SGR10S

Betriebsanleitung

Operating Instructions

Istruzioni per l’uso

ENGLISH

SGR10S Table of Contents

& ENGLISH

Table of Contents

1 Introduction _______________________________________________________2

2 Before starting _____________________________________________________3

2.1 Finding your way around these operating instructions__________________________3

2.2 Correct use___________________________________________________________3

2.3 Assembly and function __________________________________________________4

2.4 Sealing process sequence_______________________________________________4

2.5 General safety information _______________________________________________5

2.6 Installation ____________________________________________________________5

3 Basic functions_____________________________________________________6

3.1 Commissioning ________________________________________________________6

3.2 Operation_____________________________________________________________7

3.3 Setting the temperature regulator__________________________________________8

4 Fault clearance and maintenance ______________________________________9

4.1 Fault clearance checklist _________________________________________________9

4.2 Customer Service_____________________________________________________10

4.3 Maintenance plan _____________________________________________________10

4.4 Spare parts service____________________________________________________11

4.5 Spare parts order – product number allocation ______________________________13

4.6 Sealing die___________________________________________________________13

4.7 Guide die____________________________________________________________14

4.8 Spare parts order – Overview____________________________________________15

5 Technical data ____________________________________________________16

5.1 Circuit and wiring diagram 230V__________________________________________16

5.2 Circuit and wiring diagram 100 / 115V_____________________________________17

5.3 Specifications ________________________________________________________18

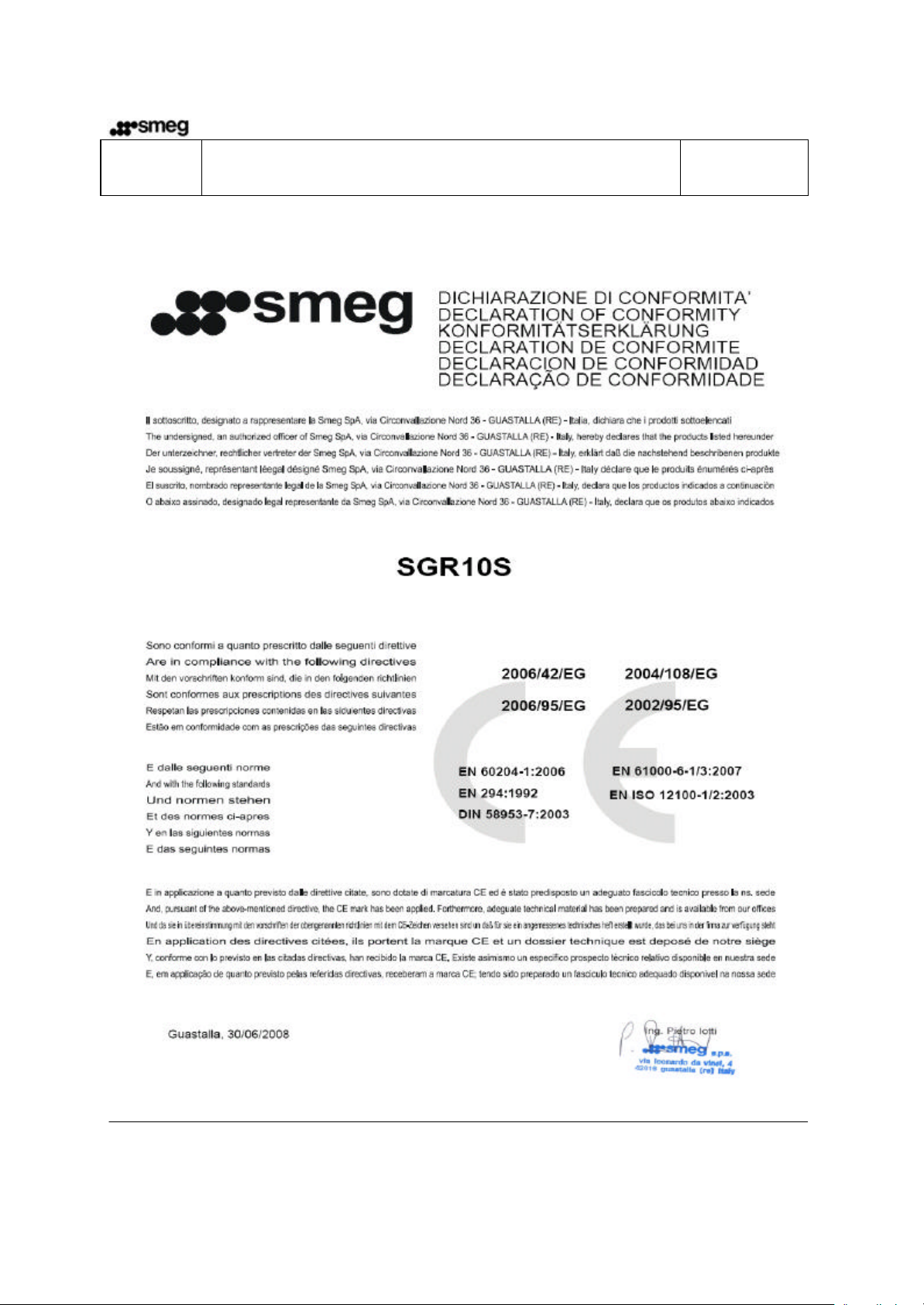

6 Declaration of conformity____________________________________________19

Page GB 1 9.696.035 Version 1.02

Note

SGR10S Introduction Chapter 1

ENGLISH

1 Introduction

Preface

First of all we would like to sincerely thank you for buying the SGR10S cycle sealing device.

In these instructions you will find information about the device, its function and operation.

Please read these operating instructions thoroughly before putting the device into

operation so that you become familiar with its capabilities and can use its functions

optimally.

F Always keep these instructions close to the device.

Important notice:

This device is a film rotary sealing device for closing sterile barrier systems.

Please observe chapter "Correct use " in these operating instructions in this respect.

In accordance with the purpose, CE certification based on the EU Directives indicated below

has been affixed: 2006/42/EC and 2006/95/EC.

Directive 93/042 EEC is not applicable to welding and sealing devices.

The limit values of IEC 60601-1 cannot be used with electrical re-tests.

The manufacturer shall accept no liability whatsoever for damage caused by tests which are not

listed in the Declaration of Conformity.

Because we are constantly improving our products

we reserve the right to update these operating

instructions and the functions described in them

accordingly.

Should you nevertheless notice errors or points that

are unclear, please let us know about them.

These operating instructions are valid for products

as from the date of manufacture of 07/2008

Page GB 2 9.696.035 Version 1.02

SGR10S Before starting Chapter 2

ENGLISH

2 Before starting

2.1 Finding your way around these operating instructions

In this ch apter you will find information about using the

device correctly, its function and advice about

Chapter 2

Before starting

Chapter 3

Basic functions

operation and installation.

PLEASE READ THIS ESSENTIAL

INFORMATION!

Adjusting and operating the device are explained here.

Chapter 4

Fault clearance and

maintenance

Chapter 5

Technical data

Chapter 6

Declaration of Conformity

Instruction on finding disturbance sources and

rectifying malfunctions.

Here you will find out about necessary servicing,

wearing parts and spare parts as well as about the

allocation of product numbers for spare parts orders.

Here you see the circuit and wiring diagram as well as

the device specification.

In this chapter you will find the Declaration of

Conformity for the SGR10S rotary sealing device.

2.2 Correct use

The SGR10S device is only designed for trade and industrial use and must only be used for the

prescribed purpose.

The SGR10S device is used for the continuous closure of sterile barrier systems made of paper

or paper laminate films.

The SGR10S cycle sealing device is not suitable for sealing polyethylene films, PVC

foils, foils and polypropylene films.

Device performance is dependant on the condition of the sealing material used.

