SMC Networks VQ100 Series Installation And Maintenance Manual

Installation and Maintenance Manual

VQ100 Series Solenoid Valve

This manual should be read in conjunction with the current valve catalogue.

For future reference, please keep this manual in a safe place

Safety Instructions

These safety instructions are intended to prevent a hazardous situation and/or equipment damage.These instructions indicate the level

of potential hazard by label of “Caution”,“Warning” or “Danger”.

To ensure safety,be sure to observe ISO4414

(Note1)

, JIS B 8370

(Note2)

and other safety practices.

Note 1: ISO 4414:Pneumatic fluid power – Recommendations for the

application of equipment to transmission and control systems.

Note 2: JIS B 8370: Pneumatic system axiom.

CAUTION : Operator error could result in injury or

equipment damage.

WARNING: Operator error could result in serious

injury or loss of life.

DANGER : In extreme conditions, there is a

possible result of serious injury or loss of life.

WARNING

1. The compatibility of pneumatic equipment is the responsibility of the person who designs the pneumatic system

or decides its specifications.

Since the products specified here are used in various operating

conditions, their compatibility for the specific pneumatic system

must be based on specifications or after analysis and/or tests to

meet your specific requirements.

2. Only trained personnel should operate pneumatically

operated machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar

with it.Assembly, handling or repair of pneumatic systems should

be performed by trained and experienced operators.

3. Do not service machinery/equipment or attempt to

remove component until safety is confirmed.

1) Inspection and maintenance of machinery/equipment should

only be performed after confirmation of safe locked-out

control positions.

2) When equipment is to be removed, confirm the safety process

as mentioned above.Switch off air and electrical supplies and

exhaust all residual compressed air in the system.

3) Before machinery/equipment is re-started, ensure all safety

measures to prevent sudden movement of cylinders etc.

(Bleed air into the system gradually to create back-pressure,

i.e. incorporate a soft-start valve).

4. Contact SMC if the product is to be used in any of the

following conditions:

1) Conditions and environments beyond the given specifica-

tions, or if product is used outdoors.

2) Installations in conjunction with atomic energy, railway, air

navigation, vehicles,medical equipment, food and beverage,

recreation equipment, emergency stop circuits, press

applications, or safety equipment.

3) An application which has the possibility of having negative

effects on people, property, or animals, requiring special

safety analysis.

CAUTION

Ensure that the air supply system is filtered to 5 micron.

