Smith Cast Iron Boilers GB200 User Manual

GB200-IM-5

42-9184

GB200 SERIES

INSTALLATION, OPERATION

& MAINTENANCE MANUAL

WITH REPLACEMENT

PARTS LIST

GAS-FIRED STEAM

CAST IRON BOILERS

85,000 TO 165,000 BTUH INPUT

INTERMITTENT PILOT/VENT DAMPER

& STANDING PILOT/VENT DAMPER

SECTION 1: INTRODUCTION

Code Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Venting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Chimney Requirements . . . . . . . . . . . . . . . . . . . . . . . . . .3

Combustion Air Requirements . . . . . . . . . . . . . . . . . . . . .3

Water Treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Shipment of Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SECTION 2: BOILER INSTALLATION

Step 1: Locating/Setting Boiler . . . . . . . . . . . . . . . . . . . . .4

Step 2: Installing Steam Piping . . . . . . . . . . . . . . . . . . . .5

Step 3: Installing Hydronic Components . . . . . . . . . . . . .5

Step 4: Venting Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Step 5: Installing/Testing Gas Piping . . . . . . . . . . . . . . . . .7

Step 6: Wiring Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

SECTION 3: START-UP & OPERATION

Sequence Of Operation . . . . . . . . . . . . . . . . . . . . . . . . .11

Prior To Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Start-Up & Adjustments . . . . . . . . . . . . . . . . . . . . . . . . .11

SECTION 4: MAINTENANCE

Before Each Heating Season . . . . . . . . . . . . . . . . . . . . .14

Steam Boiler Cleaning Instructions . . . . . . . . . . . . . . . . .15

How To Change Orifices . . . . . . . . . . . . . . . . . . . . . . . . .15

Heating System Problems & Causes . . . . . . . . . . . . . . .15

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . .16-17

WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

TABLE OF CONTENTS

WESTCAST, INC.

260 NORTH ELM STREET WESTFIELD, MA 01085

TEL. (413) 562-9631 FAX (413) 562-3799

www.smithboiler.com

2

SECTION 1: INTRODUCTION

The following terms are used throughout this manual to bring

attention to the presence of potential hazards or to important

information concerning the product:

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in minor injury or property damage.

NOTE: Used to notify of special instructions on installation, operation or maintenance which are important to

equipment but not related to personal injury hazards.

CODE COMPLIANCE

Boiler installations must conform to the requirements of the

authority having jurisdiction or, in the absence of such

requirements, to the National Fuel Gas Code ANSI Z223.1latest edition. Where required by the authority having jurisdiction, the installation must also conform to the American Society of Mechanical Engineers Code for "Controls and Safety

Devices for Automatically Fired Boilers", ANSI/ASME CSD-1.

All electrical wiring must be in accordance with National

Electric Code ANSI/NFPA No.70-latest edition and any additional state or local code requirements. If an external source

is utilized, the boiler, when installed, must be electrically

grounded in accordance with requirements of the authority

having jurisdiction or, in the absence of such requirements,

with the National Electrical Code, ANSI/NFPA No.70-latest

edition. UL listed power limited circuit cable is almost universally approved for safety controls on heating equipment,

either internally or externally, without protection of conduits or

raceway.

VENTING REQUIREMENTS

When connecting to gas vents or chimneys, vent installations

shall be in accordance with Part 7, Venting of Equipment, of

the National Fuel Gas Code, ANSI Z223.1-latest edition, or

applicable provisions of the local building codes.

Vent connectors serving appliances vented by natural draft

shall not be connected into any portion of mechanical draft

systems operating under positive pressure.

When two or more appliances vent into a common flue, the

area of the common flue should be at least equal to the area

of the largest flue plus 50% of the areas of the additional flue

or vent connectors.

