Smith Cast Iron Boilers GVIOM-5R User Manual

GVIOM-5R

GV100W

NATURAL OR PROPANE GAS BOILER

INSTALLATION & OPERATING

INSTRUCTIONS

DESIGNED AND TESTED ACCORDING TO A.S.M.E. BOILER AND PRESSURE

VESSEL CODE, SECTION IV FOR MAXIMUM ALLOWABLE WORKING PRESSURE OF

50 PSI,

345 kPa

WATER

NOTE TO INSTALLING CONTRACTOR: READ THESE INSTRUCTIONS CAREFULLY.

THEY WILL SAVE YOU TIME IN ASSEMBLING BOILER PROPERLY.

WARNING: Installation and service must be performed by a qualified installer, service

agency or the gas supplier in accordance with all local and national codes. Failure to

comply with this warning can result in a fire or explosion causing property damage,

personal injury or loss of life!

WARNING: If the information in this manual is not followed

exactly, a fire or explosion may result causing property damge,

personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

What to do if you smell gas:

• Do not try to light any appliance.

• Do not touch any electrical switch. Do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor's phone. Follow

the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

INSTALLER, THESE INSTRUCTIONS TO BE AFFIXED ADJACENT TO THE BOILER.

CONSUMER, RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE PURPOSES.

WESTCAST, INC.

260 NORTH ELM STREET WESTFIELD, MA 01085

TEL. (413) 562-9631 FAX (413) 562-3799

In Canada: 5211 Creekbank Road, Mississauga, Ont. L4W 1R3 (905) 625-2991 Fax (905) 625-6610

Page 2

GV100W BOILER

INSTALLATION & OPERATING INSTRUCTIONS

AVERTISSMENT. Assurez-vous de bien suivre les instructions données dans cette

notice pour réduire au minimum le risque d’incendie ou d’explosion ou pour éviter

tout dommoge matériel, toute blessure ou la mort

Ne pas entreposer ni utiliser d’essence ou ni d’autres vapeurs ou liquides inflammables

à proximité de cet appareil ou de tout autre appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareil.

• Ne touchez à aucun interrupteur; ne pas vous servir des téléphones se trouvant dans

le bâtiment.

• Appelez immédiatement votre fournisseur de gas depuis un voisin. Suivez les

intructions du fournisseur.

• Si vous ne purvez rejoindre le fournisseur, appelez le service des incendies.

L’installation et l’entretien doivent être assurés par un installateur ou un service

d’entretien qualifié ou par le fournisseur de gaz.

Table of Contents

Before You Start .................................................. 2

Boiler Ratings & Capacities................................. 3

Boiler Location .................................................... 3

Combustible Floor Option.................................... 4

Dimensions & Component Location .................... 5

Combustion Air.................................................... 6

Common Vent Systems ....................................... 6

Chimney & Vent Pipe Connection ....................... 7

Heating System Piping ........................................ 9

Gas Supply Piping............................................. 12

Electrical Wiring ................................................ 13

Lighting Instructions .......................................... 17

Boiler Operation ................................................ 19

Checking & Adjusting ........................................ 20

Boiler Maintenance ........................................... 21

Instructions to the Installer ................................ 22

Replacement Parts............................................ 23

Health Warnings ................................................ 24

BEFORE YOU START

WARNING : This manual must be read and fully

understood before installing, operating or servicing

this boiler! Failure to follow these instructions could

result in a fire or explosion causing extensive

property damage, personal injury or death!

These instructions cover the GV100W gas fired, induced draft

low pressure, sectional, cast iron hot water boiler. GV100W

boilers have been design certified by CSA for use with natural

and propane gas under the latest edition of ANSI-Z21.13, GasFired Low-Pressure Steam and Hot Water Boilers and CGA

4.9, Gas-Fired Steam and Hot Water Boilers.

