Page 1

SMITHYCNC 1240 BED MILL

OPERATOR’S MANUAL

VERSION 1.1

2008

Page 2

SmithyCNC 1240 BED MILL Operator’s Manual

SmithyCNC (Smithy Co.)

170 Aprill Dr., Ann Arbor, Michigan

USA 48103

Toll Free Hotline: 1-800-476-4849

Fax: 1-800-431-8892

International: 734-913-6700

International Fax: 734-913-6663

www.smithycnc.com

Copyright © 2008 SmithyCNC & Smithy Co.

All rights reserved. No part of this manual may be reproduced or transmitted in any form

by any means, electronic, mechanical, photocopying, recording, or otherwise, without prior

written permission of Smithy Co.

For information on getting permission for reprints and excerpts, comments, or suggestions,

contact info@smithy.com

While every precaution has been taken in the preparation of this manual, Smithy Co. shall

have any liability to any person or entity with respect to any loss or damage caused or

alleged to be caused directly or indirectly by the instructions contained in this manual or

by the computer software and hardware products described in it. Please see section on

warranty and safety precautions before operating the machine.

Printed and bound in the United States of America

Page 3

TABLE OF CONTENTS

1 | INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Thank You . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Important Reminder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Suggestions or Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Customer Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 | SMITHYCNC SYSTEM WARRANTY . . . . . . . . . . . . . . . . . . . . . . . 3

3 | GENERAL SAFETY GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Symbols Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Basic Points of Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Clothing & Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Aspects Related to Tools Work Holding

Safety Aspects Related to Maintenance . . . . . . . . . . . . . . . . . . . 9

Safety Aspects Related to Workpiece . . . . . . . . . . . . . . . . . . . . . 10

Safety Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . 8

4 | INSTALLATION & SET-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Set-up Clearances & Conditions . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power Requirments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

220 Plug Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Stand Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Moving from Pallet to Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Using a Forklift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Using an Engine Hoist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Attaching the Machine to the Stand. . . . . . . . . . . . . . . . . . . . . . . 19

Attaching the X & Z Axis motors . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installing Your Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5 | MECHANICAL COMPONENT IDENTIFICATION

& FUNCTIONS

6 | MECHANICAL MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . 24

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Lubrication System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Page 4

Ballscrews & Guidewats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Headstock & Spindle Bearings . . . . . . . . . . . . . . . . . . . . . . . 27

Period Maintenance Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Axis Bearing Adjustments/ Axis Backlash . . . . . . . . . . . . . . 27

Y-Axis Ballscrew End Bearing Adjustment . . . . . . . . . . . . . 28

Z-Axis Ballscrew End Bearing Adjustment . . . . . . . . . . . . . 28

Adjustment of Gibs on the X & Y Axis Slides . . . . . . . . . . . . 29

Headstock to Table Realignment. . . . . . . . . . . . . . . . . . . . . . . . . . 30

Linear Motion Guide & Bearing Maintenance . . . . . . . . . . . . . . 30

7 | TOOL HOLDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Tool Holding Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Installing the Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Removing the Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8 | CNC-1240 BED MILL SPECIFICATIONS . . . . . . . . . . . . . . . . . . 34

9 | MACHINE PARTS DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Diagram 1: Protective Sheetmetal Cover, Millhead,

Junction Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Diagram 2: Proximity Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Diagram 3: Mill-Drill Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Diagram 4: Column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Diagram 5: Table & Bed Assembly . . . . . . . . . . . . . . . . . . . . . . . . 51

10 | ELECTRICAL DIAGRAM & PIN OUTS. . . . . . . . . . . . . . . . . . . . . 59

Page 5

1

INTRODUCTION

THANK YOU FOR YOUR ORDER

Congratulations on your purchase of a SmithyCNC bed mill. With proper setup and

maintenance, your machine should provide many years of quality work and enjoyment.

This manual covers general instructions regarding machine set-up, operation,maintenance

and troubleshooting for SmithyCNC 1240 Bed Mills.

IMPORTANT

Before operating any SmithyCNC Bed Mill, this instruction manual and any accompanying

instruction manuals must be read carefully

place where they are always easily accessible for reference during the operation of the

machine.

. Instruction manuals should be kept in a safe

While this manual has been compiled to give the general description and usage

of the SmithyCNC 1240 Bed Mills, changes are possible due to continuous design and

development efforts.

Remember safety comes above all else. Carefully, read, follow and understand the safety

information outline in chapter 3 of this manual and always let common sense be your

guide.

SUGGESTIONS OR COMMENTS

e are interested in any suggestions you might have to improve our products and

W

services. Feel free to contact us with your suggestions by phone or in writing.

If you have comments about this operator’s manual, or if you have a project you’d like to

share with other SmithyCNC owners, contact the SmithyCNC Company, P.O. Box 1517,

Ann Arbor

, MI 48106-1517. Y

ou can also e-mail sales@smithy.com 24 hours a day.

Or visit www

.smithy

.com

1

Page 6

mithyCNC 1240 Operator’s Manual

S

QUESTIONS

If you have questions not covered in the manual, please call our toll-free number:

Our friendly service technicians are available Monday through Friday from 8:00 a.m. to

5:00 p.m. Eastern Standard Time. You can also e-mail your questions 24 hours a day to

sales@smithy.com. If you are calling from outside the United States, please dial 1-734913-6700

Don’t forget to check our website periodically, where we will post updates and revisions

to this manual as well troubleshooting techniques and technical advice.

. You can also fax your questions to 734-913- 6663.

CUSTOMER INFORMATION

Please record the information below about your SmithyCNC Bed Mill. Having this

information readily available will save time if you need to contact Smithy for questions,

service, accessories, or replacement parts.

1-800-476-4849

Model number: _____________________________________________

Serial Number: _____________________________________________

Purchase Date: _____________________________________________

Delivery Date: ______________________________________________

We look forward to a long working relationship with you, and thank you again for putting

your trust in SmithyCNC.

2

Call Us T

ee 1-800-476-4849

oll Fr

Page 7

2

WARRANTY INFORMATION

SMITHYCNC SYSTEM WARRANTY

30 Day Trial Offer

ry a Smithy for 30 days. If, for any reason within that time, you decide to return your

T

Smithy, just call our Customer Service department at 1-800-476-4849. We will help you

arrange shipping back to us. When we receive the machine back, we’ll refund your full

purchase price. Please note: return shipping charges and any shipping damage from

improper repacking is your responsibility.

Smithy Warranty

Smithy 3-in-1 and Dedicated Machines are warranted for two years (unless otherwise

noted)to the original purchaser against defects in materials and workmanship. During that

time, Smithy will replace any defective parts that are returned to our warehouse, free of

charge. Upon receipt of the defective parts, Smithy technicians will arrange with you to

send replacement parts immediately. This warranty does not cover parts that are worn out

through the negligence on the part of the operator nor does it cover consequential

damages resulting from defects in material or workmanship.

SmithyCNC warrants its machines and control systems for a period of one (1) year to the

original purchaser from the date of purchase. If within one (1) year form the date of

purchase a SmithyCNC machine and/or control system fails due to defect in material or

workmanship, SmithyCNC will at their choice repair and/or replace components with new

or remanufactured parts free of charge.

(Some have asked why SmithyCNC machines have a shorter warranty period than Smithy

manual machines. There are several reasons, but the greatest factor is that, on average,

CNC automated machine tools, are operated a significantly greater number of hours

per day than the average manual machine. Also, by comparison, most of our competitors

selling benchtop CNC machines only offer a six (6) months warranty

machine have a full one (1) year warranty

Most warranty repairs and/or replacements are handled routinely, but sometimes request

for warranty service many not be appropriate. This warranty does not apply to defects due

directly or indirectly to misuse, abuse, negligence, accidents, repairs, or lack of routine

maintenance. This warranty is also void if the serial number of the machine or SmithyCNC

control system has been removed or has been altered or modified.

.)

Or visit www

.smithy

.com

. Whereas SmithyCNC

3

Page 8

mithyCNC 1240 Operator’s Manual

S

I

n no event shall Smithy be liable for indirect, incidental or consequential damages for the

sale or use of the product. This disclaimer applies to both during and after the term of this

warranty.