When existing boiler is removed from common venting system, common venting system is likely to be too large for

proper venting of appliances remaining connected to it. At

time of removal of existing boiler, the following steps shall be

followed with each appliance remaining connected to the

common venting system placed in operation, while other

appliances remaining connected to the common venting system are not in operation:

1. Seal all unused openings in common venting system.

2. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deficiencies

which could cause an unsafe condition.

3. Insofar as is practical, close all building doors and windows and all doors between the space in which the appliances remaining connected to the common venting system are located and other spaces of the building. Turn on

clothes dryers and any appliance not connected to the

common venting system. Turn on any exhaust fans, such

as range hoods and bathroom exhausts, so they will

operate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

4. Place in operation the appliance being inspected. Follow

the lighting instructions. Adjust thermostat so appliance

will operate continuously.

5. Test for spillage at draft hood relief opening after 5 minutes of main burner operation. Use the flame of a match

or candle, or smoke from cigarette, cigar or pipe.

6. After it has been determined that each appliance remaining connected to common venting system properly vents

when tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any other gas-burning appliance to previous conditions of use.

7. Any improper operation of the common venting system

should be corrected so the installation conforms with

National Fuel Gas Code, ANSI Z223.1-latest edition.

When resizing any portion of the common venting system, the common venting system should be resized to

approach the minimum size as determined using the

appropriate tables in Appendix G in the National Fuel

Gas Code, ANSI Z223.1-latest edition.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death, serious injury or substantial property damage.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death, serious

injury or substantial property damage.

CHIMNEY REQUIREMENTS

DANGER: A chimney which does not meet modern

safety standards will result in a fire or deadly carbon

monoxide poisoning of the building residents.

Chimney condition is of paramount importance for a safe and

efficient boiler installation. All new and replacement installations must include a chimney inspection by a qualified individual or agency. Chimney construction materials must be

compatible with the fuel being used.

Particular attention should be paid on all oil-to-gas conversions. Soot may have accumulated in chimney and/or

degraded chimney liner. Most utilities require complete chimney cleaning. Others may require installation of new liner,

spill switches or other chimney upgrades. Check with local

utility for required safety precautions.

COMBUSTION AIR REQUIREMENTS

Provisions for combustion air must be in accordance with the

National Fuel Gas Code ANSI Z223.1 - latest edition, as well

as all applicable local codes. If the boiler is installed in an

unconfined space, adequate air will be available via normal

infiltration. However, if building construction is unusually tight

or the boiler is installed in a confined space (a space whose

volume is less than 50 cubic feet per 1000 Btu/hr of gas input

for all fuel burning equipment), adequate air for combustion

must be provided by two openings: one located about 6”

below the ceiling, the other about 6” above the floor. When

communicating directly with the outside or through a vertical

duct, each opening must have a minimum free area of one

square inch per 4000 Btu/hr of gas input. Horizontal ducts to

the outside must have a minimum free area of one square

inch per 2000 Btu/hr of gas input. When ventilation is provided by openings in doors, etc. to adjoining spaces having adequate infiltration, each opening must have a minimum free

area of one square inch per 1000 Btu/hr of gas input.

3

NOTE: Boiler employs atmospheric combustion. Combustion air must not be contaminated with halogenated

hydrocarbon vapors, aerosol propellants or freon. Otherwise, boiler heat exchanger will be subject to corrosion,

reducing boiler life.

WATER TREATMENT

Water treatment is recommended in areas where water quality is a problem. A local water treatment company should be

consulted to determine the requirements for your particular

system and locality.

NOTE: Boiler is not for use in systems where water is

replenished. Minerals in the water can build up on the

heat transfer surfaces and cause overheating and subsequent failure of the heat exchanger.

NOTE: Boiler utilizes synthetic rubber seals. Water treatment chemicals and system cleaning chemicals must be

compatible with this and all other construction materials.

SHIPMENT OF BOILER

Each boiler is shipped in a single carton.

Optional Vent Damper

When ordered, the vent damper is shipped in an individual

carton packaged with the boiler. Mounting of the damper and

flue outlet extension are required.