Each unit has been constructed and hydrostatically tested for

a maximum working pressure of 50 psi,

dance with the A.S.M.E. Boiler and Pressure Vessel

Code, Section IV for cast iron boilers. Each boiler has been

equipped with a 30 psi pressure relief valve.

This manual covers the application, installation, operation and

maintenance of a GV100W low pressure hot water boiler.

To obtain the safe, dependable, efficient operation and long life

for which this boiler was designed, these instructions must be

read, understood and followed.

Direct all questions to your Smith Cast Iron Boiler distributor

or write to the Customer Service Department, 260 North Elm

Street, Westfield, MA 01085. Always include the model and

serial numbers from the rating plate of the boiler in question.

345 kPa

in accor-

GV100W BOILER

INSTALLATION & OPERATING INSTRUCTIONS

Page 3

The owner should maintain a record of all service work

performed with the date and a description of the work done.

Include the name of the service organization for future reference.

Where required by the authority having jurisdiction, the

installation must conform to the Standard for Controls and Safety

Devices for Automatically Fired Boilers, ANSI/ASME CSD-1.

The installation must conform to the requirements of the

authority having jurisdiction or, in the absence of such

requirements, to the National Fuel Gas Code, ANSI Z223.1latest edition. In Canada, the installation must be in

accordance with the requirements of CAN/CGA B149

Installation Code for Gas Burning Appliances and Equipment.

BOILER RATINGS & CAPACITIES

Before undertaking the installation of the GV100W check the

boiler rating plate to ensure that the boiler is the proper size

for the job. The “Net I=B=R Ratings” specify the equivalent

amount of direct cast iron radiation that the boiler can handle

under normal conditions.

Also ensure that the boiler has been set up for the type of gas

available at the installation site. Other important considerations

are the availability of an adequate electrical supply, fresh air

for combustion and a suitable chimney or vent system location.

BOILER LOCATION

WARNING: This boiler is for installation on noncombustible floors only! A special base supplied by

the manufacturer must be used to install this boiler

on a combustible floor. Failure to comply with this

wwwwarning could result in property damage,

severe personal injury or death!

3. Ensure that the floor is structurally sound and will support

the weight of the boiler. This boiler is designed for noncombustible floors only! A special base supplied by Smith Cast

Iron Boilers must be used if the boiler is to be installed on a

combustible floor. Never install this boiler on carpeting!

4. Do not install this boiler in a location that would subject

any of the gas ignition components to direct contact with water

or excessive moisture during operation or servicing.

CAUTION: Do not install this boiler in a location subject

to negative pressures or improper operation will occur.

5. Do not place this boiler in a location that would restrict

the introduction of combustion air into the boiler. NEVER store

objects on or around the boiler.

WARNING: Never store combustible materials,

gasoline or any product containing flammable vapors

or liquids in the vicinity of the boiler. Failure to

comply with this warning can result in extensive

property damage, severe personal injury or death!

6. If the boiler is to be located in an alcove, closet or other

confined space the distances from the boiler and it’s vent

system to all combustible construction must be equal to or

greater than the minimum clearances in Figure 1. When

installed in a closet or confined space two permanent openings

of equal area adjoining another room or rooms having sufficient

volume to meet the requirements of an unconfined space must

be provided. Each opening must have a minimum free area of

one square inch per 1000 Btu/hr,

total input rating of all gas utilization equipment in the confined

area. Each opening must be no less than 100 in2,

in size. The upper opening must be within 12 in, 305 mm, of,

but not less than 3 in,

The bottom opening must be within 12 in,

less than 3 in,

76 mm

76 mm

, from the bottom of the enclosure.

2200 mm2/kW

based on the

64516 mm

, from the top of the enclosure.

305 mm

, of, but not

2

,

1. Locate the boiler in an area that provides good access to

the unit. Keep in mind that servicing may require the removal

of jacket panels. Accessibility clearances must take precedence

over fire protection clearances.

