Smeg K9998 Quick Start Manual

K9998

90cm rangehood, wall mount, stainless steel, peripheral lter

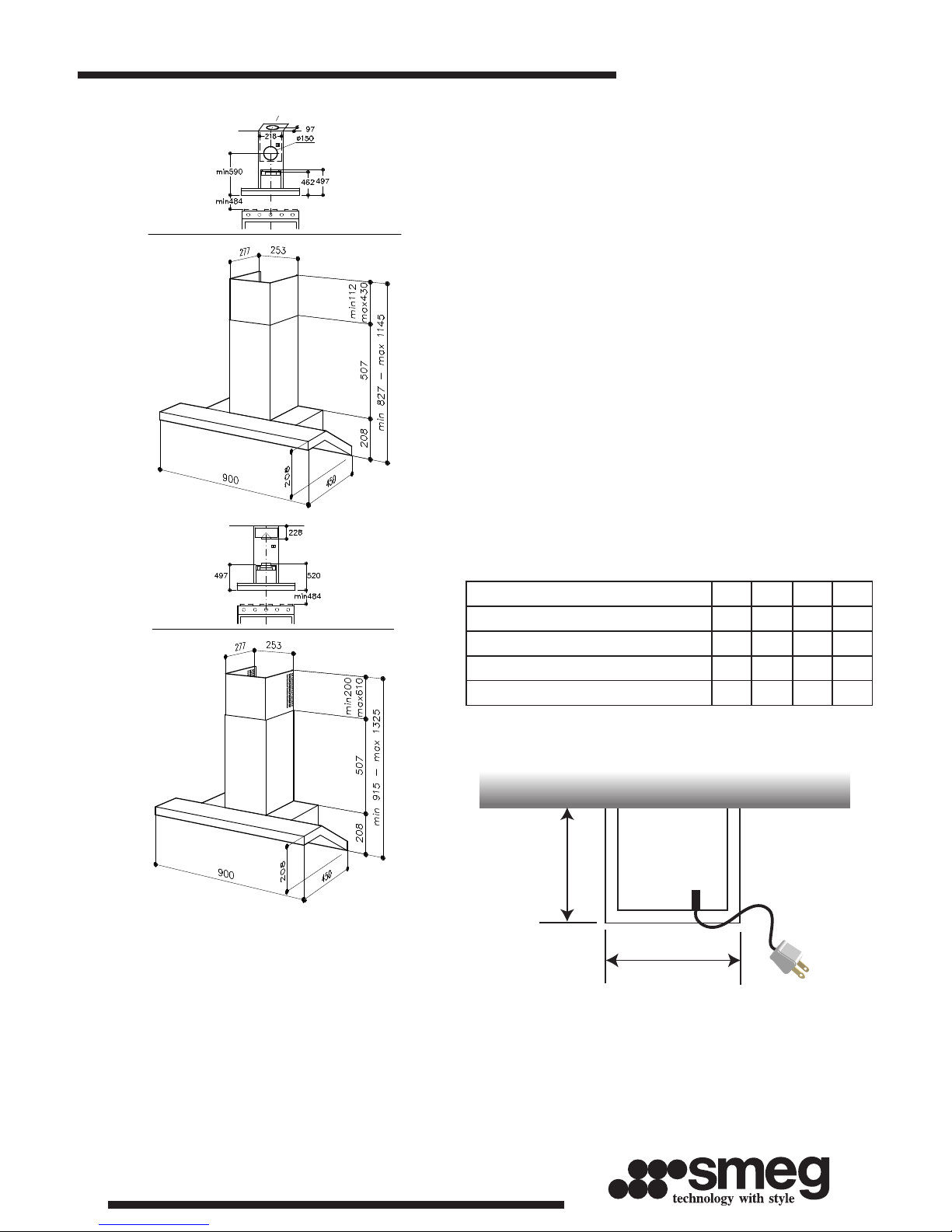

dimensions

900mm W x 450mm D x 1325mm H maximum

nish

satin stainless steel

installation

wall mount

motor

250 watt centrifugal, twin impellors, double-sided air uptake

capacity

7003m/hr net

noise rating

40–56 dBA

extraction

NB

• direct duct to atmosphere, 150mm diameter ducting required

• recirculate to kitchen, 125mm diameter ducting required

— 150/125mm diameter ducting adaptor supplied

— recirculation diverter kit supplied

illumination

two 20 watt halogen, single button ON/OFF

speeds

four speeds, four buttons

delay stop

five-minute delay stop for fan and lights

cleaning prompt

• 30-hour prompt to inspect grease lters

• 120-hour prompt to inspect charcoal lter

ltration

two stainless steel and aluminium 4-ply grease lters, removable,

concealed behind large one-piece stainless steel panel

option

activated charcoal lter cartridge for optional tment in the

recirculation installation, part number 08999802

warranty

two years parts and labour

APPLICATION

The K9998 FPX extraction/ltering unit is suitable for very varied

installations. An island or wall-mounted canopy can be designed

incorporating these rangehoods. Consider, as well, one of these

units for a difcult situation such as a corner or, when renovating,

the overhead cabinet widths are not the normal 60cm or 90cm,

making more conventional rangehoods impractical. The

completely concealed design might alone be the sole aspect of

a decor solution.

