Page 1

WARNING!

This appliance has been designed to work as a

DUCTING

hood (evacuation of the

b) The hood is supplied with two supports/hooks (a)

c) Remove the anti-grease filters, put the hood on

and level by means of the adjusting screw

• Read the instructions carefully before installing and/or using the hood.

• Before connecting, make sure that the mains voltage corresponds to the voltage on

the rating plate inside the hood. (see fig. 7)

• Once you remove the appliance from its packaging make sure it is intact. If the

product is damaged, do not use it and contact the Smeg assistance network.

• It is recommended that a qualified technician performs installation and adjustment

operations.

• The minimum distance between the cooker and the lower part of the hood must be

750mm for gas cookers and 650 mm for electric cookers.

• Before carrying out any kind of maintenance or cleaning, disconnect the hood from

the mains supply.

• Inspect and clean the filters thoroughly and in accordance with the intervals

suggested by the manufacturer.

• Do not cook or fry in a way that could result in flames being sucked into the hood and

causing a fire.

• The hood surface can be cleaned with a damp cloth and a non-bleach liquid

detergent.

• Make sure the room is properly ventilated when using the hood and other gas

appliances at the same time.

• Comply with the regulations on air discharge when operating the hood.

• The extracted air must not be routed into a duct used to discharge fumes of gas-

operated appliances.

• This appliance must not be used by children without an adult supervision

and disabled people may require assistance.

• THE MANUFACTURER CANNOT BE HELD RESPONSIBLE IF THE ABOVE

INSTRUCTIONS ARE NOT FOLLOWED .

OPERATION

air) or RECYCLING hood (recycling of the filtered air).

• DUCTED MODE: In order to use the hood in the ducted mode, connect the motor

intake, by means of a suitable ducting hose not less than 120mm diameter, directly to

the external fumes outlet.

Note: Remove any carbon filters.

• RECIRCULATION MODE: If it is not possible to discharge fumes outside, the hood

can be used to filter and recycle the air. This way, air and fumes are filtered by the

anti-odour carbon filters and recirculated through the aerating grids on the sides of

chimney.

EN 01

Page 2

INSTALLATION INSTRUCTIONS:

b) The hood is supplied with two supports/hooks (a)