2. An optimum site will be level, central to the hot water piping

system, close to a chimney or outside wall and have adequate

fresh air for combustion.

WARNING: Never install a PGV100W, propane boiler

in a closet or other confined or enclosed space!

Failure to comply with this warning could result in a

fire or explosion causing extensive property damage,

severe personal injury or death!

Page 4

GV100W BOILER

INSTALLATION & OPERATING INSTRUCTIONS

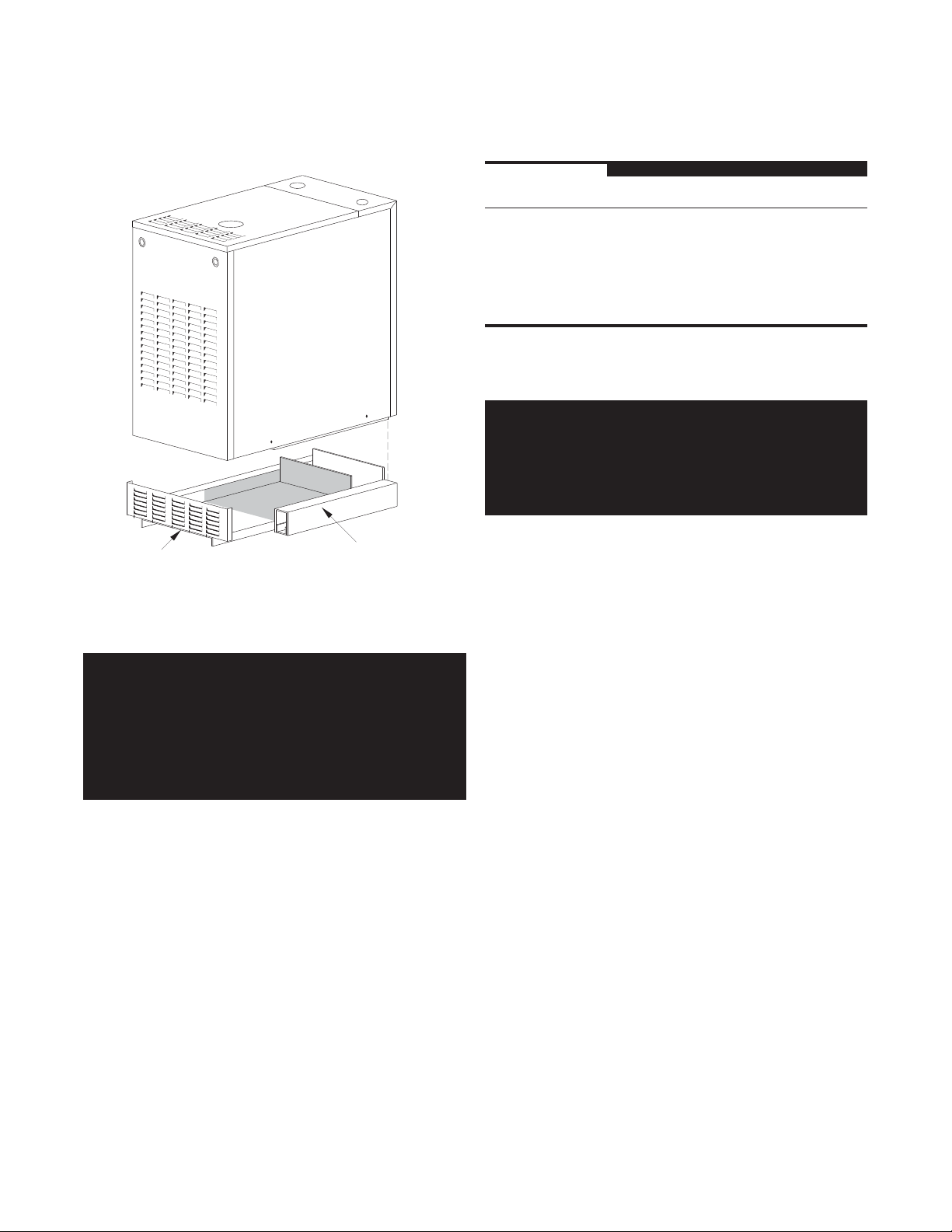

COMBUSTIBLE FLOOR OPTION

The GV100W boiler has been designed for use on noncombustible floors only. If a GV100W boiler is to be installed

on combustible flooring of any type, it MUST be installed using

the special base designed by the Smith Cast Iron Boiler Co.