Page GB 3 9.696.035 Version 1.02

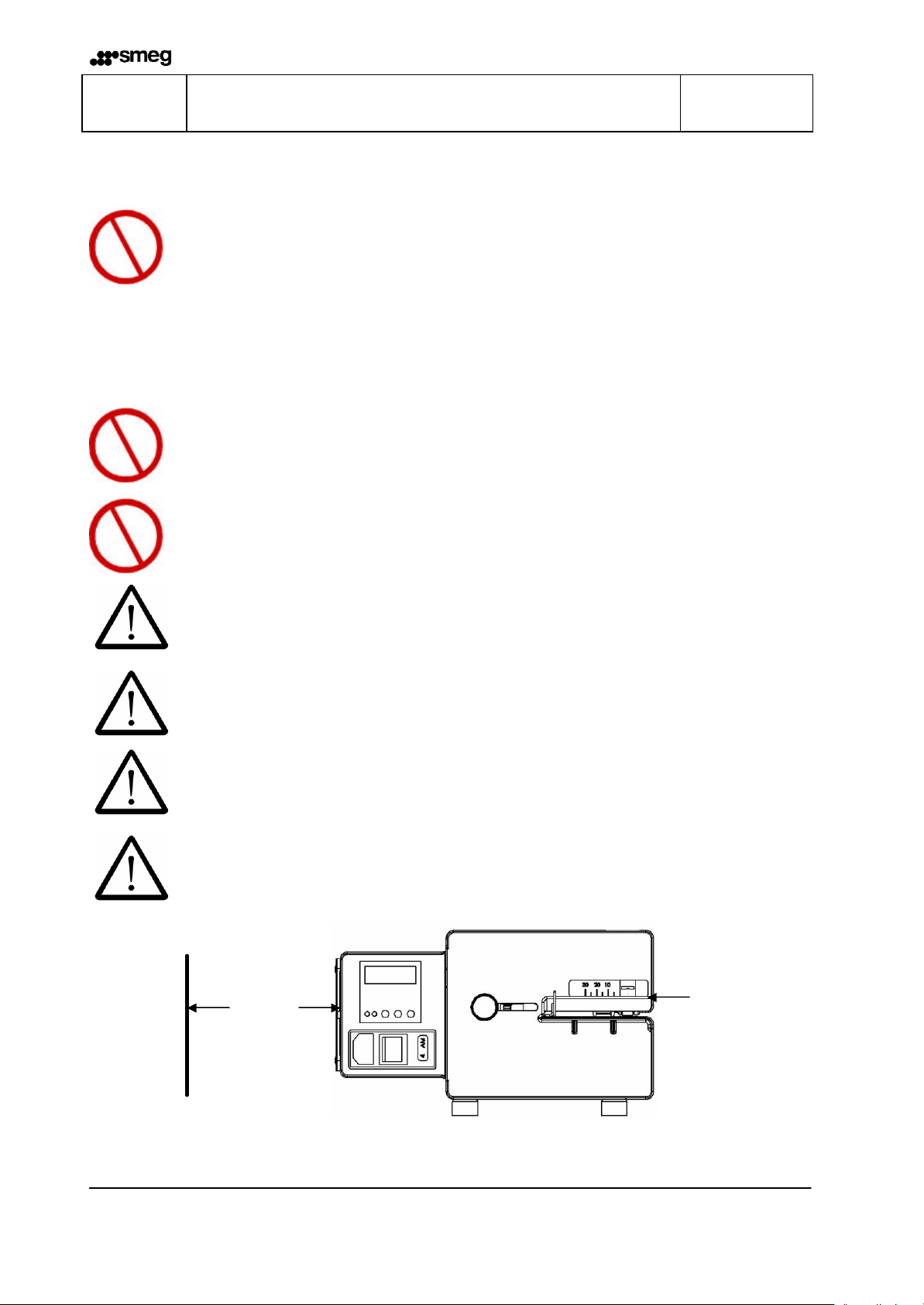

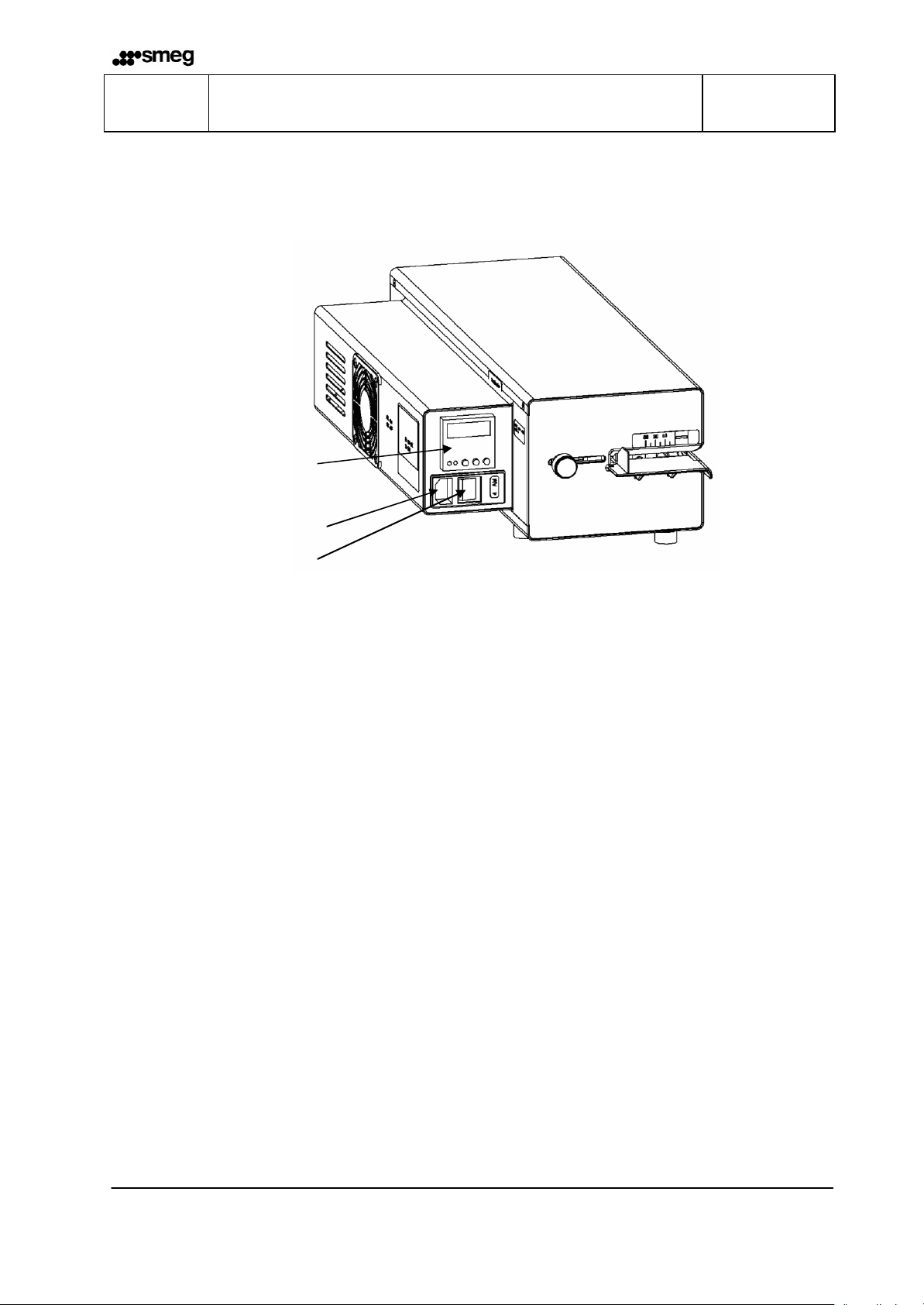

Power connection

Power switch

Mains fuses

Adjustable

Temperatur

e

ENGLISH

SGR10S Before starting Chapter 2

2.3 Assembly and function

regulator

sealing edge setting

2.4 Sealing process sequence

Step 1: After the sterilisation packaging has been inserted the transport

switches on automatically.

Step 2: The sterilisation packaging is now transported and the sealing seam area is

heated up by the heating dies positioned above and below to the sealing

temperature set.

Step 3: The sealing seam, which is now heated up, is pressed through the sealing rolls

and thus sealed.