WARNING: Adequate fresh air must be provided for

combustion. Improper boiler operation and inadequate venting of deadly flue gases may otherwise

result.

4

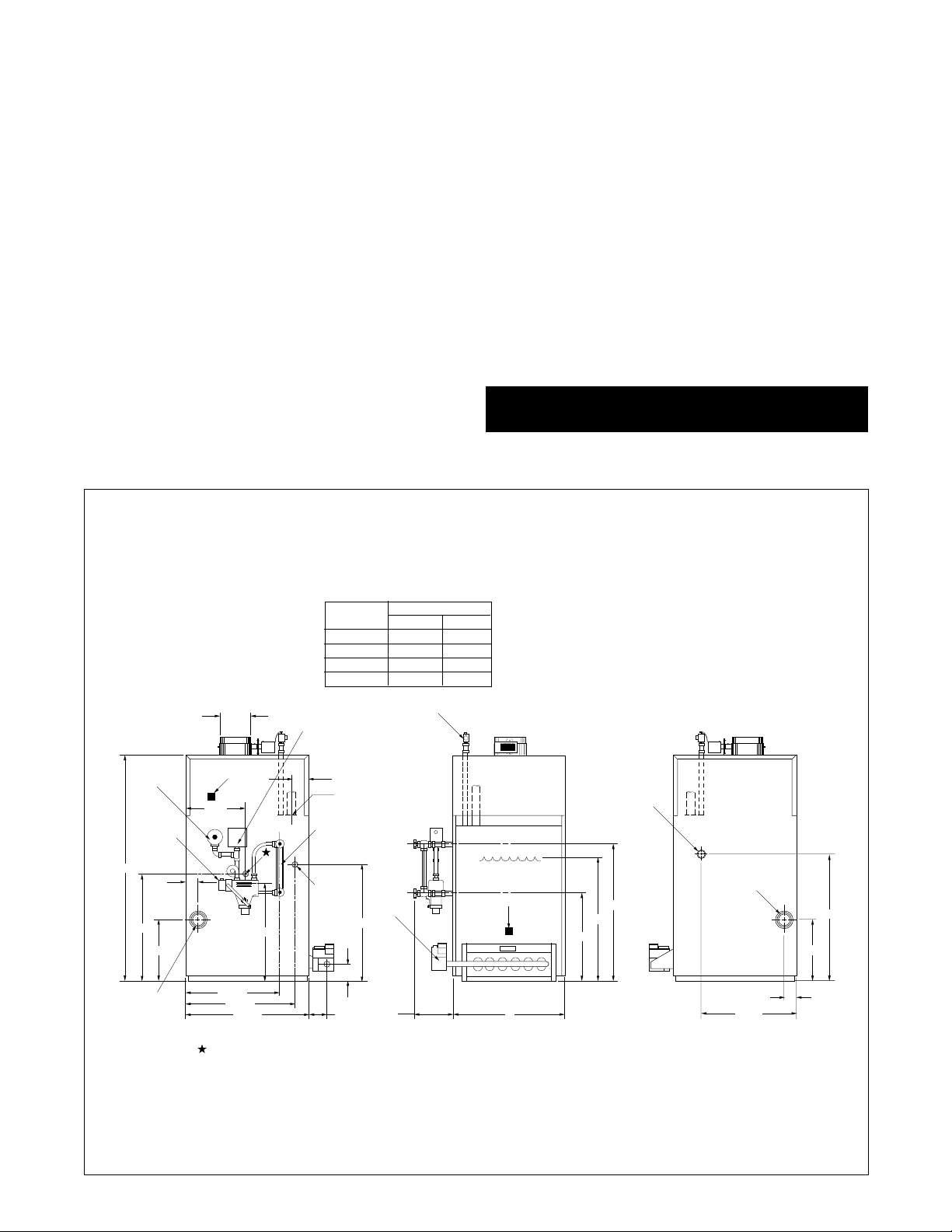

FIGURE 2.1: MODEL GB200 BOILER DIMENSIONS

WARNING: Never install boiler on carpeting as heat

damage and/or fire may result.

