Page 1

Table of Contents

1. IMPORTANT SAFETY INSTRUCTIONS ................................................................................. 4

2. DIMENSIONAL REQUIREMENTS .......................................................................................... 7

3. UNPACKING, MOVING AND POSITIONING THE RANGE .................................................... 9

4. WALL FIXING AND ANTI-TIP DEVICE ................................................................................. 10

5. ELECTRICAL REQUIREMENTS ........................................................................................... 12

6. GAS SUPPLY REQUIREMENTS .......................................................................................... 15

WARNING: If the instructions contained in this manual are not followed

precisely, a fire or explosion may result causing property damage, personal

injury or loss of life.

- Do not store or use gasoline or other flammable vapors and liquids near this

or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

• lf you cannot reach your gas supplier, call the Fire Department.

- Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

NOTE: THIS APPLIANCE MUST BE INSTALLED SOLELY AND EXCLUSIVELY BY A QUALIFIED

TECHNICIAN. ANY TECHNICAL PROCEDURES MUST BE CARRIED OUT BY AN AUTHORIZED

TECHNICIAN.

INSTRUCTIONS FOR THE INSTALLER: these are intended for the qualified technician who is able to

install, commission and test the appliance.

3

Page 2

Important Safety Instruction

1. IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS – Your safety and the safety of others are very important.

We have provided many important safety messages throughout this manual and on the appliance.

Read all the instructions before using the appliance and always obey all safety messages.

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. This symbol alerts you to potential hazards that can result in severe

personal injury or loss of life.

UNDERSTAND SIGNAL WORDS

A signal word – DANGER, WARNING, or CAUTION – is used with the safety alert symbol. DANGER

denotes the most serious hazards. It means you could lose your life or be seriously injured if you do not

immediately

the instructions are not followed. CAUTION indicates a potentially hazardous situation which, if not

avoided, could result in minor to moderate injury.

follow the instructions. WARNING means you could lose your life or be seriously injured if

The safety messages will inform you of potential hazards, on how to avoid the risk of injury and what can

occur if the instructions are not followed.

IMPORTANT: Installation, gas connections and grounding must conform to with applicable codes.

Observe all governing codes and ordinances.

WARNING: For your safety, the instructions contained in this manual must be followed to

minimize the risk of fire or explosion and to prevent property damage, personal injury or loss of

life.

- If the instructions contained in this manual are not followed precisely, a

fire or explosion may result causing property damage, personal injury

or loss of life.

WARNING

- Disconnect from the electrical supply before installing. Before turning

the power ON, be sure that all controls are in the OFF position.

- Do not store or use gasoline or other flammable vapors, liquids or

materials near this or any other appliance.

NOTE: This range is manufactured for use with natural gas. To convert the appliance to LP/Propane

gas, see the instructions in the Gas Conversion Kit provided in the literature package.

The proper gas supply connection must be available. See "Gas supply requirements”.

In the State of Massachusetts, the following installation instructions apply:

- Installation and repairs must be performed by a Massachusetts qualified or licensed contractor,

plumber, or gasfitter.

- If using a ball valve, it shall be the T-handle type.

- A flexible gas connector, when used, must not exceed 3 feet.

4

Page 3

WARNING

Important Safety Instruction

- All ranges can tip

- Bodily injury can result

- Install the anti-tip device shipped with the range

- See installation instructions

NOTE: This range is NOT designed for installation in manufactured (mobile) homes or in recreational

vehicles (RVs).

DO NOT install this range outdoors.

WARNING

- Read all instructions

- Proper installation is your responsibility. Have a qualified technician install and ground this appliance

in accordance with these installation instructions.

- It is the responsibility of the installer to comply with installation information specified on the model/

serial ID plate. This plate is visibly located in the oven door frame and must not be removed.

CAUTION: To eliminate the risk of burns or fire caused by reaching over hot surface burners, do not

store items directly above the rangetop.

- ELECTRICAL GROUNDING REQUIRED: See the “Electrical Requirements” section. It is the end

user’s responsibility:

1 To contact a qualified electrician to install the appliance

2 To ensure that the electrical system is adequate and conforms with the national ANSI / NFPA 70

ELECTRICAL CODE – latest edition – Or the CANADIAN ELECTRICAL CODE, C22.11 – 1 and

C22.2 No. 01982 – or latest edition – and all local codes and ordinances. IMPORTANT: Observe

all governing codes and ordinances.

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN LOSS OF

LIFE OR SERIOUS BURNS TO CHILDREN AND ADULTS.

