Page 1

Contents

1 Instructions 4

1.1 General safety instructions 4

1.2 Manufacturer liability 9

1.3 Appliance purpose 9

1.4 Identification plate 10

1.5 This user manual 10

1.6 Disposal 10

1.7 How to read the user manual 11

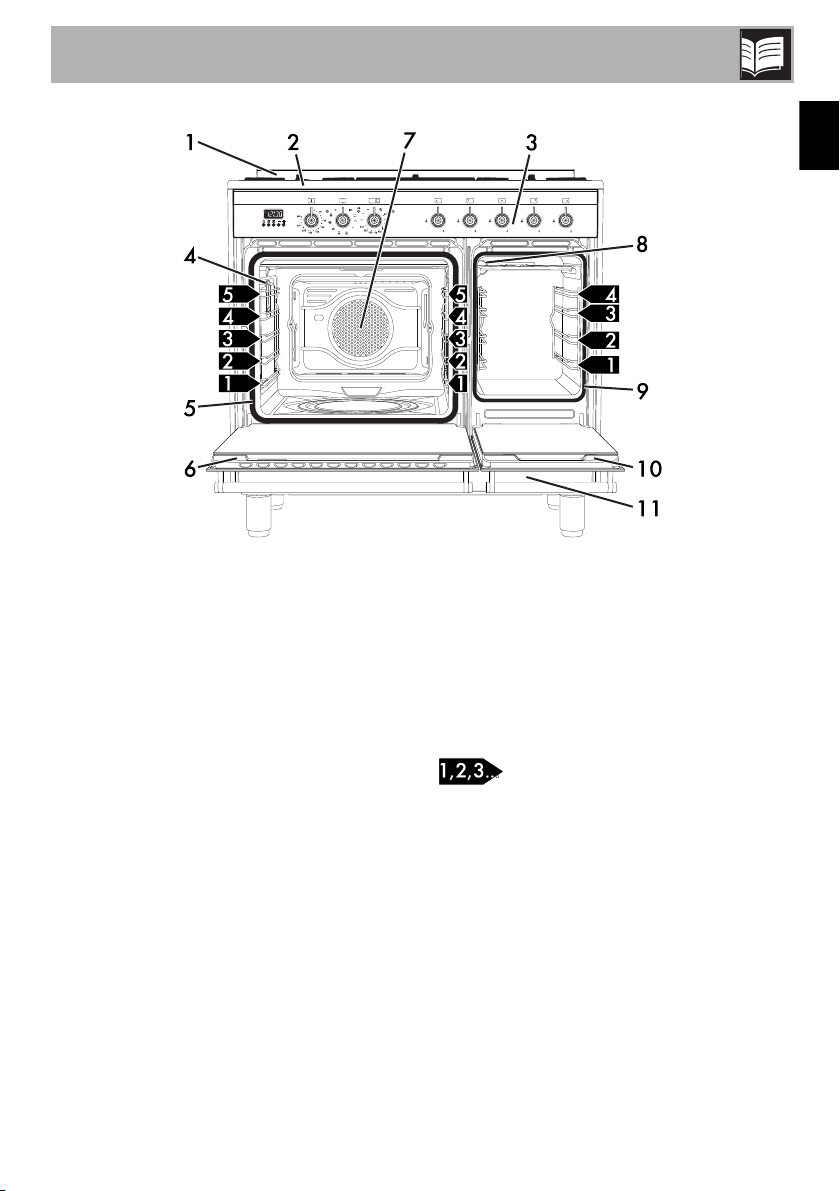

2 Description 12

2.1 General Description 12

2.2 Cooking hob 14

2.3 Control panel 14

2.4 Other parts 15

2.5 Available accessories 16

3 Use 19

3.1 To save energy 21

3.2 Using the accessories 21

3.3 Using the hob 22

3.4 Using the storage compartment 23

3.5 Using the ovens 24

3.6 Programmer clock 29

4 Cleaning and maintenance 35

4.1 Cleaning the surfaces 35

4.2 Cleaning the hob 36

4.3 Cleaning the door 37

4.4 Cleaning the oven cavities 39

4.5 Vapor Clean (on some models only) 41

4.6 Pyrolytic (on some models only) 43

4.7 Extraordinary maintenance 45

5 Installation 47

5.1 Gas connection 47

5.2 Adaptation to different types of gas 50

5.3 Positioning 55

5.4 Electrical connection 60

5.5 Instructions for the installer 62

EN

ORIGINAL INSTRUCTIONS

We advise you to read this manual carefully, as it contains all the instructions for maintaining

the appliance’s aesthetic and functional qualities.

For further information on the product: www.smeg.com

3

Page 2

Instructions

1 Instructions

1.1 General safety instructions

Risk of personal injury

• During use the appliance and

its accessible parts become

very hot. Keep children well

away from the appliance.

• Protect your hands by wearing

oven gloves when moving food

inside the oven.

• Never try to put out a fire or

flames with water: turn off the

appliance and smother the

flames with a fire blanket or

other appropriate cover.

•

This appliance can be used by

children aged from 8 years and

above and persons with reduced

physical, sensory or mental

capabilities or lack of experience

and knowledge if they have been

given supervision or instruction

concerning use of the appliance

in a safe way and understand the

hazards involved.

• Children must not play with the

appliance.

• Keep children under the age of

8 at a safe distance unless they

are constantly supervised.

• Keep children under the age of

8 away from the appliance

when it is in use.

• Cleaning and maintenance

must not be carried out by

unsupervised children.

• Make sure that the flamespreader crowns are correctly

positioned in their seats with

their respective burner caps.

• Be aware of how rapidly the

cooking zones heat up. Do not

place empty pans on the heat.

Danger of overheating.

• Cooking process should

always be kept under control.

A short cooking process must

be continuously surveyed.

4

Page 3

Instructions

• Fats and oils can catch fire if

they overheat. Do not leave the

appliance unattended while

preparing foods containing oils

or fats. If fats or oils catch fire,

never put water on them. Place

the lid on the pan and turn off

the relevant cooking zone.

• While cooking do not place

metal objects, such as cutlery or

dishes on the hob surface as

they may overheat.

• Do not insert pointed metal

objects (cutlery or utensils) into

the slots in the appliance.

• Do not pour water directly on

very hot trays.

• Keep the oven door closed

during cooking.

• If you need to move food or at

the end of cooking, open the

door 5 cm for a few seconds,

let the steam come out, then

open it fully.

• Do not open the storage

compartment (where present)

when the oven is on and still

hot.

• The items inside the storage

compartment could be very hot

after using the oven.

• Switch off the appliance after

use.

• Do not pull the cable to remove

the plug.

• DO NOT USE OR STORE

FLAMMABLE MATERIALS IN

THE STORAGE

COMPARTMENT (IF

AVAILABLE) OR NEAR THE

APPLIANCE.

• DO NOT USE AEROSOLS IN

THE VICINITY OF THIS

APPLIANCE WHILST IT IS IN

USE.

• DO NOT MODIFY THIS

APPLIANCE.

• Before any operation on the

appliance (installation,

maintenance, positioning or

movement) always wear PPM.

EN

5

Page 4

Instructions

• Before performing any

operation on the appliance,

switch off the power supply.

• Have qualified personnel carry

out installation and assistance

interventions according to the

standards in force.

• Do not try to repair the

appliance yourself or without

the intervention of a qualified

technician.

•

In order to avoid hazard, if the

power supply cable is damaged,

contact technical support and

they will replace it.

Risk of damaging the appliance

• Do not use harsh abrasive

cleaners or sharp metal

scrapers to clean the oven

door glass since they can

scratch the surface, which may

result in shattering of the glass.

• Use wooden or plastic utensils.

• Do not use steam jets to clean

the appliance.

• Do not obstruct ventilation

openings and heat dispersal

slots.

• Do not sit on the appliance.

• Racks and trays should be

inserted as far as they will go

into the side guides. The

mechanical safety locks that

prevent them from being

removed must face downwards

and towards the back of the

oven.

• Never leave the appliance

unattended during cooking

operations where fats or oils

could overheat and take fire.

Be very careful

•

Danger of fire: do not store items

on the cooking surfaces.

• Do not spray any spray

products near the oven.

• DO NOT USE THE

APPLIANCE TO HEAT

ROOMS FOR ANY REASON.

• Do not use plastic cookware or

containers for cooking.

• Do not place sealed tins or

containers in the oven cavity.

6

Page 5

Instructions

• Remove all trays and racks

which are not required during

cooking.

• Do not cover the bottom of the

oven cavity with aluminium or

tin foil sheets.

• Do not place pans or trays

directly on the bottom of the

oven cavity.

• If you wish to use greaseproof

paper, place it so that it will not

interfere with the hot air

circulation inside the oven.

• Do not use the open door to

place pans or trays on the

internal glazing pane.

• Cooking vessels or griddle

plates should be placed inside

the perimeter of the hob.

• All pans must have smooth, flat

bottoms.

• If any liquid does boil over or

spill, remove the excess from

the hob.

• Take care not to spill acid

substances such as lemon juice

or vinegar on the hob.

• Do not put empty pans or frying

pans on switched on cooking

zones.

• Do not use rough or abrasive

materials or sharp metal

scrapers.

• Do not use cleaning products

containing chlorine, ammonia

or bleach on parts made of

steel or that have metallic

surface finishes (e.g. anodizing,

nickel- or chromium-plating).

• Do not wash the removable

components such as the hob

grids, flame-spreader crowns

and burner caps in a

dishwasher.

• Never use the oven door to

lever the appliance into place

when fitting.

• Avoid exerting too much

pressure on the door when

open.

• Do not use the handle to lift or

move this appliance.

EN

• Do not use steam jets to clean

the appliance.

7

Page 6

Instructions

Installation

• THIS APPLIANCE MUST NOT

BE INSTALLED IN A BOAT OR

CARAVAN.

• This appliance must not be

installed on a pedestal.

• Position the appliance into the

cabinet cut-out with the help of

a second person.

• To prevent any possible

overheating, the appliance

should not be installed behind

a decoration door or a panel.

