SMC Networks VXS23, VXS26, VXS25, VXS24 Installation And Maintenance Manual

VXSS-TFR48

Installation and Maintenance Manual

VXS Zero Pressure Differential Type

Pilot operated 2 port solenoid valve

For Steam and Heated water

1 Safety Instructions

This manual contains essential information for the protection of users and

others from possible injury and/or equipment damage.

• Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

• Keep this manual in a safe place for future reference.

• These instructions indicate the level of potential hazard by label of

“Caution”, “Warning” or “Danger”, followed by important safety

information which must be carefully followed.

• To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

Caution

Indicates a hazard with a low level of risk, which if not

avoided, could result in minor or moderate injury.

Warning

Indicates a hazard with a medium level of risk, which

if not avoided, could result in death or serious injury.

Danger

Indicates a hazard with a high level of risk, which if

not avoided, will result in death or serious injury.

Warning

• The compatibility of equipment is the responsibility of the person

who designs the system or decides its specifications.

Since the products specified here can be used in various operating

conditions, their compatibility with a specific system must be based on

specifications or after analysis and/or tests to meet specific

requirements.

• Only trained personnel should operate pneumatically operated

machinery and equipment.

The fluid can be dangerous if an operator is unfamiliar with it. Assembly,

handling or repair of the system should be performed by trained and

experienced personnel.

• Do not service machinery/equipment or attempt to remove

components until safety is confirmed.

1) Inspection and maintenance of machinery/equipment should only be

performed after confirmation of s afe locked-out control positions.

Measures to prevent danger from the fluid should also be taken.

2) When equipment is to be removed, confirm the safety processes as

mentioned above. Release the fluid pressure and be certain there is no

danger from fluid leakage or fluid remaining in the system. Switch off

electrical supplies.

3) Before machinery/equipment is re-started, ensure all safety measures

are being implemented.

• Do not use this product outside of the specifications. Contact SMC

if it is to be used in any of the following conditions:

1) Conditions and environments beyond the given specifications, or if the

product is to be used outdoors.

2) Installations in conjunction with atomic energy, railway, air na vigation,

vehicles, medical equipment, food and beverage, recreation equipment,

emergency stop circuits, press applications, or safety equipment.

3) An application which has the possibility of having negative effects on

people, property, or animals, requiring special safety analysis.

Caution

• Ensure that the air supply system is filtered to 5 m.

2 Specifications

2.1 General Specifications

Valve

specifications

Valve construction

Zero differential pressure pilot operated 2

port piston type

Withstand pressure (with

water)

2.0 MPa

Maximum system pressure

1.0 MPa

Maximum operating

pressure differential

1.0 MPa

Minimum operating

pressure differential

0 MPa

Note 1)

Body material

Brass (C37), Stainless steel

Seal material

(Note 3)

FKM

Enclosure

Dust-tight, Water jet-proof type (IP65)

Environment

Location without corrosive or explosive

gases

Coil

specifications

Rated voltage

AC

100 VAC, 200VAC, 110VAC, 230VAC,

(220VAC, 240VAC, 48VAC, 24VAC)

Note 2)

DC

24 VDC

Allowable voltage fluctuation

±10% of rated voltage

Allowable leakage

voltage

AC

5% or less of rated voltage

DC

2% or less of rated voltage

Coil insulation type

Class H

Note 1) The operation of the valve may be unstable due to the capacity of the

pressure supply source such as pumps and compressors or the pressure loss by the

orifice of piping. Please contact SMC to check if the required valve size can be used

in the application. Contact SMC for the compatibility of the circuit and valve size.

Note 2) Voltage in brackets ( ) indicates special voltage.

2.2 Coil Specifications

2.2.1 Normally Closed (N.C.)

DC Specification

Model

Power consumption (W)

Note1)

Temperature rise (°C)

Note2)

VXS23/24

12

100

VXS25/26

15

100

Note 1: Power consumption: The value at ambient temperature of 20°C and when the

rated voltage is applied. (Variation: ±10%).

Note 2: The value at ambient temperature of 20°C and when the rated voltage is

applied. The value depends on the ambient environment. This is for reference.

