SMC Networks VK300 series, VK3000 series Installation And Maintenance Manual

Installation and Maintenance Manual

Series VK300 and VK3000 3 Port and 5 Port

Direct Operating Solenoid Valves

This Manual should be read in conjunction with the current product Catalogue

For future reference,please keep this manual in a safe place

Safety Instructions

These safety instructions are intended to prevent a hazardous

situation and/or equipment damage.These instructions indicate the

level of potential hazard by label of “Caution”,“Warning” or

“Danger”.To ensure safety, be sure to observe ISO4414

(Note1)

, JIS B

8370

(Note2)

and other safety practices.

Note 1: ISO 4414: Pneumatic fluid power – Recommendations for the

application of equipment to transmission and control systems.

Note 2: JIS B 8370: Pneumatic system axiom.

CAUTION : Operator error could result in injury or

equipment damage.

WARNING: Operator error could result in serious

injury or loss of life.

DANGER : In extreme conditions, there is a

possible result of serious injury or loss of life.

WARNING

1. The compatibility of pneumatic equipment is the

responsibility of the person who designs the pneumatic

system or decides its specifications.

Since the products specified here are used in various operating

conditions, their compatibility for the specific pneumatic system

must be based on specifications or after analysis and/or tests to

meet your specific requirements.

2. Only trained personnel should operate pneumatically

operated machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar

with it.Assembly, handling or repair of pneumatic systems should

be performed by trained and experienced operators.

3. Do not service machinery/equipment or attempt to

remove component until safety is confirmed.

1) Inspection and maintenance of machinery/equipment should

only be performed after confirmation of safe locked-out

control positions.

2) When equipment is to be removed, confirm the safety process

as mentioned above.Switch off air and electrical supplies and

exhaust all residual compressed air in the system.

3) Before machinery/equipment is re-started, ensure all safety

measures to prevent sudden movement of cylinders etc.

(Bleed air into the system gradually to create back-pressure,

i.e. incorporate a soft-start valve).

4. Contact SMC if the product is to be used in any of the

following conditions:

1) Conditions and environments beyond the given

specifications, or if product is used outdoors.

2) Installations in conjunction with atomic energy, railway, air

navigation, vehicles, medical equipment, food and beverage,

recreation equipment, emergency stop circuits, press

applications, or safety equipment.

3) An application which has the possibility of having negative

effects on people, property, or animals, requiring special

safety analysis.

CAUTION

Ensure that the air supply system is filtered to 5 micron.

ISO Symbol (Fig 1) Installation

WARNING

Before commencing installation ENSURE Air and Power supplies are

ISOLATED

DO NOT install these Valves in explosive atmospheres

DO NOT install these Valves in Corrosive Environments

If it is intended to energise a Valve for an extended period Consult

SMC

Protect Valves from Water / Oil splashes and Welding spatter.

Ensure Valves are protected from freezing

When changing Voltages the Valve must be replaced completely.

These Valves cannot be dismantled due to their Structure.

Using VK300 Series for Vacuum

If it is proposed to use the VK300 in Vacuum applications ensure that

the VK33*V,and VK33*W types are specified.

CAUTION

The preveous mentioned Valves differ from that of Vacuum retention

types.

When using Vacuum pads mount an Air suction filter (ZF Series)

between the Vacuum pad and the Valve to prevent dust from entering

the Valve.

Use a silencer in the Exhaust port.

CAUTION

Prolonged Energisation

Specify VK33*E Type for the above application and ensure that the

Valve is switched every 30 days. For Emergency Dump operation

please consult SMC.

VK3000 Series

The Air supply Port is the No.1 port of this Series,and cannot be used

in Vacuum applications.

Using VK3000 as a 3 Port Valve

It is possible to convert the VK 3000 into a 3 Port V alve either Normally

Open or Normally closed by plugging a Cylinder Port, see below:

Plug position Port No.2 Port No.4

Operation N.C N.O

JIS Symbol

WARNING

ENSURE THAT THE EXHAUST PORTS ARE LEFT OPEN WHEN

CONVERTING A VALVE T O 3 PORT CONFIGURATION.