We do not warrant or represent that the merchandise complies with the provisions of any

law or acts unless Smithy Co. so warrants. In no event shall Smithy's liability under this

warranty exceed the purchase price paid for the product. Legal actions brought against

Smithy Co. shall be tried in the State of Michigan, County of Washtenaw.

Smithy Co. shall in no event be liable for death, injuries to persons or property for

incidental, contingent, special or consequential damages arising from the use of our

products.

This is Smithy Co.’s sole warranty and any and all warranties that may be implied by law,

including any merchantability or fitness, for any particular purpose, are hereby limited to

the duration of this written warranty.

This warranty gives you specific legal rights, and you may also have other rights, which

vary from state to state. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusions may not apply

to you.

Telephone Support (Service engineers are available 8 am to 5 pm EST):

Service and Parts

Tel No. 1-800-476-4849

Fax No. 1-734-913-6663

Email Address: sales@smithy.com

Software and Programming Consultancy Services

In addition to our customary technical support for the machines and controls, we also provide technical consulting support to our customers by providing engineering and G-code

programming services. The standard rate for these services is $28.00 per hour. Our principal objective is to support you and to increase your productivity while reducing the

machining cost. Give us a call for such support as and when required.

Tel No. 1-800-476-4849

Fax No. 1-734-913-6663

Email Address: sales@smithy.com

4

Call Us T

ee 1-800-476-4849

oll Fr

Page 9

3

GENERAL SAFETY GUIDELINES

OVERVIEW

General operational techniques and safety procedures will be outlined in this manual. You

will note, for example, that all rotating parts, wherever feasible, are protected by

specially designed covers and shields. If the machine is operated in accordance with the

manufacturers instructions, it will provide you with reliable service. However, with

machines of this nature, serious accidents may occur due to improper or careless

operation. It is strongly recommended that you read this manual and accompanying

manuals and understand thoroughly the contents of the manuals. Not every example of

improper operation or unauthorized usage which may lead to malfunction or an accident

can be anticipated. If a particular operation is not documented in this manual as an

authorized usage of the equipment, it should be assumed that it is an unauthorized or

improper usage with potential danger and should be avoided or the manufacturer should

be consulted before the actual use.

SAFETY

This machine is provided with various safely devices to protect the operator and the

machine. However, these cannot cover all aspects of safety. Therefore, the operator must

thoroughly read and understand the content of this manual before the machine is turned

on and operated. The operator should also take into consideration these and other aspects

of safety related to his/her particular environmental conditions, materials and tools.

Safety Symbols Used in this Manual

Three categories of safety guidelines have been used throughout this manual. Please take

note of these symbols and understand their meanings.

If this action is not avoided, it will cause permanent harm

DANGER

WARNING

to your health, such as death or serious injury, and it may

also cause permanent damage to your machine.

If this action is not avoided, it can cause potential

harm to your health, resulting serious injury, and has

potential to cause serious harm to your machine.

Or visit www

.smithy

.com

5

Page 10

mithyCNC 1240 Operator’s Manual

S

Always observe the safety instructions inscribed on the safety nameplate fixed to the

machine.

DO NOT remove or damage these name plates.

DO NOT attempt to operate or turn on the machine until you have read and understood

the manuals supplied with the machine .

BASIC POINTS OF SAFETY

CAUTION

DANGER

I

f this action is not avoided, it may cause potential harm

t

o your health, such as minor to moderate injury, and may

also cause moderate harm to your machine.

•There are high voltage terminals on the electrical control panel, motors, junction boxes

and other equipment. DO NOT touch any of these components under any circumstances,

when the power supply is ON.

•Make sure that all safety covers are fitted and electrical boxes are closed and secured

before the power is switched to ON.

•If any components or safety covers are to be removed, first switch off or disconnect the

main plug.

WARNING

•Memorize the position of the EMERGENCY STOP BUTTON on the machine so that you

can press it immediately from any position in case of emergencies.

•

DO NOT touch any of the switches accidently while the machine is in operations.

•

DO NOT touch the tool holder while the machine is running.

•Under no circumstances, should you touch a rotating tool holder or workpiece while the

machine is in operation mode.

•To prevent incorrect operation of the machine, carefully check the position of the

switches before operation.

•If in doubt, consult this manual or a SmithyCNC technician for advise and suggestions.

•Always unplug the main plug when the machine is not in use.

6

Call Us T

ee 1-800-476-4849

oll Fr

Page 11

General Safety Guidelines

•

If more than one person is operating the machine, DO NOT proceed to the next step

w

ithout informing the other operator(s) that you are about to do so.

•DO NOT modify the machine in any way that will affect safety.

CAUTION

•

DO NOT subject the machine,control box, operator panel, or the electrical control panel

to high voltage surge.

•DO NOT change the parameters or electrical setting values without good reason. If it is

becomes necessary to change the parameters or settings, first check with a Smithy

technician to assue that it is safe to do so, then make a note of the original values so that

it can be reset to that value, if necessary.

•

DO NOT paint, soil, damage, modify, or remove any fo the safety nameplate. If the details

become illegible or if the nameplate is lost, obtain a replacement from SmithyCNC and

mount it in the original position.

•

DO NOT remove any safety covers while the machine is in automatic operation mode.

•STOP all machine operations before cleaning the machine or any of the peripheral

equipment. After a job has been completed, set up each part of the machine so that it is

ready to be used for the next series of operations.

CLOTHING & SAFETY

DANGER

•Tie back long hair to prevent entangling with rotary tools.

ear safety equipment whenever possible.

•W

•Always wear a protective mask when machining Magnesium alloys.

•Never wear loose or baggy clothes.

•

DO NOT operate the machine while under the influence of drugs or alcohol.

DO NOT operate the machine if you suffer from dizziness.

•

•Always use gloves when loading or unloading workpieces or tools and when removing

chips from the work area to protect your hands from sharp chips and burns caused by heat

generated during machining.

.com

Or visit www

.smithy

7

Page 12

mithyCNC 1240 Operator’s Manual

S

•Close all covers and junction boxes before running the machine.

•Check all electrical cables for damage to prevent electrical shock.

•

DO NOT handle coolant with bare hands to avoid irritation.

•Always use wire rope or slings as per standards, suitable for the load to be supported.

•

DO NOT remove or adjust switches to increase axis travel beyond the machine

specifications.

•DO NOT wipe the workpiece or clear away chips with your hand or with a rag while the

spindle is in operation.

WARNING

CAUTION

•

DO NOT allow chips to accumulate in the work envelope.

•Warm up the spindle and axis motion before running the machine in automatic mode.

•DO NOT operate the keyboard or operation panel switches when wearing gloves.

•DO NOT disconnect the main power cable without switching off the CNC and PC

connections.

SAFETY ASPECTS RELATED TO TOOLS & WORK HOLDING

WARNING

•Always use proper cutting tools and work holding clamps suitable for the work and

within the specifications of the machine.

•

DO NOT stall the machine during cutting due to improper feed and depth of cut suitable

for the workpiece material.

DO NOT operate the spindle above the rated speed of the accessories mounted in it such

•

as tool holders.

8

Call Us T

ee 1-800-476-4849

oll Fr

Page 13

General Safety Guidelines

•

Replace worn tools as soon as they are identified.

•Take care not to place any part of your bocy in the machine pinching areas.

CAUTION

•Make sure that the tool length to diameter ratio is proper to minimize vibration due to

excessive overhang conditions.

•Make sure the drawbar and the tool holders are tightened to the proper cutting conditions

before actual cutting operations.

SAFETY ASPECTS RELATED TO MAINTENANCE

DANGER

• Always disconnect the power to the machine before carrying out any maintenance work.

•After the power has been switched off for a minimum of 60 minutes, check voltage with

a multimeter or equivalent to make sure that there is no residual voltage.

WARNING

•Maintenance of electrical and mechanical components should only be carried out by

individuals with working knowledge of the machine tool.

•

DO NOT remove or modify switches.

•Clean the machine areas after the maintenance is completed.