Never use a substitute base when installing this boiler on

a combustible floor!

WARNING: Never install a GV100W boiler on

combustible flooring without using the special base

specifically designed for it by the Smith Cast Iron Boiler

Co. Do not alter in any way, the special base supplied

by the Smith Cast Iron Boiler Co. Failure to comply with

this warning may result in a fire causing extensive

property damage, severe personal injury or death!

To order the special base contact the nearest Smith Cast Iron

Boiler distributor and ask for Smith’s Special Base, Part No.

CB100-(sections). The number of sections is part of the model

number recorded on the rating plate. If the model number is

GV100W-7, the “-7” specifies that the boiler has seven sections.

Therefore, the proper special base would be Part No.

CB100-7. If the model number has a -3 order special base Part

No. CB100-3, etc.

If the GV100W is being installed in an alcove or closet ensure

that the distances between the boiler and all combustible

construction are greater than or equal to the minimum

distances listed in FIG. NO. 1.

CAUTION: Take care not to damage the burners, pilot or

any other gas train components during this procedure. If

a component is damaged, it must be replaced!

Determine the best boiler location by following the instructions

in the BOILER LOCATION section of this manual. Remove the

front access panel and position the boiler in front of this location

leaving room behind the boiler to work. Tightly thread a 1 1/4"

elbow onto the close nipple in the supply pipe so the opening

faces the front of the boiler. Thread a 4' length of 11/4" pipe

into the elbow and carefully lift the front of the boiler. Slide a

3" thick brick or block under the first 1" of each boiler base

side panel. Make sure the boiler is steady and won’t shift to

the side. Remove the 4' length of pipe. Rotate the 1 1/4" elbow

so it’s opening faces the back of the boiler. Thread the 4' length

of pipe, or a shorter one if necessary, back into the elbow.

Place the special base behind the boiler. Using extreme care

lift the boiler up and slide the special base under the boiler.

CAUTION: Never lift the boiler by the jacket panels or

damage to the boiler may result!

Make sure that the special base support channels are squarely

under the boiler base side panels. Carfully slide the boiler and

base into position. Center the boiler from side to side and ensure

that the back of the burner base side panels are flush with the

back of the Special Base support channels. Install the front grill

supplied with the Special Base. Complete the boiler installation

in accordance with the instructions set forth in this manual.

GV100W BOILER

INSTALLATION & OPERATING INSTRUCTIONS

FIG. NO. 1 Minimum Clearances to Combustible Construction

Page 5

Clearances A B C D E F

Alcove

in 25 * 6 4 7 4

mm 635 * 152 102 178 102

Closet

in 2526474

mm 635 51 152 102 178 102

To Service

in N/A N/A 6 4 10 10

EF

mm N/A N/A 157 102 254 254

* No front wall for alcoves.

FIG. NO. 2 Boiler Dimensions & Component Locations

18"

8 5/8"

(1)

PRESS.

SWITCH

2 11/16"

6 1/2"

C

A

C

D

B

B

2 11/16"

(1)

INDUCER

(1)

TEMP.