STEP 1: LOCATING/SETTING BOILER

Boiler may be installed in an alcove (see dimensions in Figure 2.1). Locate boiler so connecting flue pipe between draft

hood and chimney is as short as possible.

Observe the following minimum clearances to combustibles:

18" on sides...alcove at front...28" at top...18" at rear...6" from

flue pipe in any direction. Maintain a minimum 1” clearance

between hot water piping and combustible materials. Local

code requirements may specify greater clearances and must

be adhered to.

Remove boiler from carton and set it in position. Install on

non-combustible floor only, unless local codes permit use

and fabrication of a fireproof base (see Figure 2.2).

Remove all packing material from boiler. Check that burners,

draft diverter and controls are in proper position.

Boiler shall be installed such that the gas ignition system

components are protected from water (dripping, spraying,

rain, etc.) during appliance operation and service (low water

cut-off repacement, condensate trap replacement, control

replacement).

NOTE: Do not loosen tie rods on boiler absorption unit.

They are intended to accommodate thermal expansion.

Loss of boiler's structural integrity and water leaks/damage may result.

SECTION 2: BOILER INSTALLATION

PRESS.

GAUGE

LOW

WATER

CUT-OFF

41"

2 1/2"

21"

14 3/4"

2" RETURN

FRONT

MINIMUM CLEARANCES

TO COMBUSTIBLES

Top: 28"

Rear: 18"

Left & Right: 18"

Front: ALCOVE

WATER

LINE

A

23 1/4"

18 1/4"

3/4" PLUGGED

TAPPING

26 7/8"

2" RETURN

REAR

18 1/8"

B

SPILL SWITCH

9 7/8"

16 1/2"

18 1/8"

21 7/8"

20"

BOILER

MODEL

GB200-S-3

GB200-S-4L

GB200-S-4H

GB200-S-5

PRESSURE CONTROL

3"

2" STEAM

SUPPLY

WATER

LEVEL

INDICATOR

1/2"

PLUGGED

TAPPING

23 1/4"

3 3/8"

2 3/8"

15 3/8"

18 7/8"

18 7/8"

22 3/8"

PRESS.

RELIEF VALVE

GAS

VALVE

6 3/4"

DIMENSIONS

A

B

5"

6"

6"

7"

ROLLOUT SWITCH

-LEFT SIDE VIEW- -FRONT VIEW- -RIGHT SIDE VIEWPROBE LOCATION

FOR ELECTRIC

LWCO.

NOTE: OPTIONAL FLOAT LOW WATER CUT-OFF SHOWN.

23 7/8"

14 3/4"

2 1/2"