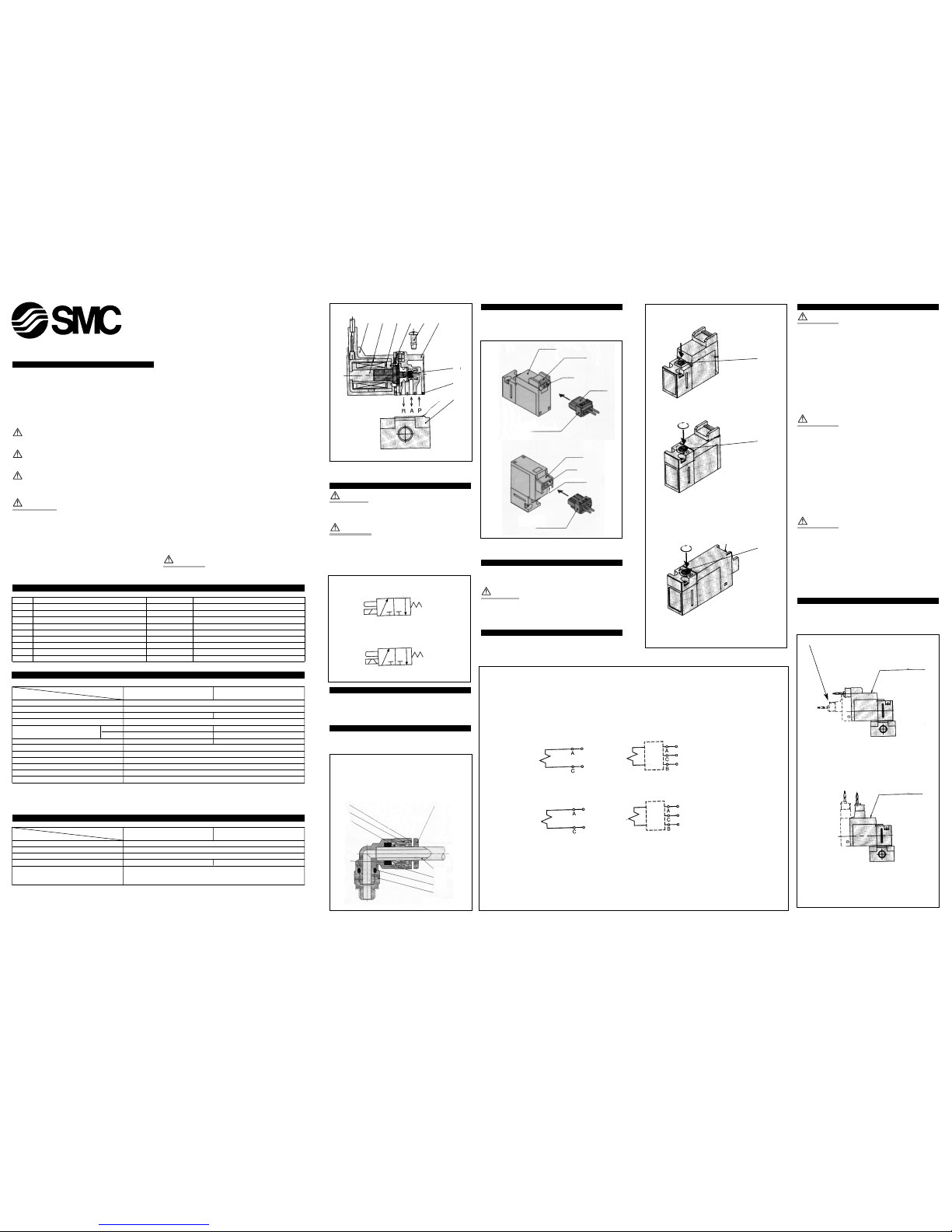

Main parts (Fig 1)

No. Description Material Note

1 Solenoid coil ––

2 Body Resin

3 Fixed iron core SUS

4 Movable iron core assembly SUS · Resin

5 Return spring SUS

6 Poppet NBR

7 Philips/ordinary round head screw Carbon steel AXT632-7-3 (M1.7x14)

8 Interface gasket NBR AXT782-11

9 Subplate ZDC AXT662-1-1/2 (1: M5,2: M3)

Valve specifications

Specifications 1 wattage

specifications

0.5 wattage

specifications

Item 0.7 MPa 0.7 MPa

Type 3 port direct operated poppet type (NC)

Fluid Air · inert gas

Max. operating pressure 0.7MPa (8.2 kgf/cm2) 0.7MPa (7.1 kgf/cm2)

Min. operating pressure 0MPa (0 kgf/cm2)

Effective orifice PRA 0.28mm2(Cv 0.016) 0.14mm2(Cv 0.008)

ARR 0.36mm2(Cv 0.02) 0.20mm2(Cv 0.011)

Response time Note 1 ON: 3.5ms,OFF: 2ms ON: 3.5ms, OFF: 2.5ms

Ambient and fluid temperature -10~+50°C Note 2

Lubrication Not required

Manual override Non-locking recessed type/Locking tool type Note 3

Mounting orientation Free

Protection structure IP40

Weight 12.6g (L/M type connector,without subplate)

Note 1:As per JISB8375-1981 (with indicator light and surge voltage suppressor; clean air), dispersion accuracy ±1ms.

Note 2: Use dry air to prevent dew condensation when operating at low temperature.

Note 3: Locking type is optional specification.

Solenoid specifications

Specifications 1 wattage

specifications

0.5 wattage

specifications

Item 0.7 MPa 0.7 MPa

Coil rated voltage 24VDC, 12VDC

Allowable voltage ±10% of rated voltage

Type of coil insulation Class B

Power consumption 1WDC 0.5WDC

Electrical entry

Plug-in, L/M type connector

(with indicator light and surge voltage suppressor)

Installation

CAUTION

Ensure all air and power supplies are isolated before commencing

installation.

WARNING

DO NOT INSTALL THESE VALVES IN EXPLOSIVE ATMOSPHERES.

If these valves are exposed to water or oil droplets, ensure that the

valves are protected.

If it is intended to energise a valve for an extended period please

consult SMC.

Tube connections-push-in fittings (Fig 2)

Ensure that the end of the tube 6 is cut square.

Push the tube 6 firmly into the fitting 7 until it stops.