• Before installation, make sure

that the local distribution

conditions (nature and pressure

of the gas) and the adjustment

of the appliance are

compatible.

• This appliance is not

connected to an exhaust system

for combustion products. It must

be installed and connected in

compliance with the current

installation regulations. Special

attention should be paid to the

relevant requirements as for

ventilation.

• The adjustment conditions for

this appliance are shown on

the gas setting label.

• Have the gas connection

performed by authorised staff.

• Installation using a hose must

be carried out so that the length

of the hose does not exceed

2 metres when fully extended

for steel hoses and 1.5 metres

for rubber hoses.

• The hoses should not come into

contact with moving parts and

should not be crushed in any

way.

• If required, use a pressure

regulator that complies with

current regulations.

• After carrying out any

operation, check that the

tightening torque of gas

connections is between 10 Nm

and 15 Nm.

• At the end of the installation,

check for any leaks with a

soapy solution, never with a

flame.

8

Page 7

Instructions

• Have the electrical connection

performed by authorised

technicians.

• The appliance must be

connected to ground in

compliance with electrical

system safety standards.

• Use cables withstanding a

temperature of at least 90 °C.

• The tightening torque of the

screws of the terminal board

leads must be 1.5 - 2 Nm.

For this appliance

• Ensure that the appliance is

switched off before replacing

the bulb.

• Do not rest any weight or sit on

the open door of the

appliance.

• Take care that no objects are

stuck in the doors.

1.2 Manufacturer liability

The manufacturer declines all

liability for damage to persons or

property caused by:

• use of the appliance other than

that specified;

• failure to comply with the

instructions in the user manual;

• tampering with any part of the

appliance;

• use of non-original spare parts.

1.3 Appliance purpose

• This appliance is intended for

cooking food in the home

environment. Every other use is

considered inappropriate.

• The appliance is not designed

to operate with external timers

or with remote-control systems.

EN

9

Page 8

Instructions

1.4 Identification plate

The identification plate bears the

technical data, serial number and

brand name of the appliance. Do not

remove the identification plate for

any reason.

1.5 This user manual

This user manual is an integral part of

the appliance and must therefore be

kept in its entirety and within the

user’s reach for the whole working

life of the appliance.

Read this user manual carefully

before using the appliance.

1.6 Disposal

This appliance must be

disposed of separately from

other waste (Directives

2002/95/EC, 2002/96/EC,

2003/108/EC). The appliance

does not contain substances in

quantities sufficient to be considered

hazardous to health and the

environment, in accordance with

current European directives.

To dispose of the appliance:

• Cut the power supply cable and

remove it along with the plug.

Power voltage

Danger of electrocution

• Disconnect the mains power

supply.

• Unplug the appliance.

10

Page 9

Instructions

• Deliver the appliance to the

appropriate recycling centre for

electrical and electronic

equipment waste, or return it to the

retailer when purchasing an

equivalent product, on a one for

one basis.

Our appliances are packaged in

non-polluting and recyclable

materials.

• Deliver the packing materials to

the appropriate recycling centre.

Plastic packaging

Danger of suffocation

• Do not leave the packaging or

any part of it unattended.

• Do not let children play with the

plastic bags.

1.7 How to read the user manual

This user manual uses the following reading

conventions:

Instructions

General information on this user

manual, on safety and final

disposal.

Description

Description of the appliance and its

accessories.

Use

Information on the use of the

appliance and its accessories.

Cleaning and maintenance

Information for proper cleaning and

maintenance of the appliance.

Installation

Information for the qualified

technician: Installation, operation

and inspection.

EN

Safety instructions

Information

Advice

1. Sequence of instructions for use.

• Standalone instruction.

11

Page 10

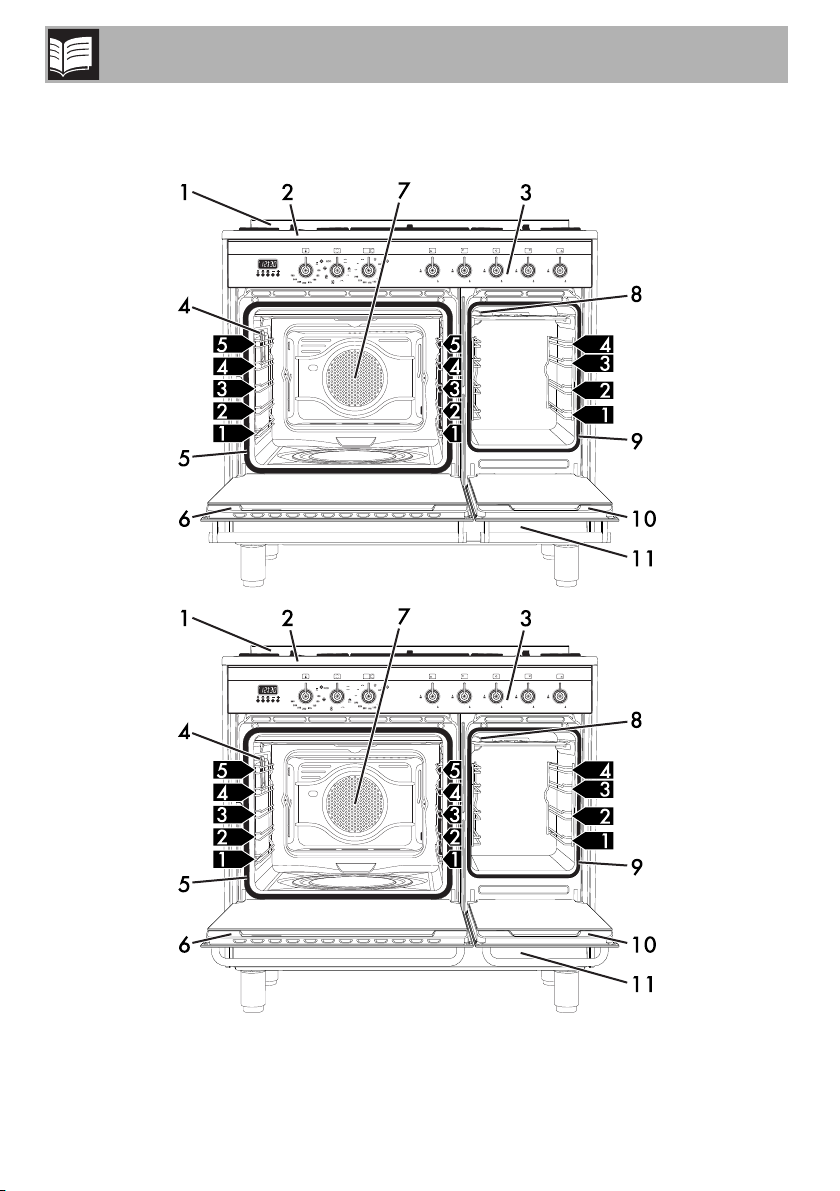

2 Description

2.1 General Description

Description

12

Multifunction models

Page 11

Description

Pyrolytic models

EN

1 Upstand

2 Cooking hob

3 Control panel

4 Main oven light

5 Main oven seal

6 Main oven door

7 Main oven fan

8 Auxiliary oven light

9 Auxiliary oven seal

10 Auxiliary oven door

11 Storage compartment

Rack/tray support frames

13

Page 12

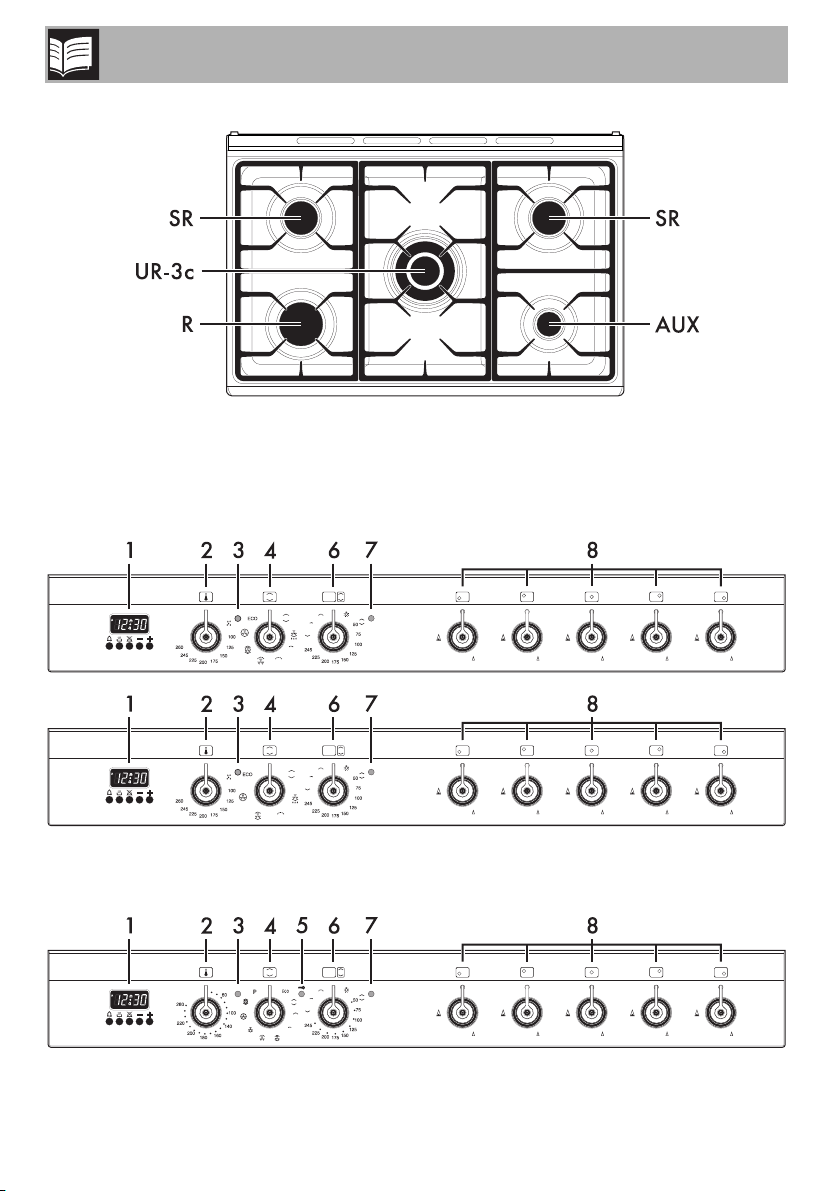

2.2 Cooking hob

Description

AUX = Auxiliary burner

SR = Semi-rapid burner

2.3 Control panel

R = Rapid

UR-3c = Ultra-rapid burner

Multifunction models

14

Pyrolytic model

Page 13

Description

1 Programmer clock

Useful for displaying the current time, setting

programmed cooking operations and

programming the minute minder timer.

