SMC Networks VX21, VX22, VX23, VVX21, VVX22 Installation And Maintenance Manual

...

Installation and Maintenance Manual

VX21/22/23, 2 Port Solenoid Valves and

VVX21/22/23, Manifold Series

This manual should be read in conjunction with the current catalogue

For future reference, please keep this manual in a safe place

Safety Instructions

These safety instructions are intended to prevent a hazardous situation and/or equipment damage.These instructions indicate the level

of potential hazard by label of “Caution”,“Warning” or “Danger”.

To ensure safety,be sure to observe ISO4414

(Note1)

, JIS B 8370

(Note2)

and other safety practices.

Note 1: ISO 4414:Pneumatic fluid power – Recommendations for the

application of equipment to transmission and control systems.

Note 2: JIS B 8370: Pneumatic system axiom.

CAUTION : Operator error could result in injury or

equipment damage.

WARNING: Operator error could result in serious

injury or loss of life.

DANGER : In extreme conditions, there is a

possible result of serious injury or loss of life.

WARNING

1. The compatibility of pneumatic equipment is the responsibility of the person who designs the pneumatic system

or decides its specifications.

Since the products specified here are used in various operating

conditions, their compatibility for the specific pneumatic system

must be based on specifications or after analysis and/or tests to

meet your specific requirements.

2. Only trained personnel should operate pneumatically

operated machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar

with it.Assembly, handling or repair of pneumatic systems should

be performed by trained and experienced operators.

3. Do not service machinery/equipment or attempt to

remove component until safety is confirmed.

1) Inspection and maintenance of machinery/equipment should

only be performed after confirmation of safe locked-out

control positions.

2) When equipment is to be removed, confirm the safety process

as mentioned above.Switch off air and electrical supplies and

exhaust all residual compressed air in the system.

3) Before machinery/equipment is re-started, ensure all safety

measures to prevent sudden movement of cylinders etc.

(Bleed air into the system gradually to create back-pressure,

i.e. incorporate a soft-start valve).

4. Contact SMC if the product is to be used in any of the

following conditions:

1) Conditions and environments beyond the given specifica-

tions, or if product is used outdoors.

2) Installations in conjunction with atomic energy, railway, air

navigation, vehicles,medical equipment, food and beverage,

recreation equipment, emergency stop circuits, press

applications, or safety equipment.

3) An application which has the possibility of having negative

effects on people, property, or animals, requiring special

safety analysis.

CAUTION

Ensure that the air supply system is filtered to 5 micron.