c) Remove the anti-grease filters, put the hood on

and level by means of the adjusting screw

Fig.1

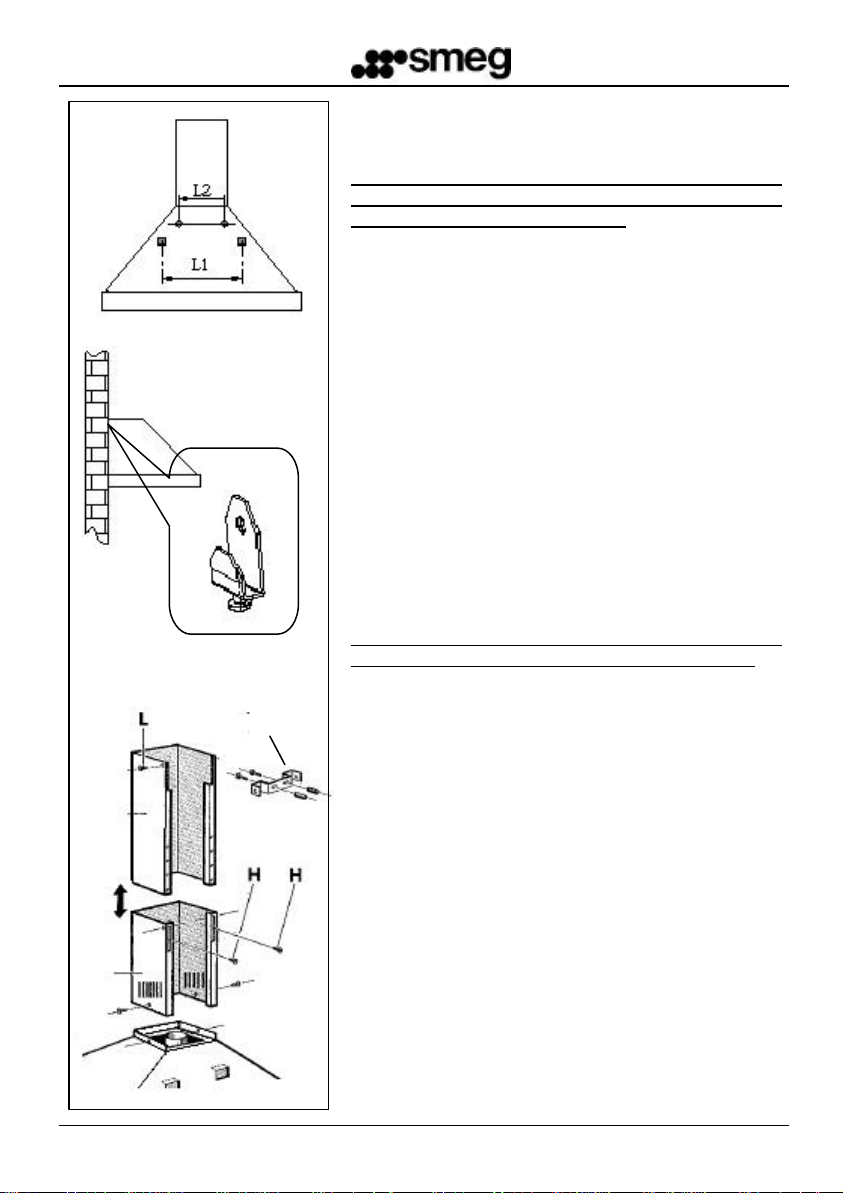

The hood is supplied with all the necessary

accessories for installation. The minimum distance

between the cooker and the lower part of the hood

must be 750 mm for gas cookers and 650 mm for

electric cookers (Fig. 1). The hood is supplied with a

motor intake (Fig 2). If it has not been assembled by

the manufacturer, you can assemble it using the

supplied screws (for type 1) or pushing (for type 2)

If the motor intake is equipped with a non-return

valve, make sure it opens and closes perfectly.

The following instructions will assist installation:

a) The hood should be centred with respect to the

cooker.

(Fig 3) or bracket (b) that need to be fixed to the

wall by means of wall anchors . The L1 holes for

these supports are on the back of the hood (fig.

4)

Fig.2

Type 1

Type 2

Fig.3

(a)

Hood levelling screw

(b)

the wall and mark the position of the holes for the

supports/hooks.

d) Drill the two previously marked holes after

removing the hood from the wall.

e) Fix the two supports/hooks to the wall.

f) Mark the L2 holes on the wall to fix the hood

safely. (fig. 4) Drill and put the anchors in the

holes.

g) Hang the hood on to the supports/hooks (fig. 5)

(fig.3).

h) Fix the hood safe by tightening both wall anchors.

Ducted mode or Recirculation mode installation:

Ducted mode:

In the ducted mode, connect the motor outlet to the

fumes outlet duct not less than 120mm diameter.

Warning: if the hood is equipped with an active

carbon filter, it must be removed (see page 7)

EN 02

Page 3

carefully. Put the chimney bracket

K

on the

B

connect it to a nearby, easily reachable socket in

suitable for the load, compliant with the rules in force

minutes before starting cooking and keep it on for at least 15 minutes after finishing

A

B

Fig.4

Fig.5

Fig.6

Recirculation mode:

Leave the motor intake free. Install the active carbon

filters as shown in page 6.

Warning: if the hood is not supplied with an active

carbon filter, it is necessary to buy it separately and

assemble it before using the hood.

i) Chimney assembly:

Adjust the two telescopic chimneys to the required

length (fig. 6).

Secure the chimneys by tightening the two H screws.

Place the chimney group on the top side of the hood

chimney (fig. 6). Mark the holes on the wall for fixing

the chimney bracket to the wall.

Remove the chimney set, drill and fix the support

bracket to the wall by means of wall anchors. Put the

chimney group back in place and fix it to the hood with

the Z screws and to the chimney bracket with the L

screws as shown in figure 6.

ELECTRICAL CONNECTION

It is recommended that all electrical connection

operations are performed by a qualified technician.

The appliance is supplied WITHOUT A PLUG. It is

K

therefore necessary to fix a plug to the cable or hard

wire direct to a spur. The plug and fuse must be in

accordance with the rating plate inside the hood. Then

B

accordance with the rules in force.

In the case of a direct connection to the mains supply,

it is necessary to put a switched spur between the

appliance and the mains supply. The switch must be

and must have a minimum contact opening of not less

than 3mm.

Z

Z

EN 03

Page 4

OPERATING INSTRUCTIONS:

minutes before starting cooking and keep it on for at least 15 minutes after finishing

A

B

ü CONTROL PANEL:

In order to achieve the best performance, it is recommended to start the hood a few

cooking or after all fumes and odours have disappeared.

To start the hood, identify your type of control panel and follow the instructions:

Ø SLIDER:

- Key (A) to turn on/off the hood’s light.

- Four-position Cursor (B):

0: Off

1/2/3: On/Speed adjustment

(A) (B)

Ø ELECTROMECHANICAL PUSHBUTTONS:

Light ON/OFF Button

0 Motor OFF button

1-2-3 On/speed adjustment button

Ø WITH KNOBS:

- Two-position Knob (A) to turn on/off

the light (0-1)

- Four-position Knob (B):

0 Motor OFF

1-2-3 Speed adjustment

(A) (B)

EN 04

Page 5

Ø ELECTRONIC PUSHBUTTONS:

Before performing any cleaning and/or maintenance operation always disconnect

Note: An excess of grease in the filter, as well as affecting the performance of the

non-bleach liquid detergent,

absolutely avoiding solvents or abrasive substances.