To reduce the risk of fire, electrical shock, personal injury, or property

damage when installing the range, some basic safety precautions must be

followed, including:

- Before you plug the electrical cord into an outlet, make sure that all the appliance controls are in the

OFF position.

- Never modify or alter the construction of the appliance. For example, do not remove adjustable legs,

panels, wiring or anti-tip brackets/screws.

CAUTION: This unit is designed as a cooking appliance. Out of safety considerations, never use it for

warming the room or as a space heater.

5

Page 4

Instructions for the Installer

- Do not obstruct oven vents or openings for air intake.

- Test the appliance immediately after installation, following the instructions in this booklet. If the

appliance does not work properly, disconnect it from the electrical power supply and call the service

center. DO NOT attempt to repair the appliance.

- All adjustments and servicing must be performed by qualified installers or service technicians.

- Do not leave the packing materials around the home. Sort the various items of waste and take them

to the nearest specialized waste collection facility.

- This appliance is intended for household use only.

- Use this appliance only for its intended purpose. The manufacturer cannot be

held liable for damage caused by improper use of this range.

WARNING

- This appliance complies with current safety regulations. Improper use of this

range can result in personal injury and property damage.

- Read all the instructions before installing or using the range for the first time.

- Keep these operating instructions in a safe place and pass them on to any

future user.

