Page 1

EZ-TROL II CONTROL SYSTEM

USER’S GUIDE

VERSION 1.1

2009

Page 2

SmithyCNC EZ-Trol II Control System User’s Guide

SmithyCNC (Smithy Co.)

170 Aprill Dr., Ann Arbor, Michigan

USA 48103

Toll Free Hotline: 1-800-476-4849

Fax: 1-800-431-8892

International: 734-913-6700

International Fax: 734-913-6663

www.smithycnc.com

Copyright © 2009 SmithyCNC &

All rights reserved. No part of this manual may be reproduced or transmitted in any form by any means,

electronic, mechanical, photocopying, recording, or otherwise, without prior written permission of Smithy Co.

For information on getting permission for reprints and excerpts, comments, or suggestions, contact

info@smithy.com

While every precaution has been taken in the preparation of this manual, Smithy Co. shall not have any

liability to any person or entity with respect to any loss or damage caused or alleged to be caused directly or

indirectly by the instructions contained in this manual or by the computer software and hardware products

described herein. Please see section on warranty and safety precautions before operating the machine.

Printed and bound in the United States of America

Smithy Co.

Page 3

TABLE OF CONTENTS

1 | INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Development Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Four Steps of Machining. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Organization of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Questions? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 | SMITHYCNC SYSTEM WARRANTY . . . . . . . . . . . . . . . . . . . . . . . 3

3 | SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 | CONTROL BOX INSTALLATION &

COMPONENT IDENTIFICATION

. . . . . . . . . . . . . . . . . . . . . . . . . . 7

Overview . . . . .

Wiring the Smithy EZ-Trol to the Bedmill. . . . . . . . . . . . . . . . . . . . 7

Installing the monitor, keyboard & mouse . . . . . . . . . . . . . . . . . . . 8

Control System Components & Function . . . . . . . . . . . . . . . . . . . . 8

Basic Electrical Components & Function. . . . . . . . . . . . . . . . . . . . 9

5 | CONNECTING EZ-TROL II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connecting the EZ-Trol II Control Box to the Bed Mill . . . . . . . 11

Connecting the EZ-Trol II to the CNC 622 Bed Mill . . . . . . . . . . 12

Connecting the EZ-Trol II to the CNC 924 Lathe . . . . . . . . . . . . . 13

6 | LAUNCHING EZ-TROL II. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Booting-up EZ-Trol II Control System . . . . . . . . . . . . . . . . . . . . . . 14

7 | NAVIGATING EZ-TROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

The Four Tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Auto Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Manual Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Settings Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Wizards Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Navigating EZ-Trol II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Backlash Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8 | HOMING & SETTING OFFSETS. . . . . . . . . . . . . . . . . . . . . . . . . . 20

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Machine Home Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Page 4

Initial Machine Homing - one axis at a time . . . . . . . . . . . . . . . . 20

Homing Your Machine on All Axes . . . . . . . . . . . . . . . . . . . . . . . . 22

Limit Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Basic G-code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Coornidate Systems & Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9 | NAVIGATING THE AUTO TAB . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Auto Tab Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Position Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Tool Path Display Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Pan Across Display Area. . . . . . . . . . . . . . . . . . . . . . . . . . 30

Zoom In or Out on the View . . . . . . . . . . . . . . . . . . . . . . . 30

Rotate Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Command Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Pause & Resume. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Verify . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Status Block

Feed Override

Speed Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

E-Stop Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Abort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Feed Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Program Display Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10 | NAVIGATING THE MANUAL TAB. . . . . . . . . . . . . . . . . . . . . . . . 33

Overview

Manual Tab Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Position Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Status Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Jog Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

X & Y Axis Positive & Negative Direction. . . . . . . . . . . . 34

Z-Axis Positive &

A-Axis Positive & Negative Direction . . . . . . . . . . . . . . . 35

Speed Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Continuous & Incremental Speed . . . . . . . . . . . . . . . . . . 35

Amount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Feed & Rapid Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Axis Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Feed Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Jog Speeds

Spindle Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Negative Direction . . . . . . . . . . . . . . . 35

Page 5

Manual Data Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

E-Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Abort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Feed Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11 | NAVIGATING THE SETTINGS TAB . . . . . . . . . . . . . . . . . . . . . . . 38

Settings Tab Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Tool Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Offsets By Random & By Length . . . . . . . . . . . . . . . . . . . 39

Zero All . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Setting-up A Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

12 | NAVIGATING THE WIZARDS TAB . . . . . . . . . . . . . . . . . . . . . . . 41

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Navigation Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Loaded Wizards List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

General Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Tool Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Add New Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Setting-up an Individual Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . 44

13 | UNDERSTANDING G-CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Overview . . . . .

Why write your own G-code? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Basic G-code Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Understanding the G-code Program . . . . . . . . . . . . . . . . . . . . . . 53

14 | PREPARING YOUR MACHINE BEFORE OPERATION . . . . . . 58

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Homing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Setting Workpiece Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Populating Tool Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

15 | ADDING COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Open Architecture Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Upgraded I/O Capacity

To Add a Simple Turn On/Off Program . . . . . . . . . . . . . . . . . . . . . 61

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Page 6

To Add More Programming the Machine . . . . . . . . . . . . . . . . . . 62

16 | ELECTRICAL PIN OUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

17 | SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

SmithyCNC 622 Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

SmithyCNC 924 Lathe Schematics . . . . . . . . . . . . . . . . . . . . . . . . 71

SmithyCNC 1240 Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Appendix

A | SETTING TOOL LENGTH OFFSETS

B | FILE SHARING BETWEEN THE EZ-TROL II CONTROL SYSTEM

& WINDOWS PC SYSTEM THAT ARE ON THE SAME

NETWORK

C | BASIC INSTRUCTION FOR CONNECTING EZ-TROL II

TO A WIRELESS NETWORK

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

. . . . . . . . . . . . . . . . . . . . . . 75

Page 7

1

INTRODUCTION

Thank you for choosing the SmithyCNC EZ-Trol II Control System as the CNC control option for

your SmithyCNC machine.

Smithy’s unique EZ-Trol II system not only opens up the world of machining to you but the world of

small shop manufacturing. The unique EZ-Trol II user interface provides an intuitive step by step

process that makes CNC machining more understandable for the novice and seasoned machinist.

No doubt you are anxious to start making chips fly, but it is important that you to take a few

minutes to read this introduction and understand the development process behind the Smithy

EZ-Trol II Control system.

Once again thank you for choosing Smithy EZ-Trol II.

DEVELOPMENT PROCESS

Smithy Company has been selling machining equipment for over twenty years. Over the years we

have seen increasing interest in low-cost bench-top CNC machines for use in the small shop

environment. The types of individuals that have shown an interest in CNC bench top machining

include home hobbyists, engineers in R & D laboratories, small job, lo-tech tech tranining centers,

shop owners and garage shop entrepreneurs. Individuals from a variety of other industries have

seen the potential of CNC machine tools to get their jobs completed more efficiently.

Historically

usually a limiting factor in small shops and CNC machines have traditionally been expensive. The

most cost effective option for many has been to purchase a manually operated machine and then

retro fit it with a CNC control system. Following this path has left machine owners with no marginal technical support. Not to mention the inordinate amount of time (and patience) it takes to convert a conventional machine to a CNC machine.

With this in mind, our development staff, which includes industry leading machine tool and control

system engineers, worked to develop a control system that would allow small shop machinists to

produce and reproduce parts with lower cost CNC tools.

, finding a good low-cost CNC machining solution has not been an easy task. Money is

ORGANIZATION OF THIS MANUAL

The organization of this manual was constructed from the point of view of a committed but still

learning CNC machinist who is unfamiliar with the EZ-T

chapters will familiarize you with the installation of the EZ-Trol II System and how to navigate the

control system and interface. The remaining chapters are intended to provide you with an overview

of how to use the

rol II control system. Studying the first few

www.smithycnc.com | 1

Page 8

w SmithyCNC EZ-Trol II Control System

control system. Please be sure you are comfortable with the concepts presented before

roceeding to using the control system.

p

QUESTIONS?

gain, thank you for choosing a Smithy product. Contact us if you have any questions not covered

A

in this manual. We can be reached by phone, Monday through Friday 8 AM to 5 PM EST or we can

be reached on the web at

info@smithy. com.

2 | Toll Free 1-800-476-4849

Page 9

2

WARRANTY

Smithy Warranty

SmithyCNC warrants its machines and control systems for a period of one (1) year to the

original purchaser from the date of purchase. If within one (1) year form the date of

purchase a SmithyCNC machine and/or control system fails due to defect in material or

workmanship, SmithyCNC will at their choice repair and/or replace components with new

or remanufactured parts free of charge.

Most warranty repairs and/or replacements are handled routinely, but sometimes request

for warranty service many not be appropriate. This warranty does not apply to defects due

directly or indirectly to misuse, abuse, negligence, accidents, repairs, or lack of routine

maintenance. This warranty is also void if the serial number of the machine or SmithyCNC

control system has been removed or has been altered or modified.

In no event shall Smithy be liable for indirect, incidental or consequential damages for the

sale or use of the product. This disclaimer applies to both during and after the term of this

warranty

.

We do not warrant or represent that the merchandise complies with the provisions of any

law or acts unless Smithy Co. so warrants. In no event shall Smithy's liability under this

warranty exceed the purchase price paid for the product. Legal actions brought against

Smithy Co. shall be tried in the State of Michigan, County of Washtenaw.

Smithy Co. shall in no event be liable for death, injuries to persons or property for

incidental, contingent, special or consequential damages arising from the use of our

products.