CAUTION

•

DO NOT use compressed air to clean the machines.

.com

Or visit www

.smithy

9

Page 14

mithyCNC 1240 Operator’s Manual

S

SAFETY ASPECTS RELATED TO THE WORKPLACE

•Always provide sufficient work space around the machine and peripheral equipment.

•Protect all cables from being damaged by cutting chips.

SAFETY EQUIPMENT

This machine is provided with various mechanical and electiracl safety devices to protect

the operator and the machine. The safety devices include interlock devices and emergency

stop switches. However

familiarizes himself with the instruction manual of the machine before operating the

machine. The manufacturer emphasizes that it is the sole responsibility of the operator to

ensure that all operations using the SmithyCNC bed mill are carried out in completely safe

manner.

WARNING

, it is absolutely recommended and necessary that the operator

Neither the manufacturer nor its representative or dealers can assume responsibility for

any mishaps, damage or personal injury which may occur as a result of improper

operation or from failure to observe the safety precautions mentioned in this manual.

10

Call Us T

ee 1-800-476-4849

oll Fr

Page 15

4

INSTALLATION & SET-UP

SET-UP CLEARANCES & CONDITIONS

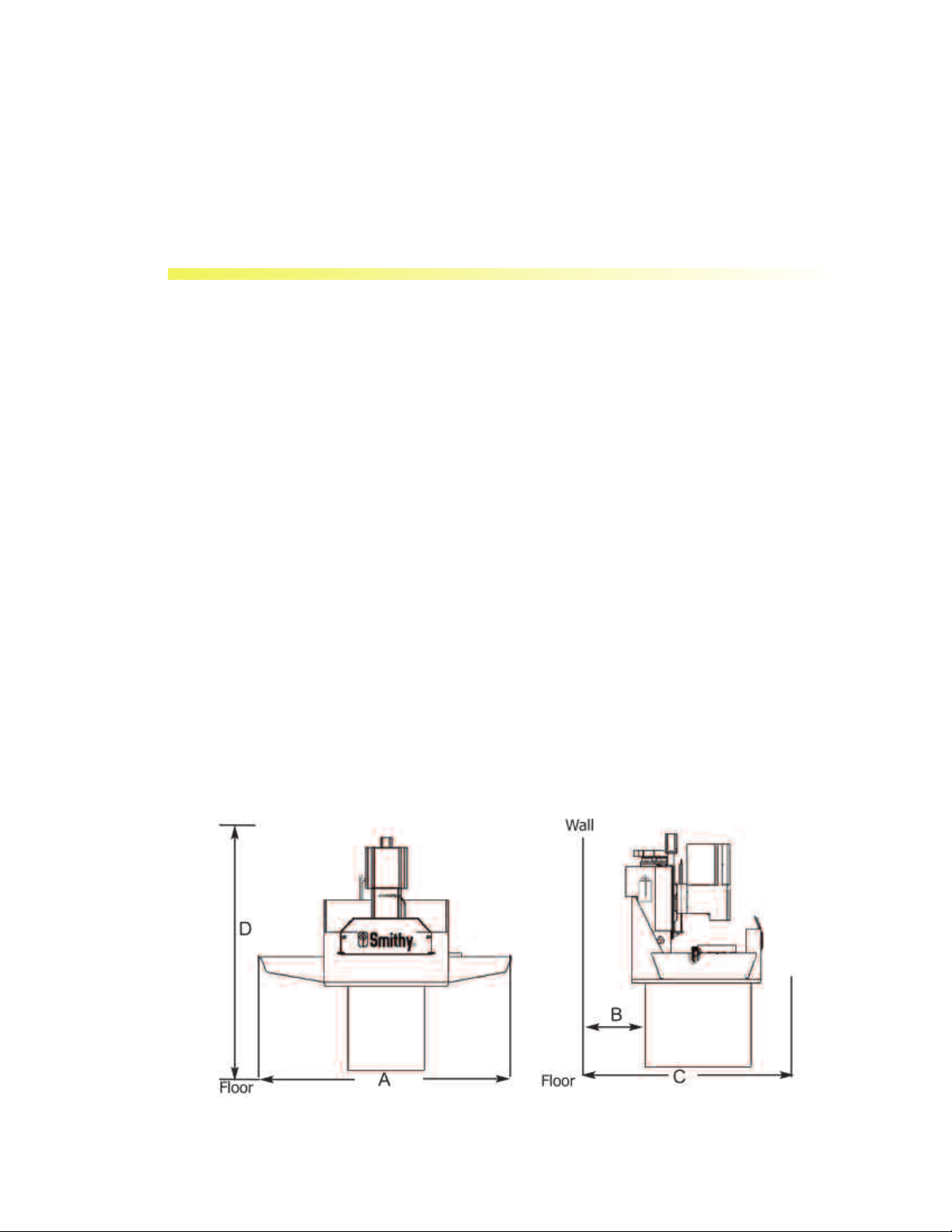

When considering the permanent location for your SmithyCNC bed mill the following

should be taken into consideration:

•The machine should be installed on a flat surface so that the machine does not rock or

slide during operation.

•This location should be considered the machine’s permanent location for your machine.

If you need to move it, remove it from the stand first.

•Make sure your stand is level prior to placing the machine on the stand. Improper

installation and an unleveled machine can cause both numerical error and loss of precision

in your machining operation.

•The maximum temperature of your shop or working environment should not exceed

125 ºF.

•Humidity levels should not exceed 80%.

•Set up the bed mill stand so you have plenty of working space. Leave at least 3 to 4 feet

of clearance on the operating side of the machine. Note the suggested clearances of the

other sides of the machine in table 4.1.

