Page 1

19 561 0121 00 – EN

21 / 07 / 15

First issue

REV. DOC.

DATE

NOTES

INSTALLATION REQUIREMENTS

WD6010 – GW6010

SMEG S.p.A. thanks you for having chosen this product.

Preliminary operations for Start-up, at Customer's care:

any necessary work of room preparation

prearrangement of properly operating systems, in compliance with the requirements and

regulations in force

machine positioning

Refer to the instructions in this manual for detailed instructions on the above.

SMEG S.p.A. disclaims any liability for damage to persons or property resulting from defective systems

or not compliant with the regulations, for improper installation of the appliance and/or accessories

made by unauthorized personnel.

Any operation on the appliance by unauthorized personnel will invalidate the warranty.

1

Page 2

WD6010-GW6010 INSTALLATION REQUIREMENTS

CAUTION

It is essential that the electrical system to which the machine is connected complies with current regulations.

All electrical testing operations and equipment electrical installation should be made by qualified personnel.

The competent personnel is responsible to check that the earthing is efficient.

Any components must always be replaced with genuine spare parts.

CIRCUIT-BREAKER

A CIRCUIT-BREAKER must be installed for each appliance.

Circuit-breaker characteristics:

a. Omnipolar: must break all live conductors;

b. Easily accessible to the user;

c. Easily operated (no tool must be required);

d. Located in close proximity to the appliance;

e. Clearly marked as the appliance circuit-breaker

The same specifications apply to the mains switch on the machine: It must be maintained Easily accessible. Do not

place objects in a way that limits its accessibility.

A PROTECTIVE DEVICE specifically for the appliance (e.g. magnetothermal breaker or fuse on every phase,

suitably rated for the electrical data stated) should be installed in the room’s electrical panel.

ELECTRICAL SYSTEM REQUIREMENTS

Refer to the Technical Data for the required connections characteristics.

The device is supplied without a plug, with a cable with insulated wire terminals: The electrical connection of the device

must be carried out with a permanent connection.

