page 45

Step 5: Reinstall the rear support and tighten the locking bolt for the brass nut.

Step 6: Recheck the backlash on the cross-slide.

Adjusting Backlash from the Longitudinal

Leadscrew

Excessive backlash in the longitudinal feed can come from two places.

• The fit of the longitudinal feed screw to the right-hand mounting trestle

• The fit of the half-nut to the feed screw

Engage the half-nut lever. Slowly turn the longitudinal handwheel clockwise as viewed

from the right end of the machine and watch the gap between the dial and the feed screw

mounting trestle. Reverse the direction you are turning the feed screw and see if the gap

increases slightly. If so then there is some backlash in the mounting. Follow the

procedure below to reduce the backlash.

Adjusting the fit of the longitudinal feed screw

to the right-hand mounting trestle

Step 1: Remove the retaining screw and washer in the right end of the longitudinal feed

handwheel.

! NOTICE !

If you find that the four adjusting screws will not stay in place, use

a small amount of thread-locking compound to keep the screws

tight. If you use a Lock-Tite® product, use the Lock-Tite® Purple,

not Red which will not allow for future adjustments

Figure 5.24 Adjusting backlash from the leadscrew

Granite 1300 Series Operator’s Manual

5-15

For

Assistance: Call

Toll Free 1-800-476-4849

Lead Screw &

Dial

Mounting

Trestle

Spanner

Nut

Handwheel

Retaining Screw

& Washer

Page 46

Step 2: Unscrew the handwheel from the end of the feed screw.

Step 3: Using a punch and a small hammer, tighten the spanner nut about one-eighth

of a turn and recheck the backlash in the leadscrew.

Step 4: If backlash is acceptable, replace the handwheel, washer, and retaining screw.

If more adjustment is needed, repeat step 3 above.

Half-Nut to Leadscrew Backlash

Worn threads on the half-nut can cause excessive backlash in the longitudinal direction.

Half nuts are made of a brass-like material and do wear out over a period of time. The

only fix for a worn half nut is to replace the worn nut with a new one.

Adjusting Mill Feed Backlash

Excessive backlash in the vertical fine feed can come from two places.