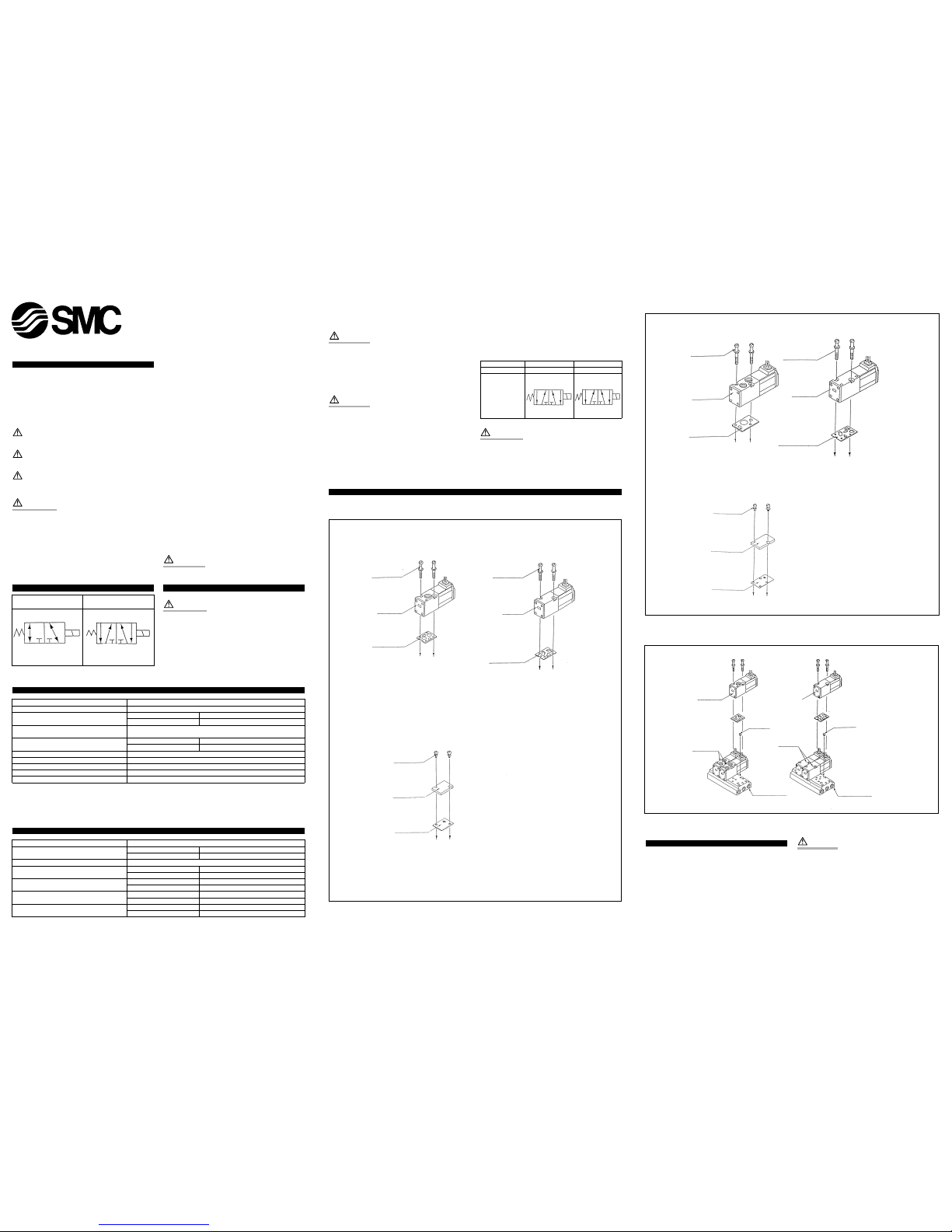

VK3000 Series (Fig 3)

082A/ENGLISH

VK300 VK3000

Specifications

Type of operation Direct operated 2-position single solenoid

Operating fluid Air

Standard 0~0.7MPa {0~7.1kgf/cm2}

Operating pressure range

Vacuum -101.2kPa~0.1MPa {1Torr~1kgf/cm

2

}

Ambient temperature and operating

fluid temperature

MAX. 50 ºC

Standard 10ms or less

* Response time

Low watt 15ms or less

Manual Operation Non-lock push type

Lubrication Unnecessary

Mounting position Any position

** Impact, vibration resistance 300m/s2, 50m/s

2

Protection IP65

* In accordance with the dynamic performance test of JIS B 8374-1981 (at the rated voltage, without surge suppressor).

** Impact resistance: No malfunction from test using drop impact tester to axis and right angle direction of main valve and armature,each

one time when energised and de-energised.

Vivration resistance: No malfunction from test with from 8.3 to 2000Hz 1 sweep to axis and right angle direction of main valve and

armature each time when energised and de-energised (Value in the initial stage).

