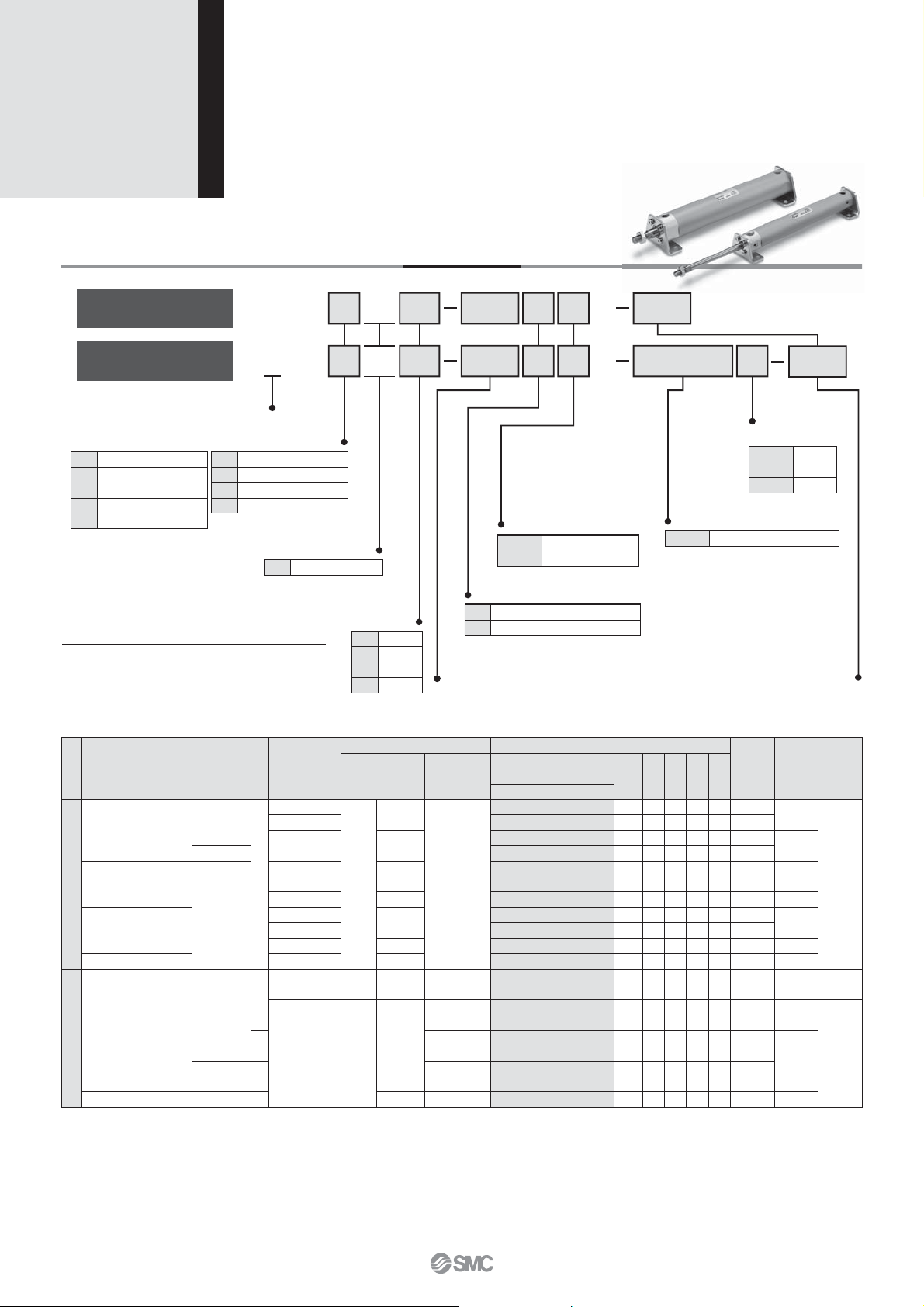

Air Cylinder

New

New

ø20, ø25, ø32, ø40, ø50, ø63, ø80, ø100

Female rod end

available as

standard

Selectable

Rod end styles

suitable for the

application can

be selected.

Easy fine adjustment of auto switch position

No trunnion mounting female thread

RoHS

Male threadFemale thread

Fine adjustment of the auto switch position

is possible by simply loosening the screw

attached to the auto switch.

Transparent switch bracket improves

visibility of indicator LED.

Fine adjustment of auto switch

LED colour indicator

Screw attached to auto switch Switch bracket

added to basic type variation

No foreign matter accumulation due

to the simple construction

No trunnion mounting female thread

Series/Made to Order set additionallySeries/Made to Order set additionally

¡

Standard type: Double rod, Single acting ¡Non-rotating type

¡

Direct mount type ¡Made to Order: Heat resistant cylinder

(-XB6), Made of stainless steel (-XC6) and Dual stroke cylinder

(-XC10, 11) etc. are added.

Series CG1

CAT.EUS20-224B-UK

Air Cylinder

Part numbers with rod end bracket and/or pivot bracket available

Not necessary to order a bracket for the applicable cylinder separately

Note) Mounting bracket is shipped together with the product, but not assembled.

Example)

Pivot bracket

— None

Pivot bracket is

shipped together

N

with the product,

but not assembled.

∗ Applicable to only mounting D,

U and T.

CDG1 N20-50Z- N W -M9BW

N: Kit of pivot bracket

and clevis

D

Mounting

Kit of pivot bracket

and trunnion

Various mounting bracket options

s3UITABLEMOUNTINGBRACKETSCANBESELECTEDFOR

the installation condition.

s)MPROVEDAMOUNTOFMOUNTINGFREEDOM

Single knuckle joint

Rod trunnion

Basic

Rod end bracket

— None

V

Single knuckle joint

Double knuckle jointW

Head trunnion

Clevis

With rod end bracket

V: Single

knuckle joint

W: Double

knuckle joint

Pivot bracket

Head flange

Axial foot

Double knuckle joint

Rod flange

Axial foot

Basic (No trunnion mounting female thread)

Easy fine adjustment of auto switch position

Fine adjustment of the auto switch set position can be performed by loosening the

auto switch attached screw without loosening the auto switch mounting band.

Operability improved compared with the conventional auto switch set position

adjustment, where the complete switch mounting

band requires loosening.

Switch bracket

Switch holder

Visibility of the indicator

LED improved with the

transparent resin switch bracket

(Standard specification)

Screw attached to auto switch

Auto switch

No environmental hazardous

substances used

Compliant with EU RoHS directive.

Lead free bushing is used as sliding material.

Specifications, performance and

mounting method are same as the

existing product.

Grease is selectable. (Option)

쐌

Grease for food processing equipment (XC85)

쐌

PTFE grease (X446)

Water resistant compact auto

switch now available

쐌

Solid state auto switch D-M9첸A(V)

Features 1

Auto switch mounting screw

Auto switch mounting band

Series CG1

Stroke Variations

Bore size [mm]

20

25

32

40

50

63

80

100

Series Variations

Series CG1-Z

Series

Standard

CG1-Z

Action

Double

acting

Rod

Single rod

Cushion

Rubber

bumper

Air

cushion

Standard stroke

75 100 125 150 200 250 30020 50

Bore size [mm]

20 25 32 40 50 63 80

100

With

rod boot

Variations

Air-hydro

Clean

series

[mm]

Page

Page 1

Non-rotating rod

CG1K-Z

Direct mount

CG1R-Z

Series CG1

Direct mount,

Non-rotating rod

CG1KR

With end lock

CBG1

Double

acting

Single

acting

Double

acting

Double

acting

Double

acting

Double

acting

Double

acting

Rubber

bumper

Double rod

Air

cushion

Single rod

(Spring return

Single rod

Double rod

Single rod

Single rod

Single rod

/extend)

Rubber

bumper

Rubber

bumper

Air

cushion

Rubber

bumper

Rubber

bumper

Air

cushion

Rubber

bumper

Rubber

bumper

Air

cushion

Page 18

Page 25

Page 30

Page 34

Page 38

www.smc.eu

Short type

Standard

CG3

Series CG3

Double

acting

Single rod

Rubber

bumper

Features 2

Combinations of Standard Products and Made to Order Specifi cations

Series CG1

: Standard

: Made to Order

: Special product (Please contact SMC for details.)

: Not available

—

Symbol Specifi cations

Standard

Long st

D

CG1쏔-쏔

CG1쏔H

10-

Note 9)

20-

R

CG1쏔

V

XB6

XB7

XB9

XB13

XC4

XC6

XC8

Standard

Long stroke

Built-in magnet

J

With rod boot ø20 to ø100

K

Air-hydro type ø20 to ø63

Clean series ø20 to ø100

Note 8)

Copper

Water resistant ø32 to ø100

Heat resistant cylinder (−10 to 150°C)

Cold resistant cylinder (−40 to 70°C)

Low speed cylinder (10 to 50 mm/s)

Low speed cylinder (5 to 50 mm/s)

With heavy duty scraper ø32 to ø63

Made of stainless steel ø20 to ø100

Adjustable stroke cylinder/

Adjustable extension type

and Fluorine-free ø20 to ø100

Series

Action/

type

Cushion

Page

Applicable bore size

ø20 to ø100

Note 7)

Note 7)

ø20 to ø100

CG1

(Standard type)

Double acting

Single rod Double rod Single rod

Rubber Air Rubber Air Rubber

Page 1 Page 18 Page 25

ø20 to ø100 ø20 to ø40

Single acting

Note 11)

—

Note 11)

Note 1)

Note 11)

Note 11)

——

Note 1)

Note 2)

Note 2)

Note 2)

Note 2) Note 5)

—

—

Note 6)

——

XC9

XC10

XC11

XC12

XC13

XC20

XC22

XC27

XC29

XC35

XC37

XC42

XC85

X446

Note 1) ø40 to ø63 only

Note 2) Without bumper

Note 3) ø32 to ø100 only

Note 4) SV type only (Heat resistant grease is used.)

Note 5) ø20 to ø63 only

Note 6) Single acting/spring return type (S) only

Note 7) The products with an auto switch are not compatible.

Note 8) Copper-free for the externally exposed part

Note 9) For details, refer to www.smc.eu.

Note 10) Long stroke is beyond the performance guarantee.

Note 11) Female rod end is available as a special order.

Adjustable stroke cylinder/

Adjustable retraction type

Dual stroke cylinder/Double rod type

Dual stroke cylinder/Single rod type

Tandem cylinder

Auto switch rail mounting ø20 to ø100

Head cover axial port ø20 to ø63

Fluororubber seal

Double clevis and double knuckle joint

pins made of stainless steel

Double knuckle joint with spring pin

With coil scraper

Larger throttle diameter of connection port

Built-in shock absorber in head cover side

Grease for food processing equipment ø20 to ø100

PTFE grease ø20 to ø100

ø20 to ø63

ø20 to ø100

ø20 to ø63

——

——

——

Note 2) Note 2)

——

Note 5) Note 5)

——

——

Front matter 1

Series CG1

(Non-rotating rod type)

CG1K

Double acting Double acting

Single rod Double rod Single rod

Rubber Air Rubber Rubber Air

Page 30 Page 34 Page 38

ø20 to ø63 ø40 to ø63 ø20 to ø63 ø20 to ø63

CG1R

(Direct mount type)

Note 10)

Note 10)

Note 10)

———

———

—

———

———

———

———

———

———

Note 2)

Note 2)

———

Symbol

Standard

Long st

D

CG1쏔-쏔

CG1쏔H

10-

Note 9)

20-

R

CG1쏔

V

XB6

XB7

XB9

XB13

XC4

XC6

CG1CG1WCG1CG1KCG1KWCG1R

Double Acting, Single RodDouble Acting, Double Rod

StandardNon-rotating RodDirect Mount

J

K

Single Acting, Spring Return/Extend

—

—

—

—

—

Note 2)

———

—

XC8

XC9

XC10

XC11

XC12

XC13

XC20

XC22

XC27

XC29

XC35

XC37

XC42

XC85

X446

Double Acting, Single RodDouble Acting, Double RodDouble Acting, Single Rod

Auto SwitchMade to Order

Front matter 2

Air Cylinder: Standard Type

Double Acting, Single Rod

Series CG1

RoHS

ø20, ø25, ø32, ø40, ø50, ø63, ø80, ø100

How to Order

CG1

With auto switch

CDG1

20NB

20 Z

100

100

Z

With auto switch

(Built-in magnet)

Mounting

B

∗

Basic (without trunnion mounting female thread)

Z

L

F

G

∗

U

∗

T

D

∗ Not available for ø80 or ø100.