Pull back on the tube 6 to ensure it is correctly gripped.

Tube disconnection (Fig 2)

Push down on the collet flange 2, via the release button 4, hold

down, and withdraw the tube 6.

Connection of plug connector (Fig 3)

Push the connector, in a straight line,onto the pins of the solenoid,

ensuring that the lip of the lever is securely positioned in the groove

of the solenoid cover.

Disconnection of plug connector (Fig 3)

Press the lever against the connector and pull the connector away

from the solenoid.

CAUTION

Do not exert excessive force on the wires, as this may cause contact

failure.

Wiring specifications (Fig 4)

The lead wires are connected to the valve as shown below.Connect

each to the power supply side.

Solenoid manual override (Fig 5)

WARNING

Exercise extreme CAUTION when operating solenoid manual

overrides, as connected equipment will commence operation.

Push non-locking type

Push down on the manual button 1 (Fig 5) until it stops (ON).

Hold this position whilst carrying out function checks.

Release the manual override button and the override will re-set to the

OFF position.

Locking type manual override (Fig 5)

Turn the manual override clockwise through 180°,using a small slotted screwdriver,until the mark P lines up with the No. 1.

Push down on the button until the override locks (ON) position.

WARNING

In this position the manual override is mechanically locked ON.

Un-locking (Fig 5)

Turn the manual override anti-clockwise through 180°,using a small

slotted screwdriver until the mark Plines up with the No.0.

Remove the screwdriver and the manual override will re-set to the

(OFF) position.

Latching Type (Fig 5)

Locking (Fig 5)

Turn the manual override clockwise 180°using a small slotted screwdriver until the mark P lines up with the letter A.

Push the override button down until it locks in position (ON).

WARNING

In this position the manual override is mechanically locked in the ON

position.

Un-locking

Turn the manual override anti-clockwise through 180° until the mark

P lines up with the letter B.

Remove the screwdriver, and the Manual override will re-set to the

OFF position.

Indicator light and surge suppressor (Fig 6a)

In the latching type, A (set) side and B (re-set) side energisation are

indicated by two colours,which match the colours of the manual override buttons. See below (Fig 6a)

019A/ENG

Symbol

Fig 2

Fig 4

Fig 6a

Fig 1

Fig 3

Fig 5

Latching type specification

1 Guide

2 Collet

3 Chuck

4 Release button

5 Packing

6 Tube

7 Body

8 O-ring

9 Stud

DC positive COM

DC negative COM

SOL.

Latching solenoid type

Single solenoid type

Lead wire colour

(-) Black

(+)Red

(-) White

SOL.

Single solenoid type

Lead wire colour

(+)Red

(-) Black

Non-locking recessed type

Latching type

Locking recessed type

Locking tool type (option)

1

2

3

4

1

2

3

5

6

7

8

9

Cover

Cover

Groove

Groove

Pin

Pin

Lever

Connector

Connector

Simultaneously

energised

protection

circuit

set

COM.

reset

Latching solenoid type

Lead wire colour

(+)Red

(-) Black

(+)White

Simultaneously

energised

protection

circuit

set

COM.

reset

SOL.

Indicator light

• ON

: Orange

(Set)

• (Reset) : Green

Indicator light

• ON

: Orange

(Set)

• (Reset) : Green

M type plug connector

Note: Dotted line shows latching type

L type plug connector

1 3 4 5 7 2

6

8

9

Lead wire colour

(-) Black

(+)Red

Valve specifications

(A)

2

3

(R)1(P)

3

(R)1(P)

(A)

2

Wiring specifications

Blanking plate (Fig 12) (VVQ100-10A-1)

This type of blanking plate is fitted to multi-connector manifolds.

Ensure that the gasket 1 is correctly fitted.

Fit the blanking plate 2 onto the manifold station.

Fit and tighten the holding down screws 3 to the same torque

figures as the valve holding down screws (see above).

Blanking plate (Fig 13) (VVQ100-10A-2)

This type of blanking plug is fitted to standard multi-connector

manifolds (plug lead).

Fitting as above.

Wiring specification (Fig 6b)

WARNING

Latching solenoid

The latching solenoid is equipped with a self-holding mechanism,

which permits a moveable iron core 4 (Fig 1),in the solenoid, to hold

the 'set' position.

CAUTION

Do not employ simultaneous ON and OFF signals, as a 10ms energisation time is required for self-latching.