This is Smithy Co.’s sole warranty and any and all warranties that may be implied by law,

including any merchantability or fitness, for any particular purpose, are hereby limited to

the duration of this written warranty

This warranty gives you specific legal rights, and you may also have other rights, which

vary from state to state. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusions may not apply

to you.

.

www.smithycnc.com | 3

Page 10

T

elephone Support (Service engineers are available 8 am to 5 pm EST):

Service and Parts

Tel No. 1-800-476-4849

Fax No. 1-734-913-6663

Email Address: sales@smithy.com

International: (734) 913-6700

Software and Programming Consultancy Services

In addition to our customary technical support for the machines and controls, we also

provide technical consulting support to our customers by providing engineering and

G-code programming services. The standard rate for these services is $28.00 per hour. Our

principal objective is to support you and to increase your productivity while reducing the

machining cost. Give us a call for such support as and when required.

Tel No. 1-800-476-4849

Fax No. 1-734-913-6663

Email Address: sales@smithy

.com

4 | Toll Free 1-800-476-4849

Page 11

3

SAFETY

OVERVIEW

This section is the most important section of the manual. Remember safety should always be

priority number one and always let common sense be your guide. The safety rules listed below are

by no way exhaustive; if any questions arise concerning safe operation, consult with the factory

before initiating the operation. Remember the operator of this control system is working with

electrical components and a shock hazard is always present.

The items listed below can cause potential harm to the health of the operator and can result in

serious harm to the machine if the action is not avoided.

1 Power must be shut off before working on any electrical components and control

box elements.

2 The control box should be kept CLOSED at all times, except when maintenance is

required.

3 Protective equipment for eyes, hands or face must be worn while working on

electrical components.

4 When working on exposed energized conductors or circuit parts, trained personnel

must use insulated tools or handling equipment.

5 Do not use flexible cords installed in the control box for raising, pulling or

lowering the control system. All cords should be disconnected first before the

equipment is moved.

6 Exposed cords and electrical connections shall be periodically inspected before

use for external defects.

7 Do not touch any electrical components when wet or in any conductive work

locations.

8 Over current or voltage protection elements of the electrical/control box must not

be changed or removed without factory consultation.

www.smithycnc.com | 5

Page 12

w SmithyCNC EZ-Trol II Control System

9 Only qualified trained personnel should perform maintenance and testing on

electrical circuits and components.

10 Do not run the machine or conduct maintenance operations in an environment

where flammable or explosive materials are present.

11 When testing or adjusting an energized circuit, a rubber mat, duckboard, or other

suitable insulation shall be used underfoot where an insulated deck does not exist.

12 When maintenance is required, make sure the machine is unplugged.

13 Whenever in doubt, consult factory before the any operation is performed.

6 | Toll Free 1-800-476-4849

Page 13

4

CONTROL SYSTEM COMPONENTS

& FUNCTIONS

The Smithy EZ-Trol II is equipped with 2 control panels located on the operator’s side of the box

(opposite the side with the control cables.) These switches are identified below and we suggest that

you become familiar with these switches before operating your machine.

COMPUTER CONTROL PANEL

This panel works and functions the same as a personal computer. The panel controls are connected to the motherboard of the control system.

2

1

3

Figure 4.1 EZ-Trol II Computer Control Panel

1. USB Ports (2) - Used for loading programs into the EZ-Trol II system.

2. Power Light – Indicates that the control is turned on.

3. Disk Light – Indicates that a program is reading or writing to the internal solid slate disk.

4. ON/OFF Switch – Turns power on and off to the comtrol.

4

Clear – Restarts (reboots) the contol.

5.

www.smithycnc.com | 7

Page 14

w SmithyCNC EZ-Trol II Control System

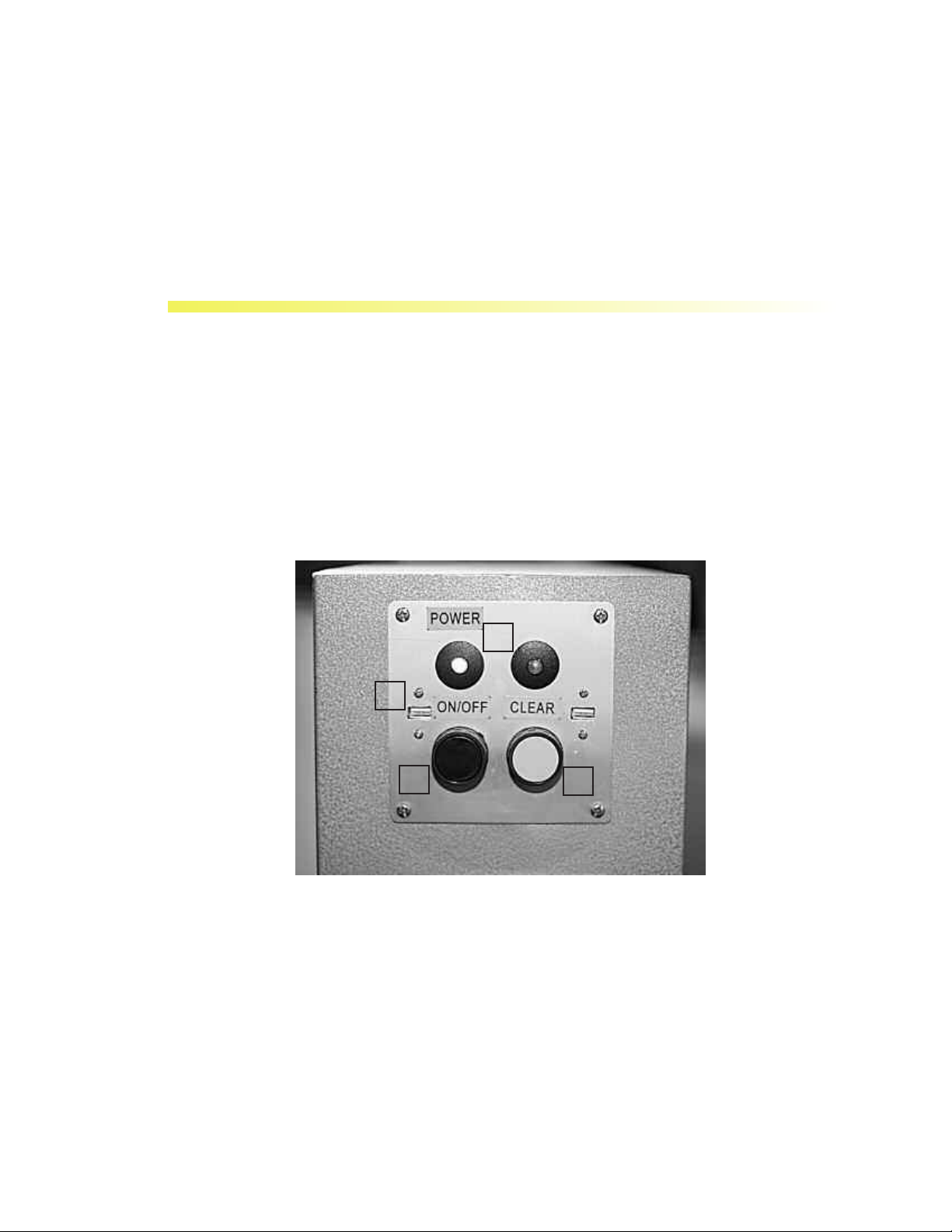

E-STOP CONTROL PANEL

1

3

2

Figure 4.2 EZ-Trol II E-Stop Control Panel

1. E-Stop Button – Round red mushroom head push button which when depressed until it latches

will cause the control system to go into emergency stop mode, or defeat any attempt to exit emergency stop mode. This button can be released from it's depressed position by rotating the mushroom shaped actuator.

2. E-Stop Reset – A shrouded blue momentary push button that when depressed and released will

cause the control system to exit emergency stop mode if all the following preconditions are met:

A. The ESTOP Button is released.

B. The HALT/RUN Key Switch is in the HALT position.

C. The CNC control software is running.

D. There are no faults in any monitored internal control system components.

Halt/Run Key Switch – This maintained action, key actuated switch has two positions:

3.

A. HALT: When the key switch is in this position power to the spindle motor drive is disconnected and the control software is switched to “MACHINE OFF” mode which disables axis movement and program execution control commands.