Solenoid Specifications

Electrical entry DIN type terminal (D)

AC 100V,110V,200V,220V,240V

Rated voltage

DC 6V,12V,24V,48V

Allowable voltage ±10%

Inrush 9.5VA/50Hz,8VA/60Hz

Apparent power

Holding 7VA/50Hz, 5VA/60Hz

Standard 4W

Power consumption

Low watt 2W

AC Varistor

Surge voltage protection circuit

DC Diode (12V or less :Varistor)

AC Neon glow lamp

Indicator light

DC LED

Fig 1

Plug

Plug

Fig 3

2

3

1

4

2

5

1

3

4

2

4

2

513

513

(1) Model VK3120

(2) Model VK3140

M3X26

Screw W/Spring

washer

Manifold gasket

DXT199-23-4

M3X8

Screw W/Spring

washer

Blanking plate

VK300-33-3

VK3000-7-1

Manifold gasket for blanking plate

VK3000-6-3

M3X26

Screw W/Spring

washer

DXT199-23-4

VK3120-OG-01

VK3140-OG

VK3000-6-1

Manifold gasket

VK3000-6-2

Applicable base

Model VV5k3-20

Model VV5k3-21

Manifold base

}

Applicable base

VK3000-9-1

Model VV5k3-40

Model VV5k3-(S)41

Model VV5k3-(S)42

Manifold base

Subplate

}

(3) Blanking plate Ass’y

Parts No.: VK3000-7-1A

Applicable base: common for all VV5k3 models

Manifold (Installation of Solenoid Valve and Blanking Plate)

VK300 Series (Fig 2)