2 Main oven temperature knob

This knob allows you to select the cooking

temperature.

Turn the knob clockwise to the required

value, between the minimum and maximum

setting.

3 Main oven indicator light

The indicator light comes on to indicate that

the oven is heating up. It turns off as soon as

it reaches the set temperature. It flashes

regularly to indicate that the temperature set

inside the oven is kept constant.

4 Main oven function knob

The oven’s various functions are suitable for

different cooking modes. After selecting the

required function, set the cooking

temperature using the temperature knob.

5 Door lock warning light (on pyrolytic

models only)

It comes on when the automatic (pyrolytic

function) cleaning cycle is activated.

7 Auxiliary oven indicator light

The indicator light comes on to indicate that

the oven is heating up. It turns off as soon as

it reaches the set temperature. It flashes

regularly to indicate that the temperature set

inside the oven is kept constant.

8 Hob burner knobs

Used for lighting and adjusting the hob

burners. Press and turn the knobs anti-

clockwise to in order to light the

relative burners. Turn the knobs to the zone

between the maximum and minimum

setting to adjust the flame. Return the

knobs to the position to turn off the

burners.

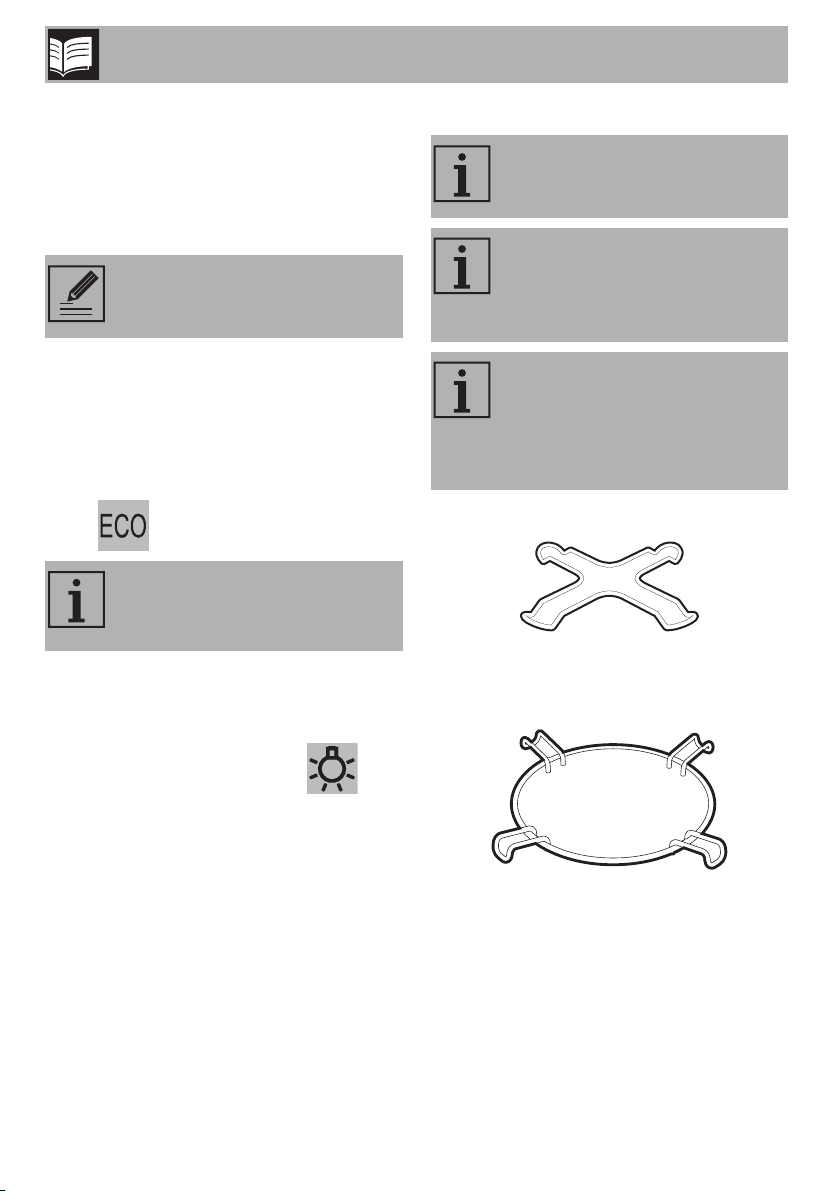

2.4 Other parts

Shelves

The appliance features shelves to position

trays and racks at different heights. The

insertion heights are indicated from the

bottom upwards (see 2.1 General

Description).

Cooling fan

EN

6 Auxiliary oven temperature/function

knob

It turns on the light inside the oven or starts

the grill and lower heating elements to a

temperature ranging from a minimum of

50 °C to a maximum of 245 °C.

At the maximum temperature it is also

possible to select some functions optimised

for specific cooking types.

15

Page 14

Description

The fan cools the appliance and comes into

operation during cooking. The fan causes a

steady outflow of air that exits from the rear

of the appliance and which may continue

for a brief period of time even after the

appliance has been turned off.

Do not obstruct ventilation

openings and heat dispersal slots.

Interior lighting

The appliance’s interior lighting comes on:

(main oven)

• when the door is opened;

• when any function is selected, apart from

the function.

when the door is open, it is not

possible to turn off the interior

lighting.

2.5 Available accessories

Not all accessories are available

on some models.

The oven accessories intended to

come into contact with food are

made of materials that comply with

the provisions of current legislation.

Original supplied and optional

accessories can be requested to

Authorised Assistance Centres.

Use only original accessories

supplied by the manufacturer.

Ring reducer

Useful when using small cookware.

(auxiliary oven)

• when the auxiliary oven temperature/

function knob is turned to the

symbol or to any function.

16

Wok rack (on some models only)

Useful when using a wok.

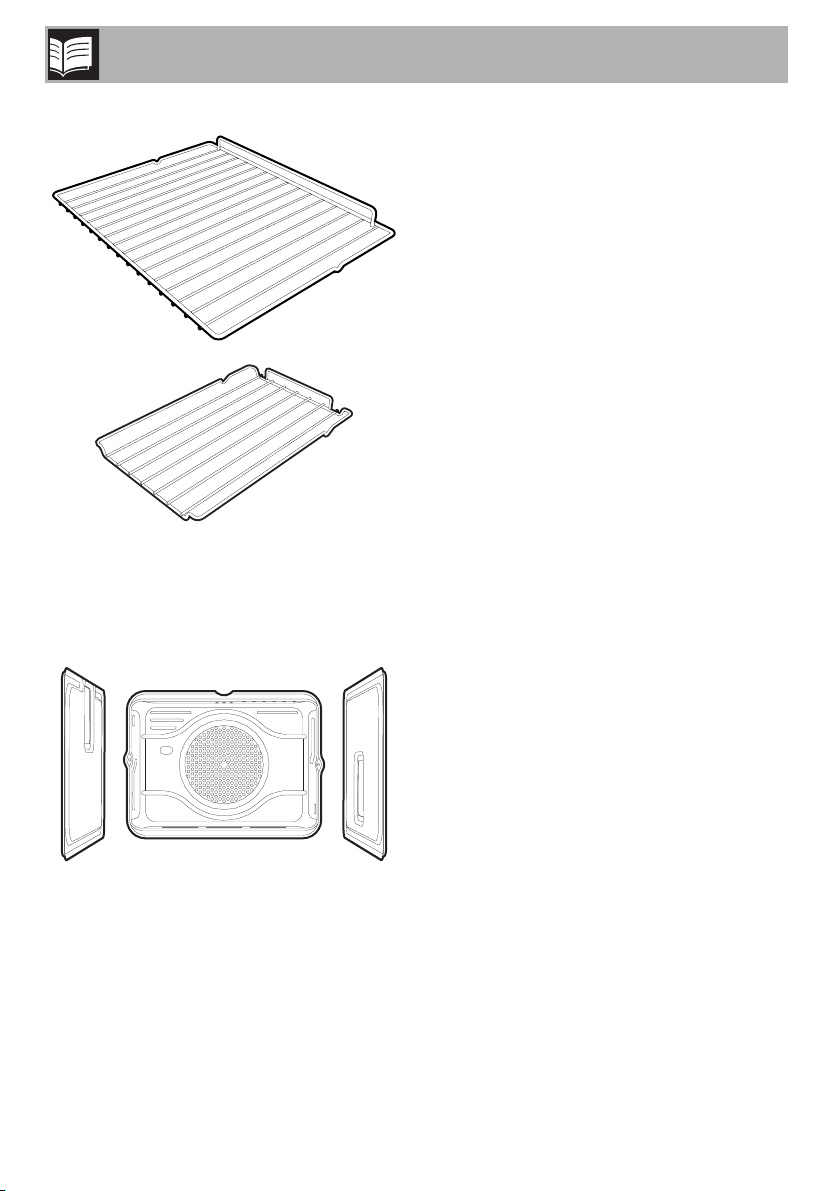

Page 15

Description

Tray (on some models only)

Useful for collecting fat from foods placed

on the rack above.

Deep tray

Tray rack

EN

To be placed over the top of the tray; for

cooking foods which may drip.

Useful for collecting fat from foods placed

on the rack above and for cooking pies,

pizzas and baked desserts.

17

Page 16

Description

Rack

Useful for supporting containers with food

during cooking.

Self-cleaning panels (on some models

only)

Useful for absorbing small grease residues.

18

Page 17

Use

3 Use

High temperature inside the oven

during use

Danger of burns

• Keep the oven door closed during

cooking.