It

Lights ON/OFF

0/1 OFF/1 speed

2-3-4 Speed adjustment

Filters reset button

OPTIONAL FUNCTIONS:

- AUTO POWER-OFF TIMER: Pushing one of the speed adjustment buttons (2-3-4)

twice, you will activate the “Auto power-off timer” function that turns the motor and light off

after 10 mins. The activation of such function is signalled by the blinking LED

above the pressed button.

- FILTERS CLEANING WARNING: When all the 4 LEDs blink at the same time (which is

programmed to happen every 100h of operation), the user is required to

clean/replace the filters.

Pressing the Reset button the 100h count will start again

Note: Pressing the reset button accidentally before the end of the 100h

cycle does not reset the filters cleaning memory

It is recommended that grease filters are cleaned every 100h and active

carbon filters are replaced every 200h.

CLEANING AND MAINTENANCE:

the hood from the mains supply.

Regular cleaning will ensure a good performance and extend the working life of the hood.

Special attention should be given to the grease filters and carbon filters (for recycling

hoods only).

hood, can also be a fire risk.

EXTERNAL CLEANING:

External and internal cleaning of the hood should be performed with a damp cloth and a

is advisable to use specific products, following their instructions. When cleaning the steel

of the hood, we suggest rubbing in the same direction as the grain.

EN 05

Page 6

METAL FILTERS CLEANING:

a fire risk. To avert fires, the filters must be cleaned

time as shown in these pictures. Wash the filters

recommended they are replaced at least once every

To reach the active carbon filters, it is necessary to

shown in fig. A and then remove them from their

Cartridge filter with bracket and threaded knob (fig.

Special attention should be reserved to the metal

grease filters. An excess of grease in the filter, as well

as affecting the performance of the hood, can also be

regularly at least once a month or more frequently, in

the case of a heavy use of the appliance.

According to your hood’s model, remove one filter at a

thoroughly with a non-bleach detergent, either by

hand or machine. Re-assemble the filters, making

sure that the handle faces the outside of the hood

CARBON FILTERS REPLACEMENT: (For recirculated version only)

The carbon filters can only retain odours for a limited

period of time. They cannot be washed, therefore, it is

six months or more frequently in the case of a heavy

use of the appliance.

Before starting, make sure the hood is disconnected

Fig.A

from the mains supply.

remove the metal filters as shown above. Use the

pictures to find the carbon filter kit of your hood.

Round filter: simply rotate the filters 90 degrees as

seats.

Spring-held cartridge filter (fig. B): press enough to

overcome the spring’s resistance and remove the

filter.

C): unscrew the knob, remove the locking bracket and

then remove the active carbon filter.

Fig.B

Re-assemble the carbon and metal filters by reversing

the procedure.

Note: only for the electronic controlled hood, reset the

filter cleaning warning by pressing the Filter reset

button.

Fig.C

EN 06

Page 7

LIGHTS REPLACEMENT:

with different kind of lighting such as incandescent,

from the control panel, unscrew the lamp and

replace the lamp, use a screwdriver to remove

d) Neon lamp: 15/18W

neon tube

.

To reach the

The hood packaging includes, together with this operating and maintenance booklet, the

(a)

Before performing any cleaning and/or

maintenance operation, disconnect the hood

from the mains supply.

According to the model, the hood can be equipped

halogen and neon lamps.

a) Incandescent lamps: E14 – 40W 230V lamps.

To replace them, remove the transparent fixture

screw in the new one.

(c)

(b)

b) Halogen lamps: G4, 20W - 12V lamps. To

the glass-supporting ring. Then remove the old

lamp and insert the new one.

Put the glass back, securing it with the ring.

c) Biax neon lamps: G23 11W lamp. Once the

fixture has been removed, remove the biax lamp

from its seat and support.

Put a new lamp in, performing the same

operations backwards.

neon tube, unscrew the glass framework screws.

Rotate the tube 90 degrees and remove the neon

lamp. Install the new neon tube and put the glass

framework back.

(d)

EN 07

Page 8

WARRANTY AND TECHNICAL ASSISTANCE

SERVICE

The hood packaging includes, together with this operating and maintenance booklet, the

Smeg Warranty Booklet. Please read the Smeg Warranty Booklet for complete

information about the warranty (N.B. bulbs and filters are not covered by your warranty).

In the case of failure, please call

Fig.7

Customer Service

0870 9909907

and provide the following data:

• The model indicated inside the hood (fig. 7)

• Your full address

• Your telephone number

• Information on the kind of failure

• Your proof of purchase

EN 08

Loading...

Loading...