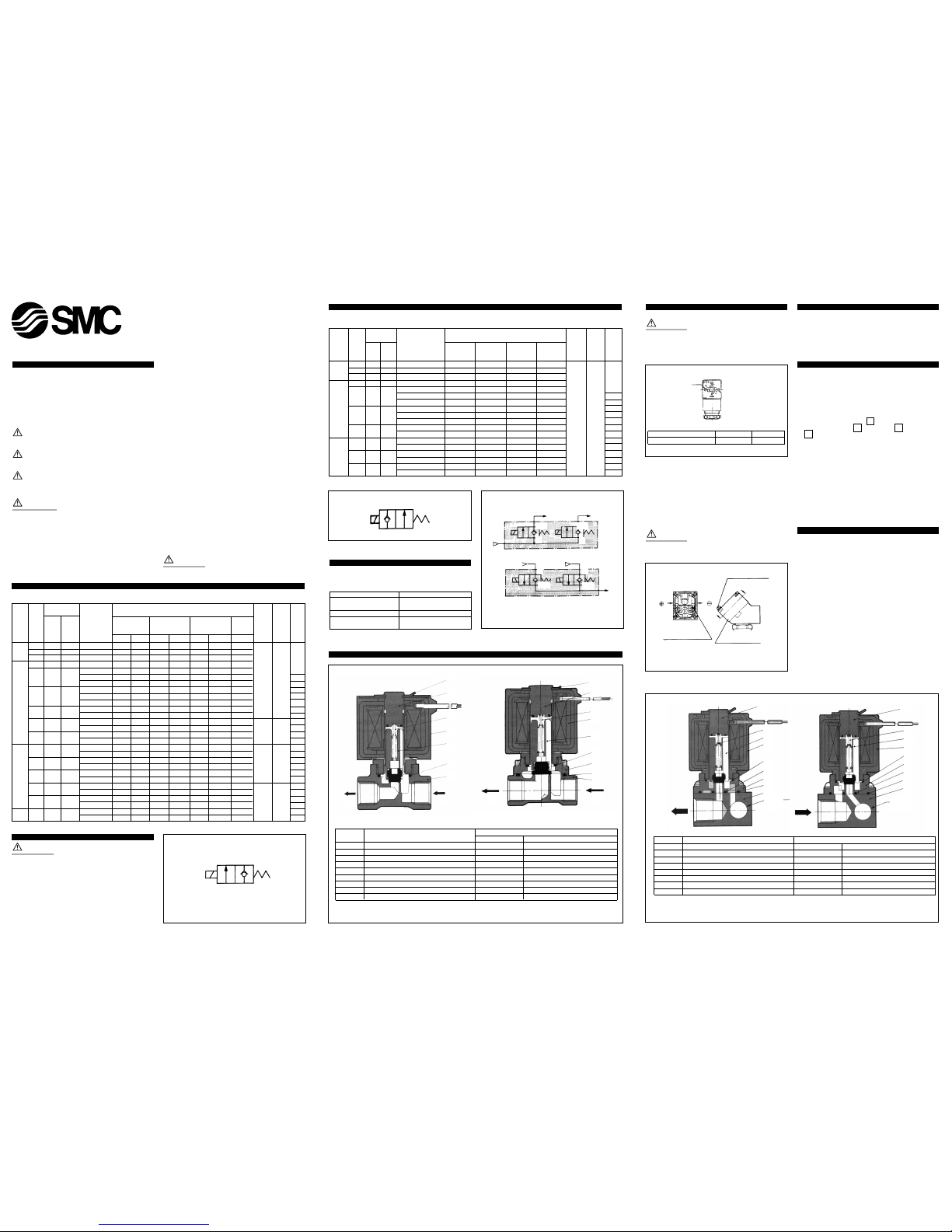

Type/Valve specifications (Energised open type)

Flow rate

Max. operating pressure Max

Orifice differential MPa (kgf/cm

2

) system Proof Weight

Port size Effective

Model

pressure pressure (g)

size (mmø) Cv area Water Air Oil Steam MPa MPa (Note)

(mm

2

) (kgf/cm2) (kgf/cm2)

AC DC AC DC AC DC AC

1

/

8

2 0.17 3 VX2110-01 2.0{20} 1.5{15} 2.0{20} 1.5{15} 1.5{15} 1.5{15} 1.0{10}

(6A) 3 0.33 6 VX2120-01 0.9{9} 0.5{5} 1.1{11} 0.6{6} 0.5{5} 0.5{5} 1.0{10}

4.5 0.61 11 VX2130-01 0.4{4} 0.2{2} 0.45{4.5} 0.2{2} 0.2{2} 0.15{1.5} 0.45{4.5} 260

2 0.17 3 VX2110-02 2.0{20} 1.5{15} 2.0{20} 1.5{15} 1.5{15} 1.5{15} 1.0{10} Water

VX2120-02 0.9{9} 0.5{5} 1.1{11} 0.6{6} 0.5{5} 0.5{5} 1.0{10} Oil

3 0.33 6 VX2220-02 1.7{17} 1.5{15} 2.0{20} 1.5{15} 1.2{12} 1.2{12} 1.0{10} Air 5.0 400