Step 4: The completed sterilisation packaging is transported to the withdrawal side.

Step 5: If no further material to be sealed is fed in the transport switches off after

approximately 30 seconds.

Page GB 4 9.696.035 Version 1.02

Œ

•

SGR10S Basic functions Chapter 3

2.5 General saf ety information

ENGLISH

The device must not be installed and operated by persons under 14

years of age.

I

The device must not be operated unattended.

Switch the device off or pull out the mains power plug when the

device is not in use.

2.6 Installation

I

I

The device must not be installed and operated in potentially

explosive areas.

Only use power outlets with a grounding conductor and a stable

voltage supply.

The device must only be set up in dry surroundings. Heavy dust,

steam, water drips or water spray compromise the function of the

device.

Please ensure that the operating voltage corresponds with the data

on the device type plate.

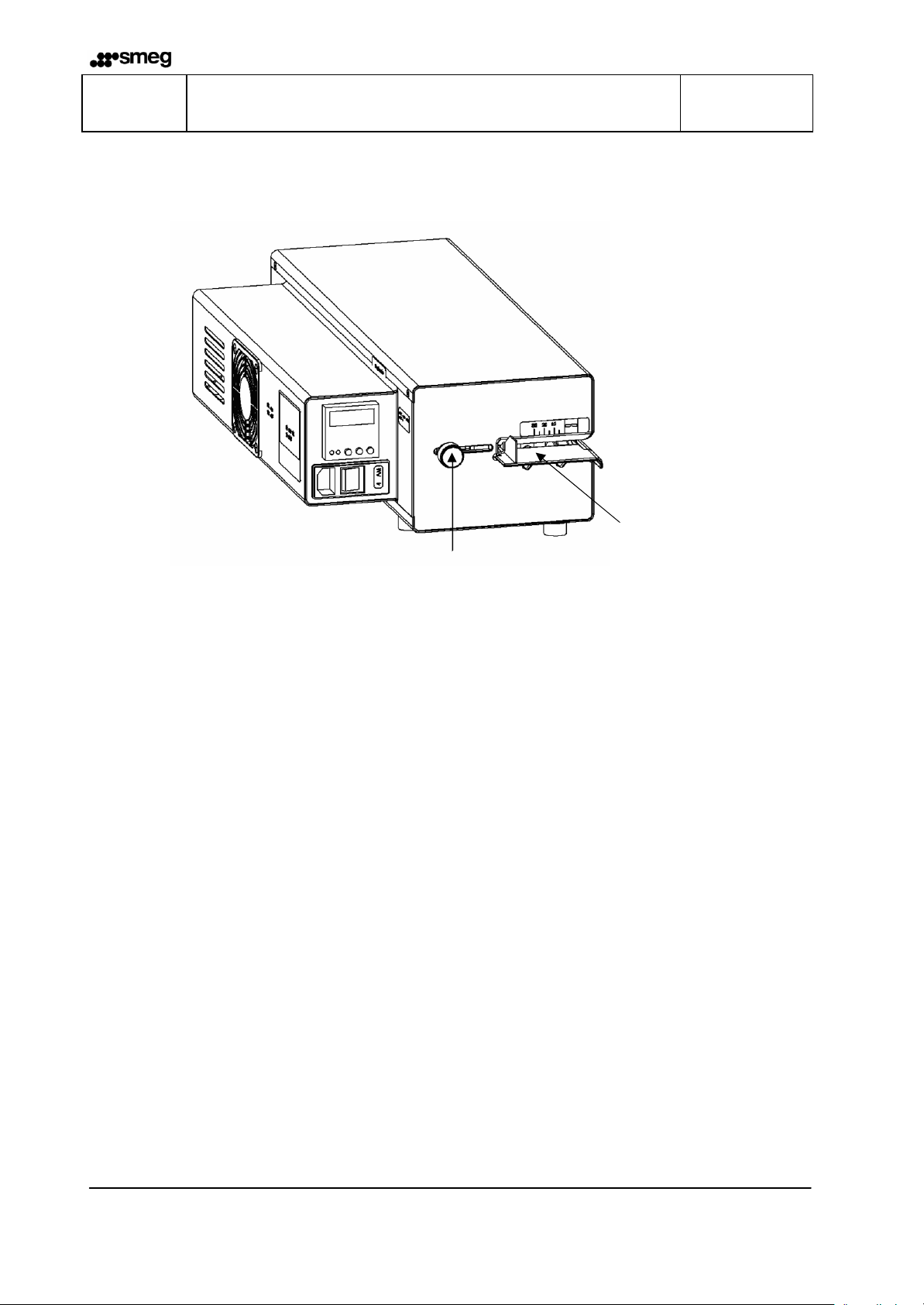

Please do not lift and transport the device at the sealing edge setting!

Œ

Leave a gap of 8 inches between the device and the wall. •

200 mm

Page GB 5 9.696.035 Version 1.02

Po

wer connection

Power switch

Temperatur

e regulator

ENGLISH

SGR10S Basic functions Chapter 3

3 Basic functions

3.1 Commissioning

Step 1: Plug power cable into power connection.

Step 2: Switch device with power switch to setting "1".

Control light in the switch illuminates.

Step 3: Set the desired sealing temperature on the temperature regulator as described in

chapter 3.3.

Step 4: As soon as the set sealing temperature is displayed the device is heated up and

ready for operation.

Page GB 6 9.696.035 Version 1.02

Adjustable

Knurled screw

SGR10S Basic functions Chapter 3

ENGLISH

3.2 Operation

Step 1: Set the desired sealing edge width. After the knurled screw has been loosened the

lower insertion plate can be set infinitely variably for sealing widths of 0 - 35mm.

Step 2: Insert packaging into the device over the insertion plate from the left.

Step 3: Take out sealed packaging at the exit side and briefly leave to cool down.

Inspecting the sealing seam

F

If points that are not tightly sealed are apparent the sealing temperature must

be increased. If the foil melts the set temperature is too high.

The appropriate sealing temperature must be identified by performing test

sealings.