Avoid using these valves in applications involving excessive vibration

(10G or more).

Do not use in high magnetic fields.

At despatch the valve is set in the 'un-latched' mode. However it is

possible that it could move to the 'latch' position during transit.Before

operating this valve ensure that it is set to the 'un-latch' position.

See chart below (Fig 7).

Latching Passage Indicator light

A-C ON (Set) 1(P)R2(A) Orange

B-C ON (Reset) 2(A)R3(R) Green

Single Passage Indicator light

A-C ON 1(P)R2(A) Orange

OFF 2(A)R3(R) ––

Fittings

Tighten fittings into the valve using the following torque figures (Fig 8).

Mounting thread Correct clamping torque N-m (kgf-cm)

M5 1.5~2.0 (15~20)

M3 0.3~0.5 (3~5)

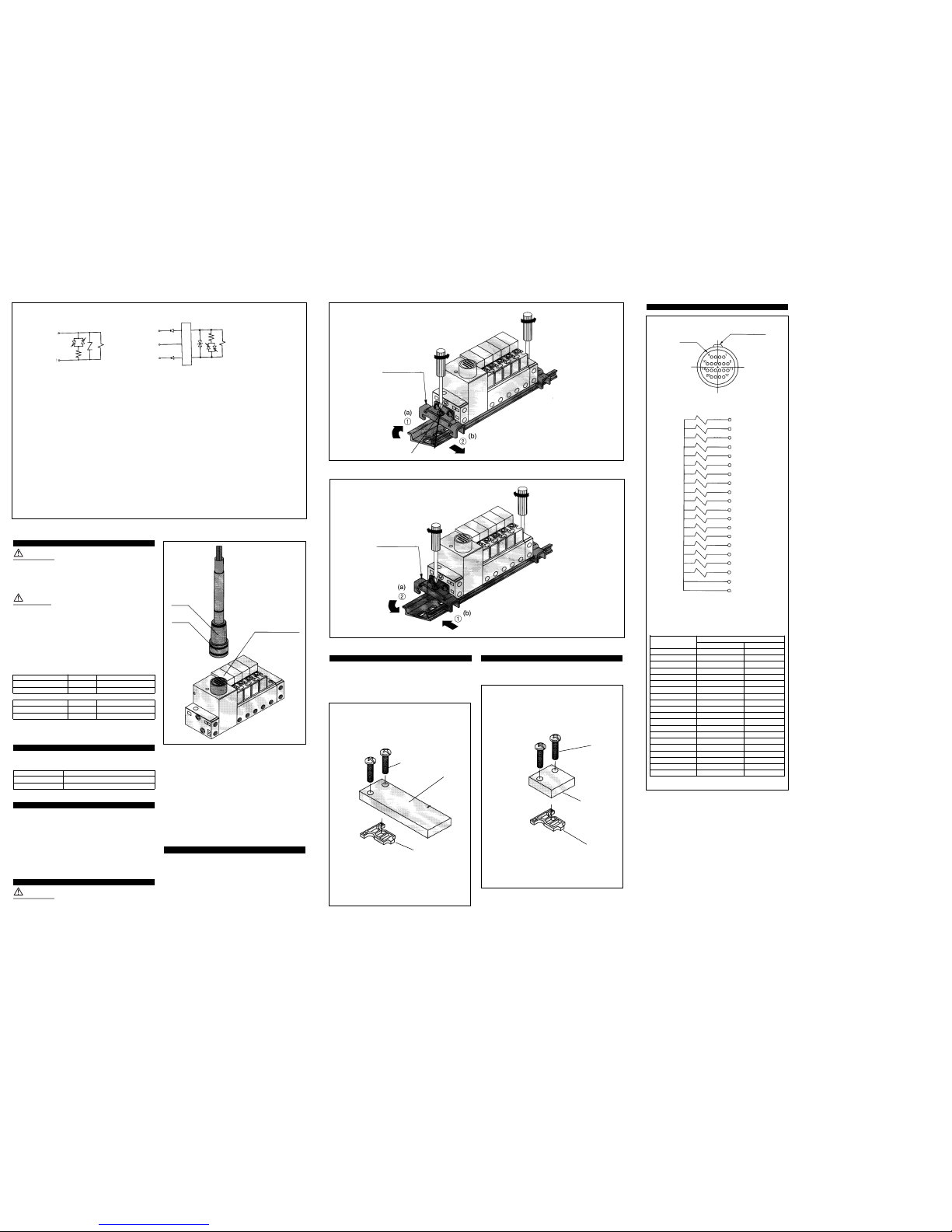

Multi-connector (Fig 9)

Connection

When fitting a connector align the positioning key 1 grooves and

ensure that the connector is vertical when inserting and that it locks

into position.