VX2320-02 2.5{25} 3.0{30} 3.0{30} 3.0{30} 1.7{17} 2.0{20} - 3.0 {50} 540

VX2130-02 0.4{4} 0.2{2} 0.45{4.5} 0.2{2} 0.2{2} 0.15{1.5} 0.45{4.5} {30} 260

1

/

4

4.5 0.61 11 VX2230-02 0.6{6} 0.35{3.5} 0.75{7.5} 0.35{3.5} 0.35{3.5} 0.3{3} 0.75{7.5} Steam 400

(8A) VX2330-02 0.85{8.5} 0.9{9} 1.0{10} 0.9{9} 0.55{5.5} 0.85{8.5} 1.0{10} 1.0 540

6 1.05 19 VX2240-02 0.35{3.5} 0.15{1.5} 0.4{4} 0.15{1.5} 0.2{2} 0.1{1} 0.4{4} {10} 400

VX2340-02 0.55{5.5} 0.3{3} 0.5{5} 0.35{3.5} 0.35{3.5} 0.3{3} 0.5{5} 540

8 1.7 31 VX2250-02 0.13{1.3} 0.08{0.8} 0.15{1.5} 0.08{0.8} 0.1{1} 0.08{0.8} 0.15{1.5} Water· 510

VX2350-02 0.17{1.7} 0.2{2} 0.2{2} 0.2{2} 0.14{1.4} 0.2{2} 0.2{2} Oil Air 3.0 650

10 1.9 34 VX2260-02 0.08{0.8} 0.03{0.3} 0.08{0.8} 0.03{0.3} 0.05{0.5} 0.03{0.3} 0.08{0.8} 1.0 {10} {30} 510

VX2360-02 0.1{1} 0.07{0.7} 0.1{1} 0.07{0.7} 0.08{0.8} 0.07{0.7} 0.1{1}

Steam 0.5 {5}

650

3 0.33 6 VX2220-03 1.7{17} 1.5{15} 2.0{20} 1.5{15} 1.2{12} 1.2{12} 1.0{10} Water 400

VX2320-03 2.5{25} 3.0{30} 3.0{30} 3.0{30} 1.7{17} 2.0{20} - Oil Air 540

4.5 0.61 11 VX2230-03 0.6{6} 0.35{3.5} 0.75{7.5} 0.35{3.5} 0.35{3.5} 0.3{3} 0.75{7.5} 3.0 {30} 5.0 400

VX2330-03 0.85{8.5} 0.9{9} 1.0{10} 0.9{9} 0.55{5.5} 0.85{8.5} 1.0{10} Steam {50} 540

3

/

8

6 1.05 19 VX2240-03 0.35{3.5} 0.15{1.5} 0.4{4} 0.15{1.5} 0.2{2} 0.1{1} 0.4{4} 1.0 {10} 400

(10A) VX2340-03 0.55{5.5} 0.3{3} 0.5{5} 0.35{3.5} 0.35{3.5} 0.3{3} 0.5{5} 540

8 1.7 31 VX2250-03 0.13{1.3} 0.08{0.8} 0.15{1.5} 0.08{0.8} 0.1{1} 0.08{0.8} 0.15{1.5} 510

VX2350-03 0.17{1.7} 0.2{2} 0.2{2} 0.2{2} 0.14{1.4} 0.2{2} 0.2{2} Water· 650

10 2.4 43 VX2260-03 0.08{0.8} 0.03{0.3} 0.08{0.8} 0.03{0.3} 0.05{0.5} 0.03{0.3} 0.08{0.8} Oil Air 3.0 510

VX2360-03 0.1{1} 0.07{0.7} 0.1{1} 0.07{0.7} 0.08{0.8} 0.07{0.7} 0.1{1} 1.0 {10} {30} 650

1

/

2

10 2.4 43 VX2260-04 0.08{0.8} 0.03{0.3} 0.08{0.8} 0.03{0.3} 0.05{0.5} 0.03{0.3} 0.08{0.8} Steam 590

(15A) VX2360-04 0.1{1} 0.07{0.7} 0.1{1} 0.07{0.7} 0.08{0.8} 0.07{0.7} 0.1{1} 0.5 {5} 730

Note: It is a grommet valve.Add the conduit 10g, the DIN connector 30g and the terminal 60g respectively.