sealing edge setting

Page GB 7 9.696.035 Version 1.02

ENGLISH

• Ž • • ‘ Œ • Ž • • ‘

-1 +1

SGR10S Basic functions Chapter 3

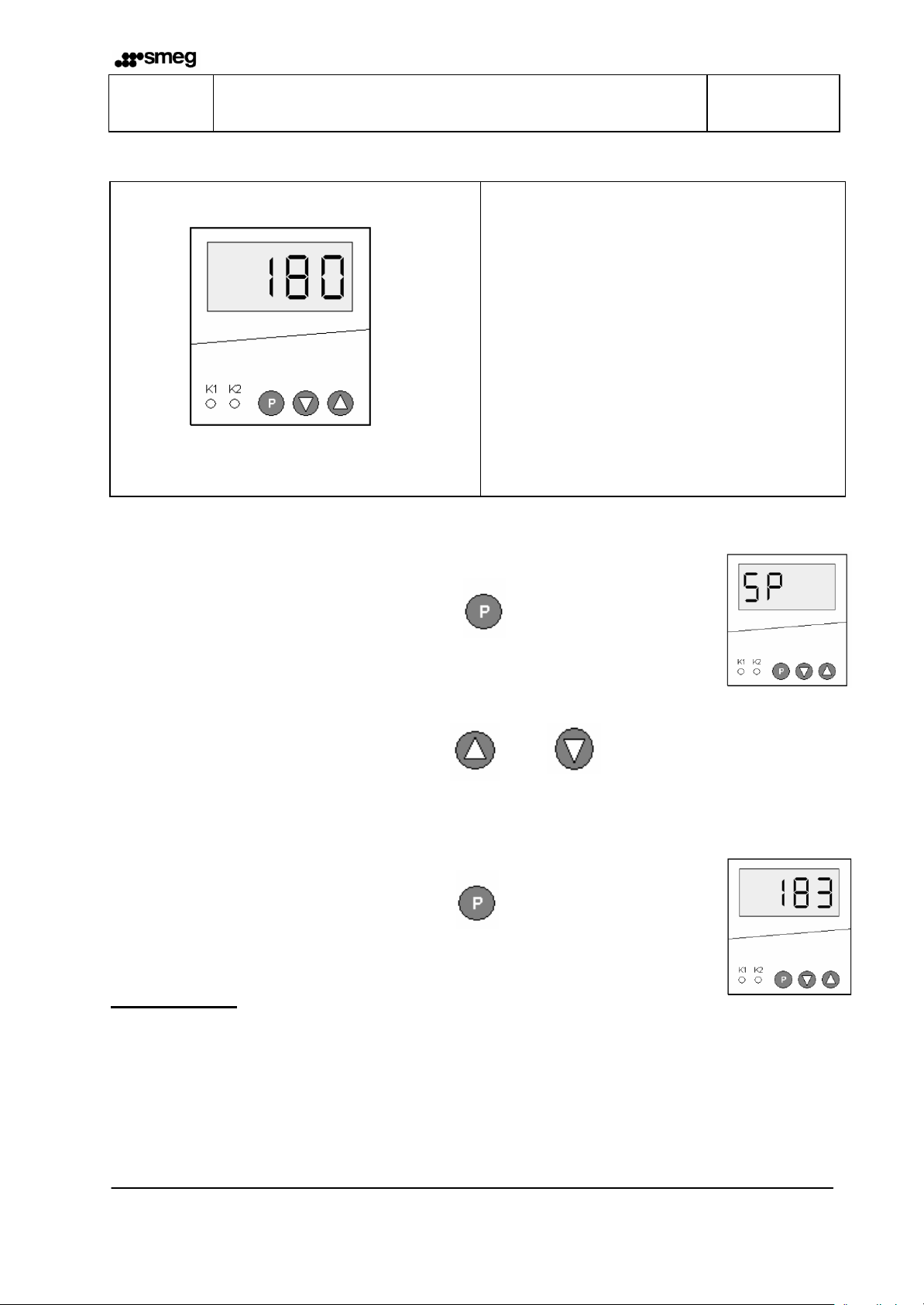

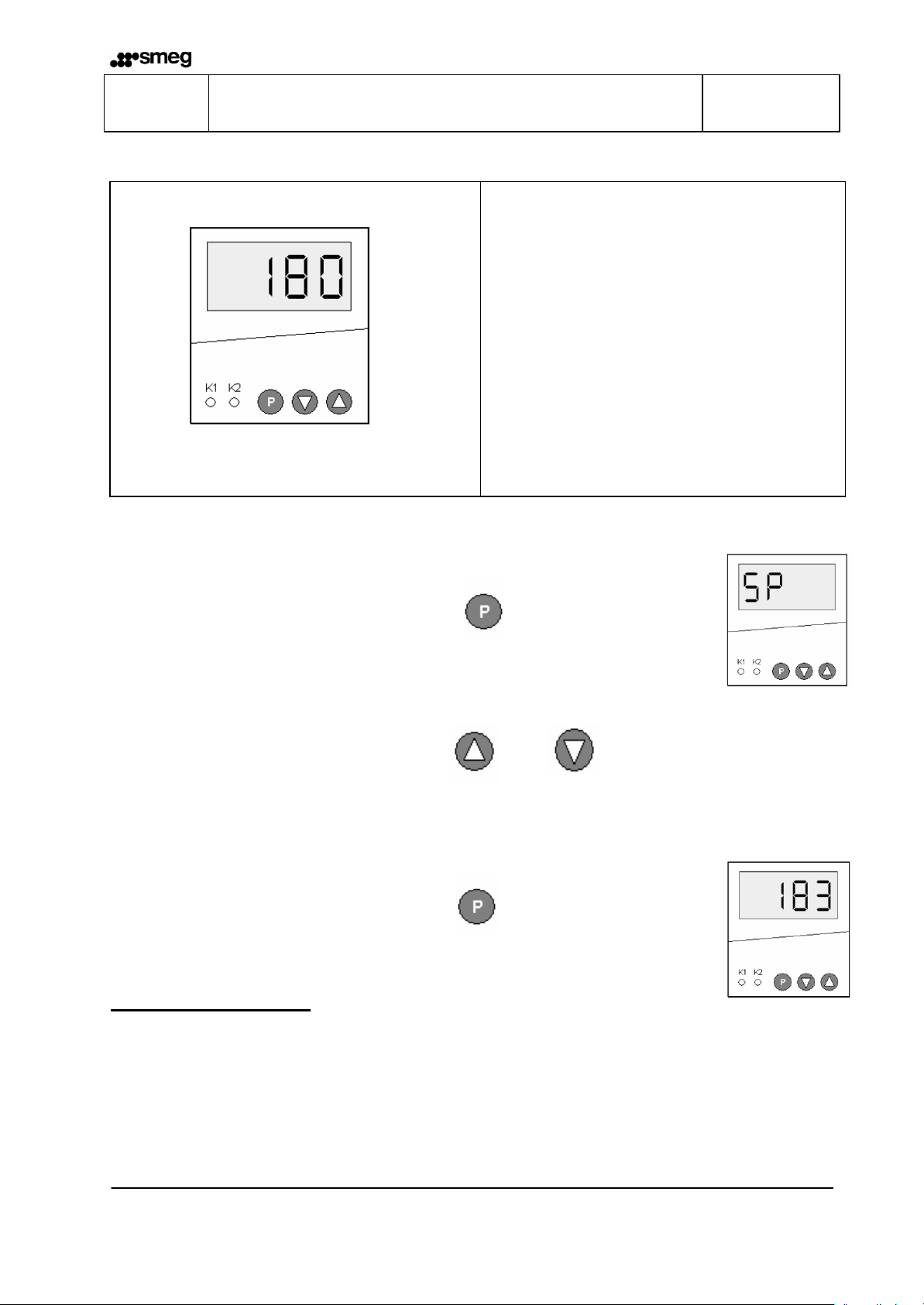

3.3 Setting the temperature regulator

Œ

Temperature display

Motor - start relay indicator

Temperature regulator indicator

Target temperature entry

Temperature value

Temperature value

Entering the target temperature

Button is pressed once 1 x

Setting the temperature with keys +1 -1

Entry is activated 2 x

Factory setting:

Target temperature 180°C

Unit of temperature °C

Page GB 8 9.696.035 Version 1.02

ENGLISH

SGR10S Fault clearance and maintenance Chapter 4

4 Fault clearance and maintenance

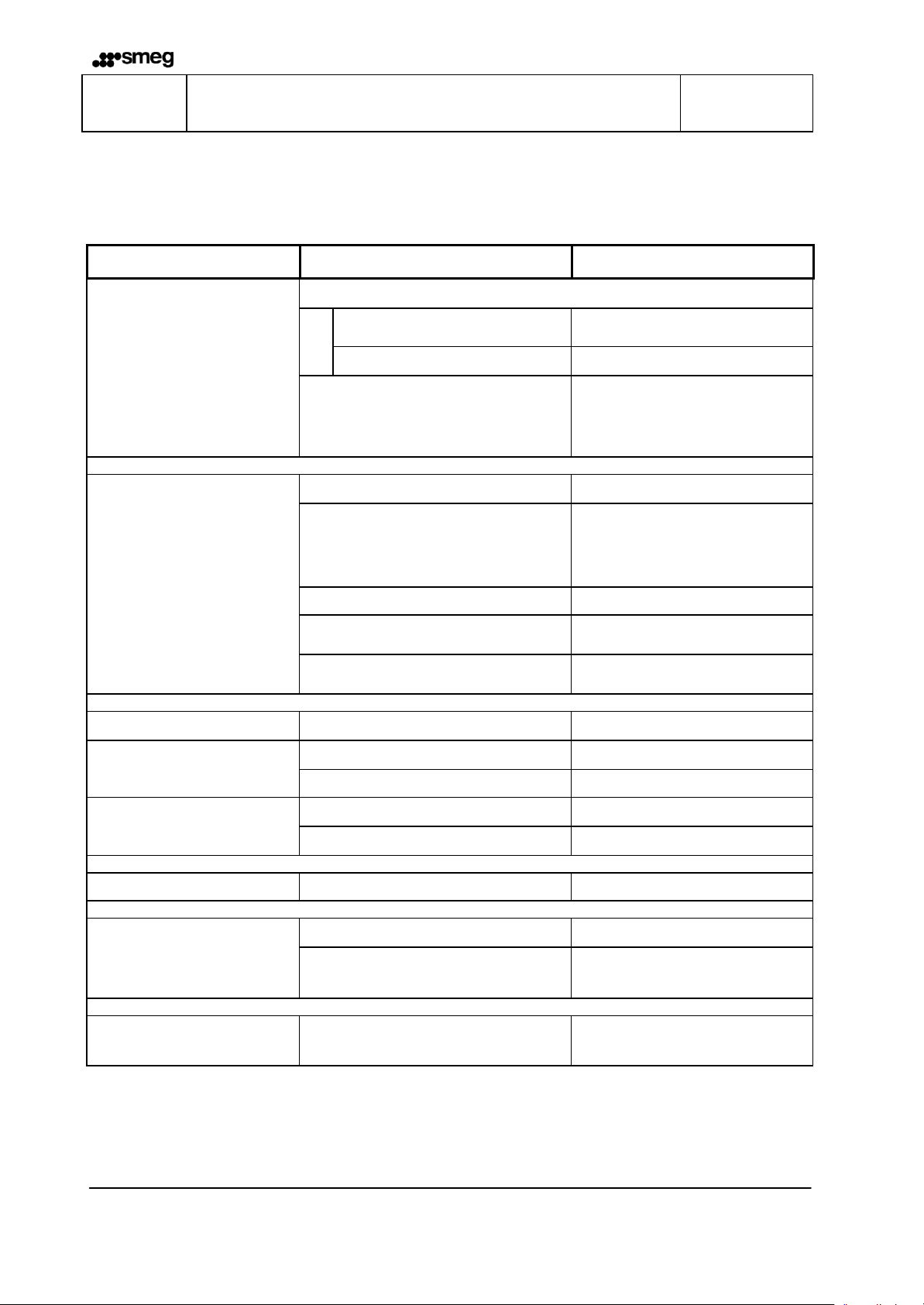

4.1 Fault clearance checklist

Malfunction Possible cause Remedy

Network connection

Check network connection; connect

another plug if necessary

Replace mains fuse.

In the event of fuses blowing

repeatedly you must compulsorily

have the device checked!

Increase target temperature

Device does not switch on

Power cable not plugged in

Power cable defective Replace power cable

Mains fuse

Target temperature too low

Overtemperature cutout has

Device is not heating

triggered

Temperature regulator

Heating element

Solid state relay

Target temperature not reached

Motor defective

No material transport

Microswitch defective

Non-symmetrical material

transport

Toothed damaged

Tooth belt not transporting

Loud running noise Motor defective

Sealing temperature too low

Sealing seam does not

hold up

Clearance between sealing dies is

too large

Sealing seam distorted or

melted

Sealing temperature too high

Press in overtemperature cutout.

In the event of repeated triggering

you must compulsorily have the

device checked!

Replace temperature regulator

Check heating elements and replace

if necessary

Replace solid state relay

Replace motor

Replace microswitch

Replace toothed belt

Check toothed belt tension

Replace motor

Increase sealing temperature

Set the sealing die to 0.5mm

Reduce sealing temperature

Page GB 9 9.696.035 Version 1.02

SGR10S Fault clearance and maintenance Chapter 4

ENGLISH

4.2 Customer Service

You can contact your Customer Service Monday to Friday from 8.30 am

(

to 6.00 pm on +3 9 (0)522 821 521.

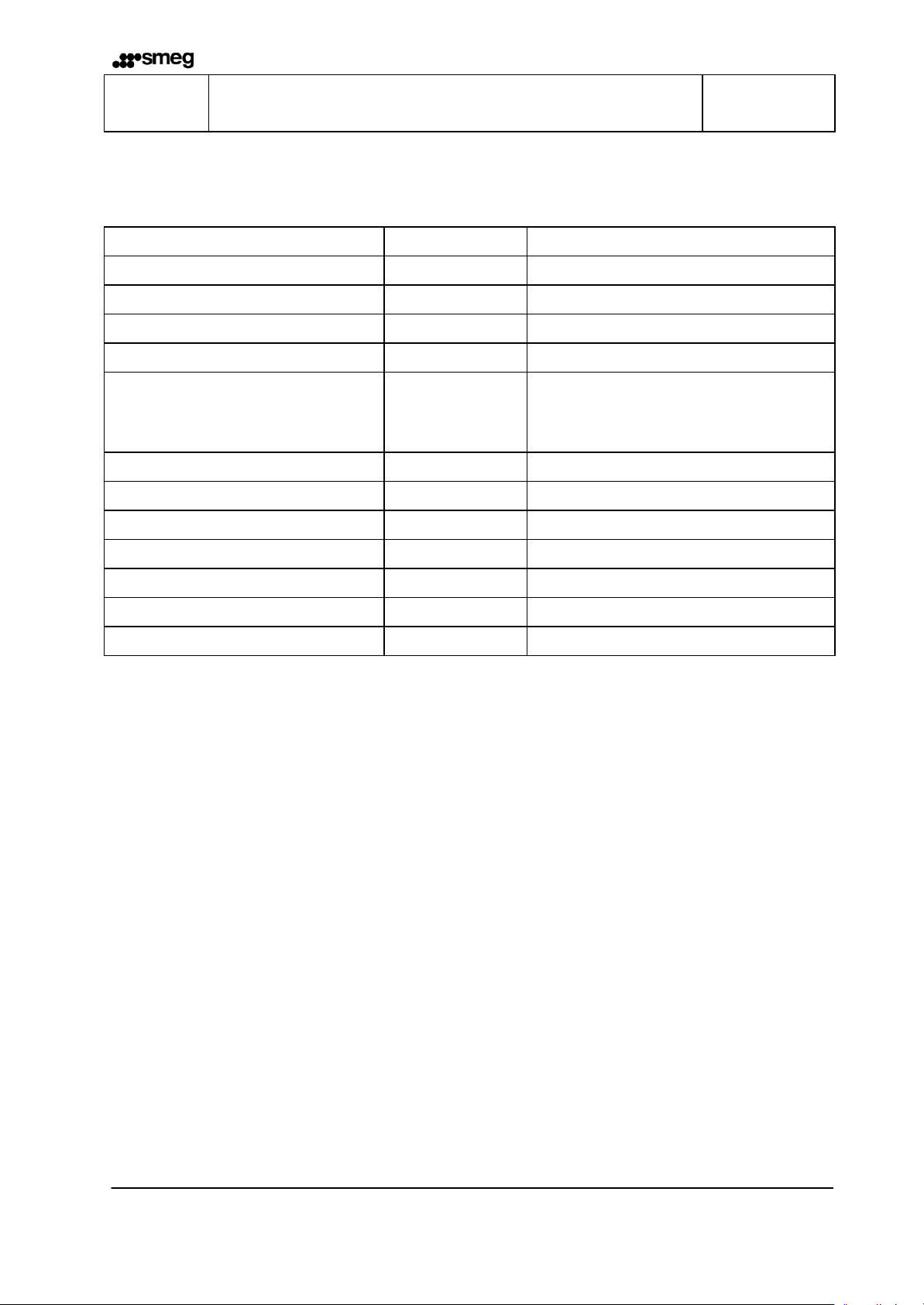

4.3 Maintenance plan

As is the case with all technical device your device is also subject to

technical wear.

In order to guarantee that your device is permanently ready to use it should

Maintenance cycle

At least every

3. Month

According to

load,

at least once

per year

Key:

be serviced by a qualified person at least once per year.

PTFE strip

Guide die

PTFE strip

Sealing

die

Pressure

roller

Toothed

belt

Check

Page GB 10 9.696.035 Version 1.02

Replace

SGR10S Fault clearance and maintenance Chapter 4

4.4 Spare parts service

F

• Enter address, fax number and

order number

• Enter serial number

• Enter device type

• Mark required items

• Enter required quantity

• Sign the order

• Fax the order

Easy spare parts ordering by fax!

