Booster regulator/

Series

VBA

Air tank/

Series

VBAT

Booster Regulator/Air Tank

0.3

MPa

0.3

MPa

0.3

MPa

0.3

MPa

0.6

MPa

Booster Regulator + Air Tank

Heavy

Light

Light

Compressor

Factory line

Series

VBA/VBAT

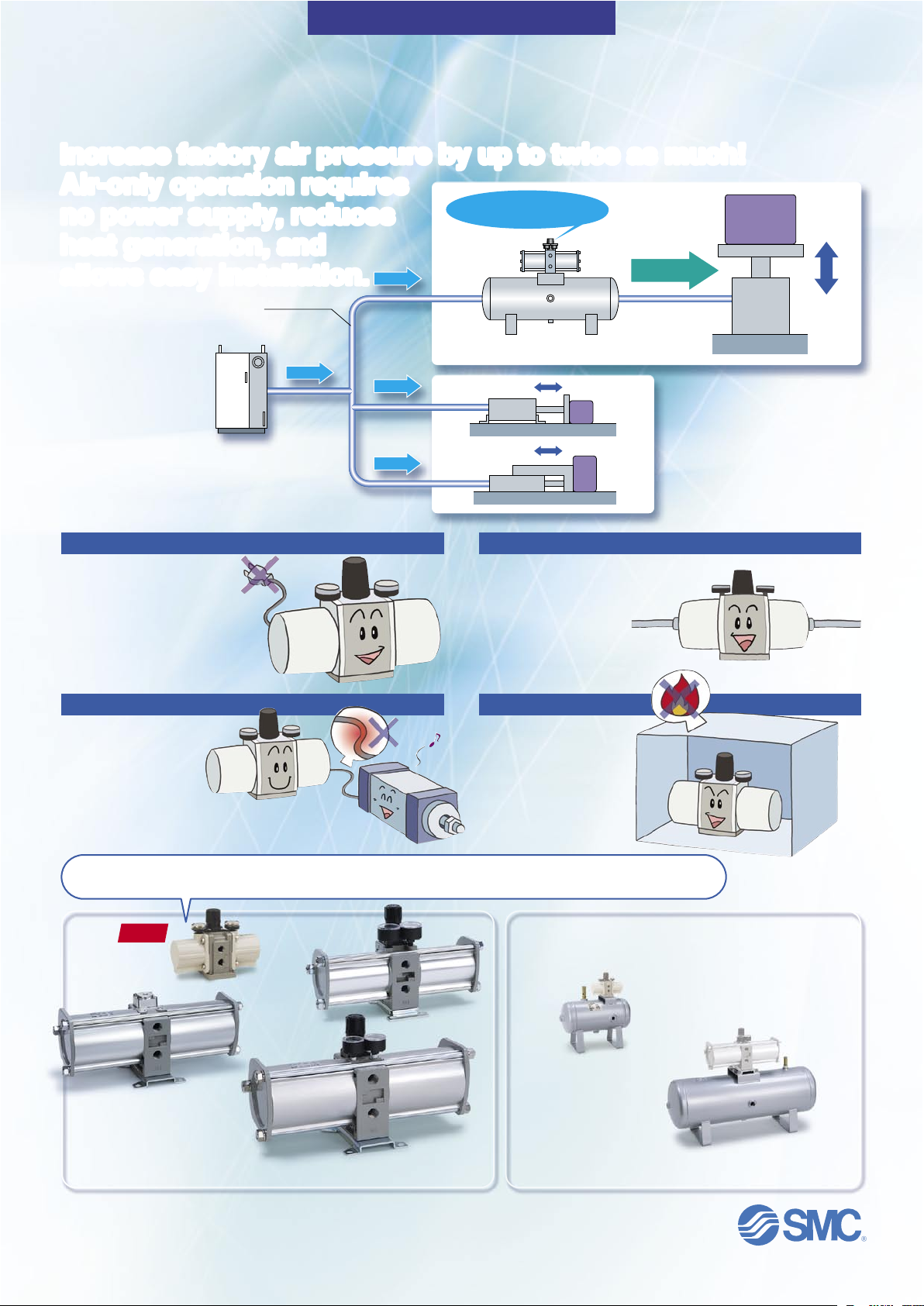

Easy installation

Low heat generation

Air-only operation

New product added to the VBA10A series!

Very little heat is

generated because

no electricity is used,

and there is no impact

on cylinders, solenoid

valves, etc.

Operation is safe

because no

electricity is used.

Simply insert the unit

in the air line.

Requires far less

space than upgrading

the compressor.

There is no need to

install dedicated

electrical wiring.

New

New

NEW

Increase factory air pressure by up to twice as much!

Air-only operation requires

no power supply, reduces

heat generation, and

allows easy installation.

Increase factory air pressure by up to twice as much!

Air-only operation requires

no power supply, reduces

heat generation, and

allows easy installation.

CAT.EUS11-96C-UK

Boost pressure

No power supply or wiring needed

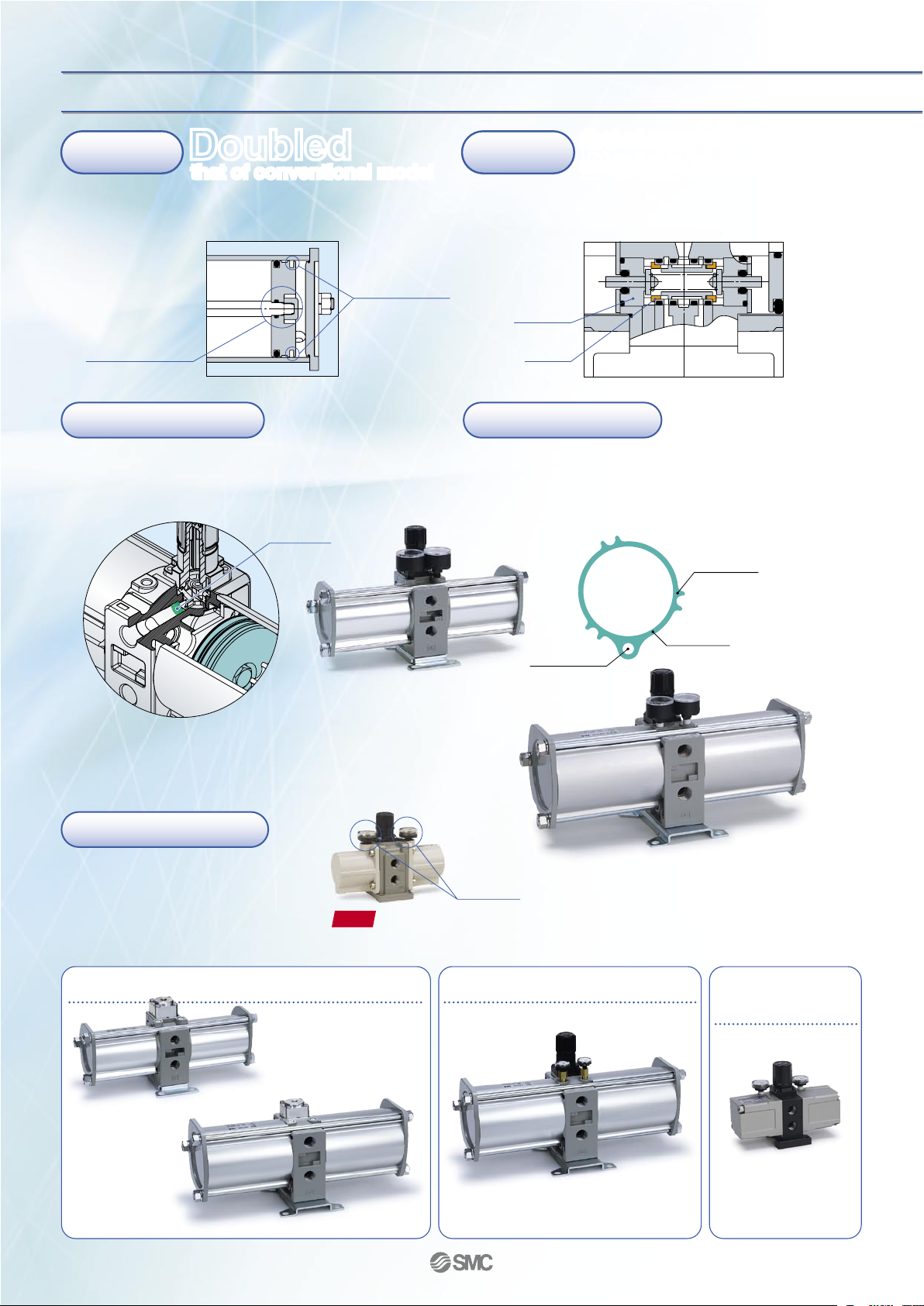

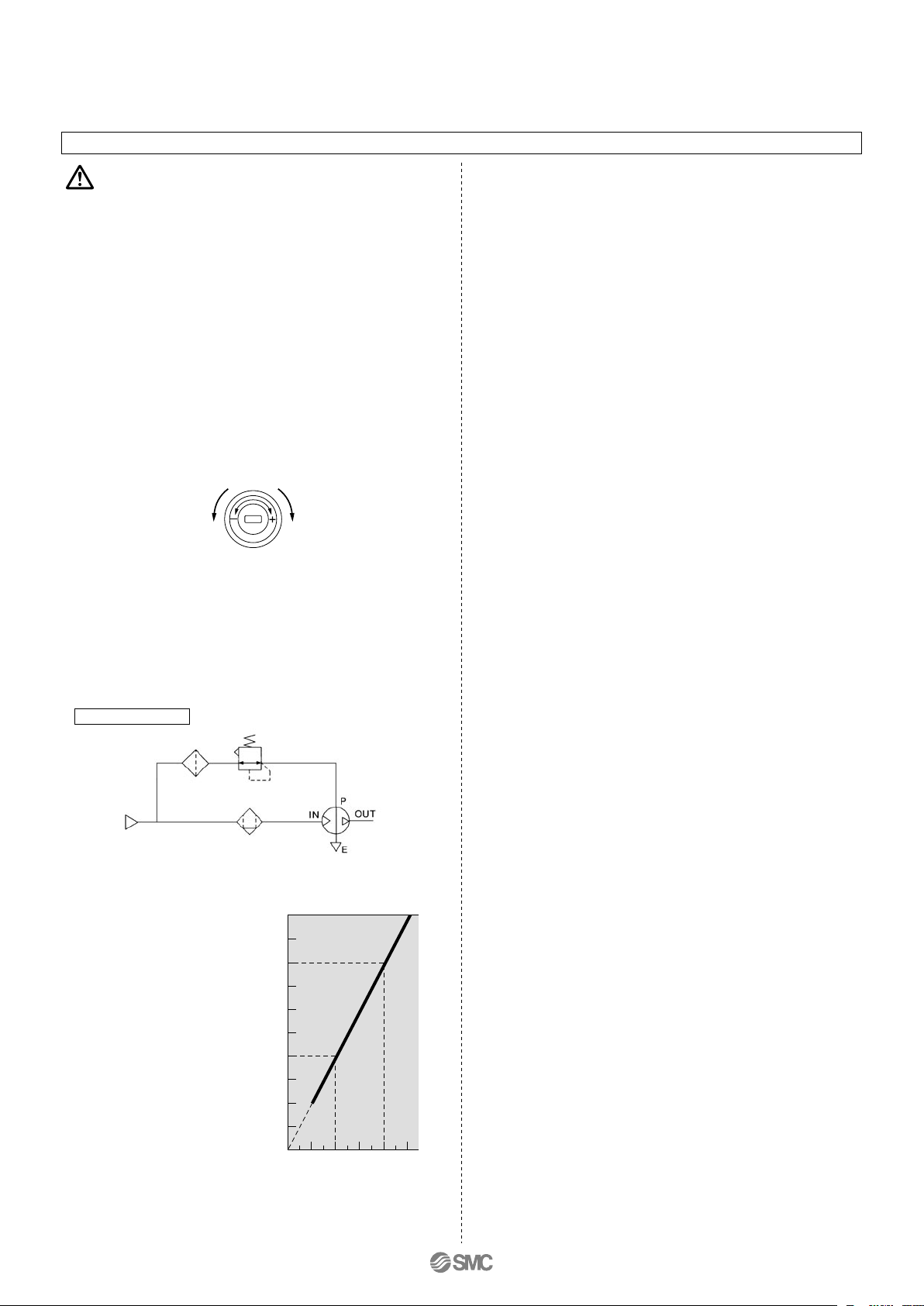

• Floating piston structure (PAT. PEND)

• Grease retaining groove

∗ Except for VBA1111.

• Prevents operation failure due to foreign matter.

∗ Except for VBA1111.

Built-in mesh filter∗ at the IN port

Cylinder tube

Tie-rod guide

Air-feeding tube

VBA22A

VBA42A

Air-operated type

VBA43A

Max. operating pressure

1.6

MPa

Fourfold pressure

increase type

Booster Regulator

Series

VBA

Improved

service life

that of conventional model

Doubled

that of conventional model

Doubled

∗

• Metal noise reduced by a damper on the impact part

of the switch valve

• Exhaust noise reduced by a high-noise reduction

silencer

∗ Except for VBA1111.

Reduced

noise

that of conventional model

Doubled

Reduced by

13 dB

(A)

compared with the conventional model

Reduced by

13 dB

(A)

compared with the conventional model

Improved reliability

• Mitigates the condensation caused by cooling

during exhaust expansion.

Integrated air-feeding tube with the

main tube

Anti-condensation

1/8" gauge ports

Allows the use of standard

fittings for remote pressure

monitoring and the like.

∗ Gauge ports changed from 1/16" to 1/8".