∗ Mounting bracket is shipped together with

the product, but not assembled.

∗

The cylinder for F, G, L, D mounting types is Z:

Basic (without trunnion mounting female thread).

Basic

Axial foot

Rod fl ange

Head fl ange

Rod trunnion

Head trunnion

Clevis

Bore size

20

25

32

40

50

63

80

100

Type

Rubber bumper

N

Air cushion

A

20 mm

25 mm

32 mm

40 mm

50 mm

63 mm

80 mm

100 mm

Pivot bracket

—

Pivot bracket is shipped together

N

with the product, but not assembled

∗ Only for D, U, T mounting types

∗ Pivot bracket is shipped together

with the product, but not assembled.

Rod end bracket

—

V

W

∗ No bracket is provided for the female rod end.

∗ Rod end bracket is shipped together with the product, but not assembled.

∗ A knuckle joint pin is not provided with the single knuckle joint.

Port thread type

Air cushion

Rc ø32 to ø100

G ø32 to ø100

Rod end thread

Male rod end

—

Female rod end

F

Cylinder stroke [mm]

Refer to “Standard Strokes” on page 2.

—

TN

TF

Rc ø20 to ø100

NPT ø20 to ø100

M5 x 0.8 ø20, ø25

G ø32 to ø100

Rubber bumper

M5 x 0.8 ø20, ø25

NPT ø32 to ø100

Applicable Auto Switches/Refer to the Auto Switch Guide for further information on auto switches.

Type

∗∗∗

∗ Lead wire length symbols: 0.5 m·················· — (Example) M9NW

1 m·················· M

3 m··················

5 m··················

None

∗ Since there are other applicable auto switches than listed, refer to page 47 for details.

∗ For details about auto switches with pre-wired connector, refer to the Auto Switch Guide.

∗ The D-A9쏔쏔/M9쏔쏔쏔 auto switches are shipped together, (but not assembled). (However, only the auto switch mounting brackets are assembled before shipment.)

Special

function

—

Diagnostic indication

(2-colour indication)

Solid state auto switch

Water resistant

(2-colour indication)

With diagnostic output (2-colour indication)

—

Reed auto switch

Diagnostic indication (2-colour indication)

Water resistant type auto switches can be mounted on the above models, but in such case SMC cannot guarantee the water resistance.

A water-resistant type cylinder is recommended for use in an environment which requires water resistance. However, please contact SMC for water-resistant products of ø20 and ø25.

Electrical

entry

Grommet

Connector

Grommet

Grommet

Connector

Grommet

Wiring

(Output)

Indicator light

3-wire (NPN)

3-wire (PNP)

2-wire 12 V

3-wire (NPN)

Yes

3-wire (PNP)

2-wire 12 V

3-wire (NPN)

3-wire (PNP)

2-wire 12 V

4-wire (NPN)

3-wire (NPN equivalent)

Yes

No

Yes

2-wire 24 V

No

Yes

No

Yes

L

··············· N (Example) H7CN

Z

Load voltage

DC AC

5 V, 12 V

5 V, 12 V

24 V

5 V, 12 V

5 V, 12 V

—5 V —

12 V

—— —

(Example) M9NWM

(Example) M9NWL

(Example) M9NWZ

Perpendicular

—

M9NAV

M9PAV

M9BAV

100 V

100 V or less

100 V, 200 V

200 V or less

——

24 V or less

∗ Solid state auto switches marked with “쑗” are produced upon receipt of order.

Auto switch model

Applicable bore size

ø20 to ø63 ø80, ø100

In-line In-line

M9NV M9N

——

M9PV M9P

——

M9BV M9B

—

H7C

M9NWV M9NW

——

M9PWV M9PW

——

M9BWV M9BW

——

∗∗∗

∗∗∗

∗∗∗

——

—

∗∗∗

M9NA

∗∗∗

M9PA

∗∗∗

M9BA

H7NF G59F

A96V A96

A93V A93

A90V A90

—

—

C73C

—

C80C

B59W

B54

B64

1

V

W

NND

None

Single knuckle joint

Double knuckle joint

—

G59

—

G5P

—

K59

—

—

G59W

—

G5PW

—

K59W

—

—

—

G5BA

—

—

—

—

—

M9BW

None

∗ In the case of w/rod boot, and a foot bracket or

rod fl ange as a bracket, those parts are to be

assembled at the time of shipment.

∗ For female rod end, no rod boot is provided.

Lead wire length [m]

0.5

(—)1[m]3(L)5(Z)

∗∗∗

——

Made to Order

For details, refer to page 2.

Number of auto switches

—

S

n

2 pcs.

1 pc.

“n” pcs.

Auto switch

Without auto switch

—

∗ For applicable auto switches,

refer to the table below.

Suffi x for cylinder (Rod boot)

—

J

K

—

—

—

—

—

—

—

—

——— —

—

——— —

—

——— —

—

—

——— — —

Without rod boot

Nylon tarpaulin

Heat resistant tarpaulin

Pre-wired

connector

None

[N]

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—— —

——

—

—

Applicable

load

IC

circuit

———

IC

circuit

—

IC

circuit

—

IC circuit

IC circuit

IC circuit

—

IC circuit

Relay,

PLC

—

Relay,

PLC

Specifi cations

Air Cylinder: Standard Type

Double Acting, Single Rod

Series CG1

Symbol

Rubber bumper

Refer to pages 42 to 47 for cylinders with

auto switches.

· Auto switch proper mounting position

(detection at stroke end) and its mounting

height

· Minimum stroke for auto switch mounting

· Operating range

· Auto switch mounting brackets/Part no.

Air cushion

Made to Order

(For details, refer to pages 49 to 65.)

Symbol Specifi cations

Change of rod end shape

-XA쏔

Heat resistant cylinder (–10 to 150°C)

-XB6

Cold resistant cylinder (–40 to 70°C)

-XB7

Low speed cylinder (10 to 50 mm/s)

-XB9

Low speed cylinder (5 to 50 mm/s)

-XB13

With heavy duty scraper

-XC4

Made of stainless steel

-XC6

Adjustable stroke cylinder/Adjustable extension type

-XC8

Adjustable stroke cylinder/Adjustable retraction type

-XC9

Dual stroke cylinder/Double rod type

-XC10

Dual stroke cylinder/Single rod type

-XC11

Tandem cylinder

-XC12

Auto switch rail mounting

-XC13

Head cover axial port

-XC20

Fluororubber seal

-XC22

Double clevis and double knuckle joint pins made of stainless steel

-XC27

Double knuckle joint with spring pin

-XC29

With coil scraper

-XC35

Larger throttle diameter of connection port

-XC37

Built-in shock absorber in head cover side

-XC42

Grease for food processing equipment

-XC85

PTFE grease

-X446

3

∗

3

∗

1

∗

3

∗

∗1 Cylinders with rubber bumper have no bumper.

∗2 Only compatible with cylinders with rubber

bumper, but has no bumper.

∗3 Only compatible with cylinders with rubber

bumper.

1

∗

2

∗

3

∗

3

∗

∗3

3

∗

Bore size [mm]

Action Double acting, Single rod

Lubricant Not required (Non-lube)

20 25 32 40 50 63 80 100

CG1CG1WCG1CG1KCG1KWCG1R

Fluid Air

Proof pressure 1.5 MPa

Maximum operating pressure

Minimum operating pressure

Ambient and fl uid

temperature

Without auto switch:

With auto switch : –10°C to 60°C

Piston speed 50 to 1000 mm/s

Stroke length tolerance

Up to 1000 st

1.0 MPa

0.05 MPa

–

10°C to 70°C

+1.4

mm, Up to 1500 st

0

(No freezing)

50

to

+1.8

mm

0

700 mm/s

Double Acting, Single RodDouble Acting, Double Rod

StandardNon-rotating RodDirect Mount

Cushion Rubber bumper, Air cushion

Mounting

∗∗

Basic, Basic (without trunnion mounting female thread),

Axial foot, Rod fl ange, Head fl ange, Rod trunnion, Head

trunnion, Clevis (used for changing the port location by 90°)

Allowable

kinetic

energy

(J)

Rubber

bumper

Air

cushion

Male

rod end

Female

rod end

Male

rod end

Female

rod end

0.28 0.41 0.66 1.20 2.00 3.40 5.90 9.90

0.11 0.18 0.29 0.52 0.91 1.54 2.71 4.54

R: 0.35

H: 0.42

R: 0.56

H: 0.65

0.91 1.80 3.40 4.90 11.80 16.70

0.11 0.18 0.29 0.52 0.91 1.54 2.71 4.54

Single Acting, Spring Return/Extend

∗ R: Rod side, H: Head side

∗∗ Cylinder sizes ø80 and ø100 do not have basic (without trunnion mounting female thread), rod

trunnion and head trunnion types. Foot, fl ange and clevis types of cylinder sizes from ø20 to

ø63 do not have trunnion mounting female thread. Operate the cylinder within the allowable

kinetic energy.

Double Acting, Single RodDouble Acting, Double RodDouble Acting, Single Rod

Accessories

Axial

Rod

Mounting Basic

Standard

∗3

∗3

Option

Rod end nut

Clevis pin — — — — — —

Single knuckle joint

Double knuckle joint

∗∗

(with pin)

Pivot bracket

∗

Rod boot

foot

————

fl ange

Head

fl ange

Rod

trunnion

∗

Head

trunnion

∗

Clevis

∗ Not available for ø80 and ø100.

∗∗ A double knuckle joint pin and retaining rings are shipped together.

Standard Strokes

Bore size [mm]

∗3

20

25

Standard stroke [mm]

25, 50, 75, 100, 125, 150, 200 201 to 1500

Note1)

Long stroke [mm]

32

40

50, 63

25, 50, 75, 100, 125,

150, 200, 250, 300

301 to 1500

80

100

Note 1) Intermediate strokes not listed above are produced upon receipt of order. Manufacture of

intermediate strokes at 1 mm intervals is possible. (Spacers are not used.)

Note 2) The long stroke shows the maximum manufacturable stroke. For details about maximum

stroke that can be used for each mounting bracket, contact SMC.

Note 2)

Auto SwitchMade to Order

2

Series CG1

Ordering Example of Cylinder Assembly

Cylinder model: CDG1DN20-100Z-NW-M9BW

Auto switch

Clevis

Rod Boot Material

Symbol Rod boot mater

J

K

∗ Maximum ambient temperature for the rod

Mounting D: Clevis

Pivot bracket N: Yes

Rod end bracket W: Double knuckle joint

Auto switch D-M9BW: 2 pcs.

∗ Pivot bracket, double knuckle joint and auto

switch are shipped together with the product, but

not assembled.