Figure 4.1 Set-up Clearances

.com

Or visit www

.smithy

11

Page 16

mithyCNC 1240 Operator’s Manual

S

A Dimension B Dimension C Dimension D Dimension

CNC 1240 Mill

83 in

2110 mm

Table 4.1 Clearance Dimensions

20 in

500 mm

67 in

1700 mm

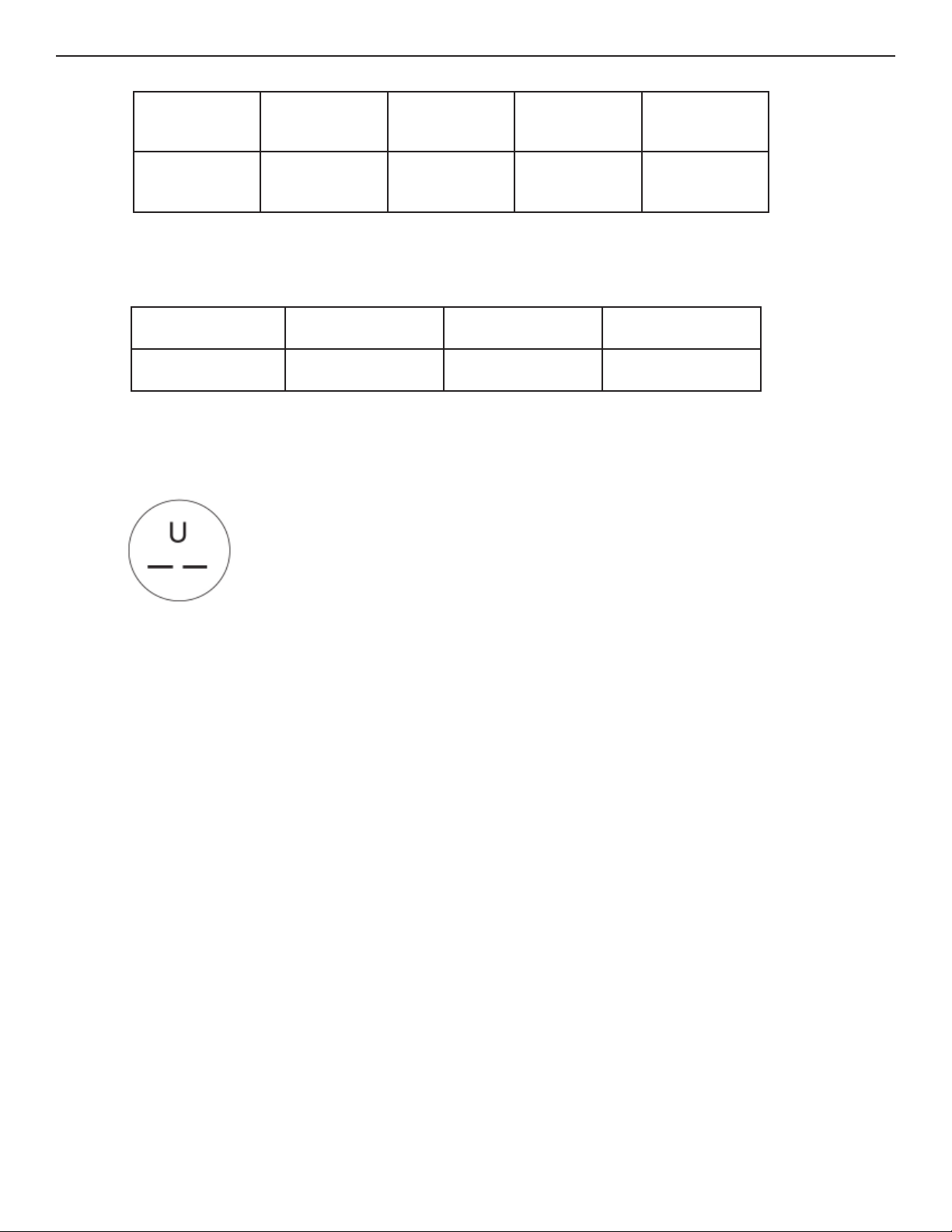

POWER REQUIREMENTS

Voltage Amps Amps

CNC 1240 Mill 220 15 Single

Table 4-2. Power Requirements

220 Plug Configuration

The power cord/plug that is supplied with the SmithyCNC EZ-Trol

System and SmithyCNC PC Control option is a 220 volt NEMA 6- 15P

plug. This plug will fit into a 220 volt NEMA 6-15R or 6-20R receptacle.

81 in

1700 mm

NOTE: Smithy recommends that you run your machine on a dedicated 20 amp breaker.

STAND REQUIREMENTS

ou will need a stand that is capable of supporting the weight of your machine plus the

Y

maximum allowable workpiece depending on your bed mill. (Please refer to the

specifications chart for the bed mill that you ordered to obtain this specification.) Y

also need to add into this figure additional weight for work holding devices, cutters and

coolant. A good rule is to build a stand that can support 5 to 6 times the weight of the

machine without any appreciable, permanent deformation. The benchtop should be rigid,

level and well-supported. If you purchased one of the optional bed mill stands available

from Smithy

machine.

Your work bench should be located in a vibration-free area with a floor that is designed to

support the full weight of the bench, machine, accessories, and materials.

If you purchased the optional Smithy Stand (Item 80-040 for the CN-1240 Mill then the

holes for mounting your machine are pre-drilled and tapped. If you are making your own

stand use the bolt pattern below

NOTE: The mounting holes in the base of the machine are 10 mm.

, these stands have been designed to support the weight of the specified

.

ou will

12

Call Us T

ee 1-800-476-4849

oll Fr

Page 17

Figure 4.3 Bolt Hole Pattern

Installation & Set-up

DANGER

SmithyCNC strongly discourages the use of casters or wheels on metalworking machine stands.

The weight of the machine could result in the stand tipping while being moved. Once the machine

is mounted, consider your work bench to be permanent. If you must move the machine, first

remove it from the bench.

LEVELING

Before any machining of the workpiece is done, it is crucial to level your machine for best

results.

Step 1: Find a relatively flat place for the installation of the machine and place the

machine stand in this spot taking note of the suggested clearances in table 4.1.

Figure 4.4 Level Shown parallel to the Y-Axis

.com

Or visit www

.smithy

13

Page 18

mithyCNC 1240 Operator’s Manual

S

S

tep 2:Position the X & Y axes slides as close to the mid-stroke position as possible. The

X

& Y axes can be repositioned manually with the knurled wheels at the end of the axes

screws. (For leveling purposes, position of the Z axis is not as critical as the X & Y Axes

slides.)

Step 3: Make sure your stand’s feet or leveling pads are touching the ground at the same

time. If not, adjust the feet to make sure the machine stand does not physically rock.

Step 4: Once all the feet or leveling pads are touching the ground and the machine is not

rocking, adjust the middle two feet (on both sides of the machine) off the ground by about

1/4 inch while the front and rear feet are on the ground.

NOTE: Pictures shown in this document are assuming you have purchased the optional

machine stand with your CNC bed mill. If you have constructed your own stand, adapt this

process for your stand.

Figure 4.5 Adjusting Stand Leveling Pads

Step 5: Place a machinist level on the mill table, parallel to the Y-axis. If the level bubble

is not in the center of the scale, adjust the left and right side feet up or down to bring the

bubble in the center (i.e you are tilting the machine sideways about the Y axis of the

machine.)

Step 6: Now, place the level parallel with the X-Axis. If it is not in the center of the scale,

adjust the feet at the front and rear of the machine to bring the bubble to the center

. (i.e

You are tilting the machine front to back about the X axis of the machine.)

Step 7: Keep the levels in place, drive the middle feet to the ground and make sure the

bubble position does not change.

Step 8: Once both adjustments are completed, reposition the slides several times and

reposition the slides in the middle stokes. (NOTE: This is done after you have hooked the

control system to your bed mill.)

Step 9: Check to confirm that the machine is still level by repeating steps 5 and 6. If the

machine appears to be unlevel, repeat steps 2-7.

NOTE: This leveling procedure should be rechecked every 6 months to ensure machine

leveling has not changed due to machine operation.

14

Call Us T

ee 1-800-476-4849

oll Fr

Page 19

Installation & Set-up

MOVING FROM PALLET TO STAND

There are four bolts securing the machine to the pallet. Use an adjustable wrench to

remove nuts located on the machine pads. Once the nuts have been removed, tap the

screws through the casting and pallet if they didn’t fall through when removing the nuts.

Figure 4.6 Remove bolts from the machine base pads

CAUTION

Use tin snips to cut the metal bands securing the milling head in place. Remember the

bands are under tension. Wear eye protection and gloves when cutting the bands.

Using a Forklift to Remove the Machine From the Pallet

Step 1: Use appropriately sized chains or tow straps when lifting your machine from the

pallet. (Lifting capacity should be three times the weight of the object you are lifting.) In

the diagram to the right we have chosen to use tow straps. These instructions are written

for that application. If you are using a chain instead, please adapt the attachment method

accordingly.

Figure 4.7 Lifting Point in Column Base

NOTE: Before utilizing the lifting straps,examine them for tears or fraying that might

reduce the lifting capacity.

Step 2: Attach a 5/8” clevis to the two eye hooks located on the base of the machine

toward the operator’s side. (Eye hooks have a rough 1” diameter opening and are 1/2”

thick.)

.com

Or visit www

.smithy

15

Page 20

mithyCNC 1240 Operator’s Manual

S

S

tep 3: Place an appropriate size rod through the lifting hole in the base of the column at

t

he back of the machine. See Figure 4.7.

Step 4: Place an end of the rod through one loop of the a tow strap.

Step 5: Clip the other end of the tow strap into the clevis/eye hook at the front of the

machine. Be certain to secure the clevis before lifting.

Figure 4.8 Close up lifting strap, clevis and eye hook

Figure 4.9 Moving with a Forklift

Step 6: Repeat step 5 with another tow strap on the opposite side of the machine.

Step 7: Slide the tow straps over the forks and slowly raise the machine from the pallet.

Before raising the machine high enough to place on the machine stand, check to make sure

the machine is relatively level. If it does not appear level, lower the machine back to the

pallet and adjust the tow straps so that the machine is balanced.

16

Call Us T

ee 1-800-476-4849

oll Fr

Page 21

Installation & Set-up

Figure 4.10 Engine Hoist Spreader correctly positioned for

lifting SmithyCNC Mill

Step 8: Now that the machine is relatively level, raise the machine so that it is hovering,

no more then 6-10 inches, over the machine stand.

