Page 1

19510096100 Fogl.OPERAZ.PRELIM.6090

1

WD6090 – GW6090

READ BEFORE STARTING THE DEVICE

This document includes important preliminary instructions for the use of the device. The

technical operations must be carried out by authorized personnel. The operations

performed by unauthorized personnel can be a source of danger to the user.

1 UNPACKING............................................................................................................................................... 1

2 BOILER FILLING.......................................................................................................................................... 2

3 ACTIVATION OF THE BOILER THERMOSTAT .............................................................................................. 3

4 OPENING THE DOOR INTRUCTIONS – EMERGENCY PROCEDURE ............................................................ 4

1 UNPACKING

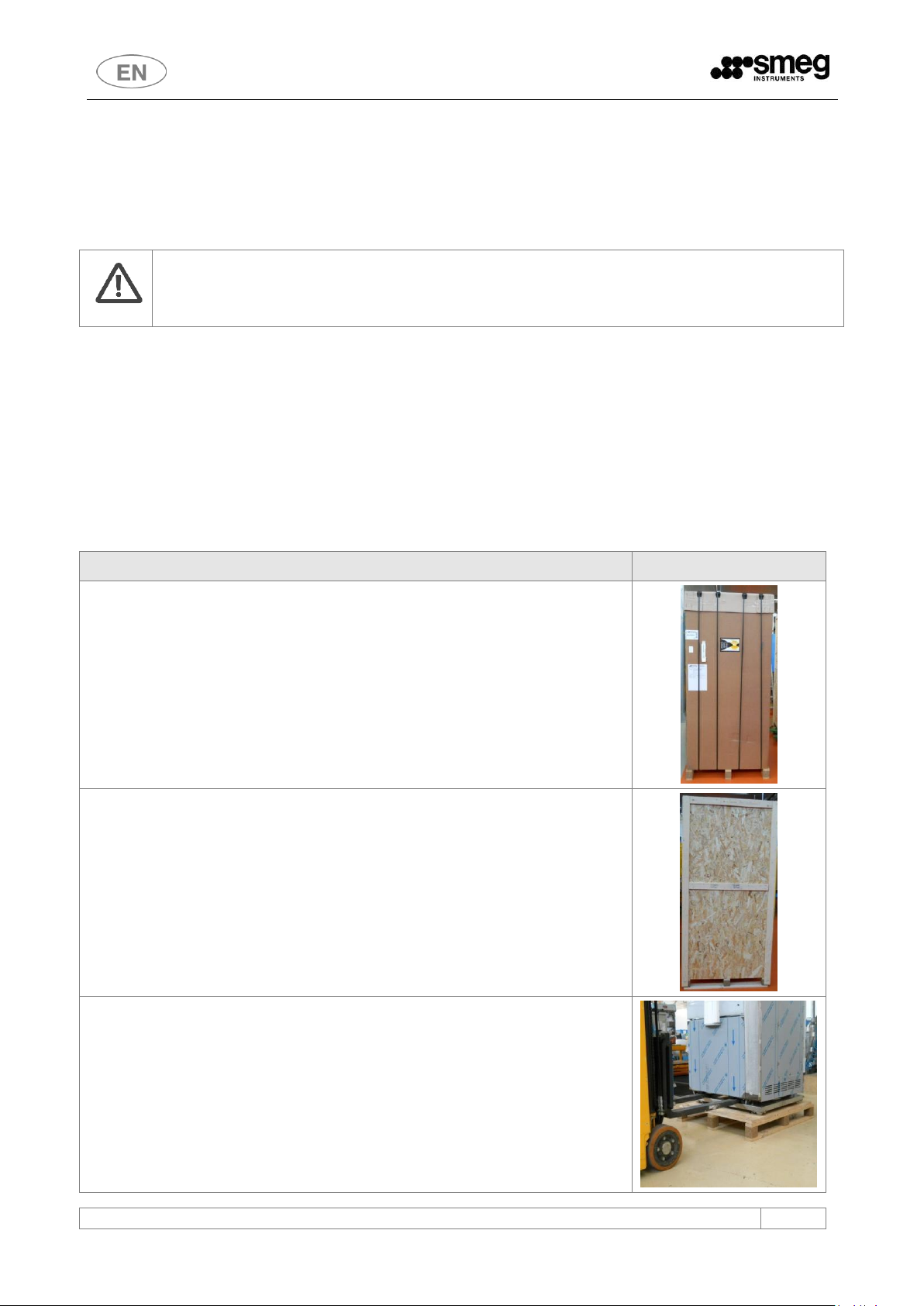

DESCRIPTION

IMAGE

The standard product is wrapped with cardboard and fastened on a wooden

pallet through straps.