All you have to do is to copy the order form.

You will find the form on the n ext page.

444444

SGR10S

ENGLISH

Page GB 11 9.696.035 Version 1.02

Signature

_____________________

To:

________________________

________________________

Your order no. _________________ Date _______________

Device type _________________ Serial number _______________

Sender:

____________________________

____________________________

þ

¨

¨

¨

¨

¨

¨

¨

¨

¨

¨

¨

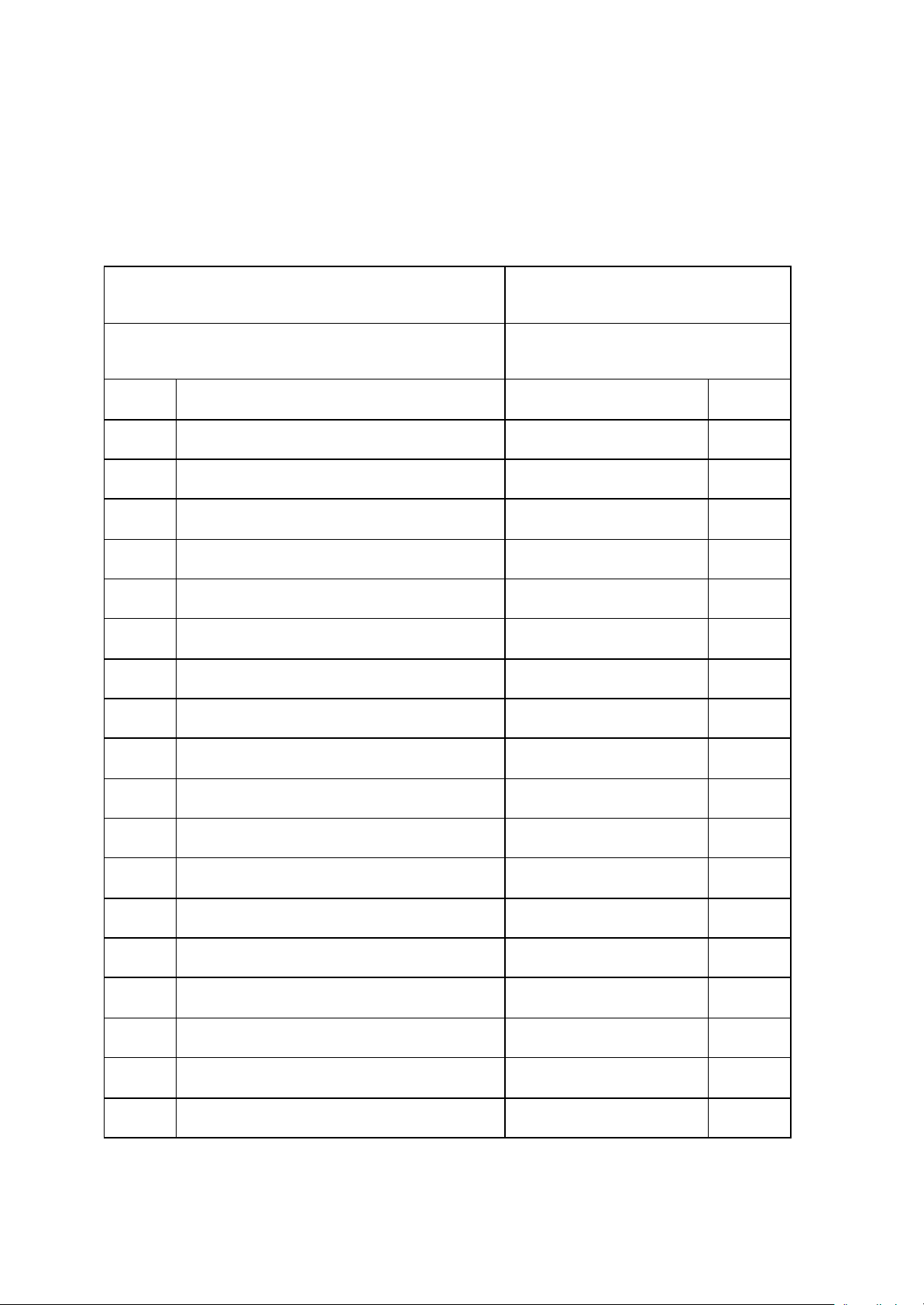

Description Item no. Pieces

Pressure roller 2.230.026

Gear motor 230 V 1.212.005

Heating element 115V 200W 6.536.032

Fan 230V 6.212.019

PTFE strip heating die 6.105.125

PTFE strip guide die 6.105.138

IEC cable feed with switch 6.562.009

Fuse element for 6.562.009 6.562.049

Power cable 230V 6.593.013

Power cable 115V 6.593.014

Opto sensor motor start 1.651.003

¨

¨

¨

¨

¨

¨

¨

SST relay 6.460.001

Temperature sensor 6.564.040

Digital temperature regulator 100 -240V

Transformer 100V -115V/230V

Only for 100V and 115V version

Overtemperature cutout 6.564.018

Transport toothed belt 6.271.001

Time control board 1.540.056

6.564.038

6.531.015

Upper sealing die

Lower sealing die

He

ating element

Temperatur

e

PTFE

strip

He

ating element

PTFE

strip

Overtemperature cutout

ENGLISH

SGR10S

Fault clearance and maintenance

4.5 Spare parts order – product number allocation

4.6 Sealing die

1.616.024

sensor

6.564.040

6.536.032

6.105.125

1.616.025

6.105.125

Chapter 4

6.536.032

6.564.018

Version 1.02 9.696.035 Page GB 13

Upper

guide die

Lower guide die

PTFE

strip

PTFE

strip

ENGLISH

SGR10S

4.7 Guide die

1.619.014

1.619.015

Fault clearance and maintenance

6.105.138

6.105.138

Chapter 4

Version 1.02 9.696.035 Page GB 14

Transport toothed belt

Temperatur

e regulator

SST relay

Time

control board

Ge

ar

motor

Fan

IEC

Cable feed with

Pressure roller

ENGLISH

SGR10S

Fault clearance and maintenance

4.8 Spare parts order – Overview

Chapter 4

2.230.026

6.271.001

switch

6.562.009

1.540.056

6.460.001

6.564.038

Version 1.02 9.696.035 Page GB 15

6.212.019

1.212.005

Opto

sensor

ENGLISH

SGR10S Technical data Chapter 5

5 Technical data

5.1 Circuit and wiring diagram 230V

Power switch

Fuse

2x 4AT

Mains 230V 50/60Hz

Time control board 30s

Motor

Overtemperatur

cutout

blue red

SST

Relais

2 x 115V 200W

Temperatur

regulator

Temperatur

sensor

Heating

elements

Version 1.02 9.696.035 Page GB 16

5 6 3 2

14 24

ENGLISH

SGR10S Technical data Chapter 5

5.2 Circuit and wiring diagram 100 / 115V

Mains 100V / 115V 50/60Hz

Sicherung

2x 6,3AT

Netzschalter

Power switch

6,3 AT

Fuse

Motor

Trafo 100V

Trafo 115V

Transformer

Opto Sensor

Motorschalter

11 A1 21 A2

3 4

1

2

9 8 L N

blau rot

Blue

SST

SST

Relais

Relais

Temperatur-

Regler

Temperatur-

Red

fühler

Temperatur

regulator

Temperatur

sensor

Zeitrelais 30s

overtemperature

cutout

Übertemperatur

M

Schutz

Heizpatronen

Motor

Heating elements

Time control board 30s

2 x 115V 200W

Version 1.02 9.696.035 Page GB 17

SGR10S Technical data Chapter 5

ENGLISH

5.3 Specifications

Power connection [ V ] 100 / 115 / 230 50/60Hz

Mains fuse 100-115V/230 V [ A ] 6.3 / 4 AT

Power consumption max. [ VA ] 500

Ambient temperature [ °C ] 5-25

Temperature control

Dimensions:

Length

Width

Height

Weight approximately [ kg ] 11,7

Cycle speed [ m / min ] 10

Sealing temperature max. [ °C ] 220

Temperature tolerance [ % ] ± 2

Sealing seam width [ mm ] 12

Sealing edge [ mm ] 0-35 infinitely variable

Sealing seam length [ mm ] unlimited

[ mm ]

electronic

505

250

145

Version 1.02 9.696.035 Page GB 18

SGR10S Technical data Chapter 5

ENGLISH

6 Declaration of conformity

Version 1.02 9.696.035 Page GB 19

ITALIANO

SGR10S Indice

& ITALIANO

Indice

1 Introduzione_______________________________________________________2

2 Prima di avviare l'apparecchiatura______________________________________3

2.1 Informazioni contenute nelle istruzioni per l'uso_______________________________3

2.2 Idoneità d'uti lizzo_______________________________________________________3

2.3 Struttura e funzioni _____________________________________________________4

2.4 Processo di sigillatura___________________________________________________4

2.5 Avvertenze generali di sicurezza __________________________________________5

2.6 Installazione __________________________________________________________5

3 Funzioni basilari____________________________________________________6

3.1 Messa in funzione ______________________________________________________6

3.2 Utilizzo_______________________________________________________________7

3.3 Impostazione del regolatore di temperatura__________________________________8

4 Eliminazione anomalie e manutenzione__________________________________9

4.1 Checklist per l'eliminazione dei difetti_______________________________________9

4.2 Assistenza clienti______________________________________________________10

4.3 Piano manutenzione ___________________________________________________10

4.4 Servizio pezzi di ricambio_______________________________________________11

4.5 Numeri dei singoli articoli per ordinare i pezzi di ricambio______________________13

4.6 Ganasce di sigillatura __________________________________________________13

4.7 Ganasce di guida _____________________________________________________14

4.8 Complessivo per ordinare i pezzi di ricambio________________________________15

5 Dati tecnici_______________________________________________________16

5.1 Schema di allacciamento e cablaggio 230 V________________________________16

5.2 Schema di allacciamento e cablaggio 100 / 115 V____________________________17

5.3 Specifiche tecniche____________________________________________________18

6 Dichiarazione di conformità __________________________________________19

Pagina I 1 9.696.035 Versione 1.02

Nota

SGR10S Introduzione Capitolo 1

ITALIANO

1 Introduzione

Premessa

Innanzi tutto desideriamo ringraziarvi nuovamente per l'acquisto della sigillatrice con

avanzamento continuo SGR10S.

Nelle presenti istruzioni troverete informazioni sull'apparecchiatura nonché sul suo

funzionamento e utilizzo.

Si prega di leggere attentamente le presenti istruzioni per l'uso prima della messa in

funzione al fine di apprendere adeguatamente le caratteristiche dell'apparecchiatura

e potere sfruttare al meglio le sue funzioni.

F Si prega di conservare sempre le presenti istruzioni per l'uso in prossimità

dell'apparecchiatura.

Avvertenza importante:

Questa apparecchiatura è una sigillatrice con avanzamento continuo per la chiusura ermetica di

sistemi di sterilizzazione.

Si prega di osservare le disposizioni contenute nel capitolo "Idoneità d'utilizzo" della presenti

istruzioni per l'uso.

Conformemente all'uso è stata applicata l'etichettatura CE ai sensi delle direttive CE sotto

elencate: 2006/42/EC e 2006/95/EC.

La direttiva 93/042 CEE non è applicabile alle sigillatrici e saldatrici.

Nelle prove elettriche di riqualifica non possono essere applicati i valori limite previsti dalla

norma IEC 60601-1.

Il produttore non è responsabile di danni derivanti da prove eseguite secondo norme non

indicate nella dichiarazione di conformità.

Poiché i nostri prodotti sono in costante evoluzione, ci riserviamo

di aggiornare le presenti istruzioni per l'uso e le funzioni ivi

descritte.

Nel caso doveste comunque riscontrare errori o punti non chiari,

vi preghiamo di informarci.

Le presenti istruzioni per l'uso sono valide per prodotti a partire

dalla data di produzione 07/200 8

Pagina I 2 9.696.035 Versione 1.02

SGR10S Prima di avviare l'apparecchiatura Capitolo 2

ITALIANO

2 Prima di avviare l'apparecchiatura

2.1 Informazioni contenute nelle istruzioni per l'uso

Capitolo 2

Prima di avviare

l'apparecchiatura

Capitolo 3

Funzioni basilari

Capitolo 4

Eliminazione anomalie e

manutenzione

Capitolo 5

Dati tecnici

In questo capitolo troverete informazioni sull'utilizzo

idoneo dell'apparecchiatura e sul suo funzionamento,

nonché istruzioni per la gestione e l'installazione.

SI PREGA DI LEGGERE ATTENTAMENTE!

Qui viene spiegato come impostare e utilizzare

l'apparecchiatura.

Istruzioni per rilevare le fonti di errori ed

eliminare le anomalie funzionali.

Qui si trovano informazioni sulla manutenzione, sui pezzi

d'usura e di ricambio e sui riferimenti ai numeri d'ordine

per richiedere i singoli ricambi.

Qui sono contenuti gli schemi di connessione e cablaggio

nonché le specifiche tecniche dell'apparecchiatura.

Capitolo 6

Dichiarazione di conformità

In questo capitolo è contenuta la dichiarazione di

conformità per la sigillatrice con avanzamento continuo

SGR10S.

2.1.1 Idoneità d'utilizzo

La sigillatrice SGR10S è adatta solo per applicazioni industriali e professionali e può essere

utilizzata esclusivamente per gli scopi prescritti.

La sigillatrice con avanzamento continuo SGR10S serve per la chiusura in continuo di sistemi di

sterilizzazione con pellicola di carta semplice o stratificata.

La sigillatrice con avanzamento continuo SGR10S non è adatta per la chiusura

ermetica di pellicole in polietilene, PVC e polipropilene.

Le prestazioni dell’apparecchiatura dipendono dalla tipologia del materiale da

sigillare utilizzato.

Pagina I 3 9.696.035 Versione 1.02

Allacciamento di rete

Interruttore di rete

Fusibili di

rete

Regolazione del

Regolatore di

ITALIANO

SGR10S Prima di avviare l'apparecchiatura Capitolo 2

2.2 Struttura e funzioni

temperatura

bordo di sigillatura

regolabile

2.3 Processo di sigillatura

Fase 1: Dopo l’introduzione del pacchetto di sterilizzazione, il sistema di trasporto si

inserisce automaticamente.

Fase 2: Il pacchetto di sterilizzazione viene trasportato e la zona del cordone di sigillatura

situata tra le ganasce di sigillatura superiori e inferiori viene riscaldata fino alla

temperatura di sigillatura.

Fase 3: Il cordone di sigillatura riscaldato viene poi pressato tra i rulli

e di quindi sigillato ermeticamente.

Fase 4: Il pacchetto di sterilizzazione pronto viene infine trasportato verso il lato di

prelevamento.

Fase 5: Se non vengono più alimentati pacchetti da sigillare, il sistema di trasporto si

disinserisce dopo circa 30 secondi.

Pagina I 4 9.696.035 Versione 1.02

• Œ

SGR10S Funzioni basilari Capitolo 3

ITALIANO

2.4 Avvertenze generali di sicurezza

L'apparecchiatura non può essere installata e utilizzata da persone di

età inferiore a 14 anni.

I

L'apparecchiatura non può essere lasciata in funzione senza

sorveglianza.

L'apparecchiatura o la relativa connessione di rete devono essere

scollegate in caso di non utilizzo.

2.5 Installazione

I

I

L'apparecchiatura non può essere installata e messa in funzione in

ambienti

a rischio di esplosione.

Utilizzare esclusivamente prese di corrente dotate di conduttore di

protezione e in cui la tensione di rete sia stabile.