VBA10A

VBA1111

VBA40A

VBA20A

NEW

Grease retaining

groove

Floating structure

Switching

valve

Damper

Mesh filter

Gauge port

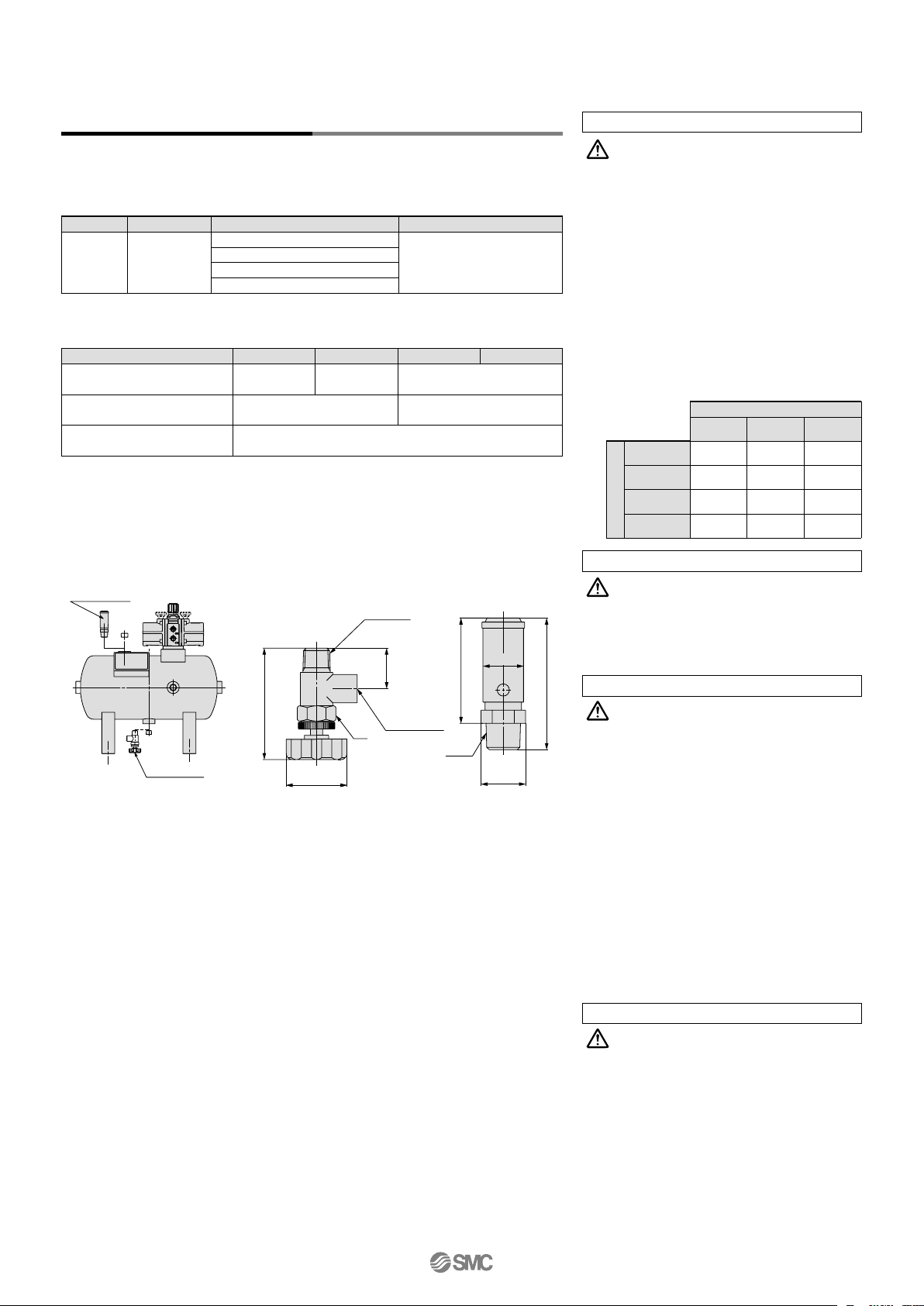

Features 1

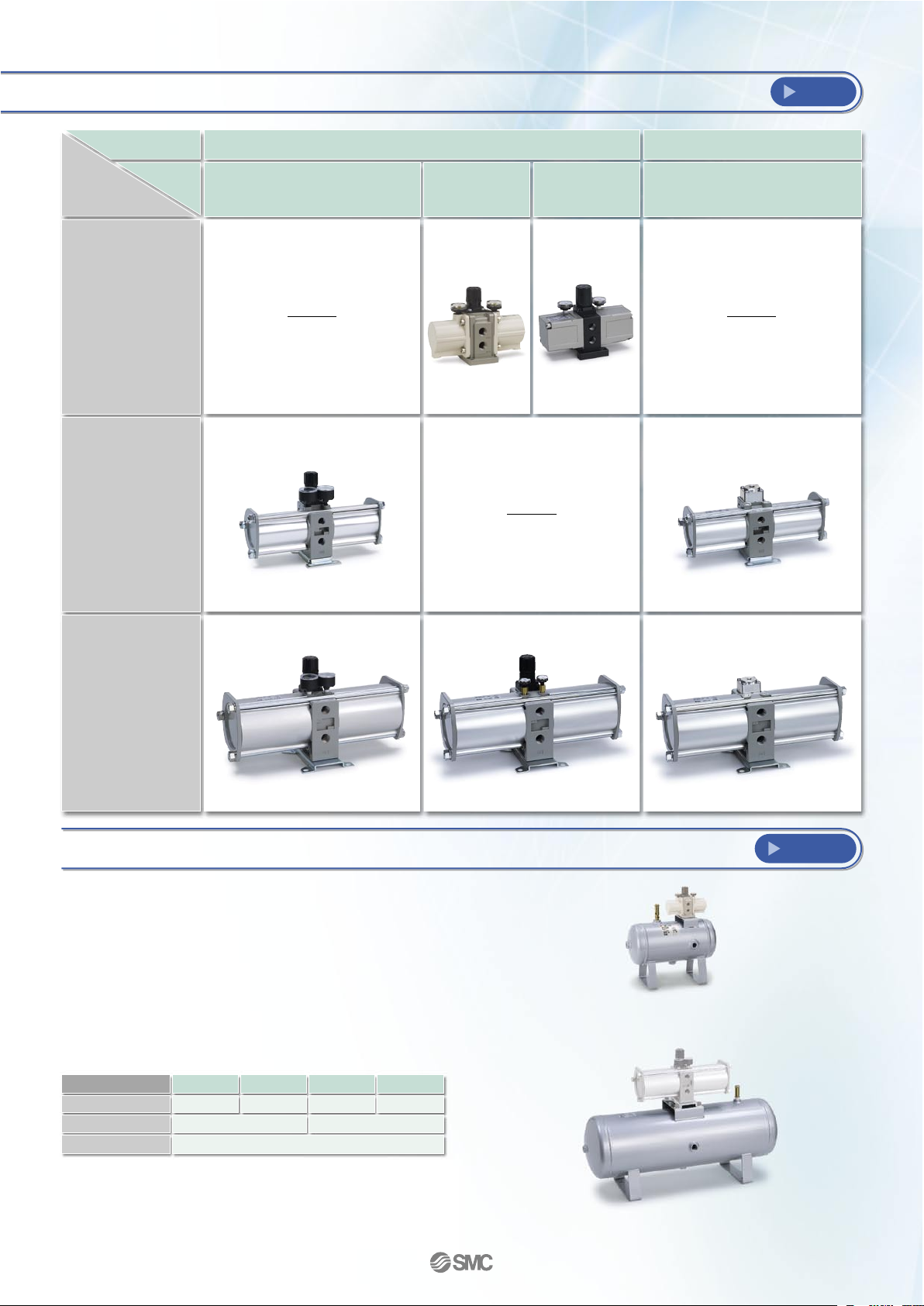

Operation

Body size

Set pressure

range

Handle-operated type (Direct operation)

0.2 to 1.0 MPa

0.2 to 1.6 MPa

(2.0 MPa)

0.2 to 2.0 MPa

VBA10A VBA1111

VBA20A-03 VBA22A-03

VBA42A-04VBA43A-04VBA40A-04

1/4"

3/8"

1/2"

Air-operated type (Remote operation)

0.2 to 1.0 MPa

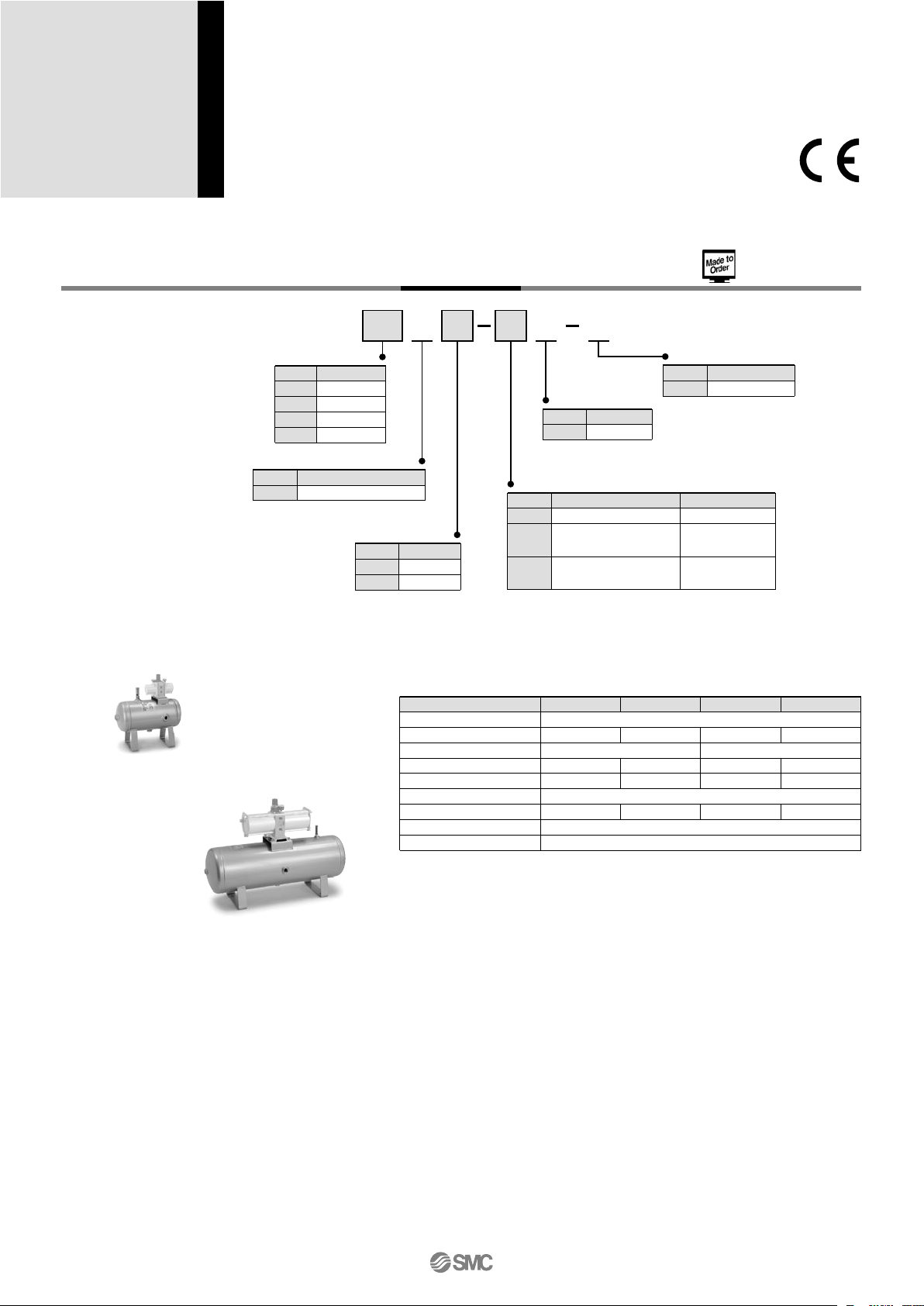

Tank capacity (l)

Max. operating pressure (MPa)

Material

Model

VBAT10A10VBAT20A

20

Carbon steel

VBAT38A

38

1.02.0

VBAT05A

5

P. 1

Air Tank

Series

VBAT

P. 12

Perfect fit with a booster regulator

This is an air tank to which a booster regulator can be connected

compactly. It can be used alone as a tank. The pressure vessel law is

different from country to country, so as an air tank suitable to a

country needs to be confirmed.

Extensive product lineup

To meet a variety of usage environment and pressure specifications,

models are available in two materials four sizes ranging from 5 liters

to 38 liters.

Features 2

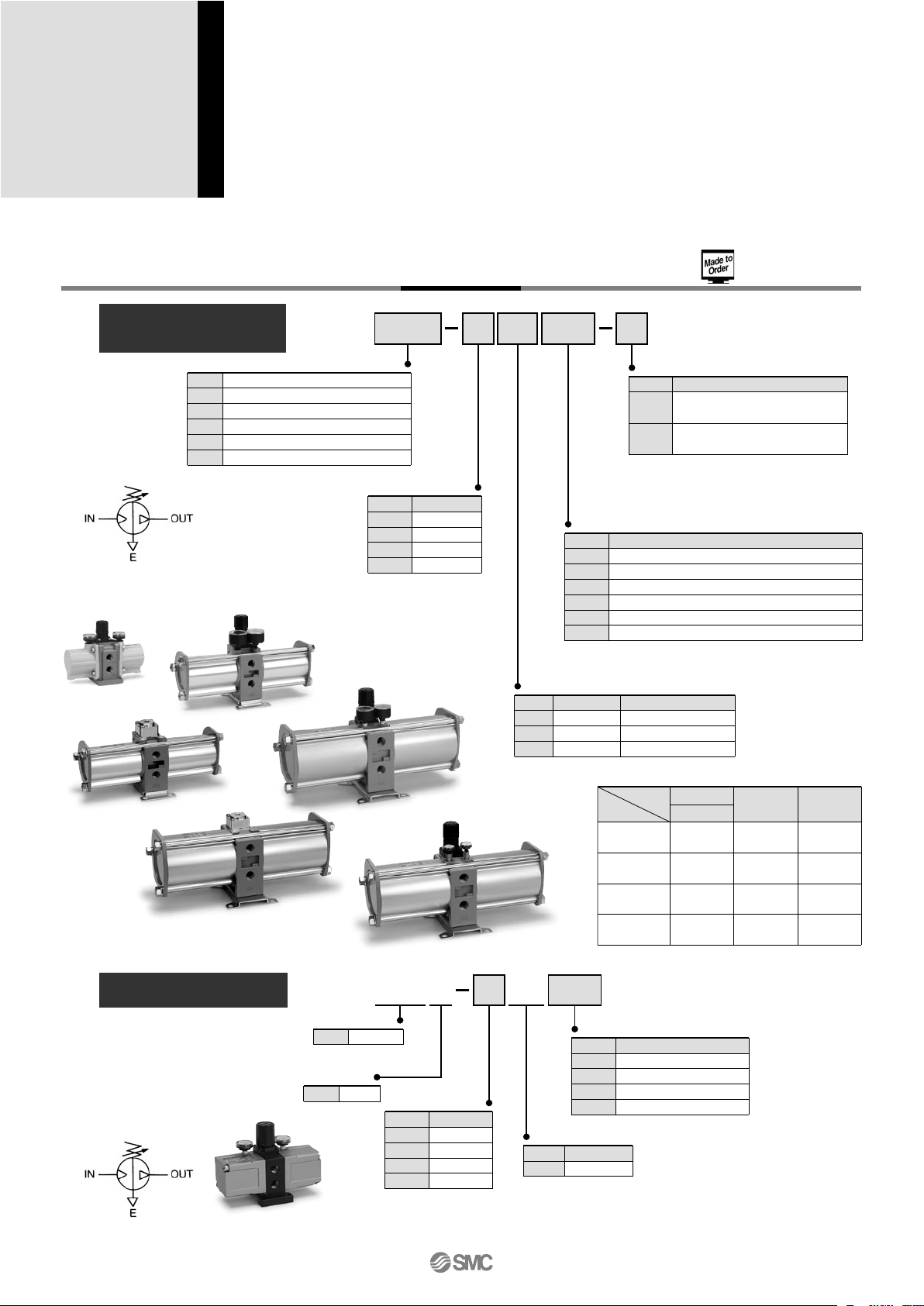

VBA

02

GN

111

1

1/4

Body size

111

4 times

Pressure increase ratio

1

Port size

02

1/4

Port sizeSymbol

Thread type

Rc

G

NPT

NPTF

Thread type

Note)

Symbol

—

F

N

T

Series

VBA1111

Option

None

Pressure gauge

Silencer

Pressure gauge, Silencer

Option

Symbol

—

G

N

GN

VBA

04

GN

40A

Port size

02

03

04

1/4

3/8

1/2

Port size

VBA10A

VBA2A

VBA4A

Applicable series

Symbol

Thread type

Rc

G

NPT

NPTF

Thread type

Note)

Symbol

—

F

N

T

Series VBA

Option

None

Pressure gauge

Silencer

High-noise reduction silencer

Note)

Pressure gauge, Silencer

Pressure gauge, High-noise reduction silencer

Note)

Option

Symbol

—

G

N

S

GN

GS

VBA1111-02

1/4, Handle-operated type

3/8, Handle-operated type

1/2, Handle-operated type

3/8, Air-operated type

1/2, Air-operated type

1/2, Max. operating pressure 1.6 MPa

Body size

10A

20A

40A

22A

42A

43A

∗ Pressure increase ratio: Twice

∗ Pressure: 2 MPa

Note) Thread type: NPT, NPTF

The SI unit type is provided for use in Japan.