1. Cut the straps.

2. Remove the cardboard cover.

3. Extract the cardboard upward.

4. There are 4 metal brackets securing the product, fastened to the

wooden pallet. Both screws and brackets must be removed in order

to extract the machine.

In some particular cases the product is packaged in a wooden box.

Dimensions (WxDxH) = 105x106x221 cm.

Packaged product weight: 390kg.

Unfasten the securing screws in order to remove the wooden panels (no. 4

side panels + top).

A forklift truck is needed to take the machine off the wooden pallet.

Page 2

19510096100 Fogl.OPERAZ.PRELIM.6090

2

2 BOILER FILLING

2.1 Introduction

The boiler integrated in the device is completely emptied at the factory.

It is therefore necessary to fill the boiler with water during installation and before the execution of a cycle,

to prevent the heating elements from running “dry”.

The boiler is supplied:

1. With hot water in the GW range (glassware washer) – solenoid valve EVC;

2. With demineralized water in the WD range (washer disinfector) – solenoid valve EVD.

The two procedures described below can be used alternatively.

2.1.1 Automatic filling

1. Consult the table of programs.

2. Start a wash cycle where the first phase calls for the type of water that goes to feed the boiler;

a. On GW run prog. 3;

b. On WD run prog. 2 “Prewash DEMI”.

3. Stop the cycle as soon as the display moves from the FILLING phase to the WASHING phase.

4. Activate the "RESET" procedure (see instruction manual).

2.1.2 Manual Filling

You need to activate the solenoid valve that feeds the boiler (EVC for the GW range and EVD for the WD

range).

The operation is to be considered completed when water enters the wash chamber in large quantities.

At the end, proceed with a total draining of the wash chamber or simply initiating the "RESET" procedure.

2.1.2.1 From the Keyboard

Use the interface to select UTILITIES -> OUTPUT STATE and turn on the feeding solenoid valve output (see §

“Status of the outputs” in the instruction manual).

2.1.2.2 From the Application WDTRACE

You need to activate the solenoid valve that feeds the boiler (“EVC” for the GW range and “EVD” for the

WD range) from the command “TEST I/O” (see § “Test input e output” in the application’s instruction

manual).

Page 3

19510096100 Fogl.OPERAZ.PRELIM.6090

3

3 ACTIVATION OF THE BOILER THERMOSTAT

Before any intervention: you need to unplug the electrical power and close the water feeding

faucets.

The thermostat is disabled at the factory to prevent the heating elements from running dry.

DESCRIPTION

IMAGE

1. Unscrew the left side metal panel. You access the knob for the

activation of the boiler thermostat.

2. Rotate the knob clockwise.

3. Correct position of the thermostat knob (correspondence

between the knob’s arrow and the sticker), which lead to the

activation of the thermostat.

4. Close the device’s panels.

-

Page 4

19510096100 Fogl.OPERAZ.PRELIM.6090

4

4 OPENING THE DOOR INTRUCTIONS – EMERGENCY PROCEDURE

Do not force manually the opening of the door; the machine is equipped with an automatic

door locking/unlocking system.

Should the door of the chamber be opened before the actual installation, this can be done by

connecting temporarily the machine in single-phase 230V, so that the automatic door is

unlocked.

Procedure:

1. Before proceeding, switch off the power supply.

2. Connect the mains cable’s BLUE wire to the NEUTRAL terminal. Connect the BROWN wire to the LIVE

terminal, connect the YELLOW-GREEN wire to EARTH terminal.

3. DO NOT CONNECT THE TWO BLACK WIRES.

4. Switch the power supply on. Make sure the green “POWER” light is on.

Switch the machine on by rotating the MAINS SWITCH 90° clockwise (position 1). Make sure the red

light is on: On/OFF indicator.

5. Press the "ENTER" key, wait for the automatic system to unlock the door.

6. Unlock the door handle manually by pulling it upward.

Detail of the power switch

Green light: "POWER" – external unit line indicator - Red light: "ON/OFF" – machine line indicator.

KEY

DESCRIPTION

ENTER KEY: press to open the door of the washing chamber. Central key of the control

panel.

19 510 0961 00

25/03/20

Rev.

Date

Smeg S.p.A. - Instruments Division

Via Leonardo da Vinci, 4 – 42016 Guastalla (RE) Italy

Tel. +39 0522 8211 – Fax +39 0522 821 592

e-mail: instruments@smeg.it – service.instruments@smeg.it

www.smeg-instruments.com

Loading...

Loading...