Step 9: Using a straight rod (all-thread works well) to align the holes in the base of the

machine to the holes in the stand. Align one corner on the front and one on the back.

Step 10: Once the holes in the machine are aligned with holes in the stand, slowly lower

the machine into position on the stand.

Step 11: Secure the machine to the stand . (See the section in this document, securing

machine to the stand.)

Figure 4.11Chain Hook Up when using an engine hoist

.com

Or visit www

.smithy

17

Page 22

mithyCNC 1240 Operator’s Manual

S

Using an engine hoist to remove the machine from the pallet

Figure 14.12 Lifting with an engine hoist

Step 1: Using an engine hoist requires 2, 6 feet pieces of chain and 4 clevis pins large

enough to attach the links of the chain that you are using together. Remember to select

chain that is rated for lifting the weight of your machine.

NOTE: If you are renting an engine hoist make sure you are given the cradle/spreader

plate that attaches to the arm of the engine hoist.

Step 2: Attach a clevis to each of the two eye hooks located on the base of the machine

toward the operator’

s side.

Step 3: Place an appropriate sized rod through the lifting hole in the base of the column

at the back of the machine.

Step 4: Position the cradle/spreader so that the chains are hanging on either side of the

millhead. Once the plate is attached to the hoist it should hang between the millhead drive

motor and the Z-axis drive motor

.

Step 5: Place the chain around the rod extruding from the back of the casting so that there

is enough chain to attach one end to the clevis which is locked into the eye hook at the

front of the machine.

Step 6: Attach the section of chain circling the bar extruding through the casting as well

as the section of chain attached to the eyehook, to the chains hanging from the hoist

spreader. Note: Before lifting the machine, check the chains to see if they will be pushing

against any sheet metal part. If the chains are rubbing or pushing against any sheet metal

parts, reposition the chains in order to prevent damage. It may be helpful to open the

millhead motor door before attaching the chains to the hoist spreader

.

Step 7: Repeat step 5 and 6 on the other side.

18

Call Us T

ee 1-800-476-4849

oll Fr

Page 23

Installation & Set-up

S

tep 8:Attach the hoist spreader to the arm of the engine hoist if you have not done so

a

lready, and slowly raise the machine from the pallet. Check to make sure that the machine

is relatively balanced between the front and back of the machine. If it is leaning too far to

the front or the back, lower the machine back to the pallet and reposition the chains to

achieve a better balance.

Step 9: Now that the machine is relatively balanced, raise the machine so that it is

hovering over the machine stand.

Step 10: Using a straight rod (all- thread works well) align the holes in the base of the

machine to the holes in the stand. Aligning one corner on the front and one on the back.

Step 11: Once the holes in the machine are aligned with holes in the stand, slowly lower

the machine into position on the stand.

Step 12: Secure the machine to the stand . (See the section in this document, securing

machine to the stand.)

ATTACHING THE MACHINE TO THE STAND

Now that your machine is in place, it is important to properly secure it to your machine

stand. If you purchased a stand from Smithy, the holes in the stand are pre-drilled and

tapped. If you make your own stand, please refer to the bolt pattern at the end of this

document. These instructions assume that you have assembled your stand per the manufacturers instructions.

Step 1: Once the holes in the base of the machine are aligned with those in the stand,

secure the machine to the stand with the bolts provided with your Smithy stand.

Step 2: If you have ordered the Kool-Catch Coolant Containment system with your

machine, please follow the assembly instructions included with the Kool-Catch system.

ATTACHING THE X & Z AXIS MOTORS

The Z and X-Axes motors have been removed for shipping. Once the machine has been

secured to the stand, re-attach the motors with the provided cap screws and couplings.

Attach the cable leading out of the junction box to the motor.

INSTALLING YOUR CONTROL BOX

Now that your machine has been set-up, you are ready to install your control system. If you

purchased a SmithyCNC EZ-T

documentation sent with your control. If you have purchased the base machine, we have

supplied you with the a set plugs that match the sockets on the junction box of the

SmithyCNC bed mill that you purchased. You will be able to use these to wire your control

system of choice to your bed mill. Please reference chapter of this manual for pin-out

information.

rol system or PC Ready System, please refer to the

.com

Or visit www

.smithy

19

Page 24

5

MECHANICAL COMPONENT IDENTIFICATION

& FUNCTIONS

OVERVIEW

This chapter will help you to familiarize yourself with the major mechanical components

and functions of your machine.

Figure 5.1 CNC 1240 Bed Mill Front View

1. Drawbar - The drawbar supports and “draws” tooling into the R-8 spindle of the CNC1240 Bed Mill. The function of the drawbar is to locate the tool holder accurately in

relationship to the main spindle taper. The clamping and unclamping of the tools is

achieved by the manual actuation of the drawbar system. (This is not visible from the

picture.)

2. Work Light - The work light is controlled with the Smithy EZ-Trol system. Please note

this is an on/off function only.

20

Call Us T

ee 1-800-476-4849

oll Fr

Page 25

Mechanical Component Indentification & Functions

3

. Emergency Stop Button-Located at the bottom left side of the mill head. Press this

b

utton to stop movement of the slides and the mill spindle.

4. Gib Adjustment Screws - The CNC-1240 have a series of gib adjustment screws along

the operator side of the saddle. These screws press a metal plate (the gib) to the ways of

the saddle, increasing or decreasing the tension when moving the cross-slide assembly.

Before adjusting the gibs, make sure they are well lubricated to achieve the desired result.

(Reference chapter 6 for details.)

5. X-Axis Stepper Motor - The CNC-1240 mill is equipped with X, Y and Z axes stepper

motors. This X-Axis stepper motor provides power for table movement along the X-Axis.

See the machines specifications for motor sizes.

6. Lifting Eye Hooks - There are two lifting eye hooks located on the operator’s side of

the machine. Use these eye hooks in conjunction with a chain or tow ropes to help move

your machine from the shipping pallet to a stand.

7. Saddle - The mill table is supported by the saddle along the Y-Axis.

8. Mill Table - The mill table supports your work piece and work holding devices. It

travels along the X & Y axes via ballscrews Both the CNC-1240 Mill have 5/8” T

-Slots.

9. Motor Cover - The motor is protected by a sheet metal cover. The motor is easily

accessible by turning the knurled knob on the right side of the cover. This cover should

remain closed while the machine is in operation

Figure 5.2 CNC 1240 Bed Mill Side View

10. Spindle Drive Motor - The fan cooled spindle drive motor is located behind the

motor cover.

.com

Or visit www

.smithy

21

Page 26

mithyCNC 1240 Operator’s Manual

S

1

1. Compressed Nitrogen Gas Cylinder -The CNC-1240 mill use a counter balance

c

ylinder to counter the weight of the Z-Axis assembly.

12. Drive Belt - The drive belt for the motor is located behind the the motor cover. The

motor cover must be removed to replace or tension the belt. (Not visable in diagram.)

13. Head Rotation Locks Bolts - There are two bolts, one on either side of the mill head

that when loosened, allow the operator to rotate the millhead between 0 and 90 degrees in

either direction.

14. Spindle with R-8 nose taper - The CNC -1240 utilizes a spindle with an R-8 taper nose

for supporting and locating work holding tools. Any standard tool holding equivalent to the

R-8 specifications can be mounted on the spindle with suitable adapters.

15. Bellows - The Y-Axis ballscrew is protected from chips and coolant by industrial

bellows.

16. Mounting Points - There are six mounting points on the CNC-1240 Bed Mill. The

mounting points are M10 holes located at each corner of the machine and one in the

middle of each side of the machine. Make sure that your machine is properly mounted

before operating it.

17. Proximity Switches - A switch is located on each axis of travel. These switches are

the mechanical end position limits and they also are used to home the slides.

18. Proximity Switch Covers - The proximity switches on the CNC-1240 bed mill is

protected from coolant and chips with removable sheet metal cover

.