Fig 2

(1) Model VK332

(2) Model VK334

M3X26

Screw W/Spring

washer

Manifold gasket

DXT199-23-4

M3X26

Screw W/Spring

washer

DXT199-23-4

VK332-OG-01

VK334-OG

VK300-41-1

VK300-33-3

Manifold gasket

VK300-41-2

Applicable base

Model VV3k3-20

Model VV3k3-21

Model VV5k3-20

Model VV5k3-21

Manifold base

Manifold base

Subplate

}

Applicable base

VK300-45-1

Model VV3k3-40

Model VV3k3-(S)42

Model VV5k3-40

Model VV5k3-(S)41

Model VV5k3-(S)42

(3) Blanking plate Ass’y

Parts No.: VK300-42-1A

M3X8

Screw W/Spring

washer

VK300-42-1

Blanking plate

VK300-41-3

Manifold gasket for

blanking plate

Applicable base: common for all VV3k3 models

}

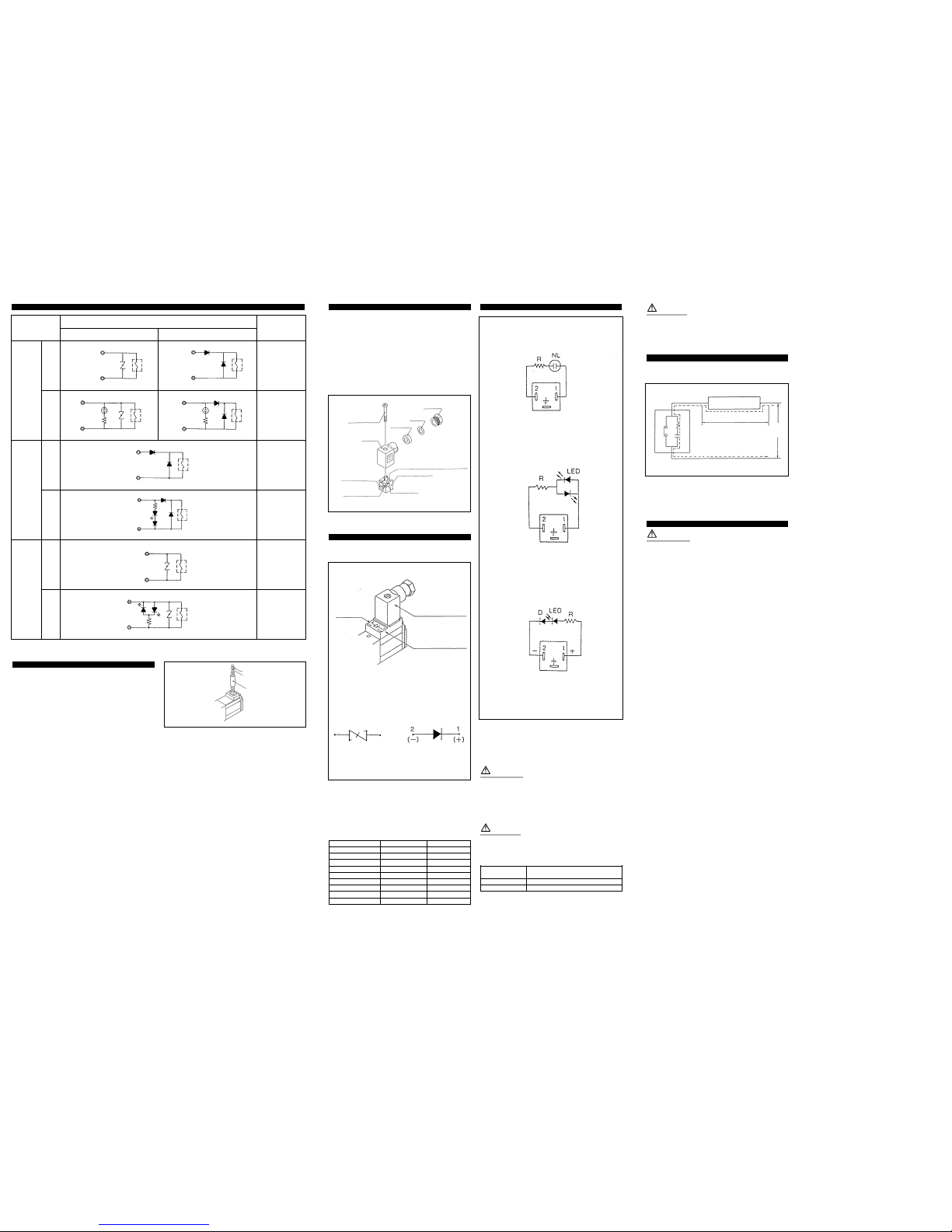

Mixed Mounting of VK300 Series and VK3000 Series (Fig 4)

It is possible to mount the VK300 onto the Manifold base of the

VK3000 Series.

(1) When specifying VV5K3-20 or VV5K3-40, ensure that the

appropriate Exhaust Port on the Manifold base is PLUGGED

using a rubber plug part No. VK3000-8-1, as this Exhaust port

becomes redundant when mounting 3 port Valves.

(2) The 3 port Valve can also be mounted on additional Manifolds i.e.

VV5K3-21, VV5K3-(S)41 and VV5K3-(S) 42 without additional

modifications.

CAUTION

• When converting a 5 port Valve, from 3 ports back to 5 ports

ensure that the exhaust plug is removed.

• When a 3 port Valve (VK300) is Mounted onto the Manifold base

of the VK3000 Series, the Valve function will be NORMALLY

CLOSED. If a NORMALLY OPEN function is required plug port No. 4

of a 5 port Valve.

• When piping from the Manifold base,the port No. 2, of the 3 port

Valve becomes the port No. 4 of the 5 port Valve. To avoid the

possibility of incorrect piping to the port No. 2 ensure that the

port No. 2 is plugged.

Fig 4

Model VV5K3-20

VK332-OG-01

VK3120-OG-01

Plug

VK3000-8-1

Plug

VK3000-8-1

Notch mark

(Recession)

Notch mark

(Recession)

VK334-OG

Model VV5K3-40

VK3140-OG

DIN Type Connector (Fig 6)

Connecting

Undo the fixing screw and remove the connector from the Solenoid

Valve terminal block.

After removing the fixing screw, insert a slotted screwdriver into the

slotted area at the bottom of the terminal block and the housing,and

lever open to separate the terminal block and the housing.

Undo the terminal screws of the block, insert the conductor of the

cable into the terminal and tighten the conductor via the terminal

screw.

Select the terminal housing direction, best suited for the application,

and insert the terminal block into the housing until it clicks into place.

Hand tighten the gland nut to retain the wires.

Connection Method for Lamp/Surge Voltage Protection Circuit (Fig 7)

When using a DIN connector with DC voltage connect the positive side

(-) to the symbol 2 of the terminal block.

Part No.of the connector without lamp:

VK300-82-1

Part No.of the connector with lamp:

Refer to the following table

Rated voltage *Marking Parts No.

AC100V 100V VK300-82-2-01

AC110V 110V VK300-82-2-03

AC200V 200V VK300-82-2-02

AC220V 220V VK300-82-2-04

AC240V 240V VK300-82-2-07

DC6V 6V VK300-82-4-51

DC12V 12V VK300-82-4-06

DC24V 24VD VK300-82-3-05

DC48V 48VD VK300-82-3-53

*Indicated on the terminal block.