Energised open type (N.C.) (Fig 3)

Manifold Series VVX21/22/23

Manifold specifications

Manifold type B Mount

Manifold base type Common pressure type,

individual pressure type (Note)

Number of valves 2~10 stations

Blanking plate VVX21···VX011-011,

(with O-rings, screws) VVX22/23···VX011-006

Note: Common port is placed on vacuum side.

Electrical connection (Fig 5)

CAUTION

Isolate both power and air supplies before removing/replacing

connector.

In the case of DIN connector and terminal block, connections are

shown below.

1. Loosen the top screw and remove the connector housing from the

terminal spades on the solenoid.

2. Remove the housing screw and insert a screwdriver into the slot

on the underside of the DIN cap and carefully remove the block.

3. Loosen the terminal screws on the block and insert the stripped

leads. Secure each lead by re-tightening the appropriate terminal

screw.

4. Tighten the housing grommet nut to secure the cable.

CAUTION

Pull connector out vertically,never at an angle.

In the case of the conduit entry,the connections are shown below.

Wiring

Should the coil be subjected to a surge voltage, place a surge suppresser in parallel with the coil if not fitted as an option.

The allowable voltage range is -10% - +10% of rated voltage.

The voltage found across the coil when de-energised is :AC: 20% or less of rated voltage

DC: 2% or less of rated voltage

Piping

1 Piping should be thoroughly flushed to remove sludge, cutting oil

and dust.

2 During piping and coupling connection, care should be taken to

prevent contamination by dirty threads or sealing materials.

When applying sealing tape to threads, the thread should extend

one screw pitch beyond the tape.

3 Pay attention to the direction of piping (solenoid valve IN,OUT.)

In the case of 2 port valves, indicates the inlet side. In the

case of 3 port valves, indicates inlet, indicates outlet,

indicates exhaust.

4 The coil should not be subjected to an external force.When tight-

ening, apply a wrench to the outside of the pipe mounting area

only.

5 In the case of solenoid valves specified for vacuum and non-leak

use, please pay special attention to the exclusion of foreign matter and leakage through the couplings.

6 In the process of piping, if the coil assembly needs to be removed,

do so by removing its retainer.

After completion of piping please reattach the retainer.

7 The piping system should not be grounded.

Grounding would cause electrolytic corrosion.

8 To prevent collection of fluid within the piping circuit please install

a relief valve within the circuit.

Mounting (Fig 7)

1 The solenoid valve may be mounted in any orientation. However

when mounted upside down, foreign material in the fluid is liable

to adhere to the iron core.This mounting position is not recommended by SMC.

2 Do not keep coil assemblies warm with insulating materials etc. It

will cause the coil to burn out.

Anti-freezing tape, heater etc. should be applied to piping and

body areas only.

3 Except in the case of steel pipes and couplings, mount the valve

with a bracket, especially in the case of non-leak and vacuum

valves.The bracket will help prevent loosening of the couplings.

4 Do not place the valve in areas of severe vibration.

In the case of manifold mounted type valves (where 00 connection

option appears in the part number), see Fig 7.

Ensure that 'O' rings item 5 in Fig 8 are not damaged and free from

any foreign bodies. Locate valve on manifold, being sure to connect

the OUT port on the manifold with the centre port on the valve.Locate

the 4 off mounting screws and tighten so as to achieve an air tight

seal between the valve and the manifold.

049A/ENG

Installation

WARNING

Ensure all air and power supplies are ISOLATED before commencing

installation.

Do not install these valves in explosive atmospheres.

If these valves are exposed to water or oil droplets ensure that they

are protected.