Pivot bracket

Double knuckle joint

boot itself.

Mounting Brackets/Part No.

Mounting

bracket

Axial foot 2

Order

q’ty

Note 1)

20 25 32 40 50 63 80 100

CG-L020 CG-L025 CG-L032 CG-L040 CG-L050 CG-L063 CG-L080 CG-L100

Flange 1 CG-F020 CG-F025 CG-F032 CG-F040 CG-F050 CG-F063 CG-F080 CG-F100

Trunnion pin 1 CG-T020 CG-T025 CG-T032 CG-T040 CG-T050 CG-T063 — —

Clevis 1 CG-D020 CG-D025 CG-D032 CG-D040 CG-D050 CG-D063 CG-D080 CG-D100

Pivot bracket

Note 2)

1

CG-020-24A CG-025-24A CG-032-24A CG-040-24A CG-050-24A CG-063-24A CG-080-24A CG-100-24A

Note 1) Order two foots per cylinder.

Note 2) Can be combined with the trunnion pin and the clevis.

Bore size [mm]

Mounting Brackets, Accessories/Material, Surface Treatment

Maximum operating

temperature

Nylon tarpaulin 70°C

Heat resistant tarpaulin

Contents

2 foots,

8 mounting bolts

1 fl ange,

4 mounting bolts

2 trunnion pins, 2 trunnion bolts,

2 fl at washers

1 clevis, 4 mounting bolts,

1 clevis pin, 2 retaining rings

1 pivot bracket

110°C

∗

Segment Description Material Surface treatment

Foot Carbon steel Nickel plating

Carbon steel (ø20 to ø63) Nickel plating

Cast iron (ø80, ø100) Nickel plating

Carbon steel (ø20 to ø63) Nickel plating

Cast iron (ø80, ø100) Nickel plating

Mounting

brackets

Flange

Clevis

Trunnion pin Carbon steel Salt-bath nitrocarburising

Trunnion pin

Trunnion bolt Carbon steel Nickel plating

Flat washer Carbon steel Nickel plating

Rod end nut Carbon steel Zinc chromated

Carbon steel (ø20 to ø32) Nickel plating

Cast iron (ø40 to ø100) Zinc chromated

Carbon steel (ø20 to ø32) Nickel plating

Cast iron (ø40 to ø100) Zinc chromated

Accessories

Single knuckle joint

Double knuckle joint

Knuckle pin Carbon steel —

Clevis pin Carbon steel —

Pivot bracket

Carbon steel (ø20 to ø63) Nickel plating

Cast iron (ø80, ø100) Nickel plating

Mounting bolt Carbon steel Nickel plating

Retaining ring Carbon tool steel Phosphate coating

Mounting Procedure

Mounting procedure for trunnion

Follow the procedures below when mounting a

pivot bracket on the trunnion.

Cylinder body

Trunnion bolt (With

scotch grip) 4 or 5

times remounting

possible

Flat washer

(Put grease on the exterior.)

Pivot bracket

Trunnion pin

Mounting procedure for clevis

Follow the procedures below when mounting a pivot bracket on the clevis.

Retaining

ring

Clevis pin

(Put grease)

Cylinder body

Pivot bracket

Retaining

ring

ø80, ø100ø20 to ø63ø20 to ø63

Retaining

ring

Clevis pin

(Put grease)

Cylinder

body

Pivot bracket

Retaining

ring

3

Air Cylinder: Standard Type

Double Acting, Single Rod

Series CG1

Weights

Bore size [mm]

Basic (B) 0.11 0.17 0.24 0.44 0.79 1.06 2.07 3.16

Basic (Z) 0.11 0.17 0.25 0.45 0.80 1.09 — —

Axial foot 0.21 0.29 0.40 0.67 1.26 1.77 3.04 4.91

Flange 0.18 0.26 0.38 0.65 1.16 1.64 2.78 4.44

Basic weight

Pivot bracket 0.08 0.09 0.17 0.25 0.44 0.80 0.98 1.75

Single knuckle joint 0.05 0.09 0.09 0.10 0.22 0.22 0.39 0.57

Double knuckle joint (with pin) 0.05 0.09 0.09 0.13 0.26 0.26 0.64 1.31

Additional weight per 50 mm of stroke 0.05 0.07 0.09 0.14 0.21 0.25 0.35 0.50

Additional weight for switch magnet 0.01 0.01 0.01 0.01 0.01 0.02 0.02 0.04

Additional weight with air cushion 0 0.01 0.04 0 0.01 0.04 0 0.04

Weight reduction for female rod end −0.01 −0.02 −0.02 −0.05 −0.10 −0.10 −0.19 −0.27

Trunnion 0.12 0.19 0.28 0.49 0.88 1.20 — —

Clevis 0.17 0.25 0.39 0.68 1.19 1.78 2.77 4.44

Calculation (Example) CDG1FN20-100Z

(Built-in magnet, Flange, ø20, 100 stroke)

20 25 32 40 50 63 80 100

¡Basic weight ··········································0.18 kg (Flange, ø20)

¡Additional weight for stroke ···················0.05 kg/ 50 mm

¡Air cylinder stroke ·································100 mm

¡Additional weight for switch magnet ······0.01 kg

0.18 + 0.05 x (100/50) + 0.01 = 0.29 kg

[kg]

CG1CG1WCG1CG1KCG1KWCG1R

Double Acting, Single RodDouble Acting, Double Rod

StandardNon-rotating RodDirect Mount

Weights of Cylinder Movable Parts

Bore size [mm]

Male rod end 40.0 68.5 96.0

Female rod end 30.9 51.7 77.0

20 25 32 40 50 63 80 100

209.7 379.1 409.7 827.8

161.0 282.0 312.5 637.4

[g]

1259.7

991.5

Additional Weights

Bore size [mm]

Additional weight per 50 mm of stroke

Switch magnet

∗

Do not apply a lateral load over the allowable range to the rod end when it is mounted horizontally.

Standard weight of movable parts

Calculation (Example) CDG1BN40-150Z (Built-in magnet, Basic, ø40, 150 stroke)

¡

Standard weight of movable parts: Male rod end, Bore size [40] ··············209.7 g

¡

Additional weight: Additional weight of stroke

¡

Switch magnet ·····························································································12.6 g

Total 457.5 g

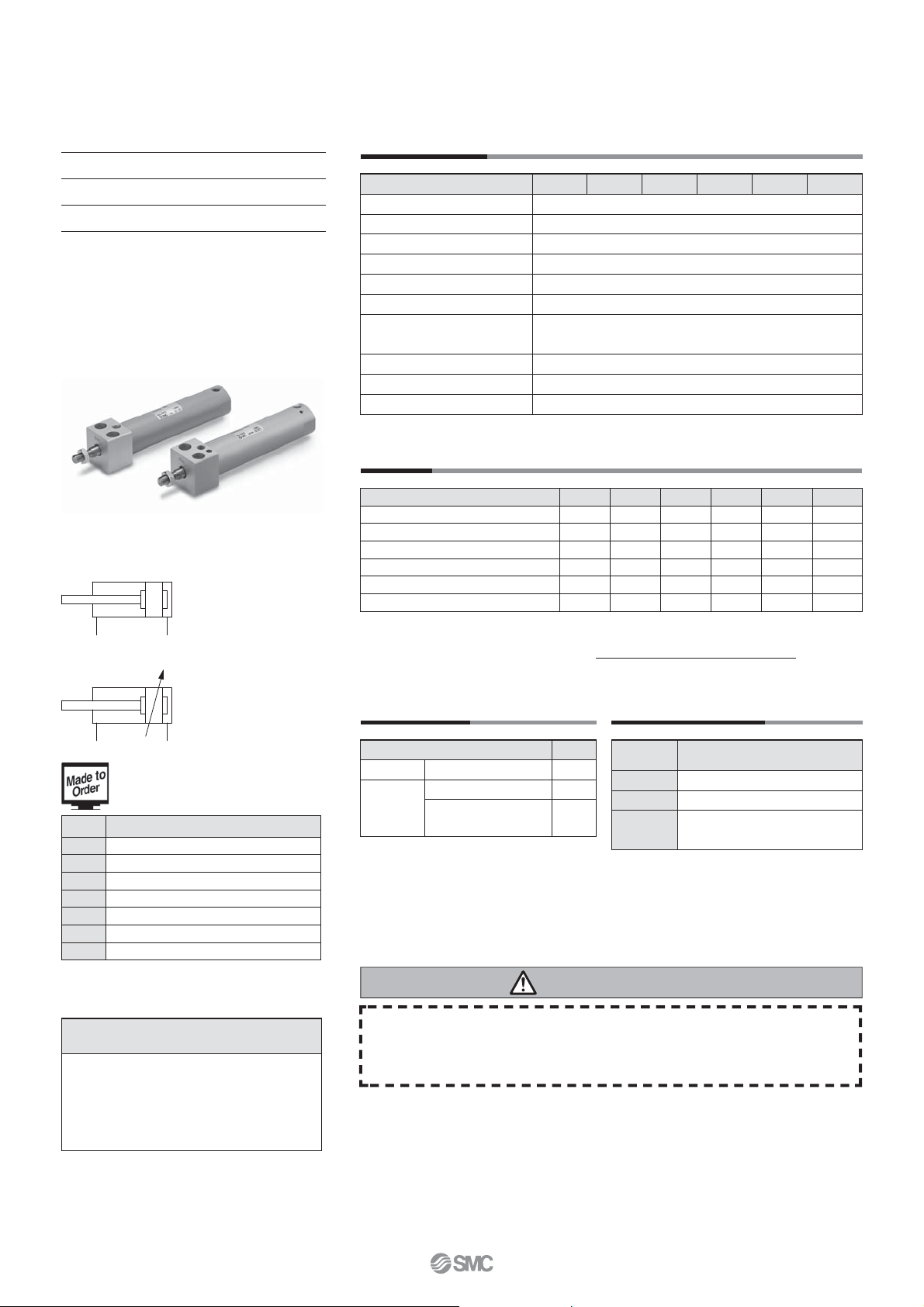

Clean Series Air-hydro

N10-CG1

Mounting style

Clean Series (With relief port)

The type which is applicable for using inside the clean room graded Class

100 by making an actuator’s rod section a double seal construction and

discharging by relief port directly to the outside of clean room.

Bore size

Stroke

Specifi cations

Bore size [mm]

Action Double acting

Fluid Air

Maximum operating pressure 1.0 MPa

Minimum operating pressure 0.05 MPa

Cushion Rubber bumper

Piston speed 30 to 400 mm/s

Relief port size M5 x 0.8

Mounting

∗ Auto switch can be mounted.

∗∗ The basic type is B type only. However, no trunnion mounting female

thread is provided.

20, 25, 32, 40, 50, 63, 80, 100

Basic, Axial foot, Rod fl ange,

Head fl ange

∗∗

Z

Mounting style

Low pressure hydraulic cylinder of 1.0 MPa or less

When using together with the CC series air-hydro unit, constant and low

speed actuation and intermediate stopping similar to hydraulic units are

possible with the use of valves and other pneumatic equipment.

Specifi cations

Bore size [mm]

Action Double acting

Fluid Turbine oil

Proof pressure 1.5 MPa

Maximum operating pressure 1.0 MPa

Minimum operating pressure 0.18 MPa

Piston speed 15 to 300 mm/s

Cushion None

Ambient and fl uid temperature

Mounting

∗ Auto switch can be mounted.