2.2.2 Normally Closed (N.C.)

AC Specification (Built-in Full-wave Rectifier Type)

Model

Apparent power (VA)

Note 1, 2)

Temperature rise (°C)

Note 3)

VXS23/24

12

100

VXS25/26

15

100

Note 1: Power consumption, apparent power: The value at ambient temperature of

20°C and when the rated voltage is applied. (Variation: ±10%)

Note 2: There is no difference in the frequency and the inrush and energized apparent

power, since a rectifying circuit is used for AC. (Built-in full-wave rectifier type).

Note 3: The value at ambient temperature of 20°C and when the rated voltage is

applied. The value depends on the ambient environment. This is for reference.

2.3 Model/Valve specifications

For STEAM / Single Unit (Can be used with heated water)

Normally closed (N.C.)

C37, Stainless steel body

Size

Port

Size

Orifice

Dia.

(mm)

Model

Flow characteristics

Weight

Note)

(g)

Av

(x 10-6 m2)

Cv

3

1/4

10

VXS235

58

2.4

600

3/8

67

2.8

4

1/2

15

VXS245

130

5.3

720

5

3/4

20

VXS255

220

9.2

1100

6 1 25

VXS265

290

12.0

1300

Note) Weight of Grommet type. Add 10g for Conduit type, 30g for DIN terminal, 60g

for Conduit terminal type.

Ambient and fluid temperature

Fluid

Temperature (°C)

Ambient temperature (°C)

Steam

183 or less

-20 to 60

Heated water

99 or less

Note) With no freezing.

2 Specifications (continued)

Valve Internal Leakage Rate

Fluid

Seal Material

Leakage rate

Note)

Steam

FKM

1 cm3/min or less

Heated water

0.1 cm3/min or less

Valve External Leakage Rate

Fluid

Seal Material

Leakage rate

Note)

Steam

FKM

1 cm3/min or less

Heated water

0.1 cm3/min or less

Note) Leakage is the value at ambient temperature 20°C.

2.4 Pneumatic Symbol

2.4.1 Valve

Valve

Symbol

Normally closed (N.C.)

Table 1

3 Installation

Warning

• Do not install the product unless the safety instructions have been read

and understood.