2

Page 3

WD6010-GW6010 INSTALLATION REQUIREMENTS

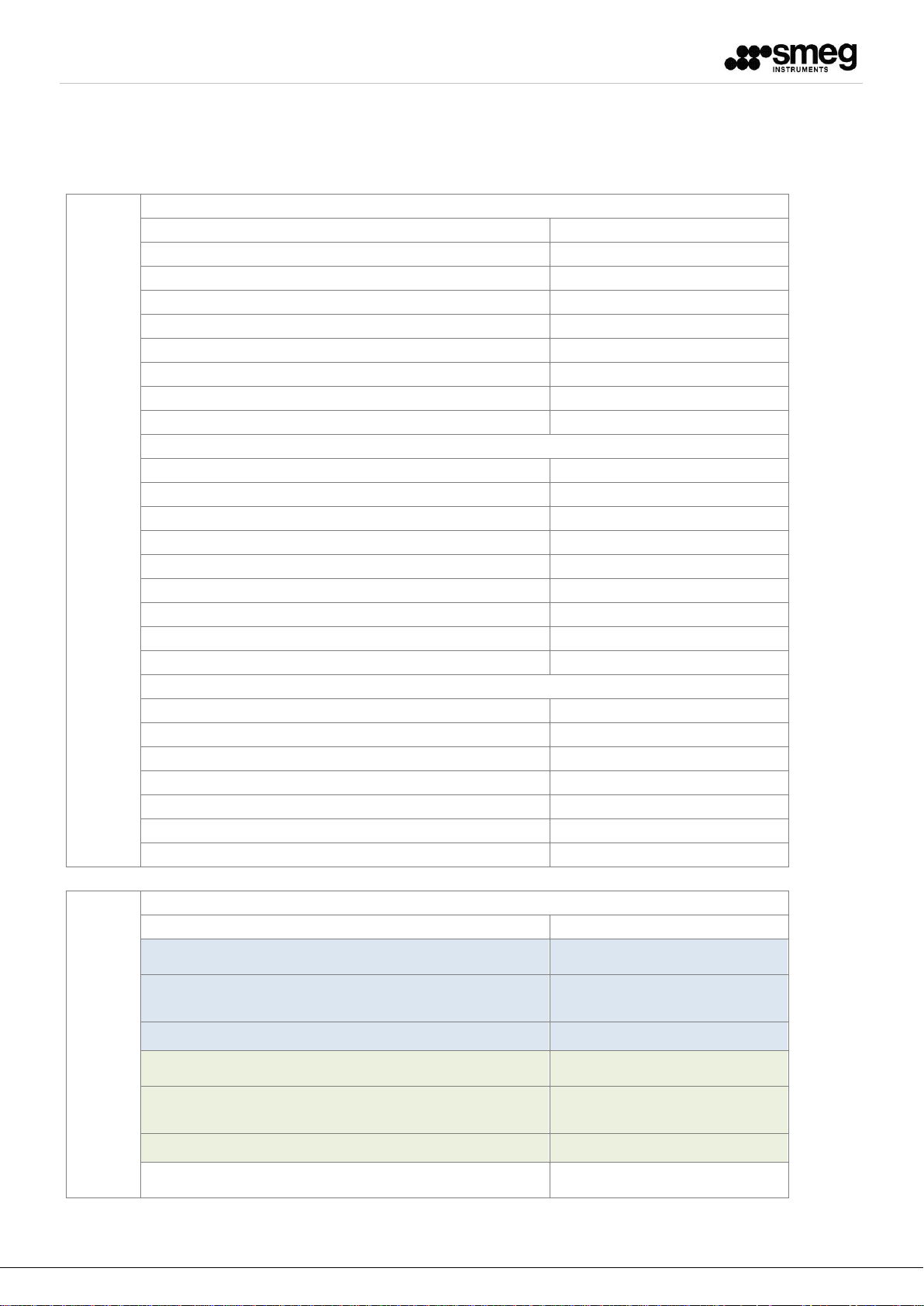

DATI TECNICI - TECHNICAL DATA

Italiano - English

Collegamenti Idraulici

Water connections

"CW" ACQUA FREDDA - COLD WATER

Connessione - Connection:

3/4" maschio-male - DN20

Portata min/max - Min/Max flow rate:

4 - 12 lt/min

Pressione dinamica min. - Min. flow pressure:

100 kPa (1,0 bar)

Pressione max. - Max. pressure:

600 kPa (6,0 bar)

Temperatura max. - Max. temperature:

35 °C

Durezza max. - Max. hardness:

10 °f

Ferro Max - Fe2+ / Fe3+ [max]

0,5 ppm

pH:

7÷8

"HW" ACQUA CALDA - WARM WATER

Connessione - Connection:

3/4" maschio-male - DN20

Portata min/max - Min/Max flow rate:

4 - 12 lt/min

Pressione dinamica min. - Min. flow pressure:

100 kPa (1,0 bar)

Pressione max. - Max. pressure:

600 kPa (6,0 bar)

Temperatura max. - Max. temperature:

60°C

Durezza max. - Max. hardness:

10 °f

Ferro Max - Fe2+ / Fe3+ [max]

0,5 ppm

pH:

7÷8

"DW" ACQUA DEMI - DEMI WATER

Connessione - Connection:

3/4" maschio-male - DN20

Portata min/max - Min/Max flow rate:

4 - 12 lt/min

Pressione dinamica min. - Min. flow pressure:

100 kPa (1,0 bar)

Pressione max. - Max. pressure:

600 kPa (6,0 bar)

Temperatura max. - Max. temperature:

60°C

Durezza max. - Max. hardness:

0 °f (0ppm CaCO3)

Conducibilità max. /pH - Max. conductivity / pH:

30 µS/cm / 5÷8 pH

Collegamenti Elettrici

Electrical connections

"EC" Connessioni elettriche - Electrical connections

Tipo - Type:

Standard

Tensione standard - Standard Voltage:

400V 3N~ / PE / 50Hz / 24A

Protezione elettrica richiesta nell'impianto -

Electrical protection required:

3P+N, 32 A

Cavo e sez.min - Cable and min. section:

5 x 6 mm2

Tensione configurabile - Configurable Voltage:

230V 3~ / PE / 50Hz / 36A

Protezione elettrica richiesta nell'impianto -

Electrical protection required:

3P, 40 A

Cavo e sez.min - Cable and min. section:

4 x 6 mm2

Potenza - Power:

13 kW

3

Page 4

WD6010-GW6010 INSTALLATION REQUIREMENTS

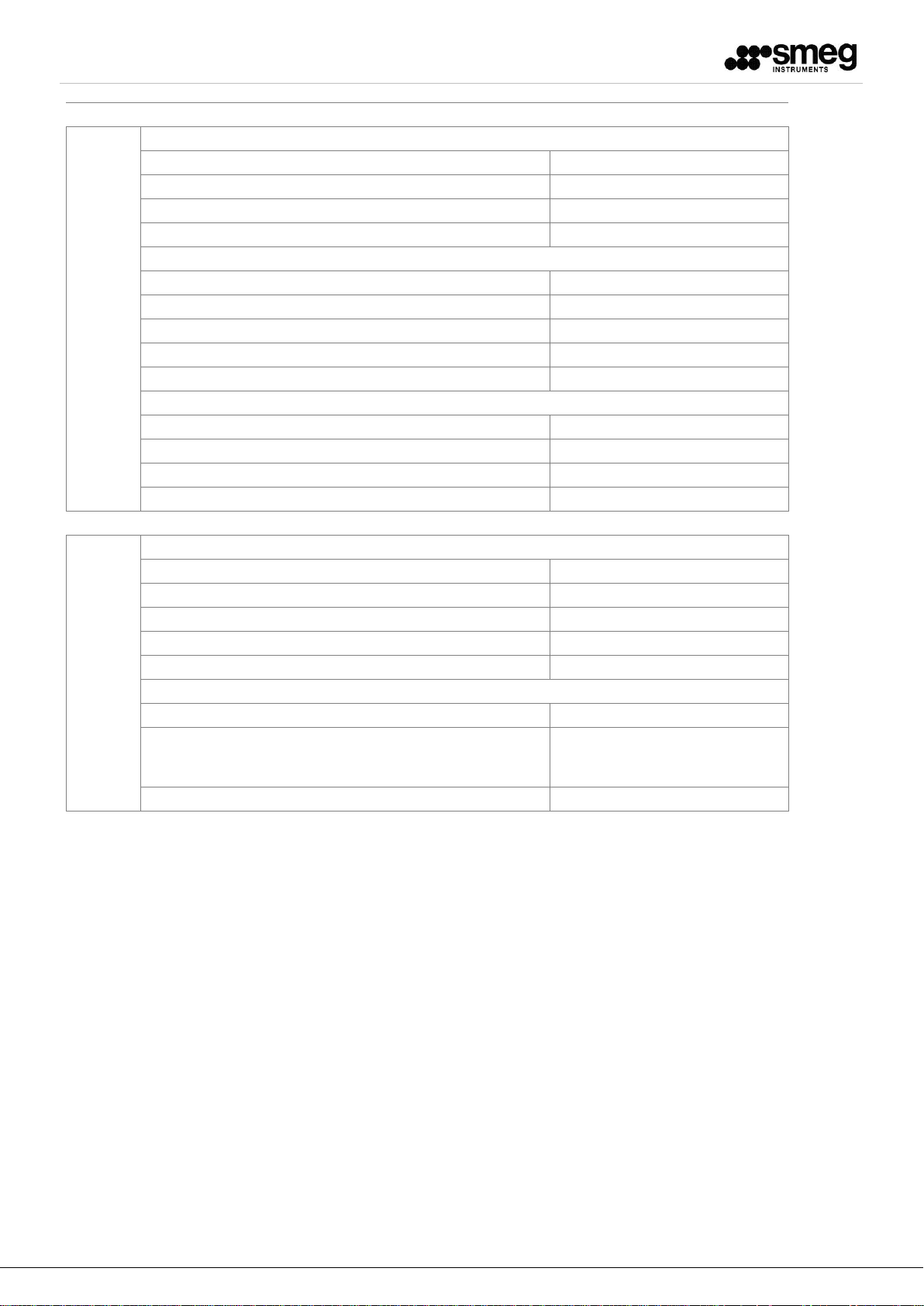

Scarico acqua e Sfiato vapori

Drain and exhaust

"EX" SCARICO VAPORI - EXHAUST DUCT

Connessione - Connection:

ø 50 mm

Portata max - Peak flow rate:

approx.220-250 m3/h

Temperatura max. - Max. temperature:

95 °C

"FD" SCARICO ACQUA A PAVIMENTO (standard) - DRAIN FLOOR (standard)

Connessione - Connection:

ø 50 mm

Portata max - Peak flow rate:

50 lt/min

Altezza max. - Max. height:

50 mm

Temperatura max. - Max. temperature:

95 °C

"D" SCARICO ACQUA A PARETE (opzionale) - DRAIN WALL (optional)

Connessione - Connection:

ø 40 mm

Portata max - Peak flow rate:

30 lt/min

Altezza max. - Max. height:

0,8 m

Temperatura max. - Max. temperature:

95 °C

Altri

Others

PESI – WEIGHTS

Netto totale massimo- total net max:

280 kg

Lordo totale massimo - total gross max:

310 kg

Max all'uso - Max. on working:

380 kg

Carico a pavimento - Floor load:

600 daN/m2 (kg/m2)

AMBIENTE - ENVIRONMENT

Temperatura - Temperature:

T = 10 - 40 °C

Umidità max - umidity max:

80% per temperature sino a 31°C

con diminuzione lineare sino a 50%

alla temperatura di 40°C.

Rumorosità - Noise level:

< 66 dB (A)

4

Page 5

WD6010-GW6010 INSTALLATION REQUIREMENTS

NOTES

1. It is the customer’s responsibility to insure that the specified pressure ranges are respected (water mains

and, if applicable, steam and air pressure). The pressure has to be measured at the point of connection to

the device.

2. It is customer responsibility to provide, if necessary, shock arrestors and / or pressure regulators to

eliminate water hammer conditions.

3. It is customer responsibility to provide shutoff valves for incoming cold, hot, demineralized water, and

steam and air (optional services). The valves must always be easily accessible to the operator.

4. It is the customer responsibility to provide a proper drainage system, according with national and local

regulations, considering the device requirements. It is necessary to prevent backflow to the device.

5. If the machine is connected to free discharge pipes for steam/fume exhaust, condensation deposit in

pipes must be prevented; moreover, the section must be equal or higher than the given dimensions and

there must not be areas with condensation deposit. In case of fume extraction, the clearances as shown

in the schemes must be observed. At any rate the indicated flow rates must be observed and the

materials must be resistant to the expected temperatures.

6. Even in case of two or more machines installed side by side, the service area required must be respected.

7. In case of double-door machines, it is customer responsibility to provide barrier wall, for the separation

between loading side (unclean side) and unloading side (clean side).

Smeg S.p.A.

Instruments Division

Via Leonardo da Vinci, 4 – 42016 GUASTALLA - R.E.

Tel +39 0522 8211 – Fax +39 0522 821 592

E-mail: instruments@smeg.it – service.instruments@smeg.it

www.smeg-instruments.com

5

Page 6

IT - DOPPIA PORTA

EN - DOUBLE DOOR

(860460)

VALVOLE NON FORNITE

SHUT-OFF VALVES NOT SUPPLIED

Via Leonardo da Vinci,4

Via Leonardo da Vinci,4

42016 Guastalla (RE) ITALIA

42016 Guastalla (RE) ITALIA

S.p.A

S.p.A

LA RIPRODUZIONE O LA CESSIONE DEL PRESENTE

DISEGNO DEVONO ESSERE AUTORIZZATE DALLA

ANY REPRODUCTION OR TRANSFER OF THE

PRESENT DRAWING MUST BE AUTHORIZED BY

FORM. A4

“SMEG” SPA

“SMEG” SPA

DOC. - DOC.ID

PREDISPOSIZIONE IMPIANTI

INSTALLATION

REQUIREMENTS

COD. DOC.