20 25 32 40 50 63 80 100

19.6 30.6 44.1 78.4

3.5 4.0 9.0 12.6

78.4 x 150/50 = 235.2 g ····235.2 g

HCG1

Bore size

Air-hydro

122.5 122.5 191.4 275.7

14.0 22.0 24.0 35.0

Stroke

Z

20, 25, 32, 40, 50, 63

5 to 60°C

Basic, Axial foot, Rod fl ange, Head

fl ange, Rod trunnion, Head trunnion,

Clevis (used for changing the port

location by 90°)

[g]

Single Acting, Spring Return/Extend

Double Acting, Single RodDouble Acting, Double RodDouble Acting, Single Rod

Auto SwitchMade to Order

S + Stroke

ZZ + Stroke

∗ Other dimensions are the same as the

double acting, single rod, standard type.

TB

Bore size

[mm]

20

25

32

40

50

63

GB TB S ZZ

12 11 77 114

12 11 77 119

12 11 79 121

13 12 87 139

14 13 102 162

14 13 102 162

4

Series CG1

Water Resistant

Bore size

Mounting style

CDG1 Z

Type

Port thread type

R

Stroke

H7BAL

-XC6

With auto switch

(Built-in magnet)

Water resistant cylinder

NBR seals (Nitrile rubber)

R

FKM seals (Fluororubber)

V

Caution

Since the scraper is press-fi t

into the rod cover, it cannot

be replaced.

Water resistant 2-colour

indication, solid state auto switch

H7BAL ø32 to ø63

G5BAL ø80, ø100

Made to Order

Applicable for use in an environment with water splashing

such as food processing and car wash equipment, etc.

Specifi cations

Bore size [mm]

Action Double acting, Single rod

Cushion Rubber bumper/Air cushion

Auto switch mounting Band mounting type

Made to Order

∗ Specifi cations other than above are the same as standard, basic type.

32, 40, 50, 63, 80, 100

XC6: Made of stainless steel

Dimensions

With rubber bumper

GBGA

(E1)

(F1)

TA

S + Stroke F

ZZ + Stroke

With air cushion

(E1)

Bore size

32

40

50

63

80

100

∗ Other dimensions are the same as the double acting single rod standard type.

∗ ( ): Denotes the dimensions for long stroke.

WA

(F1)

S + Stroke F

ZZ

+ Stroke

∗

(E1)

E

17 18 2 2 18 77 (85) 17 22

21 25 2 2 19 84 (93) 18 23

26 30 2 2 21 97 (109) 20 25

26 32 2 2 21 97 (109) 20 25

32 40 3 3 28 116 (130) — 32

37 50 3 3 29 117 (131)

(F1)

∗

GA S TA WA ZZ

F

TB

GBGA

TBTA

0

−0.05

E

ø

0

−0.05

øE

—33

[mm]

119 (127)

136 (145)

157 (169)

157 (169)

190 (204)

191 (205)

Precautions

Be sure to read before handling. Refer to back cover

for Safety Instructions. For Actuator and Auto Switch

Precautions, refer to “Handling Precaution for SMC

Products” and the Operation Manual on SMC website,

http://www.smcworld.com

Operating Precautions

Warning

1. Do not operate the cushion valve in the fully closed or

fully opened state.

Using it in the fully closed state will cause the cushion seal to be

damaged. Using it in the fully opened state will cause the piston

rod assembly or the cover to be damaged.

2. Operate within the specifi ed cylinder speed.

Otherwise, cylinder and seal damage may occur.

3.

Use caution regarding the cushion performance in the low-speed range.

There may be individual performance and effect variances when

used near 50 mm/s. Please consult with SMC about usage.

4.

When the cylinder is used as mounted with a single side fi xed or

free (basic, fl ange types), a bending moment will be applied to the

cylinder due to the vibration generated at the stroke end, and the

cylinder may be damaged. In such a case, mount a bracket to

reduce the vibration of the cylinder or use the cylinder at a piston

speed low enough to prevent the cylinder from vibrating at the

stroke end. Also, use a support bracket to reduce vibrations when

the cylinder body moves or when the cylinder is fi xed horizontally

on one side and moved at a high speed and frequency.

5. Do not apply excessive lateral load to the piston rod.

Easy checking method

Minimum operating pressure after the cylinder is mounted to the equipment

[MPa] = Minimum operating pressure of cylinder [MPa] + {Load weight [kg] x

Friction coeffi cient of guide/Sectional area of cylinder [mm2]}

If smooth operation is confi rmed within the above value, the load on the cylinder

is the resistance of the thrust only and it can be judged as having no lateral load.

Caution

1. Do not use the air cylinder as an air-hydro cylinder.

This will cause an oil leak.

2. Install a rod boot without twisting.

If the cylinder is installed with its bellows twisted, it could damage

the bellows.

3. Tighten clevis bracket mounting bolts with the following

proper tightening torque.

ø20: 1.5 N·m, ø25 to 32: 2.9 N·m, ø40: 4.9 N·m,

ø50: 11.8 N·m, ø63 to 80: 24.5 N·m, ø100: 42.2 N·m

Disassembly/Replacement

Caution

1. Do not replace the bushings.

The bushings are press-fit. To replace them, they must be

replaced together with the cover assembly.

2. To replace a seal, apply grease to the new seal before

installing it.

If the cylinder is put into operation without applying grease to the seal, it

could cause the seal to wear signifi cantly, leading to premature air leakage.

3.

Cylinders with ø50 or larger bore sizes cannot be disassembled.

When disassembling cylinders with bore sizes of ø20 through ø40, grip the double

fl at part of either the head cover or the rod cover with a vise and loosen the other

side with a wrench or a monkey wrench etc., and then remove the cover. When retightening, tighten approximately 2 degrees more than the original position.

(Cylinders with ø50 or larger bore sizes are tightened with a large tightening torque

and cannot be disassembled. If disassembly is required, please contact SMC.)

5

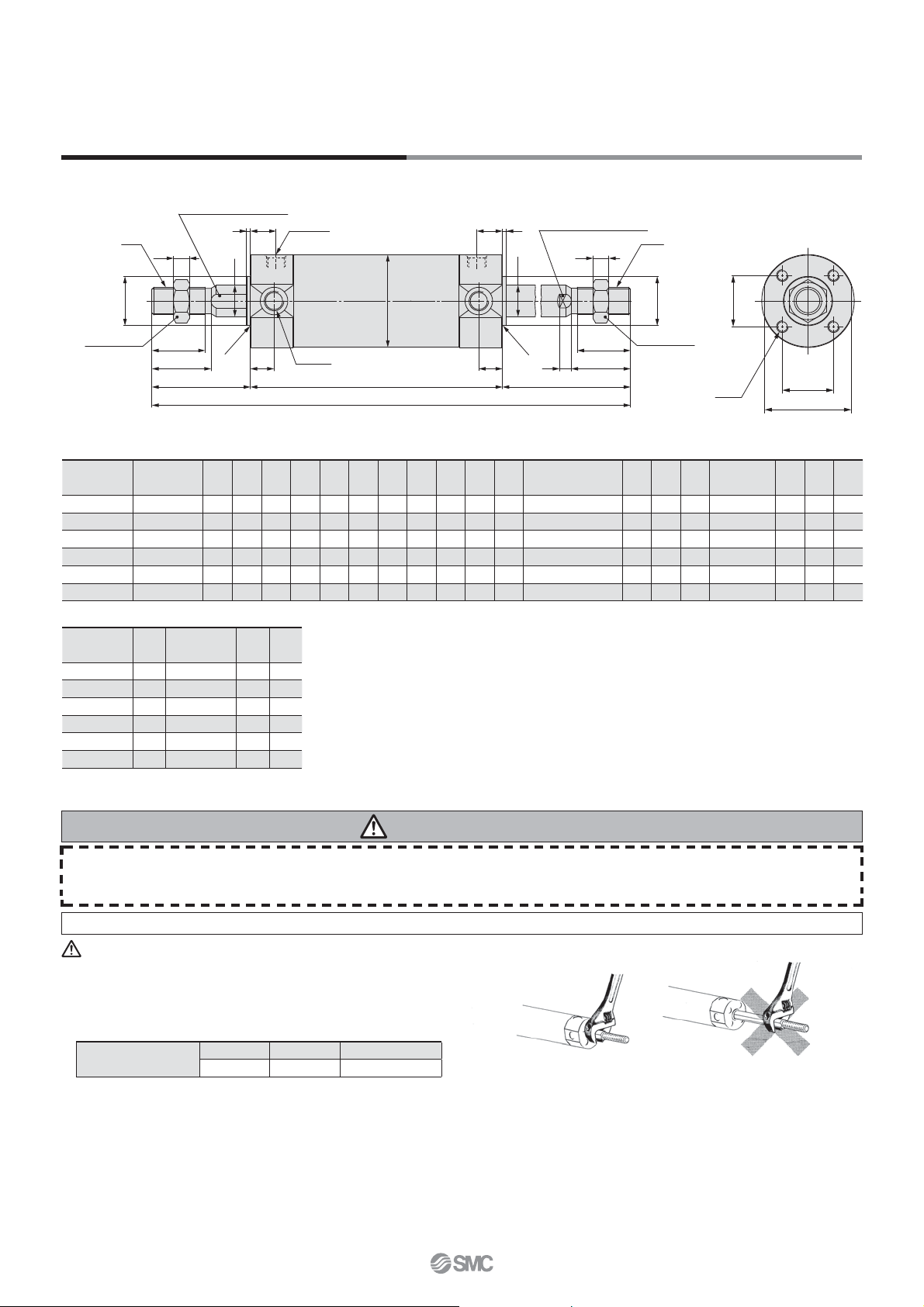

Construction

With rubber bumper

With air cushion

ø80, ø100

Air Cylinder: Standard Type

Double Acting, Single Rod

Series CG1

ø80, ø100

CG1CG1WCG1CG1KCG1KWCG1R

y

ewyy

r!0 @0 !9 @2 !8@1@2qourt u

ei

Double Acting, Single RodDouble Acting, Double Rod

u

StandardNon-rotating RodDirect Mount

Long stroke Long stroke

1001 to 1500

ow!6 !1 !3!7 !2!5 !4!0 @0 @1 !9 !8@2@2 @3qrt e

Component Parts

No. Description Material Note

1 Rod cover Aluminium alloy Hard Anodised

2 Tube cover Aluminium alloy Hard Anodised

3 Piston Aluminium alloy

4 Piston rod

5 Bushing Bearing alloy

6 Bumper Resin

7 Bumper Resin

8 Retaining ring Stainless steel Except ø80 and ø100

9 Wear ring Resin

10 Rod end nut Carbon steel Zinc chromated

11 Cushion ring A Aluminium alloy

12 Cushion ring B Aluminium alloy

Note) For cylinders with auto switches, the magnet is installed in the

piston.

∗ The material for ø20, ø25 cylinders with auto switches is made of stainless

steel.

Stainless steel

Carbon steel∗Hard chrome plating

For ø20 or ø25 with built-in magnet

∗

ø32 or larger is

common.

Long stroke

No. Description Material Note

13 Seal retainer Rolled steel Zinc chromated

Cushion

14

valve

15 Steel ball Carbon steel

16 Cushion ring A Urethane

17 Cushion ring B Urethane

18 Head cover Aluminium alloy Hard Anodised

19 Cylinder tube Aluminium alloy Hard Anodised

20 Rod seal NBR

21 Piston seal NBR

22 Tube gasket NBR

23 Valve seal NBR

ø40 or smaller

ø50 or larger

Carbon steel

Steel wire Zinc chromated

Electroless nickel plating

ø32 or larger is

common.