This product is for use outside of Japan only

according to the new Measurement Law.

Specifications

Pressure unit on the product name

label and pressure gauge: psi

Pressure unit on the product name

label and pressure gauge: MPa

Semi-standard

Symbol

—

Z

Note)

Note) Thread types apply to the IN, OUT, and EXH ports. The gauge ports are Rc thread type.

For the G thread type, add an E at the beginning of the model number

(EVBA1111-F02).

For the NPTF thread type, add an N at the beginning of the model number (NVBA1111-T02

).

Symbol

Symbol

Note) Thread types apply to the IN,

OUT, and EXH ports of the

VBA10A and to the IN, OUT,

EXH, and gauge ports of the

VBA2

A and VBA4A. The

gauge ports of the VBA10A are

Rc thread type regardless of the

thread type indication.

Note) The high-noise reduction silencer is not available on the

VBA10A-N02 and VBA10A-T02.

1 4

VBA20A-03

VBA10A-02

VBA40A-04

VBA22A-03

VBA42A-04

VBA43A-04

10A

2A

4A

Made to Order

(For details, refer to page 11.)

VBAT05A

VBAT10A

VBAT20A

VBAT38A

VBA10A

VBA1111

VBA2A VBA4A

—

—

—

—

—

Air tank compatibility chart

Booster

regulator

Air tank

Booster Regulator

Series VBA

How to Order

Related Products/Part No.

Note) Refer to page 12 for air tanks, Best Pneumatics No. 5 for mist separators

and Best Pneumatics No. 6 for exhaust cleaners.

Refer to the separate instruction manual for the connection method.

Description

Model

Mist separator

Exhaust cleaner

For

VBA10A-02

For

VBA1111-02

For

VBA20A-03

For

VBA22A-03

AM250C-02

AMC310-03

AM450C-04, 06

AMC510-06

AM550C-06, 10

AMC610-10

For

VBA40A-04

For

VBA42A-04

For

VBA43A-04

Note 1) If the OUT pressure is higher than the set pressure by the handle, excessive pressure is exhausted from the back of the handle.

Note 2) Flow rate at IN= OUT= 0.5 MPa. The pressure varies depending on the operating conditions. Refer to “Flow Characteristics” on pages 3 and 4.

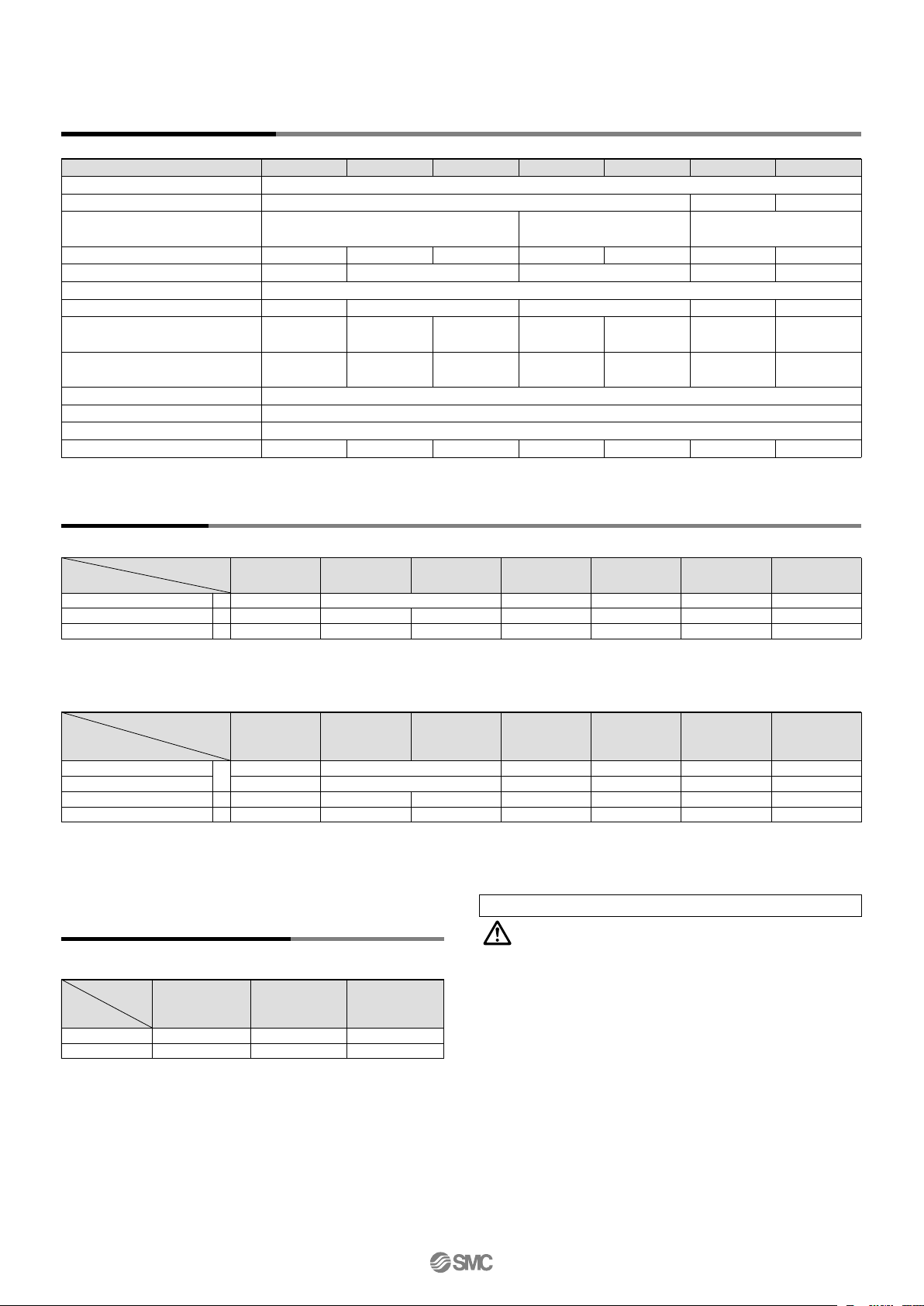

Model

Fluid

Pressure increase ratio

Pressure adjustment mechanism

Max. flow rate

Note 2)

(l/min (ANR))

Set pressure range (MPa)

Supply pressure range (MPa)

Proof pressure (MPa)

Ambient and fluid temperature

(°C)

Installation

Lubrication

Weight (kg)

Port size

(IN/OUT/EXH: 3 locations)

Pressure gauge port size

(IN/OUT: 2 locations)

VBA10A-02

VBA20A-03

VBA40A-04

VBA22A-03

VBA42A-04

VBA1111-02VBA43A-04

Compressed air

0.1 to 1.0

2 to 50 (No freezing)

Horizontal

Grease (Non-lube)

Twice

230

0.2 to 2.0

3

1/4

1/8

0.84

1000

0.2 to 1.0

1.5 1.5

0.2 to 1.0

1900 1000 1900 60

0.2 to 2.0

1600

0.2 to 1.6

Twice to 4 times

Handle-operated with relief

mechanism

Note 1)

Handle-operated with relief mechanism

Note 1)

Air-operated

Twice

3/8

1/8

3.9

1/2

1/8

3/8

1/8

1/2

1/8

8.6

3.9

8.6

3

1/4

1/16

0.98

2.4

1/2

1/8

8.6

Note 1) In the case of option GN, two pressure gauges and one silencer are included as accessories.

Note 2) KT-VBA22A-7 is a pressure gauge with fittings. (Please order two units when using with IN and OUT.)

Note 3) Only simple indication of MPA for the pressure gauges

Pressure Gauge, Silencer (When thread type is Rc or G.)

Model

Description

Pressure gauge

Silencer

High-noise reduction silencer

G

N

S

VBA43A-04

VBA43A-F04

VBA1111-02

EVBA1111-F02

VBA42A-04

VBA42A-F04

VBA22A-03

VBA22A-F03

VBA40A-04

VBA40A-F04

VBA20A-03

VBA20A-F03

VBA10A-02

VBA10A-F02

G27-20-01

AN200-02

ANA1-02

G36-10-01

AN300-03

ANA1-03

AN400-04

ANA1-04

KT-VBA22A-7

AN300-03

ANA1-03

G36-10-01

AN400-04

ANA1-04

G27-20-R1

AN200-02

—

G27-20-01

AN400-04

ANA1-04

Note 1) In the case of option GN, two pressure gauges and one silencer are included as accessories.

Note 2) KT-VBA22A-7N, KT-VBA22A-8N are pressure gauges with fittings. (Please order two units when using with IN and OUT.)

Note 3) Under the new measurement law, the pressure unit of “psi” on the pressure gauges cannot be used in Japan.

Note 4) Pressure unit of pressure gauge: psi

Note 5) Pressure unit of pressure gauge: psi and MPa

Note 6) Only simple indication of MPA for the pressure gauges

Pressure Gauge, Silencer (When thread type is NPT or NPTF.)

Model

Description

Pressure gauge ∗: no symbol

Note 6)

Pressure gauge ∗: when “-Z”

Note 4)

Silencer

High-noise reduction silencer

G

N

S

VBA10A-N02

∗

VBA10A-T02

∗

∗

: when “-Z”

VBA20A-N03

∗

VBA20A-T03

∗

∗

: when “-Z”

VBA40A-N04

∗

VBA40A-T04

∗

∗

: when “-Z”

VBA22A-N03

∗

VBA22A-T03

∗

∗

: when “-Z”

VBA42A-N04

∗

VBA42A-T04

∗

∗

: when “-Z”

VBA1111-N02

NVBA1111-T02

VBA43A-N04

∗

VBA43A-T04

∗

∗

: when “-Z”

G27-20-01

G27-P20-01

AN200-N02

—

G36-10-N01

G36-P10-N01

AN300-N03

ANA1-N03

AN400-N04

ANA1-N04

KT-VBA22A-7N

KT-VBA22A-8N

AN300-N03

ANA1-N03

G36-10-N01

G36-P10-N01

AN400-N04

ANA1-N04

G27-20-R1-X214

Note 5)

—

AN200-N02

—

G27-20-N01

G27-P20-N01

AN400-N04

ANA1-N04

Mist Separator, Exhaust Cleaner

Standard Specifications

(Rc)

(Rc)

Options/Part No.

1. System configuration

• The IN port of the booster regulator has a metallic mesh to pre-

vent dust from entering the booster regulator. However, it can-

not remove dust continuously or separate drainage. Make sure

to install a mist separator (AM series) at the inlet side of the

booster regulator.

• The booster regulator has a sliding part inside, and it generates

dust. Also, install a cleaning device such as an air filter or a

mist separator on the outlet side as necessary.

• Connect a lubricator to the outlet side, because the accumulated

oil in the booster regulator may result in a malfunction.

2. Exhaust air measures

• Provide a dedicated pipe to release the exhaust air from each

booster regulator. If exhaust air is converged into a pipe, the

back pressure that is created could cause improper operation.

• Depending on the necessity, install a silencer or an exhaust

cleaner on the exhaust port of the booster regulator to reduce

the exhausting sound.

3. Maintenance space

• Allow the sufficient space for maintenance and inspection.

Caution

Design

Booster Regulator

Series VBA

1

Related Products/Part No.

Note) Refer to page 12 for air tanks, Best Pneumatics No. 5 for mist separators

and Best Pneumatics No. 6 for exhaust cleaners.

Refer to the separate instruction manual for the connection method.

Description

Model

Mist separator

Exhaust cleaner

For

VBA10A-02

For

VBA1111-02

For

VBA20A-03

For

VBA22A-03

AM250C-02

AMC310-03

AM450C-04, 06

AMC510-06

AM550C-06, 10

AMC610-10

For

VBA40A-04

For

VBA42A-04

For

VBA43A-04

Note 1) If the OUT pressure is higher than the set pressure by the handle, excessive pressure is exhausted from the back of the handle.

Note 2) Flow rate at IN= OUT= 0.5 MPa. The pressure varies depending on the operating conditions. Refer to “Flow Characteristics” on pages 3 and 4.

Model

Fluid

Pressure increase ratio

Pressure adjustment mechanism

Max. flow rate

Note 2)

(l/min (ANR))

Set pressure range (MPa)

Supply pressure range (MPa)

Proof pressure (MPa)

Ambient and fluid temperature

(°C)

Installation

Lubrication

Weight (kg)

Port size

(IN/OUT/EXH: 3 locations)

Pressure gauge port size

(IN/OUT: 2 locations)

VBA10A-02

VBA20A-03

VBA40A-04

VBA22A-03

VBA42A-04

VBA1111-02VBA43A-04

Compressed air

0.1 to 1.0

2 to 50 (No freezing)

Horizontal

Grease (Non-lube)

Twice

230

0.2 to 2.0

3

1/4

1/8

0.84

1000

0.2 to 1.0

1.5 1.5

0.2 to 1.0

1900 1000 1900 60

0.2 to 2.0

1600

0.2 to 1.6

Twice to 4 times

Handle-operated with relief

mechanism

Note 1)

Handle-operated with relief mechanism

Note 1)

Air-operated

Twice

3/8

1/8

3.9

1/2

1/8

3/8

1/8

1/2

1/8

8.6

3.9

8.6

3

1/4

1/16

0.98

2.4

1/2

1/8

8.6

Note 1) In the case of option GN, two pressure gauges and one silencer are included as accessories.