5

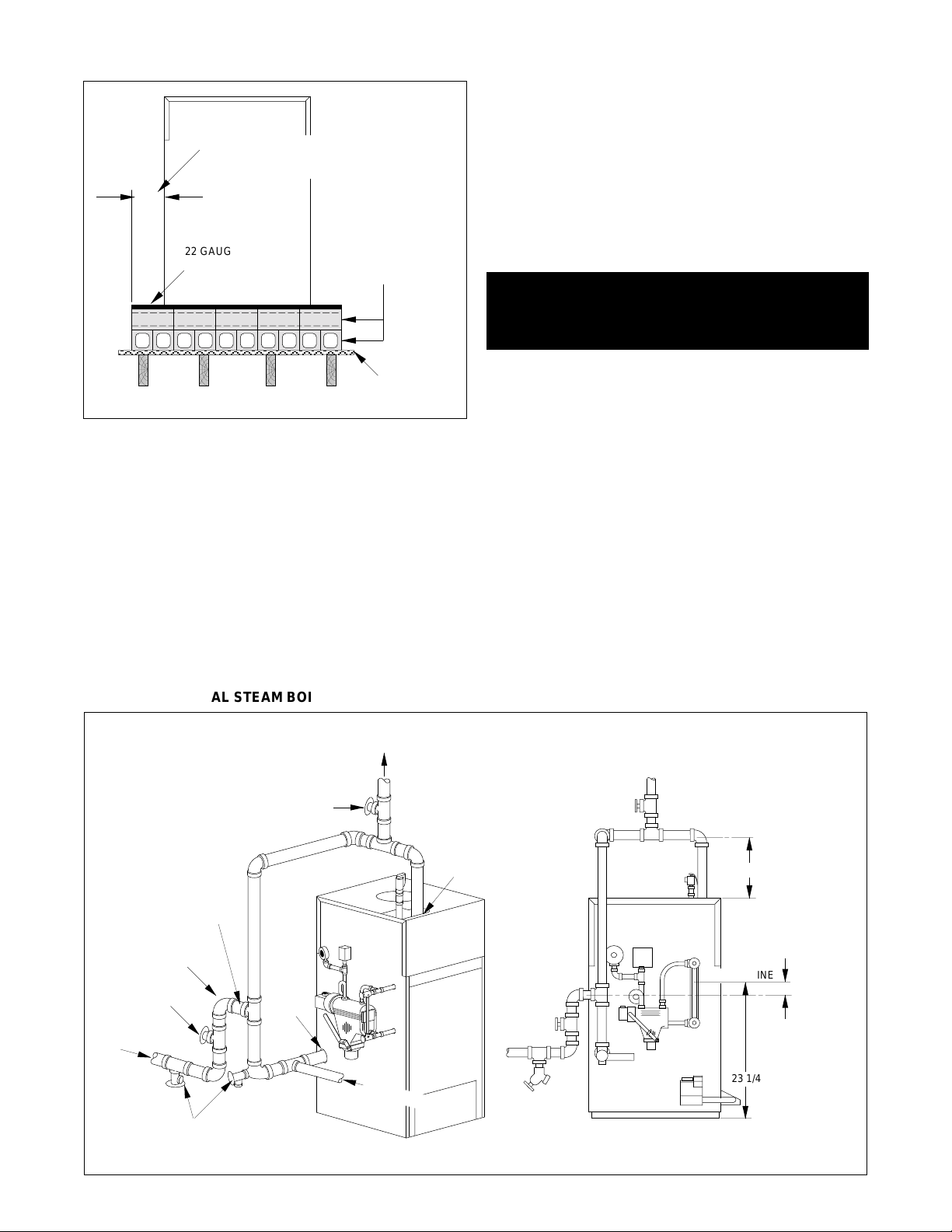

STEP 2: INSTALLING STEAM PIPING

Typical piping connections are shown in Figure 2.3. All external piping must be supported by hangers, not by the boiler or

its accessories.

Supply outlet must run full size from the boiler to a header at

least 24" above top of boiler. Condensate return piping

should be connected to boiler through a "Hartford Loop."

Install gate valves in supply and return.

Proper steam piping practices must be followed at all times.

Maintain proper clearances between piping and combustible

material.

The supply and return lines should be equipped with drain

cocks to drain sediment and sludge from lowest points of

boiler.

STEP 3: INSTALLING HYDRONIC COMPONENTS

A low-water cutoff must be installed to protect the unit from

dry fire.

Screw extension nipple into 3/4" tapping on top of the

absorption unit and install relief valve into top of nipple with

the spindle in the vertical position (i.e., with the valve discharge in the horizontal).

Most localities require the discharge piping to terminate within 6" of the floor. Check local code requirements if in doubt.

Discharge piping must be of same size or larger than the

relief valve outlet and should be run as short and straight as

possible. Elbows in the discharge piping should be placed as

close to the valve as possible. If valve discharge is to be

drained away, the discharge piping must not be hard-piped to

the drain piping (i.e., an open funnel or similar arrangement

must be used).