Replacement Parts/Seal Kit

Bore size [mm] Kit no. Contents

20

25

32

40

Note) Refer to the Specifi c Product Precautions on page 5 for Disassembly/

Replacement. Order with the kit number according to the bore size.

∗ The seal kit includes a grease pack (10 g).

Order with the following part number when only the grease pack is

needed. Grease pack part number: GR-S-010 (10 g)

CG1N20Z-PS

CG1N25Z-PS

CG1N32Z-PS

CG1N40Z-PS

Set of the nos. @0, @1, @2

Single Acting, Spring Return/Extend

Double Acting, Single RodDouble Acting, Double RodDouble Acting, Single Rod

Auto SwitchMade to Order

6

Series CG1

Basic: CG1BN

NA

2 x TC

øTD

Width across flats

TE

TFTG

Width across flats

MM

0

−0.05

øE

B

1

KA

H

1

AL

AK

H

FGA

øD

R0.4

2 x P

(Rc, NPT, G)

4 x TC

TA TB

ZZ + Stroke

TC thread detail

With air cushion

GA

2 x P

WA

(Rc, NPT, G)

Cushion valve, Width across flats WH

Basic (No Trunnion Mounting Female Thread): CG1ZN

øI

S + Stroke

WB

GB

GB

R0.4

F

0

−0.05

øE

C

C

8 x J

NA

Wθ

10°

°

Width across flats KA

MM

0

−0.05

øE

Width across flats B1

1

H

AL

AK

HS

Stroke range

Bore

size

Standard

Long stroke

Up to 200 201 to 15001210 (12)

20

Up to 300 301 to 15001210 (12)

25

Up to 300 301 to 15001210 (12)

32

Up to 300 301 to 15001310 (13)

40

Up to 300 301 to 15001412 (14)

50

Up to 300 301 to 15001412 (14)

63

Up to 300 301 to 15002016 (20)

80

Up to 300 301 to 15002016 (20)

100

Bore

NA S TA TB ZZ

size

24 69 (77) 11 11 106 (114)

20

29 69 (77) 11 11 111 (119)

25

35.5 71 (79) 11 10 (11) 113 (121)

32

44 78 (87) 12 10 (12) 130 (139)

40

55 90 (102) 13 12 (13) 150 (162)

50

69 90 (102) 13 12 (13) 150 (162)

63

86 108 (122) — — 182 (196)

80

106 108 (122) — — 182 (196)

100

Note) ( ): Denotes the dimensions for long stroke.

∗ For details about applicable maximum stroke, contact SMC.

Rc, NPT port G port

GA GB P GA GB P

1/8 12

1/8 12.5

1/8 10.5

1/8 13

1/4 14

1/4 14

3/8 17.5

1/2 17.5

10 (12)

M5 x 0.81815.5

10 (12.5)

M5 x 0.82219.5

10 (10.5)

1/8 22

10 (10)

1/8 30

12 (14)

1/4 35

12 (14)

1/4 35

16 (17.5)

3/8 40

16 (17.5)

1/2 40

[mm]

With Air Cushion

Bore

size

20

25

32

40

50

63

80

100

GA GB P

12 10 (12)

12.5

12 10 (12) 1/8 16 14 (16) 25° 1.5

13 10 (13) 1/8 17 15 (17) 20° 1.5

14 12 (14) 1/4 18 16 (18) 20° 3

14 12 (14) 1/4 18 17 (18) 20° 3

20 16 (20) 3/8 24 20 (24) 20° 4

20 16 (20) 1/2 24 20 (24) 20° 4

7

øD

R0.4

AAL

Rc, NPT, G

10 (12.5)

2 x PGAF

(Rc, NPT, G)

ZZ + Stroke

CDEFHH1IJKKAMM

B1

13

14

17

17

19

27

27

32

41

16.5

20

26

32

38

50

60

19.5

27

32

32

37

37

WA WB W θ WH

M5 x 0.8

M5 x 0.81614.5 (16)

16 15 (16) 25° 1.5

GB

øI

+ Stroke

8 12 2 35 5 26

10 14 2 40 6 31

12 18 2 40 6 38

16 25 2 50 8 47

20 30 2 58 11 58

20 32 2 58 11 72

25 40 3 71 13 89

30 50 3 71 16 110

[mm]

TC Thread

Bore

size

20

25° 1.5

25

32

40

50

63

80

100

∗ Cylinder bore sizes ø80 and ø100 do not have

trunnion mounting female thread on the width

across fl ats NA.

R0.4

0

−0.05

øE

F

M4 x 0.7 depth 7 5

M5 x 0.8 depth 7.5 5.5

M5 x 0.8 depth 8 5.5

M6 x 1 depth 12 6

M8 x 1.25 depth 16 7

M10 x 1.5 depth 16 7

M10 x 1.5 depth 22 10

M12 x 1.75 depth 22 10

6

8

10

14

18

18

22

26

M8 x 1.25

M10 x 1.25

M10 x 1.25

M14 x 1.5

M18 x 1.5

M18 x 1.5

M22 x 1.5

M26 x 1.5

[mm]

TC TD TE TF TG

M5 x 0.8 8

M6 x 0.75 10

M8 x 1.0 12

M10 x 1.25 14

M12 x 1.25 16

M14 x 1.5 18

—————

—————

+0.08

0

+0.08

0

+0.08

0

+0.08

0

+0.08

0

+0.08

0

4

5

5.5

6

7.5

11.5

0.5

1

1

1.25

2

3

10

14.5

[mm]

5.5

6.5

7.5

8.5

Basic: CG1BN

Air Cylinder: Standard Type

Double Acting, Single Rod

Series CG1

With rod boot

øe

øIJ

8

l f

h + l

ZZ + l + Stroke

88

CG1CG1WCG1CG1KCG1KWCG1R

øe

øIJ

l

f

h + l

ZZ + l + Stroke

JW

ø20 to ø63ø80, ø100

With Rod Boot

Bore

efhIJ

size

30 18 55 27 15.5 10.5

20

30 19 62 32 16.5 10.5 133 (141)

25

35 19 62 38 18.5 10.5 135 (143)

32

35 19 70 48 21.5 10.5 150 (159)

40

40 19 78 59 24 10.5 170 (182)

50

40 20 78 72 24 10.5 170 (182)

63

52 10 80 59 — — 191 (205)

80

62 7 80 71 — — 191 (205)

100

∗ The minimum stroke with rod boot is 20 mm.

JW

JH

(Reference)

(Reference)

l

/4 stroke

1

[mm]

ZZ

126 (134)

Double Acting, Single RodDouble Acting, Double Rod

JH

StandardNon-rotating RodDirect Mount

Single Acting, Spring Return/Extend

Female rod end

H

ZZ

+ Stroke

MM

Thread depth A1

Female Rod End

Bore

A1 HMM ZZ

size

8 13 M4 x 0.7 84 (92)

20

8 14 M5 x 0.8 85 (93)

25

12 14 M6 x 1 87 (95)

32

13 15 M8 x 1.25 95 (104)

40

18 16 M10 x 1.5 108 (120)

50

18 16 M10 x 1.5 108 (120)

63

21 19 M14 x 1.5 130 (144)

80

25 22 M16 x 1.5 133 (147)

100

∗ When female thread is used, use a washer etc.

to prevent the contact part at the rod end from

being deformed depending on the material of

the work piece.

[mm]

Double Acting, Single RodDouble Acting, Double RodDouble Acting, Single Rod

Auto SwitchMade to Order

8

Series CG1

Axial Foot: CG1LN

Width across flats

MM

KA

H

S

H

GA

(Rc, NPT, G)

1

øD

+ Stroke

Width across flats NA2 x P

GB

øI

C

B

8 x J

Width across flats

B

1

AL

AXY

W

K

ZLS

LT

2 x øLC

(Knock pin position)

+ Stroke

Y

ZZ + Stroke

With air cushion

WA

(Rc, NPT, G)

GA

Cushion valve, Width across flats

WH

WB

GB

2 x P

With rod boot

h + l

8

øe

øIJ

øe

øIJ

fl

Z + l

+ l + Stroke

ZZ

ø80, ø100

Stroke range Rc, NPT port G port

Bore

size

Standard Long stroke

Up to 200 201 to 15001210 (12)

20

Up to 300 301 to 15001210 (12)

25

Up to 300 301 to 15001210 (12)

32

Up to 300 301 to 15001310 (13)

40

Up to 300 301 to 15001412 (14)

50

Up to 300 301 to 15001412 (14)

63

Up to 300 301 to 15002016 (20)

80

Up to 300 301 to 15002016 (20)

100

Bore

NA S W X Y Z ZZ

size

24

20

29

25

35.5

32

44

40

55

50

69

63

86

80

106

100

∗ For female rod end, since the wrench fl ap (K and KA portions) will be inside of the bracket

when the piston rod is retracted at the stroke end, extend the piston rod to tighten the nut

using a tool, and mount a work piece on the rod end.

∗ Refer to the basic type for the female rod end.

Note) ( ): Denotes the dimensions for long stroke.

∗ For details about applicable maximum stroke, contact SMC.

GA GB P GA GB P

69 (77)

10 15 7 47

69 (77)

10 15 7 52

71 (79)

10 16 8 53

78 (87)

10 16.5 8.5 63.5

90 (102)

17.5 22 11 75.5

90 (102)

17.5 22 13 75.5

108 (122)

20 28.5 14 95

108 (122)

20 30 16 95

1/8

12

1/8

12.5

1/8

10.5

1/8

13

1/4

14

1/4

14

3/8

17.5

1/2

17.5

110 (118)

115.5 (123.5)

117.5 (125.5)

135 (144)

157.5 (169.5)

157.5 (169.5)

188.5 (202.5)

192 (206)

10 (12)

10 (12.5)

10 (10.5)

10 (10)

12 (14)

12 (14)

16 (17.5)

16 (17.5)

[mm]

AALBB1 CDHH1 I J K KALCLDLH LS LTLXLZ M MM

M5 x 0.81815.5341314 8 35 5

M5 x 0.82219.5

1/8 22

1/8 30

1/4 35

1/4 35

3/8 40

1/2 40

38.51716.5

19.545172012 40 6

27

54.51926

32

70.52732

32

82.52738

37

1013250

37

1214160

With Air Cushion

Bore

size

20

25

32

40

50

63

80

100

Rc, NPT, G

GA GB P

12 10 (12)

12.5

10 (12.5)

12 10 (12) 1/8 16 14 (16) 25° 1.5

13 10 (13) 1/8 17 15 (17) 20° 1.5

14 12 (14) 1/4 18 16 (18) 20° 3

14 12 (14) 1/4 18 17 (18) 20° 3

20 16 (20) 3/8 24 20 (24) 20° 4

20 16 (20) 1/2 24 20 (24) 20° 4

h + l

88

l

Z + l

+ l + Stroke

ZZ

ø20, ø63

10 40 6

16 50 8

20 58 11

20 58 11

25 71 13

30 71 16

26

31

38

47

58

72

89

110

WA WB Wθ WH

M5 x 0.8

M5 x 0.81614.5 (16)

16 15 (16) 25° 1.5

f

M12 x 1.751026 6 14 65 60 (74)

9

LH

15°

W

MX

M4 x 0.7

M5 x 0.8

M5 x 0.8

M6 x 1

M8 x 1.25718 5 10 40 55 (67)

M10 x 1.5718 5 12 45 55 (67)

M10 x 1.51022 6 11 55 60 (74)

[mm]

25° 1.5

4 x øLD

5

6 4 6 20 45 (53)

5.5

8 4 6 22 45 (53)

5.5

10 4 7 25 45 (53)

6

14 4 7 30 51 (60)

With Rod Boot

Bore

efhIJ

size

30 18 55 27

20

30 19 62 32

25

35 19 62 38

32

35 19 70 48

40

40 19 78 59

50

40 20 78 72

63

52 10 80 59 — —

80

62 7 80 71 — —

100

∗ The minimum stroke with rod boot is 20 mm.