SAVE THESE INSTRUCTIONS

6

Page 5

Instructions for the Installer

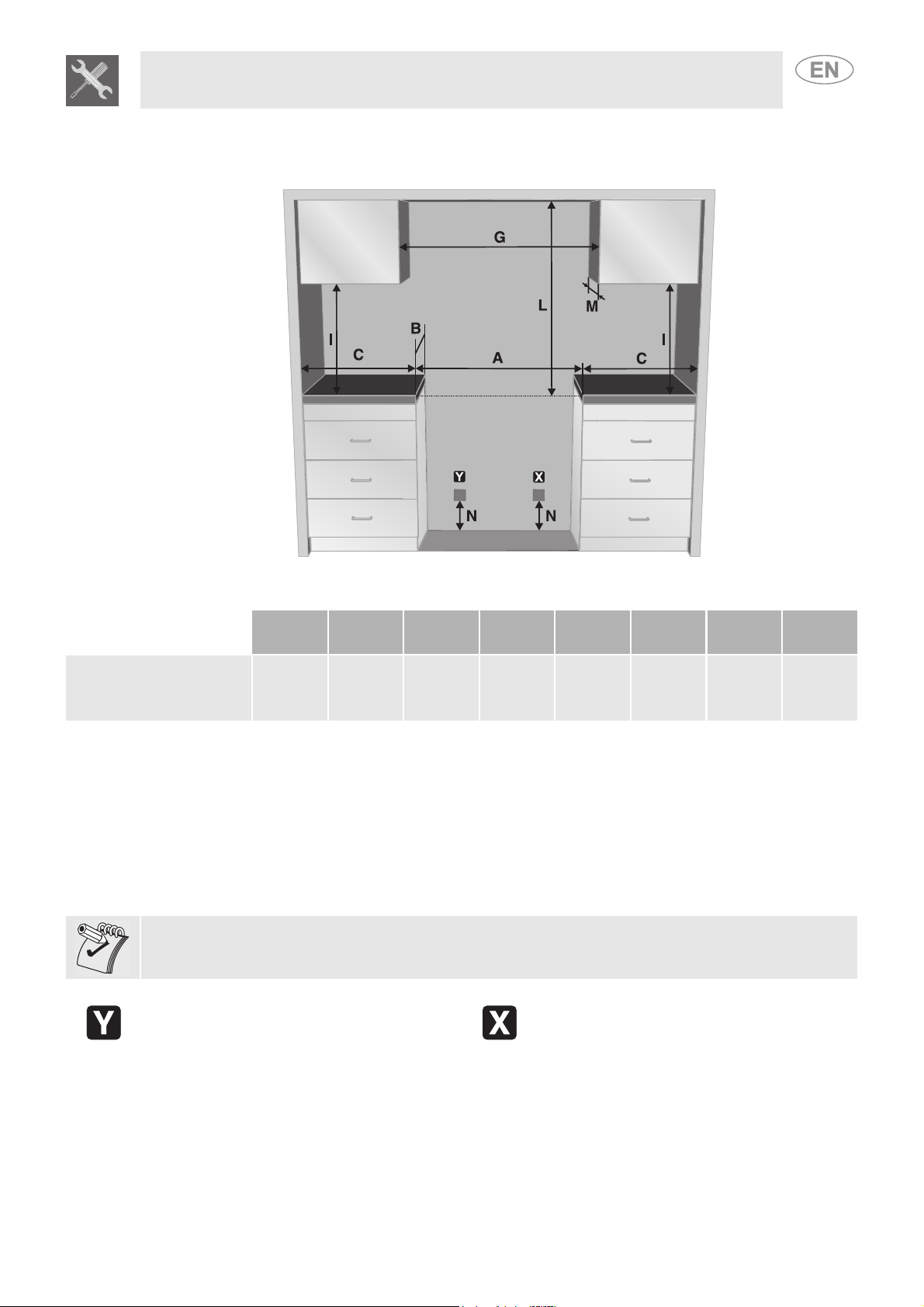

2. DIMENSION REQUIREMENTS

CLEARANCE

MODEL

C9GMXU

A B

912 mm

15

/16 ”

35

636 mm

25 ”

(5)

C

216 mm

1

/2”

8

1 min. when bottom of wood or metal cabinet is protected by not less than ¼ “ (0.64 cm) flame

retardant millboard covered with not less than No. 28 MSG sheet steel, 0.015” (0.4 mm) stainless

steel, 0.024” (0.6 mm) aluminium or 0.020” (0.5 mm) copper.

2 max. upper cabinet depth;

3 min. cabinet opening width;

4 upper cabinet to countertop;

5 min. clearance from the sides of range to side wall or other combustible material;

6 Junction box.

NOTE: Install with zero clearance sides and back.

Grounded outlet

Position within 11

7

/8” (300 cm) from the left

rear corner of the range.

(3)

G

912 mm

15

/16 ”

35

(4)

I

457 mm

18”

(1)

L

610 mm

24 ”

(2)

M

330 mm

13 ”

150 mm

5

Gas supply line

Position within 11 7/8” (300 cm) from the

right rear corner of the range.

15

N

/16”

7

Page 6

Instructions for the Installer

2.1 Product dimensions

Overall dimensions: location of electrical connection points.

A

B

C

D

Check the location where the range is to be installed. The range should be positioned for convenient

access in the kitchen.

NOTE: Observe all governing codes and ordinances.

Any openings in the wall or floor where the range is to be installed must be sealed.

Some cabinet and building materials are not designed to withstand the heat produced by the oven when

baking, roasting and broiling. Check with your builder or cabinet supplier to make sure that the materials

used will not discolor, delaminate or sustain other damage.

55 mm - 2 1/8”

698 mm - 27 7/16“

3

5

/8”

/8“

753 mm - 29

155 mm - 6 1/8”

157 mm - 6 3/16”

212 mm - 8

The cabinet opening dimensions that are shown must be used. The indicated dimensions are the

minimum clearances.

When installing a range under existing cabinets that do not satisfy the minimum cabinet clearances,

install a rangehood over the cooking surface to avoid burn hazards.

8

Page 7

Instructions for the Installer

3. UNPACKING, MOVING AND POSITIONING THE RANGE

CAUTION: This unit is designed as a cooking appliance. Out of safety considerations, never use it for

warming the room or as a space heater.

- It is recommended that the grates, the griddle plate and burner rings, burner caps, front kick panel

and oven racks be removed to facilitate handling. This will reduce the weight for moving.

- Remove the outer carton and packing material from the shipping base.

- Remove angle-mounting brackets from the range.

- Due to the weight, a dolly/fork lift with soft rubbertread wheels should be used to move this unit. The

weight must be supported uniformly across the bottom.

- The floor under the legs should be protected (wood, strips, carpet, paneling, etc.) before

pushing the unit into position.

- The anti-tip device must be installed, gas and electrical connections should be made before

the range is placed in its final position.

- Ensure that the burner caps are correctly positioned on the burner rings on the rangetop.

- Legs should be installed near to where the appliance will be used as they are not secure for long

transit. Keep the unit raised to permit the legs to be screwed into their couplings and lower the range

gently to kee any undue strain from legs and mounting hardware. It is recommended to use a pallet

or lift jack instead of tilting the unit.

- For proper performance the range must be leveled. The range is

leveled by adjusting the four legs to ensure a perfectly level plane

for the unit. To accomplish this, screw or unscrew the second part

of the legs. The adjustment range of the screw is 35 mm.

NOTE: use the appliance only with the leveling legs provided by the manufacturer.

9

Page 8

Instructions for the Installer

4. WALL ATTACHMENT AND THE ANTI-TIP DEVICE

- All ranges can tip

WARNING

- Bodily injury can result

- Install the anti-tip device packed with the range

- See installation instructions

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN LOSS OF

LIFE OR SERIOUS BURNS TO CHILDREN AND ADULTS.