B. RUN: When the key switch is in this position all machine functions are available.

CABLE CONNECTION PANEL

The Smithy EZ-T

machine. You will find the cables packed in with the machine, and labeled for easy connection.

rol II control system comes with all the necessary cables to connect it to your

8 | Toll Free 1-800-476-4849

Page 15

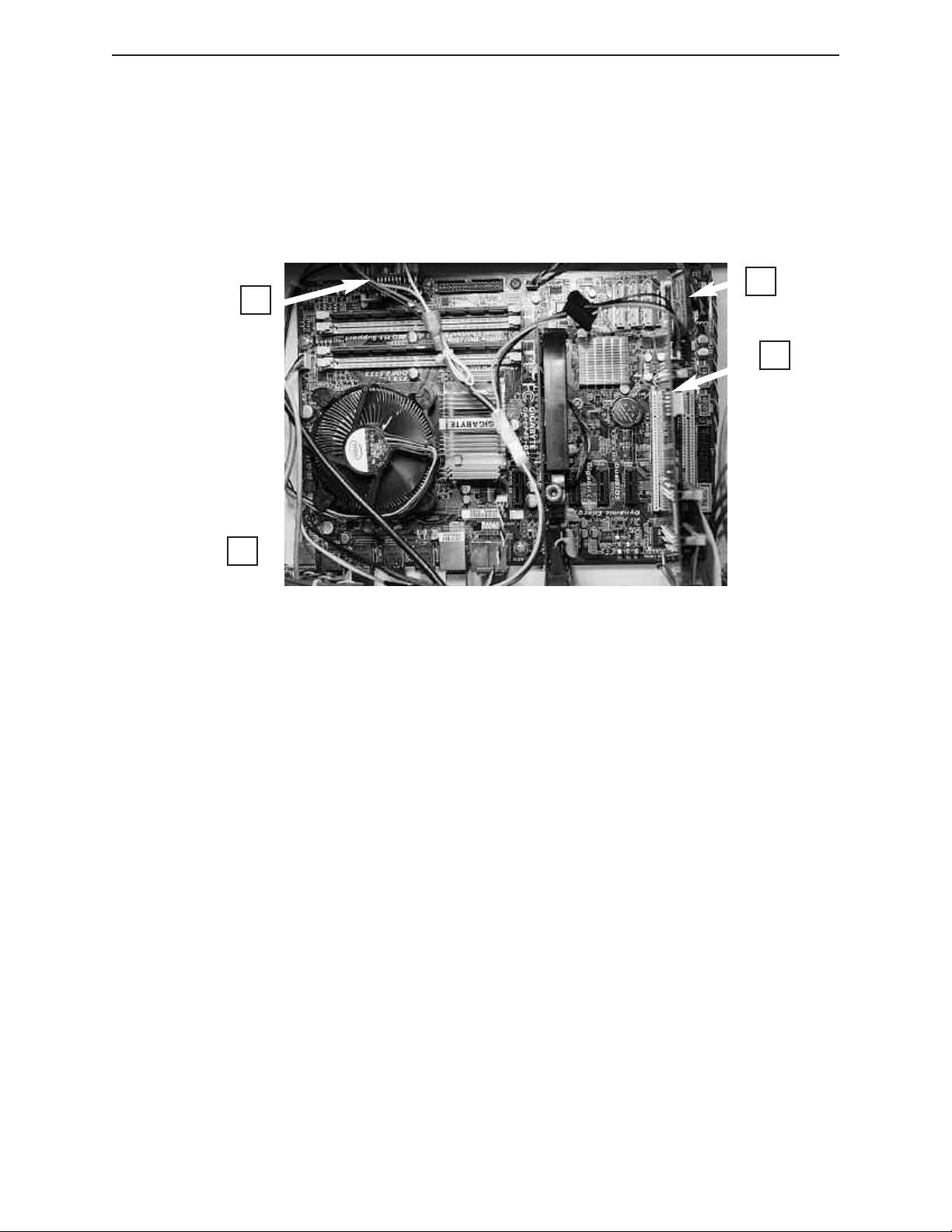

BASIC ELECTRICAL COMPONENTS AND ITS FUNCTIONS

1. Motherboard – Chosen specifically to handle the real time requirements of CNC control prorams for our machines, it has the connections for the keyboard and mouse, plus a D-subminiature

g

ype VGA connection for the monitor. The motherboard uses conductive polymer solid capacitors

t

for durabilty and long life. Intel 45nm CPU chips provide dual core capabilities while using 35% less

power. Along with the power savings of a solid state disk, this system delivers a high performance

computer using a small power supply and generates less waste heat.

3

4

2

1

Figure 4.3 EZ-Trol II

2. MESA Electronics 5I20 Card – A field programmable gate array card that is programmed gen-

erate step pulses, spindle speed control signals, and provide general pupose I/O. It delivers superior quality motion control at high speeds, and makes the graphical user interface more responsive.

This also frees up the main CPU for work on lower frequency but computationally intensive tasks

like trajectory and kinematics calculations. Connecting this outboard “helper chip” to the main

through the high speed, low latency PCI bus back plane delivers better performance than sim-

CPU

ilar systems that use USB, serial port, or Ethernet connections.

3. Compact Flash Card Adaptor – The control system software runs from a solid state disk (com-

pact flash) which greatly reduces power consumption and increases reliability by eliminating moving parts. The CF card simplifies upgrades by allowing the simple exchange of the existing card with

a new card holding file upgrades.

4. DC to DC Converter Power Supply – Converts the 24Vdc control system logic voltage to the

voltages required by the motherboard and CPU. This eliminates the standard PC power supply as a

source of trouble. This power converter has been designed for operation in automotive and industrial environments and simplifies the system power distribution.

5. Isolated I/O Boards – Converts the TTL signals from the MESA S120 Board into 24 Volt com-

patible I/O. All timing critical electrical signals, and all signals that require high fidelity data transmission for proper circuit operation are transmitted in “differential” form over two wire twisted

pair circuits, rather than the typical one wire plus ground “single ended” circuits.

Motherboard

www.smithycnc.com | 9

Page 16

w SmithyCNC EZ-Trol II Control System

a.MESA Electronics 7I47 RS-422 Interface Board (Upper

Board) – Provides 12 RS422 transmitters and 12 RS422 receivers

for differential signaling.

MESA Electronics 7I37 Isolated I/O Board (Lower

b.

Board) – Provides 16 Inputs and 8 Outputs of optically isolated

24 Volt I/O.

Figure 4.5 Isolated I/O Boards

Charge Pump to E-stop – Detects the presence of a signal generated

6.

by the CNC software when it is running. When this signal is not present due

to the CNC control software either not running or not operating correctly,

this module signals an emergency stop.

Figure 4.6 Charged

Pump to E-Stop

7. EMI and RFI Filtering devices - Restricts the undesired propagation of electromechanical and

radio frequency interference produced by the machine’

trol the interference the control system is equipped with both a power line filter module and strategically placed ferrite beads. Twisted pair wiring, shielded cables and attention to wiring layout

inside the control cabinet also reduce undesired emissions.

s spindle motor axis motor drives. To con-

10 | Toll Free 1-800-476-4849

Page 17

5

CONNECTING EZ-TROL II

Smithy lathes and mills are equipped with the required cables and connectors for connecting the

EZ-Trol system to the machine. Instructions for connecting the conrol to each SmithyCNC machine

follows below:

CONNECTING THE EZ-TROL II CONTROL BOX TO THE BED MILL

Step 1: Connect the Power Supply Box to the SmithyCNC 1240 Bed Mill

The EZ-Trol II Control Box is shipped with seven (7) 6’ cables that connect the junction box located at the back of the 1240 bed mill to the power supply box. Each cable has identifying tags that

correspond with labels on the junction box and power supply box.

Connect the corresponding plugs, first to the sockets on the junction box on at the back of the bed

mill, and then to the proper sockets on the power supply box. It is advisable to start from the upper

left moving to the right and down.

Please make sure that you have read all the labels before proceeding.

Figure 5.1 1240 Bed Mill Connected to the Power Supply Box

Step 2: Placing the Power Supply Box

The system is designed so you can place the power supply on the floor beside or behind the mill.

The cords are long enough for you to have some flexibility in positioning the box.

www.smithycnc.com | 11

Page 18

w SmithyCNC EZ-Trol II Control System

Be sure to place it in a location that is level and away from potential water exposure. The power

upply box is equipped with handles on the top of the box for easy repositioming.

s

Step 3: Connecting the Power Supply Box to the Control Box

The EZ-Trol II Control System is shipped with the two (2) 6’ cables that connect the CNC 1240

ower supply box to the control box. One cable has a round 31-pin connector and the other has a

p

50-pin connector that matches the long and narrow connection on both the front end of the power

supply box and the rear end of the control box. See image below.

Figure 5.2 SmithyCNC EZ-Trol II Control Box and Power Supply Box

Connect the corresponding plugs on each side securely and you are ready to continue. Please

make sure all threaded connections are tight.

Step 4: Connecting the Keyboard, Mouse and Monitor

The computer motherboard located inside the control box has ports for installing the keyboard,

mouse and the optional Ethernet network connection. Plug the cables into the corresponding sockets for the keyboard and the mouse. The monitor is plugged into the video card on the motherboard.

The monitor power cord can be plugged into any standard receptacle.

Figure 5.3. Keyboar, Mouse and Monitor Plug Layout

CONNECTING THE EZ-TROLL II TO THE CNC 622 BED MILL

The power supply enclosure for the CNC 622 is mounted on the right rear of the column (as you

stand facing the machine). The CNC 622 has the same two cables, with 31 pin and 50 pin

connections, as the 1240 mill. The sockets for connecting the cables are located on the power supply enclosure. Connect the 31 pin and 50 pin cables to the power supply and then to the control

box.

12 | Toll Free 1-800-476-4849

Page 19

Figure 5.4 SmithyCNC EZ-Trol II Plug Layout for SmithyCNC 622

Bed Mill

CONNECTING THE EZ-TROL II TO THE CNC 924 LATHE

The power supply enclosure for the CNC 924 is in the base of the lathe. The CNC 924 Lathe has the

same two cables as the two mill, plus an additional 9-pin cable for signals from to the spindle

encoder.

Figure 5.5 Connecting the Control Box to the SmithyCNC 924 Lathe

Please make sure that all connections are properly installed. Avoid loose connections that might

cause problems with the operation.

If any labels are missing or removed, plese replace it right away in order to avoid confusion during

re-installation.