Note 2) KT-VBA22A-7 is a pressure gauge with fittings. (Please order two units when using with IN and OUT.)

Note 3) Only simple indication of MPA for the pressure gauges

Pressure Gauge, Silencer (When thread type is Rc or G.)

Model

Description

Pressure gauge

Silencer

High-noise reduction silencer

G

N

S

VBA43A-04

VBA43A-F04

VBA1111-02

EVBA1111-F02

VBA42A-04

VBA42A-F04

VBA22A-03

VBA22A-F03

VBA40A-04

VBA40A-F04

VBA20A-03

VBA20A-F03

VBA10A-02

VBA10A-F02

G27-20-01

AN200-02

ANA1-02

G36-10-01

AN300-03

ANA1-03

AN400-04

ANA1-04

KT-VBA22A-7

AN300-03

ANA1-03

G36-10-01

AN400-04

ANA1-04

G27-20-R1

AN200-02

—

G27-20-01

AN400-04

ANA1-04

Note 1) In the case of option GN, two pressure gauges and one silencer are included as accessories.

Note 2) KT-VBA22A-7N, KT-VBA22A-8N are pressure gauges with fittings. (Please order two units when using with IN and OUT.)

Note 3) Under the new measurement law, the pressure unit of “psi” on the pressure gauges cannot be used in Japan.

Note 4) Pressure unit of pressure gauge: psi

Note 5) Pressure unit of pressure gauge: psi and MPa

Note 6) Only simple indication of MPA for the pressure gauges

Pressure Gauge, Silencer (When thread type is NPT or NPTF.)

Model

Description

Pressure gauge ∗: no symbol

Note 6)

Pressure gauge ∗: when “-Z”

Note 4)

Silencer

High-noise reduction silencer

G

N

S

VBA10A-N02

∗

VBA10A-T02

∗

∗

: when “-Z”

VBA20A-N03

∗

VBA20A-T03

∗

∗

: when “-Z”

VBA40A-N04

∗

VBA40A-T04

∗

∗

: when “-Z”

VBA22A-N03

∗

VBA22A-T03

∗

∗

: when “-Z”

VBA42A-N04

∗

VBA42A-T04

∗

∗

: when “-Z”

VBA1111-N02

NVBA1111-T02

VBA43A-N04

∗

VBA43A-T04

∗

∗

: when “-Z”

G27-20-01

G27-P20-01

AN200-N02

—

G36-10-N01

G36-P10-N01

AN300-N03

ANA1-N03

AN400-N04

ANA1-N04

KT-VBA22A-7N

KT-VBA22A-8N

AN300-N03

ANA1-N03

G36-10-N01

G36-P10-N01

AN400-N04

ANA1-N04

G27-20-R1-X214

Note 5)

—

AN200-N02

—

G27-20-N01

G27-P20-N01

AN400-N04

ANA1-N04

Mist Separator, Exhaust Cleaner

Standard Specifications

(Rc)

(Rc)

Options/Part No.

1. System configuration

• The IN port of the booster regulator has a metallic mesh to prevent dust from entering the booster regulator. However, it cannot remove dust continuously or separate drainage. Make sure

to install a mist separator (AM series) at the inlet side of the

booster regulator.

• The booster regulator has a sliding part inside, and it generates

dust. Also, install a cleaning device such as an air filter or a

mist separator on the outlet side as necessary.

• Connect a lubricator to the outlet side, because the accumulated

oil in the booster regulator may result in a malfunction.

2. Exhaust air measures

• Provide a dedicated pipe to release the exhaust air from each

booster regulator. If exhaust air is converged into a pipe, the

back pressure that is created could cause improper operation.

• Depending on the necessity, install a silencer or an exhaust

cleaner on the exhaust port of the booster regulator to reduce

the exhausting sound.

3. Maintenance space

• Allow the sufficient space for maintenance and inspection.

Caution

Design

Booster Regulator

Series VBA

2

12

11

10

9

8

7

6

5

4

3

2

1

0

Charge time per 10 liters t (s)

1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0

Pressure increase ratio P2/P

1

1.0

0.8

0.6

0.4

0.2

Outlet pressure (MPa)

0 200 400 600 800 1000 1200

Outlet air flow (l/min (ANR))

1.04

1.02

1.

0

0.98

0.96

0.94

Outlet pressure (MPa)

0 0.4 0.5 0.6 0.7 0.8 0.9 1

Inlet pressure (MPa)

1.0

0.8

0.6

0.4

0.2

Outlet pressure (MPa)

0 500 1000 1500 2000

Outlet air flow (l/min (ANR))

1.04

1.02

1.0

0.98

0.96

0.94

Outlet pressure (MPa)

0 0.4 0.5 0.6 0.7 0.8 0.9 1

Inlet pressure (MPa)

5

4

3

2

1

0

Charge time per 10 liters t (s)

1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0

Pressure increase ratio P2/P

1

60

50

40

30

20

10

0

Charge time per 10 liters t (s)

1.0 1.2 1.4 1.6 1.8 2.0

Pressure increase ratio P2/P

1

2

1.5

1

0.5

Outlet pressure (MPa)

0 100 200 300 400

Outlet air flow (l/min (ANR))

1.1

1.05

1.

0

0.95

0.

9

0.85

0.

8

Outlet pressure (MPa)

0 0.50.4 0.6 0.7 0.8 0.9 1

Inlet pressure (MPa)

P1 = 0.5 MPa

P1 = 0.4 MPa

P1 = 0.3 MPa

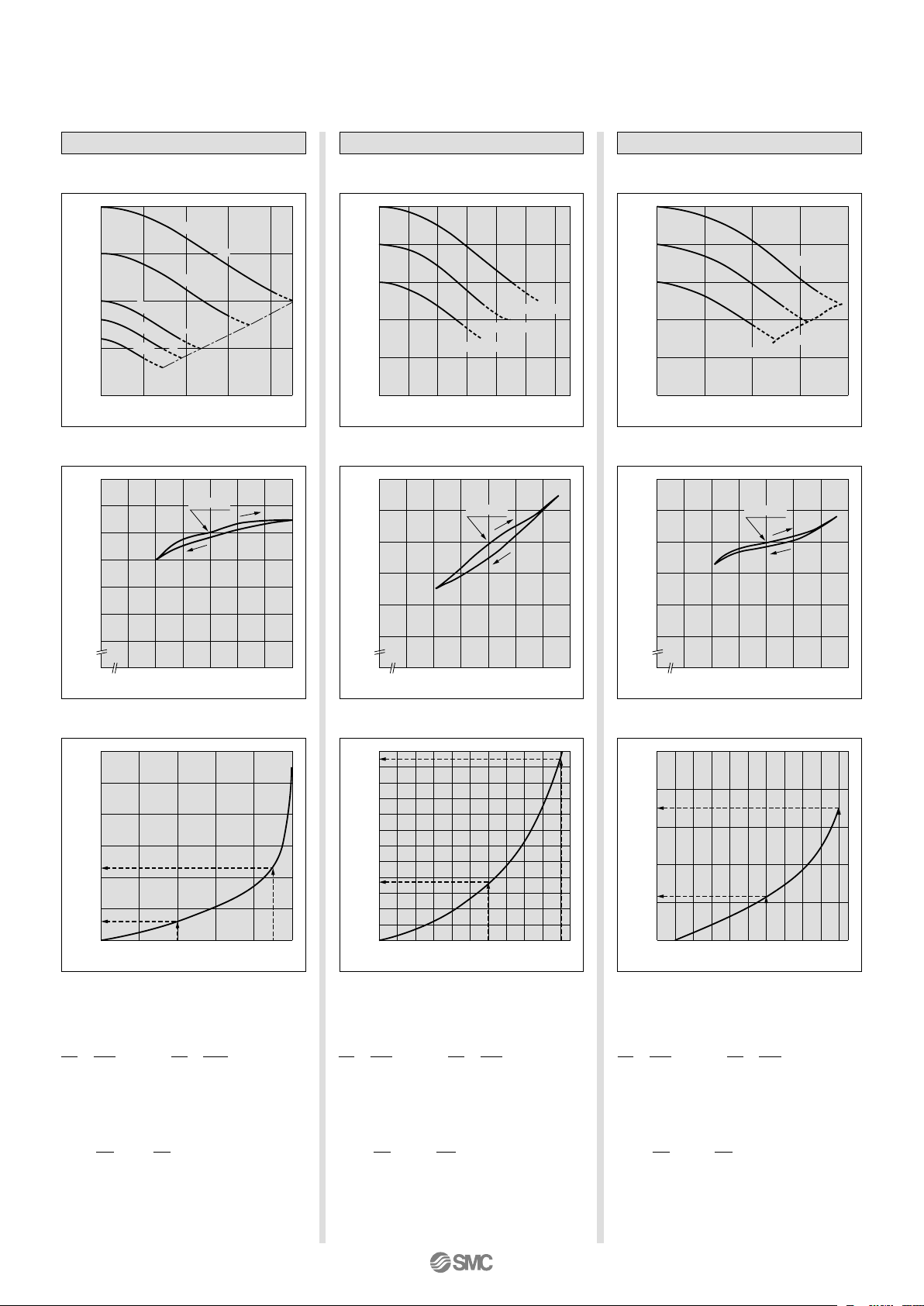

VBA20A, 22A

VBA20A, 22A

Flow Characteristics

Charge Characteristics

Set point

VBA40A, 42A

VBA40A, 42A

P1 = 0.5 MPa

P1 = 0.4 MPa

P1 = 0.3 MPa

Flow Characteristics

Charge Characteristics

Set point

VBA10A

VBA10A

Flow Characteristics

Pressure

Characteristics

Pressure

Characteristics

Pressure

Characteristics

Charge Characteristics

P

1

= 1.0 MP

a

P

1

= 0.75 MP

a

P

1

= 0.5 MPa

P

1

= 0.4 MP

a

P

1

= 0.3 MPa

P1 = P2

Set point

Inlet pressure: 0.7 MPa

Outlet pressure: 1.0 MPa

Flow rate: 20 l/min (ANR)

Inlet pressure: 0.7 MPa

Outlet pressure: 1.0 MPa

Flow rate: 20 l/min (ANR)

Inlet pressure: 0.7 MPa

Outlet pressure: 1.0 MPa

Flow rate: 20 l/min (ANR)

The time required to charge the tank pressure

from 0.7 MPa to 0.95 MPa at 0.5 MPa supply

pressure:

With the pressure increase ratio from 1.4 to 1.9,

the charge time of 23 – 6 = 17 sec. (t) is given

by the graph. Then, the charge time (T) for a

10 l tank:

P

2

P

1

0.7

0.5

= = 1.4 = 1.9 = 1.6 = 2.0

P

2

P

1

0.95

0.5

=

T = t x = 17 x = 17 (s).

V

10

10

10

The time required to charge the tank pressure

from 0.8 MPa to 1.0 MPa at 0.5 MPa supply

pressure:

With the pressure increase ratio from 1.6 to 2.0,

the charge time of 11.5 – 3.8 = 7.7 sec. (t) is

given by the graph. Then, the charge time (T)

for a 100 l tank:

P

2

P

1

0.8

0.5

=

P

2

P

1

1.0

0.5

=

T = t x = 7.7 x = 77 (s).

V

10

100

10

The time required to charge the tank pressure

from 0.8 MPa to 1.0 MPa at 0.5 MPa supply

pressure:

With the pressure increase ratio from 1.6 to 2.0,

the charge time of 3.5 – 1.1 = 2.4 sec. (t) is given

by the graph. Then, the charge time (T) for a

100

l tank:

P

2

P

1

0.8

0.5

= = 1.6 = 2.0

P

2

P

1

1.0

0.5

=

T = t x = 2.4 x = 24 (s).

V

10

100

10

Series VBA

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

Outlet pressure (MPa)

0 500 1000 1500 2000 2500 3000

Outlet air flow (l/min (ANR))

1.08

1.06

1.04

1.02

1.

0

0.98

0.96

0.94

Outlet pressure (MPa)

0 0.4 0.5 0.6 0.7 0.8 0.9 1

Inlet pressure (MPa)

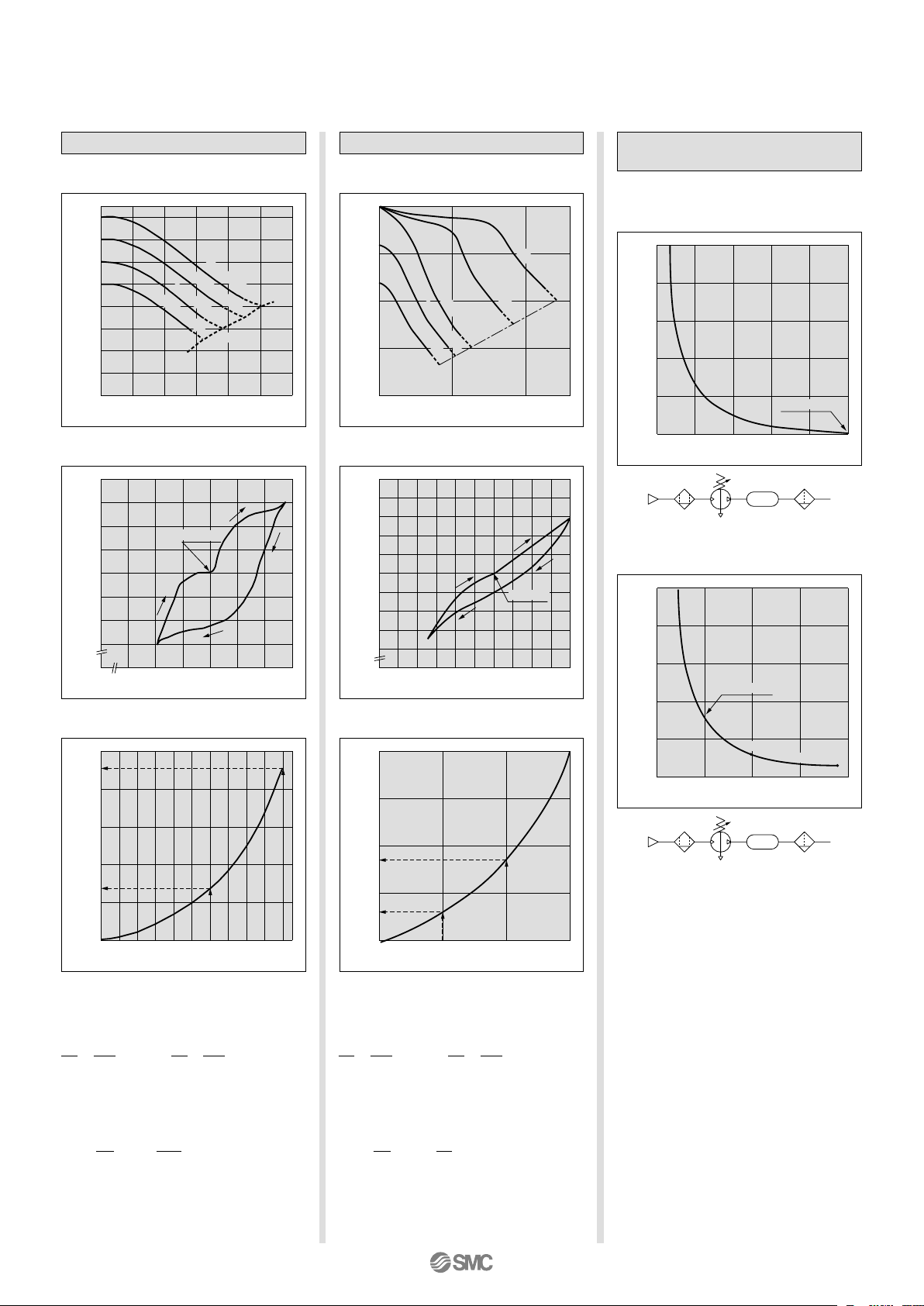

0.1

0.08

0.06

0.04

0.02

Max. pulsation range (MPa)

0 1 2 3 4 5

Capacity (l)

0.1

0.08

0.06

0.04

0.02

Max. pulsation range (MPa)

0 10 20 30 4038

Capacity (l)

400

300

200

100

0

Charge time per 10 liters t (s)

1.0 2.0 3.0 4.0

Pressure increase ratio P2/P

1

1.10

1.08

1.06

1.04

1.02

1.