(2)

30"

GAS INLET

(1)

JUNCTION BOX,

CONTROL CENTER

(2)

(2)

13 1/4"

13 1/2"

27 5/8"

SIDE VIEW

11 1/2"

5 5/8"

(2)

6 3/4"

& INDUCER RELAY

(1)

GAS VALVE

A

FRONT VIEW

CONTROL

(1)

Notes: 1. Components located behind front panel

2. Vertical dimensions must be adjusted when using a base pan or concrete foundation under the boiler

TABLE 1 Boiler Dimensions

Boiler Size Dimension Dimension Vent Dia. Vent Dia.

(# Sections) A B CATEGORY I CATEGORY III

Single Wall Galv. Horizontal Vent

in

3 107⁄8

4 135⁄8

5 163⁄8

6 191⁄8

7 217⁄8

mm

276

346

416

486

556

in

27⁄16

313⁄16

53⁄16

69⁄16

715⁄16

mm

62

97

132

167

202

in

mm

4

4

4

5

5

102

102

102

127

127

in

mm

4

4

4

4

4

102

102

102

102

102

FLAME

ROLL-OUT

SWITCH

Page 6

GV100W BOILER

INSTALLATION & OPERATING INSTRUCTIONS

FIG. NO. 3 Special Base Installation

FRONT GRILL

SPECIAL BASE

COMBUSTION AIR

WARNING: This boiler must be supplied with

combustion air in accordance with Section 5.3, Air for

Combustion & Ventilation, of the latest edition of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 and

all applicable local building codes. Failure to provide

adequate combustion air for this appliance can result

in excessive levels of carbon monoxide which can

result in severe personal injury or death!

TABLE 2 Combustion Air Duct Sizing

Fresh Air 1⁄4" Wire Metal Wooden

Duct Size Mesh Screen Louvers Louvers

3" x 12" 144,000 108,000 36,000

8" x 8" 256,000 192,000 64,000

8" x 12" 384,000 288,000 96,000

1

⁄2" x 16" 512,000 384,000 128,000

8

INPUT BTUH

COMMON VENT SYSTEMS

WARNING: Do not connect this boiler or any other

appliance using a mechanical draft system under

positive pressure to a common vent system! Failure

to comply with this warning could result in the

accumulation of carbon monoxide gas which can

cause severe personal injury or death!

If an existing appliance is removed from a common venting

system, the common venting system may then be too large for

the proper venting of the remaining appliances connected to

it. At the time of removal of an existing boiler, the following steps

shall be followed with each appliance remaining connected to

the common venting system placed in operation, one at a

time, while the other appliances remaining connected to the

common venting system are not in operation.

Au moment du retrait d’une chaudière existante, les mesures

suivantes doivent être prises pour chaque appareil toujours

raccordé au système d’évacuation commun et qui fonctionne

alors que d’autres appareils toujours raccordés au système

d’évacuation ne fonction-nent pas: système d’évacuation.

1. Seal any unused openings in the common vent system.

To operate properly and safely this boiler requires a continuous

supply of air for combustion. Oxygen is used by the burners in

the boiler to burn the gas. An adequate supply of outside air

must be available to replace the air used by this process.

Older houses often have enough “leakage” to provide an

adequate amount of combustion air provided that the demand

for combustion air is not too great. Homes that are relatively

new or “tight” will most likely require the installation of a fresh

air duct or other means of providing air for combustion. Any

home utilizing other gas burning appliances, a fireplace, wood

stove or any type of exhaust fan must be checked for adequate

combustion air when all of these devices are in operation at

one time. Sizing of an outside air duct must be done to meet

the requirements of all such devices, see Table 2.

Sceller toutes les ouvertures non utilisées du sys-tème

d’évacuation.

2. Visually inspect the venting system for proper size and

horizonal pitch and determine that there is no blockage or

restriction, leakage, corrosion and other deficiencies which

could cause an unsafe condition.

Inspecter de façon visuelle le système d’évacu-ation pour

déterminer la grosser et l’inclinaison horizontale qui

conviennent et s’assurer que le système est exempt

d’obstruction, d’étranglement de fruite, de corrosion et autres

défaillances qui pourraient présenter des risques.