PERFORMANCE

Highly-efcient air extraction of up to 700 cubic metres an hour

true (net) ensures the very swift removal of cooking vapours,

odours and heat. The higher speed selections are perfect for

the more vigorous styles of cooking such as stir frying, griddle

cooking and boiling, the lower speeds at the touch of a button

are perfect for simmers.

QUIETNESS

40 to 56 dBA. The motor/impellor encasements are smooth-

walled to minimise air drag and, hence, noise. All metal joins are

welded to reduce vibration.

SAFETY

Thermal overload protection on motor, re retardant hardened

metal and mesh, VO self-extinguishing plastic for motor housing

and internal ue.

MAINTENANCE

No tools required — easy lift-out pair of grease lters for washing.

For light replacement, simply rotate the decorative ange for

access to halogen globes.

DUCTING

Direct ducting to atmosphere ensures the maximum removal

of grease/oil/particle-laden vapour plus the odours and, very

importantly, the heat, resulting in a cleaner, cooler, more

comfortable work area.

RECIRCULATION

When the cooking vapours cannot be ducted to atmosphere, the

ltered air can simply be redirected back into the kitchen via a duct

pipe through the overhead cabinetry.

CHARCOAL FILTERS

These are purchasable accessories. One each is clipped to either

side of the centrifugal motor and are designed to absorb and

diminish cooking odours. Periodic inspection is recommended

before replacement. They are optionally used for recirculation only.

The activated charcoal lters are not to be washed.

DUCTING MATERIAL

Smooth internal walled duct pipe lengths ensure the most efcient

air movement and quieter operation. Consider either high

temperature rated PVC or galvanised sheet metal piping. The

exible ducting cab be ideal for a very short, tight run.

The rangehood’s air exit aperture is designed for 150mm (6”)

ducting; however, a 125mm diameter (5”) adaptor can be

purchased for optional use.

DELAY STOP

Ideally, a rangehood should run for several minutes after all cooking

is ceased in order to drag through residual vapours and odours.

By selecting the delay stop button at the end of the cooking, the

rangehood will turn the motor off in ve minutes as well as the lights if

they were left on.

CLEANING PROMPT

After 30 hours use the LED window will prompt visually to inspect the

grease lters for possible cleaning. Simply use the Reset button to

clear the LED window.

ID200209

code K9998

PERIPHERAL FILTER DESIGN

The K9998 FPX is distinguished by the broad one-piece stainless

steel panel raked above the cooking area. A peripheral gap

surrounds this panel. It is through this gap that the convected air

is drawn at high speed towards the two concealed grease lters.

The large stainless steel panel is easily unclipped for cleaning and

access to the grease lters.

WARNING: technical specications and product sizes can be varied by the manufacturer without

notice. Cutouts for appliances should only be by physical product measurements. The above

information is indicative only.

NB: drawings are not to scale — they are to assist only

electricity supply

240 volt, 50 Hz

electrical

connection

0.85 metre connected power cord for

plugging to standard 10 amp GPO

wattage

250 watt, 2 x 20 watt halogen globes, 290

watts total

current

1.21 amps

packaged

dimensions

1040mm x 670mm x 640mm = 0.45m³

gross weight

36.35 kg

net weight

29.10 kg

supplied

• instructions for installation, operation,

maintenance

• screws and wall bracket

• 150/125mm diameter ducting adaptor

• recirculation diverter kit

optional

activated charcoal lter cartridge to

slot below the centrifugal motor in the

recirculation installation, part number

08999802

K9998

90cm rangehood, wall mount, stainless steel, peripheral lter

ID200209

code K9998

SPEED 1 2 3 4

net air capacity m3/hr

300 430 600 700

pressure mm H20

36 42 44 45

wattage

120 160 200 250

noise dBA

40 48 54 56

direct ducting to atmosphere

recirculation to kitchen

chimney plan detail

PLEASE NOTE the difference in maximum heights between the ‘direct duct to

atmosphere’ installation and the ‘recirculation’ installation. The recirculation

installation’s maximum height is 1325mm due to the active recirculation vents

necessarily being exposed on each side of the chimney. The ‘direct duct to

atmosphere’ installation shows the now redundant recirculation vents being

concealed by the lower chimney by reversing — that is, turning the upper chimney

piece 180 degrees on the vertical.

If a higher chimney height is required for the ‘direct duct to atmosphere’

installation, that is, up to 1325mm, simply follow the ‘recirculation’ installation and

have the recirculation vents exposed, though redundant.

253

277

Loading...

Loading...