If it is intended to energise a valve for an extended period please consult SMC.

If air leakage causes associated equipment to malfunction cease using

valve and inspect for cause.

Check fixings while pressure and power are applied. Initial function

and leakage tests should be performed after installation.

Install only once safety instructions have been read and understood.

OUT

Symbol

IN

Fig 1 Fig 4

Fig 8

Fig 2

Fig 3

Fig 5

Fig 6

Energise to open type (N.C.) (Fig 1)

Energise to close type (N.O.) (Fig 2)

Type/Valve specifications (Energised close type)

Flow rate Max. operating pressure Max

Orifice differential MPa (kgf/cm

2

) system Proof Weight

Port size Effective Model pressure pressure (g)

size (mmø) Cv area Water Air Oil Steam MPa MPa (Note)

(mm2) (kgf/cm2) (kgf/cm2)

1

/

8

2 0.17 3 VX2112-01 0.9{9} 1.5{15} 0.8{8} 1.0{10}

(6A)

3 0.33 6 VX2122-01 0.45{4.5} 0.7{7} 0.45{4.5} 0.7{7}

4.5 0.61 11 VX2132-01 0.2{2} 0.3{3} 0.2{2} 0.3{3} 280

2 0.17 3 VX2112-02 0.9{9} 1.5{15} 0.8{8} 1.0{10}

VX2122-02 0.45{4.5} 0.7{7} 0.45{4.5} 0.7{7}

3 0.33 6 VX2222-02 0.8{8} 1.0{10} 0.7{7} 1.0{10} 440

1

/

4

VX2322-02 1.2{12} 1.6{16} 1.0{10} - 580

(8A)

VX2132-02 0.2{2} 0.3{3} 0.2{2} 0.3{3} Water 280

4.5 0.61 11 VX2232-02 0.3{3} 0.45{4.5} 0.3{3} 0.45{4.5} Oil 5.0{50} 440

VX2332-02 0.6{6} 0.8{8} 0.6{6} 0.8{8} Air 580

6 1.05 19 VX2242-02 0.15{1.5} 0.25{2.5} 0.15{1.5} 0.25{2.5} 3.0 440

VX2342-02 0.35{3.5} 0.45{4.5} 0.35{3.5} 0.45{4.5} {30} 580

3 0.33 6 VX2222-03 0.8{8} 1.0{10} 0.7{7} 1.0{10} Steam 440

VX2322-03 1.2{12} 1.6{16} 1.0{10} - 1.0{10} 580

3

/

8

4.5 0.61 11 VX2232-03 0.3{3} 0.45{4.5} 0.3{3} 0.45{4.5} 440

(10A) VX2332-03 0.6{6} 0.8{8} 0.6{6} 0.8{8} 580

6 1.05 19 VX2242-03 0.15{1.5} 0.25{2.5} 0.15{1.5} 0.25{2.5} 440

VX2342-03 0.35{3.5} 0.45{4.5} 0.35{3.5} 0.45{4.5} 580

Note: It is a grommet value.Add the conduit 10g, the DIN connector 30g and the terminal 60g respectively.