GV100W BOILER

INSTALLATION & OPERATING INSTRUCTIONS

Page 7

3. Insofar as is practical, close all building doors and windows

and all doors between the space in which the appliances

remaining connected to the common venting system are

located and other spaces of the building. Turn on cloths dryers

and any appliance not connected to the common venting

system. Turn on any exhaust fans, such as range hoods and

bathroom exhausts, so that they will operate at maximum

speed. Do not operate a summer exhaust fan. Close fireplace

dampers.

Dans la mesure du possible, fermer toutes les portes et les

fenêtres du bâtiment et toutes les portes entre l’espace où les

appareils toujours raccordés du système d’évacuation sont

installés et les autres espaces du bâtiment. Mettre en marche

les sécheuses, tous les appareils non raccordés au système

d’évacuation commun et tous les ventilateurs d’extraction

comme les hottes de cuisinère et les ventilateurs des salles

de bain. S’assurer que ces ventilateurs fonctionnent à la vitesse

maximale. Ne pas faire fonctionner les ventilateurs d’été.

Fermer les registres des cheminées.

4. Place in operation the appliance being inspected. Follow

the lighting instructions. Adjust the thermostat so the appliance

will operate continuously.

Mettre l’appareil inspecté en marche. Suivre les instructions

d’allumage. Régler le thermostat de façon que l’appareil

fonctionne de façon continue.

5. Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the flame of a match or

candle, or smoke from a cigarette, cigar or pipe.

Faire fonctionner le brûleur principal pendant 5 min ensuite,

déterminer si le coupe-tirage déborde à l’ouverture de décharge.

Utiliser la flamme d’une allunette ou d’une chandelle ou la fumée

d’une cigarette, d’un cigare ou d’une pipe.

6. After it has been determined that each appliance

remaining connected to the common venting system properly

vents when tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any other gas-burning

appliance to their previous condition of use.

7. Any improper operation of the common venting system

should be corrected so the installation conforms with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54. When resizing

any portion of the common venting system, the common

venting system should be resized to approach the minimum

size as determined using the appropriate tables in Appendix

F in the National Fuel Gas Code, ANSI Z223.1/NFPA 54 and

or CSA B149 Installation Codes.

Tout mauvais fonctionnement du systéme d’évacu-tion commun

devrait étré corrigé de façor que l’installation soit conforme au

National Fue Gas Code, ANSI Z223.1/NFPA 54 et (ou) aux

codes d’in-stallation CSA-B149. Si la grosseur d’une section

du système d’ évacuation doit étré modifiée, le système devrait

étré modifié pour respecter les valeurs minimales des tableaux

pertinents de l’appendice F du National Fuel Gas Code, ANSI

Z223.1/ NFPA 54 et (ou) des codes d’installation CSA-B149.

CHIMNEY VENTING

WARNING: This boiler must be vented in accordance

with Part 7, Venting of Equipment, of the latest edition

of the National Fuel Gas code, ANSI Z223.1/NFPA 54

and all applicable local building codes. In Canada,

follow CAN/CGA B149.1 or .2 Installation Codes.

Improper venting of this appliance can result in

excessive levels of carbon monoxide which can result

in severe personal injury or death!