0

0.98

0.96

0.94

0.92

Outlet pressure (MPa)

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Inlet pressure (MPa)

2

1

Outlet pressure (MPa)

0 100 13050

Outlet air flow (l/min (ANR))

5

4

3

2

1

0

Charge time per 10 liters t (s)

1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0

Pressure increase ratio P2/P

1

Pressure

Characteristics

Inlet pressure: 0.6 MPa

Outlet pressure: 1.0 MPa

Flow rate: 10

l/min (ANR)

= 2.0 = 3.0

T = t x = 110 x = 110 (s).

V

10

10

10

The time required to charge the tank pressure

from 1.0 MPa to 1.5 MPa at 0.5 MPa supply

pressure:

With the pressure increase ratio from 2.0 to 3.0,

the charge time of 170 – 60 = 110 sec. (t) is

given by the graph. Then, the charge time (T)

for a 10 l tank:

P

2

P

1

1.0

0.5

=

P

2

P

1

1.5

0.5

=

Pulsation/Pulsation is decreased

by using the tank.

If the outlet capacity is undersized, pulsation may

occur.

Conditions:

Inlet pressure: 0.5 MPa

Outlet set pressure: 1 MPa

Flow rate: Between 0 and max. flow rate

VBA2A

VBA4A

VBAT

VBA10A

•

Performance of the air tank

• Alleviates the pulsation generated on the

outlet side.

• Manages supply air to be consumed for

short periods of time by storing air through

raising the tank pressure.

Flow Characteristics

Charge Characteristics

P

1

= 0.8

M

Pa

P

1

= 0.7

M

P

a

P

1

= 0.6

M

P

a

P

1

=

0.5

M

Pa

P1 = P2

VBAT05A

Set point

VBA43A

VBA43A

VBAT05A

VBAT10A, VBAT20A, VBAT38A

VBAT10A

VBAT20A

VBAT38A

VBAT

VBA1111

VBA1111

Flow Characteristics

Charge Characteristics

P

1

=

P

2

P

1

= 1.0 MPa

P

1

= 0.75 MPa

P

1

= 0.5

M

P

a

P

1

= 0.4 MPa

P

1

= 0.3 MPa

Set point

Pressure

Characteristics

Inlet pressure: 0.7 MPa

Outlet pressure: 1.0 MPa

Flow rate: 20 l/min (ANR)

The time required to charge the tank pressure

from 0.8 MPa to 1.0 MPa at 0.5 MPa supply

pressure:

With the pressure increase ratio from 1.6 to 2.0,

the charge time of 4.5 – 1.3 = 3.2 sec. (t) is

given by the graph. Then, the charge time (T)

for a 100 l tank:

P

2

P

1

0.8

0.5

= = 1.6 = 2.0

P

2

P

1

1.0

0.5

=

T = t x = 3.2 x = 32 (s).

V

10

100

10

Booster Regulator

Series VBA

3

Booster Regulator

Series VBA

VBA43A

Flow Characteristics

1.6

1.4

1.2

1

0.8

0.6

Outlet pressure (MPa)

0.4

0.2

0 500 1000 1500 2000 2500 3000

P

Outlet air flow (l/min (ANR))

Pressure

Characteristics

1.08

1.06

1.04

1.02

1.

0

0.98

0.96

Outlet pressure (MPa)

0.94

0 0.4 0.5 0.6 0.7 0.8 0.9 1

Inlet pressure (MPa)

1

=

P

1

= 0.8

P

1

= 0.7

P

1

= 0.6

M

0.5

P

a

M

Pa

Outlet pressure: 1.0 MPa

Flow rate: 20 l/min (ANR)

Set point

M

Pa

M

P

a

2

P1 = P

Inlet pressure: 0.7 MPa

VBA1111

Flow Characteristics

2

P

1

= 0.75 MPa

P

1

P

1

= 0.4 MPa

P

1

= 0.3 MPa

1

= 0.5

M

P

a

Outlet pressure (MPa)

0 100 13050

Outlet air flow (l/min (ANR))

Pressure

Characteristics

1.10

1.08

1.06

1.04

1.02

1.

0

0.98

0.96

Outlet pressure (MPa)

0.94

0.92

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Inlet pressure (MPa)

P

1

= 1.0 MPa

2

P

=

1

P

Inlet pressure: 0.6 MPa

Outlet pressure: 1.0 MPa

Flow rate: 10

l/min (ANR)

Set point

Pulsation/Pulsation is decreased

by using the tank.

If the outlet capacity is undersized, pulsation may

occur.

VBAT05A

0.1

0.08

0.06

0.04

0.02

Max. pulsation range (MPa)

0 1 2 3 4 5

VBAT05A

Capacity (l)

VBAT

VBA10A

VBAT10A, VBAT20A, VBAT38A

0.1

0.08

0.06

0.04

VBAT10A

Charge Characteristics

5

4

3

2

1

Charge time per 10 liters t (s)

0

1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0

Pressure increase ratio P2/P

VBA43A

The time required to charge the tank pressure

from 0.8 MPa to 1.0 MPa at 0.5 MPa supply

pressure:

0.8

2

P

= = 1.6 = 2.0

1

0.5

P

With the pressure increase ratio from 1.6 to 2.0,

the charge time of 4.5 – 1.3 = 3.2 sec. (t) is

given by the graph. Then, the charge time (T)

for a 100 l tank:

V

T = t x = 3.2 x = 32 (s).

10

100

10

1.0

2

P

=

1

0.5

P

1

Charge Characteristics

400

300

200

100

Charge time per 10 liters t (s)

0

1.0 2.0 3.0 4.0

Pressure increase ratio P2/P

VBA1111

The time required to charge the tank pressure

from 1.0 MPa to 1.5 MPa at 0.5 MPa supply

pressure:

1.0

2

P

1

P

= 2.0 = 3.0

=

0.5

With the pressure increase ratio from 2.0 to 3.0,

the charge time of 170 – 60 = 110 sec. (t) is

given by the graph. Then, the charge time (T)

for a 10 l tank:

V

T = t x = 110 x = 110 (s).

10

10

10

1.5

2

P

=

1

0.5

P

1

0.02

Max. pulsation range (MPa)

0 10 20 30 4038

VBAT20A

VBAT38A

Capacity (l)

VBAT

VBA2A

VBA4A

Conditions:

Inlet pressure: 0.5 MPa

Outlet set pressure: 1 MPa

Flow rate: Between 0 and max. flow rate

Performance of the air tank

•

• Alleviates the pulsation generated on the

outlet side.

• Manages supply air to be consumed for

short periods of time by storing air through

raising the tank pressure.

4

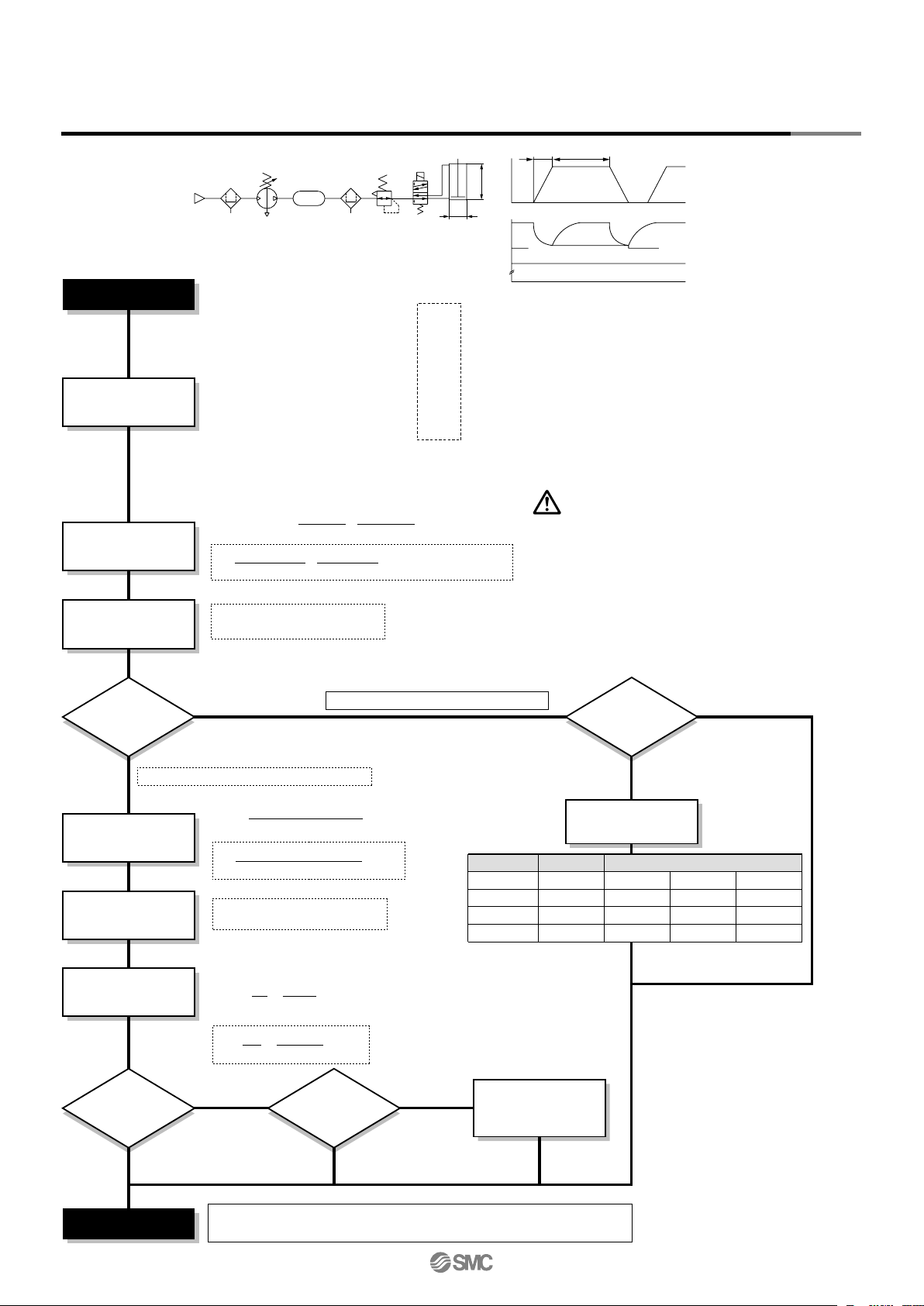

General line (low pressure) Locations requiring high pressure

VBA

VBA

VBA VBA

Operating pressure:

0.5 MPa

Bore size: ø100

Output: ≈3850N

Operating pressure:

0.8 MPa

Bore size: ø80

Output:

≈4000N

0.5 MPa

ø100

IN 0.5 MPa

E

ø80

OUT 0.8 MPa

P

2

P

1

Shortening time

Without check

valve by-pass

Time t (S)

Outlet pressure (MPa)

P

2

P

1

0

Plant line (source pressure)

(Two-stage

pressure boost)

VBA22A, VBA42A

IN (Inlet)

Governor

Booster

chamber

A

Drive

chamber

A

Switching valve

Piston

Drive

chamber

B

Booster chamber

B

Check valve

OUT

(Outlet)

E

Piston rod

Air-operated type

Pilot pressure

IN (Inlet)

Booster chamber

B

Booster

chamber

A

Piston

Check valve

OUT (Outlet)

Governor

Drive

chamber

A

E

Drive

chamber

B

Switching

valve

Equivalent

output

Circuit Example

Working Principle

The IN air passes through the check valve to booster chambers A and B. Meanwhile, air is supplied to drive chamber B via the governor and the

switching valve. Then, the air pressure from drive chamber B and booster chamber A are applied to the piston, boosting the air in booster cham-

ber B. As the piston travels, the boosted air is pushed via the check valve to the OUT side. When the piston reaches to the end, the piston causes

the switching valve to switch, so that drive chamber B is in the exhaust state and drive chamber A is in the supply state respectively. Then, the

piston reverses its movement, this time, the pressures from booster chamber B and drive chamber A boosts the air in booster chamber A and

sends it to the OUT side. The process described above is repeated to continuously supply highly pressurized air from the IN to the OUT side. The

governor establishes the outlet pressure by handle operation and pressure adjustment in the drive chamber by feeding back the outlet pressure.

• When only some of the machines in the plant require high-pressure

air, booster regulators can be installed for only the equipment that

requires it. This allows the overall system to use low air pressure

while accommodating machines requiring high-pressure air.

• When the actuator output is insufficient but space limitations prohibit

switching to a larger cylinder diameter, a booster regulator can be

used to increase the pressure. This makes it possible to boost the

output without replacing the actuator.

• When a certain level of output is required but the cylinder size must

be kept small so that the driver remains compact.

• When filling a tank or the like from a source at atmospheric

pressure, a circuit with a check valve can be used to reduce the

filling time by allowing air to pass through the check valve up to the

inlet pressure.

•

When only one side of the cylinder is used for work, booster

regulators can be installed only on the lines that require them to

reduce the overall air consumption volume.