If you need help in installation process, call us Toll Free 1-800-476-4849.

www.smithycnc.com | 13

Page 20

6

LAUNCHING EZ-TROL II

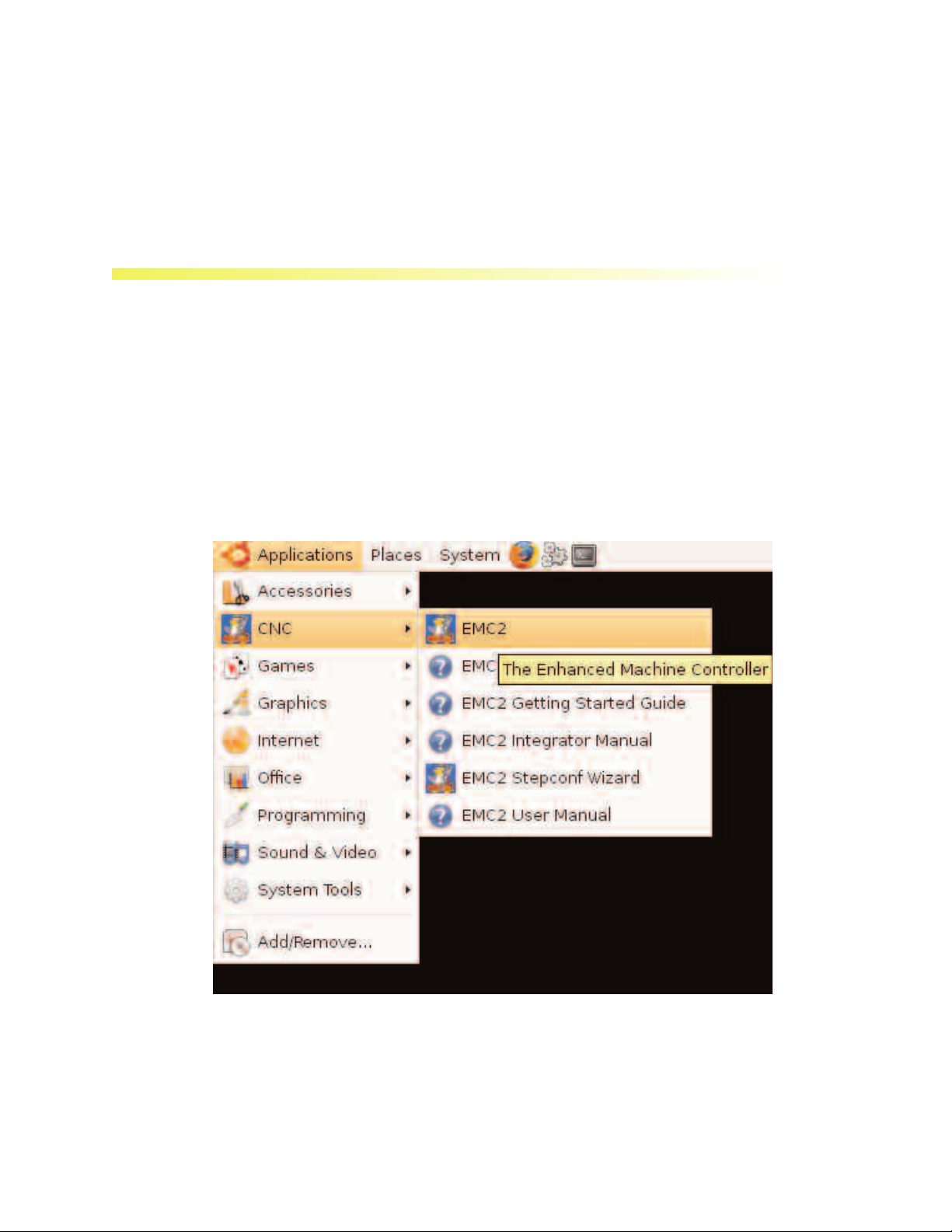

BOOTING EZ-TROL II CONTROL SYSTEM

Most of time, you will need to turn on your machine when you launch the EZ-Trol II control system

software. To turn on your machine, please refer to your operator’s manual.

Step 1: Once the machine is turned on, push the control box on/off switch. The green power

indicator light should be on. Make sure that your monitor is plugged on the wall socket and is

properly turned on.

Step 2: Wait for the desktop screen to show up.

Step 3:

Step 4:

Figure 6.1 Booting up EZ-Trol II Screenshot

Step 3: Click on the APPLICATIONS tab on the upper left hand corner of the screen.

Step 5:

Step 4: A dropdown menu will show

Step 5: A new dropdown menu will appear and click on EMC2.

14 | Toll Free 1-800-476-4849

. Click on CNC.

Page 21

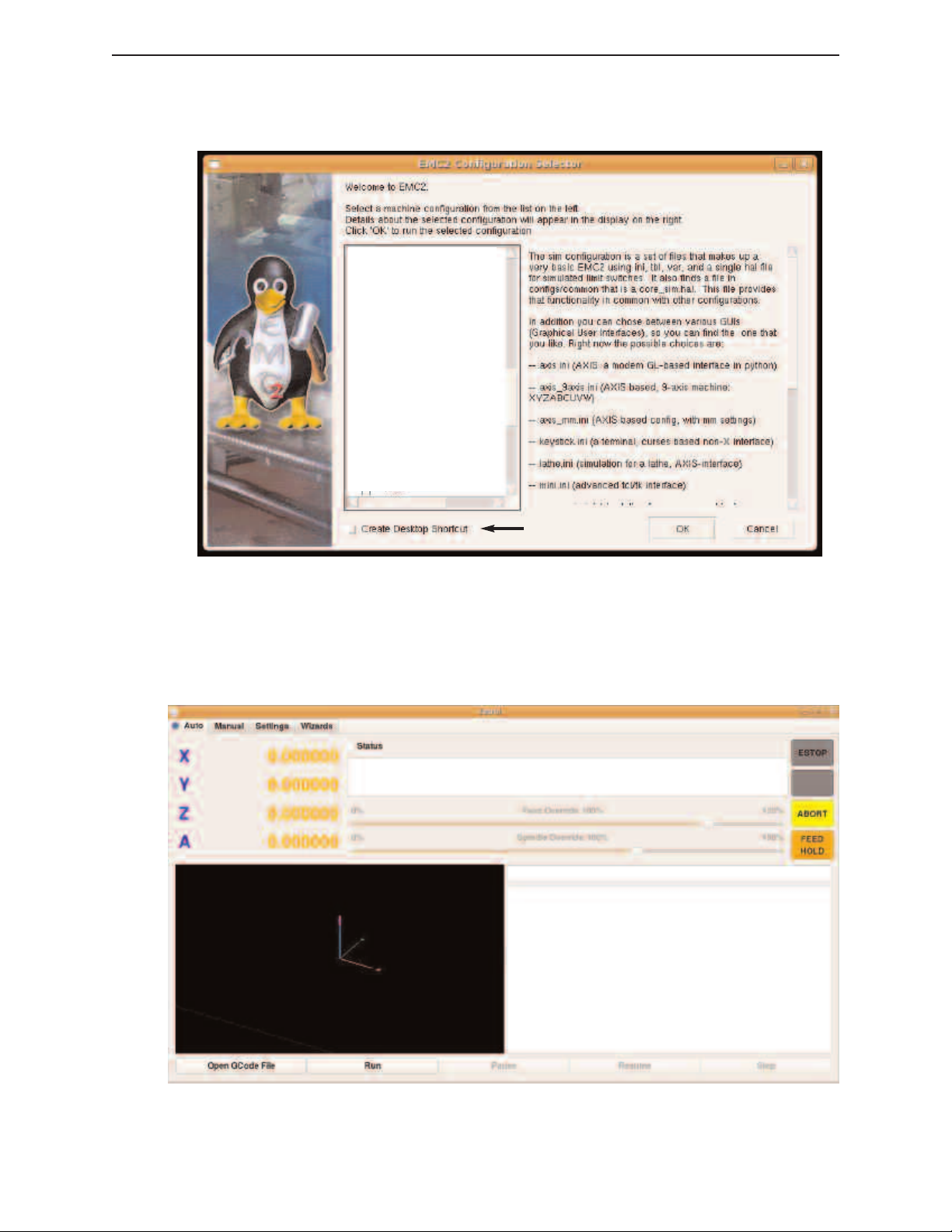

Step 6: A welcome screen will appear that will prompt you to choose what kind of machine you are

sing. Click on your machine and the Manual Tab will appear.

u

SmithyCNC

q 622 Bed Mill

240 Bed Mill

q 1

q 924 Lathe

Figure 6.2 EZ-Trol II Configuration Sector

NOTE: You may also create a Desktop Shorcut to easily boot up EZ-Trol II.