Chimney Inspection & Sizing

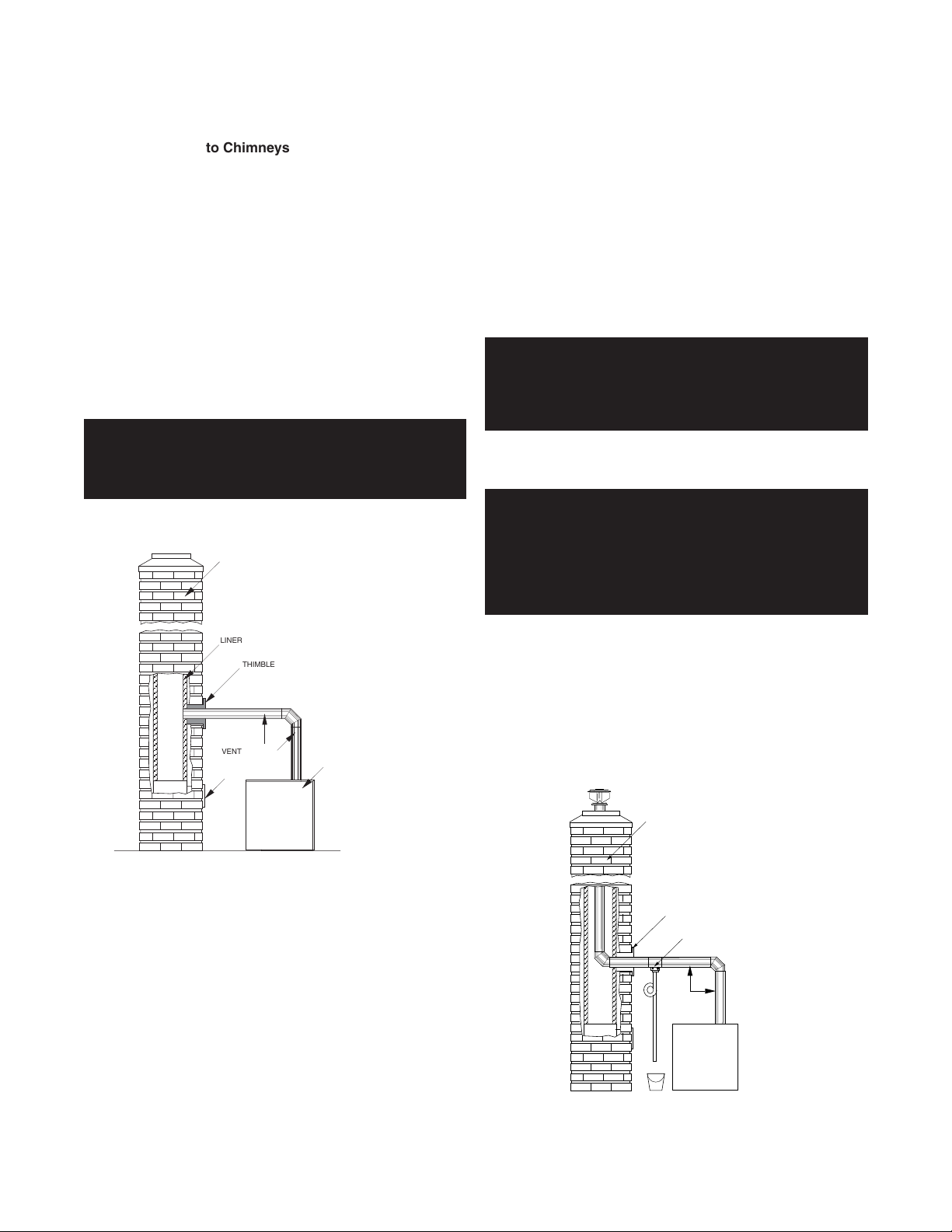

A GV100W series boiler can be vented into a masonry

chimney, FIG. NO. 4, provided several conditions are met:

• a thorough inspection of the chimney must be performed.

• the chimney must have a vitreous tile lining that is clean,

properly constructed and properly sized.

• the chimney must not be located on an external wall or be

located in an unheated space unless the chimney is lined with

a corrosion resistant metal liner and a condensate trap is

installed.

Une fois qu’il a été d éterminé, selon la métode indiquée cidessus, que chaque appareil raccordé au système

d’évacuation est mis à l’air libre de façor adéquate. Remettre

les portes et les fenêtres, les ventilateurs, les registres de

cheminées et les appareils au gaz à leur position originale.