• Protect your hands wearing heat

resistant gloves when moving food

inside the oven.

• Do not touch the heating elements inside

the oven.

• Do not pour water directly on very hot

trays.

• Keep children under the age of 8 away

from the oven when it is in use.

• If you need to move food or at the end

of cooking, open the door 5 cm for a

few seconds, let the steam come out,

then open it fully.

Improper use

Danger of burns

• Make sure that the flame-spreader

crowns are correctly positioned in their

seats with their respective burner caps.

• Oils and fats could catch fire if

overheated. Be very careful.

High temperature inside the

storage compartment

Danger of burns

• Do not open the storage compartment

when the appliance is on and still hot.

• The items inside the storage

compartment could be very hot after

using the appliance.

• It must not be used to store flammable

materials, cloths or paper.

Improper use

Risk of damage to surfaces

• Do not cover the bottom of the oven

cavity with aluminium or tin foil sheets.

• If you wish to use greaseproof paper,

place it so that it will not interfere with the

hot air circulation inside the oven cavity.

• Do not place pans or trays directly on

the bottom of the oven cavity.

• Do not use the open door to place pans

or trays on the internal glazing pane.

• Do not pour water directly on very hot

trays.

• Cooking vessels and griddle plates

should be placed inside the perimeter of

the hob.

• All pans must have smooth, flat bottoms.

• If any liquid does boil over or spill,

remove the excess from the hob.

EN

19

Page 18

Use

High temperature inside the

storage compartment

Danger of fire or explosion

• Do not spray any spray product near the

appliance.

• Do not use or leave flammable materials

near the appliance or the storage

compartment.

• Do not use plastic cookware or

containers for cooking.

• Do not place sealed tins or containers in

the oven cavity.

• Do not leave the appliance unattended

during cooking operations where fats

and oils could be released.

• Remove all trays and racks which are

not required during cooking.

A gas leak can cause an explosion.

If you smell gas or there are faults in the gas

system:

• Immediately turn off the gas supply or

close the valve on the gas cylinder.

• Extinguish all open flames and cigarettes.

• Do not turn on power switches or

appliances and do not remove plugs

from power sockets. Do not use phones

or mobile phones inside the building.

• Open the window in order to ventilate

the room.

• Call customer assistance services or your

gas supplier.

Malfunctions

Any of the following indicate a malfunction

and you should contact a service centre:

• Yellowing of the burner plate.

• Damage to kitchen utensils.

• The burners do not ignite properly.

• It is difficult to keep the burners lit.

• The burners go out when the appliance

is in use.

• It is difficult to turn the gas valves.

If the appliance does not work properly,

contact your local Authorised Service

Centre.

First use

1. Remove any protective film from the

outside or inside of the appliance,

including accessories.

2. Remove any labels (apart from the

technical data plate) from the

accessories and from the oven cavity.

3. Remove and wash all the appliance's

accessories (see 4 Cleaning and

maintenance).

4. Heat the empty oven at the maximum

temperature to burn off any residues left

by the manufacturing process.

20

Page 19

Use

3.1 To save energy

• Preheat the appliance only if the recipe

requires it.

• Unless differently stated on the package,

defrost frozen food before placing it in

the cooking compartment.

• In case of multiple cooking, it is

recommended to cook food one after

the other to exploit the already hot

cooking compartment.

• Use dark metal moulds: They help to

absorb the heat better.

• Remove all trays and racks which are not

required during cooking.

• Stop cooking a few minutes before the

time normally used. Cooking will

continue for the remaining minutes with

the heat which has accumulated inside

the oven.

• Reduce any opening of the door to a

minimum to avoid heat dispersal.

• Keep the cooking compartment clean at

all times.

3.2 Using the accessories

Ring reducers

The ring reducers must be placed on the

hob grids. Make sure they are placed

properly.

Tray rack

EN

The tray rack has to be inserted into the tray.

In this way fat can be collected separately

from the food which is being cooked.

21

Page 20

Use

Racks and trays

Racks and trays have to be inserted into the

side guides until they come to a complete

stop.

• The mechanical safety locks that prevent

the rack from being taken out

accidentally have to face downwards

and towards the oven back.

Gently insert racks and trays into

the oven until they come to a stop.

3.3 Using the hob

All the appliance’s control and monitoring

devices are located together on the front

panel. The burner controlled by each knob

is shown next to the knob. The appliance is

equipped with an electronic ignition device.

Simply press the knob and turn it

counterclockwise to the maximum flame

symbol, until the burner ignites. If the burner

does not light in the first 15 seconds, turn the

knob to and wait 60 seconds before

trying again. After lighting, keep the knob

pressed in for a few seconds to allow the

thermocouple to heat up. The burner may

go out when the knob is released: In this

case, the thermocouple has not heated up

sufficiently.

Wait a few moments and repeat the

operation. Keep the knob pressed in

longer.

In case of an accidental switching

off, a safety device will be tripped,

cutting off the gas supply, even if

the gas cock is open. Return the

knob to and wait at least

60 seconds before lighting it

again.

22

Clean the trays before using them

for the first time to remove any

residues left by the manufacturing

process.

Page 21

Use

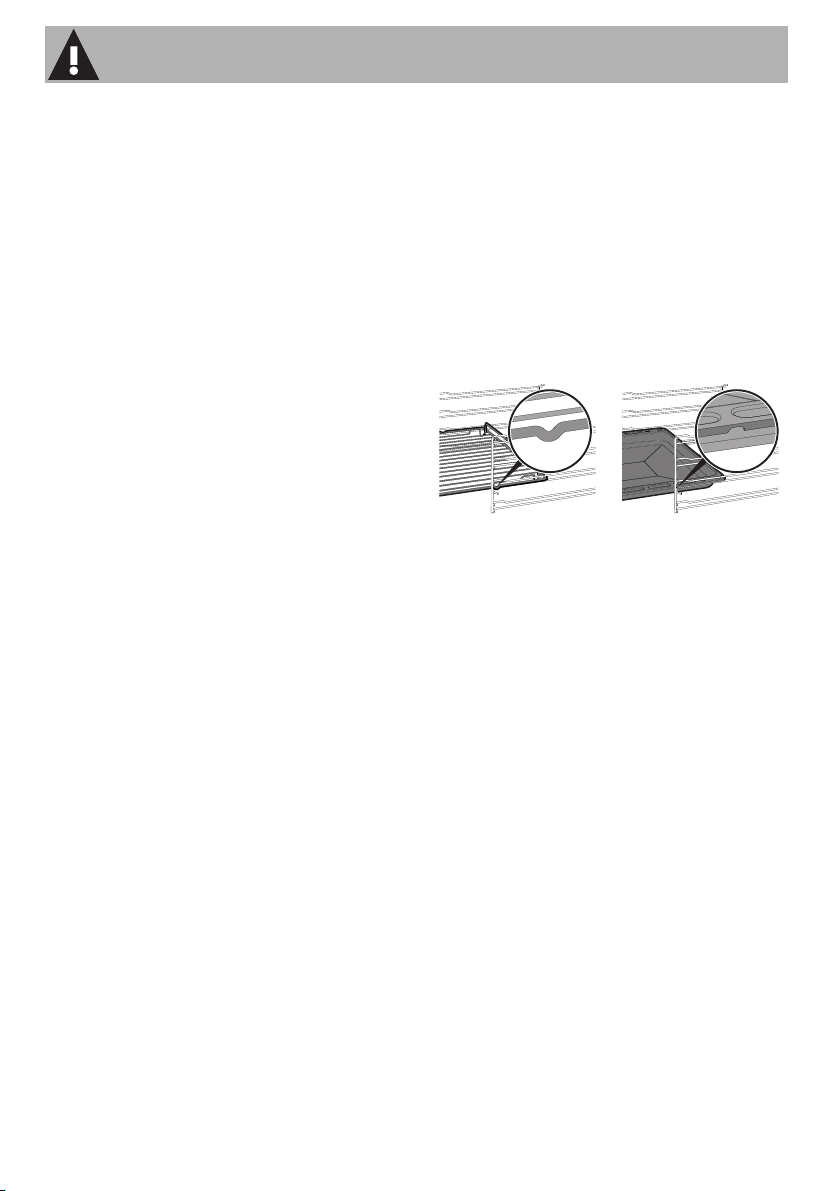

Correct positioning of the flamespreader crowns and burner caps

Before lighting the hob burners, make sure

that the flame-spreader crowns are

correctly positioned in their seats with their

respective burner caps. Make sure that the

holes 1 in the flame-spreader crowns are

aligned with the igniters 3 and

thermocouples 2.

Practical tips for using the hob

For better burner efficiency and to minimise

gas consumption, use pans with lids and of

suitable size for the burner, so that the

flames do not reach up the sides of the pan.

Once the contents come to the boil, turn

down the flame far enough to ensure that

the liquid does not boil over.

Pan diameters:

• AUX: 12 - 14 cm.

• SR: 16 - 24 cm.

• SR: 18 - 26 cm.

• UR-3c: 18 - 28 cm.

3.4 Using the storage compartment

The storage compartment is at the bottom of

the cooker. To open it, pull the handle

towards you. It can be used to store

cookware or metallic objects necessary

when using the appliance.

EN

23

Page 22

3.5 Using the ovens

Use

Switching on the main oven

1. Select the cooking function using the

function knob.

2. Select the temperature using the

temperature knob.

Ensure that the programmer clock

shows the cooking duration

symbol , otherwise it will not

be possible to turn on the oven.

Press the keys and at the

same time to reset the programmer

clock.

Main oven functions

Static

As the heat comes from above and

below at the same time, this system

is particularly suitable for certain

types of food. Traditional cooking,

also known as static cooking, is

suitable for cooking just one dish at

a time. Perfect for all types of roasts,

bread and cakes, and in any case,

particularly suitable for fatty meats

such as goose and duck.

Fan + lower element

The combination of the fan with just

the lower heating element allows

cooking to be completed more

rapidly. This system is

recommended for sterilising or for

finishing off the cooking of foods

which are already well-cooked on

the surface, but not inside, which

therefore need a little more heat.