Disconnection

To disconnect the connector,lift the locking ring 3 and remove the

body 2 in a straight line (vertically).

Maintenance

WARNING

Before carrying out any form of maintenance ensure all air and power

supplies are isolated.

Removing a valve from the sub-base (Fig 11)

Disconnect the electrical connector (Fig 3).

Remove the valve holding down screws 7 (Fig 1).

Lift off the valve.

Retain the gasket.

Refitting a valve to a sub-base

Refit the gasket to the sub-base ensuring correct orientation.

Replace the valve.

Refit the valve holding down screws.

Torque screws to the following figure:

0.9 kgf/cm.

Mounting/Removing from a DIN-rail (Fig 10)

Removing

Loosen the clamp screw of the end plate 1 on both ends of the

manifold. Lift side (a) of the manifold base, slide the end plate in the

direction of 2 to remove.

Mounting

Hook side (b) of the manifold base onto the DIN-rail.

Press down side (a) and clip the end plate onto the DIN-rail.

Tighten the clamp screws to the following torque figures:

0.8 N-m~1.2 N-m (8~12 kgf/cm).

Fig 6b

Fig 10

Fig 14

Fig 11

Fig 7

Fig 8

Note 3:The solenoid valve channel is,

A-(set): I (P)R2(A)

B-(reset) : 2AR3(R)

Note 4:Applicable to negative COM

specification model.

Single solenoid type (DC) Latching solenoid type (DC)

Note 1:Single type: non-polarity

ON: light (orange) illuminates.

Note 2: A (set) side energisation:

A light (orange) illuminates.

B (reset) side energisation:

B light (green) illuminates.

Equipped with a wiring error prevention

(stop diode) mechanism and a surge absorption.

A (-) Set

C (+) COM

B (-) Reset

Fig 9

Fig 12

Fig 13

1 station

2 stations

3 stations

4 stations

5 stations

6 stations

7 stations

8 stations

9 stations

10 stations

11 stations

12 stations

13 stations

14 stations

15 stations

16 stations

17 stations

18 stations

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

SOL.

SOL.

SOL.

SOL.

SOL.

SOL.

SOL.

SOL.

SOL.

SOL.

SOL.

SOL.

SOL.

SOL.

SOL.

SOL.

SOL.

SOL.

COM

COM

When you enquire about the product, please contact the following

SMC Corporation:

ENGLAND Phone 01908-563888 TURKEY Phone 212-2211512

ITALY Phone 02-92711 GERMANY Phone 6103-402-0

HOLLAND Phone 020-5318888 FRANCE Phone 01-64-76-10-00

SWITZERLAND

Phone 052-34-0022 SWEDEN Phone 08-603 07 00

SPAIN Phone 945-184100 AUSTRIA Phone 02262-62-280

Phone 902-255255 IRELAND Phone 01-4501822

GREECE Phone 01-3426076 DENMARK Phone 8738-0800

FINLAND Phone 09-68 10 21 NORWAY Phone 67-12 90 20

BELGIUM Phone 03-3551464 POLAND Phone 48-22-6131847

SOL.

A (-)

C (+)

SOL.

Simultaneously energised

protection circuit

1 Positioning key

2 Body

3 Ring

DIN-rail mounting

bracket

DIN-rail mounting

bracket

1

2

3

3

2

1

1

Blanking plate with 2 damp screws and gasket

Blanking plate with 2 damp screws and gasket

Pin No.

Positioning key

Multi-connector pin arrangement

Pin No.

Electrical wiring specifications

Terminal No./Lead wire colour

Terminal No.

Lead wire colour

Lead wire colour Dot marking

1 Black -–

2 Brown -–

3 Red -–

4 Orange -–

5 Yellow -–

6 Pink -–

7 Blue -–

8 Violet White

9 Grey Black

10 White Black

11 White Red

12 Yellow Red

13 Orange Red

14 Yellow Black

15 Pink Black

16 Blue White

17 Violet -–

18 Grey -–

19 Orange Black

20 Red White

Loading...

Loading...