Circuit Drawings (Fig 8)

Changing the Direction of the Connector (Cable)

After separating the Terminal block from the housing, the cable

direction can be changed 4 ways at 90º intervals.

WARNING

If the connector is fitted with a lamp, ensure that the lamp is not

damaged by the lead wire of the cable.

Applicable Cable. ( 2 conductors or 3* conductors)

Outside diameter of the cable should be ø3.5 ~ ø7mm.

Note 3 Conductor cables are used when connecting to Ground.

CAUTION

Ensure that the connector is straight during insertion or removal.

Piping tightening torque

Connecting screw

Appropriate tightening torque

N•m {kgf•cm}

M5 1.5~2{15~20}

Rc (PT) 1/8 7~9 {70~90}

Lubrication

The valve has been lubricated for life on assembly and requires no

additional lubrication.

CAUTION

However,if a lubricant is to be used, a turbine oil type #1 (ISO VG32)

should be used.

If a lubricant is used,continuous lubrication must be carried out as the

original lubricant will be washed away.

Voltage Leakage (Fig 9)

If using a C-R element in parallel with the switching element, the

leakage voltage will increase as the current flows through the C-R

element.

Keep the residual leakage voltage to 20% or less of the rated voltage

for AC coils and 2% or less of the rated voltage for DC coils.

Maintenance

WARNING

When changing the rated voltage the valve MUST be replaced,as it is

NOT possible to change the coil.

It is NOT possible to dismantle the valve due to its design.

Application of undue force to the valve may damage the valve section.

Lamp and Surge Protection Circuits

Rated

voltage

AC

DC

24V

48V

DC

6V

12V

Without lampWith lampWithout lampWith lampWithout lampWith lamp

DIN terminal (D)

Model No.

symbol

S

S

S

Z

Z

Z

Neon glow

lamp

Grommet Type Connector (Fig 5)

When using a surge Voltage protection circuit, with DC, connect the

positive side to the Red lead wire and the Negative side to the Black

lead wire.

When using AC voltage,the Blue lead wire is for 100VAC,and the Red

lead wire is for 200VAC,.The Grey lead wire is for other Voltages.

Fig 5

Fig 8

Fig 7

Varistor

Varistor

LED

LED

Varistor

No.1

No.2

No.2

No.1

(+)

No.2

(-)

Diode

No.1

(+)

No.2

(-)

Diode

Red (+)

Black (-)

}

DC type

Surge voltage

protection circuit

Fig 9

When you enquire about the product, please contact the following

SMC Corporation:

ENGLAND Phone 01908-563888 TURKEY Phone 212-2211512

ITALY Phone 02-92711 GERMANY Phone 6103-402-0

HOLLAND Phone 020-5318888 FRANCE Phone 01-64-76-10-00

SWITZERLAND

Phone 052-396 31 31 SWEDEN Phone 08-603 07 00

SPAIN Phone 945-184100 AUSTRIA Phone 02262-62-280

Phone 902-255255 IRELAND Phone 01-4501822

GREECE Phone 01-3426076 DENMARK Phone 70 25 29 00

FINLAND Phone 09-68 10 21 NORWAY Phone 67-12 90 20

BELGIUM Phone 03-3551464 POLAND Phone 48-22-6131847

PORTUGAL Phone 02-610 8922

*Marking

*Marking

For AC and DC 12V or less

For DC 24V or more

Light (built in connector)

Surge voltage protection circuit

(built into the terminal block)

AC circuit drawing

NL: Neon lamp

R: Resistor

DC circuit drawing

12V or less

LED: Light emitting diode

R: Resistor

DC circuit drawing

24V or more

D: Protective diode

LED: Light emitting diode

R: Resistor

*Contact point

C-R element

Current leakage

Voltage leakage

Valve

Power

source

Coil

Coil

Coil

Coil

Coil

Coil

Coil

Coil

No.1

No.2

No.1

No.2

No.1

Neon glow

lamp

Standard, Y, V & W type

Long-time energizing model (E)

Diode

Diode

No.2

No.1

No.2

No.1

Varistor

Fig 6

Fixing screw

Housing

(Code)

Refer to table

below

Terminal screw

(3 places)

Slotted area

(Light installation position)

Terminal block

Grommet

(Rubber)

Washer

Gland nut

Loading...

Loading...