ELECTRICAL SHOCK HAZARD

- Use extreme caution when drilling holes into the wall or floor. There may be

concealed electrical wiring located behind the wall or under the floor.

- Identify the location of the electrical circuits that could be affected by the

installation of the anti-tip device, then turn off power to these circuits.

- Failure to follow these instructions may result in electrical shock or other

personal injury.

CAUTION: PROPERTY DAMAGE

- Contact a qualified installer or contractor to determine the proper method for drilling holes through the

wall or floor material (such as ceramic tile, hardwood, etc.)

- Failure to follow these instructions may result in damage to wall or floor coverings.

4.1 Instructions for wall mounting

The anti-tip brackets are to be attached to the rear wall as shown. The height of the bracket location from

the floor is determined after the range legs have been adjusted to the installation height as shown in the

installation instructions and the range has been leveled.

10

1 Level the range

using the

adjustable

leveling legs.

2 From the floor,

measure the

height of the

notch found on

the bracket. This

notch

corresponds to

the centerline of

the holes for the

screws that will

fasten the brackets to the wall.

Page 9

Instructions for the Installer

3 Attach the two anti-tip brackets to the wall using an appropriate fastener (for example, screws

appropriate for the type of the wall). Adhere scrupulously to the heights indicated in the figure (A)

1

using the appliance’s dimensions as a guide. (Type of screw recommended

/4” ).

4 Correctly position the range so that the two

screws fit the anti-tip brackets on the range

perfectly.

C9GMXU (35

A)

3

/4 ” - 908 mm)

11

Page 10

Instructions for the Installer

5. ELECTRICAL REQUIREMENTS

WARNING

WARNING

Make sure that the power line rating matches the specifications indicated on the ID plate located on the

oven door frame.

This ID plate must never be removed.

lf codes permit and a separate ground wire is used, it is recommended that the suitability of the ground

path be checked by a qualified electrician.

When a four-wire or three-wire, single-phase, 120/208-volt, 60 Hz or 120/240-volt, 60 Hz, AC-only,

electrical supply is available, a 20 ampere maximum circuit protection is required. A time-delay fuse or

circuit breaker is recommended. The ID plate is located on the oven door frame.

Wire size and connections must conform to the requirements of the National Electrical Code, ANS/NFPA

70 ELECTRICAL CODE (*) – last edition or CSA Standard C22.1-94, Canadian Electrical code, Part 1

(**) and CSA C22.2 No. O-91 or latest edition and all local codes and ordinances for the kilowatt rating of

the range. IMPORTANT: Observe all governing codes and ordinances.

Copies of the standards listed above may be obtained from:

(*) National Fire Protection Association, One Batterymarch Park, Quincy, Massachusetts 02169-7471

(**) CSA International 8501 East Pleasant Valley Road Cleveland, Ohio 44131-5575.

ELECTRICAL GROUNDING INSTRUCTIONS

ELECTRICAL SHOCK HAZARD

- Plug into a grounded 3-prong receptacle.

- Do not cut or remove the grounding prong.

- Do not use an adaptor.

- Do not use an extension cord.

- Check with a qualified electrician if you are not sure whether the range

is grounded.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN LOSS OF

LIFE, FIRE OR ELECTRICAL SHOCK.

12

This appliance is manufactured with a green-yellow or green ground wire connected to the oven frame.

Make sure that the power has been turned off then connect the flexible connector. Connect the

appliance to the junction box using a UL listed conduit connector (see Figures 1 and 2 on pages 13-14).

Do not shorten the flexible metal connector.

Figure 1 and Figure 2 on pages 13 - 14, and the instruction provided below present the most common

way of connecting the appliance.

Your local codes and ordinaces, of course, take precedence over these instructions. Complete electrical

connections according to local codes and ordinances.

This range must be connected to a grounded, metallic, permanent wiring system or a ground connector

should be connected to the ground terminal or wire lead on the range.

Connection at the connection block must be copper wire only.

NOTE: Use this method only if local codes allow connecting the oven frame ground conductor to the

neutral wire of the power supply.

Page 11

Instructions for the Installer

WAR NING

ELECTRICAL SHOCK HAZARD

- Turn power supply off before connecting wires.

WARNING

- Electrically ground the range.

- Failure to follow these instructions can result in loss of life, fire, or

electrical shock.

- Improperly connecting the appliance grounding conductor can result in

a risk of electrical shock. Check with a qualified electrician or

serviceman if you are in doubt as to whether the appliance is properly

grounded. Do not modify the power supply cord. If it does not fit in the

outlet, have a proper outlet installed by a qualified electrician.