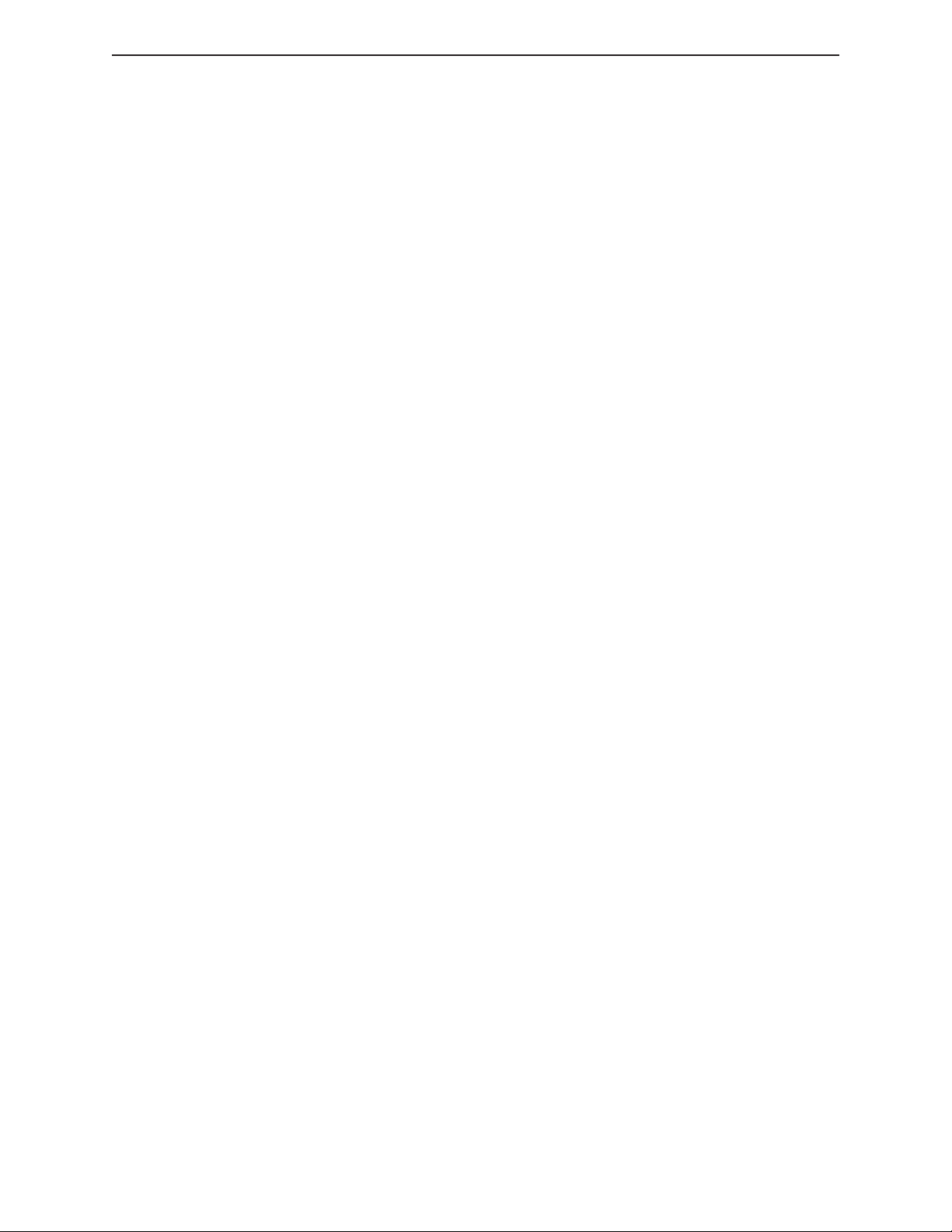

Now you are ready to use EZ-Trol II. The opening screen will appear as shown below.

Figure 6.3 EZ-Trol II Opening Page

www.smithycnc.com | 15

Page 22

7

NAVIGATING EZ-TROL II

THE EZ-TROL II TABS

EZ-Trol II’s interface is broken down into tabs. Each tab is given its own section in this manual that

describes the related functions. This chapter will only provide the operator with a brief description

of each tab and the conventions used to navigate the system.

Move from one section to another by left clicking with the mouse on the desired tab. Notice in the

screen below the blue circle located to the left of the word Manual. The blue circle indicates the

active tab. Navigation techniques will be discussed at the end of this chapter

AUTO TAB

The Auto Tab, shown below is the main screen used for executing the parts program. When EZ-Trol

is powered up note that the position coordinates are colored orange which means that the machine

must be homed. How to set-up and home the SmithyCNC machine tools will be discussed in the

next chapter. The functions of the Auto Tab screen will be explained in detail in a later chapter of

this manual.

16 | Toll Free 1-800-476-4849

Figure 7.1 Auto Tab Screenshot

Page 23

MANUAL TAB

he Manual Tab shown above is used to manually jog the machine’s axes. This is also the screen

T

where homing the machine and MDI (manual data input) operations are performed. The functions

of this mode will be explained on a later chapter of this manual.

Figure 7.2 Manual Tab

SETTINGS TAB

The Settings Tab shown in figure below are where the operator defines the work piece offsets. An

operator can also modify a file opened then either save it and send to contol or “Save as” a different filename and send to control. Tools are also defined in this screen and can be added, deleted or

modified.

Figure 7.3 Settings Tab

www.smithycnc.com | 17

Page 24

w SmithyCNC EZ-Trol II Control System

WIZARDS TAB

he newest feature of the new EZ-Trol II Control System is that it has built-in machining Wizards

T

that ease your common programming tasks. Simply select the Wizard that best represents the pattern you wish to machine. The user interface will then prompt you, in a conversational manner, to

select the dimensions and sizes required to machine your desired geometric pattern. It will also

prompt you to select tools, tool path and speeds of travel. When you are finished the Wizard will

generate the G-code based on your input. You can string together the output of several Wizards to

make a complete CNC part program. This method saves a lot of effort and is especially helpful if

you are inexperienced CNC programmer.

Figure 7.4 Wizards Tab

NAVIGATING EZ-TROL II

• Mouse Navigation - Left clicking the mouse on a desired field will select that field.

Right clicking on the tool path display window (in the Auto and Mill tabs) will display

a list of view options, which will be, explain in detail in future chapter. As described

earlier the operator moves from one tab to the next by clicking on the desired tab.

Once a button has been selected a black border will appear around the button and the

button itself will appear a shade darker.

Keyboard - The main function of the keyboard is manual data entry when creating or

•

editing a g-code file or changing the speed or feed values manually in the Auto Screen.

abbing will move the cursor between fields. This is helpful if you need to modify or

T

create a tool in the settings tab.

Here are some keyboard shortcuts that you can use:

Left, Right, Up, and Down Keys - used to move the X and Y Axis respectively

Page Up and Page Down - used to move the Z Axis

Bracket Left “[“ and Right “]” - used to move the A Axis (rotary)

.

18 | Toll Free 1-800-476-4849

Page 25

11 - used to switch the screen between fullscreen and window mode.

F

liders-Sliders such as those shown on the Auto Screen in figure 5-3 under the “Feed

• S

Override” and “Speed Override are moved by left clicking on the slide and dragging the

slider to the desired position. Sliders can also be repositioned by clicking your mouse

anywhere in the slider field, which will move the slider to or near that position where

he mouse was clicked.

t

BACKLASH COMPENSATION

In editing or compensating the backlash of the machine, you can follow these steps:

1 From your desktop, click “go to” and a drop-down menu will appear. Click for the

Home.

2 On the Home Folder, double click EMC 2 folder.

3 From the EMC 2 folder, double click CONFIG folder.

4 Then look for the SIM folder and double click it to enter.

5 Double click SMITHY.INI file.

6 A question will be prompt if you want to edit the file. Answer YES.

7 After answering Yes, a file notepad/ text file will appear. Look for BACKLASH = 0.000.

8 Edit the value of the backlash.

9 On the main menu, click FILE and SAVE the changes.

10 Click File again and CLOSE

the page.

www.smithycnc.com | 19

Page 26

8

HOMING & SETTING OFFSETS

OVERVIEW

This chapter will familiarize you with the process of setting home positions for the Smithy CNC bed

mill. The control system is capable of setting axes home positions simultaneously

good practice to set one axis at a time when you first set up the machine. This will help control the

process better and help familiarize you with the speed of the machine and the machine axis travel

parameters.

MACHINE HOME SETTINGS

The machine home setting is the position defined by the factory from where all movements are

calculated. Each axis of the machine needs to be homed in order to synchronize the physical

position of the axes with the position registered in the CNC control. There is no necessarily

appropriate or best position to set as machine home. Some companies set the home position at one

of the corners of the machine work table. The SmithyCNC system sets the machine home position

at a distance of .25” away from each of the limit switch stops at the right rear of the machine’s

operating envelope. Setting home at this position means all axes movements will be in a negative

direction.

, but it would be

INITIAL MACHINE HOMING-ONE AXIS AT A TIME

The first time the machine is homed, home one axis at a time to verify each movement. After you

have powered up your machine, follow the steps below to return the machine to the home position.

Note: Before each axis has been homed, the position coordinates will be an orange color and after

they are homed the color will change to blue.

1 Make sure the Emergency Stop button on the control is not engaged.

2 Click on the Manual Tab (See figure 8.1).

3 Click on the Axis Set-Up Button will present the pop-up window shown in figure 8.2

will appear.

4 Click on the X-Zero Button. The machine will move the X axis in the positive direction

until it stops at the X axis home position. (The table will move to the left). For safety

reasons, it is best to home the Z-Axis first if you are going to home an axis at a time.

20 | Toll Free 1-800-476-4849

Page 27

Figure 8.1 Homing Axes

Figure 8.2 Axis Set-up Screen as described on Step 3

www.smithycnc.com | 21

Page 28

w SmithyCNC EZ-Trol II Control System

As each axis moves, watch carefully to become familiar with the speed and direction

f movement. If necessary, axes can be interrupted during the homing movement by

o

pressing the E-Stop button. (There are two available to you: one on the control and one

n the software.)

o

Keep an eye on the machine table movement and carefully watch as the machine

approaches the limit switch. It is a good idea to keep your hand on the E-Stop button.

he position is Figure 8.6 shows that appropriate table location to the saddle for the X-

T

home position. As the machine approaches home, it will slow down. Once it reaches

the X axis travel limit it will back off 1/4” away from the physical limit switch. This is

the Z axis home limit.]

5 Once the machine has returned to the X-home position, repeat step four on the Y axis.

As the Y axis approaches the home position, carefully watch as the machine

approaches the limit switch, with your hand on the E-Stop button. The position in

figure 8.6 shows the appropriate table location in relation to the saddle for the Y-home

position. As the machine approaches the Y axis travel limit it will slow down. Once it

reaches the limit switch it will back off 1/4” from the physical limit switch. This is the

Y axis home limit.]