195610121.00 - A

DATA - DATE

21.07.2015

Page 7

750

PASSAGGIO MURO

WALL OPENING

650

LARGHEZZA MACCHINA

UNIT WIDTH

IT - DOPPIA PORTA

EN - DOUBLE DOOR

(860460)

PROFONDITA’ MACCHINA

712

UNIT DEPTH

30

MANIGLIA

753

70

HANDLE

VISTA FRONTALE LATO CARICO

FRONT VIEW LOADING SIDE

WALL OPENENING

1990

APERTURA MURO -

SEZIONATORE ELETTRICO

MAINS SWITCH

LATO SCARICO (PULITO)

UNLOADING SIDE (CLEAN)

- UNIT HEIGHT

1942

LATO SCARICO (PULITO)

UNLOADING SIDE (CLEAN)

ALTEZZA MACCHINA

OUT

450

VISTA LATERALE

SIDE VIEW

IN

LATO CARICO (SPORCO)

LOADING SIDE (UNCLEAN)

860

Via Leonardo da Vinci,4

Via Leonardo da Vinci,4

42016 Guastalla (RE) ITALIA

42016 Guastalla (RE) ITALIA

S.p.A

S.p.A

852

LATO CARICO (SPORCO)

LOADING SIDE (UNCLEAN)

LA RIPRODUZIONE O LA CESSIONE DEL PRESENTE

DISEGNO DEVONO ESSERE AUTORIZZATE DALLA

ANY REPRODUCTION OR TRANSFER OF THE

PRESENT DRAWING MUST BE AUTHORIZED BY

FORM. A4

“SMEG” SPA

“SMEG” SPA

VISTA IN PIANTA

PLANT VIEW

DOC. - DOC.ID

PREDISPOSIZIONE IMPIANTI

INSTALLATION

REQUIREMENTS

MAX 120

AREA LIBERA PER ACCESSO

SERVICE CLEARANCE (BOTH SIDES)

SEZIONATORE ELETTRICO

MAINS SWITCH

AREA LIBERA PER ACCESSO FUNZIONALE

CLEARANCE AREA - FUNCTIONAL ACCESS (BOTH SIDES)

COD. DOC. DATA - DATE

195610121.00 - B

(AMBO I LATI)

(AMBO I LATI)

21.07.2015

Page 8

IT - DOPPIA PORTA

NOTA: LE CONNESSIONI POSSONO ESSERE PREDISPOSTE

ANCHE SUL LATO SINISTRO

NOTE: THE CONNECTION CAN BE ARRANGED

ALSO ON THE LEFT SIDE

SCARICO VAPORI

STEAM AND AIR EXAUST

EX

90

EN - DOUBLE DOOR

(860460)

30

30

EC

2000

HW CW DW

165

AREA POSSIBILE SCARICO

DRAIN LOCATION AREA

4 PIEDI Ø50

FEET Ø50X4

FD

VISTA FRONTALE

FRONT VIEW LOADING SIDE

430

Ø 50

FD

325

84

VISTA IN PIANTA - BASAMENTO

PLANT - BASAMENT VIEW

480

110

Max 1200

Max 600

LATO SCARICO (PULITO)

UNLOADING SIDE (CLEAN)

140

50

85 543

LATO CARICO (SPORCO)

LOADING SIDE (UNCLEAN)

Max 1600

EX

Ø50

50

VISTA IN PIANTA- TOP

PLANT-TOP VIEW

260

Via Leonardo da Vinci,4

Via Leonardo da Vinci,4

42016 Guastalla (RE) ITALIA

42016 Guastalla (RE) ITALIA

S.p.A

S.p.A

LA RIPRODUZIONE O LA CESSIONE DEL PRESENTE

DISEGNO DEVONO ESSERE AUTORIZZATE DALLA

ANY REPRODUCTION OR TRANSFER OF THE

PRESENT DRAWING MUST BE AUTHORIZED BY

FORM. A4

“SMEG” SPA

“SMEG” SPA

DOC. - DOC.ID

PREDISPOSIZIONE IMPIANTI

INSTALLATION

REQUIREMENTS

COD. DOC. DATA - DATE

195610121.00 - C

21.07.2015

Page 9

IT - PORTA SINGOLA

EN - SINGLE DOOR

(860457)

VALVOLE NON FORNITE

SHUT-OFF VALVES NOT SUPPLIED

Via Leonardo da Vinci,4

Via Leonardo da Vinci,4

42016 Guastalla (RE) ITALIA

42016 Guastalla (RE) ITALIA

S.p.A

S.p.A

LA RIPRODUZIONE O LA CESSIONE DEL PRESENTE

DISEGNO DEVONO ESSERE AUTORIZZATE DALLA

ANY REPRODUCTION OR TRANSFER OF THE

PRESENT DRAWING MUST BE AUTHORIZED BY

FORM. A4

“SMEG” SPA

“SMEG” SPA

DOC. - DOC.ID

PREDISPOSIZIONE IMPIANTI

INSTALLATION

REQUIREMENTS

COD. DOC. DATA - DATE

195610121.00 - D

21.07.2015

Page 10

IT - PORTA SINGOLA

EN - SINGLE DOOR

(860457)