CAUTION: Piping must be installed from the relief valve

discharge so there will be no danger of scalding personnel.

FIGURE 2.2: RECOMMENDED FIREPROOF BASE

FIGURE 2.3: TYPICAL STEAM BOILER PIPING

WARNING: Never install any type of valve between

the boiler and the relief valve or an explosion causing

extensive property damage, severe personal injury or

death may occur!

6" OVERHANG OF BLOCKS

AND SHEETMETAL ALL

AROUND

6"

22 GAUGE

SHEETMETAL

4" HOLLOW CLAY

TILE (TWO COURSES)

OPENINGS THRU BLOCKS

IN TOP COURSE TO

BE AT 90° ANGLE

TO OPENINGS THRU

BOTTOM COURSE

FLOOR

STEAM

SUPPLY

GATE VALVE

MUST BE CLOSE

NIPPLE

HARTFORD

LOOP

GATE

VALVE

RETURN

DRAIN

COCKS

RETURN

TAPPING

2" NPT

COLD WATER FILL

SUPPLY

TAPPING

3" NPT

12" MIN.

WATER LINE

C/L OF HARTFORD

LOOP TO BE 2"

BELOW WATER

23 1/4"

LINE

6

STEP 4: VENTING BOILER

A factory-mounted spill switch is provided on all GB200 boilers (see Figures 2.4 & 2.4A).

The flue or vent connectors must be installed flush with the

inside chimney liner surface and sealed in place with furnace

cement. Horizontal positions of the single wall and type B

venting systems shall be supported by use of strap hangers

or their equivalent. Vent supports should be placed a maximum of 15 feet apart and as required to prevent sagging.

The vent connectors shall be pitched 1/4" per foot upwards

towards the chimney or vent termination.