Perfect for any type of food.

Small grill (on some models only)

Using only the heat released from

the central element, this function

allows you to grill small portions of

meat and fish for making kebabs,

toasted sandwiches and any types

of grilled vegetable side dishes.

Grill

The heat coming from the grill

element gives perfect grilling results

above all for thin and medium

thickness meat and, in combination

with the rotisserie (where fitted),

gives the food an even browning at

the end of cooking. Perfect for

sausages, spare ribs and bacon.

This function enables large

quantities of food, particularly meat,

to be grilled evenly.

24

Page 23

Use

Fan with grill

The air produced by the fan softens

the strong heatwave generated by

the grill, grilling perfectly even very

thick foods. Perfect for large cuts of

meat (e.g. shin of pork).

Fan assisted (on some models

only)

The operation of the fan, combined

with traditional cooking, ensures

consistent cooking even with

complex recipes. Perfect for biscuits

and cakes, even when

simultaneously cooked on several

levels. (For multiple-level cooking,

we recommend using the 2nd and

4th runners).

Turbo (on some models only)

The combination of fan assisted

cooking and traditional cooking

allows different foods to be cooked

on several levels extremely quickly

and efficiently, without odours and

flavours mingling. Perfect for large

volumes that call for intense

cooking.

Fan with round heating element

The combination of the fan and the

round heating element

(incorporated in the rear of the

oven) allows you to cook different

foods on several levels, as long as

they need the same temperatures

and same type of cooking. Hot air

circulation ensures instant and even

distribution of heat. It will be

possible, for instance, to cook fish,

vegetables and biscuits

simultaneously (on different levels)

without odours and flavours

mingling.

Fan + lower element (on some

models only)

The combination of the fan with just

the lower heating element allows

cooking to be completed more

rapidly. This system is

recommended for sterilising or for

finishing off the cooking of foods

which are already well-cooked on

the surface, but not inside, which

therefore need a little more heat.

Perfect for any type of food.

In pyrolytic models, the special

defrost and proving functions are

brought together under the same

function.

EN

25

Page 24

Use

Eco

This function is particularly suitable

for cooking on a single shelf with

low energy consumption.

It is recommended for all types of

food, excluding those that can

create a lot of humidity (such as

vegetables).

To obtain maximum energy savings

and reduce cooking times, it is

recommended to place food in the

oven without preheating.

When using the ECO function,

avoid opening the door during

cooking.

Cooking (and preheating) times

are longer with the ECO function.

The ECO function is a delicate

cooking function and is

recommended for food

withstanding temperatures lower

than 210 °C; in case of cooking

at higher temperatures, select

another function.

Vapor Clean (on some models

only)

This function makes cleaning easier

using the steam produced by a little

quantity of water poured onto the

appropriate groove placed on the

bottom. (see chapter “Cleaning and

maintenance”)

Pyrolytic (on some models only)

Setting this function, the oven

reaches temperatures up to

500 °C, destroying all the grease

which forms on the internal walls.

26

Page 25

Switching on the auxiliary oven

Use

Turn the temperature/function knob to the

required temperature, from a minimum of

50 °C to a maximum of 245 °C, or to the

required function (at the maximum

temperature).

Auxiliary oven functions

Light bulb

Turns on the light inside the oven

cavity.

Static (min 50 °C - max 245 °C)

As the heat comes from above and

below at the same time, this system

is particularly suitable for certain

types of food. Traditional cooking,

also known as static cooking, is

suitable for cooking just one dish at

a time. Perfect for all types of roasts,

bread and cakes, and in any case,

particularly suitable for fatty meats

such as goose and duck.

Lower heating element (245 °C)

The heat coming just from the

bottom allows you to complete the

cooking of foods that require a

higher bottom temperature, without

affecting their browning. Perfect for

cakes, pies, tarts and pizzas.

Small grill (245 °C)

Using only the heat released from

the central element, this function

allows you to grill small portions of

meat and fish for making kebabs,

toasted sandwiches and any types

of grilled vegetable side dishes.

Grill

The heat coming from the grill

element gives perfect grilling results

above all for thin and medium

thickness meat and allows you to

give the food an even browning at

the end of the cooking. Perfect for

sausages, spare ribs and bacon.

This function enables large

quantities of food, particularly meat,

to be grilled evenly.

EN

27

Page 26

Use

General advice

• Use a fan assisted function to achieve

consistent cooking at several levels.

• It is not possible to shorten cooking times

by increasing the temperature (the food

could be overcooked on the outside and

undercooked on the inside).

• For the same total weight, cooking time

will be greater for cooking a whole

piece than when it is cut into smaller

pieces.

Advice for cooking meat

• Cooking times vary according to the

thickness and quality of the food and to

consumer taste.

• Use a meat thermometer when roasting

meat, or simply press on the roast with a

spoon. If it is hard, it is ready; If not, it

needs another few minutes cooking.

Advice for cooking with the Grill

• Meat can be grilled even when it is put

into the cold oven or into the preheated

oven if you wish to change the effect of

the cooking.

• When using the Fan with grill function,

we recommend that you preheat the

oven before grilling.

• We recommend placing the food at the

centre of the rack.

• With the Grill function, we recommend

that you turn the temperature knob to the

maximum value to optimise cooking.

Advice for cooking desserts/pastries and

biscuits

• Use dark metal moulds: They help to

absorb the heat better.

• The temperature and the cooking time

depend on the quality and consistency

of the dough.

• When cooking on multiple levels, food

should ideally be positioned on the

second and fourth shelves; increase

cooking time by a few minutes and only

used fan functions.

• To check whether the dessert is cooked

right through: At the end of the cooking

time, put a toothpick into the highest point

of the dessert. If the dough does not stick

to the toothpick, the dessert is cooked.

• If the dessert collapses when it comes out

of the oven, on the next occasion reduce

the set temperature by about 10 °C,

selecting a longer cooking time if

necessary.

• The cooking time for meringues and

choux pastry will vary depending on the

size.

28

Page 27

Use

Advice for defrosting and proving

• Place frozen foods without their

packaging in a lidless container on the

first shelf of the oven.

• Avoid overlapping the food.

• To defrost meat, use the rack placed on

the second level and a tray on the first

level. In this way, the liquid from the

defrosting food drains away from the

food.

• Bread and fruit, if divided into pieces, will

take the same amount of time to defrost,

regardless of the total weight and

quantity.

• The most delicate parts can be covered

with aluminium foil.

• For successful proving, a container of

water should be placed in the bottom of

the oven.

3.6 Programmer clock

EN

Minute minder timer key

Cooking duration key

End of cooking key.

Decrease key

Increase key

The programmer clock only

controls the main oven and does

not control the auxiliary oven.

Ensure that the programmer clock

shows the cooking duration

symbol , otherwise it will not

be possible to turn on the oven.

Press the keys and at the

same time to reset the programmer

clock.

29

Page 28

Use

Setting the time

If the time is not set, the oven will

not switch on.

On the first use, or after a power failure, the

digits will be flashing on the

appliance’s display.

1. Press the keys and at the same

time. The dot between the hours and the

minutes flashes.

2. The time can be set using the key or

. Keep the key pressed in to increase

or decrease rapidly.

3. Press the key or wait 5 seconds. The

dot between the hours and the minutes

stops flashing.

4. The symbol on the display indicates

that the appliance is ready to start

cooking.

Timed cooking

Timed cooking is the function

which allows a cooking operation

to be started and then ended after

a specific length of time set by the

user.

1. After selecting a cooking function and

temperature, press the key. The

display will show the digits

and the symbol displayed between

the hours and the minutes.

2. Use the or key to set the

required minutes.

3. Wait approx. 5 seconds without pressing

any key in order for the function to

activate. The current time and the

symbols and will appear on the

display.

4. At the end of cooking the heating

elements will be deactivated. On the

display, the symbol turns off, the

30

symbol flashes and the buzzer

sounds.

Page 29

Use

5. To turn off the buzzer just press any key

of the programmer clock.

6. Press the keys and at the same

time to reset the programmer clock.

It is not possible to set a cooking

time of more than 10 hours.

After the setting, to display the

cooking time left press the

key.

To reset the set program, press the

keys and at the same

time and switch off the oven

manually.

Programmed cooking

Programmed cooking is the

function which allows a cooking

operation to be started at a set

time and then ended after a

specific length of time set by the

user.

1. Set the cooking time as described in the

previous point “Timed cooking”.

2. Press the key. The sum of the current

time plus the pre-set cooking duration

will appear on the display.

3. Use the or key to set the

required minutes.

4. Wait approx. 5 seconds without pressing

any key in order for the function to

activate. The current time and the

symbols and will appear on the

display.

5. At the end of cooking the heating

elements will be deactivated. On the

display, the symbol turns off, the

EN

symbol flashes and the buzzer

sounds.

31

Page 30

Use

6. To turn off the buzzer just press any key

of the programmer clock.

7. Press the keys and at the same

time to reset the programmer clock.

After the setting, to display the

cooking time left press the

key. To display the end of cooking

time, press the key.

Adjusting the buzzer volume

The buzzer volume can be set to 3 different

levels. When the buzzer is in operation,

press the key to change the setting.

Deleting the set data

Press the keys and at the same

time to reset the programs set.

Then switch off the oven manually if cooking

is in progress.

Minute minder timer

The minute minder timer does not

stop the cooking operation but

rather informs the user when the set

time has run out.

The minute minder timer can be activated at

any time.

1. Press the key. The display shows the

digits and the indicator light

flashing between the hours and the

minutes.

2. Use the or key to set the

required minutes.

3. Wait approx. 5 seconds without pressing

any key to finish setting the minute

minder. The current time and the symbols

and appear on the display.

It is not possible to set a cooking

time of more than 24 hours.

32

After the minute minder timer has

been programmed, the display will

go back to showing the current

time. Press the key to display

the remaining time.