650

LARGHEZZA MACCHINA

UNIT WIDTH

- UNIT HEIGHT

1942

ALTEZZA MACCHINA

LARGHEZZA MACCHINA

712

UNIT DEPTH

30

753

70

MANIGLIA

HANDLE

IN

860

50

712

VISTA FRONTALE

FRONT VIEW

VISTA IN PIANTA

PLANT VIEW

SEZIONATORE ELETTRICO

MAINS SWITCH

AREA LIBERA PER ACCESSO

SERVICE CLEARANCE (BOTH SIDES)

450

SEZIONATORE ELETTRICO

MAINS SWITCH

AREA LIBERA PER ACCESSO FUNZIONALE

CLEARANCE AREA - FUNCTIONAL ACCESS

VISTA LATERALE

SIDE VIEW

(AMBO I LATI)

Via Leonardo da Vinci,4

Via Leonardo da Vinci,4

42016 Guastalla (RE) ITALIA

42016 Guastalla (RE) ITALIA

S.p.A

S.p.A

LA RIPRODUZIONE O LA CESSIONE DEL PRESENTE

DISEGNO DEVONO ESSERE AUTORIZZATE DALLA

ANY REPRODUCTION OR TRANSFER OF THE

PRESENT DRAWING MUST BE AUTHORIZED BY

FORM. A4

“SMEG” SPA

“SMEG” SPA

DOC. - DOC.ID

PREDISPOSIZIONE IMPIANTI

INSTALLATION

REQUIREMENTS

COD. DOC. DATA - DATE

195610121.00 - E

21.07.2015

Page 11

SISTEMA

ASPIRAZIONE

AIR VENTING

SYSTEM

SCARICO VAPORI

STEAM AND AIR EXHAUST

EX

30

30

NOTA: LE CONNESSIONI POSSONO ESSERE PREDISPOSTE

ANCHE SUL LATO SINISTRO, O SUL RETRO

NOTE: THE CONNECTION CAN BE ARRANGED

ALSO ON THE LEFT SIDE OR ON THE REAR.

EC

2000

IT - PORTA SINGOLA

EN - SINGLE DOOR

(860457)

FD

VISTA FRONTALE

FRONT VIEW

AREA POSSIBILE SCARICO (ACQUA)

DRAIN LOCATION AREA

430

Ø 50

165

110

CW

DW

HW

Max 1200

Max 600

LATO SCARICO (PULITO)

UNLOADING SIDE (CLEAN)

140

Max 1600

C W, HW ,

DW, EC (D)

VISTA LATERALE

SIDE VIEW

75

15

AMBO I LATI

15015085

BOTH SIDES

4 PIEDI Ø50

FEET Ø50X4

84

VISTA IN PIANTA - BASAMENTO

PLANT - BASAMENT VIEW

Via Leonardo da Vinci,4

Via Leonardo da Vinci,4

42016 Guastalla (RE) ITALIA

42016 Guastalla (RE) ITALIA

S.p.A

S.p.A

480

FD

325

FORM. A4

50

85 543

LATO CARICO (SPORCO)

LOADING SIDE (UNCLEAN)

LA RIPRODUZIONE O LA CESSIONE DEL PRESENTE

DISEGNO DEVONO ESSERE AUTORIZZATE DALLA

ANY REPRODUCTION OR TRANSFER OF THE

PRESENT DRAWING MUST BE AUTHORIZED BY

“SMEG” SPA

“SMEG” SPA

DOC. - DOC.ID

PREDISPOSIZIONE IMPIANTI

INSTALLATION

REQUIREMENTS

EX

Ø50

260

50

VISTA IN PIANTA- TOP

PLANT-TOP VIEW

COD. DOC. DATA - DATE

195610121.00 - F

21.07.2015

Loading...

Loading...