19. Bed & Column - The bed and the column are a box type construction made of high

quality grade 25 cast iron. They are designed for high rigidity with suitable cross section

and ribs for reinforcement. Proper casting treatment is given to relieve the castings of any

undue stress before assembly and machining is done. The X-axis, Y

-axis and Z-axis slide

components including the headstock assembly and table are mounted on the same base

and column structure.

20. Lifting Point - This lifting point is used in conjunction with the lifting eyehooks. Run

an adequately sized bar through this point and attach tow ropes or chains to the bar to

assist in the mechanical lifting process.

21. One Shot Lubrication System - The one shot or single stroke lubrication system is

located on the left side of the machine. The dovetail ways, ball nuts and liner bearings are

lubricated when the lubrication system is activated. To be sure that enough lubrication is

provided, a minimum of two pumps is recommended and it is also advisable to visually

check the lubrication delivery on the lubed surfaces. Lubrication is very important for

machine tools since it greatly affects machine life. Use only recommended lubrication oils

which are clean and free from foreign matter. Follow the maintenance scheduled in this

manual. (Reference chapter 6.)

22. Bearing Guideway System - The millhead travels along the Z-Axis which is equipped

with the a linear bearing guideway system.

22

Call Us T

ee 1-800-476-4849

oll Fr

Page 27

Mechanical Component Indentification & Functions

Figure 5.3 CNC 1240 Bed Mill back view

23. Lubrication Distribution Block - The shielded metal lines of the lubrication system

intersect at this block to deliver lubrication to the various parts of your CNC- 1240 Bed

Mill.

24. Z-Axis Stepper Motor - This motor drives the Z-Axis of the machine and provides

motion of the head along the Z-Axis linear guideway

ariable Frequency Drive

25. V

- This is the drive for the main spindle motor

.

.

26. Junction Box - The control system is connected to the machine via this junction box.

27. Y-Axis Stepper Motor - This motor drives the table along the dovetail

ways of the Y

-Axis.

Or visit www

.smithy

.com

23

Page 28

6

MECHANICAL MAINTENANCE

MAINTENANCE SCHEDULE

Maintaining your machine as per the schedule documented in this manual will help

prolong the life of the machine and aid in the production of precision workpieces. It should

be noted that the maintenance schedules listed herein, are intended to be used as a guide.

The enviroment and working conditions of your shop should be taken into consideration.

Daily Maintenance

Perform these maintenance tasks at the beginning and at the end of work.

AREA OF

MAINTENANCE

Lubrication System

Cutting Tools & Tool

Holders

Coolant Level

(Optional)

Machine Work Area

Cleaning

External Wiring &

Cables

Machine General

Condition

MAINTENANCE TASK HOW OFTEN

• Check for oil level

• Pressure build up during hand pumping

• Check for distribution film of oil on all

sliding surfaces

• Check for Leaks

• Tighten the drawbar

• Tighten work holding devices

• Check for level

• Check for leakage and cleanliness

• Clean the work holding devices

• Clean guards

• Clean machine

• Clean Trays

• Check fit of cable connections

• Check for damaged cable

• Check entire machien for loose or missing

fasteners

At the start of work

At the start of work

At the start of work

At the start & end of

work

At the start & end of

work

At the start of work

At the start of work

24

Spindle

• Clean the spindle taper

Table 6.1 Daily Maintenance Table

ee 1-800-476-4849

oll Fr

Call Us T

At the start of work

Page 29

Periodic Maintenance

Perform these maintenance tasks as per the schedule below.

Mechanical Maintenance

AREA OF

MAINTENANCE

MAINTENANCE TASK HOW OFTEN

MECHANICAL

Axes Backlash • Check and compensate of necessary 6 months

Ball Screw Guards • Check condition

Drive Belt

Gib Adjustments*

Machine Base/ Table

• Check condition

• Check tension

• Check table motion for fish tailing

movement & adjust. Follow instructions.

• Check for level & mounting bolt

loosening

6 months or replace

as necessary

6 months or replace

as necessary

6 months

6 months

Tool Holder/ Drawbar • Check for breakage & thread damage 1 month

ELECTRICAL

Electrical Cabinets

Electrical Elements

• Check for cleanliness

• Check & secure any loose connections

• Check for proper working of push button

switches

3 months

3 months

Proximity Switches • Check for proper operations 3 months

Motors • Check for condition & testing 1 month

Table 6.2 Period Maintenance Table

*Additional instructions given.

Or visit www

.smithy

.com

25

Page 30

mithyCNC 1240 Operator’s Manual

S

Lubrication System

This section covers the lubrication of your machine. There are two primary areas of

lubrication: areas lubricated by the single stroke lube system and the life greased bearings.

Remember, proper lubrication is very important. It greatly affects the performance and

longevity of your machine. If a the machine is operated without supplying the lubricating

oil, it will cause seizure of the sliding sufaces. Before opearting, visually inspect the oil on

the actual machine surfaces.

Use only recommended lubrication oils which are clean and free from foreign matter.

Periodically clean the tank and strainers/filters, if provided, inspect the equipment's

functioning or lube supply pipes for damaged to ensure optimum machine operation.

CAUTION

CAUTION

LUBRICATING POINTS

Headstock Bearings

Ballscrews & Guideways

Quill & Ballscrew

Bearings

LUBRICATING SYSTEM &

RECOMMENDED OIL GRADE

Grease

Kluber Isoflex BU-15

Manual One Shot Lubrication

Mobil-1

Grease

Kluber Isoflex NBU-15

Table 6.3 Lubrication Grade Table

QUANTITY

Life Grease

1 Liter

Life Grease

Ballscrews and Guideways

The ballscrews, liner guidways and dovetail slides are lubricated by the single stoke

lubrication system. Follow the lubrication schedule in table 6.1. When lubridating the

linear guideway and dovetail slide, pull the lever of the one shotlube system away and

down from the machine. The number of pumps required will depend on your shop

environment. Enough pumps should be administered until a thin layer of lubrication is

present on the slides.

26

Call Us T

ee 1-800-476-4849

oll Fr

Page 31

Mechanical Maintenance

Headstock & Spindle Bearings

The bearings are of a precision class of accuracy. The spindle bearings are lubricated for

life with high grade grease, such as Kluber Isoflex NBU-15. This grease maintains its

lubrication properties at both low and high temperatures (- 70º F to 120º F). There is no

necessary lubrication to these bearings.

CAUTION

If the spindle starts making abnormal noises or gets very warm above (120º F), check for

damage of the spindle bearings after stopping the machine completely. The spindle should

be warmed up for approximately 15-20 minutes when the machine has been stopped for a

long period (for example 5 or more days).

PERIOD MAINTENANCE TASKS

Axis Bearing Adjustment/Axis Backlash

Backlash is the amount of movement the screw makes before the table engages. There are

a number of signs that may indicate that there is excessive backlash with your system:

• Rough/uneven surface finishes

• Dimension inaccuracies

• Table shakes under machining force

Even if none of these signs are present, it is recommended to check for backlash

compensation every 3-6 months depending on your usage of the machine. Please note,

SmithyCNC EZ-Trol software has provisions for compensating for backlash within the

program. This section of the manual is addressing mechanical backlash compensation.

There are three main mechanical reason for backlash:

1. Pre-loaded ball nut is damaged and is causing axial play between the nut and the screw

If the ball nut is damage, the only solution to this is to replace the ballscrew and ball nut

assembly.

2. The end support bearings are damaged. If you find that the end bearings are damaged,

follow the procedure below for replacing the bearings.

.

3. The ball nut mounting screws #70 on diagram 5, page 8-16 of this manual, are loose. In

this case move the table to the end of the stroke so that the nut mounting screws #70 and

#26 are accessible. Tighten the bolts and make sure the bolts or housing threads are not

damaged before tightening.

4. The end bearing tightening nut is loose. Follow step 6 and 7 in the following procedure

to tighten the bearings whenever required.

.com

Or visit www

.smithy

27

Page 32

mithyCNC 1240 Operator’s Manual

S

Y -Axis Ballscrew End Bearing Adjustment

For this procedure, you will need to refer to diagram 5 of chapter 8 of this manual.