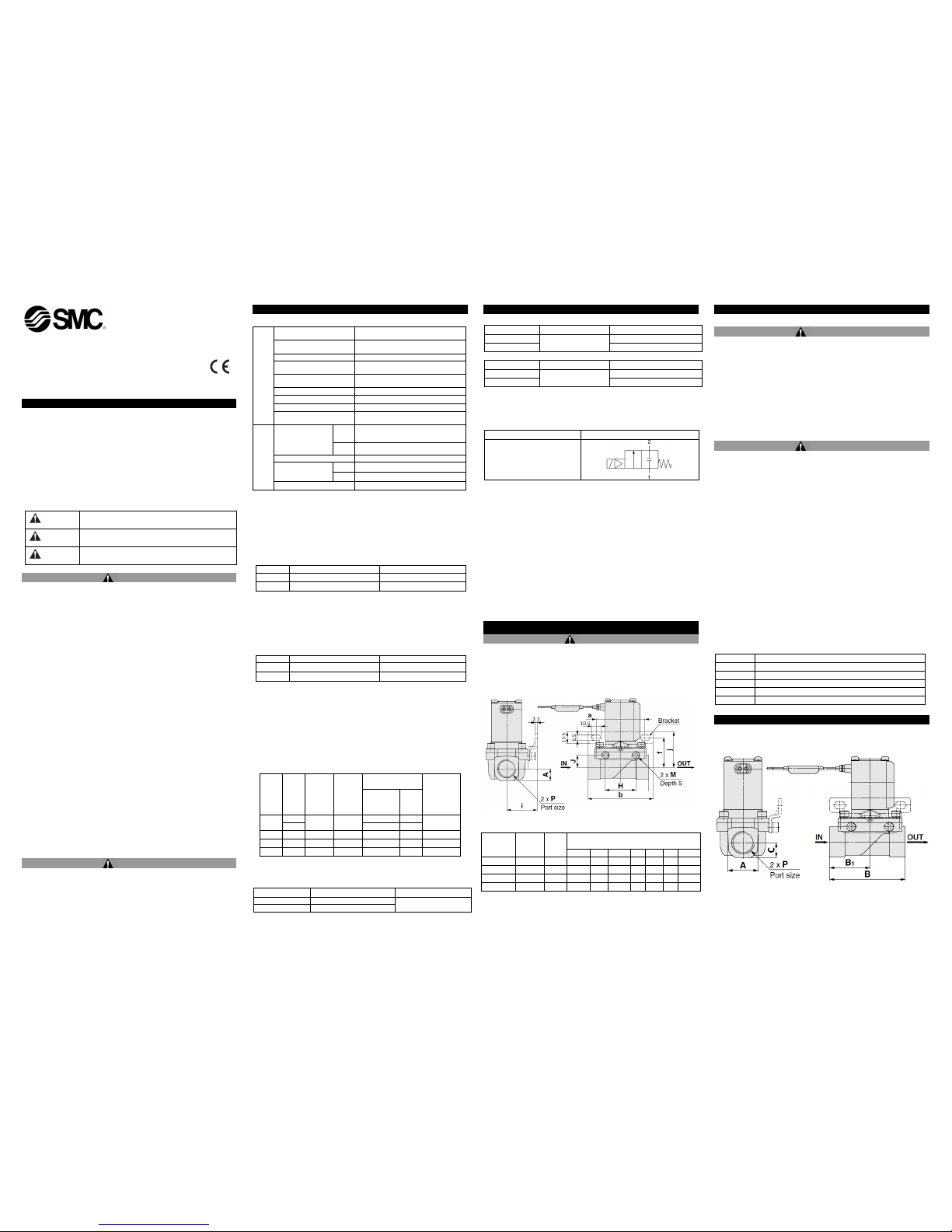

3.1 VXS Valve Mounting Bracket

C37, Stainless steel (Bracket optional)

Figure 1

Model

Port

size

P

A

(mm)

Bracket Mounting

(mm)

a b f i j H J

VXS23

1/4, 3/8

10.5

56

75

30

31

37

35

10

VXS24

1/2

14

56

75

34

35

41

35

14

VXS25

3/4

17

70.5

92

39

43

46

33

15.2

VXS26 1 20

70.5

92

41

45

48

37

17.2

Table 2

3 Installation (continued)

3.2 Environment

Warning

• Do not use in an environment where corrosive gases, chemicals, salt

water, water, water vapour are present or where there is direct contact

with any of these.

• Do not use in an explosive atmosphere.

• Do not expose to direct sunlight. Use a suitable protective cover.

• Do not install in a location subject to vibration or impact. Check the

product specifications.

• Do not mount in a location exposed to radiant heat.

• Employ suitable protective measures in locations where there is contact

with water droplets, oil or welding splatter, etc.

3.3 Piping

Caution

• Before connecting piping, it should be thoroughly blown out with air

(flushed) or washed to remove chips, cutting oil and other debris from

inside the pipe.

• Avoid connecting ground lines to piping, as this may cause electrolytic

corrosion of the system.

• When installing piping or fittings, ensure sealant material does not enter

inside the port. When using seal tape, leave 1.5 to 2 threads exposed on

the end of the pipe/fitting.

• Tighten fittings to the specified tightening torque, see Table 3.

• Install piping s o that it does not apply pulling, pressing, bending or other

forces on the valve body.

• When connecting piping, avoid mistakes regarding the supply port.

• Steam generated by a boiler contains a large amount of drainage;

ensure to operate with a drain trap installed.

• Avoid installing piping to the valve at the lowest point of the layout. If

condensate accumulates in the valve or adjacent piping, this could

cause steam hammer. If steam hammer causes a problem, install a

bypass to discharge condensate from the piping.

• If the effective area of the piping on the fluid supply side is restricted, the

operating time m ay become unstable due to the differential pressure

fluctuation when the valve is closed.

Thread

Tightening Torque N•m

Rc 1/4

12 to 14

Rc 3/8

22 to 24

Rc 1/2

28 to 30

Rc 3/4

28 to 30

Rc 1

36 to 38

Table 3

3 Installation (continued)

3.3.1 Valve Ports

C37, Stainless steel

Figure 2

VXSS-TFR48

3 Installation (continued)

Model

Port size P

(Rc)

Valve Ports

(mm)

A B B1 C VXS23

1/4, 3/8

21

57

28.5

10.5

VXS24

1/2

28

70

37.5

14

VXS25

3/4

33.5

71

38.5

17

VXS26 1 42

95

49.5

20

Table 4

3.4 Electrical connection

Caution

• Avoid mis-wiring, as this can cause malfunction, damage and fire to the

product.