Page 31

Main oven cooking information table

Food

Lasagne

Pasta bake

Weight

(kg)

3 - 4 Static 1 220 - 230 45 - 50

3 - 4 Static 1 220 - 230 45 - 50

Function Shelf

Use

Temperature

(°C)

Time

(minutes)

EN

Roasted veal

Pork loin

Sausages

Roast beef

Roast rabbit

Turkey breast

Roast pork neck

Roast chicken

Pork chops

Spare ribs

Bacon

Pork fillet

Beef fillet

Salmon trout

Delicate fish

Flounder

Pizza

Bread

Focaccia

2 Turbo/Round 2 180 - 190 90 - 100

2 Turbo/Round 2 180 - 190 70 - 80

1.5 Fan with grill 4 260 15

1 Turbo/Round 2 200 40 - 45

1.5 Round 2 180 - 190 70 - 80

3 Turbo/Round 2 180 - 190 110 - 120

2 - 3 Turbo/Round 2 180 - 190 170 - 180

1.2 Turbo/Round 2 180 - 190 65 - 70

1nd 2nd

1.5 Fan with grill 4 260 15 5

1.5 Fan with grill 4 260 10 10

0.7 Grill 5 260 7 8

1.5 Fan with grill 4 260 10 5

1 Grill 5 260 10 7

1.2 Turbo/Round 2 150 - 160 35 - 40

1.5 Turbo/Round 2 160 60 - 65

1.5 Turbo/Round 2 160 45 - 50

1 Turbo/Round 2 260 8 - 9

1 Round 2 190 - 200 25 - 30

1 Turbo/Round 2 180 - 190 20 - 25

Ring cake

Tart

Ricotta cake

Jam tarts

Chiffon cake

Profiteroles

Sponge cake

Rice pudding

Brioches

1 Round 2 160 55 - 60

1 Round 2 160 35 - 40

1 Round 2 160 - 170 55 - 60

1 Turbo/Round 2 160 20 - 25

1.2 Round 2 160 55 - 60

1.2 Turbo/Round 2 180 80 - 90

1 Round 2 150 - 160 55 - 60

1 Turbo/Round 2 160 55 - 60

0.6 Round 2 160 30 - 35

33

Page 32

Auxiliary oven cooking information table

Use

Food

Roast rabbit

Roast chicken

Chops

Hamburgers

Pork sausages

Pork spare ribs

Bacon

The times indicated in the table do not include preheating times and are provided only as a guide.

Weight

(kg)

1 Static 2

1 Static 2 190 - 200 80 - 85

0.8 Grill 4 250 13 5

0.6 Grill 4

0.6 Grill 4

0.7 Grill 4

0.6 Grill 4

Function Shelf

Temperature

(°C)

190 - 200

250

250

250 30 250

Time

(minutes)

85 - 90

1nd 2nd

73

15 -

-

10 3

34

Page 33

Cleaning and maintenance

4 Cleaning and maintenance

Improper use

Risk of damage to surfaces

• Do not use steam jets to clean the

appliance.

• Do not use cleaning products containing

chlorine, ammonia or bleach on parts

made of steel or that have metallic

surface finishes (e.g. anodizing, nickelor chromium-plating).

• Do not use abrasive or corrosive

detergents (e.g. scouring powders, stain

removers and metallic sponges) on

glass parts.

• Do not use rough or abrasive materials

or sharp metal scrapers.

• Do not wash the removable

components such as the hob grids,

flame-spreader crowns and burner caps

in a dishwasher.

We recommend the use of

cleaning products distributed by

the manufacturer.

Ordinary daily cleaning

Always use specific products only that do

not contain abrasives or chlorine-based

acids.

Pour the product onto a damp cloth and

wipe the surface, rinse thoroughly and dry

with a soft cloth or a microfibre cloth.

Food stains or residues

Do not use steel sponges and sharp

scrapers, as they will damage the surfaces.

Use normal, non-abrasive products and a

wooden or plastic tool, if necessary. Rinse

thoroughly and dry with a soft cloth or a

microfibre cloth.

Do not allow residues of sugary foods (such

as jam) to set inside the oven. If left to set for

too long, they might damage the enamel

lining of the oven.

After cleaning, dry the appliance

thoroughly to prevent water or

detergent drips from interfering

with its operation or creating

unsightly marks.

EN

4.1 Cleaning the surfaces

To keep the surfaces in good condition,

they should be cleaned regularly after use.

Let them cool first.

35

Page 34

Cleaning and maintenance

4.2 Cleaning the hob

Cooking hob grids

Remove the grids and clean them in

lukewarm water and non-abrasive

detergent. Make sure to remove any

encrustations. Dry them thoroughly and

return them to the hob.

The continuous contact between

the grids and the flame can cause

modifications to the enamel over

time in those parts exposed to

heat. This is a completely natural

phenomenon which has no effect

on the operation of this

component.

Flame-spreader crowns and burner caps

For easier cleaning, the flame-spreader

crowns and the burner caps can be

removed. Wash them in hot water and nonabrasive detergent. Carefully remove any

encrustation, then wait until they are

perfectly dry. Refit the flame-spreader

crowns making sure that they are correctly

positioned in their housings with their

respective burner caps.

Igniters and thermocouples

For correct operation the igniters and

thermocouples must always be perfectly

clean. Check them frequently and clean

them with a damp cloth if necessary.

Remove any dry residues with a wooden

toothpick or a needle.

Knobs

Do not use aggressive products

containing alcohol or products for

cleaning steel and glass when

cleaning the knobs, as these

products could cause permanent

damage.

The knobs should be cleaned with a soft

cloth dampened with warm water, then

dried carefully. They can be removed by

pulling them out of their housing.

36

Page 35

Cleaning and maintenance

4.3 Cleaning the door

Removing the door

For easier cleaning, the door can be

removed and placed on a towel.

To remove the door proceed as follows:

1. Open the door completely and insert two

pins into the holes on the hinges

indicated in the figure.

2. Grasp the door on both sides with both

hands, lift it forming an angle of around

30° and remove it.

3. To reassemble the door, put the hinges in

the relevant slots in the oven, making sure

that grooved sections A are resting

completely in the slots. Lower the door

and once it is in position, remove the pins

from the holes in the hinges.

Cleaning the door glazing

The door glazing should always be kept

thoroughly clean. Use absorbent kitchen

roll. In case of stubborn dirt, wash with a

damp sponge and an ordinary detergent.

EN

37

Page 36

Cleaning and maintenance

Removing the internal glass panes

For easier cleaning, the internal glass panes

of the door can be removed.

1. Remove the internal glass pane by

pulling the rear part gently upwards

following the movement indicated by the

arrows (1). This way, the 4 pins attached

to the glass detach from their housings in

the door.

2. Then, pull the front part upwards (2).

3. Remove the intermediate glazing pane

by lifting it upwards. Proceed in the same

way for the internal glazing pane, but

push the front part of the pane (2)

towards the inside of the appliance.

4. Clean the external glass pane and the

previously removed panes. Use

absorbent kitchen roll. In case of

stubborn dirt, wash with a damp sponge

and neutral detergent.

5. Refit the panes in the reverse order of

removal.

6. Reposition the internal glass pane. Take

care to centre and insert the 4 pins into

their housings in the oven door by

applying slight pressure.

38

Page 37

Cleaning and maintenance

4.4 Cleaning the oven cavities

For the best oven cavities upkeep, clean

them regularly after having allowed them to

cool.

Avoid letting food residue dry inside the

oven cavities, as this could damage the

enamel.

Take out all removable parts.

For easier cleaning, it is

recommended to remove:

• the door

• the rack/tray support frames

• the oven gasket

Removing racks/trays support frames

Removing the guide frames enables the

sides to be cleaned more easily. This

operation should be performed each time

the automatic cleaning cycle is used (on

some models only).

To remove the guide frames. Pull the frame

towards the inside of the oven to unhook it

from its groove A, then slide it out of the

seats B at the back.

When cleaning is complete, repeat the

above procedures to put the guide frames

back in.

EN

The oven should be operated at

the maximum temperature for

about 15-20 minutes after the use

of specific products, to burn off the

residues left inside the oven.

39

Page 38

Cleaning and maintenance

Removing self-cleaning panels and rack/

tray support frames (fitted only to some

models)

Removing the guide frames enables the

sides to be cleaned more easily. This

operation should be performed each time

the automatic cleaning cycle is used (on

some models only).

To remove the guide frames. Pull the frame

towards the inside of the oven to unhook it

from its groove A, then slide it out of the

seats B at the back.

When cleaning is complete, repeat the

above procedures to put the guide frames

back in.

Regeneration of self-cleaning panels

(catalysis cycle) (on some models only)

The regeneration cycle of the self-cleaning

panels is a cleaning method through

heating suitable for removing small grease

residues, not sugar-based ones.

1. Clean the base and the upper guard first

with a microfibre cloth soaked in water

and neutral washing up liquid. Rinse

thoroughly.

2. Set a regeneration cycle by selecting a

fan assisted function at the maximum

temperature for one hour.

3. If the panels are particularly dirty after the

regeneration cycle, remove them and

wash them with neutral washing up

liquid. Rinse and dry them.

Put the panels back in the oven and set a

fan assisted function at a temperature of

180 °C for one hour, in order to ensure that

they are thoroughly dry.

We recommend carrying out the

self-cleaning panel regeneration

cycle every 15 days.

40

Page 39

Cleaning and maintenance

4.5 Vapor Clean (on some models

only)

Vapor Clean is an assisted

cleaning procedure which

facilitates the removal of dirt.

Thanks to this process, it is possible

to clean the inside of the main

oven very easily. The dirt residues

are softened by the heat and

water vapour for easier removal

afterwards.

Improper use

Risk of damage to surfaces

• Remove any food residues or large spills

from previous cooking operations from

the inside of the oven.

• Carry out assisted oven cleaning

operations only when the oven is cold.

EN

• Spray a water and washing up liquid

solution inside the oven using a spray

nozzle. Direct the spray against the side

walls, upwards, downwards and

towards the deflector.

Preliminary operations

Before starting the Vapor Clean cycle:

• Remove all accessories from inside the

oven cavity.

• Pour approx. 40 cc of water onto the

floor of the oven. Make sure it does not

overflow out of the cavity.

We recommend spraying approx.

20 times at the most.

• Close the door.