6 Once the machine has returned to the Z-home position, repeat step four on the Z axis.

As the Z axis moves up carefully watch as the machine approaches the limit switch,

with your hand on the E-Stop button. The position in figure 8.6 shows the approximate

table location in relation to the saddle for the Z-home position. As the machine

approaches the Z upper limit it will slow down. Once it reaches the Z limit it will stop

and then back off 1/4” from the physical limit switch. This is the Z axis home position

NOTE: If the machine over travels during homing check the position of the limit and proximity

switches. See Chapter Eight of the machine manual for details.

7 If your machine is equipped with a rotary table, home the A-axis as noted in step four.

8 When all axes are at the home position, click okay to be returned to the Manual Tab.

HOMING YOUR MACHINE ON ALL AXES

After the machine has been homed for the first time and the movement of each axis has been

observed, the machine can be returned to the home position again by clicking on the “All Zero”

button in the Axis home screen picture in the figure. This will return the X, Y, and Z axes to the

machine home position.

NOTE: Before powering down the machine, make sure the X-axis is approximately in the middle

of its travel.

LIMIT OVERRIDE

Each axis has a sensor that limits the travel in each direction. The sensor is actuated by small metal

blocks attached to the moving parts of each axis, one at each end of the travel. If any axis is moved

far enough in either direction the metal block will cover the face of the sensor, telling the CNC

control, that the limit of travel for that axis has been reached. When this happens, the position

display numbers on the screen will turn red and further movement of any axis is inhibited. In order

to move the over traveled axis off of the limit sensor, follow the steps below.

22 | Toll Free 1-800-476-4849

Page 29

NOTE: You can tell if the machine is in E-Stop by the red colored E-Stop button on the machine.

ou will need to click this to start the machine. The machine is on E-Stop when the E-Stop button

Y

is grayed out. The reason behind this is when the machine is out of E-Stop, you can run a program

nd jog around the machine. The E-Stop button is RED so as to catch attention and ready to be

a

activated when an emergency happens.

1 While in the Manual Tab, click the Axis Set-Up Button.

2 The Axis Home window in figure 8.2 will pop-up. Click on the square check box to the

left of “Limit Override”. An “X” will appear in the check box.

3 Click the “Ok” button in the Axis Home window, which will close the window.

4 Click the appropriate axis jog button to move the axis towards its center of travel.

When the axis is off the limit sensor, the position display numbers will turn black. You

will need to reset the axis that ran past the physical limit of travel to the home position.

NOTE: The limit override check box will only remain active for one axis movement. To jog the

same axis again or a different axis, you will need to click on the Axis Set-up button again and

recheck “Limit Override”.

BASIC G-CODE

Before machine offsets is addressed, it is important to have a basic understanding of the language

that the SmithyCNC machines use to execute the parts program. This language is called G-Code.

SmithyCNC machine use the NIST Standard language called RS274NGC. This language is

comprised of a number of codes called G-codes and M-Codes.

An M-code is a miscellaneous code. It controls an action of some specific part of the machine. A

G-code is related to a machine motion.

If the operator is familiar with manual machines it is easy to picture how the CNC tool works.

Imagine a work piece secured in a vise which is mounted to the table of a conventional mill and

there is an end mill in the spindle.

Hand wheels on the conventional machine allow us to

alter the relationship between the tool and the part. Turn

the X-Axis hand wheel and the work piece will move

with the table away from or toward the operator in

relation to the number of turns of the hand wheel. For

instance, turn the hand wheel of the machine one

revolution. One pitch worth of change in the relationship between the tool and part will be the result of the

movement. T

fast, turn it slow and the change happens in slow motion.

The same change happens in the Y and Z hand wheels

when they are moved. Change in the position of each

axis causes a different relationship.

urn the wheel fast and the change happens

Figure 8.4 A Manual Milling Machine

www.smithycnc.com | 23

Page 30

w SmithyCNC EZ-Trol II Control System

G-Code programming is designed to tell a motor located on the end of each axis screw to act as the

and wheel for that axis. G-Code, much like any human language is made of words. G-Code words

h

are bit different than human languages in that the first letter of each word tells a control what the

ord is about. We often speak in G words, F words, S words and X, Y and Z words.

w

There are five motion words to learn which are listed in the table below:

G0

G1

G2

G3

G80

Rapid positioning - Move the axis as quickly as possible

Move to a position by feed rate equal to or slower than rapid

Move the tool or part in an arc in a clockwise direction

Move the tool or part in an arc the opposite direction of G2

Tells the machine not to move

Table 8.1 G-Code Motion Terminologies

These five-motion words tell the machine to move but only one word can be said at a time. The

machine tool will remember that one word until another word is given to the machine tool. In other

words, these words are modal. If you write G0, your machine will continue moving rapidly until

another G-Code is given to replace the G0.

To rapidly reposition the work piece so it is sitting at the Z-Axis, Y-Axis and X-Axis at zero.

The following block of code would be written:

G0 Z0

X0

Y0

It is not necessary to repeat the G0 on each line. The modal nature of the motion commands can

be both good because it saves time typing and bad because it can be forgotten to switch from the

rapid feedrate and break things.

Looking at the code just created, each axis has a separate motion. The first move is for the Z-Axis

only, then an X move alone and finally a pure Y move. The same code could be written in one

single block it would like the following:

G0 Z0 X0 Y0

This block of code will move quite differently then the one above it. Instead of moving one axis at

a time, it will move all axes at once and instead of moving the X and Y movement in a linear motion,

the combined movement of the X and Y Axis will result in diagonal motion. If the machine were

sitting at X1, Y1 and Z1, which means that it is one unit away from the zero, the home, the issued

block, would return the machine to the positron of X0, Y0 and Z0. If a square block was mounted

to your table where X1, Y1, Z1 is positioned on one corner of the block and X0, Y0 and Z0 are at the

other corner of the block, the move is through the middle of the block between these two corners.

Many G-Codes will work in conjunction with additional codes (words). For instance G1 tells the

machine to move at a certain feed rate, which means the feed rate must be given to the machine

along wit the G1 code. Feedrate, like the motion G-Codes is a modal command. Once a feedrate is

given it will stay in effect until a new feed rate is given. The first line of a set of feed moves might

look like the second line in the program shown below:

24 | Toll Free 1-800-476-4849

Page 31

G0 Z0 X0 Y0

G1 F10 M3 S1000 Z-0.25

-1

Y

X-1

Y0

X0

0 Z0

G

M2

Not only does this program set the feedrate, it adds a few new elements as well. Notice, the first

block gives the machine a starting location. By using a block like this we are getting the sequence

to start at an expected location, a known location between the tool and the work piece.

The second line tells the machine to move at a given feed rate. In this sample that given feed rate

is at is F10, which could be ten inches per minute or 10 millimeters a minute. This depends upon

another modal group that will be discussed later

. The default for SmithyCNC bed mills is inches.

Also in the second line of code you will see M3 S1000. These commands are telling the machine’s

spindle what to do. M3 turns the spindle on in the forward, clockwise direction. The S1000 means

sets the spindle speed; in this case the speed is set to 1000 revolutions per minute.

The remaining code in this block Z -0.25 tells the spindle to move the tool down, denoted by the

negative sign, into the work piece a 0.25”.

The next line, Y-1 will move the Y-Axis 1 unit away from the operator.

The line X-1 will move the X-Axis 1 unit to the right, from the operator’s view of X0.

The line Y0 will return the Y-Axis to the Y0 position. The movement will move the table toward the

operator.

The line X0 will return the X-Axis to the X0 position. The movement will move the table to left of

viewed from the operator's perspective.

The line G0 Z0 rapidly returns the Z-Axis back to Z0 from the work piece.

The last line, M2, tells the machine that the program has been completed.

Figure 8.5 below illustrates that the G-code program generated a square movement.

A programmer’s reference manual that provides a much more extensive explanation of G-codes is

included with this EZ-Trol II user’

s guide.

www.smithycnc.com | 25

Page 32

w SmithyCNC EZ-Trol II Control System

Y-Axis

G0 Z0 X0 Y0

G1 F10 M3 S1000 Z-0.25

1

Y

X1

Y1

X1

Y0

X0

G0 Z0

X-Axis

Figure 8.5 G-Code & Generated Path

NOTE: You can use the MDI entry point in the manual tab to run this program if you wish.

-1

+1

-1

Part

Zero

+1

COORDINATE SYSTEMS & OFFSETS

A number describes the position of each axis. This number represents the distance between the

current position and the machine home position. Since a work piece might be fixture to the table in

an arbitrary position with respect to machine home, it would be convenient to shift the axis positions to coincide with a defined position on the work piece. EZ-Trol allows for nine pre-defined

coordinate systems. Each of which can have their origin offset to correspond to a point relative to

the work piece. The coordinate systems are listed on the setting page next to the G-Code word

used for selection. These are defined as: G54, G55, G56, G57, G58, G59, G59.1, G59.2 and G59.3.

NOTE: G53 can be used to refer to the machine coordinate system where the home point for each

axis is 0. For instance, if you use the block of code, G53Z0, the Z-Axis will move to its home

position. The G53 word is “non-modal”.

The objective here is to give the new user a brief introduction to offsets and to understand how they

work. We will discuss setting offset in detail in later chapters.