Step 1: Remove axis motor.

Step 2: Detach bellows from saddle (Reference diagram number 5)

Step 3: Loosen the part#28 and 29 to remove the bearing housing #20. Loosen the end

bearing nuts first. Remove the damaged bearing from the housing and ball screw.

Step 4: Check the opposed pair of angular contact bearings for damage. Make sure the

bearings are not damaged or the housing of the bearing ID seating are not heavily scoured

or damaged. If the bearings are damaged, acquire the new set of bearings for replacement.

Also ensure the new set of bearings are packed with proper amount and type of grease

before tightening. (See chapter 6 for lubrication specifications.)

Step 5: Install the inner bearing #30 first on the ballscrew, making sure the bearing

orientation is the same as the original mounting direction.

Step 6: Install bearing housing #20 square with the ballscrew axis, making sure the

bearing housing #20 is securely positioned with part numbers 28 and 29.

Step 7: Install bearing #21 from the outside of the housing, making sure the bearing

orientation is the same as the original mounting direction. The bearing contact angle’s

center lines for these two bearings should be oppsed (in XFashion) to each other when

mounted.

Step 8: Tightened the first nut #25 (closer to the housing/bearing) to tighten the bearings

against the housing. Loosen the nut and re-tighten again to position the bearing properly.

Install the second jam nut #25 to secure the first nut also.

Step 9: Rotate the screw manually to ensure the motion of the screw is smooth and

uniform and the bearings are not creating any stop and go motion or are completely

jammed.

Z-Axis Ballscrew End Bearing Adjustment

For this procedure, you will need to refer to diagram 4 on chapter 8 of this manual.

Step 1: Remove axis motor.

Step 2: To replace the damaged bearings, loosen the part #9 to remove the bearing

housing #8. Loosen the end bearing nuts first. Remove the damaged bearing from the

housing #8 and ball screw #25.

Step 3: Check the opposed pair of angular contact bearings for damage. Make sure the

bearings are not damaged or the housing of the bearing ID seating are not heavily scoured

or damaged. If the bearings are damaged, acquire a new set of bearings for replacement.

Also ensure the new set of bearings are packed with proper amount and type of grease

28

Call Us T

ee 1-800-476-4849

oll Fr

Page 33

Mechanical Maintenance

b

efore tightening. (See chapter 6 for lubrication specifications.)

Step 4: Install the set of bearings #24 first on the ball screw. Make sure the bearing

orientation is same as the original mounting direction. The bearing contact angle's center

lines for these two bearings should be opposed (in X-fashion) to each other when

mounted.

Step 5: Install the bearing housing #8 square with the ball screw axis. Please make sure

bearing housing #8 is securely positioned with using Part #9.

Step 6: Now tighten the first nut,Part #23 to put the bearings against the housing. Loosen

the nut and re tighten again to position the bearing properly. Install the second jam nut,

Part #23, to secure the first nut also.

Step 7: Rotate the screw manually to ensure there is no jerky motion of the screw or the

bearings are not creating any stop and go motion or are completely jammed.

Adjustment of Gibs on the X & Y Axis Slides

The X & Y axis slides have straight gibs. If the slide motion proves out to be sloppy or

uneven, adjust the gibs evenly using he set screw provided on the front and side of the

casting.

Step 1: Make sure that the slide is properly lubricated before you start adjusting the

screws.

Step 2: Loosen the gib hex head bolts.

Step 3: Tighten the gib setscrews all the way so there is no table movement.

Step 4: Loosen all setscrews one at a time a quarter of a turn and the check the motion for

“fish tailing” and uneven motions to and fro.

Step 5: Adjust all the setscrews until the “fish tailing” movement is eliminated.

Step 6: Tighten the gib hex head bolts. Do NOT exceed 100 in-lb torque.

The tighter the gib the more accurate it will be in motion but the power required to move

the slide may also go up due to the increased sliding friction. Removing and cleaning the

gibs before installation is also helpful.

With the gibs property adjusted and the slides lubricated, the torque required to move the

slide slowly

, should not exceed 15-20% of the maximum motor torque available.

.com

Or visit www

.smithy

29

Page 34

mithyCNC 1240 Operator’s Manual

S

Headstock to Table Realignment

If you have positioned your head at an angle between +/- 0-90º, you will need to realign it

to the table by following the steps below”

Step 1: Remove the tool holders and jobs from the table

Step 2: Mount a dial indicator in the spindle of your machine.

Step 3: Loosen the head rotation lock bolts and rotate the head as necessary to realign the

spindle so that it is perpendicular to the surface of the table.

Step 4: Sweep the dial indicator 360º to check the results. Make minor adjustments as

necessary.

Step 5: Once the desired results are achieved, lock the mounting bolts and recheck the

alignment by sweeping the dial indicator 360º.

In case of a severe accident, contact Smithy for further advice.

Linear Motion Guide & Bearing Maintenance

Unlike sliding guide systems for the X & Y Axes slides, linear motion guides are free from

wear. It requires neither adjustment of the running ways due to uneven wear nor

maintenance to restore the original accuracy. Sideway systems use a quality of oil for the

forced lubrication of the sideways to form and maintain oil films. On the other hand,

linear motion (LM) guide systems require only periodical lubrication in a very small

quantity

. It contributes to easy

working environment. There are no adjustments required for such bearings and guides.

The case of failure of such bearings, replacement is the only cure.

Make sure the linear bearings are not splashed with coolant directly since the lubricate

may be contaminated with coolant which may wash off or emulsify the lubricate; thereby

significantly degrading lubrication's perforamcne. One sign of such case is the increased

noise when the Z-Axis slide moves up and down at high speed. Make sure lubrication

supply is present by checking the ends of the lubrication supply pippin for the proper oil

flow.

, reduced maintenance and to the creation of a clean

,

30

Call Us T

ee 1-800-476-4849

oll Fr

Page 35

7

TOOL HOLDING

OVERVIEW

In milling operations cutters are mounted in a tool holder which is drawn into the spindle

by a drawbar system. The CNC-1240 utilize the readily available Bridgeport® R-8 standard

tooling . The standard drawbar for R-8 tapered tooling is 7/16 diameter with 20 threads per

inch.

Tool Holding Options

There are several tool holders that can be used in the spindle of the CNC-1240.

Arbors come in different sizes and lengths with one end tapered to suit the inside spindle

, in the case of the CNC-1240, an R-8 taper is required. The term arbor is used for a

taper

general work holding device. Arbors can mount drill chucks, slitting saws, gear cutters and

shell end mills. An arbor is secured in place with the drawbar system.

Collets (Spring Collets) are the most commonly used work holding device. They come

in a variety of styles and sizes. They are bored to hold a specific diameter. As the collet is

drawn into the spindle of the machine, the spring collet “closes” or “clamps” down on the

tool securing it in place.

End Mill Adapters are made specifically to hold end mills. Like arbors they come in

different sizes with one end tapered to fit the inside spindle taper

bored to a specific size to hold endmills with a corresponding shank size. End mills are

secured in the adapter by friction and a set screw clamps down on the flat of the end mill

for extra security.

. End mill adapters are

Installing the Tooling

Once you have determined the appropriate tooling for your operation, you will need to

secure it in the mill spindle via the drawbar system. The drawbar is located inside the

protective sheet metal housing of the CNC-1240 bed mill.

Step 1: Turn the knurled knob on the right side of the mill head door to access the

drawbar.

Or visit www

.smithy

.com

31

Page 36

mithyCNC 1240 Operator’s Manual

S

Step 2: The drawbar is secured in place by the drawbar nut, but has a slight movement up

and down in the spindle which allows you to easily install your tooling.

Figure 7.1 Installing Tooling into the R-8 Spindle

Step 3: Insert your tooling into the spindle. NOTE: R-8 tooling has a milled slot on the

shank. The slot should be aligned with the pin in the spindle of the machine. The pin

prevents your tooling from rotating against the external forces during a cut.

Figure 7.2 The drawbar is located inside the protective sheet metal cover

Step 4: Once the tooling is in place, rotate the drawbar clockwise to install your tooling.