• During the assisted cleaning cycle, wash

the self-cleaning panels (where fitted),

which were previously removed,

separately in warm water and a small

amount of detergent.

41

Page 40

Cleaning and maintenance

Vapor Clean cycle setting

1. Turn the function knob to the symbol

and the temperature knob to the symbol

.

2. Set a cooking time of 18 minutes using

the digital programmer.

3. Turn the function knob to the symbol

and the temperature knob to the 0

symbol.

End of the Vapor Clean cycle

4. Open the door and wipe away the less

stubborn dirt with a microfibre cloth.

5. Use a non-scratch sponge with brass

filaments on hard to remove deposits.

6. In case of grease residues use specific

oven cleaning products.

7. Remove the water left inside the oven.

For improved hygiene and to avoid food

being affected by any unpleasant odours,

we recommend that the oven is dried using

a fan assisted function at 160 °C for

approximately 10 minutes.

We recommend wearing rubber

gloves for these operations.

For easier manual cleaning of

parts that are difficult to reach, we

recommend removing the door.

42

Page 41

Cleaning and maintenance

4.6 Pyrolytic (on some models only)

Pyrolytic cleaning is an automatic

high-temperature cleaning

procedure which causes dirt to

dissolve. Thanks to this process, it is

possible to clean the inside of the

main oven very easily.

If the auxiliary oven is on or is still

hot after cooking, it will not be

possible to start an automatic

cleaning cycle of the main oven.

If the auxiliary oven is turned on

during the pyrolytic cycle, the main

oven will stop the automatic

cleaning cycle.

Improper use

Risk of damage to surfaces

• Remove any food residues or large spills

from previous cooking operations from

the inside of the oven.

• Switch off the burners or electric hot

plates of the hob.

Preliminary operations

• For very stubborn encrustations spray an

oven cleaning product onto the glass

(read the warnings on the product);

leave for 60 minutes, then rinse and dry

the glass using kitchen roll or a microfibre

cloth.

• Remove all accessories from inside the

oven cavity.

• Remove the rack/tray support frames.

• Detach removable guides, where fitted.

• Close the door.

Pyrolytic function setting

1. Turn the function knob to symbol .

2. Press followed by .

3. Hold down and use or to

set the cleaning cycle time from a

minimum of 1 hour and 30 minutes to a

maximum of 3 hours.

Recommended pyrolytic cycle

duration:

• Light dirt: 2 hours.

• Medium dirt: 2 hours and ½.

• Heavy dirt: 3 hours.

EN

Before starting the pyrolytic cycle:

• Clean the internal glass pane following

the usual cleaning instructions.

43

Page 42

Cleaning and maintenance

Setting of programmed pyrolytic cycle

The pyrolytic cycle start time can be

programmed using the programmer clock.

4. After selecting the pyrolytic cycle

duration, press . The time when the

cleaning cycle will terminate will appear

on the display.

5. Press and hold and use or

to set the time at which you wish to

complete the pyrolytic cycle.

Pyrolytic cycle

6. Two minutes after the pyrolytic cycle has

started the door is locked (the door lock

indicator light comes on) by a device

that prevents the door from being

opened.

It is not possible to select any

function once the door lock device

has been activated.

7. At the end of the pyrolytic cycle, the door

remains locked as long as the

temperature inside the oven returns to

safety levels.

8. At the end of the pyrolytic cycle, wait for

the oven to cool down and collect the

residues deposited inside with a damp

microfibre cloth.

During the first pyrolytic cycle,

unpleasant odours may occur due

to the normal evaporation of oily

manufacturing substances. This is

an absolutely normal phenomenon

which disappears after the first

pyrolytic cycle.

During the pyrolytic cycle the fans

produce a more intense level of

noise due to a greater rotation

speed. This is an absolutely normal

operation, intended to provide

more effective heat dispersal. At

the end of the pyrolytic cycle, the

fans will continue to operate for

long enough to avoid overheating

the walls of adjacent units and the

front of the oven.

If the pyrolytic cycle gives

unsatisfactory results at minimum

duration, it is recommended to set

a longer time for successive

cleaning cycles.

44

Page 43

Cleaning and maintenance

4.7 Extraordinary maintenance

Replacing the interior light bulb

(main oven)

Live parts

Danger of electrocution

• Unplug the appliance from the mains.

1. Remove all accessories from inside the

oven cavity.

2. Remove the rack/tray support frames.

3. Remove the bulb cover using a tool

(e.g. a screwdriver).

Take care not to scratch the

enamel of the oven cavity wall.

4. Slide out and remove the light bulb.

EN

Do not touch the halogen light

bulb directly with your fingers, use

an insulating material.

5. Replace the light bulb with one of the

same type (40 W).

6. Refit the cover. Ensure the moulded part

of the glass (A) is facing the door.

7. Press the cover down as far as it will go

so that it attaches completely to the bulb

support.

45

Page 44

Cleaning and maintenance

Replacing the interior light bulb

(auxiliary oven)

1. Unscrew bulb protector A (turn anticlockwise).

2. Replace bulb B with one of the same

type (25 W). Use only oven bulbs

(T 300 °C).

3. Re-fit bulb protector A.

Installing and removing the oven seal

(pyrolitic oven excluded)

To remove the seal:

• Unhook the clips in the 4 corners then

pull the seal outwards.

To refit the seal:

• Hook the clips in the 4 corners onto the

seal.

Seal maintenance tips

The seal should be soft and elastic.

• To keep the seal clean, use a nonabrasive sponge and wash with

lukewarm water.

46

Page 45

Installation

5 Installation

5.1 Gas connection

Gas leak

Danger of explosion

• After carrying out any operation, check

that the tightening torque of gas

connections is between 10 Nm and

15 Nm.

• If required, use a pressure regulator that

complies with current regulations.

• At the end of the installation, check for

any leaks with a soapy solution, never

with a flame.

• Installation using a hose must be carried

out so that the length of the hose does

not exceed 2 metres when fully

extended for steel hoses and 1.5 metres

for rubber hoses.

• The hoses should not come into contact

with moving parts and should not be

crushed in any way.

General information

Connection to the gas mains can be made

using a continuous wall steel hose in

compliance with the guidelines established

by the standards in force. The appliance is

preset for natural gas G20 (2H) at a

pressure of 20 mbar. For supplying it with

other types of gas, see chapter “5.2

Adaptation to different types of gas”. The

gas inlet connection is threaded ½”

external gas (ISO 228-1).

Connection with a rubber hose

Verify that all following conditions are met:

• the hose is attached to the hose

connector with safety clamps;

• no part of the hose is in contact with hot

walls (max. 50 °C);

• the hose is not under traction or tension

and has no kinks or twists;

• the hose is not in contact with sharp

objects or sharp corners;

• if the hose is not perfectly airtight and

leaks gas, do not try to repair it; replace

it with a new hose;

• verify that the hose is not past its expiry

date (serigraphed on the hose itself).

Make the connection to the gas mains

using a rubber hose whose specifications

comply with current standards (verify that

the reference standard is stamped on the

hose).

EN

47

Page 46

Installation

Carefully screw the hose connector 3 to the

appliance’s gas connector 1 (½” thread

ISO 228-1), placing the seal 2 between

them. The hose connector 4 can also be

screwed to the hose connector 3,

depending on the diameter of the gas hose

used. After having tightened the hose

connector(s), push the gas hose 6 onto the

hose connector and secure it with the clamp

5 that is compliant with the standard in

force.

Connection using a rubber hose

complying with current standards is

only permitted if the hose can be

inspected along its entire length.

The inside diameter of the hose

must be 8 mm for LPG and 13 mm

for Natural gas and Town gas.

Connection with a steel hose

Make the connection to the gas mains

using a continuous wall steel hose whose

specifications comply with the applicable

standard.

Carefully screw the connector 3 to the gas

connector 1 of the appliance, placing the

seal 2 between them.

Connection with a steel hose with

bayonet fitting

Carry out the connection to the gas mains

using a steel hose with bayonet fitting

compliant with B.S. 669. Apply insulating

material to the thread of the gas hose

connector 4 and then tighten the adapter 3.

Screw the assembly to the movable

connector 1 of the appliance, placing the

supplied seal 2 between them.

48

Page 47

Installation

Connection to LPG

Use a pressure regulator and make the

connection on the gas cylinder following

the guidelines set out in the standards in

force.

The supply pressure must comply with the

values indicated in the table “Gas types

and Countries”.

Connection with a steel hose with conical

fitting

Make the connection to the gas mains

using a continuous wall steel hose whose

specifications comply with the applicable

standard.

Carefully screw the hose connector 3 to the

appliance’s gas connector 1 (½” thread

ISO 228-1), placing the supplied seal 2

between them. Apply insulating material to

the thread of connector 3, then tighten the

steel hose 4 to the connector 3.

Room ventilation

The appliance should be installed in rooms

that have a permanent air supply in

accordance with the standards in force. The

room where the appliance is installed must

have enough air flow for the regular

combustion of gas and the necessary air

change in the room itself. The air vents,

protected by grilles, must be the right size to

comply with current regulations and

positioned so that no part of them is

obstructed, not even partially.

The room must be kept adequately

ventilated in order to eliminate the heat and

humidity produced by cooking: In

particular, after prolonged use, you are

recommended to open a window or to

increase the speed of any fans.

Extraction of the combustion products

This appliance is not connected to

an exhaust system for combustion

products. It must be installed and

connected in compliance with the

current installation regulations.

Special attention should be paid to

the relevant requirements as for

ventilation.

EN

The combustion products may be extracted

by means of hoods connected to a natural

draught chimney whose efficiency is certain

or via forced extraction.

49

Page 48

Installation

An efficient extraction system requires

precision planning by a specialist qualified

in this area and must comply with the

positions and clearances indicated by the

applicable standards.

When the job is complete, the installer must

issue a certificate of conformity.

1 Extraction using a hood

2 Extraction without a hood

A Single natural draught chimney

B Single chimney with extractor fan

C Directly outdoors with wall- or window-

mounted extractor fan

D Directly outdoors through wall

5.2 Adaptation to different types of

gas

Improper installation

Risk of malfunction

• In the case of conversion to Town Gas

G110 – 8 mbar (category 1a), do not

use the burners provided, but request the

special G110 burners kit from our

Technical Assistance Service.