L'apparecchiatura può essere installata solo in ambienti asciutti. La

presenza di polvere, vapore, gocce o spruzzi d'acqua compromette il

funzionamento dell'apparecchiatura.

Si prega di controllare che la tensione d'esercizio corrisponda ai

requisiti indicati sulla targhetta di tipo dell'apparecchiatura.

Si prega di non sollevare e trasportare l'apparecchiatura in prossimità

della regolazione del bordo di sigillatura. Œ

La distanza dell’ apparecchiatura dalla parete deve essere di

almeno 200 mm. •

Pagina I 5 9.696.035 Versione 1.02

200 mm

Allacciamento di rete

Interruttore di rete

Regolatore di

ITALIANO

SGR10S Funzioni basilari Capitolo 3

3 Funzioni basilari

3.1 Messa in funzione

temperatura

Fase 1: Inserire il cavo di rete nella presa di rete.

Fase 2: Collegare l'apparecchiatura con l'interruttore di rete in posizione "1"

La lampada di controllo nell’interruttore è accesa.

Fase 3: Come descritto nel capitolo 3.3, impostare la temperatura di sigillatura desiderata

tramite il regolatore di temperatura.

Fase 4: Non appena viene visualizzata la temperatura di sigillatura impostata,

l’apparecchiatura viene riscaldata ed è pronta per l’uso.

Pagina I 6 9.696.035 Versione 1.02

Regolazione del

Vite a testa zigrinata

SGR10S Funzioni basilari Capitolo 3

ITALIANO

3.2 Utilizzo

Fase 1: Impostare la larghezza desiderata del bordo di sigillatura. Dopo avere allentato la vite

a testa zigrinata, è possibile regolare a piacere la guida inferiore di introduzione per

bordi di sigillatura di larghezza 0-35 mm.

Fase 2: Inserire nell'apparecchiatura il pacchetto di sterilizzazione da sinistra tramite la guida

di introduzione.

Fase 3: Prelevare il pacchetto di sterilizzazione sigillato dal lato di uscita e lasciarlo

brevemente raffreddare.

Controllo del cordone di sigillatura

F

Se sono presenti punti non chiusi ermeticamente, è necessario aumentare la

temperatura di sigillatura. Se la pellicola è fusa, la temperatura impostata è

troppo elevata.

La temperatura adeguata di sigillatura deve essere determinata tramite

apposite prove.

bordo di sigillatura

Pagina I 7 9.696.035 Versione 1.02

ITALIANO

• Ž • • ‘ Œ • Ž • • ‘

SGR10S

Funzioni basilari

3.3 Impostazione del regolatore di temperatura

Œ

Inserimento della temperatura nominale

Premere il tasto una volta 1 x

Impostare la temperatura con i tasti +1 -1

Il valore inserito è attivato 2 x

Visualizzatore temperatura

Indicatore motore - Relè di avvio

Indicatore regolatore temperatura

Inserimento temperatura nominale

Valore temperatura -1

Valore temperatura +1

Capitolo 3

Impostazioni di fabbrica:

Temperatura nominale 180°C

Unità di misura temperatura °C

Pagina I 8 9.696.035 Versione 1.02

ITALIANO

SGR10S Eliminazione manutenzione Capitolo 4

4 Eliminazione anomalie e manutenzione

4.1 Checklist per l'eliminazione dei difetti

Anomalia funzionale Possibile causa Rimedio

Allacciamento alla rete

Controllare la connessione di rete;

eventualmente allacciare la spina a

un'altra presa di corrente

Sostituire il fusibile di rete.

In caso di ripetuti scatti del fusibile

fare controllare l'apparecchiatura!

Aumentare la temperatura nominale

Ripristinate il fusibile della

sovratemperatura.

In caso di ripetuti scatti del fusibile

fare controllare l'apparecchiatura!

Sostituire il regolatore di temperatura

Controllare le cartucce di

riscaldamento ed eventualmente

sostituirle

L'apparecchiatura non si

accende

L'apparecchiatura non

scalda

Cavo di rete non inserito

Cavo di rete difettoso Sostituire il cavo di rete

Fusibile di rete

Temperatura nominale troppo

bassa

Il fusibile della sovratemperatura è

scattato

Regolatore di temperatura

Cartuccia di riscaldamento

Relè Solid State

Nessun materiale

trasportato

Trasporto disomogeneo di

materiale

Elevata rumorosità di

funzionamento

Temperatura nominale non

raggiunta

Motore difettoso

Microinterruttore difettoso

Cinghia dentata dann eggiata

La cinghia dentata non trasporta

Motore difettoso

Temperatura di sigillatura troppo

Il cordone di sigillatura

non è ermetico

bassa

La distanza tra le ganasce di

sigillatura è troppo grande

Il cordone di sigillatura è

deformato o fuso

Temperatura di sigillatura troppo

elevata

Sostituire il relè Solid State

Sostituire il motore

Sostituire il microinterruttore

Sostituire la cinghia dentata

Controllare il tensionamento della

cinghia dentata

Sostituire il motore

Aumentare la temperatura di

sigillatura

Impostare a 0,5 mm la distanza tra le

ganasce di sigillatura

Ridurre la temperatura di sigillatura

Pagina I 9 9.696.035 Versione 1.02

ITALIANO

SGR10S Eliminazione manutenzione Capitolo 4

Assistenza clienti

Il servizio di assistenza clienti è disponibile da lunedì a venerdì, ore

(

8.30-18.00, al numero telefonico +39 (0)522 821 521.

4.2 Piano manutenzione

Come tutte le apparecchiature tecniche, anche la vostra sigillatrice è

soggetta a usura.

Ciclo di manutenzione

Almeno ogni

3. mesi

In base

alle sollecitazioni,

almeno una volta

all’anno

Legenda:

Al fine di garantire un utilizzo affidabile, la vostra apparecchiatura deve

essere sottoposta regolarmente a manutenzione, almeno una volta all'anno,

da parte di un tecnico specializzato.

Nastro di

PTFE

Ganasce di

guida

Nastro di

PTFE

Ganasce di

sigillatura

Rullo

pressore

Cinghia

dentata

Controllare

Sostituire

Pagina I 10 9.696.035 Versione 1.02

SGR10S Eliminazione manutenzione Capitolo 4

4.3 Servizio pezzi di ricambio

F

• Indicare nome, indirizzo, numero

fax e numero d'ordine

• Indicare il numero di serie

• Indicare il tipo di apparecchiatura

• Evidenziare gli articoli richiesti

• Indicare la quantità richiesta

• Firmare l'ordine

• Spedire l'ordine via fax

Ordinate comodamente i pezzi di ricambio via fax!

E' sufficiente copiare il modulo per l'ordine

che si trova alla pagina seguente.

444444

SGR10S

ITALIANO

Pagina I 11 9.696.035 Versione 1.02

ganascia di

Firma

_____________________

A:

_______________________

_______________________

Vs. n. d'ordine _________________ Data _______________

Tipo di apparecchiatura _________________ Numero di serie _______________

Mittente:

____________________________

____________________________

þ

¨

¨

¨

¨

¨

¨

¨

¨

¨

¨

¨

Definizione N. art. Q.tà

Rullo pressore 2.230.026

Motoriduttore 230 V 1.212.005

Cartuccia di riscaldamento 115V 200W

Ventilatore 230 V 6.212.019

Nastro di PTFE

riscaldamento

Nastro di PTFE ganascia di guida 6.105.138

Cavi IEC con interruttore 6.562.009

Elemento di fissaggio per 6.562.009 6.562.049

Cavo di rete 230 V 6.593.013

Cavo di rete 115 V 6.593.014

Interruttore avvio motore 1.651.003

6.536.032

6.105.125

¨

¨

¨

¨

¨

¨

¨

Relè SST 6.460.001

Sonda della temperatura 6.564.040

Regolatore di temperatura digitale 100 240 V

Trasformatore 100V -115V/230V

Solo per versioni 100 V e 115 V

Protezione sovratemperatura 6.564.018

Cinghie dentate di trasporto 6.271.001

Relè a tempo 1.540.056

6.564.038

6.531.015

Loading...

Loading...