VBA1111VBA10A, VBA20A, VBA40A, 43A

Initially, inlet pressure (P1) passes through the check valve, fills P2,

and results in P1 = P2.

Series VBA

Tc Ts

øD

L

P2P3P1

END

START

100

100

200

1

0.5

30

0.5

0.8

NO

NO

NO

YES

YES YES YES

YES

When running continuously for longer periods of time, confirm the life expectancy.

When the life expectancy is shorter than required, select a larger sized booster regulator

.

Select the tank

from table below.

Avoid

pulsation

(Max. 0.05

MPa)

Judgement

of charge time

T ≤ Ts

Provide requisite

conditions for

selection.

Calculate

required air flow

rate Q.

Select booster regula-

tor size from flow cha-

racteristics table.

Obtain the tank

volume V.

Select the tank

volume over V.

Calculate time T

from charge charac-

teristics table.

Increase number of

booster regulators

(Z) to decrease T.

Tank part no.

VBAT05A

VBAT10A

VBAT20A

VBAT38A

VBA10A

VBA10A

—

—

—

VBA2A

VBA2A

VBA2A

—

—

VBA4A

VBA4A

Applicable combination modelInner volume

Sizing (Sizing can be achieved by using SMC Pneumatic System Energy Saving Program Ver. 3.1.

Please contact your SMC sales representative.)

Lower limit of pressure inside tank P2

Pressure

Stroke

Upper limit of pressure inside tank P3

Inlet pressure P1

Time

Necessary supply

pressure to cylinder

P2

Example

Necessary conditions:

D [mm]: Cylinder bore size

L [mm]: Cylinder stroke

W [mm/s]: Cylinder operating speed

C [pc.]: Number of cylinders

Tc [s]: Cylinder operating time

Ts [s]: Cylinder stop time

P1 [MPa]: Inlet pressure

P2 [MPa]

Note 1)

: Necessary supply

pressure to cylinder

Note 1) P2 is the necessary supply pressure to a cylinder, and set the pressure below the lower limit of pressure inside the tank

with a regulator. Adjust the pressure taking the maximum operating pressure of equipment in use into consideration.

Note 2) P3 is the output pressure of the booster regulator, which is also the upper limit of charge pressure to a tank.

Other conditions:

Q [l/min (ANR)]: Required air flow rate

Qb [l/min (ANR)]: Outlet air flow rate of booster regulator

Tc [s]: Cylinder stroke time

K: Cylinder double-acting: 2, single-acting: 1

P3 [MPa]

Note 2)

: Tank charge pressure

T1 [s]: Time to charge (Time to charge to P2)

T2 [s]: Time to charge (Time to charge to P3)

T [s]: Time to charge (Time to charge from P2 to P3)

Z: Number of booster regulators

Judgement of

flow rate

Q [l/min (ANR)] =

π x D2 x W x (P2 + 0.101)

x 60 x

C

4 x 10

6

0.101

Q =

π x 1002 x 200 (0.8 + 0.101)

x 60 x 1 = 841

[l/min (ANR)]x

4 x 10

6

0.101

Refer to “Flow Characteristics” on pages 3 and 4.

VBA2A: Qb = 600 [l/min (ANR)]

VBA4A: Qb = 1050 [l/min (ANR)]

NO: Need no tank

The VBA4A can supply necessary pressure.

The

VBA2A

cannot obtain necessary pressure.

(P3 – P2) x 9.9

V [l] =

(Q – Qb/2) x (Tc x K/60)

V = = 4.6 [l]

(1.0 – 0.8) x 9.9

Select the VBAT10A, which can be

directly connected to the VBA2A.

(841 – 600/2) x (0.5 x 2/60)

Refer to “Charge Characteristics” on pages 3 and 4.

T = ( ) x = 3.5 [s]

T [s] = ( ) x

T2 – T

1

V

10

4.6

10

Z

11.5 – 3.8

1

Extend

stop time Ts

up to charge time

T or more.

Caution

Use the VBA1111 (pressure increase ratio 4) with pressure

increase ratio of 2 to 4. Usage of pressure increase ratio below

2 is preferred for the VBA10A (pressure increase ratio 2). A

stable operation and increased life expectancy will result.

Inlet supply pressure volume is approximately twice the volume

of the outlet side. {approx. 2 times (pressure increase ratio 2),

approx. 4 times (pressure increase ratio 4)}. Booster regulator

requires that the inlet side volume should be the sum of the flow

volume running into the outlet side and the volume exhausted

from E port (for driving), because air is the power source.

5 l

10

l

20 l

38

l

Booster Regulator

Series VBA

5

Booster Regulator

Series VBA

Sizing (Sizing can be achieved by using SMC Pneumatic System Energy Saving Program Ver. 3.1.

Please contact your SMC sales representative.)

Tc Ts

START

Provide requisite

conditions for

selection.

Calculate

required air flow

rate Q.

Select booster regulator size from flow characteristics table.

P2P3P1

Necessary conditions:

D [mm]: Cylinder bore size

L [mm]: Cylinder stroke

W [mm/s]: Cylinder operating speed

C [pc.]: Number of cylinders

Tc [s]: Cylinder operating time

Ts [s]: Cylinder stop time

P1 [MPa]: Inlet pressure

Note 1)

P2 [MPa]

Note 1) P2 is the necessary supply pressure to a cylinder, and set the pressure below the lower limit of pressure inside the tank

Note 2) P3 is the output pressure of the booster regulator, which is also the upper limit of charge pressure to a tank.

Q [l/min (ANR)] =

π x 1002 x 200 (0.8 + 0.101)

Q =

4 x 10

: Necessary supply

pressure to cylinder

with a regulator. Adjust the pressure taking the maximum operating pressure of equipment in use into consideration.

π x D2 x W x (P2 + 0.101)

6

4 x 10

6

0.101

0.101

Example

100

100

200

0.5

30

0.5

0.8

x 60 x

x 60 x 1 = 841

L

Stroke

øD

Other conditions:

Q [l/min (ANR)]: Required air flow rate

Qb [l/min (ANR)]: Outlet air flow rate of booster regulator

Tc [s]: Cylinder stroke time

K: Cylinder double-acting: 2, single-acting: 1

1

P3 [MPa]

T1 [s]: Time to charge (Time to charge to P2)

T2 [s]: Time to charge (Time to charge to P3)

T [s]: Time to charge (Time to charge from P2 to P3)

Z: Number of booster regulators

Upper limit of pressure inside tank P3

Lower limit of pressure inside tank P2

Pressure

Inlet pressure P

Time

Note 2)

: Tank charge pressure

1

Caution

C

[l/min (ANR)]x

Use the VBA1111 (pressure increase ratio 4) with pressure

increase ratio of 2 to 4. Usage of pressure increase ratio below

2 is preferred for the VBA10A (pressure increase ratio 2). A

stable operation and increased life expectancy will result.

Inlet supply pressure volume is approximately twice the volume

Necessary supply

pressure to cylinder

P2

of the outlet side. {approx. 2 times (pressure increase ratio 2),

VBA2A: Qb = 600 [l/min (ANR)]

VBA4A: Qb = 1050 [l/min (ANR)]

Refer to “Flow Characteristics” on pages 3 and 4.

approx. 4 times (pressure increase ratio 4)}. Booster regulator

requires that the inlet side volume should be the sum of the flow

volume running into the outlet side and the volume exhausted

from E port (for driving), because air is the power source.

Judgement of

flow rate

VBA2A

YES

The

Obtain the tank

volume V.

Select the tank

volume over V.

Calculate time T

from charge characteristics table.

Judgement

of charge time

T ≤ Ts

NO: Need no tank

cannot obtain necessary pressure.

(Q – Qb/2) x (Tc x K/60)

V [l] =

V = = 4.6 [l]

Select the VBAT10A, which can be

directly connected to the VBA2A.

Refer to “Charge Characteristics” on pages 3 and 4.

T [s] = ( ) x

T = ( ) x = 3.5 [s]

(P3 – P2) x 9.9

(841 – 600/2) x (0.5 x 2/60)

(1.0 – 0.8) x 9.9

V

10

4.6

11.5 – 3.8

10

NO

The VBA4A can supply necessary pressure.

1

T2 – T

Z

1

Extend

stop time Ts

up to charge time

T or more.

NO

Select the tank

from table below.

Tank part no.

VBAT05A

VBAT10A

VBAT20A

VBAT38A

5 l

10

20 l

38

Increase number of

booster regulators

(Z) to decrease T.

YES

l

l

Avoid

pulsation

(Max. 0.05

MPa)

Applicable combination modelInner volume

VBA10A

VBA10A

—

—

—

VBA2A

VBA2A

VBA2A

NO

—

—

VBA4A

VBA4A

YES YES YES

END

When running continuously for longer periods of time, confirm the life expectancy.

When the life expectancy is shorter than required, select a larger sized booster regulator

.

6

Design

Warning

1. Warning concerning abnormal outlet pressure

• If there is a likelihood of causing an outlet pressure drop

due to unforeseen circumstances such as equipment malfunction, thus leading to a major problem, take safety measures on the system side.

• Because the outlet pressure could exceed its set range if

there is a large fluctuation in the inlet pressure, leading to

unexpected accidents, take safety measures against abnormal pressures.

• Operate the equipment within its maximum operating pressure and set pressure range.

2. Residual pressure measures

• Connect a 3-port valve to the OUT side of the booster regulator if the residual pressure must be released quickly from

the outlet pressure side for maintenance, etc. (Refer to the

below diagram.) The residual outlet pressure side cannot be

released even if the 3-port valve is connected to the IN side

because the check valve in the booster regulator will activate.

• After operation is finished, release the supply pressure at the inlet. This stops the booster valve from moving needlessly and

prevents operating malfunctions.

Selection

Caution

1. Verify the specifications.

• Consider the operating conditions and operate this product

within the specification range that is described in this catalogue.

2. Selection

• Based on the conditions (pressure, flow rate, takt time, etc.)

required for the outlet side of the booster regulator, select

the size of the booster regulator in accordance with the selection procedures described in this catalogue or model selection program.

• Use the VBA1111 (pressure increase ratio 4) with pressure

increase ratio of 2 to 4. Usage of pressure increase ratio

below 2 is preferred for the VBA10A (pressure increase ratio 2). A stable operation and increased life expectancy will

result.

• Inlet supply pressure volume is approximately twice the volume of the outlet side. {approx. 2 times (pressure increase

ratio 2), approx. 4 times (pressure increase ratio 4)}. Booster regulator requires that the inlet side volume should be

the sum of the flow volume running into the outlet side and

the volume exhausted from E port (for driving), because air

is the power source.

• When running continuously for longer periods of time, confirm the life expectancy. The life expectancy of a booster regulator is dependent upon the operational cycle. Thus,

when used for driving cylinders, etc. in the outlet side, life

expectancy will be reduced.

• Make sure the outlet pressure is set more than 0.1 MPa higher than the inlet pressure. A pressure difference less than

0.1 MPa makes the operation unstable and may result in

malfunction.

Mounting

Caution

1. Transporting

• When transporting this product, hold it lengthwise with both

hands. Never hold it by the black handle that protrudes from

the centre because the handle could become detached

from the body, causing the body to fall and leading to injury.

2. Installation

• Install this product so that the silver-coloured tie-rods and

cover are placed horizontally. If mounted vertically, it may

result in malfunction.

• Because the piston cycle vibration is transferred, use the following mounting bolts (VBA1: M5; VBA2, 4: M10) and tighten them with the specified torque (VBA1: 3 N· m; VBA2, 4:

24 N·m).

• If the transmission of vibration is not preferred, insert an isolating rubber material before installation.

• The pressure gauge should be mounted with the following

torque. R 1/16: 3 to 4 N, R 1/8: 7 to 9

N

Piping

Caution

1. Flushing

• Use an air blower to flush the piping to thoroughly remove

any cutting chips, cutting oil, or debris from the piping inside, before connecting them. If they enter the inside of the

booster regulator, they could cause the booster regulator to

malfunction or its durability could be affected.

2. Piping size

• To bring the booster regulator’s ability into full play, make

sure to match the piping size to the port size.

Air Supply

Caution

1. Quality of air source

• Connect a mist separator to the inlet side near the booster

regulator. If the quality of the compressed air is not thoroughly controlled, the booster regulator could malfunction

(without being able to boost) or its durability could be affected.

• If dry air (atmospheric pressure dew point: –17°C or less) is

used, the life expectancy may be shortened because dry air

will accelerate evaporation of grease inside.

Operating Environment

Caution

1. Installation location

• Do not install this product in an area that is exposed to rainwater or direct sunlight.

• Do not install in locations influenced by vibrations. If it must

be used in such an area due to unavoidable circumstances,

please contact SMC beforehand.

Series VBA

Handling

1

0.9

0.8

0.7

0.6

0.5

0.5

0.4

0.4

0.3

0.3

0.2

0.2

Pilot pressure MPa

0.1

0.1

0

Outlet pressure MPa (Q = 0)

SMC

HighLow

1. Setting the pressure on the handle-operated type

• If air is supplied to the product in the shipped state, the air

will be released.

Set the pressure by quickly pulling up on the governor han-

dle, releasing the lock, and rotating the handle in the direc-

tion of the arrow (+).

• There is an upper and lower limit for the handle rotation. If

over-rotating the handle even after reaching to the limit, the

internal parts may be damaged. If the handle suddenly feels

heavy while being turned, stop turning the handle.

• Once the setting is completed, push the handle down and

lock it.

• To decrease the outlet pressure, after the pressure has

been set, rotate the handle in the direction of the arrow (–).

The residual air will be released from the area of the han-

dle, due to the relief construction of the governor.

• To reset the pressure, first reduce the pressure so that it is

lower than the desired pressure; then, set it to the desired

pressure.

Caution

2. Setting the pressure on the air-operated type

(VBA22A, 42A)

• Connect the outlet pipe of the pilot regulator for the remote

control to the pilot port (P). (Refer to the figure below.)

• Refer to the following figure for the relation between the

pilot pressure and outlet pressure.

• The AR20 and AW20 are recommended for the pilot regula-

tor.

Pilot regulator

• The outlet pressure is twice the pilot pressure.

• When the inlet pressure is 0.4 MPa:

Pilot pressure

0.2 MPa to 0.4 MPa

Outlet pressure

0.4 MPa to 0.8 MPa

3. Draining

• If this product is used with a large amount of drainage accu-

mulated in the filter, mist separator, or the tank, the draina-

ge could flow out, leading to equipment malfunction. There-

fore, drain the system once a day. If it

is equipped with an

auto-drain, check its operation once a day.

4. Exhaust

• Exhausting time from E port may be longer for a booster re-

gulator which is set to switch in longer hour intervals. This is

not an abnormal phenomenon.

5. Maintenance

• Life expectancy varies depending on the quality of air and

the operating conditions. Signs that the unit

is reaching the

end of its service life include the following:

•

Constant bleed from under the handle.