(Reference)

15.5 10.5

16.5 10.5 74

18.5 10.5 75

21.5 10.5 83.5

24 10.5 95.5

24 10.5 95.5

C

LX

LZ

Wθ

10°

JW

3 32 44 3

3 36 49 3.5

3 44 58 3.5

3 54 71 4

4.5 66 86 5

4.5 82 106 5

4.5 100 125 5

6 120 150 7

JW

JH

l

(Reference)

°

ZZZ

67

130 (138)

137.5 (145.5)

139.5 (147.5)

155 (164)

177.5 (189.5)

/4 stroke

1

177.5 (189.5)

104

197.5 (211.5)

104

201 (215)

JH

[mm]

M8 x 1.25

M10 x 1.25

M10 x 1.25

M14 x 1.5

M18 x 1.5

M18 x 1.5

M22 x 1.5

M26 x 1.5

[mm]

Rod Flange: CG1FN

Width across flats

MM

0

øE−0.05

∗

Width across flats

B

1

H1

KA

Air Cylinder: Standard Type

Double Acting, Single Rod

GAFTF

øD

2 x P

(Rc, NPT, G)

øI

GB

R0

.4

0

øE−0.05

B

Series CG1

4 x øFD

C

±0.15

FX

øD

8 x J

CG1CG1WCG1CG1KCG1KWCG1R

Double Acting, Single RodDouble Acting, Double Rod

AL

Width across flats

NA

KA

+ Stroke

S + Stroke

h + l

l

+ l + Stroke

ZZ

WH

88

With air cushion

With rod boot

8

øe

øIJ

h + l

ZZ

l

f

+ l + Stroke

H

ZZ

2 x P

WA

(Rc, NPT, G)

GA

Cushion valve, Width across flats

∗ End boss is machined on the fl ange for øE.

øe

øIJ

ø80, ø100 ø20, ø63

Bore

size

20

25

32

40

50

63

80

100

Bore

size

20

25

32

40

50

63

80

100

∗ For female rod end, since the wrench fl ap (K and KA portions) will be inside of the bracket

when the piston rod is retracted at the stroke end, extend the piston rod to tighten the nut

using a tool, and mount a work piece on the rod end.

∗ Refer to the basic type for the female rod end.

Note) ( ): Denotes the dimensions for long stroke.

∗ For details about applicable maximum stroke, contact SMC.

Stroke range Rc, NPT port G port

Standard

Up to 200

Up to 300

Up to 300

Up to 300

Up to 300

Up to 300

Up to 300

Up to 300

KA MM NA S ZZ

Long stroke

201 to 1500 12

301 to 1500 12

301 to 1500 12

301 to 1500 13

301 to 1500 14

301 to 1500 14

301 to 1500 20

301 to 1500 20

6

M8 x 1.25 24

8

M10 x 1.25 29

10

M10 x 1.25 35.5

14

M14 x 1.5 44

18

M18 x 1.5 55

18

M18 x 1.5 69

22

M22 x 1.5 86

26

M26 x 1.5 106

GA GB P GA GB P

10 (12)

1/8 12

10 (12)

1/8 12.5

10 (12)

1/8 10.5

10 (13)

1/8 13

12 (14)

1/4 14

12 (14)

1/4 14

16 (20)

3/8 17.5

16 (20)

1/2 17.5

[mm]

With Air Cushion

Bore

size

69 (77) 106 (114)

69 (77) 111 (119)

71 (79) 113 (121)

78 (87) 130 (139)

90 (102) 150 (162)

90 (102) 150 (162)

108 (122) 182 (196)

108 (122) 182 (196)

100

AALBB1 C D E F FD FT FX H H1 IJK

10 (12)

M5 x 0.81815.5

10 (12.5) M5 x 0.82219.5

10 (10.5)

1/8 22

10 (10)

1/8 30

12 (14)

1/4 35

12 (14)

1/4 35

16 (17.5)

3/8 40

16 (17.5)

1/2 40

Rc, NPT, G

GA GB P

12 10 (12)

20

12.5

25

12 10 (12) 1/8 16 14 (16) 25° 1.5

32

13 10 (13) 1/8 17 15 (17) 20° 1.5

40

14 12 (14) 1/4 18 16 (18) 20° 3

50

14 12 (14) 1/4 18 17 (18) 20° 3

63

20 16 (20) 3/8 24 20 (24) 20° 4

80

20 16 (20) 1/2 24 20 (24) 20° 4

M5 x 0.8

10 (12.5)

M5 x 0.81614.5 (16)

40 13 14 8 12 2 5.5 6 28 35 5 26 M4 x 0.7 5

44 17 16.5 10 14 2 5.5 7 32 40 6 31 M5 x 0.8 5.5

19.5

53 17 20 12 18 2 6.6 7 38 40 6 38 M5 x 0.8 5.5

27

61 19 26 16 25 2 6.6 8 46 50 8 47 M6 x 1 6

32

76 27 32 20 30 2 9 9 58 58 11 58 M8 x 1.25 7

32

92 27 38 20 32 2 11 9 70 58 11 72 M10 x 1.5 7

37

104 32 50 25 40 3 11 11 82 71 13 89 M10 x 1.5 10

37

128 41 60 30 50 3 14 14 100 71 16 110 M12 x 1.75 10

WA WB Wθ WH

16 15 (16) 25° 1.5

WB

f

[mm]

25° 1.5

FX

F

GB

±0.15

10°

JW

With Rod Boot

Bore

efhIJ

size

30 18 55 27 15.5 10.5

20

30 19 62 32 16.5 10.5

25

35 19 62 38 18.5 10.5

32

35 19 70 48 21.5 10.5

40

40 19 78 59 24 10.5

50

40 20 78 72 24 10.5

63

52 10 80 59 — —

80

62 7 80 71 — —

100

∗ The minimum stroke with rod boot is 20 mm.

JH

(Reference)JW(Reference)

C

StandardNon-rotating RodDirect Mount

B

Wθ

°

Single Acting, Spring Return/Extend

Double Acting, Single RodDouble Acting, Double RodDouble Acting, Single Rod

JH

[mm]

[mm]

l

ZZ

126 (134)

133 (141)

135 (143)

150 (159)

170 (182)

/4 stroke

1

170 (182)

191 (205)

191 (205)

Auto SwitchMade to Order

10

Series CG1

Head Flange: CG1GN

4 x øFD

C

B

±0.15

FX

With air cushion

FX

Wθ

C

±0.15

B

°

10

8 x J

Width across flats

MM

0

øE−0.05

Width across flats

B

1

H

AL

KA

1

øD

R0.4

GAF

2 x P

(Rc, NPT, G)

øI

Width across flats NA

GB

0

E−0.05

ø

∗

KA

S + StrokeH

ZZ

+ Stroke

∗ End boss is machined on the fl ange for øE.

°

WA

GA

2 x P

(Rc, NPT, G)

Cushion valve, Width across flats

WB

WH

GB

FT

F

With rod boot

8

øe

øIJ

l

f

øIJ

h + l

ZZ + l + Stroke

ø80, ø100

Bore

size

20

25

32

40

50

63

80

100

Bore

size

20

25

32

40

50

63

80

100

∗ Refer to the basic type for the female rod end.

Note) ( ): Denotes the dimensions for long stroke.

∗ For details about applicable maximum stroke, contact SMC.

Stroke range Rc, NPT port G port

Standard

Up to 200

Up to 300

Up to 300

Up to 300

Up to 300

Up to 300

Up to 300

Up to 300

Long stroke

201 to 1500 12

301 to 1500 12

301 to 1500 12

301 to 1500 13

301 to 1500 14

301 to 1500 14

301 to 1500 20

301 to 1500 20

GA GB P GA GB P

10 (12)

1/8 12

10 (12)

1/8 12.5

10 (12)

1/8 10.5

10 (13)

1/8 13

12 (14)

1/4 14

12 (14)

1/4 14

16 (20)

3/8 17.5

16 (20)

1/2 17.5

[mm]

With Air Cushion

KA MM NA S ZZ

6

M8 x 1.25 24 69 (77) 112 (120)

8

M10 x 1.25 29 69 (77) 118 (126)

10

M10 x 1.25 35.5 71 (79) 120 (128)

14

M14 x 1.5 44 78 (87) 138 (147)

18

M18 x 1.5 55 90 (102) 159 (171)

18

M18 x 1.5 69 90 (102) 159 (171)

22

M22 x 1.5 86 108 (122) 193 (207)

26

M26 x 1.5 106 108 (122) 196 (210)

10 (12)

10 (12.5) M5 x 0.82219.5

10 (10.5)

10 (10)

12 (14)

12 (14)

16 (17.5)

16 (17.5)

Bore

size

GA GB P

12 10 (12)

20

12.5

25

12 10 (12) 1/8 16

32

13 10 (13) 1/8 17

40

14 12 (14) 1/4 18

50

14 12 (14) 1/4 18

63

20 16 (20) 3/8 24

80

20 16 (20) 1/2 24

100

11

øe

h + l

ZZ + l + Stroke

ø20, ø63

AALBB1 C D E F FD FT FX H H1 IJK

M5 x 0.81815.5

1/8 22

1/8 30

1/4 35

1/4 35

3/8 40

1/2 40

Rc, NPT, G

M5 x 0.81615 (16)

10 (12.5) M5 x 0.81614.5 (16)

40 13

44 17

19.5

53 17

27

61 19

32

76 27

32

92 27

37

104 32

37

128 41

WA WB Wθ WH

14 (16)

15 (17)

16 (18)

17 (18)

20 (24)

20 (24)

88

fl

f

14

16.5

20

26

32

38

50

60

25° 1.5

25° 1.5

25° 1.5

20° 1.5

20° 3

20° 3

20° 4

20° 4

8 12 2

10 14 2

12 18 2

16 25 2

20 30 2

20 32 2

25 40 3

30 50 3

[mm]

5.5

6 28 35 5 26

5.5

7 32 40 6 31

6.6

7 38 40 6 38

6.6

8 46 50 8 47

9

9 58 58 11 58

11

9 70 58 11 72

11

11 82 71 13 89

14

14 100 71 16 110

With Rod Boot

Bore

efhIJ

size

30 18 55 27 15.5 10.5

20

30 19 62 32 16.5 10.5

25

35 19 62 38 18.5 10.5

32

35 19 70 48 21.5 10.5

40

40 19 78 59 24 10.5

50

40 20 78 72 24 10.5

63

52 10 80 59 — —

80

62 7 80 71 — —

100

∗ The minimum stroke with rod boot is 20 mm.

JH

(Reference)JW(Reference)

JW

M8 x 1.25

M10 x 1.5

M10 x 1.5

M12 x 1.75

M4 x 0.7

M5 x 0.8

M5 x 0.8

M6 x 1

l

132 (140)

140 (148)

142 (150)

158 (167)

179 (191)

/4 stroke

1

179 (191)

202 (216)

205 (219)

JH

[mm]

5

5.5

5.5

6

7

7

10

10

[mm]

ZZ

Rod Trunnion: CG1UN

Air Cylinder: Standard Type

Double Acting, Single Rod

Series CG1

MM

0

øE−0.05

Width across

flats

B

1

Width across

flats

With air cushion

AL

A

H

KA

10°

TR

TZ

Wθ

∗

°

CG1CG1WCG1CG1KCG1KWCG1R

Double Acting, Single RodDouble Acting, Double Rod

StandardNon-rotating RodDirect Mount

Single Acting, Spring Return/Extend

GB

F

R0.4

0

øE−0.05

2 x øTDe8

(Pin O.D)

H

2 x

GA

FKTA

1

øD

R0.4

(Rc, NPT, G)

S + Stroke

P

Width across flats NA

øI

Z

ZZ

+ Stroke

∗ Constructed of a trunnion pin, fl at washer and hexagon socket head cap bolt.