• the boiler must not be connected to a flue used for a

fireplace, wood stove or other solid fuel device.

If possible the boiler and a gas fired hot water heater should

be connected to the same chimney flue. They must have their

own vent connector and enter the flue at least 6 in,

apart. Consult the latest revision of the National Fuel Gas Code,

ANSI Z223.1 and follow all local codes to ensure that the

chimney is the proper size for the given installation.

WARNING: Failure to connect this boiler to the

chimney using vent pipe of the proper diameter, as

listed in Table 1, could cause carbon monoxide

poisoning leading to death!

152 mm

Page 8

GV100W BOILER

INSTALLATION & OPERATING INSTRUCTIONS

Vent Connections to Chimneys

Use Type B1 or single wall metal vent pipe from the boiler to

the chimney. If used, a 4 in to 5 in,

increaser must be fastened directly to the boiler vent collar with

sheet metal screws no longer than 1/2 in,

shortest, straightest vent system possible for the particular

application. The vent system should be sloped up toward the

2 cm/m

chimney 1/4 in/ft,

supported and each connection securely fastened with at least

3 corrosion resistant sheet metal screws. The termination of

the vent pipe must be flush with the inside of the chimney flue.

Always provide a minimum clearance of 6 in,

single wall metal vent pipe and any combustible materials. Type

B1 vent may be used, clearance between it and any

combustible material must be as listed.

WARNING: Failure to maintain minimum clearances

between vent connectors and combustible materials

can result in a fire causing extensive property damage,

severe personal injury or death!

FIG NO. 4 Chimney Venting

. Ensure that the flue pipe is properly

CHIMNEY

102 mm to 127 mm

13 mm

. Use the

152 mm

, between

Single Wall Metal Vent

GV100W boilers may be vented vertically using single wall

metal vent pipe sized per Table 1. Galvanized sheet metal pipe

must have a minimum wall thickness of 26 gauge. In Canada,

pipe constructed of .025 in,

inch thick stainless steel may be required.

The use of thimbles, firestops and other protective devices

when penetrating combustible or noncombustible construction

must be in accordance with all applicable national and local

codes.

WARNING: Single wall vent pipe must NEVER pass

through interior walls or through floors or ceilings!

Failure to comply with this warning could result in a

fire causing extensive property damage, severe

personal injury or death!

An unused chimney flue can be used as a raceway for single

wall metal pipe, see FIG. NO. 4A.

WARNING: Never run vent pipe through a chimney flue

that has another appliance attached to it! Never

connect another appliance to a pressurized vent

system, it must serve only one appliance. Failure to

comply with this warning can result in excessive

levels of carbon monoxide causing severe personal

injury or death!

0.63 mm

, thick aluminum or .018

LINER

THIMBLE

VENT SYSTEM

CLEANOUT

BOILER

VERTICAL VENTING

B Vent

The boiler may be vented vertically using the proper size Type

B1 vent pipe. Do not use the boiler as a load bearing element.

The vent system must be fully supported by the building

structure. Use an approved vent terminal at the vent outlet

which must extend at least 3 ft,

where it passes through the roof. In addition, the vent pipe must

be at least 2 ft,

within a horizontal distance of 10 ft,

0.6 m

higher than any portion of the building

1 m

, above the highest point

3 m

.

A listed vent terminal designed for the type of pipe being used

must complete the vertical run where it exits the chimney. If

the chimney is on an outside wall or in an unheated space the

optional condensate tee and trap pictured in FIG. NO. 4A may

be required. The trap is made by ty-rapping a loop in the 3/8"

clear plastic tubing attached to the tee and filling it with water.

Do not operate the boiler without this trap!

FIG. NO 4A Vertical Venting Through a Chimney

CHIMNEY

THIMBLE

CONDENSATE

DRAIN ASS'Y.

WARNING

S

VENT

SYSTEM

BOILER

Loading...

Loading...