OUT

Symbol

IN

Symbol

Common pressure type

Individual pressure type

Port A

Port A

Port A

Port P

OUT OUT

OUT

OUT

IN

IN

IN IN

Port P

Port P

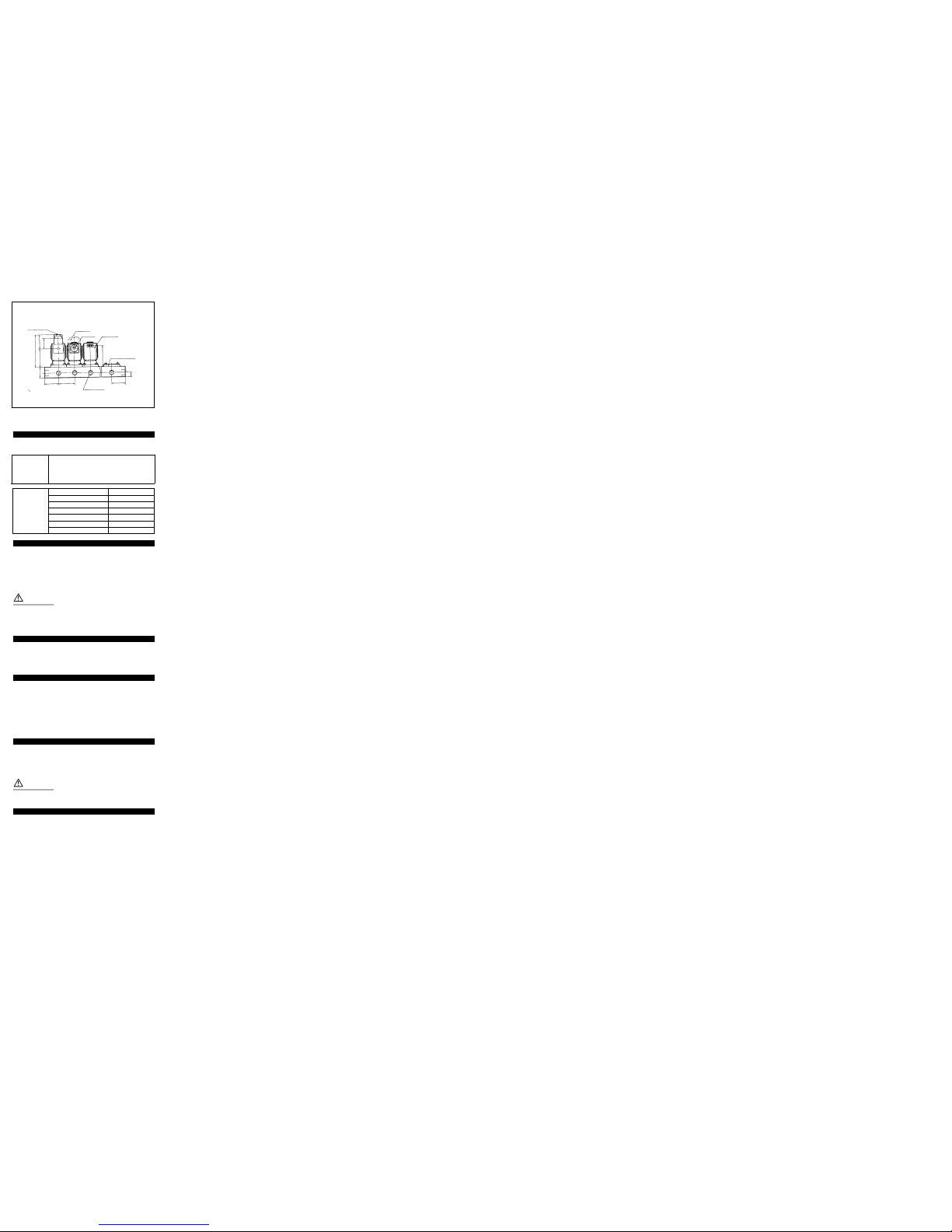

Construction and parts (Fig 4)

7

7

2

4

5

2

4

5

3

3

6

6

8

9

1

1

IN

IN

OUT

P

2

P

1

OUT

VX21/22/23 (Orifice size 2,3,4,5,6mmø) VX22/23 (Orifice size 8,10mmø)

No. Description

Material

Standard Option

1 Body Brass SUS304

2 Core assembly SUS430·Copper SUS430·Silver

3 Armature assembly SUS430·NBR SUS430·FPM/SUS430·PTFE/SUS430·EPR

4 Return spring SUS304 -

5 Coil assembly Class B molded Class H molded

6 O-ring NBR FPM/EPR/PTFE

7 Retainer SUS304 -

8 Bonnet Brass SUS304

9 O-ring NBR FPM/EPR/PTFE

1:+

2:-

Terminal No. 1 2

DIN connector + -

With DIN connector

mark mark

Conduit terminal

Phillips/ordinary

round head screw

M3

Phillips/ordinary

round head screw

M3

View A-A'