• To prevent noise and surge in signal lines, keep all wiring separate from

power lines and high voltage lines. Otherwise this can cause

malfunction.

• When a surge from the solenoid affects the electrical circuitry, install a

surge absorber, etc., in parallel with the solenoid. Or, use an option that

comes with surge voltage protection circuit.

• Use electrical circuits that do not generate chattering in their contacts.

• Use voltage that is within ±10% of the rated voltage. In cases with a DC

power supply where responsiveness is important, stay within ±5% of the

rated value. (The voltage drop is the value in the lead wire section

connecting the coil).

• Generally use electrical wire with cross sectional area 0.5 to 1.25 mm2.

• Do not bend or pull cables repeatedly.

• Do not allow excessive force to be applied to the lines.

• Do not apply AC voltage to AC type unless it has a built in full-wave

rectifier or it will be damaged.

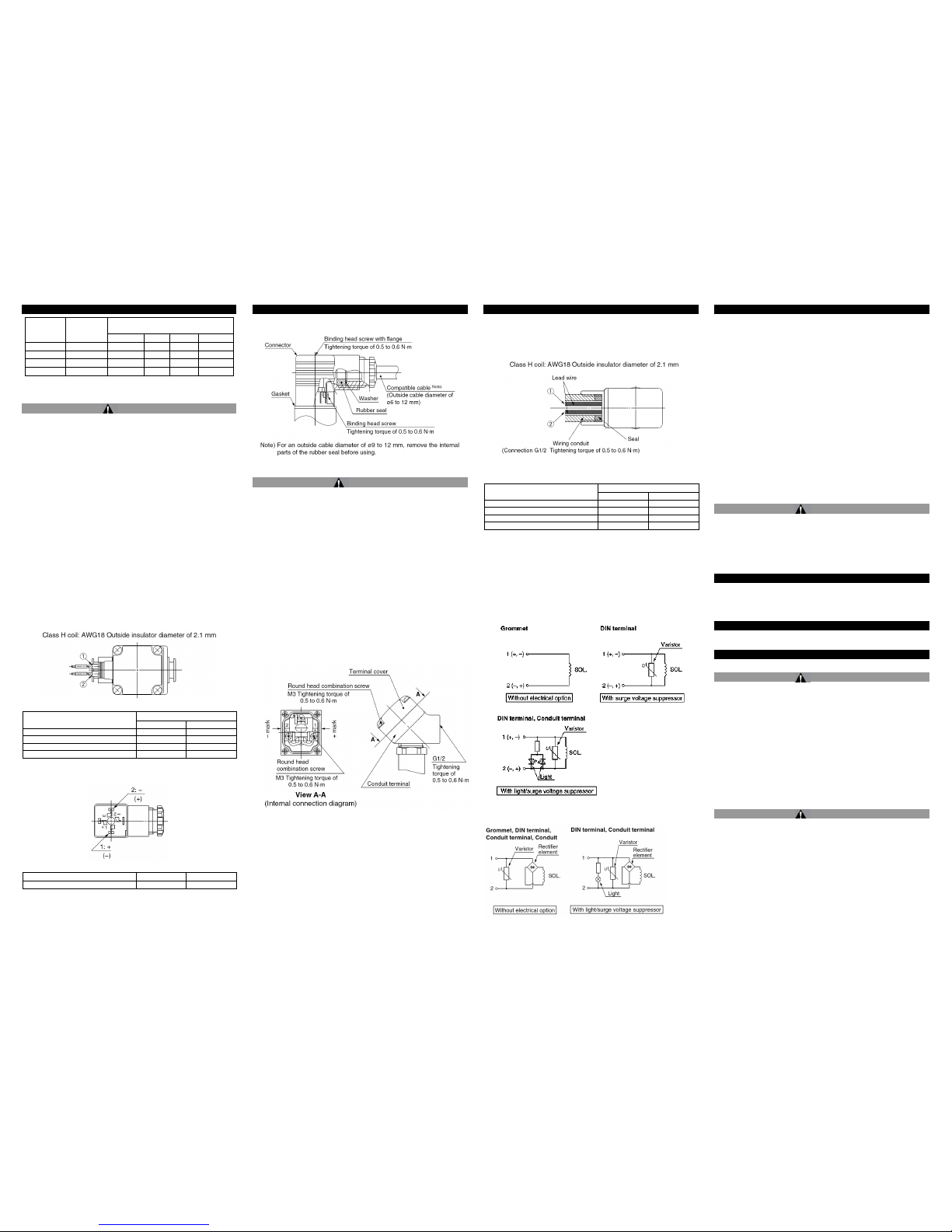

3.4.1 Grommet

Figure 3

Rated Voltage

Lead wire colour

1

2

DC

Black

Red

100 VAC

Blue

Blue

200 VAC

Red

Red

Other AC

Grey

Grey

*There is no polarity

Table 5

3.4.2 DIN Terminal

Figure 4

Terminal no.