5.1 U.S. installation only / 3-wire branch circuit

Refer to figure 1, where local codes allow the

connection of the ground wire from the oven to the

power supply cable neutral wire (white wire):

- The ground wire must be connected first;

- If local codes permit, connect the green or

yellow-green ground wire from the range and

the white wire from the range to the power

supply neutral wire (white wire).

- Connect the red and black leads from the range

to the to the matching color wires in the junction

box using UL/CSA listed wire connectors.

Fig.1)

13

Page 12

Instructions for the Installer

5.2 U.S. and Canada installation/ 4-wire branch circuit

Refer to Figure 2,

- Separate the green or yellow-green wires from

the white wires that extend out of the end of the

appliance cable.

- The ground wire must be connected first;

- Connect the green or yellow-green ground wire

from the appliance to the ground wire in the

junction box (green colored wire) using UL/CSA

listed wire connectors. Do not connect the

grounding wire to the neutral wire in the

junction box.

- Connect the red and black leads from the

appliance to the matching color wires in the

junction box using UL/CSA listed wire

connectors.

- Connect the white wire from the appliance to the

neutral white wire in the junction box using a UL/

CSA listed wire connector.

Connect to a 20A fuse or circuit breaker. Connect to copper wire, or, if connection is made to aluminum

house wiring, use UL-listed or CSA-approved connectors approved for joining aluminum and copper

wiring.

NOTE: Both leads coming out of the range must be connected according to the diagrams shown in

Figures 1 and 2

Fig.2)

14

Page 13

Instructions for the Installer

6. GAS SUPPLY REQUIREMENTS

EXPLOSION HAZARD

- Use a new AGA or CSA-certified connector.

- Install a manual shut-off valve.

1)

2)

WARNING

NOTE:

- Observe all governing codes and ordinances.

- The range must be connected to a standard gas supply.

This installation must conform with all local codes and ordinances. In the absence of local codes,

installation must conform to American National Standard, National Fuel Gas Code ANSI Z223.1 - latest

edition** or CSA-13149.1 or 2**.

If local codes permit, a flexible metal appliance connector with the new AGA or CSA design certified, 4-5

feet (1.2-1.5 m) long, 1/2" or 3/4" ID, is recommended for connecting this range to the gas supply line.

Do not bend or damage the flexible connector when moving the range. The pressure regulator has 3/8"

female pipe threads. You will need to determine the fittings required, depending on the dimension of your

gas supply line, the flexible metal connector and the shut-off valve.

- Securely tighten all gas connections.

- lf connected to LP, have a qualified technician ensure that the gas

pressure does not exceed a 14" W.C.P.

- Examples of qualified technicians include licensed heating personnel,

authorized gas company personnel, and authorized service personnel.

- Failure to do so can result in loss of life, explosion, or fire.

3)

Always use a pipe-joint compound made for use with NATURAL

GAS and L.P. GAS between pressure regulator D and NPT

adaptator C and between pressure regulator D and pipe E. If a

flexible metal connector is used, make sure that the tubing is not

kinked.

Use only pipes (E) conforming to standard regulations in force,

inserting gasket B (supplied) between fitting A adaptator C.

Always use a suitable sealing substance (such as Teflon tape)

between pressure regulator D and adaptor C and between

pressure regulator D and pipe E.

WARNING: The tightening torque of the adaptor (C ) must not be greater than 36 ozf - 10 Nm.

15

Page 14

3)

4)

Instructions for the Installer

The supply line must be fitted with an approved shut-off valve.

This valve should be located in the same room as the rangetop

and should be in a location where it can be easily opened and

closed.

Do not block access to the shut-off valve. The valve is necessary

for turning the gas to the appliance on or off.

Incoming line pressure

upstream from the regulator

must be 1” (2.5 cm) W.C.P.

higher than the manifold

pressure in order to check the

regulator. Incoming line

pressure to the regulator should

be as follows for operation and

checking the regulator setting:

- NATURAL GAS: manifold

pressure 4” W.C.P. Incoming

line pressure 3.5”-10.5” W.C.P.

- LP GAS: manifold pressure

11” W.C.P. Incoming line

pressure 8.0”13” W.C.P.

5)

Line pressure testing: Testing above 112 PSI (3.5 kPa), with 14” W.C.P. (35.6 cm) (gauge).

The range and its individual shut-off valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures greater than 1/2 psig (3.5 kPa).

Testing below 112 PSI (3.5 kPa) with 14” W.C.P. (35.6 cm) (gauge) or lower.

The range must be isolated from the gas supply piping system by closing the respective manual shut-off

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than

1/2 psig (3.5 kPa).

16

Loading...

Loading...