Tighten drawbar as noted below.

NOTE: Recommended Tightening Torque for the R8 Collet/Draw Bar

Proper torque settings depend on the application, the condition of the threads, grade of the

thread, vibration during machining, types of cut etc. The following table provides a

general idea about this tightening torque to resist any collet movements. The best practice

is to to check the joint and make sure, from time to time, that the draw bar/collet is still

tight to avoid any unsafe operation.

32

Call Us T

ee 1-800-476-4849

oll Fr

Page 37

Tool Holding

THREAD SIZE

TORQUE FOR

SAE GRADE 2

PLAIN

TORQUE FOR

SAE GRADE 2

OIL WAXED

TORQUE FOR

SAE GRADE 5

PLAIN

TORQUE FOR

SAE GRADE 5

OIL WAXED

7/16” - 20 32 - 36 ft-lbs 18 - 20 ft-lbs 52- 56 ft-lbs 28 - 32 ft-lbs

Table 7.1 Drawbar torque values

To get the best out of the draw bar/collet tightening process, the tightening procedure

is recommended as follows:

Step 1: Make sure the threads are not damaged and are free of debris.

Step 2: For a new draw bar and collet, find the thread grade and material, if possible, and

the condition of the thread surface.

Step 3: Tighten the draw bar to 2 to 2.5 times the recommended values provided in the

above table.

Step 4: Loosen the collet and retighten to the specified torque as given in the table.

Step5: Machine a few parts and ensure the collet/draw bar is not loose. Once confirmed,

note down the final torque value for future applications also.

Removing Tooling

To remove the tooling, rotate the drawbar counterclockwise. The drawbar nut works as an

upward stop when removing your tooling. When you are removing something from the

spindle that is held in place with the drawbar

preventing it from moving upward as the tooling is “pushed” out of the spindle.

, the drawbar will hit the drawbar nut,

Or visit www

.smithy

.com

33

Page 38

CNC-1240 BED MILL SPECIFICATIONS

Dimension Inch Metric

General Specifications

8

Length

Width 39.75" 1009.65 mm

Height 52.33" 1329.18 mm

Machine Weight 1175 lbs 532.97 kg

Footprint 36" x 24” 914.40 x 609.60 mm

Shipping Dimensions 41" x 37" x 48" 1041.40 x 939.80 x 1219.20 mm

Shipping Weight 1380 lbs 625.96 kg

Maximum Work Capacities

-Drilling mild steel

-Tapping 0.75" 19.05 mm

39.33" 998.98 mm

Max dia 0.781" 19.84 mm

Specifications

Table Size

Work Cube 22" x 13" x 11.50" 558 x 330.20 x 292.10 mm

Maximum Weight on Table 594 lbs 269.43 kg

T-Slot Size 5/8" 15.88 mm

Slots on Table, Qty. 4 4

Table Travel X Axis 22" 558.80 mm

Saddle Travel Y Axis 13" 330.20 mm

Head T

Castings

Table Surface Precision Ground Precision Ground

Ways (X, Y Axis) Dovetail Dovetail

Ways (Z Axis) Linear Bearings Linear Bearings

Head Swivel + or - 90º + or - 90º

ravel Z Axis

40" x 12" 1016 x 304.80 mm

11.5"

Cast Iron

292.10 mm

Cast Iron

Spindle

Motor HP Rating 2 HP 1.5 KW

Maximum Torque 94 in-lb 30 Nm

Drive System

Minimum Speed

34

Geared Belt

150 RPM 150 RPM

ee 1-800-476-4849

oll Fr

Call Us T

Geared Belt

Page 39

Specifications

Dimension Inch Metric

Maximum Speed 4000 RPM 4000 RPM

Positioning Accuracy + or - 0.0005" + or - 0.0127 mm

Repeatability 0.00025" 0.00635 mm

Quill Diameter 3.15" 80.01 mm

Spindle Bearings Angular Contact Angular Contact

Spindle to Column 11.5" 292.10 mm

Spindle Taper R-8 R-8 R-8

Axes

Stepper Motors (X, Y, Z Axis) 1700 in-oz 1700 in-oz

Ball Screws Pre-loaded Pre-loaded

Hardened & Ground Hardened & Ground

Ball Screw Size (X Axis) 0.984" 25 mm

Ball Screw Size (Y Axis) 0.984" 25 mm

Ball Screw Size (Z Axis) 0.787" 20 mm

Ball Screw Pitch 0.196" 5 mm

Ball Screw Precision P5 P5

Electrical

Power Requirement 220 VAC @ 15 A 220 VAC @ 15 A

Stand Specifications

Stand Footprint

Stand Dimensions 25.20" x 36.50" x 37" 640.08 x 927.10 x 939.80 mm

Stand W

Stand Shipping Weight 462 lbs 209.56 kg

Floor Space Required 36" x 60" x 84" 914.40 x 1524 x 2133.60 mm

NOTE: Due to continual design improvements, specifications may change. T

most up to date specifications, visit www

eight

25.20" x 36.50" 640.08 x 927.10 mm

335 lbs

.smithycnc.com.

151.95 kg

o view the

Or visit www

.smithy

.com

35

Page 40

9

MACHINE PARTS DIAGRAMS

OVERVIEW

This section shows all the necessary parts of the machine. All the diagrams are properly

labellend and numbered. The reference codes and numbers are found on the Reference

Chart after each diagram.

Please have this section ready whenever you have questions, inquiries or in need of

techinical help regarding the machine.

If replacement parts are required, please call us at Toll Free 1-800-476-4849 to talk to a

Smithy Techinician.

36

Call Us T

ee 1-800-476-4849

oll Fr

Page 41

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 37

DIAGRAM 1: Protective Sheetmetal Covers, Mill Head & Junction Box

Page 42

DIAGRAM 1: Protective Sheetmetal Covers, Mill Head & Junction Box Reference Chart

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 38

Page 43

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 39

DIAGRAM 2: Proximity Switches

Page 44

DIAGRAM 2: Proximity Switches Reference Chart

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 40

Page 45

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 41

DIAGRAM 2: Proximity Switches Reference Chart

Page 46

This page is left intentionally blank.

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 42

Page 47

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 43

DIAGRAM 3: Mill-Drill Head

Page 48

DIAGRAM 3: Mill-Drill Head Refence Chart

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 44

Page 49

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 45

DIAGRAM 3: Mill-Drill Head Refence Chart

Page 50

DIAGRAM 3: Mill-Drill Head Refence Chart

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 46

Page 51

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 47

DIAGRAM 4: Column

Page 52

DIAGRAM 4: Column Refence Chart

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 48

Page 53

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 49

DIAGRAM 4: Column Reference Chart

Page 54

This page is left intentionally blank.

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 50

Page 55

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 51

DIAGRAM 5: Table &

Bed Assembly

Page 56

DIAGRAM 5: Table & Bed Assembly Reference Chart

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 52

Page 57

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 53

DIAGRAM 5: Table & Bed Assembly Reference Chart

Page 58

DIAGRAM 5: Table & Bed Assembly Reference Chart

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 54

Page 59

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 55

DIAGRAM 5: Table & Bed Assembly Reference Chart

Page 60

DIAGRAM 5: Table & Bed Assembly Reference Chart

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 56

Page 61

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 57

NOTES:

Page 62

10

ELECTRICAL DIAGRAM & PIN OUTS

OVERVIEW

This section shows all the necessary electrical and pin out diagram of the machine. The

diagram is properly labellend and numbered. The reference codes and numbers are found

on the Reference Chart after each diagram.

Please have this section ready whenever you have questions, inquiries or in need of

techinical help regarding the machine.

If replacement parts are required, please call us at Toll Free 1-800-476-4849 to talk to a

Smithy Techinician.

58

Call Us T

ee 1-800-476-4849

oll Fr

Page 63

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 59

Page 64

Electrical Diagram & Pin Outs Reference Chart

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 60

Page 65

Call Us Toll Free 1-800-476-4849 or visit www.smithy.com 61

Electrical Diagram & Pin Outs Reference Chart

Loading...

Loading...