2 x P

WA

GA

(Rc, NPT, G)

Cushion valve, Width across flats WH

WB

GB

With rod boot

øe

øIJ

+ l

h

8

Z + l

ZZ + l + Stroke

Bore

size

20

25

32

40

50

63

Bore

size

20

25

32

40

50

63

∗ Refer to the basic type for the female rod end.

Note) ( ): Denotes the dimensions for long stroke.

∗ For details about applicable maximum stroke, contact SMC.

Stroke range Rc, NPT port G port

Standard

Up to 200

Up to 300

Up to 300

Up to 300

Up to 300

Up to 300

TA TDe8 TR TZ Z ZZ

11 8

11 10

11 12

12 14

13 16

13 18

Long stroke

201 to 1500 12

301 to 1500 12

301 to 1500 12

301 to 1500 13

301 to 1500 14

301 to 1500 14

−0.025

39

−0.047

−0.025

−0.047

−0.032

−0.059

−0.032

−0.059

−0.032

−0.059

−0.032

−0.059

47.646106 (114)

43

53

54.5

67.751113 (121)

65.5

78.762130 (139)

80

98.671150 (162)

98

119.271150 (162)

GA GB P GA GB P

10 (12)

1/8 12

10 (12)

1/8 12.5

10 (12)

1/8 10.5

10 (13)

1/8 13

12 (14)

1/4 14

12 (14)

1/4 14

With Air Cushion

[mm]

Bore

size

51

111 (119)

10 (12)

10 (12.5) M5 x 0.8

10 (10.5)

10 (10)

12 (14)

12 (14)

GA GB P

12

20

12.5

25

12

32

13

40

14

50

14

63

l

f

JH

8

JW

AALB1 DEFHH1 I K KA MM NA S

M5 x 0.8

18 15.5 13 8 12 2 35 5 26 5 6 M8 x 1.25 24 69 (77)

22 19.5 17 10 14 2 40 6 31 5.5 8 M10 x 1.25 29 69 (77)

1/8 22 19.5 17 12 18 2 40 6 38 5.5 10 M10 x 1.25 35.5 71 (79)

1/8 30 27 19 16 25 2 50 8 47 6 14 M14 x 1.5 44 78 (87)

1/4 35 32 27 20 30 2 58 11 58 7 18 M18 x 1.5 55 90 (102)

1/4 35 32 27 20 32 2 58 11 72 7 18 M18 x 1.5 69 90 (102)

With Rod Boot

[mm]

Rc, NPT, G

10 (12)

10 (12.5)

10 (12)

10 (13)

12 (14)

12 (14)

WA WB Wθ WH

M5 x 0.81615 (16)

M5 x 0.81614.5 (16)

1/8 16

1/8 17

1/4 18

1/4 18

14 (16)

15 (17)

16 (18)

17 (18)

25° 1.5

25° 1.5

25° 1.5

20° 1.5

20° 3

20° 3

Bore

efhIJ

size

30 18 55 27

20

30 19 62 32

25

35 19 62 38

32

35 19 70 48

40

40 19 78 59

50

40 20 78 72

63

∗ The minimum stroke with rod boot is 20 mm.

JW

JH

(Reference)

(Reference)

15.5 10.5

16.5 10.5

18.5 10.5

21.5 10.5

24 10.5

24 10.5

l

1

ZZZ

66

126 (134)

73

133 (141)

73

135 (143)

82

150 (159)

/4 stroke

91

170 (182)

91

170 (182)

[mm]

[mm]

Double Acting, Single RodDouble Acting, Double RodDouble Acting, Single Rod

Auto SwitchMade to Order

12

Series CG1

Head Trunnion: CG1TN

TR

2 x øTDe8

(Pin O.D)

With air cushion

°

Wθ

TZ

10°

∗

Width across flats

Width across flats

MM

0

øE−0.05

B

KA

S

H

A

AL

H

1

KGA

F

1

øD

R0.4

P

2 x

(Rc, NPT, G)

Width across flats NA

+ Stroke

øI

Z + Stroke

ZZ

+ Stroke

∗ Constructed of a trunnion pin, fl at washer and hexagon socket head cap bolt.

WA

GA

2 x P

(Rc, NPT, G)

Cushion valve, Width across flats

WH

F

GB

R0.4

0

øE−0.05

TB

WB

GB

With rod boot

+ l

h

f

l

øe

øIJ

88

Z + l + Stroke

ZZ + l + Stroke

Bore

size

20

25

32

40

50

63

Bore

size

20

25

32

40

50

63

∗ Refer to the basic type for the female rod end.

Note) ( ): Denotes the dimensions for long stroke.

∗ For details about applicable maximum stroke, contact SMC.

Stroke range Rc, NPT port G port

Standard

Up to 200

Up to 300

Up to 300

Up to 300

Up to 300

Up to 300

Long stroke

201 to 1500 12

301 to 1500 12

301 to 1500 12

301 to 1500 13

301 to 1500 14

301 to 1500 14

GA GB P GA GB P

10 (12)

10 (12)

10 (12)

10 (13)

12 (14)

12 (14)

[mm]

1/8 12

1/8 12.5

1/8 10.5

1/8 13

1/4 14

1/4 14

TB TDe8 TR TZ Z ZZ

−0.025

11 8

11 10

10 (11)

10 (12)

12 (13)

12 (13)

12

14

16

18

−0.047

−0.025

−0.047

−0.032

−0.059

−0.032

−0.059

−0.032

−0.059

−0.032

−0.059

39

43

54.5

65.5

80

98

47.6

53

67.7

78.7

98.6

119.2

93 (101)

98 (106)

101 (108)

118 (125)

136 (147)

136 (147)

106 (114)

111 (119)

113 (121)

130 (139)

150 (162)

150 (162)

10 (12)

10 (12.5)

10 (10.5)

10 (10)

12 (14)

12 (14)

With Air Cushion

Bore

size

GA GB P

12 10 (12)

20

12.5

25

12 10 (12) 1/8 16 14 (16) 25° 1.5

32

13 10 (13) 1/8 17 15 (17) 20° 1.5

40

14 12 (14) 1/4 18 16 (18) 20° 3

50

14 12 (14) 1/4 18 17 (18) 20° 3

63

AALB1 DEFHH1 I K KA MM NA S

M5 x 0.81815.5

M5 x 0.82219.5

1/8 22

1/8 30

1/4 35

1/4 35

Rc, NPT, G

M5 x 0.8

10 (12.5)

M5 x 0.81614.5 (16)

JH

JW

13 8 12 2 35 5 26 5 6 M8 x 1.25

17 10 14 2 40 6 31 5.5 8 M10 x 1.25

19.5

17 12 18 2 40 6 38 5.5 10 M10 x 1.25

27

19 16 25 2 50 8 47 6 14 M14 x 1.5

32

27 20 30 2 58 11 58 7 18 M18 x 1.5

32

27 20 32 2 58 11 72 7 18 M18 x 1.5

With Rod Boot

[mm]

WA WB Wθ WH

16 15 (16) 25° 1.5

25° 1.5

Bore

efhIJ

size

30 18 55 27

20

30 19 62 32

25

35 19 62 38

32

35 19 70 48

40

40 19 78 59

50

40 20 78 72

63

∗ The minimum stroke with rod boot is 20 mm.

JH

JW

(Reference)

(Reference)

15.5 10.5

16.5 10.5

18.5 10.5

21.5 10.5

24 10.5

24 10.5

[mm]

24

69 (77)

29

69 (77)

35.5

71 (79)

44

78 (87)

55

90 (102)

69

90 (102)

[mm]

l

ZZZ

113 (121) 126 (134)

120 (128) 133 (141)

123 (130) 135 (143)

138 (145) 150 (159)

/4 stroke

1

156 (167) 170 (182)

156 (167) 170 (182)

13

Clevis: CG1DN (ø20 to ø63)

Air Cylinder: Standard Type

Double Acting, Single Rod

Series CG1

C

With air cushion

Wθ

With rod boot

CZ

C

TZ

°

10°

8 x J

TT

MM

0

øE−0.05

Width across

flats

B

1

h + l

H

A

AL

1

H

Width across

flats

KA

88

KGA

F

øD

R0.4

WA

GA

+ Stroke

S

P

2 x

(Rc, NPT, G)

øI

Width across flats NA

Z + Stroke

+ Stroke

ZZ

2 x P

(Rc, NPT, G)

Cushion valve, Width across flats

WH

GB

WB

GB

RRL

ø

CD

H10

(Hole dia.)

d9 (Shaft dia.)

CG1CG1WCG1CG1KCG1KWCG1R

Double Acting, Single RodDouble Acting, Double Rod

StandardNon-rotating RodDirect Mount

Single Acting, Spring Return/Extend

Double Acting, Single RodDouble Acting, Double RodDouble Acting, Single Rod

øe

øIJ

f

l

Z + l + Stroke

ZZ + l + Stroke

Stroke range Rc, NPT port G port

Bore size

Standard Long stroke

Up to 200 201 to 15001210 (12)

20

Up to 300 301 to 15001210 (12)

25

Up to 300 301 to 15001210 (12)

32

Up to 300 301 to 15001310 (13)

40

Up to 300 301 to 15001412 (14)

50

Up to 300 301 to 15001412 (14)

63

Bore

RR S TT TZ Z ZZ

size

69 (77)

11

20

25

32

40

50

63

∗

A clevis pin, retaining rings and mounting bolts are included. Refer to the basic type for the female rod end.

Note) ( ): Denotes the dimensions for long stroke.

∗ For details about applicable maximum stroke, contact SMC.

13

15

18

20

22

69 (77)

71 (79)

78 (87)

90 (102)

90 (102)

GA GB P GA GB P

1/8 12

1/8 12.5

1/8 10.5

1/8 13

1/4 14

1/4 14

[mm]

Applicable

pin part no.

118 (126)

3.2

3.2

4.5

4.5

6

8

43.4

48

59.4

71.4

86

105.4

129 (137)

125 (133)

138 (146)

131 (139)

146 (154)

150 (159)

168 (177)

173 (185)

193 (205)

178 (190)

200 (212)

CD-G02

CD-G25

CD-G03

CD-G04

CD-G05

CD-G06

10 (12)

10 (12.5)

10 (10.5)

10 (10)

12 (14)

12 (14)

With Air Cushion

Bore

size

20

25

32

40

50

63

AALB1 CCDCZD E F H H1 I J K KA L MM NA

M5 x 0.81815.51314

M5 x 0.82219.51716.5

1/8 22

1/8 30

1/4 35

1/4 35

19.51720

27 1926

32 2732

32 2738

Rc, NPT, G

GA GB P

12 10 (12)

12.5

12 10 (12) 1/8 16 14 (16) 25° 1.5

13 10 (13) 1/8 17 15 (17) 20° 1.5

14 12 (14) 1/4 18 16 (18) 20° 3

14 12 (14) 1/4 18 17 (18) 20° 3

M5 x 0.8

10 (12.5)

M5 x 0.81614.5 (16)

8 29 8 12 2 35 5 26

10 33 10 14 2 40 6 31

12 40 12 18 2 40 6 38

14 49 16 25 2 50 8 47

16 60 20 30 2 58 11 58

18 74 20 32 2 58 11 72

[mm]

WA WB Wθ WH

16 15 (16) 25° 1.5

25° 1.5

JH

JW

M4 x 0.7

5 6 14 M8 x 1.25 24

M5 x 0.8

5.5 8 16 M10 x 1.25 29

M5 x 0.8

5.5 10 20 M10 x 1.25 35.5

M6 x 1

6 14 22 M14 x 1.5 44

M8 x 1.25

7 18 25 M18 x 1.5 55

M10 x 1.5

7 18 30 M18 x 1.5 69

With Rod Boot

Bore

efhIJ

size

30 18 55 27

20

30 19 62 32

25

35 19 62 38

32

35 19 70 48

40

40 19 78 59

50

40 20 78 72

63

∗ The minimum stroke with rod boot is 20 mm.