The appliance is preset for natural

gas G20 at a pressure of

20 mbar.

In case of operation with other types of gas,

the burner nozzles must be changed and

the minimum flame adjusted on the gas

taps.

Replacing nozzles

1. Remove the grids, burner caps and

flame-spreader crowns in order to

access the burner cups.

Air

Combustion products

Extractor fan

50

2. Replace the nozzles using a 7-mm socket

wrench according to the gas to be used

Page 49

Installation

(see "Nozzle and burner specification

tables").

3. Reposition the burners in their respective

housings.

Adjusting the minimum setting for natural

or town gas

Light the burner and turn it to the minimum

position. Remove the gas tap knob and turn

the adjustment screw next to the tap rod

(depending on the model) until the correct

minimum flame is obtained.

Refit the knob and verify that the burner

flame is stable. Turn the knob rapidly from

the maximum to the minimum setting: The

flame should not go out. Repeat the

operation on all gas cocks.

Adjusting the minimum setting for LPG

Tighten the screw located at the side of the

cock rod clockwise all the way.

Following adjustment to a gas

other than the one originally set in

the factory, replace the gas setting

label on the appliance with the

one corresponding to the new gas.

The label is inserted inside the

nozzle pack (where present).

Lubricating the gas taps

Over time the gas taps may become difficult

to turn and get blocked. Clean them

internally and replace the lubrication

grease.

Lubrication of the gas cocks should

be performed by a specialised

technician.

EN

51

Page 50

Gas types and Countries

Gas types

1 Natural gas G20

G20 20 mbar

G20/25 20/25 mbar

2 Natural gas G20

G20 25 mbar

3 Natural gas G25

G25 25 mbar

G25.3 25 mbar

4 Natural gas G25.1

G25.1 25 mbar

5 Natural gas G25

G25 20 mbar

6 Natural gas G27

G27 20 mbar

7 Natural gas G2.350

G2.350 13 mbar

8 LPG G30/31

G30/31 28/37 mbar

G30/31 30/37 mbar

G30/31 30/30 mbar

9 LPG G30/31

G30/31 37 mbar

10 LPG G30/31

G30/31 50 mbar

11 Town gas G110

G110 8 mbar

12 Town gas G120

G120 8 mbar

Installation

EN GB-IE FR-BE DE AT NL ES PT SE RU DK PL HU

• • •• •••••

•

•

•

•

•

•

•

•

•• • •

••

•••

•

••

•••

•

52

It is possible to identify the

available gas types based on the

country the appliance is to be

installed in. Refer to the heading

number to identify the correct

values in the “Burner and nozzle

specifications tables”.

Page 51

Installation

Burner and nozzle specifications tables

1 Natural gas G20 AUX SR R UR-3c

Rated heating capacity (kW) 1.0 1.8 2.9 4.0

Nozzle diameter (1/100 mm) 72 94 115 138

Pre-chamber (printed on nozzle) (X) (Z) (Y) (S)

Reduced flow rate (W) 400 500 800 1600

2 Natural gas G20 AUX SR R UR-3c

Rated heating capacity (kW) 1.0 1.8 2.9 4.0

Nozzle diameter (1/100 mm) 72 94 113 135

Pre-chamber (printed on nozzle) (X) (Z) (H8) (S)

Reduced flow rate (W) 400 500 800 1600

3 Natural gas G25 AUX SR R UR-3c

Rated heating capacity (kW) 1.0 1.8 2.8 4.0

Nozzle diameter (1/100 mm) 72 94 115 148

Pre-chamber (printed on nozzle) (F1) (Z) (Y) (F3)

Reduced flow rate (W) 400 500 800 1600

4 Natural gas G25.1 AUX SR R UR-3c

Rated heating capacity (kW) 1.0 1.8 2.9 4.0

Nozzle diameter (1/100 mm) 77 100 134 152

Pre-chamber (printed on nozzle) (F1) (Y) (F3) (F3)

Reduced flow rate (W) 400 500 800 1600

5 Natural gas G25 AUX SR R UR-3c

Rated heating capacity (kW) 1.0 1.8 2.9 3.9

Nozzle diameter (1/100 mm) 77 100 134 152

Pre-chamber (printed on nozzle) (F1) (Y) (F3) (F3)

Reduced flow rate (W) 400 500 800 1600

6 Natural gas G27 AUX SR R UR-3c

Rated heating capacity (kW) 1.0 1.8 2.9 3.9

Nozzle diameter (1/100 mm) 77 105 138 158

Pre-chamber (printed on nozzle) (F1) (Y) (F3) (F3)

Reduced flow rate (W) 400 500 800 1600

7 Natural gas G2.350 AUX SR R UR-3c

Rated heating capacity (kW) 1.0 1.8 2.9 4.0

Nozzle diameter (1/100 mm) 94 120 165 210

Pre-chamber (printed on nozzle) (Y) (Y) (F3) (H3)

Reduced flow rate (W) 400 500 800 1600

EN

53

Page 52

Installation

8 LPG G30/31 AUX SR R UR-3c

Rated heating capacity (kW) 1.0 1.75 2.9 4.0

Nozzle diameter (1/100 mm) 50 65 85 102

Pre-chamber (printed on nozzle) ---Reduced flow rate (W) 400 500 800 1600

Rated flow rate G30 (g/h) 73 127 211 291

Rated flow rate G31 (g/h) 71 125 207 286

9 LPG G30/31 AUX SR R UR-3c

Rated heating capacity (kW) 1.0 1.8 2.9 4.0

Nozzle diameter (1/100 mm) 50 65 81 94

Pre-chamber (printed on nozzle) ---Reduced flow rate (W) 450 550 800 1600

Rated flow rate G30 (g/h) 73 131 211 291

Rated flow rate G31 (g/h) 71 129 207 286

10 LPG G30/31 AUX SR R UR-3c

Rated heating capacity (kW) 1.0 1.8 2.9 3.8

Nozzle diameter (1/100 mm) 43 58 74 77

Pre-chamber (printed on nozzle) (H2) (M) (Z) (F4)

Reduced flow rate (W) 400 500 800 1600

Rated flow rate G30 (g/h) 73 131 211 291

Rated flow rate G31 (g/h) 71 129 207 286

11 Town gas G110 AUX SR R UR-3c

Rated heating capacity (kW) 1.0 1.8 2.8 3.8

Nozzle diameter (1/100 mm) 145 185 260 340

Pre-chamber (printed on nozzle) (/8) (/2) (/3) (/13)

Reduced flow rate (W) 400 500 800 1400

12 Town gas G120 AUX SR R UR-3c

Rated heating capacity (kW) 1.0 1.8 2.9 3.8

Nozzle diameter (1/100 mm) 145 185 260 315

Pre-chamber (printed on nozzle) (/8) (/2) (/3) Reduced flow rate (W) 400 500 800 1400

The nozzles not provided are available at Authorised Service Centres.

WARNING: In the case of conversion to Town Gas G110 – 8 mbar (category

1a), do not use the burners provided, but request the special G110 burners kit

from our Technical Assistance Service.

54

Page 53

Installation

5.3 Positioning

Heavy appliance

Crushing hazard

• Position the appliance into the cabinet

cut-out with the help of a second person.

Pressure on the open door

Risk of damage to the appliance

• Never use the oven door to lever the

appliance into place when fitting.

• Avoid exerting too much pressure on the

door when open.

Heat production during appliance

operation

Risk of fire

• Veneers, adhesives or plastic coatings

on adjacent furniture should be

temperature-resistant (not less than

90 °C).

Any wall units positioned above the

worktop of the appliance must be at a

minimum distance of at least Y mm. If a

hood is installed above the hob, refer to the

hood instruction manual to ensure the

correct clearance is left.

X 150 mm

Y 750 mm

Depending on the type of installation, this

appliance belongs to classes:

EN

This appliance may be installed next to

walls, one of which must be higher than the

worktop, at a minimum distance of X mm

from the side of the appliance, as shown in

figures “A” and “C” relative to the

installation classes.

A - Class 1

(Free-standing appliance)

55

Page 54

Installation

Appliance overall dimensions

A 900 mm

B - Class 2 subclass 1

(Built-in appliance)

C - Class 2 subclass 1

(Built-in appliance)

The appliance must be installed by

a qualified technician and

according to the regulations in

force.

B 600 mm

1

C

min. 150 mm

D 900 - 915 mm

H 750 mm

I 450 mm

2

L

1

Minimum distance from side walls or other

900 mm

flammable material.

2

Minimum cabinet width (=A).

56

Page 55

Installation

Dimensions of the appliance: locations of

gas and electric connections (mm)

A 124

B 38

C 42

D 634

F min. 105 - max. 160

H 776

L 898

E = Electrical connection

G = Gas connection

Positioning and levelling

Heavy appliance

Risk of damage to the appliance

• Insert the front feet first and then the rear

ones.

After making the electrical and/or gas

connections, screw the four adjustable feet

supplied with the appliance.

The appliance must sit level on the floor to

ensure stability.

Screw or unscrew the bottom part of the

foot until the appliance is stable and level

on the floor.

EN

57

Page 56

Installation

Fastening to the wall

The anti-tip devices must be

installed in order to prevent the

appliance from tipping over.

1. Screw the wall fastening plate to the rear

of the appliance.

2. Adjust the height of the 4 feet.

3. Assemble the fastening bracket.

4. Align the base of the hook on the

fastening bracket with the base of the slot

on the wall fastening plate.

58

Page 57

Installation

5. Align the base of the fastening bracket

with the ground and tighten the screws to

fix the measurements.

6. Use 50 mm for the distance from the side

of the appliance to the bracket holes.

7. Move the bracket onto the wall and

mark the position of the holes to be

drilled in the wall.

8. After drilling the holes in the wall, use

wall plugs and screws to fasten the

bracket to the wall.

9. Push the cooker towards the wall, and at

the same time, insert the bracket in the

plate fastened to the rear of the

appliance.

EN

59

Page 58

Installation

Assembling the upstand

The upstand provided is an