• The fit between the worm gear and the pinion gear shaft

• The fit of the quill gear to the quill rack

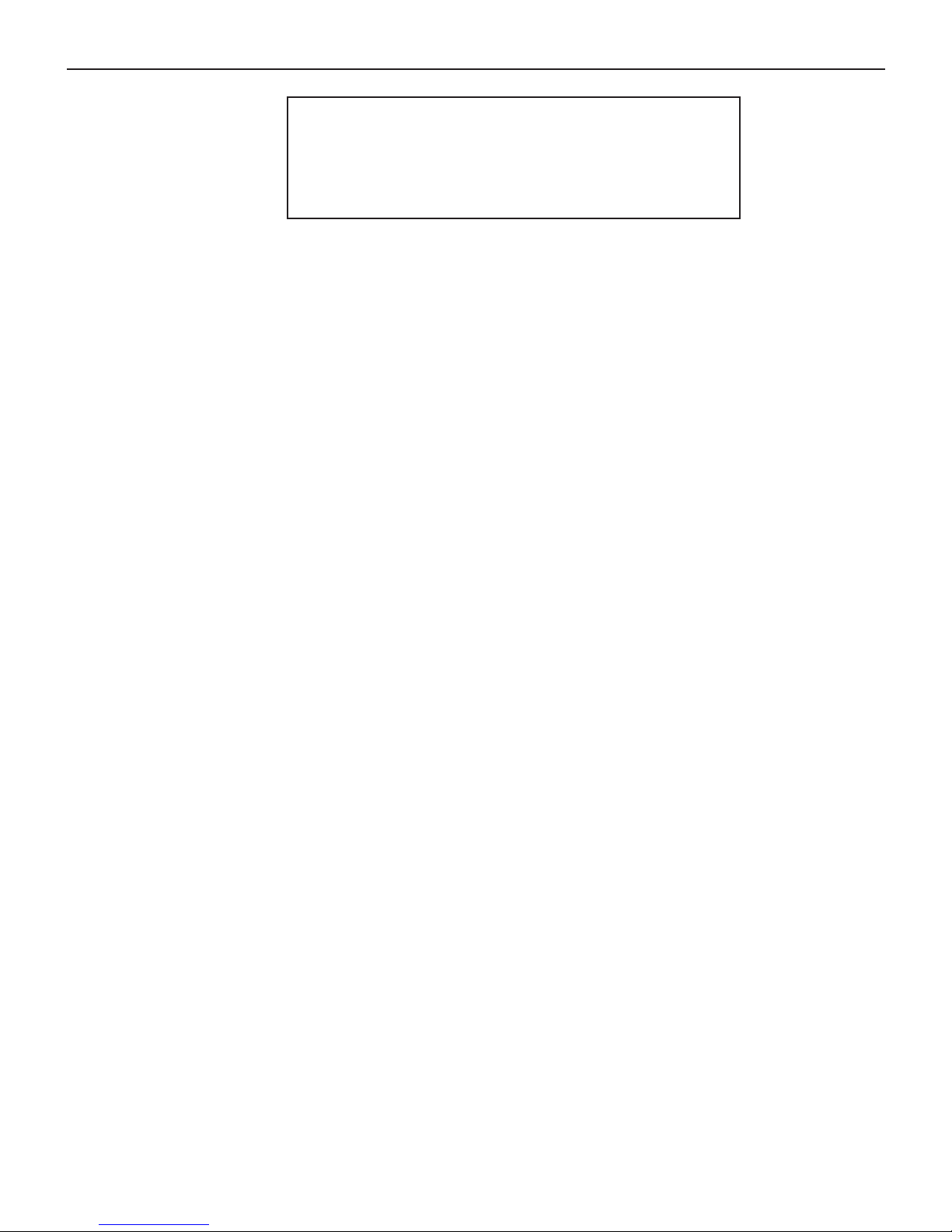

Adjusting the Fit Between the Worm Gear and

Pinion Gear Shaft

F

ollow the procedure below to adjust the fit between the worm gear and pinion gear.

Step 1: Remove the fine-feed handwheel and dial.

Step 2: Loosen the two setscrews that hold the left and right worm gear bearing sup-

ports in place. They are located on top of the vertical feed housing at the left and right

end of the worm gear.

! NOTICE !

The longitudinal handwheel (R

ack & Pinion) is intended for rapid,

coarse feed and is not calibrated for fine measurement. There is no

backlash procedure for this mechanism.

5: Preparing Your Machine For Operation

5-16

Or V

isit www

.smithy.com

! NOTICE !

The bearing housing has two holes in the outside surface

to allow a punch or spanner wrench to turn the housing.

Page 47

Step 3: Use a small spanner wrench or a punch with a small mallet to rotate the

bearing supports one at a time. The support bearings ar

e mounted slightly of

f center in

these housings and rotation of the housings will raise or lower the worm gear down

towards the pinion gear. The bearing support on the right should be rotated clockwise

and the left should be rotated counter clockwise. Rotating the right and left bearing

supports should be done in conjunction with each other.

Step 4: Turn the right housing and watch the worm gear shaft to see in which direction

it moves. Turn the housing in the direction that will move the worm gear down towards

the pinion gear.

Step 5: Move to the left housing and repeat step 4.

Step 6: Alternate moving the front a little and then the rear a little while turning the

worm gear to check for binding.

Step 7: Stop as soon as resistance is felt in the rotation of the worm gear. The

adjustment is completed.

Step 8: Tighten the setscrews to the bearing housings to lock adjustment in place.

Adjusting the fit of the Quill Gear to the Quill

Rack

Adjusting the fit between the quill shaft feed gear and the quill rack is done using the

split section of the feed gear. The feed gear is made up of two parts.

• A wide section that is locked to the feed shaft by a key and has a fixed

position on the shaft

Granite 1300 Series Operator’s Manual

5-17

For

Assistance: Call

Toll Free 1-800-476-4849

Figure 5.25 Adjusting backlash from the mill feed

Setscrews

Bearing

Housing

Worm Gear & Shaft

(Inside Casting)

Pinion Gear

(Inside Casting)

Dial

Handwheel

Drill Press Handles

Page 48

• Another section that is not as wide and is not keyed to the shaft. It is held in

place on the shaft via a locking nut and can be repositioned as desired.

The narrow section can be offset from the wide section to give the effect of a gear with

thicker teeth. This in turn will give a tighter tooth-to-tooth fit between the feed shaft gear

and the rack on the spindle.

Adjustments are made on the split gear from up inside the mill head casting. This is

accessible from under the mill head between the quill and the support column. Follow the

procedure below to make these adjustments.

Step 1: Look into the millhead casting and locate the items shown in the drawing 5.26.

Step 2: Turn the feed shaft with the coarse feed handwheel until the locking tab of the

locking washer is accessible. Lock the quill in that position with the quill lock lever on the

rear of the millhead.

Step 3: Bend the locking tab straight and use a small punch to loosen the spanner nut

just enough to be able to rotate the adjustable gear with the same punch and small hammer.

Step 4: With the quill still locked in position, have someone turn the coarse feed

handwheel clockwise unti

l it remo

ves any backlash. Then have them

hold the handle

in this position until the completion of step 6

. This will move the bottom part of the

wide fixed gear to the left as viewed from below.

Step 5: Using the punch and small hammer, tap the narrow movable gear toward the

right. This wi

l

l mak

e the gear assembly appear to ha

ve thicker teeth.

Step 6: Tighten the spanner nut wi

th the punch and hammer.

Figure 5.26 Adjusting the quill gear to the quill rack

5: Preparing Your Machine For Operation

5-18

Or V

isit www

.smithy.com

Figure 5.27 Adjusting the quill gear to the quill rack

Page 49

Step 7: With the quill still locked, move the coarse feed handle and check for a

reduction in backlash.

Step 8: Bend the locking tab back into one of the slots in the spanner nut.

Adjusting Drive Belt Tension