JW

JH

(Reference)

(Reference)

15.5 10.5

16.5 10.5

18.5 10.5

21.5 10.5

24 10.5

24 10.5

l

ZZZ

138 (146) 149 (157)

147 (155) 160 (168)

153 (161) 168 (176)

170 (179) 188 (197)

/4 stroke

1

193 (205) 213 (225)

198 (210) 220 (232)

[mm]

[mm]

14

Auto SwitchMade to Order

Series CG1

Clevis: CG1DN (ø80, ø100)

TZ

CZ

C

MM

C

0

øE−0.05

H

AK

AL

H1

FGA

øD

P

2 x

(Rc, NPT, G)

S

+ Stroke

RR

L

V

GB

ø

CD

H10

(Hole dia.)

d9 (Shaft dia.)

øI

8 x J

With air cushion

°

10°

Wθ

With rod boot

CX

+0.5

+0.3

R0.4

Width across flats KA

Width across flats B1

WA

GA

h + l

8

Width across flats NA

Z + Stroke

ZZ + Stroke

2 x P

(Rc, NPT, G)

Cushion valve, Width across flats

WH

WB

GB

øe

øIJ

Stroke range Rc, NPT port G port

Bore

size

Standard Long stroke

Up to 300 301 to 15002016 (20)

80

Up to 300 301 to 15002016 (20)

100

Bore

RR S TZ V Z ZZ

size

18

108 (122)

80

22

100

∗ Refer to the basic type for the female rod end.

Note) ( ): Denotes the dimensions for long stroke.

∗ For details about applicable maximum stroke, contact SMC.

108 (122)

GA GB P GA GB P

3/8 17.5

1/2 17.5

[mm]

Applicable

pin part no.

64 26

72 32

214 (228) 232 (246)

222 (236) 244 (258)

IY-G08

IY-G10

16 (17.5)

3/8 40 37 32 50 18 28 56 25 40 3 71 13

16 (17.5)

1/2 40 37 41 60 22 32 64 30 50 3 71 16

With Air Cushion

Bore

size

GA GB P

20 16 (20) 3/8 24 20 (24) 20° 4

80

20 16 (20) 1/2 24 20 (24) 20° 4

100

15

f

l

Z + l + Stroke

ZZ + l + Stroke

AALB1 CCDCXCZD E F H H1 I J K KA L MM NA

89

Rc, NPT, G

[mm]

WA WB Wθ WH

M10 x 1.5

110

M12 x 1.75

With Rod Boot

Bore

efhIJ

size

52 10 80 59

80

62 7 80 71

100

∗ The minimum stroke with rod boot is 20 mm.

10 22 35

10 26 43

l

1

/4

stroke

M22 x 1.5

M26 x 1.5

ZZZ

223 (237) 241 (255)

231 (245) 253 (267)

[mm]

86

106

[mm]

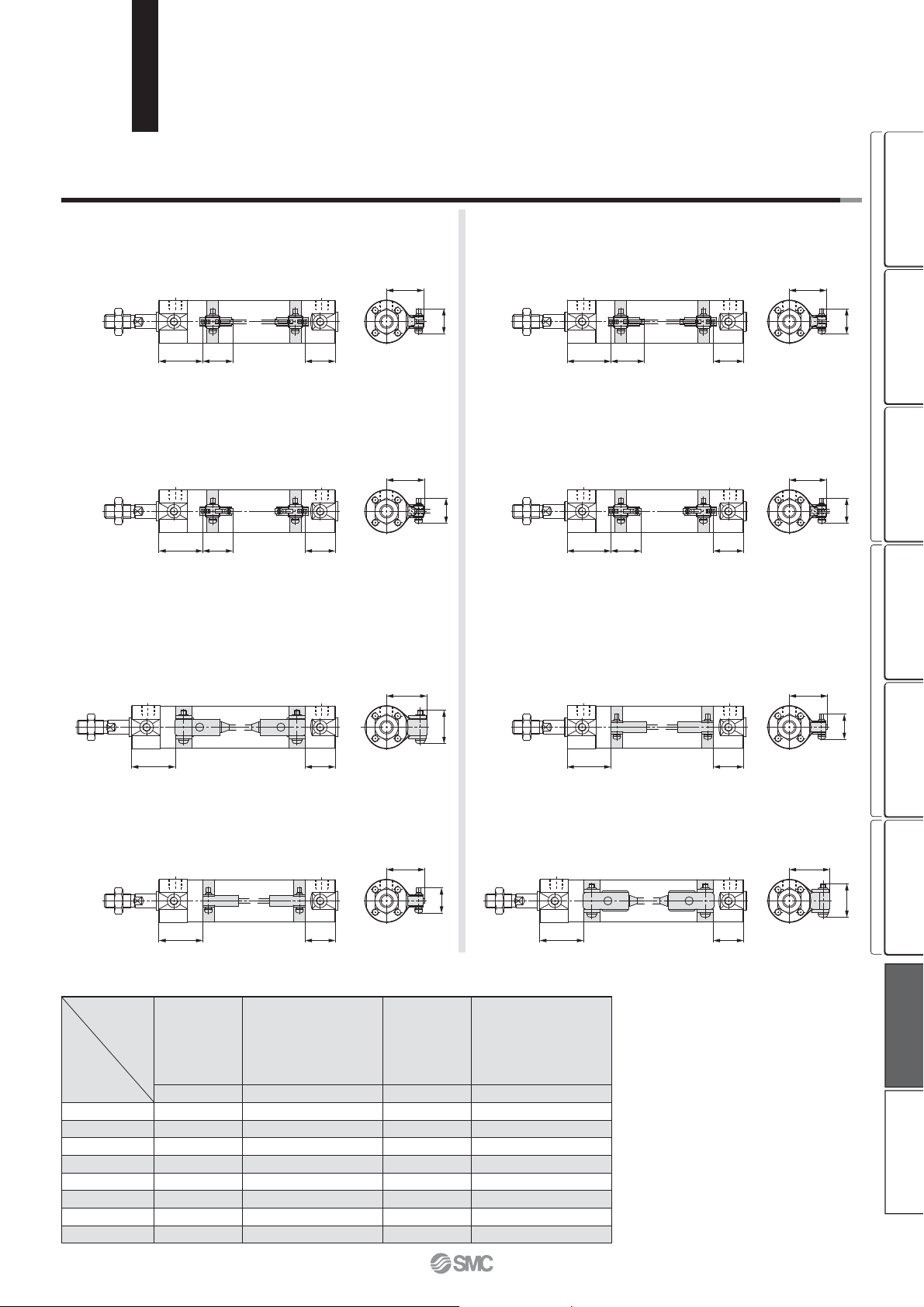

With Pivot Bracket [( ): Denotes the dimensions for long stroke.]

Air Cylinder: Standard Type

Double Acting, Single Rod

Series CG1

Rod Trunnion (U)

Z

TS

Bracket mounting range

with Pivot Bracket

B

TH

4 x øTF

Female Thread

Bore size

20

25

32

40

50

63

Male Thread

Bore size

20

25

32

40

50

63

B TETFTHTSTTTVTWTXTY Z

38 10 5.5 25 28 3.2 35.8 42 16 28 46

45.5 10 5.5 30 33 3.2 39.8 42 20 28 51

54 10 6.6 35 40 4.5 49.4 48 22 28 51

63.5 10 6.6 40 49 4.5 58.4 56 30 30 62

79 20 9 50 60 6 72.4 64 36 36 71

96 20 11 60 74 8 90.4 74 46 46 71

Head Trunnion (T)

TS

TY

TW

Bracket mounting range

øTE

TT

+0.10

0

[mm]

TX

TV

with Pivot Bracket

B

TT

TX

TV

Male Thread Female Thread

Bore size

20

25

32

40

50

63

B TETFTHTSTTTVTWTXTY Z ZZ

38 10 5.5 25 28 3.2 35.8 42 16 28

45.5 10 5.5 30 33 3.2 39.8 42 20 28

54 10 6.6 35 40 4.5 49.4 48 22 28

63.5 10 6.6 40 49 4.5 58.4 56 30 30

79 20 9 50 60 6 72.4 64 36 36

96 20 11 60 74 8 90.4 74 46 46

TH

4 x øTF

øTE

+0.10

0

Z + Stroke

[mm]

93 (101) 114 (122)

98 (106) 119 (127)

101 (108) 125 (132)

118 (125) 146 (153)

136 (147) 168 (179)

136 (147) 173 (184)

ZZ + Stroke

Bore size

20

25

32

40

50

63

71 ( 79)

72 ( 80)

75 ( 82)

83 ( 90)

94 (105)

94 (105)

[mm]

Z

24

25

25

27

29

29

TY

TW

[mm]

ZZZ

92 (100)

93 (101)

99 (106)

111 (118)

126 (137)

131 (142)

CG1CG1WCG1CG1KCG1KWCG1R

Double Acting, Single RodDouble Acting, Double Rod

StandardNon-rotating RodDirect Mount

Single Acting, Spring Return/Extend

Double Acting, Single RodDouble Acting, Double RodDouble Acting, Single Rod

Clevis (D)

with Pivot Bracket

TH

4 x øTF

øTE

B

+0.10

0

[mm]

118 (126) 139 (147)

125 (133) 146 (154)

131 (139) 155 (163)

150 (159) 178 (187)

173 (185) 205 (217)

178 (190) 215 (227)

Z

+ Stroke

ZZ + Stroke

Bore size

20

25

32

40

50

63

96 (104) 117 (125)

99 (107) 120 (128)

105 (113) 129 (137)

115 (124) 143 (152)

131 (143) 163 (175)

136 (148) 173 (185)

ø20 to ø63

TT

TX

TV

Male Thread Female Thread

Bore size

20

25

32

40

50

63

BTETFTHTTTVTWTXTYZZZ

38 10 5.5 25 3.2 35.8 42 16 28

45.5 10 5.5 30 3.2 39.8 42 20 28

54 10 6.6 35 4.5 49.4 48 22 28

63.5 10 6.6 40 4.5 58.4 56 30 30

79 20 9 50 6 72.4 64 36 36

96 20 11 60 8 90.4 74 46 46

Clevis (D)

with Pivot Bracket

ø80, ø100

Male Thread Female Thread

Bore size

80

100

B TFTHTT TVTWTX TY Z ZZ

99.5 11 55 11 110 72 85 45

120 13.5 65 12 130 93 100 60

4 x øTF

TX

TV

TH

B

Z + Stroke

ZZ

+ Stroke

[mm]

214 (228)

222 (236)

272.5 (286.5)

298.5 (312.5)

Bore size

80

100

162 (176)

173 (187)

TY

TW

[mm]

ZZZ

TT

TY

TW