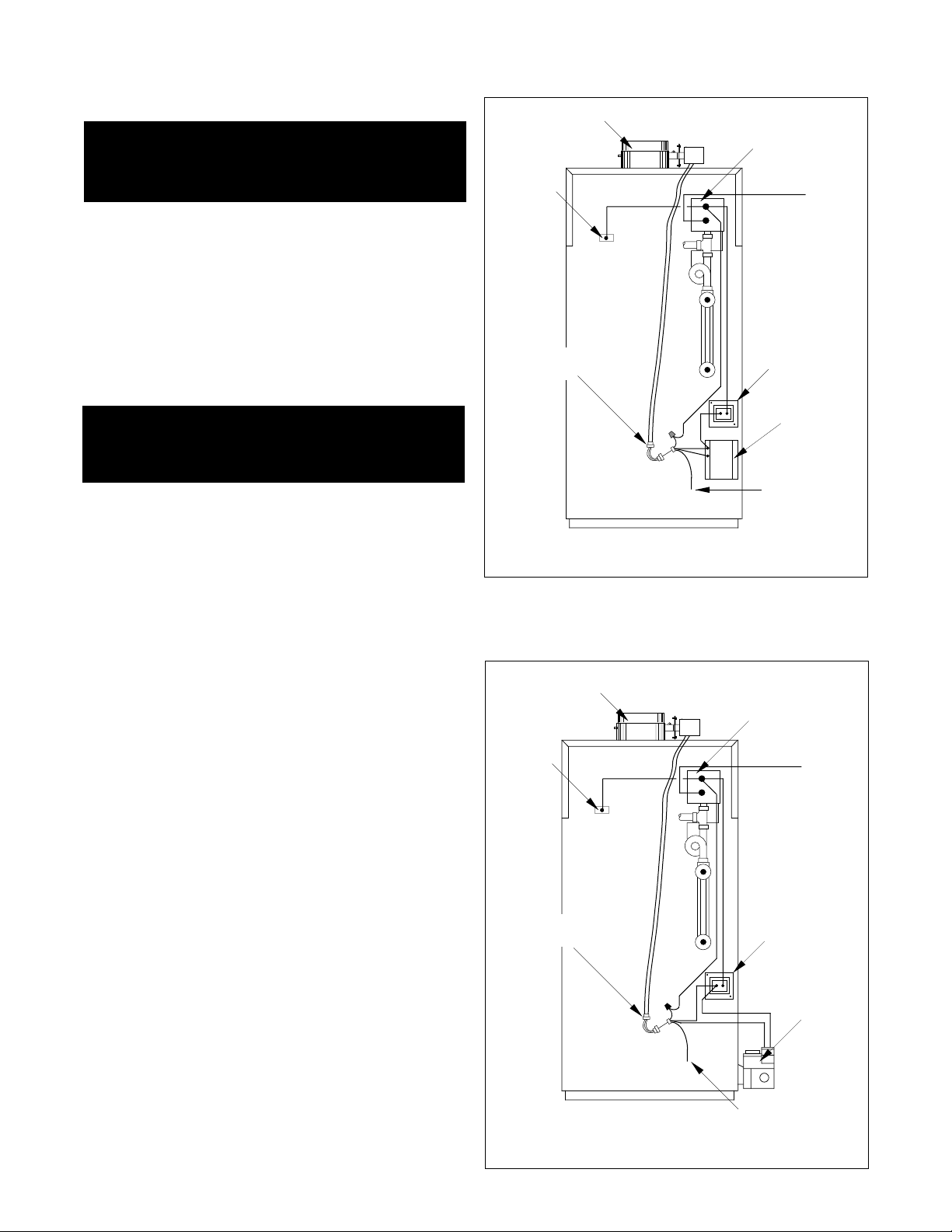

Installing Vent Damper

The vent damper must be mounted directly on top of the draft

diverter. The vent outlet extension must be installed between

the damper and the outlet to allow the damper plate to open

and close.

Locate the motor on the front side and position the cable so

that it does not touch the metal surface of the draft diverter

(see Figure 2.4). If necessary, turn angle connector on vent

damper upward until cable clears; tighten locknut to secure.

The direction of the flow arrow imprinted on the vent damper

must point upward. The damper position indicator, which is

located on the side of the vent damper opposite the motor,

must be visible.

CAUTION: A minimum of 6" between vent damper and

combustible materials must be maintained. The vent

damper must be accessible for servicing and checking

position indicator.

If applicable, remove hair pin shipping clip which holds

damper blade in closed position and observe that damper

blade rotates slowly to open position. Do not force it closed

as it may damage the gear train and void the warranty. The

blade should move freely and without obstruction.

Secure the vent damper housing to the draft diverter outlet

with sheet metal screws or pop rivets. Refer to Figure 2.5 for

fastener locations. Install flue pipe over top of vent damper

and secure to damper housing with sheet metal screws or

pop rivets.

Attach vent damper cable to cable clamp on boiler left panel

and join the Molex connector (see Figures 2.4 & 2.4A).

DANGER: Draft diverter, vent outlet and vent damper

as supplied must not be altered in any way, as proper

boiler operation would be jeopardized. Flame rollout,

fire or carbon monoxide poisoning will result.

DANGER: Only the boiler may be served by the vent

damper. Do not attempt to use it to vent an additional appliance. This will cause fire or carbon monoxide

poisoning.

FIGURE 2.4A: VENT DAMPER INSTALLATION

FOR STANDING PILOT

FIGURE 2.4: VENT DAMPER INSTALLATION

FOR INTERMITTENT PILOT

VENT DAMPER

PRESSURE

SPILL

SWITCH

CABLE

BRACKET

DK. BLUE

CONTROL

THERMOSTAT

CONNECTION

TRANSFORMER

THERMOSTAT

CONNECTION

PILOT

CONTROL

VENT DAMPER

PRESSURE

SPILL

SWITCH

CABLE

BRACKET

DK. BLUE

CONTROL

THERMOSTAT

CONNECTION

TRANSFORMER

GAS

VALVE

THERMOSTAT

CONNECTION

Loading...

Loading...