(Internal connection)

IN

P

A

R

No. Description Material

Standard Option

1 Body Aluminum -

2 Core assembly SUS430·Copper SUS430·Silver

3 Base Aluminum -

4 Armature assembly SUS430·NBR SUS430·FPM/SUS430·EPR

5 O-ring NBR FPM/EPR

6 Coil assembly Class B molded Class H molded

7 Return spring SUS304 -

Common pressure type Individual pressure type

OUT

Port A

OUT

Port A

IN

Port P

IN

Port P

2

2

7

4

6

5

5

1

5

3

7

4

6

5

1

5

5

3

VX21/22/23

Applicable fluids

VX21/22/23, 2 Port solenoid valves

Standard Water (standard, up to 60°C), air (standard, dry),

turbine oil, spindle oil, Kerosene,vacuum (up to 1

torr), carbon dioxide (CO

2

), nitrogen gas (n2),

Freon 11, 113,114

Fluid Option symbol

Steam (S,Q)

Vacuum (up to 10-3torr) (V,M)

Option Non-leak

(10-5atm cc/sec or less)

(V,M)

High temperature water (X,E,N,P)

High temperature oil (D,N)

Others

VVX21/22/23 Manifold series

Generally, the recommended viscosity of fluid is 50 cSt max. Fluids

contaminated with foreign material can promote wear of the valve

seat and iron core.To prevent this, place a filter/strainer immediately

before the valve.A mesh of 80-100 micron is recommended.

SMC valves are designed for use without lubricant. However,correctly

lubricated air will increase the life of the valve.

CAUTION

These valves are NOT EXPLOSION PROOF.When using inflammable oil

or gas, ensure that there is no leakage either inside or outside of the

valve.

Fluid temperature

Refer to the temperature range for each model.The temperature range

changes according to the sealing material, coil insulation, power

supply,etc.

Ambient conditions

Freezing.When using water in cold environments anti-freeze precautions should be taken.These include but are not limited to, draining of

pumps and valves.When using a heater, avoid applying it to the coil.

Freezing will result when the dew point of the medium is high and the

ambient temperature is low or when a large volume of fluid flows

within the valve. In such cases install a dryer, keep the valve body

warm, or take other preventative measures.

Long period energisation or de-energisation

The valve energisation period depends on the type and viscosity of the

fluid. When pure water is the medium, then the valve should be

switched at least every 10 days.If the period is longer than 10 days, a

system check mechanism should be implemented.

CAUTION

These valves are not intended for use as emergency system valves.

Vibration

These valves should not be subjected to more than 3G and in the case

of non-leak type no more than 1G.

Fig 7

n-

1

/

8

•

1

/

4

(OUT Port)

H

(Pitch)

F F

E

T

W

D

(44)

34.5

DIN connector

Terminal

Conduit

Grommet

Blanking plate

When you enquire about the product, please contact the following

SMC Corporation:

ENGLAND Phone 01908-563888 TURKEY Phone 212-2211512

ITALY Phone 02-92711 GERMANY Phone 6103-402-0

HOLLAND Phone 020-5318888 FRANCE Phone 01-64-76-10-00

SWITZERLAND

Phone 052-34-0022 SWEDEN Phone 08-603 07 00

SPAIN Phone 945-184100 AUSTRIA Phone 02262-62-280

Phone 902-255255 IRELAND Phone 01-4501822

GREECE Phone 01-3426076 DENMARK Phone 8738-0800

FINLAND Phone 09-68 10 21 NORWAY Phone 67-12 90 20

BELGIUM Phone 03-3551464 POLAND Phone 48-22-6131847

Loading...

Loading...