•

Air exhaust can be heard from the booster regulator at 10

to 20 second intervals even when there

is no air con-

sumption on the outlet side.

Conduct maintenance earlier than scheduled in such cases.

• When maintenance is required, confirm the model and serial

number of the booster regulator, and please contact SMC

for maintenance kit.

• Maintenance should be carried out according to the speci-

fied maintenance procedure by individuals possessing

enough knowledge and experiences in maintaining pneu-

matic equipment.

• The list of replacement parts and kit part number are shown

on page 9, and the figure shows the position of the parts.

Booster Regulator

Series VBA

7

Caution

1. Setting the pressure on the handle-operated type

• If air is supplied to the product in the shipped state, the air

will be released.

Set the pressure by quickly pulling up on the governor handle, releasing the lock, and rotating the handle in the direction of the arrow (+).

• There is an upper and lower limit for the handle rotation. If

over-rotating the handle even after reaching to the limit, the

internal parts may be damaged. If the handle suddenly feels

heavy while being turned, stop turning the handle.

• Once the setting is completed, push the handle down and

lock it.

• To decrease the outlet pressure, after the pressure has

been set, rotate the handle in the direction of the arrow (–).

The residual air will be released from the area of the handle, due to the relief construction of the governor.

• To reset the pressure, first reduce the pressure so that it is

lower than the desired pressure; then, set it to the desired

pressure.

SMC

HighLow

2. Setting the pressure on the air-operated type

(VBA22A, 42A)

• Connect the outlet pipe of the pilot regulator for the remote

control to the pilot port (P). (Refer to the figure below.)

• Refer to the following figure for the relation between the

pilot pressure and outlet pressure.

• The AR20 and AW20 are recommended for the pilot regula-

tor.

Handling

3. Draining

4. Exhaust

5. Maintenance

Booster Regulator

Series VBA

• If this product is used with a large amount of drainage accumulated in the filter, mist separator, or the tank, the drainage could flow out, leading to equipment malfunction. Therefore, drain the system once a day. If it

is equipped with an

auto-drain, check its operation once a day.

• Exhausting time from E port may be longer for a booster regulator which is set to switch in longer hour intervals. This is

not an abnormal phenomenon.

• Life expectancy varies depending on the quality of air and

the operating conditions. Signs that the unit

is reaching the

end of its service life include the following:

•

Constant bleed from under the handle.

•

Air exhaust can be heard from the booster regulator at 10

to 20 second intervals even when there

is no air con-

sumption on the outlet side.

Conduct maintenance earlier than scheduled in such cases.

• When maintenance is required, confirm the model and serial

number of the booster regulator, and please contact SMC

for maintenance kit.

• Maintenance should be carried out according to the specified maintenance procedure by individuals possessing

enough knowledge and experiences in maintaining pneumatic equipment.

• The list of replacement parts and kit part number are shown

on page 9, and the figure shows the position of the parts.

Pilot regulator

• The outlet pressure is twice the pilot pressure.

• When the inlet pressure is 0.4 MPa:

Pilot pressure

0.2 MPa to 0.4 MPa

Outlet pressure

0.4 MPa to 0.8 MPa

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

Outlet pressure MPa (Q = 0)

0.2

0.1

0

0.2

0.1

Pilot pressure MPa

0.3

0.4

0.5

8

Air-operated type

VBA22A, 42A

VBA1111

VBA10A VBA20A, 22A,

VBA40A, 42A, 43A

Replacement Parts/Kit Part No.

The kit includes the parts from to and a grease pack.

Model

No.

1

2

3

4

5

6

—

Piston seal

Governor assembly

Check valve

Gasket

Rod seal

Mounting screw

Grease pack

Description

Place an order with the following applicable kit part number.

Model

Kit part no.

VBA43A VBA1111VBA42AVBA22AVBA40AVBA20AVBA10A

KT-VBA10A-1 KT-VBA20A-1 KT-VBA40A-1 KT-VBA22A-1 KT-VBA42A-1 KT-VBA43A-1 KT-VBA1111-2

VBA43A VBA1111VBA42AVBA22AVBA40AVBA20AVBA10A

Quantity

2

4

2

1

8

1

— 8 12

2

1

1

8

1

12

2

1 each large and small

2 large 1 small 2

∗ The grease pack has 10 g of grease.

∗ Make sure to refer to the procedure for maintenance.

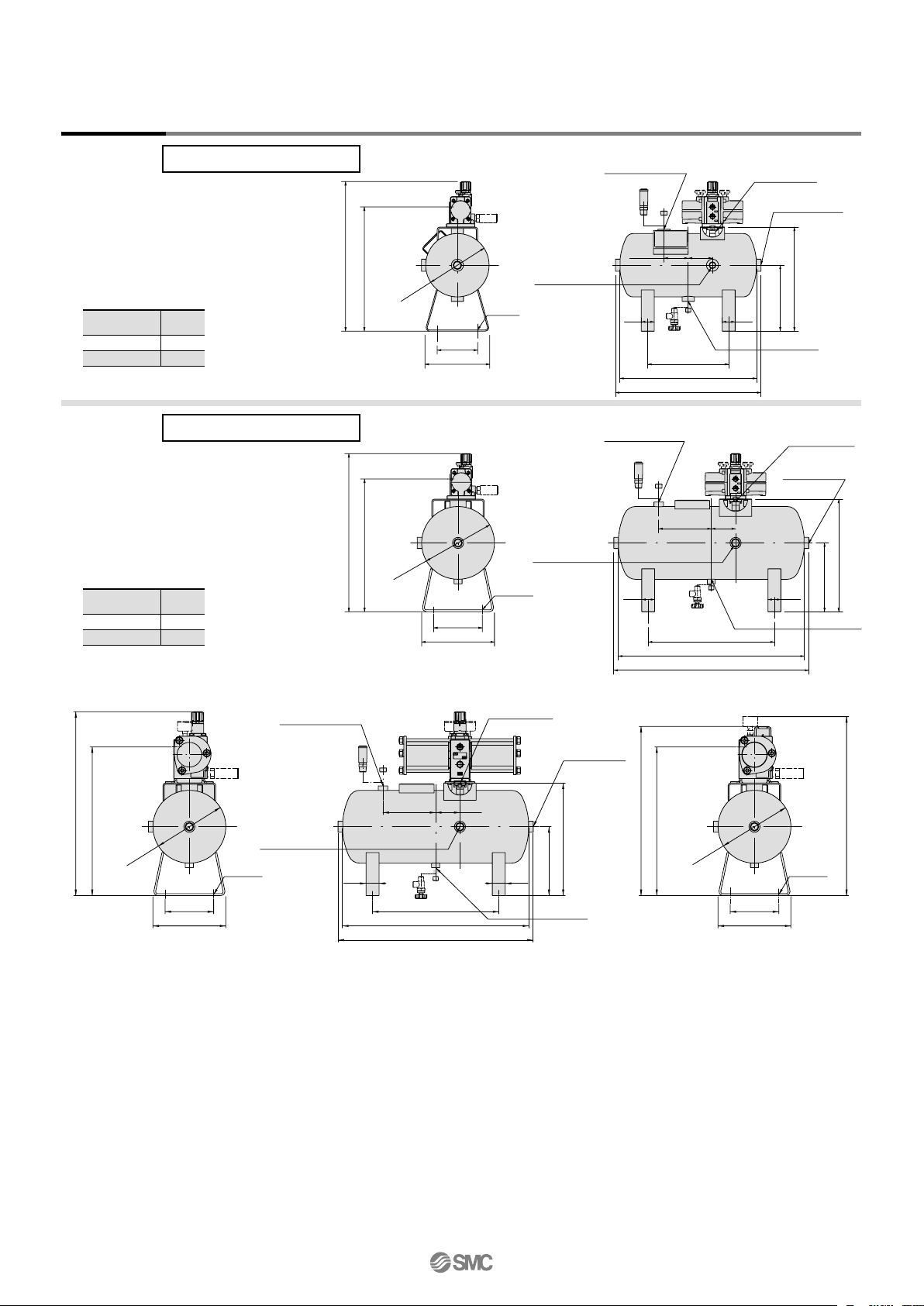

Construction/Replacement Parts

Series VBA

28

21

98

118

176

46 43

OUT port

Rc 3/8

IN port

Rc 3/8

Silencer (Option)

4 x ø12

EXH port

Rc 3/8

15

24

IN side gauge port

Rc 1/

8

300

39

OUT side gauge port

Rc 1/8

Pressure gauge (Option)

3.2

53

73

43

22

130

150

215

62.8 62

OUT port

Rc 1/2

IN port

Rc 1/2

Silencer (Option)

EXH port

Rc 1/2

EXH port

Rc 1/4

8

32

4 x ø12

IN side gauge port

Rc 1/

8

404

40

OUT side gauge port

Rc 1/8

Pressure gauge (Option)

3.2

96

116

150

60

IN side gauge port

Rc 1/

8

OUT side gauge port

Rc 1/8

Pressure gauge (Option)

40

8.5

50

113

27 23

OUT port

Rc 1/4

IN port

Rc 1/4

4 x ø5.5

EXH port

Rc 1/4

Silencer (Option)

60

70

22

28

IN

OUT

4 x ø5.5

Pressure gauge (Option)

IN port

Rc 1/4

OUT port

Rc 1/4

Silencer (Option)

IN side gauge port

Rc 1/16

OUT side gauge port

Rc 1/16

40

10

50

60

150

60

70

27 23

108.5

22

25

44

VBA10A-02

VBA1111-02

VBA20A-03

VBA40A-04

Dimensions

Booster Regulator

Series VBA

9

Dimensions

Booster Regulator

Series VBA

VBA10A-02

IN port

113

Rc 1/4

OUT port

Rc 1/4

27 23

4 x ø5.5

VBA20A-03

IN port

176

Rc 3/8

OUT port

Rc 3/8

46 43

4 x ø12

150

60

28

Silencer (Option)

22

60

70

28

21

98

118

EXH port

Rc 1/4

15

EXH port

Rc 3/8

Silencer (Option)

24

IN side gauge port

Rc 1/

8

IN side gauge port

Rc 1/

40

50

300

39

8

53

73

8.5

Pressure gauge (Option)

OUT side gauge port

Rc 1/8

Pressure gauge (Option)

OUT side gauge port

Rc 1/8

3.2

VBA40A-04

IN port

Rc 1/2

215

OUT port

Rc 1/2

62.8 62

4 x ø12

VBA1111-02

IN port

108.5

Rc 1/4

OUT port

Rc 1/4

27 23

404

40

43

IN side gauge port

8

Rc 1/

8

Silencer (Option)

22

32

130

150

44

25

60

70

EXH port

Rc 1/2

EXH port

Rc 1/4

Silencer (Option)

4 x ø5.5

116

150

OUT side gauge port

Rc 1/16

22

Pressure gauge (Option)

OUT side gauge port

Rc 1/8

96

60

IN

OUT

40

50

10

3.2

Pressure gauge (Option)

IN side gauge port

Rc 1/16

10

21

15

24

46 43

139

28

3.2

Silencer (Option)

EXH port

Rc 3/8

4 x ø12

OUT port

Rc 3/8

IN port

Rc 3/8

Pressure gauge (Option)

OUT side gauge port

Rc 1/8

IN side gauge port

Rc 1/

8

43

172

62.8 62

32

8

22

3.2

Pressure gauge (Option)

IN side gauge port

Rc 1/

8

OUT side gauge port

Rc 1/8

4 x ø12

EXH port

Rc 1/2

Silencer (Option)

OUT port

Rc 1/2

IN port

Rc 1/2

221

32

8

22

43

62.8 62

3.2

Pressure gauge (Option)

OUT side gauge port

Rc 1/8

IN side gauge port

Rc 1/

8

Silencer (Option)

EXH port

Rc 1/2

4 x ø12

OUT port

Rc 1/2

IN port

Rc 1/2

39

73

53

300

40

404

96

116

116

96

40

404

118

98

130

150

150

130

VBA22A-03

VBA42A-04

VBA43A-04

The inner or outer copper parts material has

been changed to stainless steel or aluminum. The fluorine resin parts has been

changed to general resin.

20

Made to Order

Copper-free/Fluorine-free

56

Made to Order

CE explosion-proof directive

(ATEX): Category 3GD

Ozone resistance is strengthened through

the use of fluororubber (diaphragm) and

hydrogenated NBR (valve, rod seal) for the

rubber parts of the seal material.

∗ Inquire about booster regulator with pressure gauge.

∗ This option cannot be selected for air tank with

safety valve.

∗ Weather resistant NBR (diaphragm) and

hydrogenated NBR (valve) is used for the rubber

parts of standard products.

80

Made to Order

Ozone resistant

Standard model no.

Standard model no.

Standard model no.

Made to Order

Please contact SMC for detailed dimensions,

specifications, and lead times.

Dimensions

Copper-free/Fluorine-free

1

CE explosion-proof directive (ATEX) compliant

2

Ozone resistant

3

Series VBA

11

Model (Carbon Steel)

Model

Fluid

Tank capacity

(l)

Max. operating pressure (MPa)

IN port size (Rc)

OUT port size (Rc)

Ambient and fluid temperature (°C)

Weight (kg)

Material

Paint

VBAT05A

5 10

2.0

0 to 75

Carbon steel

Outside: Silver paint, Inside: Rustproof paint

1.0

20 38

3/8

3/8

6.6

3/8

1/2

10.0

1/2

1/2

14.0

1/2

3/4

21.0

VBAT10A VBAT20A VBAT38A

∗ Accessories and options are included in the same container.

Compressed air

VBAT05A

VBAT38A

VBAT 10 A

Material

Carbon steel (SS400)

Material

Symbol

A

Inner volume

5 l

10 l

20 l

38 l

Tank inner volume

Symbol

05

10

20

38

Thread type

Rc

G

Thread type

Symbol

—

F

S

Note 1) The safety valve is not applicable for copper-free,

fluorine-free specification (20-).

Note 2) A safety valve port

is provided only when option R

or S is selected.

Note) Applicable product self-

declamation document

attached.

Option

None

Safety valve

Note 1) Note 2)

(Set pressure 1 MPa)

Applicable model

All models

VBAT20A

VBAT38A

Option

Symbol

—

R

Safety valve

Note 1) Note 2)

(Set pressure 2 MPa)

VBAT05A

VBAT10A

S

Option

Drain valve

Option

Symbol

V

Standards

CE marking

CE compatible product

Symbol

Q

• Compact connections are possible

with booster regulators.

• It can be used alone as a tank.

• Also compatible with CE standards

How to Order

Air Tank

Series VBAT

Made to Order

(For details, refer to page 11.)

