Smeg K7088D180SS Product Manual

K7088D/180

180cm wall mounted, twin chimney rangehood

ASC — automatic sensor control

ASC AUTOMATIC SENSING CONTROL

By selecting this button, the K7088D/180 automatically

senses any vapours, smoke and odours caused by the

cooking process and adjusts the speed of extraction

accordingly. The ASC will also sense and capture an

abnormal presence of gas.

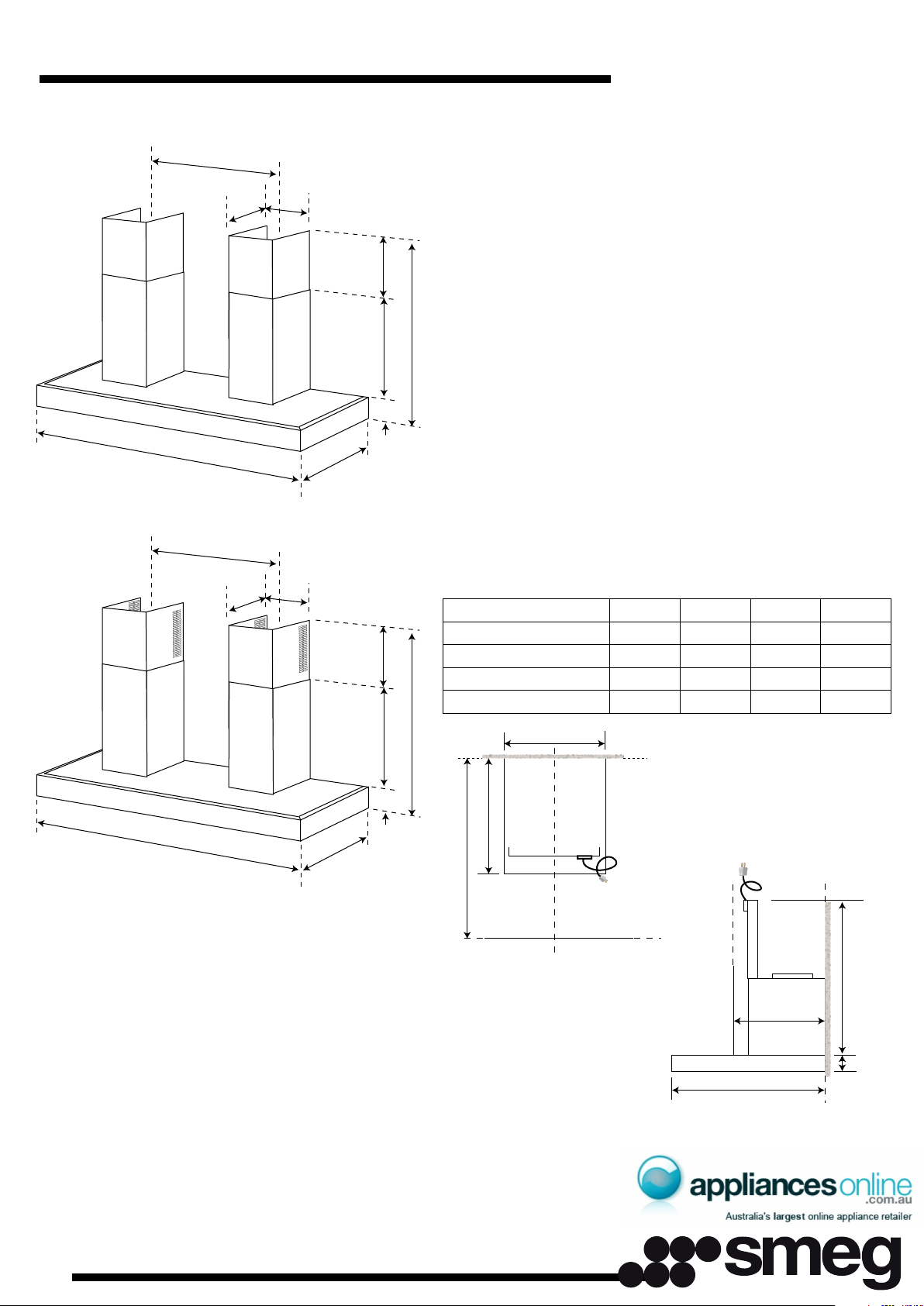

dimensions

nish

installation

motors

air extraction

capacity

illumination

noise rating

speeds

delay stop

controls

ltration

prompts

supplied

accessory

warranty

ID010708

code K7088D180

1800mmW x 500mmD x 1240mm maximum H

satin stainless steel

wall mount

2 x 250 watt centrifugal motors —

each motor: twin impellors, double air uptake

• duct direct to atmosphere — 150mm diameter ducting required

• recirculate to kitchen — 125mm diameter ducting required

NB: for recirculation, a recirculation diverter kit is supplied for each

chimney

each half: 750m³/hr net

4 x 20 watt halogens

1 x 38 dBA minimum → 2 x 58 dBA maximum

four per motor

ve minute delay stop selection

four buttons, one LED window

six removable four-ply stainless steel (washable)

via LED window ashing —

• ve-minute delay stop

• 30-hour stainless steel lter cleaning prompt

• 120-hour charcoal lter inspection prompt

• two one-way, non-return buttery valves — removable

• two 150-125mm diameter duct size adaptors

• two recirculation diverter kits

optional activated charcoal lter for each motor, part number 08999802

two years on parts and labour

DELAY STOP

When cooking is nished, it is recommended that the

rangehood be left running for a few minutes, even at a

lower speed, to pull through all residual heat, grime and

odours. Selecting the DELAY STOP eliminates the need

to return to the rangehood to turn it off manually. It will

also turn off the lights if they were previously left on.