1

2

Din Terminal

+(-)

-(+)

*There is no polarity

Table 6

• Use a heavy-duty cord with an outside cable diameter of Ø6 to 12 mm.

• Tighten screws and fittings according to Figure 5.

3 Installation (continued)

Figure 5

Caution

• For class H coil, surge voltage suppressor and full-wave rectifier (for AC)

are on DIN connector side. A SMC DIN connector must be used. Part

numbers can be found in product catalogue.

3.4.3 Conduit Terminal

• Make connections according to the marking shown in Figure 6.

• Tighten screws and fittings according to Figure 6.

• Properly seal the terminal connection (G1/2) with special wiring conduit,

etc.

Figure 6

3 Installation (continued)

3.4.4 Conduit

• When used as an IP65 equivalent use seal (VCW20-15-6) to install the

wiring conduit.

• Tighten conduit to torque shown in Figure 7.

Figure 7

Rated Voltage

Lead wire colour

1

2

DC

Black

Red

100 VAC

Blue

Blue

200 VAC

Red

Red

Other AC

Grey

Grey

*There is no polarity

(For the power saving type, there is polarity)

Table 7

3.5 Electrical circuits

3.5.1 DC circuit

Figure 8

3.5.2 AC circuit

Figure 9

3 Installation (continued)

3.6 Mounting

• Secure with brackets, except in the case of steel piping and copper

fittings.

• Avoid sources of vibration, or adjust the distance from the body to a

minimum length so that resonance will not occur.

• If air leakage increases or equipment does not operate properly, stop

operation. After mounting is completed, confirm that it has been done

correctly by performing a suitable function test.

• Do not apply external force to the coil section:

When tightening fittings, apply a wrench or other tool to the outside of

the piping connection parts.

• Do not install with the coil downwards.

If a valve is mounted with the coil positioned downwards, foreign objects

in the fluid will adhere to the iron core leading to a malfunction.

• Do not warm the coil assembly with a heat insulator, etc.

Use tape, heaters, etc., for freeze prevention on the piping and body

only. They can cause the coil to burn out.

• Painting and coating:

Warnings or specifications printed or labeled on the product should not

be erased, removed or covered up.

3.7 Lubrication

Caution

• SMC products have been lubricated for life at manufacture, and do not

require lubrication in service.

• If a lubricant is used in the system, use turbine oil Class 1 (no additive),

ISO VG32.

• Once lubricant is used in the system, lubrication must be continued

because the original lubricant applied during manufacturing will be

washed away.

4 How to Order

Refer to the catalogue for this product.

5 Outline Dimensions (mm)

Refer to the catalogue for this product.

6 Maintenance

6.1 General Maintenance

Caution

• Not following proper maintenance procedures could cause the product to

malfunction and lead to equipment damage.

• If handled improperly, compressed air can be dangero us. Maintenance

of pneumatic systems should be performed only by qualified personnel.

• Before performing maintenance, turn off the power supply and be sure to

cut off the supply pressure. Confirm that the air is released to

atmosphere.

• After installation and maintenance, apply operating pressure and power

to the equipment and perform appropriate functional and leakage tests

to make sure the equipment is installed correctly.

• Do not make any modification to the product.

• Do not disassemble the product, unless required by installation or

maintenance instructions.

• Exhaust the drainage from the piping periodically.

Warning

6.2 Removing the product:

• The valve will reach a high temperature when used with high

temperature fluids. Confirm that the valve temperature has dropped

sufficiently before performing work. If touched inadvertently, there is

danger of being burned.

1. Shut off the fluid supply and release the fluid pressure in the

system.

2. Shut off the power supply.

3. Remove the valve, ensuring any seals are retained.

Loading...

Loading...