QV

12

Drain valve

Safety valve

IN PORT

R1/4

19

OUT PORT

Rc 1/8

20

ø30

58 (CLOSE) to

63 (OPEN)

Safety valve

VBAT-R, VBAT-S

Drain valve

VBAT-V1

52

65

R 3/8

19

ø18.5

EU

CE Marking

Simple Pressure

Vessels Directive

Applicable product

Self-declaration document

attached (The G-thread type

is 6 mm longer due to plug

type differences.)

VBAT05A-SV-Q, VBAT05AF-SV-Q

VBAT10A-SV-Q, VBAT10AF-SV-Q

VBAT20A-RV-Q, VBAT20AF-RV-Q

VBAT38A-RV-Q, VBAT38AF-RV-Q

Country/Region

Law Exportable models Details

Model

VBAT05A VBAT10A VBAT20A VBAT38A

VBATA (Carbon Steel) Accessories/Part No.

VBAT5A-Y-3

VBAT-V1

VBAT10A-Y-3

VBAT20A-Y-3

Note 1) The set pressure of the safety valve cannot be changed.

Note 2) The safety valve is a safety measure that protects the tank from excess pressure. The valve opens

automatically when the specified pressure is reached, releasing express pressure inside the tank. The

valve closes again when the pressure drops below a designated value. Select a pressure valve

appropriate for the maximum operating pressure specification of the tank.

VBAT-S

(Set pressure 2 MPa)

VBAT-R

(Set pressure 1 MPa)

Booster regulator

VBA2A

VBA10A

VBA1111

VBA40A

VBA42A

—

—

—

—

—

The pressure vessel law is different from country to country, so an air tank suitable to a

country needs to be manufactured.

Please select from the below table. For details on all products except for CE markings,

please contact SMC.

Drain valve

Safety valve

VBAT05A

VBAT10A

VBAT20A

VBAT38A

List of Air Tank for Overseas

Accessory kit

Design

Warning

1. Operating pressure

• Operate this product at or below the maximum

operating pressure.

If it is necessary, take appropriate safety measures to ensure that the

maximum operating pressure is not exceeded.

• When the tank alone is used

Use a pressure switch or a safety valve to make

sure that the maximum operating pressure is

not exceeded.

2. Connection

• Connect a filter or a mist separator to the OUT

side of the tank. Because the inner surface of

the tank

is untreated, there is a possibility of

dust flowing out to the outlet side.

• Using tank accessories, a VBA booster regulator

can be connected directly in the combinations

indicated below.

Air tank

Selection

Caution

• Consider the operating conditions and operate

this product within the specification range.

• When using the air tank with a booster valve, refer to “Sizing” on page 6 or SMC Pneumatic

System Energy Saving Program.

1. Inspection

• The use of pressure vessels could lead to an

unexpected accident due to external damage or

internal corrosion caused by drainage. Therefore, make sure to check periodically for external

damage, or the extent of internal corrosion

through the port hole. An ultrasonic thickness

indicator may also be used to check for any reduction in material thickness.

2. Draining

• If this product is used with a large amount of

drainage, the drainage could flow out, leading to

equipment malfunction or corrosion inside the

tank. Therefore, drain the system once a day.

Maintenance

Warning

1. Accessories

• See the operating manual (VBAT-M1, VBAT-M2,

VBAT-M3, VBAT-M4) regarding combining

booster regulators with older model air tanks.

• The accessories are secured by bands to the

feet of the tank. Once removed, make sure not

to lose them.

2. Installation

• Tank should be installed away from people. It is

dangerous

if the accumulated air inside the tank

were to seep out.

• Do not mount the air tank on a moving part or a

place with vibration.

• When connecting a booster regulator with the

tank, refer to the operating manual first, which is

provided with the air tank before assembling.

• Refer to the operating manual regarding mounting methods when using long bolts.

• To mount the air tank on a floor surface, use the

four holes to secure the tank with bolts or anchor bolts.

Mounting

Caution

Series VBAT

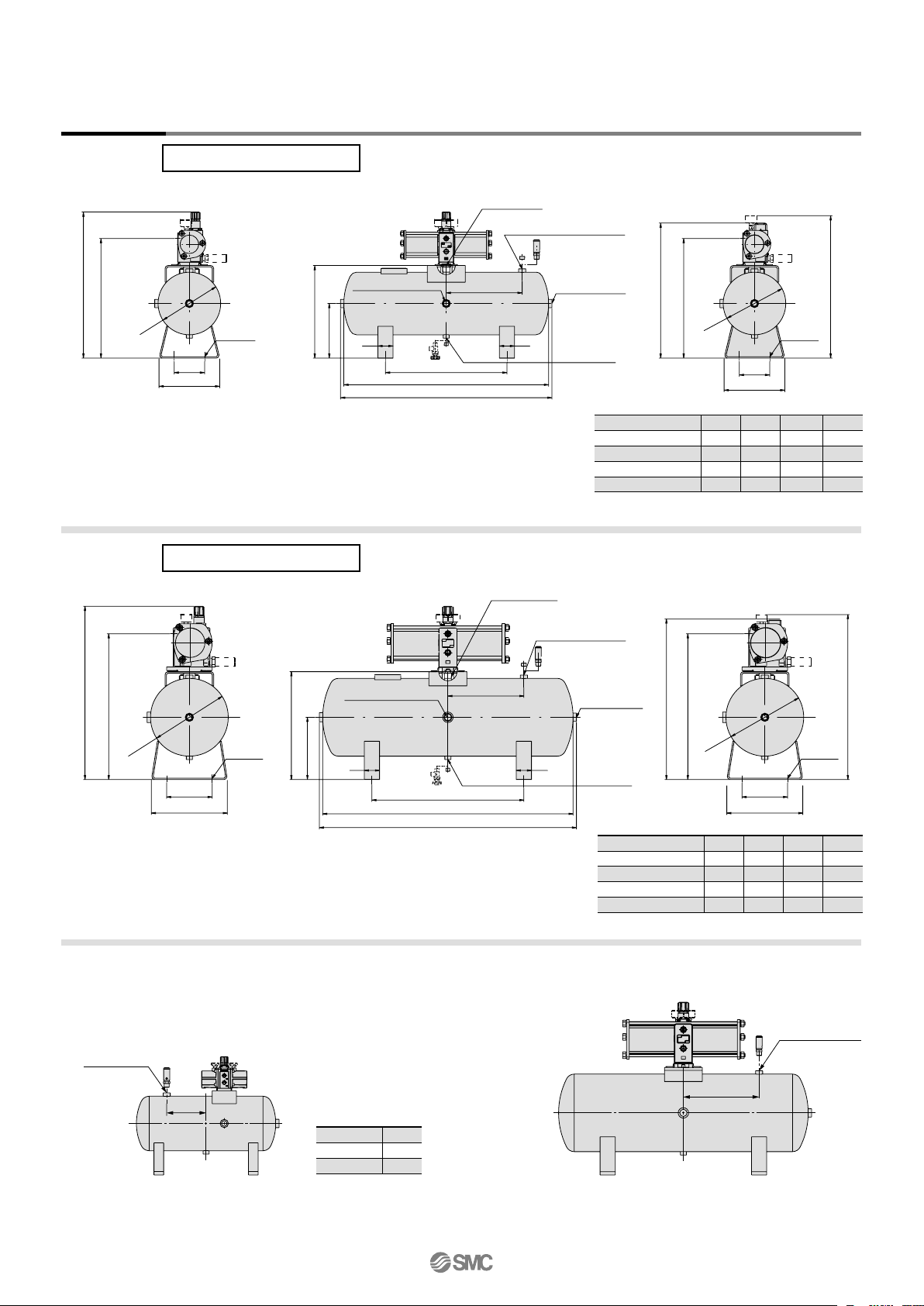

442

∗

(417)

ø180

(367)

180

120

EXH: Rc3/8

4 x ø11

Booster regulator

IN port

Rc 3/8

OUT

Booster regulator

IN port

Rc 3/8

120

180

(454)

(367)

OUT

4 x ø11

EXH: Rc 3/8

ø180

Booster regulator

IN port

Rc 1/4

OUT

(307)

(A)

EXH: Rc1/4

4 x ø11

100

160

ø156

Booster regulator

IN port

Rc 1/4

OUT

(A)

(328)

EXH: Rc1/4

4 x ø11

120

180

ø180

Tank OUT port

Rc 3/8

200

163

257

338

349

∗

6060

3232

Drain port

Rc 1/4

Inspection port

2 x Rc 1/2

Tank IN port

Rc 3/8

Tank OUT port

Rc 1/2

170

278

60130

3232

Drain port

Rc 1/4

312

460

471

∗

Inspection port

2 x Rc 1/2

Tank IN port

Rc 3/8

Safety valve port

Rc 3/8

Safety valve port

Rc 3/8

Safety valve port

Rc 3/8

Tank OUT port

Rc 1/2

Drain port

Rc 1/4

278

170

312

60130

460

471

∗

32

32

Inspection port

2 x Rc 1/2

Tank IN port

Rc 3/8

Connected to VBA20A

∗

The length may be longer than the specification if the plugs mounted on the tank are not fit to the end.

∗

The length may be longer than the specification if the plugs mounted on the tank are not fit to the end.

∗

The length may be longer than the specification if the plugs mounted on the tank are not fit to the end.

A

370

365.5

Connected to VBA22A

Booster regulator

model

VBA10A

VBA1111

A

391

386.5

Booster regulator

model

VBA10A

VBA1111

Connected to VBA10A, 1111

VBAT05A

Material: Carbon steel

Material: Carbon steel

Connected to VBA10A, 1111

VBAT10A

Dimensions

Air Tank

Series VBAT

13

Dimensions

Air Tank

Series VBAT

VBAT05A

Connected to VBA10A, 1111

Booster regulator

model

VBA10A

VBA1111

∗

The length may be longer than the specification if the plugs mounted on the tank are not fit to the end.

VBAT10A

Connected to VBA10A, 1111

Booster regulator

model

VBA10A

VBA1111

∗

The length may be longer than the specification if the plugs mounted on the tank are not fit to the end.

Material: Carbon steel

(A)

A

370

365.5

Material: Carbon steel

(A)

A

391

386.5

Booster regulator

IN port

Rc 1/4

OUT

(307)

ø156

Booster regulator

IN port

Rc 1/4

OUT

(328)

ø180

EXH: Rc1/4

4 x ø11

100

160

EXH: Rc1/4

4 x ø11

120

180

Tank OUT port

Rc 3/8

Tank OUT port

Rc 1/2

Safety valve port

Rc 3/8

Safety valve port

Rc 3/8

200

338

349

Tank IN port

Rc 3/8

Inspection port

2 x Rc 1/2

6060

257

163

3232

Drain port

Rc 1/4

∗

Tank IN port

Rc 3/8

Inspection port

2 x Rc 1/2

60130

278

170

3232

312

460

471

∗

Drain port

Rc 1/4

Connected to VBA20A

Booster regulator

IN port

Rc 3/8

(454)

(367)

OUT

ø180

120

180

EXH: Rc 3/8

Tank OUT port

Rc 1/2

4 x ø11

Safety valve port

Rc 3/8

32

Connected to VBA22A

Tank IN port

Rc 3/8

Inspection port

2 x Rc 1/2

60130

278

170

32

312

460

∗

471

∗

The length may be longer than the specification if the plugs mounted on the tank are not fit to the end.

Drain port

Rc 1/4

Booster regulator

IN port

Rc 3/8

(417)

(367)

EXH: Rc3/8

OUT

ø180

4 x ø11

120

180

∗

442

14

ø256

(A)

(B)

D

250

150

Booster regulator IN port

C

OUT

EXH: C

4 x ø13

Tank OUT port

Rc 3/4

Drain port

Rc 1/4

355

205

500

5050

824

835

∗

Tank IN port

Rc 3/4

Inspection port

2 x Rc 1/2

C

150

250

(A)

(B)

OUT

4 x ø13

EXH:

C

ø256

Booster regulator

IN port

(A)

D

(B)

ø206

200

100

EXH: C

OUT

Booster regulator IN port

C

4 x ø13

Inspection port

2 x Rc 1/2

Tank OUT port

Rc 1/2

Drain port

Rc 1/4

305

180

50

250

250

50

696

∗

400

674

Tank IN port

Rc 3/4

C

100

200

(A)

(B)

OUT

4 x ø13

EXH: C

ø206

Booster regulator

IN port

Safety valve port

Rc 3/8

Safety valve port

Rc 3/8

250

A

Safety valve port

Rc 3/8

Safety valve port

Rc 3/8

VBAT A1-

With safety valve

A

60

130

VBAT05

VBAT10

Tank model

(mm)

05

10

R

S

VBAT A1-

With safety valve

20

38

R

S

D

Note)

—

—

519

543

B

444

479.8

444

479.8

C

Rc 3/8

Rc 1/2

Rc 3/8

Rc 1/2

A

531

570

494

527

VBA20A

VBA40A

VBA22A

VBA42A

Booster regulator model

Note) Option: when G (pressure gauge) is selected

(mm)

∗

The length may be longer than the specification if the plugs mounted on the tank are not fit to the end.

Note) Option: when G (pressure gauge) is selected

(mm)

D

Note)

—

—

469

493

B

394

429.8

394

429.8

C

Rc 3/8

Rc 1/2

Rc 3/8

Rc 1/2

A

481

520

444

477

VBA20A

VBA40A

VBA22A

VBA42A

Booster regulator model

∗

The length may be longer than the specification if the plugs mounted on the tank are not fit to the end.

Connected to VBA22A, 42AConnected to VBA20A, 40A

VBAT38

A

Dimensions

Material: Carbon steel

Connected to VBA22A, 42A

Material: Carbon steel

Connected to VBA20A, 40A

VBAT20

A

Series VBAT

15

Safety Instructions

Be sure to read “Handling Precautions for SMC Products” (M-E03-3) before using.

Lithuania

+370 5 2308118 www.smclt.lt info@smclt.lt

Netherlands +31 (0)205318888 www.smcpneumatics.nl info@smcpneumatics.nl

Norway +47 67129020 www.smc-norge.no post@smc-norge.no

Poland +48 222119600 www.smc.pl office@smc.pl

Portugal

+351 226166570 www.smc.eu postpt@smc.smces.es

Romania +40 213205111 www.smcromania.ro smcromania@smcromania.ro

Russia +7 8127185445 www.smc-pneumatik.ru info@smc-pneumatik.ru

Slovakia +421 413213212 www.smc.sk office@smc.sk

Slovenia +386 73885412 www.smc.si office@smc.si

Spain +34 945184100 www.smc.eu post@smc.smces.es

Sweden +46 (0)86031200 www.smc.nu post@smcpneumatics.se

Switzerland +41 (0)523963131 www.smc.ch info@smc.ch

Turkey

+90 (0)2124440762

www.entek.com.tr smc@entek.com.tr

UK

+44 (0)845 121 5122

www.smcpneumatics.co.uk sales@smcpneumatics.co.uk