FILTER INSPECTION PROMPTS

After 30 hours of use, the LED window will visually prompt

for you to inspect the ve stainless steel grease lters

for possible washing. The cleaner the lters, the more

effective is the airow. The controls are simply reset to

zero hours and the counting starts over. The lters can

be cleaned at any time, without waiting for the prompt.

After 120 hours of operation, there is an additional

prompt to check the charcoal lters if they have been

tted for the recirculation mode.

DUCTING TO ATMOSPHERE

Extracting the air direct to atmosphere ensures the

maximum removal of grease/oil/particle-laden vapour,

odours and, very importantly, the heat — resulting in

a cleaner, more comfortable cooking environment.

An internal ducting pipe could, ideally, continue in a

straight line within the decorative ue to the kitchen

roof, then through the roof cavity and exit via a roof

cowl. If the rangehood is mounted against an external

wall, the ducting could, as effectively, exit at the rear

anywhere along the vertical line of the concealing

decorative ue and at a position that is structurally

feasible for an external wall cowl.

RECIRCULATION

When the cooking vapours cannot be ducted to

atmosphere, that is, the rangehood is mounted on an

internal wall and/or there is another storey above, the

supplied recirculation kit is inserted into the telescopic

ue. An activated charcoal lter can be tted below the

centrifugal motor. This will effectively diminish cooking

odours. The charcoal lter is not to be washed and is

replaceable.

DUCTING MATERIAL

The smooth internal walls of either galvanised sheet

metal piping or high temperature-resistant PVC will assist

in both greater unobstructed air ow and a quieter

operation. Flexible ducting can be considered for the

very short run and difcult obtuse bends.

CHARCOAL FILTER

In the recirculation mode, the rangehood is also sending

the cooking odours back into the kitchen. An activated

charcoal lter panel, part number 08999802, can be

inserted just below the motor housing to effectively

diminish the cooking odours. This charcoal lter is not to

be washed; however, it is replaceable.

K7088D/180

540

80

1800

min 700 - max 1050

min 80

max 430

750

278

253

500

540

80

1800

min 820 - max 1240

min 200

max 610

750

278

253

500

1.5 metre

power cord

253

278

500

PLAN DETAIL — electrical connection

each chimney

500

front

1.5 metre

power cord

278

80

475

RIGHT-HAND SIDE ELEVATION DETAIL

— electrical connection

180cm wall mounted, twin chimney rangehood

ASC — automatic sensor control

ID010708

code K7088D180

direct ducting to atmosphere

electricity supply

electrical connection

wattage

current

packaged dimensions

gross weight

net weight

supplied

optional

240 volt, 50 Hz

each chimney: independent 1.5 metre power

cord for connection to standard 10 amp GPO

motors: 2 x 250 watt each

lights: 4 x 20 watt halogens

total: 580 watts

2.42 amps total

• instructions for installation, operation and

maintenance

• 2 x one-way buttery valves for optional

tment to air exit apertures

• 2 x 150mm/125mm diameter duct adaptors

NB: recirculation requires 125mm diameter

ducting, direct ducting requires 150mm diameter

ducting

• xing screws

2 x activated charcoal lters (replaceable),

individual part number 08999802

SPEED 1 2 3 4

3

net air capacity m

pressure mm H

input wattage 2 x 120 2 x 150 2 x 190 2 x 250

noise level dBA 2 x 38 2 x 48 2 x 54 2 x 58

/hr 2 x 300 2 x 470 2 x 630 2 x 750

0 2 x 36 2 x 42 2 x 45 2 x 46

2

recirculation

Please note the difference in maximum heights between the

‘direct duct to atmosphere’ installation and the ‘recirculation’

installation. The recirculation installation’s maximum height

is 1240mm due to the active recirculation vents necessarily

being exposed on each side of each chimney. The ‘direct

duct to atmosphere’ installation shows the now redundant

recirculation vents being concealed by the lower chimney

piece by the reversing — that is, turning the upper chimney

piece 180 degrees on the vertical.

If higher chimney heights are required for the ‘direct duct to

atmosphere’ installation, that is, up to 1240mm, simply follow

the ‘recirculation’ installation and have the recirculation vents

exposed, though redundant.

WARNING: technical specications and product sizes can be varied by the manufacturer without notice. Cutouts

for appliances should only be by physical product measurements. The above information is indicative only.

NB: drawings are not to scale — they are to assist only

Loading...

Loading...