Notice the position of the table in figure 8.6. The depiction on the left shows machine home

position. The picture of the machine on the right shows the mid-point of the spindle is centered over

the corner of the work piece (the black block) that is mounted in the vise. This is where we offset

the G54 coordinate system. This will tell the control system that the G54 coordinate system origin

is the zero reference, starting point for the positions and distances in the program.

26 | Toll Free 1-800-476-4849

Page 33

V

ISE

STEPPER

MOTOR

M

AIN TABLE

VISE

M

AIN TABLE

Figure 8.6 Left: Machine is at Home Position (G54); Right: Part is at Home Position

SmithyCNC 1240 Bed Mill shown.

S

TEPPER

MOTOR

www.smithycnc.com | 27

Page 34

9

NAVIGATING THE AUTO TAB

OVERVIEW

This section will introduce the features of the Auto screen and explain how to execute a part

program from this screen.

AUTO TAB PARTS

Figure 9.1 Auto Tab

The auto screen, pictured in figure 9.1, will appear when the Auto Tab is selected. This screen is

clicked at the time you are ready to execute a parts program. From this screen the feed rate and

spindle speed can be adjusted. Also, operations can be aborted, stopped or paused from this

screen.

Each area of the Auto Screen that is numbered will now be described an explained in more detail.

28 | Toll Free 1-800-476-4849

Page 35

1 POSITION AREA

The position area of the Auto Tab has a digital display of the machine’s positioning of each axis. If

any of the axis displays are orange, the machine is not homed and the homing operation should be

performed before proceeding. If the numbers are blue, the machien has been homed.

2 TOOL PATH DISPLAY AREA

The tool path display area shows the tool path of the part to be produced as well as the cutter

movement. As the part program is being executed, the movement of the cutter will be shown on the

tool path display. The display can be viewed from a number of different views.

Right clicking on the tool path display window will bring up a sub-menu that shows view options.

The view options are listed below with the corresponding views:

Figure 9.2A Front View Figure 9.2B ISO View

Figure 9.2C Side View Figure 9.2D Top View

Figure 9.2E Fit View

www.smithycnc.com | 29

Page 36

w SmithyCNC EZ-Trol II Control System

2A PAN ACROSS DISPLAY AREA

The perspective of the view is changed by clicking and dragging the mouse.

2B ZOOM IN OR OUT ON THE VIEW

To change the size display area drawing first hold down the CONTROL key, click and hold the

mouse button down. Then, moving the mouse pointer up will zoom in. Pulling the mouse down will

cause the display to zoom out.

2C ROTATE IMAGE

Hold down the SHIFT key and move mouse to the left to rotate the image.

3 COMMAND MENU

The command menu is located at the bottom of the Auto Tab screen. This menu is noted as 3 on

the in figure 9.1. It is made up of a series of buttons - Open G-Code file, Run, Pause, and Resume.

Each of these functions perform a certain operation related to the execution of the parts program.

The function of each of these buttons is explained below.

3A OPEN G-CODE FILE

The open button, noted as 3.A in figure 9.1, is clicked when you want to open a part program. The

default location for storing parts program is home/smithy/gcodes. Clicking on the “Open...” button

displays a folder which holds all previously prepared and saved parts program. Double click to

select a chosen part file. NOTE: These files will have the file extension “.ngc”.

3B RUN

Clicking on the run button, denoted by 3B in figure 9.1, will cause the machine to start running and

machining the part program. NOTE: The E-Stop must be in the off position on the control box and

on the software (the button should be colored Red)

3C PAUSE & 3D RESUME

Clicking on the pause button, while the program is running, will cause the operation to stop and the

machine will stop moving at the designated point. The machine will remain in this pause status until

the “Resume” button, denoted by 3D in figure 9.1, is clicked. The program will begin again from

where it was paused. If possible, it is best to use the “Pause” button between cuts.

3E STEP

The step button, denoted by 3E on figure 9.1, works in conjunction with the Pause button and it

allows the user to step through the parts program one block of code at a time. When in pause mode,

press “Step” to progress to the next block of code. Resume the program running by clicking on the

“Resume” button. The program line being executed is highlighted in black.

4 STATUS BLOCK

The status block located at the top right hand side of the screen, will display any g-code errors

found during the verification process. Human Read Messages that are written into the program will

also be displayed in the Status block. For example, if running a program that requires a tool change,

the machine will pause, and display a message to install the appropriate tool.

NOTE: When changing tools while having the machine in “Pause” state, it is necessary to turn the

30 | Toll Free 1-800-476-4849

Page 37

key switch on the front of the control box to the “Safe” mode before proceeding with the tool

hange. This will prevent an unfortunate and dangerous accident from occurring should someone

c

inadvertently make changes at the control while the operator has hands within the machine work

rea.

a

Messages can be cleared from the screen by clicking on the square that appears before the word

“Status”.

5 FEED OVERRIDE

There are a series of charts that provide the machinist with a recommended feed rate for the type

of material being machined. Often machinists find that the feed rate needs to be “tweaked” during

the machining process to improve the surface finish. In other cases they may find that they can

increase the feed while not diminishing the surface quality to save time and money.

EZ-Trol allows the operator to adjust the feed rate up to 150% but it cannot adjust the feed rate to

a percentage that would increase the rate beyond the machine’s recommended maximum setting.

The machine has a maximum feed/jog speed so even if you command it to go 150% override, if it is

already jogging at its maximum it will not go past that limit.

Moving the slide, which is denoted as number 5 in figure 9.1, can set the Feed Override. The value

can also be entered into the field next to the wording “Feed Override”.

6 SPINDLE OVERRIDE

There are charts similar to the feed rate charts for suggested spindle speed based on the cutter

diameter and the material of the cutter. These charts do not take into consideration the motor size

and are therefore are given in a suggested range. As with feed rates, the spindle speed is often

adjusted during the machining process. The need for adjustment is often noted by the chip

coloration.

The spindle speed is adjusted in the same manner as the feed rate with the slider, denoted by item

6 in figure 9.1 or by manually inputting the value into the field after the “Speed Override” title.

The spindle speed can only increase the current setting by 200%. Trying to increase the speed past

the factory setting of your machine will essentially be ignored by the control and it will only

increase to the maximum default setting of the Smithy CNC machine

7 E-STOP BUTTON

When the E-STOP button on the machine’s control is denoted by 7 in figure 9.1, is off, it will turn

RED, which means that it is ready to be activated. If the E-Stop button is activated it will cut all

power to the machine. The machine will loose position and the machine will need to be reset to

home position.

8 ON

This button switches the machine back on after turning it off using the E-Stop button.

9 ABORT BUTTON

When the ABORT button, denoted by the 8 in figure 9.1, is clicked , the program will stop running

at the current line. The machine will not need to be re-homed, but you will need to restart the

program. You can restart your program from a given line by right clicking your mouse on the line

you wish to start.

www.smithycnc.com | 31

Page 38

w SmithyCNC EZ-Trol II Control System

10 FEED HOLD

Clicking the FEED HOLD button, denoted by 9 in figure 9.1, will “freeze” the movement of the

machine’s axes but it will not turn off the spindle. The button will also change colors, from orange

to green. Click the FEED HOLD button again and the machine will start moving again. You can

estart your program from a given time by right clicking your mouse on the line you wish start at.

r

11 FILE LOCATION ADDRESS BAR

Displays the directory where the file is saved on your computer. This will help you locate the files

easily when opening and running the program again.

12 PROGRAM DISPLAY WINDOW

When a chosen part file is opened, the g-code text or is shown on the right window it will appear in

the program display window, which is denoted by number 10 in figure 9.3.

Once the program has started running, the block line of code that is currently being executed will

be highlighted in black. There is also a slider bar on the right hand side of the screen which the

operator can move while the program is running This slider allows the operator to be aware of any

tool changes or pauses for other reasons.

NOTE: This is an active screen and modifications or changes to the g-code program cannot be

made from this screen.

Figure 9.3 Program Display Window

NOTE: On figure 9.1, the actual feedrate and spindle speed is not adjusted but overriden to a

percentage it was originally set. For example, you were pocketing a circle and you set the speed

to 20 inch per minute, then when you run the program you feel that the machine is having

difficulty, you can set the feedrate overrride to 50% and the machine will now have a feedrate

of only 10 inch per minute. This is similar to spindle override slider control.

A box will be shown in the 3D view that represents the “working cube” of the machine. Make

sure that the tool path is within this cube to avoid “program will exceed limit” when you try to

run a program with toolpaths outside the cube.

If the code was not generated in EZ-Trol, an operator will find that some rewriting of the G-code

may be needed in order to execute the program with EZ-T

programs uses a slightly different set of G-codes and M-codes for their specific machine

program. Smithy Company also offers a service for editing or creating G-code for a nominal fee.

Call 1-800-476-4849 for details.

rol. Every manufacturer and CAM

32 | Toll Free 1-800-476-4849

Page 39

10

NAVIGATING THE MANUAL TAB

OVERVIEW

This section will introduce the features of the Manual screen and describe when the features found

on this screen are used when executing a part program.

MANUAL TAB PARTS

Figure 10.1 Manual Tab Screen

Clicking the manual tab on the top menu and you will be brought to the screen pictured in figure

10.1. The operator selects the manual screen for the following functions:

Manual jogging of axes.

•

Running lines of g-code using the MDI input screen.

•

• Turning the spindle on/off manually.

Turning the coolant on/off manually.

•

The machine is also set to home position from this tab.

•

www.smithycnc.com | 33

Page 40

w SmithyCNC EZ-Trol II Control System

1 POSITION AREA

The position area of the Auto Tab displays the position of each machine axis. If the number

displayed is orange, the machine is not in machine home position and must be homed before proceeding.

2 JOG AREA & SPEED AREA

The jog area has eight buttons for bi-directional jogging of each of the X,Y,Z and A axes. Clicking

the button for the desired axis and direction will cause that axis to move in the direction chosen.

ThE Speed Area directly corresponds to the Jog area. There are two radio buttons that determine

how the jog movement is made: Continuous and Incremental speed.

• CONTINUOUS & INCREMENTAL SPEED

If the Continuous radio button is selected, when the X- or X+ button is clicked the machine table

will move in the selected direction until the mouse button is released, reaches the soft limit (soft

limits are explained in appendix A of this manual.) of travel or has reached the preset position

determined by the operator. The movement is at the jog speed represented by the Jog Speed

slider.

If the Incremental radio button is selected, when the X- or X+ button is clicked the table will move

the distance entered into the amount field. Each time the mouse is clicked the table will move that

distance until the machine has either reached the soft limits of travel or the position desired by the

operator. The movement is at the jog speed represented by the Jog Speed Slider.

• AMOUNT

The amount field allows the user to key in or use the up and down arrows on the side of the amount

field to enter the desired amount the operator would like to jog a particular axis. Clicking the up

arrow will increase the numbers from 0.001” to 0.01” 0.1” to 1”. The operator can manually key in

any number between 0.001” and 1.0”. For instance, to move the X-axis in the selected direction back

to the part home (also called part zero) a 1/2” (0.5”) of an inch at a time, enter 0.5 in the amount

field. Click on the desired direction of travel button in the Jog area. Selected the radio button for

Continuous speed. The table will then move a half an inch in the selected direction each time you

click the mouse. Hold the mouse key down until the table has moved the amount denoted in the

amount field. Selecting the incremental radio button will cause the table to move in the selected

direction a 1/2-inch at a time, until it reaches the desired position. Please note: if you have selected

the incremental radio button, an amount of desired incremental movement must be selected for

each axis.

• FEED & RAPID BUTTONS

If the Feed button is selected the machine axial movement will travel at the selected jog speed

displayed in the Jog Speed field. If you click the Rapid button, the machine’s axial movement will

progress at the maximum feed rate of 120 inches per minute.

3 AXIS SET-UP

• X & Y AXIS’ POSITIVE & NEGATIVE DIRECTION

The operator views the positive and negative directions from the front of the machine and the

34 | Toll Free 1-800-476-4849

Page 41

direction of travel is the direction that the cutter will follow as it passes the work piece. Clicking

n the X- button will cause the table to move to the right but your work piece will pass under the

o

fixed tool moving to the left This is the negative direction. By clicking on the X+ in the jog area,

he table will move to the left but the work piece will pass under the fixed tool moving to the right.

t

The direction of the cut always moves in the opposite direction of the table movement

-Axis

Y

Part

Zero

X-Axis

-1

+1

Figure 10.2 EZ-Trol X

Clicking the Y- button causes the mill table to move away from the operator and the work piece

passes under the spindle mounted tool in the opposite direction, in this case the negative direction.

When the Y+ is clicked, the table will move toward the operator and the tool will pass over the work

piece in the positive direction.

& Y Standard Direction Movement, User Facing the Machine

• Z-AXIS POSITIVE & NEGATIVE DIRECTION

The Z-Axis moves closer to the table when the Z- button is left clicked and away from the table

when the Z+ button is clicked in the jog area.

• A-AXIS POSITIVE & NEGATIVE DIRECTION

Left clicking on the A- button will rotate a 4th axis rotary table counter-clockwise and the A+

button rotates the table in the clockwise direction.

4 STATUS BLOCK

The status block located at the bottom left hand side of the screen, will display any g-code errors

foundwhen loading the G-code program during the verification process. The number that proceeds

the identified error indicates the number of errors found by running the verification process in EZ-

rol. The error messages can be cleared from the screen by clicking on the square that appears

T

before the word “Status”.

Clicking the square next to “Manual Data Input” brings up a screen that shows active G-codes,

M-codes, feed rates and spindle speeds.

Figure 10.3 Screen Shot of the Status Block showing all file information

www.smithycnc.com | 35

Page 42

w SmithyCNC EZ-Trol II Control System

5 FEED OVERRIDE

EZ-Trol allows the operator to adjust the feed rate up to 120% but it cannot adjust the feed rate at a

percentage that would increase the rate beyond the machine’s recommended maximum setting. For

instance, if the operator wanted to move the X-Axis from one limit to another and a continuous

ovement of speed had been selected that was set at a feed rate of 0.25 inches per minute, the

m

perator may want to increase the feed rate. To override the feed rate, reposition the slider until

o

you have reached the desired feed rate. A value can also be entered into the Feed Override field as

long as the value doesn't exceed the maximum feed rate of 120 inches per minute, which is set by

the factory.

6 JOG SPEED

The operator can adjust the speed of axial movement while jogging either with the slider below “Jog

Speed” or by entering a value in the field next to the “Jog Speed”.

7 SPINDLE SPEED CONTROL

The operator can also adjust the spindle speed from the manual screen by moving the slider from

left to right, which adjusts the spindle speed control by a percentage of the current speed setting.

The operator can also set the spindle speed by entering in a value in the field directly after the

Spindle Speed Control wording. Spindle speed cannot be set beyond the maximum default speed

range of the machine tool that is being operated.

8 E-STOP

The E-Stop in the manual mode is used to stop the machine in cases of emergency while the

operator is manually jogging the machine axes. Before starting manual jog moves remind yourself

that the E-Stop is available and note it’s location for easy recall as needed. When selected it will

turn red and all power to the machine will be cut. You will need to reposition the axes when the

E-Stop has been pushed.

9 ON

This button switches the machine back on after turning it off using the E-Stop button.

10 ABORT

Abort works in a similar fashion to the “Abort” function in the Auto mode. When Abort is clicked

all action will be stopped but position will not be lost. There are situations where the Abort button

is helpful. For example, if continuous feed has been selected and the operator decides to move the

table 0.5 inches but accidentally types in 5.0 inches. He would certainly quickly notice that the

machine has moved past the 0.5 inches of desired movement and clicking on the “Abort” button can

stop this action.

11 FEED HOLD

Feed Hold works in a similar fashion as the Feed Hold in the Auto mode. When the Feed Hold

button is clicked, all movement will be “paused” but the machine will continue to be “energized”

and the spindle will continue to rotate. The button will turn green when the Feed Hold button is

engaged. Clicking again on the Feed Hold button will resume axial movement through to the

completion of the part program.

36 | Toll Free 1-800-476-4849

Page 43

12 MANUAL DATA INPUT

This field is used for manually entering and executing G-code commands. For instance, it can be

used to verify the position of an offset. First home the machine and then enter a known offset

position such as G55 X0 Y0 Z0 and press enter. This block of code would instruct the machine to

o to the zero point of the offset G55. The position can then be verified with the values in the

g

osition area. (A tutorial for manual G-code program is found in the accompanying manual,

p

“SmithyCNC G-code Programming Guide”.)

13 SPINDLE

There are three options in the spindle area. The default setting is “OFF”. Selecting the Forward

radio button causes the spindle to rotate in a clockwise rotation. Selecting Reverse causes the

spindle to move in the opposite, counter clockwise rotation. This is for manual operation only; the

settings do not affect the parameters set in the program.

14 COOLANT

There are two options listed in this section, Mist or Flood. Selecting either option will turn your

coolant system on. In order for the coolant system to operate the coolant switch on the control box

must be in the manual position.

www.smithycnc.com | 37

Page 44

NAVIGATING THE SETTINGS TAB

SETTINGS TAB PARTS

11

Figure 11.1 Settings Tab Screen

The Settings tab allows the user to open, edit and save files. Work piece and tool offsets are also

created on this screen.

1 EDITOR

The editor consists of three sections denoted as 1A, 1B and 1C in figure 11.1. Item 1A is the Save

and Send to Control button which sends the program to the control for operation. 1B is the Save As

and Send to Control button where in you can rename a program and save it before sending it to the

control for operation. 1C denotes the editor display. When an existing file is opened it will be

displayed in this screen. It can be edited from this screen as well. The operator can also write a new

program in this screen.

2 TOOL TABLE

The tool table is located at the bottom of the screen and has numerical row headers and columns

which are labeled as followed:

38 | Toll Free 1-800-476-4849

Page 45

Pocket - This is used with machines that have ATC (automatic tool changers). EZ-Trol is

esigned to fit a wide range of machines, some of which may have tool an ATC.

d

Currently your mill does not come with an ATC.

FMS - not applicable with Smithy machines.

Length - This records the length of the tool.

Diameter - This field records the diameter of the tool.

Comments - Here the user can record any related information up to 120 characters.

2A and 2B denotes the “Add” and “Delete” button for adding or deleting tools. To add a tool

Items

click on the “Add” button and an additional row will appear in the tool table. Double click in the

desired field and enter the data required for the selected tool. To delete a tool, place the cursor in

one of the related fields of the tool that is to be deleted and then click the delete button to the left

of the tool table.

Double clicking in the field can modify tools that require editing.

3 OFFSETS

The offset section of the Settings Tab is where the user can define a series of part zero positions.

An explanation of offsets is given in more detail in chapter 6 and 15. An overview of the required

steps for establishing an offset is listed below.

1 Click on a radio button for the G-code number that is to be defined, for example, click

on G55.

2 Click on the Manual Tab and jog the machine axis into the desired position. (See

Chapter 15 for details on determining and setting zero points for offsets.)

3 Return to the Settings Tab. The values in the X, Y and Z fields are now less than zero.